Page 1

Operator’s Manual

CRAFTSMAN ^

2.6 cu.in./42cc 2-Cycle

GASOLINE CHAIN SAW

Model No.

358.352680 18 in. Bar

WARNING:

Read and follow all Safety Rules and Operating

A

Instructions before first use of this product.

For answers to your questions about this product:

Cali 7 am-7 pm, Mon-Sat; Sun, 10 am~7 pm

9

l“OUU"j£o0"Do/O

Sears, Roebuck and Co., Hoffman Estates, IL 60179 USA

530-08703007/01/97

Page 2

TABLE OF CONTENTS

Warranty

Safety Rules

Assembly

Operation 0 Spanish 22

Maintenance

Service and Adjustments

2 Storage 16

2

Trouble Shooting Chart

5 Parts List 19

11

14

Parts & Ordering

WARRANTY STATEMENT

FULL ONE YEAR WARRANTY ON CRAFTSMAN® GAS

CHAIN SAW

For one year from the date of purchase, when this Craftsman Gas Chairt Saw is

maintained, lubricated and tuned up according to the owner’s manual, Sears will

repair, free of charge, any defect in material or workmanship.

Thfei warranty excludes the bar, chain, spark plug and air filter, which are

expendable parts, and become worn during normal use.

If this Gas Chain Saw is used for commercial or rental purposes, this warranty

applies for 30 days from the date of purchase.

WARRANTY SERVICE IS AVAILABLE BY RETURNING THIS CHAIN SAW TO

THE NEAREST SEARS SERVICE CENTER IN THE UNITED STATES.

This warranty gives you specific legal rights, and you may also have other rights

which vary from state to state.

Sears, Roebuck and Co., D/817 WA, Hoffman Estates, IL 60179

SAFETY RULES

WARNING; Always disconnect spark

plug wire when making repairs except

for carburetor adjustments. Because a

chain saw is a high-speed woodcutting

too), careless or improper use of this

tool can cause serious injury.

PLAN AHEAD

• Restrict the use of your saw to adult

users who understand and can follow

the safety rules, precautions, and op

erating instructions found in this

manual.

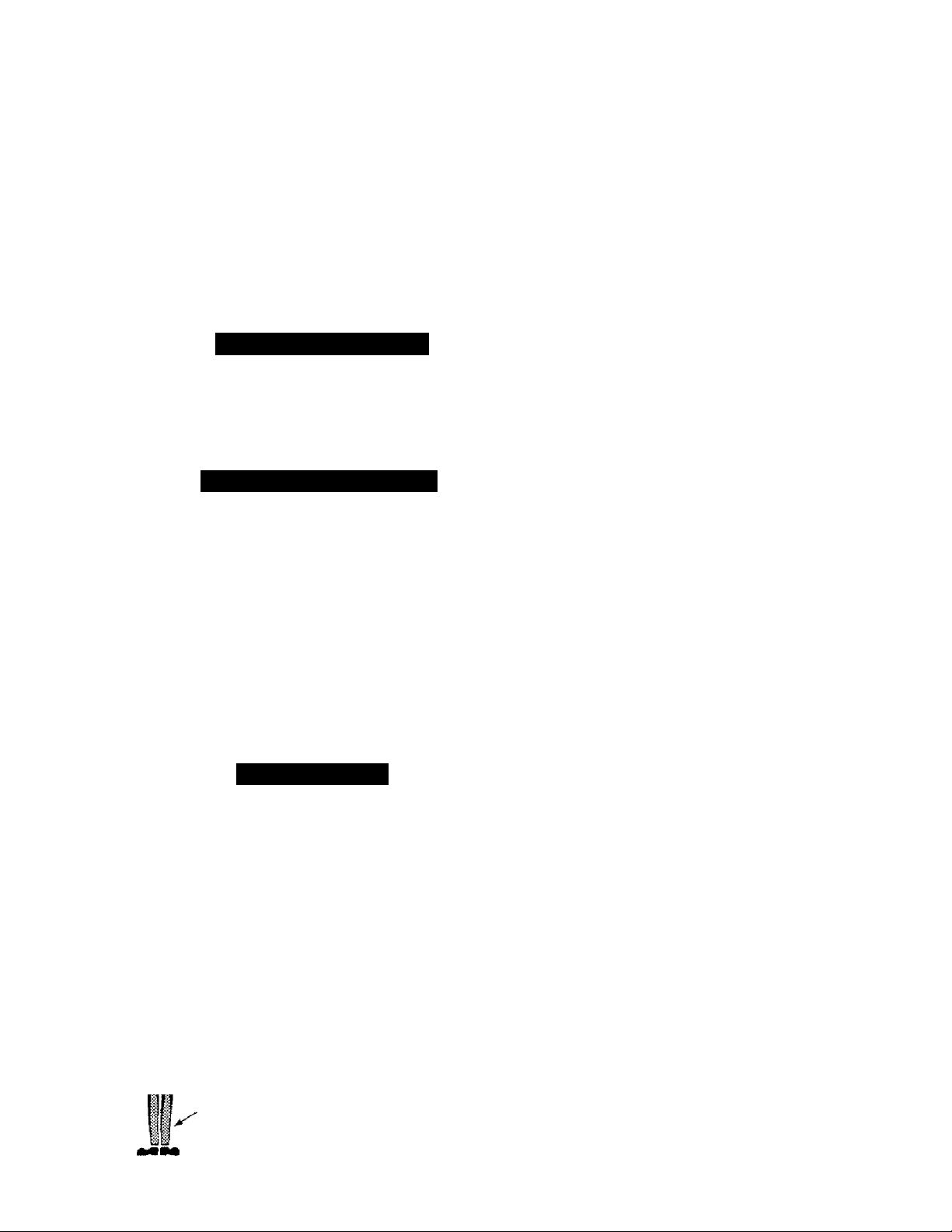

Hearing Safety Hat

Protection-..^ j Eye

Snug Protection

Fitting Heavy Duty

Clothing Gloves

/ * V

Safety

Shoes

Wear protective gear. Always use

steel-toed safety footwear with non

slip soles: snug-fitting clothing; heavy-

Safety Chaps

duty, non-slip gloves; eye protection

such as non-fogging, vented goggles

or face screen; an approved safety

hard hat; and sound barriers (ear

plugs or mufflers) to protect your

hearing. Regular users should have

hearing checked regularly as chain

saw noise can damage hearing. Se

cure hair above shoulder length,

• Keep all parts of your body away from

the chain when the engine is running.

• Keep children, bystanders, and ani

mals at least 30 feet (10 meters)

away from the work area when start

ing and using the saw.

' Do not handle or operate a chain saw

when you are fatigued, ill, or upset, or

if you have taken alcohol, drugs, or

medication. You must be in good

physical condition and mentally alert.

If you have any condition that might

be aggravated by strenuous work,

check with doctor before operating.

Do not start cutting until you have a

clear work area, secure footing, and

especially if you are felling a tree, a

retreat path.

17

Back

Page 3

• Do not operate with one hand. Seri

SAW SA(ӣL.Y

ous injury to the operator, helpers, or

bystanders may result from one

handed operation. A chain saw is in

tended for two-handed use.

• Operate the chain saw only in a wellventilated outdoor area.

• Do not operate saw from a ladder or

in a tree, unless you are specifically

trained to do so.

• Make sure the chain will not make

contact with any object while starting

the engine. Never try to start the saw

when the guide bar is in a cut.

• Do not put pressure on the saw, es

pecially at the end of the cut. Doing

so can cause you to lose control

when the cut is completed.

• Stop engine before setting saw down.

• Hand carry saw only when engine is

stopped. Carry with muffler away from

body; guide bar & chain projecting be

hind you; guide bar preferably cov

ered with a scabbard.

MAINTAIN YOUR SAW IN GOOD

WORKING ORDER

• Have all chain saw service performed

by a qualified service dealer except

the items listed in the maintenance

section of this manual.

• Make certain the saw chain stops

moving when the throttle trigger is re

leased. For correction, refer to “Car

buretor Adjustments.”

• Keep the handles dry, clean, and free

from oil or fuel mixture.

• Keep caps and fasteners securely

tightened.

• Use only Craftsman accessories and

replacement parts as recommended.

Never modify your saw.

HANDLE FUEL WITH CAUTION

• Do not smoke while handling fuel or

while operating the saw.

• Biminate all sources of sparks or flame

in areas where fuel is mixed or poured.

• Mix and pour fuel in an outdoor area

and use an approved, marked con

tainer for all fuel purposes. Wipe up

all fuel spills before starting saw.

• Move at least 10 feet (3 meters) from

fueling site before starting.

• Turn the engine off and let saw cool in

a non-combustible area, not on dry

leaves, straw, paper, etc. Slowly re- move fuel cap and refuel unit.

• Store the unit and fuel in a cool, dry

well ventilated space where fuei va

pors cannot reach sparks or open

flames from water heaters, electric

motors or switches, furnaces, etc.

GUARD AGAINST KICKBACK

Follow all safety rules to help avoid

kickback and other forces which can

result In serious injury.

WARNING: Rotational Kickback cari

occur when the moving chain contacts

an object at the upper portion of the tip

of the guide bar, Contact at the upper

portion of the tip of the guide bar can

cause the chain to dig into the object,

which stops the chain for an instant. The

result Is a lightning fast, reverse reaction

which kicks the guide bar up and back

toward the operator.

Pinch-Kickback and Pull-In occur when

the chain is suddenly stopped by being

pinched, caught, or by contacting a for

eign object in the wood. This sudden

stopping of the chain results in a rever

sal of the chain force used to cut wood

and causes the saw to move in the op

posite direction of the chain rotation.

Pinch-Kickback drives the saw straight

back toward the operator. Pull-In pulls

the saw away from the operator.

REDUCE THE CHANCE OF

KICKBACK

• Recognize that kickback can happen.

Wifri a basic understanding of kickback,

you can reduce the element of suiprise

which contributes to accidents.

• Never let the moving chain contact

any object at the tip of the guide bar.

• Keep working area free from obstruc

tions such as other trees, branches,

rocks, fences, stumps, etc. Eliminate

or avoid any obstruction that your saw

chain could hit while cutting.

' Keep saw chain sharp and properly

tensioned. A loose or dull chain can

Page 4

increase the chance of kickback. Fol

low manufacturer’s chain sharpening

and maintenance instructions. Check

tension at regular intervals, but never

with engine running. Make sure bar

clamp nuts are securely tightened.

• Begin and continue cutting at full

speed. If the chain is moving at a

slower speed, there is greater chance

of kickback occurring.

• Use extreme caution when reentering

a cut.

• Do not attempt cuts starting with the

tip of the bar (plunge cuts).

• Watch for shifting logs or other forces

that could close a cut and pinch or fail

into chain.

» Use the specified Reduced-Kickback

Guide Bar and Low-Kickback Chain.

Avoid Pirich-Ktckback:

• Be extremely aware of situations or

obstructions that can cause material

to pinch the top of or otherwise stop

the chain.

• Do not cut more than one log at a

time.

• Do not twist saw as bar is withdrawn

from an undercut when bucking.

Avoid Pull-In:

• Always begin cutting with the engine

at full speed and the saw housing

against wood.

• Use wedges made of plastic or wood.

Never use metal to hold the cut open,

MAINTAIN CONTROL

Stand to the left of the saw

Thumb on

underside

of handlebar]

keep your body from being in a direct

line with the cutting chain.

• Stand with your weight evenly bal

anced on both feet,

• Do not overreach. You could be drawn

or thrown off balance and lose control.

• Do not cut above shoulder height It is

difficult to maintain control of saw

above shoulder height.

KICKBACK SAFETY FEATURES

WARNING; The following features are

included on your saw to help reduce

hazard of kici^ack; however, such fea

tures will not totally eliminate this dan

ger. Do not rely only on safety devices.

• Handguard: designed to reduce the

chance of your feft hand contacting

the chain if your hand slips off the

front handleb^.

• Position of front and rear handlebars:

designed with distance between han

dles and “in-line” with each other. The

spread and “in-line” position of the

hands provided by this design work

together to give balance and resis

tance in controiling the pivot of the

saw back toward the operator if kick

back occurs.

