Page 1

Operator's Manual

2.4 cu.in./40cc 2-Cycle

GASOLINE CHAIN SAW

Model No.

358.351810 - 18 in. Bar

• Safety

• Assembly

• Operation

• Maintenance

• Parts List

• Espar_ol, p, 27

CRAFTSMAN°

Read and follow all Safety Rules and Operating

WARNING:

Instructions before first use of this product.

For answers to your questions about this product:

Call 7 am-7 pm, Mon-Sat; Sun, 10 am-7 pm

• 1-800-235-5878 <Hoo,olisted areCentraITime)

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

545186815 Rev. 1 6/15/08 BRW

Page 2

Warranty 2 Storage 20

Safety Rules 2 Troubleshooting Tabie 21

Assembly 6 Emissions Statement 23

Operation 7 Parts List 25

Maintenance 14 Spanish 27

Service and Adjustments 17 Parts & Ordering Back Cover

ONE YEAR FULL WARRANTY ON CRAFTSMAN GAS CHAIN SAW

When used and maintained according to the operator's manual, ifthis product fails

due to a defect in material or workmanship within one year from the date of pur-

chase, return it to any Sears store, Sears Service Center, or other Craftsman outlet in

the United States for free repair (or replacement if repair proves impossibIe).

This warranty excludes the bar, chain, spark plug and air filter, which are expend-

abIe parts that can wear out from normal use in less than one year.

This warranty applies for only 30 days from purchase date ffthis product is used

for commercial or rentat purposes.

This warranty gives you specific legal rights, and you may aIso have other rights

which vary from state to state.

Scare, Roebuck and Co., Hoffman Estates, IL 60179

_k WARNING: Always disconnect

spark plug wire when making repairs ex-

cept for carburetor adjustments. Be-

cause a chain saw is a high-speed

wood-cutting tooI, speciaI precautions

must be observed to reduce the risk of

accidents. Careless or improper use of

this toot can cause serious injury.

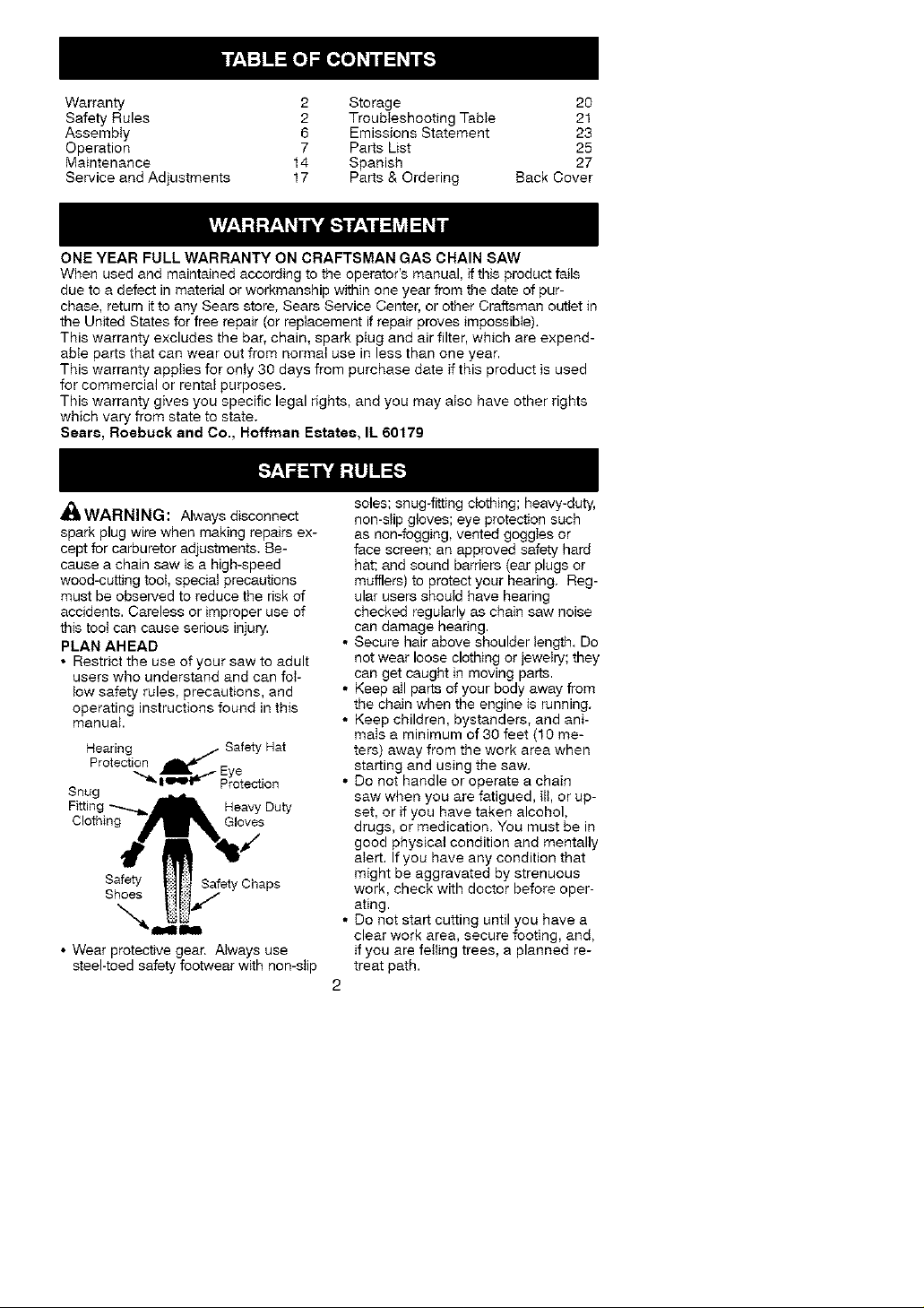

PLAN AHEAD

• Restrict the use of your saw to adult

users who understand and can foi-

tow safety rules, precautions, and

operating instructions found in this

manual.

Hearing Safety Hat

Protection ._ Eye

Snug

""_ I w'tlA_'_ Protection

Fitting _AII, Heavy Duty

Clothing#_'_i_€/Gloves

Safety _-41_[i!_Safety Chaps

• Wear protective gear. Ak,vays use

steel-toed safety footwear with non-slip

soles; snug-fitting clothing; heavy-duty,

non-slip gloves; eye protection such

as non-fogging, vented goggles or

face screen; an approved safety hard

hat; and sound barriers (ear plugs or

mufflers) to protect your hearing. Reg-

ular users should have hearing

checked regularly as chain saw noise

can damage hearing.

• Secure hair above shoulder length. Do

not wear loose clothing or jewelry; they

can get caught in moving parts.

• Keep all parts of your body away from

the chain when the engine is running.

• Keep children, bystanders, and ani-

mals a minimum of 30 feet (10 me-

ters) away from the work area when

starting and using the saw.

• Do not handle or operate a chain

saw when you are fatigued, ill, or up-

set, or if you have taken alcohol,

drugs, or medication. You must be in

good physical condition and mentally

alert. If you have any condition that

might be aggravated by strenuous

work, check with doctor before oper-

ating.

• Do not start cutting until you have a

clear work area, secure footing, and,

if you are felling trees, a planned re-

treat path.

2

Page 3

OPERATEYOURSAWSAFELY

• Donotoperateachainsawwithone

hand.Seriousinjurytotheoperator,

heipers,bystandersoranycombina-

tionofthesepersonsmayresultfrom

one-handedoperation.Achainsaw

isintendedfortwo-handeduse.

• Operatethechainsawonlyinawelt-

ventilatedoutdoorarea.

• Donotoperatesawfromaladderor

inatree.

• Makesurethechainwillnotmake

contactwithanyobjectwhilestarting

theengine.Nevertrytostartthesaw

whentheguidebarisinacut.

• Donotputpressureonthesawat

theendofthecut.Applyingpressure

can cause you to _ose control when

the cut is completed.

• Stop engine before setting saw down.

• Hand carry saw only when engine is

stopped. Carry with muffler away

from body; guide bar & chain project-

ing behind you; guide bar preferably

covered with a scabbard.

• Do not operate a chain saw that is

damaged, improperly adjusted, or

not completely and securely as-

sembled. Atways reptace bar, chain,

hand guard, or chain brake immedi-

ately if it becomes damaged, broken

or is otherwise removed.

MAINTAIN YOUR SAW IN GOOD

WORKING ORDER

,I_ WARNING: Disconnect the

spark plug before performing mainte-

nance except carburetor adjustments.

• Have nil chain saw service performed

by a qualified service dealer with the

exception of the items listed in the

MAINTENANCE section of this manual.

• Make certain the saw chain stops

moving when the throttle trigger is

released. For correction, refer to

CARBURETOR ADJUSTMENT

• Keep the handies dry, clean, and

free from oil or fuet mixture.

• Keep caps and fasteners securely

tightened.

• Nonconforming replacement compo-

nents or the removal of safety devices

may cause damage to the unit and

possible injury to the operator or by-

standers. Use only Craftsman acces-

sories and replacement parts as rec-

ommended. Never modify your saw.

• Maintain chain saw with care.

• Keep unit sharp and clean for better

and safer performance.

• FoItow instructions for lubricating and

changing accessories.

• Check for damaged parts. Before fur-

ther use of the chain saw, a guard or

other part that is damaged should be

carefully checked to determine that it

will operate properly and perform its

intended function. Check for alignment

of moving parts, binding of moving

parts, breakage of parts, mounting and

any other conditions that may affect its

operation. A guard or other part that is

damaged shouM be properly repaired

or replaced by a Sears Service Center

unless otherwise indicated elsewhere

in the operator's manual.

• When not in use, chain saws should

be stored in a dry, high or locked-up

place out of the reach of children.

• When storing saw, use a scabbard or

carrying case.

HANDLE FUEL WITH CAUTION

• Do not smoke while handling fuel or

while operating the saw.

• Eliminate att sources of sparks or

flame in the areas where fuel is

mixed or poured.

• Mix and pour fuel in an outdoor area

and use an approved, marked con-

tainer for all fuet purposes. Wipe up

atl fuel splits before starting saw.

• Move at least 10 feet (3 meters) from

fueling site before starting engine.

• Turn the engine off and let saw cooI

in a non-combustible area, not on

dry leaves, straw, paper, etc. Slowly

remove fuet cap and refuel unit.

• Empty the fuel tank before storing or

transporting the unit. Use up fueI left in

the carburetor by starting the engine

and letting it run until it stops.

• Store the unit and fuel in an area

where fuel vapors cannot reach

sparks or open flames from water

heaters, electric motors or switches,

furnaces, etc.

