Page 1

_ IMPORTANT MANUAL Do Not Throw Away

3._

Operator's

Manual

Model No.

358.351080-18"

358.351160-16"

358.351180-18"

CUSTOMER

ASSISTANCE

1-800-235-5878

HOURS (CST)

Mon. - Sat. 7 a.m. - 7 p.m.

Sun. 10 a,m.- 7 p.m.

l_k WARNING:

READ THE OPERATOR'S

MANUAL AND FOLLOW

ALL WARNINGS AND

SAFETY INSTRUCTIONS.

FAILURE TO DO SO CAN

RESULT IN SERIOUS

INJURY.

CRAFTSMRN"

Always Wear Eye Protection

CRRFTSMRN°

2.4 cu. in/40cc 2-CYCLE

2.4 cu. in/40cc 2-CYCLE

2.6 cu. in/42cc 2-CYCLE

GASOLINE CHAIN SAW

• Assembly

• Operation

• Customer Responsibilities

• Service and Adjustments

• Repair Parts

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

530-083360-1-08/4/95

Page 2

SAFETY RULES

:":_:.;

"i

: ._':.

. _.

WARNING:

ALWAYS DISCONNECT SPARK PLUG WIRE AND PLACE WIRE WHERE IT CANNOT CONTACT SPARK

PLUG TO PREVENT ACCIDENTAL STARTING WHEN SETTING UP,TRANSPORTING, ADJUSTING OR

MAKING REPAIRS EXCEPT CARBURETOR ADJUSTMENTS.

BECAUSE A CHAIN SAW IS A HIGH-SPEED WOOD-CUTflNG TOOL, SPECIAL SAFETY PRECAUTIONS

MUST BE OBSERVED TO REDUCE TIIE RISK OF ACCIDENTS. CARELESS OR IMPROPER USE OFTHIS

TOOL CAN CAUSE SERIOUS INJURY.

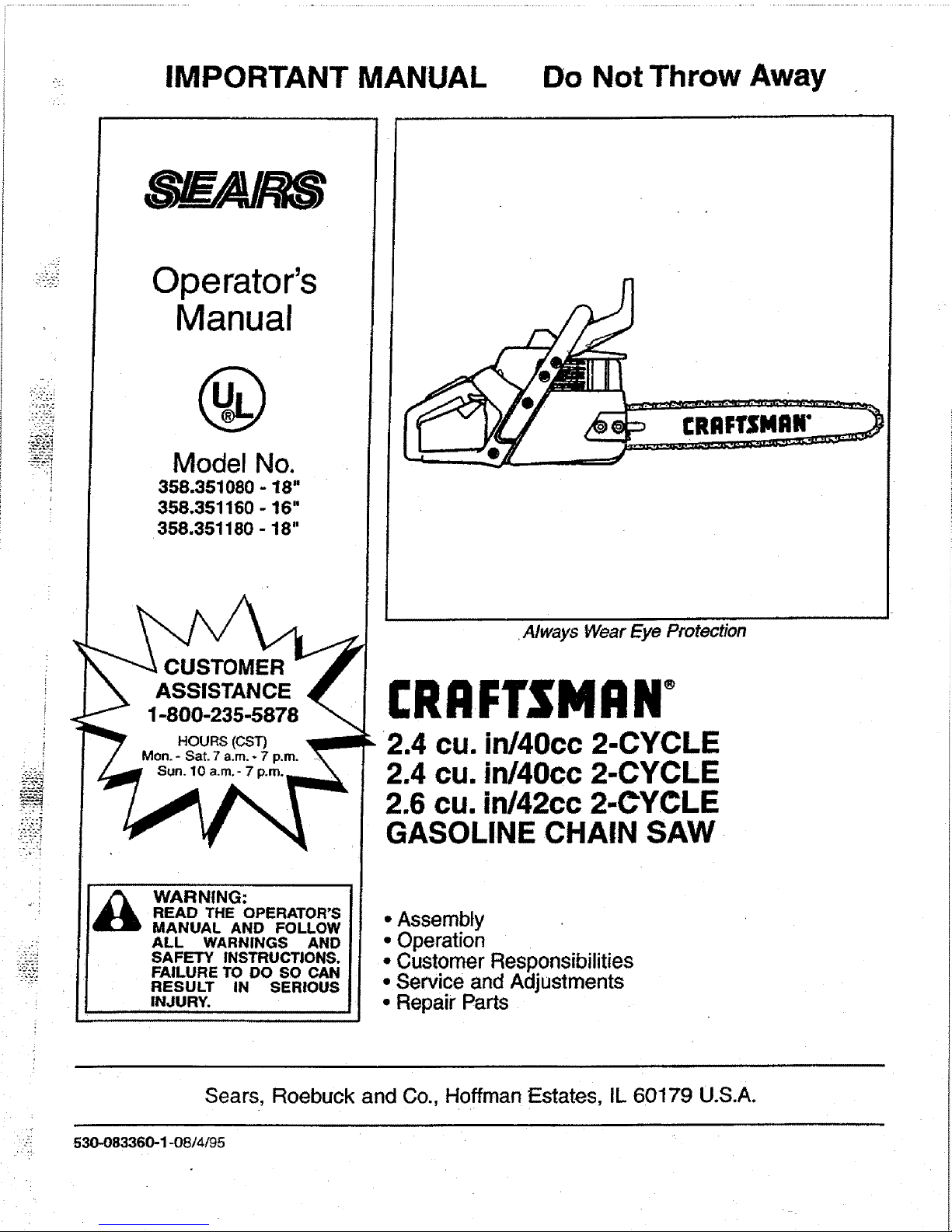

Hearing

Protection_ _1_= "=_----

Safety

Hat

Snug __=.._ Eye Protection

Fitting_---_..._

Clothing

_'="__" Heavy DutyGloves

Safety Chaps

Safety J

Shoes_._

Figure1

KNOW YOUR SAW

• Read your operator'smanual carefullyuntilyoucomplete-

ly understandandcanfollowallsafelyrules,precautions,and

operating_str_-'tions beforeattemptingtooperatetheunit.

• Restrict the use of your saw to adult users whounder-

standandcanfollowsafety rules,precautions,andoperating

instructionsfound inthis manual.

PLAN AHEAD

• Wear protectivegear Figure I Alwaysusesteel-toedsafe-

ty footwearwithnon-slipsoles;snug-f_1_clothing;heavy

duty,non-slipglo_s; eye protectionsuch as non-fogging,

venteegogg=esor racescreen:an approvedsafetyhardhat;

and soundbarriers- ear plugsor mufflers to protectyour

hearingRegularusersshouldhaveheating_ regular

lyas chainsawnoisecandamage hearing

° Keepail partsofyour bodyaway from thechainwhenthe

engine is running

• Keep children,bystanders,and animals a minimum of30

feet (10 meters) away from the work area Do notallow

olheroeopleoranimals to be nearthecha_ sawwhenstart-

ingoroperatingthe chainsaw.

• Do not handle or operate s chain saw when you are

fatigued, ilt, or upset,or ifyou havetaken alcohol,drugs,

or medication. Youmustbe ingoodphysicalconditionand

mentallyalert.Chainsawworkisstrenuous.If youhaveany

conditionthatm_ht be aggravatedbystrenuouswork,check

withyourdoctorbeforeoperatingachainsaw.

• Do not attempt to useyour chainsawduring bad weath-

er condi_onssuchasstrongwind,rain,snow,ice,etc.,orat

night

• Carefully plan your sawing operationin advance. Do not

startcuttinguntilyouhavea clearworkarea, securefooting,

and, ffyouare fellingtrees,a plannedretreatpath.

• Do not operete a chain sew thatis damaged,irnpropedy

adjusted, or not completely and securely assembled.

Always replace the handguardImmediatelyff it becomes

damaged, broken,or is otherwiseremoved

• Keep the handles dr_ clean,and free of oil or fuel mix-

ture.

• W'd_tthe engine stopped,hand carrythe chain saw with

the muffler away from your body,andt_ guidebar and

chainto the rear,preferablycoveredwitha scabbard.

FUEL HANDLING

• Eliminate all sources of sparks or flames in the areas

where fuel ismixed,poured,or storedThare shouldbeno

smoking,open flames,or woodthat could cause sparks.

Allowenginetocoolbeforerefueling.

• Mix and pour fuel inan outdoorareaon bareground;store

fuel ina cool,dry,,wellventilatedplace;and usean approved,

marked container forallfuel purposes.

• Wipe up all fuel spills before startingsaw.

° Move at least 10 feet (3 meters)from the fueling site

before starting the engine.

• DO not smoke while handling fuel or while operatingthe

saw.

• Turn the engine of_and let your saw cool |na noncom-

bustibte area, not on dry leaves,straw,paper, etc Slowly

remov_fuel cap and refuelunit.

• Storethe unitand fuel in an areawherefuel vaporscannot

reach sparks or open flames from water heaters, electric""

motors or switches,furnaces, etc.

SAFETY NOTICE

Exposure to vibra.tionsthrough prolonged use of gasolinepowered hand tools could cause blood vessel or nerve damage in the fin-

gem, hands, arm Iomts of people prone to Circulationdisordersor abnormal swellings. Prolongeduse in cold weather has been linked

toblood vessel damage in othen_se healthy people. If symptomsoccursuch as numbness, pain, loss ofstrength,change in skin color

ortexture, or loss of feelings in the fingers, hands or joints,discontinuethe use of this too_and seek medical attention.An anti-w'bra-

tionsystem does netguarantee the avoidance o_these problems.Users who operate powertoolson a continualand regular basis must

monitorctoseiytheir physical condition and the conditionof this unit.

_1 LOOK FOR THIS SYMBOLTO POINT OUT IMPORTANT SAFETY PRECAUTIONS

IT MEAN S - ATTENTION!!! BECOME ALERT!!! YOUR SAFETY IS INVOLVED

Page 3

,-. SAFETY RULES

OPERATE YOUR SAW SAFELY

• Do not operate a chain saw with one hand. Serious

injurytothe operator,helpers,bystandersor anycombina-

tionof these persons may resultfromone-handedopera-

tion.A chain saw is intendedfortwo-handeduse.

• Operate the chain saw only in well-ventilated outdoor

areas.

• Do not operate saw from a ladder or in a tree, unless

specificallytrained to do so.

• Position all parts of your body to the left of cut and

away from the chain when the engine is running.

• Cut wood only. Do not useyour saw to pryor shoveaway

limbs,roots, or other objects.

• Make sure the chain will not make contact with any

object while starting the engine, Never try to startthe

sawwhen the guide bar is ina cut or kerr.

• Use extreme caution when cutting small size brush

and saplings. Slender materialcan catchthechain and

bewhipped towardyou or pullyouoffbalance.

• Be alert for springback whencuttinga limbthatis under

tensionso you will not be struckbythe limb or sawwhen

thetensioninthe wood fibers isreleased.

• Do not put pressure on the saw at the end of a cut.

Applyingpressurecan cause you to losecontrolwhenthe

cutis completed.

• Stop.the engine before setting the saw down.

• Keep fuel and oil caps, screws, and fasteners securely

tightened.

MAINTAIN YOUR SAW IN GOOD WORKING

ORDER

• Have all chain saw service performed by your Sears

Service Center withtheexceptionofthe itemslistedinthe

"Customer Responsibilities"section of this manual.For

example,if impropertoolsare used to removeor ho{dthe

flywheelwhen servicingthe clutch, structuraldamageto

theflywheelcanoccurandcause the-flywheel toburst.

• Make certain thechain stops moving when the throttle

trigger is released, For correction,refer to 'Carburetor

Adjustments."

• Stop the saw if the chain strikes a foreign object.

Inspectunitand repair or replace parts as necessary.

• Disconnect the spark plug before performing any

maintenance exceptfor carburetor adjustments.

• Never modify your saw in any way. Use onlySEARS '

accessories and replacementpartsas recommended.

TRANSPORTING AND STORAGE

• Stopthe unit before transporting.

• Allow engine to cool, cover the guide bar and chain,and

secure the unitbefore storing or transportingina vehicle.

• Emptyfuel tank before storing or transporting the unit.Use

upany fuel left in thecarburetor by starting the engineand

letting theengine run until itstops.

• Store unitand fuel in an area where fue! vaporscannot

reach sparks or open flames from water heaters, electric

motors or switches, furnaces, etc.

• Store unit so the chain cannot accidentally cause injury.

• Store the unit out of the r_ach of children.

