IMPORTANT MANUAL

,, ,,,

SEARS

Operator's

Manual

Model No.

358.351191

Do Not Throw Away

d_b WARNING:

READ THE OPERATOR'S

MANUAL AND FOLLOW

ALL WARNINGS AND

SAFETY INS'I'RUCTIONS.

FA|LURETO DO SO CAN

RESULT IN SERIOUS

INJURY.

Always Wear Eye Protection

®

cu. in./46cc 2-CYCLE2.8

1 inch Guide Bar

Turbo Air C :aner System

GASOLINE CH SAW

• Assembly

° Operation

° Customer Responsibilities

° Service and Adjustments

• Repair Parts

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

530-083986-09/28/95

SAFETY RULES

WARNING:

ALWAYS DISCONNECT SPARK PLUG WIRE AND PLACE WIRE WHERE IT CANNOT CONTACT

SPARK PLUG TO PREVENT ACCIDENTAL STARTING WHEN SETTING UP,TRANSPORTING,

ADJUSTING OR MAKING REPAIRS EXCEPT CARBURETOR ADJUSTMENTS.

BECAUSE A CHAIN SAW IS A HIGH-SPEED WOOD-CUTTING TOOL, SPECIAL SAFETY PRECAU-

TIONS MUST BE OBSERVED TO REDUCETHE RISK OF ACCIDENTS. CARELESS OR IMPROPER

USE OF THIS TOOL CAN CAUSE SERIOUS INJURY.

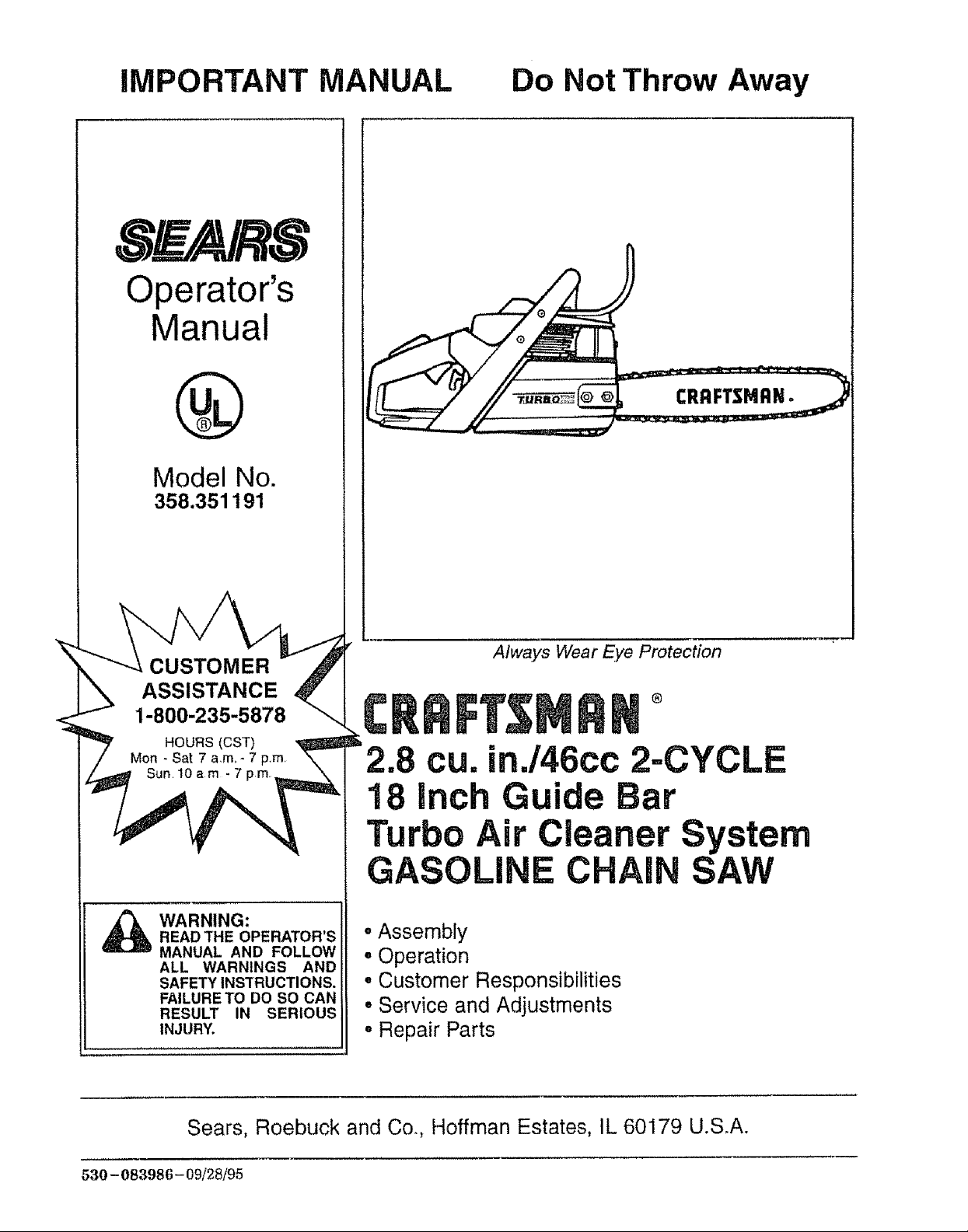

Hearing

Snug

Fitting

Clothing

Safety

Shoes _,_

,__ Safety Hat

Eye Protection

Heavy Duty Gloves

,Chaps

Figure t

KNOW YOUR SAW

- Read your operator's manual carefully until you

completely understand and can follow all safety rules,

precautions, and operating instructions before

attempting to operate the uniL

• Restrict the use of your saw to adult users who

understand and can follow safety rules, precautions,

and operating instructionsfound in this manual.

PLAN AHEAD

• Wear protective gear. Figure 1oAlways use steel-

toed safety footwear with non-slip soles; snug4itting

clothing; heavy duty, non-slip gloves; eye protection

such as non-fogging, vented goggles or face screen;

an approved safety hard hat; and sound barriers - ear

plugs or mufflers to protect your hearing. Regular

users should have hearing checked regularly as chain

saw noise can damage hearing

= Keep all parts of your body away from the chain

when the engine is running.

, Keep children, bystanders, and animals a minimum

of 30 feet (10 Meters) sway from the work area. Do not

allow other people or animals to be near the chain saw

when starting or operating the chain saw

SAFETY NOTICE 1

Exposure to v brations through prolonged use of gasoline powered hand tools could cause blood vessel or nerve damage in the|

fingers, hand and joints of people prone to circulation disorders or abnormal swellings Prolonged use in cold weather has been|

linked to bood vesse damage in otherwise healthy people, if symptoms occur such as numbness, pain, loss of strength, change|

in skin color or texture or loss of fee ng n the | ngers, hands or joints, discontinue the use of this tool and seek medical atten-|

tion An anti-vibration system does not guarantee the avoidance of these problems. Users who operate power tools on a contin-|

ual and regular basis must monitor closely their physical condition and the condition of this unit 1

- Do not handle or operate a chain saw when you

are fatigued, ill, or upset, or if you have taken alco-

hoi, drugs, or medication. You must be in good

physical condition and mentally alert. Chain saw work

is strenuous.. If you have any condition that might be

aggravated by strenuous work, check with your doctor

before operating a chain saw.

, Do not attempt to use your chain saw during bad

weather conditions such as strong wind, rain, snow,

ice, etc., or at night.

° Carefully plan your sawing operation in advance.

Do not start cutting until you have a clear work area,

secure footing, and, ifyou are felling trees, a planned

retreat path.

° Do not operate a chain saw that is damaged,

improperly adjusted, or not completely and

securely assembled. Always replace the hand-

guard immediately if it becomes damaged, bro*

ken, or is otherwise removed.

