Craftsman 358353660, 358353670, 358353690 Owner’s Manual

[Sears

owner's

manual

• Assembly

• Operation

• Maintenance

• Repair Parts

VlODEL NO.

58.353660-2.3/14"

358.353670-2.3/16"

358.353690-2.3/16"PS

WARNING:

Carefully read and follow

Safety Rules, Precautions

and Operating Instruc-

tions. Failure to do so can

result in serious personal

injury.

CRRFTSMRH

2.3/14" Z3/16" 2.3/16"PS.

GASOLINE CHAINSAWS

THIS CHA! N SAW IS FOR OCCASIONAL USE ONLY.

Record in the space provided below the Model No. and Serial No. o{

your saw. These numbers are located on the starting instructions

decal.

Model No. Serial No.

Retain these numbers for future reference.

64765-3-06183- t -06283

S(_L, s, Ro(_buck _nd C.o., Chic_o_), Ill. 60.684 U.S.A.

PRINTED IN U. S. A.

FULL ONE YEAR WARRANTY ON GASOLINE CHAIN SAW

(Excluding Bar, Chain, Spark Plug, Air Filter and Starter Rope)

For one year from date of purchase, when you maintain, lubricate, and tune up this chain saw according to the operating _

and maintenance instructions in the owner's manual, Sears will repair defects in material or workmanship in this gasoline

chain saw at no charge.

This warranty excludes the bar, chain, spark plug, air filter, and starter rope which are expendable parts and become worn

If this chain saw is used for commercial or rental purposes, this warranty applies for only 30 days from date of purchase.

WARRANTY SERVICE IS AVAILABLE BY RETURNING THE CHAIN SAW TO THE NEAREST SEARS STORE OR SERVICE

during normal use.

• CENTER IN THE UNITED STATES.

T_is warranty gives you specific legal rights; and you,may also have other rights which vary from state to state. . ._

• , " ( f e .... "- .... "

Sears,RoebuckandCo.,SearsTower, Dept. 698/731A, Chicago,IL 60684 -

TABLE OF CONTENTS

Specifications .............................. 2 Using the Power Sharp System ................ 12

Safety Rules and Precautions ..... . ............ 3 Types of Cutting ............................. 13

Know Your Chain Saw ........................ 4 A..Basic Cutting Technique .................. 13

A. IntroduCtion ........................... 4 B. Tree Felling Techniques :.' ............... 14

B. State and Local Ordinance Requirements... 4 C. Bucking .................. ............. ".15

C. CartGi]C0ntents ................... ..... 4 . ' :,D. Debranching and Pruning ..... :..... :. .... 16

Preparing Your Saw For Use ........... .......... 5 Maintenance . _... .. ......... ................ 17

A. Getting" Ready .......................... 5

B. Attaching the Handguard .... ............ 5

C. Attaching the Bar and Chain. _,.. : ...... ... 5

D. Chain Tension .................. : ....... 7

E. Engine Fuel Mixture .................. :... 8

F. Barand Chain Oi1 .................. _.... 9

G. Optional Muffler Heat Shield Assembly :... 9

Using Your Unit ............................. 10

A. Pre-Operation Checks ................... 10

B. Starting Instructions .................. .. 10

C. Controlling Kickback .................... 11

A. Guide Barand Chain ............ , ....... 17

B. Ignition, Cooling, and Exhaust Systems .... 19

C. Starter Rope Repairand Replacement ...... 19

D. Carburetor Adjustments .................. 21

E. Air Filter .............................. 22

F. Storage ............................... 22

G. Maintenance Accessories...: ; ............ 23

H. Troubleshooting Chart .................. 24

Repair Parts ................................. 26

Quick Reference Page ........................ 31

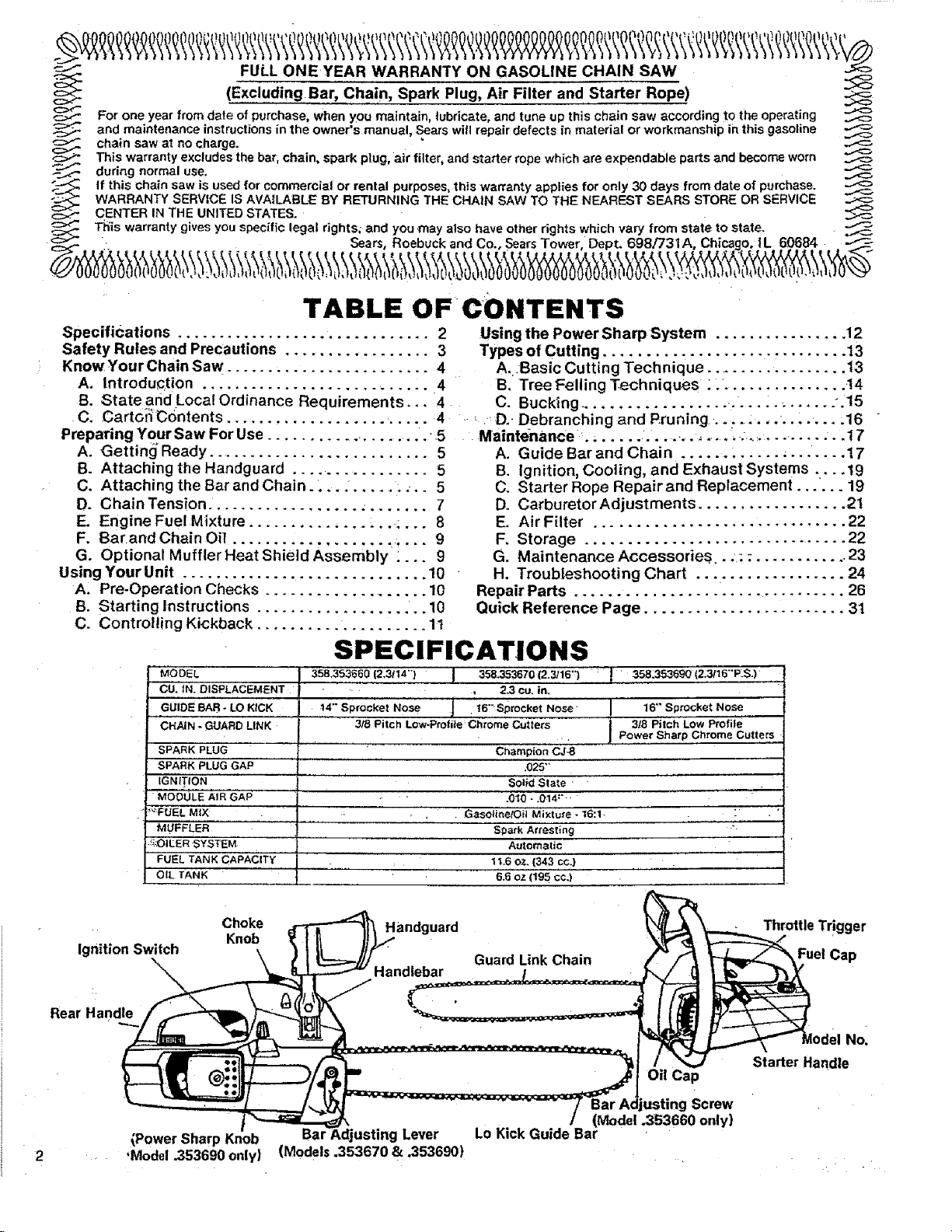

Ignition Switch

Rear Handle

SPECIFICATIONS

MODEL 358.353660 12,3114") I 358.353670 (2.3116")

CU.'IN_ DISPLACEMENT ': .... , 2.3 cu. in. ' '

,ii ............ i

,GUIDE BAR- LO KICK ......................:,,,i_,4,:"Sprocket Nose 16""Sprocket Nose

CHAIN - GUARD LINK 3/8 Pitch Low-Ptoffie Ch_,ome Cutters

SPARK PLUG ..... " Champion'CJ-8

SPARK PLUG GAP 025""

IGNITION ' ' ' Solid State • '........