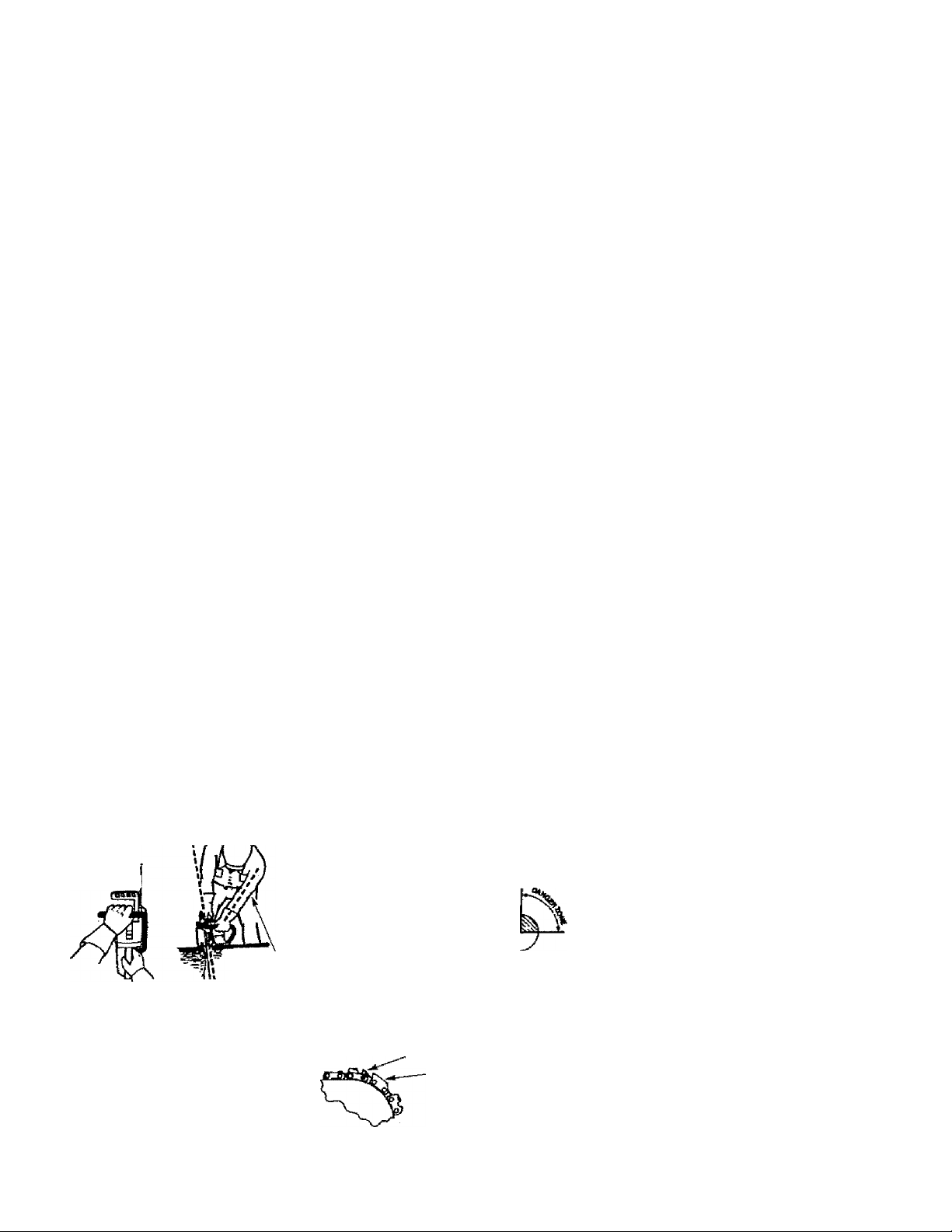

■ Reduced-Kickback Guide Bar: de

signed with a small radius tip which

reduces the size of the kickback dan

ger zone. This type bar has been

demonstrated to significantly reduce

the number and seriousness of kick

backs when tested in accordance with

ANSI B175.1.

Small Radius

Tip Guide Bar

* •

Never reverse hand positions

• A good, firm grip on the saw with both

hands will help you maintain control.

Don't let go. Grip the rear handle with

your right hand whether you are right

or left handed. Wrap the fingers of

your left hand over and around the

front handlebar, and your left thumb

under the front handlebar. Keep your

left arm straight with the elbow locked.

• Position your left hand on the front

handlebar so it is in a straight line with

your right hand on the rear handle

when making bucking cuts. Stand

slightly to the left side of the saw to

Elbow

locked

Larga Radius

Tip Guide Bar

• Low-K3ckback Chain: has met kickback

performance requirements when tested

on a representative sample of chain

saws below 3.8 cubic inch

displacement specified in ANSI B175.1.

Low-Kickback Chain

Contoured Depth Gauge

Elongated Guard Link

Deflects Kickback

Force And Allows

Wood To Gradually

Ride Into Cutter

SAFETY NOTICE: Exposure to

vibrations through prolonged use of

gasoline powered hand tools could

cause blood vessel or nen/e damage in

the fingers, hands, and joints of people

4

Page 5

prone to circulation disorders or

abnormal swelling. Prolonged use in

cold weather has been linked to blood

vessel damage in otherwise healthy

people. If symptoms occur such as

numbness, pain, loss of strength,

change in skin color or texture, or loss

of feeling In the fingers, hands, or joints,

discontinue the use of this tool and

seek medical attention. An

anti-vibration system does not

guarantee the avoidance of these

problems. Users who operate power

tools on a continual and regular basis

must closely monitor their physical

condition and the condition of this tool.

CHAIN BRAKE If this saw is to be used

for commercial togging, you must order

and install a chain brake to comply with

Federal OSHA Regulations for Com

mercial Logging. Contact your Sears

Sen/ice Center or call 1-800-235-5878.

SPARK ARRESTOR: Yoursaw is

equipped with a temperature limiting

muffler and spark arresting screen

which meets the requirements of

California Codes 4442 and 4443. All

U.S. forest land and the states of

California, Idaho, Maine, Minnesota,

New Jersey, Oregon, and Washington

require by law that many internal

combustion engines be equipped with a

spark arrestor screen, if you operate a

chain saw in a state or locale where

such regulations exist, you are legally

responsible for maintaining the

operating condition of these parts.

Failure to do so is a violation of the law.

Refer to Customer Responsibilities

chart in the maintenance section.

STANDARDS: This chain saw is listed

by Undenwriters Laboratories, Inc, in

accordance with American National

Standards for Gasoline-Powered Chain

Saws Safety Requirements (ANSI

B175.1-199T).

ASSEMBLY

CARTON CONTENTS

Check carton contents against the folfowing list

Model 358.352680

• Chain Saw (fuHy assembled}

• Bar too!

• Chain

• Carrying Case

• Gloves

• Gas Can

• Bar & Chain Lube

« 2-cycle engine oil

• Examine parts for damage. Do not

use damaged parts.

• If you need assistance or find that

parts are missing or damaged, please

call 1-800-235-5878.

NOTE: It is normal to hear the fuel filter

rattle in an empty fuel tank.

Your unit has been factory tested and

the carburetor precisely adjusted. As a

result you may smell gasoline or find a

drop of oil/fue! residue on the muifter

when you unpack the unit.

ASSEMBLY

Your saw is fully assembled; no

assembly is necessary.

Page 6

operation

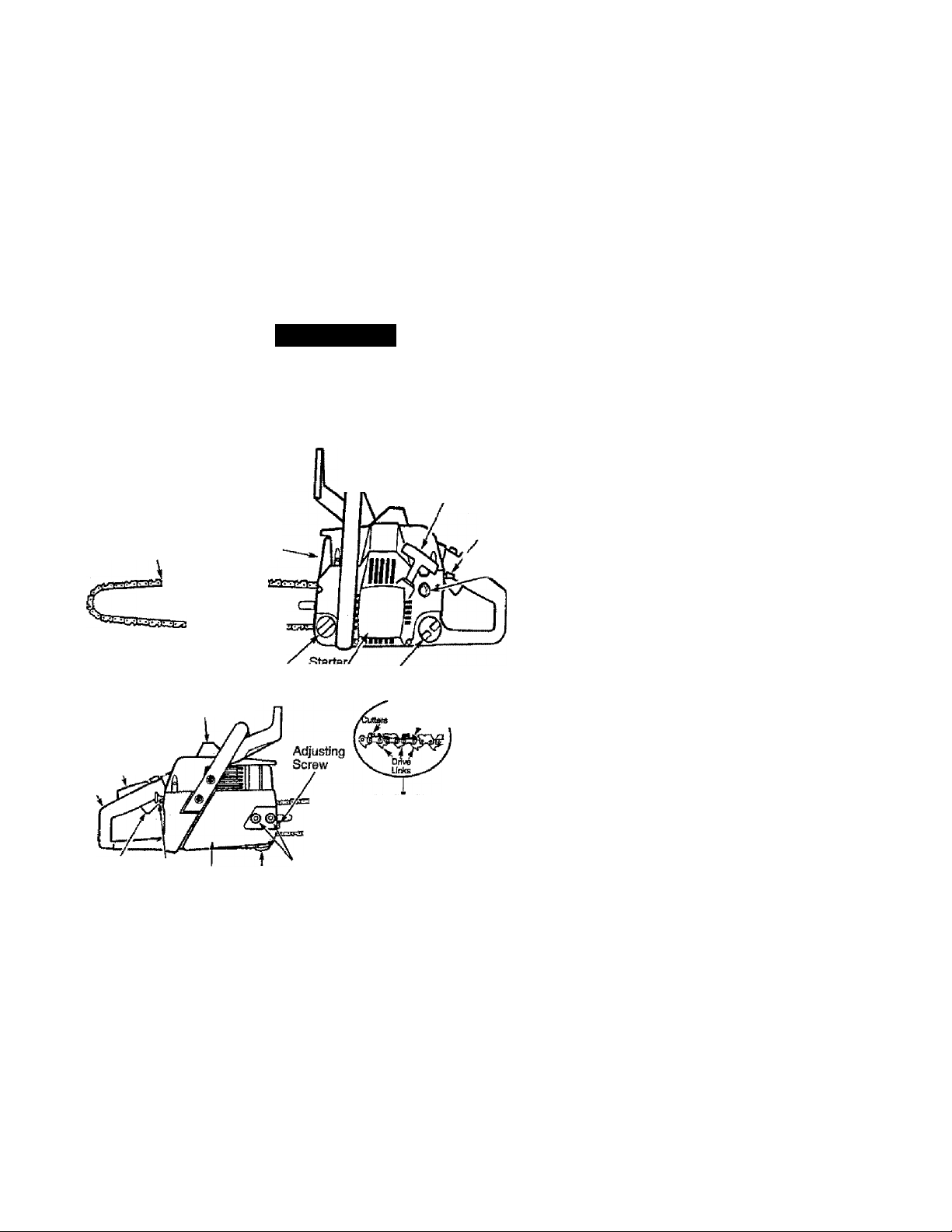

KNOW YOUR SAW

READ THIS OPERATOR’S MANUAL AND SAFETY RULES BEFORE OPERAT

ING YOUR CHAIN SAW. Compare the illustrations with your unit to tamiliarize

yourself with the location of the various controls and adjustments. Save this

manual for future reference.

Bar Tool

Chain

CRAFTSMAN*

Fast Idle

Throttle LMk

Lockout /

Rear \ r.

Handle

Throttle Choke

Trigger Knob Bar Clamp

Hand Guard

33E

Cylinder Cover

Muffler

Bar Oil Fill Cap Housing

« Startan

Bar Clamp Nuts ®tiide Bar

Front Handle

starter Rope

Fuai Mix Fill Cap

Depth Gaugm

___________________

ON/STOP

Switch

Primer

Bulb

Chain

Direction

of Travel

1^"

OWSTOP SWITCH

The ON/STOP Switch is used to stop

the engine.

THROTTLE TRIGGER

The throttle trigger controls engine

speed.

THROTTLE LOCKOUT

The throttle lockout must be pressed

before you can squeeze the throttle trig

ger. This feature prevents you from ac-

ddentally squeezing the trigger.

FAST IDLE LOCK

The fast idle lock holds the throttle trig

ger in the starting position. Activate the

fast idle lock by pressing the throttle

lockout and squeezing the throttle trig

ger. With the throttle trigger squeezed,

press the fast idle lock. Release the

throttle lockout and trigger while holding

the fast idle lock button.

CHOKE KNOB

The Choke Knob activates the choke to

provide additional fuel to the engine

during cold starting.

PRIMER BULB

The Primer Bulb circulates fuel to the

carburetor to provide quicker starting.

CHAIN TENSION

It is normal for a new chain to stretch

during first 30 minutes of operation. You

should check your chain tension fre

quently. See Chain Tension under the

Sen/ice and Adjustments section.

Page 7

BEFORE STARTING ENGINE

WARNING: Be $ure to read the fuel

handling infonnation in the safety rules

section of this manual before you begin.

If you do not understand the fuel han

dling information do not attempt to fuel

your unit. Seek help from someone that

does understand the information or call

the customer assistance help line at

1-800-235-5878.

GUIDE BAR AND CHAIN OIL

The chain oiler provides continuous lu

brication to the chain and guide bar. Be

sure to fill the bar oil tank when you fill

the fuel tank (Capacity = 6.8 fl. 02.).