, Keep the handles dry, clean, and free of oil or fuel

mixture.

o With the engine stopped, hand carry the chain

saw with the muffler away from your body, and the

guide bar and chain to the rear, preferably covered

with a scabbar&

FUEL HANDLING

° Eliminate all sources of sparks or flames in the

areas where fuel is mixed, poured, or stored. There

should be no smoking, open flames, or work that

could cause sparks. Allow engine to cool before refu-

eling.

* Mix and pour fuel in an outdoor area on bare

ground; store fuel in a coot, dry, welt ventilated place;

and use an approved, marked container for all fuel

purposes.

, Wipe up all fuel spills before starting saw.

, Move at least 10 feet (3 meters) from the fueling

site before starting the engine.

• Do not smoke while handling fuel or while operat-

ing the saw.

, Turn the engine off and let your saw cool in a non-

combustible area, not on dry leaves, straw, paper,

etc_Slowly remove fuel cap and refuel unit.

° Store the unit and fuel in an area where fuel vapors

can not reach sparks or open flames from water

heaters, electric motors or switches, furnaces, etc

[_ LOOK FOR THIS SYMBOLTO POINT OUT IMPORTANT SAFETY PRECAUTIONS.

IT MEANS - AT'rENTION!!! BECOME ALERT!!! YOUR SAFETY IS INVOLVED.

-2-

SAFETY RULES

OPERATE YOUR SAW SAFELY

- Do not operate a chain saw with one hand, Serious

injuryto the operator, heipers, bystanders or any com-

bination of these persons may result from one-hand-

ed operation. A chain saw is intended for two-handed

use,

• Operate the chain saw only in well-ventilated out-

door areas.

• Do not operate saw from a ladder or in a tree,

unless specifically trained to do so,

• Position all parts of your body to the left of cut and

away from the chain when the engine is running.

• Cut wood only. Do not use your saw to pry or shove

away limbs, roots, or other objects.

° Make sure the chain will not make contact with

any object while starting the engine. Never try to

start the saw when the guide bar is in a cut or kerr.

• Use extreme caution when cutting small size

brush and saplings. Slender material can catch the

chain and be whipped toward you or pull you off bal-

ance,

• Be alert for springback when cutting a limb that is

under tension so you will not be struck by the limb or

saw when the tension in the wood fibers is released.

° Do not put pressure on the saw at the end of a cut°

Applying pressure can cause you to losecontrol when

the cut is completed.

- Stop the engine before setting the saw down,,

- Keep fuel and oil caps, screws, and fasteners securely

tightened,

MAINTAIN YOUR SAW IN GOOD WORKING

ORDER

° Have all chain saw service performed by your Sears

Service Center with the exceptionof lhe items listed in

the maintenance section of thwsmanual_For example, if

improper tools are used to remove or hold the ltywheel

when servicing the dutch, structural damage to the fly-

wheel can occur and cause the flywhee! to burst

° Make certain the chain stops moving when the throt-

tle trigger is released. For correction, refer to

"Carburetor Adjustments,"

• Stop the saw if the chain strikes a foreign object.

Inspect unit and repair or replace parts as necessary,

• Disconnect the spark plug before performing any

maintenance except for carburetor adjustments.

° Never modify your saw in any way. Use only attach-

ments supplied or specifically recommended by the man-

ufacturer

• Use only quality SEARS accessories and replacement

parts as recommended for this unit

TRANSPORTING AND STORAGE

• Stop the unit before transporting

• Allow engine to cool, cover the guide bar and chain, and

secure theunit before storing or transporting in a vehicle

o Empty fuel tank before storing or transporting the unit

Use up any fuel left in the carburetor by starting the

engine and letting the engine run until it stops

° Store unit and fuel in an area where fuel vapors cannot

reach sparks or open flames from water heaters, electric

motors or switches, furnaces, etc

• Store unit so the chain cannot accidentally cause injury

• Store the unit outof the reach of children.

, i ,, i , ii i,iiii1,,11111,,,11 ,11

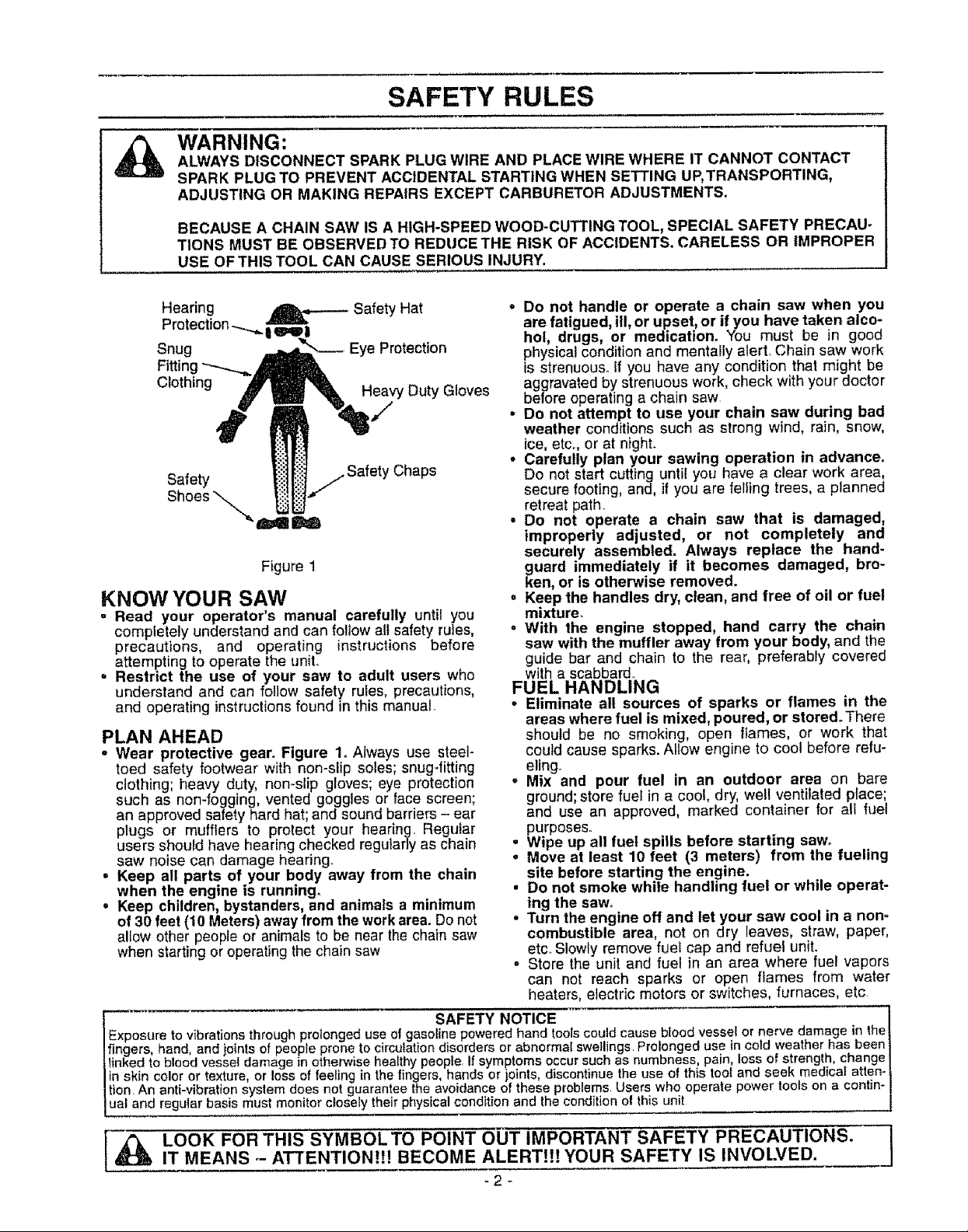

GUARD AGAINST KICKBACK - Kickback is a dangerous reaction that can lead to serious injury.

