Page 1

IMPORTANT MANUAL Do Not Throw Away

Operator's

Manual

Model No

358.352161

CUSTOMER

ASSISTANCE

1-800-235-5878

HOURS (CST)

Mon _Sat 7am-7pm

Sun 10am-7pm

WARNING:

READ THE OPERATOR'S

MANUAL AND FOLLOW

ALL WARNINGS AND

SAFETY INSTRUCTIONS.

FAILURE TO DO SO CAN

RESULT IN SERIOUS

INJURY.

CRAFTSMAN"

Always Wear Eye Protection

CRRFTSMRNo

2.2 cu. in./36cc 2-CYCLE ENGINE

16 inch Guide Bar

GASOLINE CHAIN SAW

• Assembly

• Operation

• Customer Responsibilities

• Service and Adjustments

• Repair Parts

Sears Roebuck and Co, Hoffman Estates, IL 60179 USA

530"084295-O2/20/96

Page 2

SAFETY RULES

WARNING:

ALWAYS DISCONNECT SPARK PLUG WIRE AND PLACE WIRE WHERE IT CANNOT'CONTACT SPARK

PLUG TO PREVENT ACCIDENTAL STARTING WHEN SETTING UP, TRANSPORTING, ADJUSTING OR

MAKING REPAIRS EXCEPT CARBURETOR ADJUSTMENTS.

BECAUSE A CHAIN SAW IS A HIGH-SPEED WOOD-CUTI'ING TOOL, SPECIAL SAFETY PRECAUTIONS

MUST BE OBSERVED TO REDUCETHE RISK OF ACCIDENTS. CARELESS OR IMPROPER USE OFTHIS

TOOL CAN CAUSE SERIOUS INJURY.

Safety Chaps

Safety

Shoes

Figure I

KNOW YOUR SAW

• Read your operator's manual carefully until you com-

pletely understand and can follow all safety rules, pre-

cautions, and operating instructions before attempting to

operate the unit.

• Restrict the use of your saw to adult users who

understand and can follow safety rules, precautions, and

operating instructions found in this manual.

PLAN AHEAD

• Wear protective gear. Figure 1. Always use steel-toed

safety footwear with non-slip soles; snug-fitting clothing;

heavy duty, non-slip gloves; eye protection such as non-

fogging, vented goggles or face screen; an approved

safety hard hat; and sound barriers - ear plugs or muf-

flers to protect your hearing. Regular users should have

hearing checked-regularly as chain saw noise can dam-

age. hearing.

° Keep all parts of your body away from the chain

when the engine is running.

• Keep children, bystanders, and animals a minimum

of 30 feet (10 meters) away from the work area. Do not

allow other people or animals to be near the chain saw

when starting or operating the chain saw.

• Do not handle or operate a chain saw when you are

fatigued, ill, or upset, or if you have taken alcohol,

drugs, or medication. You must be in good physical

condition and mentally alert. Chain saw work is strenu-

ous. If you haveany condition that might be aggravated

by strenuous work, check with your doctor before oper-

ating a chain saw.

• Do not attempt to use your chain saw during bad

weather conditions such as strong wind, rain, snow, ice,

etc., or at night.

° Carefully plan your sawing operation in advance. Do

not start cutting until you have a:clear work area, secure

footing, and, if you are felling trees, a planned retreat

path.

• Do not operate a chain saw that is damaged, improp-

erly adjusted, or not completely and securely assem-

bled. Always replace the handguard immediately if it

becomes damaged, broken, or is otherwise removed.

• Keep the handles dry, clean, and free of oil or fuel

mixture.

• With the engine stopped, hand carry the chain saw

with the muffler away from your body, and the guide

bar and chain to the rear, preferably covered with a scab-

bard.

FUEL HANDLING

• Eliminate all sources of sparks or flames in the areas

where fuel is mixed, poured, or stored. There should

be no smoking, open flames, or wood that could cause

sparks. Allow engine to cool before refueling.

° Mix and pour fuel in an outdoor area on bare ground;

store fuel in a cool, dry, wel! ventilated place; and use an

approved, marked container for all fuel purposes.

• Wipe up all fuel spills before_tarting saw.

• Move at least 10 feet (3 meter.s) from the fueling site

before starting the engine, _.

° Do not smoke while handling_fuel or while operating

the saw.

• Turn the engine off and let your saw cool in a non-

combustible area, not oh dry leaves, straw, paper, etc.

Slowly remove fue! cap and refuel unit.

° Store the unit and fuel in an area where fuel vapors can-

not reach sparks or open flames from water heaters,

electric motors or switches, furnaces, etc.

IExp SAFETY NOTICE

z osure to vibrations through prolonged use of gasoline powered hand tools could cause blood vessel or nerve damage in the fin-

gets, hands, and joints of people prone to c_rculat_ondisorders or abnormal swellings. Prolonged use in cold weather has been linked

to blood vessel damage in otherwise healthy people. If symptoms occur such as numbness, pain, loss of strength, change in skin color

or texture, or loss of feelings in the fingers, hands or joints, discontinue the use of this tool and seek medical attention° An anti-vibra-

lion system does not guarantee the avoidance of these problems. Users who operate power tools on a continual and regular basis must

monitor closely their physical condition and the condition of this unit.

LOOK FOR THIS SYMBOLTO POINT OUT IMPORTANT SAFETY PRECAUTIONS.

IT MEANS - A'I-rENTION!!! BECOME ALERT!!! YOUR SAFETY IS INVOLVED.

-2-

Page 3

SAFETY RULES

OPERATE YOUR SAW SAFELY

° Do not operate a chain saw with one hand. Serious

injury to the operator, helpers, bystanders or any combi-

nation of these persons may result from 0ne-handed oper-

ation. A chain saw is intended for two-handed use.

- Operate the chain saw only in well-ventilated outdoor

areas.

• Do not operate saw from a ladder or in a tree, unless

specifically trained to do so.

• Position all parts of your body to the left of cut and

away from the chain when the engine is running.

• Cut wood only. Do not useyour saw to pry orshove away

limbs, roots, or other objects.

° Make sure the chain will not make contact with any

object while starting the engine, Never try to start the

saw when the guide bar is in a cut or kerr.

• Use extreme caution when cutting small size brush

MAINTAIN YOUR SAW IN GOOD WORKING

ORDER , .-

• Have all chain saw service performed by your Sears

Service Center with the exception of the items listed in

the =Customer Responsibilities" section of this manual. For

example, if improper tools are used to remove or hold the

flywheel when servicing the clutch, structural damage to

the flywheel can occur and cause the flywheel to burst.

• Make certain the chain stops moving when the throt-

tle trigger is released. For correction,referto "Carburetor

Adjustments."

• Stop the saw if the chain strikes a foreign object.

Inspect unit and repair or replace parts as necessary.

• Disconnect the spark plug before performing any

maintenance except for carburetor adjustments.

• Never modify your saw in any way. Use only SEARS

accessories and replacement parts as recommended.

and saplings. Slender material can catch the chain and . TRANSPORTING:AND STORAGE

be whipped toward you or pull you off balance .... : .. -:Stopthe unitbefore.transporting.

• Be alert for springback whencutting a limb that is under ...... ° Allow engine to,cool,-c0ver the guide bar and chain, and

tension so you.will not be struck by the limb or saw when secure the unit before storing or transporting in a vehicle.

the tension in the wood fibers is released.

• Do not put pressure on the saw at the end of a cut.

Applying pressure can cause you to lose controlwhen the

cut is completed.

* Stop the engine before setting the saw down.

• Keep fuel and oil caps, screws, and fasteners secure-

ly tightened.

• Empty fuel tank before storing or transporting the unit. Use

up any fuel left in the carburetor by starting the engine and

letting the engine run until itstops.

° Store unit and fuel in an area where fuel vapors cannot

reach sparks or open flames from water heaters, _ectric

motors orswitches, furnaces, etc.

• Store unit so the chain cannot accidentally cause injury.

• Store the unitout of the reach of children.

GUARD AGAINST KICKBACK - Kickback is a dangerous reaction that can lead to serious injury.

_ KICKBACK WARNING:

KICKBACK CAN OCCUR WHEN THE MOV-

ING CHAIN CONTACTS AN OBJECT ATTHE

UPPER PORTION OFTHE TIP OFTHE GUIDE

BAR OR WHEN THE WOOD CLOSES IN AND

PINCHES THE CHAIN IN THE CUT. CONTACT

AT THE UPPER PORTION ()F THE TIP OF

THE GUIDE BAR CAN CAUSE THE CHAIN

TO DIG INTO THE OBJECT, WHICH STOPS

THE CHAIN FOR AN INSTANT.THERESULT

IS A LIGHTNING FAST, REVERSE: REACTION

WHICH KICKS THE GUIDE BAR UP AND

BACK TOWARD THE OPERATOR. IF THE

CHAIN IS PINCHED ALONG THE TOP OF

THE GUIDE BAR, THE GUIDE BAR CAN BE

DRIVEN RAPIDLY BACK TOWARD THE

OPERATOR. EITHER OFTHESE REACTIONS

CAN CAUSE LOSS OF SAW CONTROL

WHICH CAN RESULT IN SERIOUS INJURY.

DO NOT RELY ONLY ON THE SAFETY

DEVICES PROVIDED WITH YOUR SAW. AS

A CHAIN SAW USER, YOU MUST TAKE

SPECIAL SAFETY PRECAUTIONS TO HELP

KEEP YOUR CUTTING JOBS FREE FROM

ACCIDENT OR INJURY.

