Page 1

Sears Brands Management Corporation, Hoffman Estates, IL 60179 U.S.A.

Model No.

358.350982 - 20 in. Bar

3.1 cu.in./50cc 2-Cycle

GASOLINE CHAIN SAW

WARNING:

Read and follow all Safety Rules and Operating

Instructions before first use of this product.

For answers to your questions about this product:

Call 7 am--7 pm, Mon--Sat; Sun, 10 am--7 pm

1-800-235-5878

Operator’s Manual

(Hours listed are Central Time)

• Safety

• Assembly

• Operation

• Maintenance

• Parts List

• Español, p. 30

589441501

Rev. A 2016--08--22 KAP

LDA

V50CS

Page 2

2

TABLE OF CONTENTS

Warranty 2

Identification of Symbols 3

Safety Rules 4

Assembly 8

Operation 8

Maintenance 15

Service and Adjustments 19

Storage 22

Troubleshooting Table 23

Emissions Statement 25

Parts List 27

Spanish 30

Parts & Ordering Back Cover

WARRANTY STATEMENT

CRAFTSMAN TWO YEAR FULL WARRANTY

FOR TWO YEARS from the date of purchase, this product is warranted against any

defects in material or workmanship. A defective product will receive free repair or

replacement if repair is unavailable.

ADDITIONAL LIMITED WARRANTY ON ENGINE CRANKSHAFT

FOR THE THIRD THROUGH TENTH YEAR from date of purchase, the engine crankshaft

in this product is warranted against any defects in material or workmanship. With

proof of purchase, a defective engine crankshaft will be replaced. This additional

warranty covers only the engine crankshaft, and does not apply to any other engine

component. You must pay the labor cost of crankshaft installation.

For warranty coverage details to obtain free repair or replacement, visit the

website: www.craftsman.com

This warranty covers ONLY defects in material and workmanship.

Warranty coverage does NOT include:

• Expendable items that can wear out from normal use within the warranty period,

including but not limited to chain bar, chain, filters or spark plug.

• Product damage resulting from user attempts at product modification or repair

or caused by product accessories.

• Repairs necessary because of accident or failure to operate or maintain the

product according to all supplied instructions.

• Preventive maintenance, or repairs necessary due to improper fuel type, fuel

mixture, contaminated or stale fuel.

This warranty is void if this product is ever used while providing commercial services or if rented to another person.

This warranty gives you specific legal rights, and you may also have other rights

which vary from state to state.

Sears Brands Management Corporation, Hoffman Estates, IL 60179

REPAIR PROTECTION AGREEMENTS

Congratulations on making a smart purchase. Your new Craftsman product is

designed and manufactured for years of dependable operation. But like all products,

it may require repair from time to time. That’s when having a Repair Protection

Agreement can save you money and aggravation.

Here’s what the Repair Protection Agreement* includes:

• Expert service by our 10,000 professional repair specialists

• Unlimited service and no charge for parts and labor on all covered repairs

• Product replacement up to $1500 if your covered product can’t be fixed

WARNING

The engine exhaust from this product contains

chemicals known to the State of California to cause

cancer, birth defects or other reproductive harm.

Page 3

3

• Discount of 10% from regular price of service and related installed parts

not covered by the agreement; also, 10% off regular price of preventive

maintenance check

• Fast help by phone -- we call it Rapid Resolution -- phone support from a

Sears representative. Think of us as a “talking operator’s manual”.

Once you purchase the Repair Protection Agreement, a simple phone call is all

that it takes for you to schedule service. You can call anytime day or night, or

schedule a service appointment online.

The Repair Protection Agreement is a risk--free purchase. If you cancel for any

reason during the product warranty period, we will provide a full refund. Or, a prorated refund anytime after the product warranty period expires. Purchase your

Repair Protection Agreement today!

Some limitations and exclusions apply. For prices and additional information in the U.S.A. call 1--800--827--6655.

*Coverage in Canada varies on some items. For full details call Sears

Canada at 1--800--361--6665.

Sears Installation Service

For Sears professional installation of home appliances, garage door openers,

water heaters, and other major home items, in the U.S.A. or Canada call

1--888--331--4569.

IDENTIFICATION OF SYMBOLS

WARNING! This chain

saw can be dangerous! Careless or improper use cancause

serious or even fatal injury.

Read and understand the

instruction manual before

using the chain saw.

Always use two hands when operating the chain saw.

WARNING! Contacting the guide bar tip with any object should be

avoided; tip contact may cause the guide bar to movesuddenly upwardand

backward, which may cause serious injury.

Always wear appropriate ear

protection, eye protection

and head protection.

Measured maximum kickback value without chain

brake for the bar and chain

combination on the label.

Move ON/STOP switch to

the ON position.

Slowly press primer bulb

6 times.

Pull the starter rope

sharply 5 times with your

right hand.

Pull the starter rope sharply

with your right hand until

the engine starts.

Pull choke/fast idle lever

out to the full extent (to

the FULL CHOKE position).

Push the choke/fast idle

lever in to the HALF

CHOKE position.

Starting Reminder

Page 4

4

SAFETY RULES

WARNING: Always disconnect

spark plug wire when making repairs except for carburetor adjustments. Because a chain saw is a high-speed

wood-cutting tool, special precautions

must be observed to reduce the risk of

accidents. Careless or improper use of

this tool can cause serious injury.

PLAN AHEAD

• Restrict the use of your saw to adult

users who understand and can follow

safety rules, precautions, and operating instructions found in this manual.

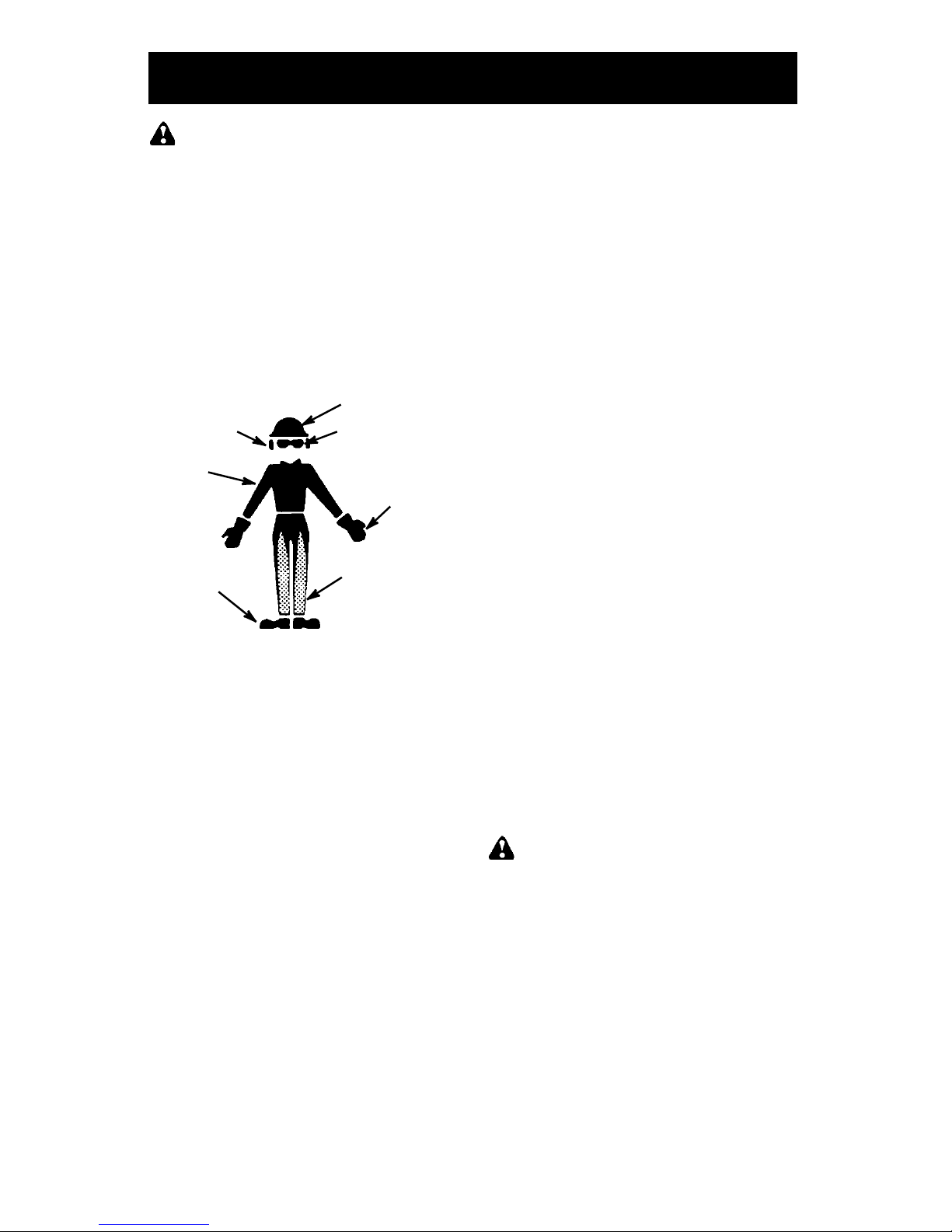

Snug

Fitting

Clothing

Safety

Shoes

Safety Chaps

Heavy Duty

Gloves

Eye

Protection

Hearing

Protection

Safety Hat

• Wear protective gear. Always use

steel-toed safety footwear with nonslip soles; snug-fitting clothing; safety

chaps; heavy-duty, non-slip gloves;

eye protection such as non-fogging,

vented goggles or face screen; an

approved safety hard hat; and sound

barriers (ear plugs or mufflers) to

protect your hearing. Regular users

should have hearing checked regularly as chain saw noise can damage

hearing.

• Secure hair above shoulder length. Do

not wear loose clothing or jewelry; they

can get caught in moving parts.

• Keep all parts of your body away from

the chain when the engine is running.

• Keep children, bystanders, and ani-

mals a minimum of 30 feet (10 meters) away from the work area when

starting and using the saw.

• Do not handle or operate a chain saw

when you are fatigued, ill, or upset, or

if you have taken alcohol, drugs, or

medication. You must be in good

physical condition and mentally alert.

If you have any condition that might be

aggravated by strenuous work, check

with doctor before operating.

• Do not start cutting until you have a

clear work area, secure footing, and,

if you are felling trees, a planned retreat path.

OPERATE YOUR SAW SAFELY

• Do not operate a chain saw with one

hand. Serious injury to the operator,

helpers, bystanders or any combination of these persons may result from

one-handed operation. A chain saw

is intended for two-handed use.

• Operate the chain saw only in a wellventilated outdoor area.

• Do not operate saw from a ladder or

in a tree.

• Make sure the chain will not make

contact with any object while starting

the engine. Never try to start the saw

when the guide bar is in a cut.

• Do not put pressure on the saw at

the end of the cut. Applying pressure

can cause you to lose control when

the cut is completed.

• Stop engine before setting saw down.

• Hand carry saw only when engine is

stopped. Carry with muffler away

from body; guide bar and chain projecting behind you; guide bar covered

with a scabbard.

• Do not operate a chain saw that is

damaged, improperly adjusted, or

not completely and securely assembled. Always replace bar, chain,

hand guard, or chain brake immediately if it becomes damaged, broken

or is otherwise removed.

MAINTAIN YOUR SAW IN GOOD

WORKING ORDER

WARNING: Disconnect the

spark plug before performing maintenance except carburetor adjustments.

• Have all chain saw service performed

by a qualified service dealer with the

exception of the items listed in the

MAINTENANCE section of this manual.

• Make certain the saw chain stops

moving when the throttle trigger is

released. For correction, refer to

CARBURETOR ADJUSTMENT.

• Keep the handles dry, clean, and

free from oil or fuel mixture.

• Keep caps and fasteners securely

tightened.

• Nonconforming replacement components or the removal of safety devices

may cause damage to the unit and

Page 5

5

possible injury to the operator or bystanders. Use only Craftsman accessories and replacement parts as recommended. Never modify your saw.

• Maintain chain saw with care.

• Keep unit sharp and clean for better

and safer performance.

• Follow instructions for lubricating and

changing accessories.

• Check for damaged parts. Before further use of the chain saw, a guard or

other part that is damaged should be

carefully checked to determine that it

will operate properly and perform its

intended function. Check for alignment

of moving parts, binding of moving

parts, breakage of parts, mounting and

any other conditions that may affect its

operation. A guard or other part that is

damaged should be properly repaired

or replaced by a Sears Service Center

unless otherwise indicated elsewhere

in the operator’s manual.

• When not in use, chain saws should

be stored in a dry, high or locked-up

place out of the reach of children.

• When storing saw, use a scabbard or

carrying case.

HANDLE FUEL WITH CAUTION

• Do not smoke while handling fuel or

while operating the saw.

• Eliminate all sources of sparks or

flame in the areas where fuel is

mixed or poured.

• Always have fire extinguishing tools

available if you should need them.

• Mix and pour fuel in an outdoor area

and use an approved, marked container for all fuel purposes. Wipe up

all fuel spills before starting saw.

• Move at least 10 feet (3 meters) from

fueling site before starting engine.

• Turn the engine off and let saw cool

in a non-combustible area, not on

dry leaves, straw, paper, etc. Slowly

remove fuel cap and refuel unit.

• Empty the fuel tank before storing or

transporting the unit. Use up fuel left in

the carburetor by starting the engine

and letting it run until it stops.

• Store the unit and fuel in an area

where fuel vapors cannot reach

sparks or open flames from water

heaters, electric motors or switches,

furnaces, etc.

