Craftsman 35834031, 35834021 Owner’s Manual

__A/RS

operator's r

manual '

• Assembly

• Operation

• Maintenance

• Repair Parts

MODEL NO.

358.34021 - 2.0/12"

358.34031 - 2.0/14"RS.

z_WARNING:

.3arefully read and follow

Safety Rules, Precautions

and Operating Instruc-

tions. Failure to do so can

result in serious personal

injury.

SEAJ,_SI£RRF1"$MI:1N®l

2.0!12" 2.0f!4"P.S.

ELECTRIC CHAIN SAWS

THIS CHAIN SAW IS FOR OCCASIONAL USE ONLY.

, , u ,, ,H,,,U,, , u,

Record in the space provided below the Model No. and Serial.No. of

your saw. These numbers are located on the starting instructions

decal.

Model No. Serial No.

Retain these numbers for future reference°

66572 - 2 ._-26685 - 1 - 26685

Se___s, Roebuck and Co., Chicag(), IlL 60684 U.S.A.

PRtNTED I NU. S. A.

FULL 1 YEAR WARRANTY ON ELECTRIC CHAIN SAW

(Excluding Bar & Chain) :_

For one year from date of purchase, Sears will repafr defects in material or workmanship in this elecldc chain saw st no ><:_

charge.

This warranty excludes bar & chain, which are expendable parts and become worn during normat use.

If this chain saw is used for commercial or rentaI purposes, this warranty applies for only 30 days from date of purchase. WARRANTY _:_<_

SERVICE IS AVAILABLE BY RETURNING THE CHAIN SAW TO THE NEAREST SEARS SERVICE CENTER IN THE UNITED

STATES. -

This warranty gives you specific legal ++_ghts,and you may also have other rights which vary from stale to slate.

Sears,Roebuckand Co.,SearsTower,Dept. 698/731A, Chicago,iL 60684

TABLE OF CONTENTS

Specifications ........................ ....... 2

SPECIAL SAFETY SECTION ............... 3, 4 & 5

Know Your Chain Saw ........................ 6

Preparing Your Saw For Use ................... 7

A, Getting Ready ........................... 7

B. Power,Source and Extension Cord .......... 7

C. Attach'+,m,+g_:theBar and Chain ................ 8

D. Chain _Tension ............................ g

E. Bar ar_ Chain Oil ........................ g

Using Yours,Saw . . ........................... 10

A. Control Devices .......................... 10

B. Pro-Operation Checks .................... 10

C. Starting and Stopping the Saw, ............. 10

Uslng,the Power Sharp _ System .............. 11

Types of "Cutting 13

A. Basic Cutting Technique ............. "..... t3

B. Tree Felting Techniques .................. 13

C. Bucking ............................... 15

D. Debranching and Pruning ................. 16

Maintenance " . ....... 17

A. Cleaning the Saw .......... ;; ............. 17

B. Guide Bar and Chain ........................ 17

C. Sprocket .............................. 19

D. Storage ............................... 20

E. Maintenance Accessories ................. 20

F. Trouble Shooting Cllart ................... 21

Parts List .................................. 22

Quick Reference Page ....................... 27

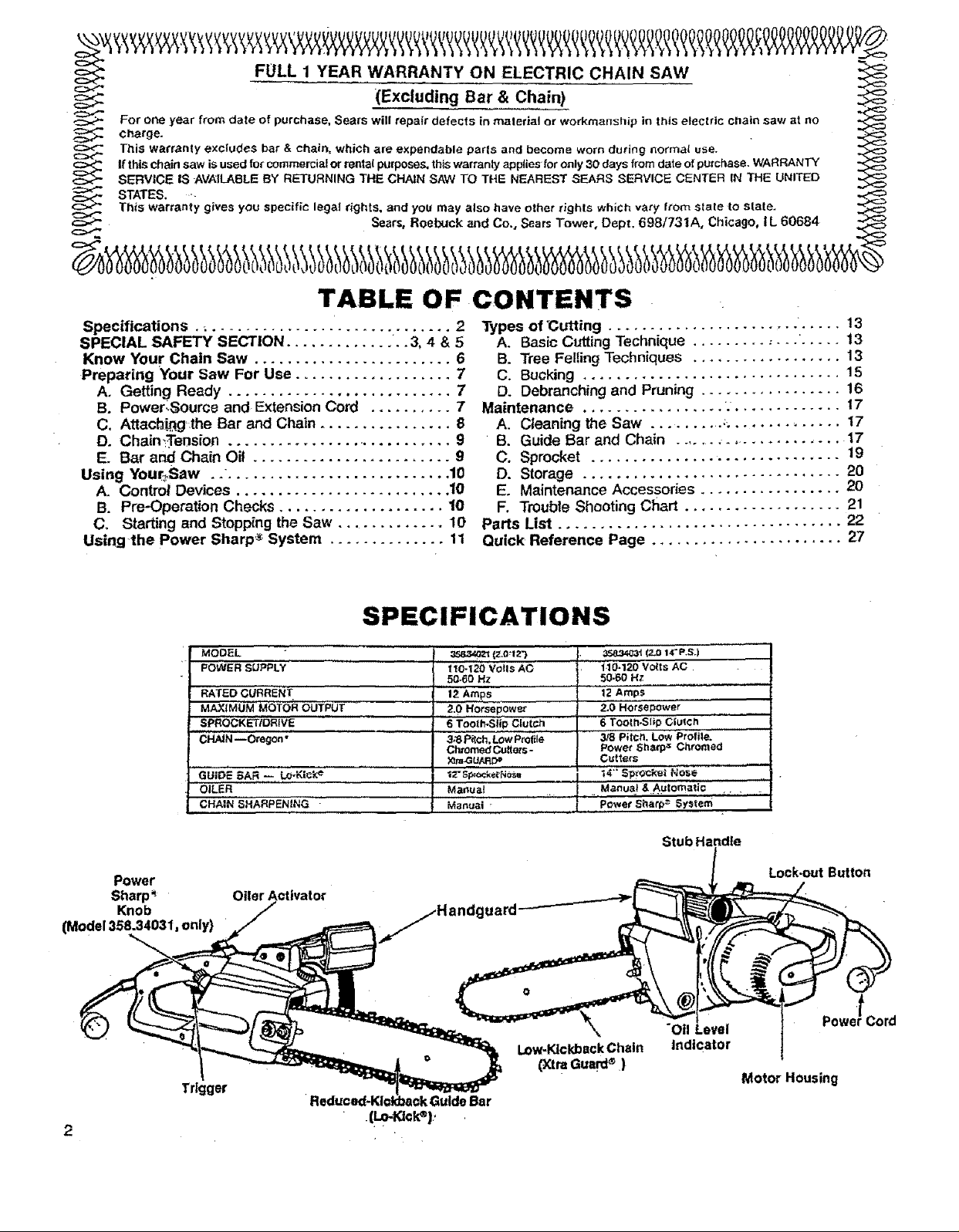

....G'UIOES_ - Lo._t_o'

Power

Sharp _

Knob

(Model 358.34031, oni_

Td_ger

MODEL

POWER SUPPLY

RATED CURRENT

MAXlMUM"'M_TOROUTPUT

SPROCKETIOR|VE ...........

