Craftsman 358351142, 358351062 Owner’s Manual

Operator'S Manual

CRi:IFTSNnN

2.2 cu. in./36cc 2-Cycle

GASOLINE CHAIN SAW

Model No.

358.351142 - 14 in. Bar

358.351062 - 16 in. Bar

@

Read and follow all Safety Rules and Operating

WARNING:

Instructionsbefore first use of this product.

Foranswerstoyourquestions aboutthis product:

Call7 am_7 pm, Mon--Sat;Sun, 10 am-7 pm

1-800-235-5878

Sears, Roebuck and Co., Hoffman Estates, IL 60179 USA

530-084293 05/06/97

Warranty 2

Safety Rules 2

Assembly 5

•Operation 6

Maintenance 11

ServiceandAdjustments 14

Storage 16

TroubleShootingChad 16

Spanish .. 22

Parts& Or_edng Back

FULL ONE YEAR WARRANTY ON CRAFTSMAN ® GAS

CHAIN SAW

Foroneyear fromthedateofpurchase,whenthisCraftsmanGasChainSaw is

maintained,lubricated and tuned-upaccordingtothe owner'smanual,Sears will

repair,freeofcharge,any defectinmaterial orworkmanship.

Thiswarrantyexcludesthebar,chain,sparkplugand airfilter,whichare

expendableparts,andbecomewornduringnormaluse.

IfthisGas Chain Saw is usedforcommercialorrentalpurposes,thiswarranty

appliesfor 30 daysfromthe dateof purchase.

WARRANTYSERVICE ISAVAILABLE BYRETURNING THIS CHAIN SAWTO

THE NEAREST SEARS SERVICE CENTER IN THE UNITED STATES.

Thiswarrantygivesyouspecificlegal rights,and youmay also haveotherrights

whichvaryfromstatetostate.

Sears, Roebuck and Co., D/817 WA, Hoffman Estates, IL60179

WARNING: Always disconnectspark

plug wirewhenmakingrepairs except

for carburetoradjustments.Becausea

chainsawis a high-speedwoodcutttng

tool,carelessorimproper use ofthis

toolcan causeseriousinjury.

;PLAN AHEAD

• Restrictthe useofyoursawto adult

userswhounderstandand canfollow

thesafetyroles, precautions,andop-

eratinginstructionsfoundinthis

manual.

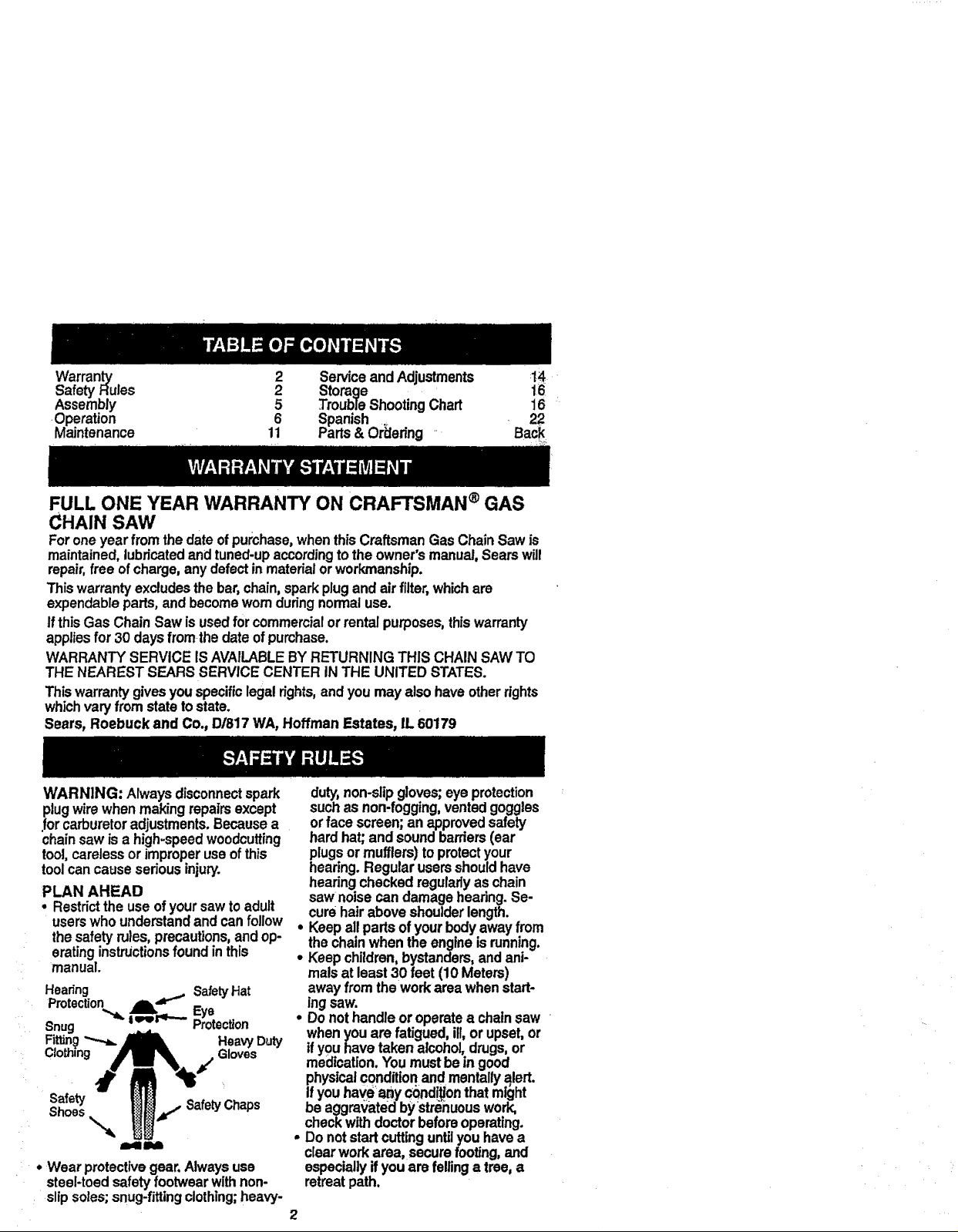

Hearing

.... j SafetyHat

_rotecUon jh. 8-_ _

Snug "_' i'_l_"" _Y_ecfion

Fit',Jng_ / HeavyDuty

__Clothing_ Gloves

J

SafetyChaps

II_llllIB

• Wearprotective gear.Alwaysuse

steel-toedsafetyfootwearwithnon-

slipsoles;snug-fittingclothing;heavy-

duty,non-slipgloves;eyeprotection

suchas non,fogging,ventedgoggles

orface screen;anapprovedsafety

hardhat; and soundbarriers(ear

plugsor mufflers)toprotectyour

hearing.Regularusersshouldhave

hearingcheckedregularlyaschain

saw noisecan damagehearing.Se-

curehairaboveshoulderlength.

• Keepall partsof yourbodyawayfrom

thechainwhen theengineis running.

• Keep children,bystanders,andani-

malsat least 30 feet (10 Meters)

away from theworkarea whenstart-

ingsaw.

• Donothandleor operatea chainsaw =

when youare fatigued,ill,or upset,or

ifyouhave takenalcohol,drugs,or

medication.Youmustbein good

physicalconditionandmentallyalert.

ifyouhave any condi_onthat mi_lht

beaggra,_atedbystr_huouswork,

checkwithdoctorbeforeoperating.

• Donotstartcuttinguntilyouhavea

clearworkarea, securefooting, and

especiallyifyouare felling a tree, a

retreatpath.

OPERATEYOURSAWSAFELY

• Donotoperatewithone:hand.Serf

ousinjurytothe operator,helpers,or

bystandersmay resultfromone-

handedoperation.A chainsaw is in-

tendedfortwo-handeduse.

• Operatethe chin saw onlyina well-

ventilatedoutdoorarea.

• Donotoperatesaw froma ladderor

ina tree, unlessyou are specifically

trainedto doso.

- Makesurethe chainwillnotmake

contactwithany objectwhilestarling

theengine. Nevertryto startthe saw

whentheguidebar is ina cut.

• Donotputpressureonthe saw at the

endofthe cuLApplyingpressurecan

causeyouto losecontrolwhenthe

cutis completed. •

• Stoptheengine beforesettingthe

saw down.

• Handcarrysaw onlywhenengineis

stopped.Carrywithmuffler awayfrom

body;gu!debar & chainprojectingbe-

hindyou,guide barpreferablycov-

ered witha scabbard.

MAINTAIN YOUR SAW IN GOOD

WORKING ORDER

, Haveallchainsaw serviceperformed

bya qualifiedservicedealerexcept

the itemslistedinthe maintenance

sectionofthismanual.

• Makecertainthe saw chainstops

moving whenthe throttletriggerisre-

leased.For con'ection,referto "Car-

buretorAdjustments," ....

• Keepthe handlesdry;clean,andfree

fromoilor fuelmixture,!.: _:

• Keepcapsand fastene_ securely

tightened. : :i:_i_ .:_:.

• UseonlyCraftsmana_C_=ssonesand

replacementpartsas Y_'ommended.

Nevermodifyyour sa_ :

HANDLE FUE_W_,CAUTION

• Do not smokewhile haritllingfuelor

whileoperatingthesaw; .

- Eliminateall sources ofsparksor

flame inthe areas wherefuel is mixed " Recognizethat kickbackcanhappen,

or poured. - " • back,youcan reducetheelementof

• Mix andpourfuel inan outdoorarea surpdsewhichcontributestoacci-

and usean approved,markedcon- dents.

tainerforall fuel purposss.Wipeup • Neverlet the movingchaincontact

allfuel spillsbeforastartingsaw. ° any objectat thetipof theguidebar.

• Moveat least10feet (3 meters)from Keepthe wo_ing areafree from ob-

fuelingsitebefore starting, structionsSUChas othertrees,

• Turntheengineoffand letsawcoolin branches,rocks,fences, stumps,etc.

a non-combustlbiearea, notondry Eliminateor avoidany obstruction

leaves,straw,paper,etc.Slowlyre-

movefuelcap at_drefuelunit.

* Storethe unitandfuel inacool,dry

wellventilatedspacewherefuelva-

porscannotreachsparksoropen

flamesfromwater heaters,electdc

motors orswitches,furnaces,etc.