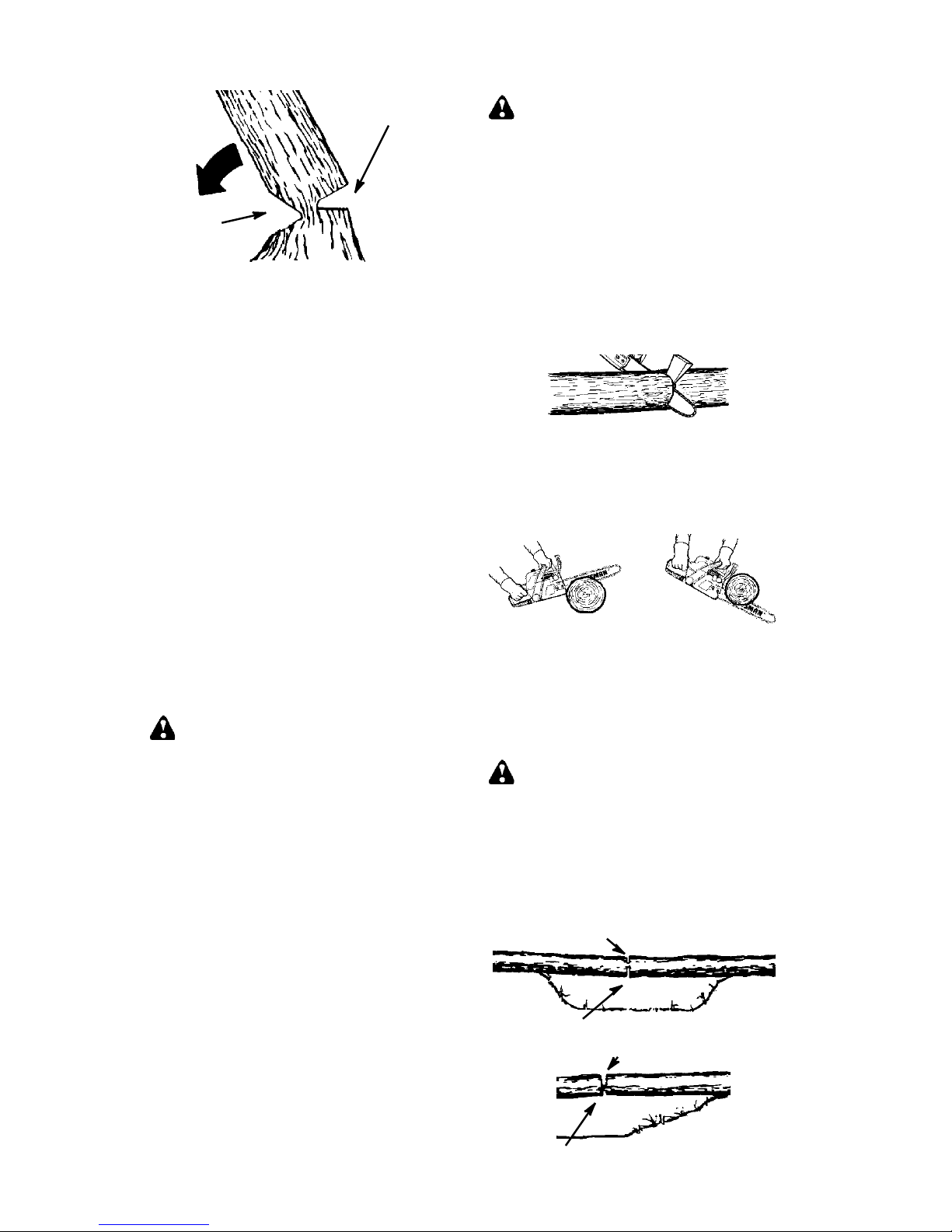

GUARD AGAINST KICKBACK

Follow all safety rules to help avoid

kickback and other forces which can

result in serious injury.

Kickback Path

Clear The

Working Area

Avoid Obstructions

WARNING: Avoid kickback

which can result in serious injury.

Kickback is the backward, upward or

sudden forward motion of the guide

bar occurring when the saw chain near

the upper tip of the guide bar contacts

any object such as a log or branch, or

when the wood closes in and pinches

the saw chain in the cut. Contacting a

foreign object in the wood can also result in loss of chain saw control.

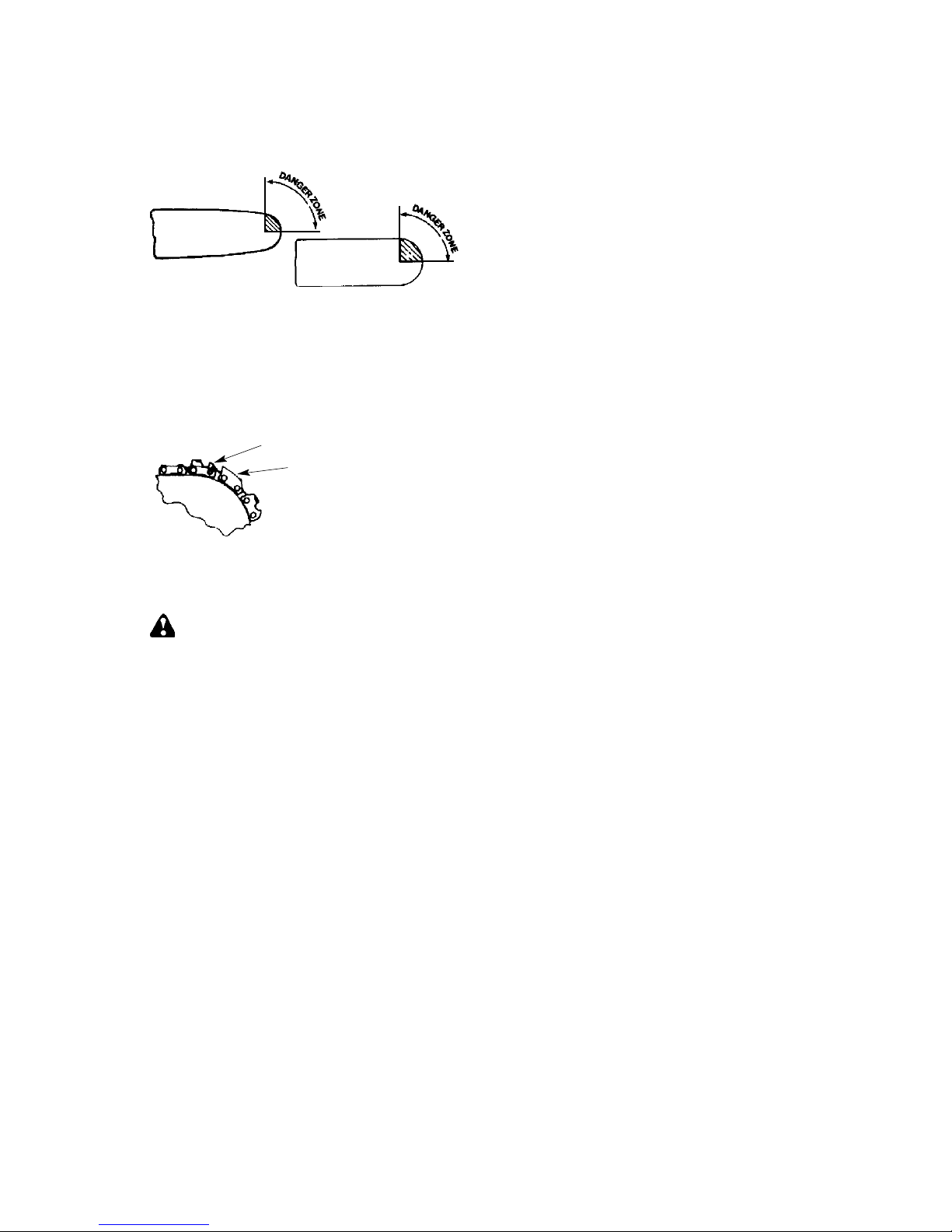

• Rotational Kickback can occur

when the moving chain contacts an

object at the upper tip of the guide

bar. This contact can cause the

chain to dig into the object, which

stops the chain for an instant. The

result is a lightning fast, reverse

reaction which kicks the guide bar up

and back toward the operator.

• Pinch-Kickback can occur when the

the wood closes in and pinches the

moving saw chain in the cut along

the top of the guide bar and the saw

chain is suddenly stopped. This sudden stopping of the chain results in a

reversal of the chain force used to

cut wood and causes the saw to

move in the opposite direction of the

chain rotation. The saw is driven

straight back toward the operator.

• Pull-In can occur when the moving

chain contacts a foreign object in the

wood in the cut along the bottom of

the guide bar and the saw chain is

suddenly stopped. This sudden stopping pulls the saw forward and away

from the operator and could easily

cause the operator to lose control of

the saw.

Page 6

6

REDUCE THE CHANCE OF

KICKBACK

• Recognize that kickback can happen. With a basic understanding of

kickback, you can reduce the element of surprise which contributes to

accidents.

• Never let the moving chain contact

any object at the tip of the guide bar.

• Keep the working area free from obstructions such as other trees,

branches, rocks, fences, stumps,

etc. Eliminate or avoid any

obstruction that your saw chain could

hit while you are cutting.

• When cutting a branch, do not let the

guide bar contact branch or other objects around it.

• Keep saw chain sharp and properly

tensioned. A loose or dull chain can

increase the chance of kickback. Follow manufacturer’s chain sharpening

and maintenance instructions. Check

tension at regular intervals, but never

with the engine running. Make sure

the bar nuts are securely tightened.

• Begin and continue cutting at full

speed. If the chain is moving at a

slower speed, there is greater

chance of kickback occurring.

• Use extreme caution when re-entering a previous cut.

• Do not attempt cuts starting with the

tip of the bar (plunge cuts).

• Watch for shifting logs or other forces

that could close a cut and pinch or

fall into chain.

• Use the Reduced--Kickback Guide

Bar and Low--Kickback Chain specified for your saw.

Avoid Pinch--Kickback:

• Be extremely aware of situations or

obstructions that can cause material to

pinch the top of or otherwise stop the

chain.

• Do not cut more than one log at a

time.

• Do not twist the saw as the bar is

withdrawn from an undercut when

bucking.

Avoid Pull--In:

• Always begin cutting with the engine

at full speed and the saw housing

against wood.

• Use wedges made of plastic or wood.

Never use metal to hold the cut open.

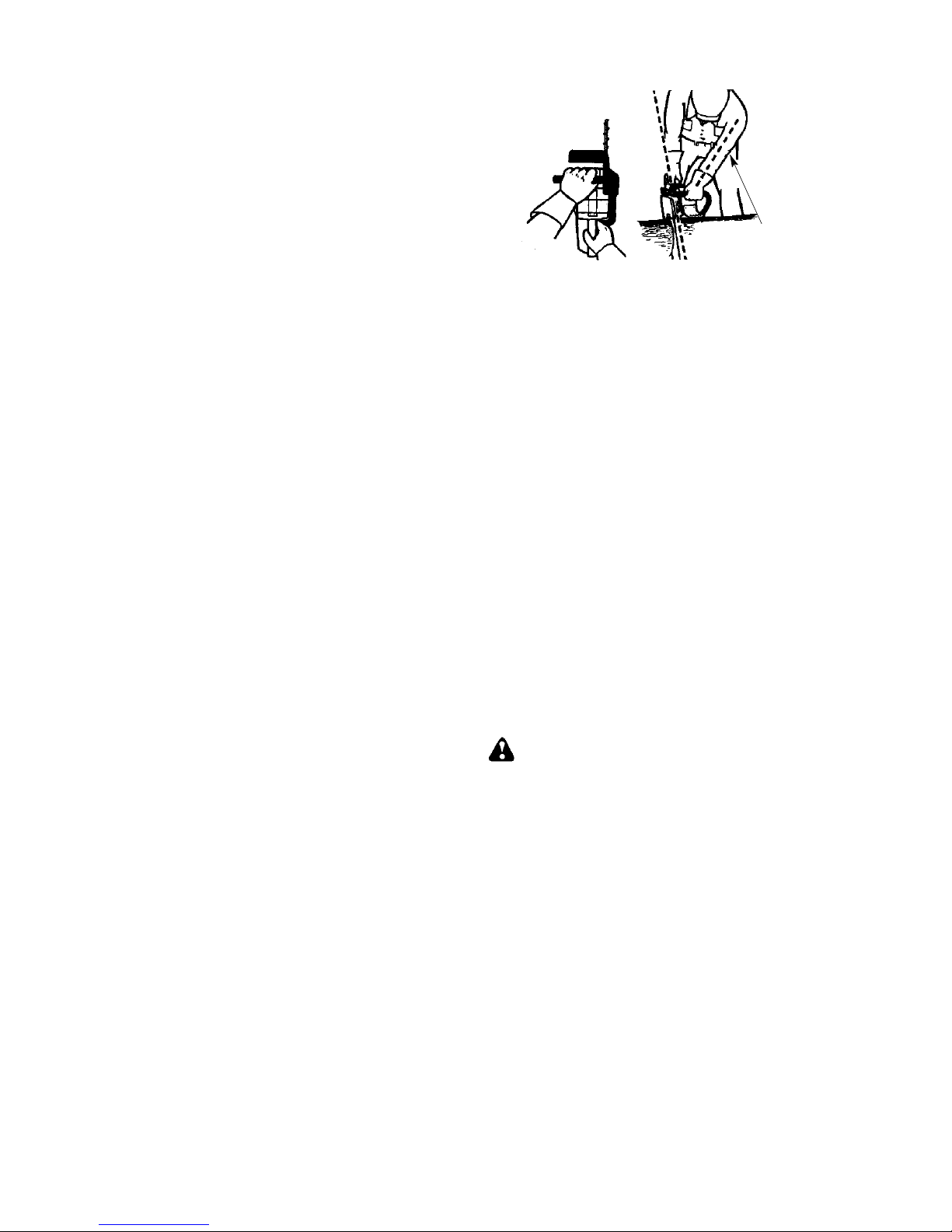

MAINTAIN CONTROL

Never reverse hand positions

Stand

to

the

leftofthe

saw

Thumb on

underside

of handlebar

Elbow

locked

• A good, firm grip on the saw with both

hands will help you maintain control.