For maximum guide bar and chain life,

we recommend you use Craftsman

chain saw bar oil. If Craftsman bar oil is

not available, you may use a good

grade SAE 30 oil until you are able to

obtain Craftsman brand. The oil output

is automatically metered during opera

tion. Your saw will use approximately

one tank of bar oi! for every tank of fuel

mix. Always fill the bar oil tank when

you fill the fuel tank.

FUELING ENGINE

This engine is certified to operate on

unleaded gasoline. Before operation,

gasoline must be mixed with a good

quality 2-cycle air-cooled engine oil. We

recommend Craftsman brand oil. Mix '

gasoline oil at a ratio of 40:1 (A

40:1 ratio is obtained by mixing 3.2 '

ounces of oil with 1 gallon of unleaded

gasoline). DO NOT USE automotive oil

or boat oil. These oils will cause engine

damage. When mixing fuel follow the

instructions printed on the container.

Once oil is added to the gasoline,

shake container momentarily to assure

that the fuel is thoroughly mixed.

Always read and follow the safety rules

relating to fuel before fueling your unit.

lines and carburetor are empty. Use fresh

fuel next season. See STORAGE instruc

tions for additional information.

Never use engine or carburetor cleaner

products In the fuel tank or permanent

damage may occur.

See the STORAGE section for additional

information.

STOPPING YOUR ENGINE

• Move On/Stop switch to STOP.

• if engine does not stop, pull choke

knob out fully.

STARTING YOUR ENGINE

COLD ENGINE OR WARM ENGINE

AFTER RUNNING OUT OF FUEL

• Fuel engine with 40:1 fuel mix.

• Fill bar oil tank with bar oil.

• Prime engine by slowly pressing prim

er bulb six times.

• Move On/Stop switch to ON.

Primer Butb

On/Stop

Switch

CHOKE POSITIONS

P

Off Full

Actuate choke by pulling choke knob

fuliy out.

Set saw on the ground. Grip front

handle with your (eft hand and place

right foot through rear handle.

Starter Rope Handle

Left Hand

on Front

Handle

IMPORTANT

Experience indicafes that alcohol blended

fuels (c^led gasohol or using ethanol or

methanol) can attract moisture which

leads to separatiiMi and formation of

acids during storage. Acidic gas can

damage tiie fael system of an engine

while in storage.

To avoid engine problems, the fuel sys

tem should be emptied before storage for

30 days or longer. Drain the gas tank,

start the engine and let it run until the fuel

Right Foot Through Rear Handle

' Set fast idle by depressing the throttle

lock with your right hand. Then,

squeeze and hold throttle trigger. With

your thumb, press the fast idle lock

down and hold. Next, release the

throttle trigger.

DO NOT squeeze throttle trigger dur

ing starting: otherwise, it will be nec

essary to reset the fast idle lock.

Page 8

NOTE; When pulling the starter rope,

do not us® the full extent of the rope.

Do not let starter rope snap back. Hold

handle. Let rope rewind slowly.

• Puli starter rope handle firmly and

quickly with your right hand until the

engine attempts to start, but no more

than 5 puiis. Then, push in choke

knob fully. Resume pulling handle un

til engine starts.

• Above 40 “F, allow engine to run for

approximately 5 seconds. Then

squeeze and release throttle trigger to

allow engine to idie.

• Below 40° F, allow engine to warm up

for 30 seconds to 1 minute with choke

at partial position. Push choke knob in

to the OFF position; then squeeze and

release throttle trigger to allow engine

to idle.

• To stop engine, move On/Stop switch

to the STOP position.

STARTING A WARM ENGINE

DO NOT use the choke to start a warm

engine or flooding and hard starting

may occur.

• Move On/Stop switch to ON.

• Set fast idle lock.

• Be sure choke is in the off position.

• With saw on ground, grip front handle

with left hand and place your right foot

through rear handle.

• Pull starter rope handle until engine

starts.

• Squeeze and release throttle trigger

to return engine to idle speed.

DIFFICULT STARTING OR

STARTING A FLOODED ENGINE

The engine may be flooded if it has not

started after fO pulls. Flooded engines

can be cleared of excess fuel with the

following procedure:

• Engage the fast idle lock.

• Verify that the On/Stop switch is in the

ON position.

• Push choke knob to the OFF position.

• With saw on ground, grip front handle

with left hand and place right foot

through rear handle.

» Pull starter rope handle until engine

starts.

« Starting could require many pulls de

pending on how badly the unit is

flooded. If engine still fails to start, re

ferió the TROUBLESHOOTING chart or

call 1-800-235-5878.

OPERATING TIPS

• Check chain tension before first use

and after 1 minute of operation. See

Chain Tension in the Mainienance

section.

• Cut wood only. Do not cut metal, plas

tics, masonry, non-wood building ma

terials, etc.

' Stop the saw if the chain strikes a for

eign object. Inspect the saw and re

pair parts as necessary.

Keep the chain out of dirt and sand.

Even a small amount of dirt will quick

ly dull a chain and increase the possi

bility of kickback.

Practice cutting a few small logs using

the following steps. This will help you

get the “feel" of using your saw before

you begin a major sawing operation.

• Squeeze the throttle trigger and al

low the engine to reach kill speed

before cutting.

• Begin cutting with the saw frame

against the log.

• Keep the engine at full speed the

entire time you are cutting.

• Allow the chain to cut for you. Exert

only light downward pressure.

• Release the throttle trigger as soon

as the cut is compfeied, allowing the

engine to idfe. If you run the saw at

full throttle without a cutting load,

unnecessary wear can occur.

• To avoid losing control when cut is

complete, do not put pressure on

saw at end of cut.

• Stop engine before setting saw down.

TREE FELLING TECHNIQUES

WARNING: Check for broken or dead

branches which can fall while cutting

causing serious injury. Do not cut near

buildings or electrical wires if you do not

know the direction of tree fall, nor cut at

night since you will not be able to see

well, nor during bad weather such as

rain, snow, or strong winds, etc.

• Carefully plan your sawing operation

in advance.

• Clear the work area. You need a clear

area all around the tree so you can

have secure footing.

• Study the natural conditions that can

cause the tree to fail in a particular

direction. These conditions include:

• The wind direction and speed.

• The lean of the tree. The lean of a

tree might not be apparent due to

uneven or sloping terrain. Use a

8

Page 9

plumb or level to determine the di

rection of tree lean.

• Weight and branches on one side.

• Surrounding trees and obstacles.

• Look for decay and rot. if the trunk is

rotted, it can snap and fall toward the

operator.

> Make sure there is enough room for

the tree to fall. Maintain a distance of

2-1/2 tree lengths from the nearest

person or other objects. Engine noise

can drown out a warning call.

Remove dirt, stones, loose bark,

nails, staples, and wire from the tree

where cuts are to be made.

Plan a dear retreat path

f

О

45*

Ч

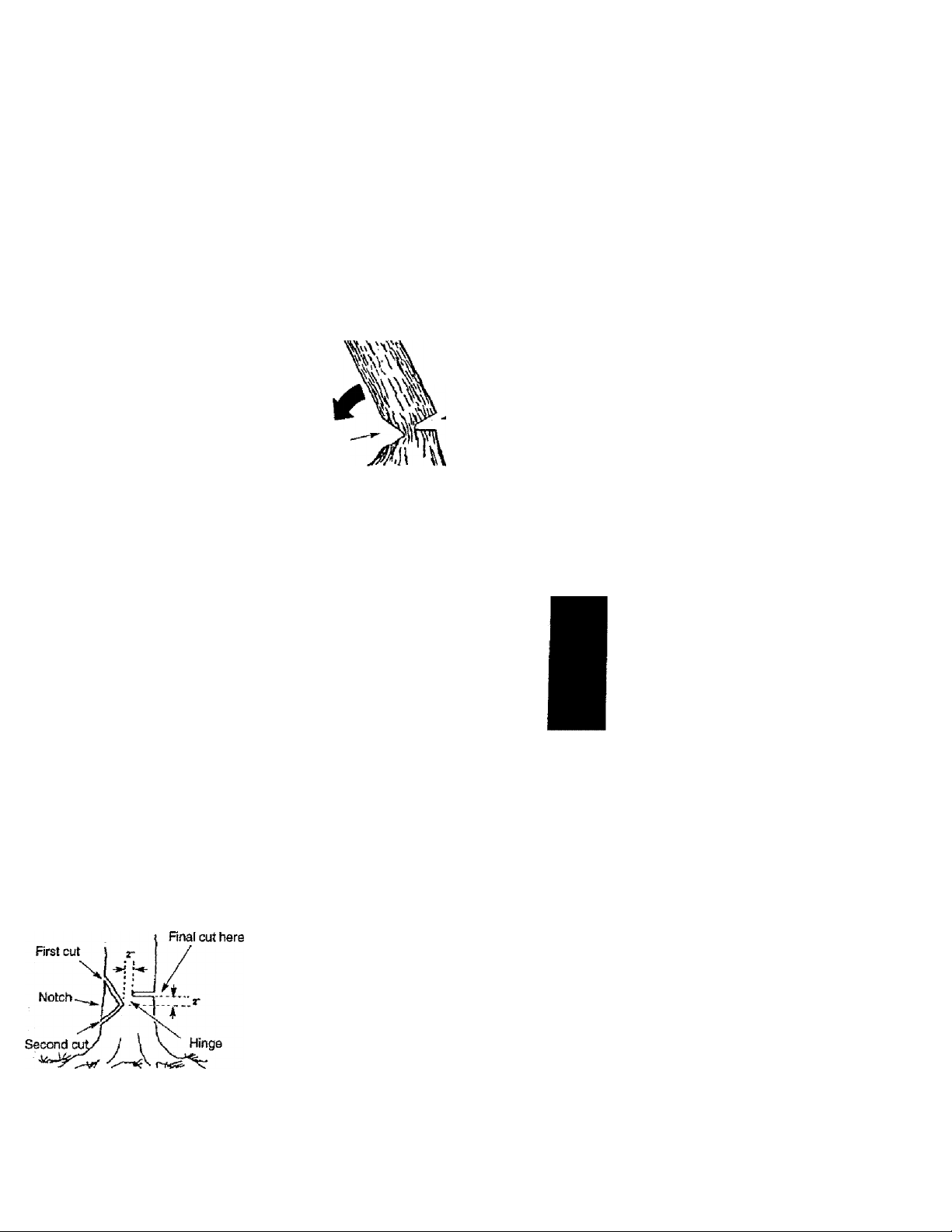

FELLING LARGE TREES

(6 inches in diameter or larger)

The notch method is used to fell large

trees. A notch is cut on the side of the

tree in the desired direction of fall. After

a felling cut is made on the opposite

side of tree, the tree will tend to fail In

the direction of the notch.

NOTE: If tree has large buttress roots,

remove them before making the notch.

NOTCH CUT AND FELLING TREE

• Make notch cut by cutting the top of

the notch first. Cut through 1/3 of the

diameter of the tree. Next complete

the notch by cutting the bottom. See

illustration. Once the notch is cut, re

move the wedge of wood from tree.

' After removing the wood, make the

felling cut on the opposite side of the

notch. This is done by making a cut

about two inches higher than the cen

ter of the notch. This will leave

enough uncut wood between the fell

ing cut and the notch to form a hinge.

► - Direction of Fall

This hinge will help prevent the tree

from falling in the wrong direction.

Hinge holds free on

stump and helps

control fall

Opening of

felling cut

Closing

of notch

NOTE; Before felling cut is complete,

use wedges to open the cut when

necessary to control the direction of fall,

To avoid kickback and chain damage,

use wood or plastic wedges, but never

steel or iron wedges.

• Be alert to signs that the tree is ready

to fall: cracking sounds, widening of

the felling cut, or movement in the up

per branches.

• As tree starts to fall, stop saw, put it

down, and get away quickly on your

planned retreat path.

» Be extremely cautious with partially

fallen trees that may be poorly sup

ported. When a tree doesn’t fall com

pletely, set the saw aside and puJI

down the tree with a cable winch,

block and tackle, or tractor. Do not

use your saw to cut down a partially

fallen tree.