GUARD AGAINST KICKBACK

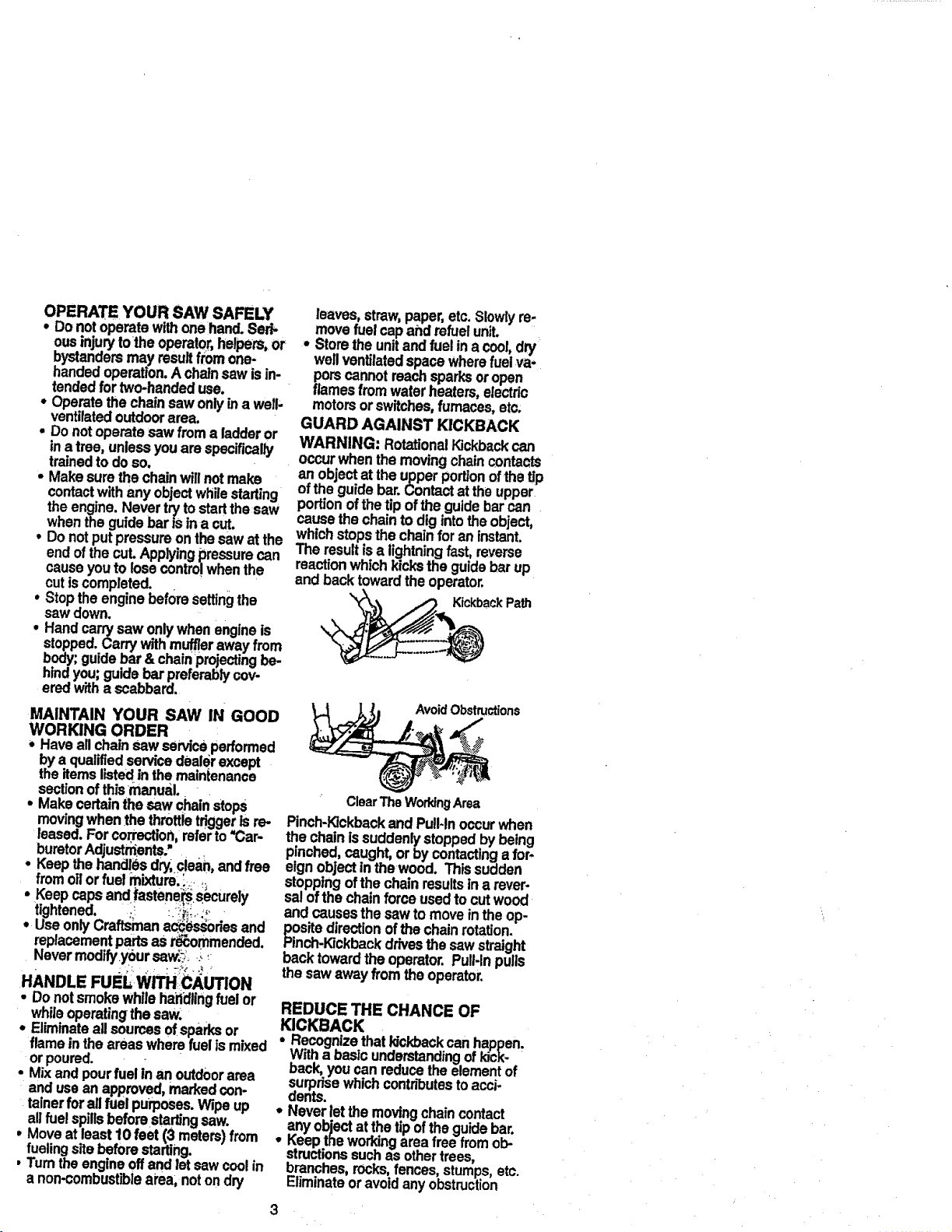

WARNING: RotationalKickbackcan

occurwhenthe movingchaincontacts

an objectat the upperportionofthe tip

ofthe guidebar.Contactat the upper

portionofthe tip ofthe guidebarcan

causethe chainto digintotheobject,

whichstops the chainfor an instant.

The resultisa lightningfast, reverse

reactionwhichkickstheguidebar up

and backtowardtheoperator.

"_ KickbackPath

AvoidObstructions

ClearTheWorkingArea

Pinch-Kickbackand Pull*Inoccurwhen

the chain issuddenlystoppedbybeing

pinched,caught,or bycontactinga for-

eignobject in thewood. Thissudden

stoppingofthe chainresultsin a rever-

salof thechain force usedtocut wood

and causesthe sawtomove inthe op-

ositedirectionofthe chainrotation.

indn-Kickbackdrivesthe sawstraight

backtowardthe operator. Pull-In pulls

the sawaway from the operator.

REDUCETHE CHANCE OF

KICKBACK

Witha basicunderstandingofkick-.

3

: thatyoursawchaincould hitwhile underthefront handlebar.Keep your

cutting. . . leftarm straightwiththeelbowloh.,ked.

• Keepsaw chainsharpano propeny • PosPJonyourlefthandon thefront

tensioned. A looseor dullchaincan handlebarsoit isIn a straightlinewith

increasethe chanceofkickback.Fot- YOUrrighthand on therearhandle

lowmanufacturer's chainsharpening whenmakingbuckingcuts.Stand

and maintenanceinstructions.Check slightlyto the lelt sideofthe sawto

tensionat regularintervals,butnever keep _our =.bodyfrom beingin a direct

withenginerunning. Makesurethe linewithth_ cuffing:chain.

bar clampnutsare securelytight- • Standwtth yourweightevenlybai-

ened. ancea on both feet.

• Beginand continuecuttingat full • Do notoverreach.Youcould be

speed. Ifthe chainismovingata _ drawnorthrownoffbalance and lose

slowerspeed, there is=greaterchance control;

of kickbackoccurring. °Do not cutaboveshoulderheight. It

° Use extremecautionwhenre-enter- isdifficultto maintaincontrolofsaw

inga cut.

• Do notattemptcutsstartingwiththe

tip ofthe bar(plungecuts).

• Watchfor shiftinglogsor otherforces

thatcouldclosea cutand pinchorfall

intochain.

• Use thespecifiedReduced-Kickback

GuideBar andLow-KickbackChain.

Avoid Pinch-Kickback:

• Be extremelyaware ofsituationsor

obstructionsthatcancausematerial

to pinchthe topof orotherwisestop

the chain.

• Do notcut morethan one log at a

time.

° Do nottwistthe sawasthe bar aswith-

drawnfrom an undercutwhenbuck-

in.

A,_n_€lPull-In:

• Alwaysbegin cuttingwiththeengine

at ful/speed and thesawhousing

againstwood.

• Usewedgesmadeof plasticorwood.

Never usemetal to holdthe cutopen.

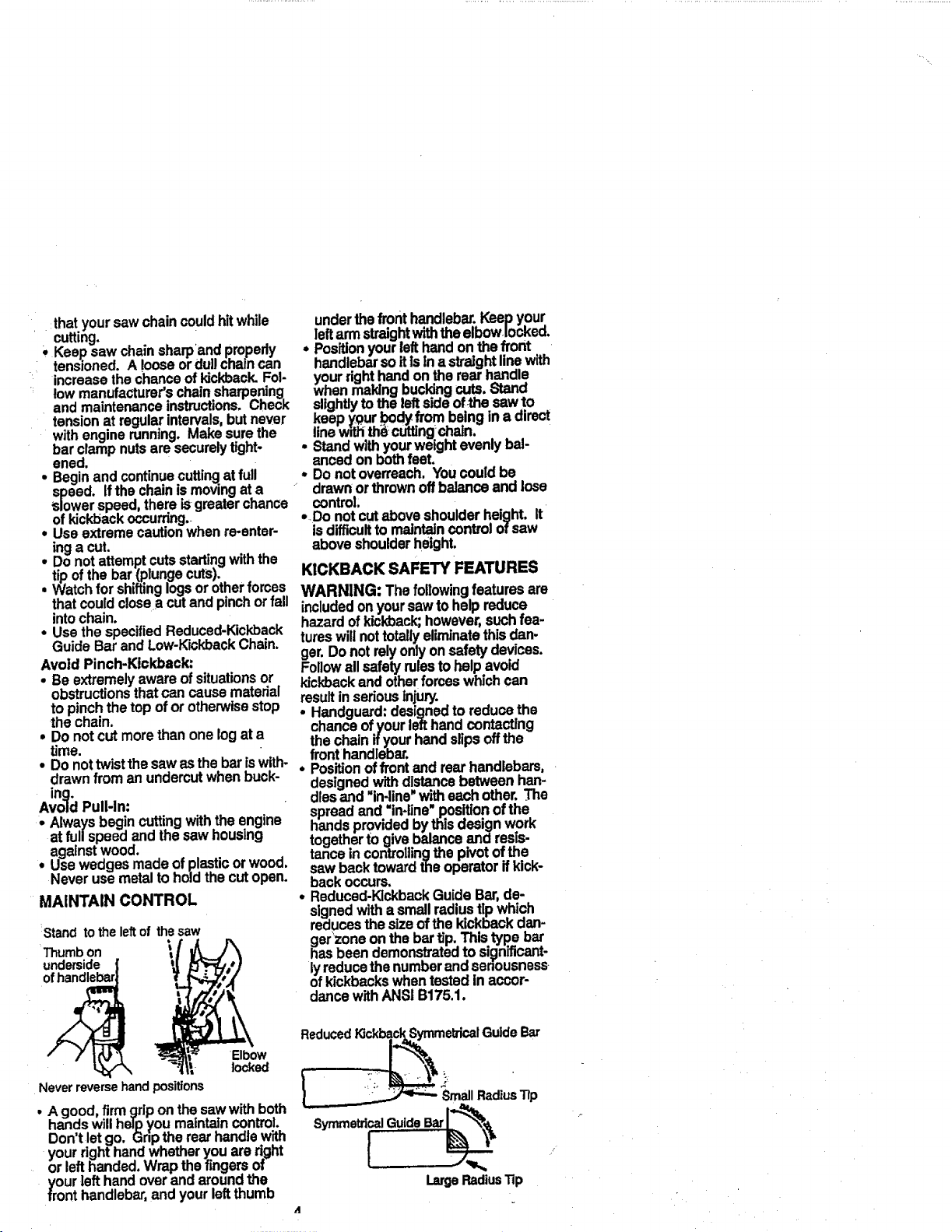

MAINTAIN CONTROL

aboveshoulderheight.

KICKBACK SAFETY FEATURES

WARNING: The following featuresare

includedonyoursaw to helpreduce

hazardofkickback; however,suchfea-

tureswillnottotallyeliminatethisdan-

ger.Do notrelyonlyonsafety devices.

Followallsafetyrulesto help avoid

kickbackand otherforces whichcan

resultinseriousinju_.

• Handguard:designedto reducethe

chanceofyour lefthand contacting

the chain _your handslipsoffthe

fronthandlebar.

• Positionoffront and rear handlebars,

designedwithdistancebetween han-

diesand "in-line"witheach other.The

spreadand "in-line• position of the

handsprovidedby this designwork

togetherto givebalanceand resis-

tancein controllingthepivot ofthe

sawbacktowardthe operatorifkick-

backoccurs.

• Reduced-KickbackGuide Bar,de-

signed witha small radiustip which

Stand to the left of the saw

Thumbon

reducesthe sizeofthe kickbackdan-

get'zone on the bartip. Thistype bar

hasbeen demonstratedto si_]nificant-

lyreducethe numberandsenousness

ofkickbackswhentested inaccor-

dance withANSI B175.1.

k

4

=Elbow

locked

Never reversehand posiUons

• A good, firmgriponthe sawwithboth

handswill heapyou maintaincontrol.

