Craftsman 35328640 Owner’s Manual

I PROFESSIO NAL I

RECiPROCATiNG SAW

Variable Angme

Doubme lnsumated

ModeJ No.

353°28640

CAUTION: Read the Safety

GuideHines and AH instructions

Carefully Before Operating this tool

Sears, Roebuck and Co., Hoffman Estates, mL(}0179 U.S.A.

Visit our Craftsman website: <www.sears.com!craftsman>

A03284- 08-16-04 Espahol, p. 21

o Safety Guidelines

o

o Maintenance

o Service

o Repair Parts

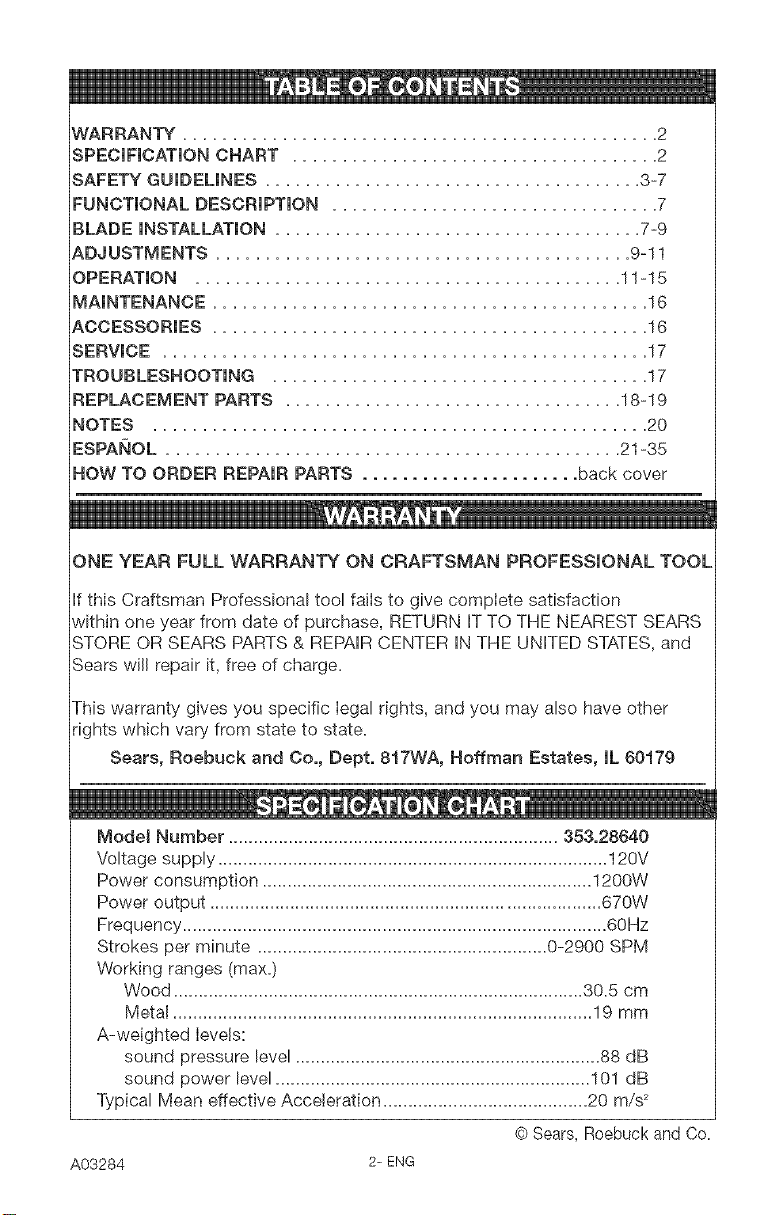

WARRANTY ................................................ 2

SPECiFiCATiON CHART ..................................... 2

SAFETY GUiDELiNES ...................................... 3-7

FUNCTIONAL DESCRiPTiON ................................. 7

BLADE iNSTALLATiON ..................................... 7-9

ADJUSTMENTS .......................................... 9-11

OPERATION ........................................... t 1-15

MAINTENANCE ............................................ t 6

ACCESSORIES ............................................ 16

SERVICE ................................................. 17

TROUBLESHOOTING ...................................... 17

REPLACEMENT PARTS .................................. t 8-19

NOTES .................................................. 20

ESPA_IOL .............................................. 21-35

HOW TO ORDER REPAIR PARTS ...................... back cover

ONE YEAR FULL WARRANTY ON CRAFTSMAN PROFESSIONAL TOOL

this Craftsman Professional tool fails to give complete satisfaction

within one year from date of purchase, RETURN IT TO THE NEAREST SEARS

STORE OR SEARS PARTS & REPAIR CENTER IN THE UNITED STATES, and

Sears will repair it, free of charge=

This warranty gives you specific legal rights, and you may also have other

rights which vary from state to state.

Scars, Roebuck and Co., Dept. 817WA, Noffman Estates, IL 60179

Model Number .................................................................. 353°28640

Voltage supply .............................................................................. 120V

Power consumption .................................................................. 1200W

Power output .............................................................................. 670W

Frequency ..................................................................................... 60Hz

Strokes per minute .......................................................... 0-2900 SPM

Working ranges (max.)

Wood .................................................................................. 30.5 cm

Metal .................................................................................... 19 mm

A-weighted levels:

sound pressure level ............................................................. 88 dB

sound power level ............................................................... 101 dB

Typical Mean effective Acceleration ......................................... 20 m/s_

6) Sears, Roebuck and Co.