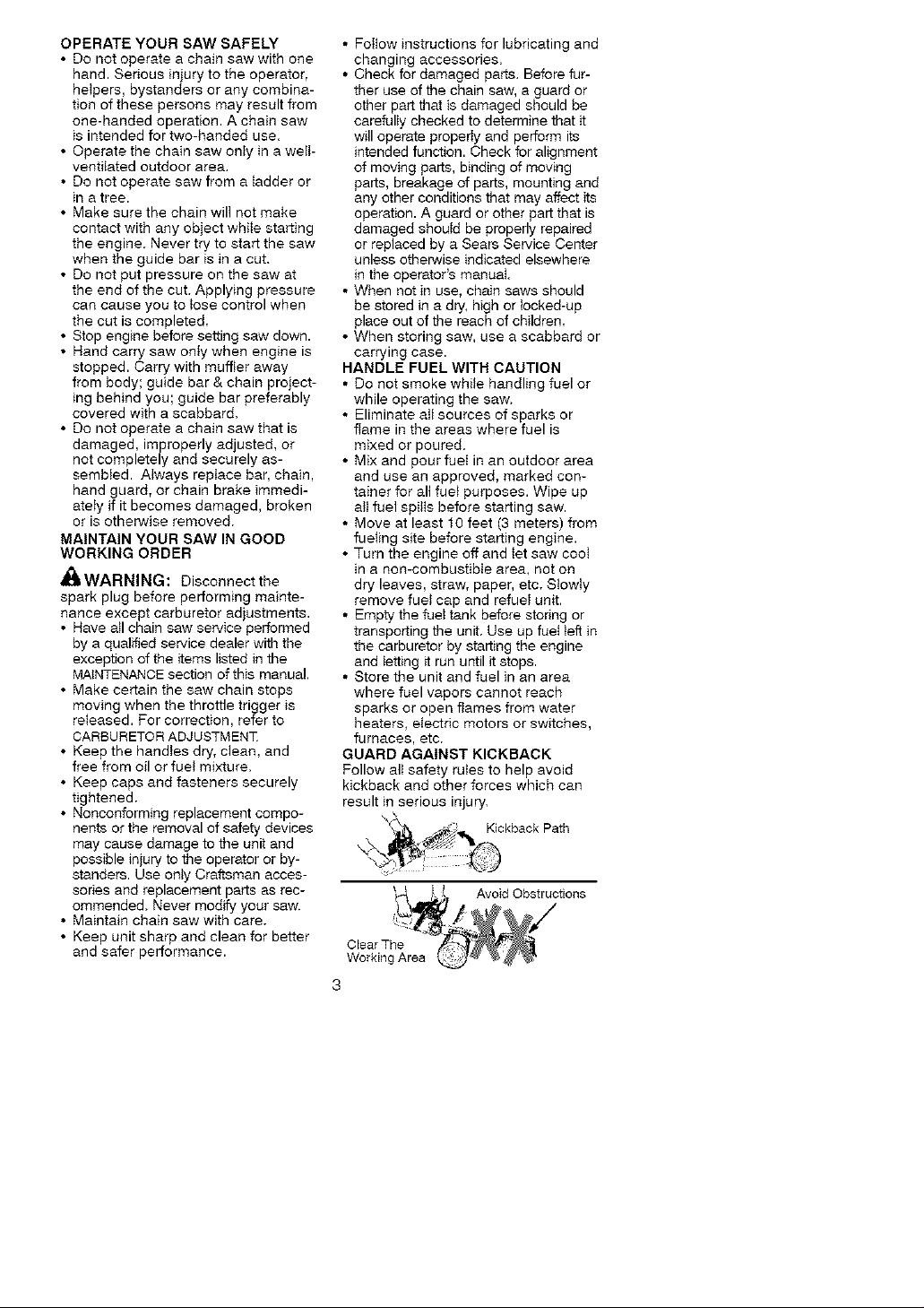

GUARD AGAINST KICKBACK

Follow alI safety ruIes to help avoid

kickback and other forces which can

result in serious injury.

_,_\ _,_ Kickback Path

Avoid Obstructions

Clear The

Working Area

Page 4

_ILWARNING: Avoid kickback

which can resuIt in serious injury.

Kickback is the backward, upward or

sudden forward motion of the guide

bar occurring when the saw chain near

the upper tip of the guide bar contacts

any object such as a log or branch, or

when the wood closes in and pinches

the saw chain in the cut. Contacting a

foreign object in the wood can also re-

suit in loss of chain saw control

• Rotational Kickback can occur

when the moving chain contacts an

object at the upper tip of the guide

bar. This contact can cause the

chain to dig into the object, which

stops the chain for an instant. The

result is a lightning fast, reverse

reaction which kicks the guide bar up

and back toward the operator.

• Pinch-Kickback can occur when the

the wood ctoses in and pinches the

moving saw chain in the cut along

the top of the guide bar and the saw

chain is suddenly stopped. This sud-

den stopping of the chain results in a

reversal of the chain force used to

cut wood and causes the saw to

move in the opposite direction of the

chain rotation. The saw is driven

straight back toward the operator.

• Pull-In can occur when the moving

chain contacts a foreign object in the

wood in the cut along the bottom of

the guide bar and the saw chain is

suddenly stopped. This sudden stop-

ping puils the saw forward and away

from the operator and could easily

cause the operator to lose control of

the saw,

REDUCE THE CHANCE OF

KICKBACK

• Recognize that kickback can hap-

pen. With a basic understanding of

kickback, you can reduce the ele-

ment of surprise which contributes to

accidents.

• Never tet the moving chain contact

any object at the tip of the guide bar.

• Keep the working area free from ob-

structions such as other trees,

branches, rocks, fences, stumps,

etc. Eliminate or avoid any

obstruction that your saw chain couId

hit white you are cutting.

• When cutting a branch, do not let the

guide bar contact branch or other ob-

jects around it.

• Keep saw chain sharp and properly

tensioned, A loose or dull chain can

increase the chance of kickback, Fol-

low manufacturer's chain sharpening

and maintenance instructions. Check

tension at regular intervals, but never

with the engine running. Make sure

the bar nuts are securely tightened.

• Begin and continue cutting at futl

speed. If the chain is moving at a

slower speed, there is greater

chance of kickback occurring.

• Use extreme caution when re-enter-

ing a previous cut,

• Do not attempt cuts starting with the

tip of the bar (plunge cuts),

• Watch for shifting logs or other forces

that could close a cut and pinch or

fail into chain,

• Use the Reduced-Kickback Guide

Bar and Low-Kickback Chain speci-

fied for your saw,

Avoid Pinch-Kickback:

• Be extremely aware of situations or

obstructions that can cause material

to pinch the top of or otherwise stop

the chain.

• Do not cut more than one log at a

time.

• Do not twist the saw as the bar is

withdrawn from an undercut when

bucking.

Avoid Putl-ln:

• Always begin cutting with the engine

at full speed and the saw housing

against wood.

• Use wedges made of ptastic or wood.

Never use metal to ho_d the cut open.

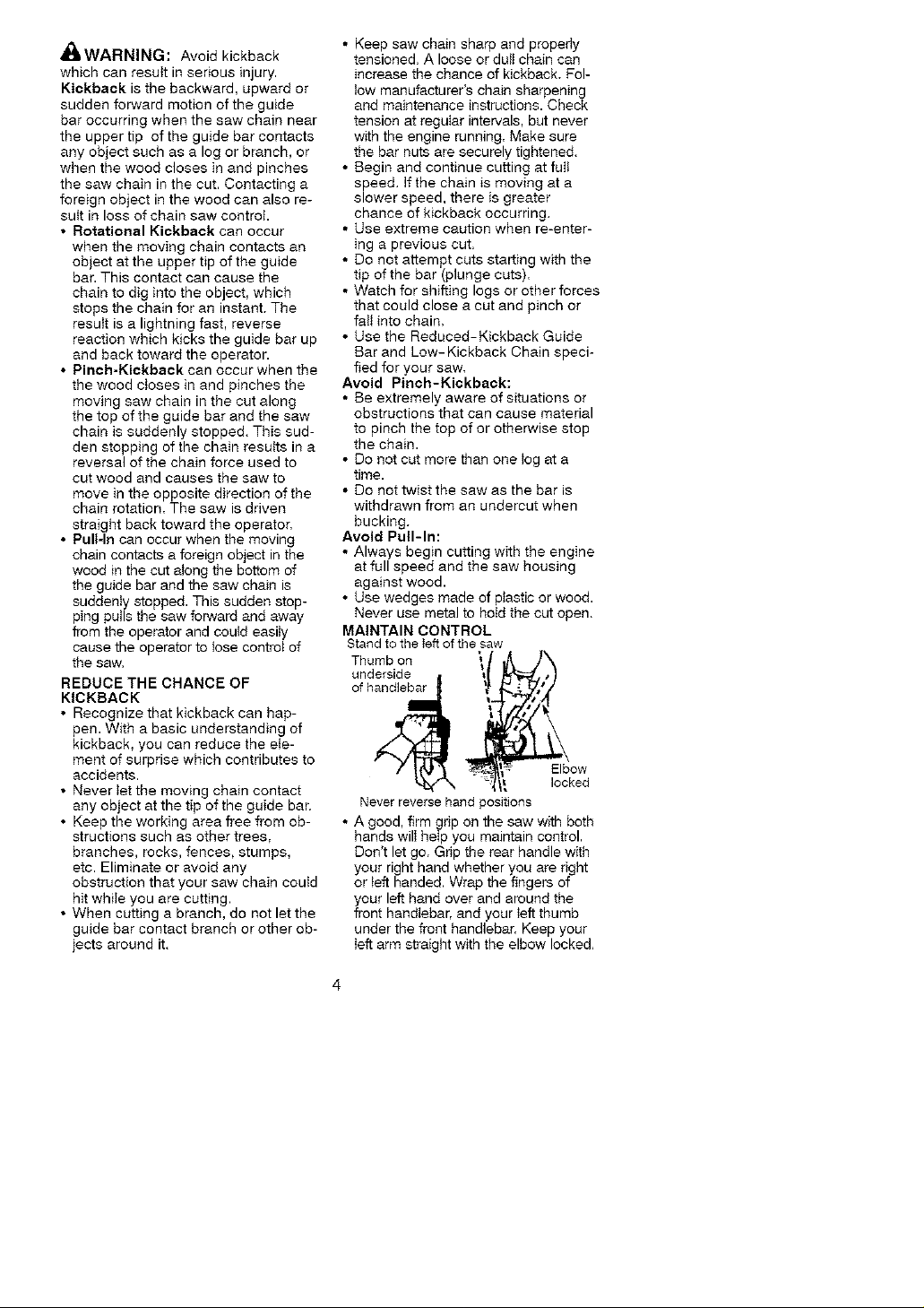

MAINTAIN CONTROL

Stand to the left of the saw

Thumb on

h O,s,de",{

Never reverse hand positions

• A good, firm grip on the saw with both

hands will heIp you maintain control.

Don't let go. Grip the rear handle with

your right hand whether you are right

or left handed. Wrap the fingers of

your left hand over and around the

front handlebar, and your teft thumb

under the front handlebar. Keep your

ieff arm straight with the elbow locked,

Page 5

• Positionyourlefthandonthefront

handtebarsoitisinastraighttine

withyourrighthandontherear

handlewhenmakingbuckingcuts.

Neverreverserightandlefthand

positionsforanytypeofcutting.

• Standwithyourweightevenlybal-

ancedonbothfeet.

• Donotoverreach.Youcouidbe

drawnorthrownoffbalanceandlose

controlofthesaw.

• Donotcutaboveshoulderheight,tt

isdifficuIttomaintaincontrolofsaw

aboveshoulderheight.

KICKBACKSAFETYFEATURES

WARNING:Thefollowingfea-

turesareincludedonyoursawtohelp

reducethehazardofkickback;however,

suchfeatureswitlnottotaityeliminate

thisdanger.Donotretyonlyonsafety

devices.Foltowatlsafetyrulestohetp

avoidkickbackandotherforceswhich

canresultinseriousinjury.