MODULE AIR GAP - ' ' .010 - ,0t4:" '....

_FUEL MIX Gasoth_elOil Mixt'u'r ,_ - t6:1- '

MUFFLER Spa_k Arresting '-

:_OIILER 'SYSTEI_: ..... Automatic ' '

FUEL TANK CAPACITY ...... 11.6 OZ. (343 CC.)

O'IL TANK ' " "......... 6,5 oz (t95 C¢,i .....

Choke Handguard

Knob

: I, 358:353e90 (2:3116"'PLS.)

"" 16" Sp_cket Nose

318 Piich' LOW Profiie '

Po,wer Sharp Chrome Cutters

ThrottleTrigger

Starter Handle

Oil Cap

Fuel Cap

No_

(Power Sharp Knob

,Model .353690 only)

Bal Lever

(Models °353670 & .353690)

Lo Kick Guide Ba_rM°del"

usting Screw

.353660 only}

SAFETY RULES AND PRECAUTIONS

-- WARNING! ]

Failure to observe the following Safety Rules andl

Precautions could result ,n serious personal injury. J

A. KNOW YOUR SAW

t. Read your Owner's Manual carefully until you

completely understand and can apply all safe-

ty rules and operating instructions before at.

.tempting to operate the unit.

2. Restdct Lthe use of your saw to users who

understand and follow all safety rules,

precautions, and operating instructions found

in this manual.

B. PLAN AHEAD

%' Wear personal protective gear.

Always use safety f0otwear;

snug-f!tting c|othing; protective

gloves; and appropriate eye,

hearing and head protectiondevices,

2-, Keep children, bystanders, and pets out of the

work area. Do not allow other people to be

near the chain saw when starting or operating

the chain saw.

3. Do not handle or operate a chain saw when

you are tired, ill or upset: or if you have taken

alcohol or drugs/medication. You must be in

good physical condition and mentally alert.

4. Do not attempt to use your saw during

bad weather conditions such as strong wind,

rain, snow, etc., or at night since you would

not ha_e :good visibility.

5. Plan yo'ursawing operation carefully in ad.

vance; DO not start cutting until you have a

clear work area, secure footing, and a planned

retreat path from the falling tree.

C. HANDLE FUEL WITH CAUTION

__,l;:.l_limJnat e allsources of sparks or flame in the

areas where fuel is mixed, poured, Or stored.

There should be no smoking, open flames, or

:w_ that could cause sparks:

,2. Mix!and store fue! in .a well.ventilated area.

3. Mix and store fuel in an approved, marked

container.

4:.Mo_e at least 10 feet (3 meters) away from

fuel and fueling site before starting the

engine.

5; Do.not smoke while handling fuel or while

Operating the saw.

6. Turn the engine off and let your saw cool

before removing the fuel tank cap and refuel-

ing the unit.

7. Let the saw cool in a non-combustible area,

not on dry leaves, straw, paper, etc.

8. Wipe up all spills, Wipe off fuel spilled on the

saw before using.

D. GUARD AGAINST KICKBACK

Kickback can lead to dangerous loss o f_icon-

trol of the chain saw and possibly cause

serious personal injury. Kickback is the up-

ward and backward motionof the guide bar that

occurs when thesaw chain contacts an object

at the nose of the guide bar. To reduce the

hazard Ofkickback:

1, Hold the chain saw firmly with both hands.

2. Do not overreach.

3. Do not let the nose of the guide bar contact

the ground, ,a log, a :branch_ or any _other

obstruction. ,_

4. Cut only with the engine running at fuli_hrot -

tie.

5. Do not cut above shoulder height.

6. Follow manufacturer, s sharpening and

maintenance instructions for the saw chain.

7. Use the Guard Link Chain and Lo Kick Guide

Bar designed for your saw to help reduce the

possibility of kickback, ,. "° -

E. OPERATE YOUR SAW SAFELY

1. Do not operate a chain saw that is damaged,

improperly adjusted, or not completely and

'securely assembled. _

2. DO not operate the saw from a ladder or in a

tree.

3. Keep all parts of your body awayfrom the saw

chain when the engine is running.

4. Cut wood only.

5, Make sure the saw chain is not touching

anything before you start the engine. :_ _

'6., Use_extreme_cautioq_ when,cutting smal{, size

brush and saplings.; Slender material may

catch the saw chain and be whipped to,ward

you or pull you off balance. ""'

7, Be,alert for springback when cutting a limb

that is under tensionso you will not be struck

by the limb or saw when the tension in the

wood fibers is released.

8. Shut off the engine before setting the saw

down.

MAINTAIN YOUR SAW IN GOOI_

Fw

WORKING ORDER

1. Have all chain saw service performed by your

SEARS Service Center other than the service

described in the maintenance section of this

manual.

2. Keep fuel and oil caps, screws and fasteners

: tight.

3. Keep the handles dry, clean, and free of oil or

fuel mixture.

4. Make certain the saw chain stops moving

when the throttle trigger is released. Refer to

page 21 for carburetor adjustment instruc-

tions if the chain does not stop.

5. Stop the saw if the chain strikes a foreign ob-

ject. inspect the unit and repair or replace

parts as necessary.

GI=

CARRY AND STORE YOUR SAW

SAFELY

1. Never carry your saw while climbing. Both

hands are needed for safe climbing.

2. carry the unit with the engine stopped, the

guide bar and chain to the rear, and the muf-

fler away from your body.

KNOW YOUR CHAIN SAW

°-_3iCarry the saw with_,,guide bar and chain

covered, preferably with an appropriate scab-

bard.

4. Allow your saw to cool completely before

transporting in any vehicle or storing in any

enclosure.

5. Drain oil and fuel tank before storing for more

than 30 days.

6. Store in a dry area outof the reach of children

and away from where fuel vapors can reach

an open flame from hot water heaters; fur-

naces, etc.

A.

INTRODUCTION :.....

The_information found in this manual.will help

you properly prepare your chain saw -for use,

understand how to operate your saw safely, and

perform maintenance required to keep your unit

in top working condition.

Your saw has been designed with safety in mind

and includes the following safety features, as

standard equipment:

Handguard

Lo Kick Guide Bar

Guard Link Chain

The chain saw should never be operated unless

these devices are properly installed on the unit.

The Lo Kick Guide Bar and Guard Link Chain

have been designed to help reduce.the incident

of KICKBACK. You should thoroughly read and

_understand the section, "CONTROLLING

KICKBACK" on page 11 before operating the

saw.

El

STATE AND LOCAL ORDINANCE

REQUIREMENTS

_Your Saw has; been; furnished with an'approved

Spark AFestorScreen which is required in some

areas bylaw. You are legally responsible for see-

ing that the Spark Arrestor is properly main-

tained in these areas. Failure to do so could sub-

ject you to liability or to a fine. See Spark Ar-

restor maintenance, page 19.