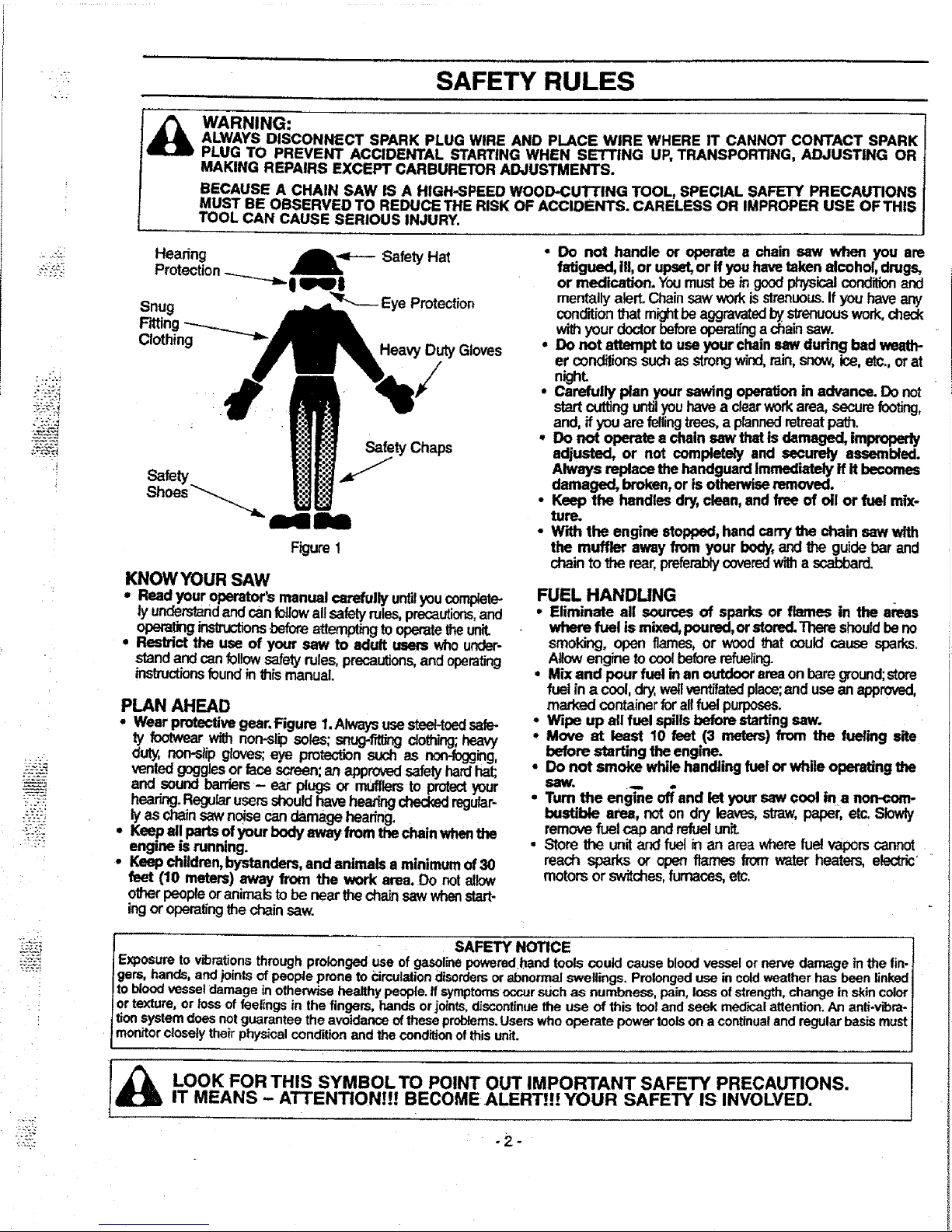

GUARD AGAINST KICKBACK - Kickback is a dangerous reaction that can lead to serious injury.

KICKBACK WARNING:

KICKBACK CAN OCCUR WHEN THE MOV-

ING CHAIN CONTACTS AN OBJECT ATTHE

UPPER PORTION OFTHETIP OFTHE GUIDE

BAR OR WHEN THE WOOD CLOSES IN AND

PINCHES THE CHAIN IN THE CUT.CONTACT

AT THE UPPER PORTION OF THE TIP OF

THE GUIDE BAR CAN CAUSE THE CHAIN

TO DIG INTO THE OBJECT, WHICH STOPS

THE CHAIN FOR AN INSTANT.THE RESULT

IS A LIGHTNING FAST,REVERSE REACTION

WHICH KICKS THE GUIDE BAR UP AND

BACK TOWARD THE OPERATOR. IF THE

CHAIN IS PINCHED ALONG THE TOP OF

THE GUIDE BAR, THE GUIDE BAR CAN BE

DRIVEN RAPIDLY BACK TOWARD THE

OPERATOR. EITHER OFTHESE REACTIONS

CAN CAUSE LOSS OF SAW CONTROL

WHICH CAN RESULT IN SERIOUS INJURY.

DO NOT RELY ONLY ON THE SAFETY

DEVICES PROVIDED WITH YOUR SAW. AS

A CHAIN SAW USER, YOU MUST TAKE

SPECIAL SAFETY PRECAUTIONS TO HELP

KEEP YOUR CUTTING JOBS FREE FROM

ACCIDENT OR INJURY.

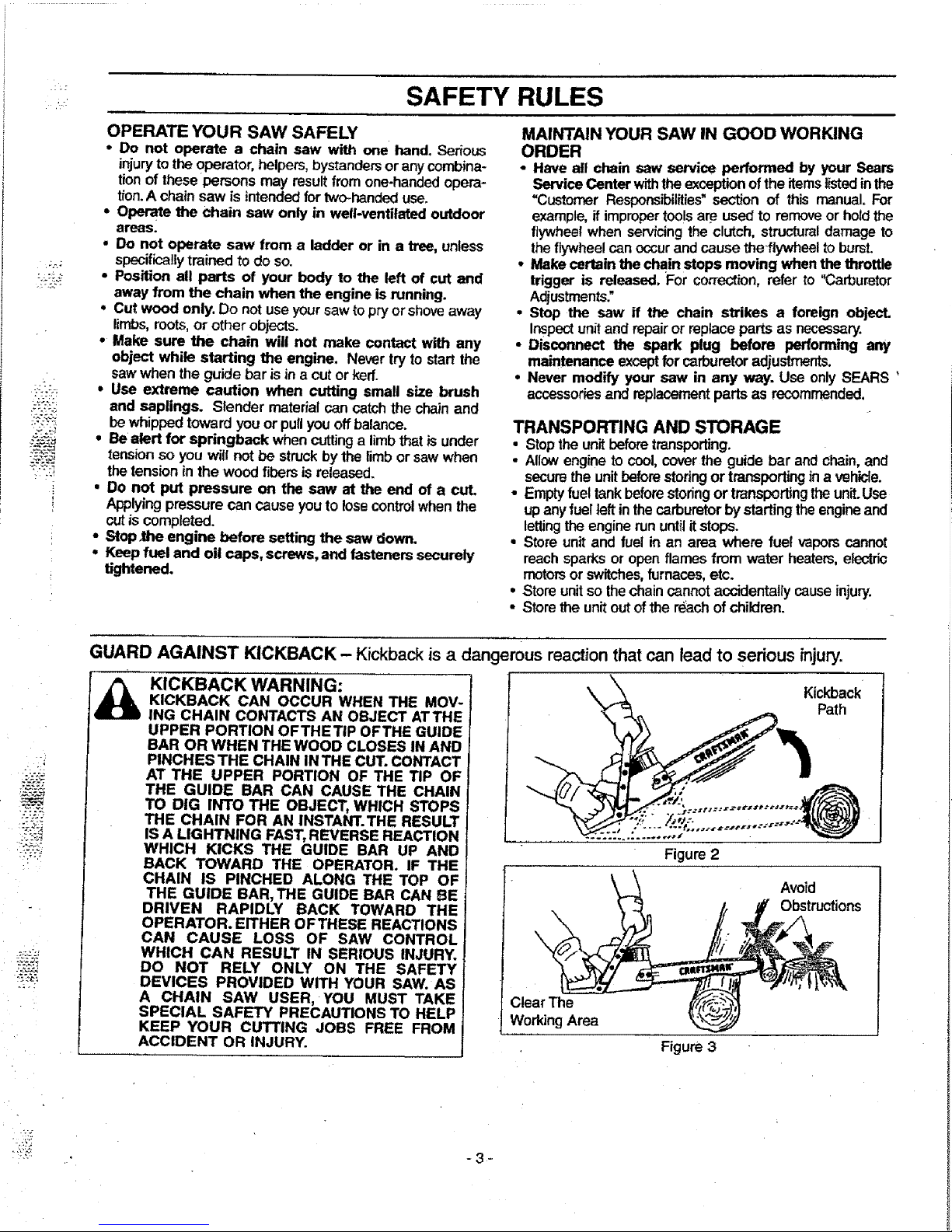

ClearThe

WorkingArea

Figure2

Figure 3

Kickback

Path

Avoid

Obstructions

-3 ¸-

Page 4

k

SAFETY RULES

"'2";

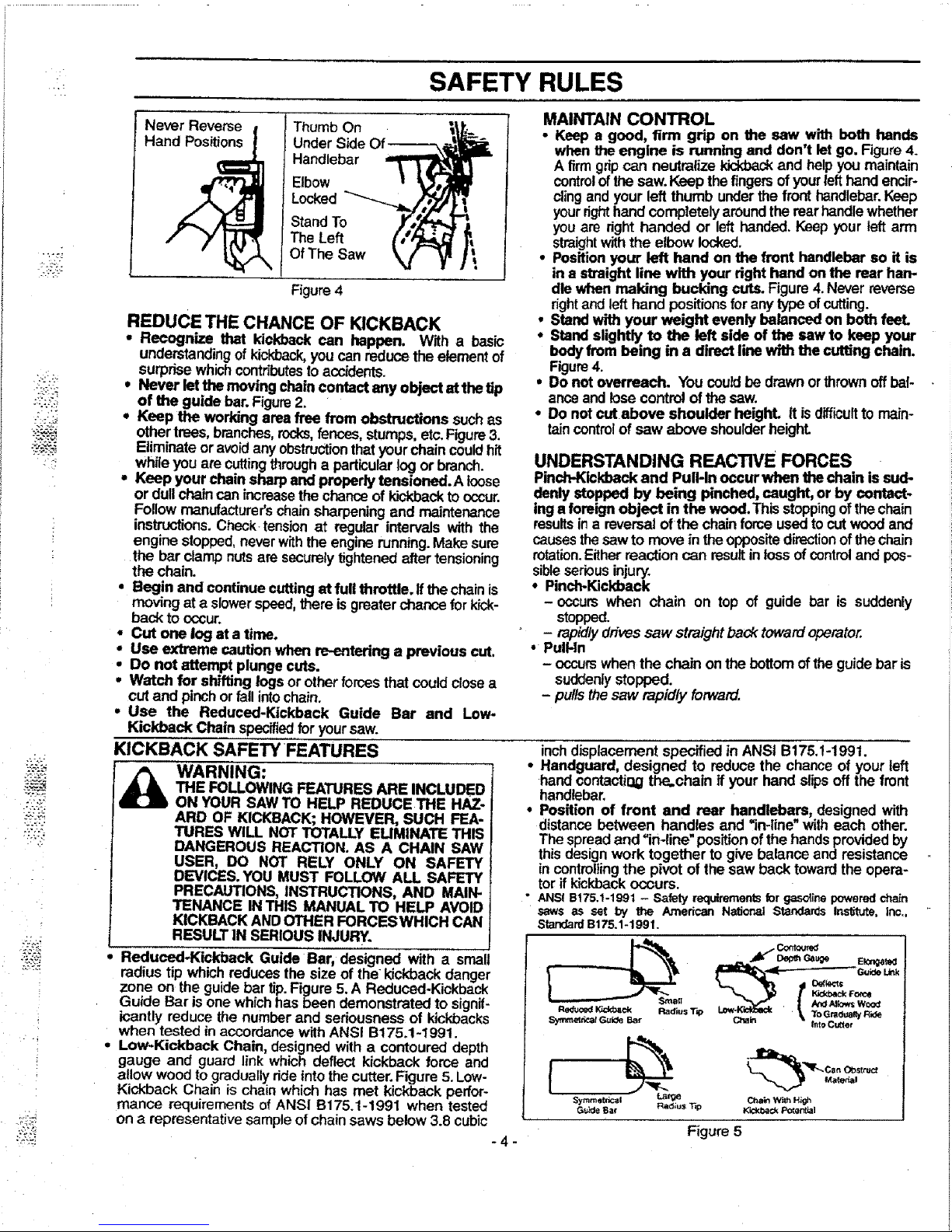

Ha ! Under Side Of

_ Handlebar

| Elbow

_Locked "'_

lstand

t OfThe Saw

Figure4

REDUCE THE CHANCE OF KICKBACK

• Recognize that kickback can happen. With a basic

understandingof kicl_ack,you canreduce the elementof

surprisewhichcontributesto accidents.

* Never letthe moving chaincontact any object at the tip

of the guide bar. Figure2.

. Keep the working area free from obstructions suchas

othertrees, branches,rocks,fences,stumps,etc.Figure3.

Eliminateor avoidanyobstructionthat your chaincouldhit

while you arecuttingthrougha particularlogor branch.

, Keep your chain sharp and properly tenaioned.A loose

or dullchaincan increasethe chanceofkickbackto occur.

Followmanufacturer'schainsharpeningand maintenance

instructions.Check tensionat regular intervals with the

engine stopped,neverwiththe engine running.Makesure

the bar clamp nutsare securelytightenedafter tensioning

the chain.

• Begin and continuecutting at full throttle. If thechain is

moving at a slowerspeed,there isgreaterchance forkick-

back to occur.

• Cut one log at a time.

• Use extreme caution when re-entering a previous cut.

• Do not attempt plunge cuts.

• Watch for shifting logsor other forcesthat couldclosea

cutand pinchorfall intochain.

° Use the Reduced-Kickback Guide Bar and Low-

Kickback Chain specked foryoursaw.

KICKBACK SAFETY FEATURES

_ WARNING:

THE FOLLOWINGFEATURES ARE INCLUDED

ON YOUR SAW TO HELP REDUCE THE HAZ-

ARD OF KICKBACK; HOWEVER, SUCH FEA-

TURES WILL NOT TOTALLY ELIMINATE THIS

DANGEROUS REACTION. AS A CHAIN SAW

USER, DO NOT RELY ONLY ON SAFETY

DEVICES. YOU MUST FOLLOW ALL SAFETY

PRECAUTIONS, INSTRUCTIONS, AND MAIN-

TENANCE IN THIS MANUAL TO HELP AVOID

KICKBACK ANDOTHER FORCESWHICH CAN

RESULT IN SERIOUS INJURY.

Reduced-Kickback Guide Bar, designed with a sma

radius tip,whichreduces the size of the kickback danger

zone on me guioe par tip. Figure 5,A Reduced-Kickback

Guide Bar is one whichhas been demonstrated to signif-

icantly reduce the number and seriousness of kickbacks

MAINTAIN CONTROL

• Keep a good, firm grip on the saw with both hands

when the engine is running and don't let go. Figure4.

