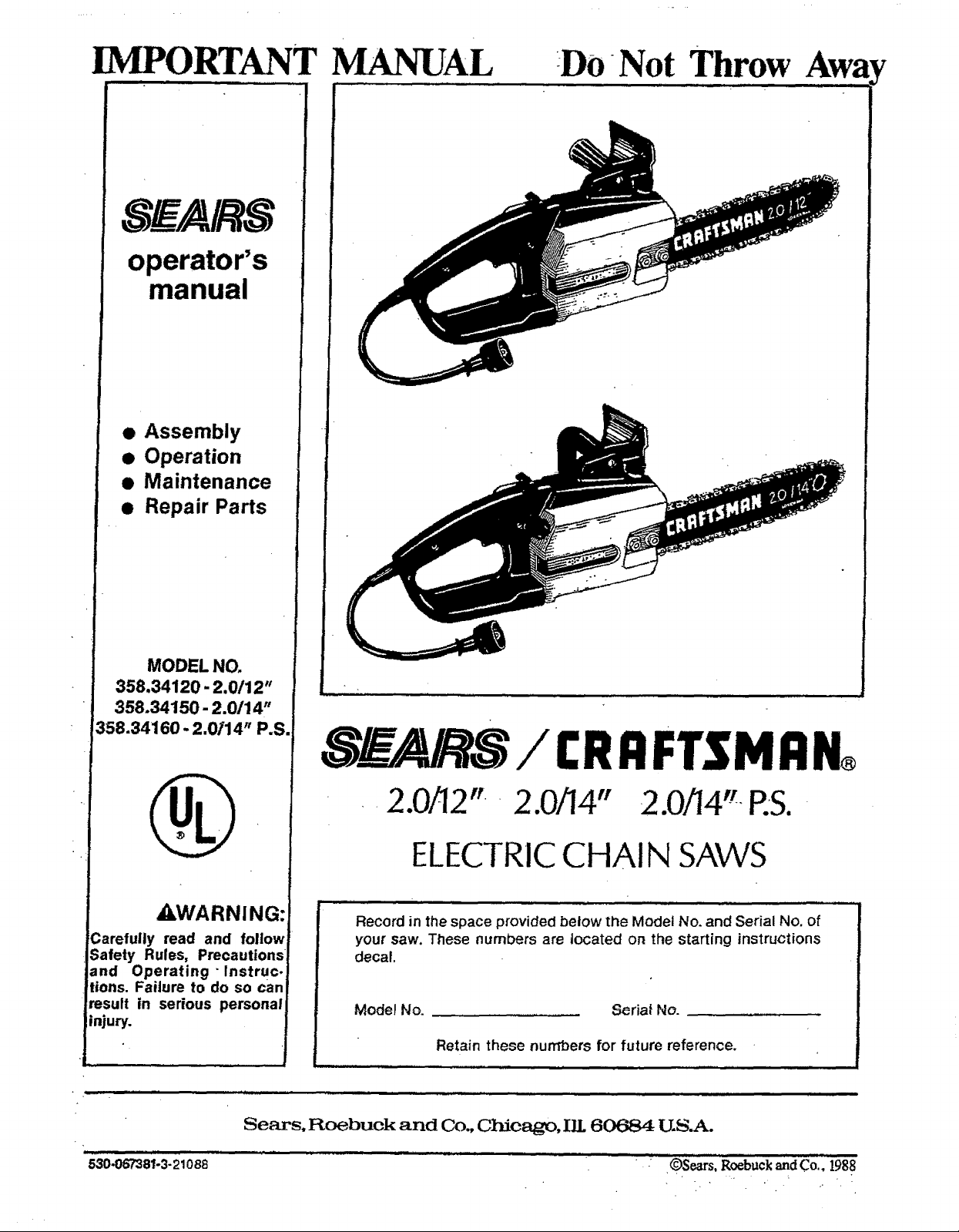

Craftsman 35834150, 35834120, 35834160 Owner’s Manual

IMPORTANT MANUAL

operator's

manual

• Assembly

• Operation

• Maintenance

• Repair Parts

DoNot Throw Away

°

MODEL NO.

358.34120" 2.0/12"

358.34150 - 2.0/14"

2.0114" P.S.

AkWAR N! NG:

read and follow

Safety Rules, PreQautions

and Operating "lnstruc.

tions. Failure to do so can

result in serious personal

injury.

@/____,_S/ CRI:1FTSMRN®

.2.0/12".. 2.0/14" 2.0/14"-ES.

ELECTRICCHAIN SAWS

, u i . ,ll,

Record in the space provided below the Model No. and Serial No. of

your saw. These numbers are located on the starting instructions

decal.

Model No. Serial No.

Retain these numbers for future reference.

530.067381-3-21088

Sears, Roebuck and Co.,Chicago, Ill 60684 U.S.A.

• -_©S_'slko_b.ck_a Coi_1988

FULL 1 YEAR-WARRANTY ON ELECTRIC CHAIN SAW

(Excluding Bar & Chain)

Forone yearfrom date ofpurchase,Sears w_ltrepairdefects inmaterial or wo_manshtp in _is 2X) ElectricChain Saw at no charge,

This warrantyexCludesb_r &chain, whic_hare expendable partsand become wornduringnormaluse.

Ifthis2J0 EfectdcChain Sawisusedforcommerciai orrentalpurposes,thiswarrantyappliesforonly30 daysfromdateofpurch ase_WARRANTY

SERV{CE ISAVAI/_ABLEBYRETUR NING THE CHAIN SAWTOTHE NEAREST SEARSSERVICE C ENTER/DEPARTMENT INTHE UNITED

STATES.

Th_Swarrantygives you specificlegal dghts,andyoumay also haVeother rightswhichvary from stateto state.