CHAINiO_gon"

OILER

CHA,%NSHARPENiNG'' :_

SPECIFICATIONS

_zt (Z.O:t23 ;_S.34_ (_-o _4"P.SJ

'" 110_'2_)rolls AC 1t0-_20 Volts AC

50-60 Hz 50-60 Hz

, 12 A,m,ps 12 Amps

....2,0 Horsepo wet _ 2.0 Horsepower

sToo,!_:,St_,pciut_:h, 6 rool..s_ipcl_|c.

3,_Pi_ch, LowProfile 3/8 Pitct_, Low Profile,

Ch_omedCu_tms- Power Sharp= Chromed

Manual Manual &,.A.ulomati¢ ....

Manuai'- I Power Sharl_+_System

Low-KickbackChain

(xtr. Guard+ )

Stub Handie

Lock.out Button

Powe!Cord

"Oil

indicator

Motor Housing

(Lo-_Ck+),

,

SPECIAL SAFETY SECTION

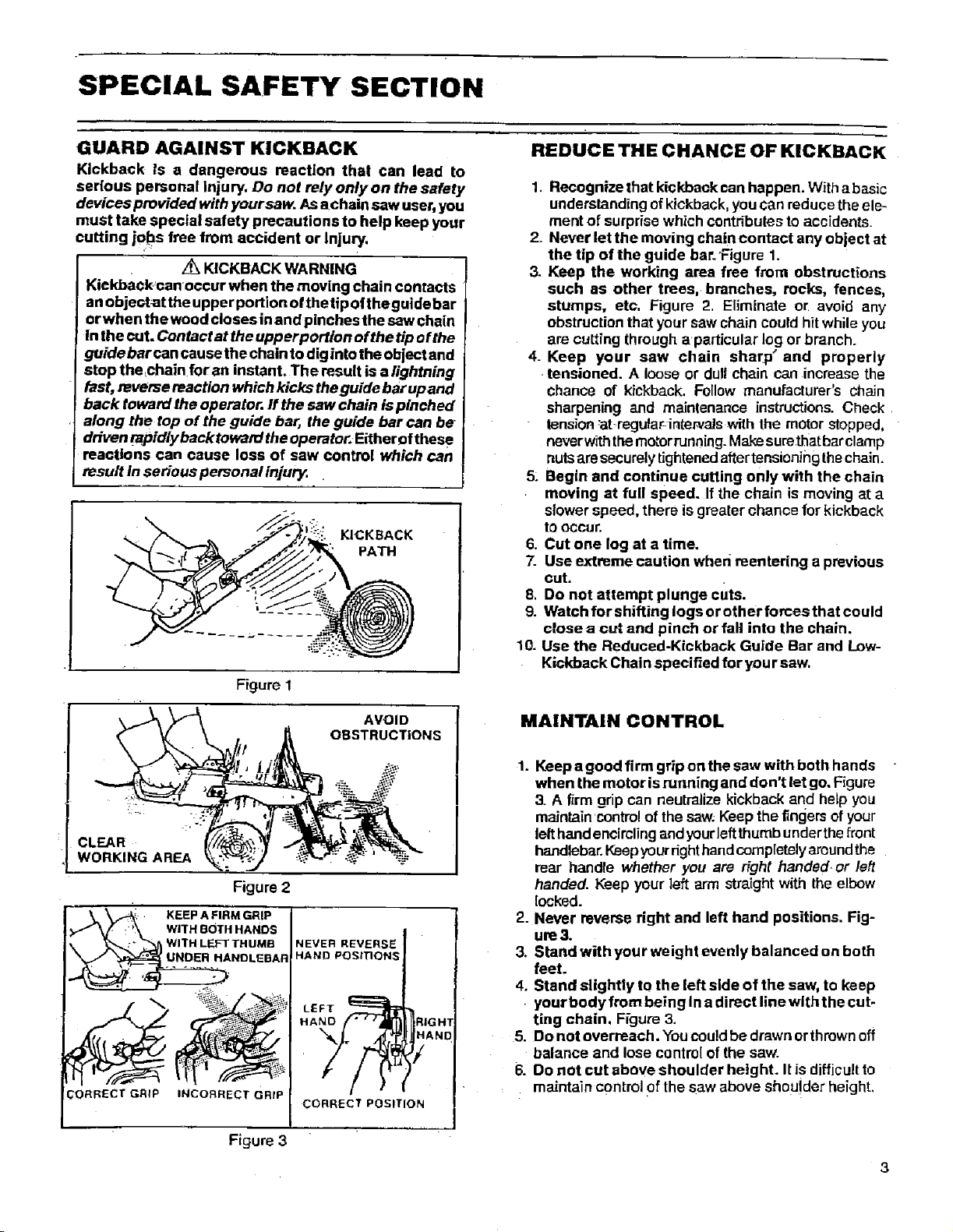

GUARD AGAINST KICKBACK

Kickback Is a dangerous reaction that can lead to

ser[o us perso hal Injury, Do not rely only on the safety

devices provided with yoursaw. Asachain saw user,you

must take special safety precautions to help keep your

cutting jobs free from accident or Injury,

KICKBACK WARNING

Kickback'can occur when the moving chain contacts

anobjec,tat the upper portion of the tip of the guide bar

orwhen the wood closes inand pinches the saw chain

In the cut. Contact at the upperportlon of the tipof the

guidebarcan causethe chain to diginto the object and

stop the,chain for an instant, The result is a lightning

fast, reverse reaction which kicks the guide bar up and

back toward the operator. If the saw chain ispinched

along the top of the guide bar, the guide bar can be"

driven _apidiy backtoward the operator. Eitherofthesa

reactions can cause loss of saw control which can

result inserious persona/ injur_,

KICKBACK

"_ PATH

Figure I

REDUCE THE CHANCE OF KICKBACK

1. Recognize that kickback canhappen, With abasic

understandingof kickback,you can reduce theele-

ment of surprise which contributes to accidents.

2. Never let the moving chain contact any object at

the tip of the guide bar. Figure 1.

3. Keep the working area free from obstructions

such as other trees, branches, rocks, fences,

stumps, etc, Figure 2. Eliminate or avoid any

obstructionthat your saw chain could hit while you

are cutting through a particular log or branch.

4. Keep your saw chain sharp _ and properly

tensioned. A loose or dull chain can increase the

chance of kickback. Follow manufacturer's chain

sharpening and maintenance instructions. Check

tension,at-regular-intervals with the motor stopped,

neverwith thernotorrunning. Make surethatbar clamp

nutsaresecurely tightenedafter tensioning thechain.

5: Begin and continue cutting only with the chain

moving at full speed. If the chain is moving at a

slower speed, there is greater chance for kickback

to occur.

6. Cut one log at a time.

7. Use extreme caution wheri reentering a previous

cut.

8. Do not attempt plunge cuts.

9. Watch for shifting logs or other forces that could

€losea cut and pinch or fall into the chain.

10. Use the Reduced.Kickback Guide Bar and Low-

Kickback Chain speciffed for you rsaw,

J

I

CLEAR

WORKING AREA

Figure 2

" _ "_,_ KEEP A FIRM GRIP

J _U_ . '\ WITH BOTH HANDS

\ _:.-- _ WITH LEFTTHUMB

NDL_:BAR

CORRECT GRIP INCORRECT GRIP

Figure 3

AVOID

OBSTRUCT|ONS

NEVER REVERSE

HAND POSITIONS

LEFT

CORRECT POSITION

RIGH

ANI

MAINTAIN CONTROL

1. Keep a good firm grip on the saw with both hands

when the motor is running and don't letgo. F3gure

3. A firm grip can neutralize kickback and help you

maintaincontrolof the saw;Keep the fingers of your

lefthand encirclingandyourleftthumb underthefront

handlebar.Keepyourrighth_ndcompletelyaroundthe

rear handle whether you are right handed=or left

handed. Keep your ]eftarm straightwith the elbow

locked.

