Craftsman 358351560 Owner’s Manual

Operator's Manual

CRRFTSMRN

2.2 cu.in./36cc 2-Cycle

GASOLINE CHAIN SAW

Model No.

358.351560 - 16in. Bar

@

Read and follow all Safety Rules and Operating

WARNING:

Instructions before first use of this product.

For answers to your questions about this product:

Call 7 am--7 pm, Mon.-Sat., or 10 arn--7 pm, Sun.

• 1-800-235-5878 (.o..,=_=_._m.)

I

'S_s, Roebuck and Co., Hoffman Estates, IL 60179 USA

530087619 06/08/98

!saW_e_n_/ules

:_mb)

)Operation

Maintenance

Service and Adjustments

11 , Pads & Ordering Back

14

Storage 16

Trouble ShootingChart 17

Pads List 20

Spanish 24

FULL ONE YEAR WARRANTY ON CRAFTSMAN ®GAS

CHAIN SAW

For one year fromthe date of purchase,when this Craftsman Gas Chain Saw is

maintained, lubdcatedand tuned upaccordingtothe owner's manual, Sears will

repair,free of charge, any defect in matedai or wodornanship.

This warranty excludes the bar,chain, spark plug and air filter,which are

expendable parts, and becomewom dudng normalusa.

Ifthis Gas Chain Saw isused for commercialor rentalpurposes,this warranty

appliesfor 30 days fromthe date ofpurchase.

WARRANTY SERVICE IS AVAILABLEBY RETURNING THIS CHAIN SAW TO

THE NEAREST SEARS SERVICE CENTER IN THE UNITED STATES.

This warranty gives you specific legal dghts,and you may also have other dghts

which vary from state to state.

Sears, Roebuck and Co., D/817 WA, Hoffman Estet_'s,:lL 60179

WARNING: Always disconnectspark

plugwire when making repairs except

forcarburetor adjustments.Because a

chain saw is a high-speed woodcutting

tool,careless or improperuse ofthis

toolcan cause sedous injury.

