Craftsman 358351162 Owner’s Manual

Operator's Manual

CRgFTSMIIN°

2.4 cu. in./40cc 2-Cycle

GASOLINE CHAIN SAW

Model No.

358.351162 - 16 In. Bar

@

_b wARNING:

9

Read and follow all Safety Rules and Operating

Instructions before first use of this product,

For answers to your questions about this product:

Call 7 am-7 pro, Mon.-Sat., or 10 am-7 pm, Sun.

1-800-235-5878 _.ou_,,=odo_ooon__0_

Sears, Roebuck and Co., Hoffman Estates, IL 60179 USA

530087297 01115/98

increasethechanceofkickback,Fol,

lowmanufacturer'schainsharpening

and maintenanceinstructions,Check

tensionat regularintervals, butnever

withenginerunning,Make surebar

clampnutsare secure/ytightened.

• Beginandcontinuecutting]atfull

speed.If the chainismovingat a

slowerspeed, thereis greaterchance

ofkickbackoccurring,

• Useextremecautionwhen reentering

a cut.

• Donotattempt cutsstartingwiththe

tipofthebar°(plungecuts).

• Watchfor shiftinglogsorotherforces

thatcouldclose acutand pinchorfall

intochain,

• Usethe specifiedReduced-Kickback

GuideBarandLow-KickbackChain.

Avoid Pinch-Kickback:

• Beextremelyawareofsituationsor

obstructionsthatcan causematedal

topinchthetop of or otherwisestop

thechain.

- Do notcutmorethan one log ata

time,

• Do nottwistsawas bariswithdrawn

from an undercutwhenbucking.

Avoid Pull-In:

atfullspeedand the saw housing

i lwaysbegincuttingwiththeengine

againstwood. . , .

Usewedgesmaae orplasticorwooa,

Neverusemetalto holdthe cutopen.

_MAINTAIN CONTRQL

Standtothe left of thesaw

keepy,ourbodyfrombeingin a direct

linewiththecuttingcnain_

• Standwithyourweightevenlyhal.....

anced onbothfeet;

• Donotoverreach.Youcouldbedrawn

orthrownoffbalanceandlosecontrol.

• Donotcutaboveshoulderheight,lt_

difficultto maintaincontrolof saw

aboveshoulderheight.

KICKBACK SAFETY FEATURES i

WARNING: The followingfeaturesarel

includedonyoursawto help reduce

hazardofkickback; however,suchfea-

tureswillnottotallyeliminatethisdan'

get,Do notrelyonlyonsafetydevices.

• Handguard:designedto reducethe

chanceofyourlefthandcontacting

thechainifyourhandslipsoffthe

fronthandlebar. ---

• Positionoffront and rearhandlebars:

designedwithdistance betweenhan-

dlesand"in-line" witheachother,The

spreadand =in-line"positionofthe

handsprovidedbythis designwork

togetherto givebalanceand resis-

tancein controliingthepivotofthe

sawbacktowardtheoperatorifkick-

backoccurs.

• Reduced-KickbackGuideBar:de-

signedwitha smallradiustipwhich

reducesthesizeofthe kickbackdan-

gerzone.Thistypebar hasbeen'

demonstratedto significantlyreduce

thenumberand seriousnessofkick-

backswhentestedinaccordancewith

ANSIB175.1,

Thumbon '__

o_ _underside

Elbow

locked

LargeRadius[

TipGuideBar

• Low-KickbackChain:hasmet kickback

performancerequirementswhentested

Tip Guide Bar

S,.a" adius

Neverreversehandpositions ona representativesampleof ct_n

• Agood,firmgriponthesawwithboth sawsbelow3,8 cubicinch

handswillhelpyou maintain control, displacementspecifiedinANSI B175.1.

Don3let go. Grtpthe rearhandlewith Low-KickbackChain

yourrighthand,whetheryou areright , ContouredDepthGauge

orlefthanded.Wrap the fingersof __ _.,,,/ ElongatedGuardLink

yourleft handoverand aroundthe _=zz;Z_'_.=----- DeflectsKickback

front handlebar,and yourleftthumb '_ _ ForceAndAllows

' underthe fronthandlebar.Keepyour _ "_,_ WoodToGradually

• leftarm straightwiththeelbowlocked, _ RideintoCutter

Positionyourlefthandonthe front SAFETY NOTICE: Exposuret_)

handlebarso it is ina straight linewith vibrationsthroughprolongeduseof

yourrighthand on therearhandle gasolinepoweredhandtoolsCould

whenmaking buckingcuts.Stand cause bloodvesselor nervedamagein

slightlytotheleftside ofthe sawto thefingers,hands,andjointsofpeople

4

pronetocirculationdisordersor

abnormalswelling.Prolongedusein

coldweatherhasbeenlinkedtoblood

vesseldamageinotherwisehealthy

people.Ifsymptomsoccursuchas

numbness,pare,lossofstrength,

change_inskincolorortexture,orloss

offeeling inthe fingers, hands,orjcints,

discontinuethe use ofthistooland

seekmedicalattention.An

anti-vibrationsystemdoesnot

guaranteetheavoidanceofthese

problems.Userswho:operatepower

toolsona continualand regularbasis

mustcloselymonitortheirphysical

conditionandthe conditionofthistool.

CHAIN BRAKEIfthissawis to be used

for commerciallogging,youmustorder

andinstalla chainbraketo complywith

FederalOSHA Regulationsfor Com-

mercialLogging.ContactyourSears

Service Centerorcall 1-800-235-5878.