Don'tlet go. Gnpthe rearhandlewith

yourrighthand whetheryou are dght

or lefthanded.Wrapthe fingersof

your left hand overand aroundthe

front handlebar,and yourleftthumb

Reduced_3ckba,c_metrica! GuideBar

tk_

SymmetrlcallGuide___Ik

LargeRadiusTip

J

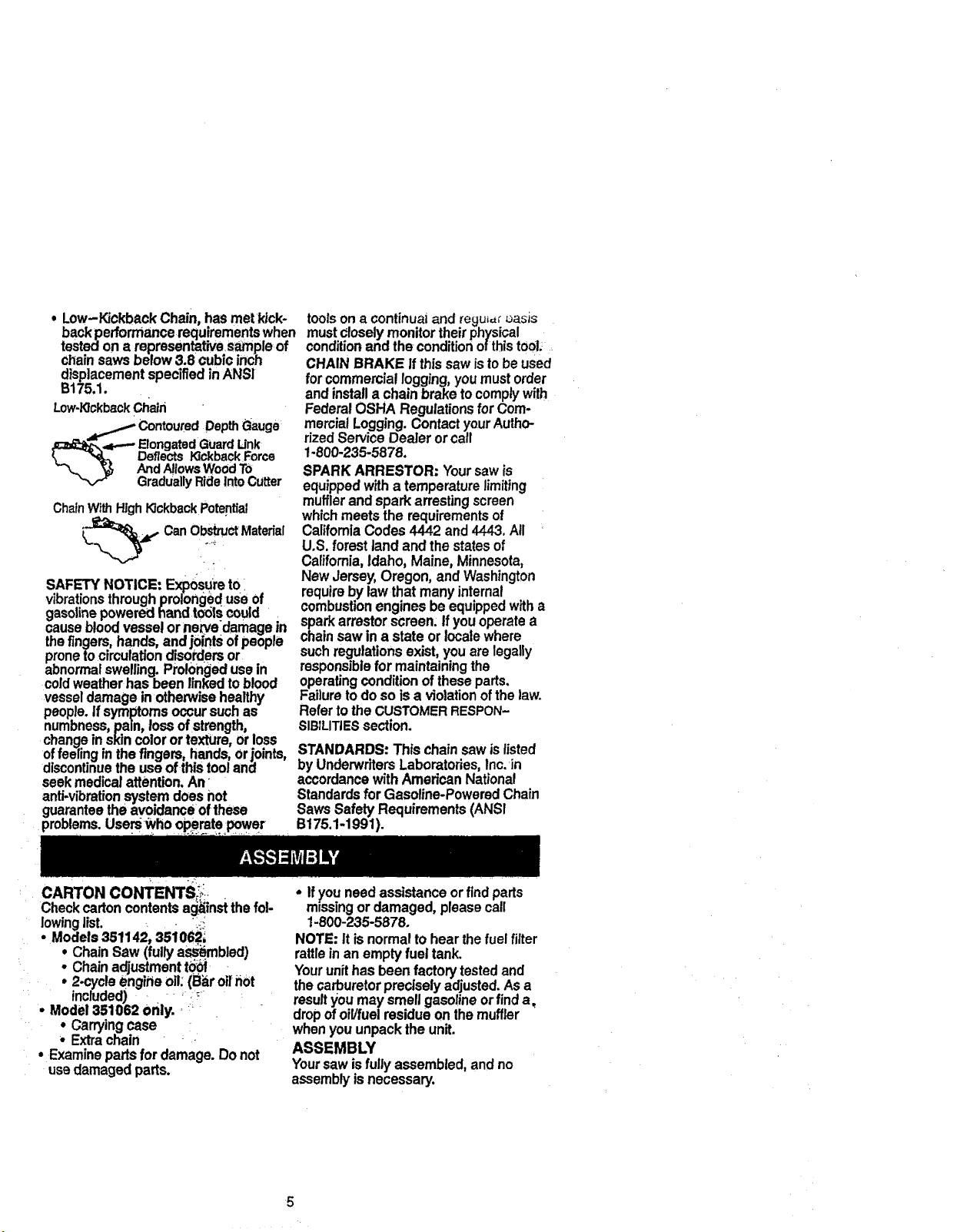

• Low-Kickback Chain, hasmet kick-

backperformancerequirementswhen

testedon a representatives_ple of

chainsawsbelow 3.8cubic inch

displacementspecifiedinANSI

B175.1.

Low-KickbackChaJri

_.I" Co.to redDop a go:

,€=_.,=---. ElongatedGUardLink

-_ DeflectsKickbackForce

_ AndA/towsWoodTo

GradUallyRideIntoCutter

ChainWithHighKickbackPoten_al

CanObstructMaterial

SAFETYNOTICE: Exposureto:

vibrationsthroughprolongeduse of

gasolinepoweredhand,t_IS could

causebloodvesselor newedamage in

thefingers,hands,andj0intsofpeople

pronetocirculationdisordersor

abnormalswelling.Prolongedusein

coldweatherhas been linkedtoblood

vesseldamagein otherwisehealthy

people,if symptomsoccursuchas

numbness,pa_n,lossof strength,

changeinskincolorortexture,or loss

offeeling inthefingers,hands,or|oints,

discontinuethe use ofthistooland

seekmedicalattention.An

anti-vibrationsystemdoesno.t

guaranteetheavoidanceofthese

toolsona continualand _egut=;_asJs

mustcloselymonitortheirPhySical

conditionandthe conditionofthistool;

CHAIN BRAKE If thissaw isto be used

for commerciallogging, youmustorder

and installa chainbraketocomplywith

FederalOSHA Regulationsfor Com-

mercialLogging.ContactyourAutho-

rizedService Dealeror call

1-800-235-5878.

SPARKARRESTOR: Yoursawis

equippedwitha temperaturelimiting

mufflerandsparkarrestingscreen

whichmeetsthe requirementsof

CalifomiaCodes 4442 and4443. All

U.S. forest landand the statesof

California,Idaho,Maine, Minnesota,

NewJersey,Oregon, and Washington

requireby lawthat manyinternal

combustionenginesbe equippedwitha

sparkarrestorscreen; Ifyouoperatea

chainsaw ina state or localewhere

suchregulationsexist,youare legally

responsiblefor maintainingthe

operatingconditionofthesepads.

Failuretodo sois a violationofthelaw.

Refertothe CUSTOMERRESPON-

SIBILITIESsection.

STANDARDS: This chainsawis listed

byUnderwritersLaboratories,lnc.in

accordancewithAmerican National

Standardsfor Gasoline-PoweredChain

SawsSafety Requirements(ANSI

B175.1-1991),

: CARTON coNTENTSI_..

Checkcartoncontentsag_iinstthefol-

lowinglist. _i

• Models 351142, 351062;

• ChainSaw (fullya_mbled)

: • Chainadjustmentt_-

• 2-cycleengirteo11.(B_r oiln0t

included) : :

• Model 351062 only. _

° Carryingcase

• Extrachain

• Examinepartsfor damage. Do not

usedamagedparts.

• If youneedassistanceorfindpads

missingor damaged,pleasecall

t-800-235-5878.

NOTE: It is normalto hearthe fuel filter

rattleinanempty fuel tank.

Yourunithas been factory testedand

thecarburetor preciselyadjusted.Asa

resultyoumay smellgasolineorfinda.

dropofoil/fuelresidueon the muffler

whenyouunpackthe unit.

ASSEMBLY

Yoursawis fully assembled,and no

assemblyisnecessary.

5

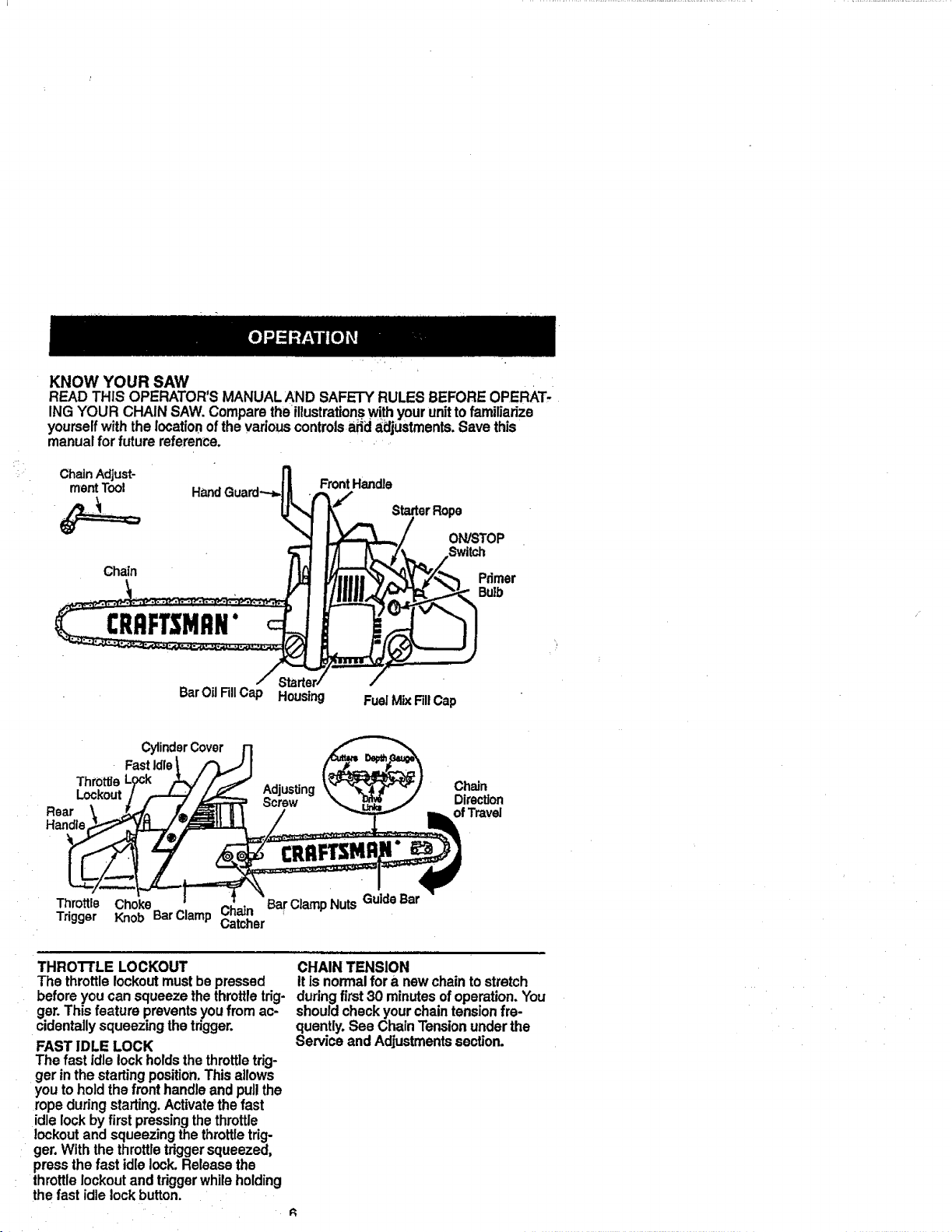

KNOWYOURSAW

READTHISOPERATOR'SMANUALAND SAFETY RULES BEFORE OPERAT-

ING YOUR CHAIN SAW.Comparethe illustrationswithyour unittofamiliarize

yourselfwith thelocation of thevariouscontrolsa_da_justments.Savethis

manualforfuture reference.

