Craftsman 358350160 Owner’s Manual

Operator's Manual

CRAFTSMRN

2.2 cu. in./36cc 2-Cycle

GASOLINE CHAIN SAW

Model No.

358.350160 -- 16 in. Bar

@

Read and follow all Safety Rules and Operating

WARNING:

Instructions before first use ofthis product.

For answers to your questions about this product:

Call 7 am-7 pro, Mon.-Sat., or 10 am-7 pm, Sun.

• 1"800-235-5878 (Hourslisted are Central Time)

Sears, Roebuck and Co., Hoffman Estates, IL 60179 USA

530087755 1/11/99

Warranty 2 Storage 16

Safety Rules 2 Trouble Shooting Chart 17

Assembly 5 Parts List 20

Operation 6 Spanish 24

Maintenance 11 Parts & Ordering Back

Service and Adjustments 14

FULL ONE YEAR WARRANTY ON CRAFTSMAN ® GAS

CHAIN SAW

Forone year fromthe date of purchase, when thisCraftsman Gas Chain Saw is

malntai0ed, lubdcated and tuned up according tothe owner's manual, Sears will

repalr_free ofcharge, any defect in material orworkmanship.

This Warranty excludes the bar, chain, spark plug and air filter, which are

expendable parts, and become worn during normal use.

Ifthis Gas Chain Saw is used for commercial or rental purposes, thiswarranty

applies for 30 days from the date of purchase.

WARRANTY SERVICE IS AVAILABLE BY RETURNING THIS CHAIN SAW TO

THE NEAREST SEARS SERVICE CENTER IN THE UNITED STATES.

This warranty gives you specific legal dghts, and you may also have other dghts

which vary from state to state.

Sears, Roebuck and Co., D/817 WA, Hoffman Estates, IL 60179

WARNING: Always disconnectspark

plugwire when making repairs except

for carburetor adjustments. Because a

chainsaw is a high-speed woodcutting

tool, careless or improper use of this

tool can cause serious injury.

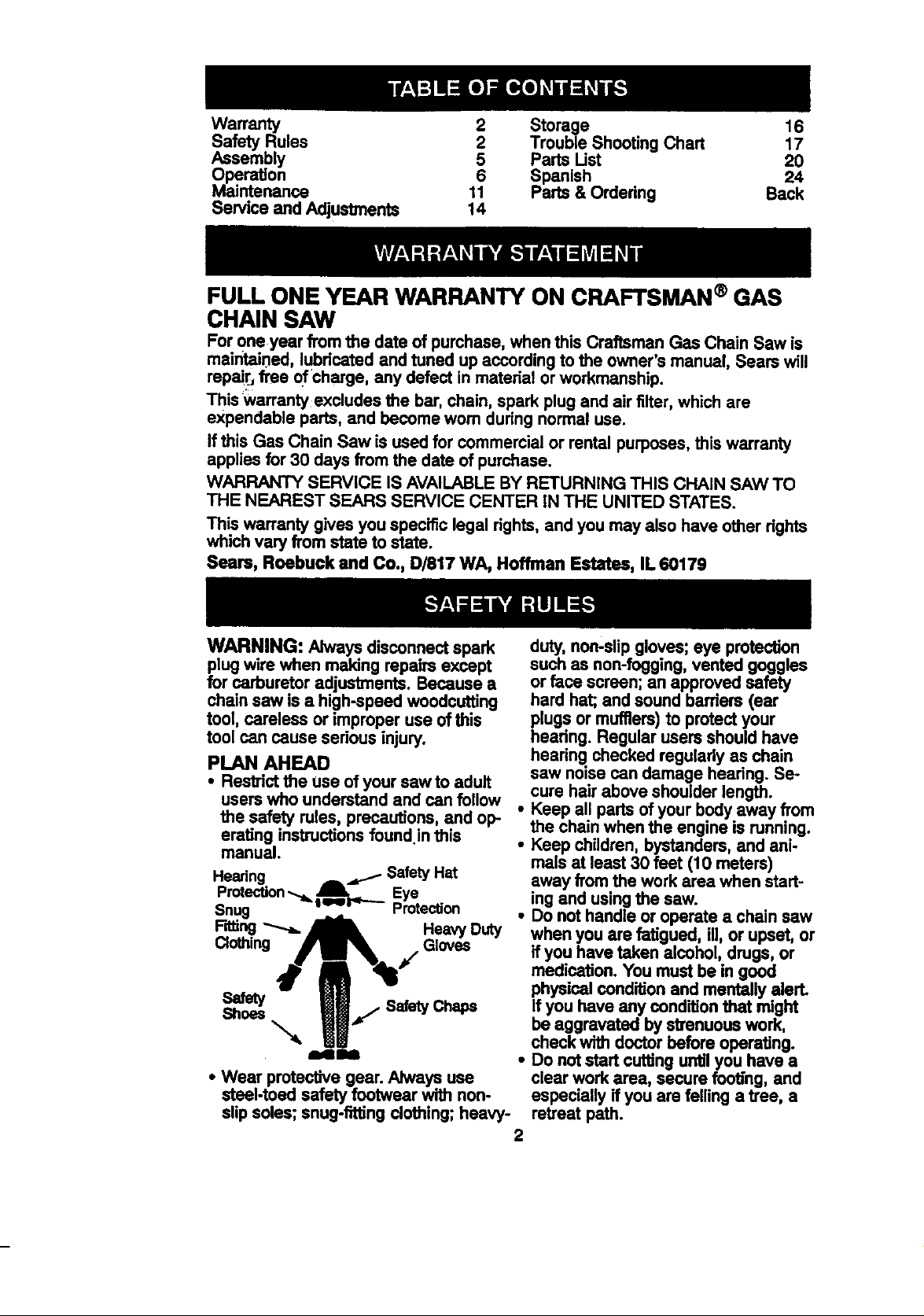

PLAN AHEAD

• Restrictthe use of yoursaw to adult

users who understand and can follow

the safety rules, precautions, and op- °

erating instructionsfound.in this •

manual.