A03284 2- ENG

Thismanualcontainsinformationthatisimportantforyoutoknowandunder-

stand.ThisinformationrelatestoprotectingYOURSAFETYandPREVENTING

EQUIPMENTPROBLEMS.Tohelpyourecognizethisinformation,weusethe

symbolsbelow.Pleasereadthemanualandpayattentiontothesesections.

indicatesanimminentlyhazardoussituationwhich,ifnot

avoided,willresultindeathorseriousinjury.

indicatesapotentiallyhazardoussituationwhich,ifnot

avoided,couldresultindeathorseriousinjury.

indicatesapotentiallyhazardoussituationwhich,ifnot

avoided,mayresultinminorormoderateinjury.

usedwithoutthesafetyalertsymbolindicatespotentially

hazardoussituationwhich,if notavoided,mayresultin

propertydamage.

Somedustcreatedbypowersanding,sawing,grinding,drilling,

andotherconstructionactivitiescontainschemicalsknown(to

theStateofCalifornia)tocausecancer,birthdefectsorotherreproductiveharm.

Someexamplesofthesechemicalsare:

leadfromIead-basedpaints

crystallinesilicafrombricksandcementandothermasonryproducts

® arsenicandchromiumfromchemically-treatedlumber

Yourriskfromtheseexposuresvaries,dependingonhowoftenyoudothis

typeofwork.Toreduceyourexposuretothesechemicals:workinawetI

ventilatedarea,andworkwithapprovedsafetyequipment,alwayswear

MSHA/NIOSHapproved,properlyfittingfacemaskorrespiratorwhenusing

suchtools.

ReadandunderstandaHinstructions,Failureto

allinstructionslistedbelow,mayresultinelectricshock,fire

and/orseriouspersonalinjury.

SAVETHESEINSTRUCTIONS,

WORK AREA

1o Keep your work area clean and well mit.Cluttered benches and dark

areas invite accidents.

2, Do not operate power tooms in expmosive atmospheres, such as in

the presence of flammable liquids, gases, or dust, Power tools

create sparks which may ignite the dust or fumes.

3, Keep bystanders, children, and visitors away while operating a

power tool Distractions can cause you to lose control.

ELECTRICAL SAFETY

1, Double insulated tooms are equipped with a polarized pBug (one

bmade is wider than the other}, This plug will fit in a polarized outmet

only one way, If the plug does not fit fully in the outlet, reverse the

pmug, If it still does not fit, contact a qualified emectrician to install a

poBarized outBet, Do not change the plug in any way, Double

Insulation [] eliminates the need for the three wire grounded power

cord and grounded power supply system.

2, Avoid body contact with grounded surfaces such as pipes,

radiators, ranges and refrigerators, There is an increased risk of

electric shock if your body is grounded.

3- ENG A03284

3, Don't expose power tooms to rain or wet conditions, Water entering

a power tool will increase the risk of electric shock.

4, Do not abuse the cord, Never use the cord to carry the rooms or pull the

plug from an outmet, Keep cord away from heat, oil, sharp edges or

moving parts, Replace damaged cords immediately,. Damaged cords

increase the risk of electric shock.

5, When operating a power too_ outside, use an outdoor extension cord

marked "W-A" or "W", These cords are rated for outdoor use and reduce

the risk of electric shock.

PERSONAL SAFETY

1, Stay alert, watch what you are doing, and use common sense when

operating a power tool, Do not use tool while tired or under the

influence of drugs, alcohom, or medication, A moment of inattention while

operating power tools may result in serious personal injury.

2, Dress proper{y. Do not wear loose c_otHng or jewemry. Contain mong

hair. Keep your hair, cmothing, and gloves away from moving parts,

Loose clothes, ]eweIry, or long hair can be caught in moving parts.

3, Avoid accidental starting, Be sure switch is OFF before pgugging in,

Carrying tools with your finger on the switch or plugging in tools that have

the switch ON invites accidents.

4, Remove adjusting keys or wrenches before turning the tool on, A

wrench or a key that is left attached to a rotating part of the tool may result

in personal injury:

5, Do not overreach, Keep proper footing and balance at aH times, Proper

footing and batance enables better control of the tool in unexpected

situations.

6, Use safety equipment. ABways wear eye protection, Dust mask, non-

skid safety shoes, hard hat, or hearing protection must be used for

appropriate conditions.

7. Use certified safety equipment, Eye protection equipment shouid comply

with ANSI Z87.1 standards, hearing equipment should comply with ANSI

$3.19 standards, and dust mask protection should comply with

MSHA/NIOSH certified respirator standards.

8, Never touch blade immediatemy after use, Contact with a hot blade will

increase the risk of a bum.

TOOL USE AND CARE

1, Use cmamps or other practicaB way to secure and support the

workpiece to a stable platform, Holding the work by hand or against your

body is unstable and may lead to Ioss of control

2, Do net force tool, Use the correct toomfor your appBication, The correct

tool will do the job better and safer at the rate for which it is designed.

3, Do not use toot if switch does not turn it on or off, Any toot that cannot

be controlled with the switch is dangerous and must be repaired.

4, Disconnect the plug from the power source before making any

adjustments, changing accessories, or storing the tool, Such preventive

safety measures reduce the risk of starting the toot accidentally.

5, Store idBetoo{s out of reach of children and other untrained persons,

Tools are dangerous in the hands of untrained users.