ChainAdjust-

ment Toot

Chain

Hand

FrontHandle

Starter Rope

ON/STOP

Switch

Pdmer

Bulb

CRRFTSHRN'

BarOil FillCap Housing FuelMix RII Cap

CylinderCovern

Throt_eL k

_ . /j/ t/_ Screw _ _ J ulrecuon

Throttle Choke. _. Chain BarClampNuts u eBar

Tdgger Knob uaru_ampCatcher

Fastidle\ I

L-z Ff ,0Joo,o,t WP P"°

G id [!

THRO'I-I'LELOCKOUT CHAIN TENSION

The throttlelockout mustbepressed It isnormalfor a newchaintostretch

beforeyou can squeezethe throttletrig- duringfirst30 minutesofoperation.You

get. Thisfeature preventsyoufrom ac- shouldcheckyourchaintensionfre-

cidentallysqueezingthetrigger, quently.See ChainTensionunderthe

FASTIDLE LOCK Service and Adjustmentssection.

The fast idle lockholdsthethrottle trig-

ger inthestartingposition.Thisallows

youtoholdthe front handleandpullthe

ropeduringstarting.Activatethefast

idlelockby firstpressingthethrottle

lockoutandsqueezingthe throttletrig-

ger.With thethrottletdggersqueezed,

pressthefast idlelock.Releasethe

throttlelockoutandtriggerwhileholding

the fast idlelockbutton.

R

BEFORE STARTING ENGINE

WARNING: Be suretoread the fuel

handlinginformationinthe safetyrules

sectionofthismanualbefore youbegin.

ifyoudonotunderstandthe fuelham

dlinginformationdonot attempttofuel

yourunit.Seekhelp fromsomeonethat

doesunderstandthe informationorcall

thecustomerassistance helplineat

1-800-235-5878.

GUIDE BAR AND CHAIN OIL

The chainoiler'providescontinuouslu-

bricationto thechain and guidebar.Be

suretofigthe baroiltank when youfill

thefuel tank(Capacity= 6:8 ft. oz.)

Formaximum guidebar and chainlife,

we recommendyou use Craftsman

chainsaw baroil.If Craftsmanbar oilis

notavailable, youmay use ago0d

gradeSAE 30 oiluntilyouareable to

obtainCraftsmanbrand.Theo!! output

isautomatically meteredduring opera-

tion.YoursawwiUuseapproximately

one tankof bar oilfor everytankof fuel

mix. Alwaysfillthebar oil tankwhen

youfillthe fueltank.

FUELING ENGINE

Thisengineis certifiedto operateon

unleadedgasoline.Beforeoperation,

gasolinemustbe mixedwitha good

quality 2-cycleair-cooled engineoil.We

recommendCraftsmanbrandoil.Mix

gasoline andoi!at a ratioof40:1 (A

40:1 ratioisobtainedby mixing3.2

ouncesofoilwith1 gallon ofunleaded

gasoline).DONOTUSEautomotiveoil

orboatoil.These oilswtl_cause engine

damage.Whenmixingfuel follow the

instructionsprintedonthe container.

Onceoilisadded tothe gasoline,

shakecontainermomentarilytoassure

thatthefuel isthoroughlymixed.

Always readand followthe safety rules

relatingtofuel beforefueling yourunit.

IMPORTANT

Experience indicatesthatalcohol

blendedfuels(calledgasoholor using

ethanolormethanol)can attractmois-

turewhichleadsto separationand

formationofacidsduringstorage;Acid-

icgascan damagethe fuel systemof

anenginewhilein storage.

Toavoidengineproblems,the fuelsys-

tem shouldbe emptiedbefore storage

for30 daysor longer.Drainthegas

tank,startthe engineand letit rununtil

the fuel linesand carburetorare empty_

Use freshfuel nextseason. See STOR,

AGEinstructionsfor additionalinforma,

tion.•

Nevez'use engineorcarburetorcleaner

productsinthe fueltank orpermanent

damagemay occur.

See the STORAGEsectionfor additional

information.

STOPPING YOUR ENGINE

• Move On/Stopswitchto theSTOP

position.

• Ifenginedoesnotstop,pullchoke

knoboutfully.

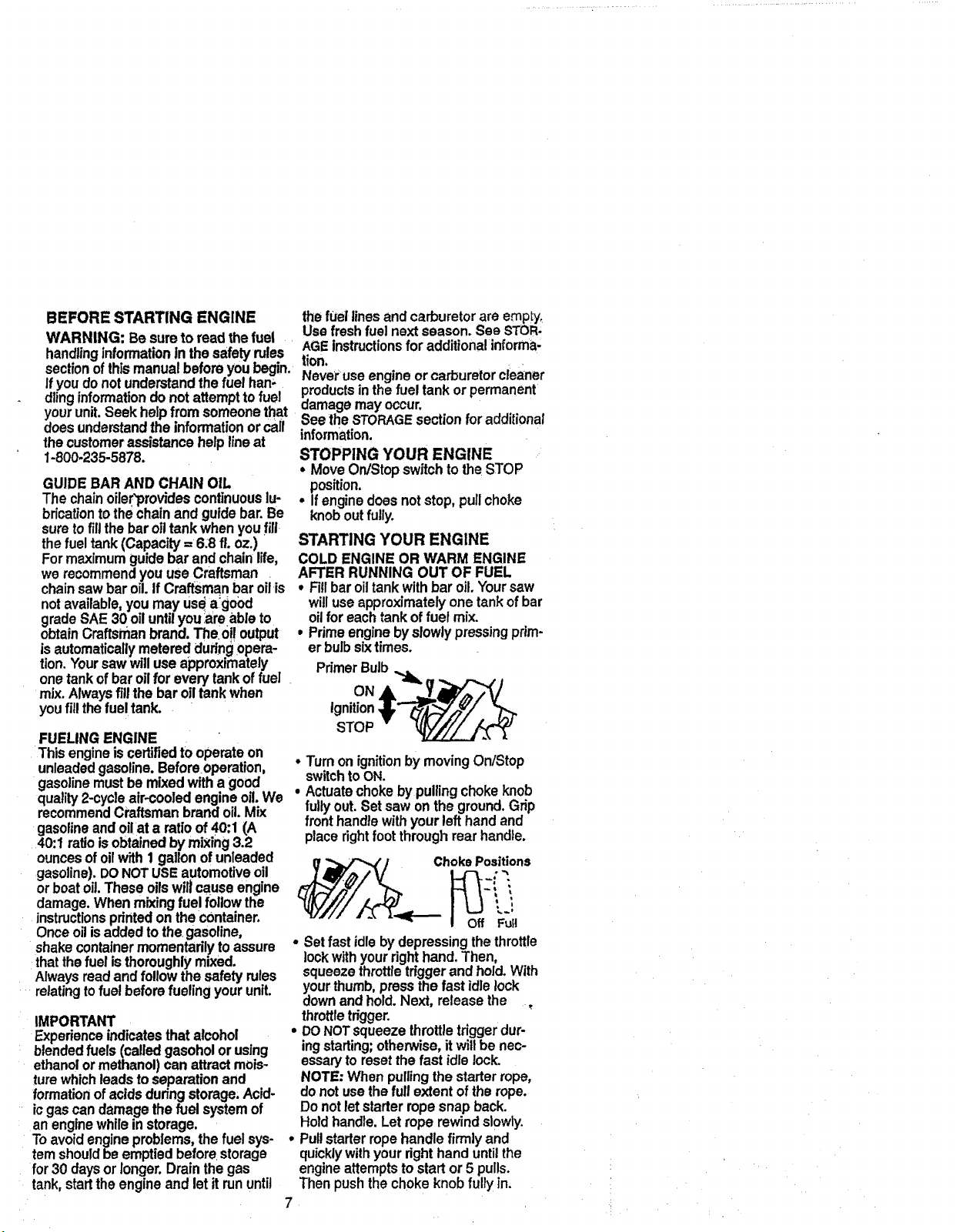

STARTING YOUR ENGINE

COLD ENGINE OR WARM ENGINE

AFTER RUNNING OUT OF FUEL

• Fillbar oiltankwithbar oil.Yoursaw

willuse approximately one tank of bar

oilfor each tank of fuel mix.

• Primeenginebyslowlypressingprim-

erbulb sixtimes.

Primer Bulb

Ignition _"_._//" V_

STOP--

Turnon ignitionby moving On/Stop

switchtoON.

Actuatechokeby pulling chokeknob

fullyout.Set saw ontheground.Grip

front handlewithyourlefthandand

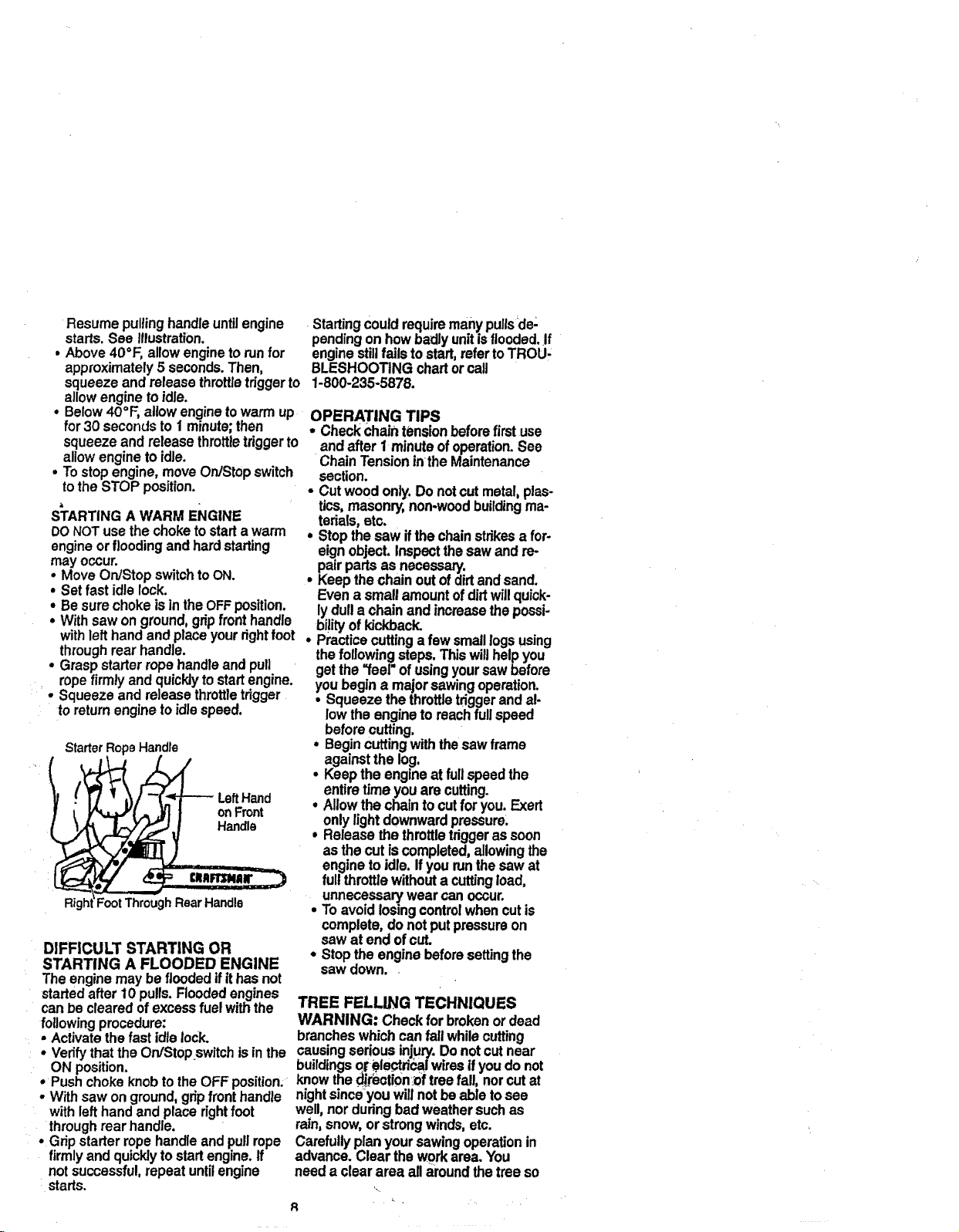

placerightfoot throughrear handle.

