Craftsman 358354871, 358354831 Owner’s Manual

I i

owner's

manual

: i_ • •

• Assembly

• Operation

• Maintenance

•e_ Repair Parts .......

r. ,

MODEL NO.

358,354831-3.7118"

358.354871-3.7/18"PS

WARNING:

Carefully read and follow

Safety • Rules, Precautions

and Operating Instructions.

Failure to =do so can result

in serious personal injury.-:-__-

C RRFTSM R,N

3.7/18"_ ,,3.7/18PS

,Jn

• CHAIN SAWS

Record in the space provided below the Model No. and Serial No. of

,your saw. These numbers are located on the starting instruction

decal.

Serial No.

Retain these numbers for future reference.

ii •

Sears, Roebuck and Co., Chicago, Ill. 60684 U.S.A.

r i rn

64983-3-24483-1-24483 PRINTED IN U. S. A.

FULL ONE YEAR WARRANTY ON GASOLINE CHAIN SAW

(Excluding Bar, Chain, Spark Plug, Air Filter and Starter Rope)

For one year from date of purchase, when you maintain, lubricate, and tune up this chain saw according tothe operating

and maintenance instructions in the owner's manual, Sears wilt repair defects in material or workmanship in this gasoline

chain saw.0at no charge.

This warranty excludes the bar, chain, spark plug, air filter, and starter rope which are expendable parts and become worn

during normal use. ,. _ :4 .... r " _

If this chain saw is used for commercial Or:l_entalpurposes, this warranty applies for only 30 days from date of purchase.

WARRANTY SERVICE IS AVAILABLE By RETURNING THE CHAIN SAW TO THE NEAREST SEARS STORE OR.SERVICE

CENTER IN THE UNITED STATES. .:,

This warranty gives you specific legal rights, and you: ma-y-_so have other rights which vary from state to state.

..... : • rSears,:,Roebuck and Co., Sears Tower, Dept. 698/731A, Chicago, IL 60684

TABLE OF CONTENTS ,

Specifications ............................... 2 Using The Power Sharp System ........ , ......... 11

Safety Rulesand Precautions ........... .. _... 3 Types of Cutting. _ 13

Know Your Chain Saw . . . . ................... \. ,_. 4. - A. Basic Cutting Technique _.;:. . ..... ' ....... .:13

A. Introduction ......... . ........ .... ;......-...... 4 B. TreeFellingTechniques_. :_.;,%_..,.;;;..,_-..... 13

B. State and Locai Ordinances ..: .... ._::_.ii4: C: Bucking... ;..;..: ..... ::.'.. ..... :.:... 14

C. carton _ntents.. ,-............... :.: ,:_;:::_ 4 • :: :_ D. Debranching and Pruning ................. 15

Preparing YourSawFor Use _;, ... ....... :;. !=:_i.:::_:_::5 Maintenance ...... :......................... 16

A. Getting Ready,,.:;.:_:,..:.. : ......... , 5::: ::A, Guide Bar and Chain .................... 16

B. Attaching the HandgiJard ,: ;.:,.. ...... 5 ::: B. Ignition, Cooling, and Exhaust Systems .... 18

C. Attaching the Spur. : 5 C. Starter Rope Repair and Replacement ...... 19

D. Attaching the Barand Chain ..... :-:.. .... .. 6

E. Chain Tension ............ ............... 7

F. Engine Fuel Mixture ..................... 7

G. Barand Chain Oil ....................... 8

UsingYour Saw ............................. 9

A. Control Devices ........................ 9

B. Starting instructions .................... 9

C. Controlling Kickback .................... 10

D. :Clutch, Drumand Sprocket ....... •.......... 20

IF_ Carburetor Adjustments 21

F. Air Filter ............................... 22

G: Counter-Vibe TMVibration System ...... -. ; .. 22

H. Storage .................................. 22 _

I. Maintenance Accessories ..... 22

J. Trouble Shooting Chart.. :...... ,:.. ;.... :.. 23

PartsList .................. _.,..,. ..... .... 24

QulckReference Page..! ...... :..... ......... , 31

POWER SHARP ADJUSTING

KNOB (MODEL .354871)

AIR FILTER

COVER KNOB_

THROTFLE:=_

LOCKOUT

CHOKE"

SPECIFICATIONS

MODEL ' .... " 358.354831 :(3.7118_) :'358.354871,,,(3.7118" P.S.)

CU; 1N.:DtSPLACEMENT : 3.7 cu. in360 cu. cm_::; _ :, .........3:.7 ,¢u, inl60 cu. cr_

GUIDE BAR":: LO-KICK", 18". ,Sp_:ket N_e' __' : 18" Sprocket NOSe ,

CHAIN ' 3/8 Extended Pitch ...................._............ 3/8 Extended Pitch

:---:i:;'::_,.,i_ '_ _:,:i_ _,\' ,_"'_ ..:_,' _:Chrome cutters-66 Drive.Unks ...... '.-Chrome'Cutters_66 Drive'Links

SPARK PLUG " • ........ _ _ : ": Champion CJ-8Y

IGNITION •:

MODULE AIR GAP

FUEL MIX

MUFFLER

OILER SYSTEM

FUEL TANK CAPACITY

,,r

OIL TANK CAPACITY

:: ; Oregon e" Xtra- Guard TM Link., OregOn ® PowerSharp e /°

.023 to .027:,SPARK PLUG GAP ,

• Solid State

,008 to .014

Gasoline/Oil Mixture 16:1

Spark Arrestin 9 Temperature Limiting

Automatic Manual

19 oz, 562 cu. cm.