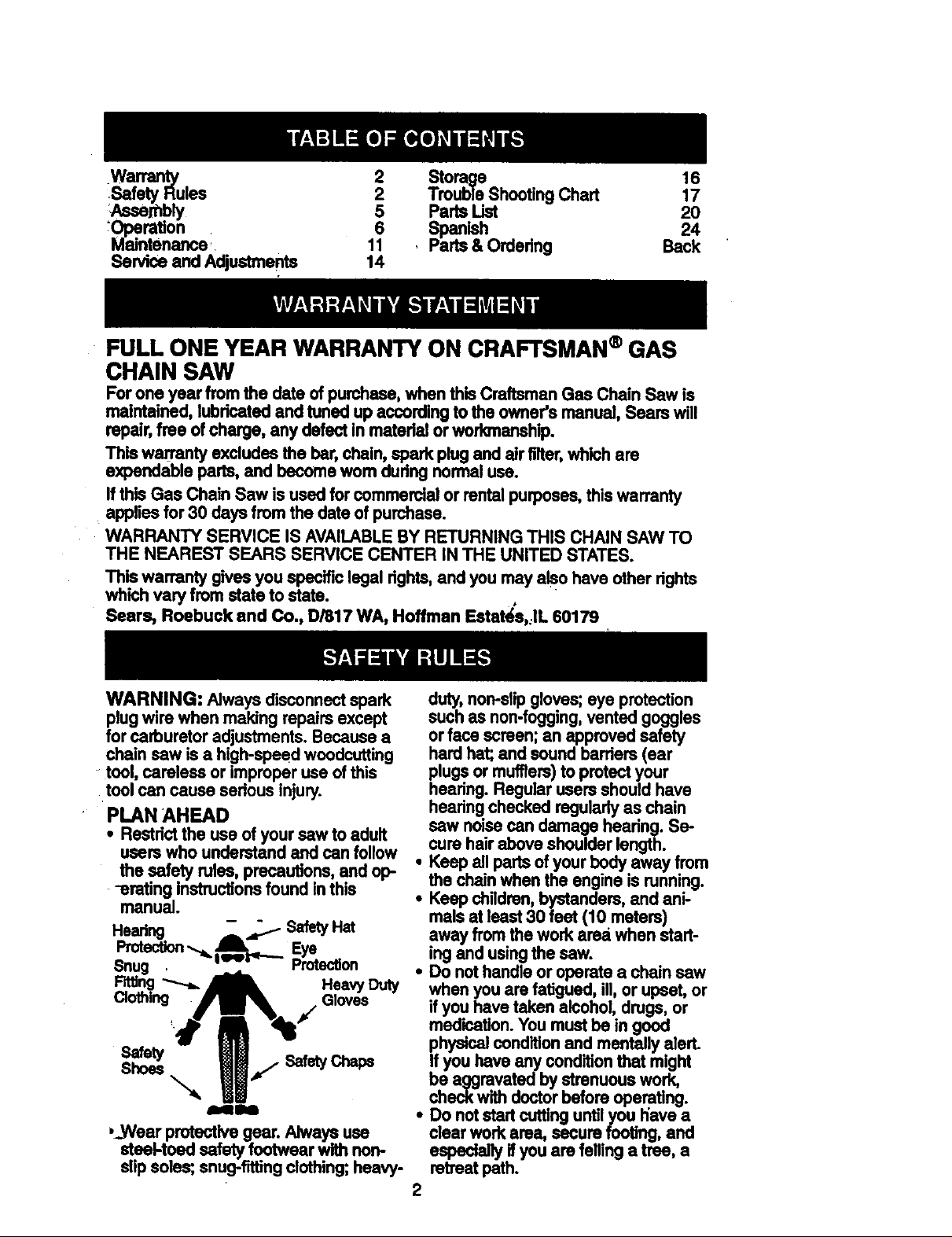

PLAN AHEAD

• Reetdctthe use of your saw to adult

users who understandand can follow

the safety rules,precautions,and op-

-erating Instructionsfound inthis

manual.

Snug

Firing _ Heavy Duty

Clothing Gloves

Safety

Shoes j Chaps

\

NM

,_Wear protectivegear. Always use

steef-toed safety f_twear with non-

slipsoles; snug-fittingclothing;heavy-

duty,non-slipgloves;eye protection

suchas non-fogging,vented goggles

or face screen;an approved safety

hard hat;and sound barriers (ear

plugsor mufflers)toprotectyour

hsadng. Regular usersshould have

headng checked regularlyas chain

saw noise can damage hearing. Se-

cure hair above shoulderlength.

• Keep aimpartsof your body away from

the chainwhen the engine is running.

• Keep chgdrsn,bystanders, and ani-

mals at least 30 feet (10 meters)

away from the work area when start-

ing and usingthe saw.

• Do nothandleor operate a chain saw

when you are fatigued, ill,or upset, or

ifyou have taken alcohol,drugs, or

medication.You mustbe in good

physicalconditionand mentallyalert.

Ifyou have any conditionthat might

be aggra.vatedby strenuous work,

check with doctorbefore operating.

• Do notstert cuttinguntilyou have a

clear work area, secure footing, and

especiallyifyou are felling a tree, a

retreatpath.

2

OPERATEYOUR SAW SAFELY

• Donotoperatewithonehand Seri-

ousinjurytotheoperator,helpers,or

bystandersmayresultfromone-

handedoperation.Achainsawisin-

tendedfortwo-h.andeduse.

• Operate the ch_unsaQwonly-ine,well-

ventilated outdoorarea.

• Do not operate saw from a ladder or

in a tree, unless you are specifically

trainedto do co.

• Make sure the chain will not make

contactwith any object whge starting

the engine NeverW tostartthe saw

• Storethe unit and fuel in a cool, dry

well ventilatedspace where fuel va-

porscannot reach sparks or open

flames fromwater heaters, electric

motorsor switches,furnaces, etc.

