Craftsman 358351240 Owner’s Manual

IMPORTANT MANUAL Do Not Throw Away

J _/AJRS

Operator's

Manual

Model No

358.351240

ASSISTANCE

WARNING:

READ THE OPERATOR'S

MANUAL AND FOLLOW

ALL WARNINGS AND

SAFETY INSTRUCTIONS,

FAILURE TO DO SO CAN

RESULT IN SERIOUS

INJURY.

CRAFTSMAN"

Always Wear Eye Protection

(:RAFTSMANo

3.7 cu. in./60cc 2-CYCLE ENGINE

24 Inch Guide Bar

GASOLINE CHAIN SAW

• Assembly

• Operation

• Customer Responsibilities

° Service and Adjustments

• Repair Parts

530-083882-2-08/03/95

Sears, Roebuck and Co, Hoffman Estates, IL 60179 USA

SAFETY RULES

r

WARNING:

ALWAYS DISCONNECT SPARK PLUG WIRE AND PLACE WIRE WHERE IT CANNOT CONTACT SPARK

PLUG TO PREVENT ACCIDENTAL STARTING WHEN SETTING UP, TRANSPORTING, ADJUSTING OR

MAKING REPAIRS EXCEPT CARBURETOR ADJUSTMENTS.

BECAUSE A CHAIN SAW IS A HIGH-SPEED WOOD-CUTTING TOOL, SPECIAL SAFETY PRECAUTIONS

MUST BE OBSERVEDTO REDUCETHE RISK OF ACCIDENTS. CARELESS OR IMPROPER USE OFTHtS

TOOL CAN CAUSE SERIOUS INJURY.

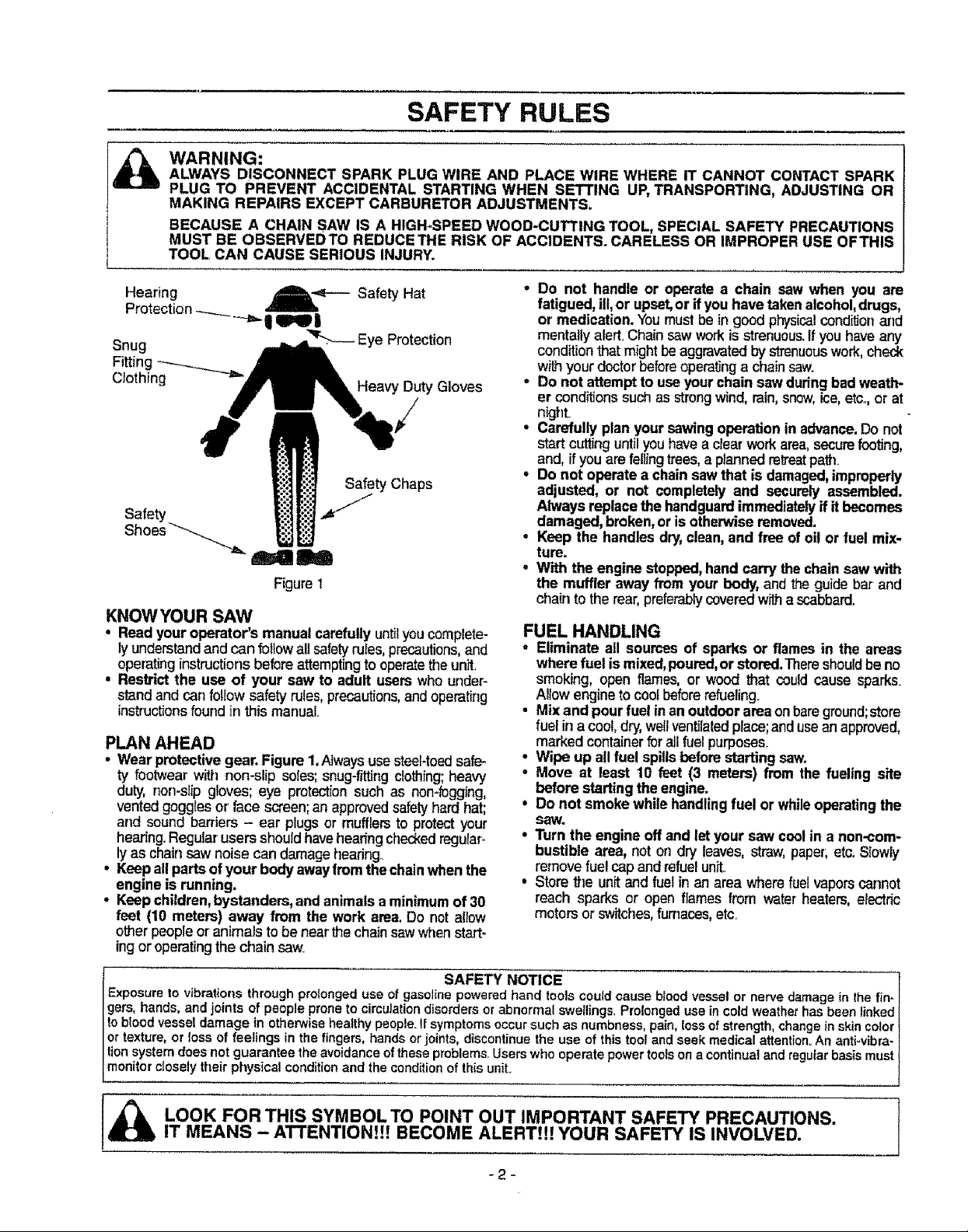

Hearing Safety Hat

Protection _..___. | _ !1

Snug ,J_/_'_"--- Eye Protection

Fitting

Clothing ,_F I'_k Heavy DutyGloves

€.- .,,i

Safety Chaps

Safety

Shoes

Figure 1

KNOW YOUR SAW

- Read your operator's manual carefully untilyoucomplete-

lyunderstandand can follow all safetyrules,precautions,and

operating instructions beforeattemptingto operatethe unit

• Restrict the use of your saw to adult users who under-

stand and can fo!low safety rules, precautions,andoperating

instructionsfound in this manual

PLAN AHEAD

• Wear protective gear. Figure 1. Alwaysusesteel.toedsafe-

ty footwear withnon-slip soles; snug-F_tingclothing;heavy

duty, non-slip gloves; eye protection such as non-fogging,

vented goggles or face screen;an approvedsafetyhard hat;

and sound barriers - ear plugs or mufflers to protectyour

hearing.Regular users should havehearingcheckedregular

lyas chainsaw noise can damagehearing_

• Keepall parts ofyour bodyawayfromthe chainwhenthe

engine is running.

• Keep children,bystanders, andanimals a minimumof 30

feet (10 meters) away from the work area. Do not atlow

other people or animals to be nearthechain sawwhen start-

ing or operatingthe chain saw.

• Do not handle or operate a chain saw when you are

fatigued,ill,or upset,or if you have takenalcohol,drugs,

or medication. You mustbe in good physicalcond_onand

mentally alert Chain sawwork is strenuous.If you have any

condition that might beaggravatedby strenuouswork, check

with your doctor before operatinga chainsaw.