SPARKARRESTOR:Yoursawis

equippedwitha temperaturelimiting

muffler andsparkarrestingscreen

whichmeetstherequirementsof

CaliforniaCodes4442and 4443. All

U.S.forest landand thestates of

California,Idaho,Maine,Minnesota,

NewJersey,Oregon,and Washington

requirebylawthatmany internal

combustionenginesbeequippedwitha

sparkarrestorscreen.Ifyouoperatea

chainsawina stateorlocalewhere

suchregulationsexist,youare legally

responsiblefor maintainingthe

operatingconditionoftheseparts.

Failuretodoso is a violationofthelaw.

RefertoCustomerResponsibilities

chartinthe MAINTENANCEsection.

STANDARDS:ThisChainsaWis=listed

byUnderwritersLaboratodes,=lnc.in

accordancewithAmericanNational

StandardsforGasoline-PoweredChain

SawsSafetyRequirements(ANSI

B175.1-1991),

CARTON CONTENTS

Checkcartoncontentsagainstthefol-

lowinglist.

• Model: 358.351162

• ChainSaw (fullyassembled)

• Chainadjustmenttool

• 2-cycleengineoil....(Baroilnot

included)

- Examinepartsfor damage.Do not

usedamagedparts.

, Ifyouneedassistanceorfindthat

partsaremissingordamaged,please

call1-800-235-5878.

NOTE: Itisnormalto hearthe fuel filter

rattleinan emptyfuel tank.

Yourunithasbeenfactorytestedand

thecarburetorpreciselyadjusted.Asa

resultyoumaysmellgasolineorfind a

dropofoil/fuelresidueonthe muffler

whenyouunpackthe unit.

ASSEMBLY

Yoursawisfully assembled,andno

assemblyis necessary.

5

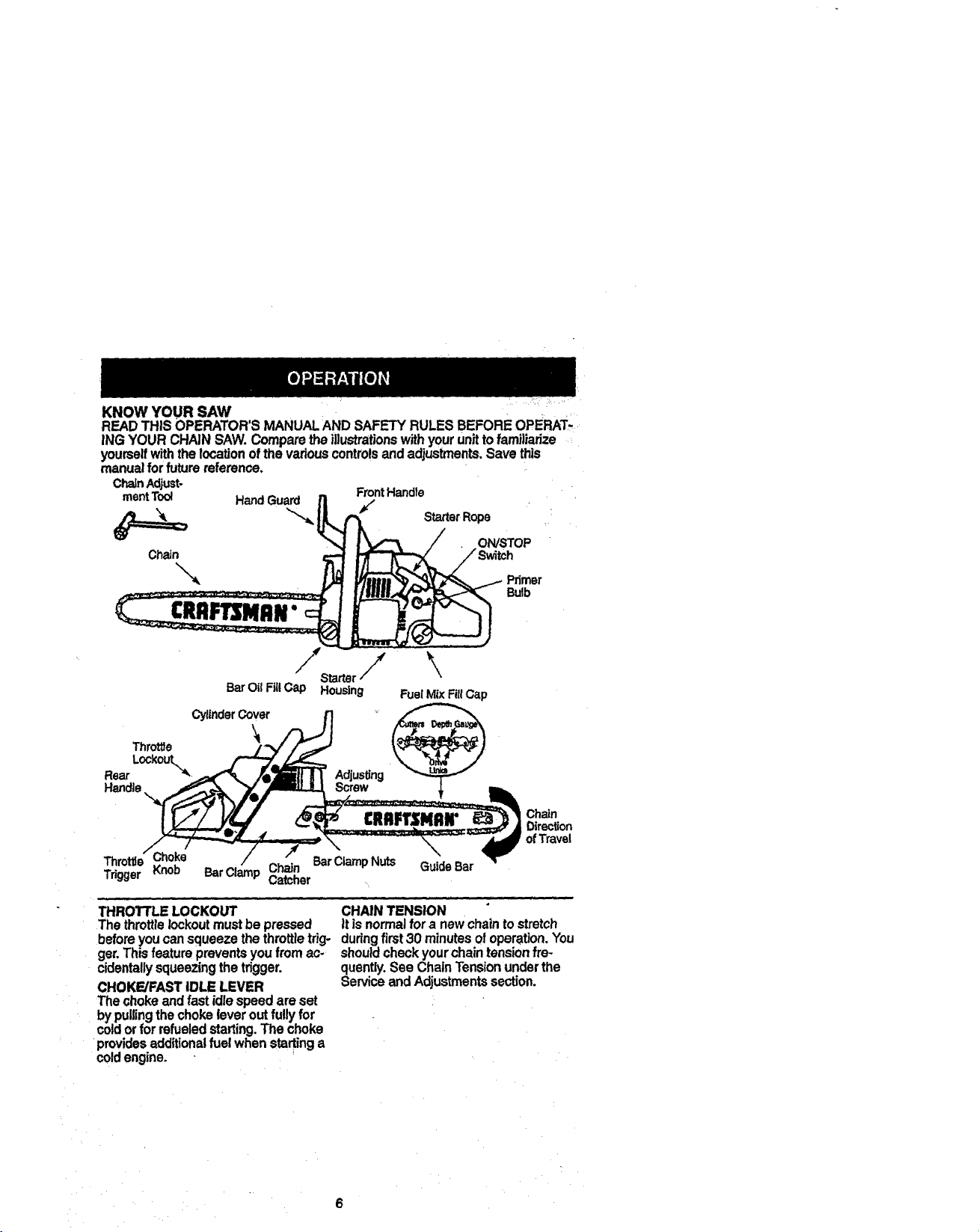

KNOW YOUR SAW

READTHIS OPERATOR'SMANUALANDSAFETY RULESBEFORE OPERAT_

ING YOUR CHAINSAW. Comparetheillustrationswithyourunittofamiliarize

yourseffwiththelocationofthe vadouscontrolsandadjustments.Save this

manualforfuture reference.