. ChokePositions

Full

• Setfast idle by depressing the throttle

lockwith your right hand. Then,

squeezethrottletrigger and hold.With

your thumb, press thefast idle lock

down and hold. Next, release the .

throttle trigger.

• DONOTsqueezethrottle triggerdur-

ing starting;otherwise, it willbe nec-

essaryto resetthe fast idlelock.

NOTE: Whenpullingthe starterrope,

donotusethe full extent ofthe rope.

Donotlet starterrope snapback.

Holdhandle.Let rope rewindslowly.

• Pullstarterropehandlefirmly and

quicklywithyour righthanduntilthe

engineattempts to startor 5 pulls.

Thenpush thechokeknobfully in.

Resume pullinghandleuntilengine

starts.See Illustration.

• Above40°F, allowengineto runfor

approximately5 seconds.Then,

squeezeand release throttletdggerto

Startingcouldrequiremanypullsde-

pendingon how badlyunitis flooded.If

enginestillfalls to start,refertoTROU-

BLESHOOTING chartorcall

1-800-235-5878.

allowengineto idle.

• Below40°F, allowenginetowarm up

for 30 secondsto 1 minute;then

squeezeand releasethrottletriggerto

allow engineto idle.

• Tostopengine,moveOn/Stopswitch

to the STOP position.

STARTING A WARM ENGINE

DONOTuse the choketo starta warm

engineorfloodingandhardstarting

may occur.

° Move On/Stopswitchto ON.

• Set fast idlelock.

Withsaw onground,gripfront handle

withlefthandand placeyourrightfoot •

i Besurechoke is intheOFFposition.

throughrearhandle.

Graspstarterropehandleandpull

ropefirmly andquickly tostartengine.

/

• Squeezeandreleasethrottletrigger

toretum engineto idlespeed.

OPERATING TIPS

• Checkchain tensionbeforefirstuse

andafter 1 minute of operation.See

ChainTensioninthe Maintenance

section.

• Cutwood only.Donotcutmetal,plas-

tics,masonry, non-woodbuildingma-

terials,etc.

• Stopthe saw ifthe chainstrikesa for-

eignobject. Inspectthe sawand re-

pairpartsas necessary.

• Keep thechain outofdirtandsand.

Evena smallamountofdirtwillquick-

lydulla chain and increasethepossi-

bilityofkickback.

Practicecuttingafew smalllogsusing

thefollowing steps.Thiswillhelpyou

getthe =feel"ofusingyoursawbefore

youbegina major sawingoperation.

Squeezethe throttletriggerandal-

low theengineto reachfull speed

beforecutting.

• Begincuttingwiththe sawframe

againstthe log.

• Keepthe engineat fullspeedthe

LeftHand

on Front

Handle

entiretime youare cutting.

• Allowthe chainto cut for you.Exert

onlylightdownwardpressure.

° Release the throttletdggeras soon

as thecut iscompleted,allowingthe

EIIRFt3_H"

Rig FootThroughRearHandle

engineto idle. Ifyou runthe saw at

full throttlewithouta cuttingload,

unnecessarywearcan occur.

• Toavoid losingcontrolwhencutis

complete,donotputpressureon

DIFFICULT STARTING OR

STARTING A FLOODED ENGINE

Theenginemay befloodedifithasnot

startedafter10 pulls.Floodedengines

canbe clearedof excessfuelwiththe

following procedure:

° Activatethe fast idle lock.

sawat end ofcut.

• Stopthe enginebeforesetting the

saw down.

TREE FELLING TECHNIQUES

WARNING: Checkfor brokenordead

brancheswhichcan fallwhilecutting

• Verifythatthe On/Stopswitchisinthe causingseriousinjury.Donot cutnear

ONposition. " buildingsqlr_lectri_ wiresif youdo not

, Push choke knobtothe OFF position, knowthedireotionoftree fall, norcutat

• Withsaw onground,gripfront handle nightsinceyou willnotbe able tosee

withlefthand and place right foot

throughrear handle.

• Gripstarterropehandleand pullrope

firmly and quicklyto startengine.If

notsuccessful,repeatuntilengine

well,nor duringbadweathersuchas

rain,snow,orstrongwinds,etc.

Carefullyplanyoursawingoperationin

advance.Clear theworkarea.You

needa clear area all aroundthe treeso

starts.

;v •

youcanhave securefooting. Studythe

naturalconditionsthatcancause the

treeto fall ina particulardirection,such

conditionsinclude: "

: Thewinddirectionandspeed.

The leanofthe tree. The lean ofa

treemightnot be apparentdueto un-

evenorslopingterrain.Usea plumb

or leveltodetermine the directionof

treelean.

Weightand br_nches0none side.

: Surroundingtreesandobstacles.

Lookfor decayand rot. Ifthetrunkis

rotted,itcanStiap and fall towardthe

operator. .'- • ,,,, ,_

Make suretllere is enough room for the

treeto fall. Maintaina distanceof2,112

treelengthsfrom the near_stpersonor

otherobjects.Engineno!s_=can drown

outa wamingcatl. _.,_

Removedirt,stones,loose bark,nails,

staples,andwirefromthe treewhere

cutsare to be made.

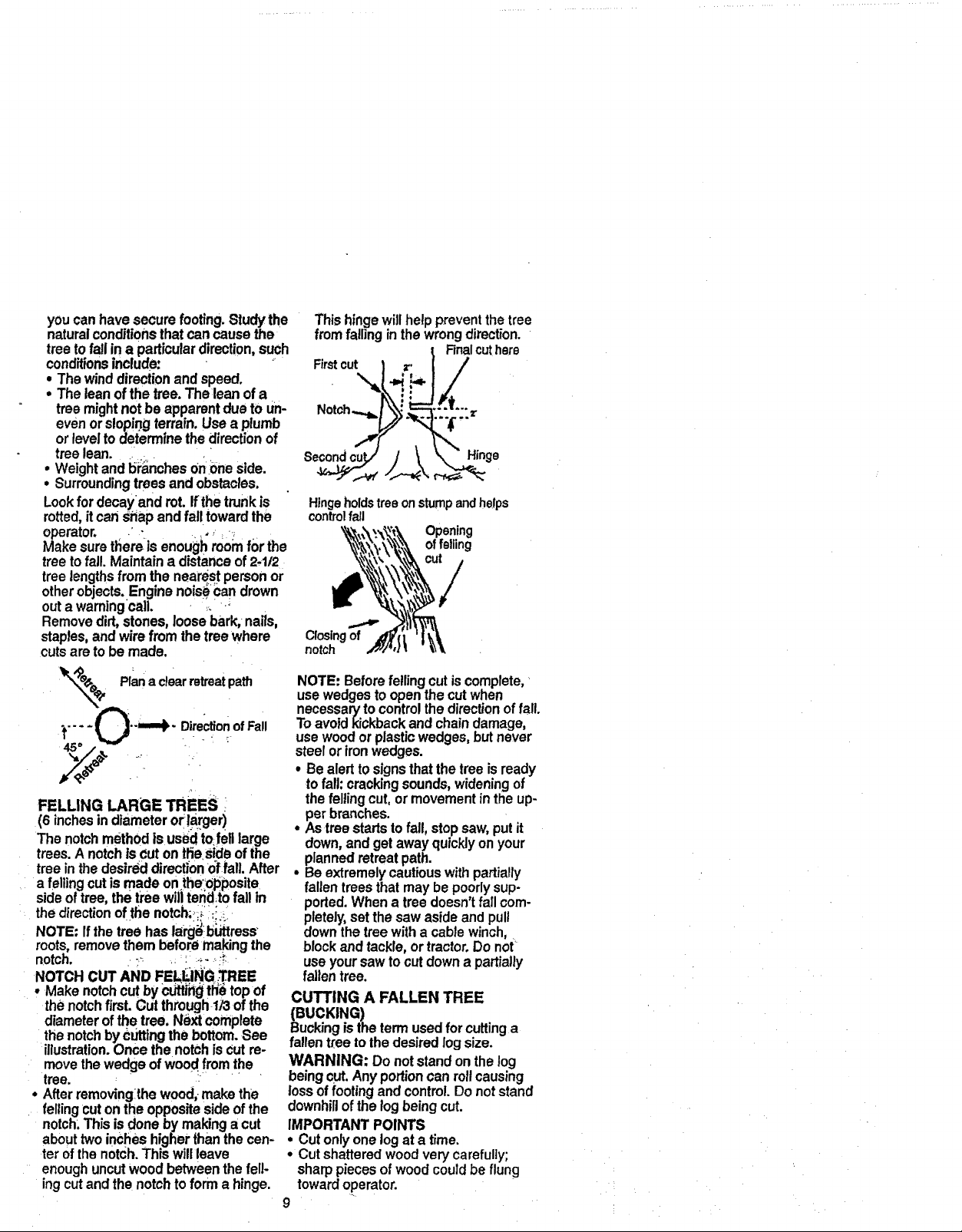

Thishingewill helpprevent the tree

fromfalling in thewrongdirection.

Firstcut

Notch...H_

Hingeholdstreeonstumpand helps

controlfall

Closingof

notch

Finalcuthere

Opening

of felling

_X_ Pl:ana clearretreatpath

,....O

FELLING LARGE TREES

(6 inchesindiameterorllarger)

The notchmethodis usedto,fell large

trees.A notchtsCUtontPieSideof the

tree inthe desireddirectionof fall.After

a fellingcut ismade ontheopposite

sideoftree,the treewillter_dtofallin

thedirection of the notch;:ii!:i_;i

NOTE: Ifthe treehaslarg_b_ress"

roots,removethembeforemaking the

notch. : :,_ ,_:: ......:_ -

NOTCH CUT AND FEL_ING_TREE

• Make notchcutbycuttirlgth_ topof

the notchfirst.Cut through1/3of the

diameterofthetree. Next complete

thenotchbycuffingthe bottom.See

illustration.Once the notchis cutre-

movethe wedge ofwoodfromthe

tree.

* Afterremovingthewood,make the

fellingcutontheoppositesideofthe

notch.Thisis doneby making a cut

abouttwoincheshigherthanthecen-

ter of thenotch.This Willleave

enoughuncutwoodbetweenthe fell-

ingcut andthenotchtoforma hinge.

NOTE: Beforefelling cut iscomplete,

use wedgesto openthe cutwhen

necessarytocontrolthedirectionoffall.

