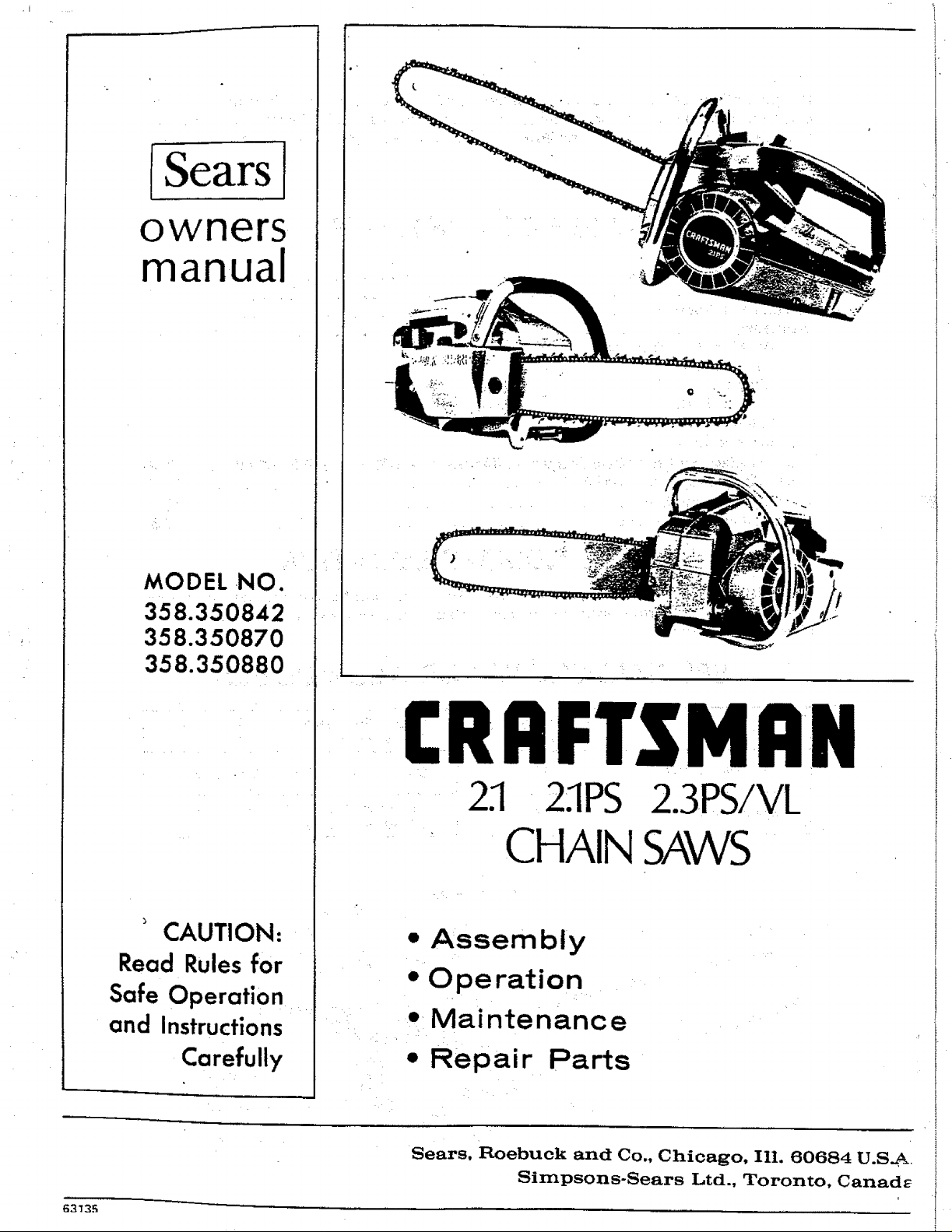

Craftsman 358350880-1976, 358350870-1976, 358350842 Owner’s Manual

owners

manual

I

I

J

J

MODEL NO.

: i

358.350842

358.350870

358.350880

'CAUTION:

Read Rules for

Safe Operation

and Instructions

CRRFTSM R'N

2.1 2,1PS

CHAINSAWS

• Assembly

•Operation

• ' Maintenance

2.3PS/VL

: _il

[

F

Carefully

• Repair Parts

[

Sears, Roebuck and Co., Chicago, Ill. 60684 U.S&

Simpsons-Sears Ltd., Toronto, Canad£

Congratulations on your purchase of our new Craftsman gas chain saw. It is the finest gas

chain saw available on the market today for the price you have paid. We ask that you take a

few minutes to read the following instructions so you can enjoy the use of this new chain

saw for many years to come.

TABLE OF CONTENTS

Bar and Chain Installation ........................

Fuel and:Oil .....................................................

Starting and Stopping ..... .......

Maintenance ......................................................

Air Filter & Carburetor

Fan Housing

Clutch

Exhaust Ports

Spark Plug

Bar and Chain

Stone Replacement and Chain Sharpening (Models 358-350870 and 358-350880)

Chain Sharpening (Model 358-350842) . .....................

Cutting With Your Saw .............................................

Parts List and Illustrations ...........................................