KICKBACK WARNING

KICKBACK CAN OCCUR WHEN THE MOV-

ING CHAIN CONTACTS AN OBJECT ATTHE

UPPER PORTION OF THE TIP OF THE

GUIDE BAR OR WHEN THE WOOD CLOSES

IN AND PINCHES THE CHAIN IN THE CUT.

CONTACT AT THE UPPER PORTION OF

THE TIP OF THE GUIDE BAR CAN CAUSE

THE CHAIN TO DIG INTO THE OBJECT,

WHICH STOPS THE CHAIN FOR AN

INSTANT. THE RESULT IS A LIGHTNING

FAST, REVERSE REACTION WHICH KICKS

THE GUIDE BAR UP AND BACK TOWARD

THE OPERATOR. IF THE CHAIN IS

PINCHED ALONG THE TOP OF THE GUIDE

BAR, THE GUIDE BAR CAN BE DRIVEN

RAPIDLY BACK TOWARD THE OPERATOR.

EITHER OF THESE REACTIONS CAN

CAUSE LOSS OF SAW CONTROL WHICH

CAN RESULT IN SERIOUS INJURY. DO NOT

RELY ONLY ON THE SAFETY DEVICES

PROVIDED WITH YOUR SAW. AS A CHAIN

SAW USER, YOU USER, YOU MUST TAKE

SPECIAL SAFETY PRECAUTIONSTO HELP

KEEP YOUR CUTTING JOBS FREE FROM

ACCIDENT OR INJURY.