A firm grip can neutralize kickbackand help you maintain

controlof the saw. Keep the fingersof your left hand encir-

cling and your left thumb under the front handlebar.Keep

your righthand completely around the rear handle whether

you are right handed or left handed. Keep your left arm

straightwiththe elbow locked,

• Position your left hand on the front handlebar so it is

in a sl_aightline with your right hand onthe rear harp

die when making bucking cuts. Figure4.Never reverse

right andlefthand positionsforany type ofcutting.

• Stand with your weight evenly balanced on both feel

• Stand slightly to the left side of the saw to keep your

bodyfrom being in a direct line with the cutting chain.

Figure4.

• Do not overreach. Youcouldbe drawnor thrownoffbal-

anceand losecontrol of the saw.

• Do not cut above shoulder heighL It isdifficult to main-

taincontrol of saw above shoulderheight.

UNDERSTANDING REACTWE FORCES

Pinch-Kickback and Puff-Inoccur when thechain issud-

denly stopped by being pinched, caught, or by contact-

inga foreignobject in the wood.This stoppingof the chain

resultsina reversal of the chain forceusedtocut wood and

causesthesawto movein the oppositedirectionofthechain

rotation.Eitherreactioncan resultinlossofcontrol and pos-

sibleseriousinjury.

• Pinch-Kickback

-occurs when chain on top of guide bar is suddenly

stopped.

- rapidlyd/_vessaw straightbacktowardoperator.

• PulHn

- occurswhen the chain on the bottomofthe guidebar is

suddenlystopped.

- pulisthesaw rapidly forward.

inchdisplacement specified in ANSI B175.1-1991.

Handguard, designed to reducethe chance of yourleft

handcontactiQgthe.chain if your hand slipsoff the front

handlebar,

Position of front and rear handlebars, designed with

distancebetween handles and =in-line"witheach other.

The spreadand =in-line" positionofthe handsprovidedby

thisdesignwork together to give balance and resistance

in centmlling the pivot of the saw back toward the opera-

tor ifkickbackoccurs.

ANS! B175.1-1991 - Safety requirements for gasotine powered chain

saws as set by the ._nedcan NaSor_l Standards Institute, inc.,

Standard B175.1-1991.

2 ._ Dep_ Gauge Ek:ng_

ReducedlGdd_ck Rad{usT_) Lo_-KL_Ee_ _ To Gra_lualty Ride

_nf_tettP..af G_i_} Bar Chain l_to C_ter

when tested in accordance with ANSI B175.t-1991.

Low-Kickback Chain, designed with a contoured depth

gauge and guard link which deflect kickback force and

allow woodto gradually ride into the cutter. Figure 5. Low-

Kickback Chain is chain which has met kickback perfor-

mance requirements of ANSI B175.1-1991 when tested

on a representative sampleof chain saws below 3.8 cubic

-4-

{

Sym_etricat Large

Guide Bat Rad;u$ T'=p

Male_l

C_ain With H_gh

Kick_¢_ Poter_ia_

Figure 5

Page 5

7:.

i

"kY_

CONGRATULATIONS on your purchase of a Sears

Craftsman Gasoline Chain Saw. It has been designed,

engineered and manufactured to give you the best possi-

ble dependability and performance.

Should you experience any problems you cannot easily

remedy, please contactyour nearest Sears Service Cen-

ter/Department orcallthe 1-800 number listedon the front

of this manual. Sears has competent, welltrained techni-

cians and the propertoolsto service or repair this unit.

Please read and retain this manual. The instructions wilt

enable you to assemble and maintain your unit properly.

Always observe the =SAFETY RULES."

MODEL NUMBER:

358.351080-18"

358.351160-16"

358.351180-18"

DATE CODE/SERIAL NO.:

DATE OF PURCHASE:

THE MODEL AND SERIAL

FOUND ON THE PRODUCT.

NUMBER WILL BE

YOU SHOULD RECORD BOTH SERIAL NUMBER

AND DATE OF PURCHASE AND KEEP IN A SAFE

PLACE FOR FUTURE REFERENCE.

J

MAINTENANCE AGREEMENT

A Sears Maintenance Agreement is available on this prod-

uct. Contact your nearestSears Store for details.

:CUSTOMER RESPONSIBILITIES

• Read and observe thesafety rules.

• Followa regularschedule in maintaining, caring for, and

, using your unit.

• Follow the instructions under "Customer Responsibi-

lities" and "Storage" sectionsof this Operator's Manual

PRODUCT SPECIRCATIONS

GUIDE BAR: ............... 16"

18"

CHAIN: ........................ Low Profile 3/8" Pitch

Chrome Cutters

DISPLACEMENT: ....... 2.4 Cubic inches (40cc)

2.6 Cubic Inches (42cc)

ENGINE: ..................... 2-cycte Air Cooled

FUEL MIX:................... 40:1 (3.2 oz.oil per gallon gas)

OILER: ........................ Automatic, 6.8 oz.Tank

IGNITION: ................... Solid State

(Air gap .010" to .014")

IGNITION TIMING: ...... Non-adjustable, fixed

SPARK PLUG TYPE: .. Champion (CJ-7Y)

SPARK PLUG GAP:......025" (.65ram)

MUFFLER: .................. Spark Arresting Screen

ENGINE RPM: ............ 12,600 RPM Maximum

SPECIAL NOTICE

Your saw is equipped with e temperature limiting muf-

tier and spark arresting screen which meets the require-

ments of Celifomla Codes 4442 and 4443. All U.S. forest

land and _e states of California, Idaho, Maine, Minnesota,

New Jersey, Washington, and Oregon require many internal

combustion engines to be equipped with a spark arrestor

screen by law.

If you operate a chain saw in a state or locale where

such regulations exist, you ere I..e_lellyresponsible lor

malntalning the operating condition of these pa.rts.

Failure to do so is a violation of the law. Refer to trio

Spark Arrestor section under "Customer Responsi-

bilities" for maintenance.

MANUFi_'_TUREO UNDER ONE OR MORE OF THE FOLLOWING U,S. PATENTS:

5,367,_J_; 4.940,028; 4,370,85S; 4,302.87_; 4,197,64_, D325_330, OTHER U,S. AND FOR-

EIGN PATENTS PENDING,

' sPECIAL NOTICE

Ifthis saw is to be used for commercial logging, you must order and install a Chain Brake, to comply

with Federal OSHA Regulations for Commercial Logging see Repair PaL_sList or call 1-800-235-5878.

FULL ONE YEAR WARRANTY ON CRAFTSMAN GAS CHAIN SAW

\

For one year fromthe date of purchase, when this Craftsman Gas Chain Saw is maintained, lubricated and tuned-up

accordingto the owner's manual Sears will repair, free of charge, any defect in matedal or workmanship.

This warranty excludesthe bar, chain, 'spark plug and air filter, whichare expendable parts, and become worn during

normal use.

Ifthis Gas Chain Saw is used for commercial or rental purposes,this warrantyapplies for 30 days fromthe date of pur-

chase.

WARRANTY SERVICE IS AVAILABLE BY RETURNING THIS CHAIN SAW TO THE NEAREST SEARS SERVICE

CENTER IN THE UNITED STATES.

This warranty givesyou specific legal rights, and you may also have other rights whichvary from state to state.

SEARS, ROEBUCK AND CO.,DI817WA, Hoffman Estates, IL 60179

-5-

Page 6

TABLE OF CONTENTS

".?_: J

___

Safety Rules...................................................................... 2

Product Specifications .........................._............................ 5

Warranty ............................................................................ 5

Accessories ....................................................................... 6

Operation .......................................................................... 8

Customer Responsibilities ............................................... :17

Service and Adjustments................................................ 22

Storage............................................................................ 27

Trouble Shooting Points.................................................. 28

Repair Parts .................................................................... 29

Repair Parts Ordering/Service .......................... Back Cover

INDEX

A

Accessories ....................................................................... 6

Air Filter........................................................................... 20

B

Bar and Chain Oil ............................................................ 10

Bucking............................................................................ 15

C

Carburetor Adjustments .................................................. 25

Carton Contents ................................................................ 7

Chain Adjustment.................................................. ,.........22

Chain Oiler ............................... _........................................ 9

Chain Sharpening ........................................................... 18

Customer Responsibilities ............................................... 17

Spark Plug ................................................. L................20

E

Engine

Fuel/Oil ......................................................................... 10

Spark Plug ................................................................. 20

Starting......................................................................... 11

Storage ........................................................................ 27

F

Fuel Filter........................................................................ 21

Fueling ............................................................................. t0

G

Guide Bar and Chain Oi!................................................. 10

Guide Bar Maintenance .................................................. 19

H

How To Use Your Chain Saw............................................. 9

K

Know YourChain Saw ................................... .....................8

L

Limbing............................................................................ 16

M

Maintenance Schedule.................................................... 17

Model Number................................................................... 5

Muffler ............................................................................. 20

O

Operation............................................................. ..............8

Ordedng Repair Parts....................................... BackCover

P

ProductSpecifications....................................................... 5

Pruning..................................................... :...................... 16

R

Repair Parts ................................. _................................... 29

S

Service and Adjustments .................................... i...........22

Spark Arrestor Screen..................................................... 20

Starter Rope.................................................................... 23

Starting ............................................................................ 11

Storage.......................................................... _................. 27

T

ThrotUeControl Group .................................................. _...g

Tree Felling...................................................................... 13

Trouble ShootingPoints.................................................. 28

W

Warranty............................................................................ 5

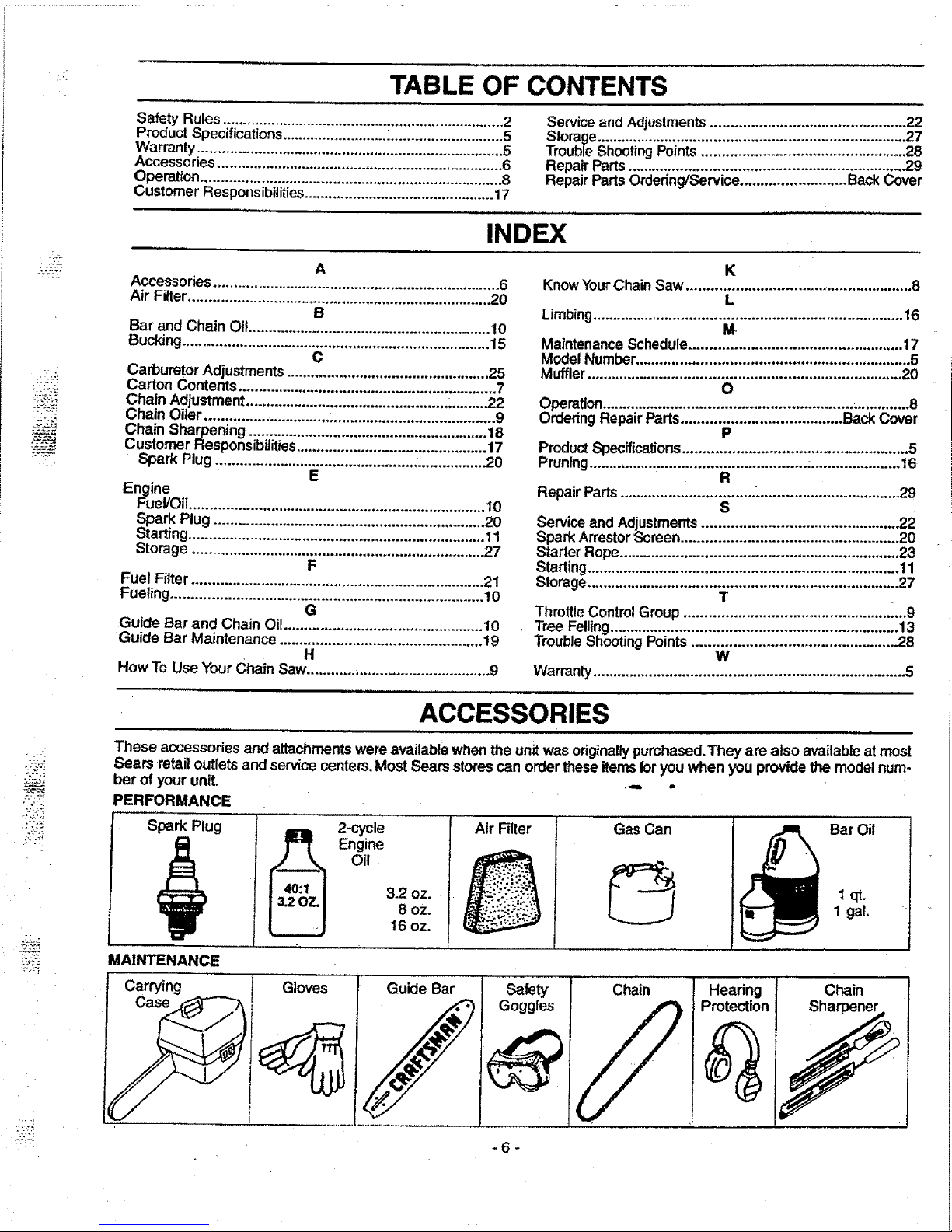

ACCESSORIES

These accessoriesand attachmentswere availablewhen the unit was originallypurchased.They are also availableat most

Sears retail outletsand servicecenters. Most Sears storescan orderthese itemsforyouwhen you provide the model num-

ber of your unit. ._ .

Air Filter Bar Oil

PERFORMANCE

Spark Plug

MAINTENANCE

Carrying

_ -cycle

Engine

Oil

3.2 oz.

8 oz.

t6 oz.