Hearing _ _ Safety Hat

Protection_ __ Eye

Snug _

F_ng "--_J Heavy Duty

_,oming _ . Gloves

• Wear protective gear. Always use

etesl-toed safety footwear with non-

slipsoles;snug-firing clothing;heavy-

=wet---- Protection

duty, non-slipgloves; eye protection

suchas non-fogging, vented goggles

or face screen; an approved safety

hard hat; andsound barriers (ear

plugs or mufflers) to protect your

hearing. Regular users should have

hearing checked regularly as chain

saw noise can damage headng. Se-

cure hair above shoulder length.

Keep all parts of your body away from

the chain when the engine is running.

Keep children, bystanders, and ani-

mals at least 30 feat (10 meters)

away from the work area when start-

ing and usingthe saw.

Do nothandle or operate a chain saw

when you are fatigued, ill, or upset, or

ifyou have taken alcohol, drugs, or

medication. You must be in good

physicalcondition and mentally alert.

If youhave any condition that might

be aggravated by strenuous work,

checkwith doctor before operating.

Do notstart cuffing untilyou have a

clear work area, secure foob'ng,and

especially if you are felling a tree, a

retreat path.

2

OPERATE YOUR SAW SAFELY

• Donotoperatewithonehand.Seri-

ousinjurytothe operator,helpers,or

bystandersmayresultfromone-

handedoperation.Achainsawis in-

tendedfortwo-handeduse.

• Operatethe chain saw only in a well-

ventilated outdoor area.

• Do not operate saw from a ladder or

in a tree, unlessyou are specifically

trained to do so.

• Make sure the chain will not make

contact with any object while starting

the engine. Never try to start the saw

when the guide bar is in a cut.

• Do not put pressure on the saw, es-

pecially at the end ofthe cut. Doing

so can cause you to lose control

when the cut iscompleted.

• Stop engine before setting saw down.

• Hand carry saw only when engine is

stopped. Carry with muffler away from

body;guide bar & chain projecting be-

hindyou; guide bar preferably cov-

ered with a scabbard.

MAINTAIN YOUR SAW IN GOOD

WORKING ORDER

• Have all chain saw service performed

by a qualified service dealer except

the items listed inthe maintenance

section of this manual.

• Make certain the saw chain stops

moving when the throttle trigger is re-

leased. For correction, refer to "Car-

buretor Adjustments."

• Keep the handles dry, clean, and free

from oil or fuel mixture.

• Keep caps and fasteners securely

tightened.

• Use only Craftsman accessodas and

replacement parts as recommended.

Never modify your saw.

HANDLE FUEL WITH CAUTION

• Do not smoke while handling fuel or

while operating the saw.

• Eliminateallsources of sparksor flame

in areas where fuel ismixedor poured.

• Mix and pour fuel in an outdoor area

and use an approved, marked con-

tainer for all fuel purposes. Wipe up

all fuel spills before starting saw.

• Move at least 10 feet (3 meters) from

fueling site before starting.

• Turn the engine off and let saw cool in

a non-combustible area, not on dry

leaves, straw, paper, etc. Slowly re-

move fuel cap and refuel unit.

• Store the unit and fuel in a cool, dry

well ventilated space where fuel va-

pors cannot reach sparks or open

flames from water heaters, electric

motors orswitches, furnaces, etc.

