Craftsman 358351182, 358351082 Owner’s Manual

Operator's Manual

CRRFTSMRN°

2.6 cu. in./42cc 2-Cycle

GASOLINE CHAIN SAW

Model No.

358.351082 - "18In. Bar

358.351182 - ,'!8 In. Bar

@

WARNING:

Read and follow all Safety Rules and Operating

Instructionsbefore first use of thisproduct.

For answers to your questions about this product:

Call 7 am-7 pro, Mon.-Sat., or 10 am-7 pm, Sun.

[]

1-800-235-5878 I.o,,_',,°,od..o_._.,_._

Sears, Roebuck and Co., Hoffman Estates, IL 60179 USA

530087298 01/18/98

Warranty 2 Se_ce andAdjustments 14

SafetyRules 2 Storage 16

Assembly 5 TroubleShootingChart 17

uperstion 6 Spanish 22

Maintenance 11 Pads& Ordedng Back

FULL ONE YEAR WARRANTY ON CRAFTSMAN ® GAS

CHAIN SAW

Foroneyearfromthedateofpumhese,whenthisCraftsmanGas ChainSaw is

maintained,lubdcatadandtuned-upaccording totheowner'smanual,Searswill

repair,freeofcharge,any defectinmaterialorworkmanship.

Thiswarrantyexcludesthe bar,chain,sparkplugandairfiitsr,whichare

expendableparts,and becomewornduringnormaluse.

tf thisGasChainSawisusedforcommercialorrentalpurposes,thiswarranty

appliesfor30 daysfrom thedateofpurchase.

WARRANTYSERVICEIS AVAILABLEBY RETURNINGTHiS CHAIN SAWTO

THE NEARESTSEARSSERVICE CENTER INTHE UNITEDSTATES.

Thiswarrantygivesyouspecificlegalr_ghts,andyou mayalsohaveotherdghts

whichvaryfrom statetostate.

Sears, Roebuckand Co., D/817 WA,Hoffman Estates,IL 60179

WARNING: Alwaysdisconnectspark

plugwirewhenmaking repairsexcept

for carburetoradjustments.8ecausea

chainsawis a high-speedwoodcutting

tool,caretessorimproperuse ofthis

toolcan causeseriousinjury.

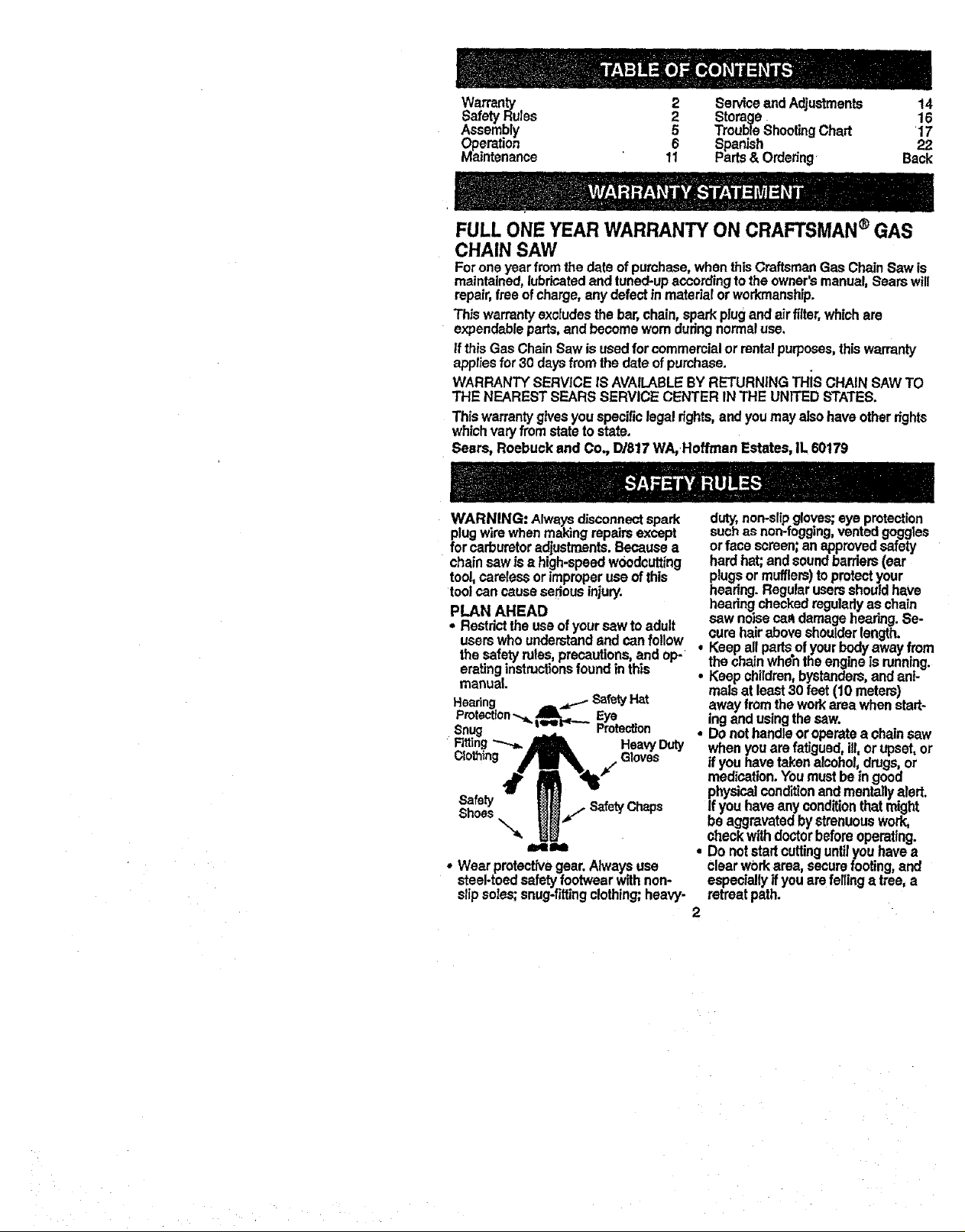

PLAN AHEAD

•Restdct theuseofyoursawtoadult

userswhounderstandend canfollow

the safetyroles,precautions,and op-

eratinginstructionsfoundinthis

manual.

Hearing dl&._._ S_fetyHat

Pmte_on_ - Eye

Snug tNr,_-- Protection

Fitting_ HeavyDuty

Clo',hing p/Gloves

Safety

Shoes_

* Wearprotectivegear,Always use

steel-toedsafety footwear Withnon-

slipsoles;snug-fittingclothing;heavy-

duty,non-slipgloves;eye protection

suchasnon-fogging,ventedgoggles

orface screen;anapprovedsafety

hardhat;andsoundbarriers(ear

plugsormufflers)toprotectyour

hearing.Regularusersshouldhave

headngcheckedregutadyas chain

saw noiseca_ damageheadng.Se-

cure hairaboveshoulderlength.

thechatnwhenthe engineis running.

Keepchildren,bystanders,andani-

malsat least30 feet (10 meters)

awayfromtheworkarea whenstart-

i eepallpa.dsof yourbodyawayfrom

ingandusingthesaw.

Donothandleor operateachainsaw

whenyouare fatigued, ill,or upset,or

ifyou havetakenalcohol,drugs,or

medication.Youmustbe in good

physicalcond'ftionandmentallyalert.

Ifyouhaveanyconditionthatmight

beaggravatedbystrenuouswork,

, checkwithdoctorbeforeoperating.

Do notstartcuttinguntilyouhave a

Clearworkarea, securefooting, and

especiallyifyouarefelling a tree,a

retreat path.

2

OPERATEYOURSAWSAFELY

• Donotoperatewithonehand.Sed-

ousinjurytotheoperator,helpers, or

bystandersmayresultfromone-

handedoperation.A chainsawis in-

tendedfortwo-handeduse.

• Operatethe chain sawonlyina wail-

ventilatedoutdoorarea.

• Donot operatesawfroma ladderor

ina tree, unlessyouate spedficaliy

trainedtodoso.

