Craftsman 358351141, 358351061 Owner’s Manual

IMPORTANT MANUAL Do Not Throw Away

S _A/RS

Operator's

Manual

@

Model No.

358.351141

358.351061

CUSTOMER

ASSISTANCE

1-800-235-5878

Mon,- Sat.7 a.m.- 7 p.m.

Sun. 10 a.m. - 7 p.m.

CRAFTSMAN"

Always Wear Eye Protection

FTSMRN°

2.2 cu. in./36cc 2-CYCLE

14 Inch Guide Bar

16 Inch Guide Bar

GASOLINE CHAIN SAW

_b ARNING:

530-083950-1-07/19/95

READ THE OPERATOR'S

MANUAL AND FOLLOW

ALL WARNINGS AND

SAFETY INSTRUCTIONS.

FAILURE TO DO SO CAN

RESULT IN SERIOUS

INJURY.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

• Assembly

• Operation

• Customer Responsibilities

• Service and Adjustments

• Repair Parts

SAFETY RULES

WARNING:

ALWAYS DISCONNECT SPARK PLUG WIRE AND PLACE WIRE WHERE IT CANNOT CONTACT SPARK

PLUG TO PREVENT ACCIDENTAL STARTING WHEN SETTING UP,TRANSPORTING, ADJUSTING OR

MAKING REPAIRS EXCEPT CARBURETOR ADJUSTMENTS.

BECAUSE A CHAIN SAW IS A HIGH-SPEED WOOD-CUTTING TOOL, SPECIAL SAFETY

PRECAUTIONS MUST BE OBSERVED TO REDUCE THE RISK OF ACCIDENTS. CARELESS OR

IMPROPER USE OF THIS TOOL CAN CAUSE SERIOUS INJURY.

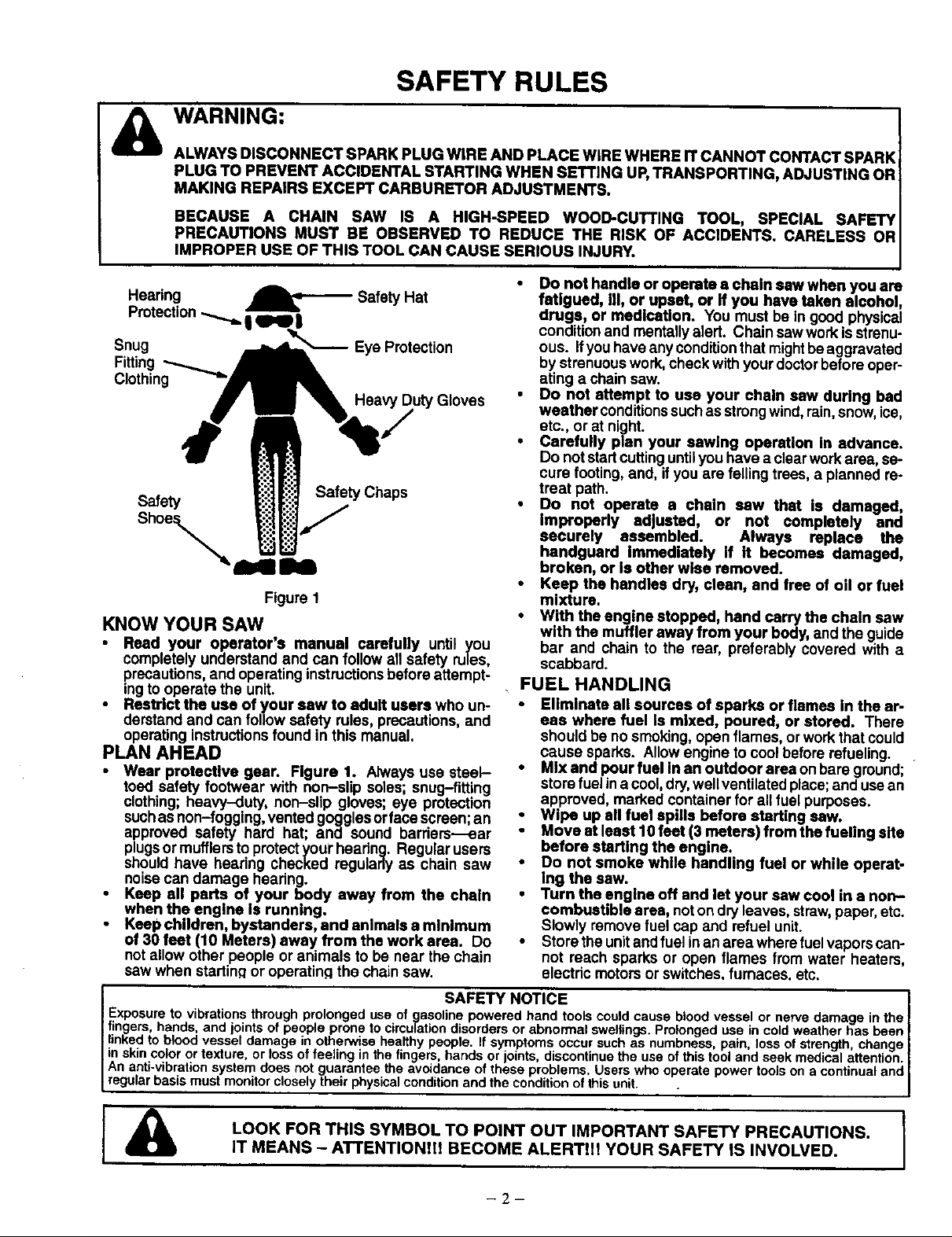

Hearing

Protection

Snug

Fitting

Clothing

Safety Safety Chaps

Shoe_

Figure 1

KNOW YOUR SAW

• Read your operator's manual carefully until you

completely understand and can follow all safety rules,

precautions,and operating instructionsbeforeattempt-

ingto operate the unit.

Restrict the use of your sew to adult users who un-

derstand and can followsafety rules, precautions,and

operating instructionsfound in this manual.

Safety Hat

Eye Protection

Heavy Duty Gloves

PLAN AHEAD

• Wear protective gear. Figure 1. Always use steel-

toed safety footwear with non-slip soles; snug-fitting

clothing; heavy-duty, non-slip gloves; eye protection

suchas non-fogging,vented gogglesorfaca screen;an

approved safety hard hat; and sound barders---ear

plugsor mufflerstoprotect your hearing. Regular users

shouldhave hearing checked regularly as chain saw

noisecan damage hearing.

• Keep all parts of your body away from the chain

when the engine Is running.

Keep children, bystanders, end animals a minimum

of 30 feet (10 Meters) away from the work area. Do

not allow other people or animals to be near the chain

saw when startinq or operatin.qthe chain saw.

SAFETY NOTICE ]

Exposuretovibrationsthroughprolongeduseof gasolinepoweredhandtoolscouldcausebloodvesselornervedamageinthe|

fingers, hands, and joints of people pronetocirculationdisordersor abnorma swe lings. Prolongedusein coldweatherhas been I

linkedto bloodvesseldamage inotherwisehealthy people. If symptoms occursuchas numbness, pa n, ossofstrength, change |

inskincolorortexture or lossoffeelinginthefingershandsor joints,discontnuetheuseofths too andseekmedica attenton I

An anti-vibrationsystemdoesnotguaranteetheavoidanceoftheseprobems. Userswhooperatepowertoolsona continualand|

regularbasismustmonitorcloselytheirphysca conditionandtheconditionof thisunit. . J

• Do not handle or operate a chain saw when you are

fatigued, III, or upset, or If you have taken alcohol,

drugs, or medication. You must be in good physical

conditionand mentallyalert. Chain saw workis strenu-

ous. ifyou have any conditionthatmightbe aggravated

bystrenuouswork, check with your doctorbefore oper-

ating a chainsaw.

• Do not attempt to use your chain saw during bad

weather conditionssuchas strongwind, rain,snow,ice,

etc., or at night.

• Carefully plan your sawing operation in advance.

Do notstartcuttinguntilyou have a clearworkarea, se-

cure footing,and, if you are felling trees, a planned re-

treat path.

• Do not operate a chain saw that is damaged,

improperly adjusted, or not completely and

securely assembled. Always replace the

handguard Immediately If It becomes damaged,

broken, or Is other wise removed.

• Keep the handles dry, clean, and free of oil or fuel

mixture.