Gas Can

1 gat,

Gloves

J

Guide Bar

Safety Chain

Goggles

Hearing

Protection

Chain

f

Page 7

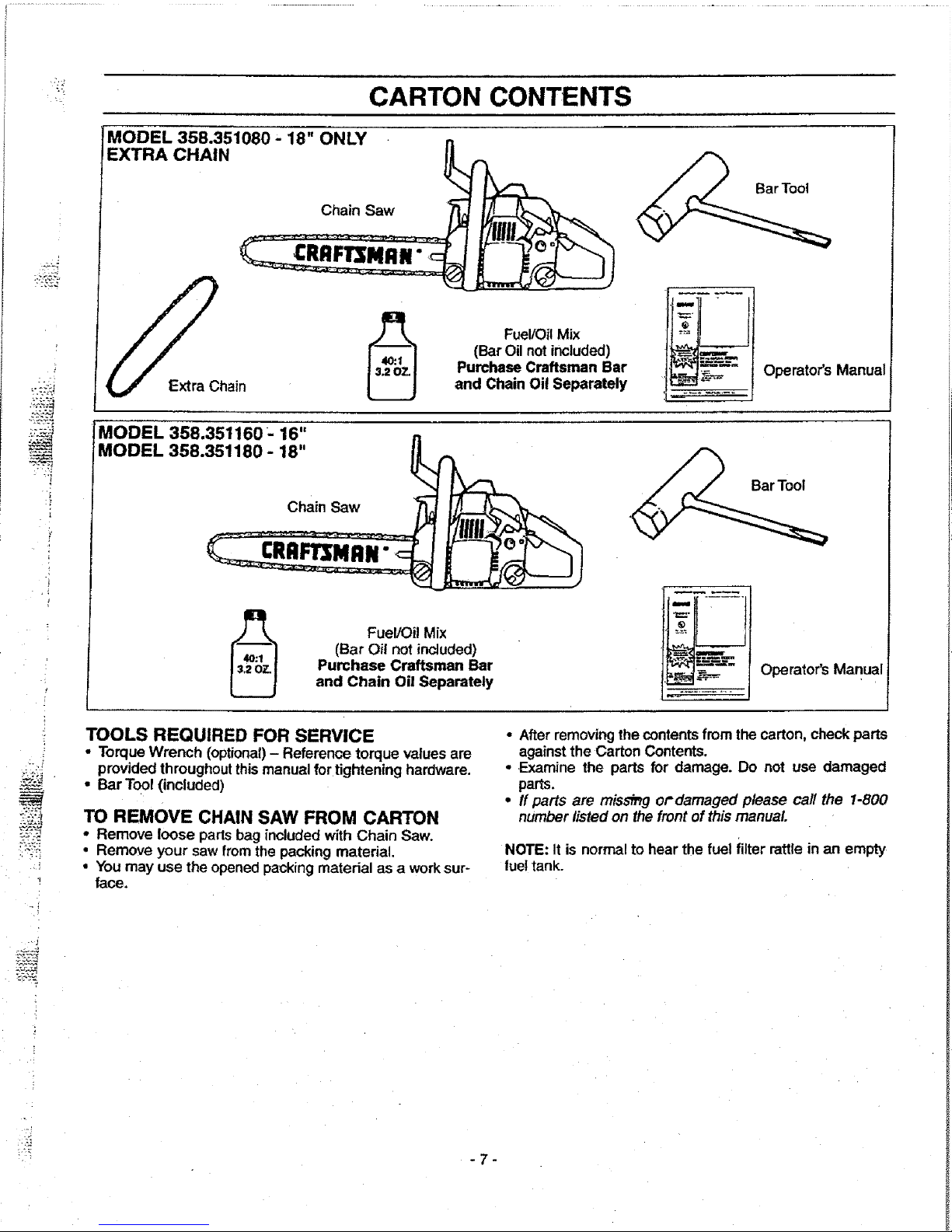

CARTON CONTENTS

?

i

.!

MODEL 358.351080.18" ONLY • n

EXTRA CHAIN _

Extra Chain

Fuel/OilMix

(Bar Oil not included)

Purchase Craftsman Bar

and Chain Oil Separately

Operator's Manual

MODEL 358.351160- 16"

MODEL 358.351180 - 18" _:_

Cha,n Saw j__

FueVOi!Mix

(Bar Oil not included)

Purchase Craftsman Bar

and Chain Oil Separately

Operator's Manual

TOOLS REQUIRED FOR SERVICE

• Torque Wrench (optional)- Reference torque values are

providedthroughoutthismanualfor tightening hardware.

• Bar Tool (included)

TO REMOVE CHAIN SAW FROM CARTON

• Remove loose paris bag included with Chain Saw.

• Remove your saw from the packing material.

• You may use the opened packing material as a work sur-

face.

• Afterremovingthe contentsfrom the carton, check parts

againstthe Carton Contents.

• .Examine the parts for damage. Do not use damaged

parts.

• tf parts are miss_g or'damaged please call the 1-800

number listedon the frontof thismanual

NOTE: It is normal to hear the fuel filter rattle in an empty

lue!tank.

-7-

Page 8

* OPERATION

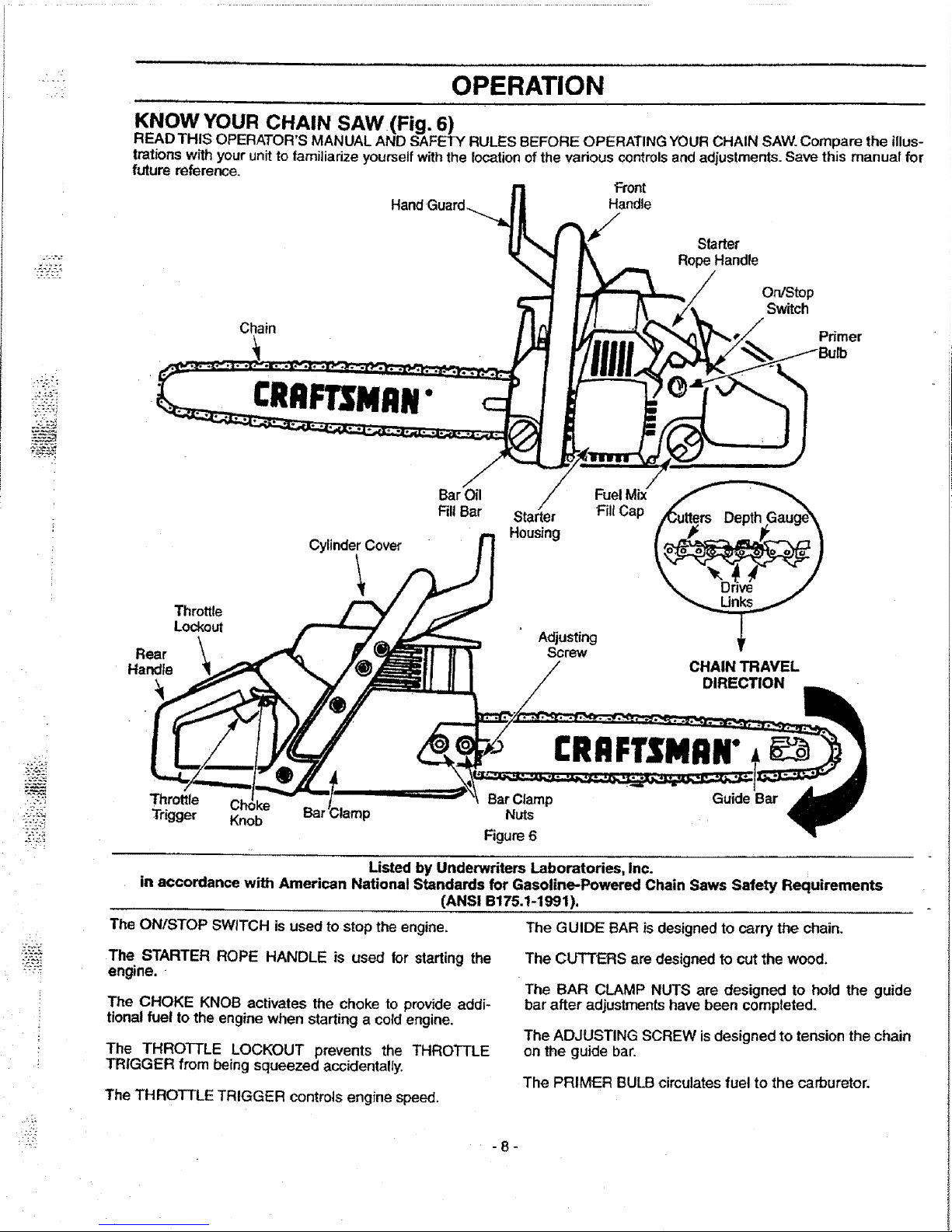

KNOW YOUR CHAIN SAW(Fig. 6)

READ THIS OPERATOR'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR CHAIN SAW.Compare the illus-

trations with your unitto familiarizeyourselfwiththe locationofthe various controlsand adjustments. Save this manual for

future reference.

Front

Hand_( Handle

Chain

Starter

RopeHandle

On/Stop

Switch

Primer

CRRFTSNRN"

Throttle

Lockout

CylinderCover

BarOil

FillBar Starter Fill Cap

Housing

Adjusting

Screw

Rear

Handle CHAIN TRAVEL

DIRECTION

CRRFTSMRN"

Guide Bar

Throttle BarClamp

Trigger Knob Bar_ Nuts

Figure6

Listed by Underwriters Laboratories, Inc.

in accordance with American National Standards for Gasoline-Powered Chain Saws Safety Requirements

(ANSI B175.1-1991 ).

The ONISTOP SWITCH is used to stop the engine.

The STARTER ROPE HANDLE is used for starting the

engine. •

The CHOKE KNOB activates the choke to provide addi-

tional fuel to the engine when starting a coldengine.

The THROTTLE LOCKOUT prevents the THROTTLE

TRIGGER from being squeezed accidentally.

The THROTTLE TRIGGER controls engine speed.

The GUIDE BAR is designed to carry the chain.

The CUTTERS are designedto cut the wood,

The BAR CLAMP NUTS are designed to hold the guide

bar after adjustments have been completed.

The ADJUSTING SCREW is designed to tension the chain

on the guide bar.

The PRIMER BULB circulates fuel to the carburetor.

" -8-

Page 9

• :,k!

.r . _"

r ,

OPERATION

HOWTO USE YOUR CHAIN SAW

STOPPING YOUR ENGINE

' Move on/stop switch to the "Stop"position.

, If engine does not stop, pullb_uechokeknobout fully.

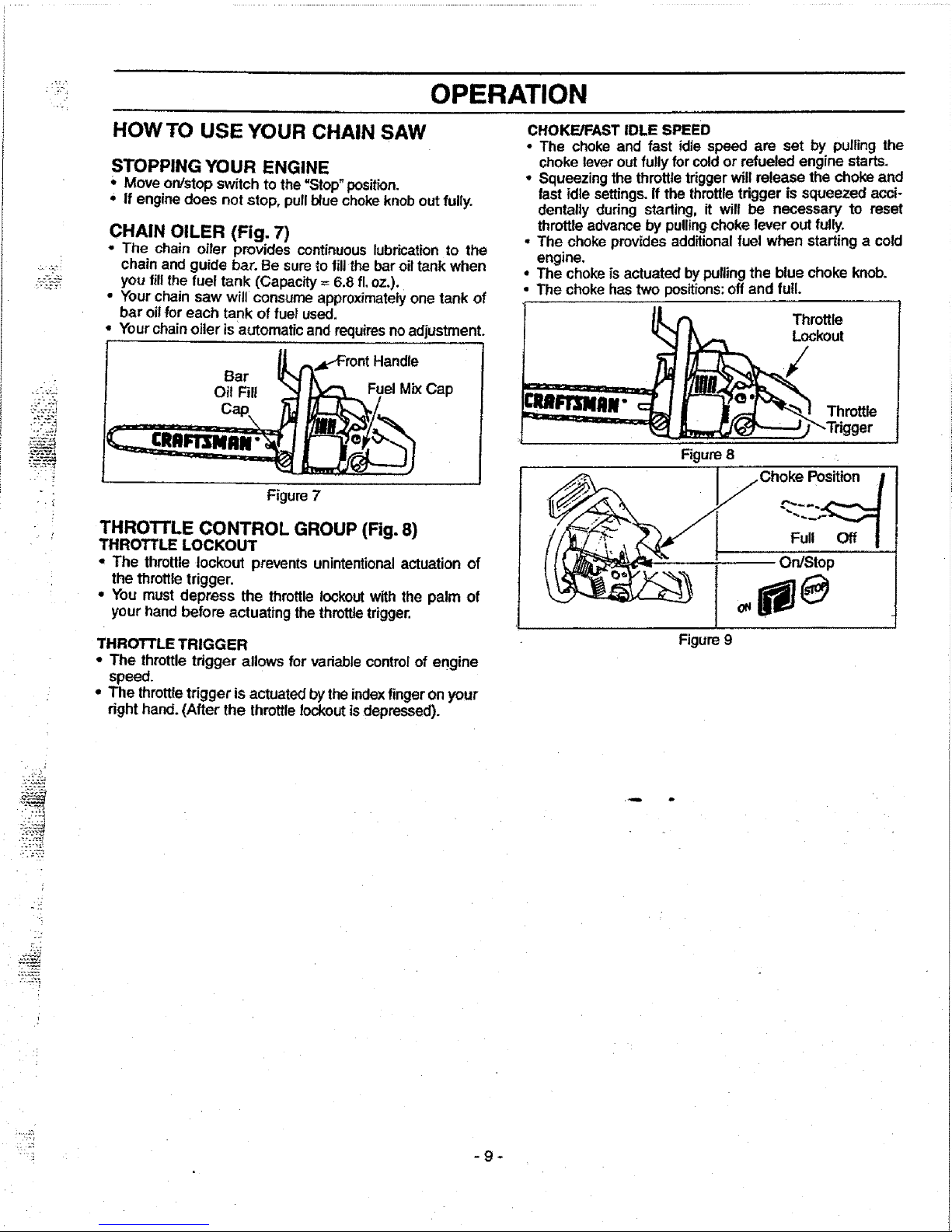

CHAIN OILER (Fig. 7)

• The chain oiler provides continuouslubricationto the

chainand guide bar.Be sureto figthe bar oiltank when

you fillthe fuel tank (Capacity= 6.8 fl,oz.).