Kickback

Path

Figure 2

Avoid

Obstructions

Clear The

Working Area

Figure 3

-3-

Page 4

SAFETY RULES

Never Reverse Thumb On _f_I_

Hand Positions Under Side O --

__ _t_\ Handlebar

Elbow

Locked

Stand To

The Left

Of The Saw

Figure 4

REDUCE THE CHANCE OF KICKBACK

* Recognize that kickback can happen. With a basic

understanding of kickback, you can reduce the element of

surprise which contributes to accidents.

• Never let the m_oving chain contact any object at the tip

of the guide bar. Figure 2.

•_ Keep the working area free from obstructions such as

other trees, branches, rocks,fences, stumps, etc.Figure 3.

Eliminate or av_0idany obstructionthat yourchain could hit

• while you are cutting through a particular log or branch.

• Keep your chain sharp and properly tensioned. A loose

or dull chain can increase the chance of kickbackto occur.

, Follow manufacturer's chain sharpening and maintenance

instructions. Check tension at regular intervals with the

engine stopped, never with the engine running.Make sure

the bar clamp nuts are securely tightened after tensioning

the chain.

o Begin and continue cutting at full throttle. Ifthe chain is

moving at a slower speed, there is greater chance for kick*

back to occur.

, Cut one log at a time.

_o Use extreme caution when re-entering a previous cut.

- Do not attempt plunge cuts.

• Watch for shifting logs or other forces that could close a

cut and pinch or fall into chain.

,, Use the Reduced-Kickback Guide Bar and Low-

Kickback Chain specified for your saw.

KICKBACK SAFETY FEATURES-

THE FOLLOWING FEATURES ARE INCLUDED

ON YOUR SAW TO HELP REDUCE THE HAZ-

ARD *OF, KICKBACK; HOWEVER, SUCH FEA-

TURES WILL NOT TOTALLY ELIMINATE THIS

DANGEROUS REACTION. AS A CHAIN SAW

USER, DO NOT RELY ONLY ON SAFETY

DEVICES. YOU MUST FOLLOW ALL SAFETY

PRECAUTIONS, INSTRUCTIONS, AND MAIN-

TENANCE IN THIS MANUAL TO HELP AVOID

KICKBACK AND OTHER FORCES WHICH CAN

RESULT IN SERIOUS INJURY.

Reduced-Kickback Guide Bar, designed with a small

radius tip which reduces the size of the kickback danger

zone on the guide bar tip. Figure 5. A Reduced-Kickback

MAINTAIN CONTROL

* Keep a good, firm grip on the saw with both hands

when the engine is running and don't let go. Figure 4.

A firm grip can neutralize kickback and help you maintain

controlofthe saw.Keep the fingers of your lefthand encir-

cling and your left thumb under the front handlebar.Keep

your right hand completely around the rear handle whether

you are right handed or left handed. Keep your left arm

straight with the elbow locked.

. Position your left hand on the front handlebar so it is

in a straight line with your right hand on the rear han-

dle when making bucking cuts. Figure 4. Never reverse

right and left hand positionsfor any type of cutting.

° Stand with your weight evenly balanced on both feet.

• Stand slightly to the left side of the saw to keep your

body from being in a direct line with the cutting chain.

Figure 4.

• Do not overreach. You could be drawn or thrown off bal-

ance and lose control of thesaw.

• Do not cut above shoulder height. It is difficultto main-

tain controlofsaw above shoulder height.

UNDERSTANDING REACTIVE FORCES

Pinch-Kickback and PulHn occur when the chain is sud-

denly stopped by being pinched, caught, or by contact-

ing a foreign object in the wood. This stopping ofthe chain

results in a reversalof the chain force used to cut wood and

causes the saw to move inthe opposite direction ofthe chain

rotation.Either reaction can result in loss of controland pos-

sible serious injury.

• Pinch-Kickback

-occurs when chain on top of guide bar is suddenly

stopped.

- rapidly drives saw straight back toward operator.

• Pull-In

- occurs when the chain on the bottom of the guide bar is

suddenly stopped.

- pulls the saw rapidlyforward.

• Handguard, designed to reduce the chance of your left

hand contacting the chain:if your hand slips off the front

handlebar. ....... ,_ -

• Position of front and rear handlebars, designed with

distance between handles and_'in-line" with each other.

The spread and "in-line" position of the hands provided by

this design work together to give balance and resistance

in controlling the pivot;_f the saw back toward the opera-

tor if kickback occurs.

* ANSi B175.1-1991 - Safety requirements for gasoline powered chain

saws as set by the American National Standards Institute, Inc.,

Standard B175.t-1991.

Guide Bar is one which has been demonstrated to signif-

icantly reduce the number and seriousness of kickbacks

when tested in accordance with ANSI Bt75.1-199t.

Low-Kickback Chain, designed with a contoured depth

gauge and guard link which deflect kickback force and

allow wood to gradually ride into the cutter. Figure 5. Low-

Kickback Chain is chain which has met kickback perfor-

mance requirements of ANSI B175.1-1991 when tested

on a representative sample of chain saws below 3.8 cubic

inch displacement specified in ANSI B175.1-1991.

-4"

./_ Cotttoured

L-_."_II_ 13epth Gauge Elongate:l

_,._ G u_de Unk

'_ ]# / _backFo_

"

ReducedKickback Radius Tip Low-K_'_ And AllowsWood

TO Gr_dua_ Ride

Symmetrica_ Guide Bat Chain Into Cutter

Mateda_

Symmetrical Large Chain With High

Guide Ba_ Radius Tip Kickback Pote_bal

Figure 5 :

Page 5

CONGRATULATIONS on your purchase of a Sears

Craftsman Gasoline Chain Saw. It has been designed,

engineered and manufactured to give you the best possi-

ble dependability and performance.

Should you experience any problems you cannot easily

remedy, please contact your nearest Sears ServiCe Cen-

ter/Department. Sears has competent, well trained, techni-

cians and the proper tools to service or repair this unit.

Please read and retain this manual. The instructions will

enable you to assemble and maintain your unit properly.

Always observe the "SAFETY RULES."

MODEL NUMBER: 358.352161

DATE CODE/SERIAL NO.:

DATE OF PURCHASE:

THE MODEL AND SERIAL NUMBER WILL BE

FOUND ON THE PRODUCT.

YOU SHOULD RECORD BOTH SERIAL, NUMBER

AND DATE OF PURCHASE AND KEEP tN A SAFE

PLACE FOR FUTURE REFERENCE.

MAINTENANCE AGREEMENT

A Sears Maintenance Agreement is available on thisprod-

uct.Contact your nearest Sears Store for details.

CUSTOMER RESPONSIBILITIES

• Read and observe the safety rules.

• Follow a regular schedule in maintaining, caring for, and

using your uniL

° Follow the instructions under "Customer Responsibi-

lities" and "Storage" sections of this Operator's Manual.

PRODUCT SPECIFICATIONS

GUIDE BAR: ............... 16" (40cm)

CHAIN: ........................ Low Profile 3/8" Pitch

Chrome Cutters

DISPLACEMENT: ....... 2.2 Cubic Inches (36cc)

ENGINE: ..................... 2-cycle Ai_"Cooled

FUEL MIX: ................... 40:1 (3.2 oz. oil per gallon gas)

OILER: ........................ Automatic, 6.8 oz.Tank

IGNITION: ................... Solid State

(Air gap .010" to .014")

IGNITION TIMING: ...... Non-adjustable, fixed

SPARK PLUG TYPE: .. Champion (CJ-7Y)

SPARK PLUG GAP: ..... 025" (.65ram)

MUFFLER: .................. Spark Arresting Screen

ENGINE RPM: __LL_.:;::12;600RPM Maximum

SPECIAL NOTICE

Your saw is equipped with alemperature limiting muf-

fler and spark arresting ,screen which meets the require-

ments of California Codes 4442 and 4443. All U.S. forest

land and the states of California, Idaho, Maine, Minnesota,

New Jersey, Washington,and Oregon require many internal

combustion engines to be equipped with a spark arrestor

screen by law.

if you operate a chain saw in a state or locale where

such regulations exist, you are legally responsible for

maintaining the operating condition of these parts.

Failure to do so is a violation of the law. Refer to the

Sp..ark Arrestor section under "Customer Responsi-

bdities"for maintenance.

MANUFACTURED UNDER ONE OR MORE OF THE FOLLOWING U,& PATENTS:

&367,988; 4,940,028; 4,370_855; 4,302,879; 4,197,640; 13325,330. OTHER U,S, AND FOR-

EIGN PATENTS PENDING.

SPECIAL NOTICE

-.If this,saw isto be used for commercial,logging, you must order and install a Chain Brake, to .comp!y

with Federal OSHA Regulations forCommerciaI,Logging,,SeeRepairPartsl_ist,orcaU 1-800-235-5878.

FULL ONE YEAR WARRANTY ONCRAFTSMAN;GAS CHAIN:SAW " "

For one year from the date of purchase, when this craftsman Gas Chain Saw is maintained, lubricated and

tuned-up according to the owners manual, Sears will repair, free of charge, any defect in material or workmanship.

This warranty excludes the bar, chain, spark plug and air filter, which are expendable pads, and become worn during

normal use.

If this Gas Chain Saw is used for commercial or rental purposes this warranty applies for 30 days from the date of

purchase.

WARRANTY SERVICE tS AVAILABLE BY RETURNING THIS CHAIN SAW TO THE NEAREST SEARS SERVICE

CENTER IN THE UNITED STATES.

This warranty gives you specific legal rights, and you may also have other rights which vary fromstate to state.