Don’t let go. Grip the rear handle with

your right hand whether you are right

or left handed. Wrap the fingers of

your left hand over and around the

front handlebar, and your left thumb

under the front handlebar. Keep your

left arm straight with the elbow locked.

• Position your left hand on the front

handlebar so it is in a straight line

with your right hand on the rear

handle when making bucking cuts.

Never reverse right and left hand

positions for any type of cutting.

• Stand with your weight evenly balanced on both feet.

• Do not overreach. You could be

drawn or thrown off balance and lose

control of the saw.

• Do not cut above shoulder height. It

is difficult to maintain control of saw

above shoulder height.

KICKBACK SAFETY FEATURES

WARNING: The following fea-

tures are included on your saw to help

reduce the hazard of kickback; however,

such features will not totally eliminate

this danger. Do not rely only on safety

devices. Follow all safety rules to help

avoid kickback and other forces which

can result in serious injury.

• Front Hand Guard, designed to reduce

the chance of your left hand contacting the chain if your hand slips off the

front handlebar.

• Position of front and rear handlebars,

designed with distance between handles and “in-line” with each other. The

spread and “in-line” position of the

hands provided by this design work

together to give balance and resistance in controlling the pivot of the

saw back toward the operator if kickback occurs.

• Reduced--Kickback Guide Bar,

designed with a small radius tip which

Page 7

7

reduces the size of the kickback danger zone on the bar tip. This type of

bar has been demonstrated to significantly reduce the number and seriousness of kickbacks when tested in

accordance with ANSI B175.1.

Large Radius

Tip Guide Bar

Small Radius

Tip Guide Bar

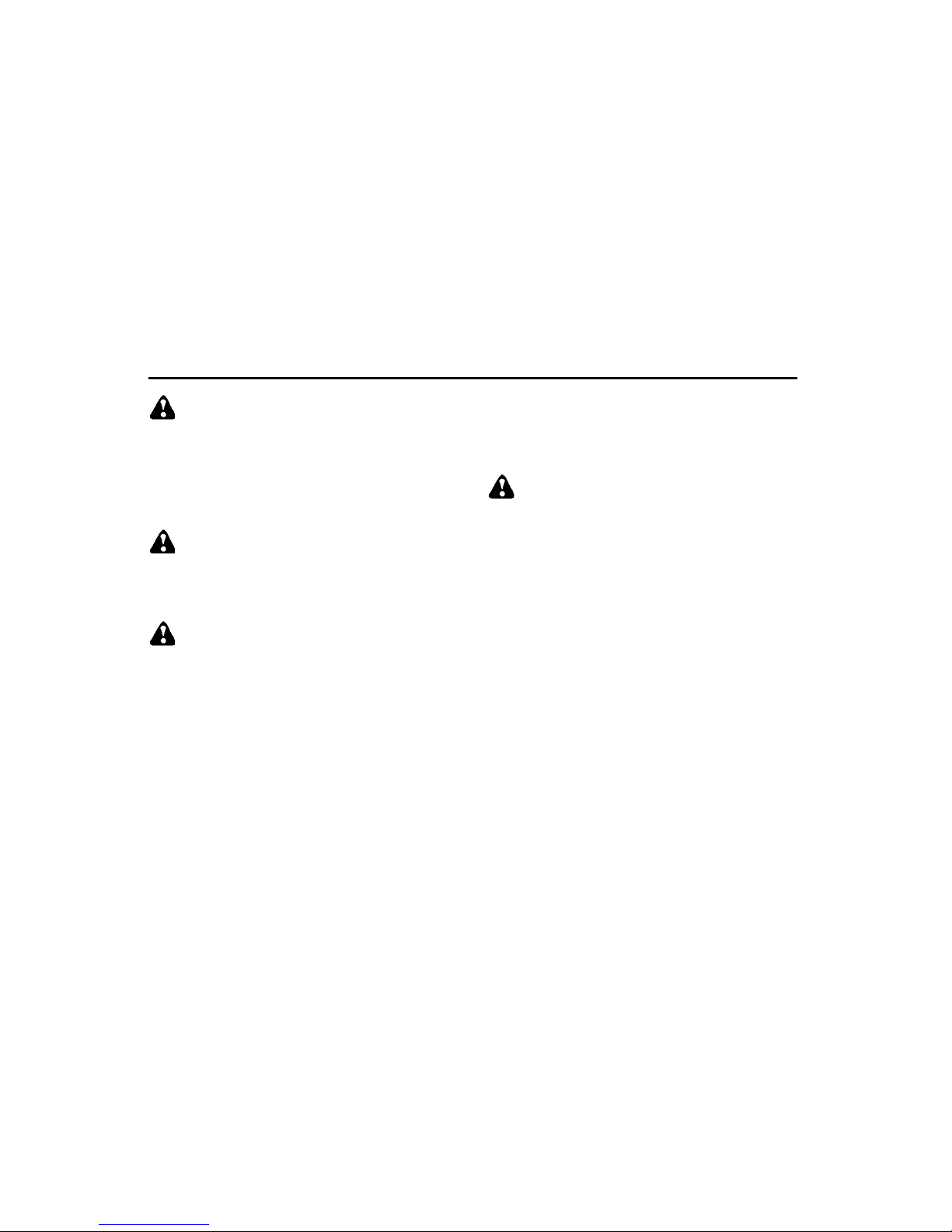

• Low--Kickback Chain, has met kickback performance requirements

when tested on a representative

sample of chain saws below 3.8

cubic inch displacement specified

in ANSI B175.1--2012.

Low-KickbackChain

Contoured Depth Gauge

Elongated Guard Link

deflects kickback

force And allows

wood to gradually

ride into Cutter

CHAIN BRAKE

• Chain Brake, designed to stop the

chain in the event of kickback.

WARNING: WE DO NOT REP-

RESENT AND YOU SHOULD NOT ASSUME THAT THE CHAIN BRAKE WILL

PROTECT YOU IN THE EVENT OF A

KICKBACK. Kickback is a lightning fast

action which throws the bar and rotating chain back and up toward the operator. Kickback can be caused by allowing contact of the bar tip in the

danger zone with any hard object.

Kickback can also be caused by

pinching the saw chain along the top

of the guide bar. This action may push

the guide bar rapidly back toward the

operator. Either of these events may

cause you to lose control of the saw

which could result in serious injury or

even death. DO NOT RELY UPON ANY

OF THE DEVICES BUILT INTO YOUR

SAW. YOU SHOULD USE THE SAW

PROPERLY AND CAREFULLY TO AVOID

KICKBACK. Reduced--kickback guide

bars and low--kickback saw chains reduce the chance and magnitude of

kickback and are recommended. Your

saw has a low kickback chain and bar

as original equipment. Repairs on a

chain brake should be made by an authorized Sears Service Center. Take

your unit to the place of purchase if

purchased from a servicing dealer, or

to your nearest Sears Service Center.

• Tip contact in some cases may cause

a lightning fast reverse REACTION,

kicking guide bar up and back toward

operator.

• Pinching the saw chain along the top

of the guide bar may push the guide

bar rapidly back toward the operator.

• Either of these reactions may cause

you to lose control of the saw which

could result in serious injury. Do not

rely exclusively upon devices built into

your saw.

This unit is equipped with an antivibration system and is intended for

occasional use only.

SAFETY NOTICE: Exposure to vibrations through prolonged use of gasoline

powered hand tools could cause blood

vessel or nerve damage in the fingers,

hands, and joints of people prone to

circulation disorders or abnormal swellings. Prolonged use in cold weather has

been linked to blood vessel damage in

otherwise healthy people. If symptoms

occur such as numbness, pain, loss of

strength, change in skin color or texture,

or loss of feeling in the fingers, hands, or

joints, discontinue the use of this tool

and seek medical attention. An anti-vibration system does not guarantee the

avoidance of these problems. Users

who operate power tools on a continual

and regular basis must monitor closely

their physical condition and the condition

of this tool.

CHAIN BRAKE: To comply with

Federal OSHA Regulations for Commercial Logging, a chain brake is

required and shall not be removed

or otherwise disabled.

SPARK ARRESTING SCREEN: Your

saw is equipped with a temperature

limiting muffler and spark arresting

screen which meets the requirements

of California Codes 4442 and 4443.

All U.S. forest land and the states of

California, Idaho, Maine, Minnesota,

New Jersey, Oregon, and Washington

require by law that many internal combustion engines to be equipped with a

spark arresting screen. If you operate

a chain saw in a state or locale where

such regulations exist, you are legally

responsible for maintaining the operating condition of these parts. Failure to

do so is a violation of the law. Refer to

the Customer Responsibilities chart in

the MAINTENANCE section.

Page 8

8

STANDARDS: This saw is tested in accordance with American National Standards for Gasoline-Powered Chain

Saws Safety Requirements (ANSI

B175.1-2012).

ASSEMBLY

WARNING: Before using chain

saw, ensure all fasteners are secure.

CARTON CONTENTS

Check carton contents against the following list.

Model 358.350982

• Chain Saw (fully assembled)

• 2-cycle Engine Oil

• Carrying Case

Examine parts for damage. Do not use

damaged parts.

If you need assistance or find that parts

are missing or damaged, please call

1-800-235-5878.

NOTE: It is normal to hear the fuel filter

rattle in an empty fuel tank.

Your unit has been factory tested and

the carburetor precisely adjusted. As a

result you may smell gasoline or find a

drop of oil/fuel residue on the muffler

when you unpack the unit.

ASSEMBLY

Your saw is fully assembled; no

assembly is necessary.

