Craftsman 358351440 Owner’s Manual

Operator's Manual

CRAFTSMRN

2.0 cu. in./33cc 2-Cycle

IF-

GASOLINE CHAIN SAW

Model No.

358.351440 - 14 in. Bar

@

J

|

i'

Read and follow all Safety Rules and Operating

WARNING:

Instructions before firstuse of this product.

For answers to your questions about this'product:

Call 7 am-7 pm, Mort-Sat; Sun, 10 am-7 pm

•• 1-800-235-5878

Sears, Roebuck and Co., Hoffman Estates, IL 60179 USA

530-087618 06/08/98

i

Warrantyl .: 2 Storage 16

Safety Rules 2 TroubleShooting Chart 17

Assembly 5 Parts Ust 20

Operation 6 Spanish 24

Maintenance 11 Parts & Ordering Back

Service and Adjustments 14

FULL ONE YEAR WARRANTY ON CRA:FTSMAN ® GAS

CHAIN SAW _

For one year from the date of purchase, when this Craftsman Gas Chain Saw is

maintained, lubricated and tuned up according to the owner's manual, Sears will

repair, free of charge, any defect in material or workmanship.

This warranty excludes the bar, chain, spark plug and air filter, which are

expendable parts, and become worn during normal use.

If this Gas Chain Saw is used for commercial or rental purposes, this warranty

applies for 30 days from the date of purchase.

WARRANTY SERVICE IS AVAILABLE BY RETURNING THIS CHAIN SAW TO

THE NEAREST SEARS SERVICE CENTER IN THE UNITED STATES.

This warranty gives you specific legal rights, and you may also have other rights

which vary from state to state.

Sears, Roebuck and Co., D/817 WA, Hoffman IEstate_, IL 60179

WARNING: Always disconnect spark

plug wire when making repairs except

for carburetor adjustments. Because a

.chain saw is a high-speed woodcutting

tool, careless or improper use of this

tool can cause serious injury.

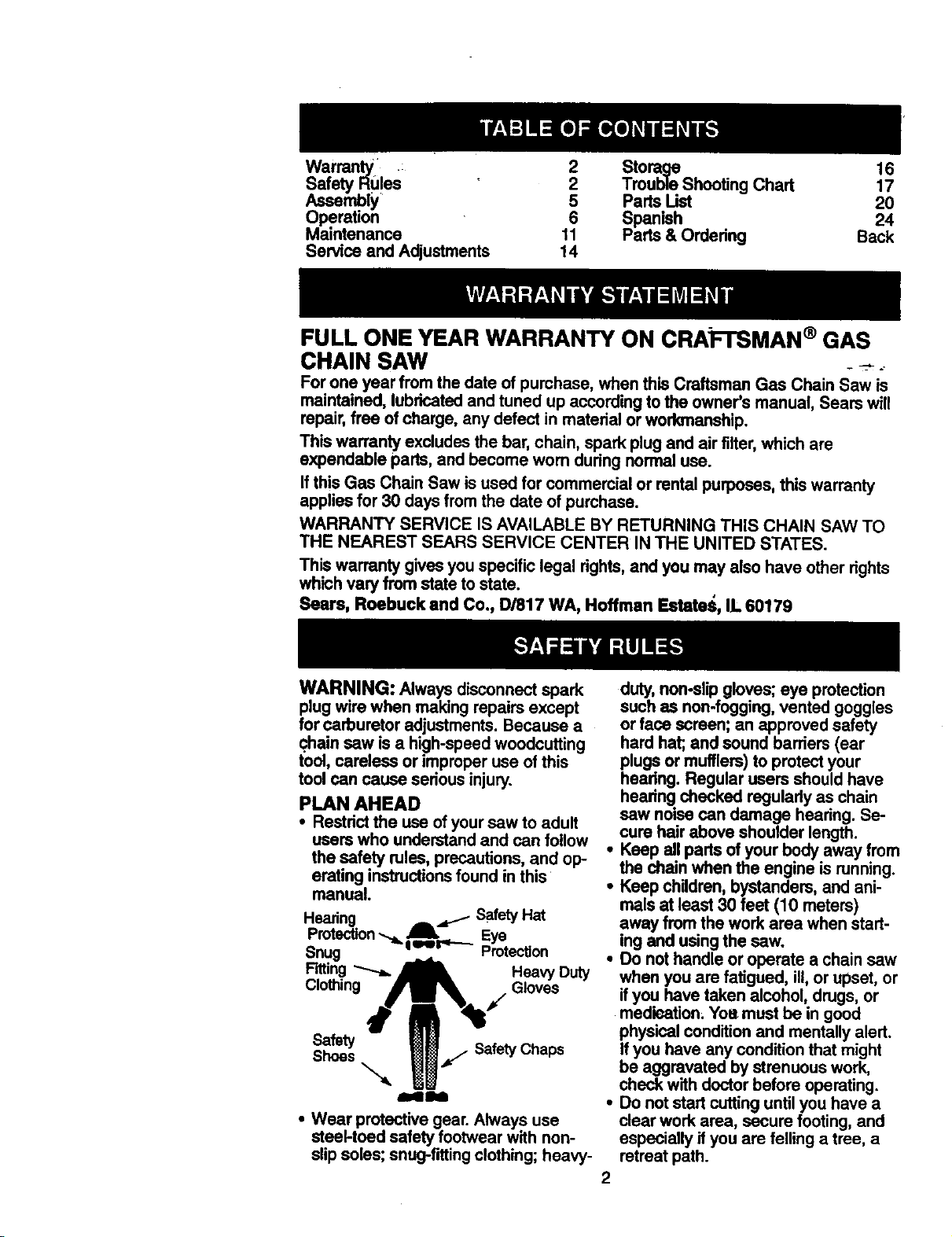

PLAN AHEAD

• Restrict the use of your saw to adult

users who understand and can follow

the safety rules, precautions, and op-

erating instructions found in this

manual.