SEARS, ROEBUCK AND CO., D/817WA, Hoffman Estates, IL 60179

-5-

Page 6

TABLE OF CONTENTS

Safety Rules ....................................... L-............................ 2

Product Specifications ....................................................... 5

Warranty ........................................................ :................... 5

Accessories ....................................................................... 6

Operation ................................................. ......................... 8

Customer Responsibilities ............................................... I7

Service and Adjustments ................................................ 22

Storage .......................... _........... ,o.................................... 27

Trouble Shooting Points .................................................. 28

Repair Parts .................................................................... 29

Repair Parts Ordedng/Service_ ......................... Back Cover

INDEX

A

Accessories ....................................................................... 6

Air Filter ............................. ;:: ........................................... 20

B

Bar and Chain Oil ............................................................ 10

Bucking..: ......................................................................... 15

C

Carburetor Adjustments .......................... ,....................... 25

Carton Contents ................................................................ 7

Chain Oiler ........................................................................ 9

Chain Sharpening ........................................................... 18

Chain Adjustment ............................................................ 22

Customer Responsibilities ............................................... 17

E

Engine

FuellOil ......................................................................... 10

Spark Plug ................................................................... 20

Starting ......................................................................... 11

Storage ........................................................................ 27

F

Fuel Filter ........................................................................ 21

Fueling ............................................................................. 10

G

Guide Bar and Chain Oil ................................................. 10

Guide Bar Maintenance .................................................. 19

H

How To Use Your Chain Saw ............................................. 9

K

Know Your Chain Saw .......................................... _............ 8

L

Limbing ............................................................................ 16

M

Maintenance Schedule .................................................... 17

Model Number ................................................................... 5

Muffler ............................................................................. 20

O

Operation ........................................................................... 8

Ordering Repair Parts ....................................... Back Cover

P

Product Specifications ....................................................... 5

Pruning ........................................... . ............................... 16

R

Repair Parts .................................................................... 29

• S

Spa_aer_stAdj_Streemen?!S:::::::::::::::::::::::::::::::::::::::::::::::: 22

Starter Rope .................................................................... 23

Starting ............................................................................ 11

Storage ............................................................................ 27

T

Throttle Control Group ...................................................... 9

Tree Felling ...................................................................... 12

Trouble Shooting Points .................................................. 28

W

Warranty ............................................................................ 5

ACCESSORIES

These accessories and attachments were available when the unit was originally purchased. They are also available at most

Sears retail outlets and service centers, lVlost Sears stores can order these items for you when you provide the model num-

ber of your unit.

PERFORMANCE

Spark Plug

MAINTENANCE

2-cycle

_ Engine

0il

3.2 oz.

8 oz.

16 oz.

Air Filter

Gas Can

.'--"\ _ I/L____

_, ,J

Bar Oil

1 qt.

1 gal.

Carrying

Gloves Guide Bar

/

Safety

Goggles

Chain

j

Hearing

Protection

Chain

y

-6-

Page 7

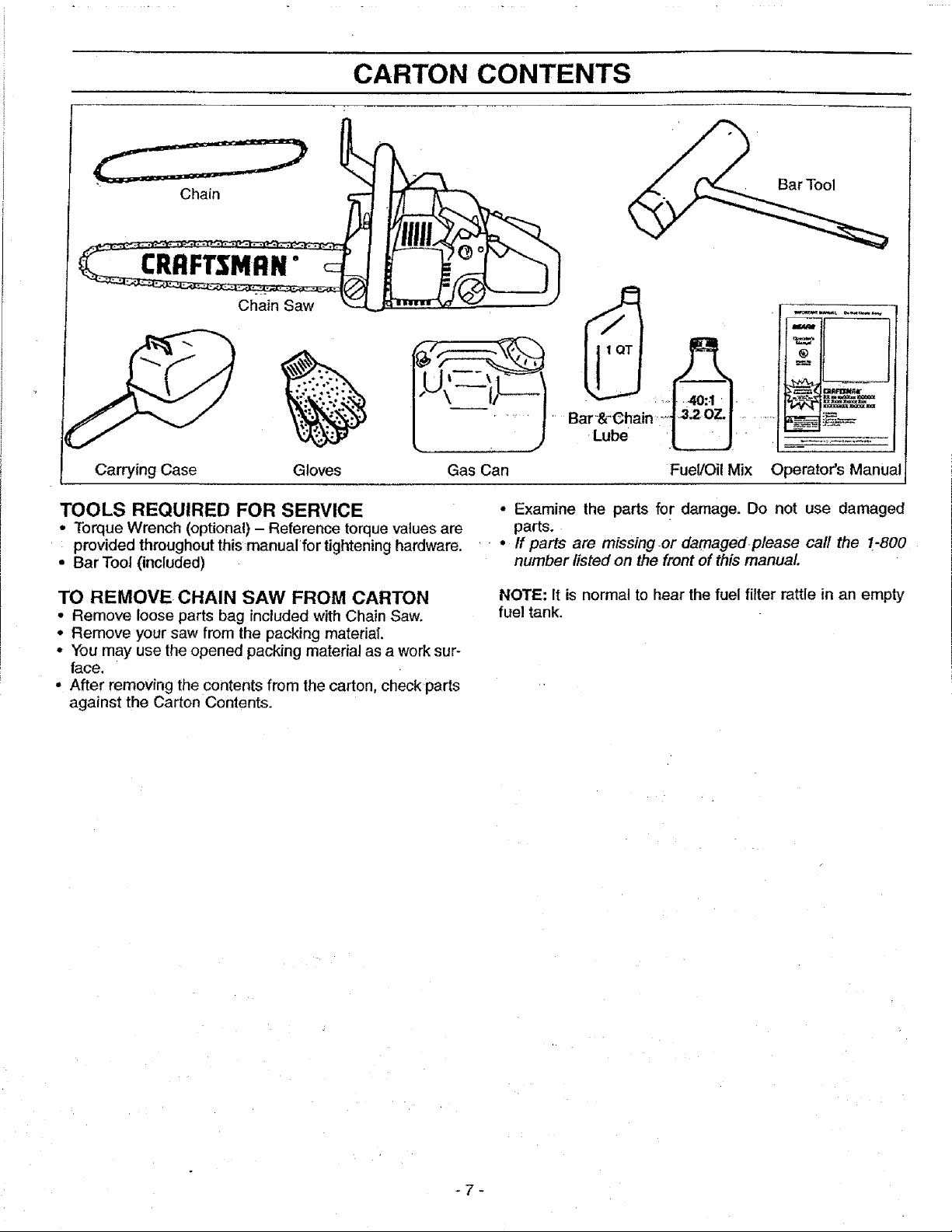

CARTON CONTENTS

Carrying Case Gloves

\ I/ _.

Gas Can

•Lu_

Fuel/Oil Mix Operator's Manual

TOOLS REQUIRED FOR SERVICE

• Torque Wrench (optional) - Reference torque values are

provided throughout this manual for tightening hardware.

• Bar Tool (included)

TO REMOVE CHAIN SAW FROM CARTON

• Remove loose parts bag included with Chain Saw.

• Remove your saw from the packing material.

• You may use the opened packing material as a work sur-

face,

• After removing the contents from the carton, check parts

against the Carton Contents.

• Examine the parts for damage. Do not use damaged

parts.

• • If parts are missing or damagedplease call the 1.-800

number listed on the front of this manual

NOTE: It is normal to hear the fuel filter rattle in an empty

fuel tank.

-7-

Page 8

OPERATION

KNOW YOUR CHAIN SAW (Fig. 6)

READ THIS OPERATOR'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR CHAIN SAW, Compare the illus-

trations with your unit to familiarize yourself with the location of the various controls and adjustments, Save this manual for

future reference,

Hand Guard

Chain

CRRFTSNRNo

Throttle

Lockout

Bar Oil "J

Fill Cap /

Starter

Cylinder Cover Housing

Fast Idle

Lock

Front

Handle

Fuel Mix

Fil! Cap

Starter

Rope Handle

On/Stop

Switch

_j_._ Primer

Bulb

Rear Adjusting

Handle Screw

CHAIN TRAVEL

DIRECTION

CRRFTSM N°

Throttle Choke Bar Clamp

Trigger Knob

Catcher

Figure 6

Clamp Guide Bar

Nuts

Listed by Underwriters Laboratories, Inc.

in accordance with American National Standards for Gasoline-Powered Chain Saws Safety Requirements

(ANSI B175.1-1991).

The ON/STOP SWITCH is used to stop the engine, The THRO'I-TLE TRIGGER controls engine speed.

The STARTER ROPE HANDLE is used for starting the

engine,

The CHOKE KNOB activates the choke to provide add!-

•t onal fuel to the engfne when starting a cold engine.

The THROTTLE LOCKOUT prevents the THROTTLE

TRIGGER from being squeezed accidentally.

The FAST IDLE LOCK allows for faster engine speeds dur-

ing starting.

The GUIDE BAR 'is designed to carry the chain.

The CUTTERS are designed to cut the wood,

The BAR CLAMP NUTS are designed to hold the guide

bar after adjustments have been completed.

The ADJUSTING SCREW is designed to tension the chain

on the guide bar,

The PRIMER BULB circulates fuel to the carburetor.

-8-

Page 9

OPERATION

HOW TO USE YOUR CHAIN SAW

STOPPING YOUR ENGINE

• Move onlstop switch to the "Stop" position.

• If engine does not stop, pull blue choke knob out fully.

CHAIN OILER (Fig. 7)

• The chain oiler provides continuous lubricatiQn to the

chain and guide bar. Be sure to fill the bar oil tank when

you fill the fuel tank (Capacity = 6.8 fL oz.).

• Your chain saw will consume approximately one tank of

bar oil for each tank of fuel used.

• Your chain citer is automatic and requires no adjustment.

L,./,_._f _ Front Handle

... _,, _,_1 I\ _ Fuel Mix

___FTSMRN" e

Figure 7

THROTTLE CONTROL GROUP (Fig. 8)

THROTTLE LOCKOUT

• The throttle lockout prevents unintentional actuation of

the throttle trigger,

• You must depress the throttle lockout with the palm of

your hand before actuating the throttle trigger.

