Craftsman 358350080 Owner’s Manual

Operator's Manual

CRRFTSMRN

2.4 cu. in./40cc 2-Cycle

GASOLINE CHAIN SAM/

Model No.

358.350080 - 18 In. Bar

@

Read and follow all Safety Rules and Operating

WARNING:

Instructions before first use of this product.

For answers to your questions about this product:

Call 7 am-7 pm, Mon.-Sat., or 10 am-7 pm, Sun.

• 1-800-235-5878 (,o..,_mc._.)

m

Se_ebuck and Co., Hoffman Estates, IL 60179 USA

530087614 08/:19/98

Warranty 2 Storage 16

Safety Rules 2 TroubleShootingChart 17

Assom.b!y 5 Raper Parts Us[ 21

Maintenance" _ 11 Pads & Ordenng Back

Service and Adjustments 14

6 Spanish . 24

FULL ONE YEAR WARRANTY ON CRAFTSMAN®GAS

CHAIN SAW

For one year fromthe date ofpurchaee, when this Craftsman Gas Chain Saw is

maintained, lubricatedand tunsd-up according to the owner's manual, Sears will

repair,free of Charge, any defect Inmatedal or wodonanship.

This warranty excludesthe bar, chain, spark plug andair filter,which are

expendableparts, and become worn duringnormal use.

Ifthis Gas Chain Saw is usedfor commercialor rental purposes,this warranty

appliesfor30 days from the date ofpurchase.

WARRANTY SERVICE IS AVAILABLE BY RETURNING THIS CHAIN SAW TO

THE NEAREST SEARS SERVICE CENTER IN THE UNITED STATES.

Thiswarranty givesyou specificlegal rights,and you may also have other rights

which vanj from state to state.

Sears, Roebuck and Co., D/817 WA, Hoffman Estate's,IL 60179

WARNING: Always disconnectspark

plugwire when making repairs except

forcarburetor adjustments. Becausea

chainsaw is a high-speedwoodcutting

tool,careless or improperuse ofthis

toolcan cause serious injury.

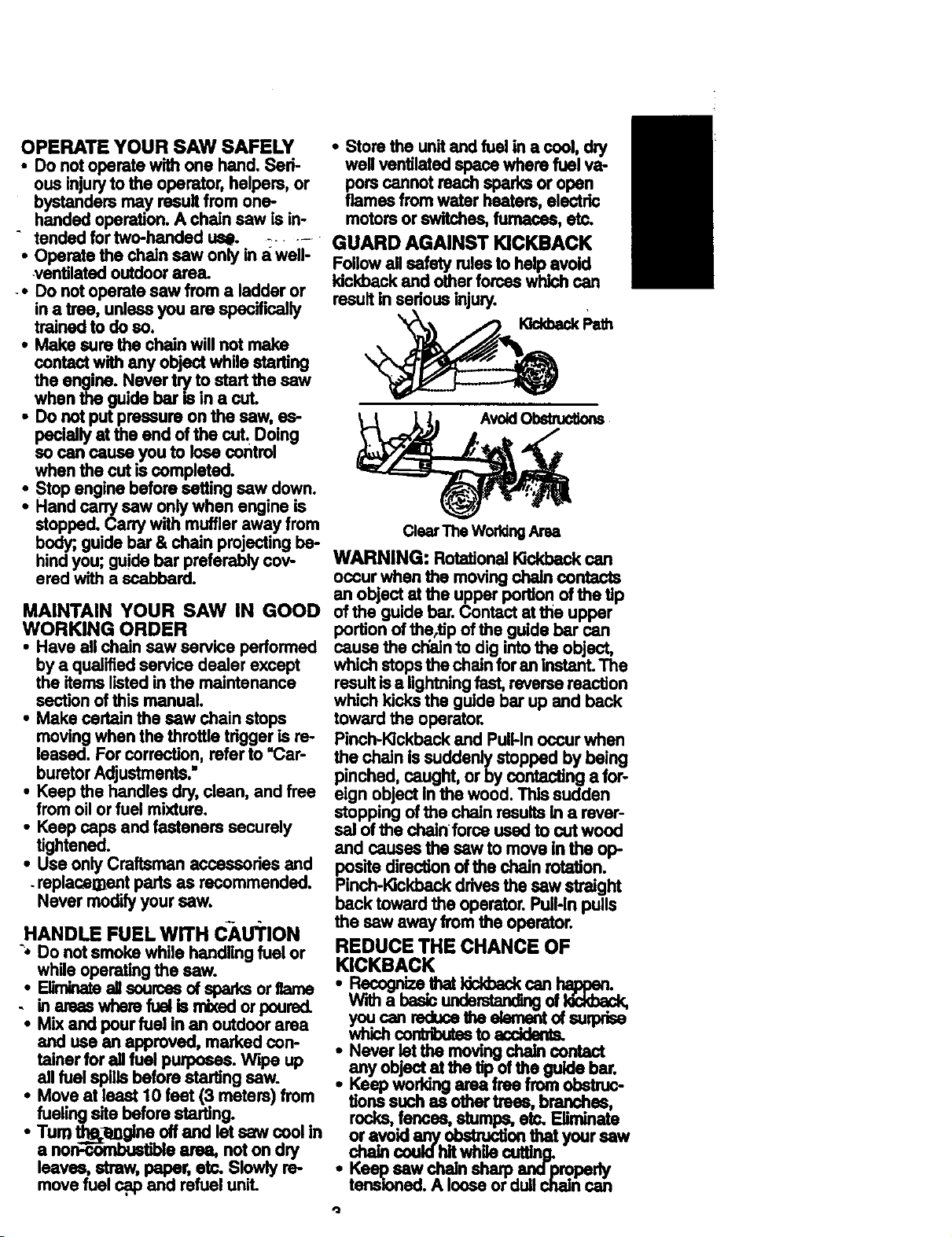

PLAN AHEAD

• Restrictthe use of yoursaw to adult

users who understandand can follow

the safety rules,precautions,and op-

ersting instructions found=nthis

manual.

