Page 1

Operator's Manual

CRRFTSNRNo

2.6 cu. in./42cc 2-Cycle

GASOLINE CHAIN SAW

Model No.

358.352680 - 18 in. Bar

@

Read and follow all Safety Rules and Operating

WARNING:

Instructions before first use of this product.

For answers to your questions about this product:

Call 7 am-7 pro, Mon-Sat; Sun, 10 am-7 pm

1-800-235-5878

Sears, Roebuck and Co., Hoffman Estates, IL 60179 USA

530-087030 07/0"_/97

Page 2

Warranty 2 Storage 16

Safety Rules 2 Trouble Shooting Chart 17

Assembly 5 Parts List 19

Operation 6 Spanish 22

Maintenance 11 Parts & Ordering Back

Service and Adjustments 14

FULL ONE YEAR WARRANTY ON CRAFTSMAN ® GAS

CHAIN SAW

For one year from the date of purchase, when this Craftsman Gas Chain Saw is

maintained, lubricated and tuned up according to the owner's manual, Sears will

repair, free of charge, any defect in material or workmanship.

This warranty excludes the bar, chain, spark plug and air filter,which are

expendable parts, and become worn during normat use.

Ifthis Gas Chain Saw is used for commercial or rental purposes, this warranty

applies for 30 clays from the date of purchase.

WARRANTY SERVICE IS AVAILABLE BY RETURNING THIS CHAIN SAW TO

THE NEAREST SEARS SERVICE CENTER IN THE UNITED STATicS.

This warranty gives you specific legal rights, and you may also have other rights

which vary from state to state.

Sears, Roebuck and Co., D1817 WA, Hoffman Estates, IL 60179

WARNING: Always disconnect spark

plugwire whenmakingrepairsexcept

forcarburetoradjustments.Because a

chainsaw is a high-speed woodcutting

tool,carelessorimproper use ofthis

toolcan cause seriousinjury.

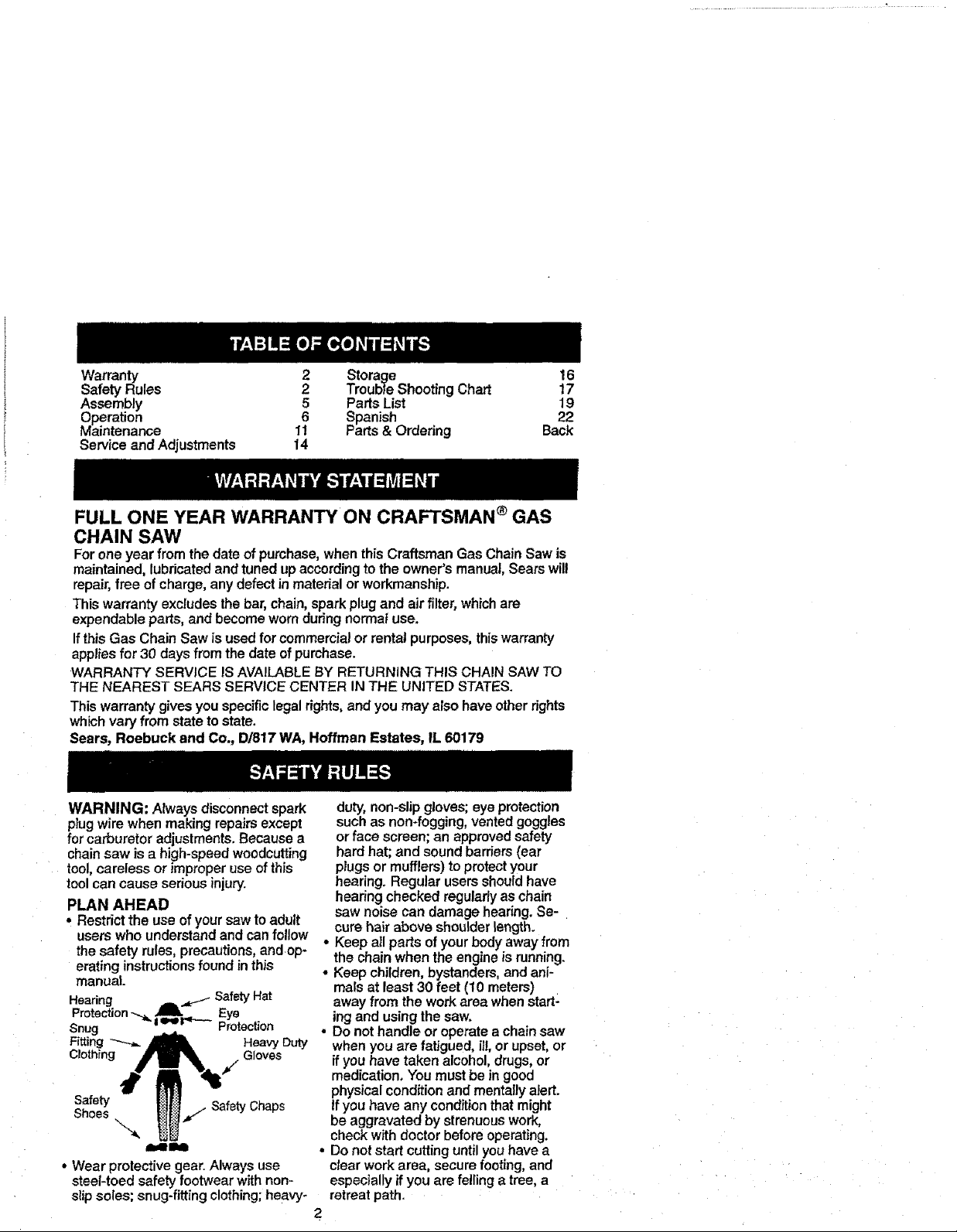

PLAN AHEAD

duty, non-slipgloves; eyeprotection

suchasnon-fogging,vented goggles

orface screen;an approvedsafety

hard hat;and sound barriers(ear

plugsormufflers) toprotect your

hearing.Regularusersshould have

hearingcheckedregularlyas chain

saw noisecan damagehearing.So-

• Restrictthe use ofyour saw toadult curehair above shoulder length.

users who understand and canfollow , Keep all parts ofyour body away from

the safety rules, precautions, andop- the chain when the engine is running.

erating instructions found inthis ° Keep children, bystanders, and ani-

manual, reals at least 30 feet (10 meters)

away from the work area when start-

Snug Protection

Fitting --_-.-_ Heavy Duty

Cfothing Gloves

/

Safety Safety Chaps

Shoes j

-\

=_llllle

, Wear protective gear. Always use

steel-toed safety footwear with non-

slip soles; snug-fitting clothing; heavy-

ing and using the saw.

Do not handle or operate a chain saw

when you are fatigued, il!, or upset, or

if you have taken alcohol, drugs, or

medication, You must be in good

physical condition and mentally alert.

If you have any condition that might

be aggravated by strenuous work,

check with doctor before operating.

Do not start cutting until you have a

clear work area, secure footing, and

especially if you are felling a tree, a

retreat path.

Page 3

........ ?

OPERATE YOUR SAW SAFELY

• Do not operate with one hand. Seri-

ous injury to the operator, helpers, or

bystanders may result from one-

handed operation. A chain saw is in-

tended for two-handed use.

• Operate the chain saw only in a well-

ventilated outdoor area.

• Do not operate saw from a ladder or

in a tree, unless you are specifically

trained to do so.

• Make sure the chain will not make

contact with any object while starting

the engine. Never try to start the saw

when the guide bar is in a cut.

• Do not put pressure on the saw, es-

pecially at the end of the cut. Doing

so can cause you to lose control

when the cut is completed.

° Stop engine before setting saw down.

• Hand carry saw only when engine is

stopped. Carry with muffler away from

body; guide bar & chain projecting be-

hind you; guide bar preferably cov-

ered with a scabbard.

MAINTAIN YOUR SAW IN GOOD

WORKING ORDER

- Have all chain saw service performed

by a qualified service dealer except

the items listed in the maintenance

section of this manual.

• Make certain the saw chain stops

moving when the throttle trigger is re-

leased. For correction, refer to "Car-

buretor Adjustments."

• Keep the handles dry, clean, and free

from oilor fuel mixture.

• Keep caps and fasteners securely

tightened.

• Use only Craftsman accessories and

replacement parts as recommended.

Never modify your saw.

HANDLE FUEL WITH CAUTION

• Do not smoke while handling fuel or

while operating the saw.

• Eliminateall sourcesof sparksor flame

in areas where fuel is mixed or poured.

• Mix and pour fuel in an outdoor area

and use an approved, marked con-

tainer for aUfuel purposes. Wipe UP

all fuel spills before starting saw.

• Move at least 10 feet (3 meters) from

fueling site before starting.

Turn the engine off and let saw cool in

a non-combustible area, not on dry

leaves, straw, paper, etc. Slowly re-

move fuel cap and refuel unit.

• Store the unit and fuel in a cool, dry

well ventilated space where fuel va-

pors cannot reach sparks or open

flames from water heaters, electdc

motors or switches, furnaces, etc.

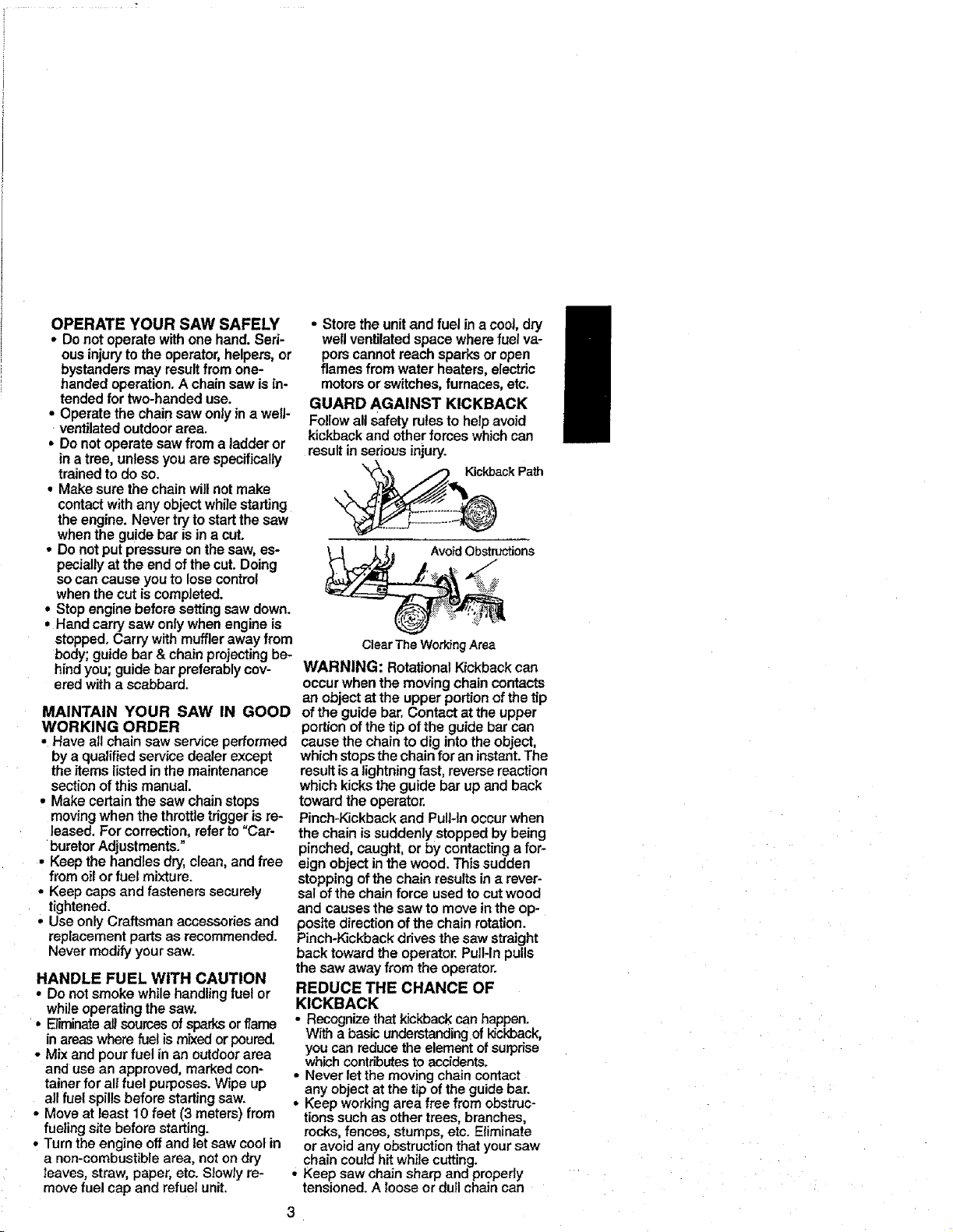

GUARD AGAINST KICKBACK

Follow all safety rules to help avoid

kickback and other forces which can

result in serious injury.

_ .,,._/, Kickback Path

Avon Obstructions

Clear The WorkingArea

WARNING; Rotational Kickback can

occur when the moving chain contacts

an object at the upper portion of the tip

of the guide bar, Contact at the upper

portion of the tip of the guide bar can

cause the chain to dig into the object,

which stops the chain for an instant. The

result is a lightning fast, reverse reaction

which kicks the guide bar up and back

toward the operator.

Pinch-Kickback and Pull-In occur when

the chain is suddenly stopped by being

pinched, caught, or by contacting a for-

eign object in the wood. This sudden

stopping of the chain results in a rever-

sal of the chain force used to cut wood

and causes the saw to move in the op-

posite direction of the chain rotation.

Pinch-Kickback drives the saw straight

back toward the operator. Pull-In pulls

the saw away from the operator.

REDUCE THE CHANCE OF

KICKBACK

• Recognize that kickback can happen.

With a basic understanding of kickback,

you can reduce the element of surprise

which contributes to accidents.

• Never let the moving chain contact

any object at the tip of the guide bar.

• Keep working area free from obstruc-

tions such as other trees, branches,

rocks, fences, stumps, etc. Eliminate

or avoid any obstruction that your saw

chain could hit while cutting.

• Keep saw chain sharp and propedy

tensioned. A loose or dull chain can

Page 4

increase the chance of kickback, Fol-

low manufacturer's chain sharpening

and maintenance instructions. Check

tension at regular intervals, but never

with engine running. Make sure bar

clamp nuts are securely tightened.

