Craftsman 358351060, 358351140 Owner’s Manual

iMPORTANT MANUAL

Operator's

Manual

Model No.

358,351140 - 14"

358.351060 - 16"

,=,o.or

CUSTOMER

ASSISTANCE

1-800-235-5878

WARNING:

READ THE OPERATOR'S

MANUAL AND FOLLOW

ALL WARNINGS AND

SAFETY INSTRUCTIONS.

FA LURE TO DO SO CAN

RESULT IN SERIOUS i

1NJURY_

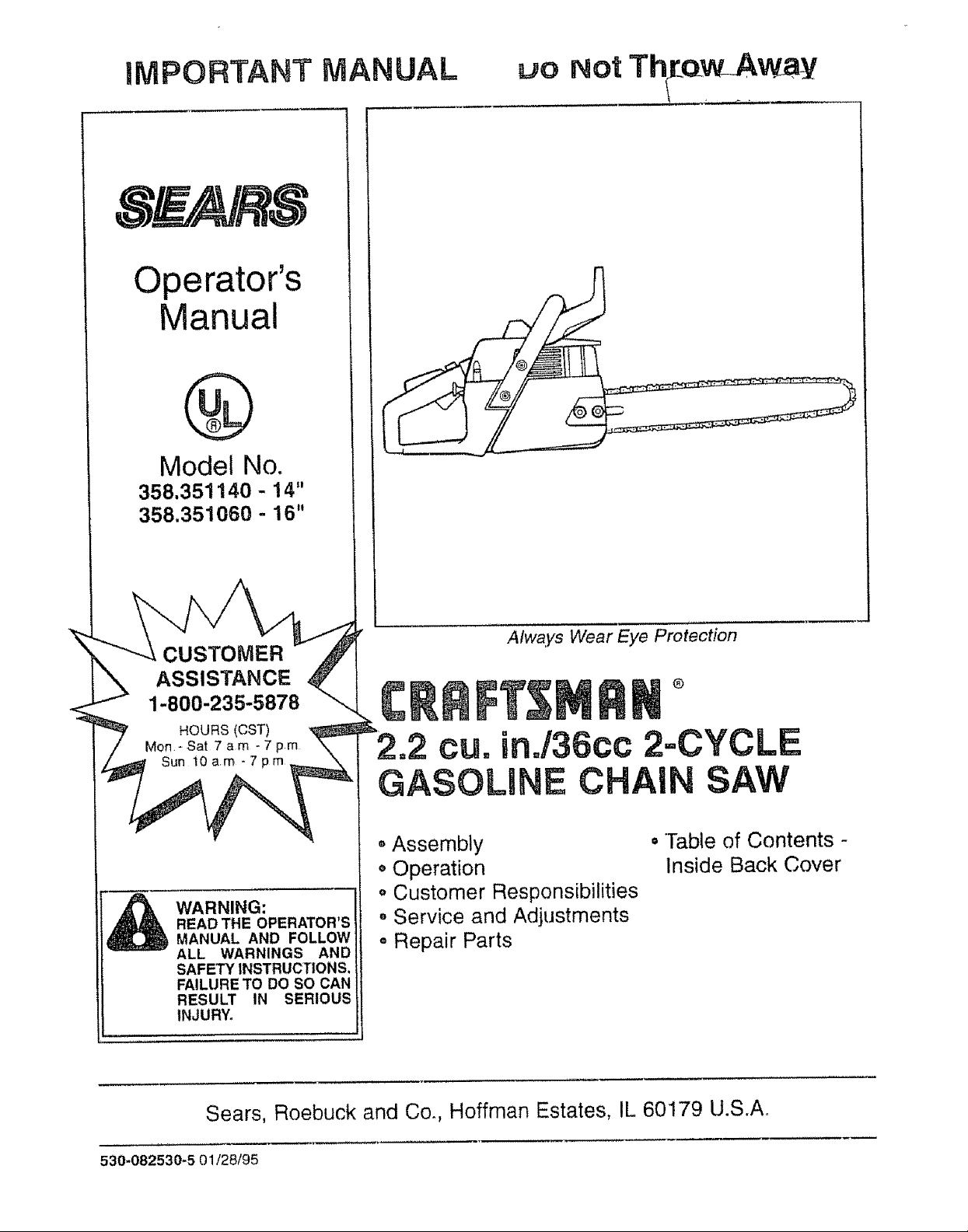

Always Wear Eye Protection

®

2.2 cuo in,/36cc 2oCYCLE

GASOLi CHAI SAW

oAssembly =Table of Contents -

oOperation Inside Back Cover

o Customer Responsibilities

o Service and Adjustments

o Repair Parts

I

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.Ao

530-082530-5 01/28/95

SAFETY RULES

WARNING:

ALWAYS DISCONNECT SPARK PLUG WIRE AND PLACE WIRE WHERE IT CANNOT CONTACT SPARK

PLUG TO PREVENT ACCIDENTAL STARTING WHEN SETTING UP, TRANSPORTING, ADJUSTING OR

MAKING REPAIRS EXCEPT CARBURETOR ADJUSTMENTS.

BECAUSE A CHAIN SAW IS A HIGH-SPEED WOOD-CUTTING TOOL, SPECIAL SAFETY

IMPROPER USE OF THIS TOOL CAN CAUSE SERIOUS INJURY.

PRECAUTIONS MUST BE OBSERVED TO REDUCE THE RISK OF ACCIDENTS_ CARELESS OR

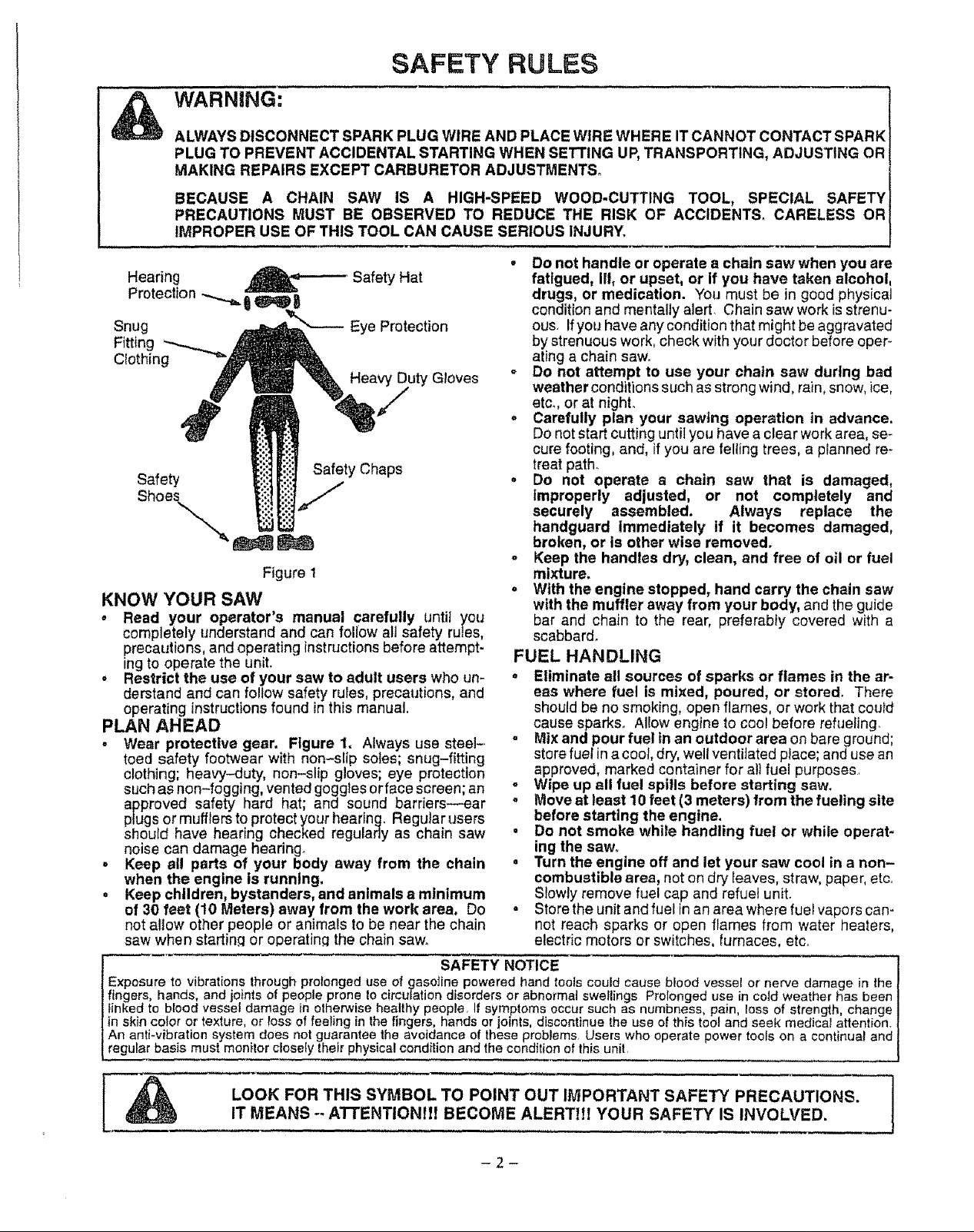

Hearing Safety Hat

Protection ....=_.._j

Snug Eye Protection

Fitting

Clothing

Heavy Gloves

Safety

Shoe_,,_

Figure I

Safety Chaps

KNOW YOUR SAW

, Read your operator's manual carefully until you

completely understand and can follow all safety rules,

precautions, and operating instructions before attempt-

ingto operate the unit.

o Restrict the use of your saw to adult users who un-

derstand and can follow safety rules, precautions, and

operating instructionsfound in this manual,

PLAN AHEAD

. Wear protective gear. Figure 1. Always use steel-

toed safety footwear with non-slip soles; snug-fitting

clothing; heavy-duty, non-slip gloves; eye protection

such as non-fogging, ventedgoggles orface screen; an

approved safety hard hat; and sound barriers--ear

plugs or mufflers to protect your hearing, Regular users

should have hearing checked regularly as chain saw

noise can damage hearing.

o Keep all parts of your body away from the chain

when the engine is runntng.