• Makesurethe chainwillnot make

contactwithanyobjectwhilestarting

theengine.Nevertryto startthe saw

whentheguidebaris ina out.

. Do notputpressureonthesaw, es-

peciallyat theend ofthecut.Doing

socan cause youtolose control

whentheoutis completed.

• Stopenginebeforesettingsaw down.

• Handcarrysaw onlywhenengineis

stopped.Carrywithmufflerawayfrom

body;guidebar&chainprojectingbe-

hindyou;guidebarpreferablycov-

eredwitha scabbard.

MAINTAIN YOUR SAW IN GOOD

WORKING ORDER

° Have all chainsawserviceperformed

bya quaiitiedservicedealerexcept

the itemslistedinthe maintenance

sectionofthis manual.

movingwhenthethrottletriggeris re-

le_sed.ForcorrectJog,referto "Car-

i Make certainthe sawchainstops

buretorAdjustments."

Keepthehandlesdry,clean, and_ree

from oilorfuelmixture.

• Keepcapsandfasteners sa¢ure_y

tightened.

• Use onlyCraftsmanaccessoriesand

_piacement partsas recommended.

evermodifyyoursaw.

HANDLE FUEL WITH CAUTION

• Do notsmokewhilehandlingfuel or

whileoperatingthe saw,

• E_n_n_ea_seurcesd s_ _ t_rne

inareaswherefuelism_l orpoured.

• Mixand pourfuelin an outdoorarea

end usean approved,markedcon-

tainerfor allfuelpurposes.Wipe up

all fuelspills beforestarlingsaw.

° Moveat least10feet(3 meters)from

fuelingsitebeforestarting.

• Turnthe engineoffandlet saw coolin

a non-combustiblearea,noton dry

leaves,straw, paper,etc. Slowlyre-

.... movefuelcapand refuelunit.

• Storethe unitandfuelin a cool,dry

wellventilatedspacewherefuelva-

porscannotreachsparksoropen

flamesfromwaterheaters,electdc

motorsor switches°furnaces,etc.

GUARD AGAINST KICKBACK

Followallsafety rulestohelpavoid

Idckbackand otherforceswhichcan

resultinsedousinjury,

Avoid ObstmclJons

ClearTheWorkingArea

WARNING: Rot,_tionaiKickbackcan

occurwhenthemovingchaincontacts

an object atthe upperportionofthe'dp

ofthe guidebar.Contactattheupper

portionofthe tip oftheguidebarcan

causethe chainto digintotheobject,

which stops thechainforaninstant.The

resultisa I,ghtningfast,reversereaction

whichRicksthe guidebar upandback

towardthe operator.

Pinch-Kickbackand Pull-inoccurwhen

thechain issuddenlystoppedby being

pinched,caught,orbycontactingafor-

etgnobjectinthe wood.Thissudden

stoppingofthe chainresultsina.rever-

ea!ofthe chainforceusedtocu_wooa

and causesthe sawtomoveinthe op-

positedirectionofthe chainrotation.

Pinch-Kickbackdrivesthesawstraight

backtowardthe operator.Pull-inpulls

the sawaway fromthe operator.

REDUCE THE CHANCE OF

KICKBACK

•ReOog thatkk a can

W'_ a basicunclerstana=ngor

youcanreducetheelementof suqorise

Whichcontributestosccidents.

Never letthe moving chaincontact

object tip

any atthe oftheguideoar.

Keepworkingarea free fromobstruc-

tionssuchasothertrees,branches,

rocks,fences,stumPs, etc.Eliminate

oravoidany obstructionthatyoursaw

chaincouldhitwhile cutting.

, Keepsaw drainsharpandproperly

tensioned.Alooseordullchaincan

increasethechanceofkickbaok.Fol-

lowmanufacturer'schainsharpening

and maintenanceinstructions.Check

tensionat regularintervals,butnever

_ith enginerunning.Makesurebar

ampnutsare securelyfightened.

keepy.ourbodyfrom beingin a direct

linewiththe cuttingch_dn.

• Stand.wttl].yourweightevenlybal-

anceo onbothfeet.

• Donotoverreach.Youcould bedrawn

orthrownoffbalanceandlosecontrol.

• Donotcutabove shoulderheight,ttis

speed,if thechainismovingat a

slowerspeed,thereisgreaterchance

i Beginand continuecutfin9 at full

of kickbackoccurring.

Useextremecautionwhenreentering

a cut.

• Donotattempt cutsstartingwiththe

tipofthe bar(plungecuts).

• Watchforshiftinglogs orotherforces

thatcouldclosea cutand pinchorfall

intochain.

• Usethe specifiedReduced-Kickback

GuideBarand Low-KickbackChain.

Avoid Pinch-Kickback:

, Be extremelyawareofsituationsor

obstructionsthatcan c_usematerial

to pinchthe top of orotherwisestop

the chain.

• Donotcut morethanone logat a

time.

• Donottwistsawas bar is withdrawn

fTOman undercutwhenbucking.

Avold Pulloln:

atfullspeed and thesawhousing

i lwaysbegincuttingwiththeengine

againstwood.

Usewedgesmadeofplasticorwood.

Neverusemetalto holdthe cut open.

MAINTAIN CONTROL

difficultto maintain controlofsaw

aboveshoulderheight.

KICKBACK SAFETY FEATURES

WARNING: The followingfeaturesare

includedonyoursawto helpreduce

hazardofkickback;however,suchfea-

tureswillnottotallyeliminatethisdan-

ger.Donotrelyonlyonsafety devices.

• Handguard:designedto reducethe

chanceofyourlefthandcontacting

thechain_yourhandslipsoffthe

front handlebar.

• Positionof frontandrearhandlebars:

designedwithdistancebetweenhan-

dlesand =in-line"witheachother,The

spreadand "in-line"positionof the

handsprovidedbythis designwork

togethertogive balanceand resis-

tancein controllingthe pivotofthe

sawbacktowardtheoperatorifkick-

backoccurs.

• Reduced-KickbackGuideBar:de-

signedwitha smallradiustipwhich

reducesthesize ofthe Idckbeckdan-

_er zone.Thistypebar hasbeen

emons_atedtosignificantlyreduce

thenumoerano seriousnessofkick*

backswhentestedinaccordance with

Standtotheleftofthesaw ANSiB175,1.

underside Tip Guide Bar

of handlebar

Thumb on \_ _ SmaU Red,us

TipGuideBar

Elbow * Low-KickbackChain:hasmetkickback

locked pe_o_ requirementswhentested

Neverreversehandpos_ons ona representativesampleofchain

• Agood,firm griponthe sawwithboth sewsbelow3.8 cubicinch

handswillhelpyou maintaincontrol, displacementSlUed inANSIB175.1.

Dont letgo. Gdpthe rearhandlewith Low.KickbackChbtn

yourdght handwhemeryou areright , ContouredDepthGauge

or le_handed.Wrapthefingersof __ _,. .w''1 ElongatedGuardUnk

yourlefthans overandaround the ,_z_ "t'-_" DeflectsKickbsck

fronthandlebar,and yourleftthumb _, _ ForceAndAllows

underthefront handlebar.Keepyour _ "_,_ WoodToGradually

leftarmstraightwiththeelbowlooked. _ RideIntoCutter

• Pos_onyourlefthand on thefront SAFETY NOTICE. Exposureto

handlebarsoit isinastraightlinewith vibrationsthroughprolongeduseof

yourrighthandon therearhandle gasolinepOweredhand toolscould

whenmaking buckingcuts.Stand cause blood,ve_e! ornews damagein

slightlyto theleftsideofthe sawto the tmgem, nanas,andjointsofpeople

4

pronetocirculationdisordersor

abnormal swelling.Prolongedusein

coldweatherhas been linl_dto blood

vessel damageinotherwisehealthy

people.If symptomsoccorsuch as

numbness,pain,lossof strength

changeinskin colorortexture,or loss

offeelingin the fingers,hands,orjoints,

oiscontinuethe useof thistooland

seek medicalattention.An

anti*vibration systemdoesnot

guaranteethe avoidance ofthese

problems.Userswhooperatepower

toolsona continualandregularbasis

mustclosely monitortheirphysical

conditionand the conditionofthistoolo

CHAIN BRAKEIfthis sawistobe used

forcommercial logging,you must order

and installa chainbrake'tocomplywith

FederalOSHA RegulationsforCom-

memialLogging.ContaclyourSears

ServiceCenterorcall 1-800-235-5878.