• FrontHandGuard,designedtoreduce

thechanceofyourlefthandcontact-

ingthechainifyourhandslipsoffthe

fronthandlebar.

• Positionoffrontandrearhandlebars,

designedwithdistancebetweenhan-

dlesand"in-line" with each other. The

spread and "in-line" position of the

hands provided by this design work

together to give balance and resis-

tance in controlling the pivot of the

saw back toward the operator if kick-

back occurs.

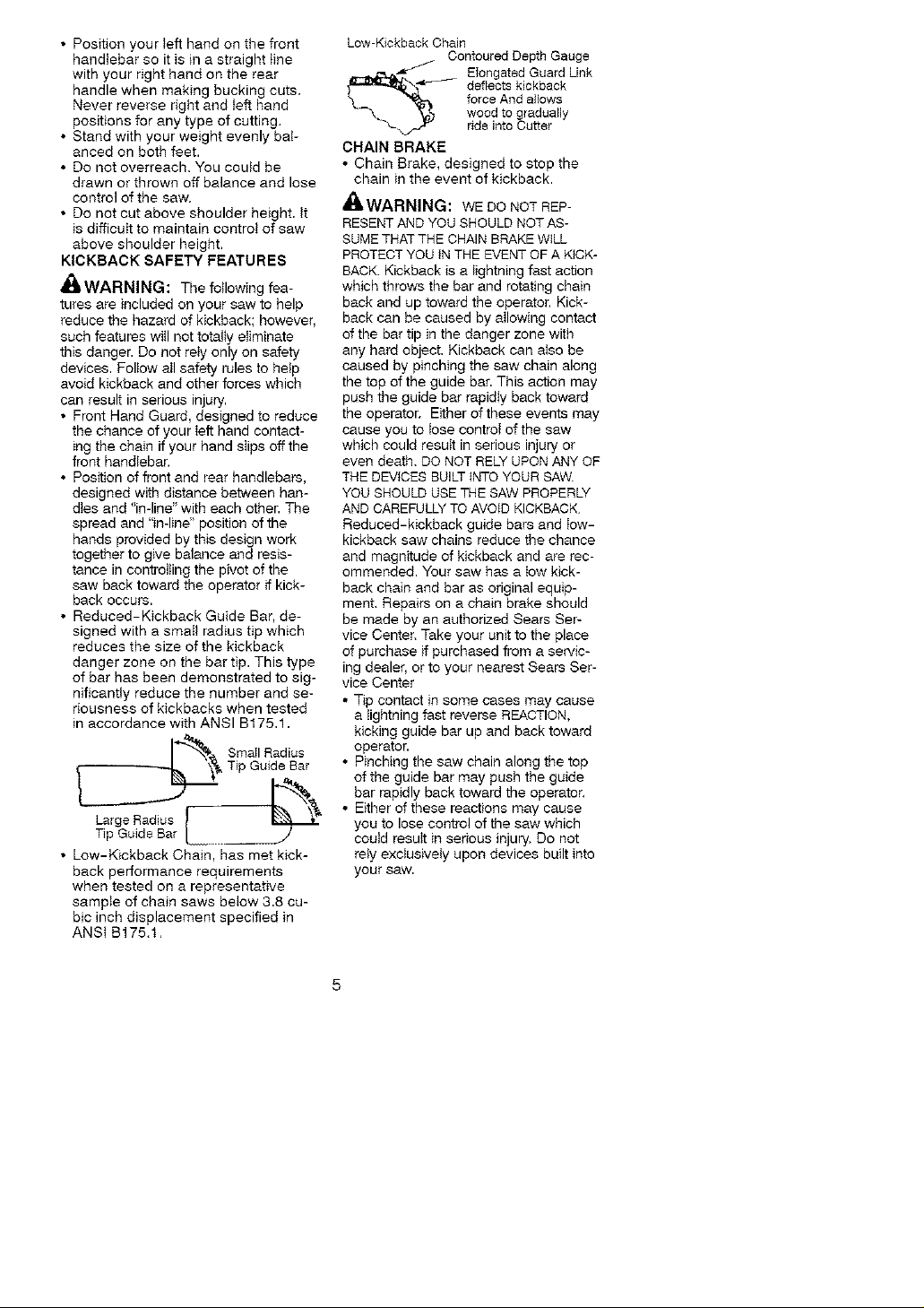

• Reduced-Kickback Guide Bar, de-

signed with a smatl radius tip which

reduces the size of the kickback

danger zone on the bar tip. This type

of bar has been demonstrated to sig-

nificantly reduce the number and se-

riousness of kickbacks when tested

in accordance with ANSI B175.1.

Tip Guide Bar

_& SmaII Radius

Large Radius _ "_

Tip Guide Bar

• Low-Kickback Chain, has met kick-

back performance requirements

when tested on a representative

sampie of chain saws below 3.8 cu-

bic inch displacement specified in

ANSi B175.1.

Low-Kickback Chain

_._ longated Guard Link

CHAIN BRAKE

• Chain Brake, designed to stop the

chain in the event of kickback.

_0&WARNING: WE DO NOT REP-

RESENT AND YOU SHOULD NOT AS-

SUME THAT THE CHAIN BRAKE WILL

PROTECT YOU IN THE EVENT OF A KICK-

BACK Kickback is a lightning fast action

which throws the bar and rotating chain

back and up toward the operator. Kick-

back can be caused by aIIowing contact

of the bar tip in the danger zone with

any hard object. Kickback can also be

caused by pinching the saw chain along

the top of the guide bar. This action may

push the guide bar rapidly back toward

the operator. Either of these events may

cause you to lose control of the saw

which could result in serious injury or

even death. DO NOT RELY UPON ANY OF

THE DEVICES BUILT iNTO YOUR SAW.

YOU SHOULD USE THE SAW PROPERLY

AND CAREFULLY TO AVOID KICKBACK.

Reduced-kickback guide bars and Jow-

kickback saw chains reduce the chance

and magnitude of kickback and are rec-

ommended. Your saw has a tow kick-

back chain and bar as original equip-

ment. Repairs on a chain brake should

be made by an authorized Sears Ser-

vice Center. Take your unit to the place

of purchase if purchased from a servic-

ing dealer, or to your nearest Sears Ser-

vice Center

• Tip contact in some cases may cause

a Iightning fast reverse REACTION,

kicking guide bar up and back toward

operator.

• Pinching the saw chain along the top

of the guide bar may push the guide

bar rapidly back toward the operator.

• Either of these reactions may cause

you to lose control of the saw which

could result in serious injury. Do not

rely exclusively upon devices built into

your SaW.

Contoured Depth Gauge

deflects kickback

force And allows

wood to gradually

ride into Cutter

Page 6

This unit is not equipped with an anti-

vibration system and is intended for

occasional use only.

SAFETY NOTICE: Exposure to vibra-

tions through prolonged use of gasoline

powered hand tools could cause blood

vessel or nerve damage in the fingers,

hands, and joints of people prone to

circulation disorders or abnormal swell-

ings. Prolonged use in cold weather has

been linked to blood vessel damage in

otherwise healthy people. If symptoms

occur such as numbness, pain, loss of

strength, change in skin color or texture,

or toss of feeling in the fingers, hands, or

joints, discontinue tile use of this toot

and seek medical attention. An anti-vi-

bration system does not guarantee the

avoidance of these problems. Users

who operate power tools on a continual

and regular basis must monitor closely

their physical condition and the condition

of this tool.

CHAIN BRAKE: If this saw is to be

used for commercial logging, a chain

brake is required and shall not be re-

moved or otherwise disabled to com-

pty with Federal OSHA Regutations for

Commercial Logging.

SPARK ARRESTING SCREEN: Your

saw is equipped with a temperature

limiting muffler and spark arresting

screen which meets the requirements

of California Codes 4442 and 4443.

All U.S, forest land and the states of

Catifornia, Idaho, Maine, Minnesota,

New Jersey, Oregon, and Washington

require by law that many internal com-

bustion engines to be equipped with a

spark arresting screen. If you operate

a chain saw in a state or locale where

such regulations exist, you are legally

responsible for maintaining the operat-

ing condition of these parts. Failure to

do so is a violation of the law. Refer to

the Customer Responsibilities chart in

the MAINTENANCE section.

STANDARDS: This chain saw is tisted

by Underwriters Laboratories, Inc. in ac-

cordance with American National Stan-

dards for Gasoline-Powered Chain

Saws Safety Requirements (ANSI

B175,1-2000).

£..

,_WARNING: Before using chain

saw_ ensure a_t fasteners are secure,

CARTON CONTENTS

Check carton contents against the fol-

lowing list.

Model 358.351810

• Chain saw (fully assembled)

• 2-cycle engine oil

Examine parts for damage. Do not use

damaged parts.

tf you need assistance or find that parts

are missing or damaged, please calt

1-800-235-5878.

NOTE: It is normal to hear the fueI filter

rattle in an empty fuel tank.

Your unit has been factory tested and

the carburetor precisely adjusted. As a

result you may smell gasoline or find a

drop of oil/fuel residue on the muffler

when you unpack the unit.

ASSEMBLY

Your saw is fully assembIed; no

assembly is necessary.