Hearing Safety Hat

Protection...._._'='_" Eye

Snug Protection

Fitting _ Heavy Duty

Clothing Gloves

Safety

Shoes

• Wear protective gear. Always use

steel-toed safety footwear with non-

slip soles; snug-fitting clothing; heavy-

qMr _--

duty, non-slip gloves; eye protection

such as non-fogging, vented goggles

or face screen; an approved safety

hard hat;,and sound barriers (ear

plugs or mufflers) to protect your

heedng. Regular users should have

hearing checked regularly as chain

saw noise can damage hearing. Se-

cure hair above shoulder length.

• Keep all parts of your body away from

the chain when the engine is running.

• Keep children, bystanders, and ani-

mals at least 30 feet (10 meters)

away from the work area when start-

ing and using the saw.

• Do not handle or operate a chain saw

when you are fatigued, ill, or upset, or

ifyou have taken alcohol, drugs, or

medication. Yoe must be in good

physical condition and mentally alert.

If you have any condition that might

be aggravated by strenuous work,

check with doctor before operating.

• Do not start cutting until you have a

clear work area, secure footing, and

especially if you are felling a tree, a

retreat path.

2

OPERATE YOUR SAW SAFELY

• Do not operate with one hand. Seri-

ous injuryto theoperator, helpers, or

bystandersmay resultfrom one-

handed operation.A chainsaw isin-

tended for two-handed use.

• Operate the chain saw onlyin a well-

ventilatedoutdoorarea.

• Do notoperate saw from a ladder or

in a tree, unlessyou are specifically

trainedto do so.

• Make sure the chain will not make

contactwith any objectwhile starting

the engine. Never tryto stad the saw

when the guide bar isin a cut.

• Do notput pressure on the saw, es-

peciallyat the end ofthe cut. Doing

so can cause you to losecontrol

when the cut iscompleted.

• Stopengine before settingsaw down.

• Hand carrysaw only when engine is

stopped. Carrywith muffleraway from

body;guide bar & chain projectingbe-

hindyou; guide bar preferablycov-

ered with a scabbard.

MAINTAIN YOUR SAW IN GOOD

WORKING ORDER

• Have allchain saw service performed

by a qualified servicedealer except

the items listedin the maintenance

section of thismanual.

• Make certain the saw chain stops

movingwhen the throttletriggeris re-

leased. For correction,refer to =Car-

buretorAdjustments."

• Keep the handles dry,clean, and free

fromoil orfuel mixture.

• Keep caps and fastenerssecurely

tightened.

• Use only Craftsman accessodes and

replacement parts as recommended.

Never modify yoursaw.

HANDLE FUEL WITH CAUTION

Do not smoke while handling fuel or

while operating the saw.

• Elirnina_ _ soun_ of s_ks or flan_

in areas where fuel ls mixed or poured.

• Mix and pour fuel in an outdoor area

and use an approved, marked con-

tainer for all fuel purposes. Wipe up

all fuel spills before starting saw.

• Move at least 10 feet (3 meters) from

fueling site before starting.

• Turn the engine off and let saw cool in

a non-combustible area, not on dry

leaves, straw, paper, etc. Slowly re-

move fuel cap and refuel unit.

• Store the unitand fuel in a cool,dr_

well ventilatedspace where fuel va-

pors cannot reach sparks or open

flames from water heaters, electdc

motors orswitches, fumacas, etc.

GUARD AGAINST KICKBACK

Follow allsafety rulesto help avoid

kickbackand otherfomes whichcan

result insedous injury.

_ 10ckbackPath

Avoid Obstructions

Clear The WorkingAre_

WARNING: Rotational Kickback

occurwhen the moving chain contacts

an object at the upper portion of the tip

ofthe guide bar.Contact at the upper

portionof the,tip of _e guide bar can

cause the chain to d,g intothe object,

which stops the chainforan instant.The

resultisa lightningfast, reversereaction

which kicksthe guide bar up and back

toward the operator.

Pinch-Kickbackand PulHn occurwhen

the chain is suddenly stopped by being

pinched, caught, or by contacting a for-

eign object in the wood. This sudden

stopping ofthe chain resultsin a rever-

sal of the chainforce used to cut wood

and causes the saw to move inthe op-

posite directionof the chain rotation.

Pinch-Kickbackddves the saw stndght

back toward the operator. Pull-Inpulls

the saw away from the operator.

REDUCE THE CHANCE OF

KICKBACK

• Recognizethatkic.Id__a_..canhappen.

With a basic understandingof kickbeck,

you can reducethe elementofsurprise

whichcontributesto accidents.

i Never let the movin_chain contact

any object at the tipof the guidebar.

Keep workingarea free from obstruc

tionssuchas other trees, branches,

rocks,fences, stumps, etc. Eliminate

or avoid any obstructionthat yoursaw

chaincould hitwhile cutting.

• Keep saw chain sharpand properly

tensioned. A loose or dullchain can

3

increasethechance of kickback. Fol-

low manufacturer's chain sharpening

and maintenance instructions. Check

tension at regular intervals, but never

with engine running. Make sure bar

clamp nuts are securel.y.tightened.

• Begin and continue cutting at full

speed. If the chain is moving at a

slower speed, there is greater chance

of kickback occurring.

• Use extreme caution when reentering

a cut.