• Do not attemptto useyourchain saw duringbad weath-

er conditions such as strongwind,rain,snow,ice,etc. or at

night

• Carefully plan your sawing operation in advance.Do not

start cutting until youhavea cleat work area, securefooting,

and, if you arefellingtrees,aplanned retreatpath

, Do not operate a chainsaw that is damaged,improperly

adjusted, or not completely and securely assembled.

Always replacethe handguardimmediatelyif itbecomes

damaged, broken,or is otherwise removed.

, Keep the handles dry,clean,and free of oil or fuel mix-

lure.

o With the engine stopped,hand carry the chain saw with

the muffler away from your body, and the guide bat and

chain to therear,preferablycovered witha scabbard.

FUEL HANDLING

- Eliminate all sources of spar'Ksor flames in the areas

where fuel is mixed, poured,or stored.Thereshouldbeno

smoking, open flames, or wood that could cause sparks.

Allow engine to cool beforerefueling.

• Mix and pourfuel inan outdoorarea on bareground;store

fuel in a cool, dry, wellventilatedplace;anduse an approved,

marked containerforattfuel purposes.

• Wipe up all fuel spills before starting saw.

° Move at least 10 feet (3 meters) from the fueling site

before startingthe engine.

• Do not smokewhile handlingfuel orwhileoperatingthe

saw.

° Turn the engine off and letyour saw coolin a non-com-

bustible area, not on dry leaves, straw,paper;etc,Stowly

remove fuel capand refuel unit.

, Store the unit and fuel in an area where fuel vaporscannot

reach sparks or open flames from water heaters, electdc

motors or switches,furnaces,etc.

SAFETY NOTICE

Exposureto vibrationsthrough prolonged use of gasoline powered hand tools couldcause b_oodvessel or nerve damage in Ihe fin-

gers, hands, and joints of people proneto circulationdisordersor abnormal sweIlings_ Prolongeduse in cold weather has been linked

toblood vessel damage in otherwise healthy people,if symptomsoccursuch as numbness, pain loss of strength change in skincolor

ortexture, or loss of fee ngs n the f ngers, hands orjoints, discontinue the use of this tootand seek medical attention. An anti-vibra.

lionsystem does not guarantee the avoidance of these problems..Users who operate powertoolsona continual and regularbasismust

monitorclosely their physical conditionand the conditionof this unit.

LOOK FOR THIS SYMBOLTO POINT OUT IMPORTANT SAFETY PRECAUTIONS.

IT MEANS - ATTENTION!!! BECOME ALERT!!! YOUR SAFETY IS INVOLVED.

SAFETY RULES

OPERATEYOUR SAW SAFELY

. Do notoperate a chain saw with onehand.Seriousinjury

to the operator, helpers, bystanders or any combination of

these persons may result from one-handed operation.A

chain saw is intended for two-handed use.

- Operate the chain saw only in well-ventilated outdoor

areas,

- Do not operate saw from a ladder or in a tree, unless

specifically trainedto do soo

• Position all parts of your body to the left of cut and

away from the chain when the engine is running,

. Cut wood only. Do not useyoursawto pryorshoveaway

limbs,roots,orother objects,

• Make sure the chain will not make contact with any

object while starting the engine. Nevertry to start the

saw when the guide bar is in a cutorkeff,

. Use extreme caution when cuttingsmall size brush and

saplings. Slender material can catchthe chain and be

whippedtoward you or pull you off balance..

- Be alert for springbeck when cutting a limb that is under

tension so you wilt not be struck by the limb or saw when

the tension inthe wood fibersis released.

• Do not put pressure on the saw at the end of a cuL

Applying pressurecan cause you to lose control whenthe

cut iscompleted.

Stop the engine before setting the saw down.

, Keep fuel and oil caps, screws,and fasteners securely

tightened,

MAINTAIN YOUR SAW IN GOOD WORKING

ORDER

• Have all chain saw service performed by your Sears

Service Center withtheexceptionofthe itemslistedinthe

"Customer Responsibilities" section of this manua!.. For

example, ifimproper tools are used to remove or hold the

flywheelwhen servicing theclutch, structuraldamage tothe

flywheel can occur and cause the flywheel to burst.

. Make certain the chain stops moving when the throttle

trigger is released. For correction, refer to "Carburetor

Adjustments:'

. Stop the saw if the chain strikes a foreign object.

Inspectunitand repairor replace partsas necessary,

• Disconnectthe spark plug before performing any main-

tenance exceptfor carburetoradjustments.

- Never modify your saw in any way. Use only SEARS

accessories and replacement partsas recommended

TRANSPORTING AND STORAGE

o Stop the unit before transporting.

• Allow engine to cool, cover the guide bar and chain, and

secure the unit before storing or transporting in a vehicle.

• Empty fuel tank before storing or transportingthe unit..Use

up any fuel left in the carburetor by starting the engine and

letting the engine run until it stops.

• Store unit and fuel in an area where fuel vapors cannot

reach sparks or open flames from water heaters, electric

motors or switches, furnaces,etc.

• Store unit so the chain cannot accidentallycause iniury.