THROTTLE TRIGGER

• The throttle trigger allows for variable control of engine

speed.

• The throttle trigger is actuated bythe index finger on your

right hand. (After the throttle lockout is depressed).

FAST IDLE LOCK

• The fast idle lock allows for faster engine speeds during

starting.

• The fast idle lock is engaged by the following steps:

- Grasp the rear handle and depress the throttle lockout.

- Squeeze the throttle trigger fully and hold.

- Depress the fast idle lock with your thumb and hold.

- Release your grip on the throttle trigger and throttle

lock while continuing to hold the fast idle lock.

NOTE: Verify the throttle trigger stays in the advanced

position.

• Squeezing the throttle trigger wilt release the fast idle

setting, tf the throttle trigger is squeezed accidentally

during starting, it will be necessary to reset throttle

advance.

IJ .,,. Fast Idle

_%,_ _ Lock Throttle

",J | _/"_ / Lockout

-Trigger

Figure 8

CHOKE (Fig. 9) --

• The choke provides additional fuel when starting a cold

engine.

• The choke is actuated by pulling the blue choke knob.

• The choke has three positions: off, partial and full.

Primer "-_ _'_f/ ]_i

STOP

Choke Positions [

._ j

Partial _Eull

Figure 9

-9-

Page 10

OPERATION

BEFORE STARTING ENGINE

WARNING:

BE SURE TO READ THE FUEL HANDLING

INFORMATION IN THE SAFETY RULES

SECTION ON PAGE 2 OF THIS MANUAL

BEFORE YOU BEGIN.

IF YOU DO NOT UNDERSTAND THE FUEL

HANDLING SECTION DO NOT ATTEMPT TO

FUEL YOUR UNIT; SEEK HELP FROM

SOMEONE THAT DOES UNDERSTAND THE

FUEL HANDLING.SECTION OR CALL THE

CUSTOMER ASSISTANCE HOTLINE AT

1-800-235-5878.

GUIDE BAR AND CHAIN OIL

For maximum guide bar and chain life,we recommend you

use Craftsman chain saw bar oil. If Craftsman bar oil is not

available, you may_se a good grade SAE30 oil until you are

able to obtain Craftsman brand. The oil output is automati-

caUy metered during operation. Your saw will use approxi-

mately onetank'0f bar oil for every tank of fuel mix. Always

fill the bar oil tank when you fill the fuel tank.

GASOLINE

The two-cycle engine on thisproduct requiresa fuel mixture

of regular unleaded gasoline and a quality 40:1

2_cycle engine oil (AIR-COOLED) for lubricationof the bear-

ings and other moving parts.The correct fuel/oil mixture is

40:1 (see Fuel Mixture Chart).Too little oilorthe incorrect oil

type will cause poor performance and may cause the engine

to overheat and seize.

Gasoline and oil must be premixed in aclean approved fuel

container. Always use fresh regular unleaded gasoline.

This engine is certified to operate on unleaded gasoline.

IMPORTANT: Experience indicates that alcohol blended

fuels called gasohol (or using ethanol or methanol) can

attract moisture, which leads to oil/gas separation and for-

mation of acids during storage. Acidic gas can damage the

fuel system of amengine while in storage. To avoid engine

problemS, the fuel_;system should be emptied before storage

for 30,days or longer. Drain the gas tank, then run the fuel

-out of the carburetor and fuel lines by starting the engine

and letting it run until it stops. Use fresh fuel next season.

See STORAGE instructions for additional information. Never

use engine or carburetor cleaner products in the fuel tank or

permanent damage may occur.

FUEL STABILIZER

Fuel stabilizer is an acceptable alternative in minimizing the

formation of fuel gum deposits during storage. Add stabiliz-

er to gasoline in fuel tank Orstorage container. Always fol-

low the fuel mix ratio found on the stabilizer container. Run

engine at least 5 minutes after adding stabilizer to allowthe

stabilizer to reach the carburetor. You do not have to drain

the fuel tank forstorage if you are using fuel stabilizer.

CRAFTSMAN 40:1 2-cycle engine oil (AIR-COOLED) is

specially blended with fuel stabilizers. If you do not use this

Sears oil, you can add a fuel stabilizer to your fuel tank.

40:1 2-CYCLE AiR-COOLED ENGINE OIL

CRAFTSMAN 40:1 2-cycle engine oil (AIR-COOLED) is

strongly recommended.This oil is specifically blended with

fuel stabilizers for increased fuel stability (extends fue! life

up to 5 times longer) and reduced smoke.

If CRAFTSMAN 40:1 2-cycle engine oil (AIR-COOLED) is

not available, use a good quality 2-cycle engine oil (AIR-

COOLED) that has a recommended fuet mix ratio of 40:1. •

IMPORTANT! Do not use:

• AUTOMOTIVE OIL

• BOAT OILS (NMMA, BIA, etc.)

These oils do not have proper additives for 2-cycle

(AIR-COOLED) engines and can cause engine damage.

GASOLINE AND OIL MIXTURE

MIX GASOLINE AND OIL AS FOLLOWS:

• Consult chart for correct quantities.

• Do not mix gasoline and oil directly in the unit's fuel tank.

FOR ONE GALLON:

• Pour 3.2 ounces of high quatity, 40:t 2-cycle engine oil

(AIR-COOLED) into an empty, approved one gallon

gasoline container.

• Add one gallon of regular unleaded gasoline to the gallon

container, then securely replace:the cap,

Shake the container momentar)ly:

The mixture is now ready for _e. Fuel stabilizer can be

added at this time if desired; follow mixing instructions on

the label.

FUEL MIXTURE CHART

40:1 Fuel:Oil Mix Ratio

Gasoline Oil {fl.oz.)

1 gallon 3.2

2.5 gallons 8.0

NOTE: Fuel containers may hold more than the specified

amount. If too much gasoline is in the container, the result-

ing gas-to-oil fuel mixture will not be correct for proper

engine operation.

-10-

Page 11

OPERATION

STOPPING YOUR ENGINE '

o Move on/stop switch to the "Stop" position.

• If engine does not stop, pull blue choke knob out fully.

WARNING:

ALWAYS WEAR GLOVES, SAFETY FOOT-

WEAR, SNUG-FITTING CLOTHING, AND

EYE, HEARING, AND HEAD PROTECTION

DEVICES WHEN OPERATING A CHAIN SAW.

THE CHAIN MUST NOT MOVE WHEN THE

ENGINE RUNS AT IDLE SPEED. REFER TO

THE ='CARBURETOR ADJUSTMENTS" SEC-

TION FOR CORRECTION.

AVOID ANY CONTACT WITH THE MUFFLER.

A HOT MUFFLER CAN CAUSE SERIOUS

BURNS.

STOP

Choke Positions

Off Partial Full I

Figure 10

NOTE: Check chain tension using instructions_ in the. ,.place:your:right_oot_hrough::opening in rear handle..

"Service and Adjustment" section. " .- _- Pull starter rope handle.until engine starts.

STARTING A WARM ENGINE

• Move on/stop switch to the "On" position.

• Activate fast idle control.

• Be sure choke is in the "Off" position.

-. With saw on ground, grip front handle with left hand and

• Before first use......

• After I minute of operation.

TO START ENGINE (Fig. 10 & 11)

COLD ENGINE START AND WARM ENGINE

START AFTER RUNNING OUT OF FUEL.

• Fuel engine with 40:1 fuel mix (3.2 oz.to 1 gal. gas).

• Fill bar oil tank with bar oil. Your saw will use approxi-

mately one tank of bar oil for each tank of fuel mix.

• Prime engine by pressing primer bulb six times.

• Turn on ignition by moving on/stop switch to the "On"

position.

• Actuate choke by pulling blue choke knob fully out.Then

set the saw on the ground. Grip the front handle with your

left hand and place your right foot through opening in

rear handle,

• Set fast idle by depressing the throttle lock with your right

hand. Then squeeze throttle trigger and hold. With your

thumb, press the fast idle lock down and hold. Next,

release the throttle trigger.

:;_. _';.,• Squeeze and _-elease_lhrottle:lrigger to .return engine to

idle speed.

[ Right Hand on STARTING POSITION

Starter Rope Handle

l [t_l_'_ _ Left Hand on

II t I_. _ }_[ _ i Front Handle

ightFoot through Opening in Rear Handle

Figure 11

o IFTHROTTLETRIGGER IS SQUEEZED ACCIDENTAL- _..:._._ ....... ._..... ...... ..... FLOODEDENGINE ......

UilP_It._ULI _.iAi'_.LiI_I,._ UM

LY DURING STARTING IT WlEL' BENECESSARYTO "_"_=........ ..... "_ _' ' _ ........

RESETTHE FAST IDLE LOCK. " .... ;:' Theengine maybe.ffooded_with:_too much fuel if it has not

knob in to the "Off" position, then squeeze and release

throttle trigger to allow engine to idle.

• To stop engine, move on/stop switch to the "Stop" posi-

tion.

NOTE: When pulling the starter rope, do not use the full

extent of the rope as this can cause the rope to break. Do

not let the starter snap back, hold the handle and let the

rope rewind slowly.

o :Pull starter rope.handle with Your right hand until the

engine attempts to start. Then push the blue choke knob

in to the partial position. Resume pulling handle until

engine starts.

• Above 40 degrees, allow engine to run for approximate-

ly 5 seconds, push the choke knob in to the "Off" posi-

tion, then squeeze and release throttle trigger to allow

engine to idle.

• Below 40 degrees, allow engine to warm up 30 seconds

- I minute with choke at partial position. Push choke

:started after_:t0 pulls:. _ ._ . . :

Flooded engines can be cleared of excess fuel with the fol-

lowing procedure:

• Activate the fast idle lock.