1

2

3

4-8

7-10

11-12

12-14

15-30

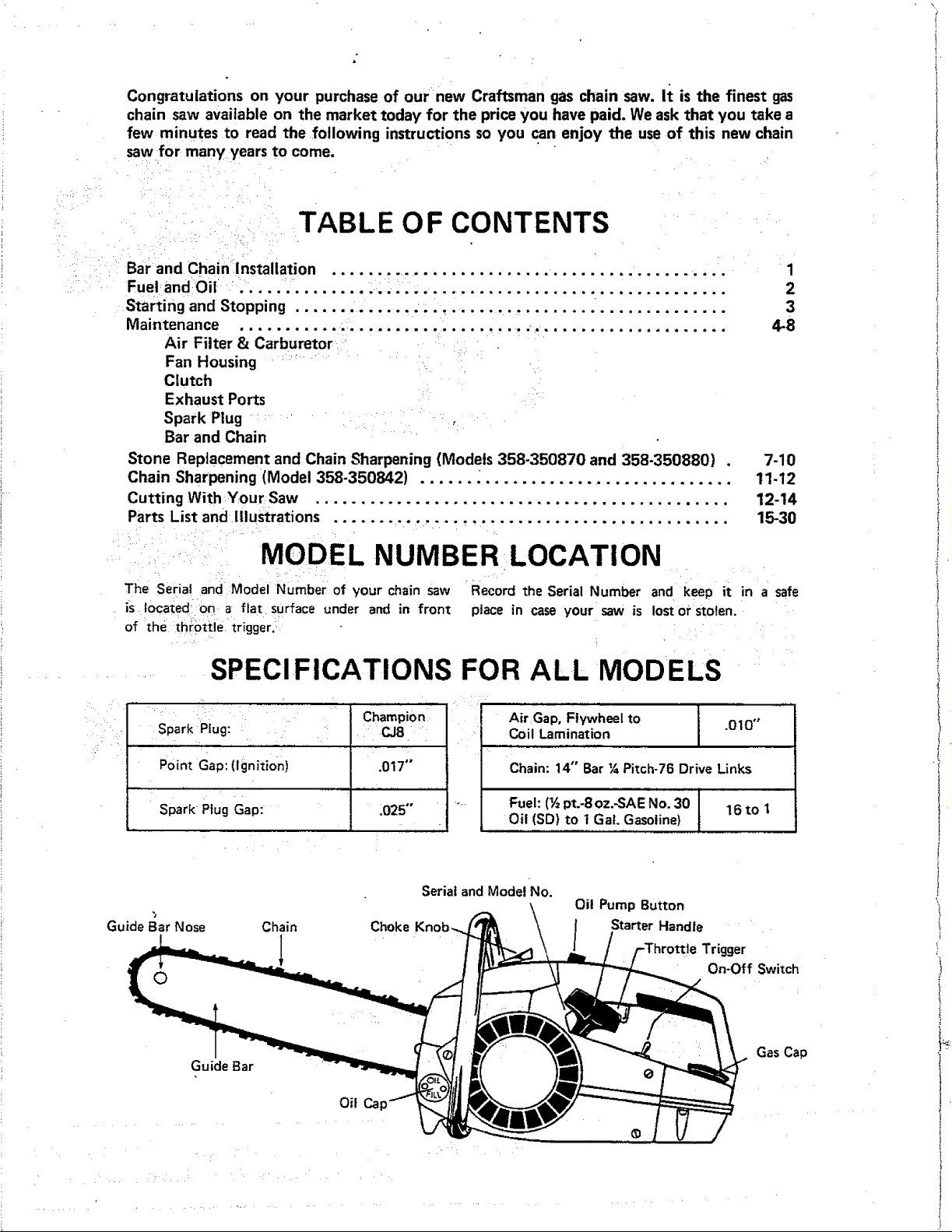

MODEL NUMBER LOCATION

The Serial and Model Number of your chain saw Record the Serial Number and keep it in a safe

is located on a fiat surface under and in front place in case your saw is lost or stolen.

of the thr0ttle trigger.

SPECIFICATIONS FOR ALL MODELS

Champion

SPark Plug: i " CJ8

Point Gap: (Ignition) .017"

Air Gap, Flywheel to | .010"

Coil Lamination

Chain: 14" Bar _ Pitch-76 Drive Links

!

J

Spark =Plug Gap: .025""

Guide Bar Nose Chain Choke

Guide Bar

Fuel: (½ pt.-8oz.-SAE No. 30 I 16 to 1

Oil (SD) to 1 GaL Gasoline)

Serial and Model No.

t

Oil Pump Button

Starter Handle

Trigger

On-Off Switch

Gas Cap

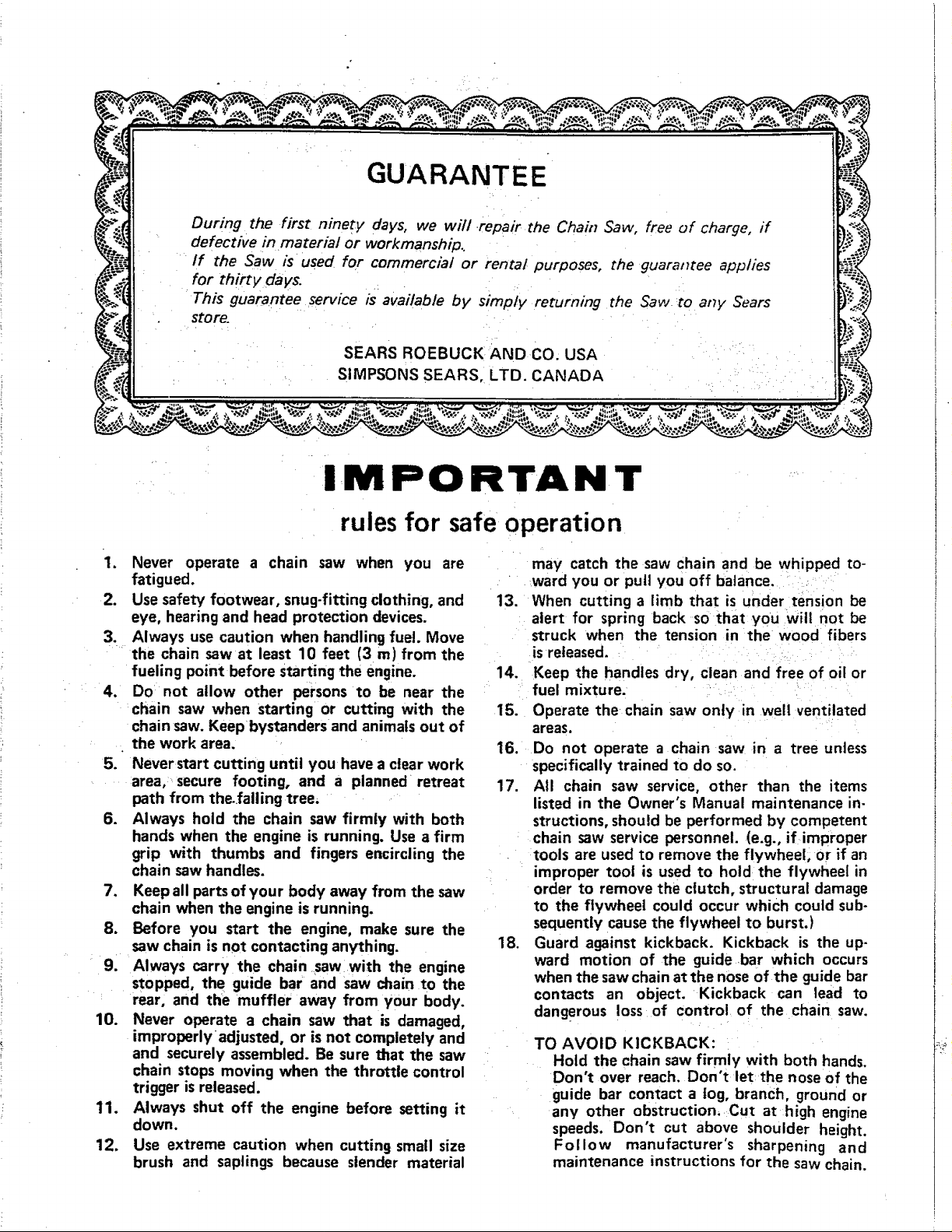

GUARANTEE

During the first ninety days, we will repair the Chain Saw, free of charge, if

defective in material or workmanship..

If the Saw is used for commercial or rental purposes, the guaratttee applies

for thirty days.

This guarantee service is available by simply returning the Saw to any Sears

store.

SEARS ROEBUCK AND CO. USA

SIMPSONS SEARS, LTD. CANADA

I MPORTANT

rules for safe operation

1. Never operate a chain saw when you are

fatigued.

2. Use safety footwear, snug-fitting clothing, and

eye, hearing and head protection devices.

3. Always use caution when handling fue!. Move

the chain sawat least 10 feet (3 m)from the

fueling point before Starting the engine.

4. Do not allow other persons to be near the

chain saw when starting or cutting with the

chain saw. Keep bystanders and animals out of

the work area.

5. Neverstart cutting until you have a clear work

area,:, secure footing, and a planned _retreat

path from the.failing tree,

6. Always hold the chain saw firmly with both

hands when the engine is running. Use a firm

grip with thumbs and fingers encircling the

chain saw handles.

7. Keepall partsofyour body away from the saw

chain when the engine is running.

8. Before you start the engine, make sure the

saw chain is not contacting anything.

9. Always carry the chain saw with the engine

stopped, the guide bar and saw chain to the

rear, and the muffler away from your body.

10. Never operate a chain saw that is damaged,

improperly adjusted, or is not completely and

and securely assembled. Be sure that the saw

chain stops moving when the throttle control

trigger is released.

11. Always shut off the engine before setting it

down.

12. Use extreme caution when cutting small size

brush and saplings because slender material

may catch the saw chain and be whipped to-

ward you or pull you off balance.

13. When cutting a limb that is under tension be

alert for spring back so that you will not be

struck when the tension in the wood fibers

is released.

14. Keep the handles dry, clean and free of oil or

fuel mixture.

15. Operate the chain saw only in well ventilated

areas.

16. Do not operate a chain saw in a tree unless

specifically trained to do so.

17. All chain saw service, other than the items

listed in the Owner's Manual maintenance in-

structions, should be performed by competent

chain saw service personnel. (e.g., if improper

tools are used to remove the flywheel, or if an

improper tool is used to hold the flywheel in

order to remove the clutch, structural damage

to the flywheel could occur which could sub-

sequently cause the flywheel to burst.)