. Store the unit out of the reachof children°

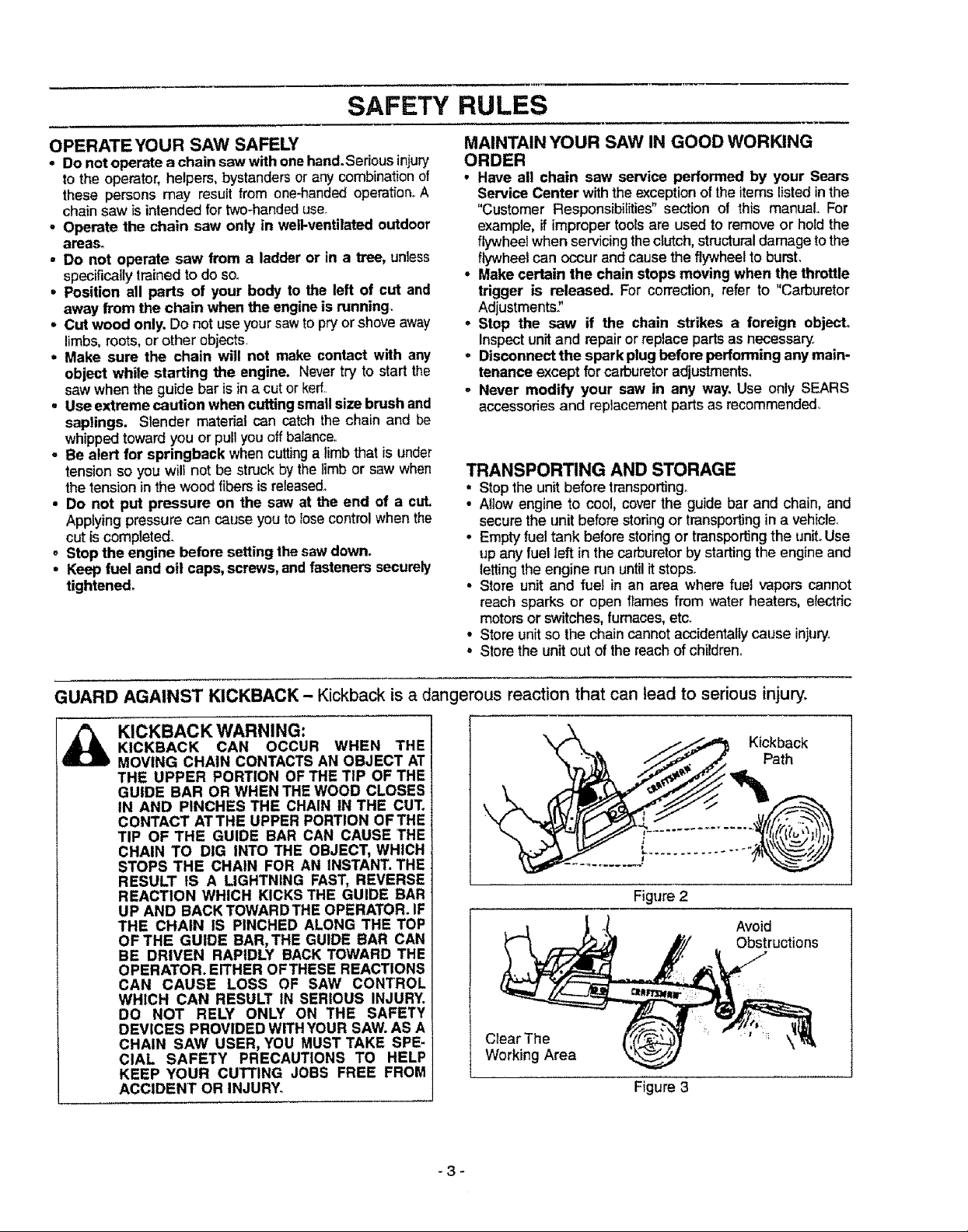

GUARD AGAINST KICKBACK - Kickback is a dangerous reaction that can lead to serious injury.

KICKBACK WARNING:

KICKBACK CAN OCCUR WHEN THE

MOVING CHAIN CONTACTS AN OBJECT AT

THE UPPER PORTION OF THE TIP OF THE

GUIDE BAR OR WHEN THE WOOD CLOSES

IN AND PINCHES THE CHAIN IN THE CUT.

CONTACT ATTHE UPPER PORTION OFTHE

TIP OF THE GUIDE BAR CAN CAUSE THE

CHAIN TO DIG INTO THE OBJECT, WHICH

STOPS THE CHAIN FOR AN INSTANT. THE

RESULT IS A LIGHTNING FAST, REVERSE

REACTION WHICH KICKS THE GUIDE BAR

UP AND BACK TOWARDTHE OPERATOR. IF

THE CHAIN IS PINCHED ALONG THE TOP

OF THE GUIDE BAR, THE GUIDE BAR CAN

BE DRIVEN RAPIDLY BACK TOWARD THE

OPERATOR. EITHER OFTHESE REACTIONS

CAN CAUSE LOSS OF SAW CONTROL

WHICH CAN RESULT IN SERIOUS INJURY.

DO NOT RELY ONLY ON THE SAFETY

DEVICES PROVIDED WITHYOUR SAW. AS A

CHAIN SAW USER, YOU MUST TAKE SPE-

CIAL SAFETY PRECAUTIONS TO HELP

KEEP YOUR CUTTING JOBS FREE FROM

ACCIDENT OR INJURY_

Figure 2

Clear The

Working Area

Figure 3

Kickback

Path

Avoid

Obstructions

SAFETY RULES

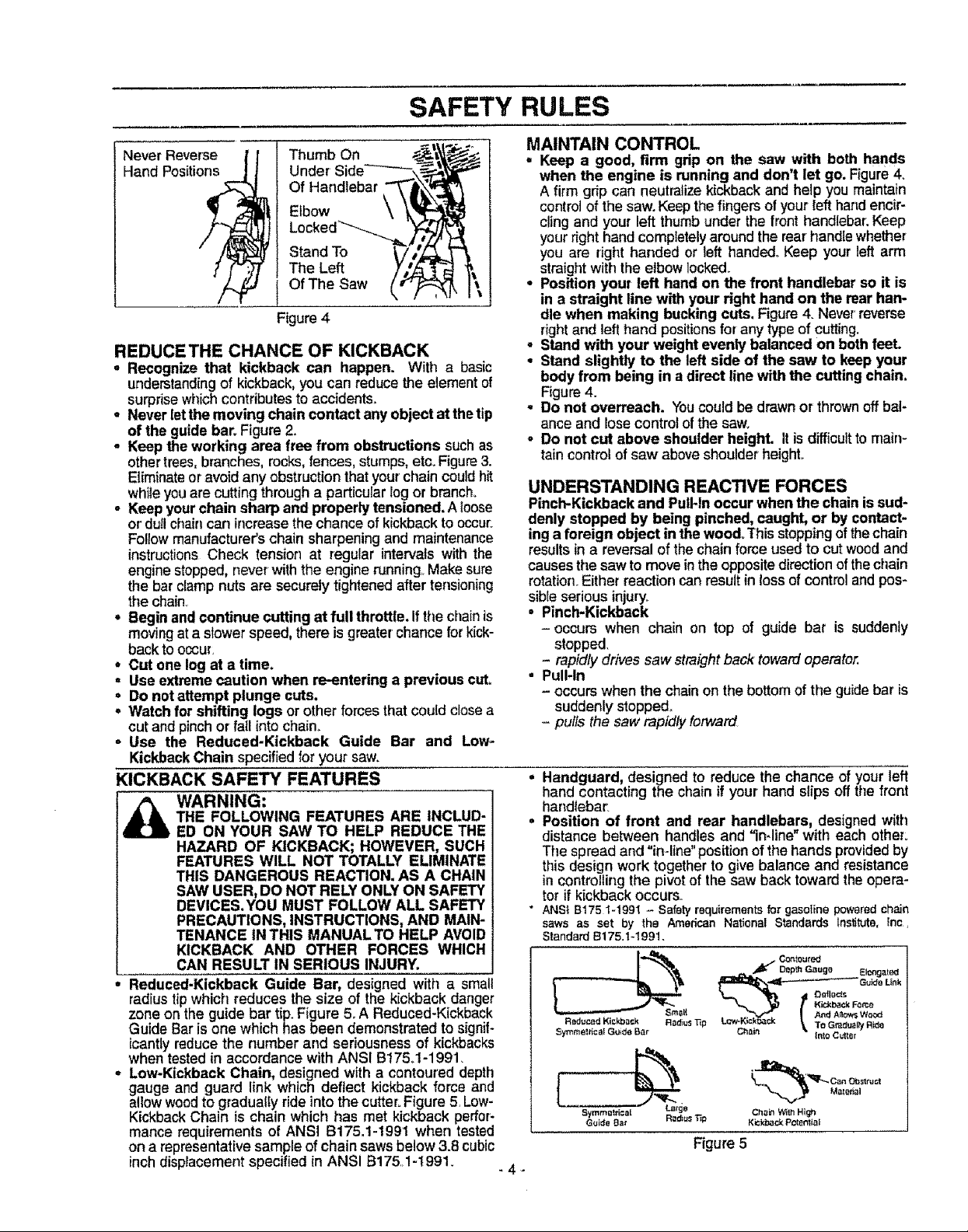

Never Reverse

Thumb On

Under Si

Of Handlebar

| Elbow \

Hand Positi_

11

Stand To

The Left

/4

Of The Saw

Figure4

REDUCETHE CHANCE OF KICKBACK

° Recognize that kickback can happen. With a basic

understandingof kickback, you can reduce the element of

surprise which contributes to accidents,,

• Never let the moving chain contact any object at thetip

of the guide bar. Figure2.