Do not attempt cuts starting with the

of the

i tip bar(plunge quts).

Watch for shifting logs or other forces

that could close a cut and pinch or fall

into chain.

• Use the specified Reduced-Kickback

Guide Bar and Low-Kickback Chain.

Avoid Pinch-Kickback:

•. Be extremely aware of situations or

obstructions that can cause matedai

to pinch the top of or otherwise stop

the chain.

• Do not cut more than one log at a

time.

• Do not twist saw as bar is withdrawn

from an undercut when bucking.

Avoid Pull-In:

• Always begin cutting with the engine

at full speed and the saw housing

against wood.

• Use wedges made of plastic or wood.

Never use metal to hold the cut open.

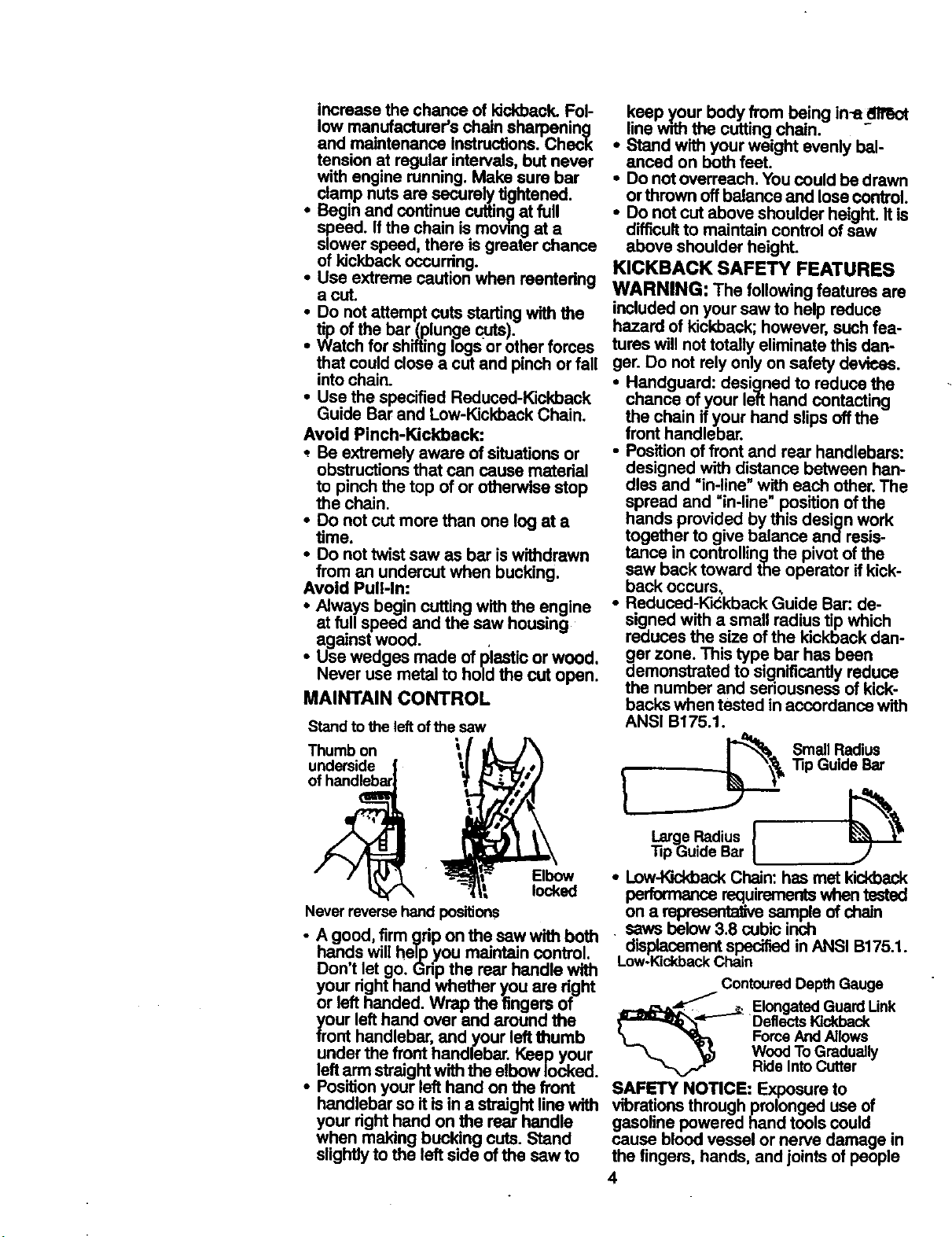

MAINTAIN CONTROL

Stand to the leftofthe saw

keep your body from being in-a 81ft_t

line with the cutting chain. -

• Stand with your weight evenly bal-

anced on both feet.

• Do not overreach. You could be drawn

or thrown off _ce and lose control.

• Do not cut above shoulder height. It is

difficult to maintain control of saw

above shoulder height.

KICKBACK SAFETY FEATURES

WARNING: The following features are

included on your saw to help reduce

hazard of k'_kback; however, such fea-

tures will not totally eliminate this dan-

ger. Do not rely only on safety devices.

• Handguard: designed to reducethe

chance of your left hand contacting

the chain if your hand slips off the

front handlebar.