• Begin and continue cutting at full

speed, if the chain is moving at a

slower speed, there is greater chance

of kickback occurring.

• Use extreme caution when reentering

cut.

• Do not attempt cuts starting with the

tip of the bar (plunge cuts).

• Watch for shifting logs or other forces

that could close a cut and pinch or fall

into chain.

• Use the specified Reduced-Kickback

Guide Bar and Low-Kickback Chain.

Avoid Pinch-Kickback:

• Be extremely aware of situations or

obstructions that can cause material

to pinch the top of or otherwise stop

the chain.

• Do not cut more than one log at a

time.

• Do not twist saw as bar is withdrawn

from an undercut when bucking.

Avoid Pull-In:

• Always begin cutting with the engine

at full speed and the saw housing

against wood.

• Use wedges made of plastic or wood.

Never use metal to hold the cut open.

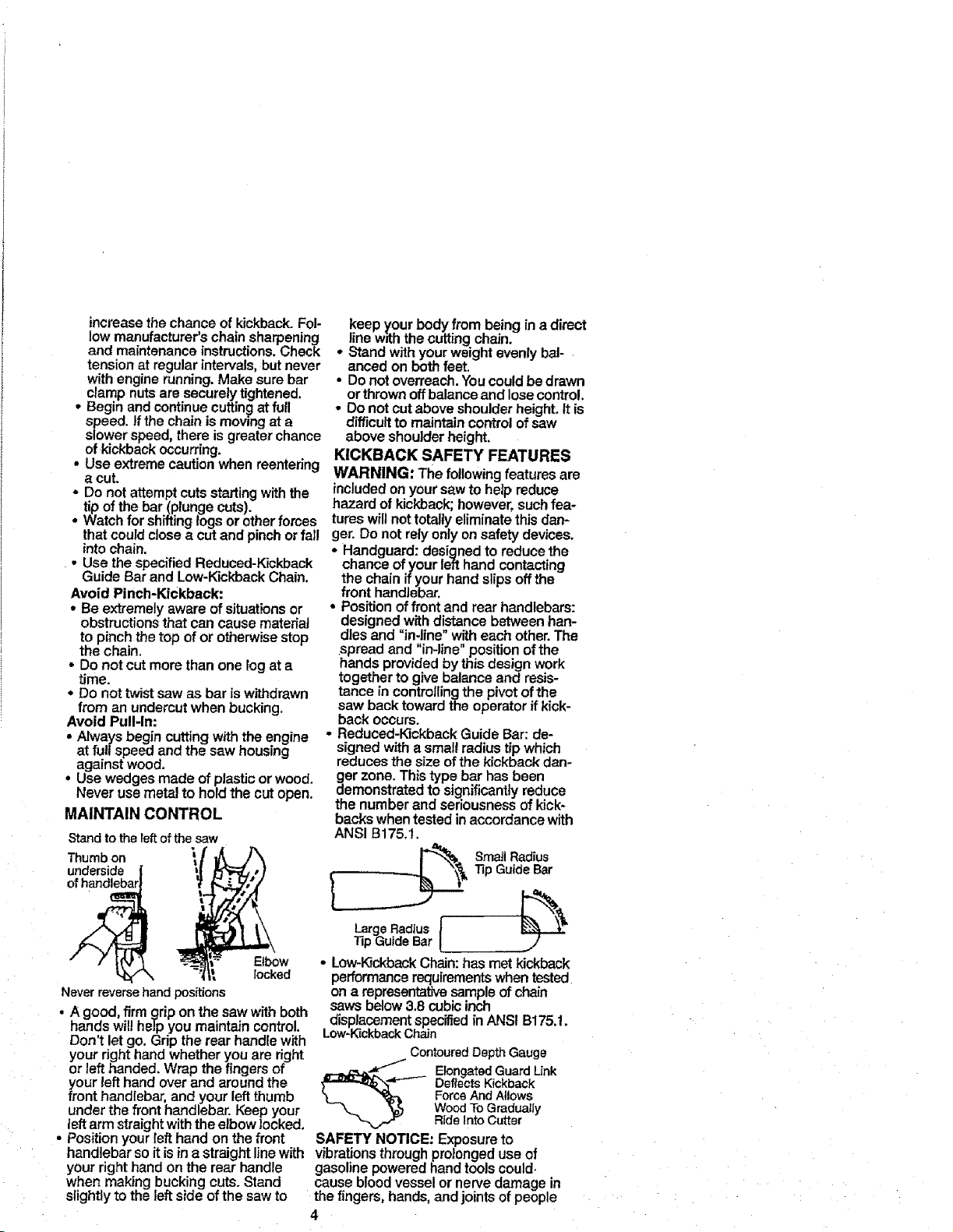

MAINTAIN CONTROL

Standto theleftofthe saw

Thumbon =

underside

of handlebar

keep _our body from being in a direct

line with the cutting chain.

• Stand with your weight evenly bal-

anced on both feet.

• Do not overreach. You could be drawn

or thrown off balance and lose control.

• Do not cut above shoulder height, tt is

difficult to maintain control of saw

above shoulder height,

KICKBACK SAFETY FEATURES

WARNING: The following features are

included on your saw to help reduce

hazard of kickback; however, such fea-

tures will nottotally eliminate this dan-

get. Do not rely only on safety devices.

• Handguard: designed to reduce the

chance ofyour left hand contacting

the chain ifyour hand slips off the

front handlebar.

• Position offront and rear handlebars:

designed with distance between han-

dles and "in-line" with each other. The

spread and "in-line" position of the

hands provided by this design work

together to give balance and resls-

tance in controlling the pivot of the

saw back toward the operator ifkick-

back occurs.

- Reduced-Kickback Guide Bar: de-

signed with a small radius tip which

reduces the size of the kickback dan-

ger zone. This type bar has been

demonstrated to significantly reduce

the number and seriousness of kick-

backs when tested in accordance with

ANSI B175.1.

SmatlRadius

Tip GuideBar

LargeRadius [i

"tipGuide Bar

Elbow

locked

Neverreversehand positions

• A good firm grip on the saw with both

hands will help you mainta n control.

Don't let go. Grip the rear handle with

your right hand whether you are right

or left handed. Wrap the fingers of

your left hand over and around the

front handlebar, and your left thumb

under the front handlebar. Keep your

. left arm straight with the elbow locked.

Position your left hand on the front

• Low-Kickback Chain: has met kickback

performance requirements when tested

on a representative sample of chain

saws below 3,8 cubic inch

displacement specified in ANSi B175.1.

Low-I_ckback Chain

Contoured Depth Gauge

Deflects Kickback

ForceAnd Allows

Wood ToGradually

_ longated Guard Link

RideInto Cutter

SAFETY NOTICE: Exposure to

handlebar soitisin a straight line with vibrationsthroughprolonged use of

your right hand on the rear handle gasoline powered hand tools could,

when making bucking cuts. Stand cause blood vessel or nerve damage in

slightlyto the leftside of the sawto the fingers, hands, andjoints of people

4

Page 5

prone to circulation disorders or

abnormal swelling. Prolonged use in

cold weather has been linked to blood

vessel damage in otherwise healthy

people. If symptoms occur such as

numbness, pain, loss of strength,

change in skin color or texture, or loss

of feeling in the fingers, hands, or joints

discont nue the use of this tool and

seek medical attention. An

anti-vibration system does not

guarantee the avoidance of these

problems. Users who operate power

tools on a continual and regular basis

must closely monitor their physical

condition and the condition of this tool.

CHAIN BRAKE If this saw is to be used

for commercial logging, you must order

and install a chain brake to comply with

Federal OSHA Regulations for Com-

mercial Logging. Contact your Sears

Service Center or call 1-800-235-5878:

SPARK ARRESTOR: Your saw is

equipped with a temperature timing

mufflerand sparkarresting screen

whichmeetsthe requirementsof

CaliforniaCodes4442 and4443. All

U.S. forestlandand thestatesof

California,Idaho,Maine, Minnesota,

New Jersey,Oregon,and Washington

requireby lawthatmanyinternal

combustion enginesbe equippedwitha

sparkarrestor screen.Ifyou operatea

chainsaw in astateorlocalewhere

suchregulationsexist,youarelegally

responsiblefor maintainingthe

operatingconditionoftheseparts.

Failureto doso is aviolationof thelaw.

Referto Customer Responsibilities

chartinthe MAINTENANCEsection.

STANDARDS: Thischainsawis listed

by UnderwritersLaboratories,inc.in

accordance withAmericanNational

Standards for Gasoline-PoweredChain

Saws SafetyRequ;rements(ANSI

B175.1-1991).

I

CARTON CONTENTS

Check carton contents against the fol-

lowing list.

Model 358.352680

• Chain Saw (fully assembled)

• Bartool

• Chain

, Carrying Case

• Gloves

• Gas Can

• Bar & Chain Lube

• 2-cycle engine oil

o Examine parts for damage. Do not

use damaged parts.

• If you need assistance or find that

parts are missing or damaged, please

call 1-800-235-5878.

NOTE: It is normal to hear the fuel filter

rattle in an empty fuel tank.

Your unit has been factory tested and

the carburetor precisely adjusted. As a

result you may smell gasoline or find a

drop of oil/fuel residue on the muffler

when you unpack the unit.

ASSEMBLY

Your saw is fully assembled; no

assembly is necessary.

Page 6

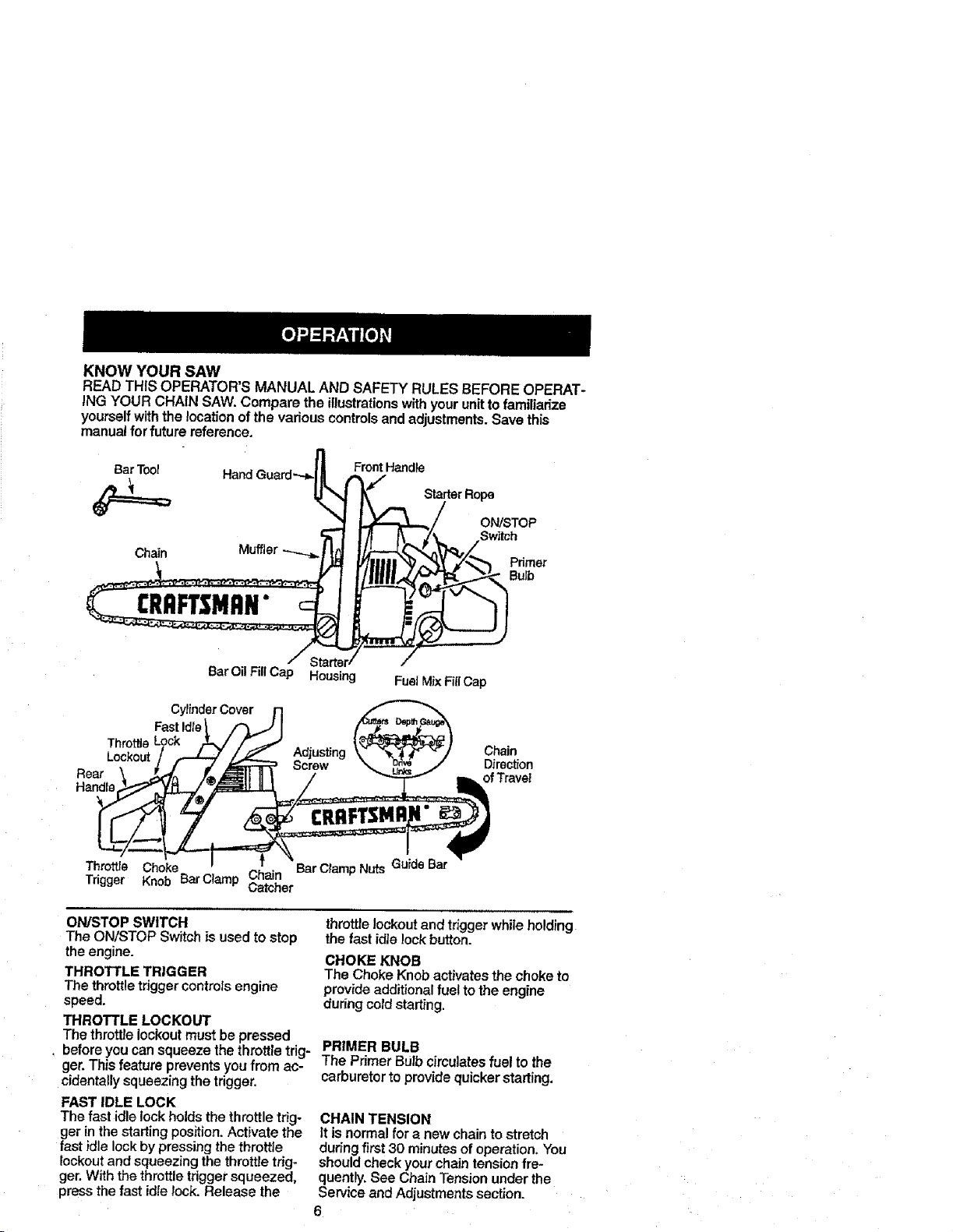

KNOWYOURSAW

READTHISOPERATOR'SMANUALANDSAFETYRULESBEFOREOPERAT-

ING YOUR CHAIN SAW, Compare the illustrationswith your unitto familiarize

yourself withthe location of the various controls and adjustments. Save this

manual for future reference.

rToo, " Hand Guard.---_ A_._. Handle

k S .or.ope

"NL .1

t I.,I I_ /_._ switch

Chain Muffler _ . Pdmer

Bar Oil Fill Cap Housing Fuel MixFillCap

Cylinder Cover

Fast Idle

Adjusting Chain

Screw Direction

ofTravel

Throttle Choke } Bar Clamp Nuts Guide Bar

Tdgger Knob Bar Clamp Chain

ON/STOP SWITCH

The ON/STOP Switch is used to stop

the engine.

THROTTLE TRIGGER

The throttletrigger controls engine

speed.

THROTTLE LOCKOUT

The throttle lockout must be pressed

before you can squeeze the throttle trig-

ger.This feature prevents you from ac-

cidentally squeezing the trigger.

FAST IDLE LOCK

The fast idle lock holds the throttle trig-

ger in the starting position, Activate the

fast idle lockby pressing the throttle

lockout and squeezing the throttle trig-

ger. With the throttle trigger squeezed,

press the fast idle lock. Release the

Catcher

throttle lockoutand trigger while holding

the fast idle lock button.