Check with your state conservation or forestry

department about regulations concerning oper-

ating your saw on forest, brush, or grass covered

areas. All U.S. forest land and the states of

California, Maine, Washington and Oregon re-

quire many internal combustion engines to be

equipped with a temperature limiting muffler by

law. Such laws require fitting your saw with an

additional muffler heat shield.

A shield which meets these requirements can be

purchased at your Sears Service Center as an

optional accessory kit. Ask for Muffler Heat

Shield Kit, Repair Part No. 69037.

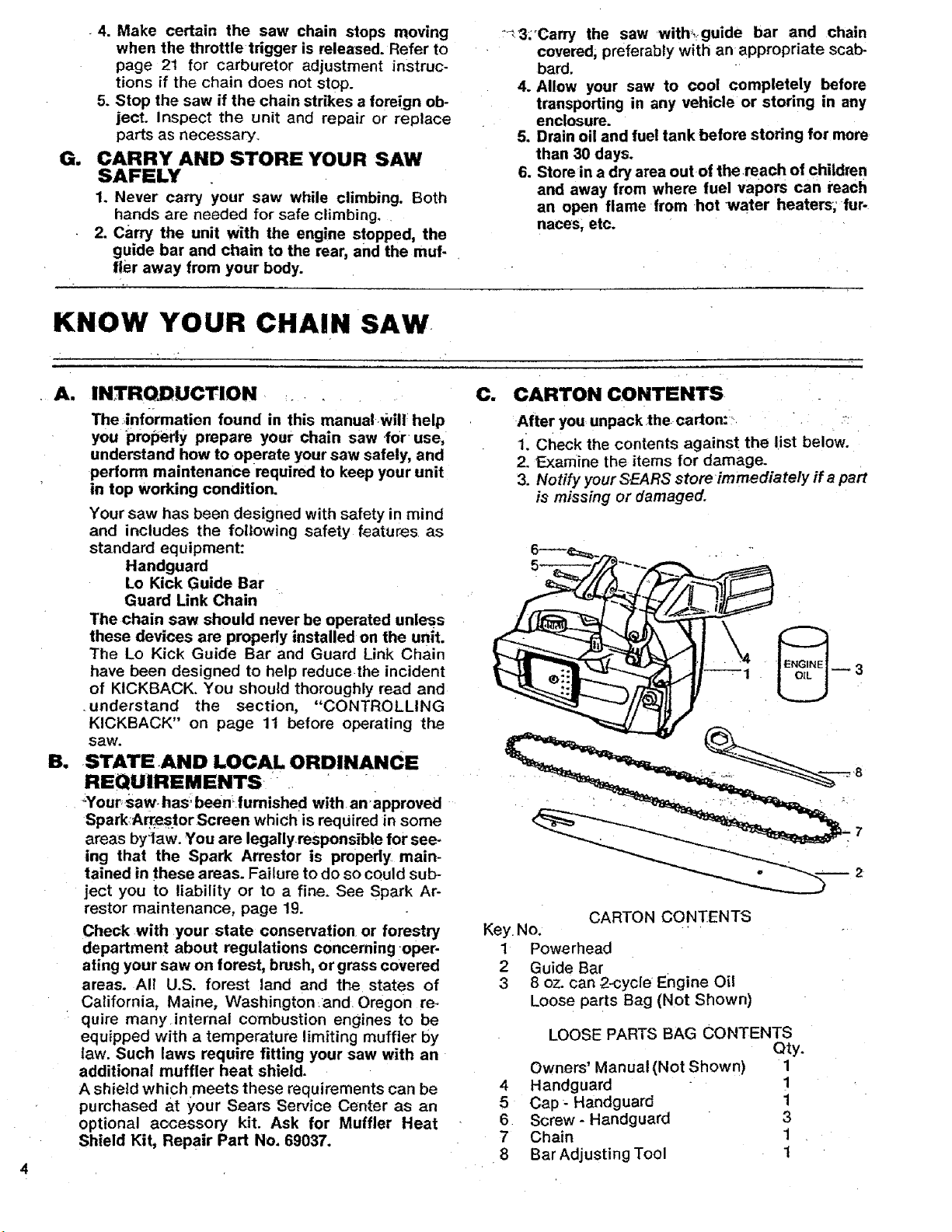

C. CARTONCONTENTS

After you unpack 1he carton:"

1. Check the contents against the list below.

2. Examine the items for damage.

3. Notify your SEARS store immediately if a part

is missing or damaged.

--3

CARTON CONTENTS

Key. No.

1 Powerhead

2 Guide Bar

3 8 oz. can 2-cycle Engine Oil

Loose parts Bag (Not Shown)

LOOSE PARTS BAG CONTENTS

Qty.

Owners' Manual (Not Shown) 1

4 Handguard !

5 Cap- Handguard 1

6 Screw- Handguard 3

7 Chain 1

8 Bar Adjusting Tool 1

PREPARING YOUR SAW FOR USE

A. GETTING READY

1. READ YOUR OWNER'S MANUAL CARE-

FULLY.