OPERATION

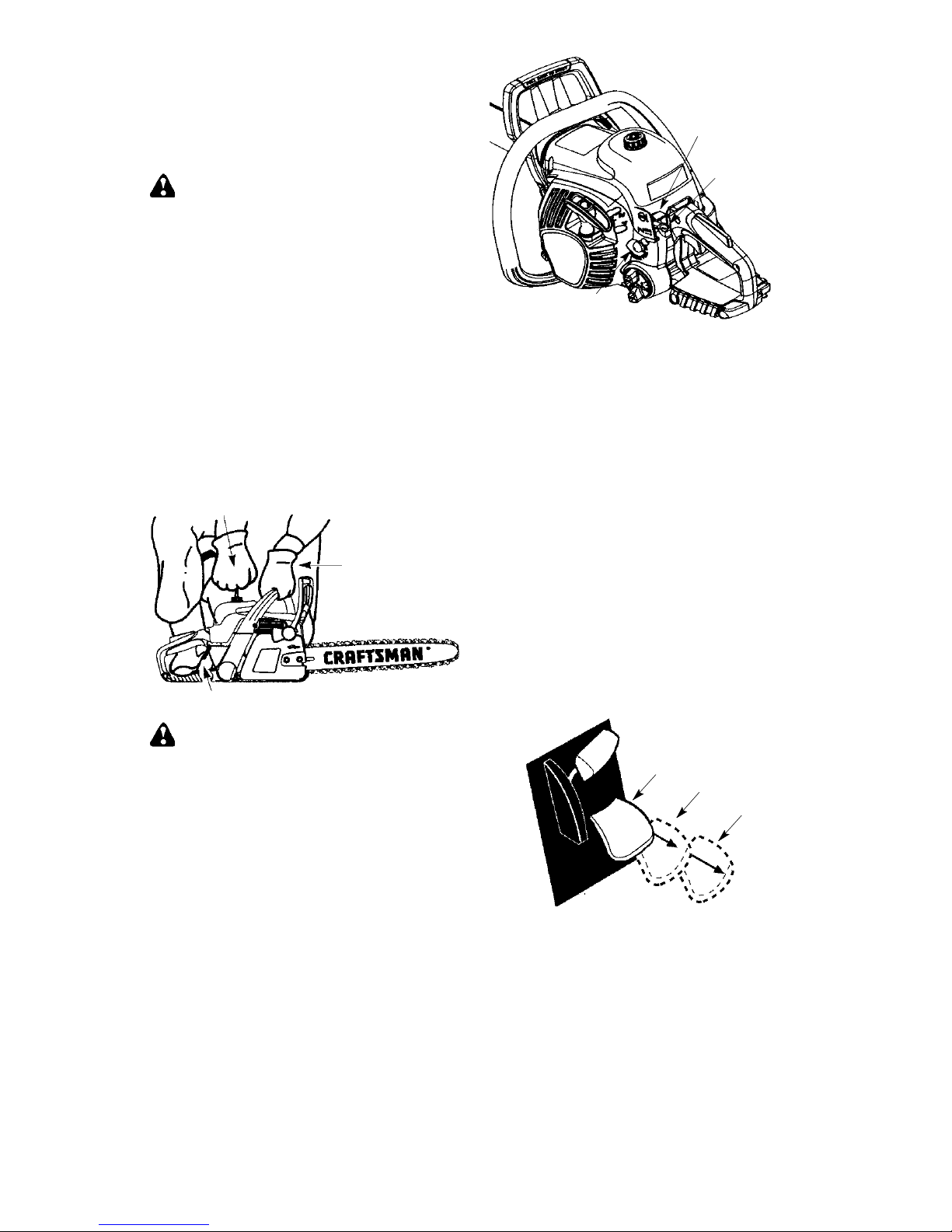

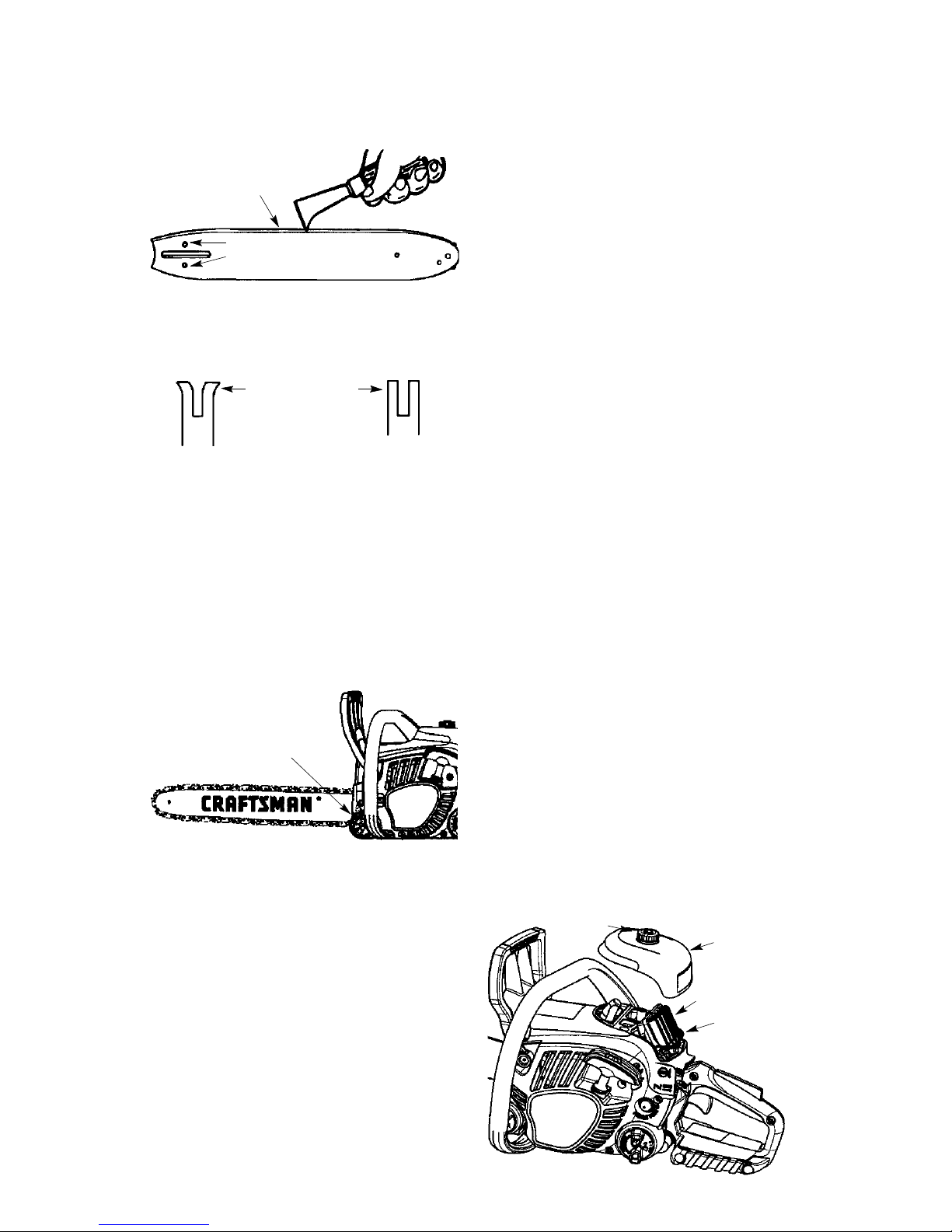

KNOW YOUR CHAIN SAW

READ THIS OPERATOR’S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR

CHAIN SAW. Compare the illustrations with your unit to familiarize yourself with the

location of the various controls and adjustments. Save this manual for future reference.

Primer Bulb

Starter Housing

Bar Oil Fill Cap

Chain

Front Hand Guard/

Chain Brake

Front Handle

Starter Rope

ON/STOP

Switch

Choke/

Fast Idle

Lever

Fuel Mix Fill Cap

Bar

Sprocket

Hole

Muffler

Guide Bar

Bar Nuts

Cylinder Cover

Throttle

Lockout

Rear

Handle

Throttle

Trigger

Chain

Direction

of Travel

Chain

Catcher

Clutch Cover

Adjusting Screw

Air Filter Cover

Chain Adjustment Tool

(Bar Tool)

ON/STOP SWITCH

The ON/STOP SWITCH is used to stop

the engine.

THROTTLE TRIGGER

The THROTTLE TRIGGER controls

engine speed.

Page 9

9

THROTTLE LOCK--OUT

The THROTTLE LOCK--OUT must be

pressed before you can squeeze the

throttle trigger. This feature prevents you

from accidentally squeezing the trigger.

CHOKE/FAST IDLE LEVER

The choke and fast idle are set by pulling the CHOKE/FAST IDLE LEVER out to

the full extent for cold starting or after

refueling. The choke provides additional

fuel to the engine during cold starting.

PRIMER BULB

The PRIMER BULB circulates fuel to the

carburetor to provide quicker starting.

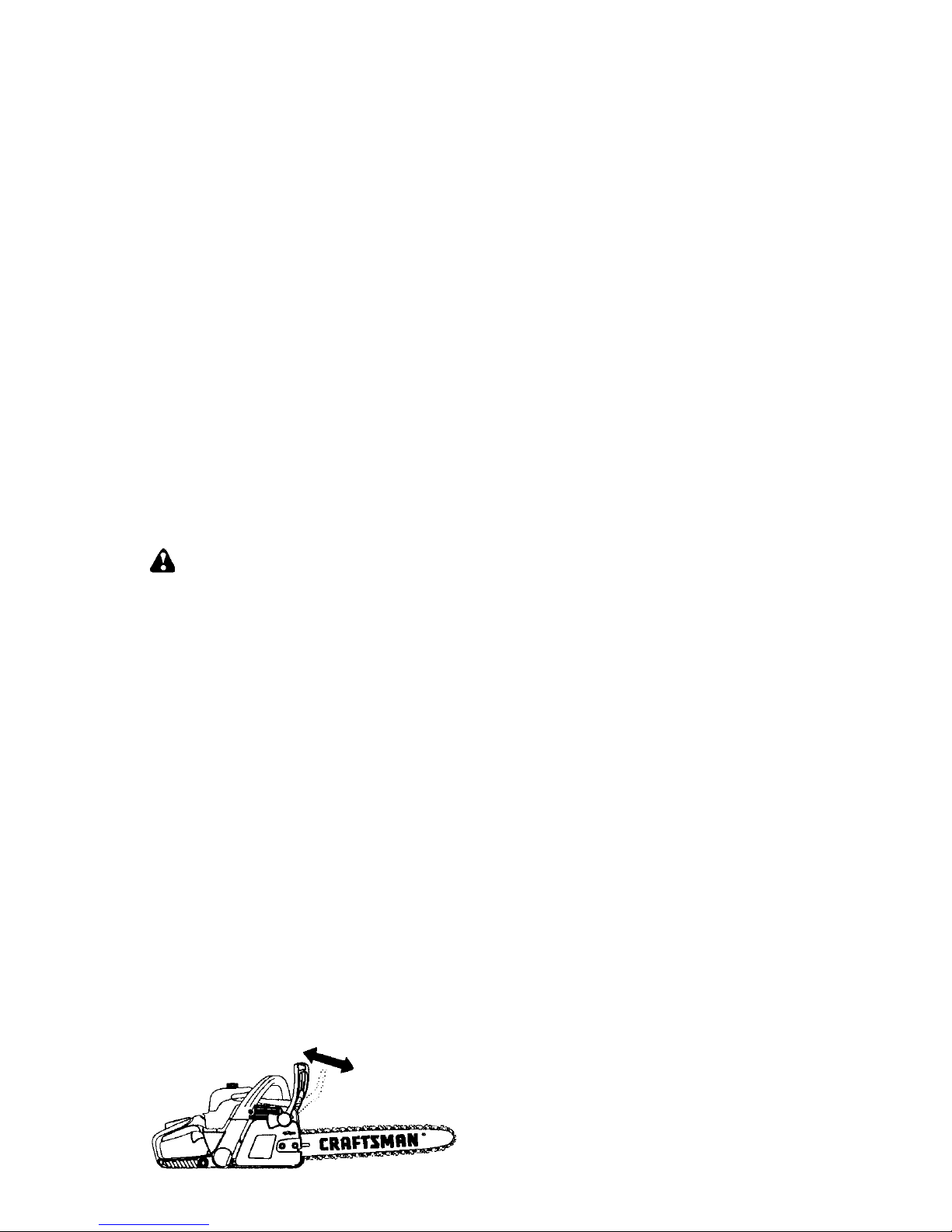

CHAIN BRAKE

The CHAIN BRAKE is a device designed

to stop the chain if kickback occurs. The

chain brake activates automatically in

the event of kickback. The chain brake

activates manually if the front hand

guard is pushed forward. The chain

brake is disengaged by pulling the front

hand guard back toward the front handle

as far as possible.

CHAIN TENSION

It is normal for a new chain to stretch

during the first 15 minutes of operation.

You should check your chain tension

each time before you start the chain

saw. See CHAIN TENSION under the

MAINTENANCE section.

WARNING: If the saw is oper-

ated with a loose chain, the chain

could jump off the guide bar and result

in serious injury to the operator and/or

damage the chain making it unusable.

BEFORE STARTING ENGINE

WARNING: Muffler is very hot

during and after use. Do not touch the

muffler or allow combustible material

such as dry grass or fuel to do so.

WARNING: Be sure to read the

fuel handling information in the safety

rules section of this manual before you

begin. If you do not understand the

fuel handling information do not attempt to fuel your unit. Seek help from

someone that does understand the information or call the customer assistance help line at 1-800-235-5878.

GUIDE BAR AND CHAIN OIL

The bar and chain require lubrication.

The chain oiler provides continuous

lubrication to the chain and guide bar.

Be sure to fill the bar oil tank when you

fill the fuel tank (Capacity = 6.8 fl. oz.).

Lack of oil will quickly ruin the bar and

chain. Too little oil will cause overheating shown by smoke coming from the

chain and/or discoloration of the bar.

For maximum guide bar and chain life,

we recommend you use Craftsman

chain saw bar oil. If Craftsman bar oil

is not available, you may use a good

grade SAE 30 oil until you are able to

obtain Craftsman brand.

The oil output is automatically metered

during operation. Your saw will use

approximately one tank of bar oil for

every tank of fuel mix. Always fill the

bar oil tank when you fill the fuel tank.

FUELING ENGINE

WARNING: Remove fuel cap

slowly when refueling.

IMPORTANT: This equipment is designed to operate on unleaded gasoline

with a minimum 87 octane (R+M/2

method), with ethanol blended up to

10% maximum by volume (E-10).

Before operation, gasoline must be

mixed with a good quality synthetic

2-cycle air-cooled engine oil designed to

be mixed at a ratio of 50:1. Craftsman

brand synthetic oil is recommended.

Mix gasoline and oil at a ratio of 50:1.

A 50:1 ratio is obtained by mixing

2.6 fluid ounces of oil with 1 gallon of

unleaded gasoline. DO NOT USE automotive oil or marine oil. These oils will

cause engine damage. When mixing

fuel, follow instructions printed on container. Once oil is added to gasoline,

shake container momentarily to assure

that the fuel is thoroughly mixed. Always

read and follow the safety rules relating

to fuel before fueling your unit. Purchase

fuel in quantities that can be used within

30 days to assure fuel freshness.

CAUTION: Never use straight gasoline

in your unit. This will cause permanent

engine damage and void the limited

warranty. Do not use alternate fuels

such as ethanol blends above 10% by

volume (E-15, E-85) or any methanol

blended fuel. Use of these fuels can

cause major engine performance and

durability problems.