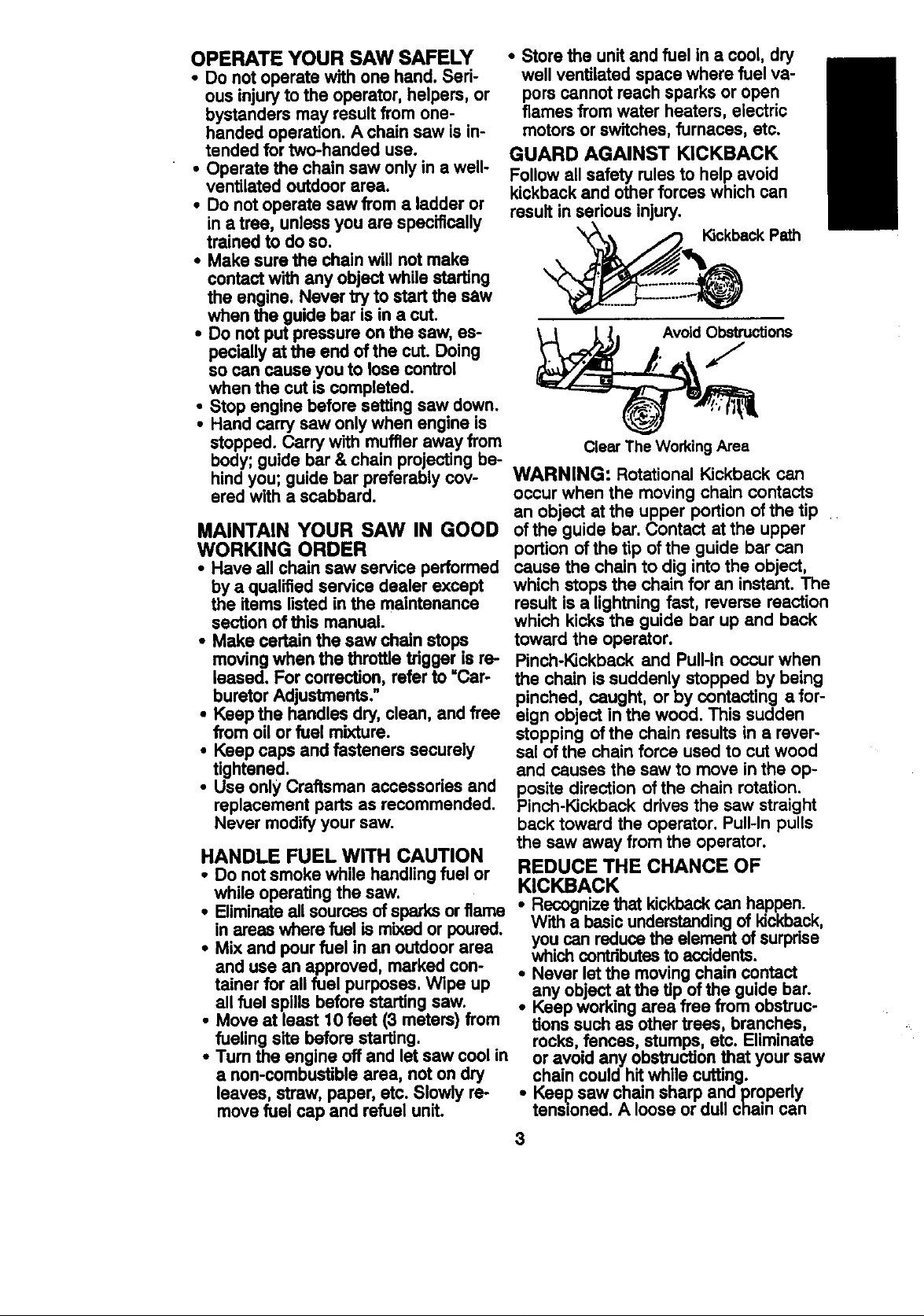

GUARD AGAINST KICKBACK

Follow all safety rules to help avoid

kickback and other forces which can

result in sedous injury.

'_ _ KickbackPath

Avoid Obstructions

ClearThe Working Area

WARNING: Rotational Kickback can

occur when the moving chain contacts

an object at the upper portion of the tip

of the guide bar. Contact at the upper

portion of the tip of the guide bar can

cause the chain to dig into the object,

which stops the chain for an instant. The

result is a lightning fast, reverse reaction

which kicks the guide bar up and back

toward the operator.

Pinch-Kickback and Pull-in occur when

the chain is suddenly stopped by being

pinched, caught, or by contacting a for-

eign object in the wood. This sudden

stopping of the chain results in a rever-

sal of the chain force used to cut wood

and causes the saw to move in the op-

posite direction of the chain rotation.

Pinch-Kickback drives the saw straight

back toward the operator. Pull-In pulls

the saw away from the operator.

REDUCE THE CHANCE OF

KICKBACK

• Recognizethat kickbackcan happen.

With a basic understandingof Idckback,

you can reducethe element of surpdse

which contributesto accidents.

Never !at the moving chain contact

object Up

_any at the ofthe guide bar.

Keep working area free from obstruc-

tions such as other trees, branches,

rocks,fences, stumps, etc. Eliminate

or avoid any obstruction that your saw

chain could hRwhile cutting.

• Kee? saw chain sharp and properly

tanmoned. A loose or dull chain can

3

increasethe chanceofkickback.Fol-

lowmanufacturer'schainsharpening

and maintenance instructions. Check

tension at regular intervals, but never

with engine running. Make sure bar

clamp nuts are securely tightened.

• Begin and continue cutting at full

speed. If the chain is moving at a

slower speed, there is greater chance

of kickback occurring.

• Use extreme caution when reentering

a cut.

• Do not attempt cuts starting with the

tip of the bar(plunge cuts).

• Watch for shifting logs or other forces

that could close a cut and pinch or fall

intochain.

• Use the specified Reduced-Kickback

Guide Bar and Low-Kickback Chain,

Avoid Pinch-Kickback:

• Be extremely aware of situations or

obstructions that can cause material

to pinch the top of or otherwise stop

the chain.

• Do not cut more than one log at a

time.

• Do not twist saw as bar iswithdrawn

from an undercut when bucking.

Avoid Pull-in:

• Always begin cutting with the engine

at full speed and the saw housing

against wood.

• Use wedges made of plastic or wood.

Never use metal to hold the cut open.