CHOKE KNOB

The Choke Knob activates the choke to

provide additional fuel to the engine

during coldstarting.

PRIMER BULB

The Primer Bulbcirculates fuel to the

carburetortoprovidequicker starting,

CHAIN TENSION

It is normal for a new chain to stretch

during first 30 minutes of operation. You

should check your chain tension fre-

quently. See Chain Tension under the

Service and Adjustments section.

6

Page 7

BEFORE STARTING ENGINE

WARNING: Be sureto read thefuel

handlinginformationinthesafety rules

sectionofthismanual beforeyoubegin.

If youdonotunderstandthefuel han-

dlinginformationdonotattempttofuel

yourunit.Seekhelpfrom someonethat

does understandthe informationorcall

the customerassistancehelp lineat

1-800-235-5878.

GUIDE BAR AND CHAIN OIL

The chain oiler provides continuous lu-

brication to the chain and guide bar. Be

sure to fill the bar oiltank when you fill

the fuel tank (Capacity = 6.8 fl. oz.).

For maximum guide bar and chain life,

we recommend you use Craftsman

chain saw bar oil. If Craftsman bar oil is

not available, you may use a good

grade SAE 30 oil untilyou are able to

obtain Craftsman brand. The oil output

is automatically metered during opera-

tion, Your saw will use approximately

one tank of bar el! for every tank of fuel

mix. Always fill the bar oil tank when

you fill the fuel tank,

.... FUEUNG ENGINE

This engine iscertified to operate on

unleaded gasoline. Before operation,

gasoline must be mixed with a good

quality 2-cycle air-cooled engine oil. We

recommend Craftsman brand oil. Mix

gasoline and oil at a ratio of 40:i (A

40:1 ratio isobtained by mixing 3.2

ounces of oilwith 1gatlon of unleaded

gasoline). DO NOT USE automotive oil

or boat oil. These oils will cause engine

damage. When mixing fuel follow the

instructions printed on the container.

Once oil is added to the gasoline,

shake container momentarily to assure

that the fuel is thoroughly mixed.

Always read and follow the safety rules

relating to fuel before fueling your unit.

lines and carburetor are empty. Use fresh

fuel next season. See STORAGE instruc-

tions for additionalinformation.

Never use engine or carburetor cleaner

products in the fuel tank or permanent

damage may occur.

See the STORAGEsection for additional

information.

STOPPING YOUR ENGINE

• Move On/Stop switch to STOP.

• If engine does not stop, pull choke

knob out fully.

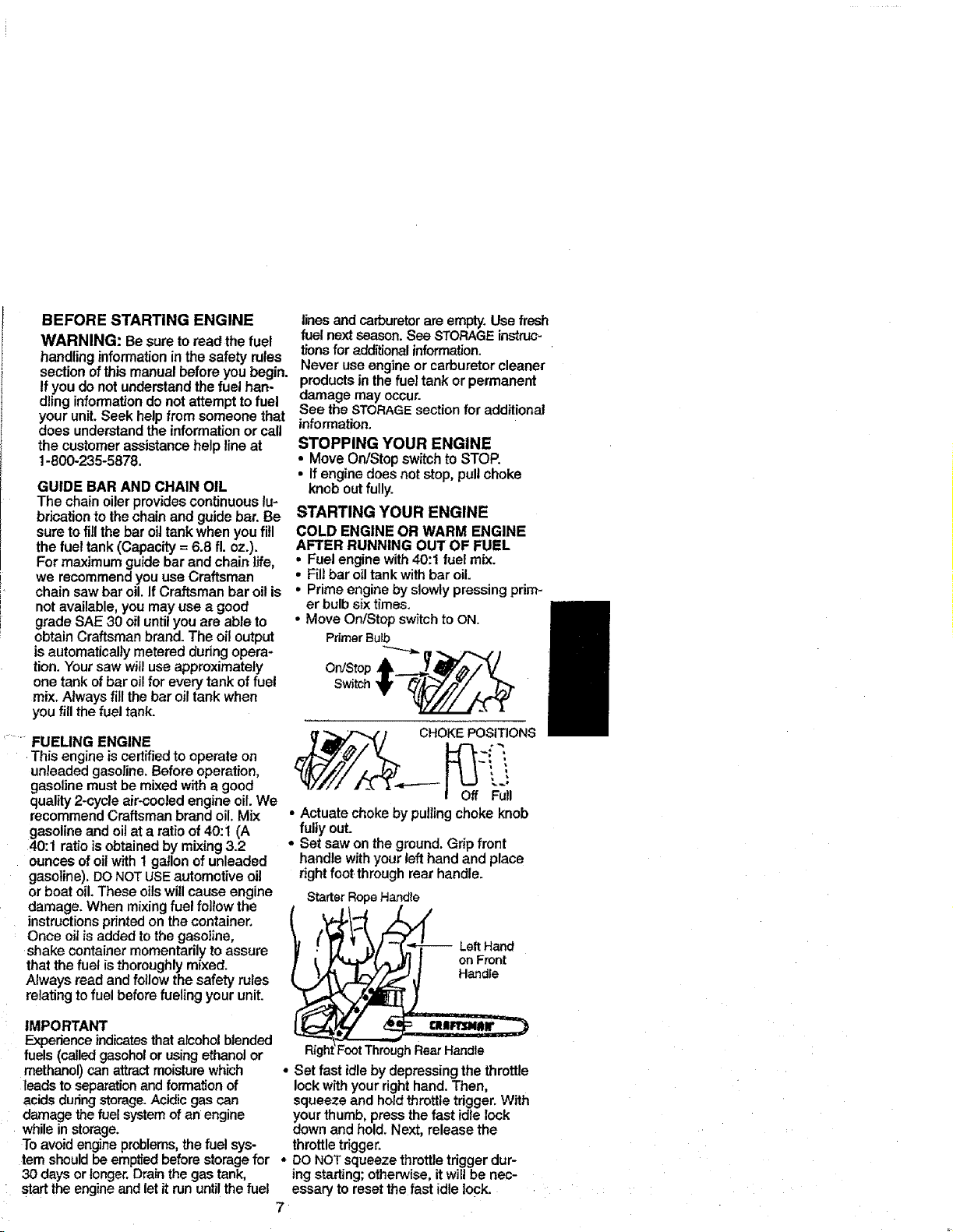

STARTING YOUR ENGINE

COLD ENGINE OR WARM ENGINE

AFTER RUNNING OUT OF FUEL

• Fuel engine with 40:1 fuel mix.

• Fill bar oil tank with bar oil.

• Prime engine by slowly pressing prim-

er bulb six times.

• Move OntStop switch to ON.

PrimerBulb

s tch

CHOKE POSITIONS

k_!

I Off Full

• Actuate choke by pulling choke knob

fulfy out.

• Set saw on the ground. Grip front

handle with your left hand and place

right foot through rear handle.

StarterRopeHandle

°.n 22t

IMPORTANT

Experience indicatesthat ak:ohol blended

fuels (calledgasohol or using ethanol or

methanol) can attract moisture which

leads to separationand formation of

acids during storage. Acidic gas can

damage the fuel systemof an engine

while in storage.

To avoid engine problems,the fuel sys-

tem should be emptiedbefore storage for •

30 days or longer. Drainthe gas tank,

start the engine and letit run until the fuel

RightFootThroughRearHandle

• Set fast idle by depressing the throttle

lock with your right hand. Then,

squeeze and holdthrottle trigger. With

dYourthumb, press the fast idle lock

own and hold. Next, release the

throttle trigger.

DO NOT squeeze throttle trigger dur-

ing starting; otherwise, it will be nec-

essary to reset the fast idle lock.

7

Page 8

NOTE: When pulling the starter rope,

do not use the full extent ofthe rope.

Do not let starter rope snap back. Hold

handle. Let rope rewind slowly.

• Pull starter rope handle firmly and

quickly with your right hand untilthe

engine attempts to start, but no more

than 5 pulls. Then, push in choke

knob fully. Resume pulling handle un-

til engine starts.

• Above 40°F, allow engine to run for

approximately 5 seconds. Then

squeeze and release throttle trigger to

allow engine to idte.

• Below 40 °F, allow engine to warm up

for 30 seconds to 1 minute with choke

at partial position. Push choke knob in

to the OFF position; then squeeze and

release throttle trigger to allow engine

to idle.

• To stop engine, move On/Stop switch

to the STOP position.

STARTING A WARM ENGINE

DONOT use the choke to start a warm

engine or flooding and hard starting

may occur.

• Move On/Stop switch to ON.

• Set fast idle lock.

• Be sure choke is in the OFF position.

• With saw on ground, grip front handle

with left hand and place your right foot

through rear handle.

• Pul!starter rope handle until engine

starts.

• Squeeze and release throttle trigger

to return engine to idle speed.

DIFFICULT STARTING OR

STARTING A FLOODED ENGINE

The engine may be flooded if it has not

started after 10 pulls. Flooded engines

can be cleared of excess fuel with the

following procedure:

• Engage the fast idle lock.

• Verifythat the On/Stop switch is inthe

ON position.

• Push choke knob to the OFF position.

• With saw on ground, grip front handle

with left hand and place right foot

through rear handle.

• Pullstarter rope handle until engine

starts.

• Starting could require many pulls de-

pending on how badly the unit is

flooded. If engine still fails to start, re-

fer to the TROUBLESHOOTING chart or

call 1-800-235-5878.

OPERATING TIPS

• Check chain tension before first use

and after 1 minute of operation. See

Chain Tension in the Maintenance

section.

• Cut wood only. Do not cut metal, plas-

tics, masonry, non-wood building ma-

terials, etc.

• Stop the saw ifthe chain strikes a for-

eign objecL Inspect the saw and re-

pair parts as necessary.

• Keep the chain out of dirt and sand.

Even a small amount of dirt will quick-

ly dull a chain and increase the possi-

bility of kickback.

• Practice cutting a few small logs using

the following steps. This will help you

get the "feel" of using your saw before

you begin a major sawing operation.

• Squeeze the throttle trigger and al-

low the engine to reach full speed

before cutting.

• Begin cuttingwith the saw frame

against the log.

• Keep the engine at full speed the

entire time you are cuffing.

° Allow the chain to cut for you. Exert

only light downward pressure.

• Release the throttle trigger as soon

as the cut is completed, allowing the

engine to idle. If you run the saw at

full throttle without a cutting load,

unnecessary wear can occur.

° To avoid losing control when cut is

complete, do not put pressure on

saw at end of cut.

• Stop engine before setting saw down.

TREE FELLING TECHNIQUES

WARNING: Check for broken or dead

branches which can fall while cutting

causing serious injury. Do not cut near

buildings or electrical wires if you do not

know the direction of tree fall, nor cut at

night since you will not be able to see

well, nor during bad weather such as

rain, snow, or strong winds, etc.

• Carefully plan your sawing operation

in advance.

• Clear the work area. You need a clear

area all around the tree so you can

have secure footing.

• Study the natural conditions that can

cause the tree to fall ina particular

direction. These conditions include:

• The wind direction and speed.

• The lean ofthe tree. The lean of a

tree might not be apparent due to

uneven or sloping terrain. Use a

Page 9

plumb or level to determine the di-

rection of tree lean.

° Weight and branches on one side.

• Surrounding trees and obstacles.

Look for decay and rot. If the trunk is

rotted, it can snap and fall toward the

operator.

Make sure there is enough room for

the tree to fall. Maintain a distance of

2.1/2 tree lengths from the nearest

person or other objects. Engine noise

can drown out a warning call.

Remove dirt, stones, loose bark,

nails, staples, and wire from the tree

where cuts are to be made.

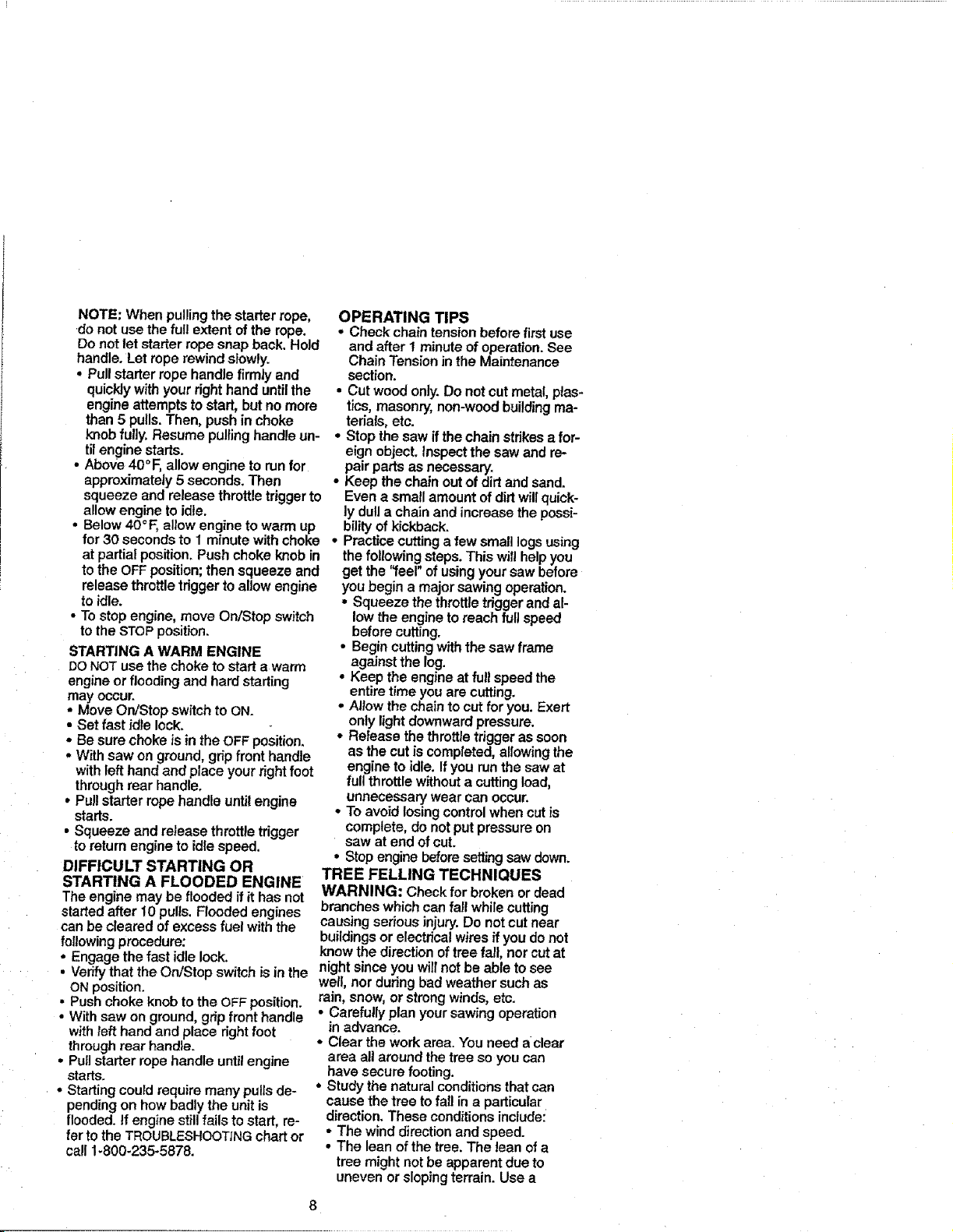

,_ Plana clear retreat path

_,.... ()--=,",==_- Directionof Fall

45° ..