Page 10

10

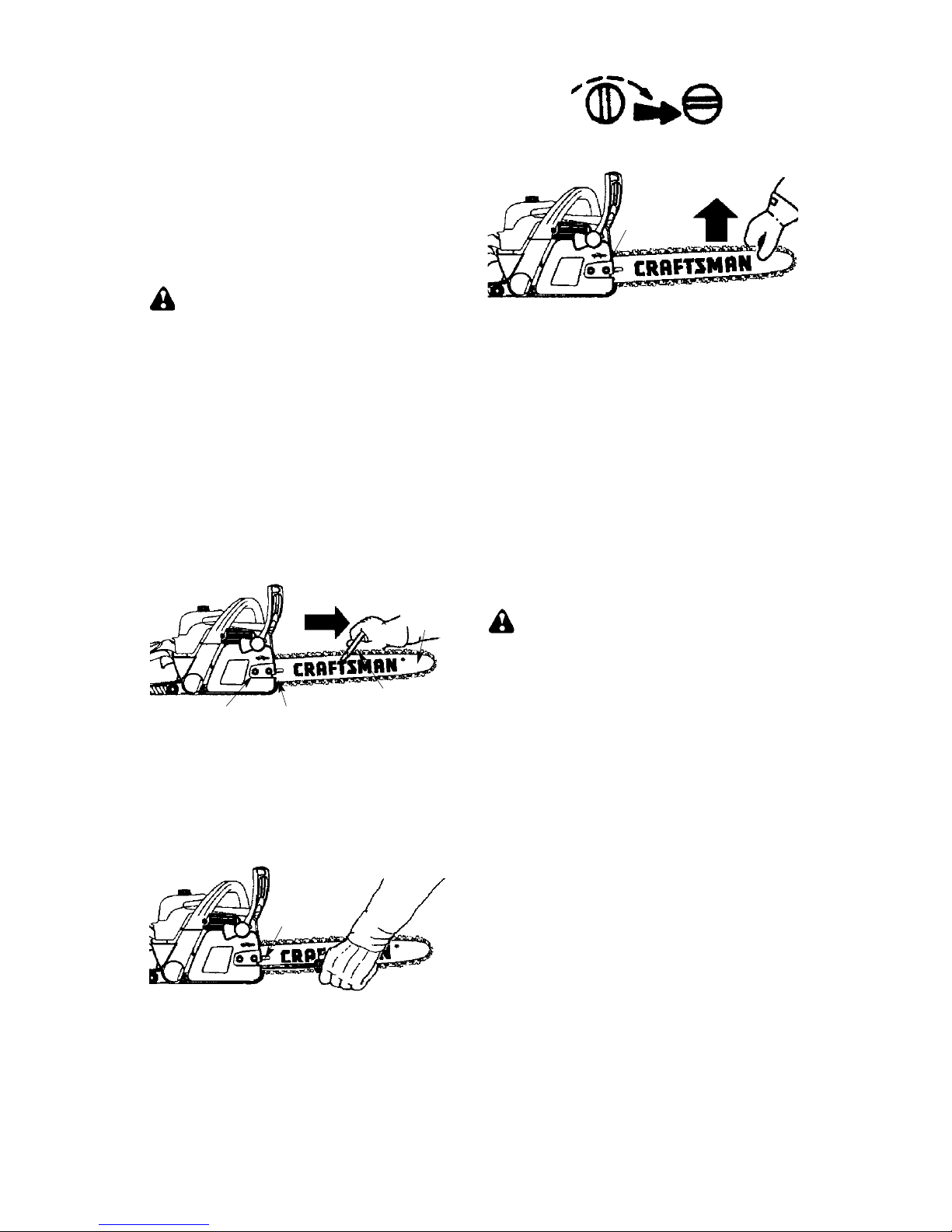

CHAIN BRAKE

Ensure chain brake is disengaged by

pulling the front hand guard back toward

the front handle as far as possible. The

chain brake must be disengaged before

cutting with the saw.

WARNING: The chain must not

move when the engine runs at idle

speed. If the chain moves at idle

speed refer to CARBURETOR ADJUST-

MENT within this manual. Avoid contact

with the muffler. A hot muffler can

cause serious burns.

STOPPING YOUR ENGINE

• Release the throttle trigger.

• Move ON/STOP switch to the STOP

position.

STARTING POSITION

• To start the engine, hold the saw

firmly on the ground as illustrated.

Make sure the chain is free to turn

without contacting any object.

Left Hand

on Front

Handle

Starter

Rope

Handle

Right Foot Through Rear Handle

WARNING: Do not attempt to

throw or drop-start the chain saw.

Doing so will put the operator at risk of

serious injury due to loss of control of

the chain saw.

IMPORTANT POINTS TO REMEMBER

When pulling the starter rope, do not

use the full extent of the rope as this can

cause the rope to break. Do not let starter rope snap back. Hold the handle and

let the rope rewind slowly. For cold

weather starting, start the unit at FULL

CHOKE; allow the engine to warm up

before squeezing the throttle trigger.

NOTE: Do not attempt to cut material

with the choke/fast idle lever in the FULL

CHOKE position.

STARTING A COLD ENGINE (or warm

engine after running out of fuel)

NOTE: In the following steps, when the

choke/fast idle lever is pulled out to the

full extent, the correct throttle setting for

starting is set automatically.

ON/STOP

Switch

Choke

Lever

Primer Bulb

1. Move ON/STOP switch to the ON

position.

2. Pull choke/fast idle lever out to the

full extent (to the FULL CHOKE position).

3. Slowly press primer bulb 6 times.

4. This unit has the Sim--pul starting

system. You do not have to pull the

starter rope handle sharply or briskly.

Using your right hand, pull starter

rope handle 5 times with a controlled

and steady motion. Then, proceed

to the next step.

NOTE: If the engine sounds as if it is trying to start before the 5th pull, stop pulling and immediately proceed to the next

step.

5. Push the choke/fast idle lever in to

the HALF CHOKE position.

OFF

HALF

CHOKE/FAST IDLE LEVER

FULL

6. Pull the starter rope with your right

hand until the engine starts.

7. Allow the engine to run for approximately 30 seconds. Then, squeeze

and release the throttle trigger to

allow engine to return to idle speed.

STARTING A WARM ENGINE

1. Move ON/STOP switch to the ON

position.

2. Pull the choke/fast idle lever out to

the FULL CHOKE position to set the

fast idle, then push the lever in to

the HALF CHOKE position.

3. Slowly press primer bulb 6 times.

Page 11

11

4. Using your right hand, pull starter

rope handle with a controlled and

steady motion until engine starts.

5. Squeeze and release throttle trigger

to allow engine to return to idle

speed.

DIFFICULT STARTING (or starting a

flooded engine)

The engine may be flooded with too

much fuel if it has not started after 10

pulls.

Flooded engines can be cleared of excess fuel by pushing the choke/fast

idle lever in completely (to the OFF

CHOKE position) and then following the

warm engine starting procedure listed

above. Ensure the ON/STOP switch is

in the ON position.

Starting could require pulling the starter rope handle many times depending

on how badly the unit is flooded. If engine fails to start, refer to the TROU-

BLESHOOTING TABLE or call

1-800-235-5878.

CHAIN BRAKE

WARNING: If the brake band is

worn too thin it may break when the

chain brake is triggered. With a broken

brake band, the chain brake will not

stop the chain. The chain brake must

be replaced if any part is worn to less

than 0.020”(0.5 mm) thick. Repairs on

a chain brake should be made by your

Sears Service Center. Take your unit

to the place of purchase or to the nearest Sears Service Center.

• This saw is equipped with a chain

brake. The brake is designed to stop

the chain if kickback occurs.

• The inertia--activated chain brake is

activated if the front hand guard is

pushed forward, either manually (by

hand) or automatically (by sudden

movement).

• If the brake is already activated, it is

disengaged by pulling the front hand

guard back toward the front handle

as far as possible.

• When cutting with the saw, the chain

brake must be disengaged.

Engaged

Disengaged

Braking function control

CAUTION: The chain brake must be

checked several times daily. The engine

must be running when performing this

procedure. This is the only instance

when the saw should be placed on the

ground with the engine running.

Place the saw on firm ground. Grip the

rear handle with your right hand and

the front handle with your left hand.

Apply full throttle by fully depressing

the throttle trigger. Activate the chain

brake by turning your left wrist against

the hand guard without releasing your

grip around the front handle. The chain

should stop immediately.

OPERATING TIPS

• Check chain tension before first use

and after 1 minute of operation, and

each time before you start the chain

saw. See CHAIN TENSION in the

MAINTENANCE section.

• Cut wood only. Do not cut metal, plastics, masonry, non-wood building materials, etc.

• Stop the saw if the chain strikes a

foreign object. Inspect the saw and

repair or replace parts as necessary.

If the chain jumps off the guide bar,

inspect the chain for damaged drive

links before reinstalling. Burrs on

drive links, which prevent them from

entering the groove of the guide bar,

can be removed with a flat file.

• Keep the chain out of dirt and sand.

Even a small amount of dirt will dull a

chain, increase the possibility of kickback, and require chain sharpening or

replacement.

• Practice cutting a few small logs using the following techniques to get

the “feel” of using your saw before

you begin a major sawing operation.

• Squeeze the throttle trigger and al-

low the engine to reach full speed

before cutting.

• Begin cutting with the saw frame

against the log.

• Keep the engine at full speed the

entire time you are cutting.

• Allow the chain to cut for you. Exert

only light downward pressure.

If you force the cut, damage to the

bar, chain, or engine can result.

• Release the throttle trigger as soon

as the cut is completed, allowing

the engine to idle. If you run the saw

at full throttle without a cutting load,

unnecessary wear can occur to the

chain, bar, and engine.

Page 12

12

To maximize operating efficiency, do not run the engine for longer than 30 seconds at a time at

full throttle.

• To avoid losing control when cut is

complete, do not put pressure on

saw at end of cut.

• Stop the engine before setting the

saw down after cutting.

TREE FELLING TECHNIQUES

WARNING: Check for broken or

dead branches which can fall while cutting causing serious injury. Do not cut

near buildings or electrical wires if you

do not know the direction of tree fall, nor

cut at night since you will not be able to

see well, nor during bad weather such

as rain, snow, or strong winds, etc. If

the tree makes contact with any utility

line, the utility company should be notified immediately.

• Carefully plan your sawing operation

in advance.

• Clear the work area. You need a clear

area all around the tree so you can

have secure footing.

• The chain saw operator should keep

on the uphill side of the terrain as the

tree is likely to roll or slide downhill

after it is felled.

• Study the natural conditions that can

cause the tree to fall in a particular direction.

Natural conditions that can cause a tree

to fall in a particular direction include:

• The wind direction and speed.

• The lean of the tree. The lean of a

tree might not be apparent due to uneven or sloping terrain. Use a plumb

or level to determine the direction of

tree lean.

• Weight and branches on one side.

• Surrounding trees and obstacles.

Look for decay and rot. If the trunk is

rotted, it can snap and fall toward the

operator. Check for broken or dead

branches which can fall on you while

cutting. Make sure there is enough

room for the tree to fall. Maintain a distance of 2-1/2 tree lengths from the near-

est person or other objects. Engine

noise can drown out a warning call.

Remove dirt, stones, loose bark, nails,

staples, and wire from the tree where

cuts are to be made.

Plan a clear retreat path to the rear

and diagonal to the line of fall.

Direction of Fall

45_

Plan a clear retreat path

FELLING LARGE TREES

(6 inches (15 cm) in diameter or larger)

The notch method is used to fell large

trees. A notch is cut on the side of the

tree in the desired direction of fall. After

a felling cut is made on the opposite

side of tree, the tree will tend to fall into

the notch.

NOTE: If the tree has large buttress

roots, remove them before making the

notch. If using saw to remove buttress

roots, keep saw chain from contacting

ground to prevent dulling of the chain.

NOTCH CUT AND FELLING THE

TREE

• Make notch cut by cutting the top of

the notch first. Cut through 1/3 of the

diameter of the tree. Next complete

the notch by cutting the bottom of the

notch. See illustration. Once the

notch is cut remove the notch of

wood from the tree.

Notch

First cut

Second cut

Final (felling) cut here, 2 inches

(5 cm) above center of notch.

Hinge

• After removing the wood from the

notch, make the felling cut on the opposite side of the notch. This is done

by making a cut about two inches (5

cm) higher than the center of the

notch. This will leave enough uncut

wood between the felling cut and the

notch to form a hinge. This hinge will

help prevent the tree from falling in the

wrong direction.

Page 13

13

Opening

of felling

cut

Closing of

notch

Hinge

holds

treeonstump

and

helps

control fall

NOTE: Before felling cut is complete,

use wedges to open the cut if necessary

to control the direction of fall. To avoid

kickback and chain damage, use wood

or plastic wedges, but never steel or iron

wedges.

• Be alert to signs that the tree is

ready to fall: cracking sounds, widening of the felling cut, or movement in

the upper branches.

• As tree starts to fall, stop saw, put it

down, and get away quickly on your

planned retreat path.

• DO NOT cut down a partially fallen tree

with your saw. Be extremely cautious

with partially fallen trees that may be

poorly supported. When a tree doesn’t

fall completely, set the saw aside and

pull down the tree with a cable winch,

block and tackle, or tractor.

CUTTING A FALLEN TREE

(BUCKING)

Bucking is the term used for cutting a

fallen tree to the desired log size.

WARNING: Do not stand on the

log being cut. Any portion can roll

causing loss of footing and control. Do

not stand downhill of the log being cut.

IMPORTANT POINTS

• Cut only one log at a time.

• Cut shattered wood very carefully;

sharp pieces of wood could be flung

toward operator.

• Use a sawhorse to cut small logs.

Never allow another person to hold

the log while cutting and never hold

the log with your leg or foot.

• Do not cut in an area where logs,

limbs, and roots are tangled such as in

a blown down area. Drag the logs into

a clear area before cutting by pulling

out exposed and cleared logs first.

TYPES OF CUTTING USED FOR

BUCKING

WARNING: If saw becomes

pinched or hung in a log, don’t try to

force it out. You can lose control of the

saw resulting in injury and/or damage

to the saw. Stop the saw, drive a

wedge of plastic or wood into the cut

until the saw can be removed easily.

Restart the saw and carefully reenter

the cut. To avoid kickback and chain

damage, do not use a metal wedge.

Do not attempt to restart your saw

when it is pinched or hung in a log.

Useawedge

to

remove

pinched

saw

Turn saw OFF and use a plastic or

wooden wedge to force cut open.