• With the engine stopped, hand carry the chain saw

with the muffler away from your body, and the guide

bar and chain to the rear, preferably covered with a

scabbard.

FUEL HANDLING

Eliminate all sources of sparks or flames In the ar-

eas where fuel Is mixed, poured, or stored. There

should be no smoking,open flames, orwork that could

cause sparks. Allow engine to cool before refueling.

• Mix and pour fuel In an outdoor area onbare ground; •

store fuel ina cool,dry,wellventilated place;and use an

approved, marked container for all fuel purposes.

• Wipe up all fuel spills before starting saw.

Move at least 10 feet (3 meters) from the fueling site

before starting the engine,

• Do not smoke while handling fuel or while operat-

Ing the saw.

• Turn the engine off and let your saw cool in a non-

combustible area, noton dryleaves, strew,paper,etc.

Slowly remove fuel cap and refuel unit.

• Store the unitandfuel inan area where fuelvapors can-

not reach sparks or open flames from water heaters,

electric motorsor switches, furnaces, etc.

LOOK FOR THIS SYMBOL TO POINT OUT IMPORTANT SAFETY PRECAUTIONS.

IT MEANS - ATTENTIONII! BECOME ALERTIH YOUR SAFETY IS INVOLVED.

-- '7--

SAFETY RULES

OPERATE YOUR SAW SAFELY

• Do not operate a chain saw with one hand. Serious

injuryto the operator, helpers, bystandersor any combina-

tion ofthese persons may resultfrom one-handed opera-

tion.A chain saw is intended fortwo-handed use.

• Operate the chain saw only in well-ventilated outdoor

areas.

• Do not operate saw from a ladder or in a tree, unless

specificallytrainedto do so.

• Position all parts of your body to the left of cut and

away from the chain when the engine Is running.

• Cut wood only. Do not useyour saw to pry or shove away

limbs, roots,or other objects.

• Make sure the chain will not make contact with any

object while starting the engine. Never try to startthe

saw when the guide bar is in a cut or kerr.

• Use extreme caution when cutting small size brush

and saplings. Slender materialcan catch the chain and

be whippedtoward you or pullyou off balance.

• Be alert for springback when cuttinga limbthat is under

tension so you will not be struckbythe limbor saw when

the tension inthe wood fibers is released.

• Do not put pressure on the saw at the end of a cut.

Applyingpressure can cause you to lose controlwhen the

cut iscompleted.

• Stop the engine before setting the saw down.

• Keep fuel and oil caps, screws, and fasteners securely

tightened.

MAINTAIN YOUR SAW IN GOOD WORKING

ORDER

• Have all chain saw service performed by your Sears

Service Center withtheexceptionofthe itemslistedinthe

"Customer Responsibilities"section of this manual. For

example, if impropertools are used to remove or holdthe

flywheel when servicing the clutch, structuraldamage to

the flywheel can occur and cause the flywheel to burst.

• Make cartaln the chain stops moving when the throttle

trigger is released. For correction, refer to "Carburetor

Adjustments."

• Stop the saw if the chain strikes a foreign object.

Inspectunitand repairor replace parts as necessary.

• Disconnect the spark plug before performing any

malntenanca except for carburetor adjustments

• Never modify your saw in any way. Use only attach-

monts suppliedor specificallyrecommended by the manu-

facturer.

• Use only Sears accessories and replacement parts

as recommended.

TRANSPORTING AND STORAGE

• Stopthe unit beforetransporting.

• Allow engine to cool, cover the guide bar and chain, and

securethe unitbeforestoringor transportingin a vehicle.

• Empty fuel tank before storingor transportingthe unit.Use

up any fuel leftinthe carburetor by startingthe engine and

lettingthe engine run untilitsteps.

• Store unit and fuel in an area where fuel vapors cannot

reach sparks or open flames from water heaters, electric

motors or switches,furnaces, etc.

• Store unit sothe chain cannotaccidentally cause injury.

• Store the unitoutof the reach of children.

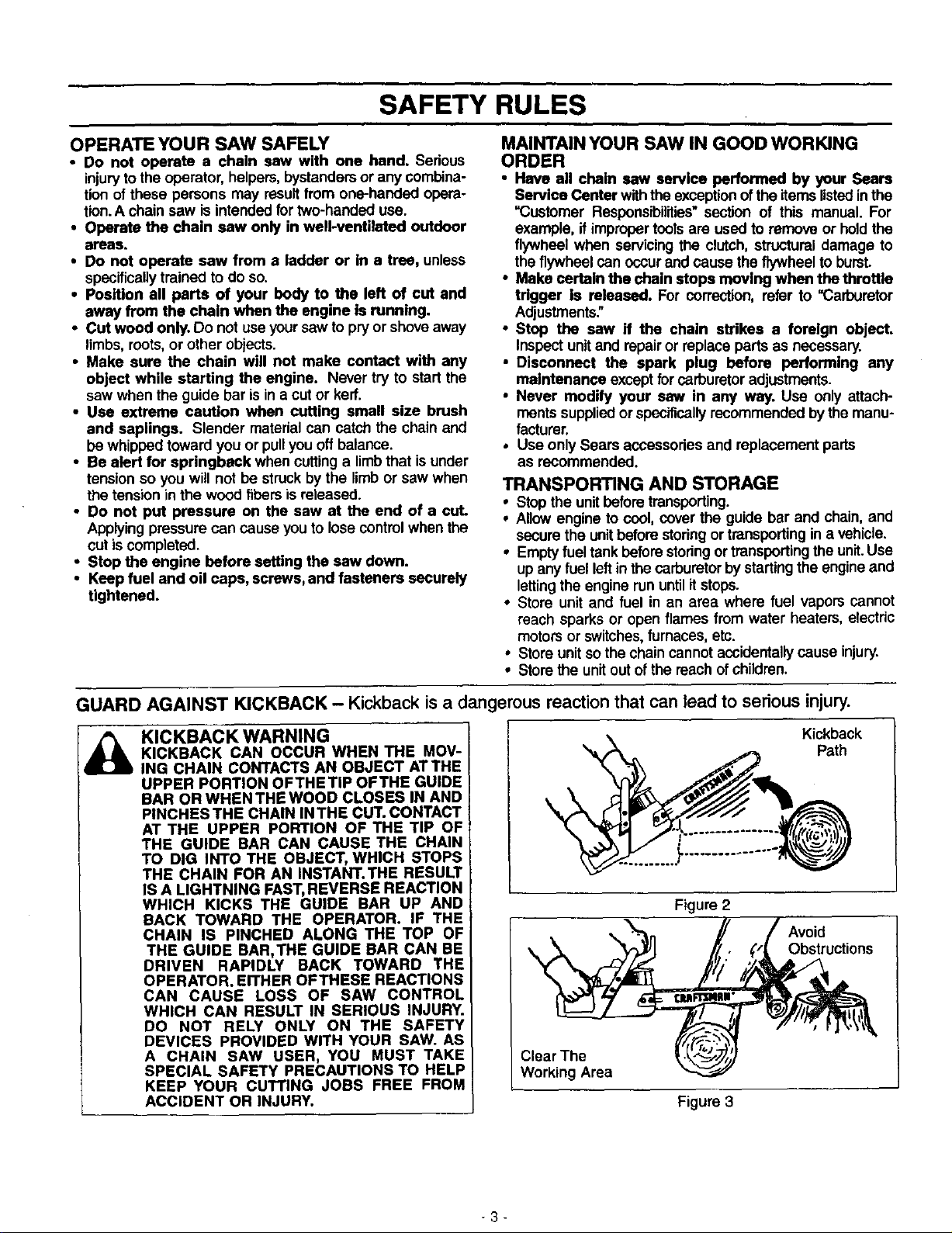

GUARD AGAINST KICKBACK - Kickback is a dangerous reaction that can lead to serious injury.