ChainAdjust- FrontHandle

meritTool HandGuard €,

StarterRope

ON/STOP

Chain

"_ Primer

+

Bulb

CRRI MRN"

\

BarOilFillCap Housing

CylinderCover

Throtl]e

RearLockout,_

Handle

Fuel Mix Fill Cap

£RFIFlrSNAr Chain

Direction

ofTravel

Throttle Choke

Trigger Knob BarClamp Chain BarClampNuts GuideBar

Catcher

THROI"rLELOCKOUT CHAINTENSION

Thethrottle lockoutmust be pressed ttisnormalfora newchaintostretch

beforeyoucansqueezethethrottle trig- duringfirst30 minutesofoperation.You

ger.Thisfeaturepreventsyoufrom ac- shouldcheckyourchaintensionfre+

cidentallysqueezingthetrigger, quently.See ChainTensionunderthe

CHOKE/FASTIDLE LEVER ServiceandAdjustmentssection.

The choke andfastidlespeedareset

bypullingthechokeleveroutfully for

coldorforrefueledstarting.The choke

providesadditionalfuel whenstartinga

coldengine.

6

BEFORE STARTING ENGINE

WARNING: Be sureto readthefuel

handlinginformationinthe safetyrules

sectionofthismanualbeforeyoubegin.

Ifyoudo notunderstandthefuelhan-

dling information do notattemptto fuel

yourunit.Seek helpfromsomeonethat

does understandtheinformationor call

the customerassistancehemplineat

1-800-235-5878.

GUIDE BARAND CHAINOIL

The chainoilerprovidescontinuouslu-

bricationtothechainandguidebar.Be

suretofillthe baroiltankwhenyoufill

thefuel tank(Capacity= 6.8 fL oz.)

Formaximum guidebarandchainlife,

we recommendyou useCraftsman

chainsaw baroiJ.tfCraftsmanbaroilis

notavailable,youmayusea good

gradeSAE 30 oiluntilyouare ableto

obtainCraftsmanbrand.Theoiloutput

isautomaticallymetered duringopera,

tion.Yoursawwilluse approximately

one tankofbaroilfor everytankoffuel

mix.Alwaysfillthebaroiltankwhen

youfillthefuel tank.

FUELING ENGINE •

Thisengineiscertifiedtooperateon

unleadedgasoline.Beforeoperation,

gasolinemustbemixedwitha good

quality2-cycleair*cooledengineoil.We

recommendCraftsmanbrandoil.Mix

gasolineandoilat a ratibof40:1 (A

40:1 ratioisobtainedbymixing3.2

ouncesofoilwith1 gallonof unleaded

gasoline).DONOTUSEautomotiveoil

or boatoil.Theseoilswillcauseengine

damage.When mixingfuel followthe

instructionsprintedonthecontainer.

Onceoilisaddedtothegasoline,

shakecontainermomentarilyto assure

thatthefuel isthoroughlymixed.

Alwaysreadandfollow thesafetyrules

relatingtofuel beforefueling yourunit.

IMPORTANT

Experienceindicatesthatalcohol

blendedfuels(calledgasoholor using

ethanolor methanol)canattractmois-

turewhichleadstoseparationand

formation ofacidsduringstorage.Acid-

icgas can damagethefuel systemof

an enginewhileinstorage.

Toavoid engineproblems,thefuel sys-

temshouldbeemptiedbeforestorage

for30 daysorlonger.Drainthegas

tank,startthe engineandletit rununtil

thefuel linesandcarburetorareempty.

Usefreshfuel nextseason.See STOR-

AGEinstructionsforadditionalinforma-

tion.

Neveruseengineorcarburetorcleaner

productsinthefueltankorpermanent

damagemayoccur.

See the STORAGEsectionforadditional

information.

STOPPING YOUR ENGINE

, MoveOn/Stopswitchtothe STOP

position.

• Ifenginedoesnotstop,pullchoke

knoboutfully.

STARTING YOUR ENGINE

COLD ENGINEOR WARMENGINE

AFTER RUNNINGOUTOFFUEL

• Fuelenginefollowinginstructionsun-

der FUELINGENGINE.

• Fillbaroiltankwithbaroil.Yoursaw

willuseapproximatelyonetankofbar

oilfor eachtankof fuel mix.

• MoveOn/Stopswitchto ONposition.

• Pullchokeknoboutfully.

° Primeenginebyslowlypressingprim-

er bulbsixtimes.

ON/STOP

Switch

PrimerBulb

• Set sawontheground.Gripfront

handlewithyourlefthandandplace

rightfoot throughrearhandle.

Chokeknob

NOTE: Whenpullingthestarterrope,

donotusethefullextentofthe rope.

Do notletstarterropesnapback.

Holdhandle.Letroperewindslowly.

. Sharplypullstarterropehandle5

timeswithyourrighthand.The en-

ginemaysoundas ifit ist_ng to

startbeforethe5thpull;ifso, proceed

tothenextstep.

7

• Fully push-in choke lever and contin-

ue to pullstarter rope handle until en-

ginestarts.