° Keep children, bystanders, and animals a minimum

of 30 feet (10 Meters) away from the work area. Do

not allow other people or animals to be near the chain

saw when starting or operating the chain saw,

. Do not handle or operate a chain saw when you are

fatigued, Iit, or upset, or if you have taken alcohol,

drugs, or medication. You must be in good physical

condition and mentally alert. Chain saw work isstrenu-

ous. Ifyou have any condition that might be aggravated

by strenuous work, check with your doctor before oper-

ating a chain saw,

- Do not attempt to use your chain saw during bad

weather conditions such as strong wind, rain,snow, ice,

etco,or at night°

o Carefully plan your sawing operation in advance.

Do notstart cuttinguntil you have a clear workarea, se-

cure footing, and, if you are felling trees, a planned re-

treat path.

. Do not operate a chain saw that is damaged,

Improperly adjusted, or not completely and

securely assembled. Always replace the

handguard Immediately if it becomes damaged,

broken, or is other wise removed.

o Keep the handles dry, clean, and free of oil or fuel

mixture.

o With the engine stopped, hand carry the chain saw

with the muffler away from your body, and the guide

bar and chain to the rear, preferably covered with a

scabbard.

FUEL HANDLING

o Eliminate all sources of sparks or flames in the ar-

eas where fuel is mixed, poured, or stored. There

should be no smoking, open flames, or work that couid

cause sparks. Al!ow engine to cool before refueling

. Mix and pour fuel in an outdoor area on bare ground;

store fuel in a coot, dry, well ventilated place; anduse an

approved, marked containerfor all fuel purposes,

- Wipe up all fuel spills before starting saw.

o Move at least 10 feet (3 meters) from the fueling site

before starting the engine.

• Do not smoke while handling fuel or while operat-

ing the saw.

• Turn the engine off and let your saw cool in a non-

combustible area, not on dry feaves, straw, paper,etc_

Slowly remove fuel cap and refuel unit.

- Store the unit and fuel in an area where fuel vapors can-

not reach sparks or open flames from water heaters,

electric motors or switches, furnaces, etc

........... SAFETY NOTICE J

re to vibrations through prolonged use of gasoJine powered hand tools could cause blood vessel or nerve damage in the t

J linked to blood vessel damage in olherwise healthy people, If symptoms occur such as numbness pain loss of strength, change J

Jinskin color or texture, or loss of feelinginthe fingers, hands orjoints,discontinuethe use el this toot and seek medical attention, l

j An anti-vibrationsystem does net guarantee theavoidance of these problems, Users who operate power tools on a continual and J

Lregularbasis mustmonitorcloselytheirphysicalcondition and the conditionof thisunit, ]

hands, and joints of people prone to circulation disorders or abnormal swellings Prolonged use in cotd weather has been J

LOOK FOR THIS SYMBOL TO POINT OUT IMPORTANT SAFETY PRECAUTIONS.

-- l

IT MEANS--ATTENTION!tl BECOME ALERTIrt YOUR SAFETY IS INVOLVED.

.......... :_U,HH,,, IH,,

.......................... i HIll,, =u=l

SAFETY RULES

,,H, =

.... MAINTAIN YOUR SAW tN GOOD WORKING

. Do not operate a chain saw with one hand. Serious ORDER

injuryto the operator, helpers, bystanders or any corn- • Have all chain saw service performed by your Sears

bination ofthese persons may result from one-handed Service Center with the exception ofthe items listed in

operation, A chain saw is intended for two-handed use,, the maintenance section of this manual For example, if

• Operate the chain saw only In well.ventilated out- improper tools are used to remove or hotd the flywheel

door areas, when servicing the clutch, structural damage to the fly-

° Do not operate saw from a ladder or in a tree, unless wheel can occur and cause the flywheel to burst.

specifically trained to do so_ • Make certain the chain stops moving when the

° Position all parts of your body to the left of cut and throttle trigger Is released. For correction, refer to

away from the chain when the engine is running. "Carburetor Adjustments."

• Cut wood only. Do not use your saw to pry or shove • Stop the saw if the chain strikes a foreign object,

away limbs, roots,or other objects. Inspect unit and repair or replace parts as necessary,

• Make sure the chain will not make contact with any ° Disconnect the spark plug before performing any

object while starting the engine. Never tryto start the

maintenance except for carburetor adjustments,,

saw when the guide bar is in a cut or keff_ o Never modify your saw in any way, Use only attach-

. Use extreme caution when cutting small size brush ments supplied or specifically recommended by the

and saplings. Slender material can catch the chain manufacturer.

and be whipped toward you or puli you off balance. TRANSPORTING AND STORAGE

o Be alert for sprtngbackwhen cutting a limbthat is un- - Stop the unit before transporting.

der tension so you will not be struck by the limb or saw o Aitow engine to cool, cover the guide bar and chain, and

when the tension in the wood fibers is released, secure the unit before storing or transporting in a ve-

- Do not put pressure on the saw at the end of a cut. hicle.

Applying pressure can cause you to Iose control when • Empty fuet tank before storing or transportingthe unit,,

the cut is completed. Use upany fuel left in the carburetor by starting the en-

• Stop the engine before setting the saw down. gine and lettingthe engine run until itstops_

• Keep fuel and oil caps, screws, and fasteners se- • Store unit and fuel in an area where fuel vapors cannot

curely tightened, reach sparks or open flames from water heaters, elec-

tric motors or switches, furnaces, etc

o Store unit sothe chain cannotaccidentally cause injury.