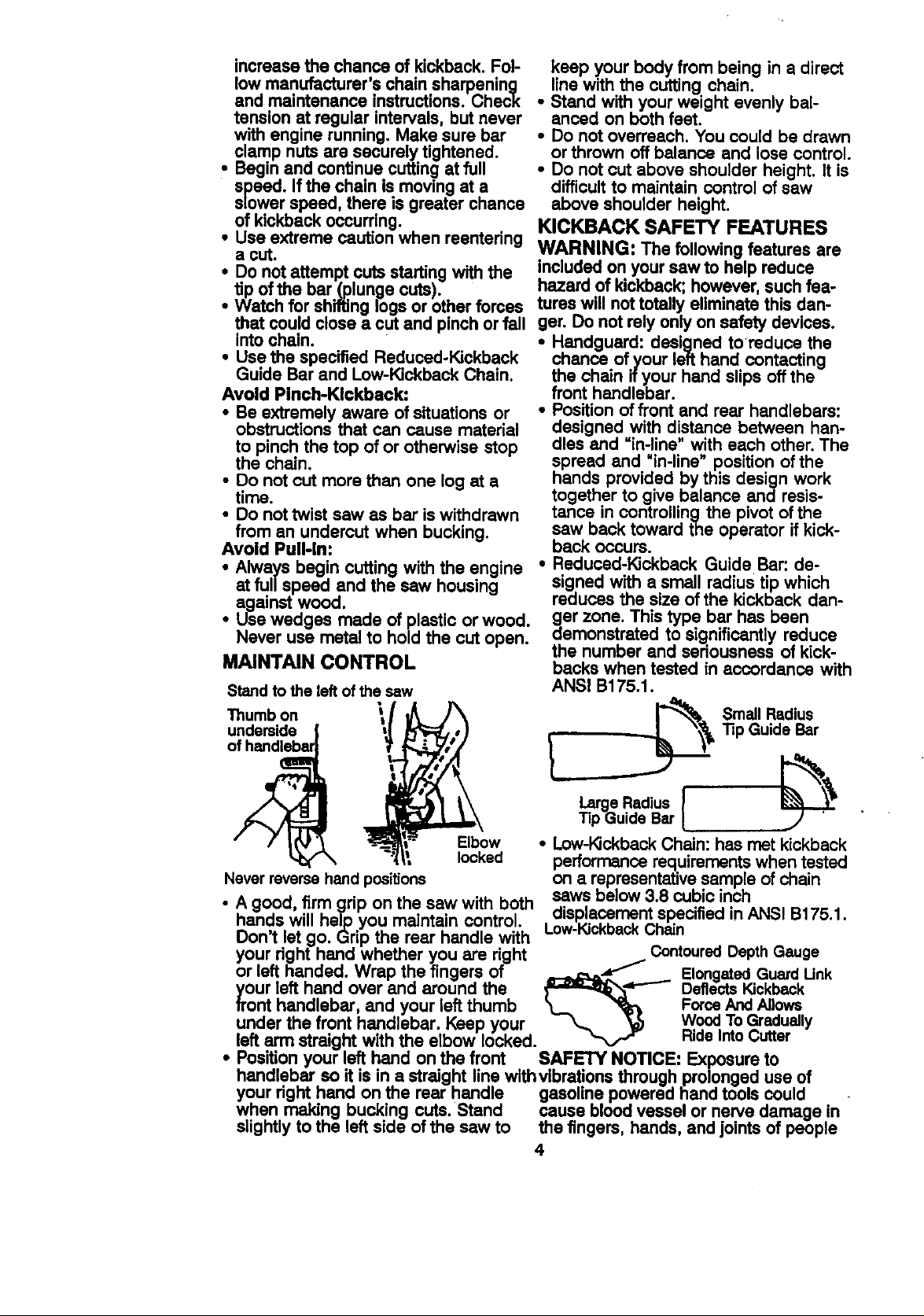

MAINTAIN CONTROL

Stand to the left of the saw

of handleba= \!

keep your body from being in a direct

linewith the cutting chain.

• Stand with your weight evenly bal-

anced on both feet.

• Do not overreach. You could be drawn

or thrown off balance and lose control.

• Do not cut above shoulder height. It is

difficultto maintain control of saw

above shoulder height,

KICKBACK SAFETY FEATURES

WARNING: The following features are

included on your saw to help reduce

hazard of kickback; however, such fea-

tures will not totally eliminate this dan-

ger. Do not rely only on safety devices.

• Handguard: designed to reduce the

chance of your left hand contacting

the chain ifyour hand slips off the

front handlebar.

• Position of front and rear handlebars:

designed with distance between han-

dles and =in-line" with each other. The

spread and "in-line" position of the

hands provided by this design work

together to give balance and resis-

tance in controllingthe pivot of the

saw back toward the operator if kick-

back occurs.

• Reduced-Kickback Guide Bar: de-

signed with a small radius tip which

reduces the size of the kickback dan-

ger zone. This type bar has been

demonstrated to significantly reduce

the number and seriousness of kick-

backs when tested in accordance with

ANSI B175.1.

Small Redius

Tip Guide Bar

Thumbon

underside_

Elbow • Low-KickbackChain: has met kickback

locked performance requirementswhen tested

Neverreversehandpositions on a representativesample of chain

• • • saws below 3 8 cubic inch

A good, firm onp on the saw with both .... " .............

han ' • • oksplacemen_specmea mAreal U](_ ]

ds w=llhel'oyou maJntam control........... • •

Don_tlet go. _rlp the rear handle with "

your right hand whether you are right _ ContouredDepth Gauge

or left handed. Wrap the fingers of _-- Elongated GuardUnk

. LOW F_ICKDSCK _n_,n

your left hand over and around the _--_"P"- DeflectsKickback

front handlebar, and your left thumb 'L_ _ FarceAndAllows

under the front ha_..dlebar.Keep your _ _k5 WoodTo Gradually

left _ straight with the elbow locked. _ RideIntoCutter

• Pos=tlonyour !.e.Rhand on the front SAFETY NOTICE: Exposure to

handlebar so it =sin a straight line withvibrafions through prolonged use of

your fight hand on the rear handle gasoline powered hand tools could

when making bucking cuts. Stand cause blood vessel or nerve damage in

slightly to the left side of the saw to the fingers, hands, and joints of people

4

proneto circulationdisordersor

abnormalswelling. Prolonged use in

cold weather has been linked to blood

vessel damage in otherwise healthy

people. If symptoms occur such as

numbness, pare, loss of strength,

change in skin color ortexture, orloss

of feeling in the fingers, hands, or joints,

discontinuethe use of this tool and

seek medical attention. An

anti-vibration system does not

guarantee the avoidance of these

problems. Users who operate power

tools on a continual and regular basis

must closely monitortheir physical

condition and the condition of this tool.