• Verify thai the ordstop switchis iiilthe =On" position: " "

• Push the choke knob to the "Off" position.

• With saw on ground, grip front handle with left hand and

place right foot through opening in rear handle.

• Pull starter rope handle until engine starts.

Starting could require pulling starter rope handle many

times depending on how badly unit is flooded. If engine still

fails to start, refer to 'q'ROUBLE SHOOTING" chart or call

the 1-800 number listed on the front page of this manual.

-11 -

Page 12

i

OPERATION

GENERAL OPERATION TIPS '

• Cut wood only. Do not cut metal; plastics; masonry; non-

wood building materials; etc.

• Stop lhe saw if the chain strikes a foreign object. Inspect

the saw and repair or replace parts as necessary.

• Keep the chain out of dirt and sand. Even asmall amount

of dirt will quickly dull a chain and thus incre&se the pos-

sibility of kickback.

To get the "feel" of using your saw before you begin a major

sawing operation, practice cutting a few small logs using

the following technique: "

° Accelerate engine to full throttle by squeezing the throttle

trigger before entering cut.

• Never cut with engine at partial speeds.

• Begin cutting with the saw chassis.against the log.

• Keep engine at full throttle during cutting procedure.

• Allow the chain to cut for you; exert only light downward

pressure. If you force the cut, damage to the bar, chain,

or engine can result.

• Release the throttle trigger as soon as the cut is com-

pleted, allowing the engine to idle. If you run the unit at

full throttle without cutting, unnecessary wear can occur

to the chain, bar, and engine.

• To avoid losing control when completing the cut, do not

put pressure on the saw during the end of the cut.

• Stop engine before setting unit down after operation.

OPERATION SAFETY

WARNING:

IF SAW BECOMES PINCHED OR HUNG IN A

LQG, DO NOT TRY TO FORCE IT OUT. YOU

CAN LOSE CONTROL OF THE SAW

RESULTING IN INJURY AND/OR DAMAGE

TO THE SAW. STOP THE SAW, DRIVE A

WEDGE OF PLASTIC OR WOOD INTO THE

CUT UNTIL THE SAW CAN BE REMOVED

EASILY. RESTARTTHE SAW AND CAREFUL-

LY REENTER THE CUT. TO AVOID KICK-

BACK AND CHAIN DAMAGE, DO NOT USE A

METAL WEDGE. DO NOT ATTEMPT TO

RESTART YOUR SAW WHEN IT IS PINCHED

OR HUNG IN A LOG.

KICKBACK CAN OCCUR WHEN THE MOV-

ING CHAIN CONTACTS AN OBJECT ATTHE

UPPER PORTION OFTHETIP OFTHE GUIDE

BAR OR WHEN THE WOOD CLOSES IN AND

PINCHES THE SAW CHAIN IN THE CUT.

CONTACT AT THE UPPER PORTION OF THE

TiP OF THE GUIDE BAR CAN CAUSE THE

CHAINTO DIG INTOTHE OBJECT AND STOP

THE CHAIN FOR AN INSTANT.THE RESULT

IS A LIGHTNING FAST, REVERSE REACTION

WHICHKICKS THE GUIDE BAR UP AND

BACK:_TOWARD THE OPERATOR. IF THE

SAW CHAIN IS PINCHED ALONG THE TOP

OF THE GUIDE BAR, THE GUIDE BAR CAN

BE DRIVEN RAPIDLY BACK TOWARD THE

OPERATOR. EITHER OF THESE REACTIONS

CAN CAUSE LOSS OF SAW CONTROL

WHICH CAN RESULT IN SERIOUS INJURY.

AVOID REACTIVE PINCH FORCES

Pinch-Kickback and Pull-In occur when the chain is sud-

denly stepped by being pinched, caught, or by contacting

a foreign object in the wood, This sudden stopping of the

chain results in a reversal of the chain force used to cut

wood and causes the saw to move in the opposite direction

of the chain rotation. Pir,ch-Kickback drives the saw

straight back toward the operator. Pull-In pulls the saw

away from the operator. Either reaction can result in loss 6f

control and possibly serious ihjury.

TO AVOID PINCH-KICKBACK:

• Be extremely aware of situations or obstructions that can

cause material to pinch the top of or otherwise stop the

chain.

• Do not cut more than one log at a time.

• Do not twist the saw as the bar is withdrawn from an

under-cut when bucking.

TO AVOID PULL-IN:

° Always begin cutting with the engine at full throttle and

the saw housing against wood_s:

° Use wedges made of plastic or.wood, (never of metal) to

hold the cut open.

-12-

Page 13

OPERATION

TREE FELLING

WARNING:

IF THE TRUNK OR LIMBS ARE ROTTING,

THEY CAN FALL UNEXPECTEDLY AND

CAUSE SERIOUS INJURY.

AS YOU MAKE YOUR FELLING CUT, IFTHE

SAW APPEARS TO BE BINDING, THE TREE

IS STARTING TO FALL IN THE WRONG

DIRECTION. IMMEDIATELY STOP THE SAW

AND USE A FELLING WEDGE AND MAUL

(HAMMER) TO FORCE THE FELLING CUT

OPEN. THE WEDGE WILL HOLD THE

FELLING CUT OPEN ALLOWING YOU TO

REMOVE THE SAW. KEEP EVERYONE AWAY

FROM THE TREE IN ALL DIRECTIONS.

DETERMINE THE NATURAL FALL DIRECTION

• Wind - A tree evenly balanced wiltfall in the same direc-

tion the wind is blowing.

• Lean - Use a carpenter's level or plumbbob to deter-

. mine if tree has a natural tean, A leaning tree will tend to

fall in direction of lean.

• • Shape - A tree wilt tend to fall towards side that is more

heavily branched.

• Other Factors - Contacting or nearby trees, buildings, or

wires can influence the direction the tree will fall.

CUTTING PROCEDURE (Fig. 12)

After determining the Natura! Fall Direction, the tree should

be cut as follows:

IMPORTANT: BEFORE FELLING A TREE, MAKE SURE

YOU HAVE AT LEAST 3 FELLING WEDGES AND A

MAUL (HAMMER) AVAI_BLE FOR USE IF NEEDED.

• Use some means to visually mark the Natural Fall

Direction.

° Mark your notch cut on the Natural Fall Direction side of

the tree approximately 18-24 inches above the ground.

• :Cut top of the notch first at a 45 degree angle.: Saw

through 1/3 of the width of the tree: ..................

• Cut bottom of the notch at a: 45 idegree .angle until yoly

meet the top notch cut. Remove notch of wood.' .... _....

° On the side of the tree opposite the notch cut, make the

felling cut. The fe!ling cut should be 2 inches above the

center point of the notch cut. Before the felling cut is

complete, use wedges to open the cut when necessary

to control the direction of the fall. Use wood or plastic

wedges, but never steel or iron, to avoid kickback and

chain damage.

• Cracking sounds, widening of the felling cut, movement

in the upper branches are all signs that the tree is ready

to fall.

• As tree begins to fall, turn off saw, and move quickly

away from direction of tall.

m

Felling Direction

Top

Notch

Cut

Bottom

Notch

Cut

Felling

F Cut

....... t

Buttress

Root

• .Ogure 12.:

If your chain saw binds in the felling cut, you have three

options:

• if the wrong direction of fal! is acceptable, carefully

remove the feffing wedge. Cut deeper in the notch side of

the 'tree until tree starts to fall.

• If the wrong direction of fall is not acceptable, attempt to

use one or more felling wedges to force the tree in the

original direction of fall. Do so by driving the wedges

deeper into the felling cut.

• Keep everyone away from the tree in all directions and

then seek professional help!

FELLING TIPS

• Clearthe work area of debris where you can have secure

footing.

Make sure there is enough room for the tree to fall.

Maintain a distance of 2 1/2 tree lengths from the near,

est person or other objects. Engine noise can drown out

a warning call.

: :,Remove_dirt,.stones, Ioose_bark,::nails,staples; and wire

.._._fromthe .treewhere_cuts_m:_o be made, _ . ......

-.Plan to stand on the up-hill;side,when cutting on a slope.

•.--Planaclearretreat_path-.to-the rear and diagonal to the

line of fall.

• Large buttress roots should be removed prior to notch

cut.

• Use a wedge if there is any chance that the tree will not

fall in the desired direction.

• We recommend you cut branches below shoulder height

before felling tree. (See Limbing and Pruning). "

Be alert to signs that the tree is ready to fall:

• Cracking sounds.

-. Widening of the felling cut.

• Movement in the upper branches.

-13-

Page 14

OPERATION SAFETY

FELLING SAFETY

DON'T PUT YOURSELF IN THESE POSITIONS

Check the wind -

Don't cut down wind

Check the lean -

Don't cut on down side

I_ ARNING:

DO NOT_CUT:

- NEAR ELECTRICAL WIRES OR

BUILDINGS.

- IF YOU DO NOT KNOW THE DIRECTION

OFTREE FALL.

- AT NIGHT.

- DURING BAD WEATHER - RAIN, SNOW,

STRONG WIND, ETC.

Check the balance -

Don't cut on weighted side

• Look for decay and rot. Ifthe trunk is rotted, itcan snap

and fal{ toward the operator.

- Check for broken or dead branches which can fall on

you while cutting.

• Be extremehJ cautious with partially fallen trees that may

be poody supported. When a tree doesn't fal! completely,

set the saw aside and pull down the tree with a cable

winch, block and tackle, or tractor.To avoid injury, do not

cut down a partially fallen tree with your saw.

-!4-

Page 15

OPERATION

BUCKING

Bucking is cutting a fallen tree to the desired• log size.