. Keep the working area free from obstructions such as

othertrees,branches, rocks, fences,stumps,etc.Figure3.

Eliminateoravoid any obstruction thatyourchaincouldhit

whileyouare cuttingthrougha particularlog or branch_

- Keep your chain sharp and properly tensioned. Aloose

or'dutlchaincan increasethe chance of kickback to occur.

Followmanufacturer's chain sharpeningand maintenance

instructionsCheck tension at regular intervalswith the

enginestopped, never withthe enginerunning_Make sure

the bar clampnutsare securely tightenedafter tensioning

the chain_

• Begin andcontinue cutting at full throttle. If the chainis

moving ata slower speed,there is greaterchanceforkick-

back to occur,

• Cut one log at a time.

• Use extreme caution when re-entering a previous cut,

= Donot attempt plunge cuts.

• Watch for shifting logs orother forcesthat couldclosea

cutand pinchor fat!intochain,.

- Use the Reduced-Kickback Guide Bar and Low-

KickbackChain specifiedfor your saw.

KICKBACK SAFETY FEATURES

l_ WARNING:

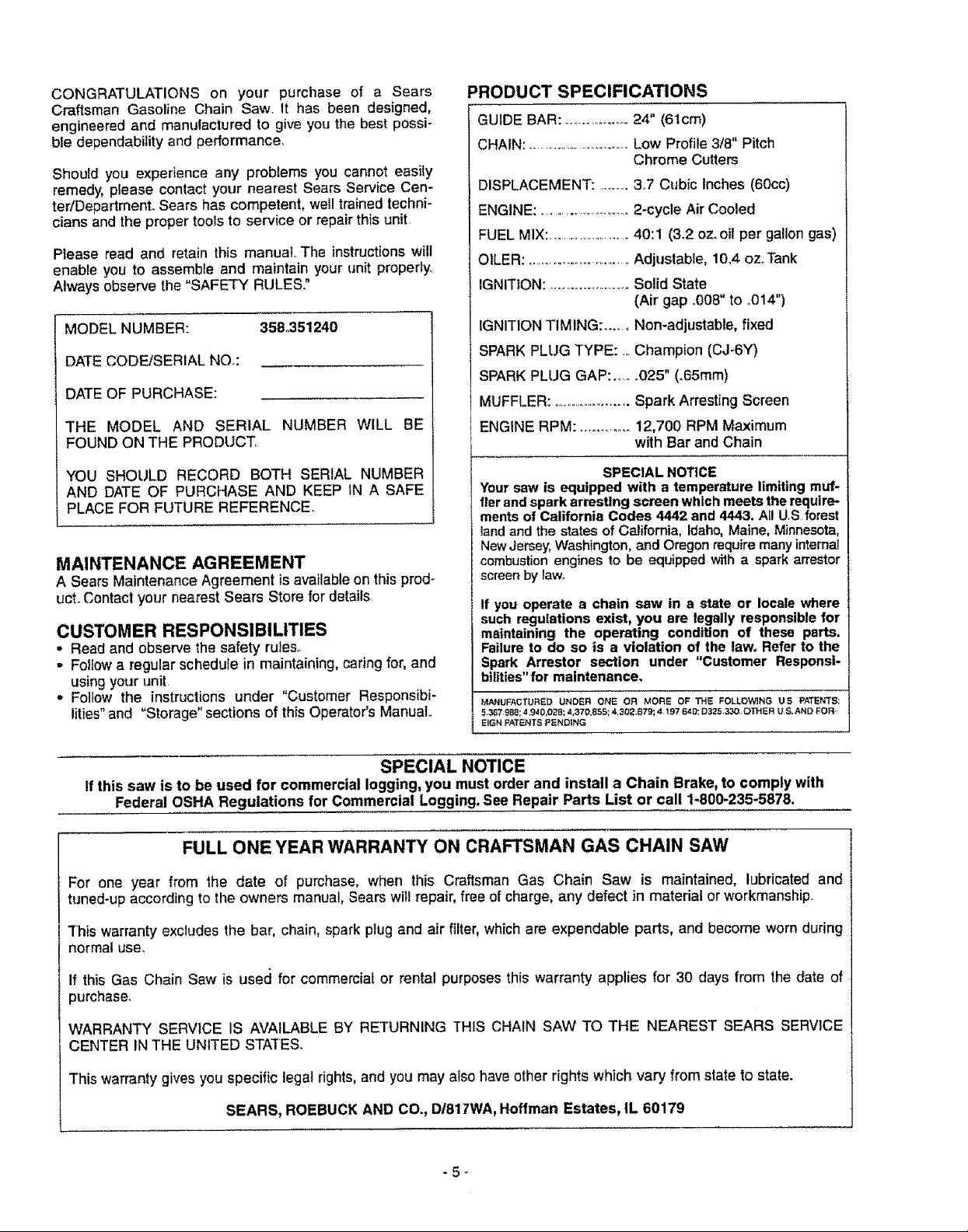

• Low-Kickback Chain, designed with a contoured depth

THE FOLLOWING FEATURES ARE INCLUD-

ED ON YOUR SAW TO HELP REDUCE THE

HAZARD OF KICKBACK; HOWEVER, SUCH

FEATURES WILL NOT TOTALLY ELIMINATE

THIS DANGEROUS REACTION. AS A CHAIN

SAW USER, DO NOT RELY ONLYON SAFETY

DEVICES.YOU MUST FOLLOW ALL SAFETY

PRECAUTIONS, INSTRUCTIONS, AND MAIN-

TENANCE IN THIS MANUALTO HELP AVOID

KICKBACK AND OTHER FORCES WHICH

CAN RESULT IN SERIOUS INJURY.

Reduced-Kickback Guide Bar, designed with a small

radiustip which reduces the size of the kickback danger

zone on the guide bar tip. Figure 5. A Reduced-Kickback

Guide Bar is one which has been demonstrated to signif-

icantly reduce the number and seriousness of kickbacks

when tested in accordance with ANSI BI75,1-199l.

gauge and guard link which deflect kickback force and

allow woodto gradually rideintothe cutter:Figure5. Low-

KickbackChain is chain which has met kickback perfor-

mance requirements of ANSI B175,,1-1991 when tested

on a representativesample ofchain saws below3.8 cubic

inchdisplacement specified in ANSI B175_1-1991.

MAINTAIN CONTROL

. Keep a good, firm grip on the saw with both hands

when the engine is running and don't let go. Figure4.

A firm gdp can neutralizekickback and help you maintain

control of the saw. Keepthe fingers of your left hand encir-

cling and your left thumb under the front handlebar:Keep

your right hand completely around the rear handle whether

you are right handed or left handed_Keep your left arm

straight with the elbow locked.

° Position your left hand on the front handlebar so it is

in a straight line with your right hand on the rear han-

dle when making bucking cuts, Figure4. Never'reverse

right and lefthand positions forany typeof cutting.

o Stand with your weight evenly balanced on bothfeet.