. 12 o7- 355 cu. cm.

HANDGUARD _ _ ,

STARTER HANDLE

_UARD

CHAIN THROTTLE

,=.: ........................

..........I

LATCH

lSWITCH

REAR

CATCHER

SAFETY RULES AND PRECAUTIONS

I WARNING!

Failure r to observe the following Safety Rules and

Precautions could result in serious personal injury;

A. KNOW YOUR SAW

_1. Read your Owner's Manual carefully until you

completely understand and can apply all safe.

ty rules and operating instructions before

attempting to operate the uniL

2.Restrict the use of your saw to users who

;understand and follow the safety rules,

_;_precautions, and operating instructions found

in this manual.

B. PLAN AHEAD

1..Wear personal protective gear. AlwaYs use

safety footwear; snug-fitting clothing;

_protective, gloves;_ and appropriate eye,

i?ihearing and head protection devices.

2. Keep children, bystanders, and pets out of the

work area. Do not allow other people to be

near the chain saw when starting or operating

thechain saw. i

• 3.DOrnOt handle or operate a chain saw when

_ you are fatigued, III, or upset;, or if you have

taken alcohol or drugsirnedication. You must

be in good physical condition and mentally

alert.

4. Do not attempt to useyour saw during bad

weather conditions such as strong wind, rain,

snow, etc., or at night since you would not

have good visibility. •

5. Plan your sawing operation carefully in ad-

vance. Do not start cutting until you have a

clear work area, secure footing, anda planned

retreat path from the falling tree.

C, HANDLE FUEL WITH CAUTION

1;_Elirninate all sources of sparks or flame in the

• " areas where fuel is mi'X'ed, poured, or stored.

There should be no smoking, open flameS, or

work that could cause =sparks.

2. Mixand store fuel in a well-ventilated area.

3. Mix and store fuel in an appreved, marked

_ container.

4._Wlpe up all spilled fuel before starting your

saw.

5.Move at least 10 feet (3 meters) away from

fuel and fueling site before, starting the

engine.

_ 6. Do ;not smoke while handling fuel orrwhile

operating the saw.

7. Turn the engine off and let your saw cool

before removing the fuel tank cap and refuel-

lng the unit.

8. Let the saw Cool in a non-combustible area,

not on dry leaves, straw,, paper,

D. GUARD AGAINST KICKBACK

Kickback can lead to dangerous loss of con.

trol of the chain saw and possibly cause

serious personal injury. Kickback is the up-

ward and backward motion of the guide bar that

occurs when the moving chain contacts anot>

ject at the nose of the guide bar. To reduce the

hazard of kickback:

1_Hold the chain saw firmly with both hands,

2. Do not overreach.

3. Do not let the nose of the guide bar contact

the ground, a log, a branch, or any other

obstruction.

4. Cut only with the engine running at lull throt..

tie,.

. 5. Do not cut;_ab0_e shoulder height.- .... i

6

.Follow manufacturer's sharpening and

maintenance instructions for the saw chain.

7. Use the Guard Link Chain; and Lo-

KiciP Guide Bar that are designed for your

saw to reduce the possibility of kickback.

E, OPERATE YOUR SAW SAFELY

1. Do not operate a chain saw that isdamaged,

improperly adjusted, or not completely and

. _' securely assembled.

2. Do not operate the saw from a ladder orin a

tree.

_;3: Keep all parts ofyour body awayfrom the saw

chain when the engine is running.

4. Cut wood only.

5:Make sure the saw chain is not touching

anything before you start the engine.

6. Use extreme caution when cutting small size

brush and saplings. Slender.. material may

catch the sawci'Lain and be whipped toward

you or pull you: off balance.

: 7. Be alert for spdngback when cuttinga limb

...._ _.that isunder tension soyou wilt notbe struck

" by the limb-or saw when the tension inthe

wood fibers is released.

8. Shut off the engine before setting the saw

down.

F, MAINTAIN YOUR SAW IN GOOD

WORKING ORDER

1. Have all chain saw service E)erformed by.your

Sears Service Center, other than the service

listed in the maintenance section of this

manual.

2. Keep fuel and oil caps, screws and fasteners

tight.

3. Keep the handles dry, clean, and free of oil or

fuel mixture. -_ • - _ :

4. Make certain the saw chain stops moving

when the throttle trigger is released, if it does

not, refer to page 21 for correct carburetor

idle adjustment mstruchons.

5. Stop the saw if the chain strikes a foreign ob-

ject. Inspect the unit and repair or replace

parts as necessary.

CARRY AND STORE YOUR SAW

Gm

SAFELY

1. Never carry your saw while climbing. Both

hands are needed for safe climbing.

2. Carry the unit with the engine stopped, the

Guide Bar and Chain to the rear, and the Muf-

fler away from your body.

3. Carry the saw with Guide Bar and Chain

covered, preferably with an appropriate scab-

bard.

KNOW YOUR CHAIN SAW

A.