2. Never reverse right and left hand positions. Fig-

ure3.

3. Stand with your weight evenly balanced on both

feet.

4. Stand stightly to the left side of the saw, to keep

yourbody from being Ina direct line with the cut-

ting chain, Figure 3.

5. Do not overreach. Youcouldbe drawnorthrownoff

balance and losecontrol of the saw.

6. Do not cut above shoulder height. It is difficultto

maintain controlof the saw above shouider height,

SPECIAL SAFETY SECTION (continued)

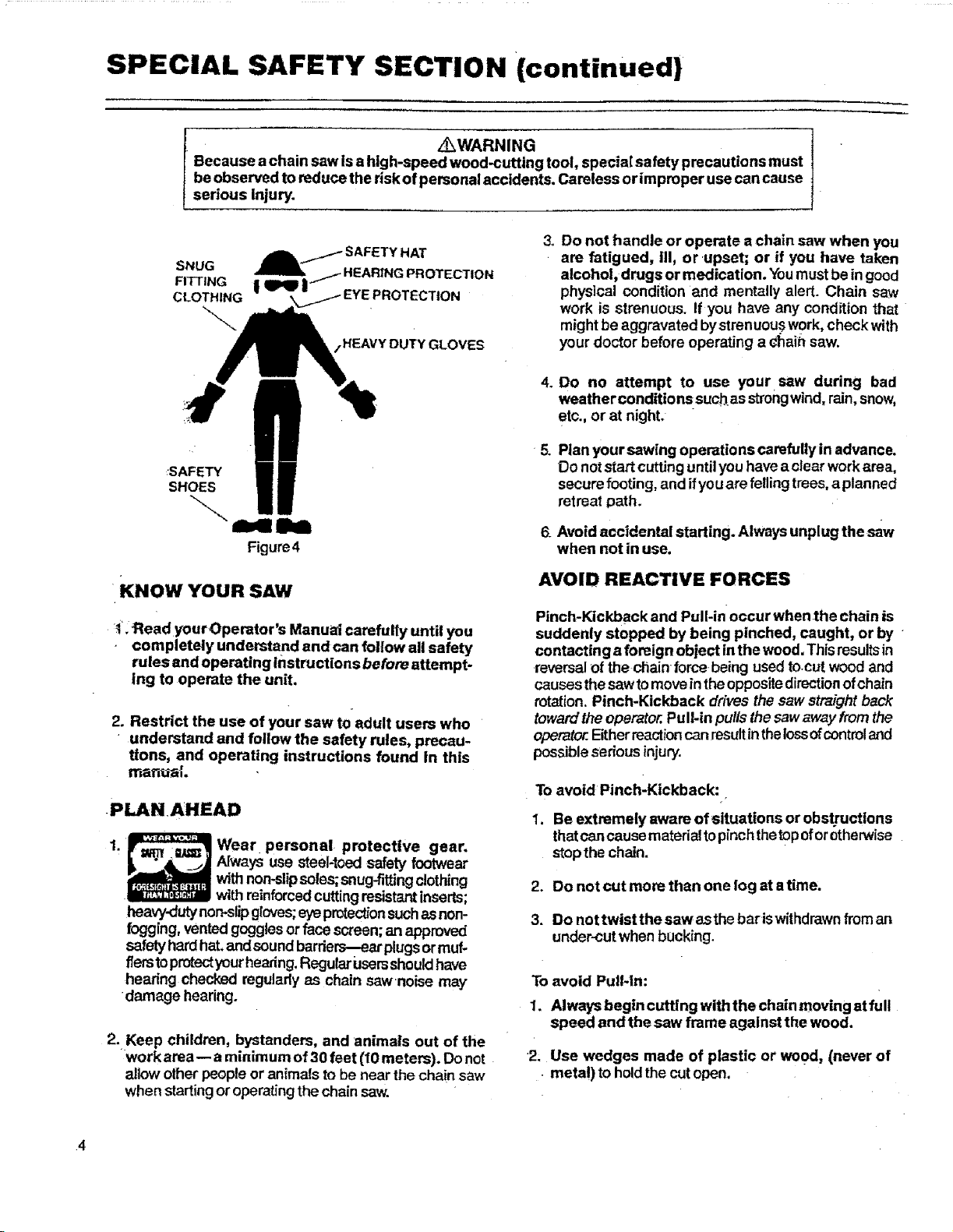

Because a chain saw isa high-speed wood-cutting tool, special safety precautions must

be observed to reduce the risk ofpersonal accidents. Careless or improper use cancause

I !hWARNING

serious Injury.

3. Do not handle or operate a chain saw when you

SNUG

FITTING

.AI.._- SAFETY HAT

HEARING PROTECTION

HEAVY DUTY GLOVES

are fatigued, i11,or upset; or if you have taken

alcohol, drags or medication. Youmustbe ingood

physical condition and mentally alert. Chain saw

work is strenuous. If you have any condition that

mightbe aggravated bystrenuou.swork, check with

your doctor before operating a Chainsaw.

.

Do no attempt to use your saw during bad

weatherconditions suchasstrongwind, rain, snow,

etc., or at night.

Plan your sawing operetionscarefully inadvance.

Do notstartcutting until youhaveaclear workarea,

secure footing,and ifyouare felling trees,aplanned

retreat Dath.

Figure4

'KNOW YOUR SAW

i, Read yourOperator's Manual carefully until you

completely understand and can follow all safety

rules and operating Instructions before attempt-

ing to operate the unit.

2. Restrict the use of your saw to adult users who

• understand and follow the safety rules, precau-

tions, and operating instructions found in this

manual

PLANAHEAD

1,

heavy-dutI non.slipgloves;eyeprotectionsuchas non-

fogging, ventedgogglesor face screen; an approved

safetyhardhat.andsoundbarriers--ear plugsormuf-

flerstoprotectyourhearing.Regu_r Usarsshouldhave

hearing checked regularlyas chain sawnoise may

damage hearing.

2. Keep children, bystanders, and animals out of the

work area-- a minimum of 30 feet (10meters). Do not

allow other people or animats to benear the chain saw

when startingor operatingthe chainsaw.

Wear personal protective gear.

Always use steel-toedsafety footwear

with non-slipsoles;snug-fiRingclothing

with reinforcedcuttingresistantinserts;

6.

Avoid accidental starting. Alwaysunplug the saw

when not in use.

AVOID REACTIVE FORCES

Pinch-Kickback and Pull-in occur when the chain is

suddenly stopped by being pinched, caught, or by

contacting aforeign object inthe wood, This resultsin

reversalof the chain forcebeing used to cut wood and

causesthe saw tomove in the oppositedirectionof chain

rotation. Pinch-Kickback drives the sawstraightback

toward the operator.Pull-in pulls the saw away fromthe

operator.Eitherreactioncanresultin thelossofcontroland

possibleserious injury.