6, Maintain tooms with care, Keep cutting tooms sharp and cmean, Properly

maintained tools with sharp cutting edge are less likely to bind and are

easier to control

7, Check for misamignment or binding of moving parts, breakage of parts,

and any other condition that may affect the tool's operation, If

damaged, have the toomserviced before using, Many accidents are

caused by poorly maintained tools.

A03284

4- ENG

8, Use only accessories that are recommended by the manufacturer for

your model Accessories that may be suitable for one tool may become

hazardous when used on another tool.

9, Use only accessories recommended for this toomthat are sold by Sears

or a Craftsman outlet, Use of any accessories purchased elsewhere may

be hazardous.

SERVICE

1, Tool service must be performed only by qualified repair personnel

Service or maintenance performed by unqualified personnel could result

in a risk of injury.

2, When servicing a tool, use onmyidenticam replacement parts, Folmow

instructions in the Maintenance Section of this manual Use of

unauthorized parts or failure to follow Maintenance Instructions may

create a risk of shock or injury.

1, Hold toomby insulated gripping surfaces when performing an

operation where the cutting tooB may contact hidden wiring or its

own cord, Contact with a "live" wire will make exposed metal parts of

the tool "live" and shock the operator.

2, Keep blades sharp, Sharp blades will do the iob better and safer.

3, Keep hands away from cutting area. When sawing never reach

underneath or behind the material being cut for any reason.

4, When you have finished a cut be careful not to come into contact

with the Made, Turn off the motor immediately.

5. Never homdwork in your hand, lap, or against other parts of your

body when sawing, The saw may slip and the blade could contact the

body, causing injury.

Exercise extreme caution when bBind cutting, Blade

contact with foreign objects such as electrical wire, conduit,

ptumbing pipes, etc., could result in a risk of shock or serious

injury.

Some wood contains preservatives which can be toxic,

Take extra care to prevent inhamation and skin contact when

working with these materiaBs, Dust or fumes from this

operation could cause breathing problems, skin irritation or

other injuries.

This tool was designed for certain applications mikethose

described in this manual Incorrect use of this tool

could result in death or serious injury. DO NOT modify or use

this tool for any application for which it was NOT designed.

5-ENG A03284

SYMBOL

V

A

Hz

W

kW

_F

........................ volts

........................ amperes

........................ hertz

........................ watts

........................ kilowatts

........................ microfarads

DEFINITION

........................ liters

kg

N/cm 2

Pa

h

min

s

........................ kilograms

........................ newtons per square centimeter

........................ pascals

........................ hours

........................ minutes

........................ seconds

........................ alternating current

3F'_

3N f-'LJ

........................ three-phase alternating current

........................ three-phase alternating current with neutral

........................ direct current

n o

........................ no load speed

........................ alternating or direct current

........................ Class li Construction

........................ splash-proof construction

_ ........................ watertight construction

._/min ........................ revolutions or reciprocation per minute

MOTOR

Some tools will operate on either

D.C. or single phase 25 to 60 cycle

A.C. current and voltage within plus or

minus 5 percent of that shown on the

tool specification plate. Some models,

however, are designed for A.C.

current only. Refer to the specification

plate on your tool for proper voltage

and current rating.

Do not operate tools

rated A,C. onmyon D,C, current, To do

so may seriously damage the tool

EXTENSION CORD SELECTmON

if an extension cord is used, make

sure the conductor size is large

enough to prevent excessive voltage

drop which will cause loss of power

and possible motor damage. A table

of recommended extension cord

sizes will be found in this section.

This table is based on limiting line

A03284 6= ENG

voltage drop to 5 volts (10 volts for

230 volts) at 150% of rated amperes.

if an extension cord is to be used

outdoors it must be marked with the

suffix W-A following the cord type

designation. For example - SJTW-A

to indicate it is acceptable for

outdoor use.

RECOMMENDEDEXTENSIONCORDSIZESFORUSEW_THPORTABLEELECTRICTOOLS

LengthofCordinFeet

115V25Ft_ 50Ft_100Ft, 150Ft_200Ft. 250Ft,300Ft_400Ft_500Ft,

230V50Ft_100Ft_200Ft. 300Ft_400Ft, 500Ft.600Ft_800Ft_1000Ft.

0-2 18 18 18 16 16 14 14 12 12

2-3 18 18 16 14 14 12 12 10 10

._ 3-4 18 18 16 14 12 12 10 10 8

4-5 18 18 14 12 12 10 10 8 8

8-6 18 16 14 12 10 10 8 8 6

6-8 18 16 12 10 10 8 6 6 6

8-10 18 14 12 10 8 8 6 6 4

®

10-12 16 14 10 8 8 6 6 4 4

z 2-14 16 12 10 8 6 6 6 4 2

14-16 16 12 10 8 6 6 4 4 2

16-18 14 12 8 8 6 4 4 2 2

18-20 14 12 8 6 6 4 4 2 2

FOREWORD

The variable angle reciprocating saw various other materials, such as

is designed for cutting wood up to plastics, fiberglass, hard rubber, etc.