INTRODUCTION

,The information found in this manual will help

you -i_roperly prepare your chain saw for use,

Understand how to operate your san-safely, and

perform maintena'nce reqbire_dto keep your unit

in go0dworking condition.

Your saw has been designed with safety in mind

and includes the following safety features as

standard equipment:

_ Handguard

Lo-Kick ® Guide Bar

Guard Link Chain

The chain saw should never be Operated unless

these devices are properly installed on the uniL

The Lo-Kick ® Guide Bar and Guard Link Chain

have been designed to reduce the incident of

kickbaCk.You should thoroughly read and

understand the section,"Controlling Kickback,"

on page 10.

STATE AND LOCAL ORDINANCE

as

REQUIREMENTS

4. Allow your saw tocool completely before

transporting inany vehicle or storing in any

enclosure.

5. Drain oil and fuel tank before storing for more

than 30 days,

6. Store in a dry area out of the reach of children

and away from where fuel vapors can reach

an open flame from hot water heaters, fur-

nances, etc.

!

Your saw is equipped with a temperature

limiting muffler and spark arresting-screen

which meets the requirements of_Califomia

_.;CodesA442 and 4443. All U.S: forest.land and :the-_

states of California, Ma_ne, Washington and

Oregon require many internal combustion

engines to be equipped with a spark arrestor

screen and a temperature limiting muffler by

law.

tf you operate a chain saw in a state or locale

where such regulations exist, you are legally

responsible for maintaining the operating condi-

tion of these parts. Failure to do so could sub-

ject youto liability or to a fine. Muffler and spark

arrestor maintenance is found on page18.

C. CARTON CONTENTS

After you unpack me barton:

1. Check the contents against the list below.

2. Examine the items for damage.

3. Notify your Sears Store immediately if a part is

missing or damaged.

,

KEY NO.

1

2

3

m

4

5

6

8

9

10

CARTON CONTENTS:

Power Head

Guide Bar

8 oz. can, 2-Cycle Engine Oil

Loose Parts Bag (not shown)

LOOSE PARTS BAG C(JNTENTS:

Owners' Manual-(not shown)

Handguard

Cap-Handguard

Screws-Handguard

Spur-:* • ......... • "

Screw-Spur

Chain

Scrench

QTY.

1

1

1

1

1

1

1

3

1

2

1

1

PREPARING YOUR SAW

A. GETTING READY

FOR USE

READ YOUR OWNER, S MANUAL CARE.

FULLY.

Your Owner's Manual has been developed to

help you prepare your saw for use and to-

understand, its safe operation. It is important

that you read your manual completely to

become •familiar with the unit .before you

begin assembly.