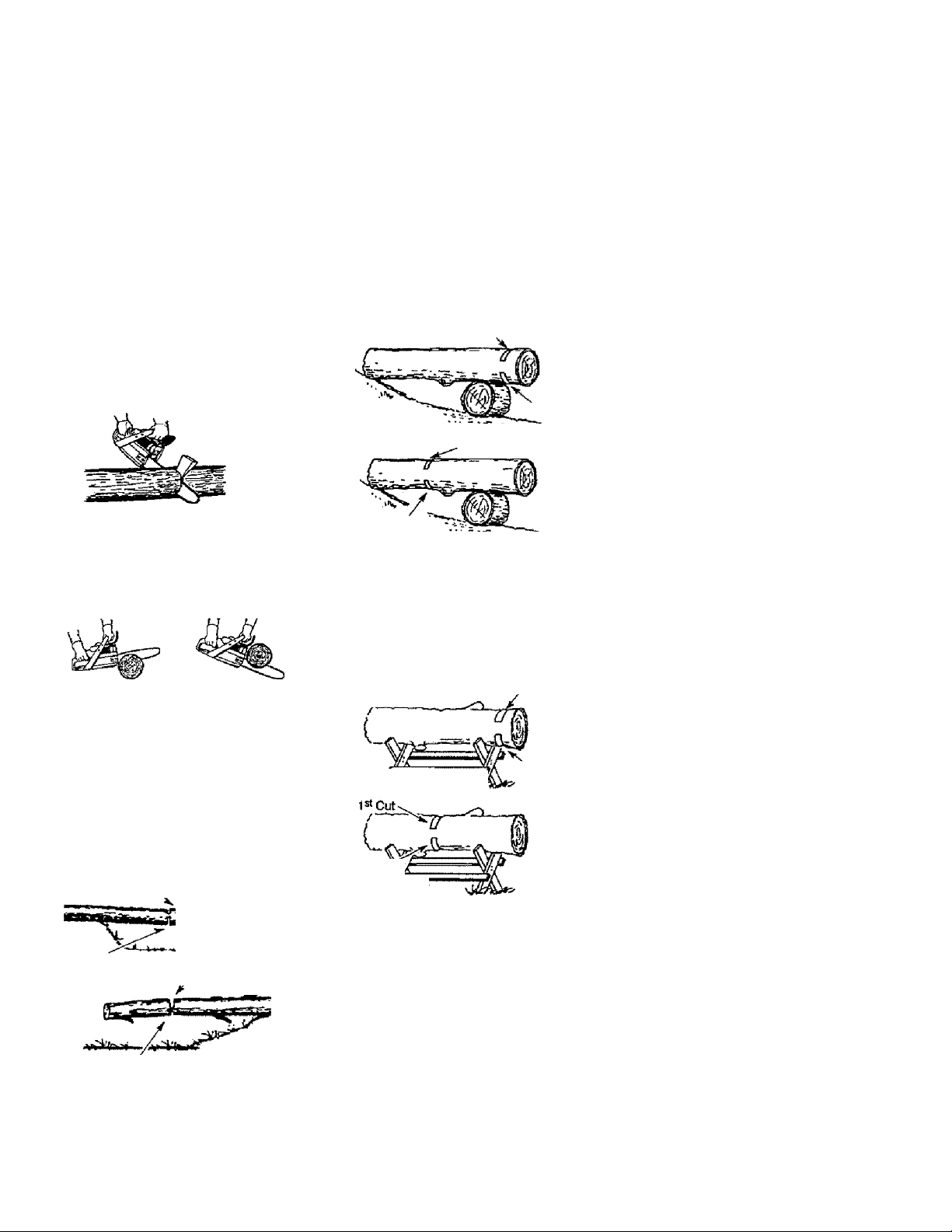

CUTTING A FALLEN TREE

(BUCKING)

Bucking is the term used for cutting a

fallen tree to the desired fog size.

WARNING: Do not stand on the log

being cut. Any portion can roll causing

loss of footing and control. Do not starid

downhill of the log being cut.

IMPORTANT POINTS

• Cut only one log at a time.

• Cut shattered wood very carefully;

sharp pieces of wood could be flung

toward operator.

• Use a sawhorse to cut small logs.

Never allow another person to hold

the log while cutting and never hold

the iog with your leg or foot.

• Do not cut in art area vrfiere logs,

limbs, and roots are tangled. Drag Icigs

into a clear area before cutting them.

BUCKING TECHNIQUES

WARNING: if saw becomes pinched

or hung in a log, don’t fry to force it out.

You can lose control of the saw result

ing in injury and/or damage to the saw.

Stop the saw, drive a wedge of plastic

Page 10

or wood Wo the cut until the saw can be

removed easily. Restart saw and carefully

reenter the cut. Do not use a metal

wedge. Do not attempt to restart your

saw when it is pinched or hung in a log.

Use a wedge to remove pinched saw

Turn saw OFF and use a plastic or

wooden wedge to force out open.

Overcutting begins on the top side of

the log with the bottom of the saw

against the log. When overcufting use

light downward pressure.

Overcutting Undercutting

Undercutting involves cutting on the

underside of the log with top of saw

against the log. When undercutting use

light upward pressure. Hold saw firmly

and maintain control. The saw will tend

to push back toward you.

WARNING: Never turn saw upside

down to undercut. The saw cannot be

controlled in this position.

Using a tog

for support

2"<*Cut

2nd Cut.

1st Cut

BUCKING USING A LOG OR

SUPPORT STAND

• Remember your first cut is always on

the compression side of the fog. (Re*

fer to the illustration below for your

first and second cut).

• Your first cut should extend 1/3 of the

diameter of the fog.

• Rnish with your second cut.

Using a support stand

1®«Cut

2"^ Cut

1st Cut

Always make your first cut on the

compression side of the log.

First cut on compression side of log

Second

cut

Second cut

First cut on compression side of fog

BUCKING WITHOUT A SUPPORT

* Overcut through 1/3 of the diameter of

the log.

* Roll the log over and finish with a sec*

ond overcut.

* Watch for logs with a compresión

side. See illustration above for cutting

logs with a compression side.

2nd Cut

LIMBING AND PRUNING

WARNING: Never climb into a tree to

limb or prune. Do not stand on ladders,

platforms, a fog, or in any position

which can cause you to lose your bal

ance or control of the saw.

IMPORTANT POINTS

• Watch out for springpoles.

Springpoies are small size limbs

which can whip toward you, or pull

you off balance. Use extreme caution

when cutting small size limbs.

• Be alert for springback. Watch out for

branches that are bent or under pres

sure. Avoid being struck by the

branch or the saw when the tension in

the wood fibers is released.

• Frequently clear branches out of the

way to avoid tripping over them.

10

Page 11

LIMBING

• Limb a tree only after it is cut down.

. Leave the larger limbs underneath the

felled tree to support the tree as you

work.

> Start at the base of the felled tree and

work toward the top, cutting branches

and limbs. Remove small limbs with

orre cut.

• Keep the tree between you and the

chain.

• Remove larger, supporting branches

with the 1/3,2/3 cutting techniques de

scribed in the bucking section.

• Always use an overcut to cut small

and freely hanging limbs. Undercut

ting couid cause limbs to fall and

pinch the saw.

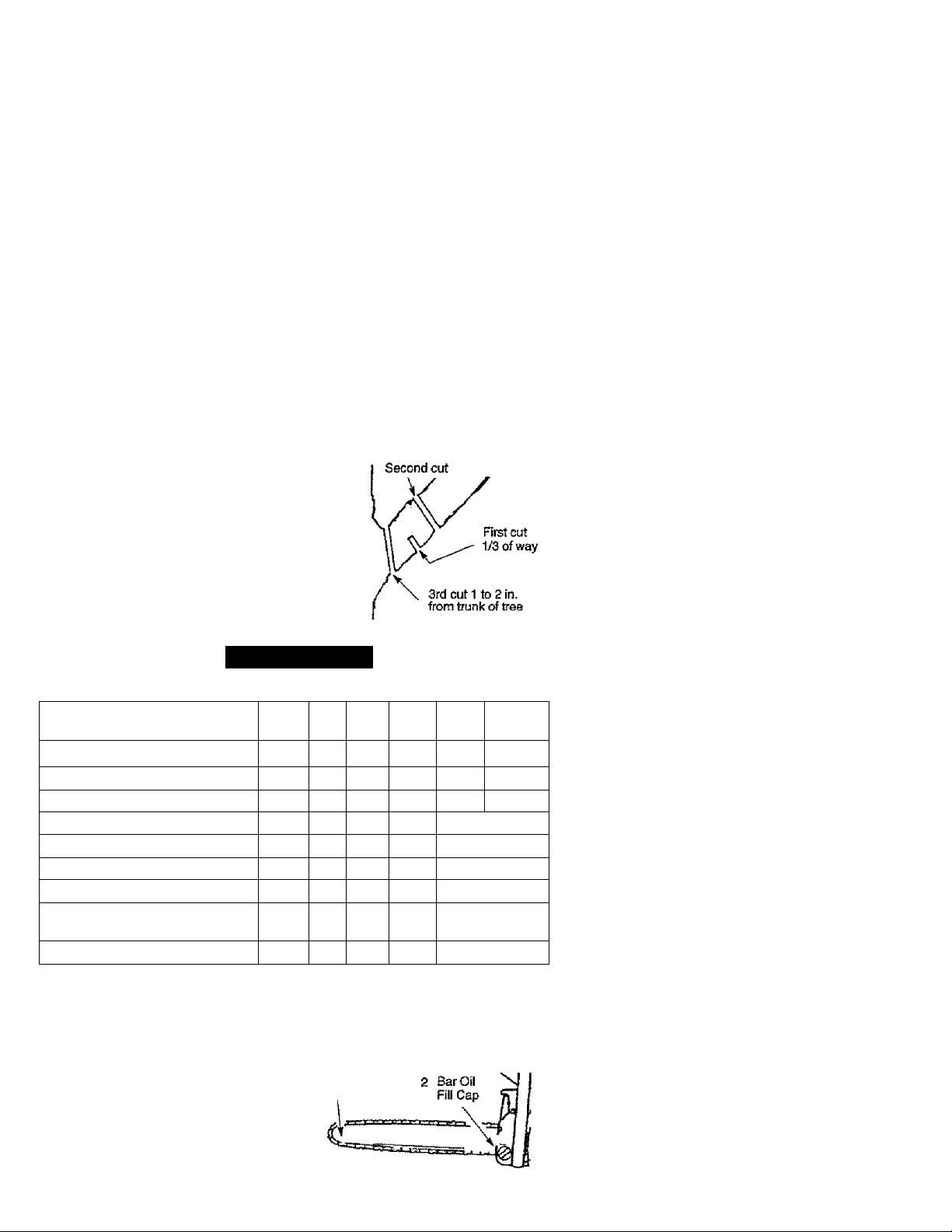

PRUNING

WARNING: Limit pruning to limbs

shouider height or below. Do not cut if

CUSTOMER RESPONSIBILITIES

Fill in dates as you complete

regular service

Check for damaged/worn parts

Check for Joose fasteners/parts

Check chain tension

Check chain sharpness

Check guide bar

Clean unit & labels

Clean air filter

Clean/inspect spark arrestor

screen & inspect muffler

Replace spark plug

branches are higher than your shoul

der. Get a professional to do the job.

• Make your first cut 1/3 of the way

through the bottom of the limb.

• Next make a second cut all the way

through the limb.

• Finish the pruning operation by using

an overcut so that the stump of the

limb protrudes 1 to 2 inches from the

trunk of the tree.

MAINTENANCE

Before

Use

u*

After

Use

Every

5hrs.

y*

Every

25hrs

y^

Yearly

У

Service

Dates

I

GENERAL RECOMMENDATIONS

The warranty on this unit does not cov

er items that have been subjected to

operator abuse or negligence. To re

ceive full value from the warranty, the

operator must maintain unit as instmct-

ed in this manual. Various adjustments

will need to be made periodically to

property maintain your unit.

* Once a year, replace the spark plug,

air filter element, and check guide bar

and chain for wear. A new spark plug

and air filter element assures proper

air-fue! mixture and helps your engine

run better and last longer.

WARNING; Disconnect the spark plug

before performing maintenance except

for carburetor adjustments.

LUBRICATION

1 Bar

Sprocket

1 Use sprocket lubrication

2 Use Craftsman chain saw bar oil

11

Page 12

CHECK FOR DAMAGED OR

WORN PARTS

Replacement of damaged/worn parts

should be referred to your Sears Ser

vice Center.

NOTE: If is normal for a small amount

of oil to appear under the saw after en

gine stops. Do not confuse this with a

leaking oil tank.

• On/Stop Switch - Ensure On/Stop

switch functions property by moving

the switch to the “Stop” position.

Make sure engine stops; then restart

engine and continue.

• Fuel Tank - Do not use saw if fuel

tank shows signs of damage or leaks.

• Oil Tank - Do not use saw if oil tank

shows signs of damage or leaks.

CHECK FOR LOOSE

FASTENERS AND PARTS

• Bar Clamp Nut

• Chain .