• Your chain saw will consume approximatelyone tank of

CHOKE/FAST IDLE SPEED

• The choke and fast idle speed are set by pulling the

chokelever outfullyfor cold or refueled engine starts.

• Squeezing the throttletriggerwill release the chokeand

fast idle settings.If the throttletrigger is squeezed acci-

dentally during starling, it will be necessary to reset

throttleadvance by pullingchoke lever out fully.

• The choke providesadditionalfuel when starting a cold

engine.

• The chokeis actuated by pullingthe blue choke knob,

• The chokehastwo positions:off and full.

bar oil for each tank of fuel used.

• Your chainoiler isautomatic and requiresnoadjustment.

Handle

Bar

Oil Fill Fuel MixCap

Figure7

THRO'n'LE CONTROL GROUP (Fig. 8)

THROTTLE LOCKOUT

• The throttle lockout prevents unintentionalactuation of

the throttletrigger.

° You must depress the throttlelockoutwith the palm of

your handbefore actuating the throttletrigger.

THROTTLE TRIGGER

• The throttle trigger allows for vadablecontrolof engine

speed.

• The throttle trigger is actuated bythe indexfingeron your

dght hand. (After the throttlelockoutisdepressed).

Throttle

Lockout

Throttle

Figure8

Figure9

".:::?

Page 10

OPERATION

.JP

£:=?_

BEFORE STARTING ENGINE

WARNING:

BE SURE TO READ THE FUEL HANDLING

INFORMATION IN THE SAFETY RULES

SECTION ON PAGE 2 OF THIS MANUAL

BEFORE YOU BEGIN.

IF YOU DO NOT UNDERSTAND THE FUEL

HANDLING SECTION DO NOT ATTEMPT TO

FUEL YOUR UNIT; SEEK HELP FROM

SOMEONETHAT DOES UNDERSTAND THE

FUEL HANDLING SECTION OR CALL THE

CUSTOMER ASSISTANCE HOTLINE AT

1-800-235-5878,

GUIDE BAR AND CHAIN OIL

For maximum guide bar and chainlife,we recommendyou

use Craftsman chain saw bar oil.if Craftsmanbar oilis not

available,you may use a goodgrade SAE30 oiluntilyou are

able to obtain Craftsman brand,The oi! outputis automati-

cally metered during operation.Your saw willuse approxi-

mately one tank of bar oilforeverytankof fuelmix.Always

fill the bar oil tank when you fill the fuel tank.

GASOLINE

The two-cycle engine on thisproductrequiresa fuel mixture

of regular unleeded gasoline and a quality 40:1

2-cycle engine oi!(AIR-COOLED) forlubricationofthe bear-

ings and other movingparts.The correctfuel/oilmixture is

40:1 (see Fuel MixtureChart).Too littleoilorthe incorrectoil

typewill cause poor performanceand maycausethe engine

to overheat and seize.

Gasoline and oll mustbe premixedina clean approvedfuel

container.Always usefresh regularunleadedgasoline.

This engine is certifiedto operateon unleadedgasoline.

IMPORTANT: Experience indicates that alcohol blended

fuels called gasohol (or using ethanol or methanol) can

attract moisture, which leads to oil/gasseparationand for-

marion of acids duringstorage.Acidicgas can damage the

fuel system of an engine whilein storage.Toavoid engine

problems, the fuel systemshouldbe emptiedbefore storage

for 30 days or longer,Drainthe gas tank, then run the fuel

out of the carburetor and fuel lines bystarting the engine

and letting it run untilit stops. Use fresh fuel nextseason.

See STORAGE instructionsforadditionalinformation.Never

use engine or carburetor cleaner productsinthefuel tank or

permanent damage may occur.

FUEL STABILIZER

Fuel stabilizerisan acceptablea.ltemativeinminimizingthe

formation offuel gum depositsduringstorage.Add stabiliz-

er togasoline infuel tank orstoragecontainer. Alwaysfol-

towthe fuel mix ratiofound on the stabilizercontainer. Run

engineat teast5 minutesafteraddingstabilizerto allow the

stabilizerto reach the carburetor.Youdo not have to drain

thefuel tankfor storageifyou are usingfuel stabilizer.

CRAFTSMAN 40:1 2-cycle engine oil (AIR-COOLED) is

specially blended w_ fuel stabilizers.If you do not use this

Searsoil,you can add a fuelstabilizer to your fuel tank.

40:1 2-CYCLE AIR-COOLED ENGINE OIL

CRAFTSMAN 40:1 2-cycle engine oil (AIR-COOLED)is

stronglyrecommended.This oil is specificallyblended with

fuel stabilizersfor increased fuel stability(extends fuel I_fe

upto 5 times longer)and reducedsmoke.

If CRAFTSMAN 40:1 2-cycleengi_neoil (AIR-COOLED).is

not avellabie, use a good quality 2-cycle engine oil (AIR-

COOLED) that has a recommended fuel mix ratio of 40:1.

IMPORTANT! Do not use:

• AUTOMOTIVE OIL

• BOAT OILS (NMMA, BIA,etc.)

These oils do not have proper additives for 2-cycle

(AIR-COOLED) enginesandcan cause engine damage.

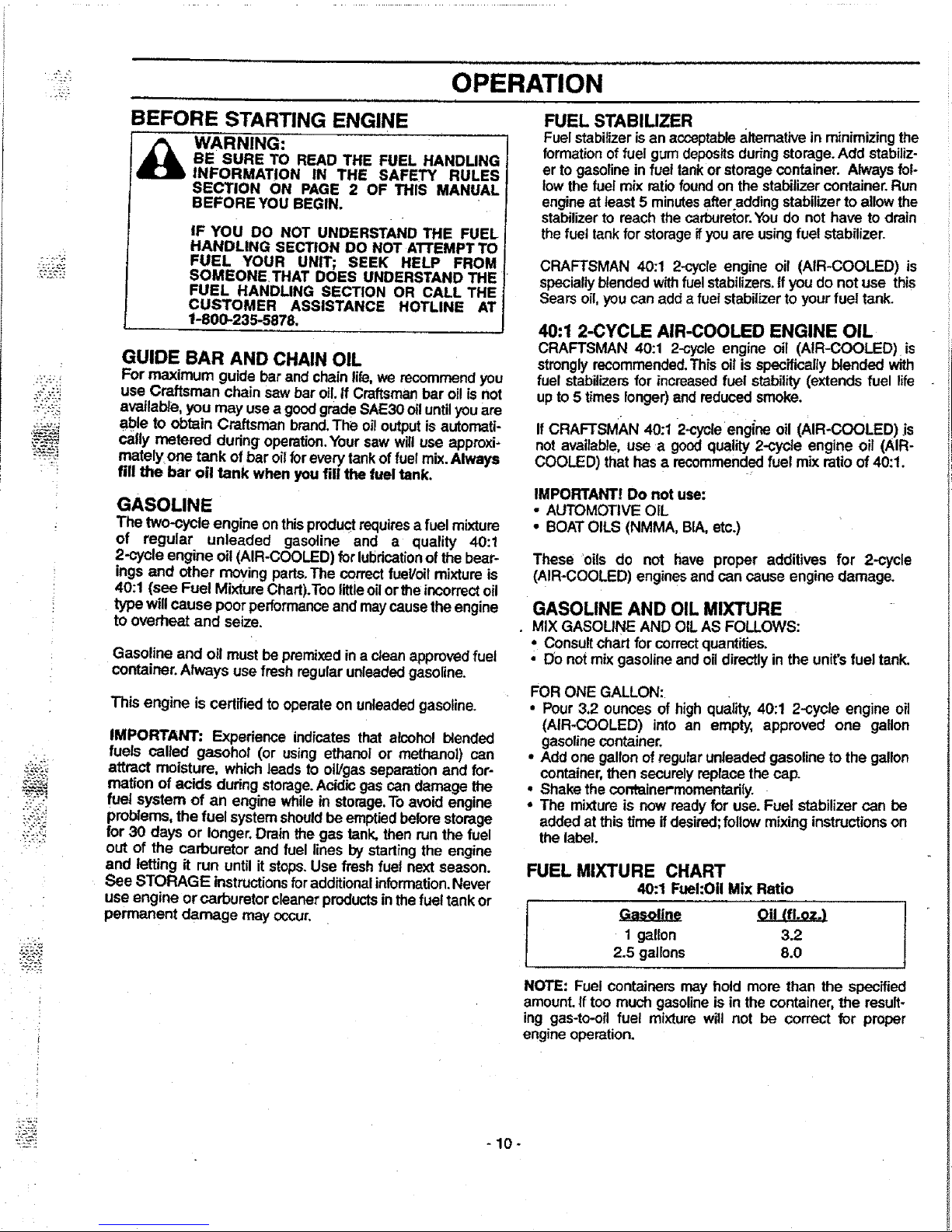

GASOLINE AND OIL MIXTURE

• MIX GASOLINE AND OIL AS FOLLOWS:

• Consultchart for correctquantities.

• Do not mix gasolineandoil directlyin the unit'sfuel tank,

FOR ONE GALLON:

• Pour 3,2 ounces of high quality,40:1 2-cycle engine oil

(AIR-COOLED) into an empty, approved one gallon

gasolinecontainer.

• Add one gallonof regular unleadedgasoline to the gallon

container,then securelyreplacethe cap.

• Shake the corttainet'momentadly.

• The mixture is nowready for use. Fuel stabilizer can be

addedat this time ifdesired;follow mixinginstructionson

thelabel+

FUEL MIXTURE CHART

40:1 Fuel:Oil Mix Ratio

I _ Oil (fLoz.I

1 gallon 3.22.5 gallons 8.0

NOTE: Fuel containers may hold more than the specified

amount.Iftoo much gasolineis in the container, the result-

ing gas-to-oil fuel mixture will not be correct for proper

engineoperation.

-10-

Page 11

OPERATION

@

STOPPING YOUR ENGINE

• Move on/stopswitchto the "Stop" position.

• if engine does notstop, pull blue chokeknob outfully.

_ WARNING:

ALWAYS WEAR GLOVES, SAFETY FOOT-

WEAR, SNUG-FITTING CLOTHING, AND

EYE, HEARING, AND HEAD PROTECTION

DEVICES WHEN OPERATING A CHAIN SAW.

THE CHAIN MUST NOT MOVE WHEN THE

ENGINE RUNS AT IDLE SPEED, REFER TO

THE "CARBURETOR ADJUSTMENTS" SEC-

TION FOR CORRECTION.

AVOID ANY CONTACT WITH THE MUFFLER.

A HOT MUFFLER CAN CAUSE SERIOUS

BURNS.

NOTE: Check chain tension using instructions in the

=Service and Adjustment" section.

• Before first use.

• After I minute of operation.

TO START ENGINE (Fig. 10 & 11)

COLD ENGINE START AND WARM ENGINE

START AFTER RUNNING OUT OF FUEL

• Fuel enginewith 40:1 fuel mix (3.2 oz.to 1 gaLgas).

• Fil! bar oil tank with bar oil Your saw will use approxi-

mately one tank of bar oil for each tank of fuel mix.

• Prime engine by pressing primer bulb six times.

• Turn on ignition by moving on/stop switch to the "On"

position.

° Putl the blue choke/fast idle control out fully to set both

the choke and fast idle for starting. Then set the saw on

the ground. Grip the front handle withyour left hand and

place your right foot through the openingin the rear han-

dle.

• IFTHROTTLETRIGGER IS SQUEEZED ACCIDENTAL-

LY DURING STARTING ff WILL BE NECESSARY TO

RESET THE CHOKFJFAST IDLE CONTROL.

NOTE: When pulling the starter rope, do not use the full

extent of the rope as thiscan cause the rope to break. Do

not let the starter rope snap back, holdthe handleand let

the rope rewindslowly.

• Pull starter rope handle with your right hand until the

engine attempts to start.Then pushthe blue choke knob

in to the partial position.Resume pulling handle until

engine starts.

• Above 40 degrees, allowengine to runtot approximate-

ly 5 seconds, push the choke knob in to the =Off" posi-

tion, then squeeze and release throttletrigger to allow

engine to idle.

• Below 40 degrees, allowengine towarm up 30 seconds

- 1 minute with choke at partial position.Push choke

knob in to the "Off" position,then squeeze and release

throttle triggerto allow engine to idle.

• To stop engine, move on/stop switchto the =Stop" posi-

tion.

Figure. 10

Position /

Full

On/Stop

@

STARTING A WARM ENGINE

• Move on/stopswitchto the "On_position.

• Engage thechokeJfastidleby pullingout the bluechoke

knobfully and pushingit back infully.

• Be sure choke is in the=Off"position.

• With saw on ground,grip fronthandlewith lefthand and

place yourright footthroughopeningin rear handle.

• Pull starter rope handle untilengine starts.

• Squeeze and release throttletrigger to returnengine to

idle speed.

RightnHand

Starter Rope Handle,

! /__ LeftHand

Right Foot throughOpening in Rear Handle

Figure 11

DIFFICULT sTARTlinG OR FLOODED ENGINE

The engine may be floodedwith too muchfuel if it has not

started after 10 pulls.