12" thick, metal up to 3/4" thick and

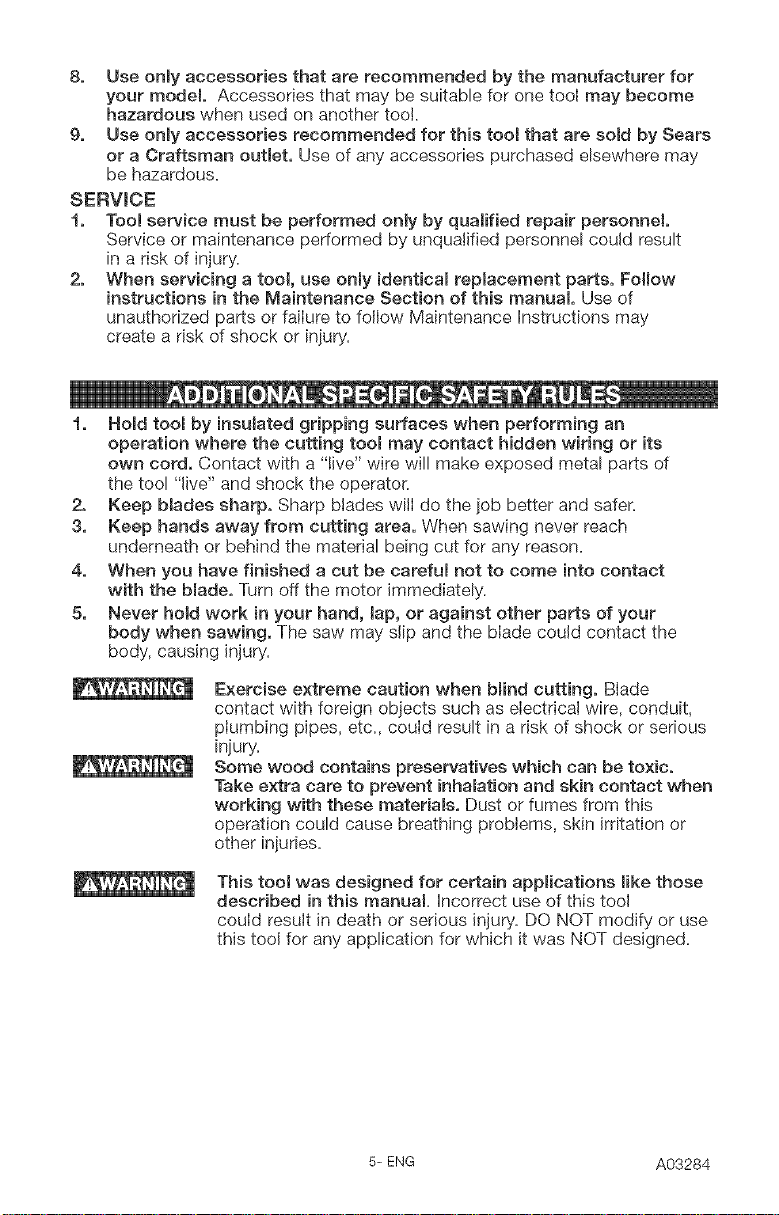

INSTALLING THE BLADE

1. The reciprocating shaft must be

fully extended to permit access to

the keyless quick-change blade

release collar (A) Fig. 1. If

necessary, gently squeeze the

trigger switch to move the

reciprocating shaft to its

outermost position (as shown in

Fig.1).

Fig. I

Disconnect teem

from power source,

Pivot the guide shoe (B) Fig. 1,

forward to improve access to the

blade clamp.