• Muffler

• Cylinder Shield

• Air Filter

• Clutch Drum/Sprocket

• Handle Screws

• Vibration Mounts

• Starter Housing

• Handguard

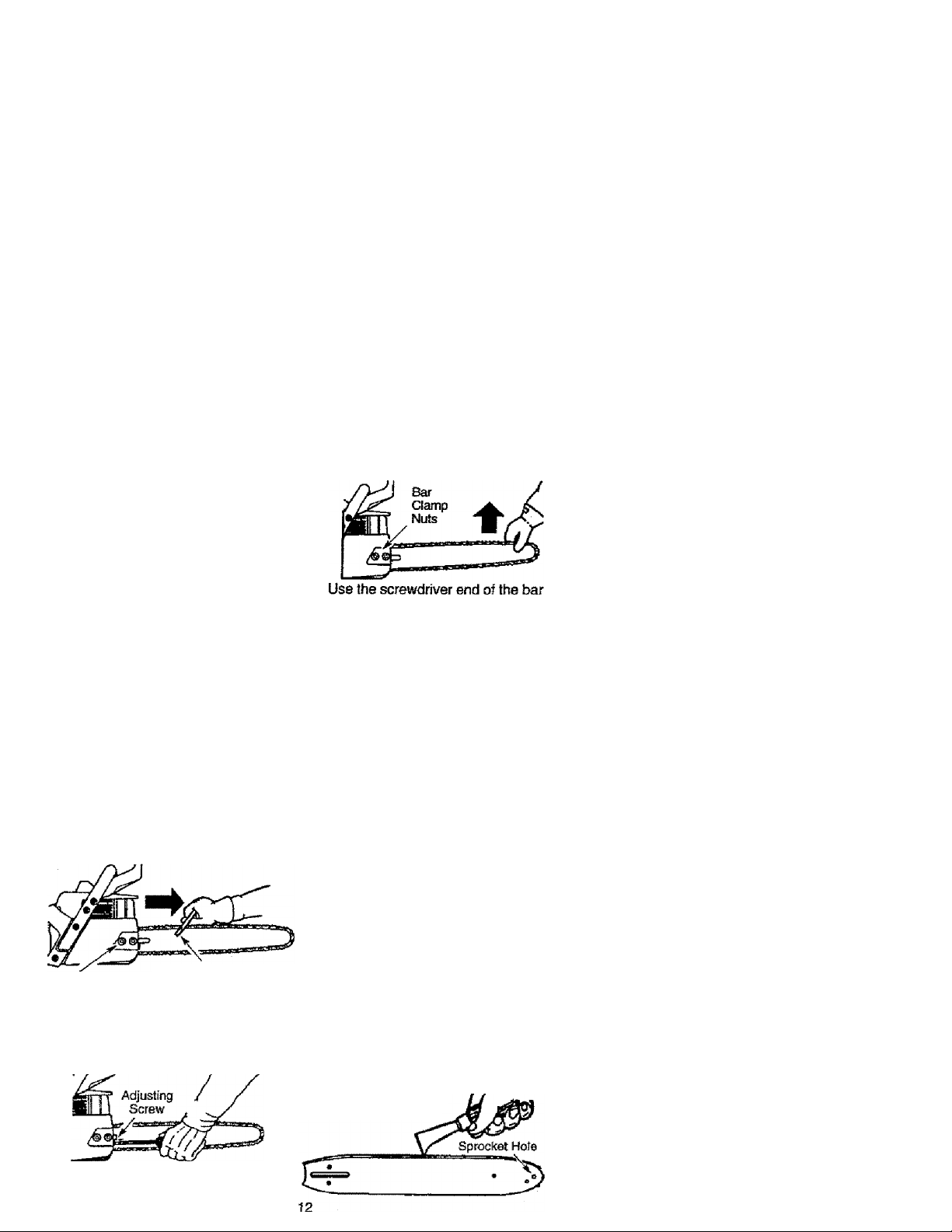

CHECK CHAIN TENSION

» Use the screwdriver end of the bar

tool to move chain around guide bar

to ensure kinks do not exist. The

chain should rotate freely.

Bar Ciamp Nuts

Bar Tool

• Loosen bar clamp nuts until they are

finger tight against the bar damp.

• Turn adjusting screw clockwise until

chain barely touches the bottom of

guide bar.

Adjust’ng Screw -1/4 Turn

• Lift up tip of guide bar to check for

sag. Release tip of guide bar, then

turn adjusting screw i/4 turn clock

wise. Repeat until sag does not exist.

While lifting tip of guide bar, tighten

bar clamp nuts with the bar tool.

Torque to 10-15 ft-lbs.

tool to move chain around guide bar.

• If chain does not rotate, it is too tight.

Slightly loosen bar damp nuts and

turn adjusting screw 1/4 turn counter

clockwise. Retighten bar damp nuts.

• If chain is too loose, it will sag below

the guide bar. DO NOT operate the

saw if the chain is loose.

CHECK CHAIN SHARPNESS

A sharp chain makes wood chips. A

dull chain makes a sawdust powder

and cuts slowly.

CHAIN SHARPENING

Chain sharpening requires special

tools. You can purchase sharpening

tools at Sears or go to a professional

chain sharpener.

CHECK GUIDE BAR

Conditions which require guide bar

maintenance:

• Saw cuts to one side or at an angle.

• Saw has to be forced through the cut.

• Inadequate supply of oii to bar/chain.

Check the condition of guide bar each

time chain is sharpened. A worn guide

bar will damage the chain and make

cutting difficuil, To maintain guide bar:

• Move On/Stop switch to “Stop.”

• Remove bar and chain from saw.

• Clean all sawdust and any other

debris from the guide bar groove and

sprocket hole after each use.

Remove Sawdust From

Guide Bar Groove

Using bar tool, roil chain around guide

bar to ensure alt finks are in bar groove.

Page 13

' Add lubricant to sprocket hole after

each use.

■ Burring of guide bar rails is a normal

process of rail wear. Remove these

burrs with a flat file.

When rail top is uneven, use a fiat file

to restore square edges and sides.

TUT

File Edges and

sides Square

Worn Groove Correct Groove

Replace guide bar when the groove is

worn, the guide bar is bent or cracked,

or when excess heating or burring of

the rails occurs. If replacement is nec

essary, use oniy the guide bar specified

for your saw in the repair parts list or on

the decal located on the chain saw.

CLEAN UNIT & LABELS

• Clean the unit using a damp cloth with

a mild detergent.

• Wipe off unit with a dean dry cloth.

CLEAN AIR FILTER

A dirty air filter decreases the life and

performance of the engine and in

creases fuel consumption and harmful

emissions. Always dean your air filter

after 15 tanks of fuel or 5 hours of op

eration, whichever comes first. Clean

more frequently in dusty conditions. A

used air filer can never be completely

cleaned. It is advisable to replace your

air filter with a new one after every 50

hours of operatiort, or annually, which

ever comes first. To dean filter:

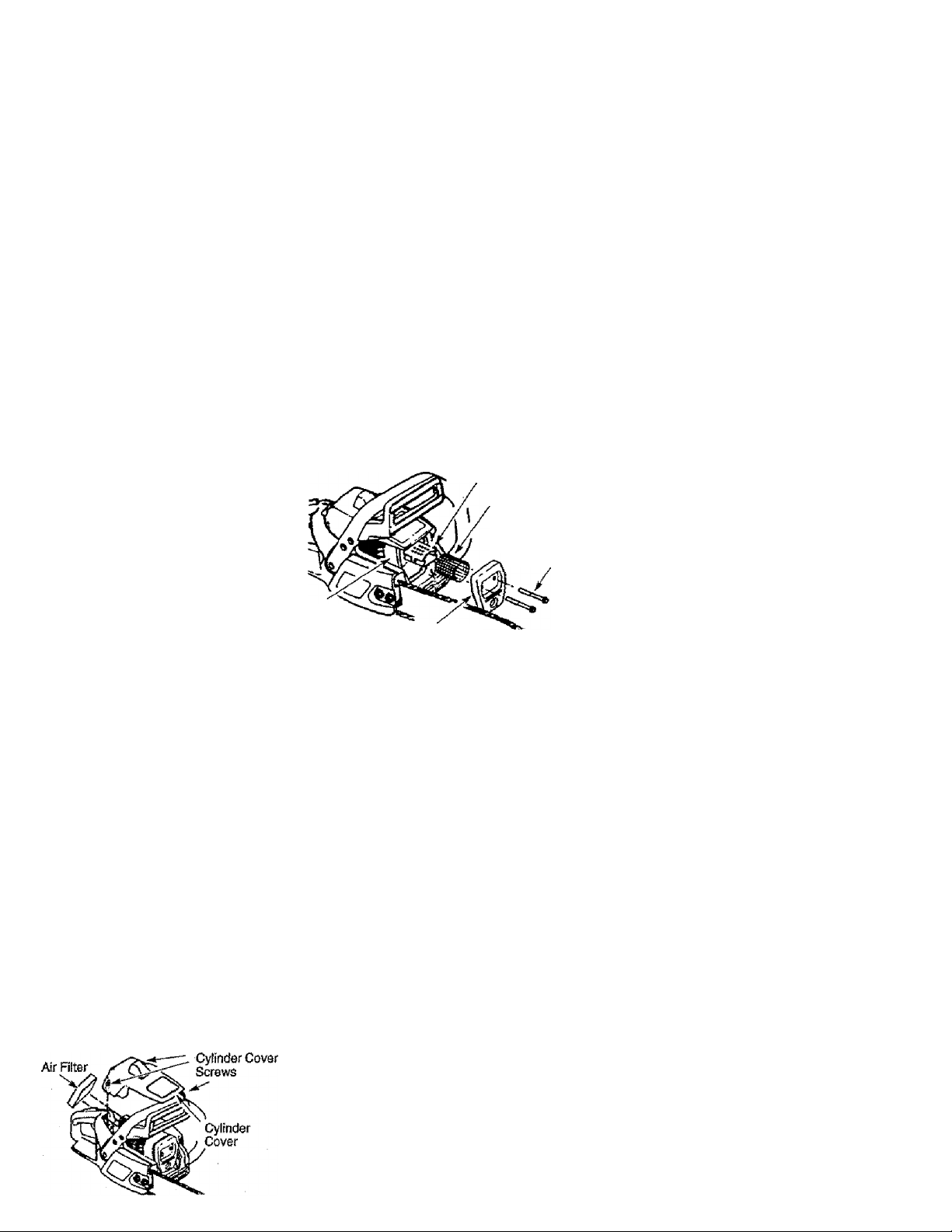

• Loosen 3 screws on cylinder cover.

• Remove cylinder cover.

• Remove air filter.

• Clean the air filter using hot soapy

water. Rinse with clean cool water.

Air dry completely before reinstalling.

• Lightly oil air filter before installing to

improve the efficiency of air filter. Use

2-cycle engine oil or motor oil (SAE

30). Squeeze excess oil from filter.

• Reinstail air filter.

• Reinstall cylinder cover and 3 screws

{15-20 in-lbs.)

m

murfler and spark

ARRESTOR SCREEN

As the unit is used, carbon deposits

build up on the muffler and spark

arrestor screen, and must be removed

to avoid creating a fire hazard or affect

ing engine performance.

Replace the spark arrestor screen if

breaks occur.

Muffler Diffuser

Muffier

Body

Muffler Cover

CLEANING THE SPARK

ARRESTOR SCREEN

Cleaning is required every 25 hours of

operation or annually, whichever comes

first.

• Loosen and remove the 2 muffier cov

er screws.

• Remove the muffler cover {cover

snaps off muffler body).

• Remove muffler diffuser and spark

arrestor screen assembly. Notice the

orientation of these parts for reassem

bling.

• Clean the spark arrestor screen with a

wire brush. Replace screen if breaks

are found.

• Replace any broken or cracked muf

fler parts.

• Reinstall diffuser and spark arrestor

screen assembly with round holes

facing up.

• Reinstall muffler cover and 2 screws

{7-8ft-lbs).

REPLACE SPARK PLUG

The spark plug should be replaced

each year to ensure the engine starts

easier and runs better. Ignition timing is

fixed and nonadjustable.

• Loosen 3 screws on cylinder cover.

• Remove the cylinder cover.

• Pul) off the sparte plug boot

• Remove spark plug from cylinder and

discard.

13

Spark

Arrestor

Screen

Muffier

Cover

Screws

Page 14

» Replace with Champion RCJ7Y spark

plug and lighten with a 3/4 inch socket

wrench (10-12 ft-Jbs). Spark plug gap

should be .025 in.

' Reinstall the spark plug boot.

' Reinstall the cylinder cover and 3

screws (15-20 in-lbs).

SERVICE AND ADJUSTMENTS

Screw!