Your Owner's Manual has been developed to

help you prepare your saw for use and, to

understand its safe operation. It is important

that you read your manual completely to

become familiar with the unit before you

begin assembly,

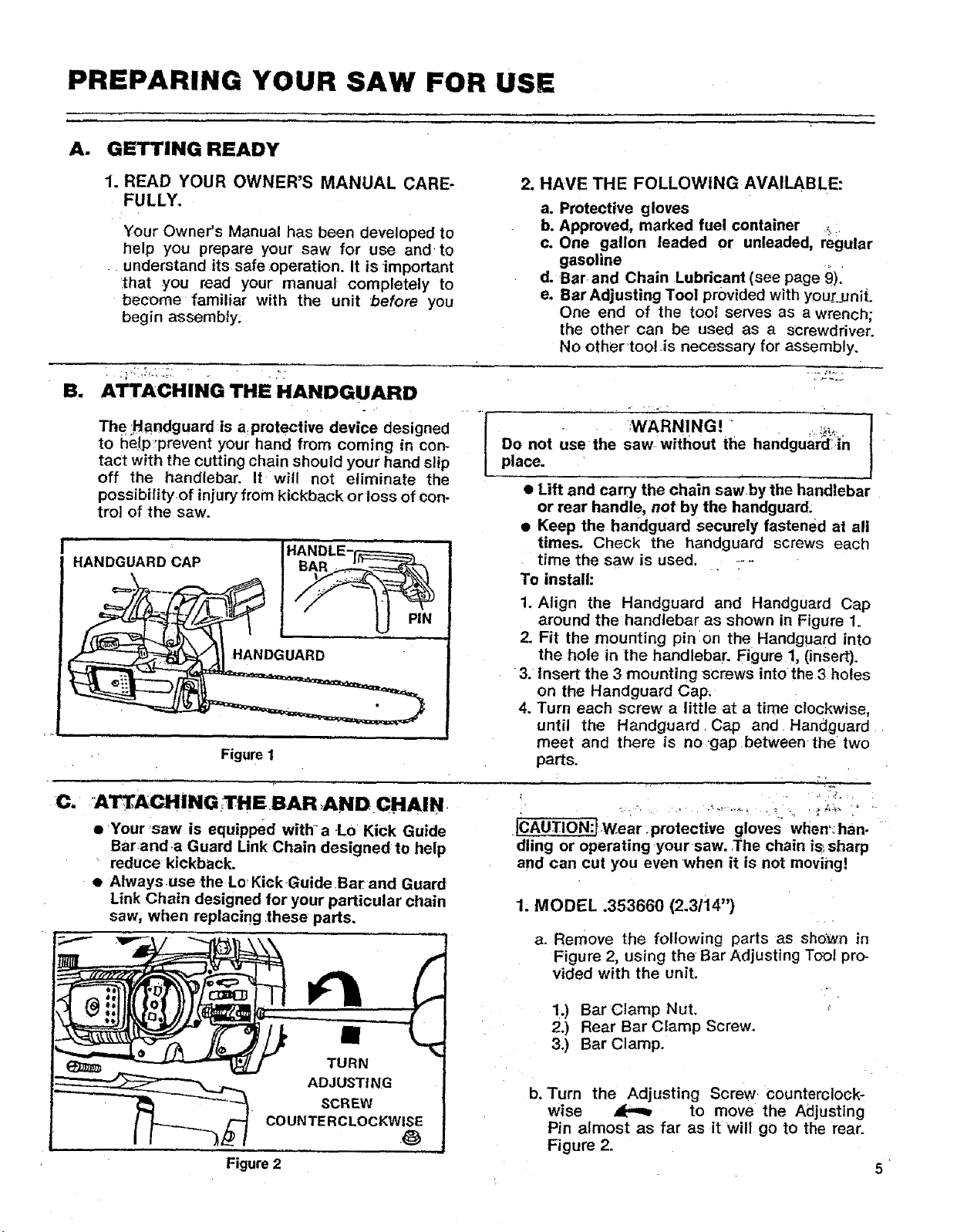

Su ATTACHING THE HANDGUARD

The. ;Ha,ndguardis a,protective device designed

to help°prevent your hand from coming in con-

tact with the cutting chain should your hand slip

off the handlebar. It will not eliminate the

possibilityof injury from kickback or loss of con-

trol of the saw.

HANDGUARD CAP

Figure I

HANDLE-_

illll

U PiN

2. HAVE THE FOLLOWING AVAILABLE:

a. Protective gloves

b. Approved, marked fuel container _...

c. One gallon leaded or unleaded, regular

gasoline

d. Bar, and Chain Lubricant (see page 9).

e. Bar Adjusting Tool provided with your_unit.

One end of the tool serves as a wrench;

the other can be used as a screwdriver.

No other too! is necessary for assembly.

Do not usethe saw.without the handguar_!':in

place.

.... ;WARNING! ' --,. t

• Lift and carry the chain sawby the handlebar

or rear handle, not by the handguard:

• Keep the handguard securely fastened at all

times. Check the handguard screws each

time the saw is used ......

To install:

1. Align the Handguard and Handguard Cap

around the handlebar as shown in Figure 1.

2. Fit the mounting pinch the Handguard into

the hole in the handlebar. Figure 1, (insert).

3. Insert the 3 mounting screws into the3 holes

on the Handguard Cap.

4. Turn each screw a little at a time clockwise,

until the Handguard Cap and Handguard

meet and there is no 'gap between the two

parts.

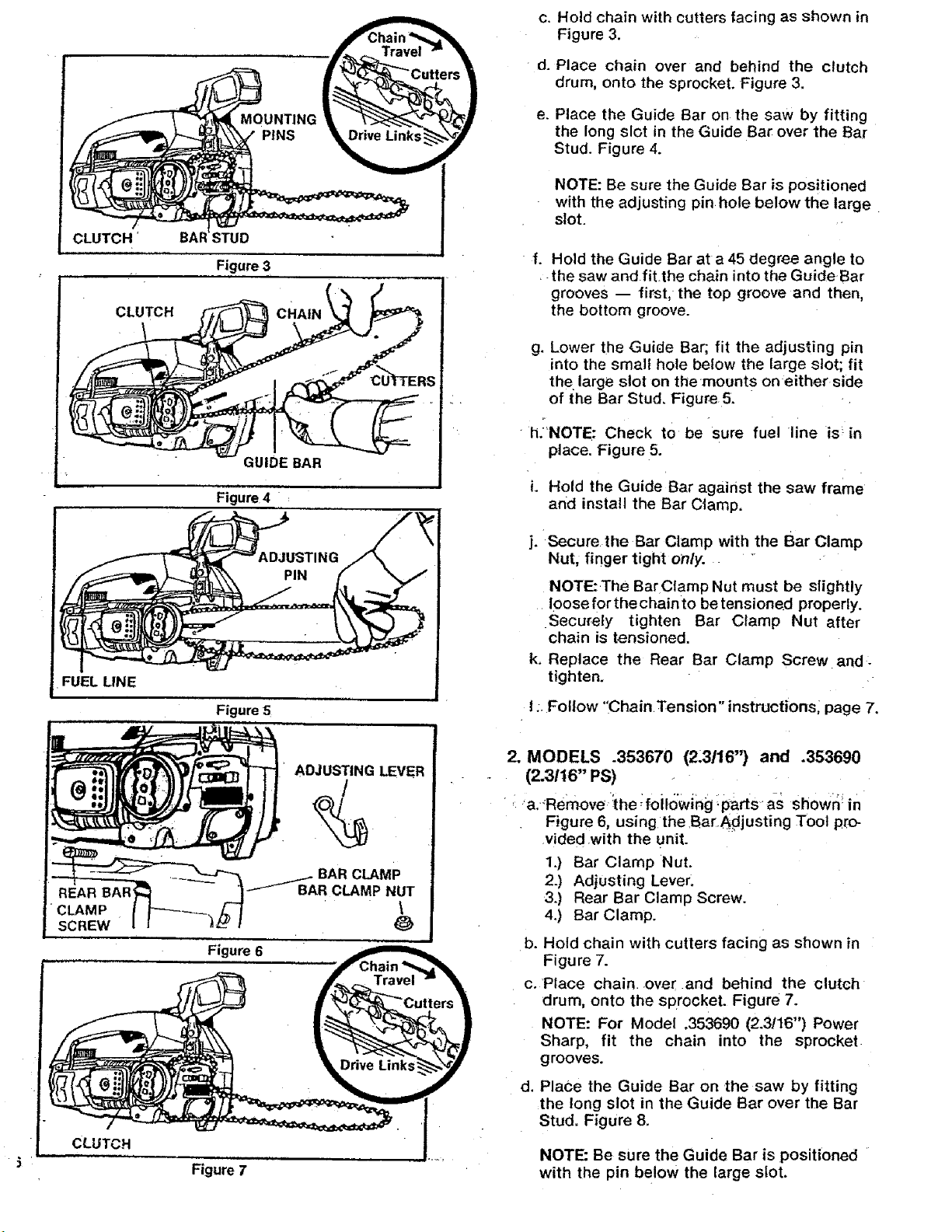

C, Alr_,ACHiNG_THE BAR,AND CHAIN,

• Your_saw is equipped with'a Lo Kick Guide

Barand.a Guard Link Chain designed to help

reduce kickback,

• Always.use .the Lo Kick-Guide Bar and Guard

Link Chain designed for your particular chain

saw, when replacing lhese pads,

TURN

ADJUSTING

SCREW

COUNTE RCLOCKW

Figure 2

•ICAu]:ION-'twear protectivegloves_wSemhan.

dling or operating your saw..The chain is; sharp

and can cut you even when it is not moving!

1. MODEL .353660 (2.3/i4")

a. Remove the following parts as sho:v_n in

Figure 2, using the Bar Adjusting Tool pro-

vided with the unit.