, Stand slightly to the left side of the saw to keep your

body from being in a direct line with the cutting chain.

Figure 4.

• Do not overreach. Youcould be drawn or thrown off bal-

ance and losecontrol of the saw.

o Do not cut above shoulder height. It isdifficult to main-

talncontrolofsaw above shoulder height.

UNDERSTANDING REACTIVE FORCES

Pinch-Kickback and PulHn occur when the chain is sud-

denly stopped by being pinched, caught, or by contact-

ing a foreign object inthe wood_Thisstoppingofthechain

results ina reversalof the chainforce usedto cut woodand

causes the saw to movein the opposite direction of the chain

rotation,.Either reaction can result in lossof control and pos-

sible serious injury.

• Pinch-Kickback

-occurs when chain on top of guide bar is suddenly

stopped.

- rapidly drives saw straight back towardoperator.

• Puff-In

- occurs when the chain on the bottom of the guide bar is

suddenly stopped,.

- pulls the saw rapidly forward

• Handguard, designed to reduce the chance ofyour left

hand contactingthe chain if your hand slips offthe front

handlebar_

• Position of front and rear handlebars, designed with

distance between handlesand "in-line" with each other:

The spread and "imline" positionof thehands providedby

thisdesignwork togetherto give balance and resistance

in controllingthe pivotof the saw back toward the opera-

tot if kickbackoccurs

• ANSI B175 1-199! _ Safety requirements for gasotine powered chain

saws as set by the American National Standards Insl_tute, Inc,

Standard B175.1-1991.

Reduc_ Kickba_k R_dius T_p

Symt_elt_c_ Guido B_r

'_ Can C_struct

G_t_e Bat Radiu_ "_p

Figure 5

_4_

ChtJ_ With High

K_k_ck ForintS!

CONGRATULATIONS on your purchase of a Sears

Craftsman Gasoline Chain Saw. It has been designed,

engineered and manufactured to give you the best possi-

bte dependability and pefformance_

Should you experience any problems you cannot easily

remedy, please contact your nearest Sears Service Cen-

ter/Department° Sears has competent, well trained techni-

cians and the proper tools to service or repair this unit

Please read and retain this manual,.The instructions will

enabte you to assemble and maintain your unit properly.

Always observe the "SAFETY RULES."

MODEL NUMBER: 358.351240

DATE CODE/SERIAL NOD:

DATE OF PURCHASE:

THE MODEL AND SERIAL NUMBER WILL BE

FOUND ON THE PRODUC_

PRODUCT SPECIFICATIONS

GUIDE BAR: .................. 24" (61cm)

CHAIN: ..............................Low Proffie 3/8" Pitch

Chrome Cutters

DISPLACEMENT: ........ 3..7 Cubic Inches (60cc)

ENGINE: .................................2-cycle Air Cooled

FUEL MIX: .............................40:1 (3.2 oz.,oil per gallon gas)

OILER: .................................Adjustable, 10.4 oz.,Tank

IGNITION: .........................Solid State

(Air gap .008" to .014")

IGNITION TIMING: .......Non-adjustable, fixed

SPARK PLUG TYPE: .,.Champion (CJ-6Y)

SPARK PLUG GAP:..... 025" (,65mm)

MUFFLER: .........................Spark Arresting Screen

ENGINE RPM: ...............12,700 RPM Maximum

with Bar and Chain

YOU SHOULD RECORD BOTH SERIAL NUMBER

AND DATE OF PURCHASE AND KEEP tN A SAFE

PLACE FOR FUTURE REFERENCE°

MAINTENANCE AGREEMENT

A Sears Maintenance Agreement isavailable on thisprod-

uct. Contact your nearest Sears Store for details

CUSTOMER RESPONSIBILITIES

° Read and observe the safety ruleso

- Follow a regular schedule in maintaining, caring for, and

usingyour unit.

o Follow the instructions under "Customer Responsibi-

lities"and =Storage" sections of this Operator's Manual..

Your saw is equipped with a temperature limiting muf-

fler and spark arresting screen which meets the require-

ments of California Codes 4442 and 4443. All US forest

land and the states of California, Idaho, Maine, Minnesota,

New Jersey, Washington, and Oregon require many intema]

combustion engines to be equipped wilh a spark arrestor

screen by law.

If you operate a chain saw in a state or locale where

such regulations exist, you are legally responsible for

maintaining the operating condition of these parts.

Failure to do so is a violation of the law. Refer to the

Spark Arrestor section under "Customer Respons|-

bilities"for maintenance.

MANUFACTURED UNDER ONE OR MORE OF THE FOLLOWING U5 PATENTS:

5.367 988; 4,940.028; 4,370,855; 4302.879; 4 197 6_0; D325.330 OTHER US. AND FOR e

EIGN PATENTS PENDING

SPECIAL NOTICE

SPECIAL NOTICE

If this saw is to be used for commercial logging, you must order and install a Chain Brake, to comply with

Federal OSHA Regulations for Commercial Logging. See Repair Parts List or call 1-800-235-5878.

FULL ONE YEAR WARRANTY ON CRAFTSMAN GAS CHAIN SAW

For one year from the date of purchase, when this Craftsman Gas Chain Saw is maintained, lubricated and

tuned-up according to the owners manual, Sears will repair, free of charge, any defect in material or workmanship.

This warranty excludes the bar, chain, spark plug and air filter, which are expendable parts, and become worn during

normal use.

If this Gas Chain Saw is usecl for commercial or rental purposes this warranty applies for 30 days from the date of

purchase.

WARRANTY SERVICE IS AVAILABLE BY RETURNING THIS CHAIN SAW TO THE NEAREST SEARS SERVICE

CENTER IN THE UNITED STATES.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

SEARS, ROEBUCK AND CO. D/817WA, Hoffman Estates, IL 60179

-5 _

TABLE OF CONTENTS

Safety Rules ...........................................................................................2

Product Specifications ...................................................................................... 5

Warranty ..............................................................................................5

Accessories................................................................................................6

Assembly ....................................................................................................7

Operation ................................................................................................10

INDEX

A

Accessories ............................................................................................. 6

Air Filter...................................................................................................22

Assembly ...................................................................................................7

B

Bar and Chain Oil............................................................................ 12

Bucking.......................................................................................17

C

Carburetor Adjustments .................................................................27

Carton Contents ...............................................................................7

Chain Oiler ...........................................................................................! 1

Chain Sharpening ..................................................................................20

Chain Adjustment ........................................................................24

Customer Responsibilities .....................................................19

E

Engine

Fuel/Oil.......................................................................................12

Spark Plug .........................................................................................22

Starting .....................................................................................................!3

Storage ...........................................................................................29

F

Fuel Filter.........................................................................................23

Fueling......................................................................................................12

G

Guide Bar and Chain Oil.......................................................I2

Guide Bar Maintenance ............................................................ 21

H

HowTo Use Your Chain Saw............................................ 11

Customer Responsibilities ..............................................................19

Service and Adjustments ...........................................................24

Storage .................................................................................... 29

Trouble Shooting Points ..................................................................30

Repair Parts ......................................................................................31

Repair' Parts Ordering/Service ..................................Back Cover

K

Know Your Chain Saw .......................................................................10