To avoid Pinch-Kickback:

1. Be extremely aware of situations or obstructions

thatcan causematerialtopinchthetopoforotherwise

stopthe chain.

2. Do notcut more than one log at a time.

3. Do nottwist the saw asthebaris withdrawnfroman

under-cutwhen bucking.

To avoid Pull-in:

I. Always begin cutting with the chain movlng at fuU

speed and the saw frame against the wood.

2; Use wedges made of plastic or wood, (never of

metal) to holdthe cutopen.

SPECIAL SAFETY SECTION (continued)

OPERATE YOUR SAW SAFELY

1. Do not operate a chain saw that is damaged,

improperly adjusted, or not completely and

securely assembled.

2. Do not use the saw if the trigger switch does not

tumth e unit on and off pmpedy. Repairstothetrig-

ger switch must be made by your Sears Service

Centero_

3. DO n0t'operate the saw from a ladder or in a tree.

4. Position all parts of your body to the left of cut

when:the motor is running.

5. Cut WOodonly, Do not use achain saw forany pur-

pose other than those described in this manual.

6. Make sure the chain will not make contaclwith

any object before starting the motor. Never tryto

startthe saw when the guide bar isin a cut or kerf.

7. Use extreme caution when cutting small size

brushandsaplings. Slender materialcan catch the

saw chain and bewh!pped toward youor pullyouoff

balance.

8. Be alert for springback when cutting a limb thatis

undertensiontoavoid beingstruckbythe iimborsaw

when the tension in the wood fibers isreleased.

9. Do not force the saw through a cut. Exert light

pressure.only. Pressure on the saw atthe end of a

cut could cause toss of control when the cut is

completed.

10. Avoid body contact with the chain anytime the

saw is plugged into a power source. The chainwill

continue to move for ashort time after the trigger is

released.

3. Keep chain and guide bar clean and properly

lubricated.

4. Keep oil cap, screws and fasteners tight.

5. Keep the handles dry, clean, and free of oil.

.

Stop the saw if the chain strikes aforeign object.

Check for alignment, binding,breakage, and mount-

ingof movingparts and anyotherconditionthatmay

affecttheoperation ofthe unit.Check guards andall

other partsto see if each willoperate°properlyand

perform itsintended function. Any partthat is dam-

aged should be pmpedy repaired or replaced by

using the_instructionsin this manual or by seeing

your Sears Service Center.

7.

Becertain the saw chain stop s moving when the

trigger switch is released.

.

Make certain thatall hand tools are removed from

• the saw before connecting the saw to the power

source.

9. Never modifyyoursawinanyway. Useontyattach-

ments suppliedorspecifically recommended bythe

manufacturer.

O. Always replace the handguard immediately if it

becomes damaged, broken or otherwise

removed.

CARRY AND STORE

YOUR SAW SAFELY

1. Never carry your saw while climbing. Both hands

are needc-d ,vr _,,,_.,..m,,,,,g.

11.'Avotddangerous s_tuatlons. Do not m'..pose the

saw to rain, or use in damp, wet, gaseous, or

explosive locations.

-12. Unplugthepowerconnection whenthesawisnot

in use.

MAINTAIN YOUR SAW IN

GOOD,WORKING ORDER

2. • 14=._ !, _ d"

Carry the un,. ,.,,p.ugue , by the front handle,

finger offthe trigger switch, and with the guide

bar and chain to the rear.

3. Carry the saw with guide bar and chain covered

by the scabbard.

.

Before transporting in any vehicle or storing in

any enclosure, allow yoursaw to cool completely,

cover the.bar and chain and properly secure toavoid

1. Unplug the saw before servicing or changing

turnover or damage.

accessories,

5.

2. Have all chain saw service(other than the ser-

Drain oil tank before storing your saw for 30 or

more days,

,#Ice described In the maintenance section of

this manual)performed by yourSeara Service 8.

Store In a dry area out of the reach of children.

Center.

SAVE THESE INSTRUCTIONS

Notice:

Refer tothe Cooe ofFedera=r_egulat{ons,oection 1910,266(5); 25.1 ofAmenu=. _.u=_=_ oL=_d=ruS_ ely Requ,re-

mentsfor Pulpwood Logging, ANSI 03.1:1978;and relevant state safety codes when using a chain saw forlogging

purposes.

•5

KNOW YOUR CHAIN SAW

A, INTRODUCTION

• Yoursaw has been designedwithsatetyin mind and

includes the following features as standard

equipment:

-- Reduced-Kickback Guide Bar (Lo-Kick _)

Low-KickbackChain(Xtra-GUARD")

Handguard

Z_ WARNING

Thefollowing features are included onyour saw to help

reduce the hazard of kickback, however, such features

wt!l not totally eliminate this dangerous reaction. As a

chain saw user, do not rely only onsafety devices. You

must follow all safety precautions, instructions and

maintenance in this manual to help avoid kickback and

other forces which can result inserious personal injury.