Kickback

Path

Figure 2

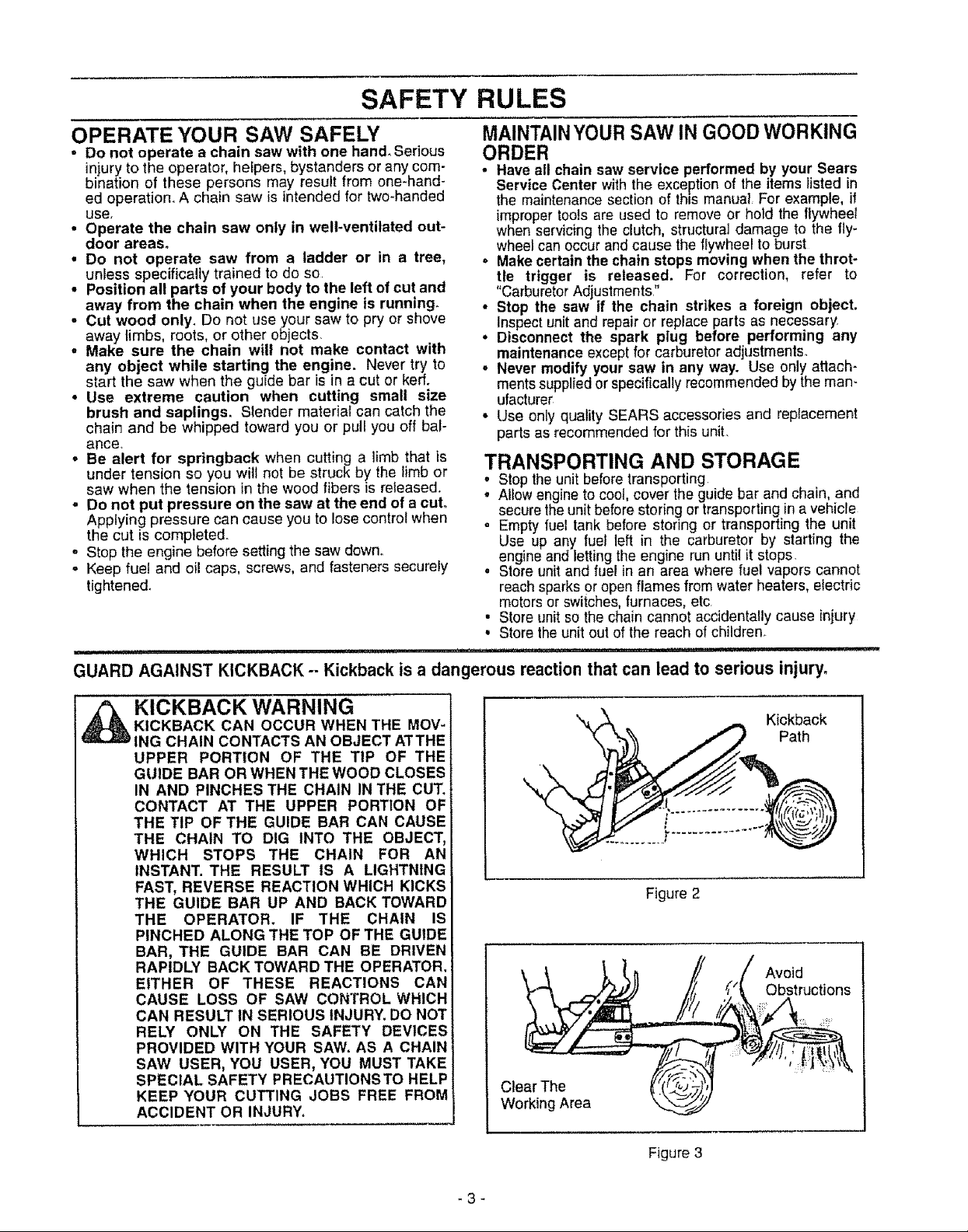

Avoid

Obstructions

Clear The

Working Area

Figure 3

-3-

SAFETY RULES

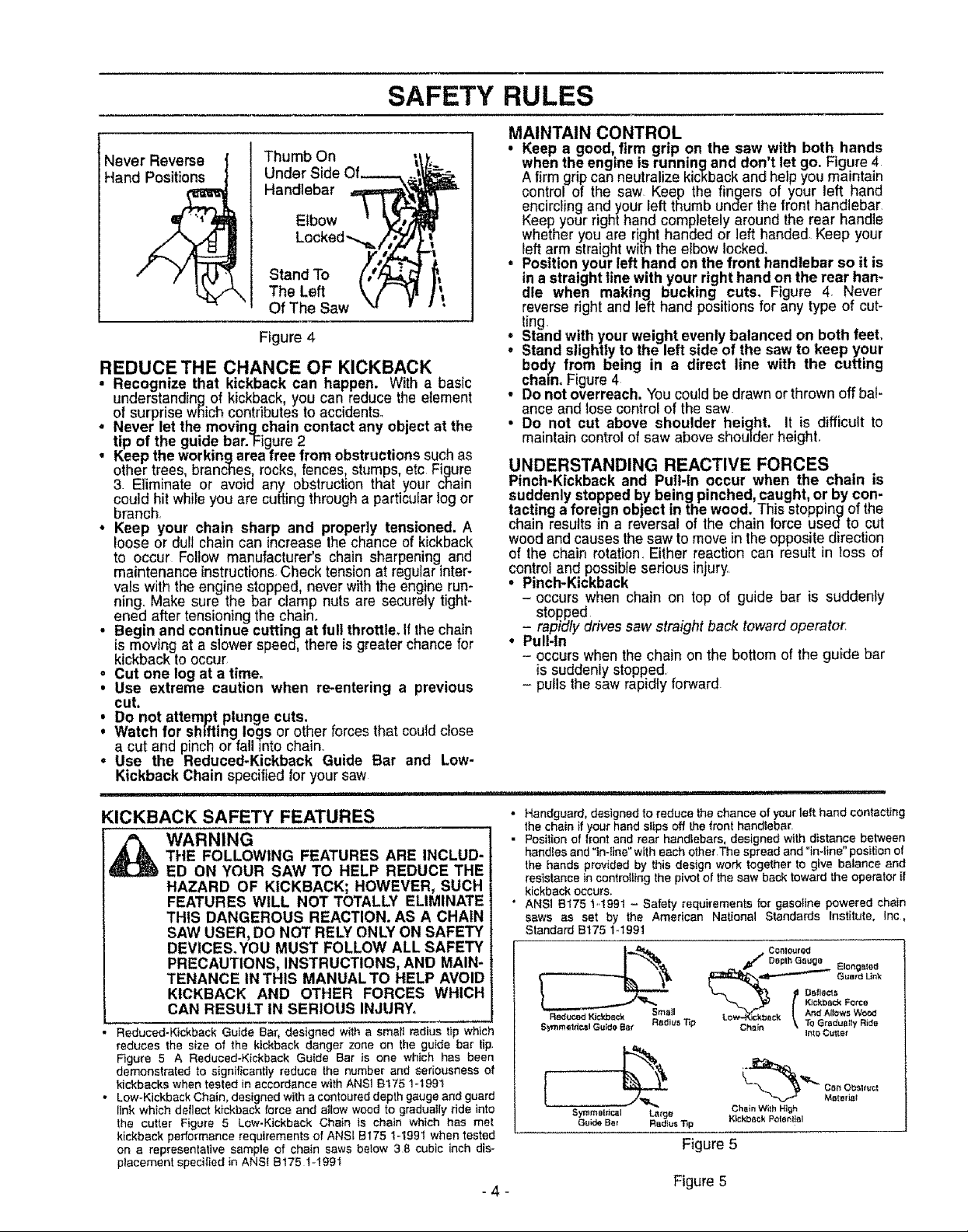

Never Reverse

Hand Positions

REDUCE THE CHANCE OF KICKBACK

understanding of kickback, you can reduce the etement

of surprise which contributesto accidents.

Never let the movingchain contact any object at the

i Recognize that kickback can happen. With a basic

tip of the guide bar.Figure 2

Keep the workingarea free from obstructions sucn as

othertrees branches rocks fences, stumps, etc Figure

3 Eliminate or avoid any obstruction that your chain

could hit while you are cutting through a particular log or

branch

• Keep your chain sharp and properly tensioned. A

loose or dull chain can increase lhe chance of kickback

to occur Follow manufacturer's chain sharpening and

maintenance instructions Check tension at regular inter-

vals with the engine stopped, never with the engine run-

ning. Make sure the bar clamp nuts are securety tight-

ened after tensioning the chain.

• Begin and continue cutting at full throttle, Ifthechain

is movingat a slower speed, there is greaterchancefor

kickback tooccur

o Cut one log at a time.

• Use extreme caution when re-entering a previous

cut,

Thumb On

Under Side Of_

Handlebar

Elbow

Stand To

The Left

Of The Saw

Figure 4

I

t

!

MAINTAIN CONTROL

• Keep a good, firm grip on the saw with both hands

when the engine is running and don't let go. Figure4

A firm grip can neutralize kickback and help you maintain

control of the saw Keep the fingers of your left hand

encirclingand your left thumb under the front handlebar

Keep your right hand completely around the rear handle

whether you are right handed or left handed Keep your

left arm straight with the elbow locked.

, Position your left hand on the front handlebar so it is

in a straight line with your right hand on the rear han-

dle when making bucking cuts. Figure 4. Never

reverse rightand left hand positionsforany type of cut-

ling

• Stand with your weight evenlybalanced on both feet,

° Stand slightly to the left side of the saw to keep your

body from being in a direct line with the cutting

chain, Figure 4

• Do not overreach. You could be drawn or thrownoff bal-

ance and lose controlof the saw

• Do not cut above shoulder height, It is difficult to

maintain controlof saw above shoulder height.

UNDERSTANDING REACTIVE FORCES

Pinch-Kickback and Putt-ln occur when the chain is

suddenly stopped by being pinched, caught, or by con-

tacting a fore=gn object in the wood. Thisstopping ofthe

chain results in a reversal of the chain force usedto cut

woodand causesthesaw to move in the oppositedirection

of the chain rotation Either reaction can result in toss of

control and possibleserious injury.

• Pinch-Kickback

- occurs when chain on top of guide bar is suddenly

stopped

- rapidly drives saw straight back toward operator_

° Pull-In

- occurs when the chain on the bottom of the guide bar

is suddenly stopped

- pulls the saw rapidly forward

Watch for shifting logs or other forcesthat coutd close

I o not attempt plunge cuts.

a cut and pinch or fall _ntochain_

Use the Reduced-Kickback Guide Bar and Low-

Kickback Chain specified for your saw

i i I I Ill"ll'l I'm I'llllll'l ,;;;,,

KICKBACK SAFETY FEATURES

_ WARNING

Reduced-Kickback Guide Bar, designed with a smelt radius tip which

reduces the size of the kickback danger zone on the guide bar tip.

Figure 5 A Reduced-Kickback Guide Bar is one which has been

demonstrated to significantly reduce the number and seriousness of

kickbacks when tested in accordance with ANSI B1751-1991

• Low-Kickback Chain, designed with acontoured depth gauge and guard

link which detlect kickback force and allow wood to gradually ride into

the cutter Figure 5 Low-Kickback Chain is chatn which has met

kickback performance requirements of ANSi B175 1-1991 when tested

on a representative sample of chain saws below 38 cubic inch dis-

placement specilied in ANS_ B175 1-199I

THE FOLLOWING FEATURES ARE INCLUD*

ED ON YOUR SAW TO HELP REDUCE THE

HAZARD OF KICKBACK; HOWEVER, SUCH

FEATURES WILL NOT TOTALLY ELIMINATE

THIS DANGEROUS REACTION. AS A CHAIN

SAW USER, DO NOT RELY ONLY ON SAFETY

DEVICES.YOU MUST FOLLOW ALL SAFETY

PRECAUTIONS, INSTRUCTIONS, AND MAIN-

TENANCE IN THIS MANUAL TO HELP AVOID

KICKBACK AND OTHER FORCES WHICH

CAN RESULT IN SERIOUS INJURY.

• Handguard, designed to reduce the chance of your left hand contacting

the chain if you_"hand slips off the front handlebe_t

• Position of lront and rear handlebars, designed with distance between

handles and "in-line" with each other The spread and "in-line" position of

the hands provided by this design work together to give balance and

resistance in controllingthe pivot of the saw back toward the operator if

kickback occurs.

* ANSi B175 1..1991 - Safety requirements for gasoline powered chain

saws as set by the American National Standards Institute, lnc,

Standard B175 1-1991

Contoured

Depth G_uge

_P""*""-_ Guard Ltnk

e_uced Kicld_¢k Small

Symm_tdc._l Guide ettt Rsdius Tip

Symmet_cal L_ge

Guide Br_r Radius 33p

Ch_iLow"P'lc_gt_< _ To Grac_ualfy Rid_

I_"_-_ Can Oi:_ltucl

Ch_n W_thHig_

K_cld_8ckP_ent_el

KickbaCk Force

_ntoCu_e_

"_"-.,.F"r _teriat

Figure 5

-4-

Figure 5

CONGRATULATIONSon yourpurchaseof a Sears

CraftsmanGasolineChainSaw.Ithasbeendesigned,

engineered and manufactured to give you the best pos-

sible dependability and performance.

Should you experience any probiems you cannot easily

remedy, please contact your nearest Sears Service

Center/Department. Sears has competent, well trained

technicians and the proper tools to service or repair this

uniL

Please read and retain this manual. The instructions witl

enable you to assemble and maintain your unit properly.

Nways observe the "SAFETY RULES."