"I_nPES OF CU'I-rlNG (Fig. 13) •

Overcutting - begin on the top side of the log with the

bottom of the saw chassis against the log; exert light

pressure downward.

• Undercutting - begin on the underside of the log with the

top of the saw chassis against the log; exert light pres-

sure upward. During undercutting, the saw will tend to

push back at you. Be prep.ared for this reaction and hold

the saw firmly to maintain control.

Saw Chassis

Figure 13

BUCKING ON THE GROUND (Fig. 14)

• Overcut with a 1t3 diameter cut.

• Roll log over and finish with an overcut.

/

Figure 14

BUCKING USING A SUPPORT (Fig. 15 & 16)

Another log or a stand, Such as a sawhorse, may be used

as supports when bucking.

• Area A - Undercut 1/3 of the way through the log.

- Finish with an ovemut.

• Area B - Overcut 1/3 of the way through the log.

- Finish with an undercut.

2nd Cut 2nd Cut

1st !1st Cut

Sawhorse

Another Log

Figure 16

BUCKING TIPS

• Cut only one log at a time.

• Cut shattered wood very carefully. Sharp pieces of wood

could be flung toward the operator.

• Use a sawhorse to cut small logs. Never allow another

person to hold the log while cutting and never hold the

log with your leg or foot.

:- Do not:cut in_anarea where, logs, limbs, and roots are

tangled suchas ina blown down area. Drag the logs into

a clear area beforecutting by pulling out exposed, and

....... cleared logs first. - ...... :

• Give special attention to logs under strain to prevent the

saw from pinching. Make the first cut on the pressure

side to relieve the stress on the log.

OPERATION SAFETY

BUCKING SAFETY

WARNING:

DO NOT STAND ON THE LOG BEING CUT'.

ANY PORTION CAN ROLL CAUSING LOSS

OF FOOTING AND CONTROL.

NEVER TURN THE SAW UPSIDE DOWN TO

UNDERCUT. THE SAW CANNOT BE CON-

TROLLED IN THIS POSITION.

° Stay on uphill side of tree when cutting.

Use Common Sense

Maintain Secure Footing

-15-

Page 16

OPERATION

PRUNING AND LIMBING

Pruning is removing branches from a standing tree.

Limbing is removing branches from a felled tree.

LIMBING (Fig. 17)

* Start at base of the felled tree and work toward the top.

- Leave the larger limbs underneath the felled tree to

support the tree as you work.

Figure 17

PRUNING (Fig. 18)

Small branches - smaller than width of guide bar.

Large branches - larger than width of guide bar.

• Remove small limbs with one cut.

• Remove larger, supporting branches with the 1/3 - 2/3

cutting techniques described in the bucking section.

PRUNING PROCEDURE

• Cut 1 - Undercut 1/3of the way.through the limb near

the trunk of the tree.

° Cut 2 - Finish with an overcut farther out from the trunk

untilthe limb falls. Keep out of the way of the falling limb.

• Pruning Cut - Cut the limb stump flush at the edge of

the collar.

' itl

Cut 2

Pruning Cut

)

I

J

Figure 18

PRUNING AND LIMBING TIPS

• Work slowly, keepingboth hands firmly gripped on the

saw. Maintain secure footing and balance,

• Keep a clear work area.'Frequently clear branches out of

the way to avoid tripping over them.

• Leave the larger limbs underneath the felled tree to sup-

port the tree as you work.

• Start at the base of the fetled tree and work toward the

top.

• Keep the tree between you and the chain. Cut from the

side of the tree opposite the branch you are cutting.

• Limit pruning to limbs shoulder height or below.

• Keep out of the way of the falling limb.

OPERATION SAFETY

PRUNING AND LIMBING SAFETY

T

_ WARNING:

NEVER CLIMB INTO A TREE TO LIMB OR

PRUNE UNLESS SPECIFICALLY TRAINED

'_ TO DO SO. DO NOT STAND ON LADDERS,

"" PLATFORMS, A LOG, OR IN ANY POSITION

WHICH CAN CAUSE YOU TO LOSE YOUR

BALANCE OR CONTROL OFTHE SAW.

BE ALERT FOR AND GUARD AGAINST

KICKBACK. DO NOT ALLOW THE MOVING

CHAIN TO CONTACT ANY OTHER BRANCH-

ES OR OBJECTS AT THE NOSE OF THE

GUIDE BAR WHEN UMBING OR PRUNING.

ALLOWING SUCH CONTACT CAN RESULT

IN SERIOUS INJURY.

DO NOT CUT IF BRANCHES ARE HIGHER

THAN YOUR SHOULDER. GET A PROFES-

SIONAL TO DO THE JOB. THIS MAY RESULT

IN SERIOUS INJURY.

, Watch out for springpoles. Use extreme caution when

cutting small size limbs. Slender material may catch the

saw chain and be whipped' toward you or pull you off

• balance.

• Be alert for springback. Watch out for branches that are

bent or under pressure as you are cutting to avoid being

struck by the branch or the saw when the tension in the

wood fibers is released.

-16-

Page 17

CUSTOMER RESPONSIBILITIES

MAINTENANCE SCHEDULE

Fill in dates as you complete regular service Before After Every Every Yearly Service Dates

Clean/inspect spark arrestor screen & inspect muffler

Replace spark plug

Replace fuel filter

GENERAL RECOMMENDATIONS

The warranty on this unit does not cover items that have

been subjected to operator abuse or negligence,To receive . :

full value from the warranty,the operator must maintain unit

as instructed in this manual.

Some adjustments will need to be made periodically to

properly maintain your unit.

All adjustments in the "Service and Adiustments" section of

this manual should be checked at least once each season.

• Once a year, replace the spark plug, replace air filter ele-

ment and check guide bar and chain for wear. A new

spark plug and a clean/new air fitterelement assures

proper air-fuel mixture and helps your engine run better

and last longer.

• Follow the maintenance schedule in this manual.

WARNING:

DISCONNECT THE SPARK. PLUG BEFORE-,

PERFORMING MAINTENANCE EXCEPT FOR

CARBURETOR ADJUSTMENTS.

INSPECTTHE ENTIRE UNIT. REPLACE DAM-

•.AGED PARTS. CHECK FOR FUEL LEAKS

AND MAKE SURE ALL FASTENERS ARE IN

PLACE AND SECURELY FASTENED.

LUBRICATION CHART

©BarOilFil/Cap _

@ Sprocket

(# Craftsman chain saw bar oil

@ Craftsman bar sprocket lube

v"

v_

v"

I ...........

BEFORE USE

CHECKFOR DAMAGEDOR WORN PARTS

The following damaged/worn pa_ts should be referred to

your Sears Service Center.

NOTE: It is normal for a small amount of oil to appear

under the saw after engine stops. Do not confuse this with

a leaking oil tank.

° On/Stop Switch - ensure on/stop switch functions prop-

erly by moving the switch to the "Stop" position and

assure that engine stops, then restart your engine and

continue.

• Fuel Tank - discontinue use of chain saw if fuel tank

show signs of damage or leaks.

• Oi! Tank - discontinueuse of chain saw if oil tankshows

signs of damage or leaks.

° Chain Catcher -replace chain ,catcher if bent, cut, or

damaged in any way.

CHECK FOR LOOSE FASTENERS AND PARTS

• Bar Clamp Nut

° Chain

....... Muffler

:_:': • 'CylinderShietd

......... : -:;Air:Filter :i :-_":'!::f:';..... ; "

_.Clutch Drum/Sprocket .....

° Handle Screws

° Starter Housing

• Handguard

CHAIN TENSION (Fig. 19 & 20)

Use the screwdriver end of the bar toot to move chain

around the guide bar.

• If chain does not rotate, itis too tight - slightly loosen bar

clamp nuts and turn adjusting screw 1/4 turn counter-

clockwise. Retighten bar clamp nuts.

• If chain is too loose, it will sag below the guide bar.

Figure 19.

sa0===j;

Figure 19

-17-

Use Use 5 Hrs. 25 Hrs.

Check for damaged or worn parts ,/ ....

...... I .....

Check for loose fasteners and parts ,/

Check chain tension ./

Check chain sharpness ,,I

Check guide bar condition_., v"

Check guide bar lube v"

Clean unit & labels ,/

Clean air filter ,/

Page 18

CUSTOMER RESPONSIBILITIES

• If chain is too loose, refer to "Chain Adjustment." Loosen

bar clamp nuts; then, turn adjusting screw 1/4 turn clock-

wise. Lift up tip of guide bar to check for sag. Retighten

bar clamp nuts. Figure 20.

Adjusting Screw

1/4 Turn

Bar Clamp

Nuts

CRRFTSMRN"

Bar

Tool

Figure 20

SHARPENIN_ CHAIN

(Fig. 21,22,23,24 , 25, 26 & 27)

WARNING:

IMPROPER CHAIN SHARPENING TECH-

NIQUES AND/OR DEPTH GAUGE MAINTE-

NANCE WILL INCREASE THE CHANCE OF

KICKBACK, WHICH CAN RESULT IN SERI-

OUS INJURY.

ALWAYS WEAR GLOVES WHEN HANDLING

THE CHAIN. THE CHAIN CAN BE SHARP

ENOUGH TO CUT YOU EVEN THOUGH IT IS

TOO DULLTO CUTWOOD.

CHAIN TERMINOLOGY & PART NAMES

Preset Tie Strap

Left Hand Cutter

FieStrap Drive Link

Right Han: ..: "e _trap

CHAIN CUTTER PART NAMES

,_ Top Gullet

Depth Gauge

Hole

CHAIN "GAUGE"

Pitch refers to chain mea-

surement. A chain's pitch is

the distance between any

three of its rivets divided by

two.