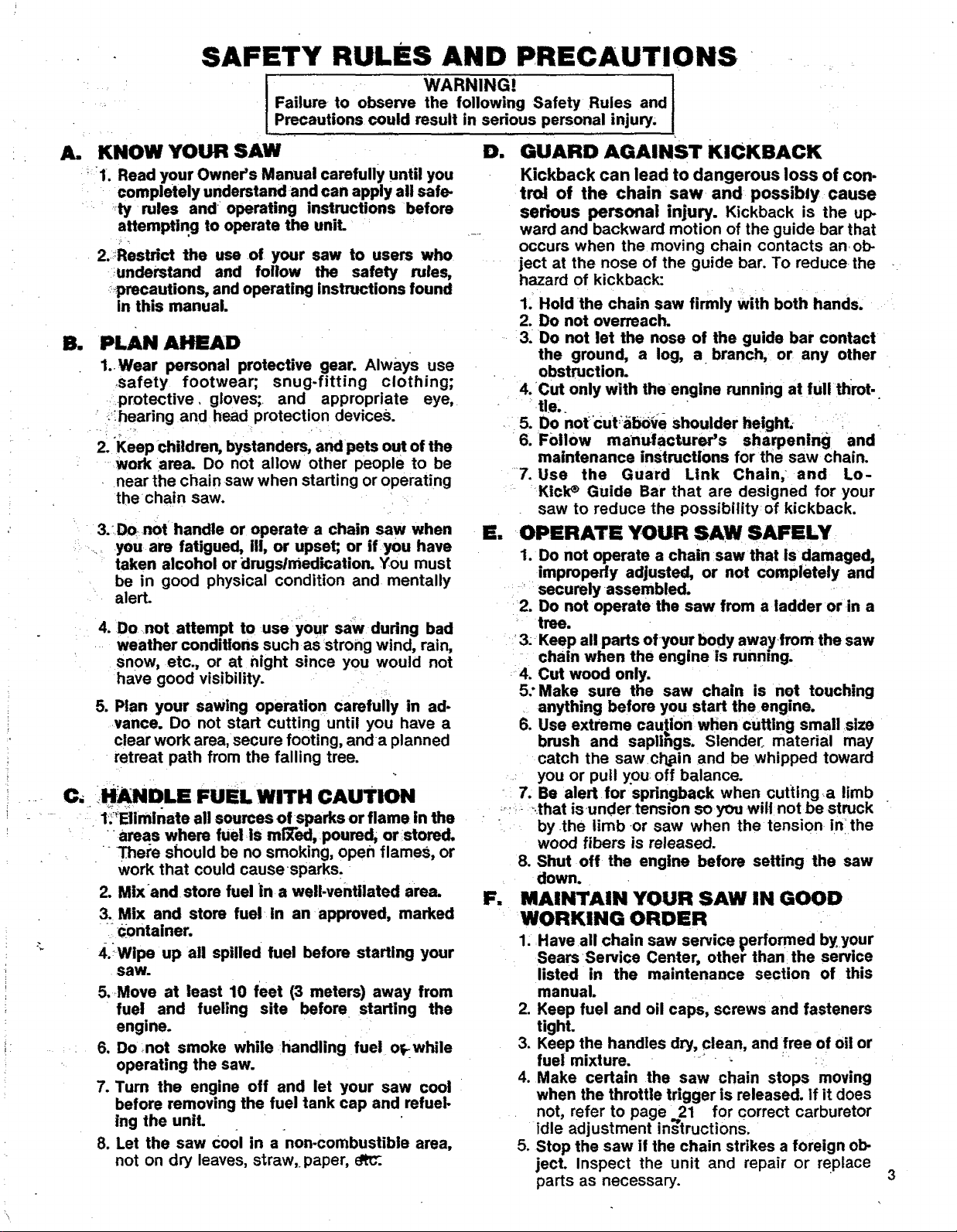

B.: _ATTACHING THE HANDGUARD

The Handguard is a protective device designed

to help prevent your hand from coming in con-

tact with the cutting chain should your hand slip

off the handlebar. It Will not eliminate the

possibility of injury from kickbackor loss of con-

tro!:of the saw.

CAP HANDGUARD

• :, _ L • Figure I

2, HAVE THE FOLLOWING AVAILABLE:

-a, Protectivegloves

b. Approved, marked fuel container

: c.'One gallon regular gasoline

d.Bar and Chain Lubricant {See pageS).

e. Scrench--provided with your unit.No other

.... tool is necessary for assembly. The long

end of the tool can be used as a slotted,

screwdriver. The small pipe end can be us.

edras a socket wrench. The larger pipe end

can be used to remove the spark plug, •

J:..:: • -. ..... _.... WARNING!. : .... ,:._ I

Do not use the•:saw without the handguard in I

place. •

• Lift and carry the chain saw by the handlebar

or rear handle, not by the handguard.

• :Keep:the handguard securelY.: fastened at all

times. Check the handguard screws each

' time rthe saw is used..

To install:

1. Align the Handguard and Handguard Cap

around the handlebar as shown in Figure 1. •

2. Fit the mounting pin onthe Handguard into

....... the hole:in the ;handlebar. Figure 1.

"3. Insert th e 3 mounting screws into the 3 holes

on the Handguard Cap. ::

4_ Turn each scr_hv a little at a time clockwise,

until the Handguard Cap" and Handguard

meet and ther_ is no gap between the two

•.... parts, _ -" ..... _. _...... :_,.......