Toavoidkickbackandchaindamage,

usewoodor plasticwedges,butnever

steelorironwedges.

* Be alerttosignsthatthe treeisready

to fall: crackingsounds,wideningof

the felling cut,ormovementin theup-

perbranches.

• Astreestartstofall, stopsaw,putit

down,and get awayquickly onyour

plannedretreatpath.

• Be extremelycautiouswithpartially

fallen treesthatmay be poorlysup-

ported.Whena treedoesn'tfallcom-

pletely,setthesaw asideand pull

downthe treewitha cable winch,

blockand tackle,ortractor.Do not

useyour sawto cutdowna partially

fallen tree.

CUTTING A FALLEN TREE

{BUCKING)

Bucking is the termusedforcuttinga

fallentree tothe desiredlogsize.

WARNING: Do notstandonthe log

beingcut.Anyportioncan roll causing

toss of footing and control. Donot stand

downhill of thelog being out.

IMPORTANT POINTS

• Cutonly one log at a time.

• Cut shattered wood very carefully;

sharppieces of wood could be flung

toward operator.

9

• Usea sawhorseto cutsmall10gs.

Never allowanotherpersonto hold

thelogwhilecuttingandneverhold

thelogwithyourleg Orfoot.

° Do notcut in an area wherelogs,

limbs,and rootsare tangled.Drag the

logsintoa cleararea beforecutting

them.

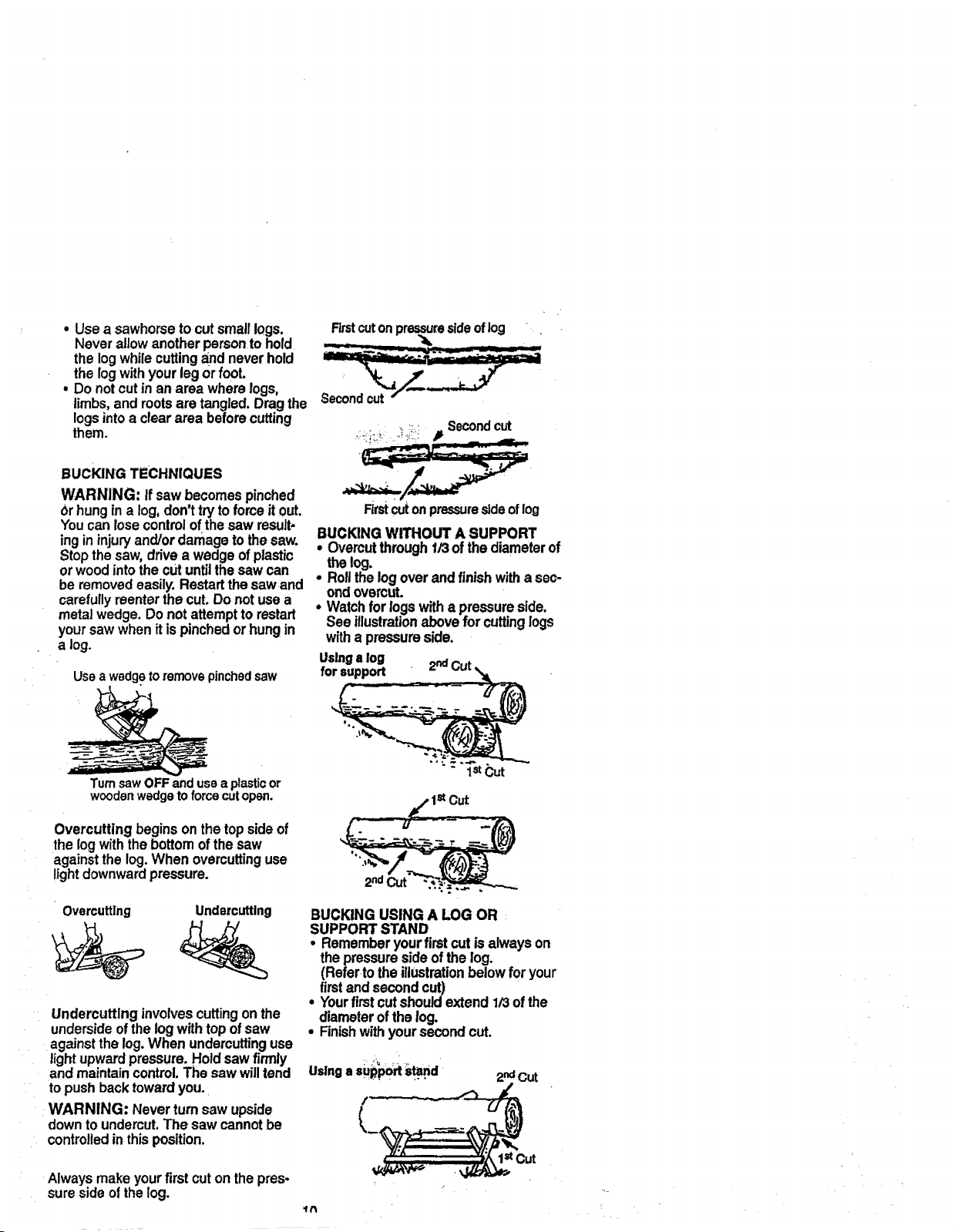

BUCKING TECHNIQUES

WARNING: Ifsawbecomespinched

Orhungina log,don'ttryto force itOut.

Youcan losecontrolofthe saw result-

ingin injuryand/ordamageto thesaw.

Stopthesaw, drivea wedgeof plastic

orwoodintothecut untilthesawcan

be removedeasily.Restartthe saw and

carefullyreenterthe cut. Do notusea

metalwedge. Do notattemptto restart

yoursawwhenit ispinchedorhungin

a log.

Usea wedgpto remove pinchedsaw

Rrstcutonpreeeeeeeee_su[esideoflog

Secondcut

Firstcut onpressuresideoflog

BUCKING WITHOUT A SUPPORT

• Overcutthrough1/3ofthe diameterof

thelog.

• Rollthelogoverand finishwitha sec-

ondovercut.

, Watchforlogswitha pressureside.

See illustration aboveforcuttinglogs

witha pressureside.

Usinga log

forsupport 2ndCut,

Turn sawOFF and use a plasticor

woodenwedgeto forcecutopen.

Overcutting beginson the topsideof

the logwiththebottomofthe saw

againstthe log.Whenovercuttinguse

lightdownwardpressure.

Overcuttlng Undercutting

Undercutting involvescuttingon the

underside ofthe logwithtop ofsaw

againstthe log.Whenundercuttinguse

lightupwardpressure.Holdsawfirmly

and maintaincontrol.The sawwilltend

topush backtowardyou.

WARNING: Neverturnsaw upside

downto undercut.The sawcannotbe

controlledinthisposition.

Alwaysmakeyourfirstcut onthe pres-

sure sideofthe log.

2rid

BUCKING USING A LOG OR

SUPPORTSTAND

• Rememberyourfirstcut isalwayson

thepressuresideof the log.

(Referto theillustrationbelow foryour

firstandsecondcut)

• Yourfirstcutshouldextend1/3of the

diameterofthelog,

• Finishwithyoursecondcut.

usl.g• 2=cut

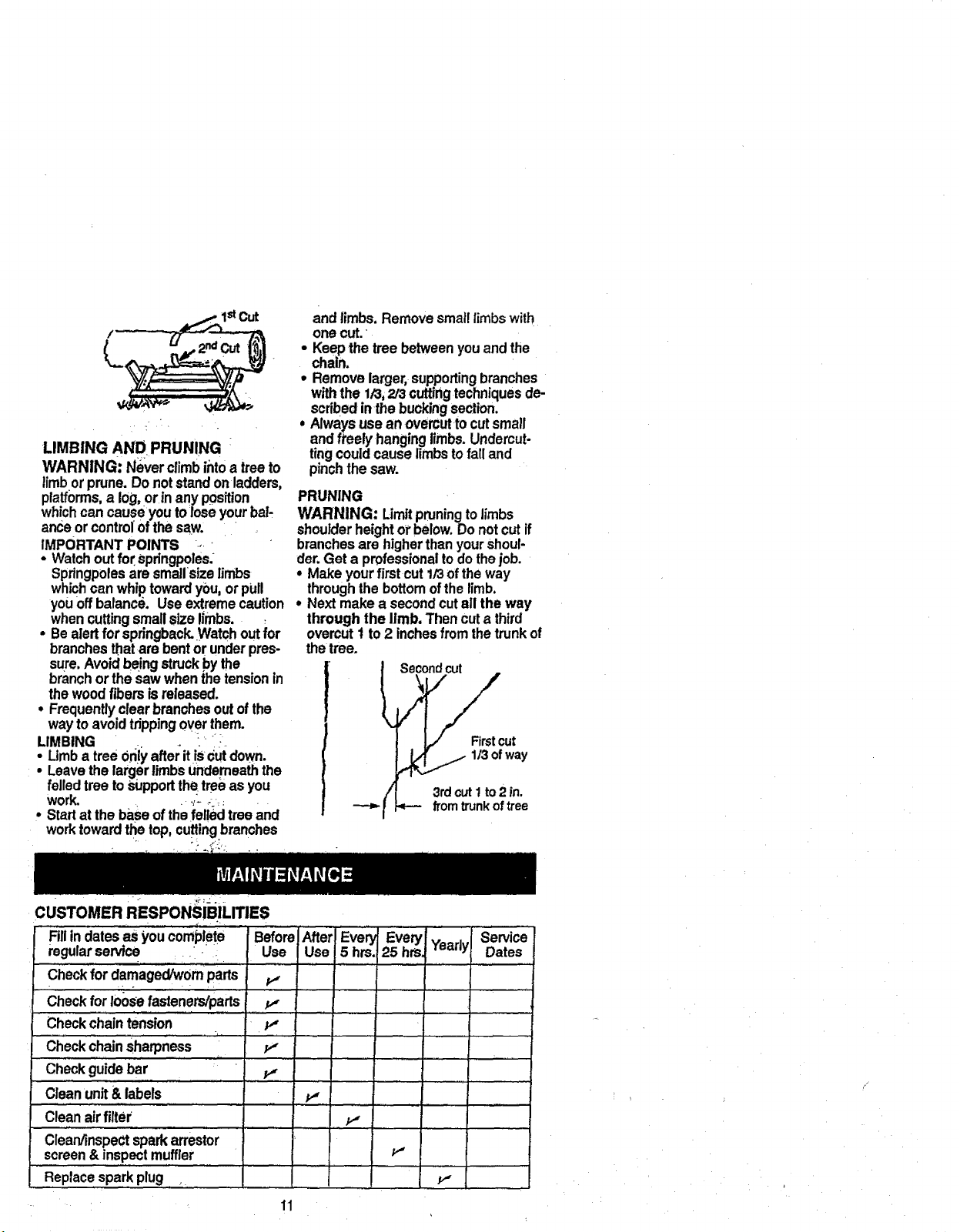

LIMBING AND PRUNING

WARNING: Neverclimbinto a treeto

limborprune. Do notstandonladders,

platforms,a log,orin any position

whichcan causeyoutolose yourbal-

anceor controlofthe saw.