• Position of front and rear handlebars:

designed with distance between hen-

dies and "in-line" with each other. The

spread and =in-line" position of the

hands provided by th|s design work

together to give balance and resis-

tance in controlling the pivot of the

saw back toward the operator if kick-

back occurs,

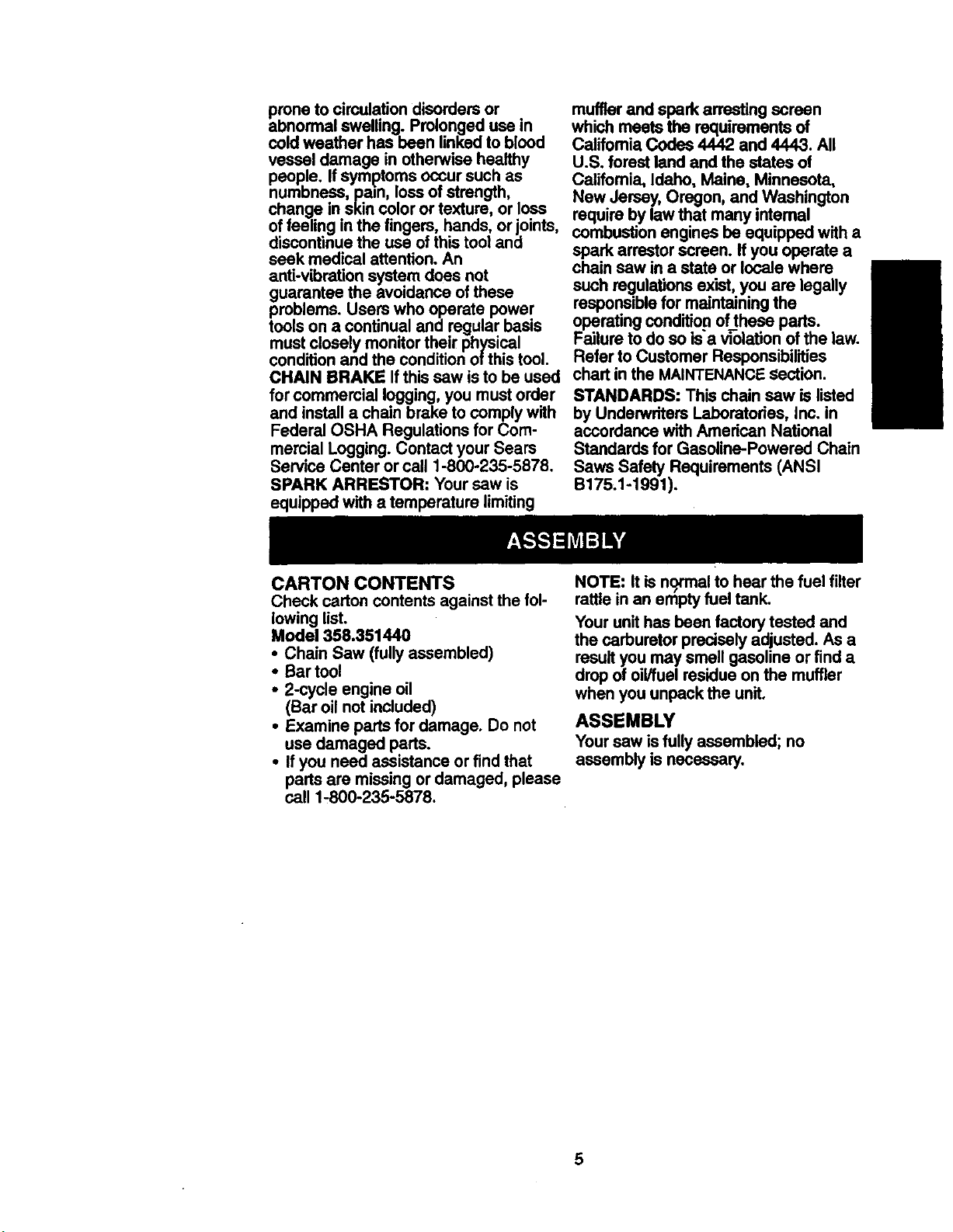

• Reduced-Kickback Guide Bar: de-

signed with a small radius tip which

reduces the size of the kickback dan-

ger zone. This type bar has been

demonstrated to significantly reduce

the number and seriousness of kick-

backs when tested in accordance with

ANSI B175.1.

underside

Thumb on \l

of handlebar

locked

Never reversehand positions

A good, firm grip on the saw with both

hands will help you maintain control.

Don't let go. Gdp the rear handle

your right hand whether you are right

or left handed. Wrap the fingers of

your left hand over and around the

front handlebar, and your left thumb

under the front handlebar. Keep your

left arm straight with the elbow locked.

• Position your left hand onthe front

handlebar so it is in a straight line with

your right hand on the rear handle

when making bucking cuts. Stand

slightly to the left side of the saw to

"13pGuide Bar

__ Small Radius

Tip Guide Bar

• Low-tQdd0a_ Chain: has met kickback

performance requirements when tested

on a representa_ve sample of chain

saws below 3.8 cubic i.nch

displacement specified JnANSI B175.1.

Low-KickbackChain

ContouredDepth Gauge

___Y_ _ Elongated Guard Link

,_IZ;_Z;;;]_'_4.---.-'--Deflects Kickback

_ Force AndAlk_s

_,r_ Wood To Gradually

Ride Into Cutter

SAFETY NOTICE: Exposure to

vibrations through prolonged use of

gasoline powered hand tools could

cause blood vessel or nerve damage in

the fingers, hands, and joints of people

4

pronetocirculationdisordersor

abnormalswelling.Prolongedusein

coldweatherhasbeenlinkedtoblood

vesseldamageinotherwisehealthy

people.Ifsymptomsoccursuchas

numbness, pare, loss of strength,

change in skin color or texture, or loss

of feeling in the fingers, hands, or joints,

discontinue the use of this tool and

seek medical attention. An

anti-vibration system does not

guarantee the avoidance of these

problems. Users who operate power

tools on a continual and regular basis

must closely monitor their PhySical

condition and the condition of this tool.