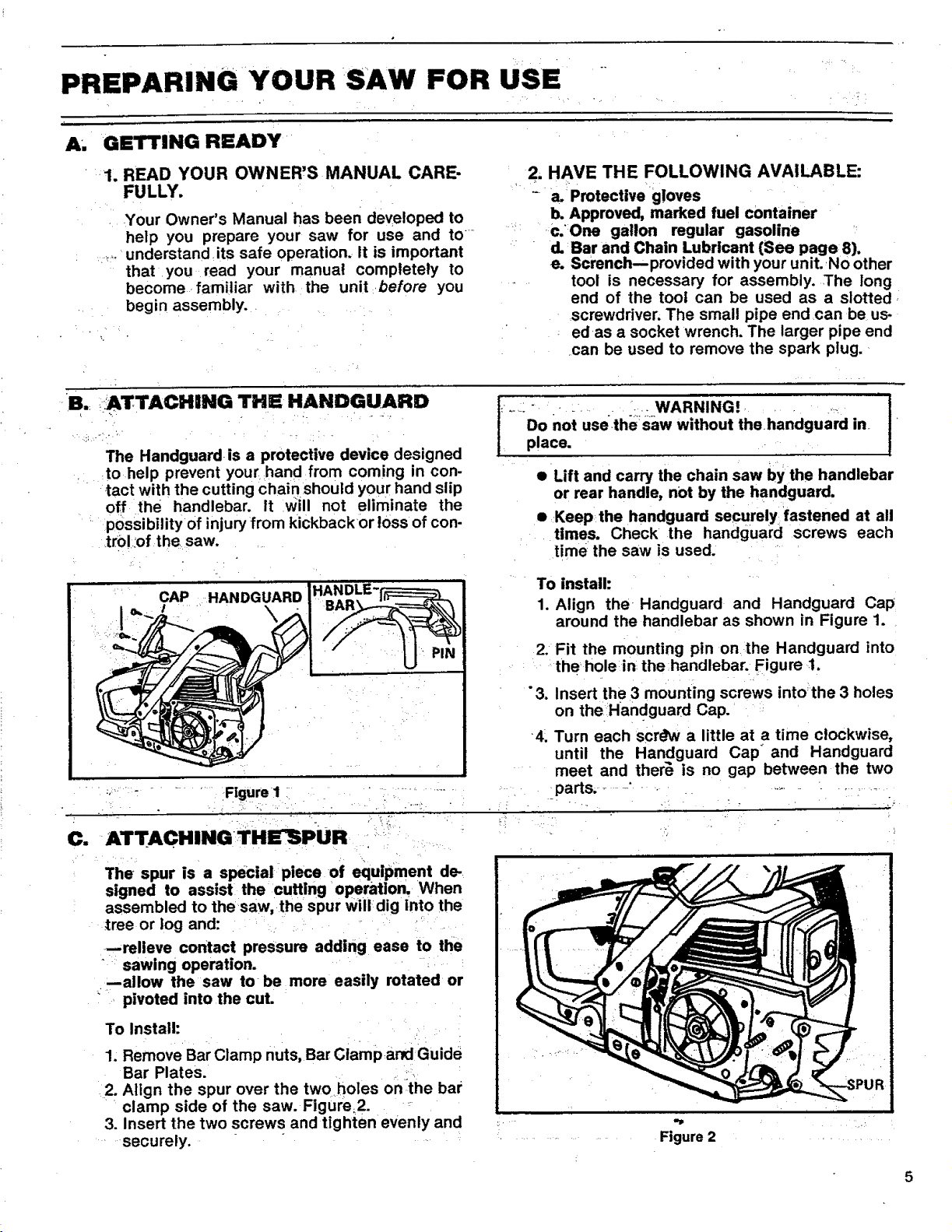

C. ATTACHINGTHE_PUR

The spur is a special piece of equipment de-

signed to assist the cutting operation. When

assembled to the saw, the spur will dig into the

_ree or log and:

--relieve contact pressure adding ease to the

sawing operation.

--allow the saw to be more easily rotated or

" pivoted into the cut.

To Install:

1. Remove Bar Clamp nuts, Bar Clamp and Guide

Bar Plates.

2. Align the spur over the two holes on the bar

clamp side of the saw. Figure_2.

3. Insert the two screws and tighten evenly and

securely.

UR

............ Figure 2 ..........

5

D. ATTACHING THE BAR AND CHAIN

H •

ICAUTION:]Wear protective gloves when han-

....dling or operating your saw. The chain is sharp. " "

and can cut you even when it is not moving!

• Your saw is equipped with a Lo-Klck® Guide

Bar and a Low.Kick chain designed to help

reduce kickback.

e.Always use the Lo-KiclP Guide Bar and Low-

:Kick Chain specified for your chain saw

_model, when replacing these parts.

. L

_ WARNING!

Donot start engine without guide bar and chain

completely assembled. Otherwise the clutch

can come off and sedous personal injury could-

resulL

a, Install theJnner, Guicle Pla-te Over the'bar-,

' .;n_;Gbnting studs. Figur_ 3;, : ,, .....i r :_ _:

.... NO_ Be sure the Inner Guide Plate curves

o!_flanges toward the saw frame away from

' the Guide Bar. Figure 4.

,,b, Mount the Guide Bar with the slotted end

over thebar mounting studs.: Figure 5.

NOTE: Be sure the Guide Bar is positioned

with the round hole below the large slot.

c. Hold Chain with cutters facing as shown in ,

....Figure 6.

d. Place chain over and behind the clutch

'_ drum onto the sprocket.

e. Slide Guide Bar to the rear of the saw as far

as possible.

f. Fit the bottom of the drive links between

the teeth in the sprocket.

g. Start at the top of the bar and fit the chain

drive links into the groove around the Guide

Bar. Figure 6.

h. Pull the Guide-Bar forward until the chain is

, .:snug in the guide bar groove. Figure 7.

i. Install the Outer guide plate.

NOTE: Be sure both the inner and outer

guide bar plates curve or flange outward

from the Guide Bar. Figure 4.

j. Install the Bar Clamp by sliding the bar

clamp over the mounting studs and ,fitting

.... -_the bar adjusting, pin into tlTe round hole_on -......

• the Guide Bar. Figure 8.

k. Replace the Bar Mounting Nuts and tighten

finger tight only.

NOTE: The Bar Clamp nuts must be slightly

loose to tension the chain correctly.

1. Follow "Chain Tension" instructions, page 7.

Figure 6

ADJUSTING PIN HOLE

Figure 7

BAR ADJUSTING PIN

Figure 5

Figure 8

6

CHAIN TENSION

mw

• Correct chain tension is very important:

--a loose chain will wear the bar and itself.

--a loose chain can jump off the bar while

you are cutting.

--a tight chain can damage the saw and/or

break.

--a chain, either too loose Ortoo rtight, can

cause injury.

e Chain tension is correct when the chain:

--can be lifted about 1/8" from the Guide Bar

at a point near the middle of the bar, and

--will move freely around the bar.

2. Check the tension by lifting the chain from

the Guide Bar at the center of the bar. Figure

10.

3. Continue turning the Adjusting Screw until

the tension is correct.

4. Idoid the tip of the Guide Bar up and tighten

the Bar Clamp Nuts with. theScrench.

5. Recheck tension.

TURN

TO LOOSEN

TENSION

TURN

• The chain stretches during use, especially

when new.. Check tension:.

--each time ,the saw, is used

..... _._m0re_frequentlywhen the chain: is;:new

_e

The Bar Clamp Nuts must be slightly loose to

tension the chain correctly.