o Store the unit out of the reach of children_

,H =,HJ,,,,,,,,h,LI. H , =l H= = =,l, = =,,= i, i i , = ,,,i i=

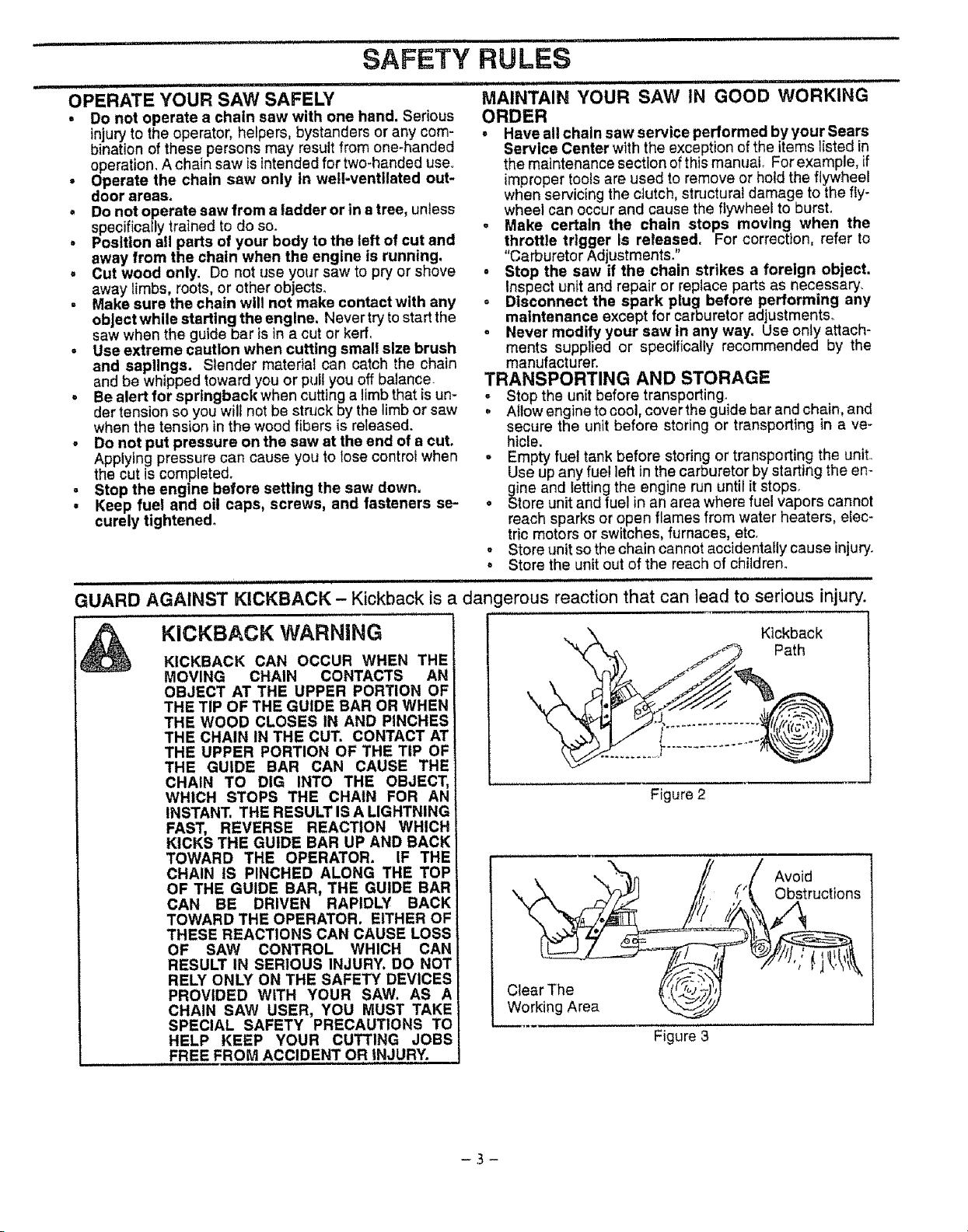

GUARD AGAINST KICKBACK - Kickback is a dangerous reaction that can lead to serious injury.

....... =, =, =,H

KICKBACK WARNING

KICKBACK CAN OCCUR WHEN THE

MOVING CHAIN CONTACTS AN

OBJECT AT THE UPPER PORTION OF

THE TIP OF THE GUIDE BAR OR WHEN

THE WOOD CLOSES tN AND PINCHES

THE CHAIN IN THE CUT. CONTACT AT

THE UPPER PORTION OF THE TIP OF

THE GUIDE BAR CAN CAUSE THE

CHAIN TO DIG INTO THE OBJECT,

WHICH STOPS THE CHAIN FOR AN

INSTANT. THE RESULT IS A LIGHTNING

FAST, REVERSE REACTION WHICH

KICKS THE GUIDE BAR UP AND BACK !

TOWARD THE OPERATOR. IF THE

CHAIN IS PINCHED ALONG THE TOP

OF THE GUIDE BAR, THE GUIDE BAR

CAN BE DRIVEN RAPIDLY BACK

TOWARD THE OPERATOR, EITHER OF

THESE REACTIONS CAN CAUSE LOSS

OF SAW CONTROL WHICH CAN

RESULT IN SERIOUS INJURY. DO NOT

RELY ONLY ON THE SAFETY DEVICES

PROVIDED WITH YOUR SAW. AS A

CHAIN SAW USER, YOU MUST TAKE

SPECIAL SAFETY PRECAUTIONS TO

HELP KEEP YOUR CUTTING JOBS

FREE FROM ACCIDENT OR INJURY.

Kickback

Path

Figure 2

Avoid

Obstructions

Clear The

Working Area

Figure 3

SAFETY RULES

,i,Ji,J,i

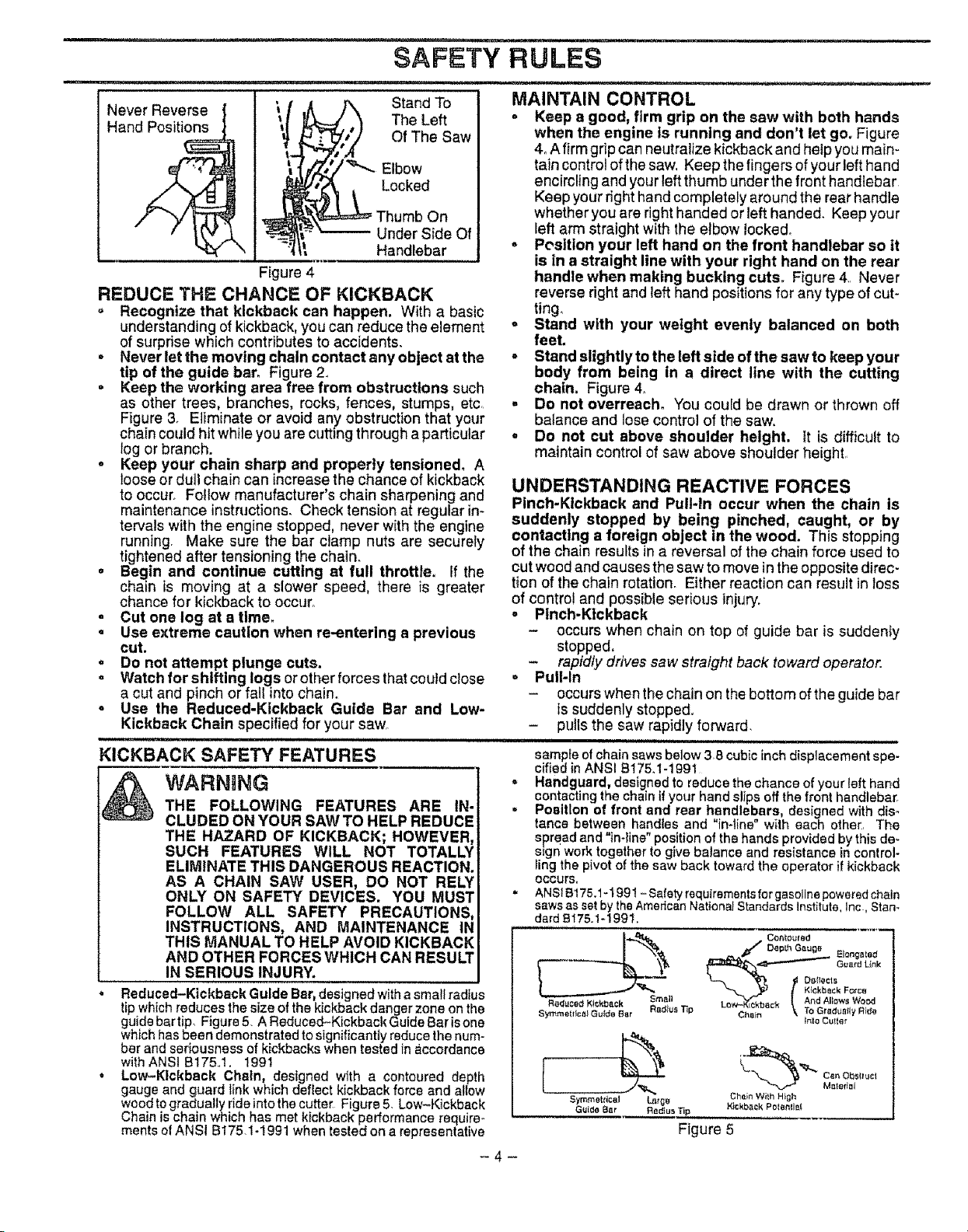

Never Reverse

Hand Positions

t

t

!

Figure 4

REDUCE THE CHANCE OF KICKBACK

. Recognize that kickback can happen, With a basic

understanding of kickback, you can reduce the element

of surprise which contributes to accidents.

* Never let the moving chain contact any object at the

tip of the guide bar. Figure 2.

, Keep the working area free from obstructions such

as other trees, branches, rocks, fences, stumps, etc

Figure 3. Eliminate or avoid any obstruction that your

chain could hit while you are cutting through a particular

fog or branch.

, Keep your chain sharp and properly tensioned. A

tooseor dut! chaincan increase the chance of kickback

to occur. Follow manufacturer's chain sharpening and

maintenance instructions° Check tension at regular in-

tervals with the engine stopped, never with the engine

running. Make sure the bar clamp nuts are securely

tightened after tensioning the chain°

o Begin and continue cutting at full throttle. If the

chain is moving at a slower speed, there is greater

chance for kickback to occur,

, Cut one log at a time.

o Use extreme caution when re-entering a previous

cut.

Do not attempt plunge cuts.

. Watch for shifting logs or other forces that could close

a cut and pinch or fall into chain.