1.) Bar Clamp Nut.

2.) Rear Bar Clamp Screw.

3.) Bar Clamp.

b. Turn the Adjusting Screw counterclock-

wise _ to move the Adjusting

Pin almost as far as it will go to the rear.

Figure 2.

5

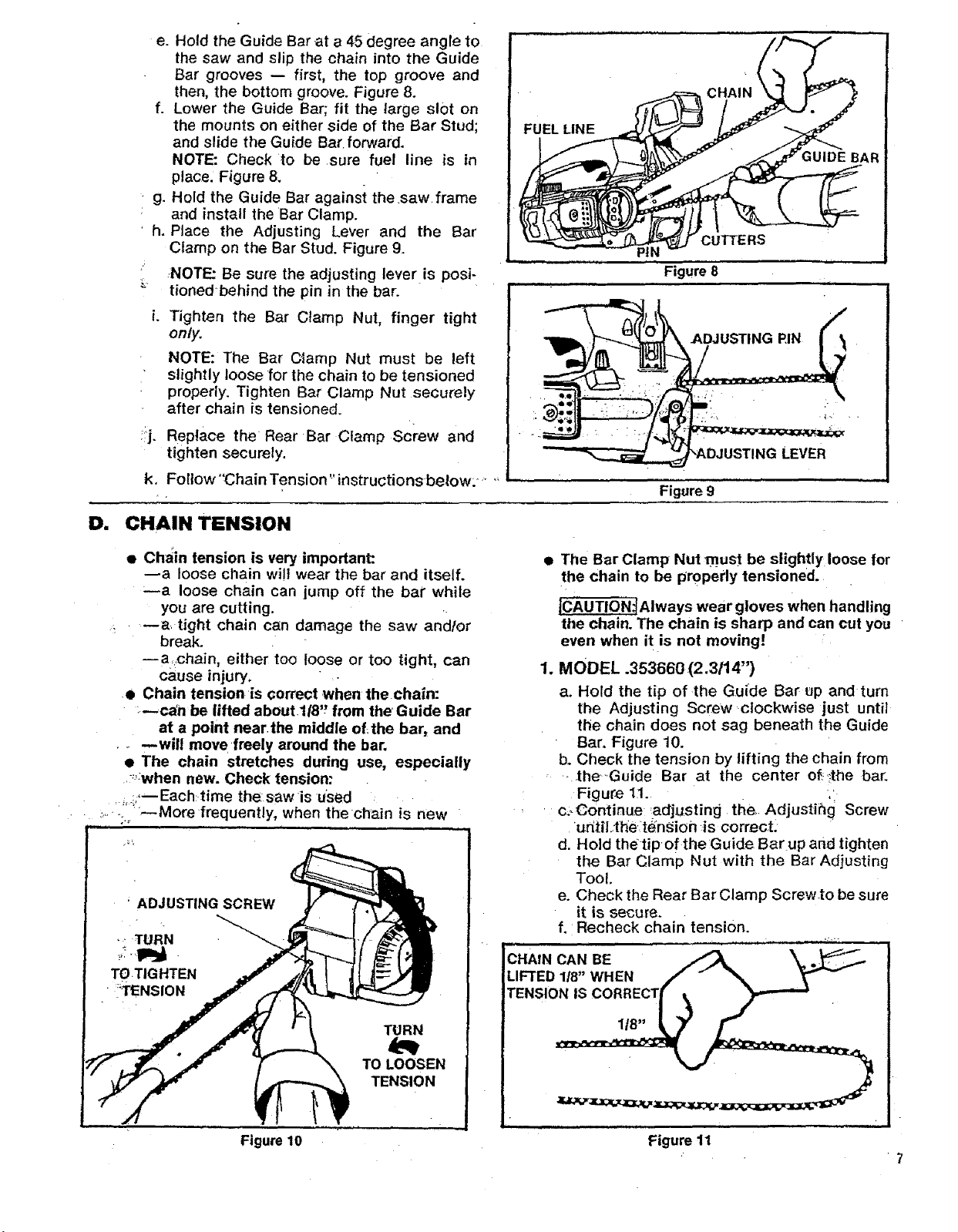

CLUTCH '

CLUTCH

Figure 3

c. Hold chain with cutters facing as shown in

Figure 3.

d. Place chain over and behind the clutch

drum, onto the sprocket. Figure 3.

e. Place the Guide Bar on the saw by fitting

the long slot in the Guide Bar over the Bar

Stud. Figure 4.

NOTE: Be sure the Guide Bar is positioned

with the adjusting pin hole below the large

slot.

f. Hold the Guide Bar at a 45 degree angle to

the saw and fi[the chain into the GuideBar

grooves -- first, the top groove and then,

the bottom groove.

g. Lower the Guide Bar; fit the adjusting pin

into the small hole below the large slot; fit

the large slot on themounts on either side

of the Bar Stud. Figure 5.

• h/NOTE: Check tO be sure fuel line is _in

place. Figure 5.

•CLAMP

SCREW

Figure 4 :

Figure 5

ADJUSTING LEVER

_BAR CLAMP

Figure 6

R CLAMP NUT

\

L Hold the Guide Bar against the saw frame

and install the Bar Clamp.

j. Secure the Bar Clamp with the Bar Clamp

Nut, finger tight only..

NOTE: The Bar Ctamp Nut must be slightly

loose for the chain to be tensioned properly.

Securely tighten Bar Clamp Nut after

chain is tensioned.

k. Replace the Rear Bar Clamp Screw and,

tighten.

I: Follow "ChainTension" instructionsl page 7.

2. MODELS .353670 (2.3116") and .353690

(2.3116" PS)

,: a ._Remove :the ;foilowing :parts. as shown!in

Figure 6, using the.Ba[._djusting Tool pro-

.vided with the unit.

1.) Bar Clamp Nut.

2.) Adjusting Lever.

3.) Rear Bar Clamp Screw.

4.) Bar Clamp.

b. Hold chain with cutters facing as shown in

Figure 7.

c. Place chain over and behind the clutch

drum, onto the sprocket. Figure 7.

NOTE: For Model 353690 (2.3!16") Power

Sharp, fit the chain into the sprocket

g rooves.

CLUTCH

Figure 7

d. Place the Guide Bar on the saw by fitting

the long slot in the Guide Bar over the Bar

Stud, Figure 8.

NOTE: Be sure the Guide Bar is positioned

with the pin below the large slot.

e. HoldtheGuideBarat a 45 degree angle to

the saw and slip the chain into the Guide

Bar grooves -- first, the top groove and

then, the bottom groove. Figure 8.

f. Lower the Guide Bar; fit the large slot on

the mounts on either side of the Bar Stud;

and slide the Guide Bar. forward.

NOTE: Check to be sure fuel line is in

place: Figure 8.

g. Hold the Guide Bar againsi thesaw frame

and install the Bar Clamp.

h. Place the Adjusting Lever and the Bar

Clamp on the Bar Stud. Figure 9.

;NOTE: Be sure the adjusting lever is posi-

tionedbehind the pin in the bar.

i. Tighten the Bar Clamp Nut, finger tight

only.

NOTE: The Bar C_amp Nut must be left

slightly loose for the chain to be tensioned

properly. Tighten Bar Clamp Nut securely

after chain is tensioned.

Jj. Replace the RearBar Clamp Screw and

tighten securely.

k. Follow 'Chain Tens'on "nstructionsbelow: .....