SafetyH,t

Oothlng

_. SafetyChaps

HeavyDuty

Gloves

\

NM

•_Vear protectivegear. Always use

steel-toedsafety footwear withnon-

slipsoles;snug-fittingclothing;,heavy-

duty,non-slipgloves;eye protection

such as non-fogging,vented goggles

or face screen; an approved safety

hard hat;,and sound barriers(ear

plu_ or mufflers)to protect your

heenng. Regular users should have

heedng checked regularlyas chain

saw noise can damage headng. Se-

cure hairabove shoulder length.

• Keep all parts ofyour body away from

the chain when the engine is running.

• Keep children,bystanders, and ani-

mals at least30 feet (10 meters)

away fromthe work area when start-

ng and usingthe saw.

• Do not handle or operate a chain saw

when you are fatigued, ill,or upset, or

ifyou have taken alcohol, drugs,or

medication. Youmust be in good

_hysical conditionand mentallyalerL

you have any conditionthat might

be aggravated by strenuouswork,

check with doctorbefore operating.

• Do not start cuffing untilyod..bavea

clearwork area, secure footing, and

especiallyifyou are felling a tree, a

retreatpath.

2

OPERATEYOUR SAW SAFELY • Stemthe unitandfuelina cool, dry

• Do not operate withone hand. Sari- wellventilated spacewhere fuel va-

ous injuryto the operator, helpers, or pore cannotreach sparks oropen

bystanders may result from one- flames fromwater heaters,electric

handed operation.A chain saw is in- motors orswitches,furnaces, etc.

" tended fortwo-handed use. -...... GUARD AGAINST KICKBACK

• Operate the chain saw only in a well-

ventilated outdoorarea.

• Do not operate saw from a ladder or

in atree, unless you are specifically

trained to doso.

• Make sure the chain will not make

contact withany object while starting

the engine. Never try to startthe saw

when the guide bar isin a cut.

• Do not put pressure onthe saw,es-

peciallyat the end ofthe cut. Doing

so can cause you to lose control

when the cut is completed.

• Stop engine before setting saw down.

• Hand carry saw only when engine is

stopped. Cany with muffleraway from

body;,guide bar & chain projectingbe-

hindyou; guidebar preferably cov-

ered with a scabbard.

MAINTAIN YOUR SAW IN GOOD ofthe guidebar.Contactatthe upper

WORKING ORDER

• Have all chain saw service performed

by a qualifiedservice dealer except

the items listed inthe maintenance

sectionof this manual.

• Make certain the saw chain stops

movingwhen the throttle triggeris re-

leased. For correction,refer to "Car-

buretorAdjustments."

• Keep the handles dry, clean, and free

fromoil or fuelmixture.

• Keep caps and fasteners securely

tightened.

• Use only Craftsman accassories and

-replacei;ilentpartsas recommended.

Never modifyyour saw.

HANDLE FUEL WITH C-AU'rlON

: Do notsmoke while handlingfuel or

while operatingthe saw.

• EUminate_ sources of spsrksor_e

- inareaswherefuel isrnixedorpoured.

• Mix and pour fuel in an outdoorarea

and usean approved, marked con-

tainerfor all fuel pu.q:_.. s. Wipe up

all fuel spillsbefore starting saw.

• Move at least 10 feet (3 meters) from

fueling site before starting, rocks,fences, stumps,etc. Eliminate

• Tum th_-e_gine offand let saw cool in or avoid any obstructionthat yoursaw

a non-_----oed)ustiblearea, noton dry onam sould hit while outting.