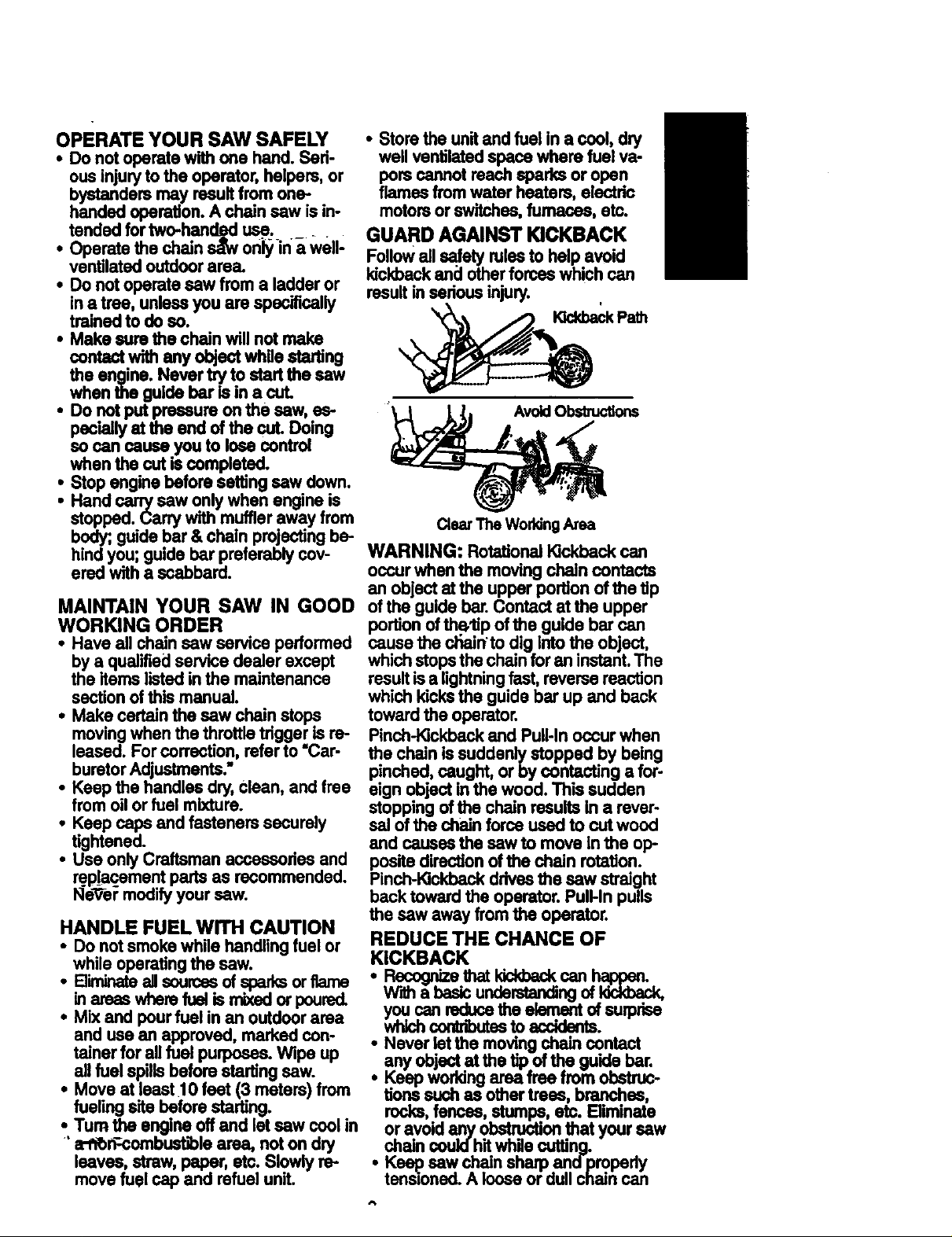

GUARD AGAINST KICKBACK

Followall safety rulesto help.avoid

kickbackand otherforces which can

resultinssdous injury.

k Path

whenthe guidebaris ina cut.

• Do notput pressure onthe saw, es-

peoiailyat the end of the cut. Doing

so can cause you to lose control

when the cut is completed.

• Stop engine before seffing saw down.

• Hand carrysaw only when engine is

stopped.Carry with muffleraway from

body;,guidebar & chain projectingbe-

hindyou; guide bar preferably cov-

ered with a scabbard.

Qear TheWoddngArea

WARNING: RotationalKickback can

occurwhen the moving chain contacts

an object at the upper portion of the tip

AvoidObstructions

MAINTAIN YOUR SAW IN GOOD ofthe guidebar.Contactat theupper

WORKING ORDER

• Have all chain saw service performed

by a qualified service dealer except

the itemslisted in the maintenance

section of this manual.

• Make certain the saw chain stops

movingwhen the throttletrigger is re-

leased. For correction, refer to"Car-

buretorAdjustments."

• Keep the handles dry,Clean, and free

from oilor fuel mixture.

• Keep caps and fasteners securely

tightened.

• Use only Craftsman accassodes and

replacement partsas recommended.

Ne'ger modifyyour saw.

HANDLE FUEL WITH CAUTION

• Do not smokewhile handling fuel or

while operatingthe saw.

• Eliminatsallsourcssofsparksor ltame

inarees wherefusl ismixed or psured.

• Mix and pourfuel in an outdoorarea

and use an approved, marked con-

tainer for all fuel purposes.Wipe up

allfuel spills before starting saw.

• Move at least 10 feet (3 meters) from

fueling site before starting.

• Turn the engine off and let saw cool in

' a-nt)rPcombustiblearea, noton dry

leaves, straw, paper, etc. Slowly re-

move fuel cap and refuel unit.

portion ofth6'tip ofthe guide bar can

cause the cl'_ainto dig intothe object,

whichstops the chainfor an instant.The

resultis a lightningfast, reverse reaction

whichkicks the guide bar up and back

toward the operator.

Pinch-K]ckhackand Pull-Inoccur when

the chain is suddenly stopped by being

pinched, caught, or by contacting a for-

eign object inthe wood. This sudden

stopping of the chain resultsin a rever-

sal of the chain force used to cut wood

and causes the saw to move in the op-

positedirectionof the chain rotation.

Pinch-Kickbackdrivesthe saw straight

back toward the operator. Pull-In pulls

the saw away from the operator.

REDUCE THE CHANCE OF

KICKBACK

• R_ thatkickbackcan

With a basicunden_mding 1ofkiddoeck,

you can reducetheelementof surprise

which conlrbutesto eccidents.

• Never let the moving chain contact

any object at the tip of the guide bar.

• Keep workingarea free from oi0struc-

tionssuch as other trees, branches,

rocks,fences, stump, et_. Eliminate

or avoid any obstructionthat your saw

chaincouldhit while cutting.

• Keep saw chain sharp and propedy

tensioned. A loose or dullchain can

happen.

increase the chance of kickback. Fol-

lowmanufacturer's chain sherpenlng

and maintenance instructions.Check

tension at regular intervals, but never

with engine running. Make sure bar

clamp nuts are securely tightened.

• Begin and continue cuttin_lat full

speed. If the chain _movmg at a

slowerspeed, there _sgreeter chance

of kickback occurring.

• Use extreme caution when reentering

a cuL

• Do not attempt cuts startingwith the

tipofthe bar(plunge cuts).

• Watch for shifting logsor oti_erforces

thatcould dose a cut and pinch orfall

intochain.

• Use the specified Reduced-Kiokback

Guide Bar and Low-KiokbackChain.

Avoid Pinch-Kickback:

• Be extremely swam of situations or

obstructionsthat can cause matedal

to pincl_,the top of or otherwisestop

the chron.