MODEL NUMBER: 35&351191

DATE CODEtSERIAL NO,

DATE OF PURCHASE:

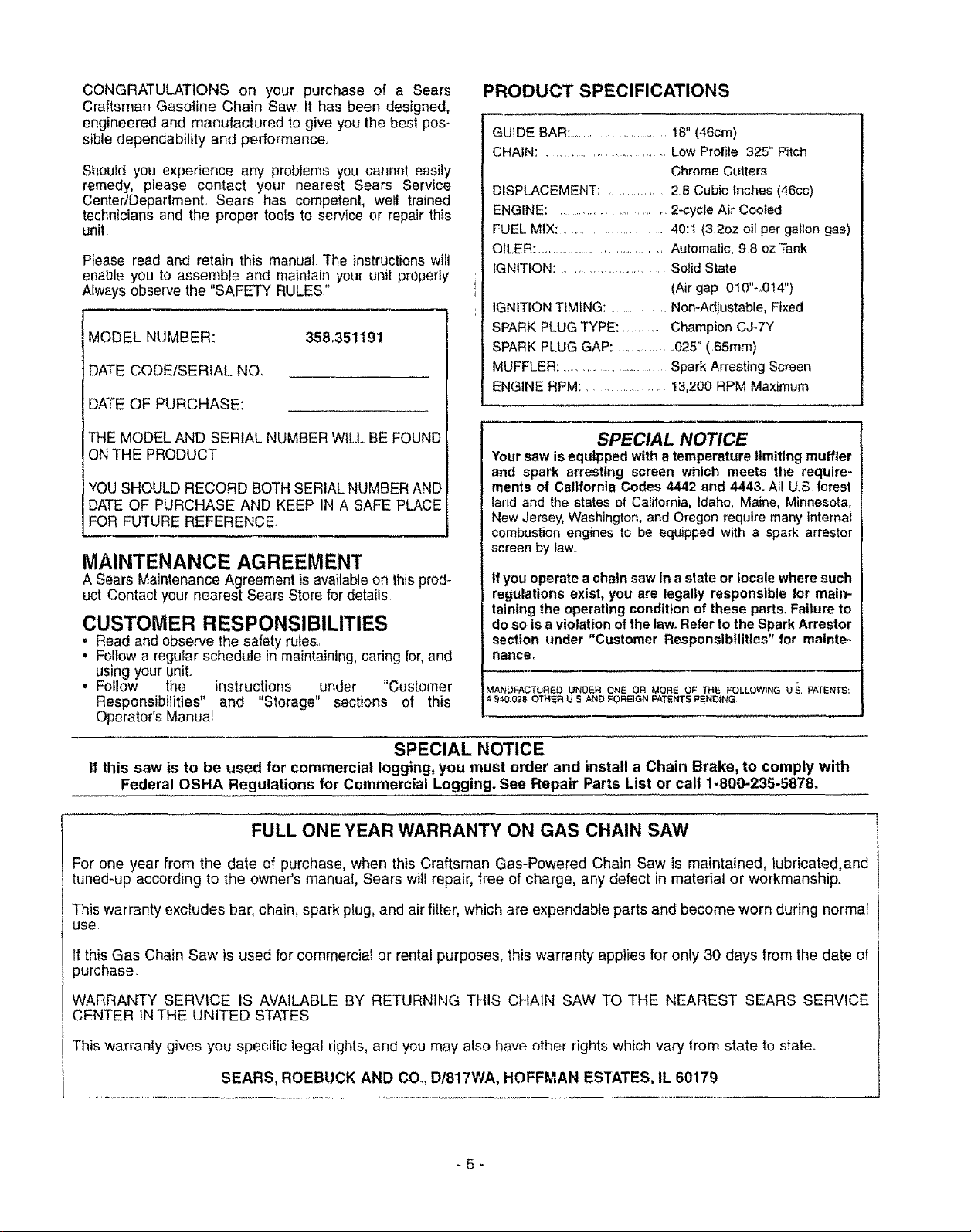

PRODUCT SPECIFICATIONS

GUIDE BAR: ..................... 18" (46cm)

CHAIN: ............................... Low Proffie 325" Pitch

Chrome Cutters

DISPLACEMENT; .............. 28 Cubic Inches (46cc)

ENGINE: ........................... 2-cycle Air Cooled

FUEL MIX: ................... 40:t (32oz oil per galIon gas)

OILER: .......................................Automatic, 9,8 ozTank

IGNITION: ...................... Solid State

(Air gap 010"-,0t4")

IGNITION TIMING: ................. Non-Adiustable, Fixed

SPARK PLUG TYPE: ............ Champion CJ-7Y

SPARK PLUG GAP: .............. 025" (65mm)

MUFFLER: ........................ Spark Arresting Screen

ENGINE RPM: ................... 13,200 RPM Maximum

THE MODEL AND SERIAL NUMBER WILL BE FOUND

ONTHE PRODUCT

YoursaWisequippedwith a temperaturelimiting muffler

SPECIAL NOTICE

and spark arresting screen which meets the require-

YOUSHOULD RECORD BOTH SERIAL NUMBER AND

DATE OF PURCHASE AND KEEP IN A SAFE PLACE

FOR FUTURE REFERENCE.

ments of California Codes4442 and 4443. Al! U,S.forest

landand the states of California, Idaho, Maine, Minnesota,

New Jersey,Washington,and Oregonrequire manyinternal

combustion engines to be equipped with a spark arrestor

MAINTENANCE AGREEMENT

screen by law

A Sears Maintenance Agreement is available on this prod-

uct Contact your nearest Sears Stere for details

CUSTOMER RESPONSIBILITIES

= Read and observethe safety rules..

• Foltow a regular schedule in maintaining, caring for, and

using your unit.

• Fol!ow the instructions under "Customer

Responsibilities" and "Storage" sections of this

Operator's Manual

SPECIAL NOTICE

If this saw is to be used for commercial logging, you must order and install a Chain Brake, to comply with

Federal OSHA Regulations for Commercial Logging. See Repair Parts List or call 1-800-235-5878,

FULL ONE YEAR WARRANTY ON GAS CHAIN SAW

For one year from the date of purchase, when this Craftsman Gas-Powered Chain Saw is maintained, lubricated,and

tuned-up according to the owner's manual, Sears will repair, free of charge, any defect in material or workmanship.

If you operate a chain saw in a state or locale where such

regulations exist, you are legally responsible for main-

taining the operating condition of these parts, Failure to

do so is a violation of the law, Refer to the Spark Arrestor

section under "Customer Responsibilities" for mainte-

nance,

MANUFACTURED UNDER ONE OR MORE OF THE FOLLOWING U_ pATENTS:

4 940.028 OTHER U S AND FOREIGN PATENTS PENDSNG

This warranty excludes bar, chain, spark plug, and air filter, which are expendable parts and become worn during normal

Use

If this Gas Chain Saw is used for commercial or rental purposes, this warranty applies for only 30 days from the date of

purchase

WARRANTY SERV{CE IS AVAILABLE BY RETURNING THIS CHAIN SAW TO THE NEAREST SEARS SERVICE

CENTER IN THE UNITED STATES

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

SEARS, ROEBUCK AND CO,, D/817WA, HOFFMAN ESTATES, IL 60179

-5-

= = i = , i n ,= i =,=,=r=,l,,,,,n,,r,,n,= =

TABLE OF CONTENTS

safe_ 'Ruies i.,,_,,ii_ii_iiii _ir,i,iiii*ii,iiiii_iiii,i [/i_.,[.,iiii,,,,_ii_2 Customer ResponsiSiiitiesi,.,,,i,,ii_i_iioi,ii,.iill .......................lg

Product Specification ..................................................................................5 Service and Adjustments .............................................................. 24