FELLING LARGE TREES

(6 inches in diameter or larger)

The notch method isused to fell large

trees. A notch is cut on the side of the

tree in the desired direction of fall. After

a felling cut is made on the opposite

side of tree, the tree will tend to fall in

the direction of the notch.

NOTE: If tree has large buttress roots,

remove them before making the notch.

NOTCH CUT AND FELLING TREE

• Make notch cut by cutting the top of

the notch first. Cut through 1/3 of the

diameter of the tree. Next complete

the notch by cutting the bottom. See

illustration. Once the notch is cut, re-

move the wedge ofwood from tree.

Finalcut here

Firstcut =- /

\

Notch -_.,_

• After removingthe wood,make the

felling cutonthe opposite side ofthe

notch.This isdoneby making a cut

about two inches higher than the cen- or hung in a log,don't try to force it out.

ter of the notch. This will leave You can lose control of the saw result-

enough uncut wood between the fell- ing in injury and/or damage to the saw.

ing cut and the notch to form a hinge. Stop the saw, drive a wedge of plastic

This hinge will help prevent the tree

from falling in the wrong direction.

Hingeholdstree on

stumpandhelps

controlfat1

Opening of

felling cut

NOTE: Before felling cutis complete,

use wedges to open the cut when

necessary to control the direction of fall.

To avold kickback and chain damage,

use wood or plastic wedges, but never

steel or iron wedges.

• Be alert to signs that the tree is ready

to fall: cracking sounds, widening of

the felling cut, or movement in the up-

per branches.

° As tree starts to fall, stop saw, put it

down, and get away quickly on your

planned retreat path.

• Be extremely cautious with partially

fallen trees that may be poorly sup-

ported. When a tree doesn't fall com-

pletely, set the saw aside and pull

down the tree with a cable winch,

block and tackle, or tractor. Do not

use your saw to cut down a partially

fallen tree.

CUTTING A FALLEN TREE

(BUCKING)

Bucking is the term used for cutting a

fallen tree tothe desired log size.

WARNING: Do not stand on the log

being cut. Any portion can roll causing

toss of footing and control. Do not stand

downhill of the log being cut.

IMPORTANT POINTS

• Cut only one log at a time.

• Cut shattered wood very carefully;

sharp pieces of wood could be flung

toward operator.

° Use a sawhorse to cut small logs.

Never allow another person to hold

the log while cutting and never hold

the log with your leg or foot.

• Do not cut in an area where logs,

limbs, and roots are tangled. Drag logs

intoa clear area before cutting them.

BUCKING TECHNIQUES

WARNING: If saw becomes pinched

9

Page 10

orwood into the cut until the saw can be

removed easily. Restart saw and carefulJy

reenter the cut. Do not use a metal

wedge. Do not attempt to restart your

saw when it is pinched or hung in a log.

Usea wedgeto remove pinchedsaw

"rumsaw OFF and use a plasticor

woodenwedgetoforce cut open.

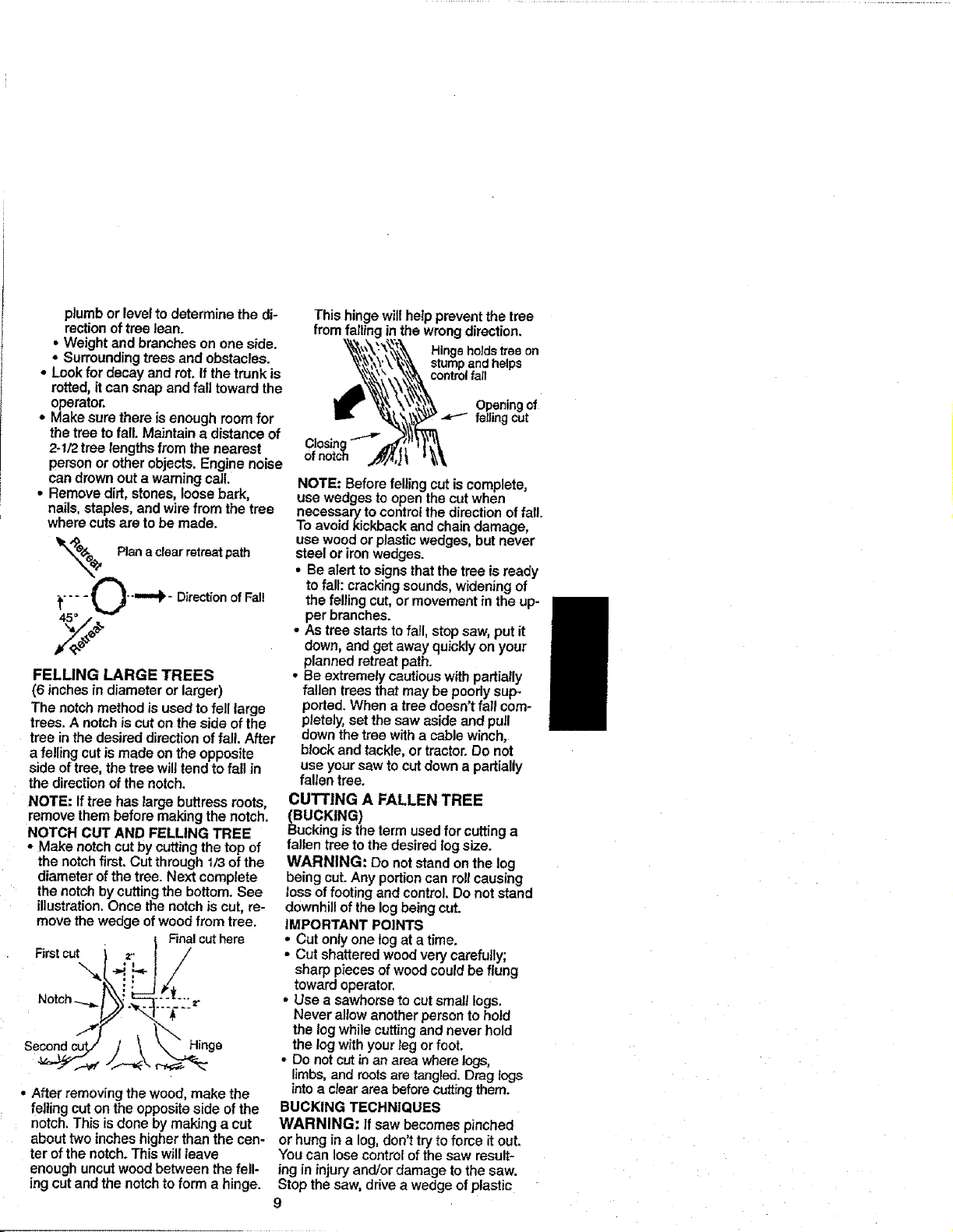

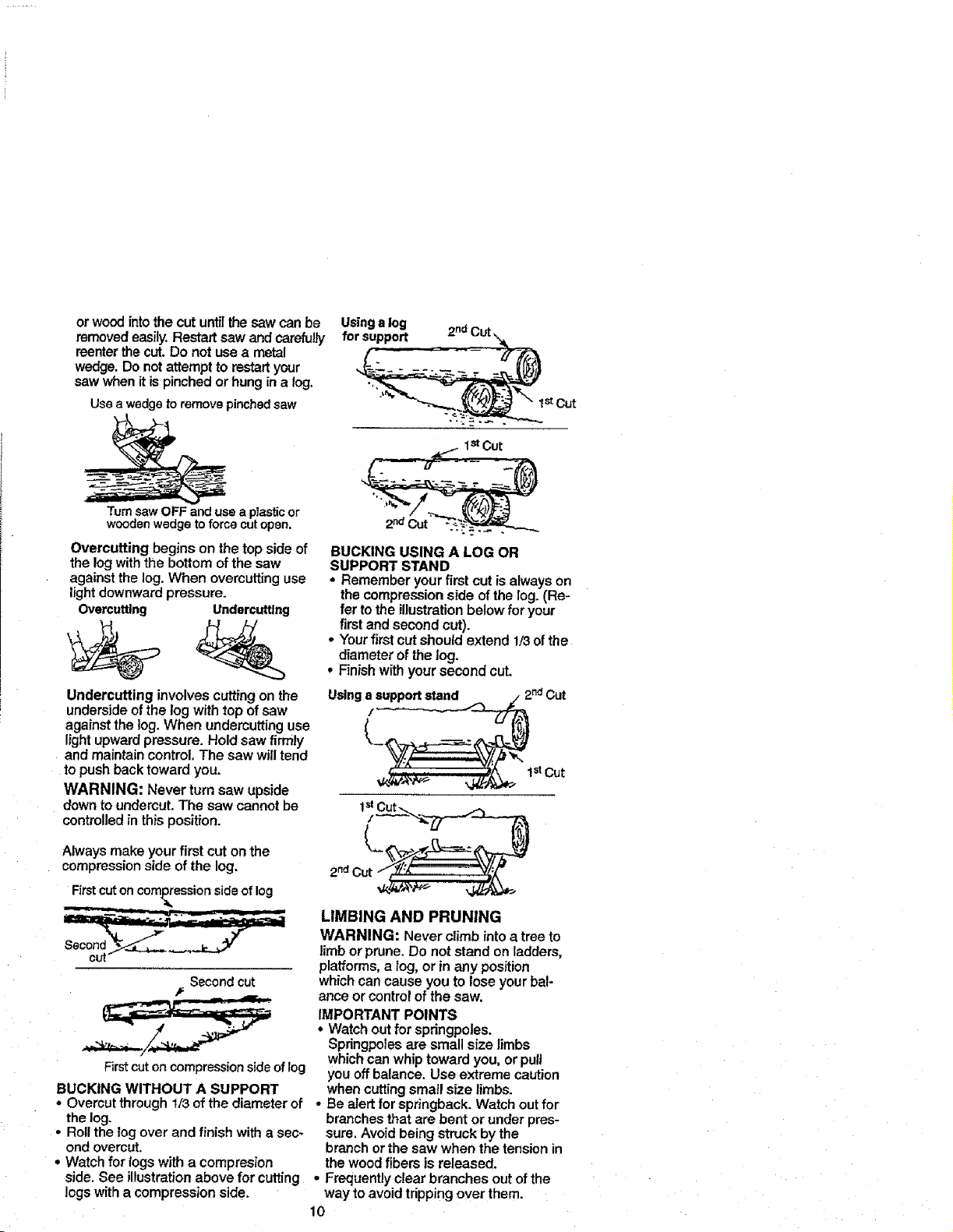

Overcutting begins on the top side of

the log with the bottom of the saw

against the log. When overcutting use

light downward pressure.

Overcuttlng Undercutting

Undercutting involves cutting on the

underside of the log with top of saw

against the log. When undercutting use

light upward pressure. Hold saw firmly

and maintain control, The saw will tend

to push back toward you.

WARNING: Never turn saw upside

down to undercut. The saw cannot be

controlled in this position.

Usinga log 2nd

for support

1stcut

1stGut

BUCKING USING A LOG OR

SUPPORT STAND

• Remember your first cut isalways on

the compression side of the log. (Re-

fer to the illustration below for your

first and second cut).

• Your first cut should extend 1/3 ofthe

diameter of the log.

• F3nishwith your second cut.

Using a_2 naCut

__lSt Cut

Alwaysmake yourfirst cut onthe

compressionside of the log.

First cut on compression side of log

LIMBING AND PRUNING

WARNING: Never climb into a tree to

limb or prune. Do not stand on ladders,

Second cut

Firstcut on compressionside of log

BUCKING WITHOUT A SUPPORT

• Overcut through 1/3 of the diameter of • Be atert for springback. Watch out for

the log. branches that are bent or under pres-

• Roll the log over and finish with a sec- sure. Avoid being struck by the

end overcut, branch or the saw when the tension in

• Watch for logs with a compresion the wood fibers is released.

side. See illustration above for cutting • Frequently clear branches out of the

logs with a compression side, way to avoid tdpping over them.

platforms, a Iog, or in any position

which can cause you to lose your bal-

ance or control of the saw,

IMPORTANT POINTS

* Watch out for spdngpoles.

Spriogpoles are small size limbs

which can whip toward you, or pull

you offbalance. Use extreme caution

when cutting small size limbs.

10

Page 11

LIMBING

• Limba tree only after it is cut down.

• Leave the larger limbs underneath the

felled tree to support the tree as you

work.

• Start at the base of the felled tree and

work toward the top, cutting branches

and limbs. Remove small limbs with

one cut.

° Keep the tree between you and the

chain.

• Remove larger, supporting branches

with the 1/3, 2/3 cutting techniques de-

scribed in the bucking section.

• Always use an overcut to cut small

and freely hanging limbs. Undercut-

ting could cause limbs to fall and

pinch the saw.