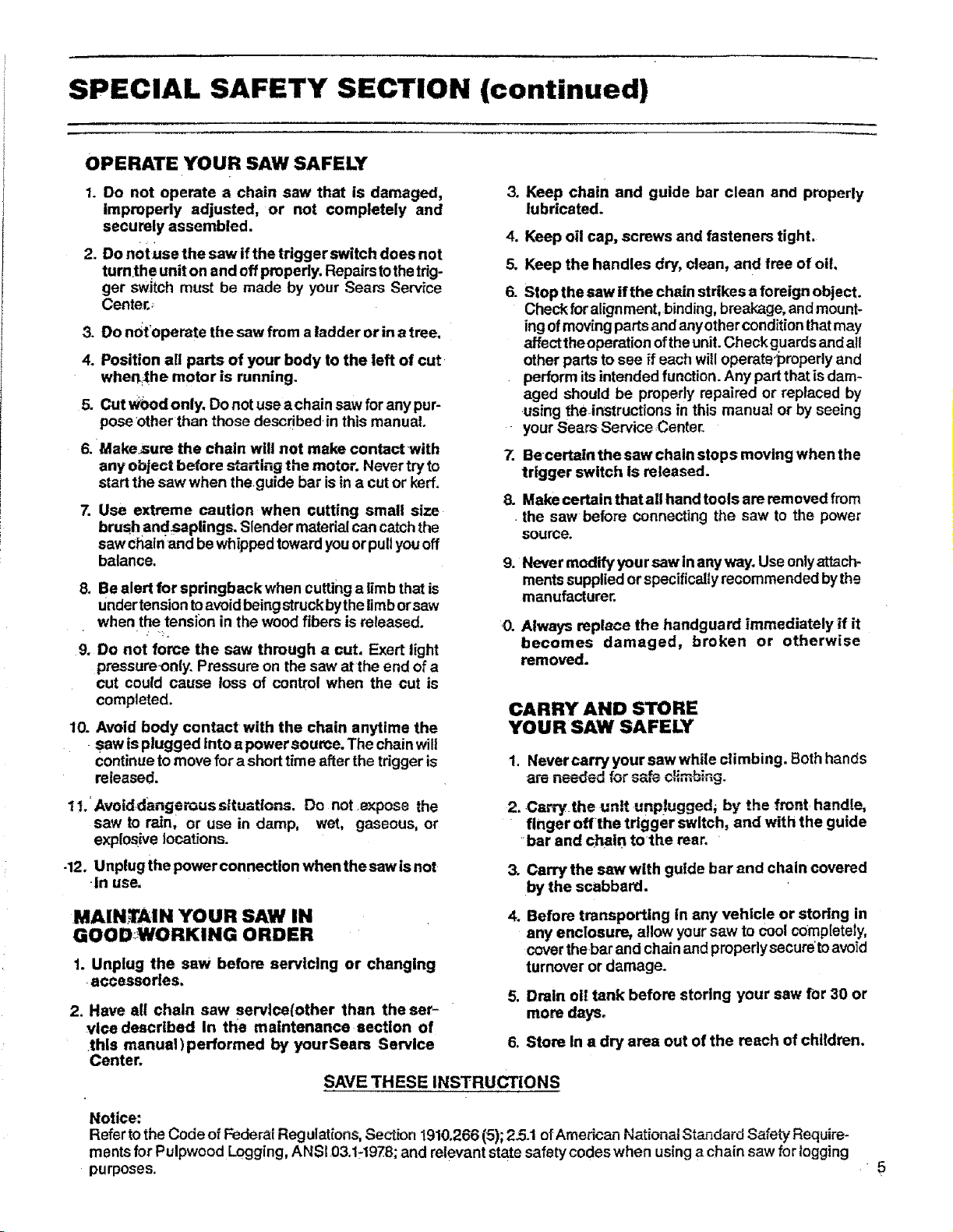

B. KICKBACK SAFETY FEATURES

•-- Red,cad-Kickback GuideBar,designedwithasmall

radiust;'pwhichreducesthesizeofthekickbackdanger

zone on the bar tip. F=gure5. A Reduced I_ckback

Guide Bar is one which has been demonstratedto

significantlyreduce the numberand seriousnessof

kickbackswhentestedin accordance withthesafety

i;eqUifementsforgasolinep<_weredct'_n sawsasset

by the American National Standards Institute,Inc.,

StandaPd8175.1- 1985.

Low-Kickback Chain, designed with a contoured

"'depth gaugeandguardlinkwhichdeflectthekickback

force and allow woodto graduallydde intothe cutter.

Figure5, LowKickbackSawChainis chain whichhas

met thekickback performancerequirementsofANSI

B17_t (SafetyRequirementsfor.Gasoline-Powered

ChainSaws)whentestedonampresentath_sampteof

chainsaws below3,8cubic inchdisplacementspeci.

fled in ANSI B175.1.(American NationalStandards

Institute,Inc.,StandardB175ol- 1985).

m Handguard,designedtoreducethechanceofyour!e_t..

handcontactingthechainifyour handslipsoffthefront

handlebar.

_ _HG_UGE

s_t_l_r K_JUL

¢_LttI_E _U_R

At.L • FORCE &_

• KICK_X

Figure 5

C. DOUBLE INSULATION

YourChain Saw is double insulated to help protect

against electric shock. Ad0ubfe insulatedtoolis con-

structedthroughout withtwb separate "layers" ofelec-

trical insulation or one double thickness of insulation

.between the operator and the electrical system ofthe

tool

Tooisbuilt with this insulation system are notintended

to be grounded. As a result, the extensiOn cord used

withyoursawcan beplugged intoany conventional 120

volt electrical outlet without concern for maintaining a

ground connection.

Safety precautions must be observed when

operating any electrical tool. The double insulation

system only supplies added protection against injury

resulting from a possible electrical insulation failure

within the saw.

D. CARTON CONTENTS

After you unpack the carton:

i. Check the contents against the list below.

2: Examine the items for damage.

& NotifyyourSearsstoreimmediate/yifapartismiss-

ing or damaged,

NOTE:, A rattie-like noise in a powerhead with an

empty oiltank is a normal condition caused by the

filter moving against thewail of the tank.

M_T£RIAI_

--Position of front and rear handlebars, designed

w_thdistance betv,_n handleswhichprovidesbetter

balance andresistance if kickbackoccurs.

.... ::..... Z_WARNING

Do not operate thechain saw unlessthe safety devices

ortheirspeclfied replacements are properly Installed

and maintained according to the Instructions in this

manual. Do notuseanyothergutde barand chain com-

bination that Isnot equtvalentto theodglnai equipment

or not certified to comply with ANSI B175.1.Failure

to follow these Instructions can result In serious per-

sonal Injury.

6

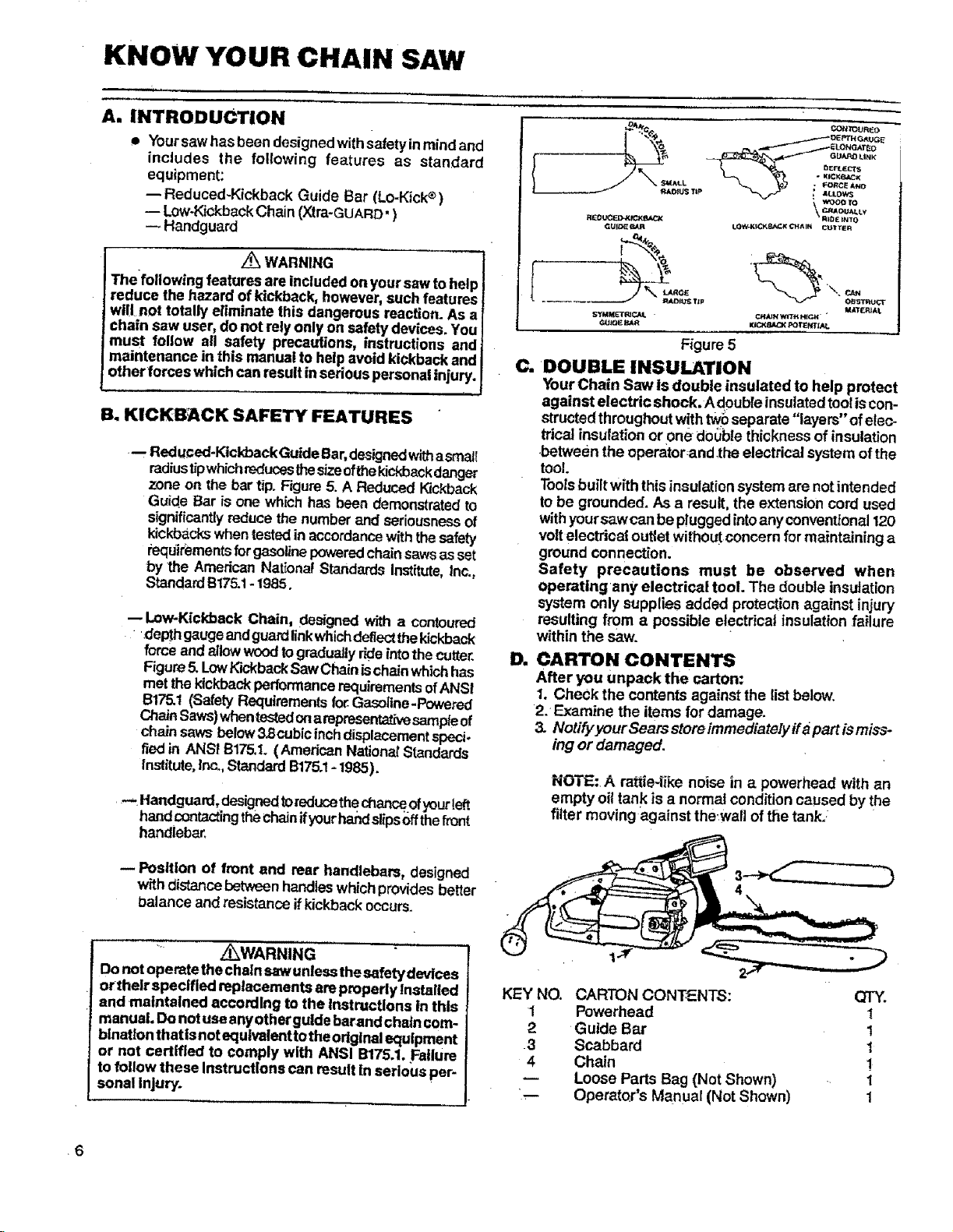

KEY NO.