IMPORTANT POINTS

* Watchout for Spdngpoles:

Springpolesare smallsize limbs

whichcanwhiptowardyou,orpull

youOffbalance. Use extremecaution

whencuttingsmallsize limbs. :

. Bealertfor springback.Watch outfor

branches_at are bentor underpres-

sure.AvoidbeingstruckbYthe

branchor thesaw whenthe tensionin

thewoodfibersis released.

, Frequentlyclearbranchesoutof the

waytoavoid trippingoverthem.

LIMBING •

• Limba tree0fillyafter'it iSdutdown.

• Leavethelargerlimbsunderneaththe

felled tree to Supportthe treeas you

work. _- __:

° start at the base ofthefelled tree and

worktowardthe top,cuttingbranches

and limbs. Removesmalllimbs with

one cut.

• Keepthe tree betweenyouandthe

chain.

• Removelarger,supportingbranches

withthe 1/3,2/3 cuttingtechniquesde-

scribedinthe buckingsection.

, Alwaysuseanovercutto cutsmall

andfreelyd hangingl_mbs.Undercut-

tingcoul cause lim s tofalland

pinchthe saw.

PRUNING

WARNING: Limitpruningtolimbs

shoulderheighto_"below.Do notcutif

branchesare higherthanyourshoul-

der.Get a professionalto do thejob.

° Make yourfirstcut1/3oftheway

throughthebottomofthe limb,

° Next make a secondcutall the way

through the limb. Thencuta third

overcutt to2 inchesfrom thetrunkof

thetree.

ut

/3ofway

i/1 3rdcut1to2 in.

I _ fromtrunkoftree

CUSTOMER RESPONSIBILfflES

.,

Fillindatesas youcomplete

regularservice

• . ...... _ , - ii

Checkfor damaged/w0mparts

Checkfor loosefasteners/pads

Checkchaintension

Checkchainsharpness

Checkguidebar

Cleanunit & labels

Cleanairfilter

Clean/inspeCtsparkarrestor

screen& inspectmuffler

Replacesparkplug _...... !

Before After Every

Use Use 5hrs.

Ii

/!

i!

p,,

p*

/i

Every Yeady Service

25 hrs, Dates

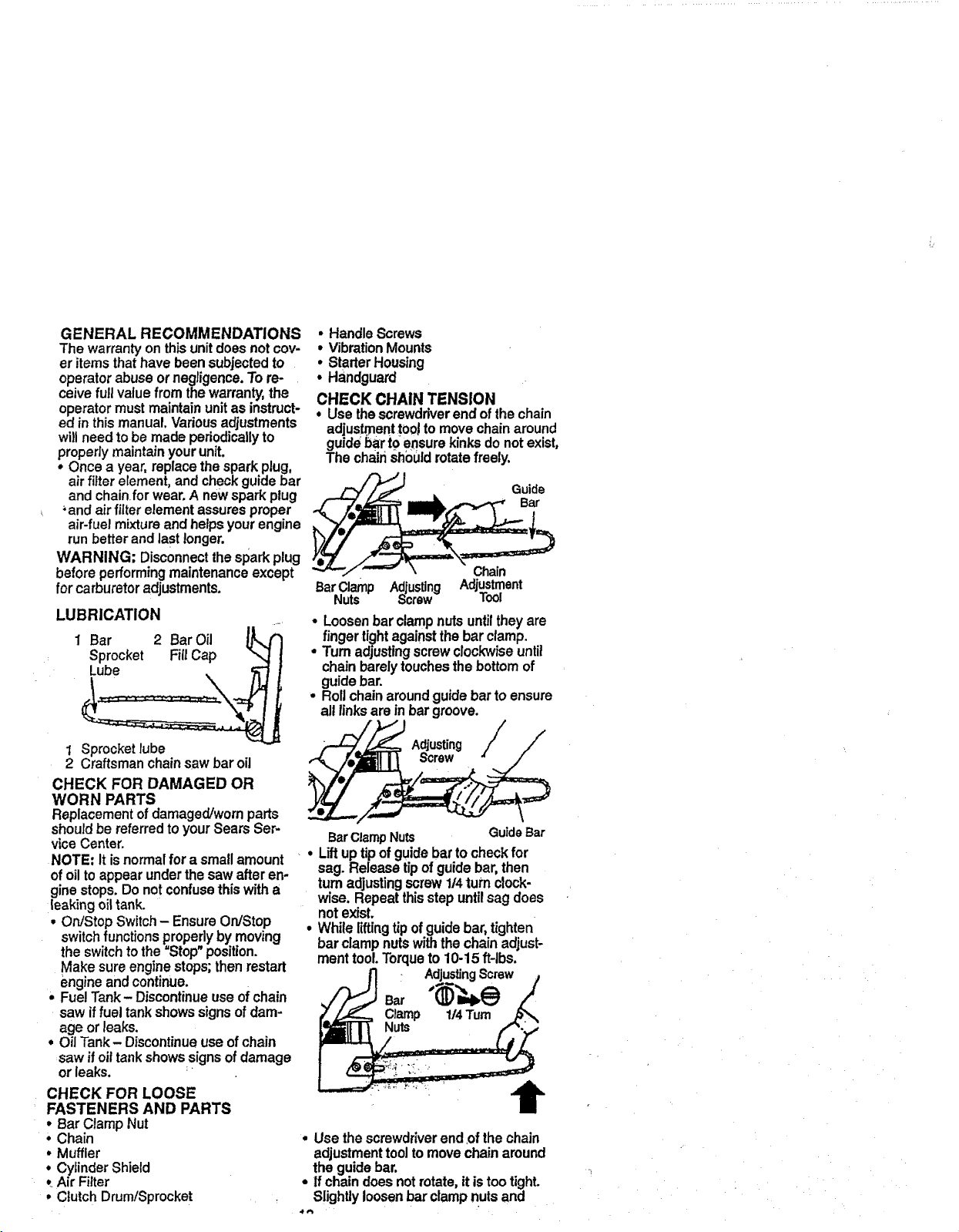

GENERALRECOMMENDATIONS

Thewarrantyonthisunitdoesnotcov-

er itemsthathave beensubjectedto

operatorabuse or negligence.Tore-

ceivefull valuefrom the warranty,the

operatormustmaintainunitas instruct-

edin thismanual,Variousadjustments

willneedto be madeperiodicallyto

propedy maintain your uniL

• Once a year,replacethesparkplug,

airfilter element,andcheckguidebar

and chainforwear.A new sparkplug

_andair filter elementassuresproper

air-fuelmixture andhelpsyourengine

runbetterandlast longer.

WARNING: Disconnectthesparkplug

beforeperformingmaintenanceexcept

for carburetoradjustments.

LUBRICATION

1 Bar 2 Bar Oil

Sprocket FillCap _ I

Lube _ !

.=.

• Rollchainaround guidebar toensure

• Handle Screws

• VibrationMounts

• StarterHousing

• Handguard

CHECK CHAIN TENSION

• Use thescrewdriverend of thechain

adjustmenttooJto movechainaround

guidebar toensurekinksdonotexist,

The chainshouldrotatefreely.

Guide

Bar

Chain

BarClamp Adjusting Adjustment

Nuts _crsw Tool

• Loosenbarclampnutsuntil theyare

fingertightagainstthebarclamp.

• Turn adjustingscrewclockwiseuntil

chainbarelytouchesthebottom of

guidebar.

all linksare in bargroove.

I Sprocket lube

2 Craftsmanchain saw bar oil

CHECK FOR DAMAGED OR

WORN PARTS

Replacementofdamaged/wornparts

shouldbe referredtoyourSears Ser-

viceCenter.

NOTE: It is normalfor a smallamount

ofoil toappear underthe saw after en-

ginestops.Donotconfusethiswitha

leaking oiltank.

• On/Stop Switch- EnsureOn/Stop

switch functions properly by moving

theswitch to the Stop" position.

Make sure engine stops; thenrestart

engine andcontinue.

• Fue!Tank- Discontinueuse ofchain

saw iffuel tankshowssignsofdam-

age orleaks.

• OilTank- Discontinueuse ofchain

saw if oil tankshowssignsof damage

orleaks. _

CHECK FOR LOOSE

FASTENERS AND PARTS

• Bar Clamp Nut

• Chain

• Muffler

• Cylinder Shield

Air Filter

• Clutch Drum/Sprocket

f-_-_"_j_,,f.._.,_ A_USreling /

BarClampNuts GuideBar

• Lift up tip of guide bar to checkfor

sag. Releasetip of guidebar, then

turn adjustingscrew1/4turn clock-

wise. Repeat this step until sag does

not exist.

• While lifting tip of guide bar, tighten

bar clampnuts withthe chain adjust-

ment tool. Torqueto 10-15ft-lbs.

AdjustingScrew

Clamp tt4 Turn

Nuts

• Use thescrewdriverendof thechain

adjustmenttoolto movechainaround

theguidebar.

• if chaindoesnotrotate,itis tootighL

Slightlyloosenbarclampnutsand

.._#'t

turnadjusting=screw1/4turncounter-

• If chainis tooloose,itwillsagbelow

theguidebar. DONOT operatethe

clockwise.Ret,ghtenbarc,ampnuts. _ _L_ _1_._ Fi'U

saw ifthe chainis loose.