PRUNING

WARNING; Limit pruning to limbs

shoulder height or below. Do not cut if

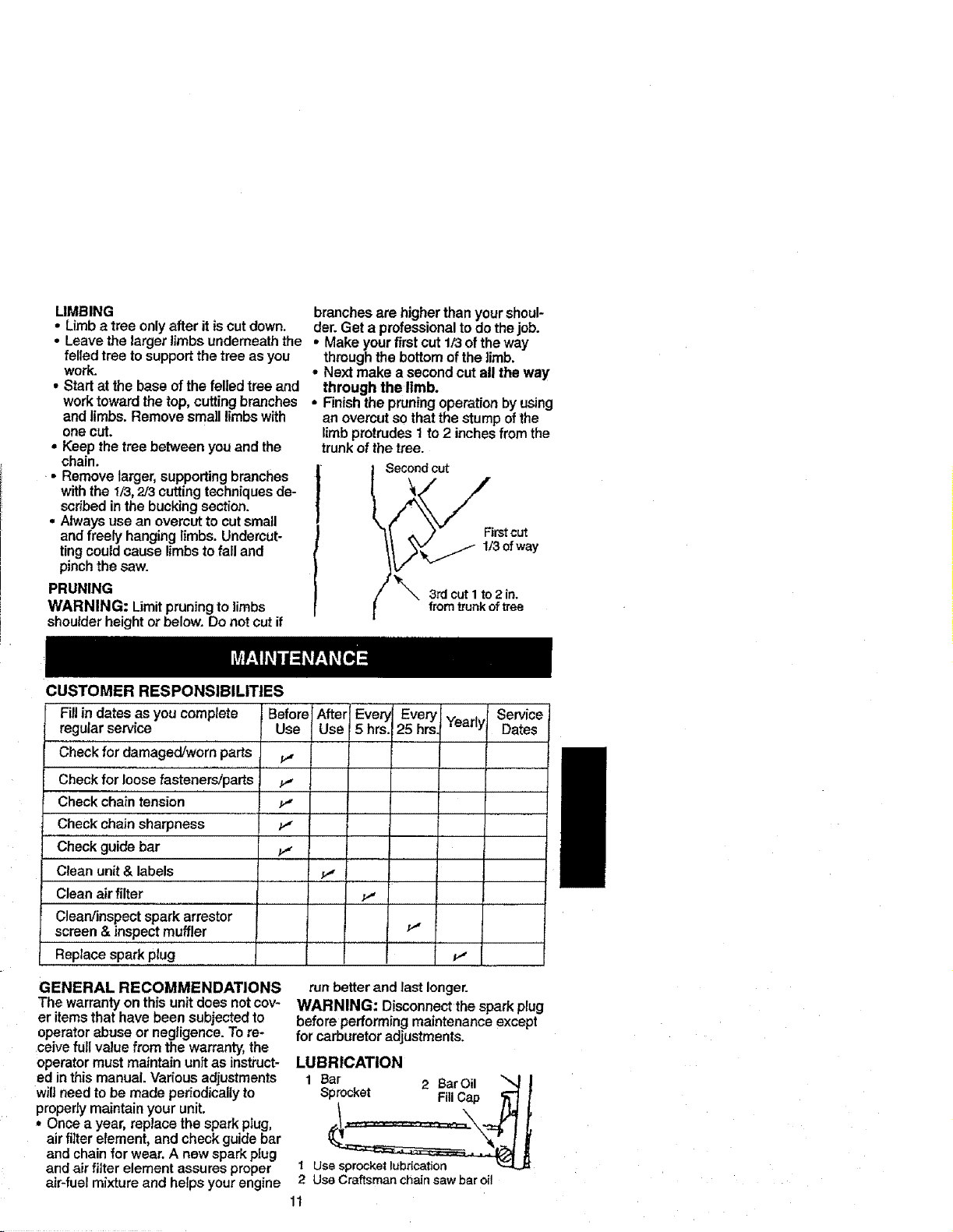

CUSTOMER RESPONSIBILITIES

FlUin dates as you complete Before After

regular service Use Use

Check for damaged/worn parts

Check for loose fasteners/parts ._,

Check chain tension

Check chain sharpness

Check guide bar

Clean unit & labels

Clean air filter

Clearv'inspect spark arrestor

screen & inspect muffler

Replace spark plug

v"

branches are higher than your shoul-

der. Get a professional to do the job.

• Make your first cut 1/3 of the way

through the bottom of the limb.

• Next make a second cut all the way

through the limb.

• Finish the pruning operation by using

an ovemut so that the stump of the

limbprotrudes t to 2 inches from the

trunk of the tree.

i | Secondcut

/ \ 3rd cutI to2in.

t fromtrunkof tree

EveryJEvery

5 hrs.125 hrs. Yearly

• r

Service

Dates

GENERAL RECOMMENDATIONS

The warrantyonthis unitdoesnotcov-

er itemsthathavebeen subjectedto

operatorabuseornegligence.Tore-

ceive fullvalue from the warranty,the

operator mustmaintain unit as instruct-

ed inthis manual. Various adjustments

will need to be made periodicallyto

properlymaintain your unit.

• Oncea year, replace the spark plug,

air filter element, and check guide bar

and chain for wear.A newspark plug

and air filter elementassures proper

air-fuel mixture and helps your engine

run better and lastlonger.

WARNING: Disconnect the sparkplug

before performingmaintenanceexcept

for carburetoradjustments.

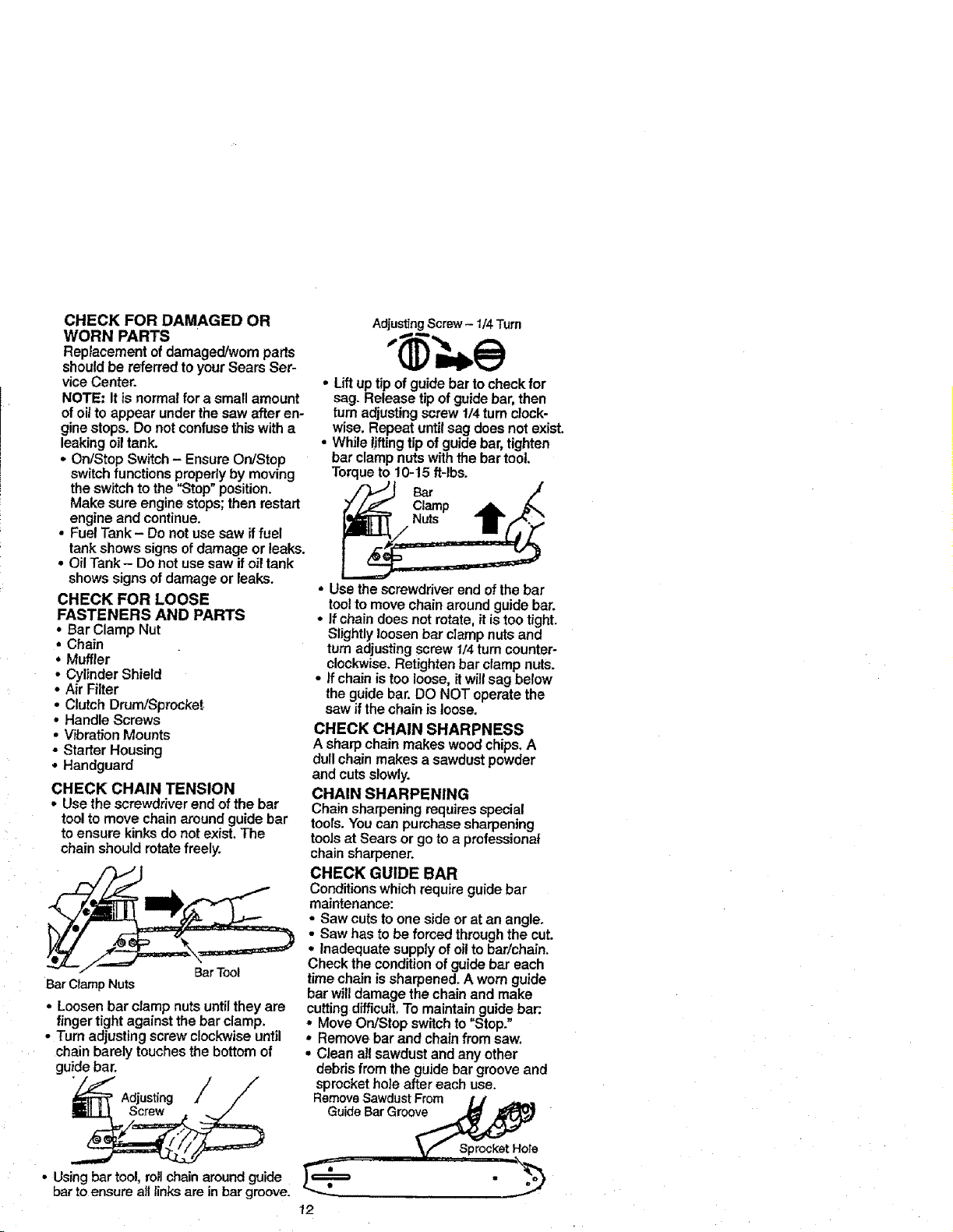

LUBRICATION

1 Bar

S-rocket 2 BarOil "_ I

I Us_

2 Use Craftsman chainsaw bar oil

F,,cap t

11

Page 12

CHECK FOR DAMAGED OR

WORN PARTS

Replacementofdamaged/wornparts

shouldbe referredtoyourSeam Ser-

viceCenter.

NOTE: It isnormalfor a smallamount

ofoil toappear underthe sawafter en-

gine stops.Do notconfusethiswitha

leakingoiltank.

oOn/Stop Switch- EnsureOn/Stop

switchfunctions propedyby moving

theswitchtothe "Stop"position.

Makesure enginestops;then restart

engineandcontinue.

• Fuel Tank- Donot usesaw iffuel

tankshowssignsofdamage orleaks.

• Oil Tank- Donotusesaw ifoil tank

showssignsofdamageor leaks.

CHECK FOR LOOSE

FASTENERS AND PARTS

° Bar Clamp Nut

• Chain

• Muffler

• Cylinder Shield

• Nr Filter

• ClutchDrum/Sprocket

° HandleScrews

• VibrationMounts

• Starter Housing

° Handguard

CHECK CHAIN TENSION

° Use thescrewdriver end of the bar

tool to move chainaround guide bar

to ensure kinks do not exist.The

chain should rotate freely.

BarTool

Bar Clamp Nuts

• Loosen bar clamp nuts until they are

finger tight against the bar clamp.

• Turn adjusting screw clockwise until

chain barely touches the bottom of

guide bar.

A iost,ogJ

Adiu_ng Screw - 1/4 rum

• Liftup tip of guide bar to check for

sag. Release tip of guide bar, then

turn adjusting screw 1/4turn clock-

wise. Repeat until sag does not exist.

• While liftingtip of guide bar, tighten

bar clamp nuts with the bar tool.

Torque to 10-15 ft-lbs,

• Use the screwdriver end of the bar

tool to move chain around guide bar.

° If chain does not rotate, it istoo tight.

Slightly loosen bar clamp nuts and

turn adjusting screw 1/4 turn counter-

clockwise. Retighten bar clamp nuts.

• Ifchain is too loose, it will sag below

the guide bar. DO NOT operate the

saw if the chain is loose.

CHECK CHAIN SHARPNESS

A sharp chain makes wood chips. A

dull chain makes a sawdust powder

and cuts slowly.

CHAIN SHARPENING

Chain sharpening requires special

tools. You can purchase sharpening

tools at Sears or go to a professional

chain sharpener.

CHECK GUIDE BAR

Conditions which require guide bar

maintenance:

• Saw cuts to one side or at an angle.

• Saw has to be forced through the cut.

• Inadequate supply of oilto bar/chaln.

Check the condition of guide bar each

time chain is sharpened. A worn guide

bar will damage the chain and make

cutting difficult,To maintain guide bar:

• Move On/Stop switch to "Stop."

• Remove bar and chain from saw,

• Clean all sawdust and any other

debris from the guide bar groove and

sprocket hole after each use.

RemoveSawdust From

GuideBarGroo_,_

° Using bar tool, rollchain around guide

bar to ensure all links are in bar groove.

12

Page 13

• Add lubricant to sprocket hole after

each use.

• Burring of guide bar roils isa normal

process of rail wear. Remove these

burrs with a flat file.

• When rail top is uneven, use a fiat file

to restore square edges and sides.

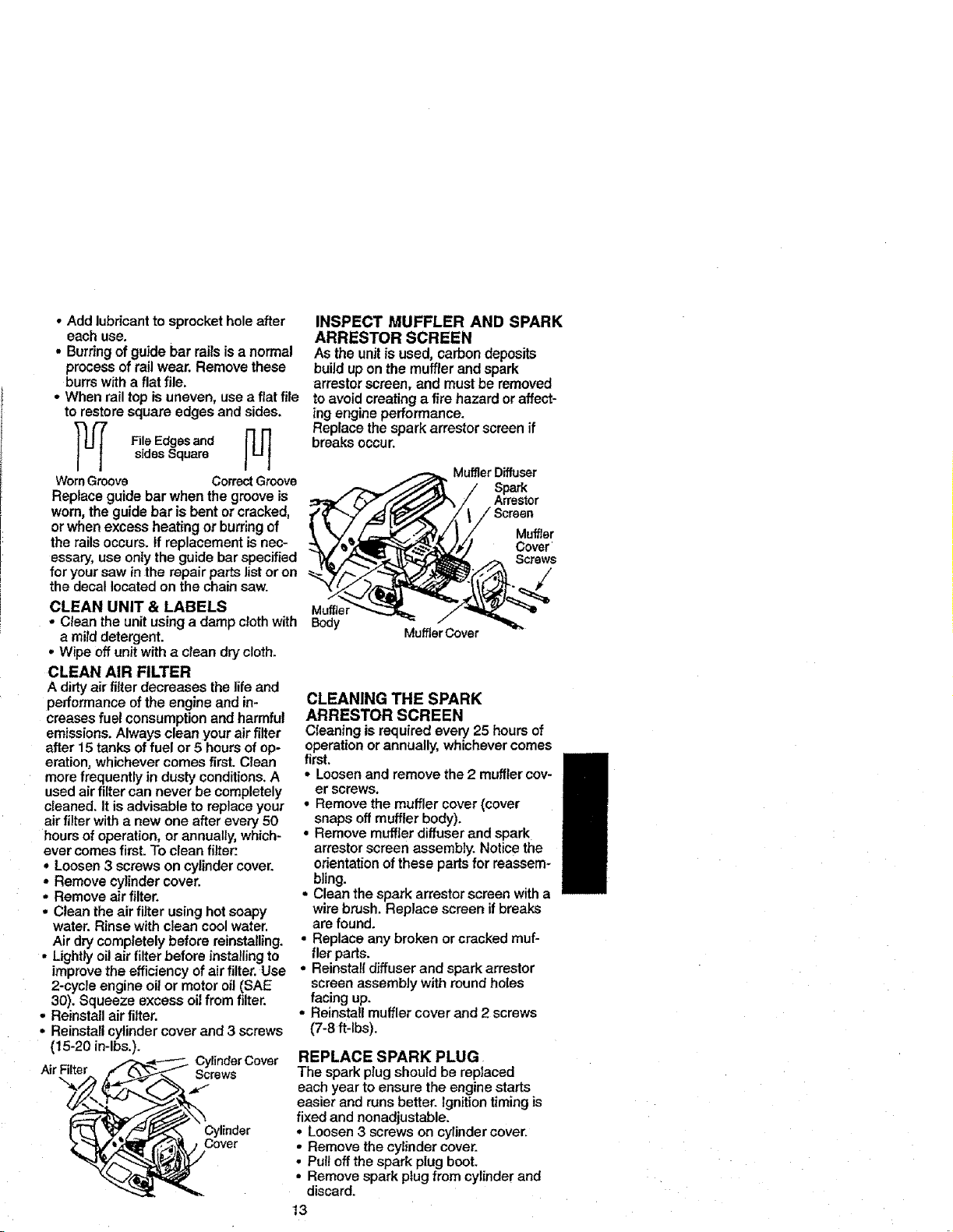

INSPECT MUFFLER AND SPARK

ARRESTOR SCREEN

As theunitis used,carbondeposits

builduponthemufflerandspark

arrestorscreen,and mustbe removed

toavoidcreatinga firehazardoraffect-

ing engineperformance.