Sears, Roebuck and Co., Sears Tower, Dept. 698/731A, Ctdcago,IL60684

TABLE OF CONTENTS

Specifications ............................... 2

SPECIAL SAFETY SECTION .................... 5

Know Your Chain Saw ........................ 6

Preparing Your Saw For Use ................... 7

A. Getting Ready ............... . ........... 7

B. Power Source and ExtensionCord--... -::: .... 7

C. Attaching the Bar and Chain ................ 8

D. Chain Tension ............ : .............. 8

E. Bar andChain Lubricant..................... 9

Using Your Saw ............................. 10

A, Control Devices .......................... 10

B. Pre-Operation Checks .... "............. ... 10

C. Starting and Stopping the Saw ............. 10

Using the Power Sharp _ System ............... 11

Types of Cutting ............................ 13

A. BasicCutting Technique .................. 13

B. Tree Felling Techniqqes-. ................. 13

C. Bucking ............................... 15

D. Debranching and Pruning ............. ,. ,... 16

Maintenance ............................... 17

A. Cleaning the Saw ............ : .......... 17

B. Guide Bar and Chain .................... 17

C. Sprocket .............................. 19

D. Storage ............................... 20

E. Maintenance Accessor'_s ................. 20

F. Trouble Shooting Chart ................... 21

Repair PartsList ............................. 22

Quick Reference Page ....................... 27

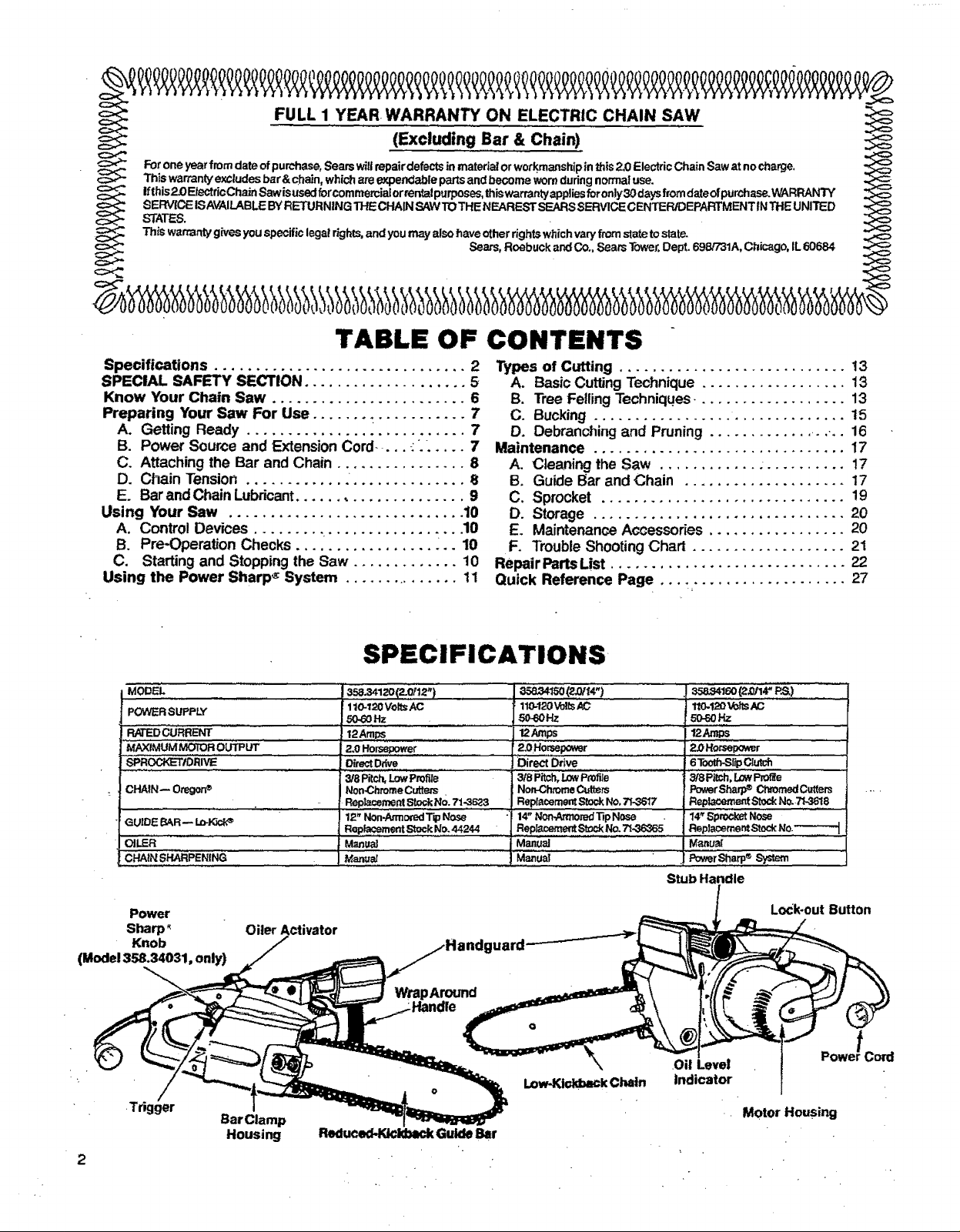

MODEL ............

POWER SUPPLY

I,. -EDCu.R

MAXIMUM MOTOR OUTPUT

;SPROCKETiDRrv_

CHNN-- Oregon®

GUIDE BAR-- LO-K3C{_

OILER

CHAtN SHARPENING

Power

Sharp. Oiler Activator

.......................3i8P_ch, LowProfile 3/8 Pitch, LowP_fi|e

SPECIFICATIONS

....._._.#120(__0/1_,) _,_4Is0(_.o/t4,)

110-120Vo_AC 110-120Vo!_sAC

_Hz 50-60 HZ

2.0 Horsepower _ .......................2.0Hopepower

0irectDdve Direct Ddve

Non-ChromeCuttem. Non,ChromeC_l_rs

Rep_tcemer_tStockNo. 71,_;23 Replacement Stock No,71-36'/7 Repla_e,'TmntStock No..7/-3618

12" Non-Armored T_ Nose 14" Notl-Armomd Tip Nose t4 • Sprocket Nose

Replacement Stock No.r44244 Rep_._t '_0_ No.7t -36365 Repl_ceme_ Stock NO.

M_nual Manual Manual

ManueJ ................:Manua! ......] PowerSharp ® System

........... 6 Tooth-SlipCJutch

_1"t0.120Vo_tSAC

50-60Hz

2,0 Horsepower

3/8 Pitch, Low Pmt_e

PowerSharp _ Chromed Cutters

Stub Handle

Lock-out Button

=OilLevel

Indicator

Powe!Cord

Motor Housing

i " i iiii iiiiiiiiiii ii i ii i J I ii i, iiii i iiiiiiiiiiiiiiiiiii iiiiiii iiiiiii i IIIIIIIII i IIII i : L_, k ,,