Tl_ckness of bottom mj=._ I i_.,=r_

section of _idve tink _= I_

Gauge refers to thickness

of that portion of drive link

which fits into saw bar

groove.

Tools required:

• Flat file

• .025 depth gauge

• 4.5mm round file & file holder

Conditions which indicate the need for chain sharpening:

• Reduction in size of wood chips. The size of the wood

chip will decrease as the chain gets duller until it

becomes more like a powder than a chip. Note that dead

or rotted wood will not produce a good chip.

• Saw cuts to one side or at an angle.

• Saw requires excessive force to cut.

• Noticeable loss of cutting speed.

Sharpening instructions:

• Move on/stop switch to the "Stop" position.

• Check chain for proper tension. Adjust chain tension if

necessary. (See Chain Tension/Adjustment).

• Check and lower depth gauges before sharpening cutters.

• Depth gauges should be checked every third sharpen-

ing. When cutting frozen wood!he depth gauges should

be checked each time you_sharpen the chain_

• To check depth gauge, place gauge tool on cutter, If the

depth gauge projects above the tool, then file it level to

the top of the depth gauge tool. See Figure 21.

Depth Gauge

File

Figure 21

.030" Squared

:_ _ Rounded Off Corner

ner

Right Way £_ _i£2 Wrong Way

Figure 22

• To sharpen the cutters, position the file holder level (90°)

so that it rests on the top edges of the cutter and depth

gauge. See Figure 23.

NOTE: The chain has both left and right hand cutters.

• Sharpen cutters on one side of the chain first. File from

the inside of each cutter to the outside. Then turn your

saw around and repeat the process for the other side of

the chain. See Figure 24.

• File on the forward stroke only. Use 2 or 3 strokes per

cutting edge.

• Keep the 30° line on the file holder parallel to the center

of the chain, Reverse procedure for other side. See

Figure 25.

• Keep all cutters the same length when filing, See Figure

26,

• File enough to remove any damage to cutting edges

(side plate and top plate) of cutter. See Figure 26,

File chain to meet the specifications shown below, See

Figure 27.

Page 19

CUSTOMER RESPONSIBILITIES

1 FULLVIEW I

I SiDE VIEW l

File Holder

tl.--___,_ File

Cu__

FRONT VIEW

.. Figure 23 ........

.,_side

Inside'_

Cutters Same

Figure 24

Holder

Figure 25

Remove Damage

Side Plate

25 °

Figure 26

I

! 85 °

i

GUIDE BAR MAINTENANCE (Fig. 28 & 29)

Conditionswhich requireguide bar maintenance:

• saw cuts to one side or at an angle,

• saw has _o be forced through the cut.

° inadequate supply of oil to the bar and chain..

Check the condition of the guide bar each time the chain is

sharpened. A worn guide bar will damage the chain and

make cutting difficult.

• Move on/stop switch to the "Stop" position.

• Remove bar and chain from saw.

• Clean all saw dust and any other debris from the guide

bar groove and guide bar lubrication hole. Figure 28.

• Lubricate guide bar hole sprocket after each use. Figure

28.

• Burring of bar rails is a normal process of guide bar rail

wear. Remove these burrs by filing guide bar rail side

edges,square,with_flat_ile_ Figure 29.

:-,,..Restore square.:edges_to_,'_.n.uneven.rail top by filing with

• i:a:flat file.Figure 29. :..::,.::.........

Remove Sawdust ...... _'_(

From,Guide Bar Groove_

_t_" --Sprocket Hole

ERAFTiMAN'v

Figure 28

Replace the guide bar when:

• the inside groove of the guide bar rails is worn.

• the guide bar is bent or cracked.

• excess heating or burring of the rails is noted.

If replacement is necessary, use only the replacement

reduced kickback guide bar specified for your saw in the

repair.parts list or as specified on the replacement bar and

chain:decal Iocated_on-/he,:chain saw. _:

Correct

Groove

Worn Grooves File Edges

Square

Figure29

Figure 27

-19-

Page 20

CUSTOMER RESPONSIBILITIES

AFTER USE "

CLEAN UNIT AND LABELS

• Clean the unit using a damp cloth with a mild detergent.

• Wipe off the unit with a clean dry cloth.

EVERY 5 HOURS

CLEAN AIR FILTER (Fig. 30)

A dirty air filter decreases the life and performance of the

engine and increases fuel consumption and harmful emis-

sions.

Always clean your air filter a{ter 15 tanks of fuel or 5 hours

of operation, whichever is less. Clean more frequently in

dusty conditions. A used air filter can never be completely

cleaned. It is advisable to replace your air filter with a new

one after every 50 hours of operation, or annually, which-

ever is less,

* Loosen 3._'scttewson cylinder cover.

Remove _y|inder cover.

"* Remove;&it :filter.

° Clean the air filter using hot soapy water. Rinse with

clean cool water and air dry completely prior to rein-

stalling.

° Lightly oil air filter prior to installing. Use 2-cycle engine

oil or motor oil (SAE 30). Squeeze excess oil from filter.

This will improve the efficiency of the air filter.

° Reinstall air filter.

= Reinstall cylinder cover and 3 screws (15-20 in-lbs.).

Cylinder

Cover

Air Screws

Filter

Cylinder

r

Figure 30

EVERY 25 HOURS

INSPECT MUFFLER AND-SPARK ARRESTOR

SCREEN (IF INSTALLED) (Fig, 31)

As the unit is used, carbon deposits build up on the muffler

and spark arrestor screen (if installed), and must be

removed to avoid creating a fire hazard or affecting engine

performance.

Required cleaning is every 25 hours of operation or annu-

ally, whichever is less.

Replace the spark arrestor screen if breaks occur.

CLEANING THE SPARK ARRESTOR SCREEN

• Loosen and remove the 2 muffler cover screws.

* Remove the muffler cover (cover snaps intomuffler body).

• Remove mufflerdiffuser and spark arrestor screen assem-

bly, Notice the orientation of these parts for reassembly.

• Clean the spark arrestor screen with a wire brush or

replace if breaks are found in the screen.

• Replace any broken or cracked:parts.

, Reinstall diffuserand spark arrestor screen assembly with

round holes facing up and towards muffler cover.

• Reinstall mufflercoverand 2 screws (7-8 ft-lbs),

.____,/Muffler Diffuser/

Spark Arrestor

Screen

t

Figure 31

YEARLY

REPLACE SPARK PLUG (Fig. 32)

The spark plug should be replaced each year to ensure the

engine starts easier and runs better. Spark plug gap

should be .025".

• Loosen 3 screws on cylinder cover.

• Remove cylinder cover.

* Twist, then pull off the spark plug boot.

• Remove spark plug from cylinder and discard.

• Replace with correct spark plug and tighten with a 3/4"

socket wrench (10-12 Ib-ft).

• Reinstall spark plug boot.

• Reinstall cylinder cover and 3 screws (t5-20 in-lb).

Cylinder Cover

Screws

Spark Plug W / \ -'3"/_ Cy'inder

Boot ____._,,,_'_ _over

Figure 32 :

- 20 -

Page 21

CUSTOMER RESPONSIBILITIES

REPLACE FUEL FILTER (Fig. 33, 34 & 35)

The fuel filter should be replaced after each season. Never

operate your saw without a fuel filter. Be careful not to

damage fuel line while removing the fuel filter.

Run fuel tank dry of fuel before proceeding withthis step.

Remove fuel cap and allow it to hang to side'of motor.

Using a small pair of needle nose pliers, grasp fuel cap

retainer, holding it in tank opening and pul! out.

With cap out of tank, use a small section of bent wire

similar to that shoWn in the illustration to catch fuel line

and slowly pull from tank:When fuel filter appears in

opening, grasp with fingers and remove from tank.

Once filter is out of tank, hold fuel line close to fuel filter.

Remove fuel filter by twisting and pulling at the same

time.

Replace fuel filter.

Reverse process for installation.

Fuel Cap

Fill Cap

Pliers

Figure 33

Figure 34

Fuel Line

!

Fuel Filter

Barrel

Filter Neck "_ _) ......

Fuel Filter

Figure 35

-21 -

Page 22

SERVICE AND ADJUSTMENTS

Now proceed to the "Chain Adjustment" section.

CHAIN REPLACEMENT (Fig. 36, 37, 38 & 39)

_ CAUTION: Wear protective gloves when han-

dling chain.The chain is sharp and can cut you

even when it is not moving.

it is normal for a new chain to stretch. Because

of this initial stretch during the first 15-30 i

minutes of operation you should recheck your

chain tension frequently and adjust the chain

tension as required. See chain tension section.

Move on/stop switch to the "Stop" position.

• Replace the old chain when it becomes worn or dam-

aged.

• Use on!y the Low-Kickback replacement chain specified

in the repair parts list or as specified on the replacement

bar and chain decal located on the chain saw.

• See your Sears Service Center to replace and sharpen

..individual cutters for matching your chain.

•,Loosen and re"move the 2 bar clamp nuts.

• Remove I:Jarclamp.

• Remove the old chain.

• .Turn adjusting_,screw by hand counterclockwise until

.adjusting pin just touches the stop.

• Slide guide bar behind clutch drum until guide bar stops

, against clutch drum sprocket.

• Carefully remove new chain from package. Hold chain

with the drive links as shown in Figure 37.

,Piace chain over and behind the clutch.

, Fit bottom of drive links between teeth in sprocket nose.

, Fit chain drive links into top of guide bar. Figure 38.

Bar Clamp

\

Clamp Nuts

Figure 36

• _/Cutte rs _/Depth Gauge

Figure 37

• Pull guide bar forward until chain is snug in guide bar

grooves.

• Now, install bar clamp making sure the adjusting pin is

positioned in the lower hole in the guide bar.