* Use the Reduced-Kickback Guide Bar and Low-

Kickback Chain specified for your saw°

Stand To

The Left

Of The Saw

Elbow

Locked

Thumb On

Under Side Of

Handlebar

MAINTAIN CONTROL

- Keep a good, firm grip on the saw with both hands

when the engine is running and don't let go. Figure

4oA firm grip can neutralize kickback and help youmain-

tain control of the saw. Keep the fingers ofyour left hand

encircling and your left thumb under the front handlebar

Keep your right hand completely around the rear handle

whether you are right handed or left handed, Keep your

left arm straight with the elbow locked°

- Position your left hand on the front handlebar so it

is in a straight line with your right hand on the rear

handle when making bucking cuts° Figure 4 Never

reverse right and left hand positions for any type of cut_

ting.

o Stand with your weight evenly balanced on both

feet.

* Stand slightly to the left side of the saw to keep your

body from being in e direct line with the cutting

chain. Figure 4_

- Do not overreach. You could be drawn or thrown off

balance and lose control of the saw,

, Do not cut above shoulder height. It is difficult to

maintain control of saw above shoulder height,

UNDERSTANDING REACTIVE FORCES

Pinch-Kickback and Pull-In occur when the chain is

suddenly stopped by being pinched, caught, or by

contacting a foreign object in the wood. This stopping

of the chain resultsina reversal of the chain force used to

cut wood and causesthesaw to move in the opposite direc-

tion of the chain rotation, Either reaction can result in Ioss

of control and possible serious injtJry.

o Ptnch-Klckback

- occurs when chain on top of guide bar is suddenly

stopped,

- rapidly drives saw straight back toward operator.

, Pull-In

- occurs whenthe chain on the bottom of the guide bar

issuddenly stopped.

- pulls the saw rapidly forward.

KICKBACK SAFETY FEATURES

& WARNgNGTHE FOLLOWING FEATURES ARE IN-

CLUDED ON YOUR SAW TO HELP REDUCE

THE HAZARD OF KICKBACK; HOWEVER,

SUCH FEATURES WILL NOT TOTALLY

ELIMINATE THIS DANGEROUS REACTION.

AS A CHAIN SAW USER, DO NOT RELY

ONLY ON SAFETY DEVICES. YOU MUST

FOLLOW ALL SAFETY PRECAUTIONS,

INSTRUCTIONS, AND MAINTENANCE IN

THIS MANUAL TO HELP AVOID KICKBACK

AND OTHER FORCES WHICH CAN RESULT

IN SERIOUS INJURY.

Reduced-KickbackGuide Bar,designedwithasmall radius

tipwhich reducesthe size ofthe kickbackdangerzone onthe

guidebartip, Figure5. A Reduced-KickbackGuideBar isone

whichhasbeen demonstratedto significantlyreducethenum-

ber and seriousnessof kickbackswhen testedinaccordance

withANSl B175,1, 1991

• Low-Kickback Chain, designed with a contoured depth

gauge and guard linkwhichdeflect kickbackforceand allow

woodto graduallyrideintothecutter Figure5. Low-Kickback

Chainis chain whichhas metkickback performancerequire-

mentsof ANSI B175.1-!991 when testedon a representative

sample ofchain sawsbelow 3,8cubic inch displacementspe-

cified in ANSI S17&I-1991

,, Handguard, designedto reducethechance ofyourleft hand

contactingthe chain ifyour hand slips offthefronthandlebar,

• Position of front and rear handlebars designed with dis_

tance between handes and "in*line" with each other., The

spreadand "in-line"positionof the handsprov dad bythis de-

sign work togetherto give balanceand resistance incontrol-

lingthepivot of the saw back toward the operatorif kickback

OCCURS,

• ANSI B175.1-1991 - Safety requirements for gasoline powered chain

saws as set by the American National Standards Institute, Inc, Stan-

dard ei75.1-1991.

Cohtogfed

,_* Depth G4_uge _,

._" _ _ongstQe

__ G*Jerd L_tlk

Kl_kb_¢k Fot_

Reduced K_ckbeck Smelt

Symmetrical Guide BBr Red}_J_ _p

Symmetrical t_tr_e

G_Ido Bar Red,us Tip

Ch_irt \ TO Gradually Rllfe

Chrtirl Wi_h H$£h

Kickback P otetllle$

l°°'°°"

ck And Allr_ws Wood

Snto Cu{_er

'_"'_ on Obsltucl

Mste_tal

Figure 5

-4-

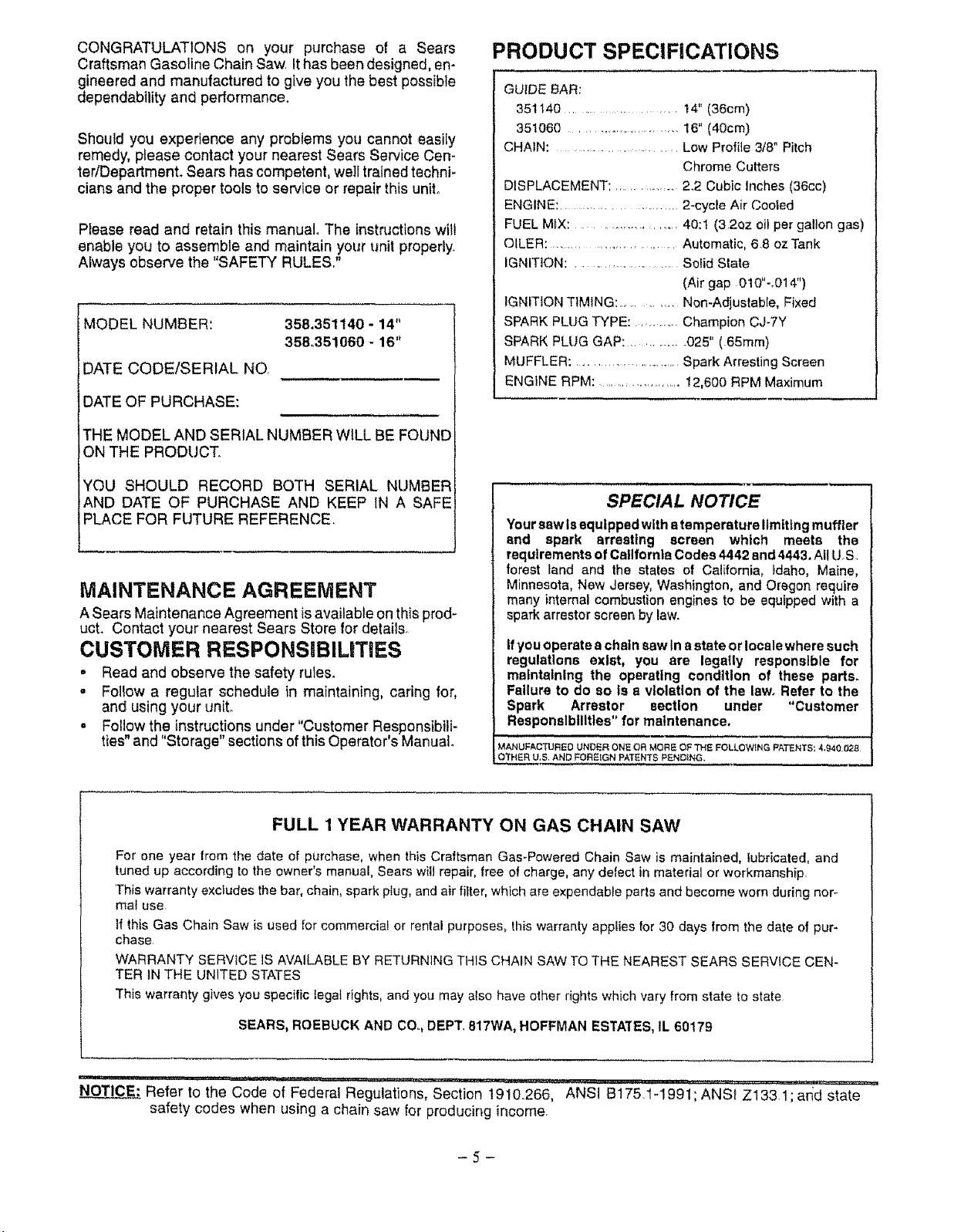

CONGRATULATIONS on your purchase of a Sears

Craftsman Gasoline Chain Saw. It has been designed, en-

gineered and manufactured to give you the best possible

dependability and performance.

Should you experience any problems you cannot easily

remedy, please contact your nearest Sears Service Cen-

ter/Department. Sears has competent, well trained techni-

cians and the proper tools to service or repair this unit°

Please read and retain this manual., The instructions wilt

enable you to assemble and maintain your unit properly.

Always observe the "SAFETY RULES,"

r

i MODEL NUMBER:

35&351140- 14"

358,351060- 16"

DATE CODE/SERIAL NO,

DATE OF PURCHASE:

THE MODEL AND SERIAL NUMBER WILL BE FOUND

ON THE PRODUCT°

YOU SHOULD RECORD BOTH SERIAL NUMBER

AND DATE OF PURCHASE AND KEEP IN A SAFE

PLACE FOR FUTURE REFERENCE.