CHAIN BRAKE If this saw is to be used

for commercial logging, you must order

and install a chain brake to comply with

Federal OSHA Regulations for Com-

mercial Logging. Contact your Sears

Service Center or call 1-800-235-5878.

SPARK ARRESTOR: Your saw is

equipped with a temperature limiting

muffler and spark arresting screen

which meets the requirements of

California Codes 4442 and 4443. All

U.S. forest land and the states of

Califomia, Idaho, Maine, Minnesota,

New Jersey, Oregon, and Washington

require by law that many internal

combustion engines be equipped with a

spark arrestor screen. If you operate a

chain saw in a state or locale where

such regulations exist, you are legally

responsible for maintaining the

operating condition of_these parts.

Failure to do so is'a violation of the law.

Refer to Customer Responsibilities

chart in the MAINTENANCE section.

STANDARDS: This chain saw is listed

by Underwriters Laboratodes, Inc. in

accordance with Amedcan National

Standards for Gasoline-Powered Chain

Saws Safety Requirements (ANSI

B175,1-1991).

CARTON CONTENTS

Check carton contents against the fol-

lowing list.

Model 358.351440

• Chain Saw (fully assembled)

• Bar tool

• 2-cycle engine oil

(Bar oil not included)

• Examine parts for damage. Do not

use damaged parts.

• If you need assistance or find that

parts are missing or damaged, please

call 1-800-235-5878.

NOTE: It is ncFrnal to hear the fuel filter

rattle in an empty fuel tank.

Your unit has been factory tested and

the carburetor precisely adjusted. As a

result you may smell gasoline or find a

drop of oil/fuel residue on the muffler

when you unpack the unit.

ASSEMBLY

Your saw is fully assembled; no

assembly is necessary.

5

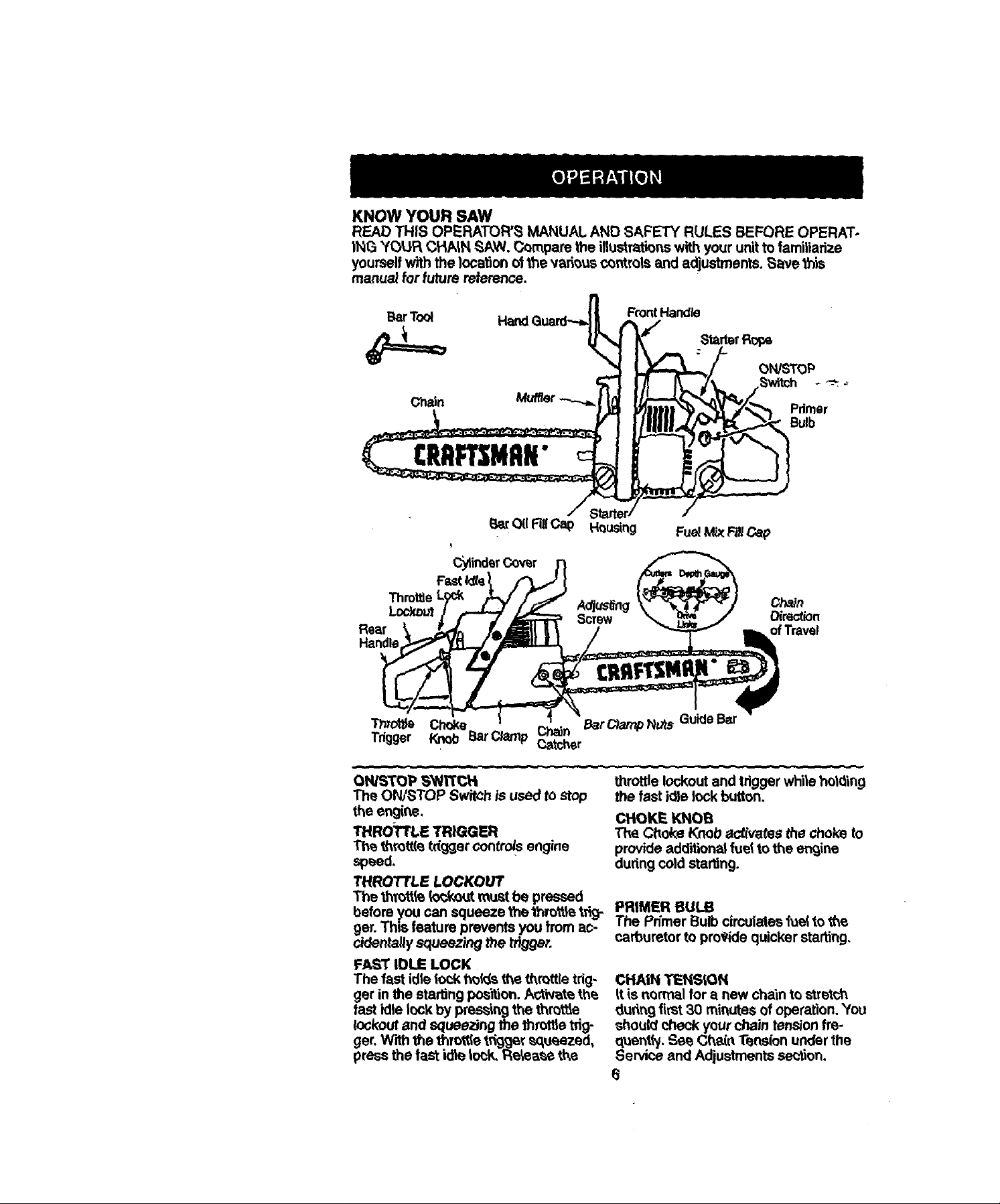

KNOW YOUR SAW

READTHISOPERATOR'SMANUALANDSAFETYRULESBEFORE OPERAT-

ING YC_URCHAIN SAW. Compare the illustrations with your unitto familiarize

yourselfwith the locationotthe variousc_ntrois and adjustments.Save th_s

manual for future reference.