SPARK ARRESTOR=Your,sawis

equippedwitha temperaturelimiting

mufflerandsparkarresting screen

whichmeetsthe requirementsof

CaliforniaCodes4442 and 4443.All

U.S.forestTandand thestatesof

CaUfomia,Idaho,Maine,Minnesota,

NewJersey,Oregon,andWashington

requirebylawthat manyinternal

combustionenginesbeequippedwitha

sparkarrestor screen.If youoperatea

chainsawina stateorlocalewhere

suchreguialionsexist,youarelegally

responsiblefor maintainingthe

operatingconditionof theseparts.

Failuretodoso isa violationofthelaw.

RefertoCustomerResponsibilities

chartin theMAINTENANCEsection.

STANDARDS:Thischainsawis listed

byUnderwdtersLaboratories,Inc.in

accordancewithAmedcanNational

StandardsforGasoline-PoweredChain

SawsSafetyRequirements(ANSI

9175.1t-t_1991).

CARTON CONTENTS

Checkcartoncontents againstthefol-

lowinglist.

• Models=358,351082& 358.351182

• Chain Saw (fullyassembled)

• Chain adjustmenttool

• 2*cycteengineoil.(Baroil not

included) . "

• Model: 358.351082*"

• Extrachain

• Examinepartsfor damage.Do not

usedamagedparts.

* if youneedassistanceor findparts

missing ordamaged,pleasecall

1-800-235-5878.

NOTE: It isnormaltoheart.hefuelfilter

rattlein an emptyfueltank.

Yourunithasbeen factorytestedand

the carburetorpreciselyadjusted.Asa

resultyoumay smellgasolineorfind a

dropofoil/fuelresidueonthe muffler

whenyou unpackthe unit.

ASSEMBLY

.Yoursaw isfully assembled,andno

assembly isnecessary.

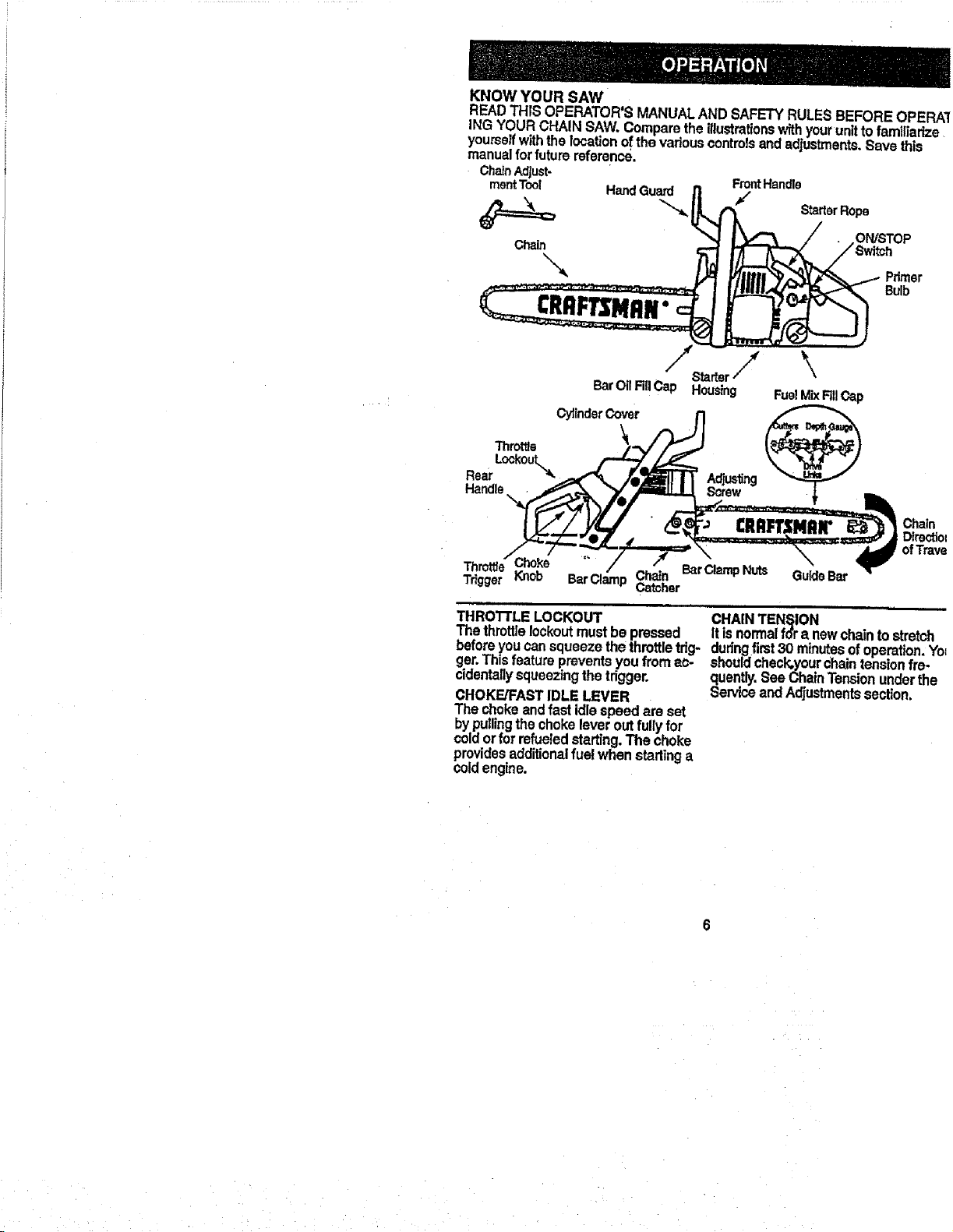

KNOW YOUR SAW

READTHIS OPERATOR'SMANUALAND SAFETYRULESBEFORE OPERA'f

ING YOURCHAINSAW,Comparetheillustrationswithyourunittofamiliarize

yoursetfwiththelocationof thevariouscontrolsandadjustments.Savethis

manualforfuturereferent.

Cha_ Adjust-

ment Tool HandGua,"d N _nt Handle

Chain _-_ _ /Switch

\

BarOilFillCap Housing Fue!MixRIICap

_'_1 _ / . ON/STOP

Throttle

RearL°ck°% Adjusting

Handle i

Thmt'JeChoke

Trigger Knob BarClarnpChain BarCl=u_npNuts GuldeBar

THRO'n'LE LOCKOUT CHAINTEN_ION

Thethrottlelockoutmustbe pressed Itis normalfdra newchainto stretch

beforeyoucansqueezethethrottletdg- duringfirst30 minutasofoperation.Yo=

get.Th=sfeaturepreventsyoufromao- shouldcheck.yourChaintensionfre-

cidentaIlysqueezingthe trigger, quently.See ChainTensionunderthe

CHOKE/FASTIDLE LEVER ServiceandAdjustmentssection.

The chokeand fastidlespeedare set

bypullingthechokeleveroutfully for

coldorfor refueledstarting.The choke

providesadditionalfuel whenstartinga

coldengine.

CylinderCover

Catcher

CRRFT iur Chain

Dlrectio=

ofTrave

H

BEFORE STARTING ENGINE

WARNING: Besuretoreadthe fuel

handlinginformationinthesafetyrules

sectionof thismanual beforeyoubegin.

Ifyoudonotunderstandthefuelhan-

dlinginformationdonotattempt tofuel

yourunit.Seek helpfromsomeonethat

doesunderstand theinformationorcall

thecustomerassistancehelplineat

1-800-235-5878.

GUIDEBAR AND CHAIN OIL

Thechainoilerprovidescontinuouslu-

bricationto thechain andguidebar.Be

suretotillthebar oiltankwhenyoufill

thefueltank (Capaoity= 6.8 ft.oz.)