SPECIAL SAFETY SECTION

'i ................ I11 IIIH Ill II IIIIIIIIIIIIIIIIIIIIIIIII I I I I I I III III

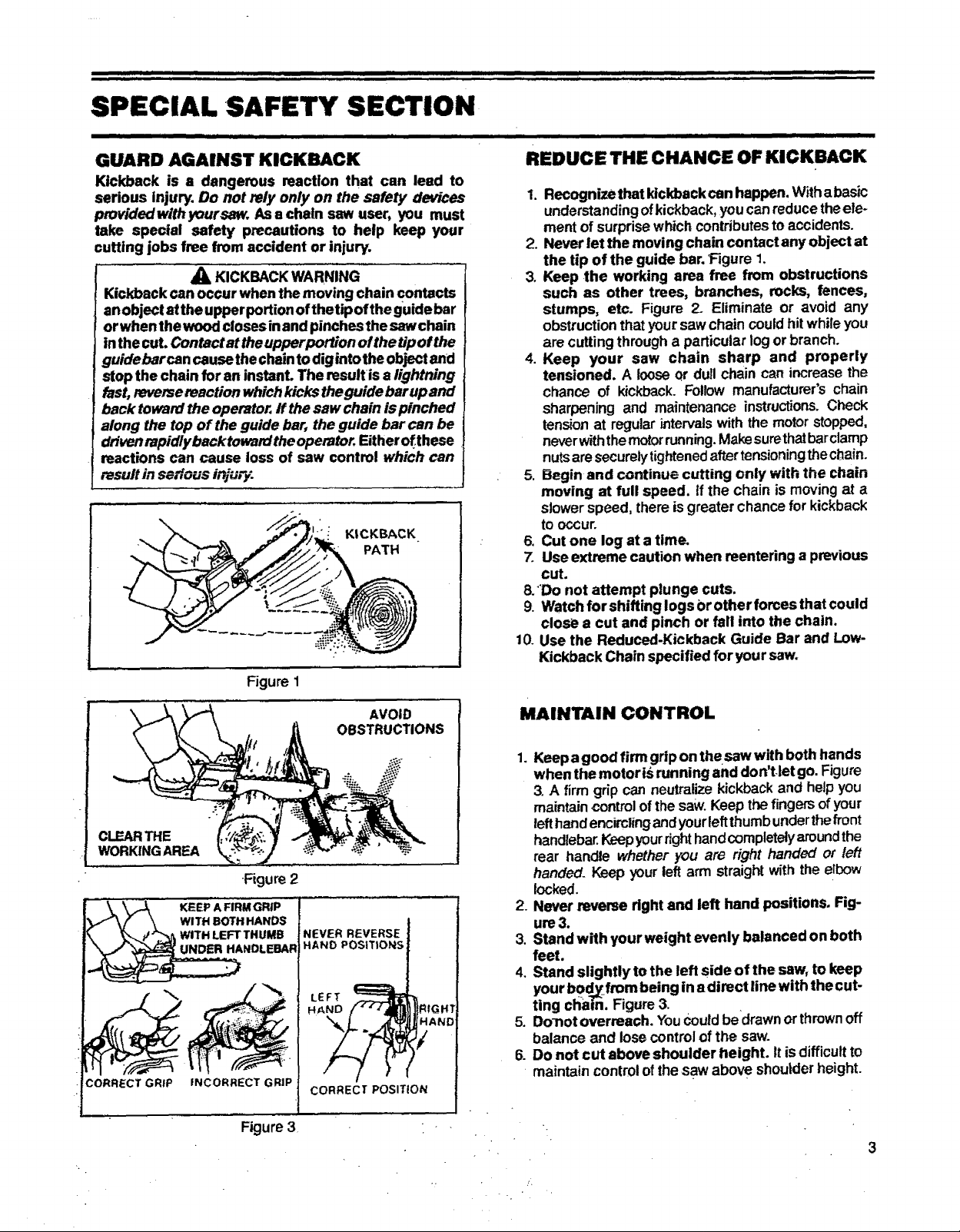

GUARD AGAINST KICKBACK

Kickback is a dangerous reaction that can lead to

serious injury. Do not rely only on the safety devices

provided wtthyoursaw. Asa chin saw user, you must

take special safety precautions to help keep your

cutting jobs free from accident or injury.

_k KICKBACK WARNING

Kickback can occur whenthe moving chain contacts

anobject atthe upper portionofthe tip of the guidebar

or when the woodclosesinand pinches the saw chain

in the cut.Contactattheupperportionofthetipofthe

guidebarcan cause thechainto digintothe objectand

stop the chain for an instant. The result is a h'ghtning

fast, reversereaction which kickstheguide bar upand

back toward the operator,ff the saw chain is pinched

along the top of the guide bar, the guide bar can be

dttvenrapidlyback towardtheoperator.Either ol_these

reactions can cause loss of saw control which can

resultin se,'lous injurj.

KICKBACK

PATH

Figure 1

1. Recognize that kickbackcan happen. With abasic

understandingofkickback,youcanreduce theele-

mentof surprise whichcontributestoaccidents.

2. Never let the moving chain contact any object at

the tip of the guide bar. Figure 1.

3. Keep the working area free from obstructions

such as other trees, branches, rocks, fences,

stumps, etc. Figure 2. Eliminate or avoid any

obstructionthat yoursaw chain couldhit whileyou

are cutting through a particular logor branch.

4. Keep your saw chain sharp and properly

tensioned. A loose or dull chain can increase the

chance of kickback. Follow manufacturer's chain

sharpening and maintenance instructions.Check

tensionat regular intervals with the motorstopped,

neverwiththemotor running.Makesurethatbarclamp

nuts are securelytightenedaftertensioningthe chain.

5, Begin and continue cutting only with the chain

moving at full speed. If the chain is moving at a

slowerspeed, there isgreater chance for kickback

to o_ur.

6. Cut one log at a time.

7. Use extreme caution when reentering a previous

cut.

8."Do not attempt plunge cuts.

9. Watch for shiffing logs Orother forces that could

close a cut and pinch or fall into the chain.

10. Use the Reduced-Kickback Guide Bar and Low-

Kickback Chain specified for your saw.

.5

CLEARTHE

WORKINGAREA

•Figure 2

KEEP A RRMGRIP

WITH BOTH HANDS

WITH LEFT THUMB

CORRECT GRIP INCORRECT GRIP

Figure3

AVOID

OBSTRUCTIONS

CORRECT POSITION

MAINTAIN CONTROL

1. Keepa good firm grip onthesaw with both hands

when the motoris running and don't let go. Figure

3. A firm grip can neutralize kickbackand help you

maintain controlof thesaw.Keep the fingersof your

lefthandencirclingandyourleftthumbunderthefront

handlebar.Keepyourrighthandcompletelyaroundthe

rear handle whetheryou are right handed or left

handed_Keep your leftarm straightwith the elbow

locked.

2. Never reverse right and left hand positions. Fig-

ure3.

3. Stand with your weight evenly balanced on both

feet.

4. Stand slightly tothe left side of the saw, to keep

your bod_ from being in a direct line with the cut-

ting chain. Figure 3.

5. Do-notoverreach. YouCouldbedrawn orthrownoff

balance and lose controlof the saw.

6. Do not cut above shoulder height. It is difficultto

maintain controlofthesaw above shoulder height.

/,

• . iii i iiiiii , i iiiiiiiiiiiiiiiiiiii i i iI i ii i iiiiiii i m i i m i i ,i i IH,HIH ,11 II tll IIIIIII

SPECIAL SAFETY SECTION (continued)