Bar Clamp

Adjusting .--"_

tt Lower Hole

\ Pin .i Guide

Figure 38

• install bar clamp nuts and finger tighten only. Do not

tighten any further at this poinL - 22 -

Nuts

Figure 39

CHAIN ADJUSTMENT (Fig. 40, 41, 42 & 43)

Roll chain around guide bar to ensure kinks do not exist

(rotates freely).

• Assure bar clamp nuts are loosened (finger tight).

• Turn adjusting screw clockwise until chain just barely

touches the bottom of guide bar.

• Roll chain around guide bar to ensure all links are in bar

groove ...... -,_

Bar Clamp Nuts Guide Bar

Figure 40

• Lift up tip of guide bar to check for sag, release tip of

guide bar, then turn adjusting screw 1/4 turn clockwise.

Repeat this step until a sag does not exist.

• While lifting tip of guide bar, tighten bar clamp nuts with

the bar tool (provided). Torque 10-15 ft-lbs.

Adjusting Screw

U4Tum

_, Figure 41

TO CHECK CHAIN TENSION

• Use the screwdriver end of the bar tool to move chain

around the guide bar (Figure 43).

• If chain does not rotate, it is too tight- slightly loosen bar

clamp nuts and turn adjusting screw 1/4 turn counter-

clockwise. Retighten bar clamp nuts.

• If chain is too loose, it will sag below the guide bar

(Figure 42).

_ ..... Sag

Figure 42 :

Page 23

SERVICE AND ADJUSTMENTS

* If chain is too loose, refer to "Chain Adjustment" Loosen

bar clamp nuts; then, turn adjusting screw 1/4 turn clock-

wise. Lift up tip of guide bar to check for sag. Retighten

bar clamp nuts.

Guide Bar

/0---_ Notch

Pu,,o

Starter Rope Jr..__ _ N/Screw

Han_

Pulley _J Putley Ratchet

Bar Clamp Adjusting Bar Figure 45

Nuts Screw Tool • Remove the rope retainer screw and remove any remain-

Figure 43 ing rope.

• Move away from the fueltank and melt the end of the

_TARTER ROPE REPLACEMENT _ ' :'_:: _new:'rope_o_be_nstalled._:Allow the melted end to drop

:Fig, '__:::-_'_,_;:onee..Then;_while_theizopeisstill hot, pull the melted end

44_,45, 46, 47 _&48) _ L _ : _.;;. ;: _.through:a_rag:to_btain:,a smooth pointed end.

A WARNING: ' _-: *Feed rope throughstarter:rope hole in starter housing.

ALWAYS WEAR EYE PROTECTION WHEN| • Guide the rope inside the pulley, then up through the pul-

U SERVICING THE STARTER ROPE. THEJ ley hole. It may be necessary to push the rope through

RECOIL SPRING BENEATH THE PULLEY IS t : with a small Phillips screwdriver inserted into the_small

UNDER TENSION. IF THE SPRING POPS| hole on the underside of the oullev

OUT, SERIOUS INJURY CAN RESULT. I • W_ap rope counterclockwise' around the pulley ratchet

NOTE: A recoil spring lies beneath the pulley and is under

tension, if the recoil spring is disturbed, considerable

time and effort will be required to reinstall. For this rea-

son you may want to let your Sears Service Center handle

this repair. If you try to repair the starter rope and the recoil

spring pops out, take the unit to your Sears Service Center.

Replace a broken starter rope or one that is badly frayed, and tuck'loose end back'under rope, leaving a 1" tail _

between the retainer rib and screw post.

• Pull rope to tighten.

° Install the rope retainer screw and tighten until snug. Do

not over-tighten.

° Rewind all the rope onto the pulley in a clockwise direc-

tion.

Starter

° Remove the four fan housing screws and loosen the two

screws on the cylinder cover.

* Remove fan housingfrom the unit.

n' Cylinder CoverScrews 1

Fan-Housing _"_/_\/, _i,,,,-__ FansH°reUwSing,

I

(Inside Fan Housing)

Figure 44

* To take out rope tension, pull out 10" of rope. While

holding down pulley ratchet with thumb, push several

inches of rope back into fan housing and catch in notch.

Either hold pulley ratchet with thumb errhold starter rope

handle. Retain rope in the notch and slowly allow pulley

to turn counterclockwise until tension is gone.

° Remove the pulley screw in the center of the pulley.

Gently twist and lift pulley while rotating counterclock-

- wise.

Starter

Rope

Hole

__ i Spring

Figure 46

• Twist and push pulley into starter housing.

° Replace and tighten the pulley screw.

Rope Retainer

Figure 47 .

Pulley Screw

- 23 -

Page 24

SERVICE AND ADJUSTMENTS

• Pull out 10" of rope and catch rope in notch in the puttey.

• Carefully turn the pulley two complete turns clockwise,

keeping the rope against the notch to wind the spring.

° White holding the pulley ratchet, pull the excess rope

through the starter rope hole. While holding tension on

the rope, let rope slowly rewind intothe housing.

_ndUp Spring

Rewind for

Tension

• Reinstall fan housing by aligning the fan housing to the

chassis. Then while holding the fan housing against the

chassis, pull the rope handle "out "until you feel the fan

housing drop into place against the chassis. Slowly, let

the rope rewind into starter housing.

• Reinstall the 4 fan housing screws and tighten the 2

cylinder cover screws. Figure 44.

Figure 48

- 24 -

Page 25

SERVICE AND ADJUSTMENTS

CARBURETOR ADJUSTMENTS

Carburetor adjustment is critical and if done improper-

ly can permanently damage the engine aswell as the

carburetor. Please read all instructions and consult the

Trouble Shooting section of this manual before'begin-

ning this process. If the engine does not operate

according to these instructions after repeating the

adjusting steps, do not use the unit. For further assis-

tance, please call our customer assistance hotline at

1-800-235-5878.

CARBURETOR PRESETS (Fig, 49)

If your engine will not start due to,suspected improper car-

buretor adjustment, the following presets may be required.

If used, it is recommended that all steps within the adjust-

ment procedure be completed in order to assure a properly

set carburetor. If presets are not needed, proceed to sec-

tion "Idle Speed Adjustment."

When making adjustments, be careful not to force the plas-

tic Iimiter caps beyond the stops or damage will occur.

WARNING:

THE CHAIN WILL BE MOVING DURING

MOST OF THIS PROCEDURE. WEAR YOUR

PROTECTIVE EQUIPMENT AND OBSERVE

ALL SAFETY PRECAUTIONS.

IN "LOW SPEED MIXTURE ADJUSTMENT;'

RECHECK IDLE SPEED AFTER EACH

ADJUSTMENT. THE CHAIN MUST NOT

MOVE AT IDLE SPEED.

If engine does not start, it may be flooded. If in doubt, read

• the section on flooded engineJn the starting section of,this,

manual prior to beginning any adjustments.

The carburetor has been adjusted at the factory for sea

level conditions. Adjustments may become necessary if the

saw is used at significantly higher altitudes or if you notice

any of the following conditions:

° Chain moves when the engine runs at idle speed. See

"Idle Speed Adjustment."

- Saw will not idte. See "Idle Speed Adjustment" and "Low

Speed Mixture Adjustment."

• Engine dies or hesitates when it should accelerate. See

"Acceleration Adjustment."

• Loss of cutting power which is not corrected by air _ter

cleaning. See "High Speed Mixture Adjustment."

NOTE: There are three adjustments on tl_e carburetor.

• The idle Speed Adjustment is marked with the letter"T:'

• The two remaining adjustments on the carburetor are the

mixture adjustments. One is marked "L" for low speed,

and the other "H" for high speed.

Very small adjustments can affect engine performance. Itis

important to make slight adjustments and test performance

before proceeding. Each adjustment should be no more

than 1/16 of a turn.

• Turn both of the mixture adjustments clockwise until

o_,they stop,,Do;noL.Qvertighten as damage to the needles

wilt occur.

• .Turn beth mixtureadjustments €0unterclockwise one full

turn.

• Turn the idle speed adjustment clockwise until it stops.

Now turn counterclockwise 4-1/2 turns.

• If engine fails to start afterperforming carburetor presets/_ ....

the unit may be flooded. Review the "Difficult Starting"

section of the manual. If problems continue, call the

1-800 number listed on the front cover of this manual for'

further assistance.

° Start the engine and operate for three (3) minutes to

warm up. Go to "Adjusting Procedure."

Idle Speed Adjustment

Low Speed

Mixture

Adj

Figure 49

Higt

Mixture-.

Adjustment

-25 :

Page 26

SERVICE AND ADJUSTMENTS

ADJUSTING PROCEDURE

IDLE SPEED ADJUSTMENT "T"

• Allow the warm engine to idle.

o Adjust the Idle Speed until the engine continues to run

without stalling and without the chain moving.

- Turn clockwise to increase engine speed ff engine

stalls or dies.

- Turn counterclockwise to slow engine down and/or to

keep the chain from turning.

• No further adjustments are necessary if chain does not

move at idle speed and if performance is satisfactory.

i_- LOW SPEED MIXTURE ADJUSTMENT"L"

° Allow engine to idle.

• Turn the Low Speed Mixture Adjustment slowly clock-

wise until the RPM starts to drop. Note the position.

° Turn the Low Speed Mixture Adjustment slowly counter-

clockwise unt_thb' RPM speeds up and starts to drop

again. Note th_ position.

• Set the Low Speed Mixture at the midpointbetween the

two positions_-

HIGH SPEED MIXTURE ADJUSTMENT "H"

IMPORTANT: DO NOT OPERATEoENGINE AT FULL

THROTTLE FOR PROLONGED PERIODS WHILE MAK-