• Then, squeeze and release the

thrott/etrigger to return engine to idle

speed.

• Tostop engine, move On/Stop switch

tothe 8TOP position.

LeftHand

onFront

Handle

StarterRopeHandle

FootThroughRearHandle

STARTINGA WARMENGINE

DONOTusethe choketo starta warm

engineorfloodingand hardstarting

mayoccur.

• MoveOn/Stopswitchto ON.

: Slowlypressprimerbulb6 times.

Setthechainsawon the ground.Grip

thefront handlewithyourlefthand

andplaceyourrightfootthroughthe

openinginthe rearhandle.

• Pullchokeleveroutfully, thenpushit

infullytoset engineinfastidleposi-

tON. ="

• Sharplypullstarterropehandlewith

yourright handuntiltheenginestarts,

butnomorethan5 times.

• Then,squeezeand releasethe

throttletriggertoreturnenginetoidle

speed.

• Tostopengine,moveOn/Stopswitch

tothe STOPposition.

DIFFICULT STARTING OR

STARTING A FLOODED ENGINE

The enginemaybefloodedifit hasnot

startedafter10pulls.Floodedengines

canbe clearedofexcessfuel withthe

followingprocedure:

• Pullchokeleveroutfully,then pushit

infullytoset enginein fast idleposi-

ton.

• VerifythattheOn/Stopswitchisinthe

ON position.

• Withsawonground,gripfront handle

withlefthandandplacerightfoot

throughrearhandle.

• Gripstarterropehandleand pul!rope

firmlyandquicklytostartengine.If

notsuccessful,repeatu.ntilengine

starts.

Startingcouldrequire manypullsde-

pendingonhowbadlyunitisflooded. If

enginestillfailstostart,refertoTROU-

BLESHOOTINGchartorcall

1-800-235-5878.

OPERATING TIPS

• Checkchaintensionbeforefirstuse

andafter t minuteofoperation.See

ChainTensionJntheMaintenance

section.

• Cutwoodonty.DOnotcutmetal,plas-

tics,masonry,non-woodbuildingma-:

terials,etc.

• Stopthesawifthechainstrikesa for-

eignobject.Inspectthe saw andre-

pairpartsas necessary.

° Keepthechainoutof dirtand sand.

Evena smallamountofdirtwillquick-

lydulla chainand increase thepossi-

bilftyof kickback.

• Practicecuttingafew smalllogsusing

thefollowingsteps.This willhelpyou

getthe=feel"of usingyoursawbefore

youbegina majorsawingoperation.

• Squeezethethrottletriggerandal-

lowtheengineto reachfullspeed

beforecutting. : • • .

• Begincuttingwiththesaw frame

againstthelog.

• Keeptheengineat full speedthe

entiretimeyouarecutting.

• Allowthe chaintocutfor you.Exert

onlylightdownwardpressure.

• Releasethethrottletriggeras soon

as thecutiscompleted,allowingthe

engineto idle.Ifyourunthesawat .....

full throttlewithoutacuttingload,

unnecessarywearcan occur.

.. Toavoidlosingcontrolwhencutis

complete,donotputpressureon

sawat endofcut.

• Stoptheenginebeforesettingthe

sawdown.

TREE FELLING TECHNIQUES

WARNING: _Checkfor broken0r:dead

brancheswhichcanfall whileCutting_

causingseriousinjury.Do hotcutnear

buildingsore!ectricalwiresifyoudo not

knowthe directibnoftree fal!_qorcut at

nightsinceyouwillnotbe ab!eto see

well,nor duringbadweathersuchas

rain,snow,or strongwinds,etc.

Carefullyplanyoursawingoperationin

advance.Clearthe workarea.You

needa clearareaall aroundthe treeso

youcanhavesecurefooting. Studythe

naturalconditionsthatcancausethe

treetofall ina particulardirection,such

conditions include:

• The winddirectionandspeed.

• The leanofthe tree.The leanofa

treemightnotbe apparentdueto un-

evenor slopingterrain.Usea plumb

or levelto determinethedirectionof

treelean.

• Weightandbranchesononeside.

• Surroundingtreesandobstacles.

Lookfor decay androt.If thetrunkis

rotted,itcan snapandfall towardthe

operator.

Makesurethereisenoughroomfor the

treetofall.Maintaina distanceof 2-1t2

treelengthsfrom thenearestpersonor

otherobjects.Enginenoisecan drown

outa warningcall.

Removedirt,stones,loosebark,nails,

staples,andwirefrom thetreewhere

cutsare to be made.

Thishingewillhelppreventthetree

from fallinginthewrongdirection.

Rnalcuthere

Notch_ ',_'_!i_ ......

Sec,ond _

Hingeholdstreeonstumpandhelps

controlfail

Opening

offetling

Closingof

notch

Planaclearretreatpath

.... (_--_- DirectionofFall

FELLING LARGE TREES

(6 inchesindiameterorlarger)

The notchmethodisusedto fell large

trees.Anotchiscutonthe sideof the

treein the desireddirectionoffall. After

a felling cutismadeontheopposite

sideoftree, thetreeshouldfall inthe

directionofthenotch.

NOTE: Ifthetreehaslargebuttress

roots,removethembeforemakingthe

notch.

NOTCHCUT AND FELLINGTREE

• Makenotchcutbycuttingthetopof

thenotchfirst.Cutthrough1/3ofthe

diameterofthetree.Nextcomplete

thenotchbycuttingthe bottom.See

illustration.Oncethenotchiscutre-

movethe wedgeof Woodfrom the

tree.