KICKBACK WARNING

KICKBACK CAN OCCUR WHEN THE MOV-

ING CHAIN CONTACTS AN OBJECT ATTHE

UPPER PORTION OFTHETIP OFTHE GUIDE

BAR OR WHEN THE WOOD CLOSES IN AND

PINCHES THE CHAIN IN THE CUT. CONTACT

AT THE UPPER PORTION OF THE TIP OF

THE GUIDE BAR CAN CAUSE THE CHAIN

TO DIG INTO THE OBJECT, WHICH STOPS

THE CHAIN FOR AN INSTANT.THE RESULT

IS A LIGHTNING FAST,REVERSE REACTION

WHICH KICKS THE GUIDE BAR UP AND

BACK TOWARD THE OPERATOR. IF THE

CHAIN IS PINCHED ALONG THE TOP OF

THE GUIDE BAR,THE GUIDE BAR CAN BE

DRIVEN RAPIDLY BACK TOWARD THE

OPERATOR. EITHER OFTHESE REACTIONS

CAN CAUSE LOSS OF SAW CONTROL

WHICH CAN RESULT IN SERIOUS INJURY.

DO NOT RELY ONLY ON THE SAFETY

DEVICES PROVIDED WITH YOUR SAW. AS

A CHAIN SAW USER, YOU MUST TAKE

SPECIAL SAFETY PRECAUTIONS TO HELP

KEEP YOUR CUTTING JOBS FREE FROM

ACCIDENT OR INJURY.

Figure 2

Clear The

Working Area

Figure 3

Kickback

Path

Obstructions

3

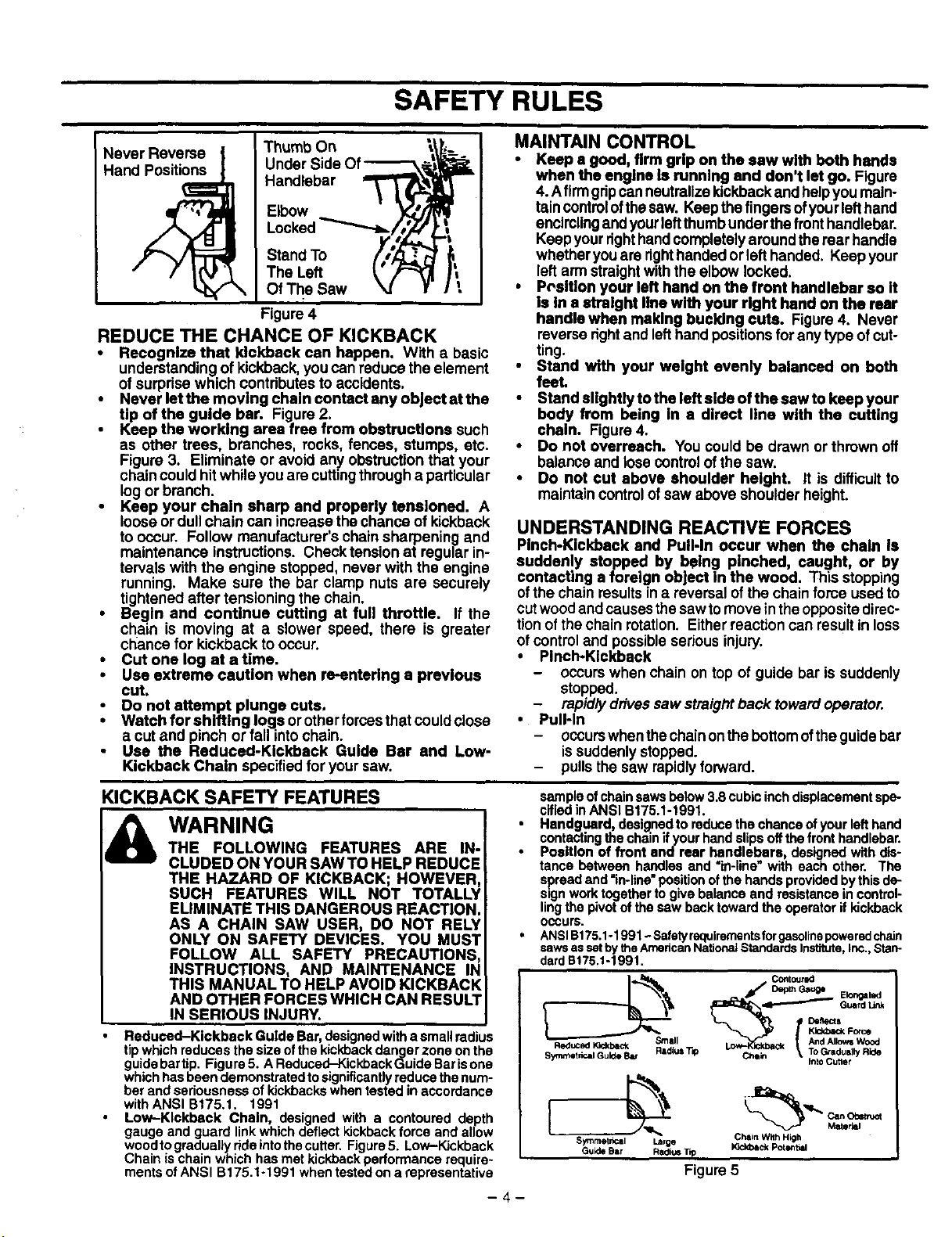

SAFETY RULES

Never Reverse

Thumb On _,\]

Hand Positions

Handlebar _

Elbow _;'/m

Locked

Stand To //_

Under Side Of _,_ "_

TheLe. t'

Of The Saw _ f

Figure 4

REDUCE THE CHANCE OF KICKBACK

• Recognize that kickback can happen. With a basic

understandingof kickback, you can reduce the element

of surpdse which contributesto accidents.

• Never let the moving chain eentact any object at the

tip of the guide bar. Figure2.

Keep the working area free from obstructions such

as other trees, branohes, rooks, fences, stumps, etc.

Figure 3. Eliminate or avoid any obstruction that your

chaincould hit while you are cuttingthrougha particular

logor branch.

• Keep your chain sharp and properly tensioned. A

looseor dull chain can increasethe chance of kickback

to occur. Follow manufacturer's chain sharpening and

maintenance instructions. Check tension at regular in-

tervals with the engine stopped, never with the engine

running. Make sure the bar clamp nuts are securely

tightenedafter tensioning the chain.

• Begin and continue cutting at full throttle. If the

chain is moving at a slower speed, there is greater

chance for kickback to occur.

• Cut one log at a time.

• Use extreme caution when re-entering a previous

cut.

Do not attempt plunge cuts,

• Watch for shifting logs or otherforcesthat could close

a cutand pinch or fall intochain.

Use the Reduced-Kickback Guide Bar and Low-

Kickback Chain specified for your saw.

MAINTAIN CONTROL

• Keep a good, firm grip on the saw with both hands

when the engine Is running end don't let go, Figure

4. Afirmgdpcanneutralizekickback and helpyou main-

taincontrolofthesaw. Keepthefingers ofyourlefthand

encirclingand yourleftthumbunderthe fronthandlebar.

Keep your dght handcompletely aroundthe rear handle

whetheryou are dghthandedor left handed. Keep your

leftarm straightwiththe elbow locked.

• Pc,sltlon your left hand on the front handlebar so It

is in a straight line with your right hand on the rear

handle when making bucking cuts. Figure 4. Never

reverse dght and left hand positionsfor anytype ofcut-

ting.

• Stand with your weight evenly balanced on both

feel

• Stand slightly to the left side of the saw to keep your

body from being In a direct line with the cutting

chain. Figure 4.

• Do not overreach. You could be drawn or thrown off

balance and losecontrolofthe saw.

• Do not cut above shoulder height. It is difficultto

maintain controlof saw above shoulder height.

UNDERSTANDING REACTIVE FORCES

Pinch-Kickback end Pull-In occur when the chain Is

suddenly stopped by being pinched, caught, or by

contacting a foreign oh|act In the wood. This stopping

ofthe chain resultsin a reversalof the chain force used to

cutwood and causesthe saw tomove in the Oppositedirec-

tionof the chainrotation. Eitherreaction can resultin loss

ofcontrol and possible serious injury.

• Pinch-Kickback

- occurswhen chain on top of guide bar is suddenly

stopped.

- rapidlydrives saw straightback toward operator.

• Pull-In

- occurswhenthe chain onthe bottom ofthe guidebar

issuddenly stopped.

- pullsthe saw rapidly forward.

KICKBACK SAFETY FEATURES

& WARNING

THE FOLLOWING FEATURES ARE IN-

CLUDED ON YOUR SAW TO HELP REDUCE

THE HAZARD OF KICKBACK; HOWEVER,

SUCH FEATURES WILL NOT TOTALLY

ELIMINATE THIS DANGEROUS REACTION.