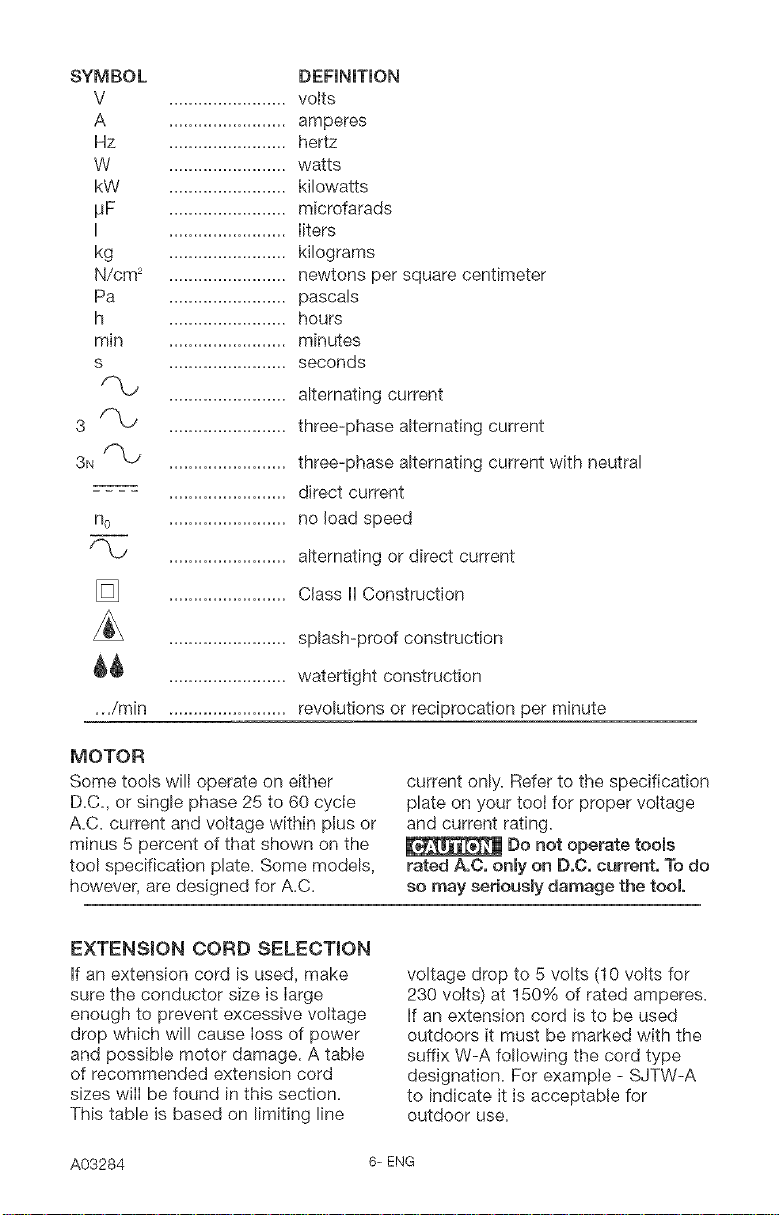

To open the blade clamp, rotate

and hold the blade retease collar

(A) Fig, 2 or Fig, 3 counter-

clockwise (as viewed from the front

of the saw).

Fig. 2

7- ENG A03284

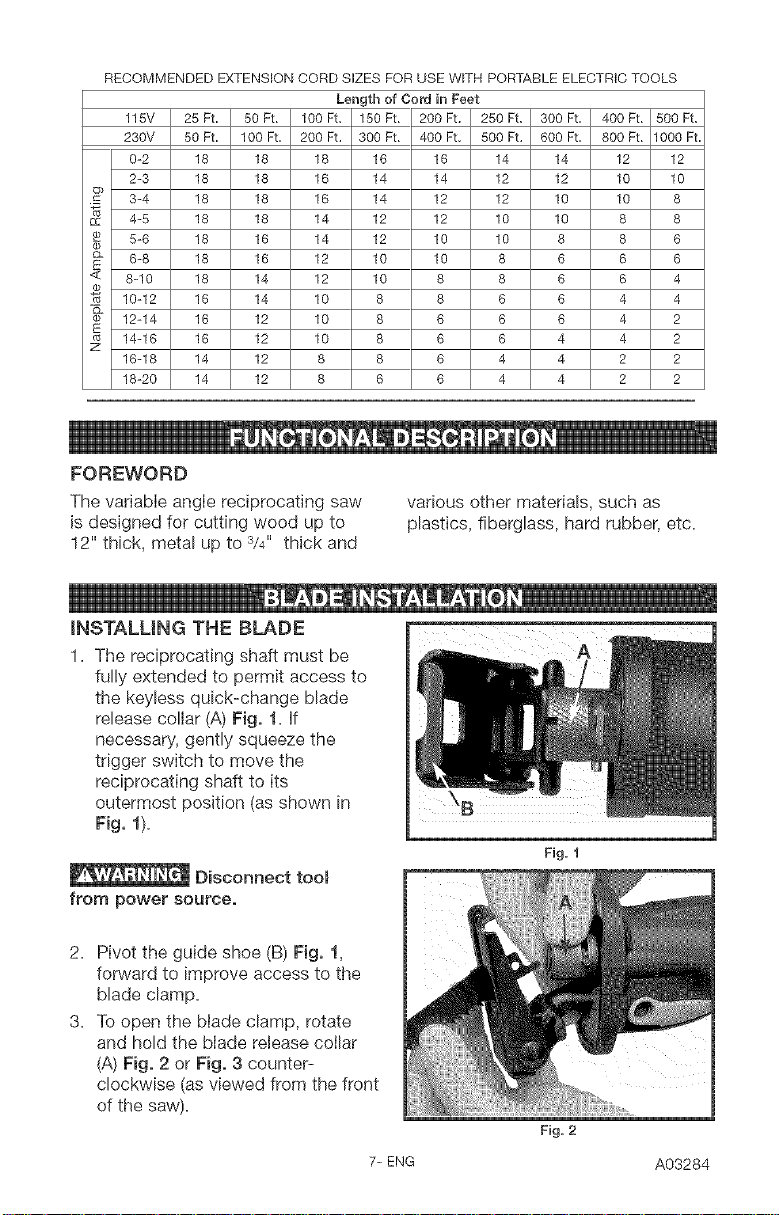

NOTE: The keytess quick-change

pivoting guide shoe can be

temporarily removed to make

blade installation easier. Release

locking lever (B) Fig. 3 to remove

(see PIVOTING GUIDE SHOE

ADJUSTMENT section of this

manual).

Do not operate the

roomwith the guide shoe removed.

4. insert the blade into the clamp

until it hits bottom. Allow the

release collar (A) Fig. 3A to rotate

clockwise to lock the blade in

place. Close locking lever (B).

NOTE: The blade can be installed

upside down if preferred, for

better reach in tight fitting

applications.

5. To remove blade, repeat steps 1

through 3, and pull blade from

blade clamp while holding the

release collar in the open

position.

NOTE: if the blade clamp collar

resists rotation to remove a blade,

work the blade up and down while

rotating the clamp (in a counter-

clockwise direction).