• Afterremovingthe wood,makethe

fellingcutontheoppositesideofthe

notch.Thisisdonebymakinga cut

abouttwoincheshigherthanthecen-

ter ofthe notch.Thiswillleave

enoughuncutwoodbetweenthe fell-

ingcutandthenotchtoform a hinge.

NOTE: Beforefelling cutiscomplete,

usewedgestoopenthe cutwhen

necessaryto controlthe directionoffall.

Toavoidkickbackandchaindamage,

usewood orplasticwedges,butnever

steelor ironwedges.

• Bealertof signsthat thetreeisready

tofall: crackingsounds,wideningof

thefelling cut,or movementintheup-

perbranches.

• As treestartstofall, stopsaw,putit

down,andget awayquicklyonyour

plannedretreatpath.

• Beextremelycautiouswithpartially

fallentreesthatmaybe poodysup-

ported.Whena treedoesn'tfallcom-

pletely,set thesawasideandpull

downthe treewitha cablewinch,

blockandtackle,ortractor.Donot

useyoursawto cutdownapartially

fallen tree.

CUTTING A FALLEN TREE

(BUCKING]

Buckingisthetermusedforcuttinga

fallentreetothedesiredlogsize.

WARNING: Do notstandonthe log

beingouLAnyportioncanrollcausing

lossoffootingandcontrol.Donotstand

downhillofthelogbeingcut.

IMPORTANTPOINTS

• Cutonlyone logat a time.

• Cutshatteredwoodverycarefully;,

sharppiecesofwoodcouldbeflung

towardoperator.

9

* Usea sawhorsetocut smalllogs.

Neverallowanotherpersontohold

thelogwhilecuttingandneverhold

thelogwithyourlegorfoot.

oDonotcutinan area wherelogs,

limbs,and rootsare tangled.Dragthe

logsintoa clearareabeforecutting Firstcutonpressuresideoflog

them, •BUCKINGWITHOUT A SUPPORT

BUCKING TECHNIQUES

WARNING: If saw becomes pinched

or hung in a log, don't try to force it out.

You can lose control of the saw result-

ing in injury and/or damage to the saw.

Stop the saw, drive a wedge of plastic

or wood intothe out untilthe saw can

be removed easily. Restart the saw and

carefully reenter the cut. Do not use a

metal wedge. Do not attempt to restart

your saw when it is pinched or hung in

a log.

Use a wedgeto removepinchedsaw

Turnsaw OFFand

usea plasticorwooden

wedgetoforcecut open,

• Overcutthrough1/3ofthe diameterof

thelog.

• Rollthelog overandfinishwitha sec-

ondovemut.

• Watchfor logswitha pressureside.

See illustrationabovefor cuttinglogs

witha pressureside.

Usingalog 2nd "

for support Cut

Ovemuttingbeginsonthe topside of

thelog withthe bottomof the saw

againstthelog.Whenovercuttinguse

light downwardpressure.

BUCKINGUSINGA LOG OR

SUPPORTSTAND

Orang UndercutUng

• Rememberyourfirstcutisalwayson

thepressuresideofthelog.

(Refertotheillustrationbelowfor'your

first andsecondcut)

• Yourfirstcutshouldextendt/3ofthe

diameterofthelog.

Undercuttinginvolvescuttingonthe

undersideofthe log withtopofsaw

• Finishwithyoursecondcut.. ....

againstthelog.Whenundercuttinguse

light upwardpressure.Holdsawfirmly

and maintaincontrol.The sawwilltend

topushbacktowardyou.

WARNING: Neverturnsawupside

downtoundercuLThe sawcannotbe

controlledinthisposition.

Alwaysmakeyourfirst outonthepres-

suresideofthelog.

Firstcutonpressuresideoflog

%

t0

LIMBING AND PRUNING

WARNING: Never climbintoatree to

limborprune.Do notstandon ladders,

platforms,a log,or inanyposition

whichcancauseyouto loseyourbal-

anceorcontrolof the saw.

IMPORTANTPOINTS

• Watchoutfor springpoles.

Springpolesare smallsizelimbs

whichcanwhiptowardyou,orpull

youoffbalance. Useextremecaution

whencuttingsmallsizelimbs.

• Be alertfor spdngbecl_Watchoutfor

branchesthatarebentorunderpres-

sure.Avoidbeingstruckbythe

branchor thesawwhenthetensionin ° Finishthe pruningoperationbyusing

thewoodfibersisreleased, an overcutsothatthe stumpofthe

• Frequentlyclearbranchesoutofthe

waytoavoid'trippingonthem.

LIMBING

Limba treeonlyafterit is cutdown.

•"Leavethelargerlimbsunderneaththe

felledtreetosupportthe tree asyou

work.

° Startat the baseof thefelledtree and

worktowardthetop,cuttingbranches

and limbs,Removesmalllimbswith

onecut.

• Keepthetreebetweenyouandthe

chain.

° Removelarger,supportingbranches

withthe1/3,2/3 cuttingtechniquesde-

scribedinthebuckingsection.

• Alwaysusean overcuttocutsmall

andfreelyhanginglimbs.Undercut-

tingcouldcauselimbstofalland

pinchthesaw.

PRUNING

WARNING: Limitpruningtolimbs

shoulderheightorbelow.Do notcutif

branchesarehigherthanyourshoul-

der.Get aprofessionaltodo thejob.

• Makeyourfirstcut1/3oftheway

throughthebottomofthe limb.