18. Guard against kickback. Kickback is the up-

ward motion of the guide bar which occurs

when the sawchain at the nose of the guide bar

contacts an object. Kickback can lead to

dangerous loss of control of the chain saw.

TO AVOID KICKBACK:

Hold the chain saw firmly with both hands.

Don't over reach. Don't let the nose of the

guide bar contact a log, branch, ground or

any other obstruction, Cut at high engine

speeds. Don't cut above shoulder height.

Follow manufacturer's sharpening and

maintenance instructions for the saw chain.

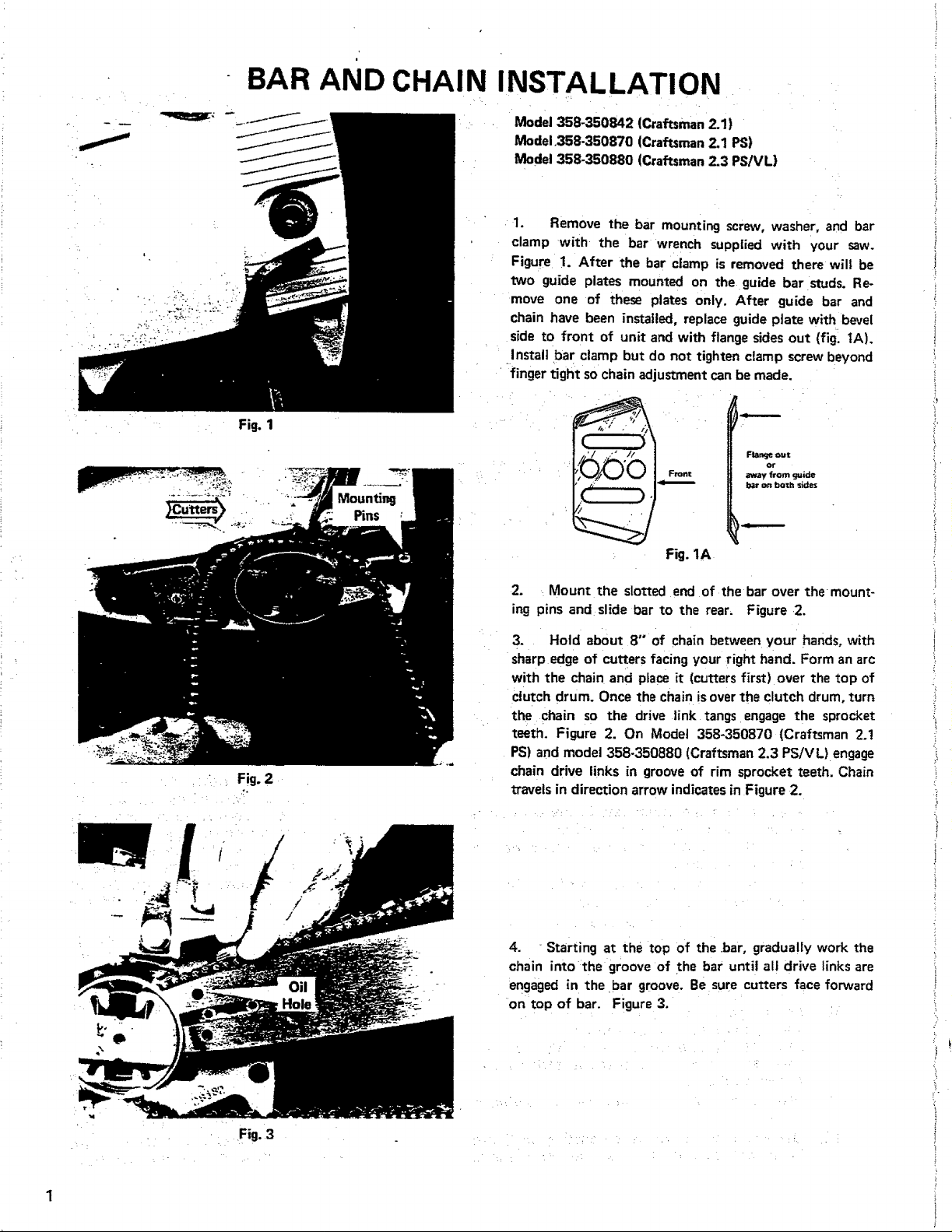

BAR AND CHAIN INSTALLATION

Model 358-350842 (Craftsman 2.1)

Model,358-350870 (Craftsman 2.1 PS)

Model 358-350880 (Craftsman 2.3 PS!VL)

1. Remove the bar mounting screw, washer, and bar

clamp with the bar wrench supplied with your saw.

Figure 1. After the bar clamp is removed there wit| be

two guide plates mounted on the guide bar studs. Re*

move one of these plates only. After guide bar and

chain have been installed, replace guide plate with bevel

side to front of unit and with flange sidesout (fig. tA).

Install bar clamp but do not tighten clamp screw beyond

finger tight sochain adjustment can be made.

Fig. 1

Fla_je out

or

_ay from clzzide

bar On both sid_

• Fig. 2

Fig. 1A

2. Mount the slotted end of the bar over the mount-

ing pins and slide bar to the rear. Figure 2.

3. Hold about 8" of chain between your hands, with

sharp edge of cutters facing your right hand. Form an arc

with the chain and place it (cutters first) over the top of

clutch drum. Once the chain isover the clutch drum, turn

the chain so the drive link tangs engage the sprocket

teeth. Figure 2. On Model 358-350870 (Craftsman 2.1

PS) and model 358-350880 (Craftsman 2.3 PS/VL) engage

chain drive links in groove of rim sprocket teeth. Chain

travels in direction arrow indicates in Figure 2.

4. Starting at the top of the .bar, gradually work the

chain into the groove of the bar until all drive links are

engaged in the bar groove. Be sure cutters face forward

on top of bar. Figure 3.

Fig. 3

CHAIN INSTALLATION (CONT'D.)

Model358-350842(Craftsman2.1)