Replacethe sparkarrestorscreenif

breaksoccur.

sidesSquare

FileEdgesand

WornGroove Correct Groove

Replace guide bar when the groove is

worn, the guide bar is bent or cracked,

or when excess heating or burring of

the rails occurs, tf replacement is nec-

essary, use only the guide bar specified

for your saw in the repair parts list or on

the decal located on the chain saw.

CLEAN UNIT & LABELS Muffler

• Clean the unit using a damp cloth with Body

a mild detergent.

• Wipe off unit with a clean dry cloth.

CLEAN AIR FILTER

A dirty air filter decreases the life and

performance of the engine and in-

creases fuel consumption and harmful

emissions. Always clean your air filter

after 15 tanks of fuel or 5 hours of op-

eration, whichever comes first. Clean

more frequently in dusty conditions. A

used air filter can never be completely

cleaned. It is advisable to replace your

air filter with a new one after every 50

hours of operation, or annually, which-

ever comes first. To clean filter:.

• Loosen 3 screws on cylinder cover.

• Remove cylinder cover.

, Remove air filter.

• Clean the air filter using hot soapy

water. Rinse with clean cool water.

Air dry completely before reinstafling.

• Lightly oil air filter before installing to

improve the efficiency of air filter. Use

2-cycle engine og or motor oil (SAE

30). Squeeze excess oilfrom filter.

• Reinstall air filter.

• Reinstall cylinder cover and 3 screws

(15-20 in-lbs.).

Air Filter Screws

CylinderCover

Cylinder

Cover

CLEANING THE SPARK

ARRESTOR SCREEN

Cleaning is required every 25 hours of

operation or annually, whichever comes

first.

• Loosen and remove the 2 muffler cov-

er screws.

• Remove the muffler cover (cover

snaps off muffler body).

• Remove muffler diffuser and spark

arrestor screen assembly. Notice the

orientation of these parts for reassem-

bling.

• Clean the spark arrestor screen with a

wire brush. Replace screen if breaks

are found.

• Replace any broken or cracked muf-

flerpans.

• Reinstall diffuser and spark arrestor

screen assembly with round holes

facing up.

• Reinstall muffler cover and 2 screws

(7-8 ft-lbs).

REPLACE SPARK PLUG

The spark plug should be replaced

each year to ensure the engine starts

easier and runs better. Ignition timing is

fixed and nonadjustable.

° Loosen 3 screws on cylinder cover.

• Remove the cylinder cover.

• Pull off the spark plug boot.

• Remove spark plug from cylinder and

discard.

13

Muffler Diffuser

MufflerCover

Spark

Arrestor

Muffter

Cover

Screws

/

Page 14

• Replace with Champion RCJ7Y spark

plug and tighten with a 3'4 inch socket

wrench (10-12 ft-lbs). Spark plug gap Plug Boot

should be .025 in.

• Reinstall the spark plug boot.

• Reinstall the cylinder cover and 3 Spark

screws (t5-20 in-lbs). Plug

Cylinder

Cover

CHAIN REPLACEMENT

CAUTION: Wear protective gloves

when handling chain. The chain is

sharp and can cut you even when it is

not moving.

It is normal for a new chainto stretchdur-

ing thefirst 15 minutes of operation.You

should recheck your chain tensionfre-

quenfiy and adjustthe chain tension as

required. See Chain Tension section.

• Move On/Stop switch to the Stop

position.

• Replace the old chain when it be-

comes worn or damaged.

• Use only the Low-Kickback replace-

ment chain specified in the repair

parts list. The correct replacement bar

and chain is also specified on a decal

located on the chain saw.

• See your Sears Service Center to re-

place and sharpen individual cutters

on your chain.

• Remove bar clamp nuts.

• Remove bar clamp.

• Remove the old chain.

Bar

Clamp

Cutters Dep_ Gauge

Drive Links

• Place chain over and behind clutch.

• Fit bottom of drive links between teeth

in sprocket nose.

• Fit chain drive linksinto bar groove.

•Putl guide bar forward until chain is

snug in guide bar groove.

, Now, install bar clamp making sure

the adjusting pin ispositioned in the

lower hole in the guide bar.

Lower

Adjusting Guide Bar

Pin

Hole

• install barclampnuts andfinger tight-

enonly.Do nottightenany further at

this point.

, Turn adjusting screw by hand coun-

terclockwise until adjusting pin just

touches the stop.

• Slide guide bar behind clutch drum

until guide bar stops against clutch

drum sprocket.

° Carefully remove new chain from

package. Hold chain with the drive

links as shown.

".f?} o,o No,o

CHAIN ADJUSTMENT

See "Chain Tension"inMaintenance

section.

14

Page 15

CLEAN FUEL FILTER

To clean fuel filter, drain your unit by

running dry of fuel, remove fuel cap/re-

tainer assembly from tank. Pull filter

from tank and remove from llne. Clean

with mild detergent and rinse. Dry thor-

oughly,reassemble.

CARBURETOR ADJUSTMENT

WARNING: The chain will be moving

during most of this procedure. Wear

your protective equipment and observe

all safety precautions. During the low

speed mixture adjustment recheck idle

speed after each turn of the screw. The

chain must not move at idle speed.

Carburetor adjustment is critical and if

done improperly can permanently dam-

age the engine as well as the carbure-

tor. if you require further assistance or

are unsure about performing this proce-

dure, calt our customer assistance help

line at 1-800-235-5878.

Old fuel, a dirty air filter, dirty fuel filter,

or flooding may give the impression of

an improperly adjusted carburetor.

Check these conditions before adjust-

ing the carburetor.

The carburetor has been carefully set at

the factory. Adjustments may be neces-

san/if you notice any of the following

conditions:

• Chain moves at idle. See "Idle Speed"

under adjusting procedure.

• Saw will not idle. See "Idle Speed"

and "Low Speed Mixture"under ad-

justing procedure.

• Engine dies or hesitates when it

should accelerate. See =Acceleration

Check" under adjusting procedure.

• Loss of cutting power. See "High

Speed Mixture H"under adjusting

procedure.

There are three adjustment screws on

the carburetor. They are labeled H, L,

and T. They are located in the area just

above the primer bulb.

CARBURETOR PRESETS

When making adjustments, do not force

the plastic timiter caps beyond the

stops or damage wifl occur.

If carburetor presets are not needed,

proceed to "Idle Speed-T."

• Turn both mixture screws counter-

clockwise until they stop.

• Turn the idle speed screw clockwise

until itstops. Now turn counterclock-

wise 4-1/2 full turns.

Start motor, let it run for 3 minutes, and

proceed to the adjustment section. If

engine does not start, refer totrouble-

shooting chart or call 1-800-235-5878.

if engine performance is acceptable at

the preset positions and there is no

chain movement at idle, no further ad-

justment is necessary.

ADJUSTING PROCEDURE

idle Speed-T

Allow engine to idle. Adjust speed until

engine runs without chain movement or

stalling.

• Turn clockwise to increase engine

speed ifengine stalls or dies.

• Turn counterclockwise to decrease

speed.

No further adjustments are necessary if

chain does net move at idle speed and

if performance is satisfactory.

Low Speed Mixture-L

Allow engine to idle. Then accelerate

the engine and note performance. If en-

gine hesitates, bogs down, or smokes

during acceleration, turn mixture screw

clockwise in1/16-turn increments until

performance is satisfactory. Repeat this

procedure as necessary for proper ad-

justment. After completing adjustments,

check for acceleration and chain move-

ment at idle. Reset if necessary.

High Speed Mixture-H

DO NOT operate engine at full throttle

for prolonged periods while making ad-

justments. Damage tothe engine can

occur. Make a test cut. Based on per-

formance of the saw while cutting, ad-

just the high speed mixture setting in

1/16-turn increments as follows:

• Clockwiseuntil saw has goodpower in

the cutwithno hesitation.Do not adjust

by sound or speed, butjudge by how

well the saw perfoilT_ in the cut.

• Counterclockwise if the saw has

speed, but dies in the cut or lacks

power in the cut.

After completing adjustments, check for

acceleration and chain movement at

idle. Reset ifnecessary.

Acceleration Check

if the engine dies or hes_tes instead of

accelerating,turnthe low speed m_ure

adjustment counterclockwiseuntil you

have smooth acceleration with no chain

movement at idle, Recheck and adjust as

necessary for acceptable performance.

15

Page 16

Prepareyourunitforstorageat theend

oftheseasonor ifit will notbe usedfor

30 daysormore.

WARNING:

• Allow theenginetocoot,and secure

theunitbeforestoring or transporting.

• Storechainsaw and fuelin a well

ventilated area where fuel vapors

cannot reach sparks or open flames

from water heaters, electric motors or

switches, furnaces, etc.

• Store chainsaw with all guards in

placeand position chain saw sothat

anysharp object cannot accidentally

causeinjury.

• Storechainsawwell out ofthe reach

ofchildren.

EXTERNAL SURFACES

Ifyourchainsaw istobe stored for a

periodoftime,cleanitthoroughlybe-

fore storage.Store in a cleandry area.

• Lightlyoilexternalmetal surfaces and

guide bar.

• Oil the chainand wrap it in heavy pa-

per or cloth.

FUEL SYSTEM

UnderFuelingEnginein the Operating

Section ofthismanual,seemessage

labeled IMPORTANTregardingthe use

ofgasohol inyourchainsaw.

Fuelstabilizerisan acceptablealtema-

tire in minimizingthe formationof fuel

gumdepositsduringstorage.Addstabi-

lizer tothe gasolineinthe fueltank or

fuel storagecontainer. Followthe mix

instructions found on stabilizercontain-

ers. Run engineatleast 5 minutes after

adding stabilizer.

CRAFTSMAN40:1, 2-cycle engine oil

(air cooled) is especially blendedwith

fuel stabilizer. If you do notuse this

Sears oil, you can add a fuel stabilizer

toyour fuel tank.

ENGINE

• Remove sparkplugand pour1tea-

spoonof40:1, 2-cycleengine oil (air

cooled)through the sparkplug open-

ing.Slowly pull the starter rope 8 to

10 timesto distribute oil.

• Replace spark plugwithnew one of

recommendedtypeand heatrange.

* Cleanair filler.

• Check entireunitfor loose screws,

nuts, andbo_ts.Replace any dam-

aged,broken,orwornparts.

. At thebeginningofthe nextseason,

useonly fresh fuel havingthe proper

gasolinetoollratio.

OTHER

• Do notstoregasolinefrom onesea-

sonto another.

• Replace your gasoline can if it starts

tOrust,

16

Page 17

TROUBLE SHOOTING CHART

!TROUBLE CAUSE .......

Enginewiltnot r• ignitionswitchoff.

startorwillrun !• Engineflooded,

onlya few • Fueltankempty.

secondsafter • Spark plugnotfiring.

starting. • Fuel notreaching

carburetor.

- Carburetor requires

adjustment.

• None of the above.

EnginewUlnot

idle properly,

Engine wilt not

accelerate,

lacks power,

or dies under

a load.

Engine smokes

excessively.

Engine runs

hot.

Oil inadequate - Oil tank empty. • Fill oil tank.

for bar and • Oil pump or oil filter • Contact Sears See,ice.

chain clogged.

lubrication. • Guide bar oilhole ° Remove bar and clean.

• Idle speed set too high

or too low.

• Low Speed Mixture

requires adjustment.

• Crankshaft seals worn.

• Compression low.

• None of the above.

• Air filter dirty.

• Spark plug fouled.

• Carburetor requires

adjustment.

• Exhaust ports or muf-

fler outlets plugged.

° Compression low.

• None of the above.

• Choke partially on.

• Fuel mixture incorrect.

• Air filter dirty.

• High Speed Mixture

requires adjustment.

• Crankcase leak.

, Fuel mixture incorrect. ° See "Fueling Your Unit."

• Spark plug incorrect. • Replace with correct plug.

• High Speed Mixture • See "Carburetor Adjustments."

set too lean.

• Exhaust ports or muf-

fler outlets plugged.

• Carbon build-up on

muffler outlet screen.

• Fan housing/cylinder

fins dirty.

• None of the above.

blocked.

REMEDY

• Move IgnitionSwitch to ONI

• See "Starting instructions."

• Fill tank with correct fuel mixture

: install new spark plug.

Check for dirtyfuel filter; replace

Check for kinked or split fuel line

repair or replace.

• See =Carburetor Adjustments."

• Contact Sears Service.

,, See "Carburetor Adjustments."

• See =Carburetor Adjustments."

• Contact Sears Service.

• Contact Sears Service.

. Contact Sears Service.

• Clean or replace air filter.

• Clean or replace plug

and regap.

• See "CarburetorAdjustments."

• Contact Sears Service.

- Contact Sears Service.

• Contact Sears Service.

• Adjust choke.

• Empty fuel tank and refill with

correct fuel mixture.

° Clean or replace air filter.

• See "Carburetor Adjustments."

• Contact Sears Service.

• Contact Sears Service.

• Clean spark arrestor screen.

° Clean area.

, Contact Sears Service.

17

Page 18

TROUBLE SHOOTING CHART - Continued

TROUBLE

Chain moves

at idle speed.