• Nextmakea secondcutall the way

through the limb.

limbprotrudes1to2 inchesfrom the

trunkofthetree.

_ Firstcut

/\

fromtrunkof'tree

CUSTOMER RESPONSIBILITIES

Fillindatesas youcomplete Before After Every•Even Yea_' S.e_ce

regularservice Use Use 5 hrs.25 hrs.. _• ... Dates

Check,!ordar.age ornpartsv' . _........

Checkfor loosefasteners/parts _ ................... = .

Checkchaintension _.. ..... ..................

! Checkcha!nsharpness p-

Checkguidebar _.

Cleanunit&labels ................... i ,P" I.........

Cleanairfilter _'

.........Clean!inspectsparkarrestor

screen&inspectmuffler _' ............

Replacesparkplug P"

11

GENERALRECOMMENDATIONS

Thewarrantyonthisunitdoesnotcov-

eritemsthathavebeensubjectedto

operatorabuseornegligence,Tore,

ceivefull valuefrom thewarranty,the

operatormust maintainunitas instruct-

edinthismanual Variousadjustments

willneedtobemadeperiodicallyto

properlymaintainyourunit.

• Oncea year,replacethesparkplug,

airfilter element,andcheckguidebar

andchainforwear.A newsparkplug

andair filter elementassuresproper

air-fuelmixtureandhelpsyourengine

runbetterandlastlonger.

WARNING: Disconnectthe sparkplug

beforeperformingmaintenanceexcept

forcarburetoradjustments.

LUBRICATION

tl _

t Bar 2 BarOil

Sprocket FillCap _ |

Lube ,_ _ !

• HandleScrews

• VibrationMounts

• StarterHousing

• Handguard

CHECK CHAIN TENSION

• Usethescrewdriverendof the chain

BarClamp Adjusting Adjustment

• Loosenbar clampnutsuntiltheyare

• Turnadjustingscrewclockwiseuntil

• Rollchainaround guide barto ensure

adjustmenttooltomovechainaround

guidebarto ensurekinksdonotexist,

The chainshouldrotatefreely.

Guide

Bar

Chain

Nuts Screw Tool

fingertightagainstthebarclamp.

chainbarelytouchesthebottomof

guide bar,

all links arein bargroove.

1 Sprocketlube

2 Craftsmanchainsawbar oil

CHECK FOR DAMAGED OR

WORN PARTS

Replacementofdamaged/wornparts

shouldbereferredto ydiJrSears Ser-

viceCenter.

NOTE: it is normalfor a smallamount

ofoiltoappearunderthesawafteren-

ginestops.Donotconfusethiswitha

leakingoiltank.

° On/StopSwitch- EnsureOn/Stop

switchfunctionsproperlyby moving

theswitchtothe"Stop• position,

Make sureenginestops;thenrestart

engineandcontinue.

• FuelTank- Discontinueuseof chain

sawiffueltankshowssignsofdam-

ageorleaks.

• OilTank- Discontinueuseof chain

saw if oiltankshowssignsofdamage

orleaks.

CHECK FOR LOOSE

FASTENERS AND PARTS

• BarClampNuts

• Chain

• Muffler

• CylinderShield

• AirFiller

• ClutchDrum/Sprocket

Adjusting

=Screw

BarClampNuts GuideBar

• Lift uptipofguidebar to checkfor

sag. Releasetip ofguidebar,then

turnadjustingscrew1/4turnclock-

wise.Repeatthisstep untilsagdoes

not exist.

• Whilelifting tipofguidebar,tighten

barclampnutswiththe_haJnadjust-

menttool.Torqueto 10-15ft-lbs.

AdjustingScrew

Bar "_4_

Clamp I/4Turn

Nuts

t

• Usethescrewdriverendof the chain

adjustmenttoolto movechain around

theguidebar.

• Ifchaindoesnot rotate,itistootight.

Slightlyloosenbar clampnutsand

turnadjustingscrew1/4turncounter,

clockwise.Retightenbarclampnuts.

• Ifchainistooloose,itwiltsag below

theguidebar.DONOT operatethe

saw ifthechainisloose.

CHECK CHAIN SHARPNESS

Asharpchainmakeswoodchips.A

dultchainmakesa sawdustpowder

andcutsslowly.

CHAIN SHARPENING

Chainsharpeningrequiresspecial

tools.Youcanpurchasesharpening=

toolsatSearsor gotoa professional

chainsharpener.