Floodedengines can be cleared of excessfuel withthe fol-

lowingprocedure:

• Pull out the blue choke/fast idle control fully and then

pushit back into the=Off"positionto setthefast idlecon-

trotto the start position.

° Verifythat the on/stop switch isin the "On" position.

• Push the choke knob to the =Off" position.

• With saw on ground, grip fronthandle with lefthand and

place right footthrough opening in rear handle.

• Pull starter rope handle untilengine starts.

Starting could require pulling starter rope handle many

times depending on how badly unit is flooded. If enginestill

fails to start, refer to "TROUBLE SHOOTING" chart orcal!

the 1-800 number listedon the front page of thismanual.

-11-

Page 12

•7:i

.... =

OPERATION

,.,,, ,,............ ii

GENERAL OPERATION TIPS

• cut woodonly.Do not cutmetal;plastics;masonry;non-

woodbuilding materials;etc.

• Stopthe saw ifthe chain strikesa foreignobject.Inspect

the saw and repair or replace parts as necessary.

• Keepthe chain outof dirtand sand. Evena sma!lamount

of dirt will quicklydull a chain and thusincreasethe pos-

sibilityof kickback.

To getthe =feel"of usingyoursaw beforeyoubegina major

sawing operation, practice cutting a few small Jogsusing

the following technique:

• Accelerate engine tofullthrottleby squeezingthethrottle

triggerbefore enteringcut.

• Never cutwith engine at partialspeeds.

• Begincuttingwith the saw chassisagainst the log.

• Keep engine at full throttleduringcuttingprocedure.

• Allow the chainto cut for you;exert only lightdownward

pressure.If you force the cut,damage to the bar, chain,

or enginecan result.

• Release the throttletrigger as soon as the cut is com-

pleted, allowingthe engine to idle.If you run the unit at

full throttlewithoutcutting,unnecessarywear can occur

tothe chain, bar, and engine.

• To avoid losingcontrolwhencompleting the cut, do not

put pressureon the sawduringthe endof the cut.

• Stop engine beforesettingunitdownafter operation.

OPERATION SAFETY

,,i,,.Hi m Hi L i,H Hi =

WARNING:

IF SAW BECOMES PINCHED OR HUNG IN A

LOG, DO Nor TRY TO FORCE IT OUT.YOU

CAN LOSE CONTROL OF THE SAW

RESULTING IN INJURY AND/OR DAMAGE

TO THE SAW. STOP THE SAW, DRIVE A

WEDGE OF PLASTIC OR WOOD INTO THE

CUT UNTIL THE SAW CAN BE REMOVED

EASILY. RESTARTTHE SAW AND CAREFUL-

LY REENTER THE CUT. TO AVOID KICK-

BACK AND CHAIN DAMAGE, DO NOTUSE A

METAL WEDGE. DO NOT ATTEMPT TO

RESTART YOUR SAW WHEN IT IS PINCHED

OR HUNG IN A LOG.

KICKBACK CAN OCCUR WHEN THE MOV-

ING CHAIN CONTACTS AN OBJECT ATTHE

UPPER PORTION OFTHETIP OFTHE GUIDE

BAR OR WHEN THE WOOD CLOSES IN AND

PINCHES THE SAW CHAIN IN THE CUT.

CONTACT AT THE UPPER PORTION OF THE

TIP OF THE GUIDE BAR CAN CAUSE THE

CHAINTO DIG INTOTHE OBJECT AND STOP

THE CHAIN FOR AN INSTANT.THE RESULT

IS A LIGHTNING FAST,REVERSE REACTION

WHICH KICKS THE GUIDE BAR UP AND

BACK TOWARD THE OPERATOR, IF THE

SAW CHAIN IS PINCHED ALONG THE TOP

OF THE GUIDE BAR, THE GUIDE BAR CAN

BE DRIVEN RAPIDLY BACK TOWARD THE

OPERATOR. EITHER OFTHESE RE.ACTIONS

CAN CAUSE LOSS OF SAW CONTROL

WHICH CAN RESULT IN SERIOUS INJURY.

AVOID REACTIVE PINCH FORCES

Pinch*Kickbackand Pull-in occur when the chain is sud-

denly stoppedby being pinched,caught, or by contacting

a foreign object in the wood.This sudden stoppingof the

chain resultsin a reversalof the chain force used to cut

woodand causesthe sawto move inthe opposite direction

of the chain rotation. Pinch-Kickback drives the saw

straight back toward the operator:Pull-In pulls the saw

away fromthe operator.Eitherreactioncan resultin loss of

controland possiblyseriousinjury,

TO AVOID PINCH-KICKBACK:

• Be extremelyaware of situationsorobstructionsthat can

cause material to pinchthe top of or otherwisestop the

chain.

• Do not cut more than one log at a time.

• Do not twist the saw as the bar is withdrawn from an

under-cutwhen bucking.

TO AVOID PULL-IN:

,, Always begin cuffing with the engine at full throttle and

the saw housingagainst wood.

• Use wedges made,of plasticor wood, (neverof metal) to

hold the cuto_pen.

..::_'i - 12 -

Page 13

OPERATION

:23_

/

TREE FELLING

WARNING:

IF THE TRUNK OR LIMBS ARE ROTTING,

THEY CAN FALL UNEXPECTEDLY AND

CAUSE SERIOUS INJURY,

AS YOU MAKE YOUR FELLING CUT, IF THE

SAW APPEARS TO BE BINDING, THE TREE

IS STARTING TO FALL IN THE WRONG

DIRECTION, IMMEDIATELY STOP THE SAW

AND USE A FELLING WEDGE AND MAUL

oHAMMER) TO FORCE THE FELLING CUT

PEN. THE WEDGE WILL HOLD THE

FELLING CUT OPEN ALLOWING YOU TO

REMOVETHE SAW.KEEP EVERYONE AWAY

FROM THE TREE IN ALL DIRECTIONS.

DETERMINE THE NATURAL FALL DIRECTION

• Wind - A tree evenlybalanced willfall inthe samedirec-

tionthe wind is btowing.

• Lean - Use a carpenter's level or plumbbob to deter-

mine if tree has a naturallean.A leaningtree willtendto

fall in direction of lean.

• Shape - A tree will tend to fail towards side that is more

heavily branched.

• Other Factors- Contactingor nearby trees, buildings,or

wires can influencethe directionthe tree wiltfall.

CUTTING PROCEDURE (Fig. 12)

Afterdetermining the Natural FallDirection,the treeshould

be cutas follows:

IMPORTANT: BEFORE FELLING A TREE, MAKE SURE

YOU HAVE AT LEAST 3 FELLING WEDGES AND A

MAUL (HAMMER) AVAILABLEFOR USE IF NEEDED.

• Use some means to visually mark the Natural Fall

Direction.

* Mark your notch cut on the Natural Fall Directionside of

the tree approximately 18-24 inches above the ground.

• Cut top of the notch first at a 45 degree angle. Saw

through 1/3 of the width of the tree.

• Cut bottom of the notchat a 45 degree angle untilyou

meet the top notchcut. Remove notch of wood.

• On the side of the tree opposite the notchcut, makethe

fellingcut. The felling cut shouldbe 2 inches above the

center point of the notch cut. Before the felting cut is

complete, use wedges to open the cut when necessary

to control the direction of the fall. Use wood or plastic

wedges, but never steel or iron, to avoid kickbackand

chain damage.

• Cracking sounds, widening of the felling cut, movement

in the upper branches are all signs that the treeis ready

to fall.

• As tree begins to fall, turn off saw, and move quickly

away from directionof fall

Felling._Direction _2" 1S_I_

Top i g

Notch_

cut

Bottom

Notch

Cut /3 _ Buttress

\ °oo,

Figure 12

If your chain saw binds in the felling cut, you have three

options:

• If the wrong direction of fall is acceptable, carefully

remove the felling wedge. C_ deeper in the notchsideof

the tree untiltree starts to fall.

• If the wrong directionof fall isnot acceptable, attemptto

use one or more felling wedges to force the tree in the

original direction of fall. Do so by drivingthe wedges

deeper intothe fellingcut.

• Keep everyone away from the tree in all directions and

•then seek professionalhelp!

FELLING TIPS

• Clear the work area of debriswhere youcan have secure

footing.

• Make sure there is enough room for the tree to fall.

Maintain a distance of 2 1/2 tree lengths from the near-

est person or other objects. Engine noise can drown out

a warning call.

• Remove dirt, stones, loose bark, nails, staples, and wire

from the tree where cuts are to be made.

• Plan to stand on the up-hill side when cuttingon a slope.

• Plan a clear retreat path to the rear and diagonal to the

line of fall.

• Large buttress roots should be removed prior to notch

CUt.

" Use a wedge if there is any chance that the tree will not

fall in the desired direction.

• We recommend you cut branches below shoulder height

before felling tree. (See Limbing and Pruning).

Be alert to signs that the tree is readyto fall:

• Cracking sounds.

• Widening of the felling cut.

° Movement in the upper branches.

Page 14

OPERATION SAFETY

FELLING SAFETY

DON'T PUT YOURSELF IN THESE POSITIONS

Check the wind -

Don't cut down wind

Check the lean -

Don'tcut on down side

Check the balance -

Don'tcut on weighted side

I_IL WARNING:

DO NOT CUT."

- NEAR ELECTRICAL WIRES OR

BUILDINGS.

- IF YOU DO NOT KNOW TH E DIRECTION

OF TREE FALL.

- AT NIGHT.

- DURING BAD WEATHER - RAIN, SNOW,

STRONG WIND, ETC.

• Look for decay and rot. If the trunk is rotted,itcansnap

and falltoward the operator,

• Check for broken or dead branches which can fall on

you whilecutting.

• Be extremelycautious with partially fallen treesthat may

be poorlysupported. When a tree doesn't fallcompletely,

set the saw aside and pull down the tree w_tha cable

winch, blockand tackle, or tractor.To avoid injury,do not

cut downa Dartially fallen tree with your saw.

.... i

•-_:-

.:_::J,J

-14-

Page 15

OPERATION

":. :G?]

,i

"2-

i_

BUCKING

Buckingis cuttinga fallen tree to the desired log size.

TYPES OF CUTTING (Fig. 13)

• Overcutting - begin on the top side of the log with the

bottom of the saw chassis against the log; exert light

pressure downward.

• Undercutting-begin on the undersideofthe tog withthe

top of the saw chassisagainst the log; exert light pres-

sure upward. During undercutting,the saw will tend to

push backat you,Be preparedforthis reaction and hold

the saw firmly to maintain control,

Saw Chassis

BUCKING USING A SUPPORT (Fig. 15 & 16)

Anotherlog or a stand, suchas a sawhorse, may be used

as supportswhen bucking.

• Area A - Undemut 1/3 of the way throughthe log.

- Finishwith an ovetcut,

• Area B - Overcut 1/3 of theway throughthe log.

- Finishwith an undercut.

A_ -<----- B-------m_ -.<--A-_

,.,cu, I.cot

Figure 15

_ B _ .<--A--_

1st Cut 2nd Cut

Ovemut "_

Undercut

Figure 13

BUCKING ON THE GROUND (Fig. 14)

* Overcut with a 1/3 diameter cut.

• Roll log over and finish withan overcut.

Figure 14

Another Log

Figure 16

BUCKING TIPS

° CUt only one log at a time.

• Cut shattered wood verycarefully.Sharp pieces ofwood

couldbe flung towardthe operator.

• Use a sawhorse to cut small logs. Never allow another

personto hold the log while cutting and never hold the

logwith your leg or foot.

• Do not cut in an area where logs,limbs, and roots are

tangled such as ira bl6wndown area. Drag thelogs into

a clear area before cutting by pulling outexposed and

cleared logs first. '

• Give special attention to logsunder strain to preventthe

saw from pinching. Make the first cut on the pressure

side to relieve the stress on the log.

OPERATION SAFETY

BUCKING SAFETY

WARNING:

DO NOT STAND ON THE LOG BEING CUT,

ANY PORTION CAN ROLL CAUSING LOSS

OF FOOTING AND CONTROL,

NEVER TURN THE SAW UPSIDE DOWN TO

UNDERCUT. THE SAW CANNOT BE CON-

TROLLED IN THIS POSITION.

• Stay on uphill side of tree when cutting.

Use Common Sense

-15-

Maintain Secure Footing

Page 16

':.! OPERATION

-"_21

PRUNING AND LIMBING

Pruningis removingbranchesfrom a standing tree.

Limbingis removing branchesfrom a felled tree.

LIMBING (Fig. 17)

• Start at base of the felledtree and work toward the top.

• Leave the larger limbs underneath the felled tree to

supportthe tree as you work.

Figure 17

PRUNING (Fig. 18)

Small branches- smaller than width of guidebar.

Large branches- larger than width of guide bar.

• Remove small limbs with one cut.

• Remove larger, supportingbranches with the 1/3 - 2/3

cuttingtechniquesdescribed in the buckingsection.

PRUNING PROCEDURE

• Cut 1 - Undercut 1/3 of the way through the limb near

the trunk of the tree.

• Cut 2 - Finish with an overcut farther out from the trunk

until the limb falls. Keep out of the way of the fairing limb.

• Pruning Cut - Cut the limb stump flush at the edge of

l Cut 2

Pruning Cut

Cut 1

• ' , Figure18

J

PRUNING AND LIMBING TIPS

• Work slowly, keeping both hands firmly gripped on the

saw.Maintain secure footingand balance.

• Keep a clear workarea.Frequently clear branchesoutof

the way to avoidtrippingover them.

• Leave the larger limbsunderneath the felledtree to sup-

portthe tree as you work.

• Start at the base of thefelled tree and work towardthe

top.

° Keep the tree betweenyou and the chain. Cut fromthe

side of the tree oppositethe branch you are cutting.

• Limit pruningto limbsshoulder height or below. "

• Keep out of the way ofthe falling limb.