__ADJUSTING

e.e

CUTTERS

Figure 8

'ADJUSTING LEVER

Figure 9

BAR

,

_IN

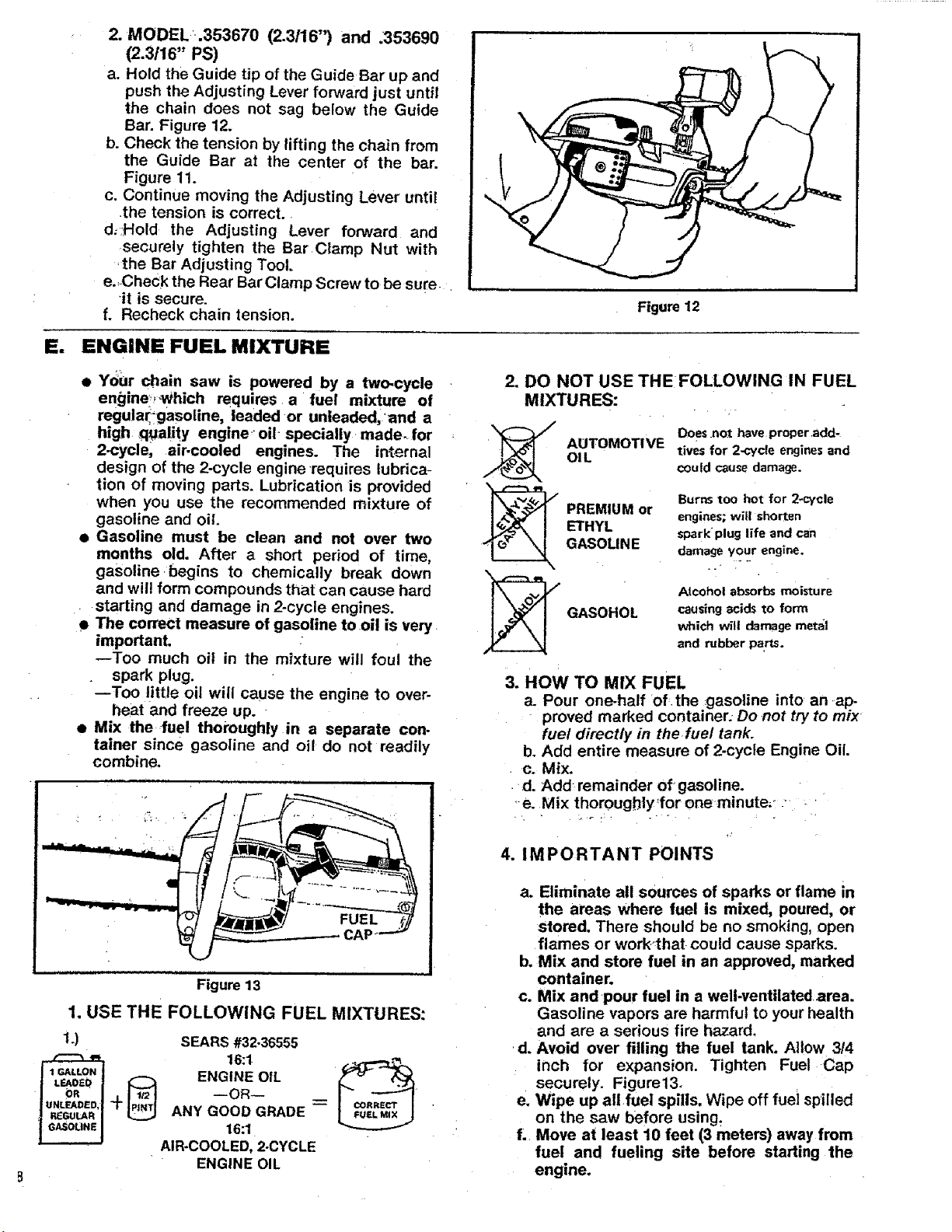

D. CHAIN TENSION

• Chain tension is very important:.

--a loose chain wi!t wear the bar and itself.

--a loose chain can jump off the bar while

you are cutting.

--a tight chain can damage the saw and/or

break.

--a:chain, either too loose or too tight, can

cause injury.

• Chain tension is correct when thechain:

:_can be lifted aboutll8'_ from the Guide Bar

at a point near the middle of_the bar, and

• _ --will move freely around the bar.

• The chain stretches during use, especially

::_;when new. Check tension:

,--Each:time the: saw is used

• _.'_:'i,i'_More frequentlyl when thechain is new

,,,,,

• The Bar Clamp Nut _must be slightly loose for

the chain to be propedy tensioned.

]CAUTION_Always wear gloves when handling

the chain. The chain is sharp and can cut you

even when it is not moving!

1, MODEL .353660 (2.3/14")

ao Hold the tip of the Guide Bar up and turn

the Adjusting Screw clockwise just until

the chain does not sag beneath the Guide

Bar. Figure 10.

b. Check the tension by lifting the chain from

- 1he.Guide Bar at the center of_;the bar.

Figure 11. .'.

.... c;.Continue adjusting the, Adjustii_g Screw

until:tlle tension :is correct.

d. Hold the tipof theGuide Bar up and tighten

the Bar Clamp Nut with the Bar Adjusting

Tool.

e. Check the Rear Bar Clamp Screw-to be sure

it is secure.

f. Recheck chain tension.

CH,,NCANBE

LIFTED 1t8" WHEN

TENSION IS

TURN

TO LOOSEN

TENSION

1t8"

Figure 10 Figure "11

L. i i'

7

2. MODEL.353670 (2.3/16") and .353690

(2.3/16" PS)

a. Hold the Guide tip of the Guide Bar up and

push the Adjusting Lever forward just until

the chain does not sag below the Guide

Bar. Figure 12.

b. Check the tension by lifting the chain from

the Guide Bar at the center of the bar.

Figure 11.

c, Continue moving the Adjusting Lever until

the tension is correct.

d, Hold the Adjusting Lever forward and

securely tighten the Bar Clamp Nut with

'the Bar Adjusting Tool.

e.,CheCk the Rear Bar Clamp Screw to be suie

it is secure.

f. Recheck chain tension.

E. ENGINE FUEL MIXTURE

Figure 12

• Ydur chain saw is powered by a two-cycle

engine?-Which requires a fuel mixture of

regula_gasoline, leaded or unleaded,'and a

high ,quality engine, oil- specially made- for

2-cycle, air-cooled engines. The internal

design of the 2-cycle engine requires lubrica-

tion of moving parts. Lubrication is provided

when you use the recommended mixture of

gasoline and oil,

• Gasoline must be clean and not over two

months old. After a short period of time,

gasoline begins to chemically break down

and wil! form compounds that can cause hard

starting and damage in 2-cycle engines.

• The correct measure of gasoline to oil is very

importanL

--Too much oil in the mixture will foul the

spark plug.

--Too little oil will cause the engine to over-

heat and freeze up.

• Mix the ,fuel thoroughly in a separate con-

tainer since gasoline and oil do not readily

combine,

2. DO NOT USE THEFOLLOWING IN FUEL

MIXTURES:

Does not have properadd-

OIL

AUTOMOTIVE

tires for 2-cycleenginesand

couldcausedamage.

BurnStoo hot for 2*_'ycle

ETHYL

_ REMIUM or

_ GASOHOL

GASOLINE

engines; will shorten

spark plug life andcan

damage your engine.