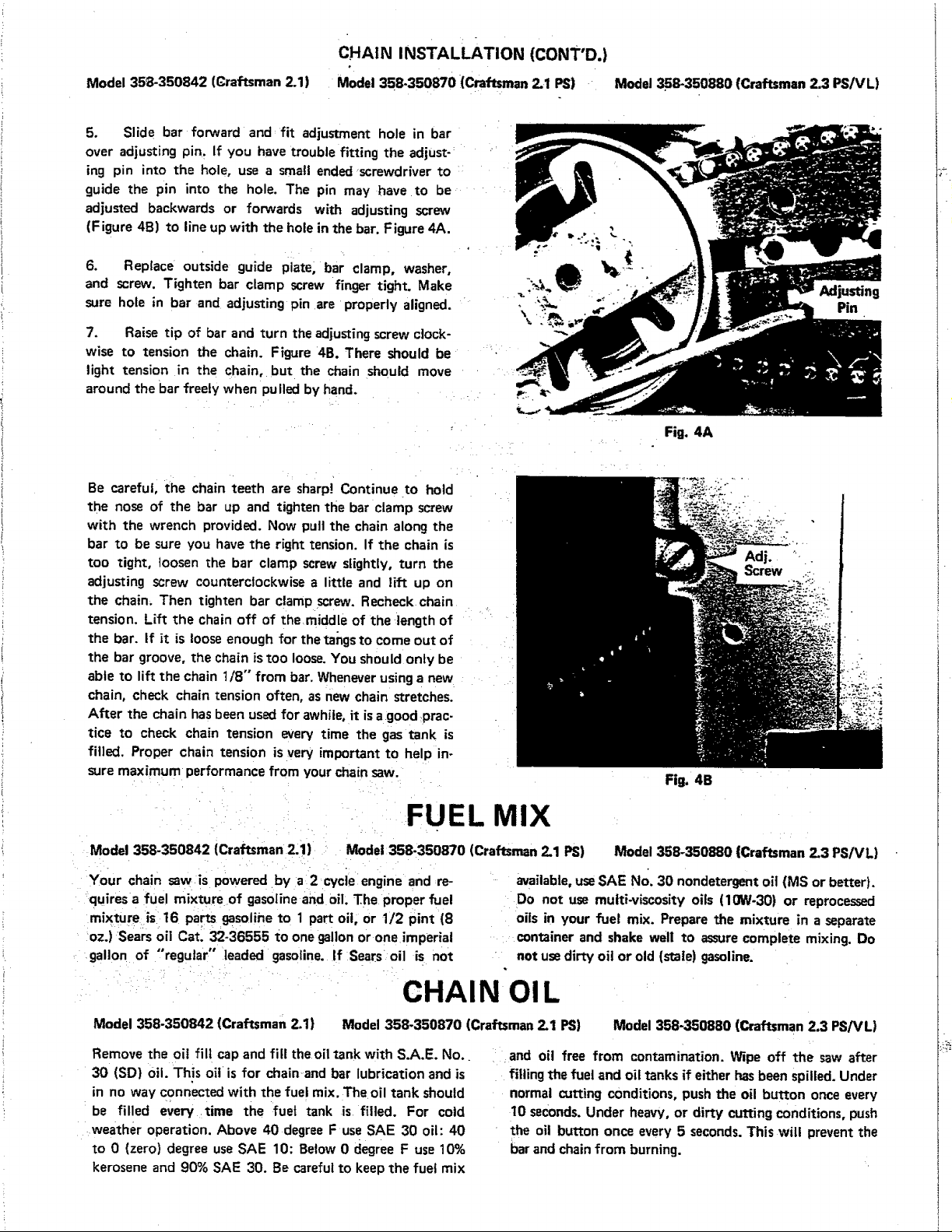

5. Slide bar forward and:fit adjustment hole in bar

over adjusting pim if you have trouble fitting the adjust- ....

ing pin into the hole, use a small ended screwdriver to :

guide the pin into the hole. The pin may have to be ......

adjusted backwards or forwards with adjusting screw

(Figure 4B) to line up with the hole in the bar. Figure 4A.

6. Replace outside guide piate, bar clamp, washer,

and screw. Tighten bar clamp screw finger tight. Make

sure hole in bar and adjusting pin are properly aligned.

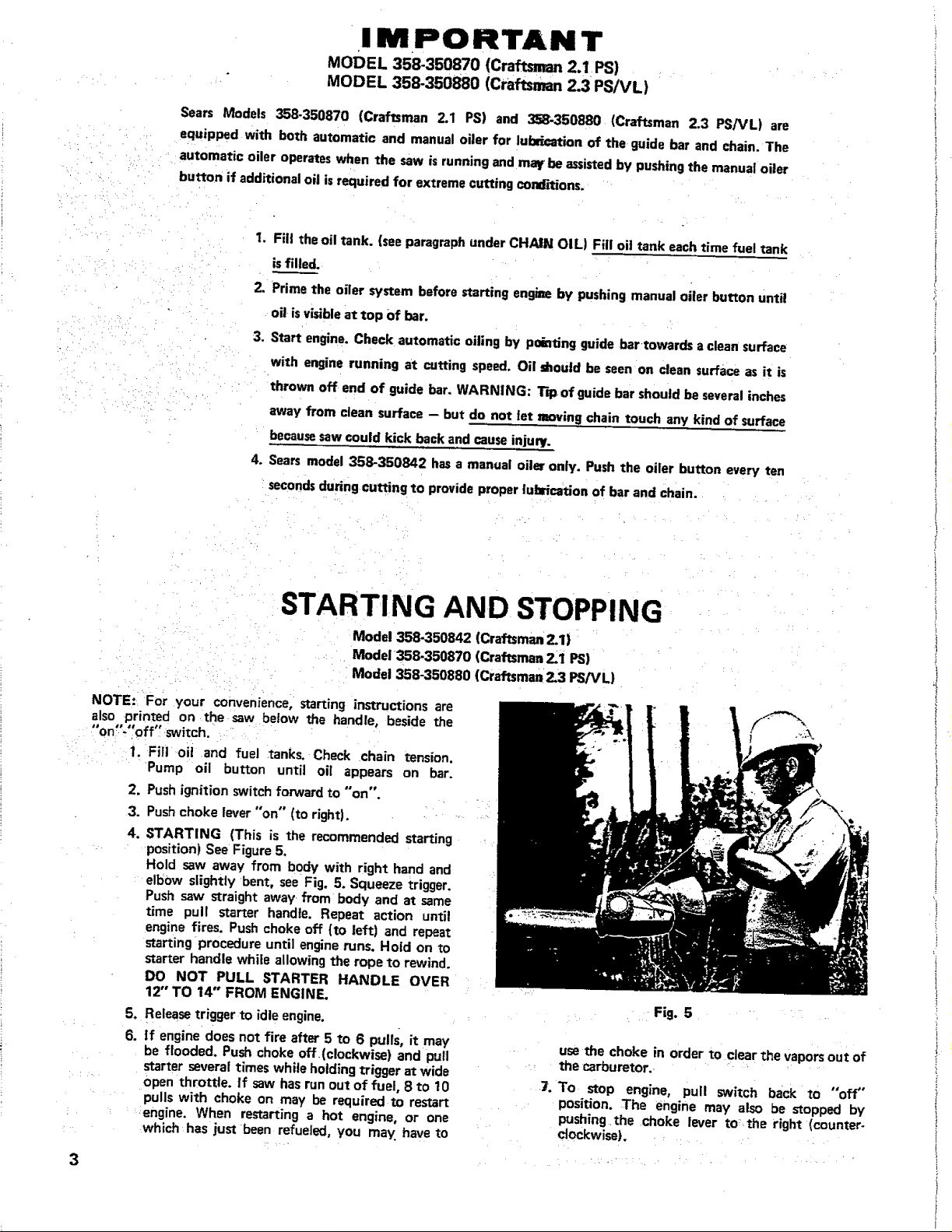

7. Raise tip of bar and turn the adjusting screw clock-

wise to tension the chain. Figure 4B. There should be _,

light tension in the chain, but the chain should move

around the bar freely when pulled by hand,

Be careful, the chain teeth are sharp] Continue to hold

the nose of the bar up and tighten the bar clamp screw

with the wrench provided. Now pull the chain along the

bar to be sure you have the right tension. If the chain is

too tight, toosen the bar clamp screw slightly, turn the

adjusting screw counterclockwise a little and lift up on

the chain. Then tighten bar clamp screw. Recheck chain

tension. Lift the chain off of the middle of the length of

the bar. if it is loose enough for thetangsto come out of

the bar groove, the chain istoo loose. You should only be

able to lift the chain 1/8"" from bar. Whenever using a new

chain, check chain tension often, as new chain stretches.

After the chain has been used for awhile, it is a goodprac-

tice to check chain tension every time the gas tank is

filled. Proper chain tension is very important to help in-

sure maximum performance from your chain saw.

Model 358-350870(Craftsman 2.1 PS) Model 35.8-350880 (Craftsman 2.3 PSFVL)

Adjusting

Pin

Fig. 4A

Fig. 4B

FUEL MIX

Model 358-350842 (Craftsmen 2.1) Model 358-350870

Your chain saw is powered by a 2 cycle engine and re-

quires a fuel mixture of gasolineand oil. The proper fuel

mixture i116 parts gasoline to 1 part oil, or 1/2 pint (8

oz.) Sears oil Cat. 32-36555 to one gallon or one imperial

gallon of "regular" leaded gasoline. If Sears oil is not

CHAIN OIL

Model 358-350842 (Craftsman 2.1)

Remove the oil flit capand fill the oil tank with S.A.E. No..