Warranty .....................................................................................5 Storage ..................................................................................................29

Accessories ................................................................................6 Trouble Shooting Points ....................................... .................... 30

Assembly .........................................................................................8 Repair Parts ....................................................................................31

...................................................... 10 Repair Parts Ordering/Service ....................... Back Cover

,,11,1,1111i1,111, i1,1 i, i i iiiii

INDEX

i1,1 ,,i, i i , ,,i ,11,1,11111,,r i ,111,1,,,i,,,,,11,,i I i i1,1 i

A

Accessories .............................................................................6

Air Filter .................................................................................22

Assembly .................................. .............................................. 8

B

Bar and Chain Oif................................................................. 12

Bucking ..................................................................................... 17

C

Carburetor Adjustments ................................................................27

Carton Contents ...............................................................................7

Chain Oiler .................................................................................11

Chain Sharpening ............................................................ 20

Chain Adjustment ...................................................................24

Customer Responsibilities ..................................................19

E

Engine

Fuel/Oil ............................................................................... 12

Spark Plug .... .................................................................... 22

Starting ................................................................................. 13

Storage ......................................................................................29

F

Fuel Filter ...................................... ............................................... 23

Fueling .............................................. ........................................... 12

G

Guide Bar and Chain Oil .....................................................12

Guide Bar Maintenance ........................................................21

H

How To Use Your Chain Saw .....................................................11

Know Your Chain Saw .............................................................10

Lirabing ...............................................................................................18

Maintenance Schedule .........................................................19

Model Number .............................................................................5

Muffler ...........................................................................................22

Ope ration ............................................................................t0

Ordering Repair Parts ..............................................Back Cover

Product Specifications .........................................................5

Pruning ...................................................................................18

Repair Parts ....................................................................................31

Service and Adjustments .............................................................24

Spark Arrestor Screen ...................................................................22

Starter Rope ....................................................................................25

Starting ........................................................................................13

Storage ...... ..................................................................................... 29

Throttle Control Group ..........................................................11

Tree Felling ....................................................................................15

Trouble Shooting Points ...................................................30

Warranty ..................................................................................... 5

K

L

M

O

P

R

S

T

W

,=1== .....................

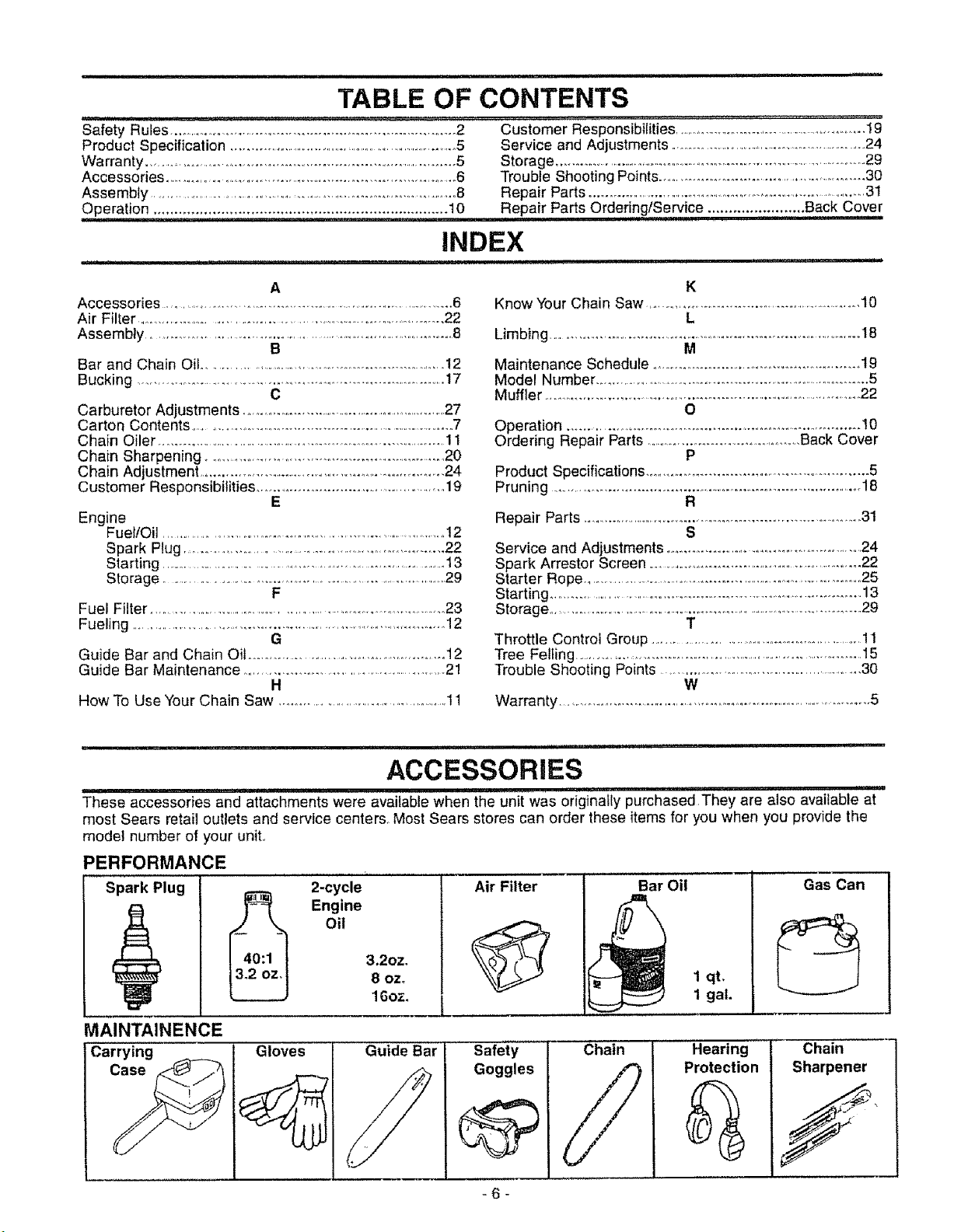

ACCESSORIES

These accessories and attachments were available when the unit was o';iglnatly purchas'ed They are also available at

most Sears retail outlets and service center& Most Sears stores can order these itemsfor you when you provide the

model number of your unit.,

PERFORMANCE

Spark Plug 2-cycle

_ Engine

MAINTAINENCE

Carrying _

Gloves Guide Bar

Oil

3.2oz.