leaves, straw, paper, etc. Slowly re- • Kee0 saw chain sharp aml-proPerly

movefuel _ and refuel uniL tans|oned.A loose ordullchaincan

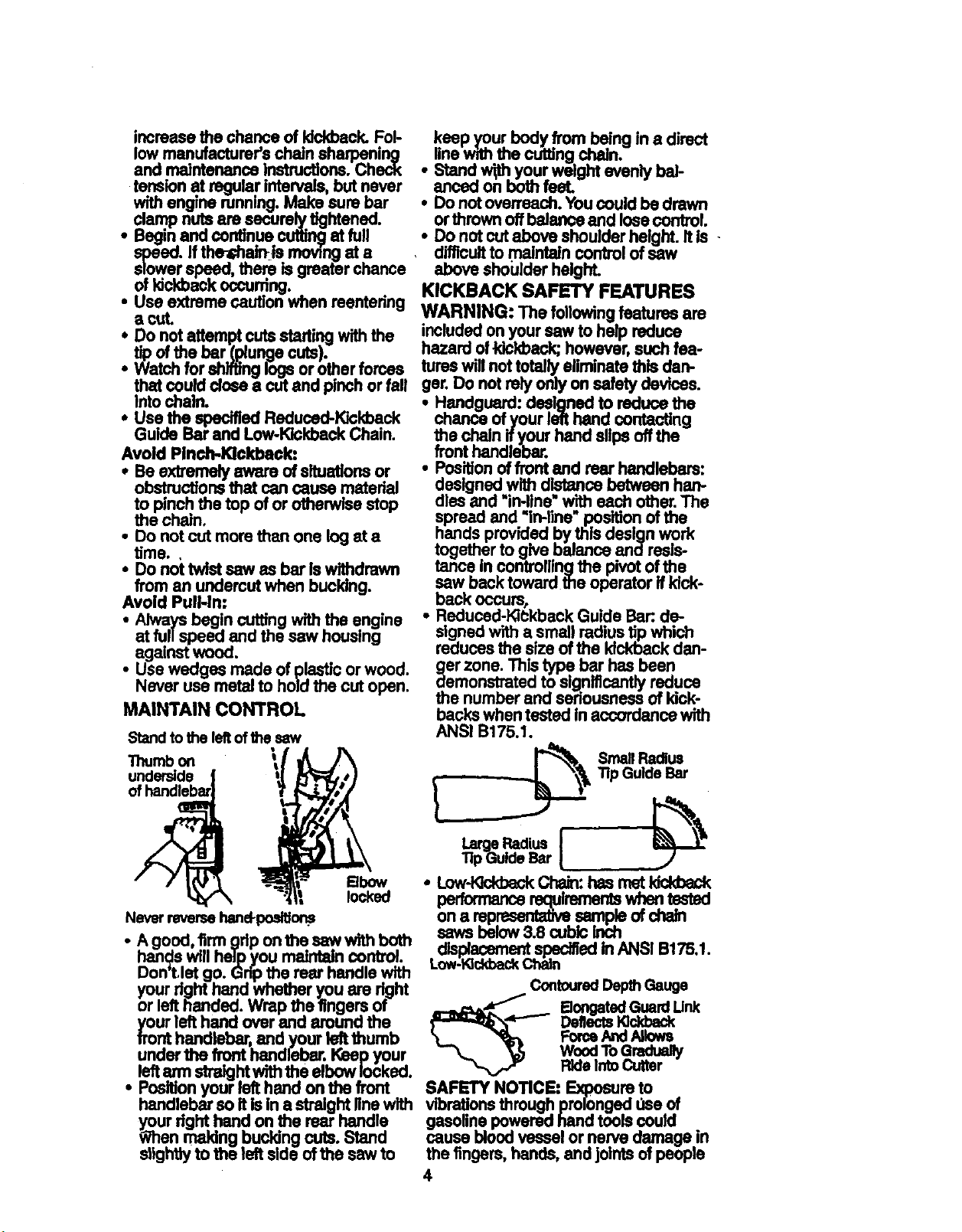

Followall safety mlea to helpavoid

kickbackand other forceswhichcan

resultin sarious injury.

ClearTheWoddngArea

WARNING: RotationalKickbackcan

occurwhen the movingchain contacts

an object at the upper portionof the tip

portion of the,tip of the guide bar can

cause the chin to dig intothe object,

whichstops the chain foran instant.The

resultisa lightningfast,reversereaction

which kicksthe guide bar up and back

toward the operator.

Pinch-Kickbackand Pull-inoccur when

the chain issuddenly stopped by being

pinched, caught, or by contactinga for-

eign object in the wood. This sudden

stopping ofthe chain resultsina rever-

sal of the chain force used to cut wood

and causes the saw to move in the op-

posite directionof the chain rotation.

Pinch-Kickbackdrivesthe saw stndght

back towardthe operator. Pull-Inpulls

the saw away from the operator.

REDUCE THE CHANCE OF

KICKBACK

• Recognize.thatkickbackcanhappsn.

W'_ha basicundemta_ of_

you can reducethe eleme_ ofsurpnsa

whichcontrbutes to acddents.

i Never let the movingchaincontact..anyobject at the tip Ofthe guide bar.

Rasp workingarea free fromobstruc-

tions suchas other traes,branches,

'3

increase the chance of kickback.Fol- keep your body .frombeing in a direct

low manufacturer'schain sharpening linew]th.thecumng cru_n.

and maintenance instructions.Check • Stand_ your weight evenly bal-

tension at regular intervals, but never

anced on I:k_ feat.

with engine running.Make sure D.ar • Do notoverreach.You could be drawn

_an?p.nuts.aresecure_ffghteneo, or thrownoff balanceand losecontrol

• ueg=nand cormnue cumn9 at full • Do not cutabove shoulder height. ItIs

speed. Ifthe_halr_b movingat a , difficultto maintain control of saw

slowerspeed, them isgreater chance above shoulder height.

of kickback accumng. . KICKBACK SAFETY FEATURES

• Use extreme caution when reentanng WARNING: The lot|owingfeatures are

e cut.

D.onot attemptcutsstartingwith the includedon yoursaw to help reduce .