30 (SD) oil. This oil is for chainand bar lubrication and is

in no way connected with the fuel mix. The oil tank should

be filled every time the fuel tank is filled. For cold

weather operation. Above 40 degree F use SAE 30 oil: 40

to 0 (zero) degree use SAE 10: Below 0 degree F use 10%

kerosene and 90% SAE 30. Be carefulto keep the fuel mix

Model 358-350870 (Craftsman 2.1 PS) Model 358-350880 (Craftsman 2.3 PS/VL)

(Craftsman 2.1 PS) Model 358-350880 (Craftsman 2.3 PS/VL)

available, useSAE No. 30 nondetergent oil (MS or better).

Do not use multi-viscosity oils (10W-30) or reprocessed

oils in your fuel mix. Prepare the mixture in a separate

container and shake well to assurecomplete mixing. Do

not use dirty oil or old (stale) gasoline.

and oil free from contamination. Wipe off the saw after

filling the fuel and oil tanks if either has been spilled. Under

normal cutting conditions, push the oil button once every

10 seconds.Under heavy, or dirty cutting conditions, push

the oil button once every 5 seconds.This will prevent the

bar andchain from burning.

Sears Models 358-350870 (Craftsman 2.1 PS) and 358-350880 (Craftsman 2.3 PS/VL) are

equipped with both automatic and manual oiler for lubd,eation of the guide bar and chain.The

.!,

, automatic oiler operates when the saw is running and may be assistedby pushing the manual oiler

button if additional oil isrequired for extreme cutting cond'xtions,

H •

_i_! ::_i:_i:, _ •

H

"• •••_••L:;I; ii¸ •;

IMPORTANT

MODEL 358.350870 (Craftsman 2.1 PS)

MODEL 358-350880 (Craftsnmn 2.3 PS/VL)

1. Fill the oil tank, (see paragraphunder CHAIN OIL) Fill oil tank each time fuel tank

isfilled.

2. Prime the oiler system before starting engim by pushing manual oiler button until

oil isvisible at top Of bar,

3. Start' engine. Check automatic oiling by pokxting guide bar towards aclean surface

with engine running at cutting speed. Oil dhouid be seen on clean surface as it is

thrown off end of guide bar. WARNING: T'q=of guide bar should be severalinches

away from clean surface - but do not let moving chain touch any kind of surface

becausesaw could kick back and causeinjury,

.

Sears model 358-350842 has a manual oiiw only. Push the oiler button every ten

secondsduring cutting to provide proper lubrication of bar and chain.

STARTING AND STOPPING

Model 358-350842 (Craftsman 2.1)

Model 358-350870 (Craftsman 2-1 PS)

Model 358-350880 (Craftsman2-3 PS/VL)

NOTE: For your convenience, starting instructions are

also printed on the saw below the handle, beside the

"on'L'_off '' switch.

1. Fill oil and fuel tanks. Check chain tension.

Pump oil button until oil appears on bar.

2. Push ignition switch forward to "on".

3. Push choke lever "on" (to right).

4. STARTING (This is the recommended starting

position) See Figure 5.

Hold saw away from body with right hand and

elbow slightly bent, see Fig, 5. Squeeze trigger,

Push saw straight away from body and at same

time pull starter handle. Repeat action until

engine fires. Push choke off (to left) and repeat

starting procedure until engine runs. Hold on to

starter handle while allowing the rope to rewind.

DO NOT PULL STARTER HANDLE OVER

12'"TO 14" FROM ENGINE.

5_

Release trigger to idle engine.

6.

If engine does not fire after 5 to 6 pulls, it may

be flooded. Push choke off(clockwise) and pull

starter several times while holding trigger at wide

open throttle. If saw has run out of fuel, 8 to 10

pulls with choke on may be required to restart

engine. When restarting a hot engine, or one

which has just been refueled, you may. have to

]

Fig. 5

use the choke in order to clear the vaporsout of

• the carburetor,. ....

7. To stop engine, pull switch back to "off"

position. The engine may also be stopped by

pushing •the ,choke lever to, the right (counter-

clockwise).

3

CARE AND MAINTENANCE

Model. 358-350842 (Craftsman 2.1) Model 358.350870 (Craftsman 2.1 PS) Model 358.350880(Craftsman 2.3 PS/VL)

Follow these helpful hints on care and maintenance to

get the best possible service from your saw, to prevent

major breakdown and costly repair bills. Careful servicing

of your saw is one of the most important steps in preven-

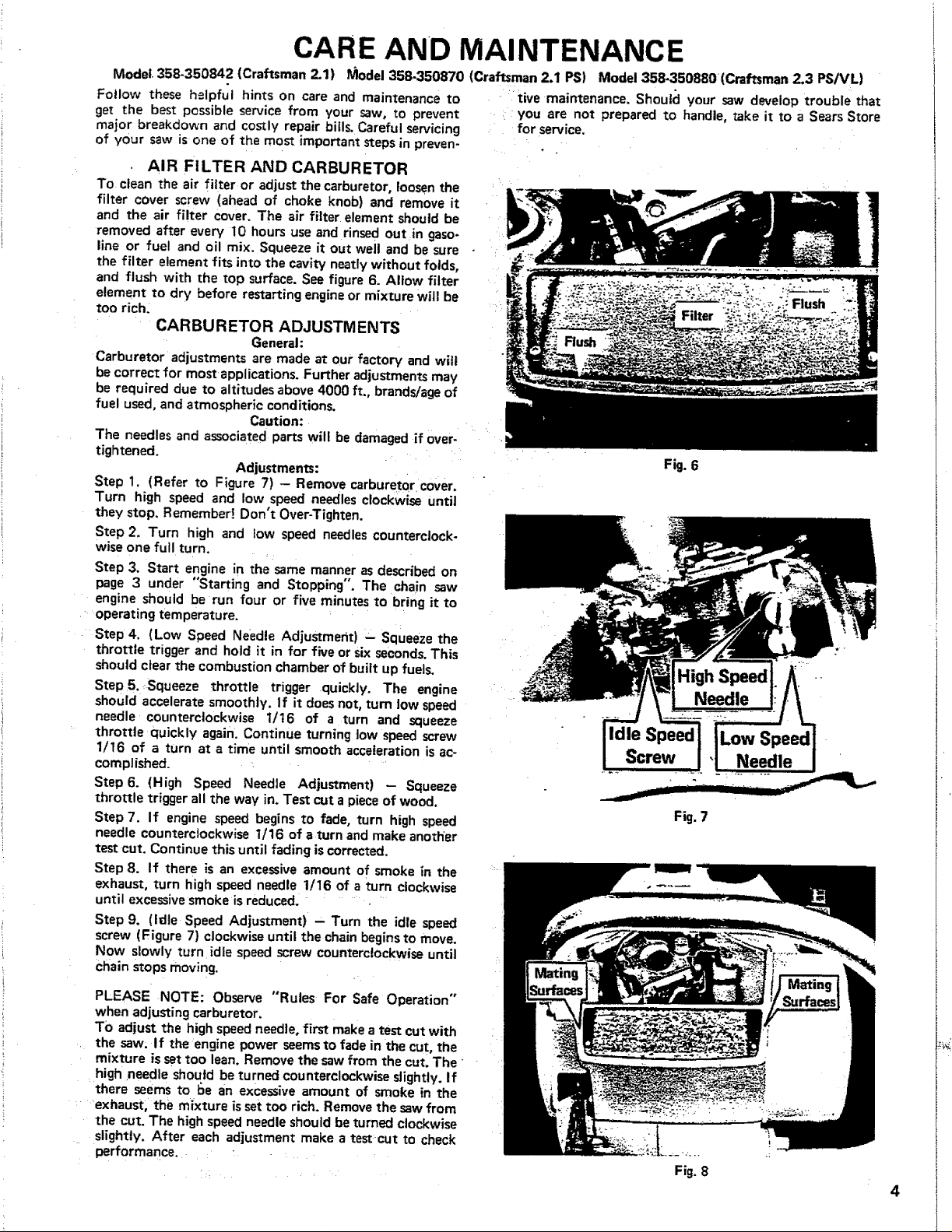

AIR Fi LTER AND CARBURETOR

To clean the air filter or adjust the carburetor, loosen the

filter cover screw (ahead of choke knob) and remove it

and the air filter cover. The air filter element should be

removed after evew 10 hours use and rinsed out in gaso-

line or fue! and oil mix. Squeeze it out well and be sure

the filter element fits into the cavity neatly without folds,

and flush with the top surface. See figure 6. Allow filter

element to dry before restarting engine or mixture will be

too rich;