1

2

3

4

' ,_,,_.

CARTON CONTENTS: QTY.

Powerhead 1

Guide Bar 1

Scabbard 1

Chain !

Loose Parts Bag (Not Shown) I

Operator's Manual (Not Shown) 1

PREPARING YOUR SAW FOR USE

A. GETTING READY

1. READ YOUR OPERATOR'S MANUAL CARE-

FULLY.YourOperator'sManual hasbeen developed

tohelpyou prepare yoursaw for use and to unders-

tand itssafeoperation: Itis importantthat youread

:yourman ualcompletely to becomefamiliar withthe

unit before you begin assembly.

i,,,,,,,,,,,, _ ....

B. POWER SOURCE AND EXTENSION CORD

1.,POWER SOURCE

Use only an A.C. voltage supply identical to that

shown on thename plate_ofthe sawto power this

•.chain saw.

m

Z_WARNING

All electrical repairs to this saw, including housing,

switch, motor, etc., must be diagnosedand repairedby

your_Sears Service Center or nearest Sears store.

Failure to do so can cause the double Insulation

construction to become Ineffective andresuit in

serious personal injury,

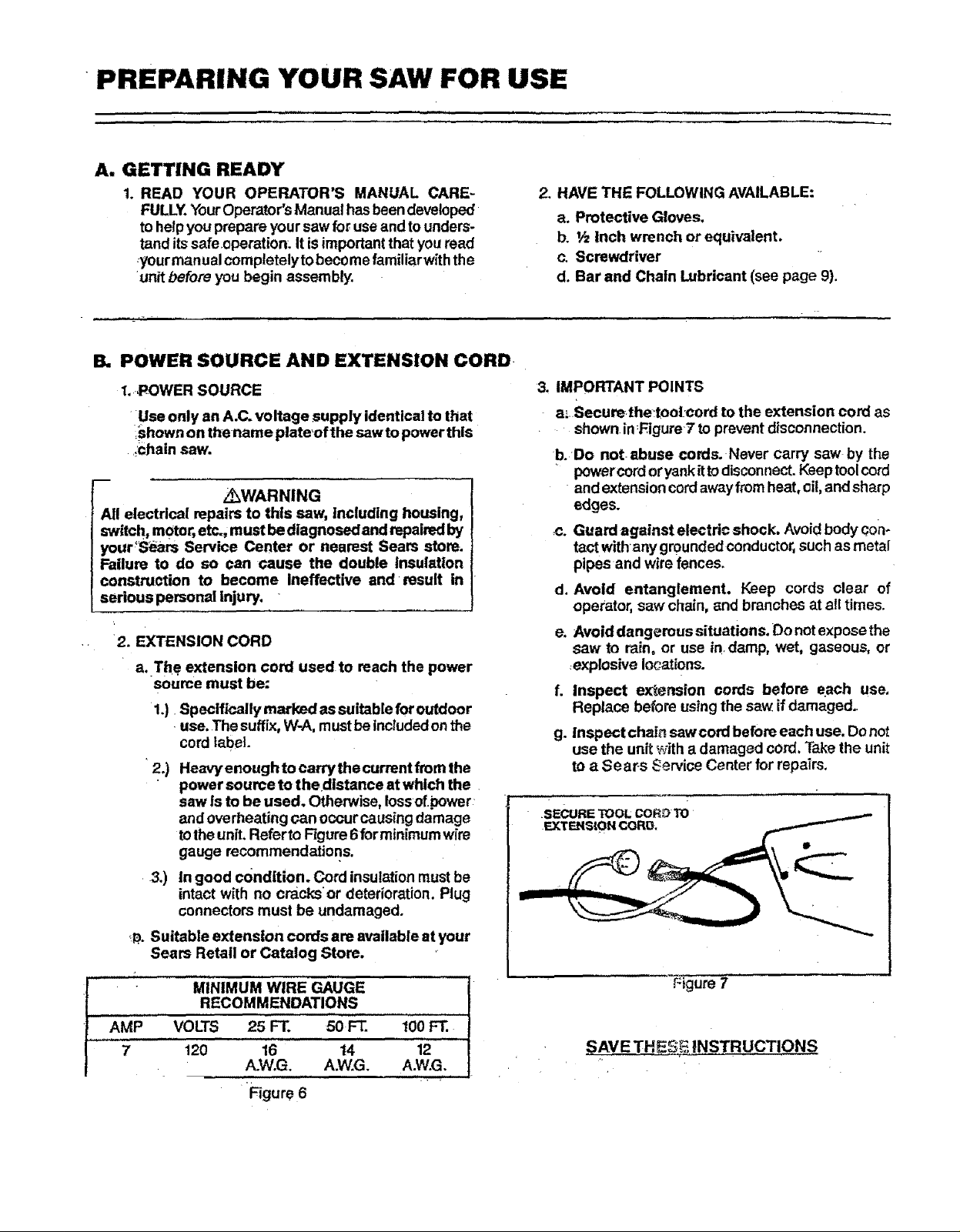

2. EXTENSION CORD

a. The extension cord used to reach the power

source must be:

1.) Specifically marked as suitable for outdoor

use. The suffix, W-A, must beincludedon the

cord label.

2.) Hemty enoughto oarryths current frem the

power source to the distance st which the

saw Is to be used. Otherwise, lossof power

and Dyerheating can occur causing damage

to lhe unit. Refer toRgure 6for minimumwire

gauge recommendations.

3.) In good condition. Cord insulation mustbe

intact with no cracks or deterioration. Plug

connectors must be undamaged.

_. Suitable extension cords are available at your

Sears Retail or Catalog Store.

2. HAVE THE FOLLOWING AVAILABLE:

3. IMPORTANT POINTS

a. Protective Gloves.

b. V=Inch wrench or equivalent.

c. Screwdriver

d. Bar and Chain Lubricant (see page 9).

a._Seeurethe:toolcord to the extension cord as

shown in_FigureT toprevent diseonnection.

borDo not abuse cords. Never carry saw by the

powercord oryank it todisconnect.Keeptoolcord

and extensioncordaway fromheat, oil, and sharp

edges.

<:. Guard against electric shock. Avoid body con*

tact withany grounded conductor,such asmetal

pipes and wire fences.

d. Avoid entanglement. Keep cords clear of

operator, saw chain, _nd branches at all times.

e. Avoiddangeroussituations, Donotexposethe

saw to rain, or use in damp, wet, gaseous, or

explosive locations.

L Inspect extension cords before each use.