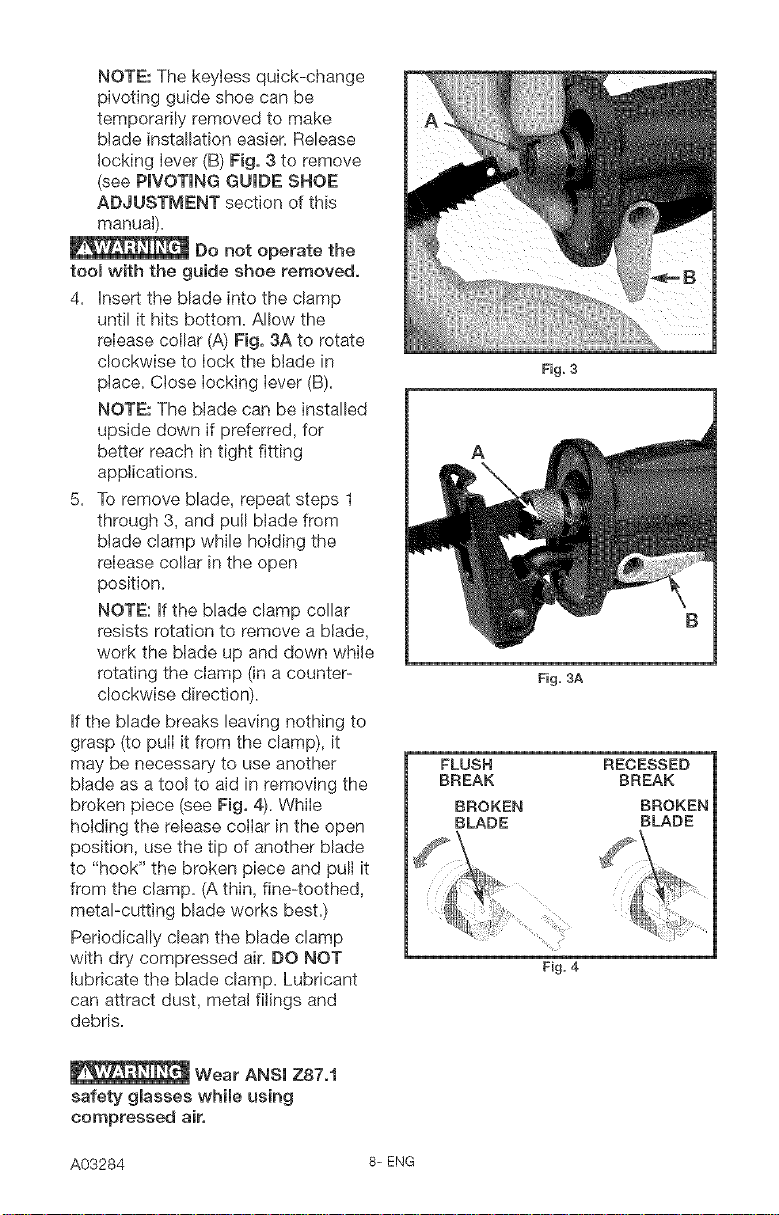

if the blade breaks leaving nothing to

grasp (to pull it from the clamp), it

may be necessary to use another

blade as a tool to aid in removing the

broken piece (see Fig. 4). While

holding the release collar in the open

position, use the tip of another blade

to "hook" the broken piece and pull it

from the clamp. (A thin, fine-toothed,

metal-cutting blade works best.)

Periodically clean the blade clamp

with dry compressed air. DO NOT

lubricate the blade clamp. Lubricant

can attract dust, metal filings and

debris.

A

FLUSH

BREAK

BROKEN

BLADE

Fig. 3

B

Fig. 3A

RECESSED

BREAK

BROKEN

BLADE

Fig. 4

Wear ANSI Z87,1

safety glasses while using

compressed air.