,1111 I i i i mm,wml,,i ml,II I I i H iml=l, i=i. ill ,mHIml .H " I

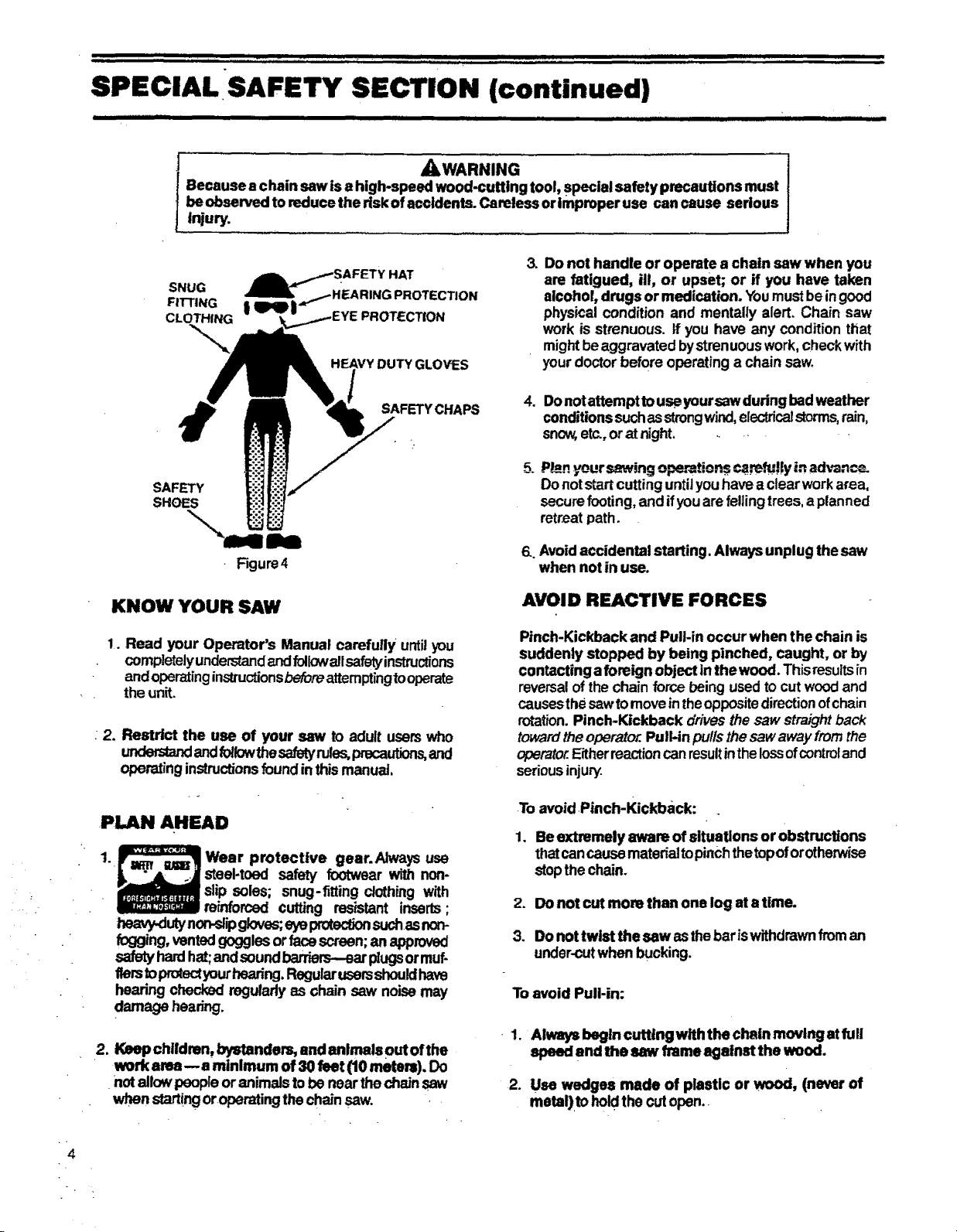

_kWARNING

Because a chain saw is ahigh-speed wood-cutting tool, Special safety precautions must

beobserved to reduce the rlskof accidents.Careless orImproper use can cause serious

injury.

:t

Do not handle or operate a chain saw when you

SNUG

FITTING

CL_

DUTY GLOVES

SAFETYCHAPS

SAFETY

SHOES

""\m!l lie

Figure4

are fatigued, ill, or upset; or if you have taken

alcohol, drugs or medication. Youmust be ingood

physical condition and mentally alert. Chain saw

work is strenuous. If you have any condition that

mightbe aggravated bystrenuouswork,check with

yourdoctorbefore operating achain saw.

.

Donotattempt touseyoursaw during badweather

conditions suchasstrongwind,electricarstorms,rain,

snow,etc.,or at night.....

.

P_n your sewing opemtions c_l!y in advance.

Do notstartcutting until youhavea clearworkarea,

securefooting, andifyouarefelling trees,a planned

retreat path.

6..Avoidaccidental starting. Always unplug the saw

when not in use.

KNOW YOUR SAW

1. Read your Operator's Manual carefully untilyou

completelyunders_ndandfollowallsafetyinstructions

andoperatingins_nJctionsbeforeattemptingtooperate

the unit.

2. Restrict the use of your saw to adult userswho

underaandand_k_vthesef_rule_ _ and

operating instructionsfoundinthis manual

PLAN AHEAD

1. Wear protective gear.Always use

steel-toed safety footwear with non-

slip soles; snug-fitting clothing with

Jm_rorcod cutting resistant inserts;

heawAuty non-slipgloves;eyeproCecfJonsuch.asnon-

fogging, vented gogglesorfacescreen;an approved

safetyhardhat;andsoundbarriers--ear p_ugsormuf-

fte_ toprotectyourhearing,Regularusersshouldhave

hearing checked regularlyas chain saw noise may

damage hearing.

2. Keep children, bystandem, and animals out ofthe

work area-- aminlmum of 30 feet (10meters). Do

not allowpeople or animalstobe near the chainsaw

when startingoroperating thechainsaw.

AVOID REACTIVE FORCES

Pinch-Kickback and Pull-in occur when the chain is

suddenly stopped by being pinched, caught, or by

contacting aforeign object in thewood. Thisresultsin

reversalof the chainforce beingusedtocut woodand

causesthesawtomoveintheopposite directionofchain

rotation.Pinch-Kickback drivesthe saw straightback

towardtheoperator.Pull-in pullsthesaw awayfromthe

operator.Eitherreactioncan resultinthe lossofcontroland

sedousinjury.

To avoidPinch-Kickback:

,

Be extremely aware of situations or obstructions

thatcancause matedaltopinchthetopoforotherwise

stopthe chain.

.

Do not cutmore than one log at a time.

3.

Do nottwist the saw as the bariswithdrawn froman

under-cutwhenbucking.

To avoid Pull-in:

• 1. Alwa_beglncutt/ngwlththecl_inmovl_3atfull

speed and the saw frame against the wood.

2. Use wedges made of plastic or wood, (never of

metal)to holdthecutopen.

4

SPECIAL SAFETY SECTION (continued)

...... III . . I II II I II I m I IIIII I I El I I II IIIIIIIII

OPERATE YOUR SAW SAFELY

1. Do not operate a chain saw that is damaged,

improperly adjusted, or not completely and

securely assembled.

2. Do not use the saw if the trigger switch does not

turn the uniton and off properly.Repairstothe trig-

ger switch must be made by your Sears Service

Center.

3. Do not operate the sawfrom a ladder or in a tree.

4. Position all parts of your body to the left of cut

when the motor is running.

5. Cut wood only. Donotcutmetal, plastics,masonry,

non.vKx_buildingmaterials,etc. Donotuseyoursaw

topryor shoveawaylimbs,rootsorotherobjects.

6. Make sure the chain will not make contact with

any object before starting the motor. Never try to

start the saw when the guide bar is in a cut or kerf.

7. Use extreme Caution when cutting small size

brush and saplings. Slender materialcancatchthe

saw chain and bewhippedtov;ardyouorpul!youoff

balance.

8. Be alert for springback when cuttinga limb that is

undertension to avoid beingstruck bythe limbor saw

when"the tensionin the wood fibers is released.

9. Do not force the saw through a cut. Exert light

pressure only.Pressure on the sawat the end of a

cut could cause loss of control when the Cut is

completed.

10.

Avoid body contact with the chain anytime the

saw isplugged into a power source. The chain will

continueto move fora shorttime afterthe trigger is

released.

11.

Avoid dangerous situations. Donotexposethesaw

to rain, or use in damp, wet, gaseous,orexplosive

locations.

I2.

Unplug the powerconnection when the saw is not

in use.

MAINTAIN YOUR SAW IN

GOOD WORKING ORDER

I. Unplug the saw before servicing or changing

accessories.

2. Have all chainsawservice,(other than theservice

described in the maintenance section of this

manual) performed byyour Sears Service Center.

3, Keep chain and guide bar clean and properly

lubricated.

4. Keep oii cap, screws and fasteners tight.

5. Keep the handles dry, clean, and free of oil

6. Stop the saw if the chain strikes a foreign object.

Checkforalignment,binding,breakage,andmount-

ingof moving partsand anyotherconditionthatmay

affecttheoperationofthe unit.Check guardsand all

other pads tosee if each willoperate properlyand

perform itsintendedfunction. Any partthat is dam-

aged should be properly repaired or replaced by

using the instructionsin this manual or by seeing

yourSears Service Center.