AS A CHAIN SAW USER, DO NOT RELY

ONLY ON SAFETY DEVICES. YOU MUST

FOLLOW ALL SAFETY PRECAUTIONS

INSTRUCTIONS, AND MAINTENANCE IN

THIS MANUAL TO HELP AVOID KICKBACK

AND OTHER FORCES WHICH CAN RESULT

IN SERIOUS INJURY.

Reduced-Kickback Guide Bar, designed witha small radius

tipwhich reduces the size of the kickback danger zone on the

guidebartip. Figure5. A Reduced-KickbackGuide Barisone

whichhas been demonstrated to significantlyreduce the num-

ber and seriousness of kickbackswhen tested in accordance

withANSI B175.t. 1991

Low--Klokbeck Chain, designed with a contoured depth

gauge and guard link which deflect kickback force and allow

woodtograduallyrideintothecutter. Figure5. Low-Kickback

Chain ischain which has met kickback pedormance require-

ments of ANSI B175.1-1991 when tested on a representative

-4-

sample ofchain saws below3.8 cubic inch displacement spe-

cified in ANSI B175.1-1991.

Hendguard, designed to reduce the chance ofyour lefthand

contacting_e chain ifyour hand slips off the front handlebar.

Position of front sndresr handlebars, designed with dis-

tance between handles and "in-line"with each other. The

spread and =in-line" positionof the hands provided bythis de-

_iing(nt_,/O_vtoO_toe_jertog_l_abc_,anwC_r_ndresislal_Crei_r_control_

• g p" to eope to " kickba

occurs.

ANSIel 75.1-1991- Safetyrequirementsforgasolinepoweredchain

sawsassetbytheAmedcanNationaJStandardsInstitute,Inc.,Stan-

dardB175.1-1991.

Contour¢d

j/ Ded_Gauge Ek_ga_d

__ Guardk_

Reduced )Ockback Smell

Symmet,ical Guide Bar Radius T_O

Symmet,_cll Large

auk_ Bar RadkJSTip

_min _. _ _edually Ride

Chain With High

_ Potlm_d

_nto Cutter

Figure5

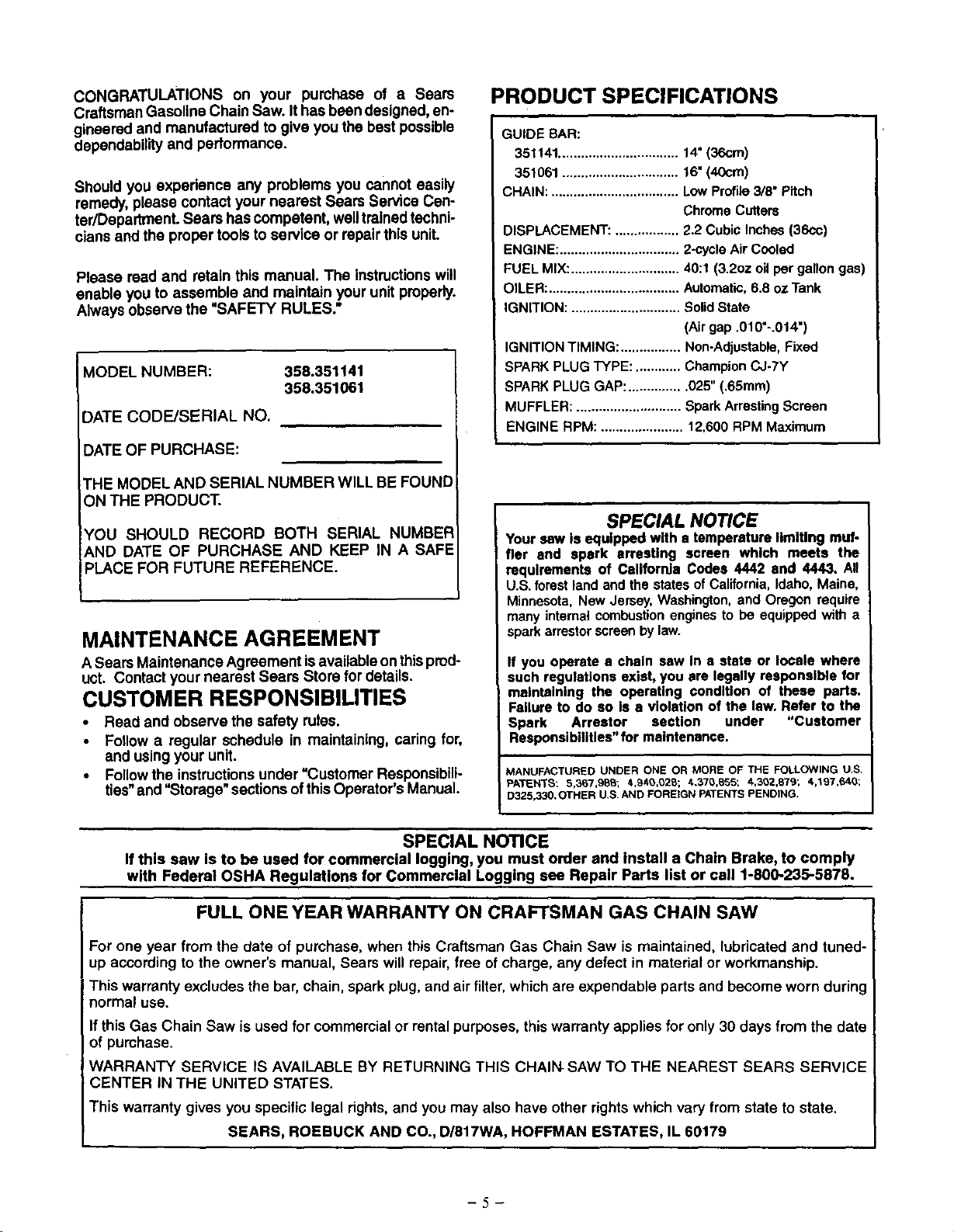

CONGRATULATIONSon your pumhaseof a Sears

CraftsmanGasoline Chain Saw. It has been designed, en-

gineered and manufactured to give you the best possible

dependability and performance.

Should you experience any problems you cannot easily

remedy, please contact your nearest Sears Service Cen-

ter/Department. Sears has competent, welltrained techni-

cians and the proper tools to service or repairthis unit.

Please read and retain this manual. The Instructions will

enable you to assemble and maintain your unit properly,

Always observe the "SAFETY RULES."

MODEL NUMBER:

358.351141

358.351061

DATE CODEJSERIAL NO.

DATE OF PURCHASE:

THE MODEL AND SERIAL NUMBER WILL BE FOUND

ON THE PRODUCT.

IYOU SHOULD RECORD BOTH SERIAL NUMBEF_

AND DATE OF PURCHASE AND KEEP IN A SAFE

PLACE FOR FUTURE REFERENCE.

MAINTENANCE AGREEMENT

ASears Maintenance Agreement isavailableon thisprod-

uct. Contact your nearest Sears Store for details.

CUSTOMER RESPONSIBILITIES

• Read and observe the safety rules.

Follow a regular schedule in maintaining, caring for,

and usingyour unit.

• Followthe instructionsunder"Customer Responsibili-

ties"and "Storage" sections of thisOperator's Manual.

PRODUCT SPECIFICATIONS

GUIDE BAR:

351141................................14"(36cm)

351061...............................16"(40cm)

CHAIN:..................................LowProfile 3/8" Pitch

ChromeCutters

DISPLACEMENT:.................2.2 CubicInches(36cc)

ENGINE:................................2-cycleAirCooled

FUELMIX:.............................40:1(3.2ozoilper gallongas)

OILER:...................................Automatic,6.8 ozTank

IGNITION:.............................SolidState

(Airgap.010"-.014")

IGNITIONTIMING:................Non-Adjustable,Fixed

SPARKPLUGTYPE:............ ChampionCJ-7Y

SPARKPLUGGAP:...............025"(.65mm)

MUFFLER:............................SparkArrestingScreen

ENGINERPM: ......................12,600RPM Maximum

SPECIAL NOTICE

Yoursaw is equipped with s temperaturelimiting muf-

fler and spark arresting screen which meets the

requirements of California Codes 4442 and 4443. All

U.S.forestlandandthestatesofCalifornia,Idaho,Maine,

Minnesota,NewJersey,Washington,andOregonrequire

manyinternalcombustionenginesto be equippedwith a

sparkarrestorscreenbylaw.