Page 7

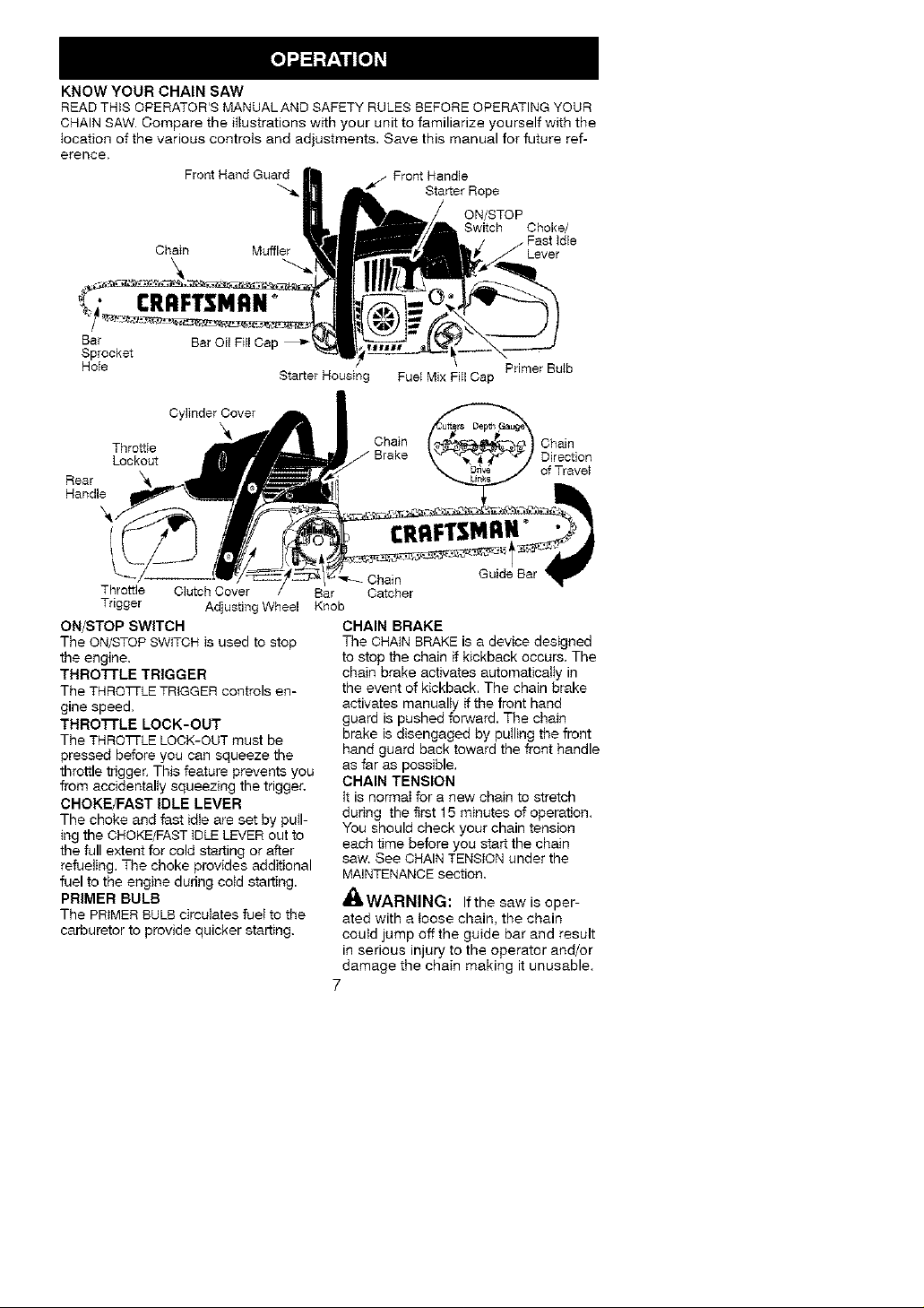

KNOW YOUR CHAIN SAW

READ THIS OPERATOR'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR

CHAIN SAW. Compare the ittustrations with your unit to familiarize yourself with the

location of the various controis and adjustments. Save this manual for future ref-

e_'ence,

Front Hand Guard Front Handle

Starter Rope

ON/STOP

Switch Choke!

Chain Muffler Lever

CRAFTSMAN°

Bar Bar Oil Fill Cap

Sprocket

Hote

Cylinder Cover

Throttle X_ Chain } Chain

Lockout Direction

Starter Housing Fuet Mix FiIICap

Rear

Handle

CRAFTSMAN °

Primer Bulb

of Travel

Throttle Clutch Cover

Trigger Adjusting Wheel

ON/STOP SWITCH

The ON/STOP SWITCH is used to stop

the engine.

THRO'I-rLE TRIGGER

The THROT[LE TRIGGER controls en-

gine speed.

THRO'TrLE LOCK-OUT

The THRO'F[LE LOCK-OUT must be

pressed before you can squeeze the

throttle trigger. This feature prevents you

from accidentally squeezing the trigger.

CHOKE/FAST IDLE LEVER

The choke and fast idle are set by pull-

ing the CHOKE/FAST IDLE LEVER out to

the full extent for cold starting or after

refueling. The choke provides additional

fuel to the engine during cold starting.

PRIMER BULB

The PRIMER BULB circulates fuel to the

carburetor to provide quicker starting.

Guide Bar

Bar Catcher

Knob

CHAIN BRAKE

The CHAIN BRAKE is a device designed

to stop the chain if kickback occurs. The

chain brake activates automatically in

the event of kickback. The chain brake

activates manually if the front hand

guard is pushed forward. The chain

brake is disengaged by pulling the front

hand guard back toward the front handle

as far as possible.

CHAIN TENSION

It is normaI for a new chain to stretch

during the first 15 minutes of operation.

You should check your chain tension

each time before you start the chain

saw, See CHAIN TENSION under the

MAINTENANCE section,

,I_WARNING: Ifthe saw is oper-

ated with a loose chain, the chain

could jump off the guide bar and result

in serious injury to the operator and/or

damage the chain making it unusable.

Page 8

BEFORESTARTINGENGINE

_ll, WARNING: Muffter is very hot

during and after use. Do not touch the

muffIer or allow combustible material

such as dry grass or fuel to do so.

_LWARNING: Be sure to read the

fuel handling information in the safety

rules section of this manual before you

begin, tf you do not understand the

fuel handling information do not at-

tempt to fuel your unit. Seek help from

someone that does understand the in-

formation or can the customer assis-

tance help line at 1-800-235-5878.

GUIDE BAR AND CHAIN OIL

The bar and chain require lubrication.

The chain oiler provides continuous

Iubrication to the chain and guide bar.

Be sure to fiIt the bar oil tank when you

fill the fueI tank (Capacity = 6.8 ft. oz.).

Lack of oil win quickly ruin the bar and

chain. Too little oil will cause overheat-

ing shown by smoke coming from the

chain and/or discoloration of the bar.

For maximum guide bar and chain life,

we recommend you use Craftsman

chain saw bar oil. If Craftsman bar oit

is not available, you may use a good

grade SAE 30 oiI until you are aMe to

obtain Craftsman brand. The oil output

is automatically metered during opera-

tion. Your saw will use approximately

one tank of bar oil for every tank of fuel

mix. Atways fill the bar oil tank when

you fill the fuet tank.

FUELING ENGINE

_WARNING: Remove fuel cap

slowly when refueling.

This engine is certified to operate on

unteaded gasoline. Before operation,

gasotine must be mixed with a good

quatity synthetic 2-cycIe air-cooIed en-

gine oil. We recommend Craftsman

brand synthetic oil. Mix gasoline and

oit at a ratio of 40:1. A 40:1 ratio is ob-

tained by mixing 3.2 ounces of oil with

1 gailon of unleaded gasoline. Included

with this saw is a 3.2 ounce container of

oil Pour the entire contents of this con-

tainer into 1 gallon of gasoline to

achieve the proper fuel mixture.

DO NOT USE automotive or boat oil

These oils wiit cause engine damage.

When mixing fuel fottow the instruc-

tions printed on the oil container. Once

oil is added to the gasoline, shake

container momentarily to assure that

the fuet is thoroughly mixed. Always

read and follow the safety rules relat-

ing to fueI before fueling your unit.

IMPORTANT

Experience indicates that alcohol-

blended fueis (called gasohol or using

ethanot or methanol) can attract mois-

ture which leads to separation and

formation of acids during storage. Acidic

gas can damage the fuel system of an

engine while in storage. To avoid engine

problems, the fuel system should be

emptied before storage for 30 days or

longer. Drain the gas tank, start the en-

gine and let it run until the fuel lines and

carburetor are empty. Use fresh fuel

next season. Never use engine or car-

buretor cteaner products in the fuel tank

or permanent damage may occur,

See the STORAGE section for additionai

information

CHAIN BRAKE

Ensure chain brake is disengaged by

pulling the front hand guard back toward

the front handle as far as possible. The

chain brake must be disengaged before

cutting with the saw.

_ WARNING: The chain must not

move when the engine runs at idle

speed. If the chain moves at idle

speed refer to CARBURETOR ADJUST-

MENT within this manual. Avoid contact

with the muffler. A hot muffler can

cause serious burns.

STOPPING YOUR ENGINE

• Release the throttle trigger.

• Move ON/STOP switch to the STOP

position.

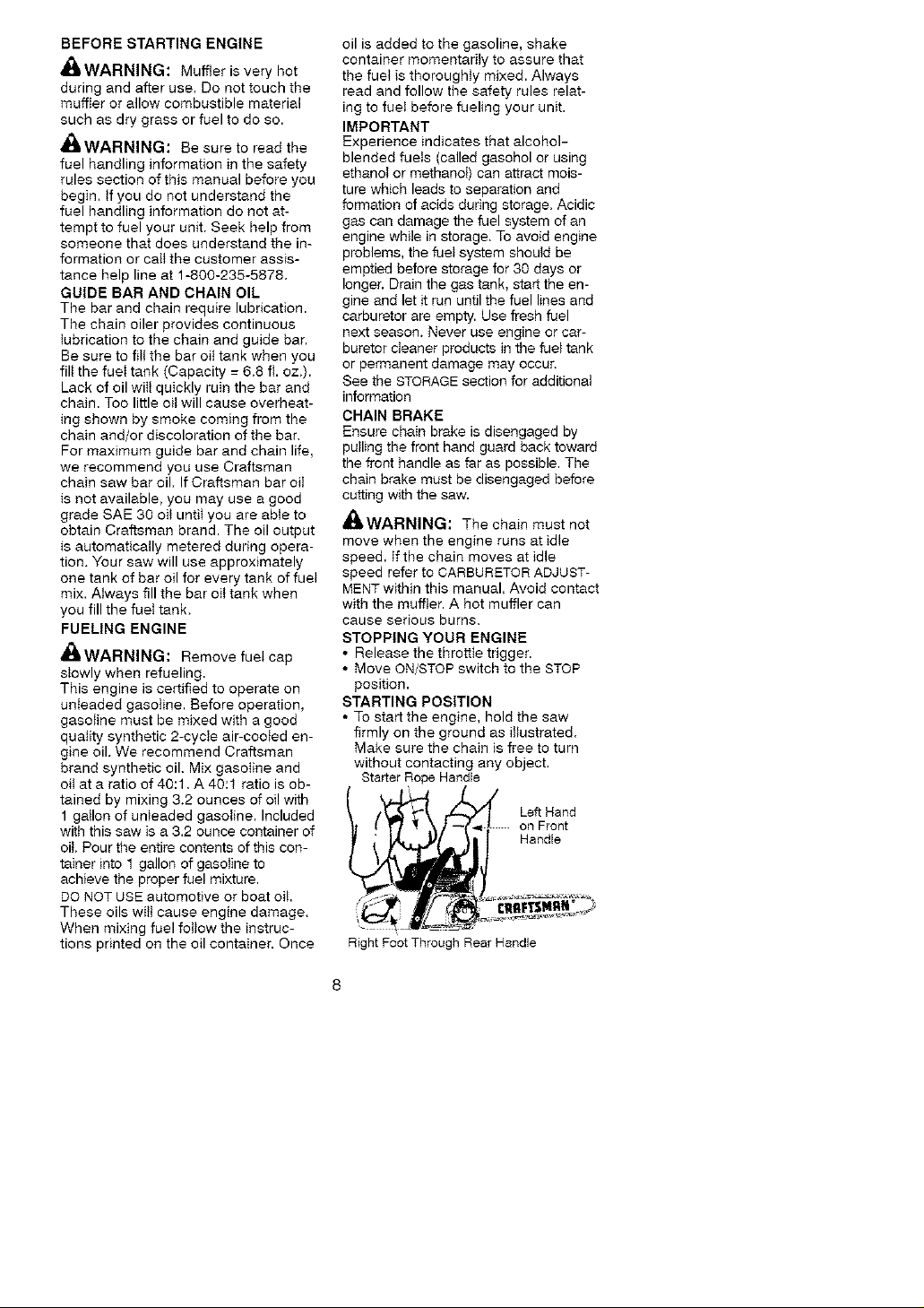

STARTING POSITION

• To start the engine, hold the saw

firmly on the ground as iitustrated.

Make sure the chain is free to turn

without contacting any object.