A03284 8- ENG

INSTALLING THE OPTmONAL

BLADE ADAPTER

Disconnect tool from

power source,

1, Standard jig saw blades may be

used in the vadabIe angle

reciprocating saw with the proper

blade adapter installed (sold

separately), To prepare for

installing a standard jig saw blade

follow steps 1 through 3 in

INSTALLING THE BLADE section

of this manual,

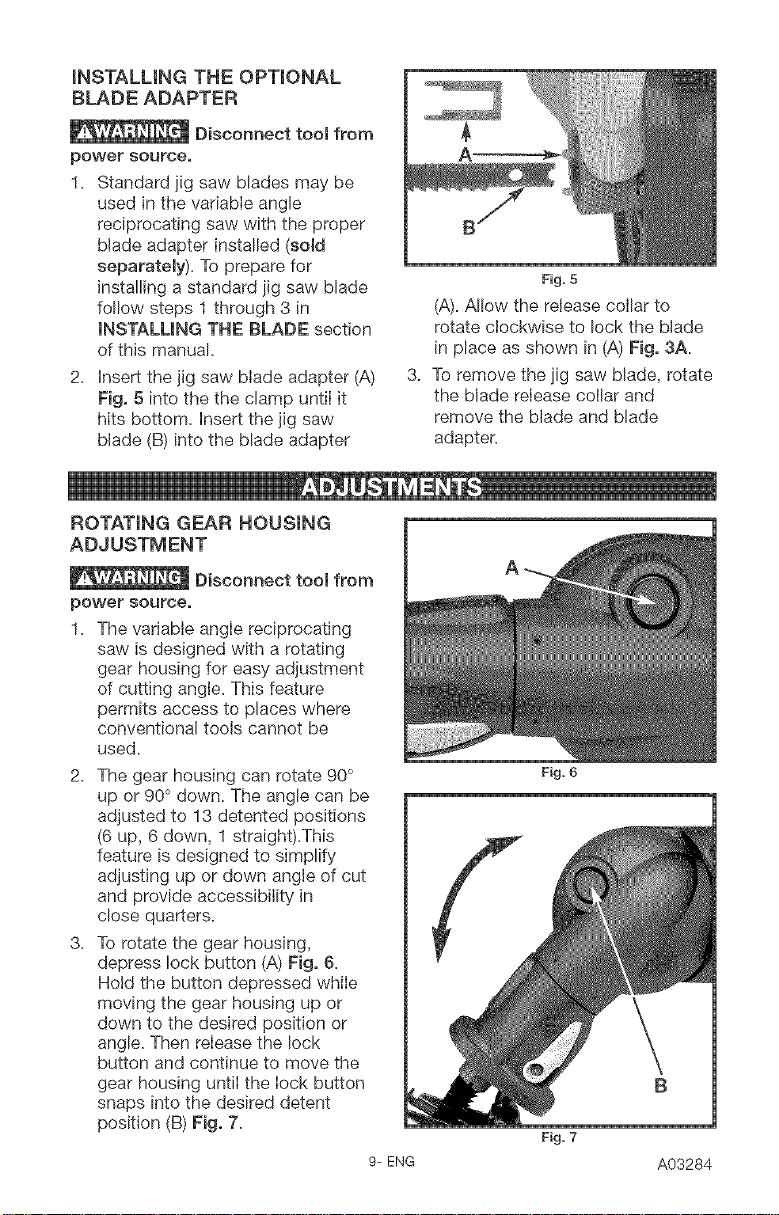

2, Insert the jig saw blade adapter (A)

Fig. 5 into the the clamp untiI it

hits bottom, Insert the jig saw

blade (B) into the blade adapter

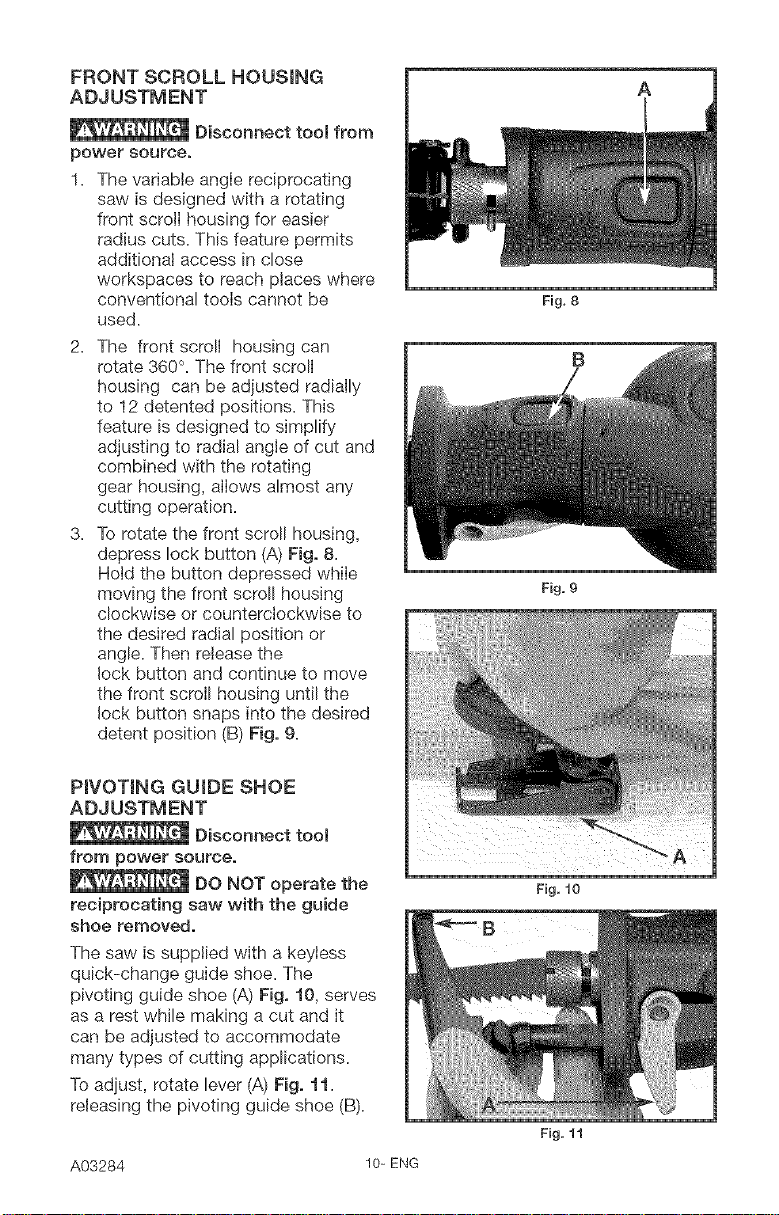

ROTATING GEAR HOUSING

ADJUSTMENT

Disconnect tool from

power source,

1, The variable angIe reciprocating

saw is designed with a rotating

gear housing for easy adjustment

of cutting angle. This feature

permits access to places where

conventional tools cannot be

used,

The gear housing can rotate 90°

up or 90 ° down, The angle can be

adjusted to 13 detented positions

(6 up, 6 down, 1 straight),This

feature is designed to simplify

adjusting up or down angle of cut

and provide accessibility in

close quarters,

To rotate the gear housing,

depress lock button (A) Fig. 6,

Hotd the button depressed while

moving the gear housing up or

down to the desired position or

angle, Then reIease the lock

button and continue to move the

gear housing until the Iock button

snaps into the desired detent

position (B) Fig. 7,

A'

Fig, 5

(A)_Allow the release collar to

rotate clockwise to lock the blade

in place as shown in (A) Fig. 3A.