If you operate a chain saw in s state or locale where

such regulations exist, you are legally responslMe for

maintaining the operating condition of these parts.

Failure to do so is a violation of the law. Refer to the

Spark Arrestor section under "Customer

Responsibilities" for maintenance.

MANUFACTURED UNDER ONE OR MORE OF THE FOLLOWING U.S.

PATENTS: 5,367,98S; 4.94e,o2_,; 4,370,B55; 4,302,879; 4,197,640;

D325,330.OTHER U.S.AND FOREIGN PATENTS PENDING,

SPECIAL NOTICE

If this saw is to be used for commercial logging, you must order end install a Chain Brake, to comply

with Federal OSHA Regulations for Commercial Logging see Repair Parts list or call 1-800-235-5878.

FULL ONE YEAR WARRANTY ON CRAFTSMAN GAS CHAIN SAW

For one year from the date of purchase, when this Craftsman Gas Chain Saw is maintained, lubricated and tuned-

up according to the owner's manual, Sears will repair, free of charge, any defect in material or workmanship.

This warranty excludes the bar, chain, spark plug, and air filter, which are expendable parts and become worn during

normal use.

If this Gas Chain Saw is used for commercial or rental purposes, this warranty applies for only 30 days from the date

of purchase.

WARRANTY SERVICE IS AVAILABLE BY RETURNING THIS CHAIN SAW TO THE NEAREST SEARS SERVICE

CENTER IN THE UNITED STATES.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

SEARS, ROEBUCK AND CO., DI617WA, HOFFMAN ESTATES, IL 60179

-5-

TABLE OF CONTENTS

Safety Rules ...................................................................... 2 Service and Adjustments ................................................ 22

Product Specifications ....................................................... 5 Storage ............................................................................ 27

Warranty ............................................................................ 5 Trouble Shooting Points .................................................. 28

Accessories ....................................................................... 6 Repair Parts.................................................................... 29

Operation ........................................................................... 8 Repair Parts Ordering/Service .......................... Back Cover

Customer Responsibilities ............................................... 17

INDEX

A

Accessories ....................................................................... 6

Air Filter ........................................................................... 20

B

Bar and Chain Oil ............................................................ 10

Bucking ............................................................................ 15

C

Carburetor Adjustments .................................................. 25

Carton Contents ................................................................ 7

Chain Adjustment ............................................................ 22

Chain Oiler ........................................................................ 9

Chain Sharpening ........................................................... 17

Customer Responsibilities ............................................... 14

Spark Plug ................................................................... 20

E

Engine

Fuel/Oil ......................................................................... 10

Spark Plug ................................................................... 20

Starting ......................................................................... 11

Storage ........................................................................ 27

F

Fuel Filter ........................................................................ 21

Fueling ............................................................................. 10

G

Guide Bar and Chain Oil ................................................. 10

Guide Bar Maintenance .................................................. 19

H

How To Use Your Chain Saw ............................................. 9

K

Know Your Chain Sew ....................................................... 8

L

Limbing............................................................................ 16

M

Maintenance Schedule .................................................... 17

Model Number ................................................................... 5

Muffler ............................................................................. 20

O

Operation ........................................................................... 8

Ordering Repair Parts ....................................... Back Cover

P

Product Specifications....................................................... 5

Pruning ............................................................................ 16

R

Repair Parts .................................................................... 29

S

Service and Adjustments ................................................ 22

Spark Arrestor Screen ..................................................... 20

Starter Rope .................................................................... 23

Starting ............................................................................ 11

Storage ............................................................................ 27

T

Throttle Control Group ...................................................... 9

Trouble Shooting Points .................................................. 28

Tree Felling ...................................................................... 12

W

Warranty ............................................................................ 5

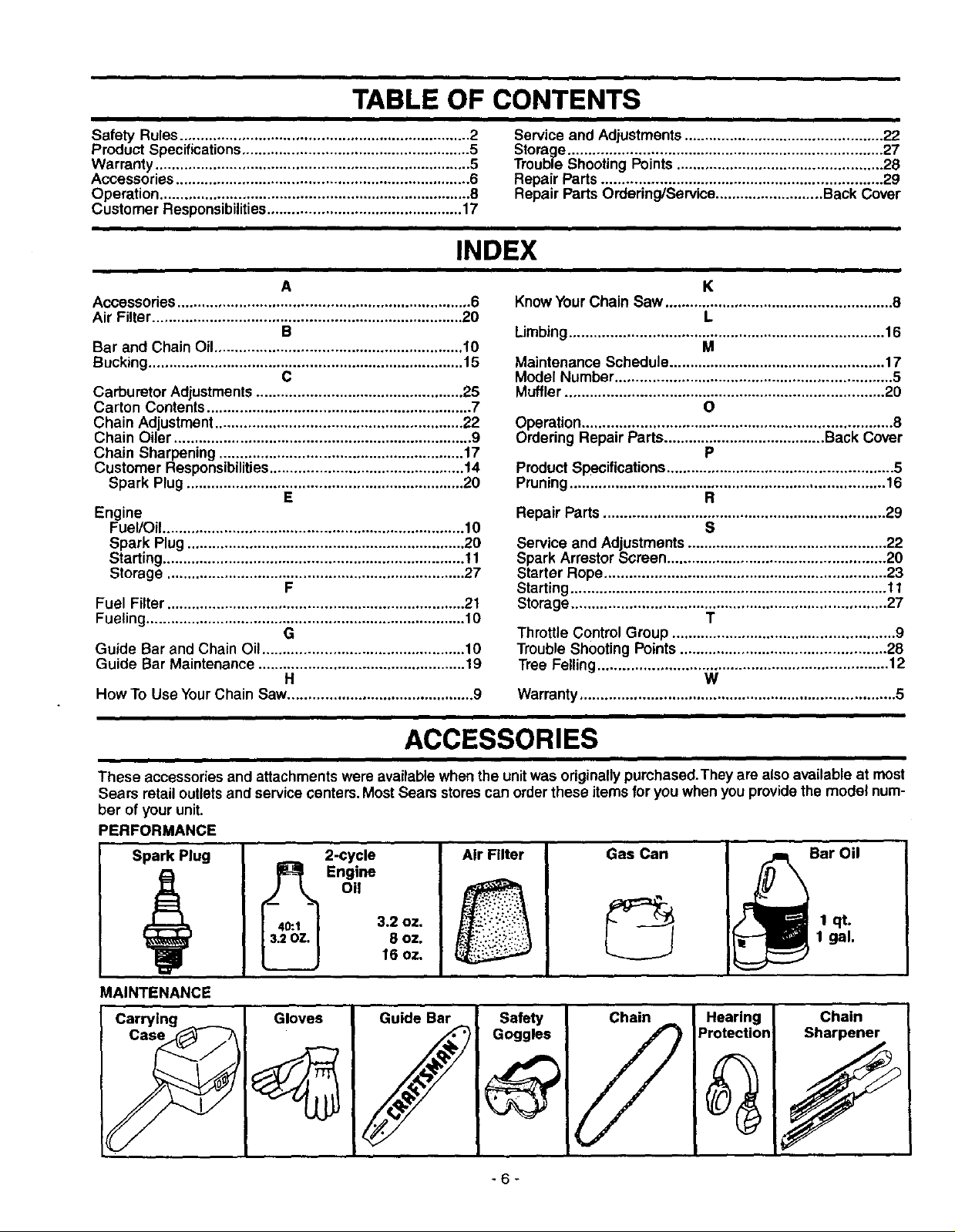

ACCESSORIES

These accessories and attachments were availablewhen the unitwas originally purchased.They are also available at most

Sears retail outletsand service (:enters. Most Sears storescan orderthese items for you when you providethe model num-

ber of your unit.

PERFORMANCE

Spark Plug Bar Oil2-cycle

Oil

3.2 oz.

_ Engine

MAINTENANCE

• Safety _ Chain _ ]prHoetmcitnogn"[

8 oz.

16 oz,

Air Filter Gas Can

1 qt.

1 gal.