Bar Tool . _1 FrontHandle

• f sta.er

• Muffler _'*-I 1_4 i_,.i,,'_., "_ ._'_'._ Pdmer

Hand Guaro...-.,4s ..,

I

Throttle Chin

Rear of Travel

T_ Choke Bar Clamp NtJ_sGuide Bar

Trigger Knob Bar C/a,-np C)_n

ON/STOP s'wn'c_

The ON/STOP Switch is used to stop

theengine.

THROTTLE TRIGGER

The thrott(etdq_gercontrolsengine

speed,

Oil FillCap Housin Fuel M_ Fill

Direction

C_tcher

throttle lockoutand triggerwhile holding

the fast icgelock button.

CHOKE KNOB

The Choke Knobacf_des the choke to

provideadd'Klon_dfuel to the engine

dudngcoldstarting.

THROTTLE LOCKOUT

The thTott_ (ockoutmust be pressed

before you can squeeze the thmt_._ t_

get. This feature prevents you from ac

cidentallysqueezing the trigger.

PRIMER BULB

The Primer Bulb cimulates f_ to the

iP.

carburetor to proeide quicker starting,

FAST IDLE LOCK

The fast idle lock hok_sthe thrace tdg-

ger in the startingpos'Kion.A_tivatethe

fast idle lock by pressingthe thr_t_e

lOckoutand squeezing the throttle _g-

ger, Withthe thtot_te*_dg_ersqueezed,

press the tast idle Io_. Release the

CHAIN TENSION

it is normal fora new cha'lnto stretch

dunngfi_st 30 minutesof operation,You

shouldcheck yourchain tension fre-

quentS. See Ch_n Tensionunder the

Service and Adjustmentsse_on.

6

BEFORE STARTINGENGINE

WARNING: Be sure to read the fuel

handling information in the safety rules

section of this manual before you begin.

If you do not understand the fuel han-

dling information do not attempt to fuel

your unit. Seek help from someone that

does understand the information or call

the customer assistance help line at

1-800-235-5878.

GUIDE BAR AND CHAIN OIL

The chain oiler provides continuous lu-

brication to the chain and guide bar. Be

sure to fill the bar oil tank when you fill

the fuel tank (Capacity = 6.8 fl. oz.).

For maximum guide bar and chain life,

we recommend you use Craftsman

chain sew bar oil. If Craftsman bar oil is

not available, you may use a good

grade SAE 30 oil until you are able to

obtain Craftsman brand. The oil output

is automatically metered during opera-

tion. Your saw will use approximately

one tank of bar oil for every tank of fuel

mix. Always fill the bar oil tank when

you fill the fuel tank.

lines and carburetor are empty.Use fresh

furl next season. See STORAGE instruc- "

tions for additional information.

Never use engine or carburetor cleaner

products in the fuel tank or permanent

damage may occur.

See the STORAGE section for additional

information.