Chain does

notmove

whenengine

isaccelerated.

Chainclatters

or cutsroughly,

i .....

Chain stops

within the cut.

Chain cuts at

anangle.

CAUSE

• Idlespeedrequires

adjustment.

• Clutch requiresrepair.

• Chain tension too

tight.

E*Carburetor requires

adjustment.

• Guide bar rails

pinched.

• Clutch slipping.

• Chain tension incorrect.

• Cutters damaged.

• Chain worn.

• Cutters dull, improperly

sharpened, or depth

gauges too high.

I. Sprocket worn.

• Chain installed

backwards.

• Chain cutter tops not

filed flat.

• Guide bar burred or

bent; rails uneven.

, Clutch slipping

• Cutters damaged on

one side.

• Chain dull on one side.

• Guide bar bent or worn.

REMEDY

• See "Carburetor Adjustments."

* Contact SearsService.

o See "ChainTension,"

• See =CarburetorAdjustments."

• Repairor replace.

• ContactSearsService.

• See =ChainTension."

• ContactSearsService.

• Resharpenor replace chain.

• See =SharpeningChain."

• Contact Sears Service.

• Install chain in right direction.

• See "Sharpening Chain."

• Repair or replace guide bar.

• Contact Sears Servk'e.

• See "Sharpening Chain."

• See "Sharpening Chain,"

• Replace guide bar.

Ifsituations occur which are not covered in this manual, use care and good

judgement. If you need assistance, contact Sears Service or the CUSTOMER

ASSISTANCE HELPUNE at 1-800-235-5878.

18

Page 19

1 3

REPAIR PARTS

53 52 50

t -- 51

6 7

Desorrption Rat,

Trigger & Lockout Kit 24,

2. 53_26119

3, 530037809

4. 530037803

5, 530015917

6. 530047989

7. 53O038406

530069803

9. 530094188

10, 530047061

11, 530015611

12. 530014949

13. 53_8227

14. 530016M9

15, 53CO38264

16. 530015922

17. 530025850

18.; 530015905

19.J 5300"[5997

20 530015826

22, 53006961 t

23, : 530038238 BarMcuntJng Plate

(includes Pin)

Check Valve 26.

Wire -Throttle 28.

CJutch Cover 29,

Nut- Bat Mounting 301

*_Oke Lever 31.

,_rororoet--Choke Knob 3?- :

3hassis Kit 33.

_utch Spdng 34.

Clutch Drum Ass'¥- 35,

wiBrg.

Washer- Clutch

ClutchAss'y.

SwitchLever

Sw;tchSpring

Pl_-Bronze Vent

Nut

ChainCatcher

Screw

Washer- Thrust

Pin,-Bar Adjusting

)SatAdjustingScrew

K_

36.

38.

40.

41.

42,

43_

44.

45.

46.

47.

48.

Part NO.

530069957

530010846

53C016080

530016064

530019206

530049477

530038373

530037821

530030189

530015775

58_069_47

530047192

530016133

530047663

530016020

530016132

530015905

530037820

530019231

530037799

530038224

Desodptlon Ref. Part NO.

OilPump I_ 49. 53C015940

(tnoJ, 30, 31 & 45) 50, 530037485

Oil Cap Ass'y. 51. 530069232

Screw 52. 530015892

Screw 53. 530049336

Seat Biock 54. 530027531

Elbow-Oil Pickup 55. 530037817

Pick--Up Oiler 56. 530039187

Oil Filter 57. 530400897

Plug- OU Filter 58. 530001717

Screw 59, 530016"_34

FuelLine _31

(Large Die.)

FuelCap ASS_i,

wlRetainer

BoJt- Bar

Oi_Pickup Ass'y,

(tncl. 32, 33 & 34)

Screw

Screw

Screw

WormGear Spring

DustSeal

FrontHandJe

Handguard

60. 530015920

61. 7%-3619

62. 71-,36374

Not Shown

19

530087030

530049248

530038486

530053122

530052362

530053121

Description

Screw

Starter Hendle

Rope Krt

Screw

Fan Housing

Recoil Spring

Starter Pulley

R_I Ass_.

Washer

Washer

Nut-Ry_eel

Screw

Chain - 18"

Bar- 18"

Operator Manual

DecaF-Star_ing

Instruction

DecaF-Stop

Decal-Clutch Cover

Decs_-Chain

Readjust

Oscal,.-Fan Hs_j.

Page 20

lUlnlIIIIIIIHII IIInI II

REPAIR PARTS

: i i i

14 12 13

17

28 15

3 4 5 6 16

2O

1

34

25

29 42

Rsf. Part NO.

1_ 530031163

2, 530037793

3. 530016101

4. 530037804

5. 5300697O3

6, 530019239

7. 530015810

8. 530069929

9. 530016187

$0. 530016102

11. 530037798

12. 530038318

13. 530038317

14. 530049244

15= 530_47566

16. 53C_B9216

17, 530019210

'_8, 71-85849

19. 530019249

20. 530069607

21, 530069605

92_ 530038729

23. 530015697

Description

Bar Wrench

Foam-Air FiJter

Nut

Air Filter Housing

Ca,'bu retor t_

(lasL 12 & 13)

Cash. Gasket

Screw

Ce_. Adapter K_t

Screw

Screw

Cylindar Shield

Limiter Cap-High

Umiter Cap-,Low

Gtommet-Carb Adjust

Air Pucge Ass'y.

Primer Line K_t

(SmallO_a)

A_r 8ox Seal

Spark Rug (CJ-TY)

Gasket,,,,Cerb Adaptor

Cyt_de_ )_

Piston Kit

(InoL 22 & 23)

PistonRing

Retainer-Piston Pin

Re L Part No.

24, 530047062

25. 530047827

26, 530037935

27. 530016136

28, 530016090

29. 530069608

30. 530052296

31. 53C014382

32. 530037652

; 33. 530019221

34. 530038237

35, 5300472O7

36= 530037813

37. 53O036103

38, 530016132

39. 530052277

40. 53CO15905

41. 530047442

42. 952706606

Not Shown

20

30

95203t t 64

36 37

35

Deasdptten

CrankshaftAss_

Seal & BearingAss'y,

Cap.-Crankc_se

Clip

Screw

EngineGasketKit

(tncL6, 17,19& 33)

W_reHarnessAss'),.

Fuet Ff_up Ass'y.

Heat/nsu{ator

Muter Gasket

MufflerBack Plate

MufflerAss'y,

Muffler Diffuser

Spark An'esterSc1_en

Screw

Ignition Module

Screw

GroundStrap

ChainBrake Kit

Carrying Case

38

Page 21

REPAIR PARTS

..N. = ..1, L ill i ,

Assembly Kit Number #530069703

KiT --_ _[T

R4. Part No, Descdptlon

1,

2.

3.

5°

6.

7.

8,

5300383_8

530038,31_7

530069826

53O069844

530035383

53G035384

530035293

530035295

Lim_ter Cap-High

Limlter Cap-Low

C_rburetor Repafr Kit

{KIT = Contents}

GeskedDiephragm Kit

(* =C_ntents)

Needle-Low Speed

Needle-Hfgh Speed

Needle Spring-Low Sp_sct

NeodEe Spdng,,*-High Speed

21

Page 22

sarantfa 22 .sF.n,icioyApSes 36

Reglas de Segufidad 22 _rnacenammemo 38

Montaj_ 26 Tabla Diagn_'tica 40

Uso 27 Repuestos y Encargos Contmtapa

Mantenimiento 33

GARANTIA COMPLETA DE UN AP',IOPARA LA SIERRA

DE CADENA A GASOLINA CRAFTSMAN®

Porun m3oa contarde la fed_ de compra,siemprequeesta Sierrade C,ader_ a Gasolina

Craftsmanest(_mantenida,lubdcaday ajustadadeacuerdo al manualdelusuario,Sears

repara.,dgratuitamente cuaJquierdefectodemateriaJeso manode dora.

Estagarantfa excluyela barra, la cadena,la bujlay elfiltrode aJre,que sonarb'cdos

fungiblesy se ga.standuranteelfuncionamierdonormal

Sise usa esta Siena deCadena a Gasolinaparap_os comerdaJeso dealquiler,esta

garardiatendrd validezde 30 dfas contadosapartirde lafecha decompra.

EL SER'V_C10BAJOGARANTIA ESTAA SU DISPOSICION CONSOLO DEVOLVERLA

SIERRA DE CADENA AL C_Ti'RO DE SERVtCIO SEARS MASCERCANO EN LOS

ESTADOS UNIDOS.

Estagarantia le confierederechosjurfdicosespec_cos;ademds ud.podr_tenerotros

derectzosclue vadan entre estados.

Sears, Roebuck and CO.,D/817 WA, Hoffman Estates, IL 6017g

ADVERTENCIA: Desconecte

siempreel calde de la bujfa al reparar

el aparato, excepto en el ca,so de

ajustesal carburador. Debido a que las

sierras de cadena son instrumentos

pare cortar madera a alta velocidad,el

uso descuidado o indebido de esta

herramienta puede causar graves

heridas.

PIENSE ANTES DE PROCEDER

. Lin_e el uso de la sierraa aquellos

usuadosaduttosque cc_nprendany

puedanimplementar todas las

prec_uciones,regl_.sde seguridade

tns_tuccionesdeusoque seencuentmnen

estemanual.

Protecck_ de O_dos CascoDuro

Oj06

.A_s/ada"'...._ Guantesde

_ Cuerpo

tos de

uridad deSeguddad

llPiN

• UseequlpOprotector.Siempreusecalzado

de seguddad conpuntasdeaceroy.suelas

anti-deslizantes;,ropaa_us_adaal cuerpo;

guantesgruesosde usoindustrial

ant_deslizantes; protecci6nde ojostales

22

UsolndusUbl

Page 23

comogabsdesegurldadque no se la

cam; cascoduroaprobado; ybarrerade

sonido(taponesde ofdo uorejeres

antJ-sonido)paraprotegerlaauo'_'6n.Los

que usan sierrasde fuet-zahabilualmente

deberdnhacerserevisarla audici6n

frecuentementeya cluee!ruidede les

sierrasdecadenapuede daF,ar losoidos.

Mantenga e!¢abellopor e_ de|nivel

de los hombros,atdndotopare teJefectosi

fuerenecesario.

• Mantengatcdas lespartesde!cuerpo

alejadesde lacadenasiempreque elmotor

estden _Jndona_ento.

• Mantengaa losnifios,espectadoresy

ardrnalesauna d'mtanclaminimade 10

metros(30pies) del drea de trabajoo

cuandoest_ hac;endoarrancary uso

elmotor.

• Nolevantenioperefassierras de ca.dena

cuandeestdfatigado,enfermo,ansiosoosl

ha tornadoalcohol,drogeso ren-,e_os.Es

inpresclndiblequeud.est_ en buenas

condiclonesfisicasyalerta mentalmente.

Siud. sufmdecuakiuiercondici6nque

pueciaempeorarconel trabajoarduo,

esesSreseconsu m_:_cfico.

• Nopongaenmarchala sierra sin tenet un

dreade trabajodespejada,una superEde

establepareparame y,stest_ denubando

drbo_es,uncarnlnopredetem]inadode

retroceso.

USE LA SIERRA OBSERVANDO

TODOS LOS PROCEDIMIENTOS

DE SEGURIDAD

• Mantengalas dosmanos en lasman_

siempreque elaparatoest_ en _ El

usode|aparatoconur_ solamano puede .

causargravesheddasaJusua,do,a los

adstentes o a k_sespectaderes.Las

sierrasdecadena _ dIseFk_lespara

que se las useconbs dos manosentodo

moIT_tdo, o

• Hagauso de lasierradecadena

•(¢dcamenteeniuga_esextedoresbien

vent_dos.

• Nohaga usode/a sierradesdeles

escalerasport_blesnilosdrboles,a menos

cluetengaelenkenamientoespedficopard

hacerlo.

• Aseg,3resede quela cadena novayaa

hacer contactocon ningdnobjetoantesde RECULADAS

porterenrnarchael motor.Nuncaintente Ud. debe seguir todes las precauciones e

hacer atrancarlasierracon labarraguia

dentrode un code.

• No aplique presidn a la sierra, especial-

. mente al finaldel corte. La applicacidn

de presiSn puede causar que se pierda

el control al completarse el corte,

• Pareel motorantesde apoyar _ siena en

ning_nlac!o.

• Cuandotra_ade lasierraenlamano,

hdgalodnicamenteconetmotorpazado.

Udvela conelsi/enciadorapartadodel

cueqooy la barray cadenaI'_ciaateds,con

la barrade preferenciacu_erta por tma

funda. 23

MANTENGA LA SIERRA EN

BUENAS CONDICIONES DE

FUNCIONAMIENTO

L/evelasierrade cadenaa unproveedor

de servidoautodzadepara quehaga todo

serviciomenosaquellosprocedimlentos

lisiz_Iosen lasecc_6nde mantenimientode

estemanual.

• AsegOresede que lacadenase detenga

porcornpletocuandose sueltael galztlo.

Pare hacercorrecciones,yea los"Ajustes

al _ckx'.

• MantengaI_ rnar,-_sseces,r_pies y

libresdeaceite ode mezcla de

combusb'ble.

fijos.

Mantengalastapesy los fijadores bien

Use exdusivarnentelos accesodosy

repuestosCraftsmanrecornendados.

Nuncamod'r_quelasiena.

MANEJE EL COMBUSTIBLE CON

EXTREMO CUIDADO

• No fumemientrastrabaja conel

combush_lenicuandoestd haciendo uso

de lasierra.

• E_rninetodeslespo_'blesfuentesde

chispesollamas en/as drees dondese

mezc_ ovierteelcombustible.

• Mezde yviertae!combustibleafuem yuse

siernprere_pienteapmbadopara

corn_ibl_ es ymarca_ como_. Limp_e

todoslosdenames decombu_ble antes

de ponerel aparatoen man:ha.

• Aldjesea pot Iomenos 3 metros(10 pies)

dellugardeabastecimientoantesde poner

el motoren mamha.

Apagueel motory deje que lasierrase

enfde en unlugarlibre de substancies

cornl_._J'blesynosobrehojesseces, paja,

paper,etc,Retirela tapa tentamente y

reabestezcael epar-atoo

Guardeelaparatoye/cornbu_'ble en un

espado fresco,secoy bienventilado

deride losvaporesde| combustibleno

puedenentrarencontactoconchispesni

llamasabierlesprovenientesde

tem'_otangues,motoresotntemJptores

el_:tricos,ca[efactorescentra/es,etc.