Formaximum guidebarandchainlife,

we recommendyou useCraftsman

chainsawba.roil.If Cr"_tsma.nbaroilis

notavailable,you mayu.sea good

gradeSAE 30 oiluntilybuareableto

obtainCraftsmanbrand,The oiloutput

isautomaticallymetereddudngopera-

lion.Yoursaw wiltuseapproximately

onetankof baroilfor everytankoffuel

mix.Alwaysfillthe baroiltank when

youfillthe fueltank.

FUELINGENGINE

Thisengineis oertified tooperateOn

unleadedgasoline.Beforeoperation,

gasolinemustbe mixedwitha good

quality2-cycle=dr-cooledengineoil We

recommendCraftsmanbrandoil.Mix

gasoUneandoilat a ratioof40:1 (A

40:1 ratioIsobtainedbymixing3,2

ouncesofo_withI gallonofunleaded

gasoline).DONOTUSEautomotive oil

orboatoil.These oilswillcause engine

damage.When mixingfuelfollowthe

instruotoneprintedon the container.

Onceoilis addedtothegasoline,

shakecontainer momentarilytoassure

thatthefuelisthoroughlymixed.

Alwaysreadand followthesafetyrules

relatingto fuel beforefuelingyourunit.

IMPORTANT

Experienceindicatesthat alcoho_

blendedfuels(calledgaseholorusing

ethanolormethanol)canattractrnols-

turswhichleadsto separationand

formationof a_ds duringstorage.Acid-

ic gascan damagethefuel systemof

an enginewhilein storage.

Toavoidengineproblems,thefuelsys-

ternshouldbeemptiedbeforestorage

for30 daysor longer.Drainthegas

tank, starttheengine andletitrununtil

the fuel linesandcarburetorareempty.

Usefreshfuelnext season.See STOR-

AGEinstructionsforadditional informa-

tion.

Neveruseengineorcarburetor cleaner

productsinthefueltankorpermanent

damagemayoccur.

SeetheSTORAGEsectionfor additional

information.

STOPPING YOUR ENGINE

• MoveOn/Stopswitchtothe STOP

position.

• If enginedoesnotstop,pullchoke

knoboutfully.

STARTING YOUR ENGINE

COLD ENGINE ORWARM ENGINE

AFTER RUNNING OUT OF FUEL

• Fuelenginefollowinginstructionsun-

• derFUELING ENGINE.

• Fillbar oilt_nkwithbaroiLYoursaw

willuseapproximatelyonetankof bar

oilfor eachtank offuelmix.

• MoveOn/Stopswitch toONposition.

• Pullohokeknoboutfully.

° Primeenginebyslowlypressingprim-

erbulb sixtimes.

I

ON/STOP

Switch

PdmerBulb

• Set sawon the ground.Gripfront

handlewithyourlefthandandplaoe

rightfoot through rearhandle.

Chokeknob

NOTE."When pullingthe starterrope,

donotusethefullextentof therope,

Do notletstarterropesnapback.

Holdhandle.Let roperewindslowly.

• Sharplypullstarterropehandle5

timeswithyour dghthand.The en-

ginemaysoundas Ifitis tryingto

stad beforethe 5thpull;ifso,proceed

•tothe nextstep.

7

• Fullypush-inchokeleverandcontin-

uetopullstarterropehandleuntilen-

ginestarts.

• Then,squeezeand releasethe

throttletriggerto returnenginetoidle

speed.

• Tostopengine,moveOn/Stopswitch

tothe STOPposition. '

StarterRopeHandle

Rig FootThroughRearHandle

STARTINGA WARM ENGINE

DONOTusethechoketo starta warm

engineorfloodingand hardstarting

may occur.

* MoveOn/StopswitchtoON.

• Slowly pressprimerbulb6 times.

, Setthechainsawontheground.Grip

thefronthandlewithyourlefthand

end placeyourrightfootthroughthe

openinginthe rearhandle.

* Pullchokelever outfully,thenpushit

in fully toset engineinfast idleposi-

ton.

* Sharplypullstarterrepehandlewith

your fight handuntilthe enginestarts,

but no morethan 5 times.

* Then, squeezeandreleasethe

throttletriggertoreturnengineto idle

speed.

° Tostopengine,moveOn/Stopswitch

tothe STOP position.

DIFFICULT STARTING OR

STARTING A FLOODED ENGINE

The enginemaybefloodedifithas not

startedafter10pulls.Floodedengines

canbe clearedofexcessfuelwiththe

followingprocedure:

. Pullchokeleveroutfully,thenpushit

infullytoset enginein fastidlepost-

ton.

° VerifythattheOn/Stopswitchisinthe

ONposition,

• With sawonground,gripfront handle

withlefthandand placefightfoot

throughrearhandle.

, Gripstarterropehandleandpullrope

firmlyandquicklyto startengine.If

notsuccessful,repeatunt'_engine

starts.

Startingcouldrequiremanypullsde-

pendingon howbadlyunitisflooded.If

enginestillfailsto start,referto TROU-

BLESHOOTINGchartorcall

1-800-235-5878.

OPERATING TIPS

• Checkchaintensionbeforefirstuse

and after I minuteofoperation.See

ChainTensioninthe Maintenance

section.

• Cutwoodonly.Donotcut metal,plas-

tics,masonry,non-woodbuildingma-

tefials,etc.

• Stopthesaw ifthechainstrikesa for-

eignobjest.Inspectthe sawand re-

pairpartsas necessary.

• Keepthe chainoutofdirtandsand.

Evena smallamountofdirtwillquick-

lydulla chainand increasethepossi-

bilityofkickback.

• Practicecuttinga fewsmalllogsusing

thefollowingsteps. Thiswillhelpyou

getthe "feel"ofusingyoursawbefore

youbegin a majorsawingoperation.

° Squeezethethrottletriggerandal-

lowthe enginetoreachfullspeed

beforecutting.

againstthelog.

_ Begincuttingwiththesawframe

Keep the engineat fullspeedthe

entiretimeyouare_lttlng,

• Allowthechaintocutforyou.Exert

onlylightdownwardpressure.

• Releasethethrottletriggeras soon

asthe out iscompleted,allowingthe

enginetoidle.Ifyou runthesawat

full throttlewithoutacuttingload,

unnecessa_wear canoccur.

° Toavoidlosingcontrolwhencutis

complete, donotputpressureon

saw at end ofcut.

° Stopthe enginebeforesettingthe

saw down.

TREE FELLING TECHNIQUES

WARNING: Checkforbroken ordead

brancheswhichcanfall whilecutting

causingserlous_tr_jury.Donotcutnear

buildingsor electd_l wiresif youdonot

knowthedirectionoftreefall,nor_ut at

nightsinceyou will notbe abletosee

well,norduringbadweathersuchas

rain,snow,orstrongwinds,etc.

Carefullyplanyoursawingoperationin

advance.Cleartheworkarea.You

needa cleararea allaroundthetreeso

youcanhave securefooting.Studythe

8

naturalconditionsthatcancausethe

treetofallinaparticular direction,such

conditionsinclude;

• The winddirectionand speed.

• The leanofthetree.The leanof a

treemightnotbeapparentduetoun-

evenorslopingterrain.Usea plumb

orleveltodeterminethe directionof

treelean.

° Weightandbranchesononeside.

• Surroundingtreesand obstacles.

Lookfordec_yand rot.If thetrunkis

rotted,itcan snapand falltowardthe

_aerator.

kesurethere isenoughroomfor the

treeto fall.Maintaina distanceof2-1/2

treelengthsfrom thegearest personor

otherobjects.Enginenoisecan drown

outa warningc_l.

Removedirt, stones,loosebark,nails,

staples,and wirefrom thetreewhere

cutsare to be made.