8 ozo

16ozo

Air Filter Bar Oil

Safety

Chain

Goggles

-6-

1 qt,

1 gaL

Hearing

Protection

Gas Can

Chain

Sharpener

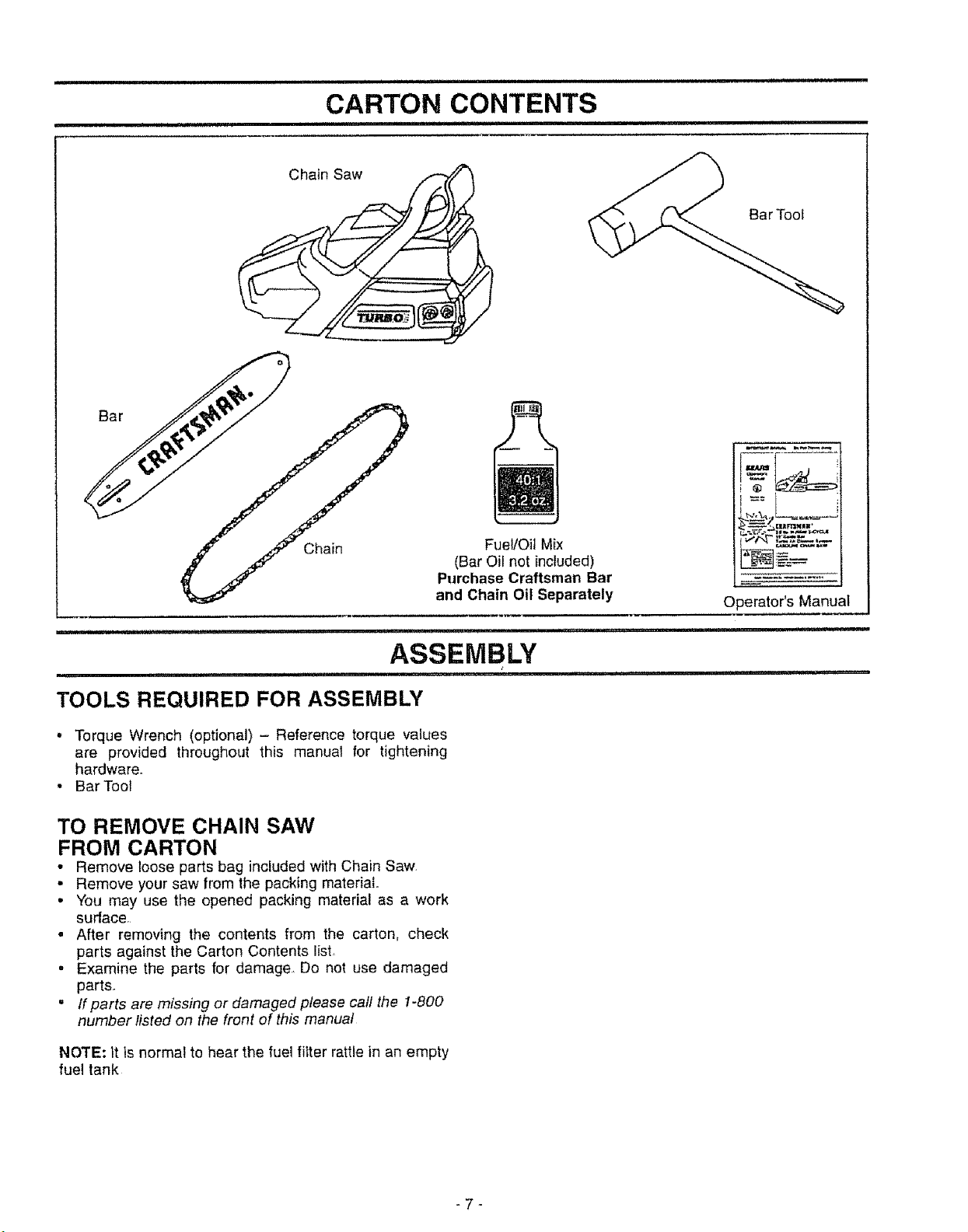

CARTON CONTENTS

ii iii iiiiiiiiiiiii

Chain Saw

Chain

ASSEMBLY

, ilulllll,lll, i,i ................. i ii ,i, ii ,,11111

TOOLS REQUIRED FOR ASSEMBLY

• Torque Wrench (optional) - Reference torque values

are provided throughout this manual for tightening

hardware.

• Bar Toot

TO REMOVE CHAIN SAW

FROM CARTON

• Remove loose parts bag included with Chain Saw

• Remove your saw from the packing material.

• You may use the opened packing material as a work

surface

= After removing the contents from the carton, check

parts against the Carton Contents list.

• Examine the parts for damage.. Do not use damaged

parts.

° If parts are missing or damaged please call the 1-800

number listed on the front of this manual

Fuel/Oil Mix

(Bar Oil not included)

Purchase Craftsman Bar

and Chain Oil Separately

Operator's Manual

NOTE: it is normal to hear the fuel filter rattle in an empty

fuel tank

-7-

ASSEMBLY

_ ANGER:

DO NOT START THE ENGINE WITHOUT

THE GUIDE BAR AND CHAIN COM-

PLETELY ASSEMBLED. OTHERWISE,

THE CLUTCH CAN COME OFF AND

SERIOUS INJURY CAN RESULT.

ALWAYS WEAR GLOVES WHEN HAN-

DLING THE CHAIN.THE CHAIN CAN BE

SHARP ENOUGH TO CUT YOU EVEN

THOUGH IT ISTOO DULLTO CUTWOOD.

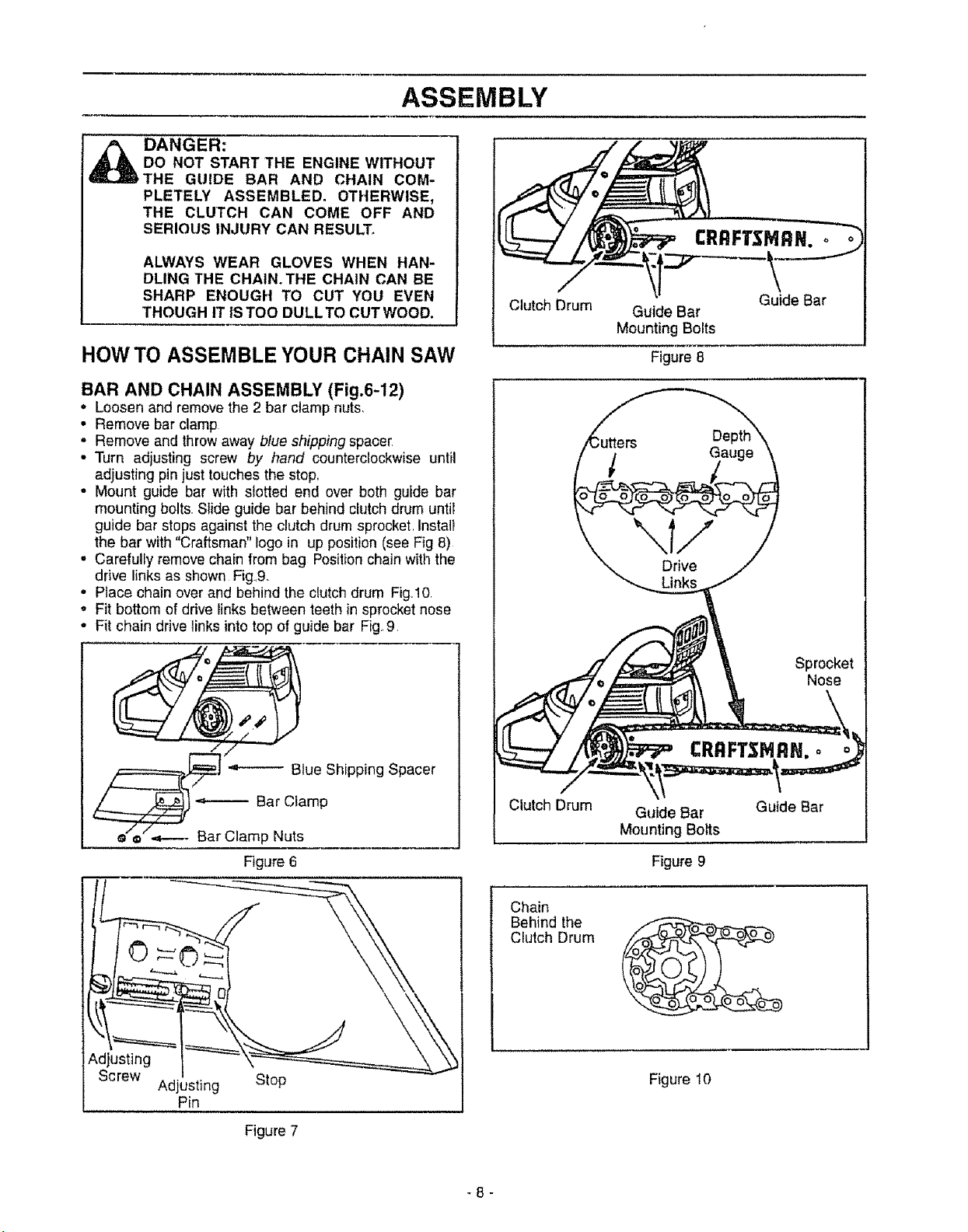

HOW TO ASSEMBLE YOUR CHAIN SAW

BAR AND CHAIN ASSEMBLY (Fig.6-12)

• Loosen and remove the 2 bar clamp nuts,

• Remove bar clamp

= Remove and throw away blue shipping spacer,

• Turn adjusting screw by hand counterclockwise until

adjusting pin just touches the stop.