PROTEJASE CONTRA LAS

instruccionesdeseguridadparaayudar

a evitar las reculadasy lasdem_.s

fuerzas que puedencausargraves

heridas,

Page 24

ADVERTENCIA:LaReculada

Rotacionalpuedeacontecercuandola

cadenaenmovimientoentraen

contactoconalgt]nobjetoenlaenla

parlesuperiordelapuntadelabara

gu[apuedecausarquetacadenaentre

al material yse detengapot un

instante.Elresultadoes unareacoi6n

inversa,a velocidadde rel_mpago,que

hacerecularlabarra guia haciaardba y

hacia atrAshaciael usuario.

La Reculada porPresi6ny la lmpulsi6n

acontecencuando lacadena se

detiene repentinamenteporquee.st_

apretada, atmpada oen contactocon

algr3nobjetoextmfioa la madera.Esta

detenci6n repentinade la cadenatiene

como resultade una inversi6nde la

fuerza de la cadena usada paracortar

madera ycausa que la sierra se mueva

en senfidoopuestoal de la mtaci6nde

ia cadena. La Reculada pot Pres_n

propulsalasierradirectamentehacia

atms en direcoi6nal usuario.La

Impulsi6nalejala sierra de! usuado.

REDLIZCA LAS

PROBABILIDADES DE

RECULADA

o Est_ conscientede la posibilidadde

reculada.Teniendo una buena

comprensi6nbdsicade la reculada,

ud.podrdreducirel elementode

• Empiecey efeckte latotal!dadde

cadacorte conel aceleradorafondo.

Si lacadena se estdmoviendea una

velocidadmenor quefamdxima,hay

•mils probabilidadde queiasierra

recule.

° Usecuidadoextremoalentrarde

nuevo enun code yaempezado.

• No intentehacercodes empezando

con la puntade la barm(cortesde

taladro).

° Tengac_idadocontroncosquese

desplazany conlasdemdsrue=as

.quepodfian cerrar uncodey apretar

la cadena o biencaersobreella.

• Use !a Barm Gu[a Reducidorade

Reculadasyla Cadena Minimizadora

d.eReculadasrecomendadasparasu

sierra.

Evite la Reoulada pot Presi6n:

• Mant_ngasesiemprealtantode.toda

situaci6nu obstrucci6nquepueda

apretar lacadena en lapartesuperior

de la barrao detener!acadenade

cualquierforma.

• No code mdsqueun troncoa lavez.

• AI seccionartroncosconcode

ascendiente,notuerzala sierraal

sacarla barb del code.

Evite la Impulsi6n:

motoracelerado a fondo y lacajade

i mpieceloscortessiemprecon el

!asierraapoyadaen la madera.

Usecutlas de pl;_tico o demadera,

no de meted,para mantenerabiertoel

code.

MANTENGA EL CONTROL

Pfirese hac_ _ izquierdadela siena

accidentes, dE]e_jog_ddeP_r_rnan_

- Nunca permita que la cadena en

movfi'nientotoqueningdnobjetoen ta

punta de labarra gu[a.

° Mantenga el drea de trabajo librede

obstmccionescomoper ejemplo

otrosdrboles, ramas, piedras, cercas, '

tocones, etc.El!mineo evitetoda

obstmcci6n que !a cadena pueda

tocar mientras est_ cortando.

o Mantenga !a sierra afilada y con !a

tensiSn correcta_ Las cadenas con

Ix)CO file o fiojas incrementan la ":

probabilidad de reculada. Siga las i_,:

msttucciones del fabricante para afifar

y efectuar mantenimiento de la _;

cadena. Venfique la tensi6n a

intervalos regulares con el motor

parado, nunca en marcha. Asegdrese

de que las tuercas de !a abrazadera

de la barra estdn ajustadas

firmemente.

Nuncainviertala posick_ de lasmanos

• Sostenerfirmementeconlasdosmanosle

ayudar& a mantener el controlde la sierra.

Noaffoje.Manten_ la manoderecha

envolviendototalmentela man_ trasera,

sea ud. derechoo zurdo.Sostengala

rnan_aaelantera conla manoizquierda,

cof.ocandoel pulgardeba_odela rnan_ay

rooe_uxIolamanijacon losdedos.

Mantenga el brazoizquierdototalmente

extendidocon elcod<>_o.

• Coloque la mano izquierda en la

manija delantera, de modo que quede

en lfnea recta con la mano demcha

24

Codor_gido

Page 25

en la manijatmsera,cuandoest_

haciendocodesdeseccionamiento.

Pdrese levementehaciala izquierda

de la sierraparaevitarqueel cuerpo

est6 en ifnea directaconla cadena.

• Pdrese conelpesodistdbuido

igualmenteentrelosdospies.

• No se extiendaexcesivamente.La

sierra puedeirnpulsadoo empuj.adoy

ud. puede perderel equit_doy el

controlde la sierra.

• No code arribadel nivelde los

hombros, puedstoque tomadiffcil

mantener elcontrolde |asierra.

DISPOSITIVOS DE SEGURIDAD

CONTRA I.AS RECULADAS

ADVERTENCIA: Lossiguientes

dL_>sitivos hensidoincluidosen la

s_errapara ayudara reducirelriesgo

de recutadas;sinembargo,tales

implementosnopuedeneliminar

totalmente estareacci6npeligrosa.No

se conffeexclusivamenteenlos

d'rspositivosde osguddad.

PuntsdeRadio

_er_ z°"=d° Pequefio_

ro _Z_ de

PuntadeRadioGrar_eB_maGufa

• Les CadenasMinimizadorasde

Recutadashartsatisfecholos

requisitosde rendimientoenpruebas

conunamuestrarepresentativade

sierrasde cadenacon

desplazamientode menosde3,8

pulgadas,como seespecif'_caen

ANSIB175.1.

CadenaM_ndzadoradeReculadas

,_,/Marcador d'eProfundidad

,¢=x_:_.,P---Eslab_PmtectorPJarg_oo

_ Desv=*alaFuerzade

Perfilado . .

_._ Reacci6ny Permitequela

MaderaEntre

Gradualmentea laCuchilla

* Protector deMane, diseSadopara

reducirla pmbabi_dadquesu mane

izquierda entreen contactoconla

cadena, si lamanose desprendede

la manFjadelantera.

• La Pos=ci6ndelasman_jasdelantera

y trasera, diseSadascondistancia

entre las manijosy =enlinea"la una

con la otra. Laseparaci6ny la

colocaci6nenEneaqueestedisefio

provee se combinanparadar

"equilibdoy resistenciaparacontro|ar

la ptopulsi6nde la sierrahaciael

usuariosi aconteceuna reculad_L

* BarraGui'aReductdorade Reculadas,

disefiadaconpuntade radiopeque5oque

reduceeltama,5odelazonadepellgro.

Estetipode barraha dernostmdoque

reduce significat_amentela can_dady

lasededaddelasreculaaascuanoo

ha sido exarninado deacuerdocon

ANSI (American National Standards

Institute, Inc.) Bt75.1.

AVISO DE SEGURIDAD: Elestar

expuestoalas vibracioensa travdsdel

usopmlongadode herramientasde

fuerzaa gasolinapuedecausardzu3os

a losvasossangufneoso a losnervios

delosdedos,lasmanos y las

coyunturasen aqueltas personasque

tienenpropenstdada lostrastomosde

lacirculaci6no alas hinchazones

anormales.El us<>prolongadeen

tiempofn'ohasidoasociadoconda_os

a losvasossanguineosde personas

queper otrapartese encuentranen

perfectoestadode salud.Si ocurren

s_ntomastalescomoel

entumecimiento,eldolor,la falta de

fuerza, loscambk_senel coloro la

texturade lapiei o falta de sentidoen

losdedos,lesmanoso lascoyunturas,

pare de usar esta mdquina

inmediatamente y procure atenci6n

/

25

Page 26

m_dica. Los sistemas de anti-vibraci6n

nogarantizan que se evitentales

problemas. Los usuariosque hacen

use eontinuoy prolongando de las

herramientas de fueFzadeben fiscalizar

atentamentesu estadofisico y el

estadodelaparato.

FRENO DE CADENA Si esta sierra ha

de usarsepara el tumbadocomercial

de drboles, ud. deber_ encargare

instalarun freno de cadenapara

cumplirconlos Reg|amentosFederates

del OSHApara el TumbadoComercial

deArboles.Entreen contactocon

etServicio Sears ollame al

1-800-235-5878.

REJILLA ANTICHISPA: Su sierra

viene equipadaconsilenciador

limitador de temperaturay con rejilla

antichispaque cumplecon los

requisitesde los C6dig'osde California

4442 y 4443. Todaslas tierras

forestadas fsderales, mdslos estados

de California,Idaho,Maine, Minnesota,

Nueva Jersey,Oreg6n y Washington,

requieren por ley que muchosmotores

de combusti6nintema est_n equipados

conrej_llaantichispa. Si usted usa una

siena de cadenadonde existen tales

reglamentos,usted tiene la

i responsabilidadjun'dica de mantener

:estas.piezas en conectoestado de

funcionamiento. De Io contrario,estarfi

eninfmcci6n de la ley.Veala tablade

RESPONSABILIDADES DELUSUARIOa la

s__e_i<_n de MAINTENIMIENTO.

PADRONES: Este sierra de cadena

constaenla lista de Underwriters

Laboratories, Inc., de acuerdoa los

Requisites Nacionales de Seguddad

Estadounidenses para Sierras de

Cadenaa Gasolina (ANSI

B175.1-1991).

CONTENIDO DE LA CAJA

Use lasiguientelistaparaverifcar el

contenido.

Modelo 358.352680

• Sierra de cadena(completamente

montada)

• Herrienta de labarra

• Cadena

• Estuche de transporte

• Guantes

• Lata para gasolina

• Barra y cadena lubricaci6n

• Mezcla decombustible/aceite

° Verifiqueque nohaya piezas dar3adas. No

use piezasdar_adas.

- Sinecesitaayudaosi_ piezaso

encuentrapiezasdar3ada.s,favordeUamar

al1-800-235-5878.

AVISO: Es normaloirel golpeteodel

filtrodecombustibleenel tanque vacfo.

Su apamtoha sidopuestoa prueba en

la fdbdca y se le ha ajustadocon

precisiSnelcarburador.Como

resultado,as posiblequese sienta un

olora gasolinao ques.eencuentreuna

gota deresiduode aceite o

combustilbeen el silenciadoral

desempacarel aparato.

MONTAJE

Elaparatovienecompletamente

armadoy no hay necesidadde

montaje.

26

Page 27

CONOZCA EL APARATO

LEA ESTE MANUAL DEL USUARIO Y LAS REGLAS DE SEGURIDAD ANTES

DE USAR LA SIERRA DE CADENA. Compare las _ustraciones con su aparato

para famiE_e con la ubicaci6n de losratios contmles y ajustes. Guarde este

manualpard usofuturo.

Herramientade Ajuste _1 =_,,_ r_l_,_._

de la Cadena _ | ._"=_ .........

ProtectordeMaJ',o-_._ _f,, _'_^ de Arranque

_ j lntermptor

..... Silenciador _ l_ _/J-.-_ -_,_-/

Lubdcan,e de Barra Caja delArmnque ,_T_,....,,,Tapap.,omb_.zs_,_e_.e

TapadelCilindro _ _,,

Traba deMatcha, JJ eo_desy=_ _.

LentaAoelerada _ _ J (.- _

Trabadel

Acelerader/ _ _ Ajuste __ Rotaci6nde la

. _ /..._ Tomglodet_ _r'_) DirecciSrlde

de

Mar.ja',. | / ca="a

Ace1_ Cebador .

EN/TOPE INTERRUPTOR tras mantiene opdmida la traba de mar-

El En/Tope Interruptor estd acostum- cha lenta acelerada.

• brado a detener la mdquina. PERILLA DEL CEBADOR

GA'I3LLO DE ACELERADOR La Penlladel Cebador provee comlous-

El Gatillo de Acelerador controla veloci- tz_leacr_cionalal motor al_ en frio.

dad de mdquina. BOMBEADOR

TRABA DEL ACELERADOR El Bombeador c_rculacombustible al

Es necesarioapretarpdmero la traba del carbumdor.

aceleradorpa_ poder accionar el acel- TENSION DE LA CADENA

erador. Ested_.spos_opreviene el ac- Es normal que las cadenas nuevas se

cionamientoac_dentaf del acelerador, est_rendurante lospdmeros 30 minu-

TRABA DE LA MARCHA LENTA tos de uso. Deberd verificarse la ten-

ACELERADA si6n de la cadena frecuentemente. Vea

La traba de la m_rcha tents acelerada Tenel6n de Ia Cadena en la seccidn de

mantiene el gatillo en la posici_n de Serv_cioy Ajustes.

arranque. Accione la traba de marcha ANTES DE PONER EL MOTOR EN

lenta acelerada de la siguente manera: MARCHA:

Aprete la traba de! acelerador y luego ADVERTENCIA: Lea toda la informacibn

aprete el gatil[oacelerador. Con el sobre el manejo del _ en la

acelerador apretado, opdma la traba secci&qde reglasde seguddad de este

de marcha lenta acelerada. Suelte la manual antes de empezar. _ no com-

traba del acelerador y el gatillo mien- pre_de la info_ sobre el manejo

Abraz_lem Qeb.Bar_ .......

del _e, no intente abastecer su

27

Page 28

aparato.Procureayudade alguienque

comprendalainformaci6nollame al

teT_fonodeayuda atconsumidoral

1--800.-235-5878.

ACEITE PARA BARRA Y LA CADENA

[] lubricadorde la cadena provee

lubricaci6ncontinuaala cadenay ala

barmgufa.No se olvidedellenar el

tanquede aeeite parebarrasiempre

queIleneeltanque de combustible

(Capacidad=6,8ft. oz.).Para obtenerla

mdximaprelongaci6ndela vidadela

barny la cadena,recomendamosque

useelaceite parabarrasdesierrade

cadena Craftsman.Si elaceite

Craftsmannoe.,_ddispondible,puede

usarseunacelteSAE 30 de buena

calidadhestaobtenerel aceite mama

Craftsman.Lacantidadde lubdcaci6n

es medidaautomdticamenteduranteel

funcionamientode la sierra.Lasierra