MAINTENANCE AGREEMENT

A Sears Maintenance Agreement is available on this prod-

ucL Contact your nearest Sears Store for details°

CUSTOMER RESPONSIBILmES

• Read and observe the safety rules,

• Follow a regular schedule in maintaining, caring for,

and using your uniL

= Fellow the instructions under "Customer Responsibili-

ties" and "Storage' sections of this Operator's Manual°

PRODUCT SPECIFICATIONS

GUIDE BAR:

351140 ...................... 14" (36cm)

351060 ........................... 16" (40cm)

CHAIN: ............................... Low Profile 3/8" Pitch

Chrome Cutters

DISPLACEMENT: ................ 2.2 Cubic Inches (36cc)

ENGINE: ......................... 2-cycle Air Cooled

FUEL MiX: ....................... 40:1 (3 2oz oil per gallon gas)

OILER: ................................ Automatic, 6.8 oz Tank

IGNITION: ....................... Solid State

(Air gap 0t0"-.014")

IGNiTiON TIMING: ............. Non-Adjustable, Fixed

SPARK PLUG TYPE: ......... Champion CJ-7Y

SPARK PLUG GAP: ............. 025" (65ram)

MUFFLER: ........................... Spark Arresting Screen

ENGINE RPM: ...................... 12,600 RPM Maximum

SPECIAL NOTICE

Your sew is equlppedwlth a temperature limiting muffler

end spark arresting screen which meets the

requirements of California Codes 4442 and 4443. All US,

forest land and the states of California, Idaho, Maine,

Minnesota, New Jersey, Washington, and Oregon require

many internal combustion engines to be equipped with a

spark arrestor screen by law.

If you operate a chain saw In a state or locale where such

regulations exist, you are legatty responsible for

maintaining the operating condition of these parts.

Failure to do so Is a violation of the law. Refer to the

Spark Arrestor section under "Customer

Responslblllt|es" for maintenance,

MANUFACTURED UNDER ONE OR MORE OF THE FOLLOWING PATENTS: 4,_40,02B

OTHER U.$,AND FOREIGN PATENTS PENDING,

FULL 1 YEAR WARRANTY ON GAS CHAIN SAW

For one year from the date of purchase, when this Craftsman Gas-Powered Chain Saw is maintained, lubricated, and

tuned up according to the owner's manual Sears willrepair, free of charge, any defect in material or workmanship.

']'his warranty excludes the bar, chain, spark plug, and air filter,which are expendable parts and become worn during nor-

mal use.

If this Gas Chain Saw is used for commercial or rental purposes, this warranty applies for 30 days from the date of pur-

chase

WARRANTY SERVICE IS AVAILABLE BY RETURNING THIS CHAIN SAW TO THE NEAREST SEARS SERVICE CEN-

TER iN THE UNITED STATES

This warranty gives you specific tegat rights, and you may also have other rights which vary from state to state,

SEARS, ROEBUCK AND CO., DEPT. 817WA, HOFFMAN ESTATES, tL 60179

NOTICE_ : Refer to the Code of Federal Regulations, Section 1910.266, ANSi B175.i-1991;ANSt Z133.1;an'd state

safety cedes when using a chain saw for producing income.

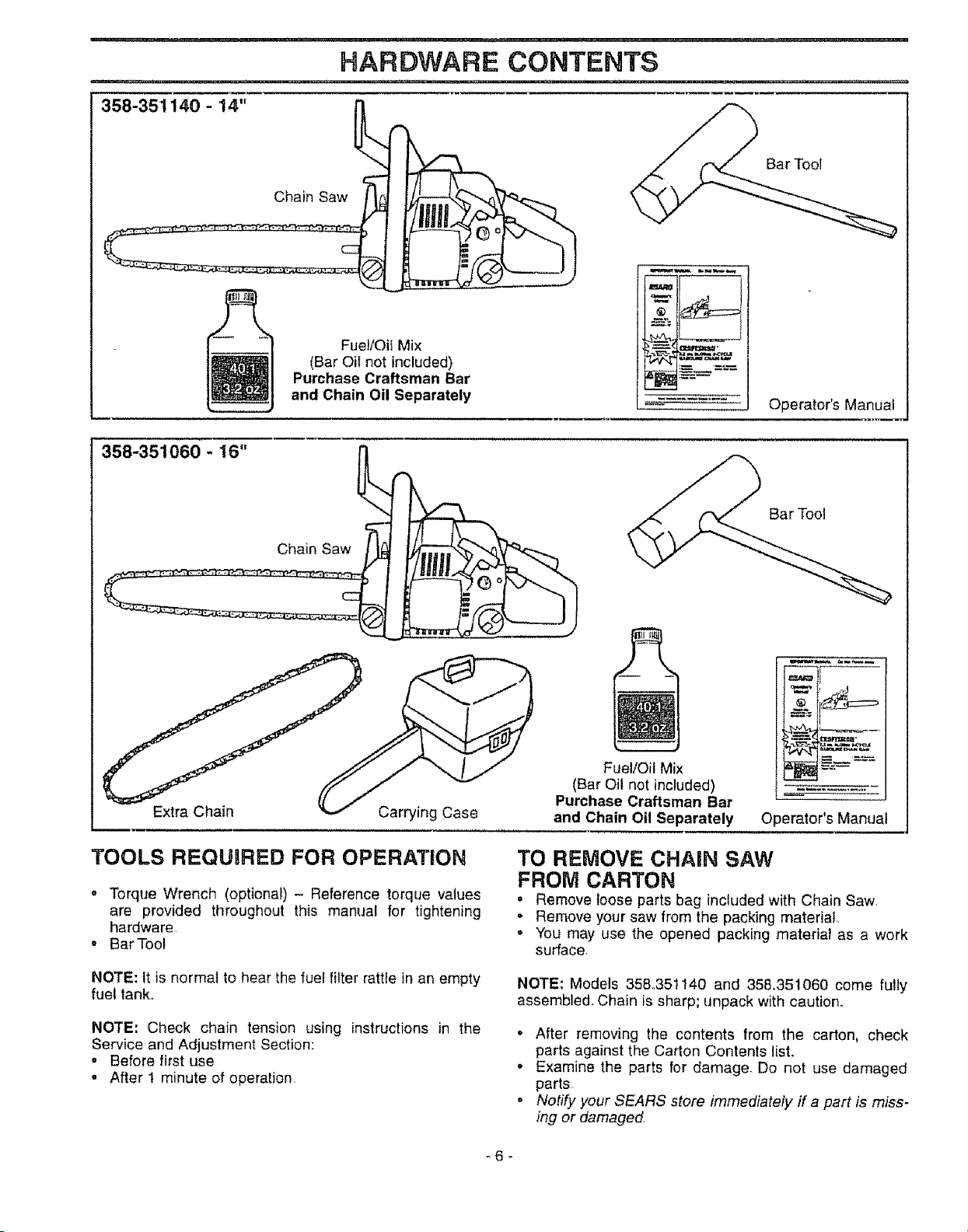

358-351060 - 16"

FueVOi! Mix

(Bar Oil not included)

Purchase Craftsman Bar

and Chain Oil Separately

Chain Saw

Bar Toot

Operator's Manual

Bar Tool

Extra Chain

Carrying Case

TOOLS REQUIRED FOR OPERATION

. Torque Wrench (optional) - Reference torque values

are provided throughout this manual for tightening

hardware

, Bar Too!

NOTE: tt is normal to hear the fuel filter rattle in an empty

fuel tank,,

NOTE: Check chain tension using instructions in the

Service and Adjustment Section:

= Before first use

. After t minute of operation,

Fuel/Oil Mix

(Bar Oil not included)

Purchase Craftsman Bar

and Chain Oil Separately Operator's Manual

TO REMOVE CHAIN SAW

FROM CARTON

• Remove loose parts bag included with Chain Saw,

• Remove your saw from the packing material

• You may use the opened packing material as a work

surface

NOTE: Models 358,351140 and 358.351060 come fully

assembled, Chain is sharp; unpack with caution.

, After removing the contents from the carton, check

parts against the Carton Contents list.