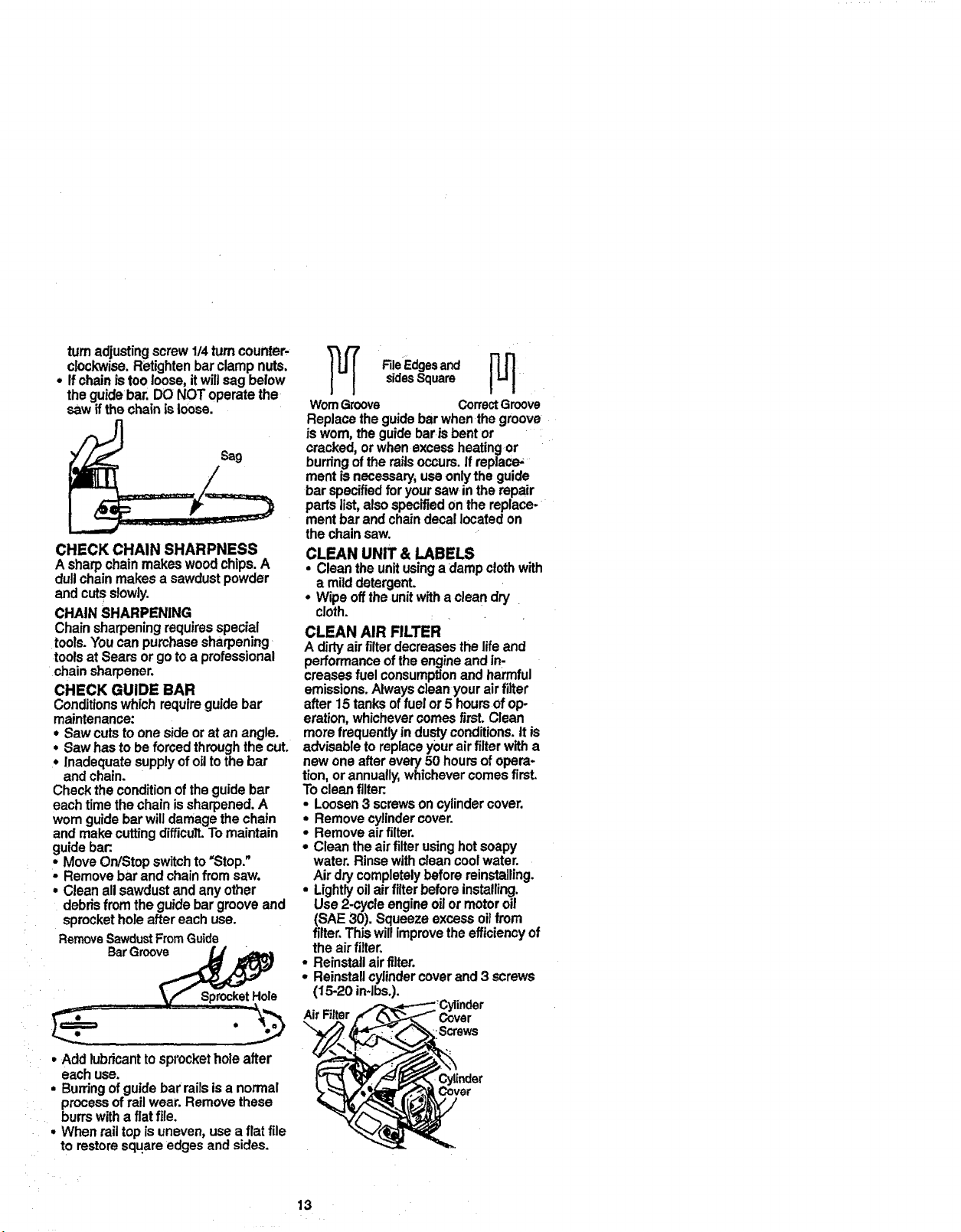

CHECK GUIDE BAR

Conditionswhichrequireguidebar

maintenance:

• Sawcutsto onesideorat anangle.

• Sawhastobeforced throughthecut.

• inadequatesupplyofoil tothebar

andchain.

Checktheconditionoftheguidebar

eachtimethechainissharpened.A

wornguidebarwilldamagethechain

andmakecuttingdifficult.Tomaintain

guidebar:.

- MoveOn/Stopswitchto"Stop.•

• Removebarandchainfrom saw.

• Cleanallsawdustand any other

debrisfrom theguidebargrooveand

sprocketholeaftereachuse.

RemoveSawdustFromGuide

BarGrcx__e

T_ FileEdgesand

WornGroove CorrectGroove

Replacetheguidebarwhenthe groove

is worn,theguidebarisbentor

cracked,orwhenexcessheatingor

burringoftherailsoccurs.If replace*

ment isnecessary,useonlythe guide

bar specifiedforyoursawin therepair

partslist,alsospecifiedonthereplace-

mentbarandchaindecallocatedon

thechainsaw.

CLEAN UNIT & LABELS

• Cleantheunitusinga dampclothwith

a milddetergent.

• Wipeofftheunitwithacleandry

cloth.

CLEAN AIR RLTER

A dirtyair filterdecreasesthelifeand

performanceoftheengineandin-

creasesfuel consumptionand harmful

emissions.Alwayscleanyourairfilter

after 15tanksoffuel or5 hoursofop

eration,whichevercomesfirst. Clean

morefrequentlyindustyconditions,itis

advisabletoreplaceyourairfilter witha

newone afterevery50 hoursofopera-

tion,orannually,whichevercomesfirst.

Tocleanfilter:.

• Loosen3 screwsoncylindercover.

• Removecylindercover.

• Removeairfilter.

• Cleantheairfilterusinghotsoapy

water.Rinsewithcleancoolwater.

Air drycompletelybeforereinstalling.

• Lightlyoilair filterbeforeinstalling.

Use2-cycleengineoilormotoroil

(SAE30). Squeezeexcessoilfrom

filter.Thiswillimprovetheefficiencyof

theair filter.

• Reinstallairfilter.

• Reinstallcylindercoverand 3 screws

(15-20 in.lbs°).

sidesSquare _L_I|

• Add lubricanttosprocketholeafter

eachuse.

• Burringofguidebar railsis a normal

processofrailwear.Removethese

burrswitha fiatfile.

• Whenrailtopisuneven,usea flatfile

to restoresquareedgesandsides.

13

•Screws

Cylinder

Cover

INSPECTMUFFLERANDSPARK

ARRESTORSCREEN

Astheunitisused,carbondeposits

builduponthe mufflerand spark

arrestorscreen,andmustberemoved

toavoidcreatinga firehazardoraffect-

ing engineperformance.