OPERATION SAFETY

PRUNING AND LIMBING SAFETY

I_ WARNING:

NEVER CUMB INTO A TREE TOLIMB OR

PRUNE UNLESS SPEClRCALLY TRAINED

TO DO SO. DO NOT STAND ON LADDERS,

PLATFORMS, A LOG, OR IN ANY POSITION

WHICH CAN CAUSE YOU TO LOSE YOUR

BALANCE OR CONTROL OFTHE SAW.

BE ALERT FOR AND GUARD AGAINST=

KICKBACK. DO NOT ALLOW THE MOVING

CHAIN TO CONTACT ANY OTHER BRANCH-

ES OR OBJECTS AT THE NOSE OF THE

GUIDE BAR WHEN LIMBING OR PRUNING.

ALLOWING SUCH CONTACT CAN RESULT

IN SERIOUS INJURY.

DO NOT CUT IF BRANCHES ARE HIGHER

THAN YOUR SHOULDER. GET A PROFES-

SIONAL TO DO THE JOB.THIS MAY RESULT

IN SERIOUS INJURY.

I

Watch out for spdn.gpoles. Use extreme cautionwhen

cuttingsmall sl'i'2elirfibs.Slender material may catchthe

saw chain and be whipped toward you or pul! you off

balance.

Be alert for springback_Watch out for branches that are

bentor under pressureas you are cutting to avoid being

struckbythe branch orthe saw when the tension inthe

woodfibers is released.

-16-

Page 17

H ,

.:i= CUSTOMER RESPONSIBILITIES

;

..... \

MAINTENANCE SCHEDULE

Fill in dates as you complete regularservice

C"eckfordamagedorwornpa.s

Check for loose fasteners and parts

Check chain tension'

Check chain sharpness

Check guide bar'condition

Check guide bar lube

Clean unit & labels

Clean air filter

CleaWinspect spark arrestor screen & inspect muffler

Replace spark plug

R'ep'i'acef ,er .............. 1.......

Beforet After

Use Use

v" !

,/

€"

€"

Every Every Yearly Service Dates

5 Hrs. 25 Hrs.

...............

,,u

v"

GENERAL RECOMMENDATIONS

The warranty on this unit does notcover items that have

been subjected tooperatorabuseornegligence.Toreceive

fullvaluefrom the warranty,the operatormustmaintainunit

as instructedin this manual.

Some adjustments will need to be made periodically to

properlymaintain your unit.

All adjustmentsinthe =Service and Adjustments"sectionof

this manual should be checked at Ieast once each season,

• Once ayear, replacethe spark plug, replaceair filter ele-

ment and check guide bar and chain for wear. A new

spark p{ug and a clean/new air filter element assures

properair-fuel mixture and helps your engine run better

and lastlonger.

• Follow the maintenance schedulein this manual.

WARNING:

DISCONNECT THE SPARK PLUG BEFORE

PERFORMING MAINTENANCE EXCEPT FOR

CARBURETOR ADJUSTMENTS.

INSPECTTHE ENTIRE UNIT. REPLACE DAM-

AGED PARTS. CHECK FOR FUEL LEAKS

AND MAKE SURE ALL FASTENERS ARE IN

PLACE AND SECURELY FASTENED.

LUBRICATION CHART

@Bar Oil

®Bar

Sprocket FillCap

Lube

(DCraftsman chain saw bar oil

® Craftsman bar sprocket lube

-17-

BEFORE USE

CHECK FOR DAMAGED OR WORN PARTS

The followingdamaged/worn parts should be referred to

your Sears Service Center.

NOTE: It is normal for a small amount of oil to appear

underthe saw after engine stops.Do not confuse thiswith

a leakingoil tank.

• On/Stop Switch ensure on/stop switch functionsprop-

erly by moving the switch to the =Stop" position and

assurethat engine stops, then restart your engine and

continue.

o_Fuel Tank - discontinue use of chain saw ff fuel tank

show signs of damage or leaks.

• Oil Tank - discontinue use of chain saw if oil tank shows

signs of damage or leaks.

• Chain Catcher- replace chain catcher if bent, cut, or

damaged in any way,

CHECK FOR LOOSE FASTENERS AND PARTS

• BarClamp Nut

• Chain

• Muffler ... .

• CylinderShield

• Air Filter

° ClutchDrum/Sprocket

• Handle Screws

• VibrationMounts

° StarterHousing

• Handguard

CHAIN TENSION (Fig. 19 & 20)

Use the screwddver enid of the bar tool to movechain

aroundthe guide bar.

• If chaindoesnot rotate, it istootight - slighttyloosenpar

clamp nuts and turn adjusting screw 1/4 turn counter-

clockwise.Retighten bar clamp nuts.

• If chain is too loose, it will sag below the guide bar.

Figure19.

Sag

Figure 19

Page 18

CUSTOMER RESPONSIBILITIES

:,.r£:.._i

• If chain is too loose, refer to =Chain Adjustment." Loosen

bar clamp nuts; then, turn adjusting screw 1/4 turn clock-

wise. Lift up tip of guide bar to check for sag. Retighten

bar clamp nuts. Figure 20.

Guide Bar

CRRFTSMRN'

Tool

SHARPENING CHAIF_ure20

(Fig. 21, 22, 23, 24, 25, 26 & 27)

WARNING:

IMPROPER CHAIN SHARPENING TECH-

NIQUES ANDIOR ,DEPTH GAUGE MAINTE-

NANCE WILL INCREASE THE CHANCE OF

KICKBACK, WHICH CAN RESULT IN SERI-

OUS INJURY.

ALWAYS WEAR GLOVES WHEN HANDLING

THE CHAIN. THE CHAIN CAN BE SHARP

ENOUGH TO CUT YOU EVEN THOUGH IT IS

TOO DULLTO CUTWOOD.

CHAIN TERMINOLOGY & PART NAMES

Preset Tie Strap

LeftHand Cutter

. Link

Right Hand Cutter "_._ _

Guard Tie Strap_

!CHAIN CUTTER PART NAMES

Top Plate .......__Gullet

_1_ =/ / Depth Gauge

Side Plate --_--1_ .{_p;_l_

Toe _ !vet Hole

CHAIN "PITCH" CHAIN "GAUGE"

Pitch refers to chain mea- Gauge refers to thickness

surement.A chain's pitchis of that portion of drive link

the distance between any which fits into saw bar

three of its rivets divided by groove.

two.

Toolsrequired:

• Rat fife

• .025 depth gauge

• 4.5mm roundfile & file holder

Conditionswhichindicatethe need for chain sharpening:

• Reductionin size of wood chips.The size of the wood

chip wil! decrease as the chain gets duller until it

becomesmore likea powderthan a chip.Note that dead

or rottedwood wiltnotproducea good chip.

• Saw cuts to one sideor at an angle.

- Saw requires excessiveforceto cut.

• Noticeable tossofcuttingspeed.

Sharpeninginstructions:

• Move on/stopswitchto the "Stop"position.

• Check chain for proper tension.Adjust chain tension if

necessary. (See ChainTension/Adjustment).

• Checkand lowerdepthgaugesbeforesharpeningcutters.

• Depth gauges shouldbe checked every third sharpen.

ing.When cuttingfrozen woodthe depth gauges should

be checked eachtime you sharpen the chain.

• Tocheck depth gauge, place gauge tool on cutter.If the

depthgauge projects above the tool, then file it level to

thetop ofthe depth gauge tool.See Figure21.

Depth File

Gauge

Figure21

.030" Squared

. Rounded Off Comer

Right Way " Wrong Way

Figure22

• To sharpen the cutters,position the file holderlevel (90°)

sothat it rests on the top edges of the cutter and depth

gauge.See Figure23.

NOTE: The chain has both leftand right handcutters.

• Sharpen cutters on one sideof the chainfirst. File from

the inside of each cutter to the outside.Then turn your

saw around and repeat the processfor the other side of

thechain. See Figure 24.

• File on the fon_vardstroke only.Use 2 or 3 strokes per

cuttingedge.

• Keep the 30° line on the file holder parallel to the center

of the chain. Reverse procedure for other side. See

Figure25.

• Keep all cuttersthe same lengthwhen filing. See Figure

26.

• Fite enough to remove any damage to cutting edges

(side plate and top plate) of cutter.See Figure 26.

° File chain to meet the specificationsshown below. See

Figure 27.

18-

Page 19

CUSTOMER RESPONSIBILITIES

1 FULL VtEW ]

I SIDE VIEW I

File Holder

1FRONT VIEW 1

"-Guide Bar

& Chain

Figure 23

Outside

/

Inside_

Figure 24

GUIDE BAR MAINTENANCE (Fig. 28 & 29)

Conditionswhichrequireguide bar maintenance:

• saw cutsto one side orat an angle.

• saw has to be forced through the cut.

• inadequate supply of oilto the bar and chain.

Check theconditionofthe guidebar each time the chain is

sharpened, A worn guide bar will damage the chain and

make cuttingdifficult.

• Move on/stop switch to the "Stop _position.

• Remove bar and chainfrom saw.

• Clean all saw dust and any other debris from the guide

bar groove and guide bar lubrication hole. Figure 28.

• Lubricate guide bar hole sprocket after each use. Figure

28.

• Burring of bar rails is a normal process of guide bar rail

wear. Remove these burrs by filing guide bar rail side

edges square with a flat file. Figure 29.

• Restore squareedges to an uneven rail top by filing with

a flat file. Figure 29.

RemoveSawdust l_f'

FromGuide Bar Groove _ j_7_

- Sprec_t Hole

CRRFTSMRN"•

I

I

30o

Cutters Same

2e°o ,

n

File

Holder

Figure 25

t Remove Damage

Side Plate TopPlate

Figure 26

Figure 28

Replace theguide bar when:

• the inside grooveof the guide bar rails is worn.

• the guidebar isbent or cracked.

• excess heating orburring of the rails'is noted.

If replacement is necessary, use only the repiacernent

reduced kickback guide bar specified for your saw in the

repair parts list or as specified on the replacement bar and

chain decal locat_ Onthe chain saw.

Correct Worn Grooves

Groove

File Edges

Square

Figure 29

Figure 27

-19-

Page 20

i CUSTOMER RESPONSIBILITIES

•..,J

k_.

AFTER USE

CLEAN UNIT AND LABELS

• Clean the unit usinga dampclothwitha mild detergent.

• Wipe off the unit witha cleandry cloth,

EVERY 5 HOURS

CLEAN AIR FILTER (Fig. 30)

A dirtyair filter decreases the life and performance of the

engine and increases fuelconsumptionand harmfulemis-

sions,

Alwaysclean your air filter after 15 tanksoffuel or 5 hours

of operation, whichever is less.Clean more frequently in

dustyconditions.Aused air filtercan never be completely

cleaned. It is advisable to replaceyourair filter with a new

one after every 50 hours ofoperation,or annually,which-

ever is less.

• Loosen 3 screws on cylindercover,

• Remove cyUndercover.

* Remove air filter.

• Clean the afr filter using hot soapy water. Rinse with

clean cool water and air dry completely prior to rein-

stalling.

• Lightly oil air filter priortOinstalling.Use 2-cycle engine

oilor motor oil (SAE 30). Squeeze excessoil from filter.

This will improvethe efficiencyof the air filter.

• Reinstall air filter.

Reinstall cytindei"coverand 3 screws (15-20 in-lbs.).

Air Cover

Filter Screws

,f

Cylinder

Cover

Figure30

EVERY 25 HOURS

INSPECT MUFFLER AND

SPARKARRESTORSCREW.INSTA,LEO)

s the unitisused,carbondepositsbuild up onthe muffler

and spark arrestor screen (if installed), and must be

removedto avoidcreatinga fire hazard oraffectingengine

performance.

Required cleaningis every 25 hours of operationor annu-

ally,whicheveris less.

Replace thesparkarrestor screen if breaksoccur.

CLEANING THE SPARK ARRESTOR SCREEN

• Loosen and removethe 2 mufflercoverscrews.

• Remove the muffler cover (cover snaps into muffler

body).

• Remove muffler diffuser and spark arrestor screen

assembly. Notice the orientation of these parts for

reassembly,

_ lean the spark arrestor screen with a wire brush or

replace if breaksare foundinthe screen.

Replace any brokenor cracked parts.

• Reinstall diffuser and spark arrestor screen assembly

with roundholesfacing up and towardsmufflercover.

Reinstall muffler coverand 2 screws (7-8 ft-lbs).

MufflerDiffuser/

Muffler

Cover

Screws

/

Body

Cover

Figure31

YEARLY

REPLACE SPARK PLUG (Fig. 32)

The spark plugs_ould.bereplaced each year toensure the

engine starts easier and runs better. ::_parkplug gap

should be .025".

• Loosen 3 screws on cylindercover.

• Remove cylindercover.

• Twist, then pulloff the spark plug boot.

• Remove spark plugfrom c_ncter and discard.

Replace withcorrect spark plug and tightenwitha 3/4"

socketwrench (10-12 Ib-ft).

Reinstallspark plug boot.

Reinstallcylindercover and 3 screws (15-20 in-lb).

SCrews

Plug Boot

Cylinder

Cover

Plug

- 2O

Figure32

Page 21

CUSTOMER RESPONSIBILITIES

÷....

REPLACE FUEL FILTER (Fig. 33, 34 & 35)

The fuel filtershouldbe replacedafter each season,Never

operate your saw without a fuel filter. Be careful not to

damage fuel line while removingthe fuel filter.

• Run fuel tank dry offuelbefore proceedingwiththisstep.

• Remove fuel cap and allowit to hangto side of motor.

• Using a small pair of needle nose pliers,grasp fuel cap

retainer,holding it in tank opening and pullout.