* Examine the parts for damage Do not use damaged

parts,

. Notify your SEARS store immediately ff a part is miss-

ing or damaged

_6_

i , ,i i, , i i i i,uu_,,lUJ i i,t ii1,1 ,11 i .......... :-:: u,,

OPERATION

' EL I,II,lllrll[ I '11 lilt lU,,I II II I II1' II II I'

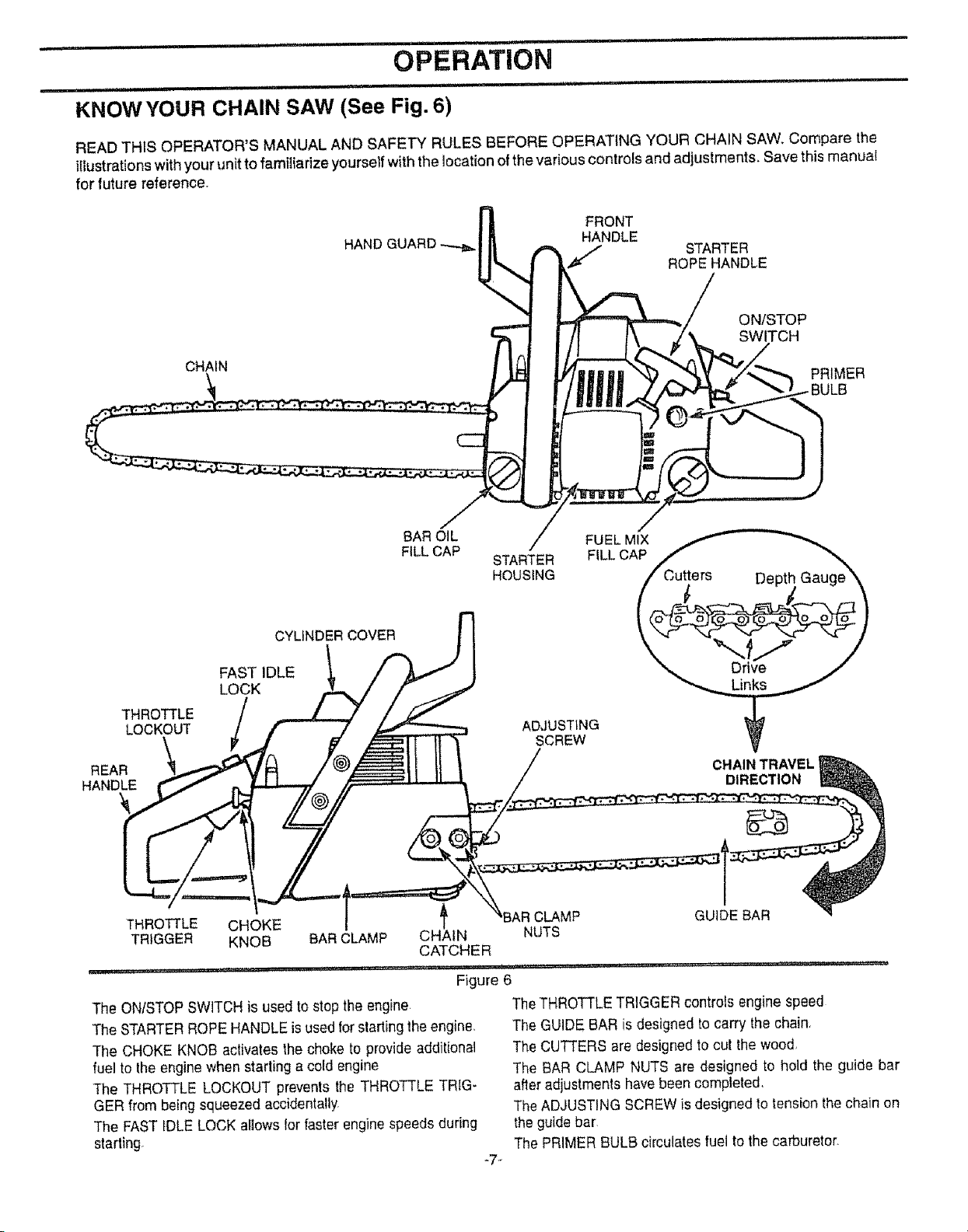

KNOW YOUR CHAIN SAW (See Fig. 6)

READ THIS OPERATOR'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR CHAIN SAW. Compare the

illustrations with your unit to familiarize yourself with the location of the various controls and adjustments, Save this manual

for future reference.

1 FRONT

HANDGUARD _!_ _' ,H,,ANDLE STARTER

ARoO,L / FUELM,X

LL P STARTER FILL CAP'f

FAST IDLE "_... Drive /

LOCK

THROTTLE

LOCKOUT ADJUSTING

SCREW

REAR CHAINTRAVEL

HANDLE DIRECTION

THROTTLE CHOKE 1' GUIDE BAR

TRIGGER KNOB BARCLAMP CHAIN NUTS

The ON/STOP SWITCH is used to stop the engine,

The STARTERROPEHANDLE isused forstarling theengine,

The CHOKE KNOB activates thechoke to provide additional

fuel to the engine when starling a cold engine

The THROTTLE LOCKOUT prevents the THROTTLE TRIG-

GER from being squeezed accidentally

The FAST _DLELOCK a_lowsfor _aslerenginespeeds during

starting.

CATCHER

Figure 6

TheTHROTTLE TRIGGER controls engine speed

The GUIDE BAR is designed to carry the chain,

TheCUTTERS are designed to cut the wood,

The BAR CLAMP NUTS are designed to hold the guide bar

afteradjuslmenls have been completed,

The ADJUSTING SCREW is designed to tension the chain on

theguide bar,

The PRIMER BULB circulates fuel to the carburetor,

*7"

OPERATION

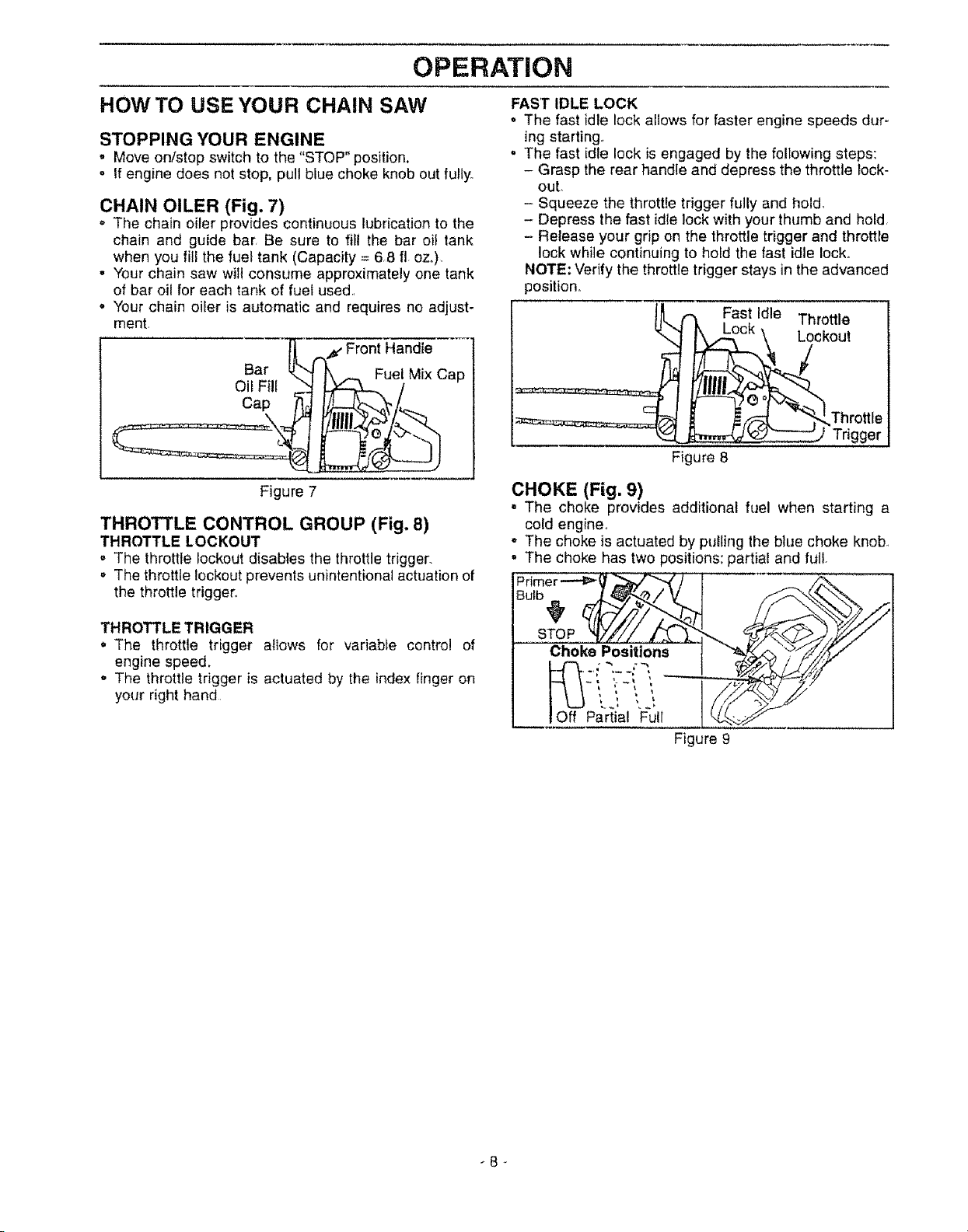

HOW TO USE YOUR CHAIN SAW

STOPPING YOUR ENGINE

, Move on/stop switch to the "STOP" position,

o If engine does not stop, pull blue choke knob out fully.