Starter Rope Handle

Left Hand

on Front

Handle

Right Foot Through Rear Handle

Page 9

_ILWARNING: Do not attempt to

throw or drop-start the chain saw,

Doing so witt put the operator at risk of

serious injury due to loss of controI of

the chain saw.

IMPORTANT POINTS TO REMEMBER

When puIIing the starter rope, do not

use the full extent of the rope as this

can cause the rope to break. Do not let

starter rope snap back. HoM the han-

dle and let the rope rewind stowty.

For cold weather starting, start the unit

at FULL CHOKE; allow the engine to

warm up before squeezing the throttle

trigger.

NOTE: Do not attempt to cut material

with the choke/fast idle lever in the FULL

CHOKE position.

STARTING A COLD ENGINE (or warm

engine after running out of fuel)

NOTE: tn the following steps, when the

choke/fast idle lever is pulled out to the

fult extent, the correct throttte setting for

starting is set automatically,

IGNITION

SWITCH

ON

Lever

1. Move ON/STOP switch to the ON

position.

2. Pult choke/fast idle lever out to the

full extent (to the FULL CHOKE posi-

tion).

3. Slowly press primer bulb 6 times.

4. Putt the starter rope sharply 5 times

with your right hand. Then, pro-

ceed to the next step.

NOTE: Ifthe engine sounds as if it is try-

ing to start before the 5th pull, stop pull-

ing and immediately proceed to the next

step.

5. Push the choke/fast idle lever in to

the HALF CHOKE position.

CHOKE/FAST IDLE LEVER

oil iFHALF

ITm . / FULL

6. Putt the starter rope sharply with

your right hand until the engine

starts.

7, Allow the engine to run for approxi-

mately 30 seconds. Then, squeeze

and release the throttle trigger to

allow engine to return to idle

speed.

STARTING A WARM ENGINE

1. Move ON/STOP switch to the ON

position.

2. Putt the choke/fast idle lever out to

the FULL CHOKE position to set the

fast idle, then push the lever in to

the HALF CHOKE position.

3. Stowly press primer bulb 6 times.

4. Putt the starter rope sharply with

your right hand untit the engine

starts.

5. Squeeze and release throttle trigger

to allow engine to return to idle

speed.

DIFFICULT STARTING (or 8tatting a

flooded engine)

The engine may be flooded with too

much fuet if it has not started after 10

pulls.

Flooded engines can be cleared of ex-

cess fuel by pushing the choke/fast

idle lever in completeIy (to the OFF

CHOKE position) and then following the

warm engine starting procedure listed

above. Ensure the ON/STOP switch is

in the ON position,

Starting could require pulling the start-

er rope handle many times depending

on how badly the unit is flooded, If en-

gine fails to start, refer to the TROU-

BLESHOOTING TABLE or call

1-800-235-5878.

Page 10

CHAINBRAKE

_b'WARNING: If the brake band is

worn too thin it may break when the

chain brake is triggered. With a broken

brake band, the chain brake will not

stop the chain. The chain brake must

be replaced if any part is worn to tess

than 0.020" (0.5 ram) thick. Repairs on

a chain brake should be made by your

Sears Service Center. Take your unit

to the piace of purchase or to the near-

est Sears Service Center.

• This saw is equipped with a chain

brake. The brake is designed to stop

the chain if kickback occurs.

• The inertia-activated chain brake is

activated if the front hand guard is

pushed forward, either manually (by

hand) or automatically (by sudden

movement).

• Ifthe brake is already activated, it is

disengaged by puiting the front hand

guard back toward the front handle

as far as possible.

• When cutting with the saw, the chain

brake must be disengaged.

Braking function control

CAUTION: The chain brake must be

checked several times daily. The en-

gine must be running when performing

this procedure. This is the onIy

instance when the saw shouid be

placed on the ground with the engine

running.

Place the saw on firm ground. Grip the

rear handle with your right hand and

the front handle with your left hand.

Apply futt throttle by fully depressing

the throttle trigger. Activate the chain

brake by turning your left wrist against

the hand guard without releasing your

grip around the front handle. The chain

shoutd stop immediately.

Inertia activating function control

_kWARNING: When performing

the foitowing procedure, the engine

must be turned off.

Grip the rear handte with your right hand

and the front handle with your teft hand.

Hotd the chain saw approximately 14

inches (35 cm) above a stump or other

wooden surface. Reiease your grip on

the front handle and use the weight of

the saw to let the top of the guide bar

fall forward and contact the stump.

When the tip of the bar hits the stump,

the brake should activate.

OPERATING TIPS

• Check chain tension before first use

and after 1 minute of operation, and

each time before you start the chain

saw. See CHAIN TENSION in the

MAINTENANCE section.

• Cut wood only. Do not cut metaI, plas-

tics, masonry, non-wood building ma-

terials, etc.

• Stop the saw if the chain strikes a

foreign object. Inspect the saw and

repair or replace parts as necessary.

If the chain jumps off the guide bar,

inspect the chain for damaged drive

links before reinstalling. Burrs on

drive links, which prevent them from

entering the groove of the guide bar,

can be removed with a flat rite.

• Keep the chain out of dirt and sand.

Even a smaII amount of dirt will dull a

chain, increase the possibility of kick-

back, and require chain sharpening or

replacement.

• Practice cutting a few small logs us-

ing the following techniques to get

the "feeF of using your saw before

you begin a major sawing operation.

• Squeeze the throttIe trigger and allow

the engine to reach full speed before

cutting.

• Begin cutting with the saw frame

against the log.

• Keep the engine at full speed the

entire time you are cutting.

• Altow the chain to cut for you. Exert

onty light downward pressure, tf

you force the cut, damage to the

bar, chain, or engine can result.

• Release the throttle trigger as soon

as the cut is completed, allowing

the engine to idle. Ifyou run the saw

at full throttle without a cutting toad,

unnecessary wear can occur to the

chain, bar, and engine. To maxi-

mize operating efficiency, do not

run the engine for longer than 30

_econd_ at a time at full throttle.

• To avoid losing control when cut is

complete, do not put pressure on

saw at end of cut.

• Stop the engine before setting the

saw down after cutting.

10

Page 11

TREE FELLING TECHNIQUES

_II, WARNING: Check for broken or

dead branches which can fall while cut-

ting causing serious injury. Do not cut

near buildings or electrical wires if you

do not know the direction of tree falt, nor

cut at night since you will not be aIe to

see well, nor during bad weather such

as rain, snow, or strong winds, etc. tf

the tree makes contact with any utility

Iine, the utility company should be noti-

fied immediately.

•Carefuily plan your sawing operation

in advance.

• Ctear the work area. You need a ciear

area nil around the tree so you can

have secure footing.

• The chain saw operator shoutd keep

on the uphill side of the terrain as the

tree is likely to roll or slide downhill

after it is felled.

• Study the natural conditions that can

cause the tree to fall in a particular di-

rection.

Natural conditions that can cause a tree

to fail in a particular direction include:

• The wind direction and speed.

• The lean of the tree. The tean of a

tree might not be apparent due to un-

even or sloping terrain. Use a piumb

or level to determine the direction of

tree lean.

• Weight and branches on one side.

• Surrounding trees and obstactes.

Look for decay and rot. If the trunk is

rotted, it can snap and fall toward the

operator. Check for broken or dead

branches which can fall on you while

cutting. Make sure there is enough

room for the tree to fail Maintain a dis-

tance of 2 _/2tree lengths from the near-

est person or other objects. Engine

noise can drown out a warning call.

Remove dirt, stones, loose bark, naiis,

staples, and wire from the tree where

cuts are to be made.

Plan a ctear retreat path to the rear

and diagonal to the line of fail

FELLING LARGE TREES

(6 inches (15 cm) in diameter or larger)

The notch method is used to fell large

trees. A notch is cut on the side of the

tree in the desired direction of fall. After

a felling cut is made on the opposite

side of tree, the tree wiII tend to fail into

the notch.

NOTE: If the tree has large buttress

roots, remove them before making the

notch. If using saw to remove buttress

roots, keep saw chain from contacting

ground to prevent dulling of the chain.

NOTCH CUT AND FELLING THE

TREE

• Make notch cut by cutting the top of

the notch first. Cut through 1/3of the

diameter of the tree. Next compiete

the notch by cutting the bottom of the

notch. See iiiustration. Once the

notch is cut remove the notch of

wood from the tree.

Final (felting) cut here, 2 inches

(5 cm) above center of notch

i' _.j..

Notch _ _t =

• After removing the wood from the

notch, make the felling cut on the op-

posite side of the notch. This is done

by making a cut about two inches (5

cm) higher than the center of the

notch. This witt leave enough uncut

wood between the felling cut and the

notch to form a hinge. This hinge wili

help prevent the tree from faliing in the

wrong direction.

Hinge holds tree on stump and helps

control fall

Opening

of felling

_ Plan a clear retreat path

"_ -- =O "_ - Direction of Fal_

Closing of

notch

NOTE: Before felling cut is complete,

use wedges to open the cut if necessary

to control the direction of fall. To avoid

11

Page 12

kickback and chain damage, use wood

or p}astic wedges, but never steel or iron

wedges.

• Be alert to signs that the tree is

ready to fail: cracking sounds, widen-

ing of the feI}ing cut, or movement in

the upper branches.

• As tree starts to fall stop saw, put it

down, and get away quickly on your

ptanned retreat path.

• DO NOT cut down a partially fatten tree

with your saw. Be extremely cautious

with partially fallen trees that may be

poody supported. When a tree doesn't

falI comptetely, set the saw aside and

pul} down the tree with a cable winch,

bIock and tackle, or tractor.

CUTTING A FALLEN TREE

(BUCKING)

Bucking is the term used for cutting a

fallen tree to the desired tog size.

dab WARNING: Do not stand on the

tog being cut. Any portion can rott

causing toss of footing and control, Do

not stand downhill of the log being cut.

IMPORTANT POINTS

• Cut on}y one tog at a time.

• Cut shattered wood very carefully;

sharp pieces of wood could be f_ung

toward operator.

• Use a sawhorse to cut small logs.

Never allow another person to hold

the Iog white cutting and never hold

the Iog with your teg or foot.

• Do not cut in an area where _ogs,

timbs, and roots are tangled such as

in a blown down area. Drag the togs

into a ctear area before cutting by

putHng out exposed and cIeared togs

first.

TYPES OF CUTTING USED FOR

BUCKING

_WARNING: If saw becomes

pinched or hung in a log, don't try to

force it out. You can tose control of the

saw resulting in injury and/or damage

to the saw. Stop the saw, drive a

wedge of plastic or wood into the cut

until the saw can be removed easily.

Restart the saw and carefully reenter

the cut. To avoid kickback and chain

damage, do not use a metal wedge.

Do not attempt to restart your saw

when it is pinched or hung in a log.

Use a wedge to remove pinched saw

Turn saw OFF and use a plastic or

wooden wedge to force cut open.

Overcutting begins on the top side of

the log with the bottom of the saw

against the _og. When overcutting use

light downward pressure,

6%

Undercutting:

Undercutting involves cutting on the

underside of the log with top of saw

against the _og. When undercutting

use light upward pressure. Hotd saw

firmty and maintain control. The saw

wiI_tend to push back toward you.