L

Limbing..................................................................................................18

M

Maintenance Schedule .................................................................19

Model Number.....................................................................................5

Muffler ..............................................................................................22

O

Operation ...............................................................................10

Ordering Repair Parts...........................................Back Cover

P

Product Specifications ............................................................5

Pruning....................................................................................18

R

Repair Parts ...........................................................................3t

S

Service and Adjustments .............................................................24

Spark Arrestor Screen .......................................................22

Starter Rope............................................................................25

Starting ........................................................................................ 13

Storage .........................................................................................29

T

Throttle Control Group ..................................................... 11

Tree Felling.............................................................................15

Trouble Shooting Points .......................................................30

W

Warranty..................................................................................5

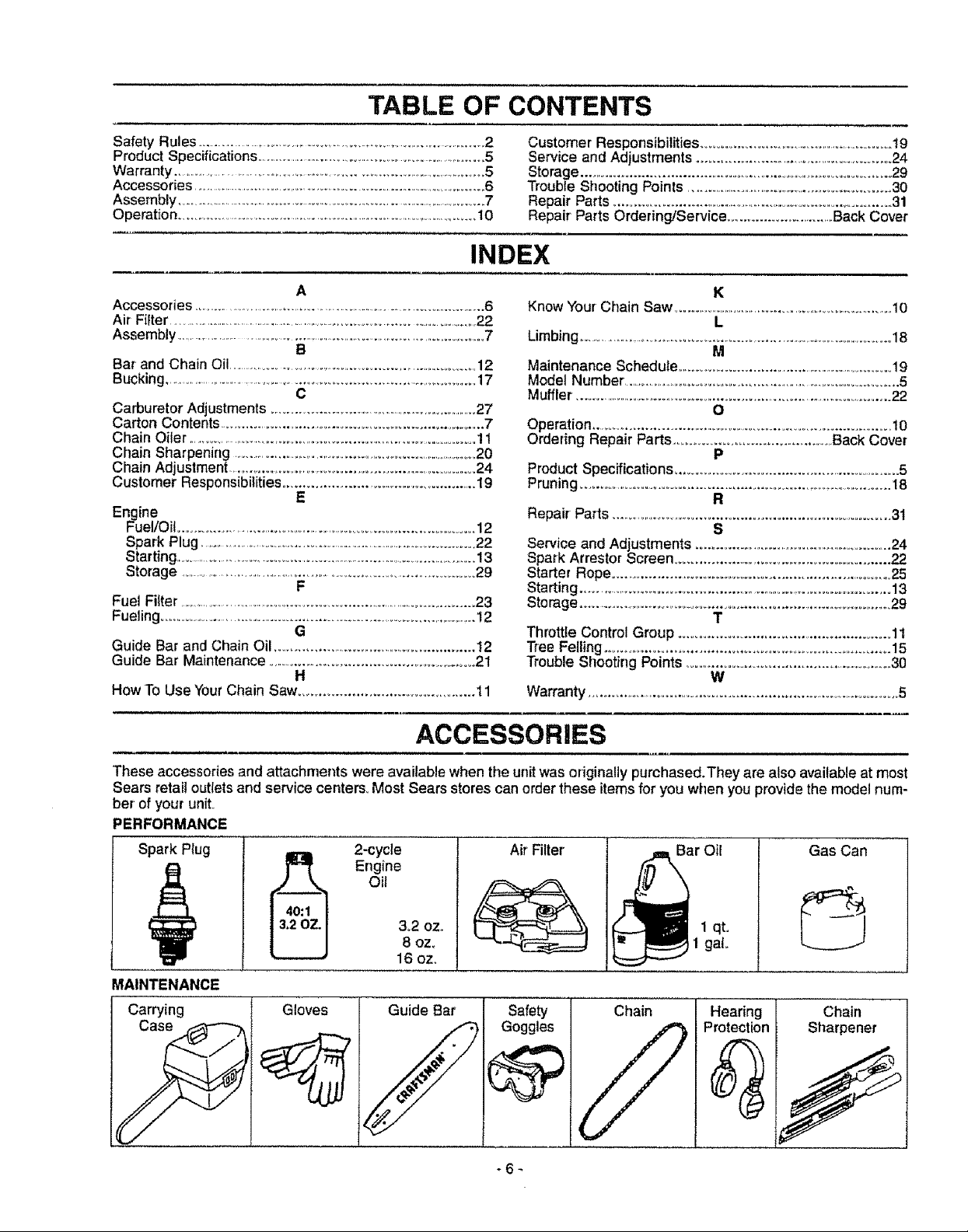

ACCESSORIES

These accessories and attachments were availablewhen the unit was originallypurchased.They are also available at most

Sears retail outletsand service centers°MostSears stores can orderthese itemsfor you when you providethe model num-

ber'ofyour unit.

PERFORMANCE

Spark Plug

MAINTENANCE

Carrying

Gloves

2-cycle

Oil

Engine

/

&2 oz,

8 oz_

16 oz_

Guide Bar'

Air Filter' Bar Oil

Safety

Goggles

Chain

2'

-6-

1 qt.