7 Be certain the sawchain stops moving when the

trigger switch is released.

8. Make certain that alrhand toolsare removed from

the saw before connecting the saw to the power

source.

9. Nevermodify your sawin any way.Useonlyattach.=

ments suppliedor specificallyrecommendedbythe

manufacturer.

10.

Always replace the handguard immediately if it

becomes damaged, broken or otherwise

removed.

CARRY AND SI"ORE

YOUR SAW SAFELY

o

Never carry yoursaw while climbing. Both hands

are needed for safe climbing,

.

Carry the unit unplugged, by the front handle,

finger off tWetrigger switch, and with the guide

bar and chain to the rear.

3.

Carry the saw with guide bar and chain covered

by the scabbard.

4.

Before transporting in any vehicle or storing in

any enclosure, allow yoursaw to cool completely,

coverthe barand chainand propedysecureto avoid

turnover ordamage.

5.

Drain oil tank before storing your saw for 30 or

more days.

6. Store in a dry area out of the reach of children.

NOTE

Exposuretovibrationsthroughprolonged use of this tool may produce Whitefingerdisease (Raynaud's phenomenon)

This phenomenon reduces the hand's ability to feel and regulate temperature, produces numbness and burning

sensations and can cause nerve and circulation damage and tissue necrosis.

An anti-vibration system designed to reduce engine vibration is recommended for those using power tools on a

regular or sustained basis. An anti-vibration system does not guarantee the avoidance of Whitefinger disease,

Continual and regular users must monitor closely theii- use of power tools and physical condition.

THIS CHAIN SAW IS FOR OCCASIONAL USE ONLY.

Notice:

Refer tothe Code of Federal Regulations,Section 1910.266(5);2.5.1 ofAmerican NationalStandard SafetyRequire-

mentsfor Pulpwood Logging,ANSI 03.1-t978; and relevantstate safetycodeswhen usinga chain saw for logging

purposes.

• • . . • • . , . , •

KNOW YOUR CHAIN SAW

A. INTRODUCTION

• Yoursawhasbeendesignedwithsafetyin mind and

includes the following features as standard

equipment:

Reduced-KickbackGuideBar (Lo-Kick_)

m Low-KickbackChain (Xtra-GUARD®)

Handguard

AWARNING

The following features are included on your saw to

help reduce the hazard of kickback. However, such

features will nottotally eliminate this dangerous mac-

tion. As a chain saw user, do not rely only on safety

devices. You must follow all safety precautions, in-

structions and maintenance in this manual to help

avoid kickback and other forces which can result in

serious injury.

B. KICKBACK SAFETY' FEATURES

-- Reduced-KJckbackGuideBar,designedwithasmal|

radiustipwhichreducesthesfzeofthekickbackdanger

zone on the bar tip. Figure5. A Reduced Kickback

Guide Bar is one which has beendemonstratedto

significantlyredu(/ethe number and seriousnessof

kickbacks whentestedinaccordancewiththe safety

requirementsfor gasolinepoweredchainsawsas set

by the American National StandardsInstitute,Inc.

Standard B175.1-1985.

_--Low-Kickback Chain, designed with a contoured

depthgauge andguardlinkwhichdeflectthekickback

force and allowwood_ograduallyride intothe cutter,

Figure5. LowKickback SawChainischain whichhas

met thekickbackperformancerequirementsofANSI

B175.1(Safety Requirementsfor Gasoline-Powered

Chain Saws)whentestedona representativesample

ofchainsawsbelow38 cubicinchdisplacementspeci-

fied in ANSI B175.1.(American.NationalStandards

In_tute, inc.,StandardBi75.1- 1985).

-- Handguard, designedtoreducethe chanceofyourleft

handcontactingthe chainifyourhandslipsoffthefront

handlebar.

,,L .......... _ , ,,,,,

Figure 5

C, DOUBLE INSULATION

YourChain Sawis double insulated to help protect

against electric shock. Adouble insulatedt0oliscon-

strucl_dthroughoutwithtwoseparate "layers" ofelec-

trical insulationor one double thicknessof insulation

between the operatorand the electrical systemof the

toot.

Toolsbuiltwith thisinsulationsystemare notintended

tobe grounded. As a result, the extensioncord used

withyoursawcanbe pluggedintoanyconventional 120

voltelectricaloutletwithout concern formaintaining a

groundconnection.

Safety precautions must be observed when

operating any electrical tool. The double insulation

systemonly suppliesadded protectionagainst injury

resultingfrom a possible electrical insulation failure

withinthe saw.

D. CARTON CONTENTS

After you unpack the carton:

1. Check the contents against the list below.

2. Examine the itemsfor damage.

3. Notifyyour Searsstoreimmediatelyffa part ismiss-

ingor damaged.

NOTE: A rattle-like noise in a powerhead with an

empty oiltank is a nori-nal_ondition caused bythe

filtermovingagainst the wall of the tank.

-- Position offront andrear handlebars, designedwith

distance between handles which provides better

balanceandresistanceifkickbackoccurs.

_kWARNING

Do not operate the chain saw unlessthesafety devices

or their specified replacements areproperly installed

and maintained according to the instructions in this

manual. Do not useanyotherguide barand chaincom-

bination that isnot equivalentto the original equipment

or not certified to comply with ANSI B175.1. Failure

to follow these instructions can result in serious

injury.

KEY NO.

1

2

3

4

CARTON CONTENTS: QTY,

Powerhead 1

Guide Bar 1

Scabbard 1

Chain 1

Operator's Manual (Not Shown) 1

i i im ii " ....I............

i; , .... ,,,, ,,,ll i

PREPARING YOUR SAW FOR USE

A. GETTING READY

I. READ YOUR OPERATOR'S MANUAL CARE-

FULLY.YourOperator'sManualhasbeendeveloped

tohelpyouprepare yoursawfor useand to unders-

tand itssafeoperation. Iris importantthat you read

yourmanuat completelytobecome familiarwiththe

unitbefore you begin assembly.

iiiiiiiiiiii

2. HAVE THE FOLLOWING AVAILABLE:

a. Protective Gloves.

b. ½ inch wrench or equivalent.

c. Screwdriver

d. Bar and Chain Lubricant (see page 9).

....... J,,_,,,,,ii illl iii ill i ill

ii ,,,,,,,,,,,,,,,

B. POWER SOURCE AND EXTENSION CORD

1. POWER SOURCE

Use only an A.C.voftagesupply identica! tothat

shown onthe name plate ofthe saw to power this

chain saw.

_k WARNING

All elactdcal repairs to this saw, including housing,

switch, motor,etc., must be diagnosed andrepaired by

your Sears Service Center or nearest Sears store.

Failure to do so can cause the double insulation

construction to become ineffective and result in

serious injury.

2. EXTENSION CORD

a. The extension cord used to reach the power

source must be:

1.) Specifically marked as suitable for outdoor

use. The suffix,W-A,mustbeincludedon the

cordlabel.

2,) Heavyenough to carry'the current from the

power source to the distance atwhich the

saw isto be used. Otherwise, lossof power

and overheating can occur causingdamage

tothe unit. RefertoFigure6 forminimum wire

gauge recommendations.

3.) In good condition. Cord insulationmustbe

intact with no cracks or deterioration. Plug

connectors must be undamaged.

b. Suitable extension cords are available at your

Seam Retail or Catalog Store.