-6-

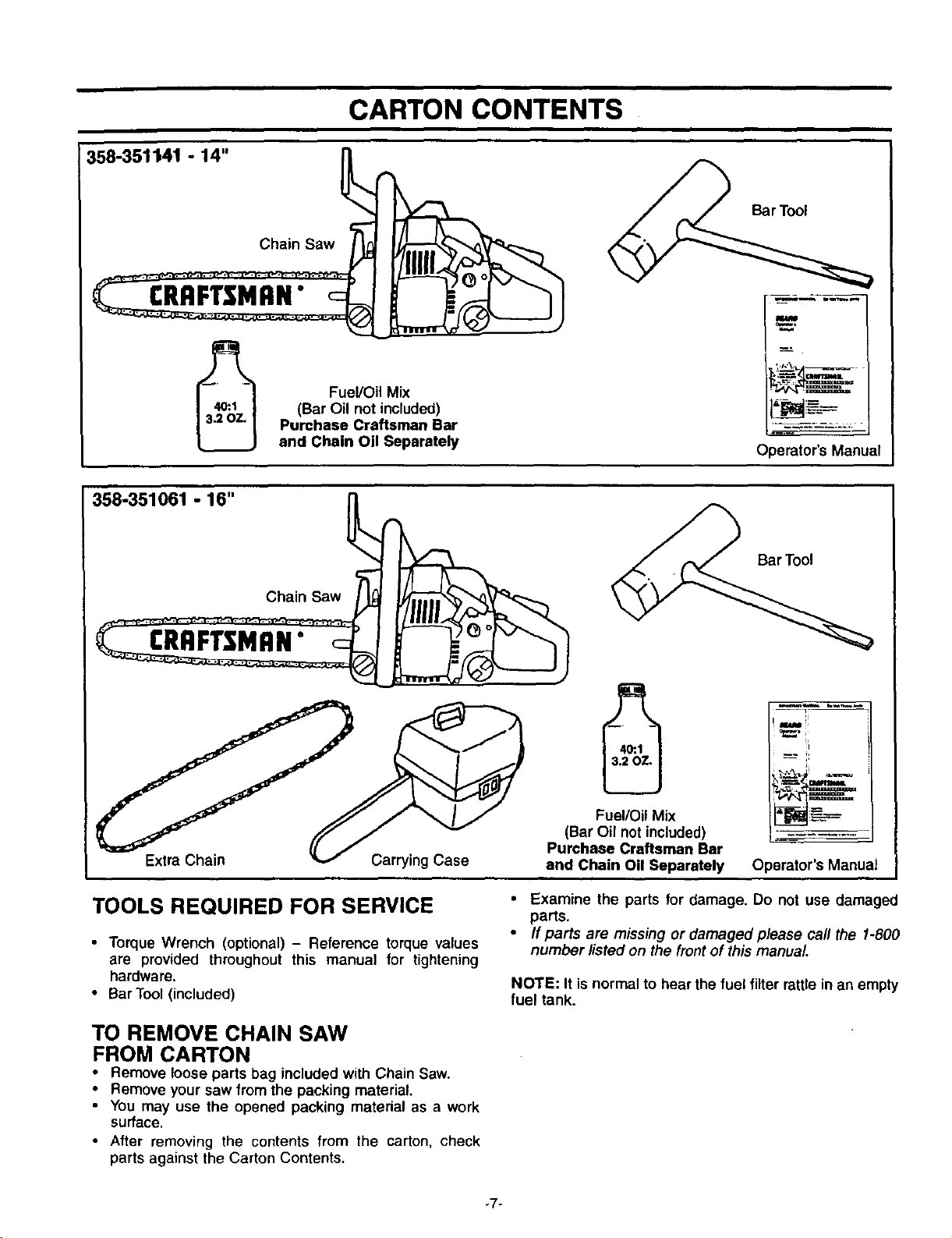

358-351141 - 14"

(Bar Oil not included)

Purchase Craftsman Bar

and Chain Oil Separately

Fuel/Oil Mix

358-351061 - 16" {_

CARTON CONTENTS

_r_ol

Operator's Manual

Bar Tool

Chain Saw

Extra Chain

Carrying Case

TOOLS REQUIRED FOR SERVICE

• Torque Wrench (optional) - Reference torque values

are provided throughout this manual for tightening

hardware.

• Bar Tool (included)

TO REMOVE CHAIN SAW

FROM CARTON

• Remove loose parts bag included with Chain Saw.

• Remove your saw from the packing material.

• You may use the opened packing matedal as a work

surface.

• After removing the contents from the carton, check

parts against the Carton Contents.

i oP==.i_

Fuel/Oil Mix

(Bar Oil not included)

Purchase Craftsman Bar

and Chain Oil Separately

• Examine the parts for damage. Do not use damaged

parts.

• If parts are missing or damaged please call the 1-800

number listed on the frontof this manual

NOTE: It is normal to hear the fuel filter rattle in an empty

fuel tank.

Operator's Manual

ii 111 • m ill ,

OPERATION

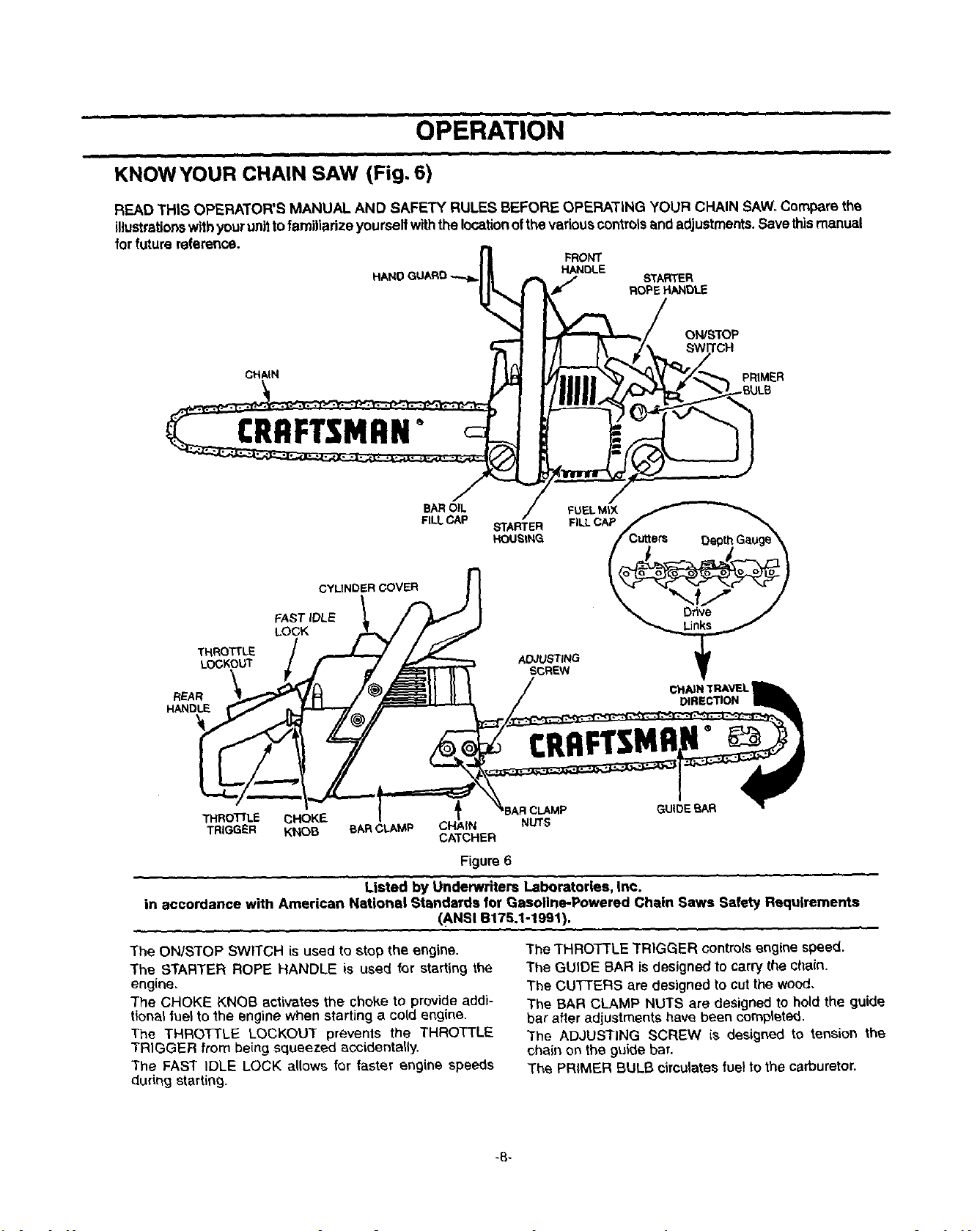

KNOWYOUR CHAIN SAW (Fig, 6)