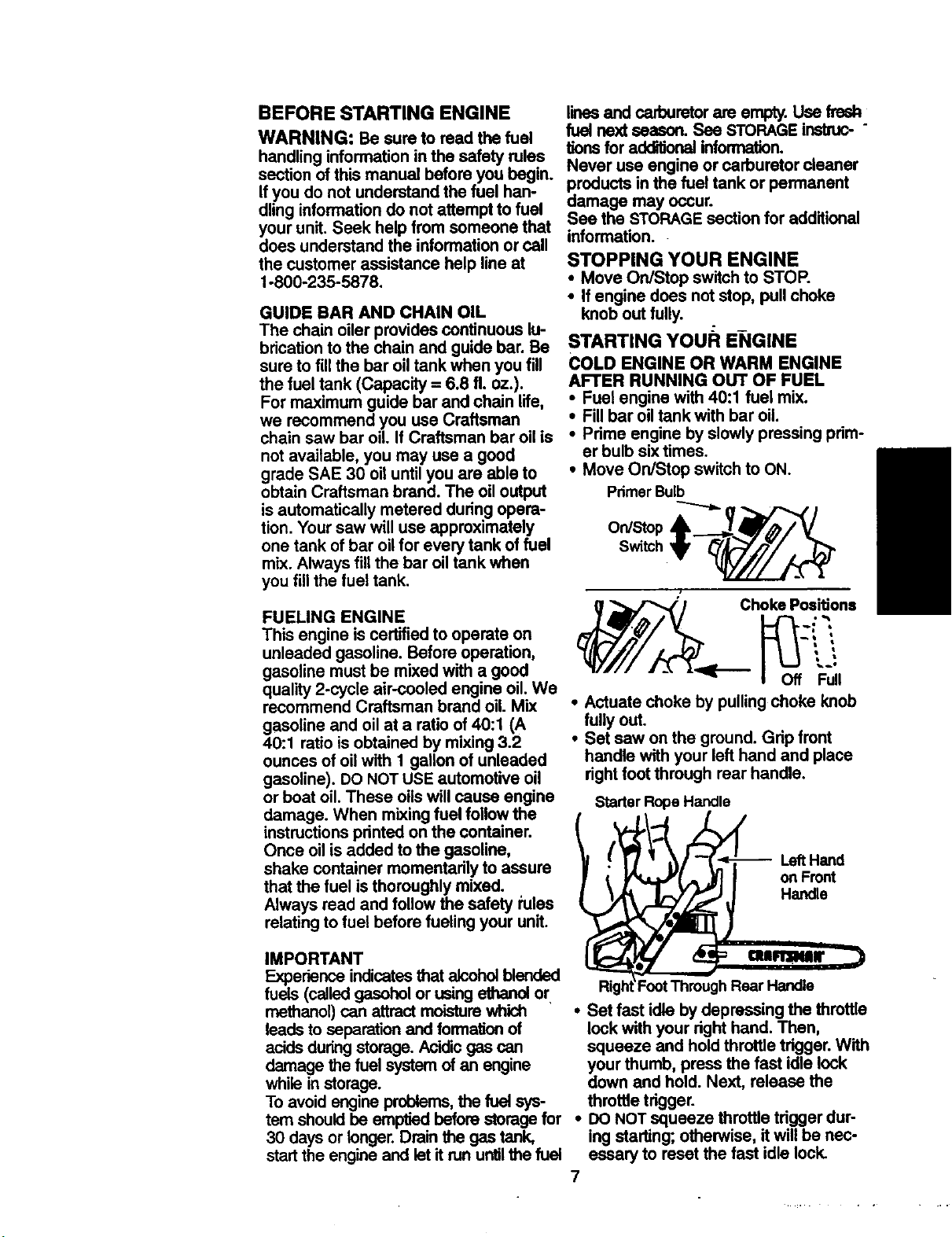

STOPPING YOUR ENGINE

• Move On/Stop switch to STOP.

• If engine does not stop, pull choke

knob out fully.

STARTING YOUR ENGINE

COLD ENGINE OR WARM ENGINE

AFTER RUNNING OUT OF FUEL

• Fuel engine with 40:1 fuel mix.

• Fill bar oil tank with bar oil.

• Prime engine by slowly pressing prim-

er bulb six times.

• Move On/Stop switch to ON.

Pdmer Bulb

FUELING ENGINE

This engine is certified to operate on

unleaded gasoline. Before operation,

gasoline must be mixed with a good

quality 2-cycle air-cooled engine oil. We

recommend Craftsman brand oil. Mix

gasoline and oil at a ratio of 40:1 (A

40:1 ratio is obtained by mixing 3.2

ounces of oil with 1 gallon of unleaded

gasoline). DO NOT USE automotive oil

or boat oil. These oils will cause engine

damage. When mixing fuel follow the

instructions printed on the container.

Once oil is added to the gasoline,

shake container momentarily to assure

that the fuel is thoroughly mixed.

Always read and follow the safety iules

relating to fuel before fueling your unit.

IMPORTANT

Experience indicates that alcohol blended

fuels (called gasohol or using ethanol or,

methanol) can attract moisture which

leads to separation and formation of

acids during storage. Acidic gas can

damage the fuel system of an engine

while in storage.

To avoid engine problems, the fuel sys-

tem should be emplk3d before storage for

30 days or longer. Drain the gas tank,

start the engine and let it run until the fuel

Choke Posi_ons

o •

t •

I t

Off Full

• Actuate choke by pulling choke knob

fully out.