.

H01d the tip of the Guide Bar up and turn the

Adjusting Screw just until the chain does not

sagbeneath theGuide Bar. Figure 9.

NOTE: Turn screw clockwise to tighten ten-

sion. Turn screw counterclockwise to loosen

tension.

F. ENGINE FUEL MIXTURE

• Your chain saw is powered by a two-cycle

engine which requires a fuel mixture of

=regular gasoline and a high quality engine oil

specially made for 2-cycle, air-cooled

engines. The internal design of the 2-cycle

engin_ requires lubrication of moving" parts.

Lubi:icatlon is provided whenyouuse the

Tecomrnended mixture of gasoline and oi1.

• Gasoline-must be clean and not over two

months• old. After a short period of • time,

gasoline begins to chemically break down

and will form compounds that can cause hard

starting and damage in 2-cycle engines.

• The correct measure of gasoline to oil is very

important.

--:Too much oil in the mixture will foul the

spark plug.

--Too little oil will cause the engine to over-

heat resulting in damage.

• Mix the fuel thoroughly in a container since

gasoline and oil do not readily combine. Do

not try to mix fuel directly in the fuel tank.

r •

Fiaure 9-

Figure 10

1. USE THE FOLLOWING FUEL MIXTURES:

. SEARS #32-36555

'o,

1r_u.o" ENGINE OIL -

I "'

• _ = ANYGOOD GRADE --

2. DO NOT USE THE FOLLOWING IN FUEL

MIXTURES:

_ AUTOMOTI VE

GASOHOL

. __OR__ _

AIR-COOLED, 2-CYCLE

ENGINE OIL

Does not have properaddi-

tives for 2;cycteengines and

OIL

could cause damage.

Burnstoo hot for 2-cycle

engines;will shorten

spark plug life and could •

damage your engine.

Alcoholabsorbs moisture

causing acids to form

_hich will damage metal

and rubber parts.

TIGHTEN

TENSION

3. HOW TO MIX FUEL

4. IMPORTANT POINTS

a. Pour one-half of the gasoline into an ap-

proved, marked container. Do not try to mix

oil and gasoline directly in the fuel tank.

b. Add entire measure of 2-cycleEngine Oil.

c_ Mix.

d. Add remainder of gasoline.

e. Mix'thoroughly for one minute.

_- Figure 11

G. BARAND CHAIN OIL

,e_The guide bar and cutting chain require con-

tinuous lubrication in order to remain in oper-

i:ating condition. Lubrication is provided by

the automatic oiler system when the oil tank

iskept filled.

--Lack of oil will quickly ruin the bar and

chain.

--Too little oil will cause overheating shown

..... by smoke coming from the chain and/or

discoloration of the guide bar rails.

• Use Sears Bar and Chain Lubdcant #36554

or clean SAE 30W oil.

• in freezing weather oil will thicken, making it

necessary to thin bar and chain oi! with a

small:amount of Diesel Fuel #1 or Kerosene.

Bar and chain oil mustbe free flowing for the

i`= ';::_:_6ili_:sY_stemtO'puml_ ie_0ugh"oit 'for adequate

lubd'_tion.

i

FI1.L THE OIL TANK

EACH TIME THE

FUEL TANK 1_

FILLED

Figure 12

a. Use only recommended fuel mixtures.

b. Eliminate all sources of sparks Or flame in

the areas where fuel is mixed, poured, or

stored. There should be no smoking, open

flames or work that could cause sparks.

c. Mix and store fuel in an approved, marked

container.

d. 'Mix and pour fuel in a well.ventilated area.

Gasoline vapors are harmful to your health

and are a serious fire hazard.

e. Avoid over lilling the fuel tank, Allow 3/4

inch for expansion. Tighten Fuel Cap

securely. Figure 11.

f. Wipe up all fuel spills. Wipe off any fuel

spilled on the saw. Completely dry the saw

before using.

g. Move at least 10 feet(3, meters) away from .....

_fuel andfuelihg sitebefore starting,the

engine.

1. USE THE FOLLOWING:

30°F or above -- Lubricant -_ undiluted.

30OF - 0°F 95% lubricant to 5% Diesel

Fuel #1 or Kerosene.

Below 0°F 90% lubricant to 10%

Diesel Fuel #1 or Kerosene.

2. HOW TO FILL THE OIL TANK

a. Stopthe engine.

b. Turn saw on its side with oil cap up. Figure

!.2.

c. Loosen cap slowly and wait for pressure in

the tank to be released before removing the

o

......cap ..... : ....

d: Filiith_e :oil, tank: , . ::_i: -:...... .....

e. Replace the oil cap securely.

' 3. IMPORTANT POINTS TO REMEMBER

a. Fill the oil tank each time you refill the fuel

tank to ensure there will, be sufficient oil for

the chain whenever you start and run the

saw.

b. The saw will use about 112 tank of chain oil

for each tank of fuel mixture. If less oil is

used, check for a plugged oil hole in the

...._ : c. it is normal for a small amountofoil to ap

guide bar.

pear under the saw after the engine stops.

This is due to oil draining from the bar and

chain when not in use.