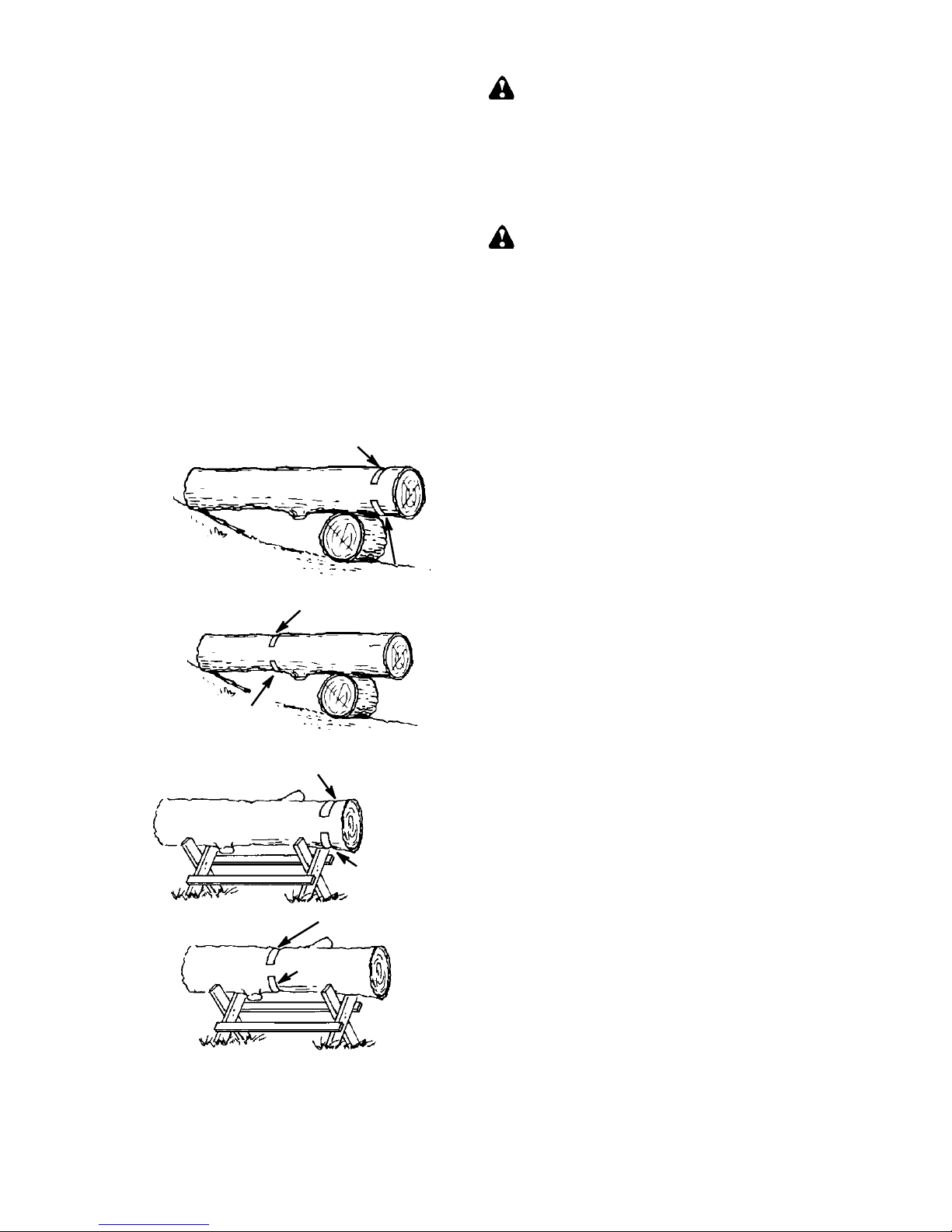

Overcutting begins on the top side of

the log with the bottom of the saw

against the log. When overcutting use

light downward pressure.

Overcutting

Undercutting

Undercutting involves cutting on the

underside of the log with top of saw

against the log. When undercutting

use light upward pressure. Hold saw

firmly and maintain control. The saw

will tend to push back toward you.

WARNING: Never turn saw up-

side down to undercut. The saw cannot be controlled in this position.

Always make your first cut on the compression side of the log. The compression side of the log is where the pressure of the log’s weight is

concentrated.

Second cut

First cut on compression side of log

First cut on compression side of log

Second cut

Page 14

14

BUCKING WITHOUT A SUPPORT

• Overcut through 1/3 of the diameter

of the log.

• Roll the log over and finish with a

second overcut.

• Watch for logs with a compression

side to prevent the saw from pinching. See illustrations for cutting logs

with a compression side.

BUCKING USING A LOG OR

SUPPORT STAND

• Remember your first cut is always on

the compression side of the log.

(Refer to the illustrations below for

your first and second cut)

• Your first cut should extend 1/3 of the

diameter of the log.

• Finish with your second cut.

1stCut

2ndCut

Using

a

log

for

support

2ndCut

1stCut

1stCut

2ndCut

Using a support stand

1stCut

2ndCut

LIMBING AND PRUNING

WARNING: Be alert for and

guard against kickback. Do not allow

the moving chain to contact any other

branches or objects at the nose of the

guide bar when limbing or pruning.

Allowing such contact can result in

serious injury.

WARNING: Never climb into a

tree to limb or prune. Do not stand on

ladders, platforms, a log, or in any position which can cause you to lose your

balance or control of the saw.

IMPORTANT POINTS

• Work slowly, keeping both hands firmly

gripped on the saw. Maintain secure

footing and balance.

• Watch out for springpoles. Springpoles

are small size limbs which can catch

the saw chain and whip toward you or

pull you off balance. Use extreme caution when cutting small size limbs or

slender material.

• Be alert for springback. Watch out for

branches that are bent or under

pressure. Avoid being struck by the

branch or the saw when the tension

in the wood fibers is released.

• Keep a clear work area. Frequently

clear branches out of the way to avoid

tripping over them.

LIMBING

• Always limb a tree after it is cut

down. Only then can limbing be done

safely and properly.

• Leave the larger limbs underneath the

felled tree to support the tree as you

work.

• Start at the base of the felled tree and

work toward the top, cutting branches

and limbs. Remove small limbs with

one cut.

• Keep the tree between you and the

chain. Cut from the side of the tree

opposite the branch you are cutting.

• Remove larger, supporting branches

with the cutting techniques described

in BUCKING WITHOUT A SUPPORT.

• Always use an overcut to cut small

and freely hanging limbs. Undercutting could cause limbs to fall and

pinch the saw.

Page 15

15

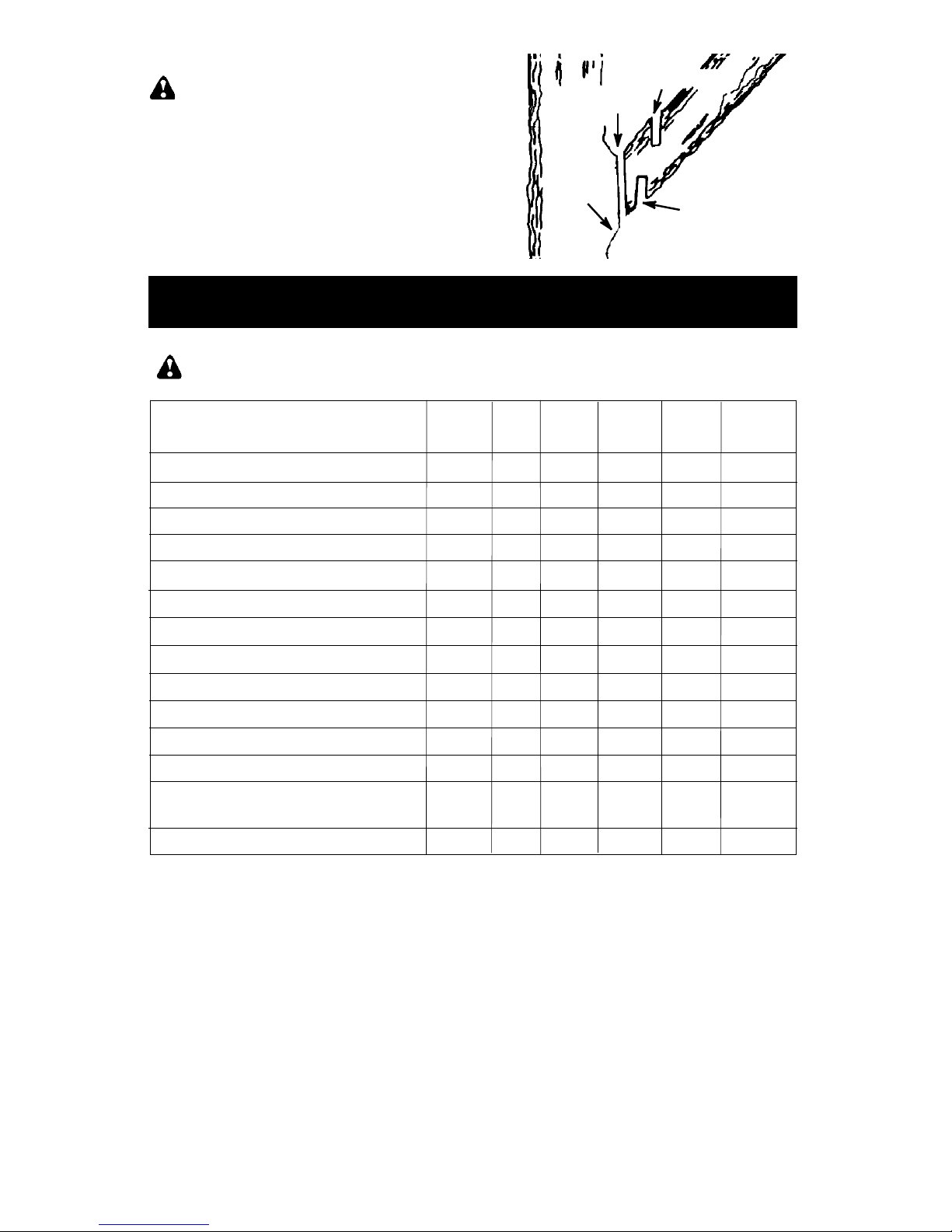

PRUNING

WARNING: Limit pruning to limbs

shoulder height or below. Do not cut if

branches are higher than your shoulder.

Get a professional to do the job.

• Make your first cut 1/3 of the way

through the bottom of the limb.

• Next make a 2nd cut all the way

through the limb. Then cut a third

overcut leaving a 1 to 2 inch (2.5 to 5

cm) collar from the truck of the tree.

First cut

Second cut

Third cut

Collar

Pruning technique

MAINTENANCE

Fill in dates as you complete

regular service

Check for damaged/worn parts

Check for loose fasteners/parts

Check chain tension

Check chain sharpness

Check guide bar

Inspect and clean unit & decals

Clean air filter

Clean/inspect muffler and spark

arresting screen

Replace spark plug and fuel filter

Before

Use

After

Use

Every

5 hrs.

Every

25 hrs.

Yearly

Service

Dates

•

•

•

•

•

•

•

•

•

•

Check fuel mixture level

Check guide bar and chain oil

•

•

Check chain brake

WARNING: Disconnect the spark plug before performing maintenance

except for carburetor adjustments.

CUST

OMER

RESPONSIBILITIES

Clean guide bar groove

•

Clean cooling system

•

GENERAL RECOMMENDATIONS

The warranty on this unit does not cover items that have been subjected to

operator abuse or negligence. To receive full value from the warranty, the

operator must maintain unit as

instructed in this manual. Various

adjustments will need to be made periodically to properly maintain your unit.

• Once a year, replace the spark plug,

air filter, and check guide bar and

chain for wear. A new spark plug and

air filter assures proper air-fuel mixture

and helps your engine run better and

last longer.

CHECK FOR DAMAGED OR

WORN PARTS

Contact your Sears Service Center for

replacement of damaged or worn parts.

NOTE: It is normal for a small amount of

oil to appear under the saw after engine

stops. Do not confuse this with a leaking

oil tank.

• ON/STOP Switch -- Ensure ON/STOP

switch functions properly by moving

the switch to the STOP position. Make

sure engine stops; then restart engine

and continue.

• Fuel Tank -- Do not use saw if fuel

tank shows signs of damage or leaks.

• Oil Tank -- Do not use saw if oil tank

shows signs of damage or leaks.

Page 16

16

CHECK FOR LOOSE

FASTENERS AND PARTS

• Bar Nuts

• Chain

• Muffler

• Cylinder Shield

• Air Filter

• Handle Screws

• Vibration Mounts

• Starter Housing

• Front Hand Guard

CHECK CHAIN TENSION

WARNING: Wear protective

gloves when handling chain. The chain

is sharp and can cut you even when it is

not moving.

Chain tension is very important. Chains

stretch during use. This is especially true

during the first few times you use your

saw. Always check chain tension each

time before you start the chain saw.

1. Use the screwdriver end of the

chain adjustment tool (bar tool) to

move chain around guide bar to

ensure kinks do not exist. The

chain should rotate freely.

Bar Nuts

Guide

Bar

Adjusting

Screw

Chain Adjustment

Tool

(Bar Tool)

2. Loosen bar nuts until they are

finger tight against the clutch cover.

3. Turn adjusting screw clockwise

until chain solidly contacts bottom

of guide bar rail.

Adjusting

Screw

4. Using bar tool, roll chain around

guide bar to ensure all links are in

bar groove.

5. Lift up tip of guide bar to check for

sag. Release tip of guide bar, then

turn adjusting screw1/4turn clockwise. Repeat until sag does not

exist.

Adjusting Screw --1/4Turn

6. While lifting tip of guide bar, tighten

bar nuts securely.