CARBURETOR ADJUSTMENTS

General:

Carburetor adjustments are made at our factory and wil|

be correct for most app ications. Further adjustments may

be required due to altitudes above 4000 ft., brands!age of

fuel used, and atmospheric conditions.

Caution:

The needles and associated parts will be damaged if Over-

tightened.

Adjustments:

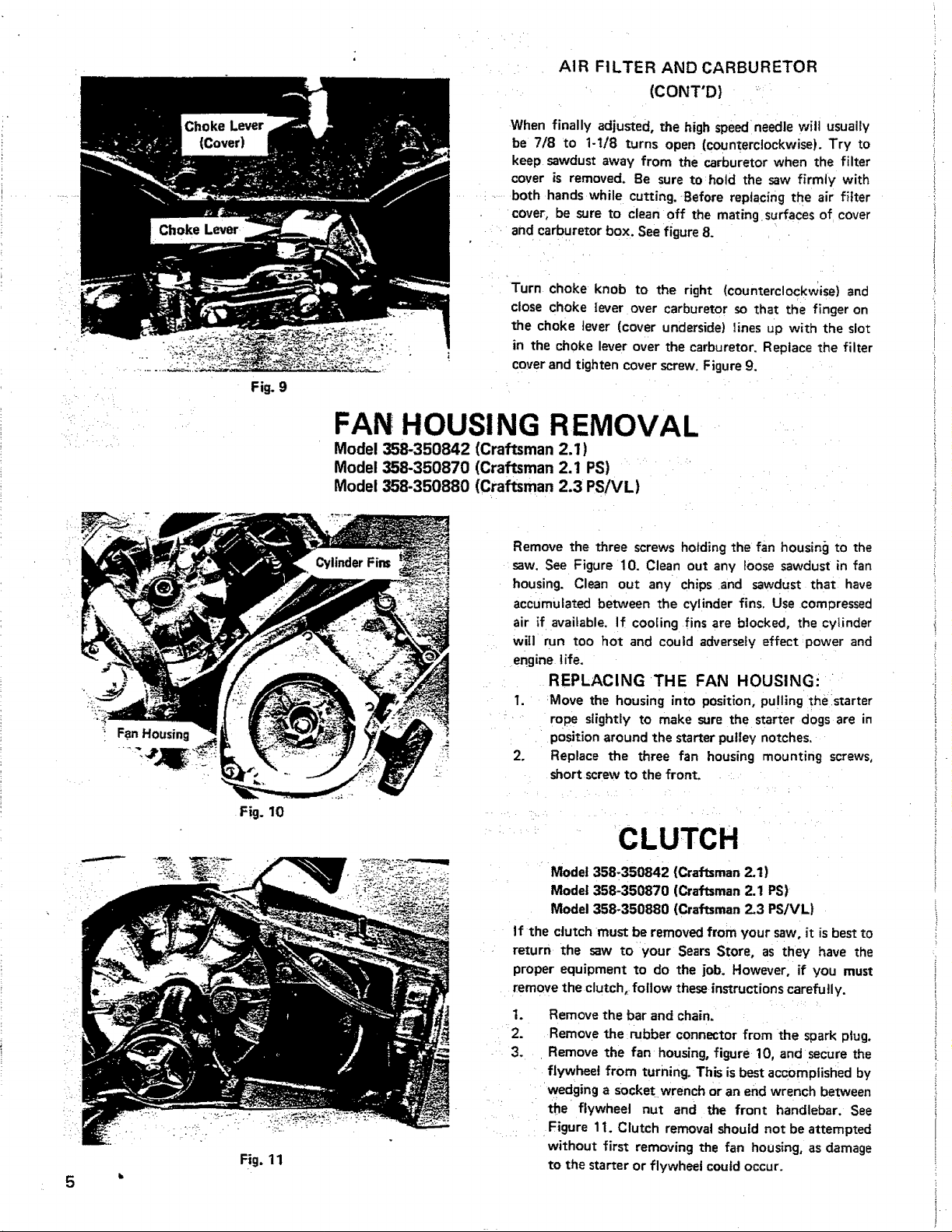

Step 1. (Refer to Figure 7) -- Remove carburetor cover,

Turn high speed and low speed needles clockwise until

they stop, Remember! Don't Over-Tighten.

Step 2. Turn high and low speed needles counterclock-

wise one full turn.

Step 3. Start engine in the same manner asdescribed on

page 3 under "Starting and Stopping". The chain saw

engine should be run four or five minutes to bring it to

operating temperature.

Step 4. (Low Speed Needle Adjustmeht) " Squeeze the

throttle trigger and hold it in for five or six seconds.This

should clear the combustion chamber of built up fuels.

StepS. Squeeze throttle trigger .quickly. The engine

should accelerate smoothly. If it does not, turn low speed

needle counterclockwise 1/16 of a turn and squeeze

throttle quickly again. Continue turning tow speed screw

1/16 of a turn at a time until smooth acceleration isac-

complished.

Step6. (High Speed Needle Adjustment) -Squeeze

throttle trigger all the way in. Test cut a piece of wood.

Step 7. If engine speed begins to fade, turn high speed

needle counterclockwise 1/16 of aturn and make anoth'er

test cut. Continue this until fading is corrected.

Step 8. If there is an excessive amount of smoke in the

exhaust, turn high speed needle 1/16 of a turn clockwise

until excessive smoke is reduced. .........

Step 9. (Idle Speed Adjustment) -- Turn the idle speed

screw (Figure 7) clockwise until the chain beginsto move.

Now slowly turn idle speed screw counterclockwise until

chain stops moving.

"live maintenance. Shoutct your saw develop trouble that

_, you are not prepared to handle, take it to a Sears Store

for service.

Fig. 6

Needle

Idle Speed Low Speed

Screw Needle

Fig. 7

PLEASE NOTE: Observe "Rules For Safe Operation"

when adjusting carburetor.

TO adiust the high speedneedle, first make a testcut with

the saw; If the engine power seemsto fade in the cut, the

mixture isset too lean. Remove the saw from the cut. The"

high needle should be tu rnedcounterclockwise slightly. If

there seems to !_ean excessive amount of smoke in the

exhaust, the mixture is set too rich. Remove the saw from

the cut. The high speed needle should be turned clockwise

slightly. After each adjustment make a testcut to check

performance. :....

Fig. 8

4

Fig. 9

AIR FILTER AND CARBURETOR

(CONT'D}

When finally adjusted, the high speedneedle will usually

be 7/8 to 1-1/8 turns open (counterclockwise). Try to

keep sawdust away from the carburetor when the filter

cover is removed. Be sure to hold the saw firmly with

both hands while cutting. Before replacing the air filter

cover, be sure to clean off the mating surfaces of cover

and carburetor box. See figure8.