Replace before usingthe saw if damaged.

g. Inspect chain saw cord before each use. Donot

use the unit with a damaged cord, Take the unit

to a Sears _ervice Center for repairs.

SECURE TOOL CORDTO

EXTEHS{ONCOP,[},

I AMP7

MINIMUM WIRE GAUGE

RECOMMENDATIONS

VOLTS 25 FT. 50 FT. 100 F_.

120 16 14 12

A.W.G. A.W.G. A.W.G.

Figure 6

Figure7

_;AVE THES_ iNSTRUCTIONS

• Your saw is equipped with a Reduced-Kickback

Guide Barand aLow-Kickback Chain designed to

help reduce kickback.

• Always use the Reduced-Kickback Guide Bar and

low-Kickback chain specified foryour particular

saw, when replacing these parts.

TURN AOJfJST{NGSCREW_K_'_II '_

COUNT_RCLGCK_/9_ISE _

ADJUS_"ING PIN }iDLE EIARCLAMP NUTS

ICAUTION:J Wear protective gloves when hand-

ling oroperaUng your saw. The chain is sharp and

can cut you even when it is not moving!

=___WARNING

Avoid accidental starting. Always unplug the saw

from the power source before installing a bar and/or

chain.

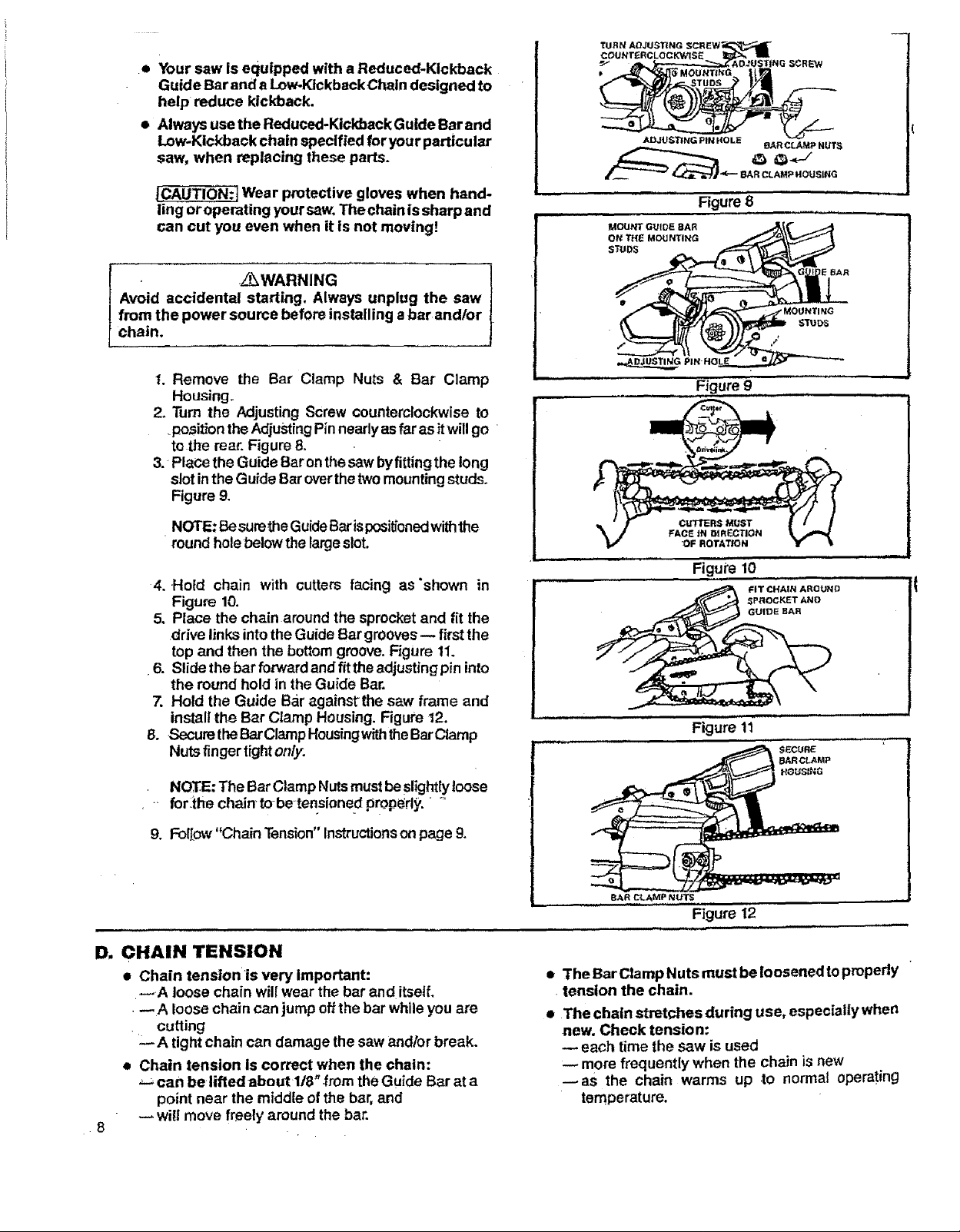

1. Remove the Bar Clamp Nuts & Bar Clamp

Housing.

2, "rum the Adjusting Screw counterclockwise to

•posit_onthe AdjustingPinnearlyas far as it willgo

tothe rear. Figure 8.

3. Place the Guide Bar onthe saw byfittingthe long

slotinthe Guide Bar overthetwo mountingstuds,

Figure 9,

NOTE: BesuretheGuideBar ispositionedwiththe

roundhole belowthe largeslot.

4. Hold chain with cutters facing as'shown in

Figure 10.

5. Place the chain around the sprocket and fit the

drive links intothe Guide Bar grooves-- firstthe

top and then the bottomgroove. Figure 11.

6. Slidethebarforwardandfittheadjustingpin into

the round hold in the Guide Bar.

7. Hold the Guide Bar againstthe saw frame and

install the Bar Clamp Housing. Figure 12.

8. Secure the BarClampHousingwiththe BarClamp

Nutsfinger tighton/y.

MOUNT G_]IDE BAR

ON THE MOUNTING

STUDS

Figure 8

Figure g

Ngute 10

Figure 11

SPROCKET AND

GUIDE BAR

SECUR_

NOT.E:The BarClamp Nutsmust beslightly loose

for:the chain" tobe-tensioned propejrt_'......

9. FolTow Chain Tension Instructions on page 9.

D. CHAIN TENSION

• Chain tenslonis very Important:

--A loose chain will wear the bar and itself.

•_A loose chain canjump off the bar whileyou are

cutting

L- A tight chain can damage the saw andlor break.

• Chain tension is correct when the chain:

_-;can be liffedabout 1t8" from the Guide Bar at a

point near the middle of the bar,and

•8

wi!l move freely around the bar.

BAR C_AMP NUT_

Figure 12

,,,,,, ,,,, j ,,,,,,,,u,,, i

• The Bar Clamp Nuts must be loosened topropedy

tension the chain.

• The chain stretches during use, especial|y when

new. Check tension:

each time the saw is used

more frequently when the chain isnew

_as the chain warms up to normal operating

temperature.

_- /t_WARNING

I Avoid accidental starting. Always unplug the saw

I from the power source before adjusting chain

I tension.

1, Hold the tip ofthe Guide Bar up and turn the Adjust-

ingScrew clockwisejustuntilthe chain does notsag

beneath the Guide Bar. Figure 13.