Bar Nuts

7. Use the screwdriver end of the bar

tool to move chain around guide bar.

8. If chain does not rotate, it is too

tight. Slightly loosen bar nuts and

loosen chain by turning the adjusting screw1/4turn counterclockwise. Retighten bar nuts.

9. If chain is too loose, it will sag below the guide bar. DO NOT operate

the saw if the chain is loose.

NOTE: The chain is tensioned correctly

when the weight of the chain does not

cause it to sag below the guide bar

(with the chain saw sitting in an upright

position), but the chain still moves freely

around the guide bar.

WARNING: If the saw is operated

with a loose chain, the chain could jump

off the guide bar and result in serious

injury to the operator and/or damage the

chain making it unusable. If the chain

jumps off the guide bar, inspect each

drive link for damage. Damaged chain

must be repaired or replaced.

CHECK CHAIN SHARPNESS

A sharp chain makes wood chips. A dull

chain makes a sawdust powder and

cuts slowly. See CHAIN SHARPENING.

CHECK GUIDE BAR

Conditions which require guide bar

maintenance:

• Saw cuts to one side or at an angle.

• Saw has to be forced through the cut.

• Inadequate supply of oil to bar/chain.

Check the condition of guide bar each

time chain is sharpened. A worn guide

bar will damage the chain and make

cutting difficult.

After each use, ensure ON/STOP

switch is in the STOP position, then

clean all sawdust from the guide bar

and sprocket hole.

To maintain guide bar:

• Move ON/STOP switch to STOP.

Page 17

17

• Loosen and remove bar nuts and

clutch cover. Remove bar and chain

from saw.

• Clean the oil holes and bar groove

after each 5 hours of operation.

Remove Sawdust From

Guide Bar Groove

Oil Holes

• Burring of guide bar rails is a normal

process of rail wear. Remove these

burrs with a flat file.

• When rail top is uneven, use a flat file

to restore square edges and sides.

Correct GrooveWorn Groove

File Rail Edges

and Sides

Square

Replace guide bar when the groove is

worn, the guide bar is bent or cracked,

or when excess heating or burring of the

rails occurs. If replacement is necessary,

use only the guide bar specified for your

saw in the repair parts list or on the decal located on the chain saw.

CHECK FUEL MIXTURE LEVEL

• See FUELING ENGINE under the OP-

ERATION section.

LUBRICATION

Bar Oil

Fill Cap

• See GUIDE BAR AND CHAIN OIL un-

der the OPERATION section.

INSPECT AND CLEAN UNIT AND

DECALS

• After each use, inspect complete unit

for loose or damaged parts. Clean the

unit and decals using a damp cloth

with a mild detergent.

• Wipe off unit with a clean dry cloth.

COOLING SYSTEM

To keep the working temperature as

low as possible the machine is

equipped with a cooling system.

The cooling system consists of:

• Air intake on the starter

• Air guide plate

• Fins on the flywheel

• Cooling fins on the cylinder

• Cylinder cover (directs cold air over

the cylinder)

Clean the cooling system with a brush

after each use, more often in demanding conditions. A dirty or blocked cooling system results in the machine

overheating which causes damage to

the piston and cylinder.

CHECK CHAIN BRAKE

See CHAIN BRAKE in the OPERATION

section.

CLEAN AIR FILTER

CAUTION: Do not clean filter in gaso-

line or other flammable solvent to

avoid creating a fire hazard or producing harmful evaporative emissions.

Cleaning the air filter:

A dirty air filter decreases the life and

performance of the engine and increases fuel consumption and harmful

emissions. Always clean your air filter

after 10 tanks of fuel or 5 hours of operation, whichever comes first. Clean

more frequently in dusty conditions. A

used air filter can never be completely

cleaned. It is advisable to replace your

air filter with a new one after every 50

hours of operation, or annually, whichever comes first.

1. Loosen knob on air filter cover.

Remove air filter cover.

2. Press down on wire clamp to re-

lease air filter. Remove air filter.

3. Clean the air filter using hot soapy

water. Rinse with clean cool water.

Air dry completely before reinstalling.

4. Reinstall air filter and reposition

wire clamp.

NOTE: Ensure air filter is correctly

installed and fully seated in pocket

before repositioning wire clamp and

reinstalling air filter cover.

5. Reinstall air filter cover. Tighten

knob securely.

Air Filter

Cover

Knob

Air Filter

Wire

Clamp

Page 18

18

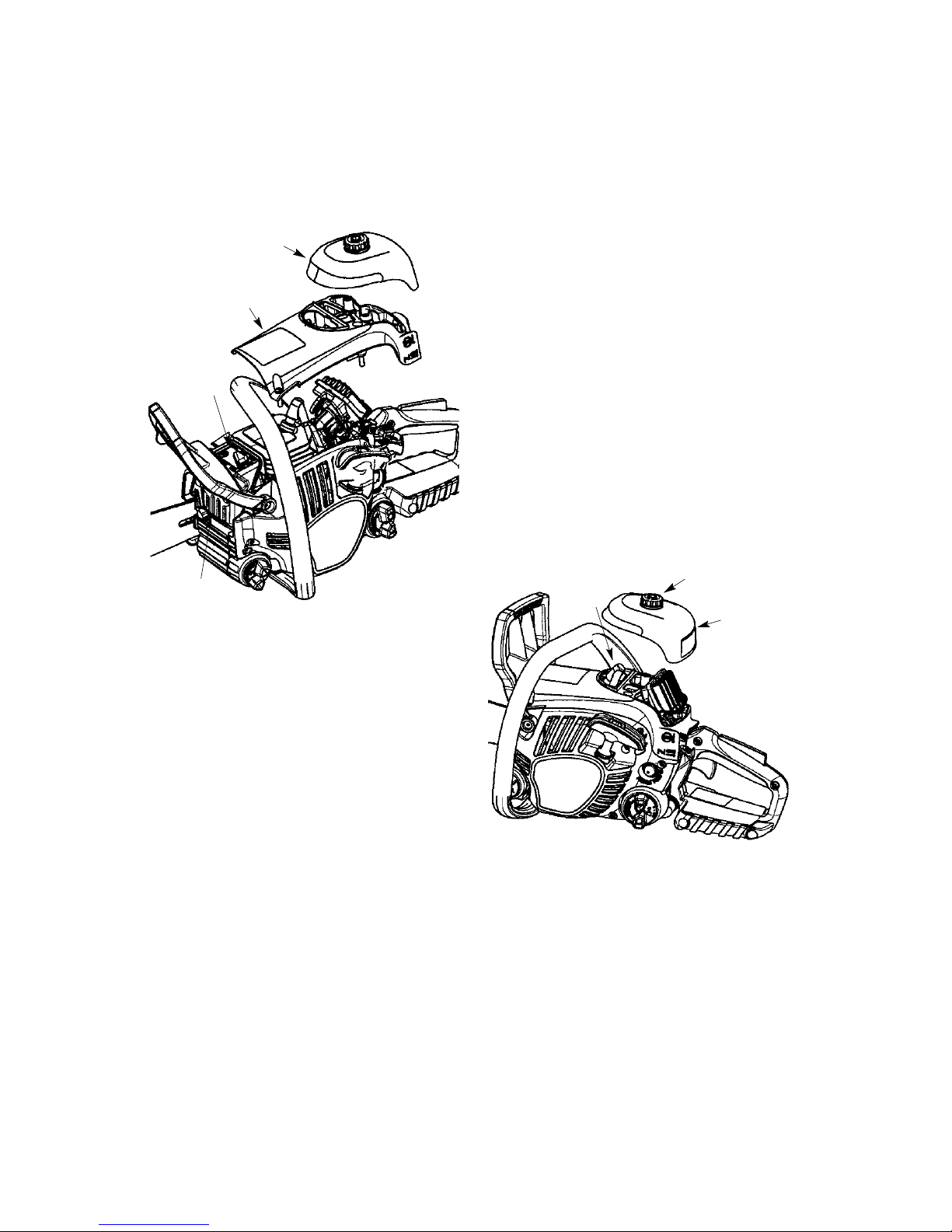

INSPECT MUFFLER AND SPARK

ARRESTING SCREEN

As the unit is used, carbon deposits

build up on the muffler and spark arresting screen, and must be removed

to avoid creating a fire hazard or affecting engine performance.

Replace the spark arresting screen if

breaks occur.

Muffler

Muffler

Exhaust

Outlet

Cover

Cylinder Cover

Air Filter Cover

CLEANING THE SPARK ARRESTING SCREEN

Cleaning is required every 25 hours of

operation or annually, whichever

comes first.

1. Loosen knob on air filter cover.

Remove air filter cover.

2. Loosen 3 screws on cylinder cover.

Remove the cylinder cover.

3. Loosen and remove the screw from

the muffler exhaust outlet cover.

4. Remove spark arresting screen.

Handle screen carefully to prevent

damage.

5. Clean the spark arresting screen

gently with a wire brush. Replace

screen if breaks are found.

6. Replace any broken or cracked

muffler parts.

7. Reinstall spark arresting screen.

8. Reinstall screw in muffler exhaust

outlet cover.

9. Reinstall the cylinder cover and 3

screws. Tighten securely.

10. Reinstall air filter cover. Tighten

knob securely.

REPLACE SPARK PLUG

The spark plug should be replaced

each year to ensure the engine starts

easier and runs better. Ignition timing

is fixed and nonadjustable.

1. Loosen knob on air filter cover.

Remove air filter cover.

2. Pull off the spark plug boot.

3. Remove spark plug from cylinder

and discard.

4. Replace with Champion RCJ--7Y

spark plug and tighten securely

with a3/4inch (19 mm) socket

wrench. Spark plug gap should be

0.025 inch (0,6 mm).

5. Reinstall the spark plug boot.

6. Reinstall air filter cover. Tighten

knob securely.

Spark Plug

Boot

Air Filter

Cover

Knob

REPLACE FUEL FILTER

To replace fuel filter, drain your unit by

running it dry of fuel. Remove fuel cap

and its connected retainer from tank.

Pull filter from tank and remove from

line. Replace and reassemble.

Page 19

19

SERVICE AND ADJUSTMENTS

WARNING: Disconnect the

spark plug before performing maintenance, service, or adjustments except

for carburetor adjustments.

CHAIN SHARPENING

WARNING: Improper chain

sharpening techniques and/or depth

gauge maintenance will increase the

chance of kickback which can result in

serious injury.

WARNING: Wear protective

gloves when handling chain. The chain

is sharp and can cut you even when it is

not moving.

Conditions which indicate the need for

chain sharpening:

• Reduction in size of wood chips. The

size of the wood chip will decrease

as the chain gets duller until it becomes more like a powder than a

chip. Note that dead or rotted wood

will not produce a good chip.

• Saw cuts to one side or at an angle.

• Saw has to be forced through the cut.

Tools required:

• 7/32 inch (5 mm) diameter round file

and file holder

• Flat file

• Depth gauge tool

TO SHARPEN CHAIN:

1. Move ON/STOP switch to the STOP

position.

2. Check chain for proper tension.

Adjust chain tension if necessary.

See CHAIN TENSION section.

3. Sharpen cutters.

• To sharpen the cutters, position

the file holder (10°) so that it rests

on the top edges of the cutter and

depth gauge.

NOTE: The chain has both left

and right hand cutters.

Depth Gauge

File

File Holder

Cutter

10°

• Align the 25° file holder marks

parallel with the bar and to the

center of the chain.

Cutter

Cutter

25°

File Holder Line

• Sharpen cutters on one side of

the chain first. File from the inside

of each cutter to the outside.

Then, turn the chain saw around

and repeat the process for the

other side of the chain.

• File on the forward stroke only.

Use 2 or 3 strokes per cutting

edge.

• Keep all cutters the same length

when filing.

• File enough to remove any damage to cutting edges (side plate

and top plate of cutter).

All

Cutters

Same Length

Remove

Damage

Top Plate

Side Plate

• File chain to meet the specifications as shown.

25°

60°

60°

Rounded

Corner

0.025 inch

(0.65 mm)

Right

Hook Angle

Wrong

Squared

Of

f

Corner

TooMuch

Hook

Angle

WARNING: Maintain the proper

hook angle according to the manufacturer’s specifications for the chain you

are using. Improper hook angle will

increase the chance of kickback which

can result in serious injury.

Page 20

20

4. Check and lower depth gauges.

Depth Gauge Tool

Depth Gauge

File

• Place gauge tool on cutter.

• If the depth gauge is higher than

the depth gauge tool, file it level to

the top of the depth gauge tool.

• Maintain rounded front corner of

depth gauge with a flat file.

NOTE: The very top of the depth

gauge should be flat with the front

half rounded off with a flat file.

If you require further assistance or are

unsure about performing this procedure,

contact your Sears Service Center or

call our customer assistance help line at

1--800--235--5878.

CHAIN REPLACEMENT

WARNING: Wear protective

gloves when handling chain. The

chain is sharp and can cut you even

when it is not moving.

It is normal for a new chain to stretch

during the first 15 minutes of operation.

You should recheck your chain tension

each time before you start the chain saw

and adjust the chain tension as required.

See CHAIN TENSION section. Replace

the old chain when it becomes worn or

damaged. Use only the Low-Kickback

replacement chain specified in the repair

parts list. The correct replacement bar

and chain is also specified on a decal

located on the chain saw. See your

Sears Service Center to replace and

sharpen individual cutters on your chain.

NOTE: CHAIN BRAKE MUST BE

DISENGAGED BEFORE CLUTCH

COVER CAN BE REMOVED OR REINSTALLED ON THE CHAIN SAW.