CHAIN BRAKE If this saw isto be u_sbd

for commercial logging, you must order

and install a chain brake to comply with

Federal OSHA Regulations for Com-

mercial Logging. Contact your Sears

Service Center or call 1-800-235-5878.

SPARK ARRESTOR: Your saw is

equipped with a temperature limiting

muffler and spark arresting screen

which meets the requirements of

California Codes 4442 and 4443. All

U.S. forest land and the states of

California, Idaho, Maine, Minnesota,

New Jersey, Oregon, and Washington

require by law that many internal

combustion engines be equipped with a

spark arrestor screen. If you operate a

chain saw in a state or locale where

such regulations exist, you are legally

responsiblefor maintaining the

operating condition ofthese parts.

Failure to do so is aviolation of the law.

Refer to Customer Responsibilities

chart in the k_AtWi'ENANCEsection.

STANDARDS: This chain saw is listed

by Underwriters Laboratories, Inc. in

accordance with American National

Standards for Gasoline-Powered Chain

Saws Safety Requirements (ANSI

B175.1-1991).

CARTON CONTENTS

Check carton contents against the fol-

lowing list.

Model 358.350160

• Chain Saw (fully assembled)

• Bar tool

• 2-cycle engine oil

• Log Carder

• Carrying Case

• Examine parts for damage. Do not

use damaged parts.

• Ifyou need assistance or find that

parts are missing or damaged, please

call 1-800-235-5878.

NOTE: It is normal to hear the fuel filter

raffle in an empty fuel tank.

Your unithas been factory tested and

the carburetor precisely adjusted. As a

result you may smell gasoline or find a

drop of oil/fuel residue on the muffler

when you unpack the unit.

ASSEMBLY

Your saw is fully assembled; no

assembly is necessary.

5

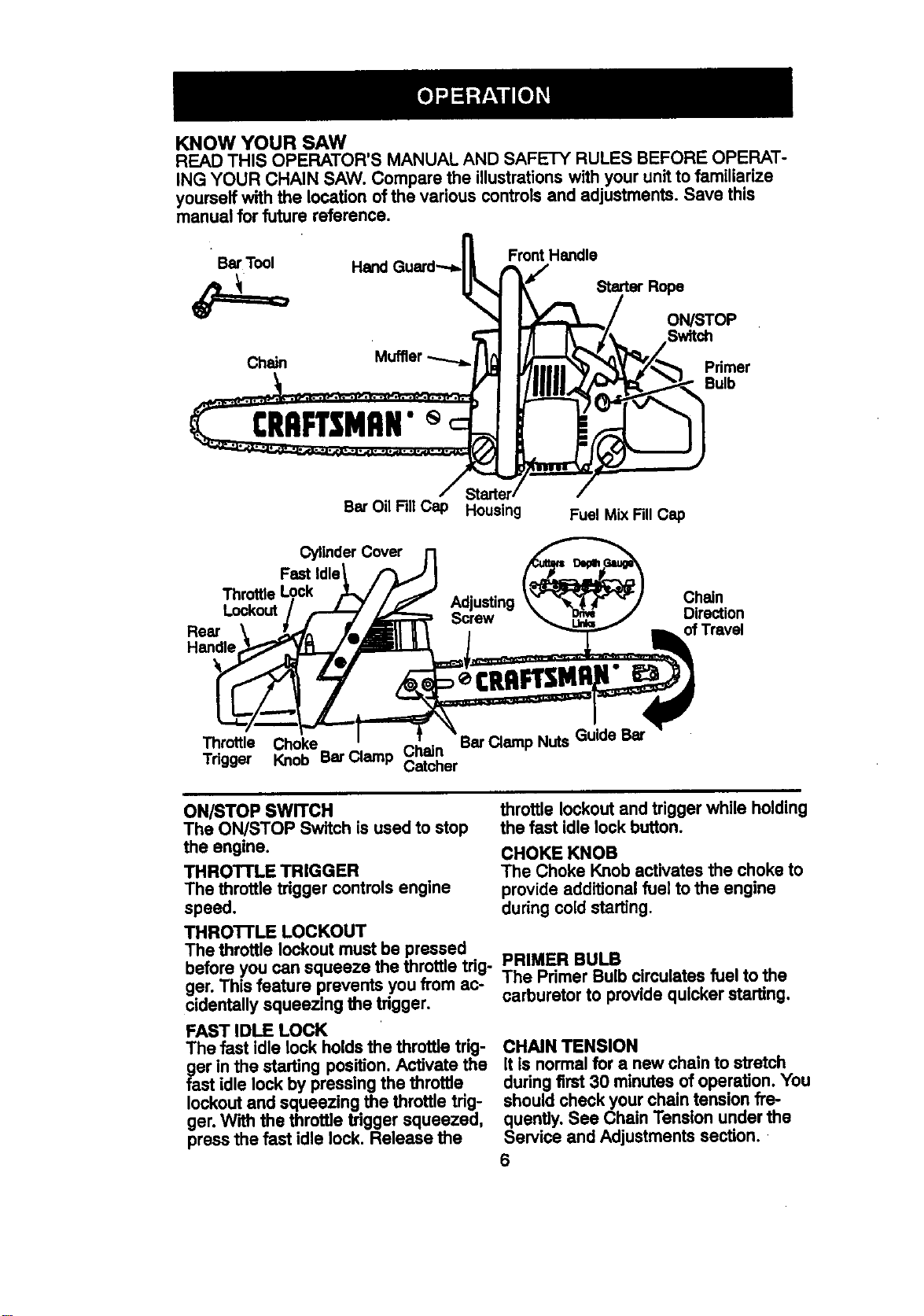

KNOW YOUR SAW

READTHISOPERATOR'SMANUALANDSAFETYRULESBEFOREOPERAT-

INGYOURCHAINSAW.Comparethe illustrationswithyourunittofamiliarize

yourseffwiththe location of the various controls and adjustments. Save this

manual for future reference.