• Do not cut more than one log at e

time.

• Do not twist saw as bar iswithdrawn

from an undercut when bucking.

Avoid PulHn:

• Alwaysbegin cutting withthe engine

at full speed and the saw housing

against wood.

• Use wedges made of plastic or wood.

Never usa metal to hold the cut open.

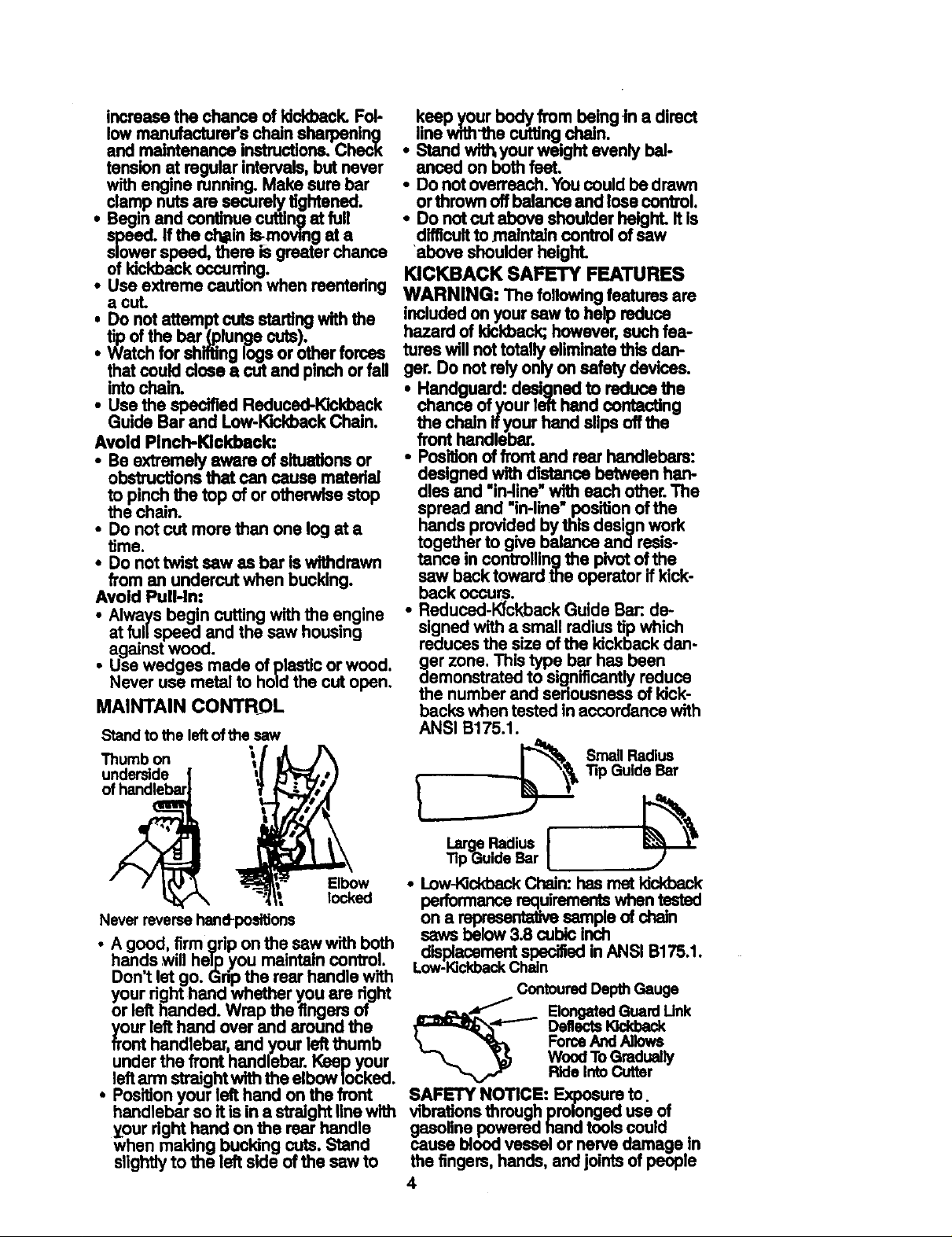

MAINTAIN CONTROL

Stand to the left of the saw

underside

of handlebar

keep your body from being in a direct

line with'the cuffing chain.

• Stand with,yourwalght evenly bal-

anced on both feet.

• Do not overreach.You could be drawn

or thrown offbalance and lose control.

• Do notcut above shoulderheight. ItIs

difficultto maintain control of saw

'above shoulderheight.

KICKBACK SAFETY FEATURES

WARNING: The followingfeatures are

includedon your saw to help reduce

hazard of kickback;however, such fea-

tures willnot totally eliminate this dan-

ger. Do notrely only on safety devices.

• Handguard: designed to reduce the

chance of your left hand contacting

the chain ifyour hand slipsoff the

front handlebar.

• Positionof front and rear handlebars:

designed _ distance between han-

dles and ",n-line"with each other.The

spread and."in-line" position ofthe

hands prodded by this design work

together to give balance and rasm-

tance in controlling the pivot ofthe

saw back toward the operator if kick-

back occum.