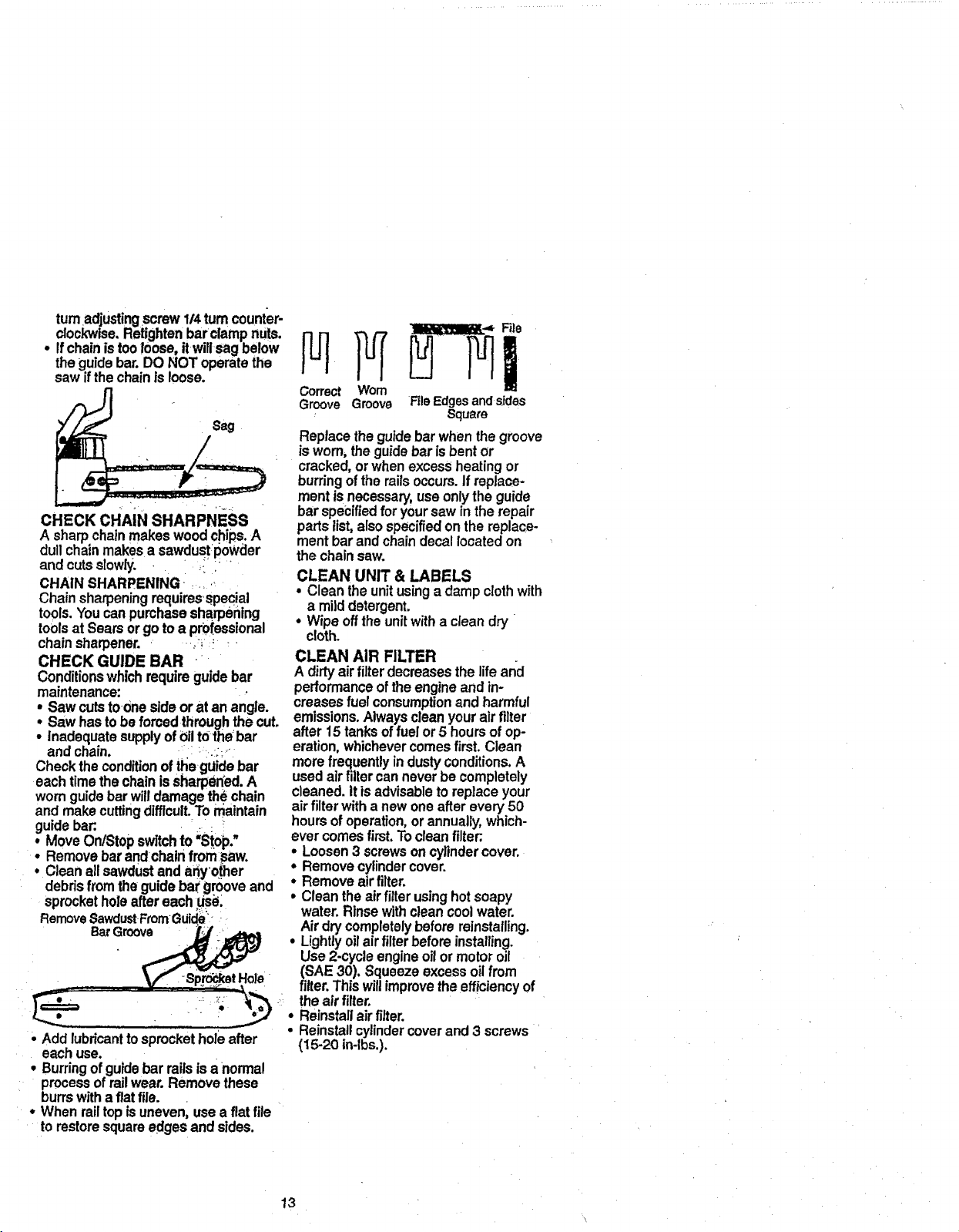

Correct Worn

Groove Groove FileEdgesandsides

, Square

Replacethe guidebar whenthe groove

isworn,the guidebar isbentor

cracked,orwhenexcessheatingor

burringoftherailsoccurs.Ifreplace-

mentis necessary,use only the guide

CHECK CHAIN SHARPNESS

A sharpchainmakeswoodchips.A

dullchainmakesa sawdustPoWder

and cutsslowly. _:

CHAIN SHARPENING. :,_._

Chainsharpeningrequires,special

tools.Youcanpurchasesharpening

toolsat Sears orgo toa professional

chainsharpener. :; :

CHECK GUIDE BAR

Conditionswhichrequireguidebar

maintenance:

• Saw cutstoone sideorat an angle.

• Saw hastobe forced throughthe cut.

• Inadequatesupplyof_il t0 thebar

and chain. : '=,

= , . .....

Checktheconditionof thegUidebar

eachtimethechainissharpen_ed.A

wornguidebarwilldamagethechain

and makecuttingdifficult.Tornaintain

guide bar:. ::

Move On/Stopswitchto"StoP."

Removebar and:chainfrom_aw.

• Cleanallsawdustandady o!her

debrisfrom theguidebar grooveand

sprocketholeaftereachUse:

RemoveSawdustFromGuic[e"_

bar spei;ifiedfor your saw inthe repair

partslist,alsospecified on thereplace-

mentbarand chaindecallocatedon

thechainsaw.

CLEAN UNIT & LABELS

• Cleantheunitusingadampclothwith

a milddetergent.

• Wipe offtheunitwitha clean dry

cloth.

CLEAN AIR FILTER

A dirtyair tilterdecreasesthe lifeand

performanceofthe engineand in-

creasesfuel consumptionand harmful

emissions.Alwayscleanyour airfilter

after15 tanksoffuel or5 hoursofop-

eration,whichevercomesfirst. Clean

morefrequently industyconditions.A

usedair tiltercanneverbe completely

cleaned.Itis advisableto replaceyour

air filter witha newoneafter every50

hoursofoperation,or annually,which-

ever comesfirst.Tocleanfilter:.

• Loosen3 screwsoncylindercover.

• Removecylindercover.

• Removeairfilter.

• Cleantheair filterusinghotsoapy

water.Rinsewithclean coolwater.

Airdrycompletelybeforereinstalling.

• Lightlyoilairfilterbeforeinstalling.

Use2-cycleengineoilor motoroil

sp etHole

(SAE 30). Squeezeexcessoilfrom

filter.This willimprovethe efficiencyof

the airfilter.

• Reinstallairfilter.

• Add lubricanttosprocketholeafter

eachuse.

• Reinstallcylindercoverand3 screws

(15-20 in-lbs.).

• Burringofguidebar railsisa normal

processofrailwear.Removethese

burrswitha fiatfile.

• When railtopis uneven,usea fiat file

torestoresquareedgesand sides.

13

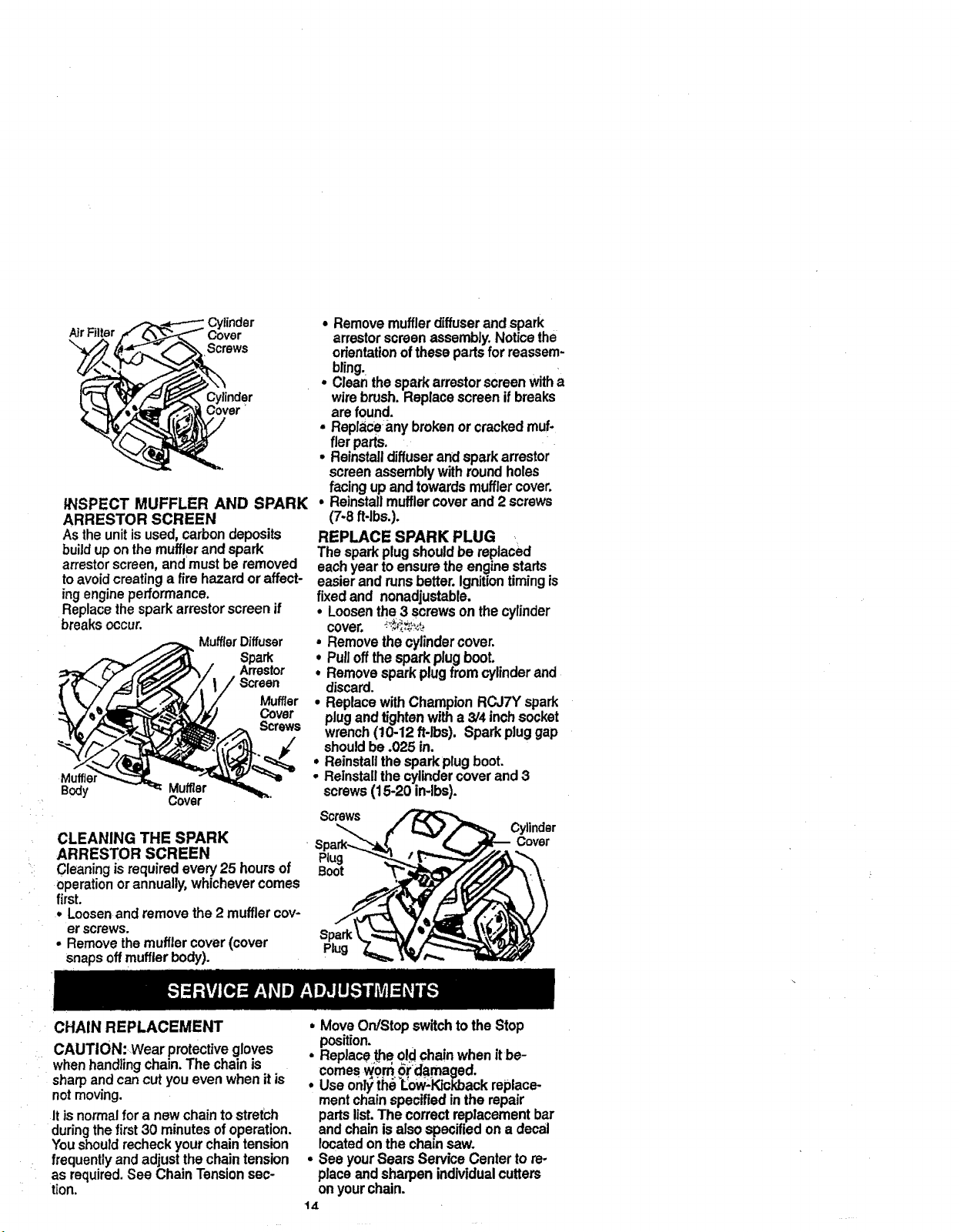

Cylinder

Cover

Screws

Cylinder

Cover

INSPECT MUFFLER AND SPARK

ARRESTOR SCREEN

Asthe unitis used, carbondeposits

build uponthe mufflerand spark

arrestor screen,and mustbe removed

toavoid creatinga firehazardor affect-

ingengine performance.

Replacethe spark arrestor screen if

breaks occur.

,__,,.,__/Mu filerDiffuser

Spark

Arrestor

P_="-,Y I],(_/_'f Y / Screen

1___,/_ Cover

Body _"=_ Muffler ''_.

Cover

CLEANING THE SPARK

ARRESTOR SCREEN

Cleaningis requiredevery25 hours of

operationorannually,whichevercomes

first.

• Loosenand removethe 2 mufflercov-

erscrews.

• Removethemufflercover(cover

snapsoffmufflerbody).

, Removemufflerdiffuserandspark

arrestorscreenassembly.Noticethe

orientationofthese partsforreassem-

bling.

• Cleanthesparkarrestorscreenwitha

wirebrush.Replacescreenif breaks

arefound.

, Replaceany brokenorcrackedmuf-

flerparts.

. Reinstalldiffuserandsparkarrestor

screenassemblywithroundholes

facingupand towardsmufflercover.

• Reinstallmufflercoverand 2 screws

(7-8 ff-lbs.).

REPLACE SPARK PLUG .

The sparkplugshouldbe replaced

eachyear toensuretheenginestarts

easierand runs better.Ignitiontimingis

fixedand nonadjustable.

, Loosenthe3 screwsonthe cylinder

cover. _,_ _

• Removethe cylindercover.

Pulloffthesparkplugboot.

Removesparkplugfrom cylinderand

discard.

• ReplacewithChampionRCJ7Y spark

plugandtightenwitha 3/4inchsocket

wrench(10-12 ff-tbs), Sparkpluggap

shouldbe .025 in.

• Reinstallthesparkplugboot.

° Reinstallthe cylindercoverand 3

screws(t5-20 in-lbs).

Screws

Cylinder

Cover

Plug

Boot

Spark

Plug

CHAIN REPLACEMENT

CAUTION:Wear protective gloves

when handling chain. The chain is

sharp and can cut you even when it is

notmoving,

It is normal for a new chain to stret_;h

during the first 30 minutes of operation.

You should recheck your chain tension

frequently and adjust the chain tension

as required. See Chain Tension sec-

tion.

• Move On!Stopswitchto theStop

position.

ReplaceDe old chainwhen itbe-

i comes_qm.er damaged.

UseonlytheI_ow-Kickback replace-

mentchainspecifiedinthe repair

partslist.The corre_ replacementbar

andchainis alsospecifiedona decal

locatedonthe chainsaw.

, See yourSearsServiceCenterto re-

placeand sharpenindividualcutters

onyourchain.

1,1

Loading...

Loading...