Spark

Plug Boot

Spark

Plug

Cylinder

Cover

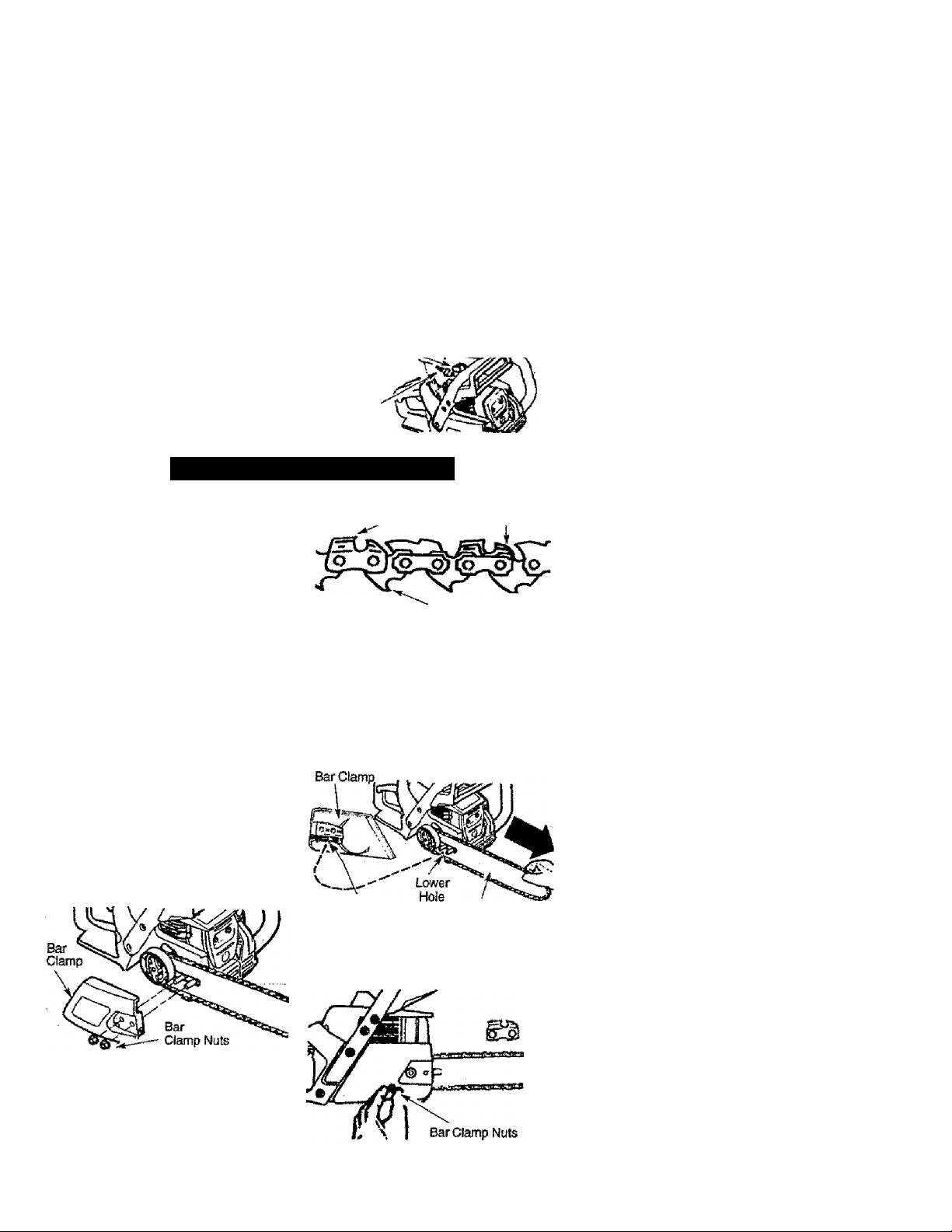

CHAIN REPLACEMENT

CAUTION: Wear protective gloves

when handling chain. The chain is

sharp and can cut you even when it is

not moving.

it is nonmal for a new chain to stretch dur

ing the first 15 minutes of cpeiation. You

should recheck your chain tension fre

quently and adjust the chain tension as

required. See Chain Tension section.

• Move On/Stop switch to the Stop

position.

• Replace the old chain when it be

comes worn or damaged.

• Use only the Low-Kickback replace

ment chain specified in the repair

parts list The correct replacement bar

and chain is also specified on a decal

located on the chain saw.

• See your Sears Service Center to re

place and sharpen individual cutters

on your chain.

• Remove bar clamp nuts.

• Remove bar clamp.

• Remove the old chain.

Cutters

Drive Links

Depth Gauge

‘ Place chain over and behind clutch.

► Fit bottom of drive links between teeth

in sprocket nose.

' Fit chain drive links into bar groove.

' Pull guide bar forward until chain is

snug in guide bar groove.

Now, install bar clamp making sure

the adjusting pin is positioned in the

lower hole in the guide bar.

Adjusfing

Pin

Guide Bar

Install bar clamp nuts and finger tight

en only. Do not tighten any further at

this point.

' Turn adjusting screw by hand coun

terclockwise until adjusting pin just

touches the stop.

Slide guide bar behind dutch drum

until guide bar stops against clutch

drum sprocket.

Carefully remove new chain from

package. Hold chain with the drive

links as shown.

CHAIN ADJUSTMENT

See “Chain Tension" in Maintenance

section.

14

Page 15

CLEAN FUEL FILTER

To dean fuel filter, drain your unit by

running dry of fuel, remove fuel cap/re-

lainer assembly from tank. Pull filter

from tank and remove from line. Clean

with mild detergent and rinse. Dry thor

oughly, reassemble.

CARBURETOR ADJUSTMENT

WARNING: The chain will be moving

during most of this procedure. Wear

your protective equipment and observe

all safety precautions. During the low

speed mixture adjustment recheck idle

speed after each turn of the screw. The

chain must not move at idle speed.

Carburetor adjustment is critical and if

done improperly can permanently dam

age the engine as well as the caiburetor. If you require further assistance or

are unsure alsout performing this proce

dure, call our customer assistance help

line at 1-800-235-5878.

Oid fuel, a dirty air filter, dirty fuel filter,

or flooding may give the impression of

an improperly adjusted carburetor.

Check these conditions before adjust

ing the carburetor.

The carburetor has been carefully set at

the factory. Adjustments may be neces

sary if you notice any of the following

conditions:

• Chain moves at idle. See “Idle Speed”

under adjusting procedure.

• Saw wilt not idle. See “Idle Speed”

and “Low Speed Mixture"under ad

justing procedure.

• Engine dies or hesitates when it

should accelerate. See “Acceleration

Check” under adjusting procedure.

• Loss of cutting power. See “High

Speed Mixture H” under adjusting

procedure.

There are three adjustment screws on

the carburetor. They are labeled H, L,

and T. They are located in the area just

above the primer bulb.

CARBURETOR PRESETS

When making adjustments, do not force

the plastic limiter caps beyond the

stops or damage will occur.

If carburetor presets are not needed,

proceed to "idle Speed-T.”

• Turn both mixture screws counter

clockwise until they stop.

• Turn the idle speed screw clockwise

until it stops. Now turn counterclock

wise 4-1/2 fui) turns.

Start motor, let it run for 3 minutes, and

proceed to the adjustment section. If

engine does not start, refer to trouble

shooting chart or call 1-800*235-5878.

If engine performance is acceptable at

the preset positions and there is no

chain movement at idle, no further ad

justment is necessary.

ADJUSTING PROCEDURE

Idle Speed-T

Allow engine to idle. Adjust speed until

engine runs without chain movement or

stalling.

• Turn clockwise to increase engine

speed if engine stalls or dies.

• Turn counterclockwise to decrease

speed.

No further adjustments are necessary if

chain does not move at idle speed and

if performance is satisfactory.

Low Speed Mixture-L

Allow engine to idle. Then accelerate

the engine and note performance. If en

gine hesitates, bogs down, or smokes

during acceleration, turn mixture screw

clockwise in l/i6-tum increments until

performance is satisfactory. Repeat this

procedure as necessary for proper ad

justment. After completing adjustments,

check for acceleration and chain move

ment at idle. Reset if necessary.

High Speed Mixture-H

DO NOT operate engine at full throttle

for prolonged periods while making ad

justments. Damage to the engine can

occur. Make a test cut. Based on per

formance of the saw while cutting, ad

just the high speed mixture setting in

1/16-turn increments as follows:

• Clockviflse until saw has good pov^r in

ttie cut with no hesitation. Do not adjust

by sound or speed, but judge by how

well the saw performs in the cut

• Counterclockwise if the saw has

speed, but dies in the cut or lacks

power in the cut.

After completing adjustments, check for

acceleration and chain movement at

idle. Reset if necessary.

Acceleration Check

if the engine dies or hesitates instead of

accelerating, torn the low speed mixture

adjustment counterclockwise until you

have smooth acceleration with no chain

movement at idle. Recheck and adjust as

necessary for acceptable performance.

15

Page 16

STORAGE

Prepare your unit for storage at the end

of the season or if it will not be used for

30 days or more.

WARNING:

• AJIow the engine to cool, and secure

the unit before storing or transporting.

• Store chain saw and fuel in a well

ventilated area where fuel vapors

cannot reach sparks or open flames

from water beaters, electric motors or

switches, furnaces, etc.

• Store chain saw with all guards in

place and position chain saw so that

any shaip object cannot accidentally

cause injury.

• Store chain saw well out of the reach

of children.

EXTERNAL SURFACES

If your chain saw is to be stored for a

period of time, dean it thoroughly be

fore storage. Store in a clean dry area.

• Lightly oil external metal surfaces and

guide bar.

• Oil the chain and wrap it In heavy pa

per or cloth.

FUEL SYSTEM

Under Fueling Engine in the Operating

Section of this manual, see message

labeled important regarding the use

of gasohol in your chain saw.

Fuel stabilizer is an acceptable alterna-

five In minimizing the formation of fuel

gum deposits during storage. Add stabi

lizer to the gasoline in the fuel tank or

fuel storage container. Follow the mix

instructions found on stabilizer contain

ers. Run engine at least S minutes after

adding stabilizer.

CRAFTSMAN 40:1, 2-cycle engine oil

(air cooled) is especially blended with

fuel stabilizer. If you do not use this

Sears oil, you can add a fuel stabilizer

to your fuel tank.

ENGINE

• Remove spark plug and poor 1 tea

spoon of 40:1,2-cycle engine oil (air

cooled) through the spark plug open

ing. Slowly pull the starter rope 8 to

10 times to distribute oil.

■ Replace spark plug with new one of

recommended type and heat range,

• Clean air fitter.

• Check entire unit for loose screws,

nuts, and bolts. Replace any dam

aged, broken, or worn parte.

• At the beginning of the next season,

use only fresh fuel having the proper

gasoline to oil ratio.

OTHER

• Do not store gasoline from one sea

son to another.

• Replace your gasoline can if it starts

to rust.

16

Page 17

TROUBLE SHOOTING CHART

TROUBLE

Engine will not

start or will run

only a few

seconds after

starting.

Engine will not

idle property.

Engine will not

accelerate,

lacks power,

or dies under

a load.

Engine smokes

excessively.

Engine runs

hot.

Oil inadequate

for bar and

chain

lubrication. •

CAUSE

• Ignition switch off.

• Engine flooded.

• Fuel tank empty.

• Spark plug not firing.

• Fuel not reaching

carburetor.

• Carburetor requires

adjustment.

• None of the above.

• Idle speed set too high

or too low.

• Low Speed Mixture

requires adjustment.

• Crankshaft seals worn.

• Compression low.

• None of the above.

• Air fitter dirty.

• Spark plug fouled.

• Carburetor requires

adjustment.

• Exhaust ports or muf

fler outlets plugged.

• Compression low.

• None of the above.

• Choke partially on.

• Fuel mixture incorrect.

• Air filter dirty.

• High Speed Mixture

requires adjustment.

• Crankcase leak.

• Fuel mixture incorrect.

• Spark plug incorrect.

• High Speed Mixture

set too lean.

• Exhaust ports or muf

fler outlets plugged.

• Carbon build-up on

muffler outlet screen.

Fan housing/cylinder

fins dirty.

«

None of the above.

Oil tank empty.

Oil pump or oil filter

clogged.

Guide bar oil hole

blocked.

REMEDY

• Move Ignition switch to ON.

• See “Starting Instructions.”

• Fill tank with correct fuel mixture.

• install new spark plug.

• Check for dirty fuel filter; replace.

Check for kinked or split fuel line; |

repair or replace.

• See “Carburetor Adjustments.”

• Contact Sears Service.

• See “Carburetor Adjustments.”

• See “Carburetor Adjustments.”

• Contact Sears Service.

• Contact Sears Service.

• Contact Sears Service.

• Clean or replace air filter.

• Clean or replace plug

and regap. j

• See “Carburetor Adjustments."

• Contact Sears Service.

• Contact Sears Service.

• Contact Sears Service.

• Adjust choke.

• Empty fuel tank and refill with

correct fuel mixture.

• Clean or replace air filter.

• See “Carburetor Adjustments.”

• Contact Sears Service.

• See “Fueling Your Unit.”

• Replace with correct plug.

• See “Carburetor Adjustments.”

• Contact Sears Service.

• Clean spark arrestor screen.

• Clean area.

' Contact Sears Service.

Fill oil tank.

Contact Sears Service.

Remove bar and clean.

17

Page 18

TROUBLE SHOOTING CHART - Continued

Trouble

Chain moves

at idle speed.