MINIMUM WIRE GAUGE I

RECOMMENDATIONS

AMP VOLTS 25 FT. 50 FT. 100 F_. ]

12 120 16 14 10

A.W.G. A.W.G. A.W.G.

i

r

• ii iiii II i iii ii iii

3. IMPORTANT POINTS

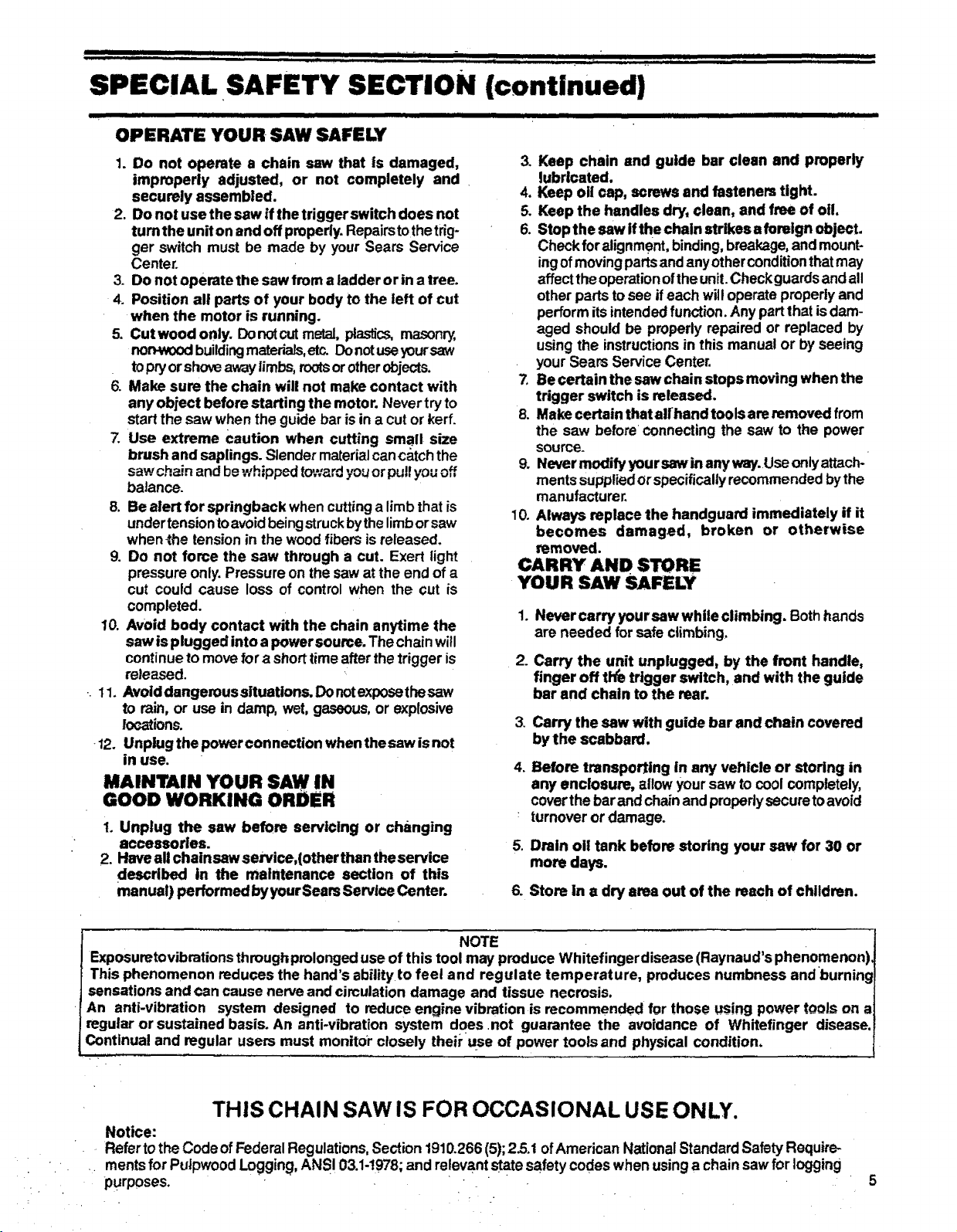

a. Secure, the tool cord to the extension cord as

shown inFigure 7 topreventdisconnection,

b,

Do not abuse cords. Never carry saw by the

powercordoryank ittodisconnect,Keeptoolcord

and extensioncordawayfrom heat, oil,andsharp

edges.

c. Guard against electric shock. Avoidbody con-

tact withany groundedconductor,suchas metal

pipes and wirefences.

d. Avoid entanglement. Keep cords clear of

operator,sawchain, and branches atall times.

e. Avoid dangerous situations, Donor exposethe

saw to rain, or use in damp, wet, gaseous, or

explosive locations.

f. inspect extension cords before each use.

Replace before using thesaw if damaged,

g, Inspect chain saw cordbefore .eachuse. Do not

use the unitwith a damaged cord. Takethe unit

to a Sears Service Center.for repairs.

SECURE TOOL CORD TO

EXTENSION CORD._

. t

Figure 7

SAVE THESE INSTRUCTIONS

Figure 6

7

¢, ATTACHING THE BAR AND CHAIN

• Your saw is equipped with a Reduced-Kickback

Guide Barand aLow-Kickback Chain.

e

Use only the Reduced.Kickback Guide Bar and

Low-Kickback Chainspecified foryourchain saw

model: when replacing these parts, See "Specifi-

cations;' page 2.

|CAUTION._ Wear protective gloves when hand-

ling or operating your saw,Thechain issharp and

can cut you even when it is not moving!

Avoid accidental starting. Always unplug the saw

from the power source before installing a barand/or

l AWARNING

chain.