Replacethesparkarrestorscreenif

breaksoccur.

MufflerDiffuser

Spark

Arrestor

Screen

Muffler

Cover

Screws

• Replaceanybrokenorcrackedmuf-

tierparts.

• Reinstalldiffuserandsparkarrestor

screenassemblywithholesfacing up

andtowardsmufflercover.

• Reinstallmufflercoverand 2 screws

(7-8ft-ibs.).

REPLACE SPARK PLUG

Thesparkplugshouldbereplaced

eachyear toensuretheenginestarts

easierandrunsbetter.Ignitiontimingis

fixedand nonadjustable.

• Loosenthe3 screwsonthe cylinder

cover.

• Removethecylindercover.

; Pulloffthe sparkplugboot.

Removesparkplugfrom cylinderand

discard.

Body Muffler

Cover

CLEANING THE SPARK

ARRESTOR SCREEN

Cleaningisrequiredevery25 hoursof

operationorannually,whichevercomes

first.

• ReplacewithChampionCJ7Yspark

plugandtightenwitha 3/4 inchsocket

wrench(10-12ft-lbs). Sparkpluggap

shouldbe,025in.

• Reinstallthe sparkplugboot.

• Reinstallthecylindercoverand3

screws(15-20in-lbs).

• Loosenandremovethe2 mufflercoy- Screws

er screws.

• Removethe mufflercover(cover

snapsoffmufflerbody). Plug

• Removemufflerdiffuserandspark Boot

arrestorscreenassembly.Noticethe

orientationof thesepartsforreassem-

bling.

° Cleanthesparkarrestorscreenwitha Spark

wirebrush, Replacescreenif breaks Plug

arefound.

. . . , , !

Cylinder

Cover

CHAIN REPLACEMENT

CAUTION: Wearprotectivegloves

whenhandlingchain.The chainis

sharpandcan cutyoueven whenitis

notmoving.

Itis normalfora newchainto stretch

duringthefirst30 minutesofoperation.

You shouldrecheckyourchaintension

frequently andadjustthechaintension

as required.SeeChainTensionsec-

tion.

• MoveOn/Stop:switchto the Stop

position.

• Replacetheoldchainwhenit be-

comeswornordamaged.

• UseonlytheLow-Kickbackreplace-

mentchainspecifiedintherepair

partslist.The correctreplacementbar

and chainisalsospecifiedona decal

locatedonthechainsaw.

• See yourSearsServiceCenterto re-

placeandsharpenindividualcutters

onyourchain.

i,

• Removebarclamp nuts.

° Removebar clamp.

• Removetheoldchain.

Bar

Clamp

\

I

Bar

CiarnpNuts

, Turnadjustingscrewbyhandcoun-

terclockwiseuntiladjustingpinjust

touchesthestop.

• Slideguidebarbehindclutchdrum

untilguidebarstopsagainstclutch

drumsprocket.

• Carefullyremovenewchainfrom

package.Holdchainwiththedrive

linksas shown.

Cuffers Dep_ Gauge

D_ve Unks

• Race chainoverandbehind the

clutch.

• Fitchaindrivelinksintobargroove.

Fit bottomofddvelinksbetweenteeth

insprocketnose.

• Pullguidebarforward untilchainis

snugIn guidebargroove.

• Now,installbarclampmakingsure

theadjustingpinispositionedinthe

lowerholeintheguidebar.

/

/

Adjusting

Pin

Lower

Hole Guid_

Bar

, Installbarclampnutsandfingertight-

enonly.Do nottightenany furtherat

thispoint

CHAIN ADJUSTMENT

See =ChainTension"inMaintenance

section.

CLEAN FUEL FILTER

Tocleanfuelfilter,drainyourunitby

runningdryoffuel,removefuelcap/re-

tainerassemblyfromtank.Pullfilter

fromtankandremovefromline.Clean

withmild detergentand rinse.Drythor-

oughly,reassemble.

CARBURETOR ADJUSTMENT

WARNING: The chainwillbemoving

dudngmostof thisprocedure.Wear

yourprotectiveequipmentandobserve

allsafetyprecautions.Duringthelow

speedmixture adjustmentrecheckidle

speedaftereachturnofthescrew.The

chainmust notmoveat idlespeed.

Carburetoradjustmentiscriticalandif

doneimproperly=can permanentlydam-

agetheengineas wellasthecarbure-

tor.if yourequirefurtherassistanceor

are unsureaboutperformingthisproce-

dure,callourcustomerassistancehelp

lineat 1-800-235-5878.

Oldfuel,a dirtyairfilter,dirtyfuelfilter,

orfloodingmaygivetheimpressionof

an improperly adjustedcarburetor.

Checktheseconditionsbeforeadjust-

ingthecarburetor.

The carburetorhasbeencarefullysetat

thefactory.Adjustmentsmaybeneces*

saryifyou noticeanyof thefollowing

conditions:

• Chainmovesat idle.See =idleSpeed"

underadjustingprocedure.

° Saw willnotidle.See "IdleSpeed"

and_LowSpeed Mixture'underad-

justingprocedure.

° Enginediesor hesitateswhenit

shouldaccelerate.See "Acceleration

Check"underadjustingprocedure.

° Lossofcuttingpower.See=High

SpeedMixtureH"underadjusting

procedure.

There arethree adjustmentscrewson

thecarburetor._TheyarelabeledH,_L,

15

Loading...

Loading...