NOTE: Totighten tension, turn the adjusting screw

clockwise _ .Toloosentension, turn the adiust-

ing!screw counterclockwise_.

2. Check the tension byliftingthe chainfrom the Guide

Ba_"at the center of the bar.Figure 14.

3: C_ntinueturning the AdjustingScrew until the ten-

sion is correct,

4, Hold the tipofthe Guide Bar upand tighten the Bar

Clamp Nuts with awrench.

5. Recheck tension.

AOJUSTING

TURN TUR_

TO T_HTIEN TO LOOSEN

TENSION TF3415_ON

Figure 13

Figure 14

Ell BAR AND CHAIN OIL

• The guide bar and cutting chain require con-

tinuous lubrication in order to remain in

operating condition.

--Lack of oil will quickly ruin the bar and

chain.

--Too little oil will cause overheating shown

by smoke coming from the chain and/or

discoloration of the guide bar raits.

e_0se Sears Bar and Chain Lubricant #71-

36554 to fill the oil tank. Clean SAE 30W oil

may also be.used. Never use waste oil for this

,purpose.

1. IMPORTANT POINTS

a.;Fill the oil tank every time you use the saw.

b. Wipe off surfaces before filling with oil to

avoid sawdust or debris accidently falling

into the tank and causing damage.

c. Use a funnel to fill the tank and wipe up all

spills. Do not use the saw until it is wiped

clean an_3is completely dry fr_omspil+iedoil.

.d, Reptace the oil c=,p securely to ensure

proper operation of the oiler.

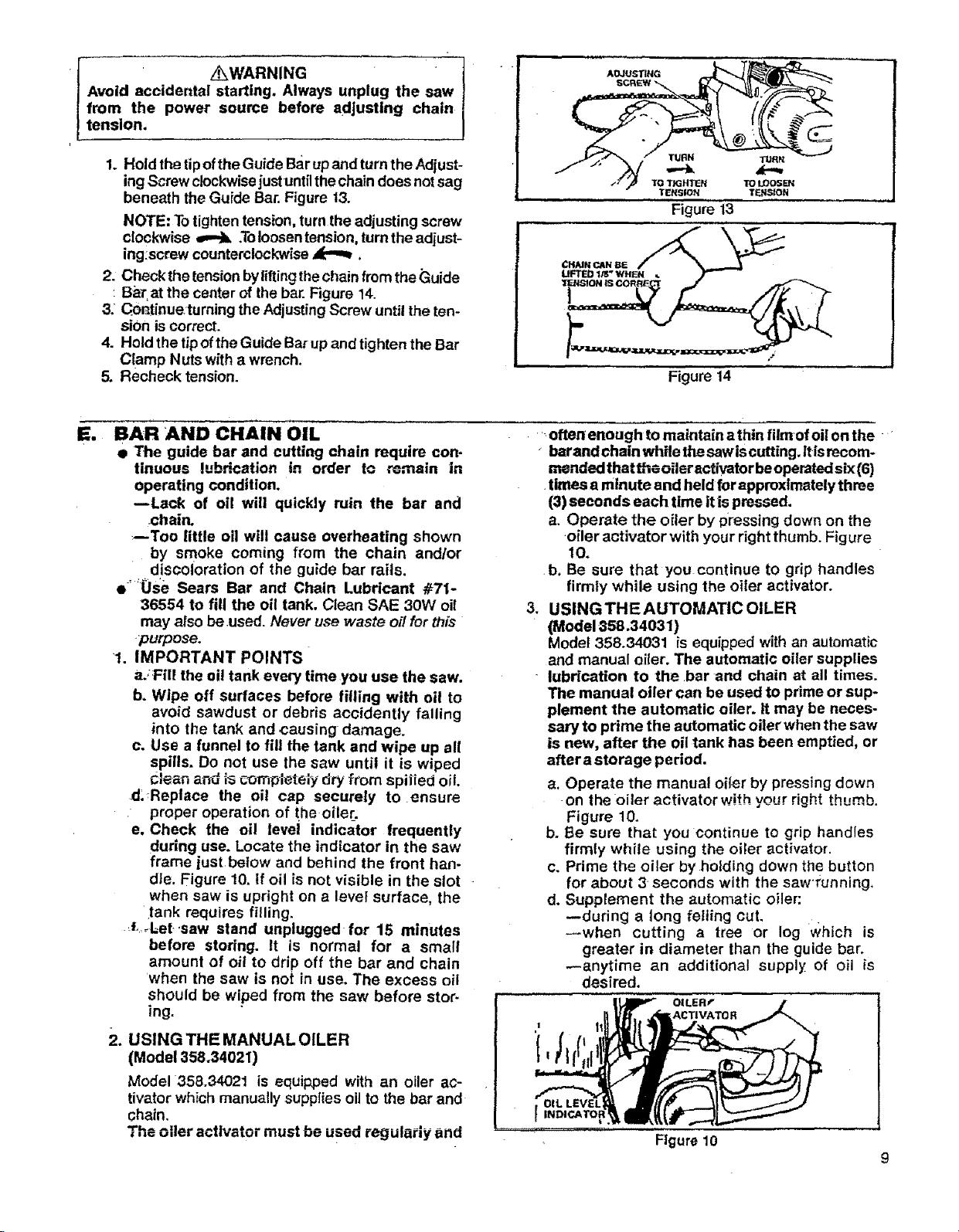

e, Check the oil level indicator frequently

during use. Locate the indicator in the saw

frame just betow and behind the front han-

dle. Figure 10. If oil is not visible in the slot

when saw is upright on a level surface, the

tank requires filling,

_fJ,_bet-.saw stand unplugged for 15 minutes

before stodng. It is normal for a small

amount of oil to drip off the bar and chain

when the saw is not in use. The excess oil

should be wiped from the saw before stor-

ing.

2. USING THE MANUAL OILER

(Model 358.34021)

Model 358.34021 is equipped with an oiler ac-

tivator which manually suppfies oil to the bar and

chain,

The oiler activator must be used regularly and

oftenenough to maintain a thin filmof oil on the

-barand chain w'nilethesawis cutting, Itisrecom-

msnded that the oileractivater beoperatedsix(6)

times aminute and held for approximately th me

(3) seconds each time itis pressed.

a. Operate the offer by pressing down on the

oiler activator with your right thumb. Figure

10.

b. Be sure that you continue to grip handles

firmly while using the oiter activator.

.

USING THE AUTOMATIC OILER

(Model 358.34031)

Model 358.34031 is equipped withan automatic

and manual oiler. The automatic oiler supplies

lubrication to the bar and chain at all times.

The manual oiler can be used to prime or sup-

plement the automatic oiler, it may be neces-

saw to prime the automatic oiler when the saw

is new, after the oil tank has been emptied, or

after a storage period.

a. Operate the manual oiler by pressing down

on the oiler activator with your right thumb.

Figure 10.

b. Be sure that you continue to grip handles

firmiy while using the oiler activator.

c. Prime the oiler by holding clown the button

for about 3-seconds with the sawrunning,

d. Supplement the automatic oiler:

--dudng a long letting cut.

--when cutting a tree or log which is

greater in diameter than the guide bar.

_anytime an additional supply of oil is

desired.

OlLERf

AC 1"1VATO R

.... Figure 10

9