• Reduced-I_ckback Guide Bar:.de-

signedwith a small radius tip which

reduces the size of the kickback dan-

_er zone. This type b.mhas been

emonstrated to significantlyreduce

the number and sedousness of kick-

backs when tested inaccordance with

ANSI B175.1.

Small Radius

Tip Guide Bar

Thumbon

I

i

Elbow

\ locked

Neverreverse han@podtJons

• A good, firm grip on the saw with both

hands will help ,youmaintain control.

Don't let go. Gdp the rear handle with

your dght hand whether you are dght

or left handed. Wrap the tingem of

your left hand over and around the

front handlebar, and your left thumb

under the fiord handlebar. Keep your

left arm straightwith the elbow locked.

• Positionyour !eft hand on the front

handlebar so it isin a straightline with

your dght hand on the rear handle

when making bucking cuts. Stand

slightlyto the left side of the saw to

• Low-KickbackChain: hasmet kickback

performance r_jui_ whentested

on a represent_ve sample of chain

saws below 3.8 cubicinch

displacementspecifiedinANSI B175.1.

Low-_ckbackChain

ContouredDepth Gauge

Deflects

ForceAnd Allows

_ longsted GuardLink

Wood ToGrsdu_

Ride IntoCutter

SAFETY NOTICE: Exposure to.

_"mations through prolonged use of

gasoline powared hand tools could

cause blood vessel or nerve damage in

the fingers, hands, and joints of people

4

proneto circulation disorders or n_.er and spark arre_ s_rsan

abnormalswelling. Prolonged use in whichmeets the re remanteof

coldweather has been linkedto blood California Codes 4442 and 4443. All

vesseldamage in otherwisehealthy U.S. forest land and the slates of

people. If symptoms occursuch as Califomia, Idaho, Maine, Minnesota,

numbness,10am,lossof strpng__,_ New Jersey, Oregon, and Washington

change in.sldncolor o'ttextu-re,or_ require by lawthat many internal

of fee._. m the fingers, hands,'orjoints,

discontinuethe use of th=stool and

seek medical attention. An

anti-vibrationsystem does not

guaranteethe avoidance ofthese

problems.Users who operate power

toolson a continual and regular baszs

mustcloselymonitor their physical.

cond_on and the condrdion of thzstooL

CHAIN BRAKE If this saw isto be used chart in the MAINTENANCEsection.

forcommerciallogging,you must order

and installa chain brake to comply with

FederalOSHA Regulations for Com-

merciaiLogging. Contact your Sears

ServiceCenter or call 1-800-235-5878. Saws Safety Requirements (ANSI

SPARK ARRESTOR: Yoursaw is B175.11-t_1991).

equipped with a tempomtum limiting

combustion engines be equipped with a

spark arrestorscreen. If you operate a

chainsawina stateorlocaleW,hem

n_oonr_llationse.xi_,youare legally

• for m=,nteiningthe

operatingcondition ofthese pads.

Failure to do so is a viola_on ofthe law.

Refer to Customer Responsibilities

STANDARDS."This chain saw is listed

by UndenmitersLaboratories, Inc. in

accordancewith American National

Standards for Gasoline-Powered Chain

CARTON CONTENTS

Check cation contents against the fol-

lowinglist.

Model 358.351560

• ChainSaw (fully assembled)

• Bartool

• 2-cycleengine oil

• Examineparis for damage. Do not

usedamaged parts.

• If you need assistanceor find that

partsare missing or damaged, please

call 1-800-235-5878.

NOTE: It is normal to hear the fuel filter .

rattleinan empty fuel tank.

Your unithasbeen factorytested and

the carburetorprecisely a_usted. As a

resultyou may smell gasoSneorflnd a

dropof oil/fuel residue on the muffler

when you unpackthe unit.