_tip ofthe cuts), hazard ofk_.kback;however, such fee

Watch forber'_ungeal_linglogsorother force,s. tureswill not totallyeliminatethis darv

that could dose a cut ano pinchor ra, get. Do notrely only onsafety devices.

intochain. . • Handguerd: dealgned to reduce.the

• Use the spacif!_ Reduced-Kickbeck chance ofyour le]thand cor_tctmg

Guide Bar and Low K]ckbeckChain. the chain ifyour hand slips off the

Avoid Plnoh-K]okbeok: fronthandlebar.

• Be extremely aware of sltu_ionc or

obstructionsthat can cause material

to pinch thetop of or otherwise stop

the chain.

• Do not cutmore than one log 8t a

time..

• Do not twbt saw es ber b withdrawn

from an undemut when bucking.

Avoid Pull-in:

• Always begin cutting withthe engine

at full speed and the saw housing

against wood.

• Use wedges made of plastic orwood.

Never use metal to hotd the cutopen.

MAINTAIN CONTROL

• Pos_on offront and rear handlebars:

designed with d_ce b@_._n h_an-

dies and "inqlne"with sac_ omer. ] ne

spread and =in-line" _positionof the

hands provided bYthis desl_lnwork

together togive balance ana resis-

tance in controlling the pivotof the

saw backtoward the operator if kick-

back occurs,

• Reduced-KiCkback Guide Bar:.de-

signed with a small radius tip which

reduces the size of the kickback den-

_er zone. Thistype bar has been

emDnstratedto slgnfficentlyredu_

the number and seriousness of kiCK

backs whentested In accordance with

ANS! B175.1.

Stand to the leftofthe saw

Thumb on \l

Elbow

locked

Never reverse hand-poslffonF.

• A good, firm gflp onthe _ with b.oth

hands will help you mmmaJncontrol

Don'tJet go. Gdp the rear handle .with

your righthand whether .youare ngin

or left handed. Wrap me,ngers or

your lefthand over and arotmd the

front handlebar, and your leftthumb

underthe front han.d[eher.Keep your

leftann straightwiththe elbow locked.

• Positionyour left hand on .t_. front.

handlebar so It isin astrmgnt,he w_n

your dght hand onthe _ handle

When making oucking outs.Stand

stlghtlyto the left side ofthe sawm

TipGuideBar

_._ SrnallRadius

TipGuideBar

• Low.Kk_ck Chain:hes mat _

on a represer_=__,earn.pp or cnam

sews below3.8 cubic inch

LdiSp_. ent s_ in ANSI B175,1.

ow-K]ckbackChain

ContouredOep_Gauge

FomeAndAllows

WoodToGradually

RideIntoCu'der

SAFETY NOTICE: Exposureto

vibrationsthrough pro|onged.,',saof

gasolinePoweredhand tools.cou]a .

cause bloodvessel or nerve aamage_ln

the fingers,hands, and joints ofpeopke

4

pronetocirculationd_orders.or .

abnormalswelling.Prolongeausein

cold weather has been linkedto blood

vessel damage in othmwisa healthy

people. If symptomsoccur suchas

- numbness, pare, loss ofstr_angm,

change in skincolor ortex_re, 6t loss

offeeling inthe fingers, hands, or joints,

discontinue the use of this tooland

" seek medk_l attention. An

anti-vibrationsystem does not

guarantee the avoidance ofthese

problems. Usam who operate power

tools ona continual and regularbasis

must closelymonitortheir physical

condifion and the condition of this tool.

CHAIN BRAKE If this saw isto be used

forcommercial logging,you must order

and installa chain brake to complywith

Federal OSHA Regulationsfor Com-

mercial Logging. Contact your Sears

Service Center or call 1-800-235-5878.

SPARK ARRESTOR: Your saw is

equippedwith a temperature limiting

muffler and spark arrestingscreen

which meets the requirementsof

Caiifomla Codes 4442 and 4443. All

U.S. forest landand the states of

California, Idaho,Maine, Minnesota,

New Jersey,Oregon, and Washington

require b.ylaw _at many internal .

combustion enginesbe equipped Witha

sparkarrestorscreen. If you operate a

chainsaw in e state or IocaJewhere

such regulationsexist, you am legally

responsiblefor maintainingthe

operatingconditionofthesa pads.

Failure todo so is a wolatlon of the law.

Refer to Customer Responsibil_es

chart in the MAINTENANCE_;ection.

STANDARDS: This chainsaw islisted

by Undsr_vdtersLaboratories,Inc. in

accordancewi_ American National

Standards forGasoline-Powered Chain

Saws Safety Requlmmants (ANSI

B175.1-1991).

CARTON CONTENTS

Check carton contents against the fol-

lowing list.

Model 358.350080

• Chain Saw (fully assembled)

• Chain adjustment tool

• 2-cycle engine oil

• Chain

• Carrying Case

• Bar Oil

• Examine pa)tsfoi damage. Do not

use damaged parts.

• If you need assistanceor findthat

paris are missingordamaged, please

call 1-800-235-5878.

NOTE: It is normalto hear the fuel filter

rattle in an emptyfuel tank.

Your unithasbeen factory tested and

the carburetorpreciselya_usted. As a

resultyoumay smellgasoline orfind a

drop ofoil/fuel residueonthe muffler

when you unpackthe unit.