A_ILWARNING: Never turn saw up-

side down to undercut. The saw can-

not be controlled in this position.

Always make your first cut on the com-

pression side ofthe Iog. The compres-

sion side of the tog is where the pres-

sure of the log's weight is

concentrated.

_rst cut On compression side of log

Second cut

First cut on compression side of log

BUCKING WITHOUT A SUPPORT

• Overcut through 1/3of the diameter

of the log.

• Roll the Iog over and finish with a

second overcut.

• Watch for togs with a compression

side to prevent the saw from pinch-

ing. See ittustrations for cutting togs

with a compression side.

BUCKING USING A LOG OR

SUPPORT STAND

• Remember your first cut is a_ways on

the compression side of the log.

(Refer to the illustrations below for

your first and second cut)

Second cut

12

Page 13

• Your first cut should extend 1/3 of the

diameter of the log.

• Finish with your second cut.

Using a log for support

f/1 stCut

Using a support stand

2nd Cut X

L

LIMBING AND PRUNING

_IIWARNING: Be alert for and

guard against kickback. Do not allow the

moving chain to contact any other

branches or objects at the nose of the

guide bar when limbing or pruning. Al-

lowing such contact can resutt in serious

injury.

_iI_WARNING: Never climb into a

tree to limb or prune. Do not stand on

ladders, platforms, a log, or in any posi-

tion which can cause you to lose your

balance or control of the saw.

IMPORTANT POINTS

• Work slowly, keeping both hands firmty

gripped on the saw. Maintain secure

footing and balance.

• Watch out for springpotes, SpringpoIes

are smalt size limbs which can catch

the saw chain and whip toward you or

pull you off balance. Use extreme cau-

tion when cutting small size limbs or

slender material,

• Be alert for springback. Watch out for

branches that are bent or under

pressure, Avoid being struck by the

branch or the saw when the tension

in the wood fibers is released.

• Keep a clear work area. Frequently

clear branches out of the way to avoid

tripping over them.

LIMBING

• Always timb a tree after it is cut

down. OnIy then can limbing be done

safely and properly.

• Leave the larger limbs underneath the

fetted tree to support the tree as you

work.

• Start at the base of the foiled tree and

work toward the top, cutting branches

and limbs. Remove smaII limbs with

one cut.

• Keep the tree between you and the

chain. Cut from the side of the tree op-

posite the branch you are cutting.

• Remove larger, supporting branches

with the cutting techniques described

in BUCKING WITHOUT A SUPPORT.

• Always use an overcut to cut smalI

and freety hanging limbs. Undercutting

could cause limbs to fail and pinch the

SaW.

PRUNING

_I'WARNING: Limit pruning to limbs

shoulder height or below. Do not cut if

branches are higher than your shoulder,

Get a professional to do the job.

• Make your first cut 1/3of the way

through the bottom of the limb.

• Next make a 2nd cut all the way

through the limb. Then cut a third

overcut leaving a 1 to 2 inch (2,5 to 5

cm) collar from the truck of the tree,

I • ,_r_ _ •

,I sooondout"//

Third ctt_/

Co,,ar _ V_,.__ First cut

/ Pruning technique

13

Page 14

CUSTOMER RESPONSIBILITIES

_WARNING: Disconnect the spark plug before performing maintenance

except for carburetor adjustments.

Filt in dates as you complete Before After Ever Every Service

regular service Use Use 5 hrs 25 hrs. Yeady Dates

Check for damaged/worn parts .,I

Check for loose fasteners/parts

Check chain tension i_"

Check chain sharpness _'

Check guide bar _'

Check fuel mixture leveI _'

Check guide bar and chain oit _'_

Inspect and ctean unit &decaIs _"

Check chain brake /I

CIean guide bar groove

Clean air filter /-"

C_ean/inspect muffler and spark

arresting screen _'_

Replace spark plug and fueI filter _-

GENERAL RECOMMENDATIONS

The warranty on this unit does not cov-

er items that have been subjected to

operator abuse or negligence. To re-

ceive futt vatue from the warranty, the

operator must maintain unit as

instructed in this manual, Various ad-

justments wilt need to be made period-

icaHy to propedy maintain your unit.

• Once a year, replace the spark plug,

air filter, and check guide bar and

chain for wear. A new spark plug and

air fitter assures proper air-fue_ mixture

and helps your engine run better and

last _onger.

CHECK FOR DAMAGED OR

WORN PARTS

Contact your Sears Service Center for

reptacement of damaged or worn parts.

NOTE: It is norma_ for a smalt amount of

oiI to appear under the saw after engine

stops. Do not confuse this with a leaking

oit tank.

• ON/STOP Sw_tch - Ensure ON/STOP

switch functions properly by moving

the switch to the STOP position. Make

sure engine stops; then restart engine

and continue.

• Fuet Tank - Do not use saw if fuel

tank shows signs of damage or leaks.

• Oil Tank - Do not use saw if oil tank

shows signs of damage or leaks.

CHECK FOR LOOSE

FASTENERS AND PARTS

• Bar Knob

• Chain

• Muffler

• Cylinder Shield

• Air Fitter

• Handle Screws

• Vibration Mounts

• Starter Housing

• Front Hand Guard

CHECK CHAIN TENSION

_WARNING: Wear protective

gloves when handling chain. The chain

is sharp and can cut you even when it is

not moving.

Chain tension is very important, Chains

stretch during use. This is especiatty true

during the first few times you use your

saw. A}ways check chain tension each

time before you start the chain saw.

1. Use a screwdriver to move chain

around guide bar to ensure kinks

do not exist. The chain should ro-

tate freeSy.

14

Page 15

Guide

Ear

_ J

Screwdriver

Adjusting Wheel Knob

2. Lift lever on bar knob and turn

counterclockwise 1 turn to loosen

bar clamp.

CRAF

LOOSEN

3. Turn adjusting wheel (downward

direction) to tension chain until

chain solidly contacts bottom of

guide bar rail. Lift tip of guide bar

while adjusting tension.

Tighten Loosen

chain chain

Adjusting Wheel

4. Using a screwdriver, move chain

around guide bar to ensure all links

are in bar groove.

5. White lifting tip of guide bar, tighten

bar knob securely (clockwise).

Hand tighten onlyt

TIGHTEN

6. Push lever on bar knob down to re-

turn lever to closed/locked position.

_WARNING: Failure to push lever

on bar knob down to closed/locked

position could result in serious person-

al injury or damage to your chain saw.

7. Use a screwdriver to move chain

around guide bar.

8. If chain does not rotate, it is too

tight. Loosen bar knob 1 turn

tcounterctockwise); then, loosen

chain by turning the ad usting

wheel 1/4.turn (upward direction).

Retighten bar knob.

9. If chain is too loose, it will sag be-

low the guide bar. DO NOT operate

the saw if the chain is loose.

NOTE: The chain is tensioned correctly

when the weight of the chain does not

cause itto sag below the guide bar

twith the chain saw sitting in an upright

position), but the chain still moves freely

around the guide bar.

_WARNING: If the saw is operated

with a loose chain, the chain could jump

off the guide bar and result in serious

injury to the operator and/or damage the

chain making it unusable. If the chain

jumps off the guide bar, inspect each

drive link for damage. Damaged chain

must be repaired or replaced.

CHECK CHAIN SHARPNESS

A sharp chain makes wood chips. A dull

chain makes a sawdust powder and

cuts slowly. See CHAIN SHARPENING.

CHECK GUIDE BAR

Conditions which require guide bar

maintenance:

• Saw cuts to one side or at an angle.

• Saw has to be forced through the cut.

• Inadequate supply of oil to bar/chain.

Check the condition of guide bar each

time chain is sharpened. A worn guide

bar will damage the chain and make

cutting difficult.

15

Page 16

Aftereachuse,ensureON/STOP

switchisintheSTOPposition,then

cleanallsawdustfromtheguidebar

andsprockethole.

Tomaintainguidebar:

• MoveON/STOPswitchtoSTOR

• Loosenandremovebarnutsand

clutchcover.Removebarandchain

fromsaw.

• Cleantheoilholesandbargroove

aftereach5hoursofoperation.

• Burringofguidebarrailsisanormat

processofrailwear.Removethese

burrswithafiatfile.

• Whenrailtopisuneven,useaflat

filetorestoresquareedgesand

sides.

and Sides

rT_ File Rail Edges _ _]__

Worn Groove Correct Groove

Replace guide bar when the groove is

worn, the guide bar is bent or cracked,

or when excess heating or burring of the

rails occurs, tf replacement is necessary.

use only the guide bar specified for your

saw in the repair parts list or on the de-

cal located on the chain saw.

CHECK FUEL MIXTURE LEVEL

• See FUELING ENGINE under the OP-

ERATION section.

LUBRICATION

Square

CHECK CHAIN BRAKE

See CHAIN BRAKE in the OPERATION

section.

CLEAN AIR FILTER

CAUTION: Do not clean filter in gaso-

line or other flammable solvent to

avoid creating a fire hazard or produc-

ing harmful evaporative emissions.

Cleaning the air filter:

A dirty air filter decreases the life and

performance of the engine and in-

creases fuel consumption and harmful

emissions. Always clean your air filter

after 10 tanks of fuel or 5 hours of op-

eration, whichever comes first. Clean

more frequently in dusty conditions. A

used air filter can never be completely

cleaned, tt is advisable to replace your

air filter with a new one after every 50

hours of operation, or annually, which-

ever comes first.

1. Loosen 3 screws on cylinder cover.

2. Remove cylinder cover.

3. Remove air filter cover and air filter.

4. Clean the air filter using hot soapy

water. Rinse with clean cool water.

Air dry completely before reinstal-

ling.

5. ReinstaII air fitter and air fitter cov-

er.

6. Reinstall cytinder cover and 3

screws. Tighten securely.

Air Filter Cover

Cover

CyIinder

• See GUIDE BAR AND CHAIN OIL un-

der the OPERATION section.

INSPECT AND CLEAN UNIT AND

DECALS

• After each use, inspect compIete unit

for loose or damaged parts. Clean the

unit and decals using a damp cloth

with a mild detergent.

• Wipe off unit with a clean dry cloth.

INSPECT MUFFLER AND SPARK

ARRESTING SCREEN

_WARNING: The muffler on this

product contains chemicats known to

the State of California to cause cancer.

As the unit is used, carbon deposits

build up on the muffler and spark ar-

resting screen, and must be removed

to avoid creating a fire hazard or af-

fecting engine performance.

16

Page 17

Replace the spark arresting screen if

breaks occur.

Spark Exhaust

Arresting Outlet

Screen Cover

z

Nut

Muffler

CLEANING THE SPARK ARREST-

ING SCREEN

Cleaning is required every 25 hours of

operation or annually, whichever

comes first.

1. Loosen and remove the nut from

the exhaust outlet cover.

2. Remove the exhaust oulet cover.

3. Remove spark arresting screen.

Handle screen carefuIty to prevent

damage.

4. Clean the spark arresting screen

gently with a wire brush. Replace

screen if breaks are found.

5. Replace any broken or cracked

muffler parts,

6. Reinstall spark arresting screen, ex-

haust outlet cover, and nut. Tighten

nut securely.

REPLACE SPARK PLUG

The spark plug should be replaced

each year to ensure the engine starts

easier and runs better. Ignition timing

is fixed and nonadjustable.