,

USING YOUR SAW

A. CONTROL OEVICES

Understanding the control dev_es on your saw

is an important part of learning how .to properly

and safely operate the unit. Figure 13.

1;'!The Ignition Switch is a toggle switch which

is moved up for the "Start" position and mov-

ed down for the "Stop" position.

2;-!The two-position Choke helps to start the

:saw by controlling the air flow to the fuel

system.

..... 3; The Trigger accelerates and controls the

speed of the engine and is designed to be

used with the Throttle Lock.

4.The Throttle Lock is a control feature which

_ ,_prevents the Trigger from becoming accident-

ly engaged, The Throttle Lock must be press-

ed before the Trigger can be activated,

5. The Throttle Detent Button holds the Throttle

Lock and Trigger in position while the engine

is being started. Release the Throttle Detent

Button afterthe engine is started by lightly

squeezing the trigger.

B. iiSTARTING iNSTRUCTIONS

1. IMPORTANT POINTS

a.Hold saw firmly with the saw chain free to

turn without contacting any object. Figure

_,_14.

b. Pull starter rope quickly, using no more

than 15-18 'inches of rope per pull. Using,

the full length of the starter rope, may

cause it to break. Do notlet the starter rope

snap back. Hold the handle and let the rope

rewind slowly.

THROTTLE

DETENT

BUTTON

.., START

•, SWITCH

TRIGGER

_ CHOKE

Figure 13 •

6. The Manual Oiler is placed to be operated by

your r!ght-thumb._ Use the manual OHer_tosup-

plement the automatic oilen.

during a long felling cut

when cutting into a log or tree which is

greater in diameter than the length of the

guide bar.

--anytime an additional supply of oil is de-

sired.

WARNING!

Always wear gloves; safety footwear;, .snug-

fitting clothing; and appropriate eye, hearing,

and head protection devices when operating a

Chain saw.

TO START -- HOLD FRONT HANDLE-

BAR AND PLACE RIGHT

FOOT THROUGH. HANDLE.

:: _-_i_i_ic,°!Pull starter rope .no more:than 3-5 times.

Otherwise the eng_e mayflood.

d. Release the throttle detent button after

engine starts, allowing the engine to idle.

The chain must not move when the engine

runs at idle speed. If correction is required,

refer to"Carburetor Adjustments," page 21.

_:e. Stop engine by moving the ignition switch

to the "STOP" position (Figure 13). ,_

Avoid bodily contact with the muffler when Starting

a warm engine. The muffler car become very hot I

and can cause serious bums. ..... J

Figure 14

WARNING. = !

' 2. STARTING PROCEDURE

MovoTgn_*_n Pull choke knob Prsssthroms Press tisrottto PuRst;sKi_tope Push chokil kr_otiPua s'_" rope Squeezet]rl_

"_" gine r

a. Cold En x

b. Warm Engine x

c. Refueled Engine after running x x x x 3-Stimes x x x

out of gas .,

d. Flooded Engine x chokeo, X x X X

e. Cold Weather starting x x x x _t_== ,=_fc,o,s- x x

* Allow engine to warm-ul_ thoroughly on half-choke, then move choke to the "Off" position. Do not cut with the

choke at the "On" or "Half" position. Figure 13. 9

to I_t choke lockand delent T)utton untJ engfnefires " in unW _glM m_ to _m

L squee,-_'_igg_' ralezze trigger tt_t_l _d

X X X 3-5 times X X X

choke Off X X 1-2 times X

(out of cut)