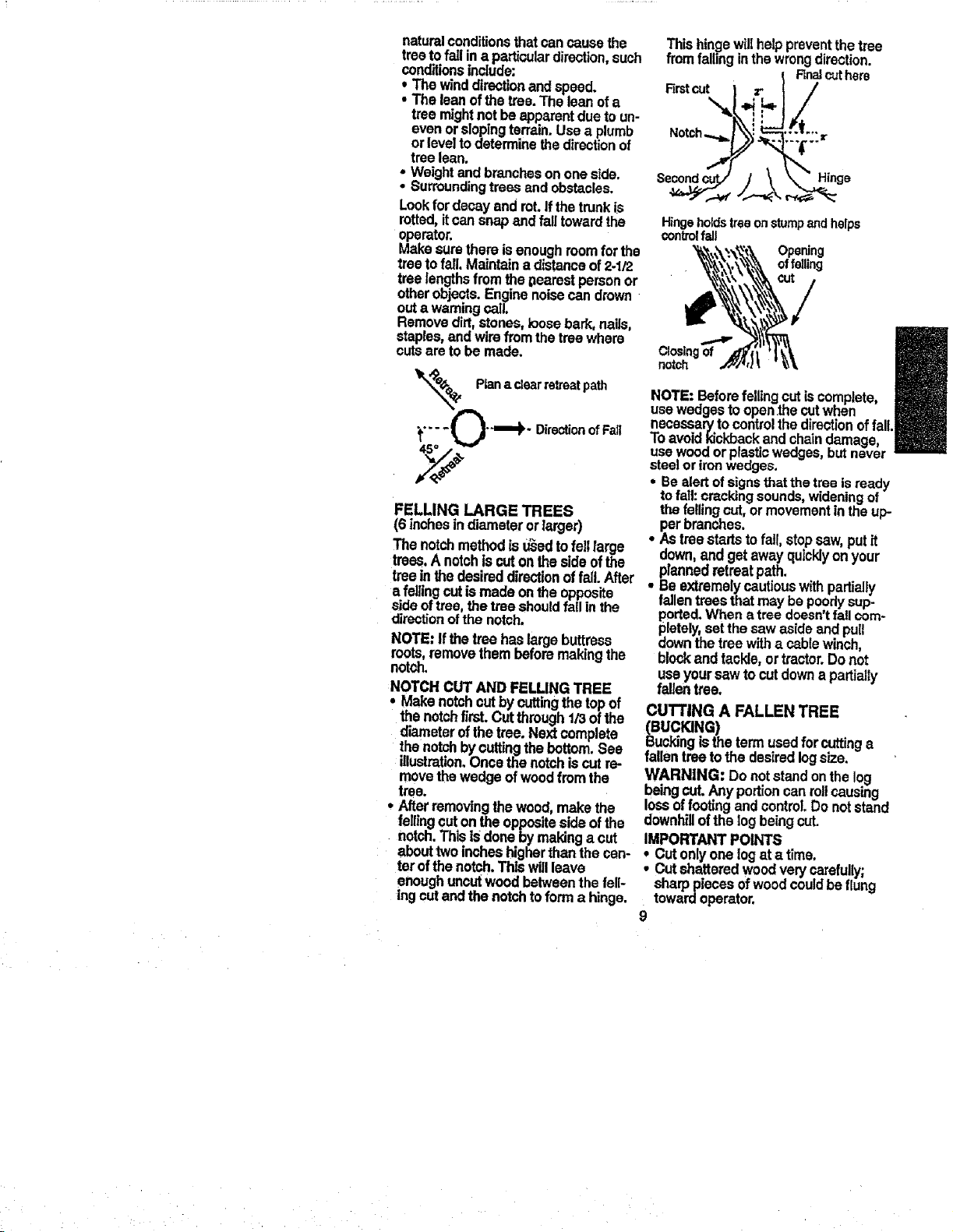

Thishingewill helppreventthe tree

fromfallinginthewrongdirection.

Rnalcuthere

Rrstcut",,_ -_,,,4-_

g°

Hingeholdstreeonstumpand helps

controlfall

Opening

offelting

_ Ptanaclearretreatpath

_--- -O-'_- DirectionofFa_t

FELLING LARGE TREES

(6 inchesindiameterorlarger)

The notchmethod isU_edtofelllarge

trees,A notchiscutonthe sideofthe

treeinthe desireddirectionoffall.After

a fellingcutismadeonthe opposite

sideoftree,the treeshouldfallinthe

directionofthe notch.

NOTE: Ifthe tree haslargebuttress

roots,removethembeforemaking the

notch,

NOTCH CUT AND FELLING TREE

• Makenotchcutby cuttingthetopof

thenotchfirst.Cutthrough1t3ofthe

diameterofthetree. Nextcomplete

thenotchbycuttingthebottom.See

illustration.Oncethe notchiscutre-

movethe wedgeofwoodfromthe

tree.

• Afterremovingthe wood,makethe

telling cut onthe oppositeside of the

notch.Thisis donebymaking a cut

abouttwoincheshigherthan the ten- Outonlyonelogat a time.

terof the notch.Thiswillleave _ Gutshatteredwoodverycarefully;

enoughuncutwoodbetweenthe fell- sharppiecesofwoodcouldbeflung

ingcut andthe notchtoformahinge, towardoperator.

NOTE. Beforefellingcutiscomplete,

usewedgesto openthe cutwhen

necessarytocontrolthedirectionoffalt.l_ili

Toavoidkickbackandchaindamage,

usewoodor ptasti¢wedges,butnever

steelorironwedges.

• Bealertof signsthatthe treeisready

tofail: crackingsounds,wideningof

thefelling cut,ormovementinthe up-

perbranches.

• Astree startsto tall, stopsaw,putit

down,andgetaway quicklyonyour

• plannedretreatpath.

Beextremelycautiouswithpartially

fallen treesthatmaybepoodysup-

ported.Whena tree doesn'tfailcom-

pletely,set thesaw asideandpull

Clownthe treewitha cable winch,

blockandtackle,ortractor.Donot

useyoursaw tooutdowna partially

fallentree.

CU'I-rlNG A FALLEN TREE

_BUCIQNG)

uckingisthe termusedforcuttinga

fallentree tothe desiredlogsize.

WARNING: Donotstandonthe log

beingout.Anyportioncanrollcausing

lossoffooting andcontrol.Donotstand

downhillofthe togbeingcut.

IMPORTANT POINTS

9

* Use a sawhorsetocutsmalllogs.

Neverallowanother persontohold

the logwhilecuttingandneverhold

thelogwith yourlegorfoot.

• Donotcutinanarea wherelogs,

limbs,and rootsare tangled.Dragthe

logsintoa clearareabeforecutting

them.

BUCKING TECHNIQUES

WARNING: if sawbecomespinched

Orhungin a log,don'ttryto forceitout.

Youcanlosecontrolofthe sawresult-

ingininjuryand/ordamagetothesaw.