1. Loosen 3 screws on cylinder cover.

2. Remove the cylinder cover.

3. Pull offthe spark plug boot.

4. Remove spark plug from cylinder

and discard.

5. Replace with Champion RCJ-7Y

spark plug and tighten securely

with a 3/4 inch (19 mm) socket

wrench, Spark plug gap should be

0,025 inch (0,6 mm),

6, Reinstall the spark plug boot.

7, Reinstall the cylinder cover and 3

screws. Tighten securely,

Cy}inder

Cover

Spark

Plug Boot

Spark

Plug

REPLACE FUEL FILTER

To replace fuel filter, drain your unit by

running it dry of fuel. Remove fuel cap

and its connected retainer from tank.

Puit filter from tank and remove from

line. Replace and reassemble.

,_b,WARNING: Disconnect the

spark plug before performing mainte-

nance, service, or adjustments except

for carburetor adjustments.

CHAIN SHARPENING

_I_WARNING: Improper chain

sharpening techniques and/or depth

gauge maintenance will increase the

chance of kickback which can result in

serious injury.

_ WARNING: Wear protective

gloves when handling chain. The chain

is sharp and can cut you even when it is

not moving.

Conditions which indicate the need for

chain sharpening:

• Reduction in size of wood chips, The

size of the wood chip wilt decrease

as the chain gets duller until it be-

comes more like a powder than a

chip. Note that dead or rotted wood

will not produce a good chip.

• Saw cuts to one side or at an angle,

• Saw has to be forced through the cut.

Tool8 required:

• 5/32 inch (4 mm) diameter round file

and file holder

• Flat file

• Depth gauge tool

TO SHARPEN CHAIN:

1. Move ON/STOP switch to the STOP

position.

2. Check chain for proper tension.

Adjust chain tension if necessary.

See CHAIN TENSION section.

17

Page 18

3. Sharpencutters.

• Tosharpenthecutters,position

thefileholderlevel(90°)sothatit

restsonthetopedgesofthecut-

teranddepthgauge.

NOTE:Thechainhasbothleft

andrighthandcutters.

Too Much Hook Angle Squared Off

Wrong

Corner

File H!_ _ File_

CLltter_o _ ,'Y ! _/

Depth Gauge r

• Align the 30 ° file holder marks par-

allel with the bar and to the center of

the chain.

30 °

File Holder Lille

• Sharpen cutters on one side of the

chain first. Fite from the inside of

each cutter to the outside. Then,

turn the chain saw around and re-

peat the process for the other side

of the chain.

• File on the forward stroke only.

use 2 or 3 strokes per cutting

edge.

• Keep all cutters the same length

when filing.

• File enough to remove any dam-

age to cutting edges (side plate

and top plate of cutter).

All Cutters Remove Damage

SomeLen i

• File chain to meet the specifica-

tions as shown.

b.. 85° /"., 60°

30°'

Hook Angle

k_ O025inch

------_ (0.65 ram)

_Rounded

Right Corner

_WARNING: Maintain the proper

hook angle according to the manufac-

turer's specifications for the chain you

are using. Improper hook angle will

increase the chance of kickback which

can result in serious injury.

4. Check and lower depth gauges.

• Place gauge tool on cutter.

• tf the depth gauge is higher than

the depth gauge toot, file it level to

the top of the depth gauge toot.

• Maintain rounded front corner of

depth gauge with a flat file.

NOTE: The very top of the depth

gauge should be flat with the front

half rounded off with a fiat file.

tf you require further assistance or are

unsure about performing this procedure,

contact your Sears Service Center or

call our customer assistance help line at

1-800-235-5878.

CHAIN REPLACEMENT

_iL WARNING: Wear protective

gloves when handling chain. The

chain is sharp and can cut you even

when it is not moving.

It is normal for a new chain to stretch

during the first 15 minutes of operation.

You should recheck your chain tension

each time before you start the chain saw

and adjust the chain tension as required.

See CHAINTENSION section. Replace

the old chain when it becomes worn or

damaged. Use onty the Low-Kickback

replacement chain specified in the repair

parts list. The correct replacement bar

and chain is also specified on a decal

located on the chain saw.

See your Sears Service Center to

replace and sharpen individuaI cutters

on your chain.

TO REPLACE CHAIN:

1. Move ON/STOP switch to the STOP

position.

18

Page 19

2. Loosenandremovebarknobcom-

pletelybyliftingteverandturning

counterclockwise,

CRRF

LOOSEN

3. Loosen chain tension by turning

adjusting wheel (upward direction),

Remove clutch cover.

\

Bar

Knob

4. Slide guide bar on bar bolts until

guide bar stops against clutch

drum sprocket.

Guide bar

Bar bolts

5. Remove the old chain.

6. Carefully remove the chain from the

package. Hold chain with the drive

links as shown.

7. Place chain over and behind clutch

retainer, fitting the drive links in the

clutch drum sprocket.

8. Fit bottom of drive links between

the teeth in the sprocket in the

nose of the guide bar.

9. Fit chain drive links into bar groove.

10. Putt guide bar forward until chain is

snug in guide bar groove. Ensure

all drive links are in the bar groove.

11. install clutch coven Be sure adjust-

ing pin is in the adjusting pin hole

in the guide bar,

CAUTION: tt is very important when

installing the clutch cover that the adjust-

ing pin aligns into the adjusting pin hole

in the bar. Failure to install the clutch

cover correctly may result in permanent

damage to your chain saw.

Adjusting

12. install bar knob and finger tighten

only. Do not tighten any further at

this point. Proceed to CHAIN AD-

JUSTMENT.

CHAIN ADJUSTMENT

See CHECK CHAIN TENSION in MAINTE-

NANCE section.

CARBURETOR ADJUSTMENT

,_. WARNING: The chain wilt be

moving during most of this procedure.

Wear your protective equipment and

observe all safety precautions. The

chain must not move at idle speed.

The carburetor has been carefully set

at the factory. Adjustments may be

necessary if you notice any of the fol-

lowing conditions:

• Chain moves at idle. See IDLE

SPEED-T adjusting procedure.

• Saw witt not idle. See iDLE SPEED-T

adjusting procedure.

Drive Links

view of

clutch

cove[

B_ck

DHRECTtONOF ROTATION

19

Page 20

IdleSpeed-T

Allowenginetoidle.Ifthechainmoves,

idleistoofast.Iftheenginestalls,idleis

tooslow.Adjustspeeduntilengineruns

withoutchainmovement(idletoofast)or

stalling(idletooslow).Theidlespeed

screwis tocated in the area above the

primer bulb and is labeled T.

• Turn idle screw (T) clockwise to in-

crease engine speed.

• Turn idle screw (T) counterclockwise

to decrease engine speed.

tf you require farther assistance or are

unsure about performing this procedure,

contact your Sears Service Center or

call our customer assistance help line at

1-800-235-5878.

dlllWARNING: Perform the follow-

ing steps after each use:

• Allow the engine to coot, and secure

the unit before storing or transporting.

• Store chain saw and fuel in a well

ventilated area where fuel vapors

cannot reach sparks or open flames

from water heaters, electric motors or

switches, furnaces, etc.

• Store chain saw with all guards in

place and position chain saw so that

any sharp object cannot accidentally

cause injury.

• Store chain saw well out of the reach

of children.

SEASONAL STORAGE

Prepare your unit for storage at the

end of the season or ff it wilt not be

used for 30 days or more.

If your chain saw is to be stored for a

period of time:

• Clean saw thoroughly before storage.

• Store in a clean dry area.

• Lightly oil external metal surfaces

and guide bar.

• Oil the chain and wrap it in heavy pa-

per or cloth.

FUEL SYSTEM

Empty the fuel system before storage

for 30 days or longer. Drain the gas

tank, start the engine and let it run until

the fuel lines and carburetor are empty.

Use fresh fuel next season.

Under FUELING ENGINE in the OPERA-

TION section of this manual, see mes-

sage labeled IMPORTANT regarding

the use of gasohot in your chain saw.

Fuel stabilizer is an acceptabIe alter-

native in minimizing the formation of

fuel gum deposits during storage. Add

stabilizer to the gasoline in the fueI

tank or fuel storage container.

Follow the mix instructions found on

stabilizer containers. Run engine at

least 3 minutes after adding stabilizer.

Craftsman 40:1,2-cycle engine oil (air

cooled) is blended with fuel stabilizer, tf

you do not use this oil, you can add a

fuel stabilizer to your fuel tank.

ENGINE

• Remove spark pIug and pour 1 taa-

spoon of 40:1,2-cycte engine oil (air

cooled) through the spark plug open-

ing. Slowly pull the starter rope 8 to

10 times to distribute oil.

• Replace spark plug with new one of

recommended type and heat range.

• Clean air filter.

• Check entire unit for loose screws,

nuts, and bolts. Replace any dam-

aged, broken, or worn parts.

• At the beginning of the next season,

use only fresh fuel having the proper

gasoline to oil ratio.

OTHER

• Do not store gasoline from one sea-

son to another.

• Replace your gasoline can if it starts

to rust.

20

Page 21

TROUBLESHOOTING TABLE

_, WARNING: Always stop unit and disconnect spark plug before perform-

ing all of the recommended remedies below except remedies that require

operation of the unit.

TROUBLE CAUSE

Engine will not

start or will run

only a few

seconds after

starting.

Engine will

not idle

properly

Engine wilI not

accelerate,

lacks power,

or dies under

a _oad.

Engine

smokes

excessively.

Engine runs

hot.

Oil inadequate 1. Oil tank empty. 1. Fill oil tank.

for bar and 20i_ pump or oil filter 2. Contact Sears Service (see back cover).

chain clogged.

lubricaflon. 3. Guide bar oi_hole 3. Remove bar and clean

Chain moves at 1. Idle speed requires t See "Carburetor Adjustment" in the

idle speed, adjustment. Service and Adjustments Section.

1. ON/STOP switch in

STOP position.

2. Engine flooded.

3 Fuel tank empty.

4. Spark plug not firing.

5 Fuel not reaching

carburetor.

6 Carburetor requires

adjustment.

7 None of the above

1. Idle speed set too high

or too low.

2 Low Speed Mixture

requires adjustment.

3. Crankshaft seals worn.

4. Compression low.

5 None of the above

t. Air filter dirty.

2. Spark plug fouled.

3. Carburetor requires

adjustment.

4. Exhaust ports or muf-

fler outlets plugged.

5. Compression low

6. Chain brake engaged.

7. None of the above.

1. Choke partially on

2. Fuel mixture incorrect

3 Air filter dirty.

4 High Speed Mixture

requires adjustment.

5 Crankcase leak

1. Fuel mixture incorrect

2. Spark plug incorrect.

3 High Speed Mixture

set too lean.

4 Exhaust ports or muf-

fler outlets plugged

5 Carbon build-up on

spark arresting screen.

6 Starter housing dirty

7 None of the above

blocked.

2. Clutch requires repair. 2 Contact Sears Service (see back cover).

REMEDY

1. Move ON/STOP switch to ON.

2. See "Difficult Starting" in the

Operation Section.

3. Fill tank with correct fuel mixture.

4. Install new spark plug.

5. Check for dirty fuel filter; replace.

Check for kinked or split fuel line;

repair or replace.