1 gaL

Hearing

Protection

Gas Can

Chain

Sharpener

f

_J

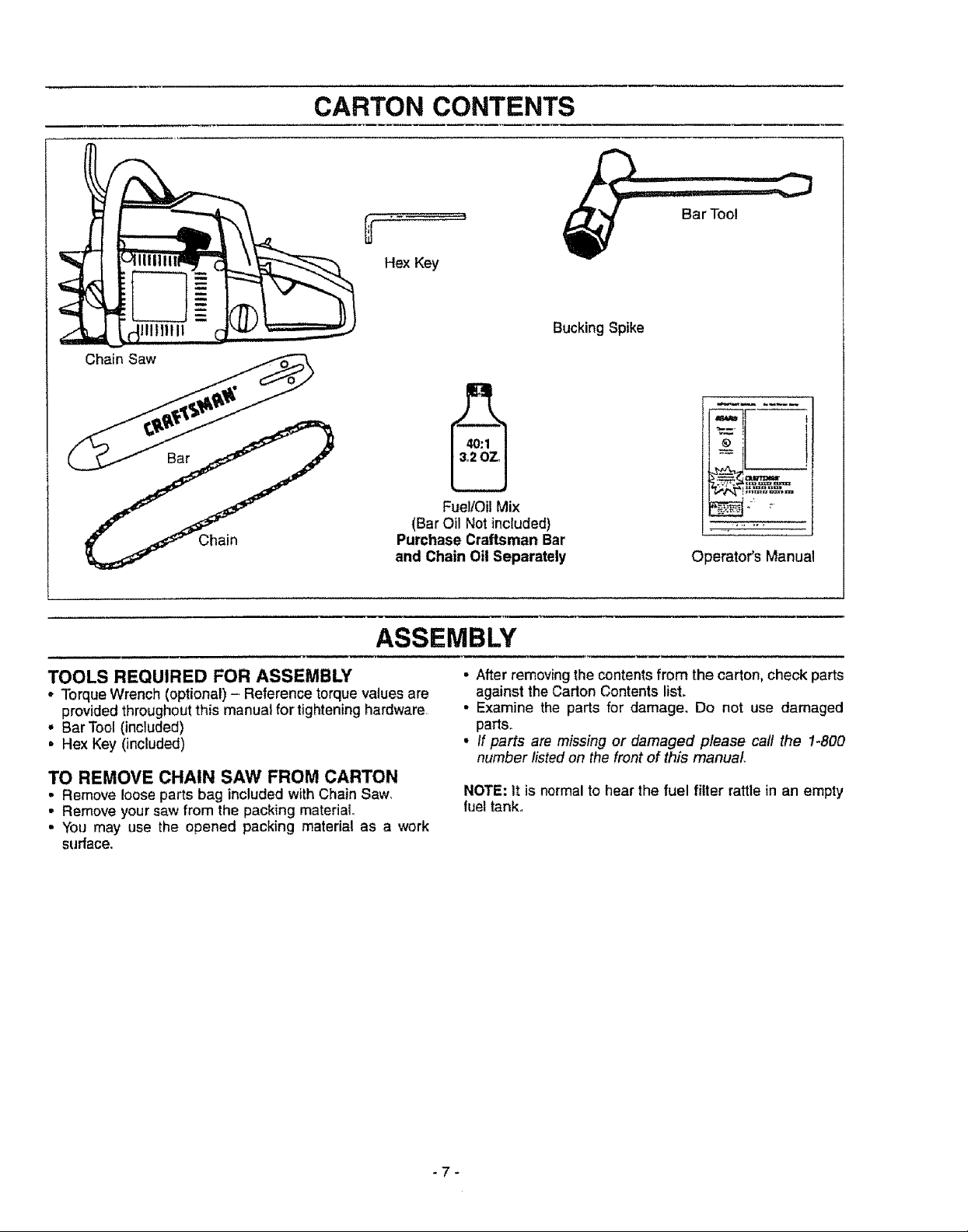

Chain Saw

_Chain

Illllllll

CARTON CONTENTS

Hex Key

FueI/Oil Mix

(Bar Oil Not included)

Purchase Craftsman Bar

and Chain Oil Separately

Bucking Spike

_,.m+ !

Operator's Manual

ASSEMBLY

TOOLS REQUIRED FOR ASSEMBLY

• Torque Wrench (optional) - Reference torque values are

provided throughout this manual for tightening hardware

• BarTool (included)

• Hex Key (included)

TO REMOVE CHAIN SAW FROM CARTON

• Remove looseparts bag included with Chain Saw_

• Remove your saw from the packing material

• You may use the opened packing material as a work

surface,,

• After removing the contents from the carton, check parts

against the Carton Contents list.

• Examine the parts for damage. Do not use damaged

parts+

• Ifparts are missing or damaged please carl the 1+800

number listed on the front of this manual

NOTE: tt is normal to hear the fuel filter rattle in an empty

fueltank.

-7-

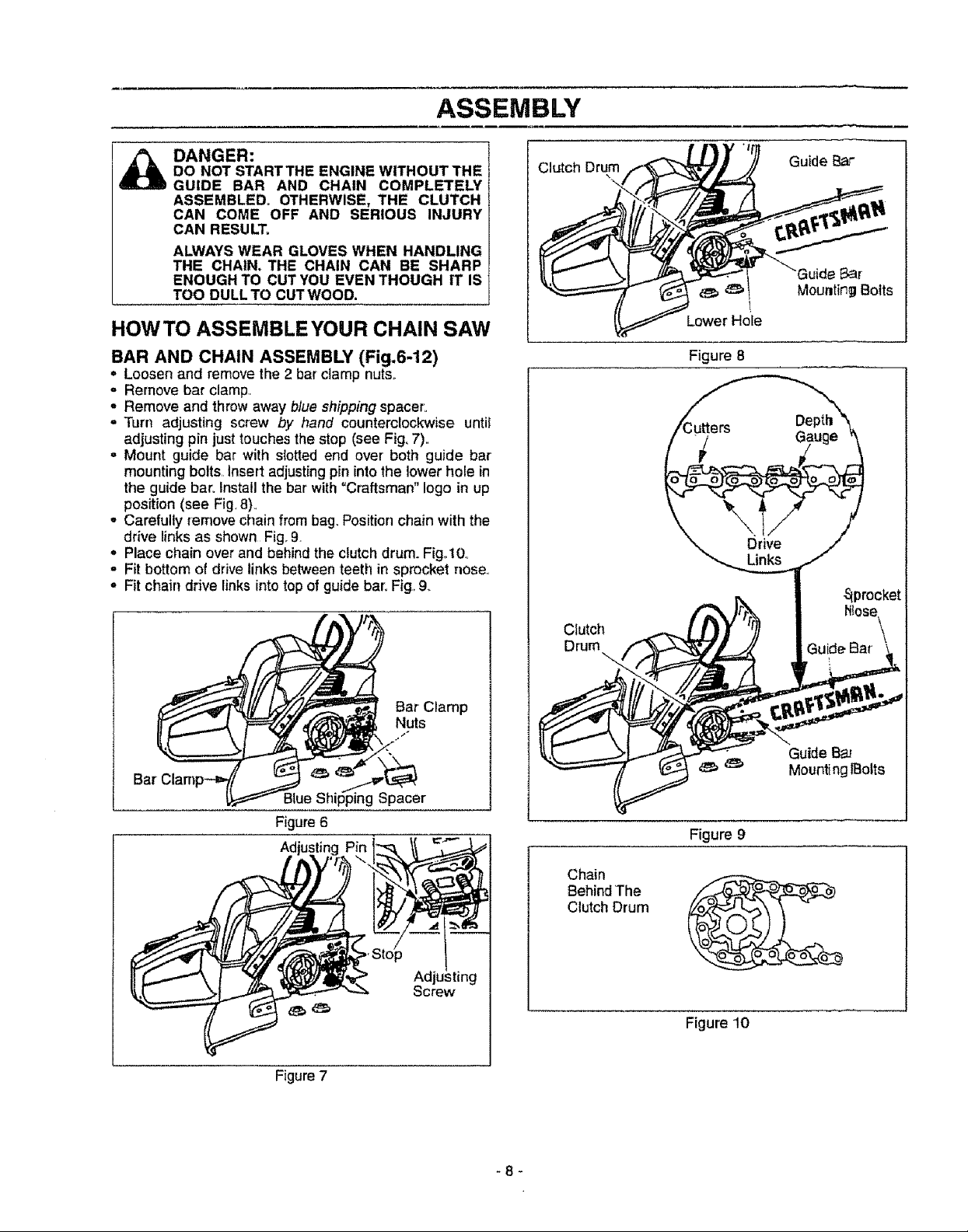

ASSEMBLY

DANGER:

DO NOT STARTTHE ENGINE WITHOUT THE

GUIDE BAR AND CHAIN COMPLETELY

ASSEMBLED° OTHERWISE, THE CLUTCH

CAN COME OFF AND SERIOUS INJURY

CAN RESULT.

ALWAYS WEAR GLOVES WHEN HANDLING

THE CHAIN, THE CHAIN CAN BE SHARP

ENOUGH TO CUT YOU EVEN THOUGH W IS

TOO DULLTO CUTWOOD.