Stopthesaw,drivea wedgeofplastic

orwoodintothe cutuntilthesawcan

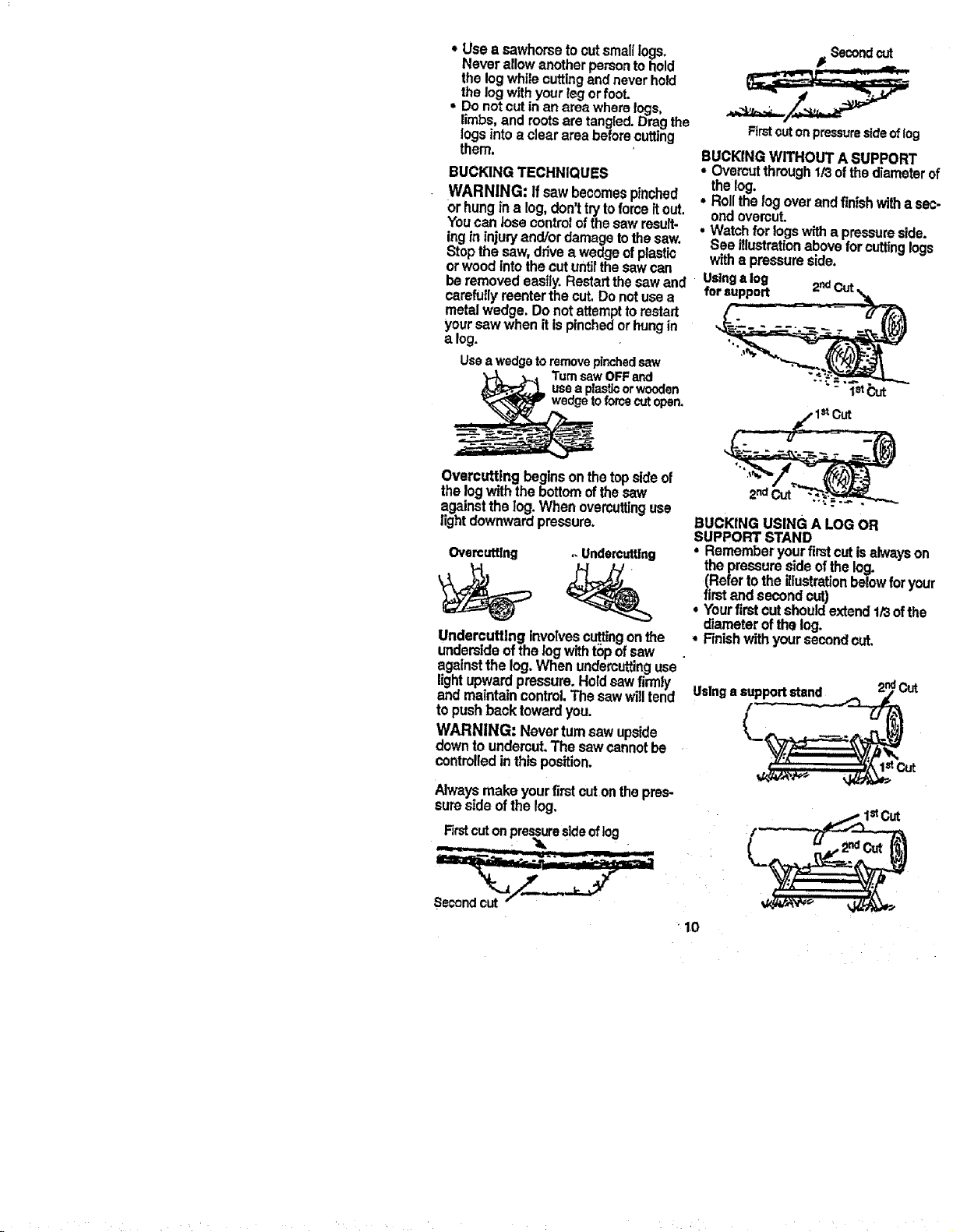

Firstcuton pressurerideof tog

BUCKINGWITHOUT ASUPPORT

• Overcutthrough1/3ofthediameterof

thelog.

• Rollthelogoverandfinish witha sec-

ondovercut.

• Watchfor logswitha pressureside.

See illustrationabovefor cuttinglogs

witha pressureside.

beremovedeasily.Restartthe sawand Usinga log

carefullyreenterthecut.Donotusea

metalwedge. Donotattempttorestart

yoursawwhen it Ispinchedorhungin

a log.

Useawedgetoremovepinchedsaw

TurnsawOFFand

/=Secondcut

2_ Cut

Overcuttlng beginsonthe topsideof

thelogwiththebottomofthesaw

againstthelog. When ovsrcuttinguse

light downwari:lpressure.

BUCKING USING A LOG OR

2ndCut

SUPPORTSTAND

Overcuffing =,Undercutting

• Rememberyourfirstcutis alwa_ on

thepressuresideof thelog.

(Refer tothe illustrationbelowforyour

firstandsecondcut)

• Yourfirstcutshouldextend1/3ofthe

diameterofthelog.

Undercutting involvescuttingonthe

• Finishwithyoursecondcut,

undersideofthe log withtopof saw

againstthe log.Whenundercuttinguse

and maintaincontrol.Thesawwilltend Usings

lightupwardpressure.Holdsawfirmly s__Cut

topushbacktowardyou. /

downto undercut.The sawcannotbe _ __ _

WARNING: Neverturnsawupside ______..__ - =

controlledinthisposition, v<_ut

Alwaysmake yourfirst cutonthepres-

sureside ofthe log.

Rrstcutonpressuresideoflog

..... ' ' - '... _ :_ - ij,__ I J]l I_111[_.

• 10

LIMBINGANDPRUNING withthe1/3,2/3cuttingtechniquesde-

WARNING: Neverclimbintoa treeto scdbedinthebuckingsection.

limborprune.Do notstandonladders, • Alwaysuseanovercuttooutsmall

platforms,a log,orinany position andfreelyhanginglimbs. Undercut-

whichcancauseyouto loseyourbat- tingcouldcauselimbstofailand

ante orcontrolofthe saw. pinchthesaw,

IMPORTANTPOINTS PRUNING

• Watchoutfor spdngpoles. WARNING: Limitpruningto limbs

Spdngpolesare smallsize limbs shoulderheightorbelow.Donotcutif

whichcanwhiptowardyou,orpull branchesare higherthanyourshoul-

youoffbalance, Use extremeca_on def. Geta professionalto dothejob.

whencuttingsmallsize limbs. • Makeyourfirst cut1/3ofthe way

• Bealertforspdngback,Watchoutfor throughthe bottomofthe limb.

branchesthatare bentor underpres- • Next makea secondcutall the way

sure.Avoidbeingstruckby the throughthe limb.

branchorthesaw whenthe tensionin , Finishthepruningoperationbyusing

thewoodfibersistelex.sad, an overcutsothatthestumpofthe

• Frequentlydear branchesoutof the limbprotrud.ec1 to2 inchesfromthe

waytoavoid tdppingonthem. trunkofthetree.

LIMBING

• Limba treeonlyafter itiscut down. I SecOndcut

• Leavethe largerlimbsunderneaththe I //_,

felledtree tosupportthetree as you

work.

• Stadatthebase ofthe felledtree and

worktowardthe top,cuttingbranches

and limbs.Removesmalllimbswith

one cut.

° Keepthetreebetweenyouandthe

chain.