•,_..... " . _ FrontHandle

iu_ ,u_, HandGuara.--.b_ y Start, Rope

,-"= g o=o,

Chain Muffler"'"='1 t_ _ _'_ _J/_ Primer

/ Starter /

BarOil FillCap HousJn FuelMixFill Cap

Cylinder Cover

Throttle Look Adjusting Chain

Lockout Screw Direction

Rear of Travel

Handle

Throttle Choke Bar Clamp Nuts Guide Bar

Tdgger Knob Bar Clamp Chain

ON/STOP SWITCH

The ON/STOP Switch is used to stop

the engine.

THROTTLE TRIGGER

The throttle trigger controls engine

speed.

THROTTLE LOCKOUT

The throttle lockout must be pressed

before you can squeeze the throttle trig-

ger. Thin feature prevents you from ac-

cidentally squeezing the trigger.

FAST IDLE LOCK

The fast idle lock holds the throttle trig-

ger in the starting position. Activate the

fast idle lock by pressing the throttle

lockoutand squeezing the throttle trig-

ger. With the throttle trigger squeezed,

press the fast idle lock. Release the

Catcher

throttle lockout and trigger while holding

the fast idle lock button.

CHOKE KNOB

The Choke Knob activates the choke to

provide additional fuel to the engine

duringcold starting.

PRIMER BULB

The Primer Bulb circulates fuel to the

carburetor to provide quicker starting.

CHAIN TENSION

It is normal for a new chain to stretch

duringfirst 30 minutes of operation. You

should check your chain tension fre-

quently. See Chain Tension under the

Service and Adjustments section.

6

BEFORE STARTING ENGINE

WARNING: Be sure to read the fuel

handling in._.rmation in the safety rules

section of th,s manual before you begln.

If you do not understand the fuel han-

dling information do not attempt to fuel

your unit. Seek help from someone that

does understand the information or call

the customer assistance help line at

1-800-235-5878.

GUIDE BAR AND CHAIN OIL

The chain oiler provides continuous lu-

brication to the chain and guide bar. Be

sure to fill the bar oil tank when you fill

the fuel tank (Capacity = 6.8 ft. oz.).

For maximum guide bar and chain life,

we recommend you use Craftsman

chain saw bar oil. if Craftsman bar oil is

not available, you may use a good

grade SAlE30 oil until you are able to

obtain Craftsman brand. The oil output

is automatically metered during opera-

tion. Your saw will use approximately

one tank of bar oil for every tank of fuel

mix. Always fill the bar oil tank when

you fill the fuel tank.

linesand carburetorare empty.Use fresh

fuel next season. See STORAGEinstruc-

tions foradditionalinformation.

Never use engine or carburetor cleaner

products in the fuel tank or permanent

damage may occur.

See the STORAGEsection for additional

information.

STOPPING YOUR ENGINE

• Move On/Stop switch to STOP.

• If engine does not stop, pullchoke

knob out fully.