TO DISENGAGE CHAIN BRAKE,

PULL THE FRONT HAND GUARD

BACK TOWARD THE FRONT HANDLE AS FAR AS POSSIBLE (SEE

ILLUSTRATION).

Engaged

Disengaged

TO REPLACE CHAIN:

1. Move ON/STOP switch to the STOP

position.

2. Disengage chain brake.

3. Remove bar nuts.

4. Remove clutch cover.

NOTE: If clutch cover can not be

easily removed from the chain saw,

ensure chain brake is disengaged by

pulling the front hand guard back toward

the front handle as far as possible.

5. Remove the old chain.

Clutch Cover

Bar

Nuts

6. Turn adjusting screw by hand

counterclockwise to loosen chain

tension.

7. Slide guide bar on bar bolts until

guide bar stops against clutch

drum sprocket.

Guide Bar

Bar

Bolts

Clutch

Drum

8. Carefully remove the chain from the

package. Hold chain with the drive

links as shown.

CUTTERS MUST FACE IN

DIIRECTION OF ROTATION

Tip of

Bar

Page 21

21

Cutters

Depth

Gauge

Drive Links

9. Place chain over and behind clutch

drum, fitting the drive links in the

clutch drum sprocket.

10. Fit bottom of drive links between

the teeth in the sprocket in the

nose of the guide bar.

11. Fit chain drive links into bar

groove.

12. Pull guide bar forward until chain is

snug in guide bar groove. Ensure

all drive links are in the bar groove.

13. Now, install clutch cover making

sure the adjusting pin is positioned

in the lower hole in the guide bar.

Remember this pin moves the bar

forward and backward as the

screw is turned.

Clutch

Cover

Lower Hole

Guide

Bar

Adjusting Pin

14. Install bar nuts and finger tighten

only. Do not tighten any further

at this point. Proceed to CHAIN

ADJUSTMENT.

CHAIN ADJUSTMENT

See CHAIN TENSION in MAINTENANCE

section.

CARBURETOR ADJUSTMENT

WARNING: The chain will be

moving during most of this procedure.

Wear your protective equipment and

observe all safety precautions. The

chain must not move at idle speed.

The carburetor has been carefully set

at the factory. Adjustments may be

necessary if you notice any of the following conditions:

• Chain moves at idle. See IDLE

SPEED--T adjusting procedure.

• Saw will not idle. See IDLE SPEED--T

adjusting procedure.

Idle Speed--T

Allow engine to idle. If the chain moves,

idle is too fast. If the engine stalls, idle is

too slow. Adjust speed until engine runs

without chain movement (idle too fast) or

stalling (idle too slow). The idle speed

screw is located in the area above the

primer bulb and is labeled T.

• Turn idle screw (T) clockwise to increase engine speed.

• Turn idle screw (T) counterclockwise

to decrease engine speed.

If you require further assistance or are

unsure about performing this procedure,

contact your Sears Service Center or

call our customer assistance help line at

1--800--235--5878.

Page 22

22

STORAGE

WARNING: Perform the follow-

ing steps after each use:

• Allow the engine to cool, and secure

the unit before storing or transporting.

• Store chain saw and fuel in a well

ventilated area where fuel vapors

cannot reach sparks or open flames

from water heaters, electric motors or

switches, furnaces, etc.

• Store chain saw with all guards in

place and position chain saw so that

any sharp object cannot accidentally

cause injury.

• Store chain saw well out of the reach

of children.

SEASONAL STORAGE

Prepare your unit for storage at the

end of the season or if it will not be

used for 30 days or more.

If your chain saw is to be stored for a

period of time:

• Clean saw thoroughly before storage.

• Store in a clean dry area.

• Lightly oil external metal surfaces

and guide bar.

• Oil the chain and wrap it in heavy paper or cloth.

FUEL SYSTEM

Empty the fuel system before storage

for 30 days or longer. Drain the gas

tank, start the engine and let it run until

the fuel lines and carburetor are empty.

Use fresh fuel next season.

Under FUELING ENGINE in the OPERA-

TION section of this manual, see mes-

sage labeled IMPORTANT regarding

the use of gasohol in your chain saw.

Fuel stabilizer is an acceptable alternative in minimizing the formation of

fuel gum deposits during storage. Add

stabilizer to the gasoline in the fuel

tank or fuel storage container.

Follow the mix instructions found on

stabilizer containers. Run engine at

least 3 minutes after adding stabilizer.

Craftsman 50:1, 2-cycle engine oil (air

cooled) is blended with fuel stabilizer. If

you do not use this oil, you can add a

fuel stabilizer with 2--cycle engine oil to

your fuel tank.

ENGINE

• Remove spark plug and pour 1 teaspoon of 50:1, 2-cycle engine oil (air

cooled) through the spark plug opening. Slowly pull the starter rope 8 to

10 times to distribute oil.

• Replace spark plug with new one of

recommended type and heat range.

• Clean air filter.

• Check entire unit for loose screws,

nuts, and bolts. Replace any damaged, broken, or worn parts.

• At the beginning of the next season,

use only fresh fuel having the proper

gasoline to oil ratio.

OTHER

• Do not store gasoline from one season to another.

• Replace your gasoline can if it starts

to rust.

Page 23

23

TROUBLE CAUSE REMEDY

Engine will not

start or will run

only a few

seconds after

starting.

1. ON/STOP switch in

STOP position.

2. Engine flooded.

3. Fuel tank empty.

4. Spark plug not firing.

5. Fuel not reaching

carburetor.

6. Carburetor requires

adjustment.

7. None of the above.

1. Move ON/STOP switch to ON.

2. See “Difficult Starting” in the

Operation Section.

3. Fill tank with correct fuel mixture.

4. Install new spark plug.

5. Check for dirty fuel filter; replace.

Check for kinked or split fuel line;

repair or replace.

6. Contact Sears Service (see back cover).

7. Contact Sears Service (see back cover).

Engine will

not idle

properly.

1. Idle speed set too high

or too low.

2. Low Speed Mixture

requires adjustment.

3. Crankshaft seals worn.

4. Compression low.

5. None of the above.

1. See “Carburetor Adjustment” in the

Service and Adjustments Section.

2. Contact Sears Service (see back cover).

3. Contact Sears Service (see back cover).

4. Contact Sears Service (see back cover).

5. Contact Sears Service (see back cover).

1. Air filter dirty.

2. Spark plug fouled.

3. Carburetor requires

adjustment.

4. Exhaust ports or muffler outlets plugged.

5. Compression low.

6. Chain brake engaged.

7. None of the above.

Engine will not

accelerate,

lacks power,

or dies under

a load.

1. Clean or replace air filter.

2. Clean or replace plug and regap.

3. Contact Sears Service (see back cover).

4. Contact Sears Service (see back cover).

5. Contact Sears Service (see back cover).

6. Disengage chain brake.

7. Contact Sears Service (see back cover).

WARNING: Always stop unit and disconnect spark plug before perform-

ing all of the recommended remedies below except remedies that require

operation of the unit.

TROUBLESHOOTING

T

ABLE

Engine

smokes

excessively.

1. Choke partially on.

2. Fuel mixture incorrect.

3. Air filter dirty.

4. High Speed Mixture

requires adjustment.

5. Crankcase leak.

1. Adjust choke.

2. Empty fuel tank and refill with

correct fuel mixture.

3. Clean or replace air filter.

4. Contact Sears Service (see back cover).

5. Contact Sears Service (see back cover).

Engine runs

hot.

1. Fuel mixture incorrect.

2. Spark plug incorrect.

3. High Speed Mixture

set too lean.

4. Exhaust ports or muffler outlets plugged.

5. Carbon build-up on

spark arresting screen.

6. Starter housing dirty

7. None of the above.

1. See “Fueling Engine” in the Operation

section.

2. Replace with correct plug.

3. Contact Sears Service (see back cover).

4. Contact Sears Service (see back cover).

5. Clean spark arresting screen.

6. Clean starter housing area.

7. Contact Sears Service (see back cover).

Oil inadequate

for bar and

chain

lubrication.

1. Oil tank empty.

2. Oil pump or oil filter

clogged.

3. Guide bar oil hole

blocked.

1. Fill oil tank.

2. Contact Sears Service (see back cover).

3. Remove bar and clean.

Chain moves at

idle speed.

1. Idle speed requires

adjustment.

2. Clutch requires repair.

1. See “Carburetor Adjustment” in the

Service and Adjustments Section.

2. Contact Sears Service (see back cover).

Page 24

24

TROUBLE CAUSE REMEDY

TROUBLESHOOTING TABLE -- Continued

Chain does not

move when engine is accelerated.

1. Chain tension too

tight.

2. Carburetor requires

adjustment.

3. Guide bar rails

pinched.

4. Clutch slipping.

5. Chain brake engaged.

1. See “Check Chain Tension” in the

Maintenance Section.

2. Contact Sears Service (see back cover).

3. Repair or replace.

4. Contact Sears Service (see back cover).

5. Disengage chain brake.

Chain clatters

or cuts roughly.

1. Chain tension incorrect.

2. Cutters damaged.

3. Chain worn.

4. Cutters dull, improperly

sharpened, or depth

gauges too high.

5. Sprocket worn.

6. Chain installed

backwards.

1. See “Check Chain Tension” in the

Maintenance Section.

2. Contact Sears Service (see back cover).

3. Resharpen or replace chain.

4. See “Chain Sharpening” in the

Service and Adjustments Section.

5. Contact Sears Service (see back cover).

6. Install chain in right direction.

Chain stops

within the cut.

1. Chain cutter tops not

filed flat.

2. Guide bar burred or

bent; rails uneven.

3. Clutch slipping.

1. See “Chain Sharpening” in the

Service and Adjustments Section.

2. Repair or replace guide bar.

3. Contact Sears Service (see back cover).

Chain cuts at

an angle.

1. Cutters damaged on

one side.

2. Chain dull on one side.

3. Guide bar bent or worn.

1. See “Chain Sharpening” in the

Service and Adjustments Section.

2. See “Chain Sharpening” in the

Service and Adjustments Section.

3. Replace guide bar.

If situations occur which are not covered in this manual, use care and good

judgement. If you need assistance, contact Sears Service or the CUSTOMER

ASSISTANCE HELPLINE at 1-800-235-5878.

Page 25

U.S. EPA / CALIFORNIA / ENVIRONMENT CANADA EMISSION CONTROL WARRANTY STATEMENT

IMPORTANT: This product is compliant with U.S. EPA Phase 3 regulations for exhaust and evaporative emissions. To ensure EPA Phase

3 compliance, we recommend using only genuine replacement parts. Use of non-compliant replacement parts is a violation of federal law.

YOUR WARRANTY RIGHTS AND OBLIGATIONS: The U.S. Environmental Protection Agency, California Air Resources Board,

Environment Canada and Sears Brands Management Corporation, U.S.A. (Sears) are pleased to explain the emissions control system

warranty on your year 2016 and later off-road engine. In California, all small off-road engines must be designed, built, and equipped to

- smog standards. SEARS must warrant the emission control system on your small off-road engine for the

periods of time listed below provided there has been no abuse, neglect, or improper maintenance of your small off-road engine. Your

emission control system includes parts such as the carburetor, the ignition system and the fuel tank, line, and cap. Where a warrantable

condition exists, SEARS will repair your small off-road engine at no cost to you. Expenses covered under warranty include diagnosis, parts

and labor.

MANUFA If any emissions related part on your engine (as listed under Emissions Control Warranty

Parts List) is defective or a defect in the materials or workmanship of the engine causes the failure of such an emission rel ated part, the

part will be repaired or replaced by SEARS.

As the small off-road engine owner, you are responsible for the performance of the

required maintenance listed in your instruction manual. SEARS recommends that you retain all receipts covering maintenance on your

small off-road engine, but SEARS cannot deny warranty solely for the lack of receipts or for your failure to ensure the performance of all

scheduled maintenance. As the small off-road engine owner, you should be aware that SEARS may deny you warranty coverage if your

small off-road engine or a part of it has failed due to abuse, neglect, improper maintenance, unapproved modifications, or the use of p arts

not made or approved by the original equipment manufacturer. You are responsible for presenting your small off- road engine to a SEARS

authorized repair center as soon as a problem exists. Warranty repairs should be completed in a reasonable amount of time, no t to exceed

30 days. If you have any questions regarding your warranty rights and responsibilities, you should contact your nearest authorized service

center.

Please call SEARS at 1-888-331-4569 or send e-mail correspondence to emissions@husqvarnagroup.com.

WARRANTY COMMENCEMENT DATE: The warranty period begins on the date the small off-road engine is purchased.

LENGTH OF COVERAGE: This warranty shall be for a period of two years from the initial date of purchase, or until the end of the product

warranty (whichever is longer).

WHAT IS COVERED: REPAIR OR REPLACEMENT OF PARTS. Repair or replacement of any warranted part will be performed at no

charge to the owner at an approved SEARS servicing center. If you have any questions regarding your warranty rights and responsibilities,

you should contact your nearest authorized service center. Please call SEARS at 1-888-331-4569 or send e-mail correspondence to

emissions@husqvarnagroup.com.

WARRANTY PERIOD: Any warranted part which is not scheduled for replacement as required maintenance, or which is scheduled only

2 years. Any warranted part which is

scheduled for replacement as required maintenance shall be warranted for the period of time up to the first scheduled replacement point

for that part.

DIAGNOSIS: The owner shall not be charged for diagnostic labor which leads to the determination that a warranted part is defective if the

diagnostic work is performed at an approved SEARS servicing center.