° Removelarger,supportingbranches

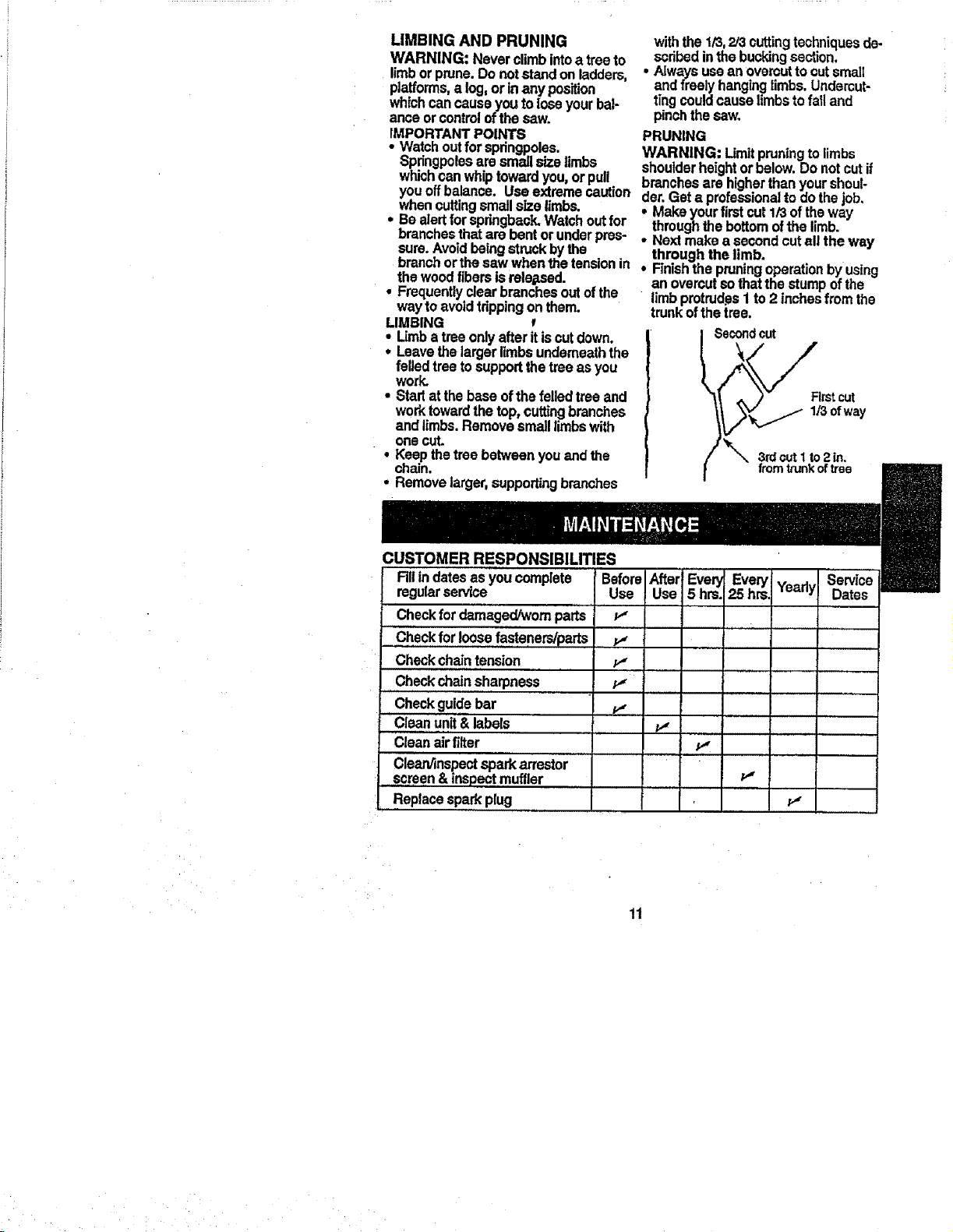

CUSTOMER RESPONSIBILITIES

Fillindatesas youcomplete BeforeAfter

regularservice Use Use

Checkfordamaged&yoreparts ii

..........,,,,,,,,,,

Checkforloosefasteners/parts p,

Checkchaintension p,,

,,,,, ,,

....Checkchainsharpness p_

Checkguidebar p,,

Cleanunit&labels

Cleanairfilter

Clean/inspectsparkarrestor

screen&inspectmuffler ...............

Replacesparkplug

11

Every Every Ysady

5hrs. 25hrs

,,,, _,

,,,,,,, ,,,,

/i

Service

Dates

GENERALRECOMMENDATIONS• HandleScrews

The warrantyonthisunitdoesnotcov-

eritemsthathave beensubjectedto

operatorabuseor negligence.Tore-

calvefurlvaluefromthewarranty,the

operatormustmaintain unitasinstruct-

edinthismanual. Variousadjustments

willneedto be madeperiodicallyto

properlymaintainyourunit.

• Onceayear,replacethesparkplug,

airfilter element,andcheckguidebar

andchainfor wear.A newspark plug

andairfilterelementassuresproper

air*fuelmixture and helpsyourengine

runbetterandlast longer.

WARNING: Disconnectthespark plug

beforeperformingrnslntenanceexcept

forcarburetoradjustments.

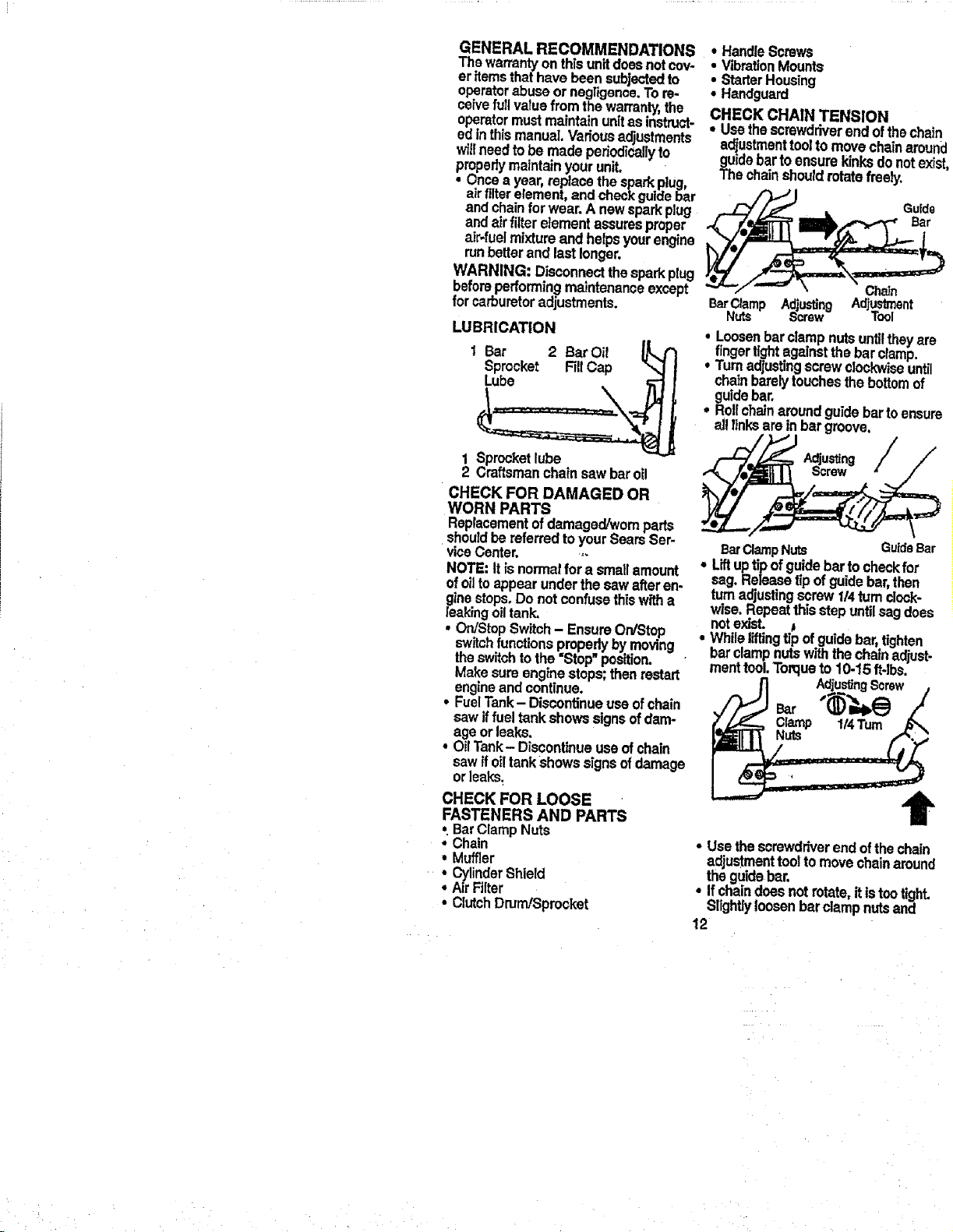

LUBRICATION

1 Bar 2 Bar Oil {jL,j_

Sprocket FillCap _ I

Lube _ f

• VibrationMounts

• StarterHousing

• Handguard

CHECK CHAIN TENSION

• Usethescrewdriver endofthechain

adjustmenttoolto movechainaround

guidebartoensurekinksdonotexist,

Thechainshouldrotatefreely.

BarClamp Adjusting Adj._S_llent

Nuts Screw

• Loosenbarclampnutsuntiltheyare

fingertightagainstthebar clamp.

• Turnadjustingscrewclockwiseuntil

chainbarelytouchesthebottomof

guidebar.

• Rollchainaroundguidebartoensure

all linksare In bargroove.

Chain

1 Sprocketlube

2 Craftsmanchainsaw baroil

CHECK FOR DAMAGED OR

WORN PARTS

Replacementofdamaged/wornparts

shouldbe referredtoyourSearsSer-

viceCenter. =-

NOTE: Itis normalfora smallamount

ofoiltoappear underthesawafteren-

ginestops.Donotconfusethiswitha

leakingolltank,

• On/StopSwitch- EnsureOn/Stop

switchfunctionspropedybymoving

theswitchto the Stop position.