ASSEMBLY

Yoursaw is fullyassembled, and no

assembly is necessary.

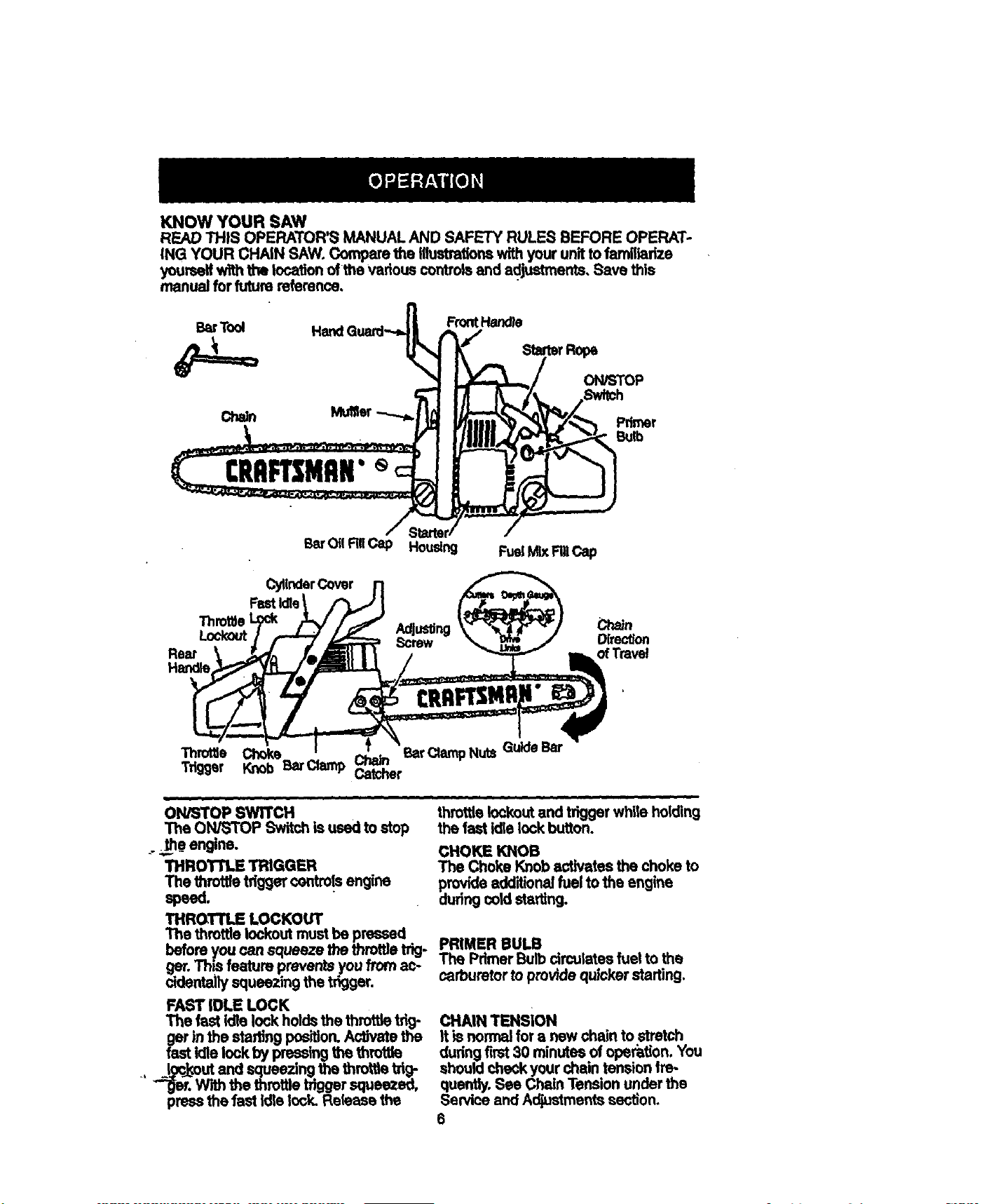

KNOW YOUR SAW

READ THIS OPERATOR'S MANUAL AND SAFETY RULES BEFORE OPERAT-

ING YOUR CHAIN SAW. Compare the illustrationswithyourunit tofarnillarize

yourseff wlth the locationof the variouscontrolsand adjustments,Save this

manual for future reference,

BarTool Front Handle

Starter Rope

Primer

Bulb

CRIWI'ZMRN"

sarO_Fmcap Hou_ng

CylinderCover

FastIdle_

Lockout Screw

Rear

Handle

Throt_e _C:lx_k'eBarClamP BarClamp Nuts GuldeBar

Trigger Ct_in

i i • i i

ON_-'roP SWITCH

The ON/STOP Switch is usedto stop

_-_+ engine.

THROTTLE TRIGGER

The throttletdgger contro!sengine

speed.

THROTTLE LOCKOUT

The throttle lockoutmustbe pressed

beforeyouc?nsquee thethro e

get. Jn= testure preventsyou _romac-

cidentallysqueezingthe tngger.

FAST IDLE LOCK

The.fast idle .l_.k hol_ the throttle trig-

ger mthe sta_ng pos._on,Activatethe

fast idle lockby p_.mg the throtUe

, 19¢_ut and squesTJng.thethrottle tdg-

"_er. W'_hthe throttle triggersqueezed,

pressthe fast Idle lock. Release the

Adjusting

Catcher

i i i i i i i

throttlelockoutandtrigger white holding

the fast Idle lockbutton.