3, To remove the jig saw blade, rotate

the blade release collar and

remove the blade and blade

adapter,

Fig. 6

Fig. 7

9- ENG

A03284

FRONT SCROLL HOUSING

ADJUSTMENT

Disconnect tool from

power source,

1. The variable angle reciprocating

saw is designed with a rotating

front scroll housing for easier

radius cuts. This feature permits

additional access in close

workspaces to reach places where

conventional tools cannot be

used.

The front scroll housing can

rotate 360°. The front scroll

housing can be adjusted radially

to 12 detented positions. This

feature is designed to simplify

adjusting to radial angle of cut and

combined with the rotating

gear housing, allows almost any

cutting operation.

To rotate the front scroll housing,

depress lock button (A) Fig, 8.

Hold the button depressed while

moving the front scroll housing

clockwise or counterclockwise to

the desired radial position or

angle. Then release the

lock button and continue to move

the front scroll housing until the

lock button snaps into the desired

detent position (B) Fig, 9.

A

Fig, 8

B

Fig. 9

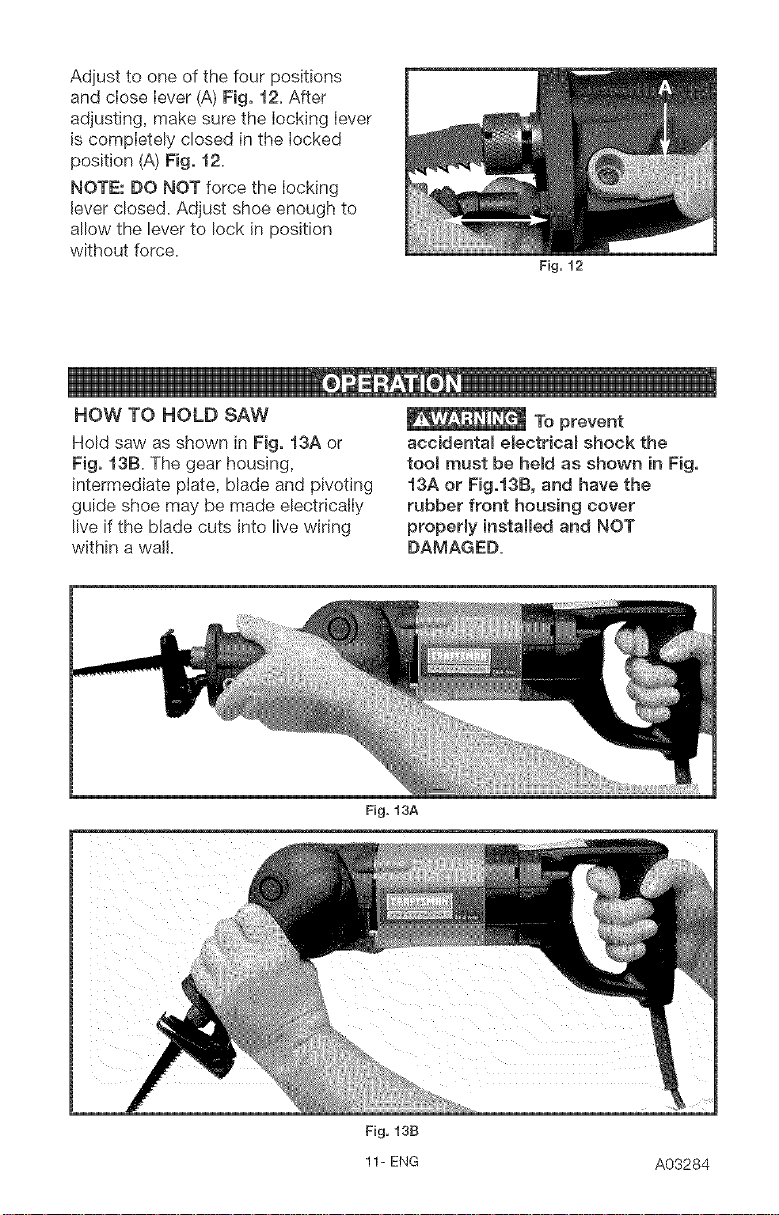

PIVOTING GUIDE SHOE

ADJUSTMENT

Disconnect tool

from power source,

DO NOT operate the

reciprocating saw with the guide

shoe removed,

The saw is supplied with a keyiess

quick-change guide shoe. The

pivoting guide shoe (A) Fig, f0, serves

as a rest while making a cut and it

can be adjusted to accommodate

many types of cutting applications.

To adjust, rotate lever (A) Fig, 11.

releasing the pivoting guide shoe (B).

A03284 10-ENG

Fig. 10

Fig. 11

Adjust to one of the four positions

and close lever (A) Fig. 12. After

adjusting, make sure the locking lever

is completely closed in the locked

position (A) Fig. 12.

NOTE: DO NOT force the locking

lever closed. Adjust shoe enough to

allow the lever to lock in position

without force.

Fig. 12

HOW TO HOLD SAW

Hold saw as shown in Fig. 13A or

Fig. 13Ba The gear housing,

intermediate plate, blade and pivoting

guide shoe may be made electrically

live if the blade cuts into live wiring

within a wail

To prevent

accidental electricaB shock the

tooB must be held as shown in Fig,

i3A or Fig.i3B, and have the

rubber front housing cover

properly installed and NOT

DAMAGED=

Fig. 13A

Fig, 13B

11- ENG A03284

Loading...

Loading...