HOWTO ASSEMBLEYOUR CHAIN SAW

BAR AND CHAIN ASSEMBLY (Fig.6-12)

, Loosen and remove the 2 bar clamp nuts°

= Remove bar clamp.

° Remove and throw away blue shipping spacer:

= Turn adjusting screw by hand counterclockwise untii

adjusting pin just touches the stop (see Fig.7)..

= Mount guide bar with slotted end over both guide bar

mounting bolts. Insert adjusting pin into the lower hole in

the guide bar. Install the bar with "Craftsman" logo in up

position(see Fig. 8)_

- Carefully remove chain from bag. Position chain with the

drive links as shown Fig,.9.

° Place chain over and behind the clutch drum. Fig..10..

= Fit bottom of drive links between teeth in sprocket nose.

o Fit chain drive links into top of guide bar: Fig. 9.

Clutch Drum

Guide Bar

Mourltin_;Bolts

Lower Hole

Figure 8

Bar

Clutch

Drum

Bar Clamp

Nuts

Blue Shi Spacer

Figure6

Figure 9

Chain

Behind The

Clutch Drum

Screw

Figure 10

Figure7

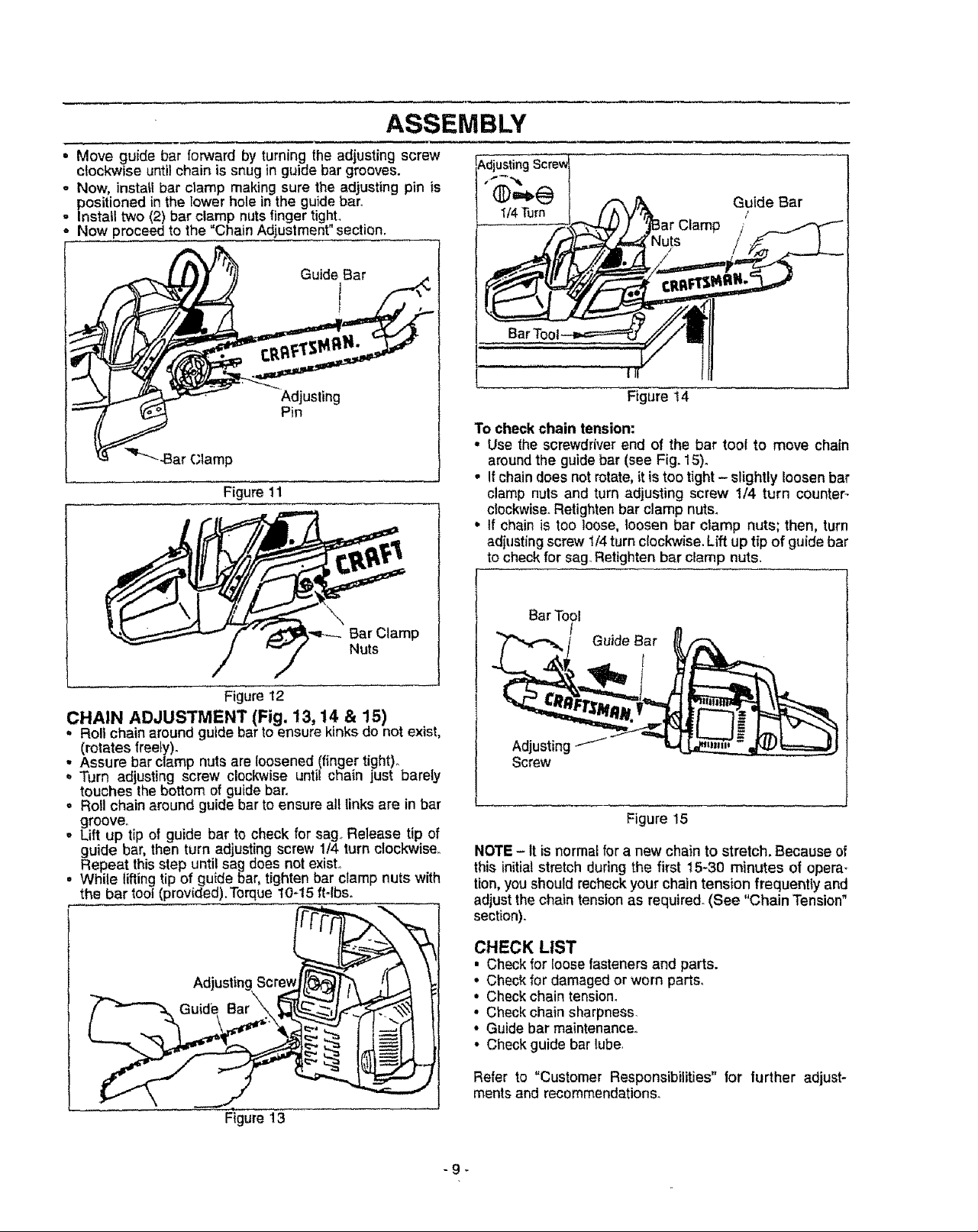

ASSEMBLY

• Move guide bar forward by turning the adjusting screw

clockwise until chain is snug in guide bar grooves.

o Now, install bar clamp making sure the adjusting pin is

positioned inthe lower hole in the guide bar,

Install two (2) bar clamp nuts finger tight

,_Now proceed to the "Chain Adjustment section.

Guide Bar

t

Guide Bar

/

Adjusting

Pin

"__ -Bar Clamp

Figure 11

Bar Clamp

Nuts

Figure 12

CHAIN ADJUSTMENT (Fig, 13, 14 8=15)

Roll chainaround guide bar to ensure kinks do not exist,

(rotates freely).

Assure barclamp nuts are loosened (fingertight).

Turn adjusting screw clockwise until chain just barely

touches the bottom ot guide bar.

= Roll chainaround guide bar to ensure all links are in bar

groove..

• Lift up tip of guide bar to check for sag.,Release tip of

guide bar, thenturn adjustingscrew 1/4 turn clockwise.

Repeat thisstep untilsag does not exist..

• While lifting tip of guide bar, tighten bar clamp nuts with

the bar tool(provided). Torque 10-15 ft-lbs.

Figure t4

To check chain tension:

• Use the screwdriver end of the bar tool to move chain

around the g[,tidebar (see Fig. 15)_

• Ifchain does not rotate, it is too tight - slightly loosen bar

clamp nuts and turn adjusting screw 1/4 turn counter-

clockwise. Retighten bar clamp nuts.

• If chain is too loose, loosen bar clamp nuts; then, turn

adjusting screw 1/4turn clockwise, Lift up tip of guide bar

to check for sag Retighten bar clamp nuts,

Bar Tool

/

Guide Bar

t

Adjusting

Screw

Figure 15

NOTE- Itis normal for a new chain to stretch, Because of

this initial stretch during the first 15-30 minutes of opera.

lion,you should recheck your chain tension frequently and

adjust the chain tension as required. (See "Chain Tension"

section).

Figure 13

CHECK LIST

• Check for loosefasteners and parts.

• Check for damaged or worn parts°

• Check chain tension,

• Check chain sharpness_

• Guide bar maintenance.

• Check guide bar lube,

Refer to "Customer Responsibilities" for further adjust-

ments and recommendations_

-9_

Loading...

Loading...