READ THIS OPERATOR'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR CHAIN SAW. Compare the

illustrationswithyour uni_to familiarize yourseltwiththe locationofthe variouscontrolsand adjustments. Save thismanual

for future reference.

i ,J

THROTTLE

LOCKOUT

REAR

HANDLE

HAt,K)GUARD _ _ H_NDLE STARTER

ROPE HANDLE

FRONT

ON/STOP

CH/_N PRIMER

CRRFTgMRN°

CYLINDER COVER

FAST IDLE

LOCK

BAR OIL

FILL CAP

STARTER FILL CAP /

HOUSING

ADJUSTING _1_

FUEL MIX

SCREW 11r

CHAIN TRAVEL

DIRECTION

CRfl

THROTTLE CHOKE _ I CLAMP

TRIGGER KNOB BAR CLAMP CHAIN NUTS

Listed by Underwriters Laboratories, Inc.

in accordance with American National Standards for Gasotine-Powered Chain Saw,= Safety Requirements

The ONiSTOP SWITCH is used to stop the engine.

The STARTER ROPE HANDLE is used for starting the

engine.

The CHOKE KNOB activates the choke to provide addi-

tional fuel to the engine when starting a cold engine.

The THRO]_LE LOCKOUT prevents the THROTTLE

TRIGGER from being squeezed accidentally.

The FAST IDLE LOCK allows for faster engine speeds

during starting.

CATCHER

Figure6

(ANSI B175.1-1991).

The THROTTLE TRIGGER controls engine speed.

The GUIDE BAR is designed to carry the chain.

The CU'I_'ERS are designed to cut the wood.

The BAR CLAMP NUTS are designed to hold the guide

bar after adjustments have been completed.

The ADJUSTING SCREW is designed to tension the

chain on the guide bar,

The PRIMER BULB circulates fuel to the carburetor.

-8-

OPERATION

HOWTO USE YOUR CHAIN SAW

STOPPING YOUR ENGINE

• Move on/stop switch to the "stop" position.

• If engine does not stop, pull bluechoke knob out fully.

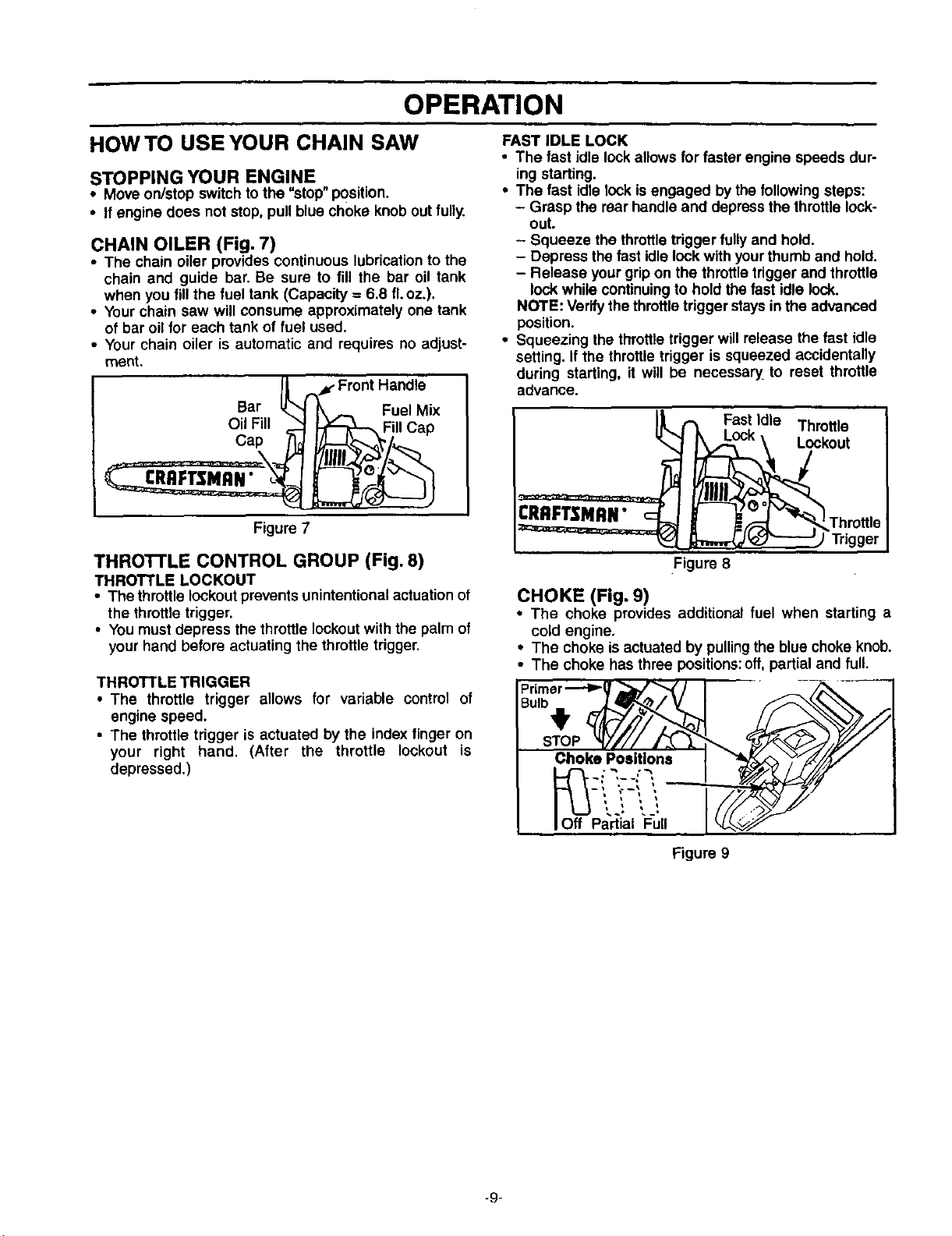

CHAIN OILER (Fig. 7)

• The chain oiler provides continuous lubricationto the

chain and guide bar. Be sure to fill the bar oil tank

when you fill the fuel tank (Capacity = 6.8 fLoz.).

• Your chain saw will consume approximately one tank

of bar oil for each tank of fuel used.

• Your chain oiler is automatic and requires no adjust-

roent,

Bar

Oil Fill

Cap

CRRFTSMRN"