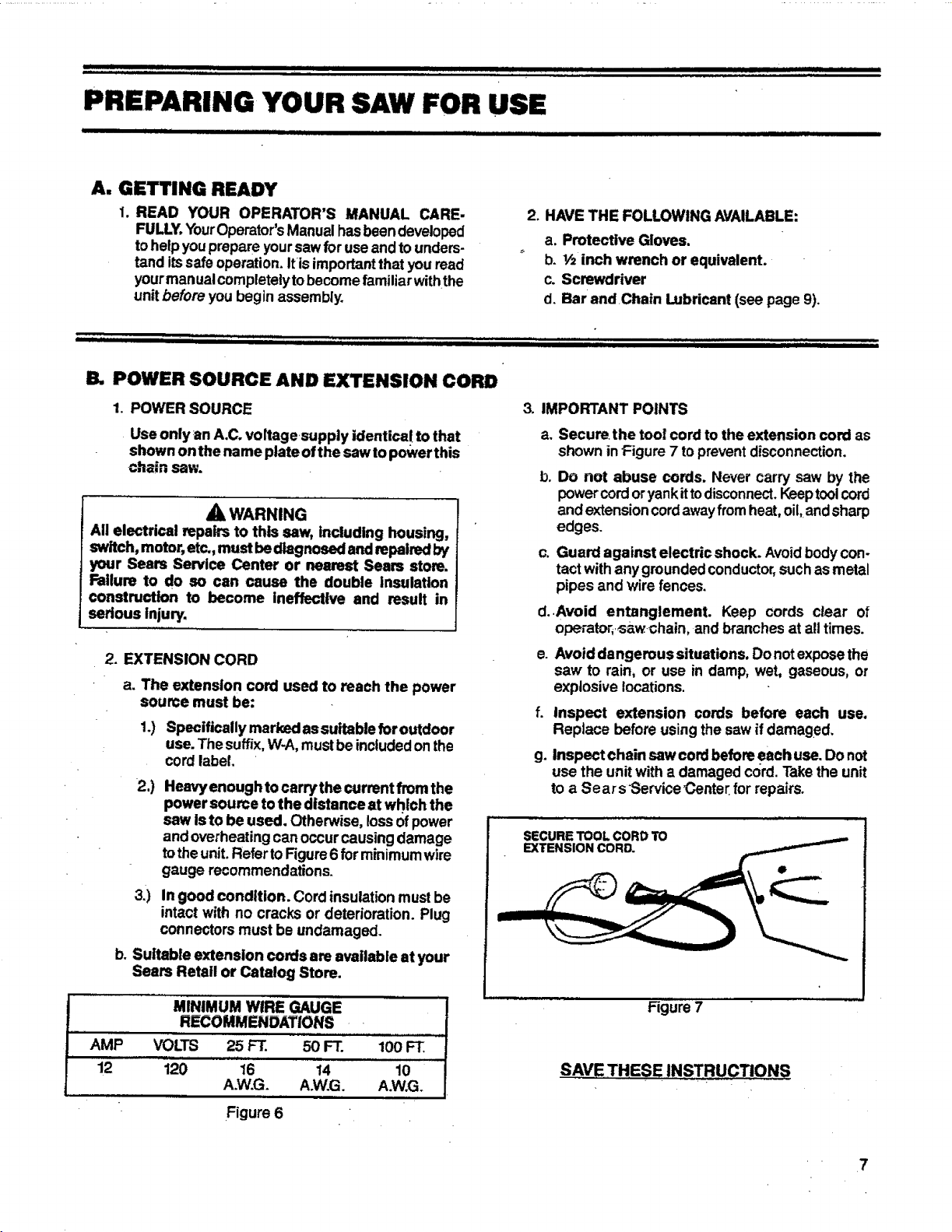

1, Remove the Bar Clamp Nuts & Bar Clamp

Housing,

2. Turnthe AdjustingScrew counterclockwisetomove

theAdjustingPinalmostasParasitwillgotothe rear.

Figure8.

3 Placethe GuideBaron thesawbyfittingthe long

slotinthe Guide Baroverthe twomountingstuds.

Figure 9,

NOTE: BesuretheGuideBarispositionedwiththe

• roundhole belowthe largeslot,

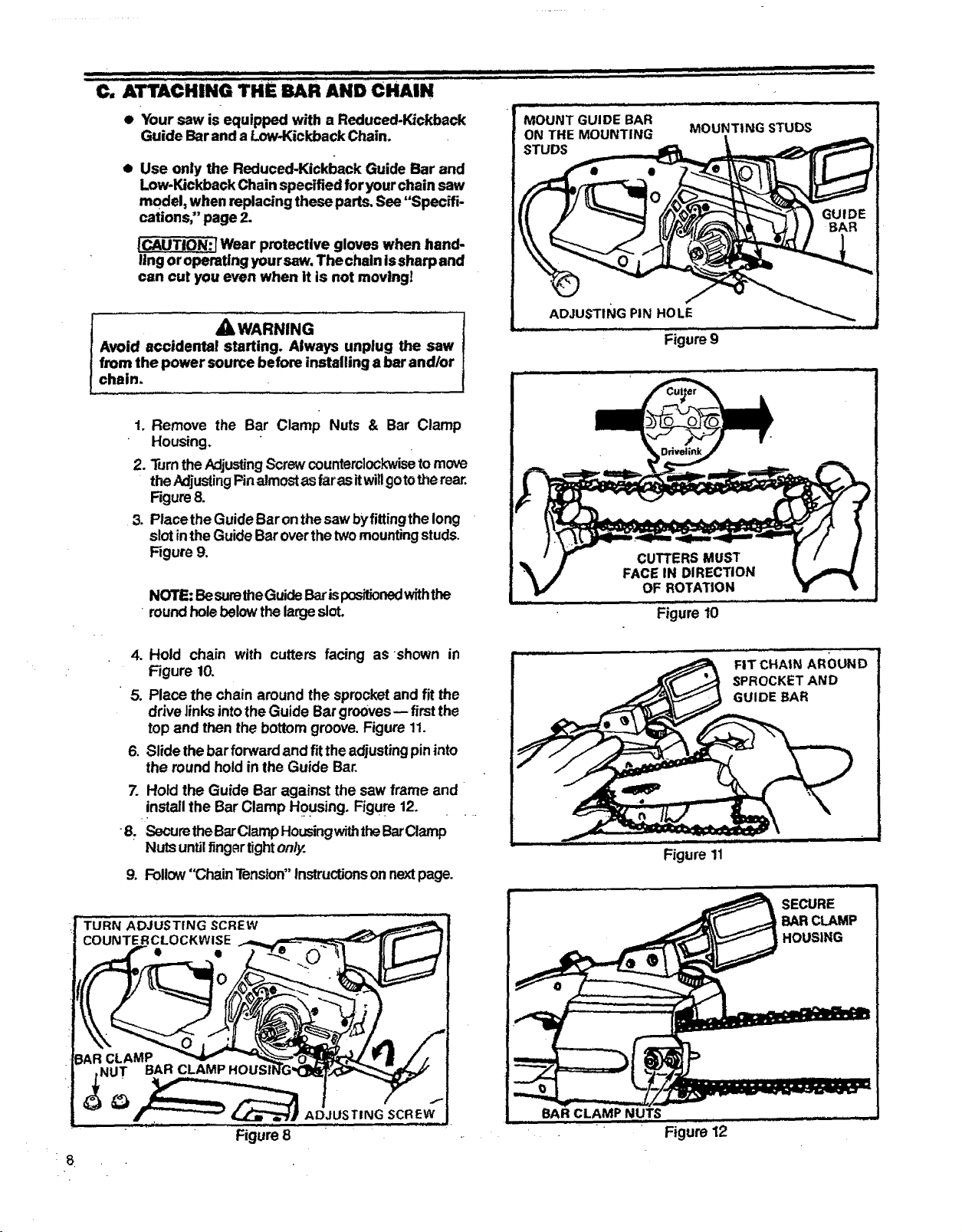

4. Hold chain with cutters facing as shown in

Figure 10.

5. Place the chain around the sprocketand fit the

drive JinksintotheGuide Bargrooves-- first the

top and then the bottomgroove. Figure 11.

6. Slide thebarforward and fitthe adjustingpininto

the round hold in the Guide Bar.

7. Hold the Guide Bar against the saw frame and

installthe Bar Clamp Housing. Figure 12. . ..

8, 'SecuretheBarClampHousingwiththe BarClamp

Nuts untilfingertighton/y.

9. Follow"Chain Tension"Instructionsonnextpage.

TURN ADJUSTING SCREW

COUNTE

Figureg

CUTTERSMUST

FACE IN DIRECTION

OF ROTATION

Figure 10

FIT CHAIN AROUND

SPROCKET AND

GUIDE BAR

Figure 11

,jr

SECURE

BARCLAMP

HOUSING

• Figure 8

......BARCLAMP N_U.1"S , r _ ...... -

0 Figure 12

............. _! IIIIFIIIIIIII _IIIIILI II I I III _llili II I LIIIII I i III il I

D. CHAIN TtNSi0N

* Chain tension Is very important:

--A loose chain willwearthe bar and itself.