6. Contact Sears Service (see back cover).

7. Contact Sears Service {see back cover).

1. See 'Carburetor Adjustment" in the

Service and Adjustments Section.

2 Contact Sears Service (see back cover).

3. Contact Sears Service (see back cover).

4. Contact Sears Service (see back cover).

5. Contact Sears Service (see back cover).

1. Clean or replace air flIter.

2. Clean or replace plug and regap.

3. Contact Sears Service (see back cover).

4. Contact Sears Service (see back cover).

5 Contact Sears Service (see back cover).

6 Disengage chain brake.

7 Contact Sears Service (see back cover).

1. Adjust choke.

2. Empty fuel tank and refill w_th

correct fuel mixture.

3. Clean or replace air filter.

4. Contact Sears Service (see back cover)

5. Contact Sears Service (see back cover)

1. See "Fueling Engine" in the Operation

section

2. Replace with correct plug.

3. Contact Sears Service (see back cover)

4. Contact Sears Service (see back cover)

5. Clean spark arresting screen

6. Clean starter housing area.

7. Contact Sears Service (see back cover)

21

Page 22

TROUBLESHOOTING TABLE - Continued

TROUBLE

Chain does not

move when en-

gine is acceler-

ated

Chain clatters

or cuts roughty.

Chain stops 1. See "Chain Sharpening" in the

within the cut. Service and Adjustments Section.

Chain cuts at 1. See "Chain Sharpening" in the

an angle. Service and Adjustments Section

tf situations occur which are not covered in this manual, use care and good

judgement, tf you need assistance, contact Sears Service or the CUSTOMER

ASSISTANCE HELPUNE at t-800-235-5878,

CAUSE

t. Chain tension too

tight.

2. Carburetor requires

adjustment

3. Guide bar rails

pinched.

4-.C_utchslipping

5. Chain brake engaged.

t. Chain tension incorrect.

2. Cutters damaged.

3. Chain worn

4. Cutters dulI, improperly

sharpened, or depth

gauges too high.

5. Sprocket worn.

6. Chain insta}led

backwards.

1. Chain cutter tops not

filed flat.

2 Guide bar burred or

bent; rails uneven.

3 Clutch slipping.

t Cutters damaged on

one side.

2 Chain duII on one side

3 Guide bar bent or worn. 3. Replace guide bar

REMEDY

1.See "Check Chain Tension" in the

Maintenance Section

2. Contact Sears Service (see back cover)

3. Repair or replace.

4. Contact Sears Service (see back cover)

5. Disengage chain brake

1. See "Check Chain Tension" in the

Maintenance Section.

2 Contact Sears Service (see back cover).

3. Resharpen or replace chain.

4. See "Chain Sharpening" in the

Service and Adjustments Section.

5. Contact Sears Service (see back cover).

6 Install chain in right direction.

2 Repair or replace guide bar

3. Contact Sears Service (see back cover).

2. See 'Chain Sharpening" in the

Service and Adjustments Section

22

Page 23

YOUR WARRANTY RIGHTS AND

OBLIGATIONS: The U.S. Environ-

mental Protection Agency/California

Air Resources Board and Sears, Roe-

buck and Co., U.S.A., are pieased to

explain the emissions control system

warranty on your year 2007 and later

small off-road engine. In California, all

small off-road engines must be de-

signed, built, and equipped to meet the

State's stringent anti-smog standards.

Sears must warrant the emission con-

trot system on your small off-road en-

gine for the periods of time ]isted below

provided there has been no abuse, ne-

glect, or improper maintenance of your

small off-road engine. Your emission

controt system inciudes parts such as

the carburetor, the ignition system and

the fuel tank (California only). Where a

warrantable condition exists, Sears witt

repair your small off-road engine en-

gine at no cost to you. Expenses cov-

ered under warranty include diagnosis,

parts and labor. MANUFACTURER'S

WARRANTY COVERAGE: If any

emissions related part on your engine

(as listed under Emissions Control

Warranty Parts List) is defective or a

defect in the materials or workmanship

of the engine causes the failure of

such an emission related part, the part

wiIt be repaired or replaced by Sears.

OWNER'S WARRANTY RESPONSI-

BILITIES: As the small off-road en-

gine engine owner, you are responsi-

ble for the performance of the required

maintenance listed in your operator's

manual. Sears recommends that you

retain all receipts covering mainte-

nance on your small off-road engine,

but Sears cannot deny warranty solely

for the lack of receipts or for your fail-

ure to ensure the performance of ait

scheduled maintenance. As the small

off-road engine engine owner, you

shouid be aware that Sears may deny

you warranty coverage if your smaIt

off-road engine engine or a part of it

has failed due to abuse, neglect, im-

proper maintenance, unapproved

modifications, or the use of parts not

made or approved by the original

equipment manufacturer. You are re-

sponsible for presenting your small

off-road engine to a Sears authorized

repair center as soon as a problem ex-

ists. Warranty repairs should be com-

pleted in a reasonable amount of time,

not to exceed 30 days. If you have

any questions regarding your warranty

rights and responsibiIities, you should

contact your nearest authorized ser-

vice center or call Sears at

1-800-469-4663. WARRANTY COM-

MENCEMENT DATE: The warranty

period begins on the date the small

off-road engine is purchased.

LENGTH OF COVERAGE: This war-

ranty shaII be for a period of two years

from the initial date of purchase.

WHAT IS COVERED: REPAIR OR

REPLACEMENT OF PARTS. Repair

or replacement of any warranted part

will be performed at no charge to the

owner at an approved Sears Service

Center. If you have any questions re-

garding your warranty rights and re-

sponsibilities, you shouM contact your

nearest authorized service center or

caIt Sears at t-800-469-4663. WAR-

RANTY PERIOD: Any warranted part

which is not scheduled for replace-

ment as required maintenance, or

which is scheduled only for regular in-

spection to the effect of"repair or re-

place as necessary" shall be war-

ranted for 2 years. Any warranted part

which is scheduled for replacement as

required maintenance shall be war-

ranted for the period of time up to the

first scheduled repIacement point for

that part. DIAGNOSIS: The owner

shaIi not be charged for diagnostic la-

bor which leads to the determination

that a warranted part is defective if the

diagnostic work is performed at an ap-

proved Sears Service Center. CONSE-

QUENTIAL DAMAGES: Sears may be

liable for damages to other engine

components caused by the failure of a

warranted part still under warranty.

WHAT IS NOT COVERED: All failures

caused by abuse, neglect, or improper

maintenance are not covered. ADD-

ON OR MODIFIED PARTS: The use

of add-on or modified parts can be

grounds for disallowing a warranty

ctaim. Sears is not liable to cover fait-

23

Page 24

ures of warranted parts caused by the

use of add-on or modified parts.

HOW TO FILE A CLAIM: If you have

any questions regarding your warranty

rights and responsibi$ities, you should

contact your nearest authorized ser-

vice center or call Sears at

1-800-469-4683. WHERE TO GET

WARRANTY SERVICE: Warranty ser-

vices or repairs shalt be provided at aIt

Sears Service Centers. CaIt

1-800-469-4683. MAINTENANCE,

REPLACEMENT AND REPAIR OF

EMISSION RELATED PARTS: Any

used in the performance of any war-

ranty maintenance or repair on emis-

sion related parts will be provided with-

out charge to the owner if the part is

under warranty. EMISSION CON-

TROL WARRANTY PARTS LIST:

spark plug (covered up to mainte-

nance schedule), ignition module, muf-

fler including catalyst (if equipped), fuet

tank (California only). MAINTENANCE

STATEMENT: The owner is responsi-

ble for the performance of all required

maintenance as defined in the opera-

tor's manual

Sears approved replacement part

The information on the product label indicates which standard your engine is certified.

Example: (Year) EPA Phase t or Phase 2 and/or CALIFORNIA.

This engine is certified to be emissions compliant for the following use:

[] Moderate (50 hours)

[] Intermediate (125 hours)

[] Extended (300 hours)

24

Page 25

REPAIR PARTS

8EARS CHAINSAW MODEL 358.351810

16

/\ 36

28

26

514

46

45

44

Ref Pa_ No. De_¢ri_ion Ref Pa_ No. Descrip_on Ret Part No. Deseri_ion

1

530057893 Knob Choke 22 530021178

2

530057908 Spring Ign Switch 23 530059677

3

530057891 Level Ign Switch 24 530021180

4

530016080 Screw 25 530071966

5

530071888 Kit Trigger/kockout

6

530069216 Kit Fue! Line (Ia_o_ 26 545039604

7

530069247 Kit FueE Line (small) 27 530056402

8

530095649 Assy Fuel Pick Up 28 530069232

9

530023877 Filing Fuel Line 29 530016432

10

530071945 Kit C_utch Washer 30 530042095

11

530057905 A6sy clutch drum 3/_ 3! 530016080

12

530071945 Kit Clutch Washer 32 530058786

13

530057907 Assy Clutoh 33 530057_6

14

530016419 Washer Large Olutch 34 530057897

15

530047192 Assy Fuel Cap wret 35 530016416

16

530016064 Screw 36 545028306

17

530015922 Nut'U'_peBpeed

18

530059685 Asgy F_ywheei

19

530057911 Shield Heal 37 530071893

20

530015127 Washer Flywheel 38 530016432

21

530016134 Nut Nywheel 39 53001613_

WARNING

A" repairs, adju,;trnent6 and I

maintenance not described in 52

LheOperato;'s Mar=uai must be

performed by qualifieG 9e_lce

personnel

Screw Shouldel 41 530016064

Sta_e[Hub EPS 42 530059999

Spring EPS 43 545039501

Kit EPS _a_er puIle! 44 545040604

(Inc[22,23,24,31) 45 545027614

Housing Fan 46 530150000

Handle Sta_er 47 545157401

Kit Rope 48 71 3619

Screw 49 71 36638

Spring Sta_er 50 530016432

Screw 51 530057888

Assy O[IVent 52 530071945

Assy Oil Cap wsret

Handguard 58 530057924

Spring Handguard 54 530071891

Assy Chassis (Inc!

,5,6,7,&9J 5,16,17, 55 530016064

,19,32,33,85,39) 56 530057931

Kit Ch_nbrake 57 530037820

Screw

40 530057910

Bok Bar

Plate Bar

Screw

Cover Gearbox

WheeE Bara_ust

A_sy EZ'Tknob

Cover EZT

Assy Adiscrew

Pin Bar A_ust

Chain 18"

Bar18"

Screw

Handle Front

Kit Olutcil Washel

(Incl 10,!2)

Assy Oil pick up

Kit Oil pump

(_ncl 55,56,57)

Screw

A_sy OiIPump

Gear Worm

25

Page 26

9

10

39

WARNING

All repairs, ad}ustments and

maintenance not described in

the Operator's Manual must be

pelfolmed by qualified sewice

pe_sonneE

REPAIR PARTS

SEARS CHAtNSAW MODEL 358351810

2O

24

4O

Ref part No

1 5800588,37

2 530016153

3 530059806

4 530059238

5 530016432

6 530047442

7 530057943

8 530058687

9 530057925

10 530016425

11 530057892

12 545070601

13 530069247

14 530047721

15 580071889

16

530071894

17

Dhampion

18

530071864

19

530016186

20

545006007

21

580057942

22

530071894

23

545006056

Description

Shie!d Cyl (Incl 2,8)