Chain does

not move

when engine

is accelerated.

Chain datters

or cuts roughly.

Chain stops

within the cut.

Chain cuts at

an angle.

.....

•

If situations occur which are not covered in this manuaf, use care and good

judgement. If you need assistance, contact Sears Service or the CUSTOMER

ASSISTANCE HELPLINE at 1-800-235-5878.

CAUSE

• Idle speed requires

adjustment

• Clutch requires repair.

• Chain tension too

tight

• Carburetor requires

adjustment.

• Guide bar rails

pinched.

• Clutch slipping.

• Chain tension incorrect

• Cutters damaged.

• Chain worn.

• Cutters dull, improperly

sharpened, or depth

gauges too high.

• Sprocket worn.

• Chain installed

backwards.

• Chain cutter tops not

filed flat

• Guide bar burred or

bent; rails uneven.

• Clutch slipping

Cutters damaged on

one side.

Chain dull on one side.

Guide bar bent or worn.

REMEDY

• See “Carburetor Adjustments.”

• Contact Sears Service.

• See “Chain Tension.”

• See “Carburetor Adjustments.”

• Repair or replace.

• Contact Sears Service.

• See “Chain Tension.”

• Contact Sears Service.

• Resharpen or replace chain.

• See “Sharpening Chain.”

• Contact Sears Service.

• install chain in right direction.

• See “Sharpening Chain.”

• Repair or replace guide bar,

• Contact Sears Service.

• See “Sharpening Chain.”

• See “Sharpening Chain.”

• Replace guide bar.

18

Page 19

All repairs, adjustments and

metntenanca nrtt deeorlPed

In the Operator’s Manual

must be petfamied by quallOsd servica personnel.

REPAIR PARTS

, w-4 I

31 Э2 3334

Rdf

Part No. Oo8CrfptE(»1 Ref

t.

530069723 Trisger & Li^out 24. 530069957 Oil Pump Kit

2,

530026119 Check 26. 530010846

3. 530037809 Wire-ThrottJd 28.

4.

530037803 Cltiidi Cover 29. 5300160S4 Screw

5. 530015917 Nut- Bar Mounting

6. S300479S9

7.

530038406

8- 530069803 Chassis Юг 33. 530037821 Oil Filter

9. 530094183 Clutch Spring 34.

IQ. 530047061 Clutch Drum AssV“ 55. 53001S77S Screw

11. S30O1S611 Washer-Clutch

12. 5300149^ Ciuicli Ass'y. 38. 5300471^

530Ш8227 Switch Lever w/Retainer

43.

14. -530019149 Swteh Spring 40. 530016133 Bolt-Bar

15. 530038264

16. 530015922 Nut (Incl. 32, 33 & 34)

17.

530029850 <3iaen Catehef 42. 530016020 Screw

18. 530015905 Screw 43. 530016132 Screw

19.

53CO1S907

530015826 Pin *.®af Adjusting 45.

22. 530069611 3ar Adjusting Screw 46.

23. 53003S23S I

ilncludes Ptn)

Choke L^ver

6rommet4Jhok0 Knob

ш/Brg.

Plug-Bronze Vfent

Afasher-Thrust 44.

Kit 47. 530037799

Bar Mouning Plate 4a 530038224 Handguard

Part No.

530016080 Screw 52.

30. 530013206 Seal Block 54.

31.

S30049477 Elbow-Oit Pickup 65.

32. 530038373 Plck-l^ Oiiar

5Э003018Э Plug- Oil Rlter 58.

36. 530069247 Fuel Line Kit

41.

530047653 Oil-Pidcup Ass’y.

5КЮ15905 Screw

5300378Й5

530019231 E)u$t Seal

Description Inef

{Incl. 30, 31 & 45)

Oil Cap Ass’y. 51,

(Large Dta.} 61.

Fuel Cap Ass'y,

Worm Gear Spring

Front Handle Readjust

19

I

г ft'

Pert No. Oescripllon

49. 530015940

50.

530037465 Starter Handle 1

530069232 RopeKS I

530015892 Screw 1

53. 530049336

530027531 Recoil Spdng 1

530037817 starter Pulley 1

5a 530039187

57. S30400S97 Washer 1

530001717' Washer 1

59. 530016134

60. 530015920 Screw 1

7143613 Chain -18"

62.

71-36374

.

5300S703Q Operator Manual

530049246

530038486 Decal-Siop

S30053122 DecahClutch Cover

530052362

530053121

Screw 1

Fan Housing I

flywheel AssY I

Nut-flywheel I

8ar-18"

Instruction

Decal-Chain

DecahFat! Hsg. I

Page 20

REPAIR PARTS

Engine

Gask^ Brake

i«t

29

Rsf. Part No.

1.

2. 530037793

3. 530016101

4. 530037804

s.

s. 530019239

7.

6. 5300639^ Carb> Ajapter Kit

9. 530016187

10. 530016102 Screw

Î1.

ia. 530038318

13. 530038317

14. 530049244

15.

IS. 530069216

17. 53001^10

IS. 71-85849

19. 530019249

20.

21. 530069605 Piston Kit

22.

23. [

Chain

Ki!

Deacriptton

530031163

53EX5S9703

530015810 Screw

530037798 Cjlinder aiield

53Û04756S Air Purge Assy

530069607 Cylinder Kfi

530038729

530015697 J

Ba/ Wrench

Foartb^ir Filter

Nut

Air Filter Housing

Carbureter Kit

(Ind. 12 & 13)

Cait. Gasket

Screw

Limiter Cap-High

Umiier Cap-tow

Gfijmmet-Carb Adjust

Pfiraer Line Krt

(Small Ola)

Ar Bax Seal

^rkPlug(CJ-7Y)

Gasket-Carb Adaptor

(IncL 22 8 23)

Piston Ring

Retainer-Piston Pin j

Ret.

24.

25. 630047827

26.

27.

28.

29.

30.

31.

32.

33.

34-

35.

36.

37.

3Ô.

39.

40.

41.

42.

Not S

1

1

20

Part No.

530047062

S3003793S

530016136

530016090 Screw

530089608

530052296

530014382

530037652

530019221

530038237

530047207

530037813

63oo3ei<»

530016132

S3Q052277

S3001S90S Screw

530047442 Ground Strap

952706606

952031164

Description

Crankshaft Assy

Seal & Bearhg Ass'y.

Cap-Crankcase

Clip

Engine Gaskei Kii

(Ind. 6,17,19433)

VWre Harness As$y.

Fuel Pf^up Ass’y-

Heat Insulator

Mulder Gasket

Muffler Back Plata

Muffler Ass'y,

(incl. 33-34 4 36-36)

Muffler Diffuser

Spark Arrester Screen

Screw

Ignition Module

Chain Brake Kit

Carrying Case

Page 21

REPAIR PARTS

gflaiutaacA^wmMy Kit Numiw.

KIT*

Gaste!/

Dlaph.

m

Garb.

Rapair

iOt

Ret. Part No.

530033318 Limiter Cap-High

1.

2, 530030317

3. 53006&326

830063844 Qaaket/Diaphtagm Kit

■ 4.

530035333 N^I&4.ow Speed

5-

530036384 Neadia-High Speed

6.

7. S30O3S293

a 530035295

D«$ef1pt{on

Limiter Cap-Low

Carburetor Reparr Kit

(KIT ^Contents)

(* a Contents)

Needle Spring-Low Speed

Nesdie Spring-High Speed

21

Page 22

TABLA DE CONTENIDOS

Garantía

Reglas de Seguridad

Montaje

Uso

Mantenimiento

22

22

26

27

33

Servido y Apistes 36

AInfâcenamiento 38

Tabla Diagnósfica 40

Repuestos y Bicargos Contrataqpa

DECLARACION DE GARANTIA LIIVIITADA

GARANTIA COMPLETA DE UN ANO PARA LA SIERRA

DE CADENA A GASOLINA CRAFTSMAN®

Por un año a contarde la fedta de conpra, йепфге que esta Sierra de Caiena a GasrÆna

CraRsman esté manteada, lubricada y ajustada de acuerdo al manual del usuario, Sears

reparará gratuitamente cualquier defecto de materides o mano de obra.

Esta garartb'a exduye la baña, la cadena, la tx^ía y el filtro de aire, que son artículos

fungibles y se gastan durante el fundonamiento normal. -

Sí se usa esta Sierra de Cadena a Gasolina рша prc^ddtos cwnera'a^es o de aíqtÁlcr, esta

garantía tendrá vaSdez de 30 días contadr»; a parfir de la fecha de compra.

EL SERViaO BAJO GARANTIA ESTA A SU DISPOSICION 03N SOLO DEVOLVER LA

SIERRA DI CADENA AL CENTRO DE SERVICIO SEARS MAS CERCANO ét LOS

ESTADOS UNIDOS.

Esta garantía le confiere deredws junrficos específicos; además ud. podrá tener otros

derechos que vanan entre estados.

Sears, Roebuck and Со., DÍB17 WA, Hoffinan Estates, IL 60179

REGLAS DE SEGURIDAD

ADVERTENCIA: Desconecte

siempre el cable de la bujía al reparar

d aparato, excepto en el caso de

ajustes al carburador. Debido a que las

sierras de cadena son instrumentos

para cortar madera a alta veloddad, el

uso descuidado o índebick» de esta

berramienta puede causar graves

heridas.

PIENSE ANTES DE PROCEDER

• lirtite el uso de la siena á aquellos

usuarios adultos que ccxnpretxian y

puedan hnplementar todas las

precauciones, regias de seguridad e

instrucciones de uso que se encuentran en

este tnaiít^.

Protecdón de Oídos

Ropa ^

Apstada

dCuerpo

Zapatos de

Seguridad

"4.

' Use eqü^ protector. Sien^re use calzado

de seguridad con puntas de агяго y suelas

anS-dedizantes; ropa ajustada al cuerpo;

guantes gruesos de uso industrial

antí-desSzantes; protección de oje® tales

Case» Duro

F^ecdónde

Ojos

Guantes de

Uso industróJ

Pantoírilteras

de Seguridad

22

Page 23

como gafe$ de $egundad que no se >a

casco duro agrot^ado* y barréis de

sonido (tapones de oído u orejeras

anti-sonicío) para proteger la audicwn. Los

que usan sierras de fuerza habrtuatmerite

deberán hacerse revisar la audtdón

hecuentemente ya que el ruido de las

sierras de cadena puede dañar kjs oídos.

Mantera el cabello por endma del nivel

de tos hombros, atándolo para taJ efecto sí

fuere necesario.

• Mantenga todas las partes del cuerpo

alejadas de !a cadena siempre que el motor

esté en luncionamíento.

• Mantenga a los niños, espectadores y

svtimales a una distancia mínima de 10

metros {30 pies) del área de 1гаЬф o

cuando está haciendo arrancar y uso

eí motor.

• No levante ni opere las sierras de cadena

cuando está faSgado, enfermo, ansiosoosi

ha tomado alcohol, drogas o remedos. Es

inpresdndible que ud. esté en bueres

condiciones fíi^cas y alerta mentalmente.

Si ud. sufre de cuak^uer condidén que

pueda enpeorar con eC babafo arduo,

asesórese con su médco.

• No ponga en marcha la derra sin tener un

área de trabajo despejada, una st^erfide

estable pesa pararse y, sí está dei^ancto

&boles, un camtoo predetermnado de

Fetr0C6S0«

USE LA SIERRA OBSERVANDO

TODOS LOS PROCEDIMIENTOS

DE SEGURIDAD ,

• Mantenga las dos manos en las man^

siempre que el eparato esté en mart^ El

uso del aparato con una sola mano puede .

causar graves heridas a! usuario, a tos

asistentes o a tos espectadcMcs. Las

demás de cadena están cSseñadas para

que se las use con las dos mattos en todo

mometita ,

« Шда uso de la siena de cadena

- (kícamente en Jugares ejcteriores Ыеп

ventilados.

• No haga uso de la sierra desde las

escaleras portáriles ni los árboles, a menos

que tenga el entrenamiento especifico para

hacerlo.

• Asegr№ese de que la cadena no vaya a

hacer contacto con ningún objeto antes de

poner en гшгсЬа el motor. Nuntteirriente

hacer arratxrar la sierra con la barra guia

dentro de un corle.

• No aplique presión a la sierra, especial

mente al final del corte. La appitoación

de presión puede causar que se pierda

el control al completarse eí corte.

• Pare el motor antes de apoyar la sierra en

ningún lado.

• Cuando traslade la siena en la mano,

hágalo únicamente c»n el motor parado.

Llévela con ei silendador apartado del

cuerpo y la barra y cadena hada atrás, con

ta barra de preferenda cutsierta por una

funda 23

MANTENGA LA SIERRA EN

BUENAS CONDICIONES DE

FUNCIONAMENTO

• Lleve la siena de cadena a Ш proveedor

de senñdo autorizado para que haga todo

servido metxis aquelk^ procedimientos

listedos en lasecdón de mantenimiento de

este manual.