Figure 7

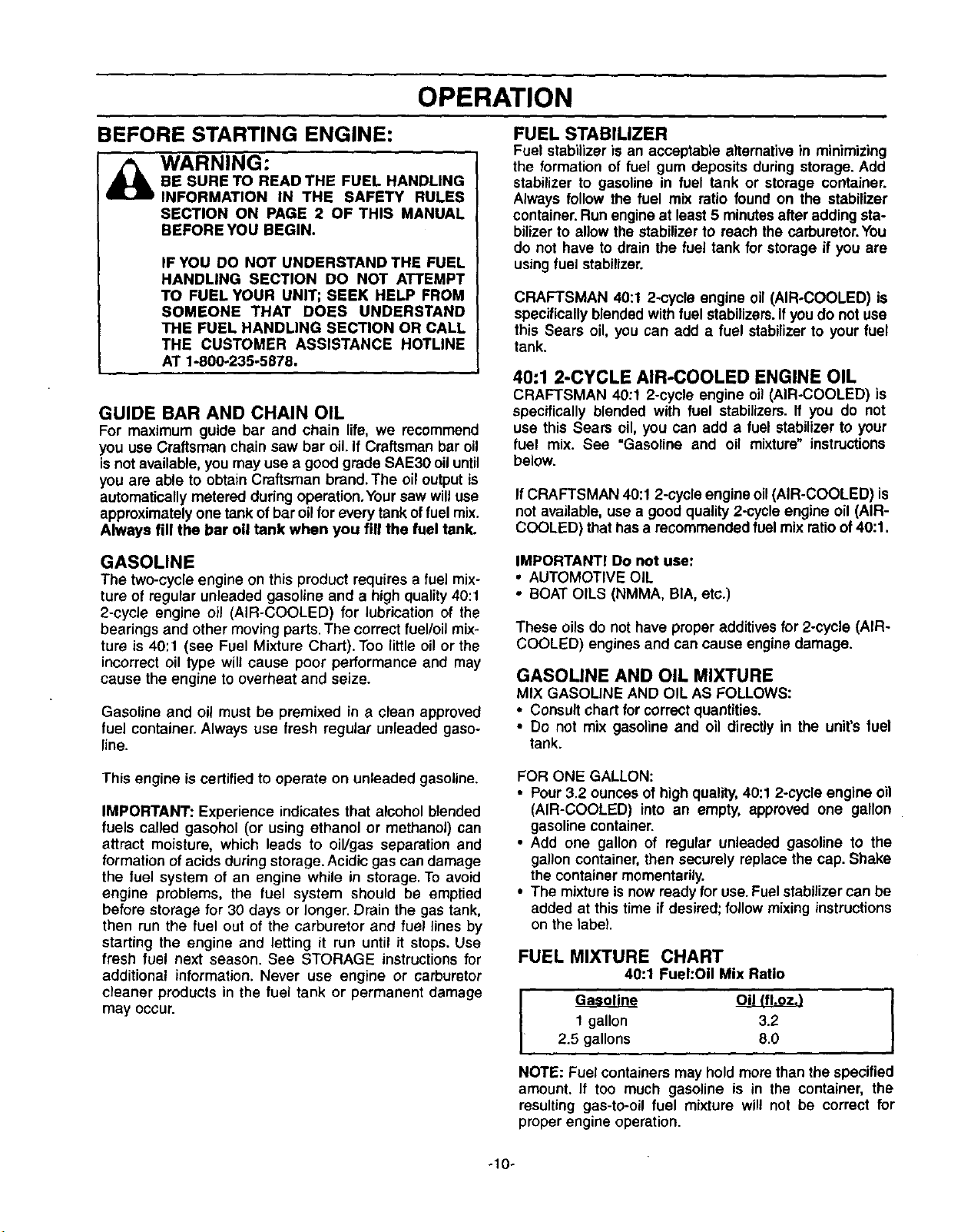

THRO'I-rLE CONTROL GROUP (Fig. 8)

THROTTLE LOCKOUT

• The throttle lockoutprevents unintentional actuation of

the throttletrigger.

• You must depress the throttle lockoutwith the palm of

your hand before actuating the throttle trigger.

THROTTLE TRIGGER

• The throttle trigger allows for variable control of

engine speed.

• The throttle trigger is actuated by the index finger on

your right hand. (After the throttle lockout is

depressed.)

Fuel Mix

II Cap

FAST IDLE LOCK

• The fast idle lock allows for faster engine speeds dur-

ing starting.

• The fast idle lock isengaged by the followingsteps:

- Grasp the rear handle and depress the throttle lock-

out.

- Squeeze the throttletrigger fully and hold.

- Depress the fast idlelock with yourthumb and hold.

- Release your gripon the throttletrigger and throttle

lock while continuingto hold the fast idle lock.

NOTE: Verify the throttle trigger staysin the advanced

position.

• Squeezing the throttle trigger will release the fast idle

setting. If the throttle trigger is squeezed accidentally

during starting, it will be necessary, to reset throttle

advance.

CRRFT_MRN"

Trigger

Figure 8

CHOKE (Fig. 9)

• The choke provides additional fuel when starting a

cold engine,

• The choke is actuated by pullingthe blue choke knob.

• The choke has three positions:off,partial and full.

Choke Positions

-9-

O_ff -_p!_iaiiii!,,

Figure 9

OPERATION

BEFORE STARTING ENGINE:

WARNING:

BE SURE TO READ THE FUEL HANDLING

INFORMATION IN THE SAFETY RULES

SECTION ON PAGE 2 OF THIS MANUAL

BEFORE YOU BEGIN.

IF YOU DO NOT UNDERSTAND THE FUEL

HANDLING SECTION DO NOT ATTEMPT

TO FUEL YOUR UNIT; SEEK HELP FROM

SOMEONE THAT DOES UNDERSTAND

THE FUEL HANDLING SECTION OR CALL

THE CUSTOMER ASSISTANCE HOTMNE

AT 1-800-235-5878,

GUIDE BAR AND CHAIN OIL

For maximum guide bar and chain lifo, we recommend

you use Craftsman chain saw bar oil if Craftsman bar oil

isnot available, you may use a good grade SAE30 oil until

you are able to obtain Craftsman brand.The oil output is

automatically metered during operation.Your saw willuse

approximatelyone tank ofbar oilfor every tank of fuel mix.

Always fill the bar oil tank when you fill the fuel tank.

GASOLINE

The two-cycle engine on this product requires a fuel mix-

ture of regular unleaded gasoline and a high quality 40:1

2-cycle engine oil (AIR-COOLED) for lubrication of the

bearings and other moving parts. The correct fuel/oil mix-

ture is 40:1 (see Fuel Mixture Chart).Too little oil or the

incorrect oil type will cause poor performance and may

cause the engine to overheat and seize.

Gasoline and oil must be premixed in a clean approved

fuel container. Always use fresh regular unleaded gaso-

line.

FUEL STABILIZER

Fuel stabilizer is an acceptable alternative in minimizing

the formation of fuel gum deposits during storage. Add

stabilizer to gasoline in fuel tank or storage container.

Always follow the fuel mix ratio found on the stabilizer

container. Run engine at least 5 minutes after adding sta-

bilizer to allow the stabilizer to reach the carburetor.You

do not have to drain the fuel tank for storage if you are

using fuel stabilizer.

CRAFTSMAN 40:1 2-cycle engine oil (AIR-COOLED) is

specifically blendedwith fuel stabilizers.Ifyou do not use

this Sears oil, you can add a fuel stabilizerto your fuel

tank.

40:1 2-CYCLE AIR-COOLED ENGINE OIL

CRAFTSMAN 40:1 2-cycle engine oil (AIR-COOLED) is

specifically blended with fuel stabilizers. If you do not

use this Sears oil, you can add a fuel stabilizer to your

fuel mix. See "Gasoline and oil mixture" instructions

below.

If CRAFTSMAN 40:1 2-cycle engine oil (AIR-COOLED) is

not available, use a good quality 2-cycle engine oil (AIR-

COOLED) that has a recommended fuel mix ratio of 40:1.

IMPORTANT! Do not use:

• AUTOMOTIVE OIL

• BOAT OILS (NMMA, BIA, etc.)

These oils do not have proper additives for 2-cycle (AIR-

COOLED) engines and can cause engine damage.

GASOLINE AND OIL MIXTURE

MIX GASOLINE AND OIL AS FOLLOWS:

• Consult chart for correctquantities.

• Do not mix gasoline and oil directly in the unit's fuel

tank.

This engine is certified to operate on unleaded gasoline.

IMPORTANT: Experience indicates that alcohol blended

fuels called gasohol (or using ethanol or methanol) can

attract moisture, which leads to oil/gas separation and

formation of acids during storage. Acidic gas can damage

the fuel system of an engine while in storage. To avoid

engine problems, the fuel system should be emptied

before storage for 30 days or longer. Drain the gas tank,

then run the fuel out of the carburetor and fuel lines by

starting the engine and letting it run until it stops. Use

fresh fuel next season. See STORAGE instructions for

additional information. Never use engine or carburetor

cleaner products in the fuel tank or permanent damage

may occur.

FOR ONE GALLON:

• Pour 3.2 ounces of high quality, 40:1 2-cycle engine oil

(AIR-COOLED) into an empty, approved one gallon

gasoline container.

• Add one gallon of regular unleaded gasoline to the

gallon container, then securely replace the cap. Shake

the container momentarily.

• The mixture is now ready for use. Fuel stabilizer can be

added at this time if desired;follow mixing instructions

on the label.

FUEL MIXTURE CHART

40:1 FuehOil Mix Ratio

1 gallon 3.2

2.5 gallons 8.0

NOTE: Fuel containers may hold more than the specified

amount. If too much gasoline is in the container, the

resulting gas-to-oil fuel mixture will not be correct for

proper engine operation.

-10-

Loading...

Loading...