--A loose chain canjump offthe barwhileyou are

cutting

-- Atightchain candamagethe saw andlorbreak.

e The chain stretches dudng use, especlallywhen

new. Check tension:

-- each time the saw is'used

-- more frequently when the chainis new

--as' the chain warms up to normal operating

temperature.

_WARNING

Avoid accidental starting. Always unplug the saw

from the power source before adjusting chain

f

tension.

• Chain tensioning procedure:

NOTE:Thebardamp nutsmustbenomorethanfinger

tighttotensionthe chaincorrectly.

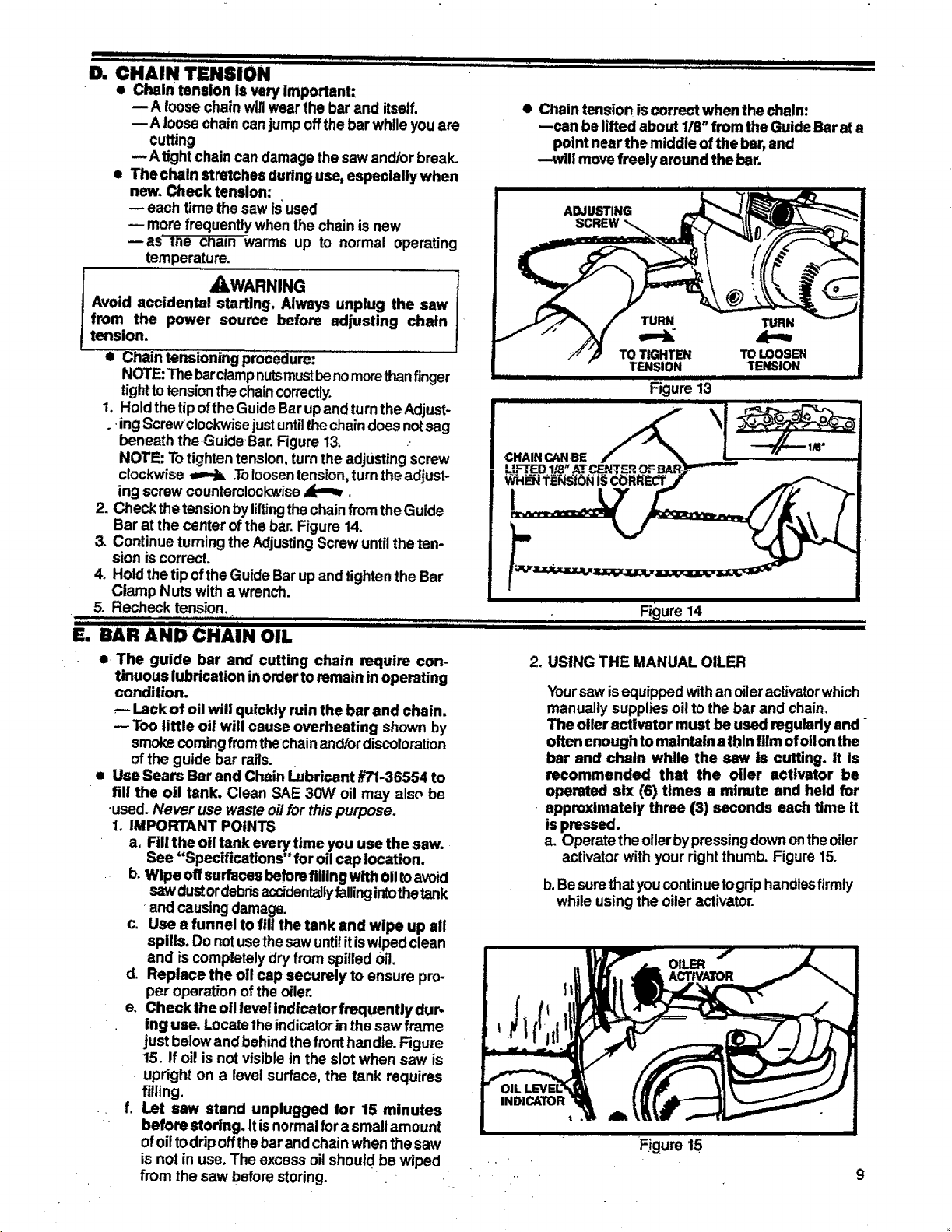

1. Holdthe tipofthe GuideBar upand turntheAdjust-

. ing Screwclockwise just untilthe chaindoesnotsag

beneath the Guide Bar.Figure 13. .-

NOTE: Totighten tension,turnthe adjustingscrew

clockwise _ .Toloosentension,turn theadjust-

ing screw counterclockwise_.

2. Check thetensionby liftingthechainfrom theGuide

Bar at the centerof the bar.Figure 14.

3. Continue turningthe AdjustingScrew untilthe ten-

sion iscorrect.

4. Hold thetip ofthe Guide Barup andtightenthe Bar

Clamp Nuts with awrench.

5. Recheck tension.

E' BAR ANDCHAIN OIL

• The guide bar and cutting chain require con-

tinuous lubrication inorderto remainin operating

condition.

--- Lack of oil will quickly ruin the bar and chain.

-- Too little oil will cause overheating shown by

smokecomingfromthechain and/ordiscoloration

ofthe guide bar rails.

• Use Sears Bar and Chain Lubricant #71-36554 to

fill the oil tank. Clean SAE 30W oil may also be

-used. Never use waste oi/for thispurpose.

1. IMPORTANT POINTS

a. RI! the oil tank every time you use the saw.

See "Specifications" for oil cap location.

b. Wipe offsurfacesbe_reflliing with oiltoavoid

sawdust ordebrisaccidentallyfallingintothetank

•andcausingdamage.

c. Use a funnel to fill the tank and wipe up all

spills. Do notusethe sawuntilitiswipedclean

and iscompletelydry from spilled oil.

d. Replace the oil cap securely to ensure pro-

per operation ofthe oiler.

e. Check the otl level indicator frequentJydur-

ing use. Locatetheindicatorinthe sawframe

just belowandbehindthe front handte. Figure

15. If oil is not visible inthe slot when saw is

upright on a level surface, the tank requires

filling.

f. Let saw stand unplugged for 15 minutes

before storing, It isnormal fora small amount

ofoiltodripoff thebarand chain when the saw

is not{nuse. The excess oil should be wiped

from thesaw beforestoring.

II III II III'1 I

Iipjiiiiiiiiiii Iiiiiiiiiiiiiii I II iiiii i iiiiiiiiiii *1 I i iiiiii

• Chain tension is correct when the chain:

--can be lifted about 118"from the Guide Bar ata

--will move freely around the bar.

CHAIN, CAN BE t

i i i [ i i ii

2. USING THE MANUAL OILER

Yoursaw isequipped withan oileractivatorwhich

manually supplies oilto the bar and chain.

The oiler activator must be used regularly and-

often enough to maintain athin film of oilonthe

bar and chatn whlle the saw Is cutting. It is

recommended that the oiler activator be

operated six {6) times a minute and held for

approximately three (3) seconds each time It

is pressed.

a. Operate the oilerbypressingdownontheoiler

b. Besurethat youcontinuetogrip handlesfirmly

i , , , , i,

point near the middle of the bar,and

Figure 13

Figure 14 ....

activator withyour rightthumb. Figure 15.

while usingthe oiler activator.

Figure 15

Loading...

Loading...