Makesureenginestops;then resta{t

engineand continue.

• FuelTank- Discontinueuseofchain

sawiffueltank showssignsofdam-

ageorleaks.

• OilTank- Discontinueuse ofchain

sawifoil tankShowssignsofdamage

orleaks_

CHECK FOR LOOSE

FASTENERS AND PARTS

*.BarClampNuts

• Chain

• Muffler

• CylinderShield

• AirRIter

• ClutchDrum!Sprocket

Adjusting

Screw

BarClampNuts GuideBar

• Liftuptipofguide bartocheck for

sag.Releasetipof guidebar,then

turnadjustingscrew114turnclock-

wise,Repeatthisstepuntilsagdoes

notexisL j

• Whileliftingtip ofguidebar,tighten

barclampnutswiththechainadjust-

menttool.Torqueto10-15 ft-lbs,

Adjust'rigScrew j

• Usethescrewdriverendofthechain

adjustmenttoo|to movechainaround

theguidebar.

• Ifchaindoesnot rotate,itistootight.

Slightlyloosenbarclampnutsand

12

turnadjustingscrew114turncounter-

clockwise.Retightenbarclampnuts.

• Ifchainistooloose,itwillsag below

theguidebar.DO NOToperatethe

sawifthe chainis loose.

CHECK CHAIN SHARPNESS

A sharpchainmakes woodchips.A

dullchainmakesa sawdustpowder

andoutsslowly. •

CHAIN SHARPENING

Chainsharpeningrequiresspecial

tools.Youcanpurchasesharpening

toolsatSears or goto a professional

chainsharpener.

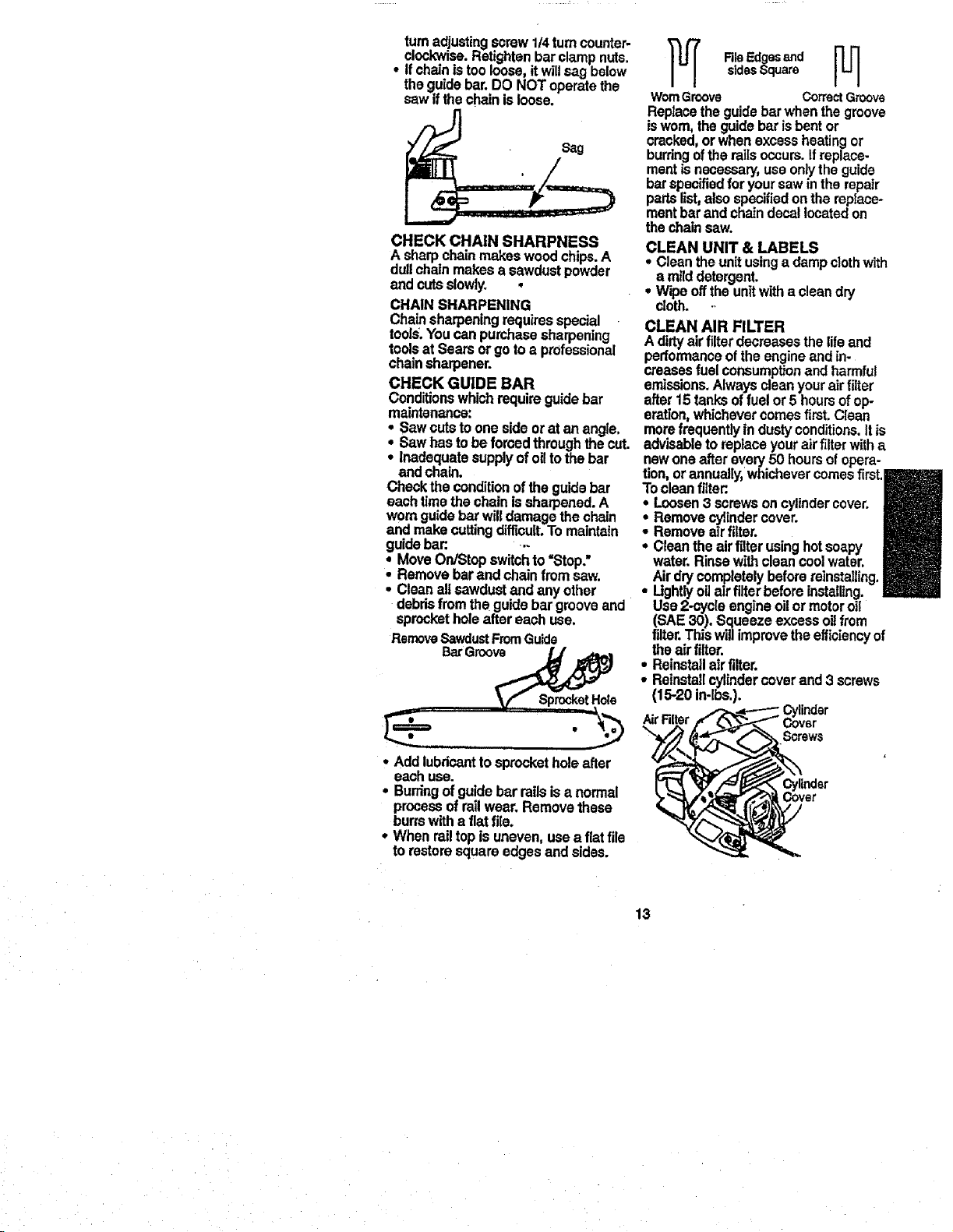

CHECK GUIDE BAR

Conditionswhichrequireguidebar

maintenance:

• Sawouts toonesideorat an angle.

• Sawhas tobe forcedthroughthe cut.

• Inadequatesupplyofoiltothe bar

and chain.

Checktheconditionofthe guidebar

eachtime thechainissharpened.A

wornguidebarwilldamagethechain

and makecuttingdifficu[LTomaintain

guidebar:...

• MoveOn/Stepswitchto=Stop."

• Removebarand chain fromsaw.

• Cleanall sawdustand any other

debdsfromthe guidebar grooveand

sprocketholeafter eachuse.

RemoveSawdustFromGuido

BarGroo_

SprocketHole

sidesSquare

FileEdgesand _J_

Worn Groove Correct Groove

Replacetheguidebarwhenthegroove

isworn,the guidebarisbentor

cracked,orwhenexcessheatingor

burdngofthe railsoccurs.If replace-

mentisnecessary,useonlythe guide

barspecifiedforyoursawinthe repair

partslist,alsospecifiedonthe reptace-

merit barand chaindecallocatedon

the chainsaw.

CLEAN UNIT & LABELS

• Cleanthe unitusingadempclothwith

a milddetergent.

• Wipeofftheunitwitha cleandry

cloth. .,

CLEAN AIR RLTER

A dirtyairfilterdecreasesthefifeand

performanceof theengineand in-

creasesfuelconsumptionandharmful

emissions.Alwayscleanyourairfilter

after15 tanksoffuelor5 hoursofop-

eration,whichevercomesfirst.Clean

morefrequentlyin dustyconditions.It is

advisabletoreplaceyourairfilterwitha

newoneafter every50 hoursof opera-

tion,or annually,whichevercomesfirst.

Tocleanfilter:.

° Loosen3 screwson cylindercover.

° Removecylindercover.

° Removeairfilter.

° Cleantheairfilterusinghotsoapy

water.Rinsewithcleancoolwater.

• Airdrycompletelybeforereinstalling.

Lightlyoil airfilterbeforeinstalling.

Use2-cycleengineoilormotoroit

(SAE30). Squeezeexcessoilfrom

filter.Thiswillimprovetheefficiencyof

theairfilter.

• Reinstallair filter.

• Reinstallcylindercover and3 screws

(15-20 in-lbs.).

AirRlter Cover

Cylinder

Screws

• Addlubricantto sprocketholeafter

eachuse.

• Burringofguidebar rails isa normal

processofrailwear. Removethese

burrswitha flatfile.

• When railtopisuneven,usea fiat file

to restore square edgesandsides.

13

Cylinder

Cover

Loading...

Loading...