ASSEMBLY

Yoursaw is fullyassembled; no

assamUyle

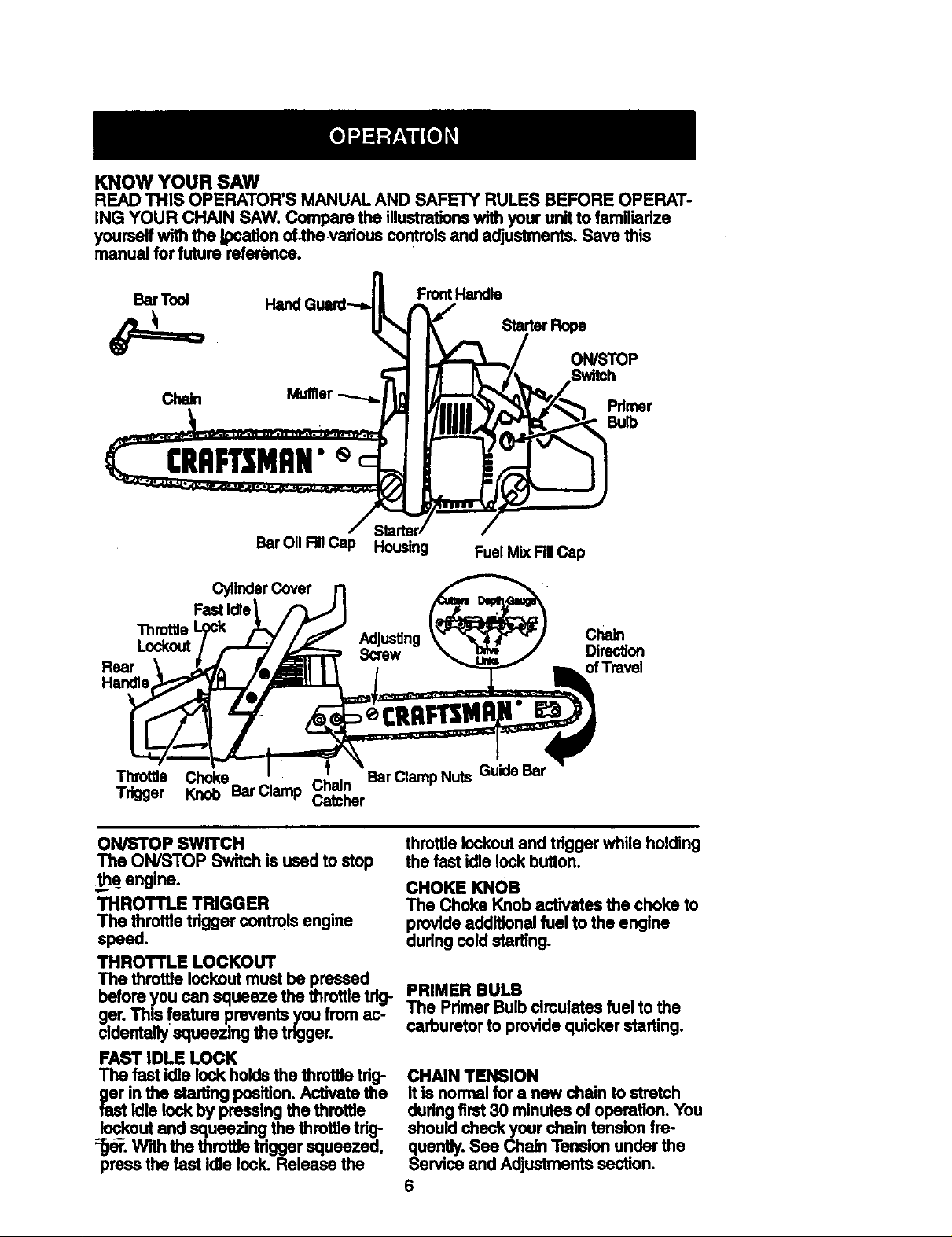

KNOW YOUR SAW

READ THIS OPERATOR'S MANUAL AND SAFETY RULES BEFORE OPERAT-

ING YOUR CHAIN SAW. Compare the illustrationswith your unit to familiadze

yourseffwiththe _ocation of_thevadous controlsand adjustments. Save this

manual for future reference. '

Bar Tool FrontHandle

Starter Rope

OWSTOP

CRRFT3MRN"

Bar Oil RII Cap Housing

CylinderCover

Fast Idle

Lockout Adjus_ng Ct_n

Rear ofTravel

Handle

Throttle Choke

Tdgger Knob BarClarnp Chain Bar Clamp Nuts GuideBar

ON/STOP SWITCH

The ON/STOP Switch is used to stop

the engine.

THROTTLE TRIGGER

The throttletdgger controlsengine

speed.

Screw Direction

Catcher

thmffie lockoutand tdgger whileholding

the fast idle lockbutton.

CHOKE KNOB

The Choke Knob activates the choke to

provideadditionalfuel to the engine

duringcoldstarting.

Fuel Mix RII Cap

THROTTLE LOCKOUT

The throttlelockoutmust be pressed

before you can squeeze the throttletrig-

ger.This feature prevents you fromac-

cidentallysqueezing the tdgger.

PRIMER BULB

The Pdmer Bulb circulates fuel to the

carburetor to provide quicker starting.

F_ IDLE LOCK

The fast idle lockholdsthe throttle tdg-

ger in the startingposition.Activate the

fast idlelock by pressing the throttle

lockoutand squeezing the throttle tfig-

_e_. With the throttle rigger squeezed,

press the fast idle lock. Release the

CHAIN TENSION

Itis normal fora new chainto stretch

dudngfirst30 minutes of operation.You

shouldcheck your chain tensionfre-

quent. See Chain Tension under the

enaca and Adjustmentssection.

6

BEFORE STARTING ENGINE

WARNING: Be sure to read the fuel

handlinginformationin the safety rules

section of this manuel before you begin.

Ifyou do not understandthe fuel hen-

dlinginformationdo net attempttofuel

your unit.Seek helpfrom someone that

does understandthe informationor cell

the customerassistance help line at

1-800-235-5878.

GUIDE BAR AND CHAIN OIL

The chain oiler providescontinuouslu-

bricationto the chainand guide bar. Be

sureto fillthe bar o01.tankwhen you fill

the fuel tank (Capacity = 6.8 ft. oz.).

Formaximum guidebar and chain life,

we recommendyou use Craftsman

chainsaw bar oil. If Craftsmen bar oil is

notavailable, you may use a good

gradeSAE 30 oiluntilyou are able to

obtainCraftsmen brand. The oil output

isautomatically metered duringopera-

tion.Your saw will use approximately

onetank of bar oilfor every tank of fuel

mix.Always fillthe bar oil tank when

you flilthe fuel tank.

linesand catouratorare emply. Use fresh

fuel nsxt ssason. See STORAGEk_'truc-

tions for edd_x_ informa_on.