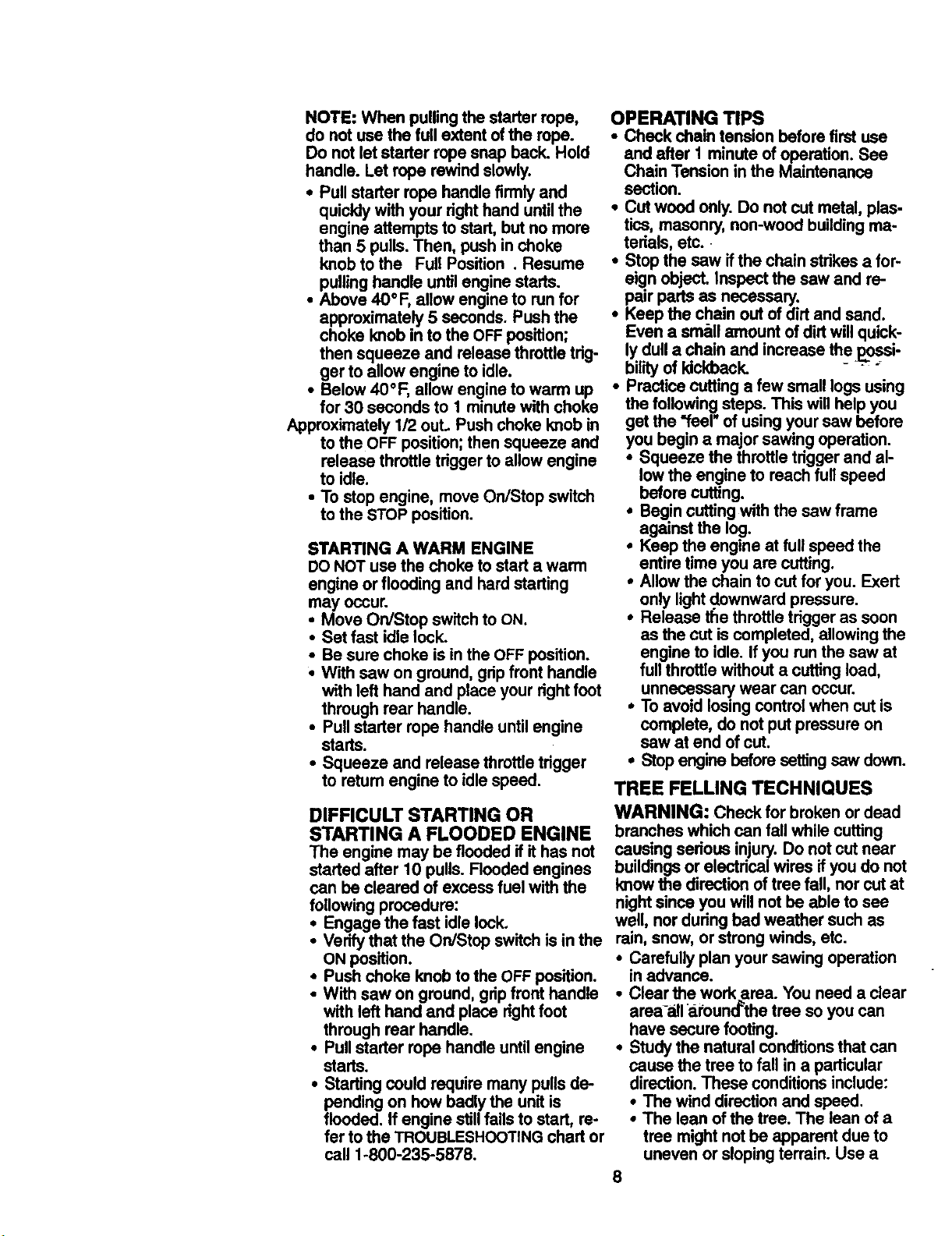

• Set saw on the ground. Grip front

handle with your left hand and place

right foot through rear handle.

Starter Rope Handle

LeftHand

on Front

Handle

'Foot ThroughRear Handle

• Set fast idle by depressing the throttle

lock with your right hand. Then,

squeeze and hold throttle trigger. With

your thumb, press the fast idle lock

down and hold. Next, release the

throttle trigger.

• DO NOT squeeze throttle trigger dur-

ing starting; otherwise, it will be nec-

essary to reset the fast idle lock.

7

NOTE:Whenpullingthestarterrope,

donotusethefullextentoftherope.

Donotletstarterropesnapbeck.Hold

handle.Letroperewindslowly.

• Pull starter rope handle firmly and

quickly with your right hand until the

engine attempts to start, but no more

than 5 pulis. Then, push in choke

knob to the Full Position . Resume

pulling handle until engine starts.

• Above 40°F, allow engine to run for

approximately 5 seconds. Push the

choke knob into the OFF position;

then squeeze and release throttle trig-

ger to allow engine to idle.

• Below 40°F, allow engine to warm up

for 30 seconds to 1 minute with choke

Approximately 1/2 out, Push choke knob in

to the OFF position; then squeeze and

release throttle trigger to allow engine

to idle.

• To stop engine, move On/Stop switch

to the STOP position.

STARTING A WARM ENGINE

DO NOT use the choke to start a warm

engine or flooding and hard starting

may occur.

• Move On/Stop switch to ON.

• Set fast idle lock.

• Be sure choke is in the OFF position.

• With saw on ground, grip front handle

with left hand and place your right foot

through rear handle.

• Pull starter rope handle until engine

starts.

• Squeeze and release throttle trigger

to return engine to idle speed.

DIFFICULT STARTING OR

STARTING A FLOODED ENGINE

The engine may be flooded if if has not

started after 10 pulls. Rooded engines

can be cleared of excess fuel with the

following procedure:

• Engage the fast idle lock.

• Verify that the On/Stop switch is in the

ON position.

• Push choke knob to the OFF position.

• With saw on ground, grip front handle

with left hand and place right foot

through rear handle.

• Pull starter rope handle until engine

starts.

• Starting could require many pulls de-

pending on how badly the unit is

flooded. If engine still fails to start, re-

fer to the TROUBLESHOOTING chart or

call 1-800-235-5878.

OPERATING TIPS

• Check chain tension before first use

and after 1 minute of operation. See

Chain Tension in the Maintenance

section.

• Cut wood only. Do not cut metal, plas-

tics, masonry, non-wood building ma-

terials, etc.

• Stop the saw it the chain strikes a for-

eign object. Inspect the saw and re-

pair parts as necessary.

• Keep the chain out of dirt and sand.

Even a small amount of dirt will quick-

ly dull a chain and increase the p_o,:_si-

bility of kickback.

• Practice cutting a few small logs using

the following steps. This will help you

get the "feel" of using your saw before

you begin a major sawing operation.

• Squeeze the throttle trigger and al-

low the engine to reach full speed

before cutting.

, Begin cutting with the saw frame

against the log.

• Keep the engine at full speed the

entire time you are cutting.

• Allow the chain to cut for you. Exert

only light downward pressure.

• Release the throttle trigger as soon

as the cut is completed, allowing the

engine to idle. If you run the saw at

full throttle without a cutting load,

unnecessary wear can occur.

• To avoid losing control when cut is

complete, do not put pressure on

saw at end of cut.

• Stop engine before setting saw down.

TREE FELUNG TECHNIQUES

WARNING: Check forbroken ordead

branches whichsan fall while cutting

causing seriousinjury.Do not cut near

buildingsor electricalwires if you do not

know the directionof tree fall, nor cutat

nightsince you willnot be able to see

well, norduringbad weather such as

rain,snow,or strong winds, etc.

• Carefully plan your sawing operation

in advance.

• Clear the work area. You need a clear

area-allafound_thetree so you can

have secure footing.

• Study the natural conffltionsthat can

cause the tree to fall in a particular

direction.These conditionsinclude:

• The wind directionand speed.

• The leanof the tree. The lean of a

tree might notbe apparent due to

uneven or slopingterrain. Use a

8

Loading...

Loading...