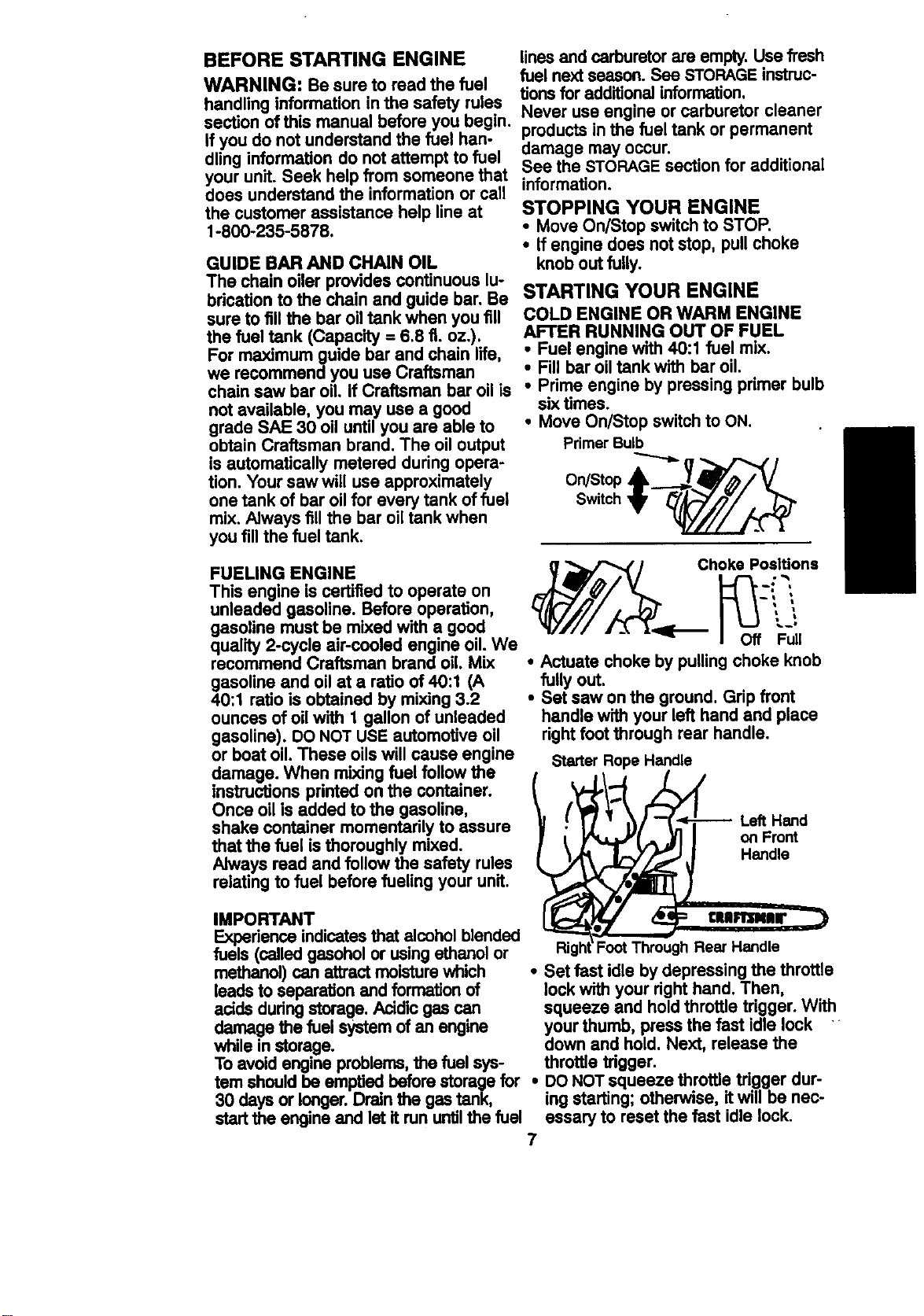

STARTING YOUR ENGINE

COLD ENGINE OR WARM ENGINE

AFTER RUNNING OUT OF FUEL

• Fuel engine with40:1 fuel mix.

• Fill bar oiltank with bar oil.

• Prime engine by pressing pdmer bulb

six times.

• Move On/Stop switch to ON.

Primer Bulb

FUELING ENGINE

This engine is certified to operate on

unleaded gasoline. Before operation,

gasoline must be mixed with a good

quality 2-cycle air-cooled engine oil. We

recommend Craftsman brand oil. Mix

gasoline and oil at a ratio of 40:1 (A

40:1 ratio is obtained by mixing 3.2

ounces of oil with 1 gallon of unleaded

gasoline). DO NOT USE automotive oil

or boat oil. These oils will cause engine

damage. When mixing fuel follow the

instructionsprinted on the container.

Once oil is added to the gasoline,

shake container momentarily to assure

that the fuel is thoroughly mixed.

Always read and follow the safety rules

relating to fuel before fueling your unit.

IMPORTANT

Experienceindicatesthat alcohol blended

fuels (calledgasoholor usingethanolor

methanol) can at_act moisturewhich

leads to separationand formationof

acidsdudngstorage. Acidicgas can

damage the fuel system of an engine

while in storage.

Toavoid engine problems,the fuel sys-

tem shouldbe emptied before storagefor

30 days or longer. Drain the gas tank,

startthe engine and letit rununtilthe fuel

Choke Posl_ons

t I

•1/I// 4._ lqI[_ Off Full

• Actuate choke by pulling choke knob

fully out.

• Set saw on the ground, Grip front

handle with your left hand and place

right footthrough rear handle.