Never use engine or carburetor deener

products inthe fuel tank or permanent

damage may occur.

See the STORAGEsection for additional

information.

STOPPING YOUR ENGINE

• MoveOn/Stopswitchto STOP.

• Ifenginedoesnotstop,pullchoke

knoboutfully.

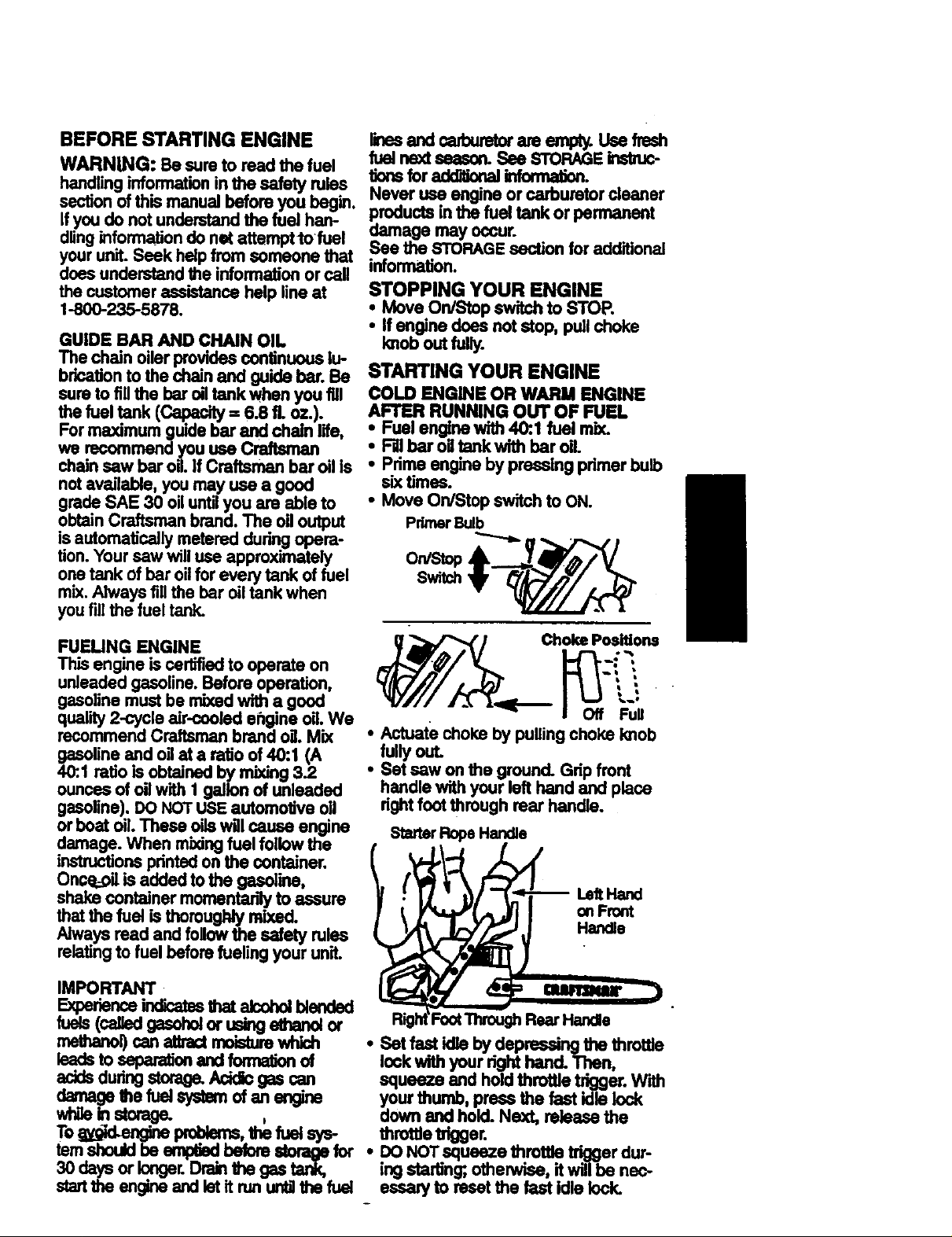

STARTING YOUR ENGINE

COLD ENGINE OR WARM ENGINE

AFTER RUNNING OUT OF FUEL

• Fuel engine with 40:.1fuel mix.

• Fillbar oiltenk with bar oil.

• Prime engine by pressing primer bulb

six times.

• Move On/Stop switch to ON.

PrimerBulb

FUELING ENGINE

This engine is certifiedto operate on

unleaded gasoline. Before operation,

gasoline must be mixedwith a good

quality2-cycle air-ccoled ehgine oil.We

recommend Craftsman brand o,1.Mix

gasoline and oil at a ratio of 40:1 (A

4_.1 ratio is ob_nsd by mixing 3_.

ounces of oil with 1 gallonof unleaded

gasoline). DO NOTUSEautomotive oil

or boat oil. These oilswill cause engine

damage. When mbdngfuel follow the

• Full

• Acluate choke by pulling choke knob

fully ouL

• Set saw on the ground. Grip front

handle with your left hand and place

rightfootthrough mar handle.