CHOKE K_OB

The Choke Knobactivates the choke to

provideedditional fuelto the engine

duringcold starting.

PRIMER BULB

The Primer Bulbcirculatesfuel tothe

carburetorto providequickerstarting.

CHAIN TENSION

It is normalfor a new chain to stretch

duringfirst 30 minutes of operation.You

shouldcheck yourchaintension tre-

quently,See Chain Tensionunderthe

Servic_ and Adjustmentssection.

6

FudMb¢FeCap

BEFORE STARTING ENGINE

WARNING: Be sure to read the fuel

handlinginformation inthe safety rules

section of this manuel before you begin.

. Ifyou do not understand_ fuel han-

dlinginformationdo notattiBtnptt6 rue]

yourunit.Seek helpfrom someone that

cloesunderstandthe informationorcall

the customerassistance help line at

1.800-235-5878.

GUIDE BAR AND CHAIN OIL

The chainoiler provides continuouslu-

bricationto the chain and guide bar. Be

sure to fillthe bar o, tank when you ml

the fuel tank (Capacity = 6.8 fl. o.z.).

For maximum guide barand chain life,

we recommendyou use Craftsman

chainsaw bar oil. If Craftsman bar oil is

not available, you may use a good

grade SAE 30 oil untilyou are able to

obtain Craftsman brand.The oil output

isautomatically metered duringopera-

tion.Your saw will use approximately

one tank of bar oilfor every tank of fuel

mix. Always fillthe bar oil tank when

you fillthefuel tank.

the fuel lines and carburetor are empty.

Use fresh fuel next season. See STOR-

AGE instructionsforadditionalinforma-

tion.

Never use engine or cad0uretorcleaner

products inthe fuel tankor permanent

damage mayoccur.

See the STORAGEsectionfor additional

information.

STOPPING YOUR ENGINE

i

* Move On/Stop switchto the STOP

pcait_.n.

• ifeng,nedoesnotstop,pullchoke

knoboutfully.