CHAIN OILER (Fig. 7)

= The chain oiler provides continuouslubrication to the

chain and guide bar Be sure to fill the bar oii tank

when you fill the fuel tank (Capacity = 6,8 fl oz°),

- Your chain saw wilt consume approximately one tank

of bar oil for each tank of fuel used,,

° Your chain oiler is automatic and requires no adjust-

mont.

Bar _

Oil Fill

Cap

Figure 7

THROTTLE CONTROL GROUP (Fig. 8)

THROTTLE LOCKOUT

o The throttle lockout disables the throttle trigger.

o The throttle lockout prevents unintentional actuation of

the throttle trigger°

Front Handle

"_.,_., Fuel Mix Cap

FAST IDLE LOCK

= The fast idle lock allows for faster engine speeds dur-

ing starting°

, The fast idle lock is engaged by the following steps:

- Grasp the rear handle and depress the throttle lock-

out,

- Squeeze the throttle trigger fully and hold,

- Depress the fast idle lock with your thumb and hold,

- Release your grip on the throttle trigger and throttle

lock while continuing to hold the fast idle lock,,

NOTE: Verify the throttle trigger stays in the advanced

position,

tJ[. t'_ Fast Idle Throttle

Lookout

..... 'q_ _ Trigge r

Figure 8

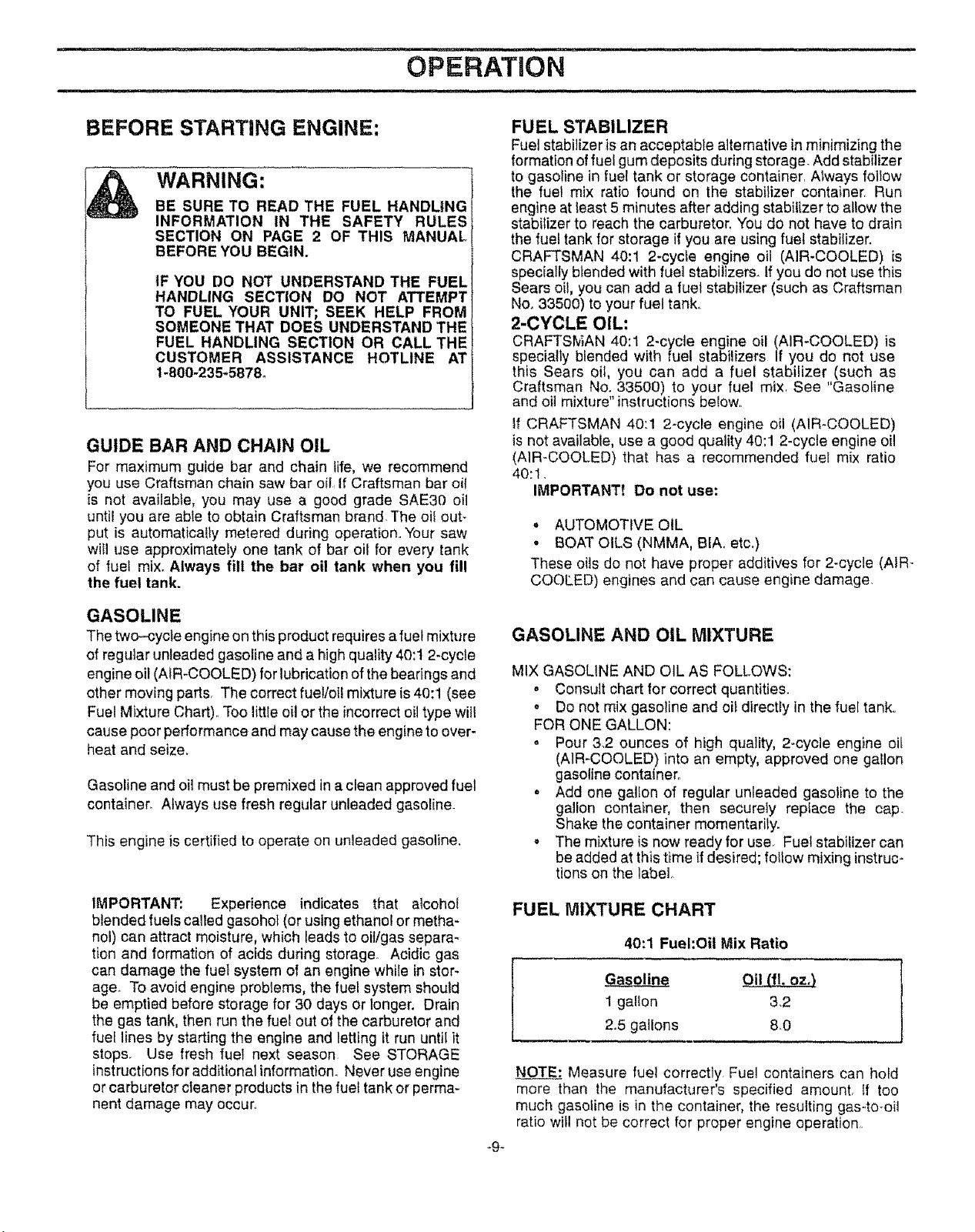

CHOKE (Fig. 9)

° The choke provides additional fuel when starting a

cold engine,

o The choke isactuated by pulling the blue choke knob,

, The choke has two positions: partial and full,

Primer_

Bulb

THROTTLE TRIGGER

o The throttle trigger atlows for variable control of

engine speed.

= The throttle trigger is actuated by the index finger on

your right hand

STOP

Choke Positions

t

Off Partial Full

Figure 9

-8 _

OPERATION

BEFORE STARTING ENGINE:

WARNING: 1

&

GUIDE BAR AND CHAIN OIL

For maximum guide bar and chain life, we recommend

you use Craftsman chain saw bar oif, If Craftsman bar oil

is not available, you may use a good grade SAE30 oil

until you are able to obtain Craftsman brand The oil out-

put is automatically metered during operation.Your saw

will use approximately one tank of bar oil for every tank

of fuel mix_ Always fill the bar oil tank when you fill

the fuel tank.

BE SURE TO READ THE FUEL HANDLING|

INFORMATION IN THE SAFETY RULES|

SECTION ON PAGE 2 OF THIS MANUAL|

BEFORE YOU BEGIN.

IF YOU DO NOT UNDERSTAND THE FUEL

HANDLING SECTION DO NOT ATTEMPT

TO FUEL YOUR UNIT; SEEK HELP FROM

SOMEONE THAT DOES UNDERSTAND THE

FUEL HANDLING SECTION OR CALL THE

CUSTOMER ASSISTANCE HOTLINE AT

1-800-235-5878_

FUEL STABILIZER

Fuel stabilizer isan acceptable alternative in minimizing the

formation offuel gum deposits during storage. Add stabilizer

to gasoline in fuel tank or storage container. Always follow

the fuel mix ratio found on the stabilizer container Run

engine at least 5 minutes after adding stabilizer to allow the

stabilizer to reach the carburetor, You do not have to drain

the fuel tank for storage if you are using fuel stabilizer.

CRAFTSMAN 40:1 2-cycte engine oil (AIR*COOLED) is

specially blended with fuel stabilizers. If you do not use this

Sears oil, you can add a fuel stabilizer (such as Craftsman

No. 33500) to your fuel tank.

2-CYCLE OIL:

CRAFTSrv_AN 40:1 2-cycte engine oil (AIR_COOLED) is

specialty blended with fuel stabilizers if you do not use

this Sears oil, you can add a fuel stabilizer (such as

Craftsman No. 33500) to your fue! mix See "Gasoline

and oil mixture" instructions below..

if CRAFTSMAN 40:1 2-cycle engine oil (AIR-COOLED)

is not available, use a good quality 40:1 2-cycle engine oil

(AIR-COOLED) that has a recommended fuet mix ratio

40:1.

IMPORTANTt Do not use:

o AUTOMOTIVE OIL

• BOAT OILS (NMMA, BIA. etc.)

These oils do not have proper additives for 2-cycle (AIR-

COOLED) engines and can cause engine damage.

GASOLINE

The two-cycle engine on this product requires afuel mixture

of regular unleaded gasoline and a high quality 40:t 2-cycle

engine oil (AIR-COOLED) for lubrication of the bearings and

other moving parts. The correct fue!!oil mixture is40:1 (see

Fuel Mixture Chart)° Too little oil or the incorrectoil type will

cause poor performance and may cause the engine to over-

heat and seize.

Gasoline and oil must be premixed in a clean approved fuel

container Always use fresh regular unleaded gasoline.