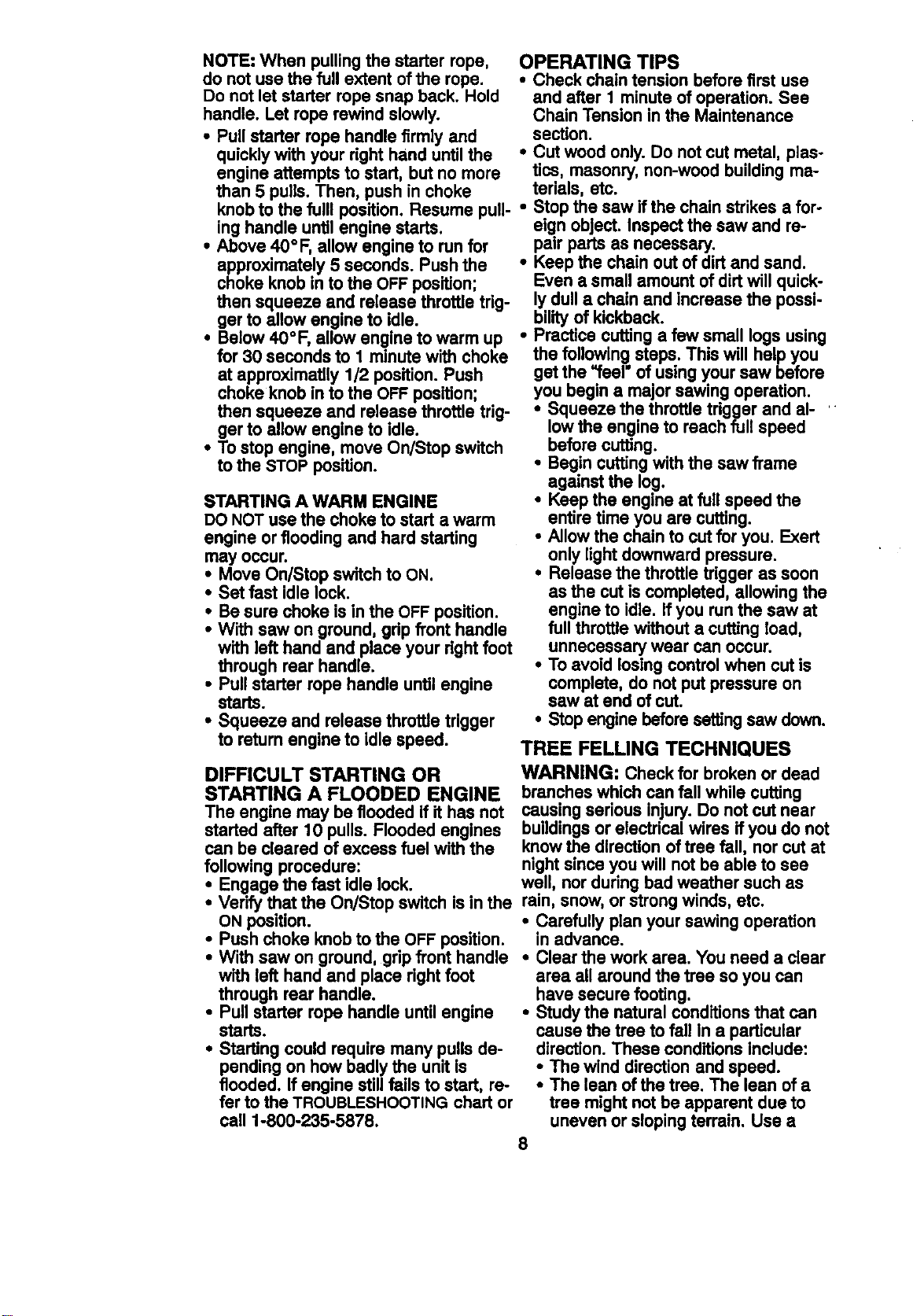

Starter Rope Handle

Left Hand

on Front

Handle

Foot Through RearHandle

• Set fast idle by depressing the throttle

lock with your dght hand. Then,

squeeze and hold throttle trigger. With

your thumb, press the fast idle lock '

down and hold. Next, release the

throttle trigger.

• DONOT squeeze throttle trigger dur-

ing starting; otherwise, it will be nec-

essary to reset the fast idle lock.

7

NOTE:Whenpullingthestarterrope,

do notusethe fullextentofthe rope.

Do not let starter rope snap back. Hold

handle. Let rope rewind slowly.

• Pull starter rope handle firmly and

quickly with your right hand untilthe

engine attempts to start, but no more

than 5 pulls. Then, push in choke

knob to the fulll position. Resume pull-

ing handle until engine starts.

• Above 40°F, allow engine to runfor

approximately 5 seconds. Push the

choke knob in to the OFF position;

then squeeze and release throttle trig-

ger to allow engine to idle.

• Below 40°F, allow engine to warm up

for 30 seconds to I minute with choke

at approximatily 1/2 position. Push

choke knob into the OFF position;

then squeeze and release throttle trig-

ger to allow engine to idle.

• To stop engine, move On/Stop switch

to the STOP position.

STARTING A WARM ENGINE

DO NOT use the choke to start a warm

engine or flooding and hard starting

may occur.

• Move On/Stop switch to ON.

• Set fast idle lock.

• Be sure choke is in the OFF position.

• With saw on ground, grip front handle

with left hand and place your right foot

through rear handle.

• Pull starter rope handle untilengine

starts.

• Squeeze and release throttle trigger

to return engine to idle speed.

DIFFICULT STARTING OR

STARTING A FLOODED ENGINE

The engine may be flooded if it has not

started after 10 pulls. Flooded engines

can be cleared of excess fuel withthe

following procedure:

• Engage the fast idle lock.

• Verify that the On/Stop switch isin the

ON position.

• Push choke knob to the OFF position.

• With saw on ground, grip front handle

with left hand and place rightfoot

through rear handle.

• Pull starter rope handle until engine

starts.

• Starting could require many pulls de-

pending on how badly the unit Is

flooded. If engine still fails to start, re-

fer to the TROUBLESHOOTINGchart or

call 1-800-235-5878.

OPERATING TIPS

• Check chain tension before first use

and after I minute of operation. See

Chain Tension in the Maintenance

section.

• Cut wood only. Do not cut metal, plas-

tics, masonry, non-wood building ma-

terials, etc.

• Stop the saw if the chain strikes a for-

eign object. Inspect the saw and re-

pair parts as necessary.

• Keep the chain out of dirtand sand.

Even a small amount of dirt will quick-

ly dull a chain and increase the possi-

bility of kickback.

• Practice cutting a few small logs using

the following steps. This will help you

get the =feel" of using your saw before

you begin a major sawing operation.

• Squeeze the throttle trigger and al-

low the engine to reach full speed

before cutting.

• Begin cutting withthe saw frame

against the log.

• Keep the engine at full speed the

entire time you are cuffing.

• Allow the chain to cut for you. Exert

only light downward pressure.

• Release the throttle trigger as soon

as the cut is completed, allowing the

engine to idle. Ifyou runthe saw at

full throttle without a cutting load,

unnecessary wear can occur.

• To avoid losingcontrolwhen cut is

complete, do not put pressure on

saw at end of cut.

• Stopengine before settingsaw down.

TREE FELLING TECHNIQUES

WARNING: Check for broken or dead

branches which can fall while cutting

causing serious injury. Do not cut near

buildingsor electrical wires if you do not

know the direction of tree fall, norcut at

nightsince you will not be able to see

well, nor during badweather such as

rain, snow, or strong winds, etc.

• Carefully plan your sawing operation

in advance.

• Clear the work area. You need a clear

area all aroundthe tree so you can

have secure footing.

• Study the natural conditions that can

cause the tree to fall in a particular

direction. These conditions include:

• The wind direction and speed.

• The lean of the tree. The lean of a

tree might not be apparent due to

uneven or sloping terrain. Use a

8

Loading...

Loading...