• Asegúrese de que la cadena se detenga

por completo cuando se suelta el gabllo.

Para hacer correcdones, vea км “Ajustes

al Carburador'.

• Mantenga las manijas secas, tapias y

libres de aceite o de mezda de

combusblile.

• Mantenga fas tapas y tos fijsíores bien

fijos.

• Use eJoJosívamente tos accesorios y

repuestos Craftsman recomendados.

Nunca modifique la siena.

MANEJE EL COMBUSTIBLE CON

EXTREMO CUIDADO

• Nótate mientras trabaja con el

combustible ni cuando está haciendo uso

de la detra.

• EBmine todas las posibles fuentes de

chispas o Oamas en las áreas donde se

mezcla o vierte el combustible.

• Mezde y vierta el combustible aiiteta y use

siempre redpiente aprobatto para

combttólibles y marcado como tal. Lmiple

todos tos derrames de combusSble antes

de poner el aparato en marcha.

• Aléjese a por lo metK»s3metrM(10 pies)

del lugar de abastedmiento arfies de poner

el motor en marcha

• Apague el motor y deje que la aerra se

enfríe en un lugar libre de substancias

contoustibles y no sctore hcf'as secM, p^a,

papel, eta Reb’re la tapa lentamente y

reabastezca et aparato.

• Guarde el aparato y d cotrtbusKtle en un

espado irasco, seco y bren ventüado

donde los vapores del combustible no

puerto entrar en contacto ccm dji^ras ni

llamas abiertas provenientes de

termotangues, motores o interruptores

eléctricos, calefectores cenftaJes, etc.

PROTEJASE CONTRA LAS

RECULADAS

Ud. dtí>e seguir todas las precattoiones e

instrucdones de seguridad para ayudar

a evitar Jas lecufadas y las demás

fuerzas que pueden causar graves

heridas.

Trayectoria de la|

'^reculada

Page 24

Despee el Area de ТгаЬф

ADVERTENCIA: La Reculada

Rotacional puede acontecer cuando la

cadena en movimiento entra en

contacto con algún objeto en la en la

parte superior de la punta de la bata

guía puede causar que la cadena entre

al material y se detenga por un

instante. El resultado es una reacción

inversa, a velocidad de relámi^go, que

hace recular la barra guía hacía ar^a y

hacía atrás hacia el usuarío.

La Reculada por Presión y la Inpulsión

acontan cuando la cadena se

detiene repentinamente porque está

apretada, atrapada o en contacto con

a^ón o^eto extraño a la madera. Esta

detención repentina de la cadena tiene

como resultado una inversión de la

fuerza de la cadena usada para cortar

madera y causa que la sierra se mueva

en sentido opuesto al de la rotación de

la cadena La Reculada por Presión

propulsa la sierra directamente hada

atrás en dirección al usuario. La

Impulsión aí^a la sierra de! usuario.

REDUZCA LAS

PROBABILIDADES DE

RECULADA

• Esté consciente de la posibilidad de

reculada Teniendo una buena

comprensión básica de la reculada

ud. podrá reducir el elemento de

sorpresa que contribuye a los

accidentes.

• Nunca permita que la cadena en

movimiento toque ningún objeto en la

punta de la barra guía.

• Mantenga el área de trabajo libre de

obstrucdones como por ejemplo

otros árboles, ramas, piedras, cercas,

tocones, etc. Elimine o evite toda

obstaicdón que la cadena pueda

tocar mientras está cortando.

• Mantenga la sierra afilada y con la

tensión conecta Las cadenas con „

poco file o flojas incrementan la '

probabilidad de reculada. Siga las /¿ '

instrucdones del fabricante para айшг

y efectuar mantenimiento de la

cadena. Verifique la tensión a Г

intervalos regulares con el motor

parado, nunca en marcha. Asegúrese

de que las tuercas de la abrazadera

de la barra estén ajustadas

firmemente.

• Etrpiece y efectúe la totalidad de

cada corte con el acelerador a fondo.

Si la cadena se está moviendo a una

veloddad menor que Ш máxima, hay

más probabilidad de que la siena

recule.

• Use cuidado extremo al entrar de

nuevo en un corte ya empezado.

• No intente hacer cortes empezMdo

con fa punta de la barra (cortes de

taladro).

• Tenga cuidado cor» troncos que se

deslazan y con las demás nieizas

que podrían cerrar un corte y apretar

la cadena o bien caer sobre ella.

• Use la Ban^ Guía Reducidora de

Reculadas y la Cadena Mínimizadora

de Reculadas recomendadas para su

sierra

Evite la Reculada por Presión:

« Мш11ёпдазе siempre al tanto de toda

srUadón u obslnicdón que pueda

apretar la cadena en la parte superior

de la barra o detener la cadena de

cualquier forma

• No corte más que un tronco a la vez.

• Al seccionar troncos con corte

ascendiente, no tuerza ia sierra al

sacar la barra del corte.

Evite la impulsión:

• Empiece ios cortes siempre con el

motor acelerado a fondo y la caja de

ia sierra apoyada ert la mattera.

• Use cuñas de plástico o de madera,

no (te metal, para mantener abierto el

corte.

MANTENGA EL CONTROL

Párese hada ia izquierclá de la derra

Bpuigarpor

debajo de la manífa >1

Nunca invierta la posic«^ de las manos

’ Sostener firmemente con las dos manos le

ayudará a mantener el oontrol de la derta.

No afloje. Mantertga la mano derecha

envolwendo totalmente la maiga trasera,

sea ud. derecho o zurdo. Sostenga la

manqa delantera con la mano izquierda,

colocando ef pulgar debajo de la roanga y

rodeando la manija corr los dedos.

Mantenga ei brazo izquierdo totalmente

extendida con el codo fijo.

Coloque la mano izquierda en la

manqa delantera, de modo que quede

en línea recta con la mano deredia

24

Codo rigido

Page 25

en manp ttasera, cuando esté

haciendo cortes de secdonamiento.

Párese levemente hacia la izquierda

de la siena para evitar que el cuerpo

esté en línea directa con la cadena.

I Párese con el peso distribuido

igualmente entre ios dos pies.

■ No se extìenda excesivamente. La

sierra puede impulsarlo o empujarlo y

ud. puede perder el equilibrio y el

control de la sierra.

No corte arrSra del nivel de los

hombros, puedsto que toma ciifídl

mantener el control de la siena.

DISPOSmVOS DE SEGURIDAD CONTRA LAS RECULADAS

ADVERTENCIA: Los siguientes

díi^^ositivos han ddo incluidos en la

sierra para ayudar a reducir el riesgo

de reculadas: sin embargo, tales

implementos no pueden eliminar

totalmente esta reacción peligrosa. No

se confíe exclusivamente en los

dispositivos de seguridad.

Punía de Ractio

Pequeño^

^ Guia

*^Zcfia de

Punta de Radio Grande Barra Gute

• Las Cadenas Minimizadoras de

Reculadas han satisfecho ios

requteítos de rendimiento en pruebas

con una muestra representativa de

sierras cte cadena con

desplazamiento de mertos de 3,8

pulgadas, como se especifica en

ANSiB175.t.

Cadena Mteimkadora de Reculadas

tca£fev<i — Eslabón Protector Alargado

í Desvía la Fuerza de

- Marcador de Profundidad

Perfilado

« Reacción y Penníte que la

Madera Entre

Gradualmente a la C^jchllla

• Protector (te Mano, diseñado para

redticif la probabidad que su mano

izquierda «itre en contacto cím la

cadena, si la mano se desprende de

la manña delantera.

• La Posidón de las manijas delantera

y trasera, diseñadas con distancia

entre las manijas y *en línea" la una

con la otra. La separación y la

coiocadón en línea que este diseño

provee se combinan para dar

equilibrio y resistencia para controlar

la propulsión de la sierra hacía ei

usuario si acontece una reculada.

• Barra Guía Reducidora de Reculadas,

diseñada con punta de radío pequ^ que

reduce el tamaño de la zona de peligro.

Este tipo dé barra ha demostrado que

reduce significativamente la cantidad y

la seriedad de las reculadas cuando

ha sido examinado de acuerdo con

ANSI (American National Standards

InsStute, Inc.) B175.1.

AVISO DE SEGURIDAD: El estar

expuesto a las vibraraoens a través del

uso prolongado de herramientas de

fuerza a gasolina puede causar daños

a los vasos sanguíneos o a los nertños

de ios dedos, las manos y las

coyunturas en aquellas personas que

tienen propensidad a los trastornos de

la drcuiación o a las hinchazcmes

anormales. El uso prdongado en

tiempo frió ha sido asociado con daños

a los vasos sanguíneos de personas

que por otra parte se encuentran en

perfecto estado de salud. Si ocurren

síntomas tales como el

entumedmiento, el dolor, la falta de

fuerza, los cambios en eí color o la

textura de la piel o falta de sentido en

le« dedos, las manos o las coyunturas,

pare de usar esta máquina

inmedatamente y procure atención

25

Page 26

médica. Los sistemas de anti-vibración

no garantizan que se eviten tales

problema. Los usuarios que hacen

uso continuo y prolongando de las

hetramientas de tuerza deben fiscalizar

atentamente su estado físico y el

estado del aparato.

FRENO DEWiDENA SÍ esta sierra ha

de usarse para e! tumbado comerciai

de árboles, ud. deberá errcargar e

instsdar un freno de cadena para

cumplir con los Reglamentos Federales

del OSHA para el Tumbado Comerdal

de Arboles. Entre en contacto con

el Servicio Sears o liame al

1-SOO-235-5878.

REJILLA ANTICHISPA: Su sierra

viene equipada con silenciador

Bmrtador de temperatura y con rejilla

antichispa que cumple con los

requisitos de los Códigos de California

4442 y 4443. Todas las tierras

forestadas federales, más ios estados

de Califomia, Idaho, Maine, Minnesota,

Nueva Jersey, Oregon у Washington,

requieren por ley que muchos motores

de combustión interna estén equipados

con rejilla antíchispa. Sí usted usa una

sierra de cadena donde existen tales

reglamentos, usted tiene la

responsabilidad jurídica de mantener

estas piezas en correcto estado de

funcionamiento. De lo contrario, estará

en infracción de la ley. Vea la tabla de

RESPONSABILIDADES DEL USUARIO a la

sección.de MAINTENIMIENTO.

PADRONES: Este sierra de cadena

consta en la lista de Undenwriters

Laboratories, Inc., de acuerdo a los

Requisitos Nacionales de Seguridad

Estadounidenses para Sierras de

Cadena a Gasolina (ANSI

В175Л-1991).

MONTAJE

CONTENIDO DE LA CAJA

Use la siguiente lista para verificar el

conteríido.

Modelo 358.352680

» Sierra de cadena (completamente

montada)

• Herrienta de la barra

• Cadena

• Estuche de transporte

• Guantes

• Lata para gasolina

• Barra y cadena lubricación

• Mezcla de combustibie/aceite

• Verifique que no haya piezas dañadas. No

use piezas dañadas.

•

• Si necesita ayuda o si faWan piezas o

encuentra piezas dañadas, favor de llamar

aJ 1~800--235-S878.

AVISO: Es normal oir el golpeteo del

filtro de combustible en el tanque vacío.

Su aparato ha sido puesto a prueba en

la fábrica y se le ha ajustado c»n

precisión el carburador. Como

resultado, es posible que se sienra un

olor a gasolítra o que se encuentre una

gota de residuo de aceite o

combustilbe en el silenciador al

desempacar el aparato.

MONTAJE

El aparato viene completamente

armado y no hay necesidad de

montaje.

26

Page 27

CONCXiSCA EL APARATO

LEA ESTE MANUAL DEL USUARIO Y lAS REGUS DE SEGURIDAD ANTES

DE USAR LA SIERRA DE CADENA. Conpare las ÍIustraciOTes con su aparato

para familiarizarse con la ubicación de los varios controles y ajustes. Guarde este

manual para uso futuro.

Herramienta de Agiste

de la Cadena

^ Protector de Mano

Cadena

Silenciador

Manña Delarrtera

r\^

de Atranque

CRAFTSMAN*

Inteuuptor

ON/STOP

B<Ȓibeador

Tapa del Tanque de

Lr^ncante de Barra

Traba de Mi '

Lenta Acelerada

Traba del

Acelerador

Manija

Trasei

Gaüilo

Aceler^for

EN/TOPE INTERRUPTOR

El En/Tope Interruptor estó acostum-

. brado a detener la máquina.

GATILLO DE ACELERADOR

El Gatillo de Acelerador controla veloci

dad de máquina.

TRABA DEL ACELERADOR

Es necesario apretar primero ta traba del

aceloador pata po^r acdonar el actíetador. Este (Sspoáfivo previene el ac