This engine is certified to operate on unleaded gasoline,

IMPORTANT: Experience indicates that alcohol

blended fuels called gasohot (or using ethanol or metha-

nol) can attract moisture, which leads to oil/gas separa-

tion and formation of acids during storage. Acidic gas

can damage the fuel system of an engine while in stor_

age. To avoid engine problems, the fuel system should

be emptied before storage for 30 days or longer. Drain

the gas tank, then run the fuel out of the carburetor and

fuel lines by starting the engine and letting it run until it

stops. Use fresh fuel next season See STORAGE

instructions for additional information. Never use engine

or carburetor cleaner products in the fuel tank or perma-

nent damage may occur1

GASOLINE AND OIL MIXTURE

MIX GASOLINE AND OIL AS FOLLOWS:

° Consult chart for correct quantities.

o Do not mix gasoline and oil directly in the fuel tank.

FOR ONE GALLON:

. Pour 3.2 ounces of high quality, 2-cycle engine oil

(AIR-COOLED) into an empty, approved one gallon

gasoline container°

= Add one gallon of regular unleaded gasoline to the

gallon container, then securely replace the cap.

Shake the container momentarily.

° The mixture isnow ready for use. Fuel stabilizer can

be added at this time if desired; follow mixing instruc-

tions on the label

FUEL MIXTURE CHART

40:1 Fuel:Oil Mix Ratio

1 gal!on 3.2

2°5 gallons 80

NOTE; Measure fuel correctly Fuel containers can hold

more than the manufacturer's specified amount, tf too

much gasoline is in the container, the resulting gas-to-oil

ratio will not be correct for proper engine operation

_9-

OPERATION

STOPPING YOUR ENGINE

- Move on/stop switch to the "STOP" position.

* if engine does not stop, pull blue choke knob out fully

WARNING:

ALWAYSWEAR GLOVES; SAFETY FOOT-

WEAR, SNUG-FITTING CLOTHING; AND

EYE, HEARING, AND HEAD PROTECTION

DEVICES WHEN OPERATING A CHAIN

SAWo

THE CHAIN MUST NOT MOVE WHEN THE

ENGINE RUNS AT IDLE SPEED. REFER

TOTHE "CARBURETOR ADJUSTMENTS"

SECTION FOR CORRECTION.

NOTE: Check chain tension using instructions in the

Service and Adjustment Section:

, Before first use.

o After 1 minute of operation_

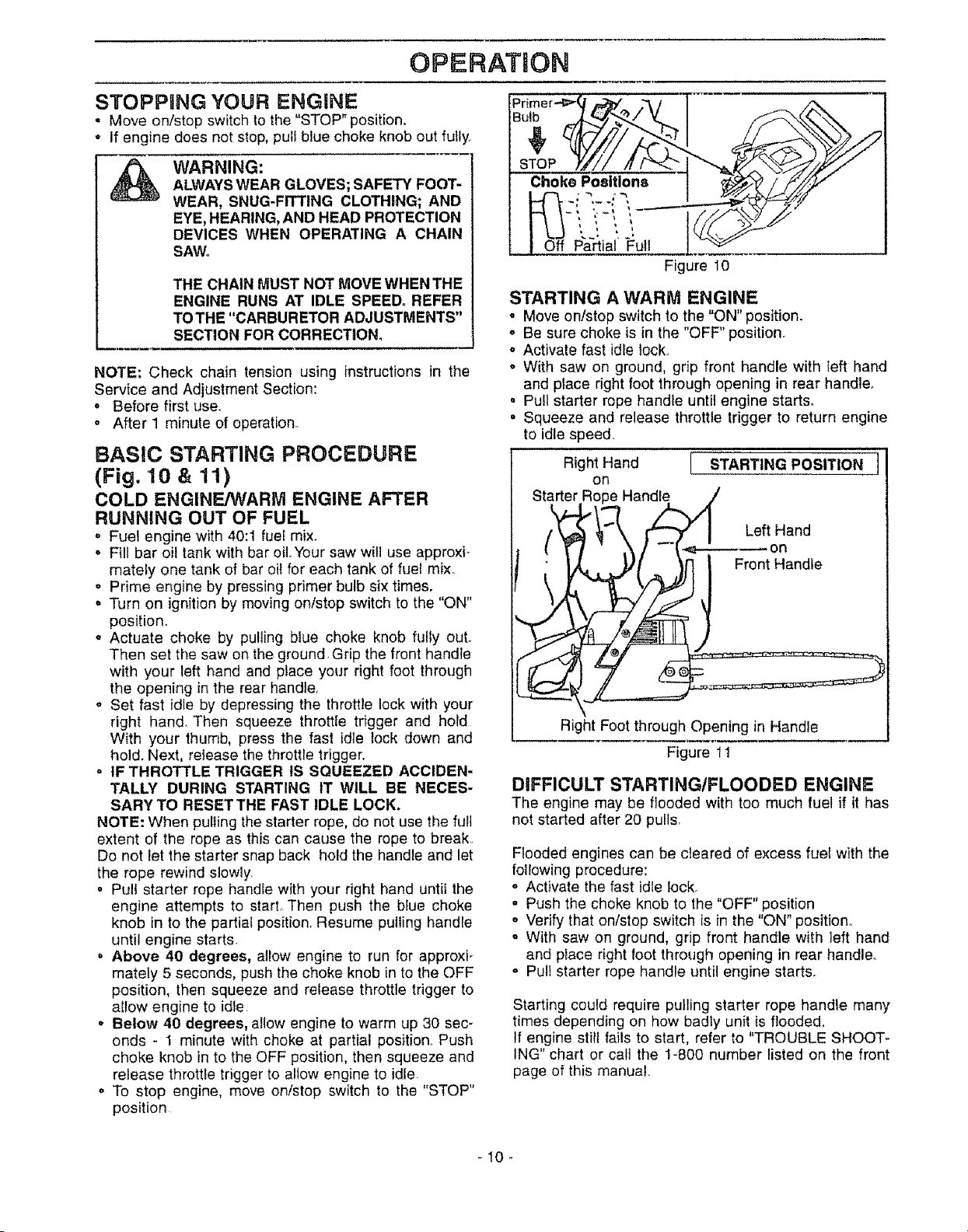

BASIC STARTING PROCEDURE

(Fig.10 & 11)

COLD ENGINE/WARM ENGINE AFTER

RUNNING OUT OF FUEL

', Fuel engine with 40:1 fuei mix.

, Fill bar oil tank with bar oil.Your saw will use approxi-

mately one tank of bar oil for each tank of fue! mix

o Prime engine by pressing primer bulb six times.

= Turn on ignitionby moving on/stop switch to the "ON"

position.

° Actuate choke by pulling blue choke knob fully out.

Then set the saw on the ground Grip the front handle

with your left hand and place your right foot through

the opening in the rear handle.

o Set fast idle by depressing the throttle lock with your

right hand. Then squeeze throttle trigger and hold

With your thumb, press the fast idle lock down and

hold. Next, release the throttle trigger.

o IF THROTTLE TRIGGER IS SQUEEZED ACCIDEN-

TALLY DURING STARTING IT WILL BE NECES-

SARY TO RESET THE FAST IDLE LOCK.

NOTE: When pulling the starter rope, do not use the full

extent of the rope as this can cause the rope to break

Do not let the starter snap back hold the handle and let

the rope rewind slowly.

° Pull starter rope handle with your right hand until the

engine attempts to start Then push the blue choke

knob in to the partial position. Resume pulling handle

until engine starts.

° Above 40 degrees, allow engine to run for approxi-

mately 5 seconds, push the choke knob in to the OFF

position, then squeeze and release throttle trigger to

allow engine to idle.

° Below 40 degrees, allow engine to warm up 30 sec-

onds - 1 minute with choke at partial position, Push

choke knob in to the OFF position, then squeeze and

release throttle trigger to allow engine to idle.

• To stop engine, move onfstop switch to the "STOP"

position

STOP

Choke .....

Positions

Y,,f/ / .,1/"'<_-___"_',.,_

Pa_ial Cull

Fi ure 10

STARTING A WARM ENGINE

, Move on/stop switch to the "ON" position.

o Be sure choke is in the "OFF" position.

° Activate fast idle lock=.

o With saw on ground, grip front handle with Ieft hand

and place right foot through opening in rear handle.

o Pull starter rope handle until engine starts.

. Squeeze and release throttle trigger to return engine

to idle speed

Right Hand

on

Starter Rope Handle

t

Right Foot through Opening in Handle

STARTING POSITION I

Left Hand

on

Front Handle

Figure 11

DIFFICULT STARTING/FLOODED ENGINE

The engine may be flooded with too much fuel if it has

not started after 20 pulls,

Flooded engines can be cleared of excess fuel with the

following procedure:

o Activate the fast idle lock.

o Push the choke knob to the "OFF" position

,, Verify that ontstop switch is in the "ON" position..

o With saw on ground, grip front handle with left hand

and place right foot through opening in rear handle°

,, Pull starter rope handle until engine starts.

Starting could require pulling starter rope handle many

times depending on how badly unit is flooded,

If engine stilt fails to start, refer to "TROUBLE SHOOT-

ING" chart or call the 1-800 number listed on the front

page of this manual

-10-

Loading...

Loading...