• With cap out of tank, use a small section of bent wire

similar to that shown in the illustrationto catch fuel line

and slowly pull from tank.When fuel filter appears in

opening, grasp with fingersand removefrom tank.

• Once filter is out oftank, holdfuel lineclose to fuel filter.

Remove fuel filter by twistingarid pulling at the same

time.

• Replace fuel filter.

• Reverse process for installation.

Pliers

\

Fil!Cap

Figure33

Figure34

:: :%:

.-.,,Z =

Fuel Line Barrel

Filter Neck _ _)

Fuel Filter

• }

Figure35

- 21 -

Page 22

tl i,

• SERVICE AND ADJUSTMENTS

2

_._

;.ro_

,,,,,,lli

CHAIN REPLACEMENT (Fig. 36_37, 38 & 39)

CAUTION: Wear protective gloves when

ndlingchain.The chain is sharp and can cut

you evenwhen It is not moving.

It is normalfor a new chainto stretch.Because

of this initial stretch during the first 15-30

_hin.ut_.sof oPeration you shouldrecheckyour

am tension _uentty and adjust the chain

tenslonas requlred, See chaintensionsection.

• Moveon/stopswitchtothe "Stop"position.

o"Replacefileoldchainwhenit becomeswornordamaged.

use ontytheLow-Kickbackreplacementchainspecifiedinthe

S_. yourSea_ ServiceCentertoreplaceandsharpenindi-.vidua/cuttersmrmat_chingyourchain.

Loosenand removethe2 barclampnuts.

Removebardamp.

Removetheoldchain.

i urna_ustingscrewbyhandcounterclockwiseuntiladju_ng

pinnl_'usttouchesthestop. "

Slide guide bar behind dutch drum u_l guidebar stops

againstclutchdrumsprocket. "

Care_IIyremo'..'enewo_f'nfrom package.Holdohainwiththe

ddvelinksas snowninF._ure37.

Placechain overandbehindthe dutch.

._ Fitbottomofdrivelinks betweenteethinsprocketnose.

• Fd chaindrivelinksintotopof guide bar.Figure38.

Pullguidebarforwarduntilchainissnuginguidebargrooves.

_ow, !nsta_lbarclampmakingsuretheadjustingpinisposi-

tioneointhelowerholeinthe guidebar.

Bar Clamp Nuts

Figure36

F_jure37

Bar Clamp

Adjusting ..-t .i Hole

k.. Pin.... i Lower Guide

F'_ure 38

• Instalt bar clamp nutsand finger tighten only.Do not _ghten

any furlPer at l_is point.

• Now proceed to the "Chain Adjusbnen_ section.

Bar Clamp Nuts

Figure39

CHNN ADJUSTMENT (Fig. 40, 41,42 & do43)not

• Roll chain aroundguidebar to ensurekinks

exist

(rotates freely).

• Assurebarclamp nutsareloosened(fingertight).

• Turnadjustingscrewcloc_viseuntilchainjustbarelytouches

thebottomofguidebar.

• Rollchain aroundguidebartoensurealllinksareinbargroove,

Bar Clamp Nuts Guide Bar

F_jure40

• Liftupt_pofguidebartocheckforsag,release_pofguidebar,

thenturnadjus_ngscrew1/4 turnelockwise.Repeatthis step

untila sagdoes rot exist.

• WhileI_ng t_pof guidebar,tightenbar clampnutswiththebar

toot(provided).Torque10-15ftJbs.

,AdjustingSorew

!

Figure41

To check chain tension

• Usethescrewdriverendofthebartoottomovechainaround

the guide bar (Figure43).

• If chain does not rotate,it is too tight- slightly loosen bar

clamp nuts and turn adjustingscrew 1/4 tum counterclock-

wise.Retightenbar clampnuts.

If chainistoo loose,itwillsag belowtheguidebar (Rgum 42).

...........Sag

- 22 - Figure 42

Page 23

SERVICE AND ADJUSTMENTS

22 "2

• If chain is too loose, refer to "Chain Adjustment." Loosen

bar clamp nuts;then,turn adjustingscrew1/4 turn clock-

wise. Lift up tip of guide bar tocheckfor sag.Retighten

bar clamp nuts.

Guide Bar

Bar Clamp Adjusting Bar

Nuts Screw Tool

Figure 43

STARTER ROPE REPLACEMENT

(Fig. 44, 45, 46, 47 & 48)

WARNING: J

ALWAYS WEAR EYE PROTECTION WHEN I

SERVICING THE STARTER ROPE. THE I

RECOIL SPRING BENEATH THE PULLEY IS I

UNDER TENSION. IF THE SPRING POPS J

OUT, SERIOUS INJURY CAN RESULT.

Replace a broken starterrope or one thatis badlyfrayed.

NOTE: A recoil spring liesbeneath the pulleyand is under

tension, if the recoil spring is disturbed, considerable

time and effort will be required to reinstall. For this rea-

sonyou may want to let yourSears Service Center handle

this repair.If you try to repair the starterrope and the recoil

springpops out, take theunitto yourSears Service Center.

• Remove the four fan housing screwsand loosenthetwo

screws on the cylindercover.

• Remove fan housing from the unit.

CylinderCoverScrews

Screw

\

Fan Housin(

Screw

CRARr NAN"

Starter Rope Housing

(Inside Fan Housing)

Figure 44

• To take out rope tension, pull out 10" of rope. While

holding down pulley ratchet with thumb, push several

inches of rope back intofan housingandcatch in notch.

Either hold pulley ratchet with thumborhold starter rope

handle. Retain rope in the notchand slowlyaltow pulley

toturn counterclockwise untiltension isgone.

• Remove the pulley screwin the center ofthe pultey.

° Gently twist and lift pulley while rotating counterclock-

wise.

Pulley

StaH_aerRope _ . #¢ "_-_Screw

Figure 45

° Removethe roperetainerscrewand removeany remain-

ingrope.

• Move away from the fuel tank and melt the end of the

new rope to be installed,Allowthe melted end to drop

once.Then,while the rope isstillhot,pull the meltedend

througha rag to obtain a smoothpointed end.

° Feed rope throughstarter rope holein starter housing.

• Guide the ropeinsidethe pulley,then up throughthe pul-

ley hole. It may be necessary to push the rope through

with a small Phillips screwdriverinserted into the small

holeon the underside of thepulley.

• Wrap rope counterclockwisearound the pulley ratchet

and tuck loose end back under rope, leaving a 1" tail

between the retainer riband screw post.

• Pull rope to tighten.

• Installthe rope retainer screwand tighten untilsnug. Do

not over-tighten.

• Rewind all the rope onto the pulley in a clockwisedirec-

tion.

Starter _

Housing_

_" I r_ _ !_'- "--'--'- Starter

Rope

Figure 46

• Twistand pushpulley intostarter housing.

• Replace and tighten the pulley screw.

,_ _ Rope Retainer

"_,/ _\ /Screw

P

Figure 47

_ _23 -

Page 24

r _,.:

SERVICE AND ADJUSTMENTS

• Pull out 10" ofrope and catch ropein notchinthe pulley.

• Carefully turn the pulley twocomplete turnsclockwise,

keeping the rope againstthe notchto wind the spdng.

• While holding the pulley ratchet,pull the excess rope

through the starter rope hole.While holdingtension on

the rope, let rope slowlyrewindintothe housing.

• Reinstall fan housing by aligningthe fan housingto the

chassis.Then while holdingthe fan housingagainst the

chassis, pull the rope handleout until you feet the fan

housing drop into place againstthechassis. Slowly,let

the rope rewind into starter housing.

• Reinstall the 4 fan housing screws and tighten the 2

cylindercoverscrews. Figure 44.

Wind Up Spring

Rewind for-

Tension

Figure48

"C_'-

°

_T._._

r

• - 24-

Page 25

SERVICE AND ADJUSTMENTS

_t

CARBURETOR ADJUSTMENTS

Carburetor adjustment is critical and if done improper-

ly can permanently damage the engine as well as the

carburetor. Please read all instructions and consult the

Trouble Shooting section of this manual before begin-

ning this process. If the engine does not operate

according to these instructions after repeating the

adjusting steps, do not use the uniL For further assis-

tance, please call our customer assistance hotline at

1-800-235-5878.

WARNING':

THE CHAIN WILL BE MOVING DURING

MOST OF THIS PROCEDURE. WEAR YOUR

PROTECTIVE EQUIPMENT AND OBSERVE

ALL SAFETY PRECAUTIONS.

IN "LOW SPEED MIXTURE ADJUflTME_"

RECHECK IDLE SPEED AFTER EACH

ADJUSTMENT. THE CHAIN MUST NOT

MOVE AT IDLE SPEED.

If engine does not start, it may be flooded, ifindoubt, read

the sectionon fleoded engine in the starting section of this

manual prior to beginning any adjustments.

The carburetor has been adjusted at the factory for sea

level conditions.Adjustments may become necessaryifthe

saw is used at significantly higher altitudes or if you notice

any of the following conditions:

• Chain moves when the engine runs at idle speed. See

"ldte Speed Adjustment."

• Saw will not idle. See "Idle Speed Adjustment" and "Low

Speed Mixture Adjustment."

• Engine dies or hesitates when it should accelerate. See

"Aoceteration Adjustment."

• Loss of cutting power which is not corrected by air filter

cleaning. See "High Speed Mixture Adjustment."

NOTE -There are three adjustments on the carburetor.

• The Idle Speed Adjustment is marked withthe letter "T."

• The two remaining adjustments on the carburetor are the

mixture adjustments. One is marked "L" for low speed,

and the other "H" for high speed.

CARBURETOR PRESETS (Fig. 49)

Ifyour engine wiltnotstart due to suspectedimpropercar-

buretoradjustment, the followingpresetsmaybe required.

If used, itis recommended thatall steps withinthe adjust-

mentprocedurebe completed inordertoassurea properly

set carburetor.If presets are not needed, proceed to sec-

tion "Idle Speed Adjustment."

When makingadjustments,be careful not toforcethe plas-

ticlimiter caps beyondthe stops or damage willoccur.

Verysmall adjustmentscanaffect engineperformance.Itis

importantto make slightadjustmentsandtestperformance

before proceeding. Each adjustment°shouldbe no more

than 1/16 of aturn.

•Tum both of the mixture adjustments clockwise until

they stop,Do not overtightenas damageto the needles

willoccur

• Turnboth mixtureadjustments counterclockwiseone full

turn

• Turnthe idle speed adjustment clockwiseuntilit stops

Now turn countemlockwise4-1/2 turns

• If enginefails tostart after performingcarburetor presets,

the unit may be ftooded. Review the "Difficult Starting"

section of the manual. If problems continue, call the

1-800 number listedon the front coverof this manual for

further assistance.

° Start the engine and operate for three (3) minutes to

warm up.Go to =Adjusting Procedure."

Idle Speed Adjustment

Figure 49

Mixture

Adjustment

r::_

" 25 "

Page 26

-.; SERVICE AND ADJUSTMENTS

:iz-.!

ADJUSTING PROCEDURE

IDLE SPEED ADJUSTMENT "T"

• Allowthe warm engine toidle.

• Adjustthe Idte Speed until the engine continuesto run

withoutstallingand withoutthe chain moving,

- Turn clockwise to increase engine speed ff engine

stalls or dies.

- Turn countemlockwiseto slow engine down and!or to

keep the chain from turning.

• No further adjustments are necessary if chain does not

move at idle speed and ff performance is satisfactory.

LOW SPEED MIXTURE ADJUSTMENT "L"

• Allow engine to idle.

• Turn the Low Speed Mixture Adjustment slowly clock-

wise untilthe RPM starts to drop.Note the position.

• Turn the Low Speed Mixture Adjustmentslowlycounter-

clockwiseuntil the RPM speeds up and starts to drop

again, Note the position.

° Set the Low Speed Mixture at the midpointbetween the

two positions.

HIGH SPEED MIXTURE ADJUSTMENT "H"

IMPORTANT: DO NOT OPERATE ENGINE AT FULL

THRO]-TLE FOR PROLONGED PERIODS WHILE MAK-

ING HIGH SPEED ADJUSTMENTS AS DAMAGE TO THE

ENGINE CAN OCCUR.

° Make a test cut.

• Based on performance of the saw while cutting, adjust

the high speed mixture in 1/16 turn increments as fol-

lows:

- ClOse ff saw loses power in the cut.Do not adjust

for best power by sound or speed, but#Jdge by how

well the saw performs in the cut.

- Counterclockwise if the saw has speed while out of the

cut, but dies in the cut or lacks power while cutting.

° Repeat the test cut.

• Continuewith 1/16 turn adjustments until the saw perfor-

mance is acceptable while cutting.

• After completingadjustments, checkfor acceleration.

ACCELERATION CHECK

• If the engine dies or hesitates instead ofaccelerating,

turnthe LowSpeed MixtureAdjustment 1/16 ofa turn at

a time counterclockwiseuntilyouhave smooth accelera-

tion.

° Check the idle speed for stability and no chain move-

ment.Adjust as necessary.

• Recheckfor smooth acceleration and stableidle.Repeat

processas necessary for acceptable performance.

"_':zt2

Page 27

STORAGE

- ._.j

Immediately prepare your unit for storage at the end of the

season or ff it will not be used for 30 days or more,

WARNING:

ALLOW THE ENGINE TO COOL, AND

SECURE THE UNIT BEFORE STORING OR

TRANSPORTING IN A VEHICLE.

STORE UNIT AND FUEL IN AN AREA

WHERE FUEL VAPORS CANNOT REACH

SPARKS OR OPEN FLAMES FROM WATER

HEATERS, ELECTRIC MOTORS OR SWITCH-I

STORE UNIT WITH ALL GUARDS IN PLACE.

POSITION SO THAT ANY SHARP OBJECT

CANNOT ACCIDENTALLY CAUSE INJURY