• Mount guide bar with slotted end over both guide bar

mounting bolts, Slide guide bar behind clutch drum until

guide bar steps against the clutch drum sprocket, Install

the bar with "Craftsman" logo in up position(see Fig 8)

• Carefully remove chain from bag Position chain with the

drive links as shown Fig_9,

• Place chain over and behind the clutch drum Fig,10

, Fit bottom of drive links between teeth in sprocket nose

• Fit chain drive links into top of guide bar Fig,9,

Clutch Drum

Guide Bar

Guide Bar

Mounting Bolts

Figure 8

Gauge

Drive

Adjusting

Screw

Figure 6

Adjusting Stop

Pin

Clutch Drum

Chain

Behind the

Clutch Drum

CRRFTSMRN

Guide Bar

Mounting Bolts

Figure 9

Figure 10

Sprocket

Nose

Guide Bar

Figure 7

-8-

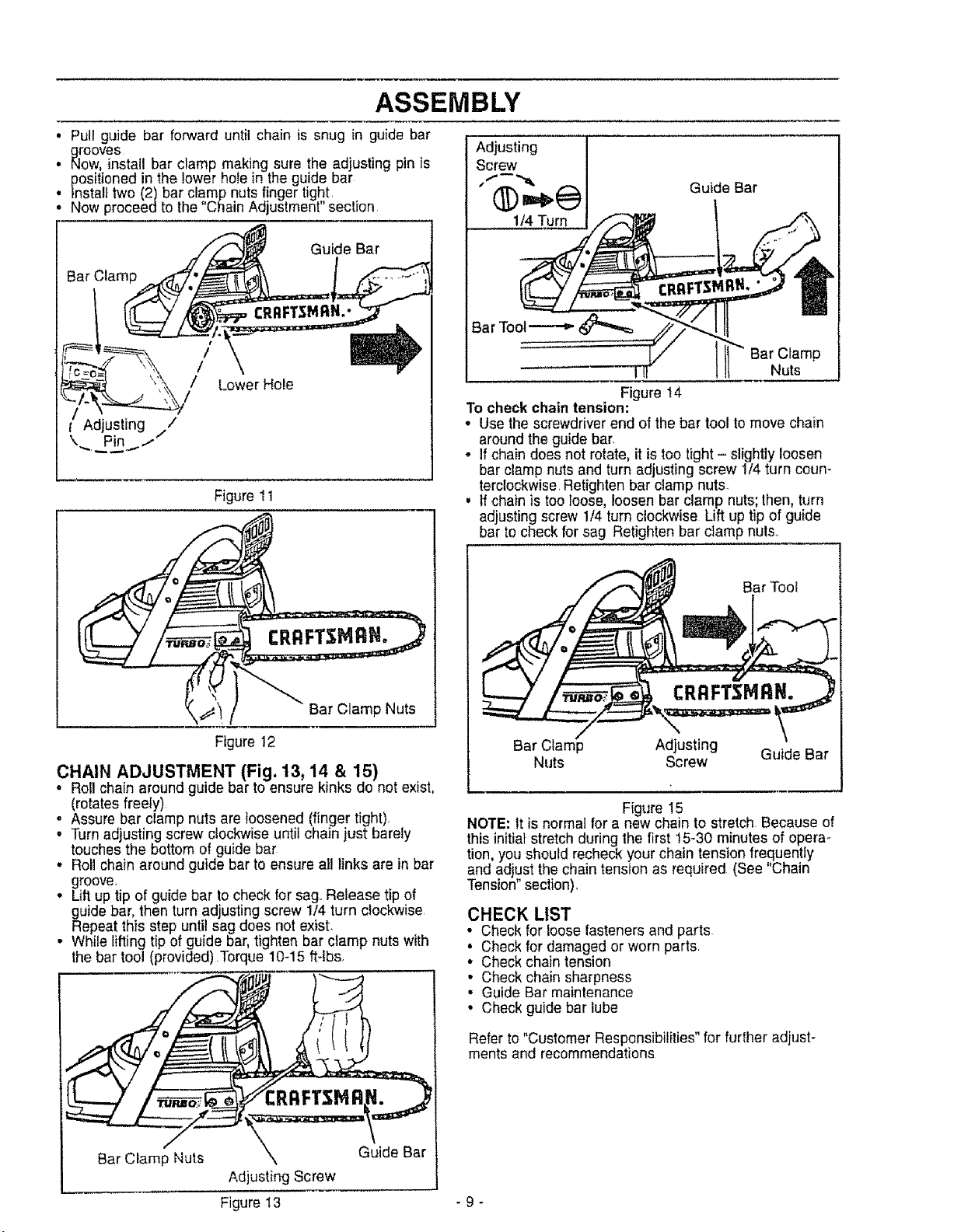

ASSEMBLY

o Pull guide bar forward until chain is snug in guide bar

qrooves

positioned in the lower hole in the guide bar

i low, install bar clamp making sure the adjusting pin is

Install two (2) bar clamp nuts finger tight.

Now proceed to the "Chain Adjustment" section

Guide Bar

Bar Clamp

CRRFT_MRN.-

jt

/

// Lower Hole

Figure 11

Adjusting

Screw

Guide Bar

1/4 Turn

Bar Toot_

Bar Clamp

Nuts

Figure t4

To check chain tension:

• Usethe screwdriver end of the bar tool to move chain

around the guide bar.

- If chain does not rotate, it is too tight - slightly loosen

bar clamp nuts and turn adjusting screw 1/4 turn coun-

terclockwise. Retighten bar clamp nuts.

, tf chain is too loose, loosen bar clamp nuts; then, turn

adjusting screw 1/4 turn clockwise Lift up tip of guide

bar to check for sag Retighten bar clamp nuts..

Bar Tool

CRRFTSMRN°

Bar Clamp Nuts

Figure 12

CHAIN ADJUSTMENT (Fig. 13, 14 & 15)

Roll chain around guide bar to ensure kinks do not exist,

(rotates freely)

Assure bar clamp nuts are loosened (finger tight).

Turn adjusting screw clockwise until chain just barely

touches the bottom of guide bar

• Roll chain around guide bar to ensure all links are in bar

groove,

• Lift up tip of guide bar to check for sag..Release tip of

guide bar, then turn adjusting screw 1/4 turn clockwise.

Repeat this step until sag does not exist.

• While lifting tip of guide bar, tighten bar clamp nuts with

the bar tool (provided)Torque 10-15 ft-lbs

Bar Clamp

Nuts Screw Guide Bar

NOTE: It is normal for a new chain to stretch. Because of

thisinitiat stretch during the first 15-30 minutes of opera-

tion, you should recheck your chain tensionfrequently

and adjust the chain tension as required (See "Chain

Tension"section).

Figure 15

CHECK LIST

• Check for loose fasteners and parts

Check for damaged or worn parts.

Check chain tension

• Check chain sharpness

• Guide Bar maintenance

° Check guide bar lube

Refer to "Customer Responsibilities" forfurther adjust-

ments and recommendations

Bar Clamp Nuts

:RR

_'_G uide Bar

Adjusting Screw

Figure 13 - 9 -

Loading...

Loading...