Starter Rope Handle

t •

instructionspdntedonthe container.

Once.oilisaddedtothegasoline,

shakecontainer momentarilyto assure

that the fuel is thorougldymlxed.

Alwaysread and followthe safetyrules

relatingto fuel before fueling your unit.

LeJtHand

on Front

Handle

IMPORTANT

ExpedenceindicaWsthatelcohoiblanded

(ce,edgasoh¢or or

mathenoi)cen atirad moielurewhich

lesdsto eepar_on and_ of

adds duringstorage.Addio gas can

whdd_,_ethe fuel systemof an engine your thumb, press the fast idle lock

storage. , down and hold. Next, release the

To_Q_-engine problems,thefuel sys- throttie _gger.

tem shouldbe emplbd before storagefor • .DONOTsqueeze throttie triggerdur-

30claysor longer.Dlain the gas tank, ing starling;othelwise, it will be nec-

staxtthe engine and letit run unffithefuel essary to msot the fast Idle iock.

• Set fast idle by depressing the throUle

lock with your right hand. Then,

squeeze end holdthrottie trigger. With

RearHandle

NOTE: When pullingthe starter rope, OPERATING TIPS

do not use the full extent of the rope. • Check chain tendon before first use

Do not let stinter rope snap bad_ Hold and aftor,1 minute of operation. See

handle. Let rope rewind slowly. Chain Tension in the Maintenance

• Pull miter rope handle firmly and

quicklywith your righthand untl"lthe

engineattemptsto start or 5 pulls.

Then pushtl_ chokeknob fully in.

Resume pullinghandle until engi0e

starts. See Igustration.

• Above 40°F, allow engineto runfor

approximately5 seconds. Push the

choke knob in tothe OFF position;

then squeeze and release throttle trig.

ger to allow engineto idte.

• Below 40°F, allow engine to warm up

for 30 saconds to 1 mirnJte.Push

choke knob in 1/2 way;,then squeeze

and release throffie tdgger to allow

engine to idle.

• To stop engine, move On/Stop switch

to the STOP position.

8eotJon.

• Cut woed only.Do not out metsl, plas-

tics, masonry,non-wood buildingrna-

tedab, etc;

• Stop the saw ifthe chatn atnlcsea for-

eign object.Inspectthe saw and re-

pairpaits as .r.r._.:

• Keep the chain out of dirt and sand.

Even a smallamount of dirtwillquick.

blYduliachainandincreasethepossl-

llHyofidcid:)ask.

• Practicecuttinga few small logsusing

the foflowingsteps. This wil helpyou

get the "feet"of usingyour saw before

you begina majorsawing operaSon.

• Squeeze the throttle _gger andal-

lowtheenginetoreachfullspeed

beforecutting.

• Begincuttingwiththe saw frame

againstthe log

STARTING A WARM ENGINE

DO NOT use thechoke to start a warm

engine or floodingandhard starting

may occur.

• Move On/Stop switchto ON.

• Set fast idle lock.

• Be sure choke is in the OFF position.

• With saw on ground,gdp front handle

with left hand and place your dght foot

through rear handle.

• Pull starter ropehandle until engine

starts.

• Squeeze and releasethrottle trigger

to returnengine to idlespeed.

DIFFICULT STARTING OR

STARTING A FLOODED ENGINE

The engine may be flooded if it has not

started after 10 pulls.Flooded engines

;can be cleared of excess fuel with the

followingprocedure:

• Engage the fast idl_lock.

• Verifythat the On/Stop switch ls inthe

ON position.

Pushchoke knob to the OFF position.

•"With saw on ground,gnp front handle

with left hand and place dght foot

through rear handle.

• Pull starter rope handle until engine

starts.

• Starting could require many pulls de-

pending on how badly the unit is

_ flooded, if en_ne stillfails to start, re-

-fer to the TROUBLESHOOTING chart or

call 1-800-235-5878.

• Keep the engineat full speed the

enbretimeyou are cutting.

• AJIowthe chain to cut for you. Exert

onlylightdownward pressure.

• Release the throttletdgger as soon

as the cutis completed, allowingthe

engineto idle. If you run the saw at

full throttle withouta cuffingload,

unnecessarywear can occur.

• Toavoidlosingcontrol when cut is

complete, do not put pressureon

saw at end ofcut.

• Stopenginebeforesettingsawdown.

TREE FELUNG TECHNIQUES

WARNING: Check for broken or dead

brancheswhichcan fall while cutting

ca_ing serious .injury.DOnot cut near

buddingeorelectrical wires if you donot

know the directionof tree fall, norcut at

nightsinceyou will not be able to see

well, nordudngbad weather suchas

rain, snow,or strongwinds, etc.

• Carefullyplanyour sawing operation

in advance.

• Clear the workarea. You need a dear

area allaroundthe tree so you can

have securefooting.

• Studythe naturalconditions thatcan

_usa the treeto fall in a partbular

direction.These conditions include:

• The wind directionand speed.

• The lean ofthe tree. The lean ofa

tree mightnotbe apparent due to

uneven or sloping terrain. Usea

8

Loading...

Loading...