Alcohol absorbs moisture

causing acids to form

which will damage meta|

and nlbber pa.rts.

3..owTo.IXFUEL

a. Pour one-half Of.the gasoline into an ap-

proved marked container; Do not try to mix

fuel directly in the fuel tank.

b. Add entire measure of 2-cycle Engine Oil.

c. Mix.

d. Add, remainder of gasoline.

,-e. Mix thoroughly'for one minute,: • '

. o

Figure 13

1. USE THE FOLLOWING FUEL MIXTURES:

i.) SEARS #32-36555

ENGINE OIL

--OR-

+ ANY GOOD GRADE --

16:1

AIR*COOLED, 2-CYCLE

ENGINE OIL

4. IMPORTANT POINTS

a. Eliminate all sources of sparks or flame in

the areas where fuel is mixed, poured, or

stored. There should be no smoking, open

flames or work_that could cause sparks.

b, Mix and store fuel in an approved, marked

container.

c. Mix and-pour fuel in a well.ventilated area.

Gasoline vapors are harmful to your health

and are a serious fire hazard.

Avoid over filling the fuel tank. Al!ow 3/4

.d.

inch for expansion. Tighten Fuel Cap

securely. Figure13.

e. Wipe up all fuel spills. Wipe off fuei spilled

on the saw before using_

f.. Move at least 10 feet (3 meters) away from

fuel and fueling site before starting the

engine.

F!

BAR AND CHAIN OIL

• The guide bar and cutting chain require con-

stant lubrication in order to remain in

operating condition, Lubrication is provided

by the automatic oiler system when the oil

tank is kept filled.

--Lack of oil will quickly ruin the bar and

chain,

--Too little oil will cause overheating shown

,by smoke coming from the chain andJor

,discoloration of the guide bar rails.

e Use SEARS Bar and Chain Lubricant #36554

or clean SAE 3OW oil,

• o' InTfreezing weather oil will thicken, making it

._°-_h_b_e:ssaryto thin barand chain oil with a

small amount of Diesel Fuel #1 or Kerosene.

Bar and chain oit must be free flowing for the

oil system to pump enough oil for adequate

lubrication.

1__E THE FOLLOWING:

30°F or above--Lubricant--undiluted.

30°F- 0°F --95% Lubricant to

, ,_;.!_'_,:_ 5% Diesel Fuel #1

or Kerosene.

Below 0°F --90% Lubricant to

10% Diesel Fuel #1

or Kerosene.

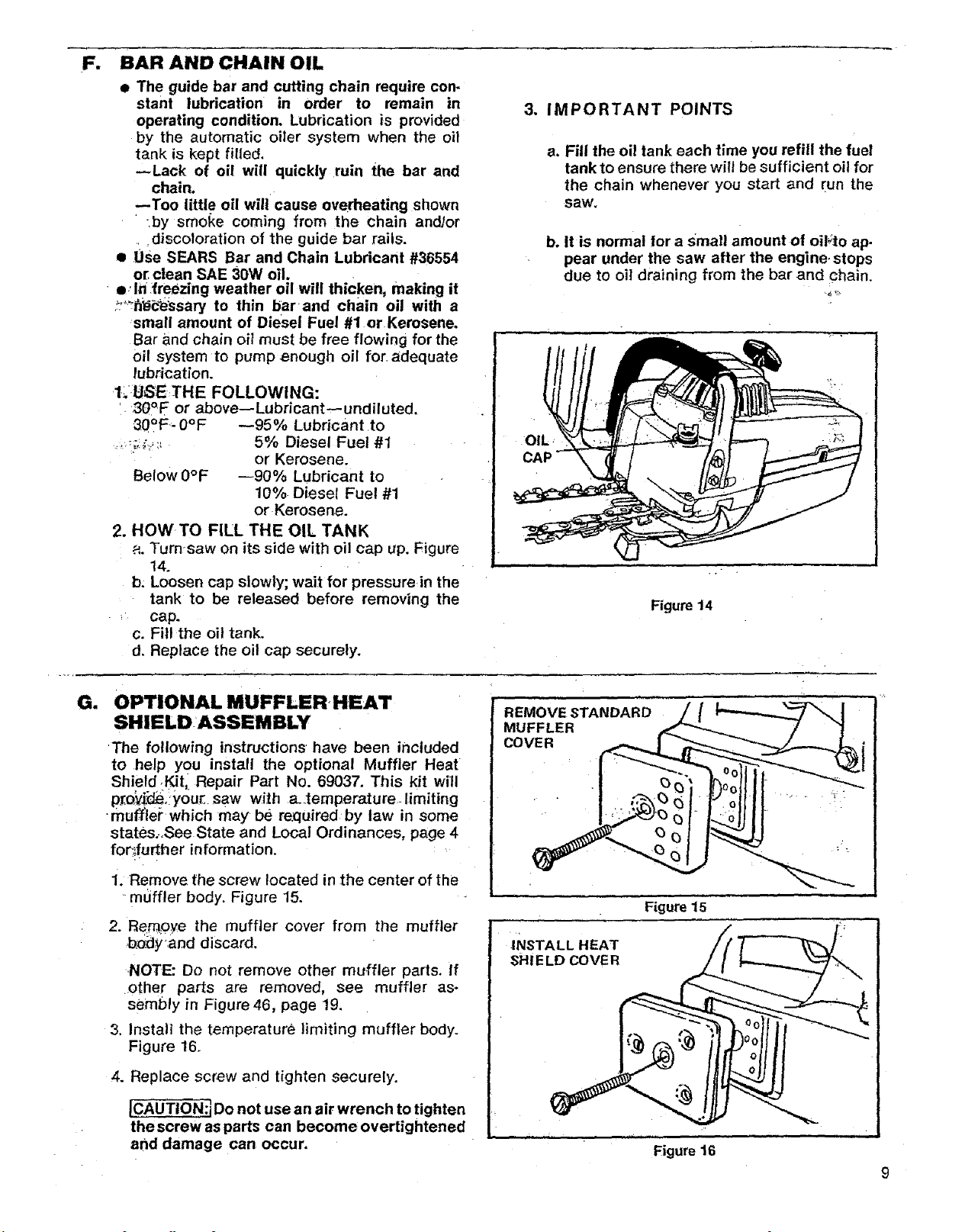

2. HOWTO FILL THE OIL TANK

a. Turn-saw on its side with oil cap up. Figure

14.

b. Loosen cap slowly; wait for pressure,in the

tank to be released before removing the

: cap.

c. Fill the oil tank,

d. Replace the oil cap securely,

3. IMPORTANT POINTS

a. Fill the oil tank each time you refill the fuel

tank to ensure there will be sufficient oil for

the chain whenever you start and Fun the

saw.

b, it is normal for a Small amount of oil;to ap-

pear under the saw after the engine, stops

due to oil draining from the bar and _hain.