Turn choke knob to the right (counterclockwise) and

close choke lever over carburetor so that the finger on

the choke lever (cover underside) lines up with the slot

in the choke lever over the carburetor. Replace the filter

cover and tighten cover screw Figure 9.

FAN HOUSING REMOVAL

Model 358-350842 (Craftsman 2.1)

Model 358-350870 (Craftsman 2.1 PS)

Model 358.350880 (Craftsman 2.3 PS/VL)

._o.

Fan Housing

t=

Fig. 10

F!g. 11

Remove the three screws holding the fan housing] to the

saw. See Figure 10. Clean out any loose sawdust in fan

housing. Clean out any chips and sawdust that have

accumulated between the cylinder fins. Use compressed

air if available. If cooling fins are blocked, the cylinder

will run too hot and could adversely effect power and

engine life.

REPLACING THE FAN HOUSING!

I. Move the housing into position, pulling the starter

rope slightly to make sure the starter dogs are in

position around the starter pulley notches.

2. Replace the three fan housing mounting screws,

short screwto the front.

CLUTCH

Model 358-350842 (Craftsman 2.1)

Model 358-350870 (Craftsman 2.1 PS)

Model 358-350880 (Craftsman 2.3 PSiVL)

If the clutch must be removed from your saw, it is bestto

return the saw to your Sears Store, as they have the

proper equipment to do the job. However, if you must

remove the clutch, follow these instructions carefu!ly.

1.

Remove the bar and chain.

2.

Remove the rubber connector from the spark plug.

3.

Remove the fan housing, figure 10, and secure the

flywheel from turning. This is best accomplished by

wedging a socket wrench or an end wrench between

the flywheel nut and the front handlebar. See

Figure 11. Clutch removal should not be attempted

without first removing the fan housing, as damage

to the starter or flywheel could occur.

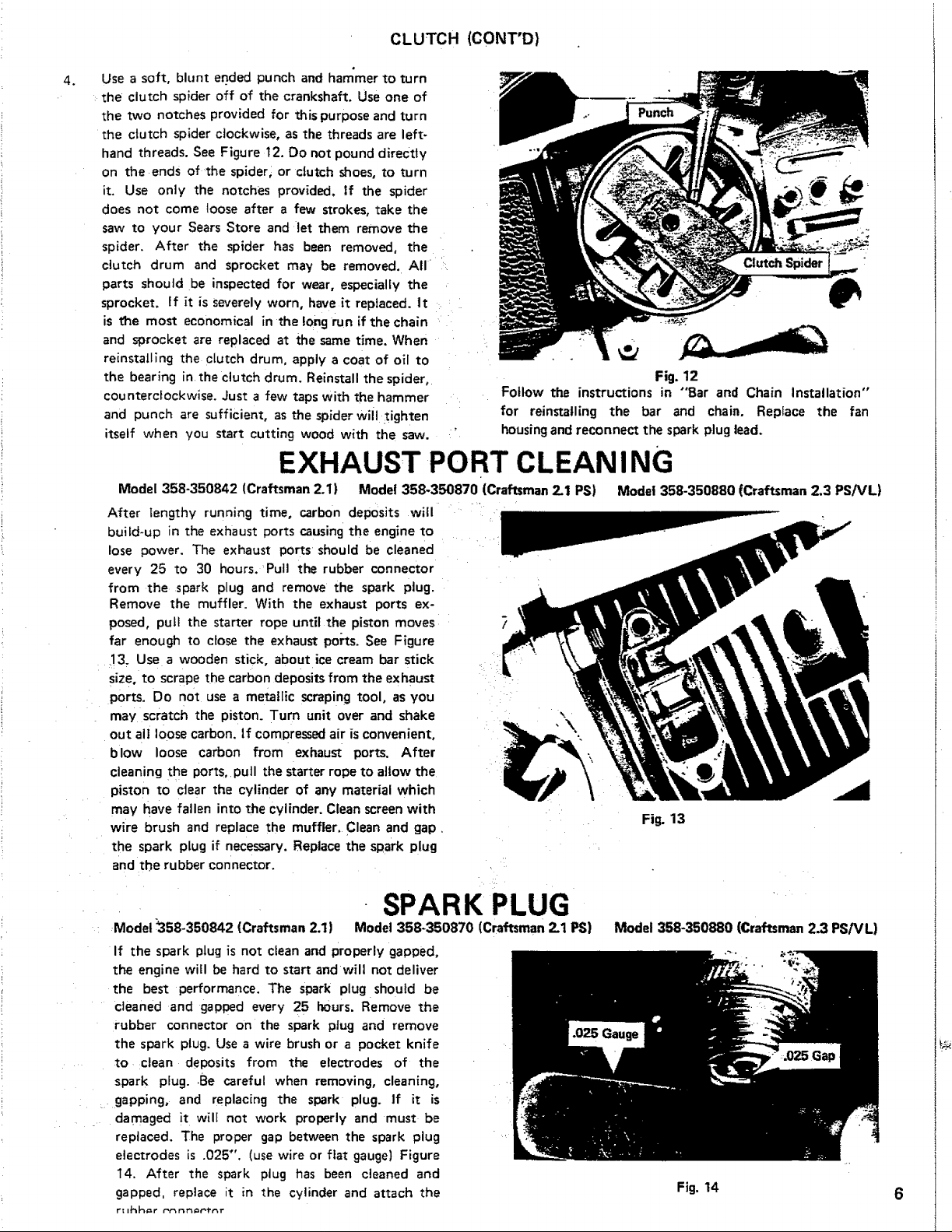

Use a soft, blunt ended punch and hammer to turn

4_

the clutch spider off of the crankshaft. Use one of

the two notches provided for *,,hispurpose and turn

the clutch spider clockwise, as the threads are left-

hand threads. See Figure t2. Do not pound directly

on the ends of'the spideri or clutch shoes, to turn

it. Use only the notches provided. If the spider

does not come loose after a few strokes, take the

saw to your Sears Store and let them remove the

spider. After the spider has been removed, the

clutch drum and sprocket may be removed. All _

parts should be inspected for wear, especially the

sprocket, tf it is severely worn, have it replaced, it _ i

is the most economical in the long run if the chain

and sprocket are replaced at the same time. When

reinstalling the clutch drum, apply a coat of oil to

the bearing in the clutch drum. Reinstall the spider,

counterclockwise. Just a few taps with the hammer

and punch are sufficient, as the spiderwiil tighten

itself when you start cutting wood with the saw. '

EXHAUST PORT CLEANING

Model 358-350842 (Craftsman 2.1) Model 358-350870 (Craftsman 2.1 PS)

After lengthy running time, carbon deposits will

build-up in the exhaust ports causing the engine to

lose power. The exhaust ports should be cleaned

every 25 to 30 hours. 'Pull the rubber connector

from the spark plug and remove the spark plug.

Remove the muffler. With the exhaust ports ex-

posed, pull the starter rope until the piston moves

far enough to close the exhaust port_. See Figure

!3, Use a wooden stick, about ice cream bar stick

size, to scrape the carbon deposits from the exhaust

ports. Do not use a metallic scraping tool, as you

may scratch the piston. Turn unit over and shake

out all loose carbon. If compressed air is convenient,

blow loose carbon from exhaust ports. After

cleaning the ports, pull the starter rope to allow the

piston to clear the cylinder of any material which

may have fallen into the cylinder. Clean screen with

wire brush and replace the muffler. Clean and gap.

the spark plug if necessary. Replace the spark plug

and the rubber con hector.

CLUTCH (CONT'D)

Fig. 12

Follow the instructions in "Bar and Chain Installation"

for reinstalling the bar and chain. Replace the fan

housing and reconnect the spark plug lead.