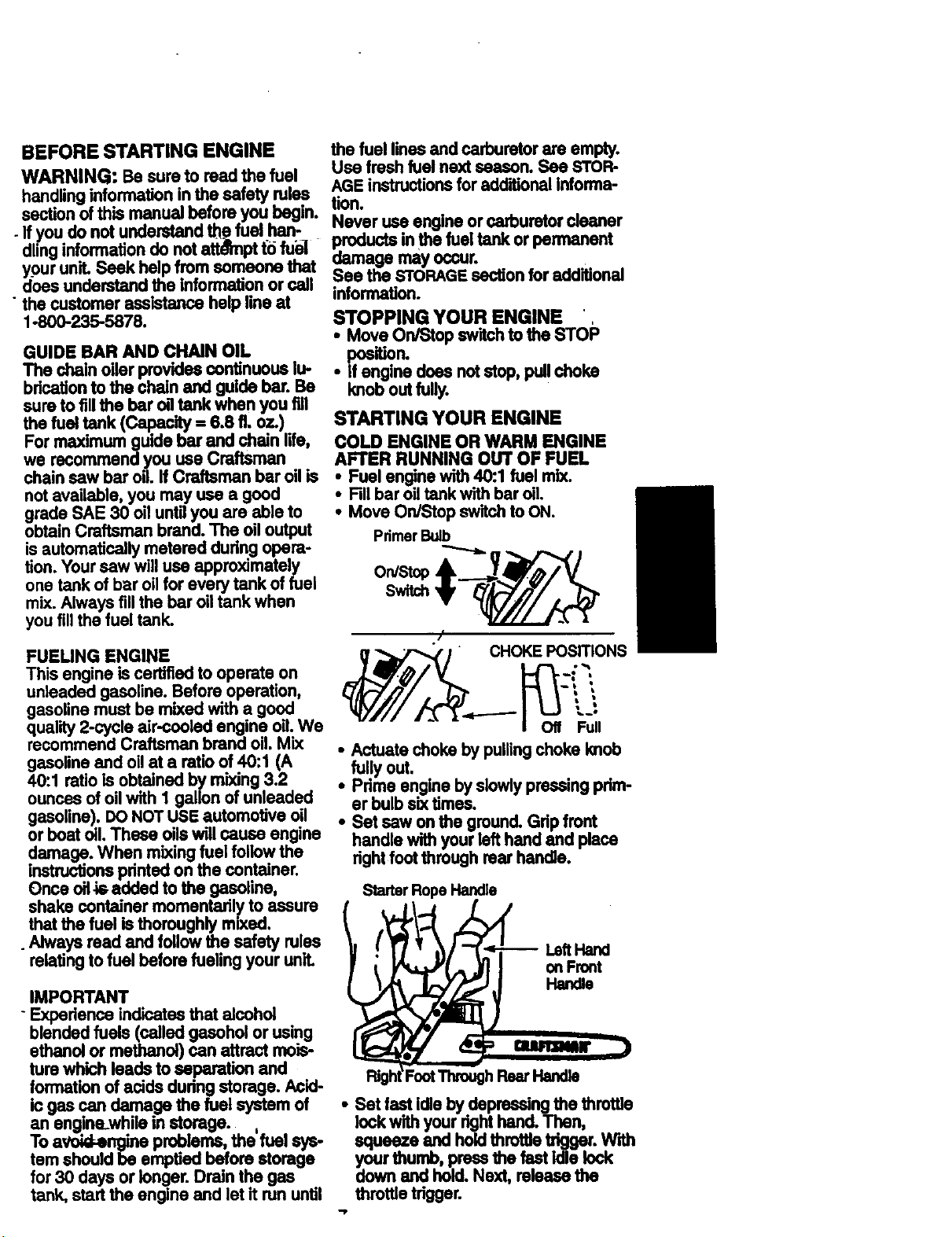

STARTING YOUR ENGINE

COLD ENGINE OR WARM ENGINE

AFTER RUNNING OUT OF FUEL

• Fuel engine with40:1 fuel mix.

• Fill bar oiltank withbar oil.

* Move On/Stop switchtoON.

PrirnerBulb

FUEUNG ENGINE

This engine is certifiedto operate on

unleaded gasoline. Before operation,

gasoline must be mixed with a good

quality2-cycle air-cooled engine oil.We

recommend Craftsman brand oil. Mix

gasolineand oil at a ratioof 40:1 (A

40:1 ratiois obtained by mixing3.2

ounces of oilwith I gallon of unleaded

gasoline). DONOTUSEautomotive oil

or beat oil. These oils will cause engine

damage. When mixing fuel followthe

• Actuate choke by pullingchoke knob

fully out.

• Prime engine byslowlypressingprim-

er bulb sixtimes.

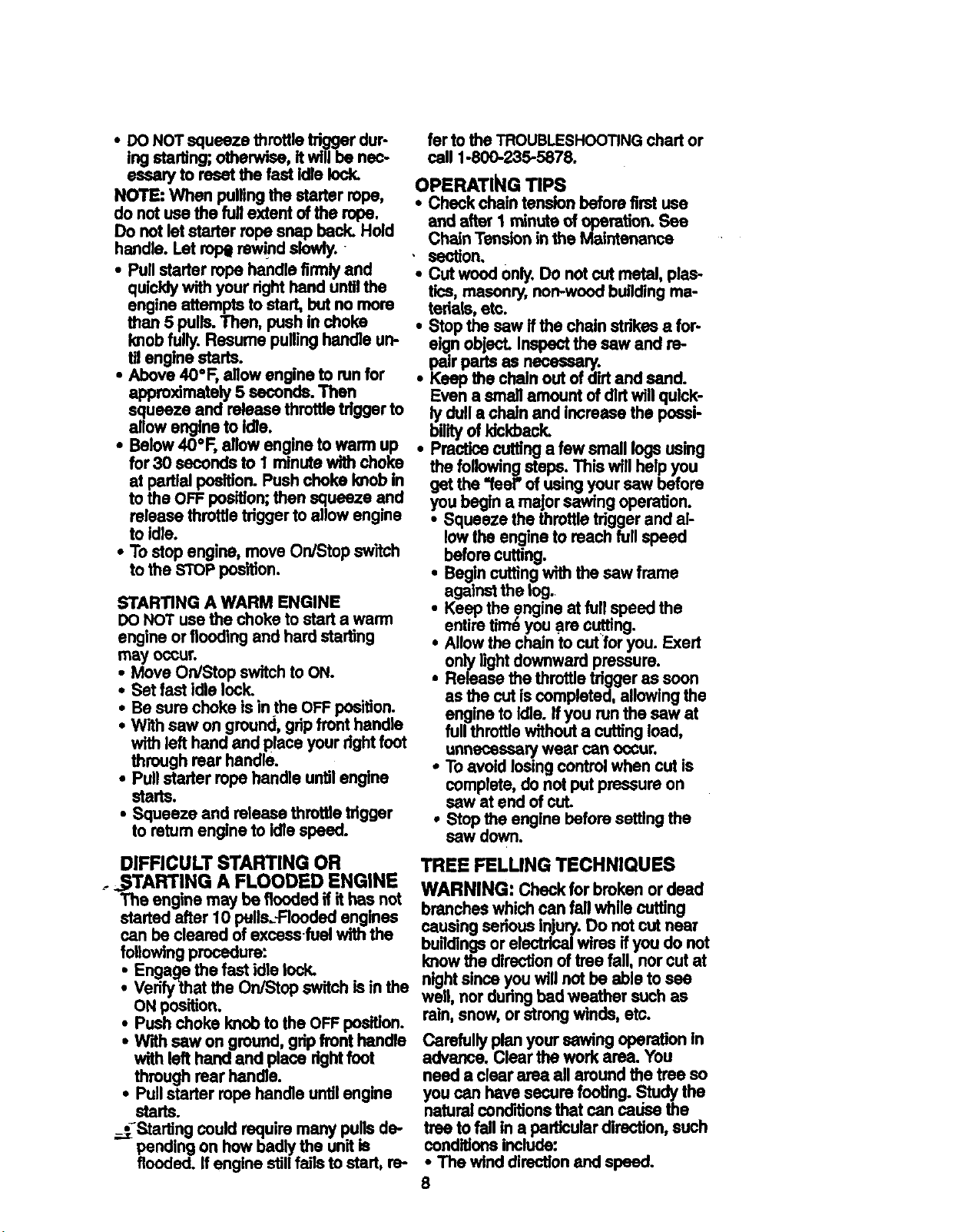

• Set saw onthe ground. Gripfront

handle with yourlefthand and place

rightfootthrough rear handle.