OIL •

CAP

Figure 14

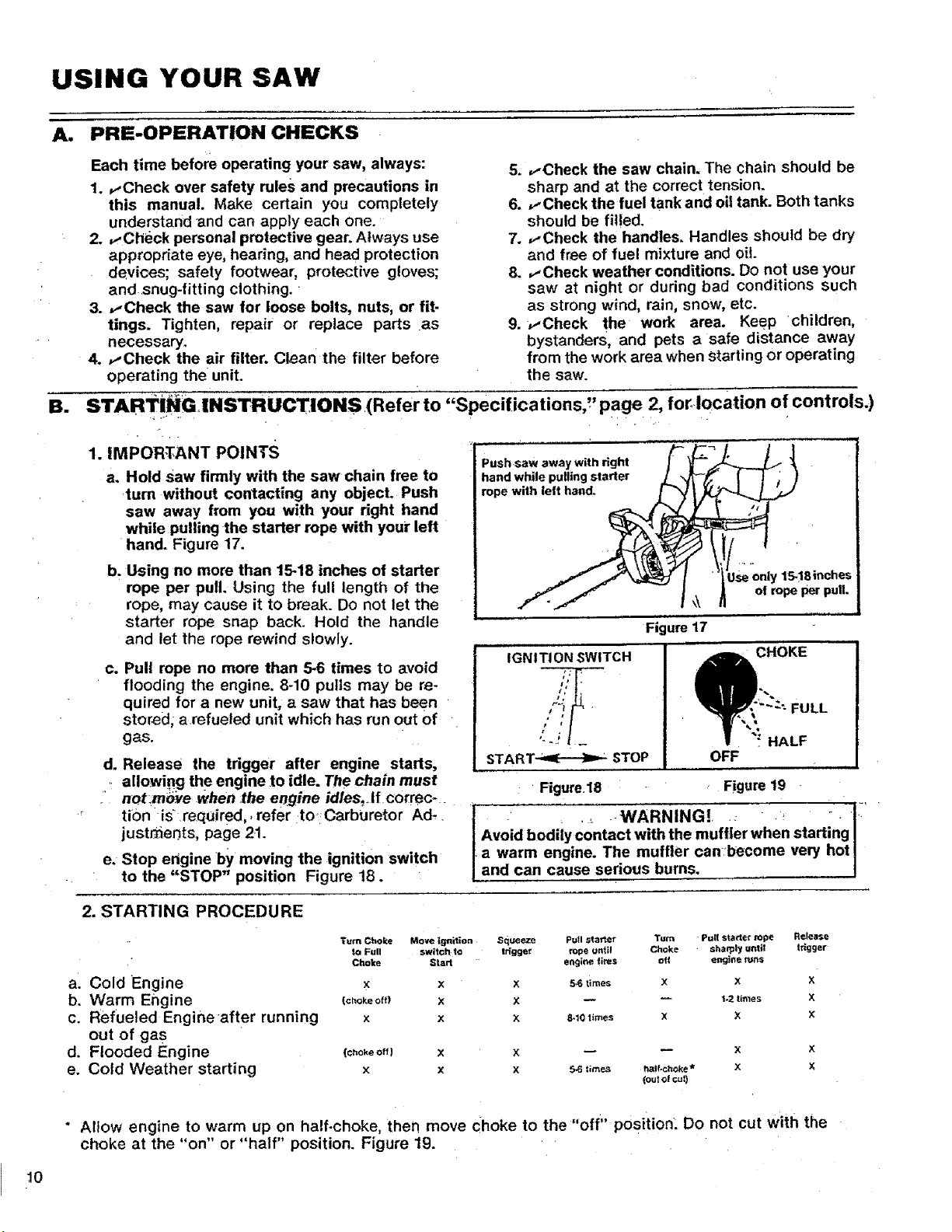

Gm

OPTIONAL MUFFLER, HEAT

SHIELD:ASSEMBLY

•The following instructions have been included

to help you install the optional Muffler Heat

Shield ,Kit,_Repair Part No. 69037. This kit will

pf.o_(_, you_ saw with a_temperatureolimiting

•muffle/" which may be re:quired by law in some

states;,See State and Local Ordinances, page 4

for_further information.

1. Remove the screw located in the center of the

-muffler body. Figure 15.

2. Rem_o_e the muffler cover from the muffler

b_dy'and discard.

NOTE: Do not remove other muffler parts. If

.other parts are removed, see muffler as*

sembly in Figure 46, page 19.

3. Install the temperature limiting muffler body.

Figure 16.

4. Replace screw and tighten securely.

JCAUTION:i Do not use an air wrench to tighten

the screw as parts can become overtightened

and damage can occur,

REMOVE STANDARD

MUFFLER

F{gure 15

INSTALL HEAT

sH iE LD COVE R

i i

Figure 16

9

USING YOUR SAW

A. PRE-OPERATION CHECKS

Each time before operating your saw, always:

1. vCheck over safety rules and precautions in

this manual. Make certain you completely

understand "and can apply each one.

2. ,,-Check personal protective gear. Always use

appropriate eye, hearing, and head protection

devices; safety footwear, protective gloves;

and snug-fitting clothing.

3. ,,-Check the saw for loose bolts, nuts, or fit-

tings. Tighten, repair or replace parts as

necessary.

4. ,.-Check the air filter. Clean the filter before

operating the unit.

STARTING INSTRUCTIONS (Refer to

BE

1. IMPORTANT POINTS

a. Hold saw firmly with the saw chain free to

turn without contacting any objecL Push

saw away from you with your right hand

whilepulling the starter rope with your left

hand. Figure 17.

b. Using no more than 15-18 inches of starter

rope per pull. Using the full length of the

rope, may cause it to break. Do not let the

starter rope snap back. Hold the handle

and let the rope rewind slowly.

C*

Pull rope no more than 5-6 times to avoid

flooding the engine. 8-10 pulls may be re-

quired for a new unit, a saw that has been

stored; a refueled unit which has run out of

gas.

d. Release the trigger after engine starts,

allowing the engine to idle. The chain must

• not.mo_e when .the engine idles, Jfcormc-

ti0n is_required,, refer to':Carburetor Ad.

justr_ents, page 21.

e. Stop engine by moving the ignition switch

to the "STOP" position Figure 18.

5. ,.-Check the saw chain. The chain should be

sharp and at the correct tension.

6. ,..Check the fuel tank and oil tank. Both tanks

should be filled.

7. ,,-Check the handles. Handles should be dry

and free of fuel mixture and oil.

8. ,..Check weather conditions. Do not use your

saw at night or during bad conditions such

as strong wind, rain, snow, etc.

9.,.-Check the work area. KeeP children,

bystanders, and pets a safe distance away

from the work area when starting or operating

the saw.

,'Specifications," page 2, for,location of controls.)

Push saw away with right

hand while pulling starter

rope with ielt hand.

15-!Sinches

ol rope per pull.

Figure17

IGNITION SWITCH

# •

s J

START-,_:-----)I,-- STOP

Figure.18 Figure 19

• ._ WARNING!_ : _ : I:"

Avoid bodily contact with the muffler when starting !

a warm engine. The muffler canbecome very hot I

and can cause serious burns.

_WI_. ,_":; FULL

/CHOK E 1

oFYF ""." HALF

2. STARTING PROCEDURE

Turn Choke Move ignition

to Full switch to

Cl_oke Start

a. Cold Engine x x

b. Warm Engine (c,o,_o,_ x

c. Refueled Engine after running x x

out of gas

d. Flooded Engine (:,o,_of{) x

e. Cold Weather starting x x

Squeeze Pull starter "rum Pull starter tope

ttigge_ rope until Choke sharply unfit

X 5-6 times X X

X _ _ %2 times

X 8-10 times X X

engine fires off engine tuns

m

5-6 times t_Ifocl_oke _

(outol cut)

" Allow engine to warm up on half.choke, then move choke to the "off" position: Do not cut with the

choke at the "on" or "half" position. Figure 19.

10

Release

trigger

x

x

x

Loading...

Loading...