Model 358-350880 (Craftsman 2,3 PS/VL)

Fig. 13

SPARK PLUG

Modei_358-350842 (Craftsman 2.1) Model 358-350870 (Craftsman 2-1 PS)

If the spark plug is not clean and properly gapped,

the engine will be hard to start and will not deliver

the best performance. The spark plug should be

cleaned and gapped every 25 hours. Remove the

rubber connector on the spark plug and remove

the spark plug. Use a wire brush or a pocket knife

to clean deposits from the electrodes of the

spark plug..Be careful when removing, cleaning,

:gapping, and replacing the spark plug. If it is

damaged it will not work properly and must be

replaced. The proper gap between the spark plug

electrodes is .025 _'. (use wire or flat gauge} Figure

14. After the spark plug has been cleaned and

gapped, replace it in the cylinder and attach the

r_ ihh_=r r'_nr_=P1"_r

Model 358-350880 (Craftsman 2.3 PS/VL)

Fig. 14

Model 358-350880 (Craftsman 2.3 PS/VL)

The rubber,vibration" mounts are designed so that a failure

of one of the mounts will not affect the safety of the saw.

Operation of the saw With a broken rubber mount may

cause excessive wear to other components, resulting in a

hazardous situation. Should a rubber mount break, take it

to a Sears Store immediately and have it replaced.

Check a|l vibration mount screws and nuts for tightness

every two to three hours of operating time.

Sprocket Nose Bar

HOW TO SHARPEN YOUR CHAIN

Craftsman 2.1 PS and Craftsman 2.3 PS/VL are equipped

with a sprocket nose bar. The sprocket nose does not re-

quire grease. Bearings have been greased and sealed at the

factor/, Remember, keep the saw chain well oited. A well

oiled saw chain witl greatly increase the life of saw chain,

bar and saw chain drive sprocket.

Two Vibration Mounts

Vibration

Mount

O

Vibration Mount

Model 358-350870 (Craftsman 2.1 PS) Only

Model 358-350880 (Craftsman 2.3 PS!VL) Only

OPERATING-STONE REPLACEMENT AND CHAIN FILING WITH POWER SHARP

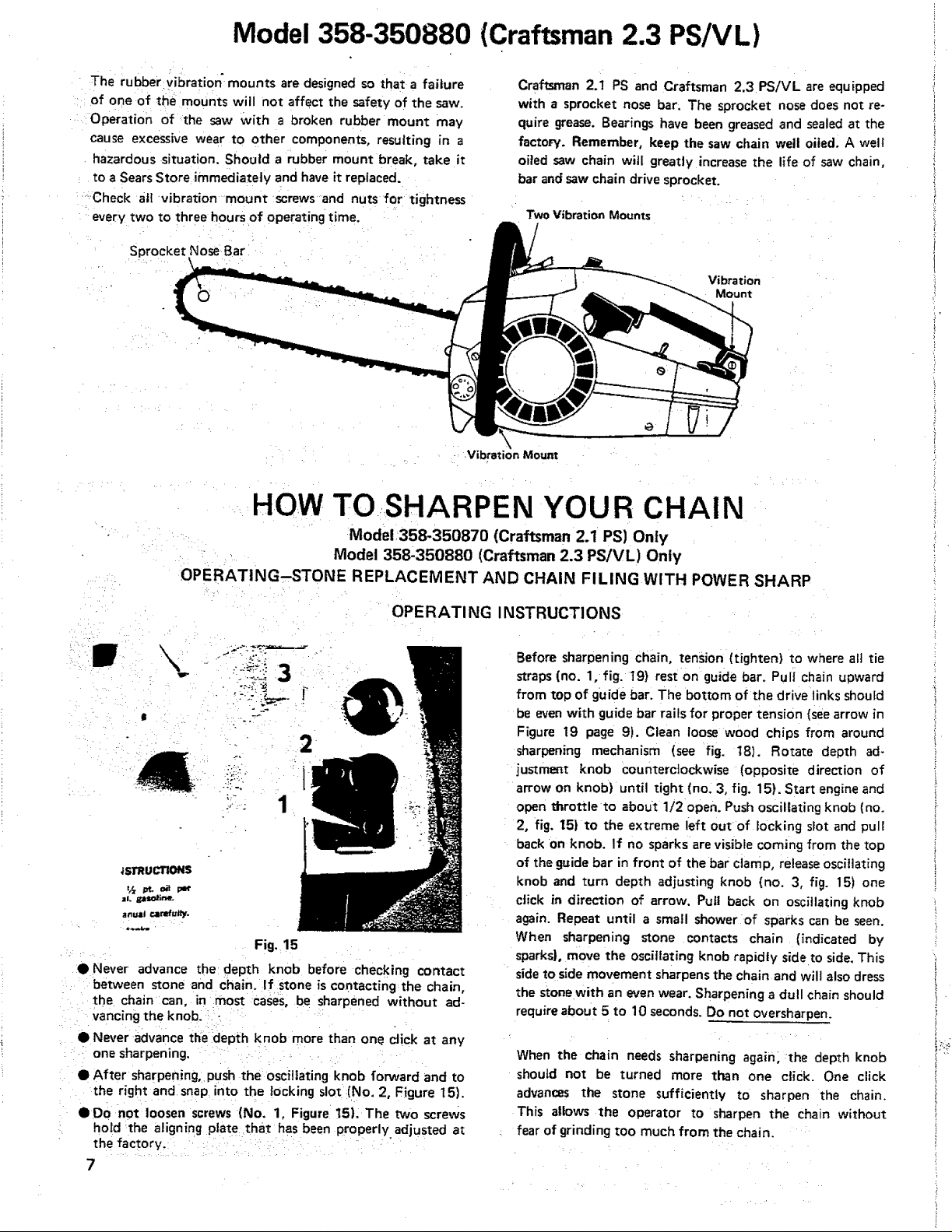

OP ERATI NG INSTRUCT! ONS

_SI"RUCI30NS

½ ;o_.._ per

aL _lt, oline.

anua! camfu_l,/.

Fig. 15

• Never advance the depth knob before checking contact

: between stone and Chain. If stone is contacting:the chain,

the chain can. inmost cases, be sharpened without ad-

Vancing the knob.- : _::

• Never advance the depth knob more than one. click at any

• one sharpening. : ,

• After sharpening, push the oscillating knob forward and to

the right and snap into the locking slot :(No. 2, Figure 15).

• Do not loosen screws (No. 1, Figure 15). The two screws

hoJdthe aligning plate that has been properly adjusted at

the factory,_ _ :, _ i i i "

7

Before sharpening chain, tension (tighten) to where alt tie

straps (no. 1, fig. 19) rest on guide bar. Pull chain upward

from top of guide bar. The bottom of the drive links should

. .

be evenwith guide bar rails for proper tension (seearrow in

Figure 19 page 9). Clean loose wood chips from around

sharpening mechanism (see fig. lB). Rotate depth ad-

justment knob counterclockwise (opposite direction of

arrow on knob) until tight (no. 3, fig. 15). Start engineand

open throttle to about 1/2 open. Push oscillating knob (no.

2, fig. 15) to the extreme left outof locking slot and pull

back on knob. If no sparks are visible coming from the top

of the guide bar in front of the bar clamp, release oscillating

knob and turn depth adjusting knob (no. 3, fi_]. 15) one

click in direction of arrow. Pull back on osci!lating knob

again. Repeat until a small shower of sparks can be seen.

When sharpening stone contacts chain (indicated by

sparks), move the oscillating knob rapidly side to side. This

sideto side movement sharpensthe chain and will also dress

the stone with an evenwear. Sharpening a dull chain should

require about 5 to 10 seconds.Do not oversharpen.

When the chain needs sharpening again_ the depth knob

should not be turned more than one click. One click

advances the stone sufficiently to sharpen the chain.

This allows the operator to sharpen the chain without

fear of grinding too much from the chain.

Loading...

Loading...