_t t

k5

Off Full

instructionspdnted on the container.

Once oil_sadded to the gasoline,

StarterRopeHandle

shake container momentarily to assure

thatthe fuel isthoroughly mixed.

. Always read and followthe safety rules

mistingto fuel before fueling your unit.

LeftHand

on Front

Handle

IMPORTANT

- Experience indicatesthat alcohol

blendedfuels (called gesohoi or using

ethanol or methanol) can attract mois-

ture which leads toseparation and FootThroughRearHandle

formationof acidsduring storage. Acid-

icgas can damage the fuel system of • Bet fast idleby depressingthe throttle

an engine_whilein atomge. , lock with your righthand.Then,

ToaVoid.engine problem.s,the fuel sys- squeeze and holdthrottle rigger. W'_

tem shouldbe emptied before storage yourthumb, pressthe fast idle lock

for30 days or longer. Drain the gas downand hold.Next, release the

tank, start the engine and let itrun until throttle trigger.

• DO NOTsqueeze throttle rigger dur-

ing starting; otherwise, it will be nec-

essary to reset the fast idle lock.

NOTE: When pullingthe starter rope,

donot use the fullextent of the rope.

Do notlet starter rope snap beck. Hold

handle. Let roPll rewind slowly.

• Pull starter rope handlefirmlyand

quicklywith your dght handuntilthe

engine attemptsto start, butno morn

than 5 pulis.Then, push inchoke

knob fully. Resume pulhnghandle un-

til enginestarts.

• Above 40•F, allow engine to run for

approximately 5 seconds.Then

squeeze and mlsaee throttletriggerto

allow engine to idle.

• Below 40°F, allow engine to warm up

for 30 seconds to I minute with choke

at partielposition. Pushchoke knobin

to the OFF pueltion; then squeeze and

mlsese throttle triggerto allowengine

to idle.

• To stopengine, move On/Stop switch

to the STOPposition.

STARTING A WARM ENGINE

DONOTuse the choke to start awarm

engine or floodingand hard starting

may occur.

• Move On/Stop switchto ON.

• Set fast idlelock.

• Be surechoke is inthe OFFposition.

• W'_hsaw on ground,gripfront handle

with lefthand and place your dght foot

through roar handle.

• Pull starter ropehandle until engine

starts.

• Squeeze and release throttle rigger

to retum engine to idlespeed.

fer to the TROUBLESHOOTINGchart or

call 1-800-235-5878.

OPERATING TIPS

• Check chain tensionbefore firstuse

and after I rnin.uteof operation.See

Chain Tensionmthe Maintenance

• section.

• Cut wood 0nly.Do notcut metal, plas-

tics, masonry, non-wood buildingma-

tedais, etc.

• Stop the saw if the chain stdkee a for-

eign object.Inspectthe saw and re-

pairparts as necessary.

• Keep the chainout of dirtand sand.

Even a smallamount of dirtwillquick-

ly dulla chain and increase the possi-

bilityof kickback.

• Practicecuttinga few sm_l logs using

the followingstep_;...This wdlhelp you

get the "feel"of umngyour sew before

you begin a major sewing operation.

• Squeeze the throttle rigger and al-

lowthe engineto roach fullspeed

beforecutting.

• Begincuttingwiththe sew frame

againstthe tog.

Keep the engine at full .speedthe

i entire you are cutting.

timb

Allowthe chainto cut foryou. Exert

onlylight downwardpressure.

• Release the throttle trigger as soon

as the cut iscompleted, allowingthe

engine to Idle. Ifyou runtha sew at

full throttle withouta cuttingload,

unnecassarywear can occur.

• To avoid losingcontrolwhen cut is

complete,do not putpressure on

sew at end of cut.

• Stop the engine before settingthe

sew down.

DIFRCULT STARTING OR

.._STARTING A FLOODED ENGINE

The engine may be floodedif ithas not

startedafter 10 pulis=-Rooded engines

can be cleared of excess fuel with the

followingprocedure:

Engage the fast idlelock.

Verifythat the On/Stop switchis mthe

ON position.

• Push choke knob to the OFF position.

• W_...dhsaw on ground, gdpfront handle

with lefthand and place dghtfoot

through roar handle.

• Pull starter ropehandle untilengine

starts.

j-Starting could requiremany pullsde-

pending on how badlythe unit is

flooded. Ifengine stillfailsto start, re-

TREE FELLING TECHNIQUES

WARNING: Check for broken or dead

brancheswhich can fall while cutting

causing seriousinjury.Do not cutnear

buildingsor electricalwires if you do not

know the directionof tree fall, norcut at

nightsinceyou willnot be ableto see

well, nor dudngbad weather such as

rain,snow, orstrongwinds, etc.

Carefullyplan your sawing operationin

advance. Clear the work area. You

need a clear area all aroundthe tree so

you can havesecure footing. Studythe

naturalcond'dionethat can cause the

tree tofall in a pedloular direction,such

conditions include:

• The wind directionandspeed.

8

Loading...

Loading...