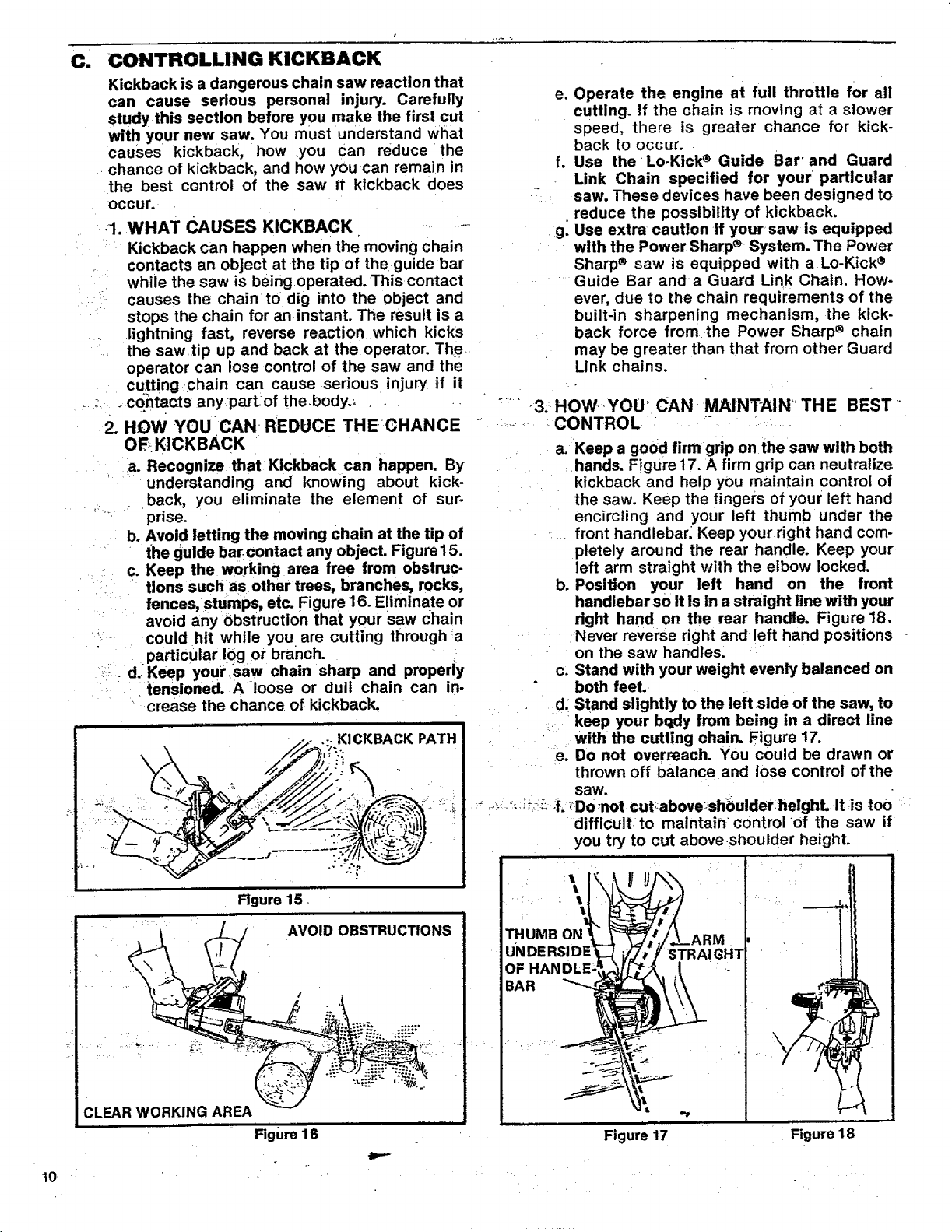

CONTROLLING KICKBACK

Kickback is a dangerous chain saw reaction that

can cause sedous personal injury. Carefully

study this section before you make the first cut

with your new saw. You must understand what

causes kickback, how :you can reduce the

chance of kickback, and how you can remain in

the best control of the saw it kickback does

Occur.

•.1. WHAT CAUSES KICKBACK ....

Kickback can happen when the moving chain

contacts an object at the tip of the guide bar

while the saw is beingoperated. This contact

causes the chain to dig into the object and

stops the chain for an instant. The result is a

lightning fast, reverse reaction which kicks

the saw.tip up and back at the operator. The

operator can lose control of the saw and the

cutting chain can cause serious injury if it

,_co._t'aats anypart:of thebody._ .,

2. HOW YOU 'CAN REDUCE THE:CHANCE

OFr_KICKBACK .

a. Recognize that Kickback can happen. By

understanding and knowing about kick-

back, you eliminate the element of sur-

prise.

b. Avoid letting the moving Chain at the tip of

" • •the guide bar:contact any object. Figure15.

. c. Keep the working area free from obstruc-

tions suchas other trees, branches, recks,

fences, stumps, etc. Figure 16. Eliminate or

avoid any Obstruction that your saw chain

could hit while you are cutting through :a

particular 10g or branch.

,- d..Keep yoursaw chain sharp and properly

tensioned. A loose or dull chain can in-

crease the chance of kickback.

K! CKBACK PATH

e. Operate the engine at full throttle for all

cutting. If the chain is moving at a slower

speed, there is greater chance for kick-

back to occur..

Use the Lo-Kick ® Guide Bar' and Guard

f.

Link Chain specified for your particular

saw. These devices have been designed to

reduce the possibility of kickback.

g: Use extra caution if yoursaw is equipped

with the Power Sharp ® System. The Power

Sharp ® saw isequipped with a Lo-Kick ®

....Guide Bar and a Guard Link Chain. How-

ever, due to the chain requirements of the

built-in sharpening mechanism, the kick-

back force from the Power Sharp ® chain

may be greater than that from other Guard

Link chains.

: " 3: HOW YOU_ CAN - MAINTAIN" THE BEST '

.,r...........CONTROL/ .... ....

a. Keep a good firm grip on the saw with both

hands. Figure 17. A firm grip can neutralize

kickback and help you maintain control of

the saw. Keep the fingers of your left hand

encircling and your left thumb under the

front handlebar: Keep your right hand com-

pletely around the rear handle. Keep your

left arm straight with the elbow locked.

b. Position your left hand on the front

handlebar so it is in a straight line with your

right hand on the rear handle, Figure 18.

Never reverse right and left hand positions

on the saw handles.

c. Stand with your weight evenly balanced on

both feet,

d. Stand slightly to the left side of the saw, to

keep your bqdy from being in a direct line

with the cutting chain. Figure 17.

e. Do not overreach. You could be drawn or

thrown off balance and lose control of the

saw.

•_.;",:;:-"_.;L_Do_notcut,:above_shbulderheight, It is too

difficult to maintain control of the saw if

you try to cut above •shoulder height.

CLEAR WORKING AREA

t0 ¸

Figure 15

Figure 16

AVOID OBSTRUCTIONS

OF

BAR

\

t

:r

Figure 17 Figure 18

Loading...

Loading...