Craftsman 351275931 Owner’s Manual

Operator's Manual

CRR.FTSMRN°

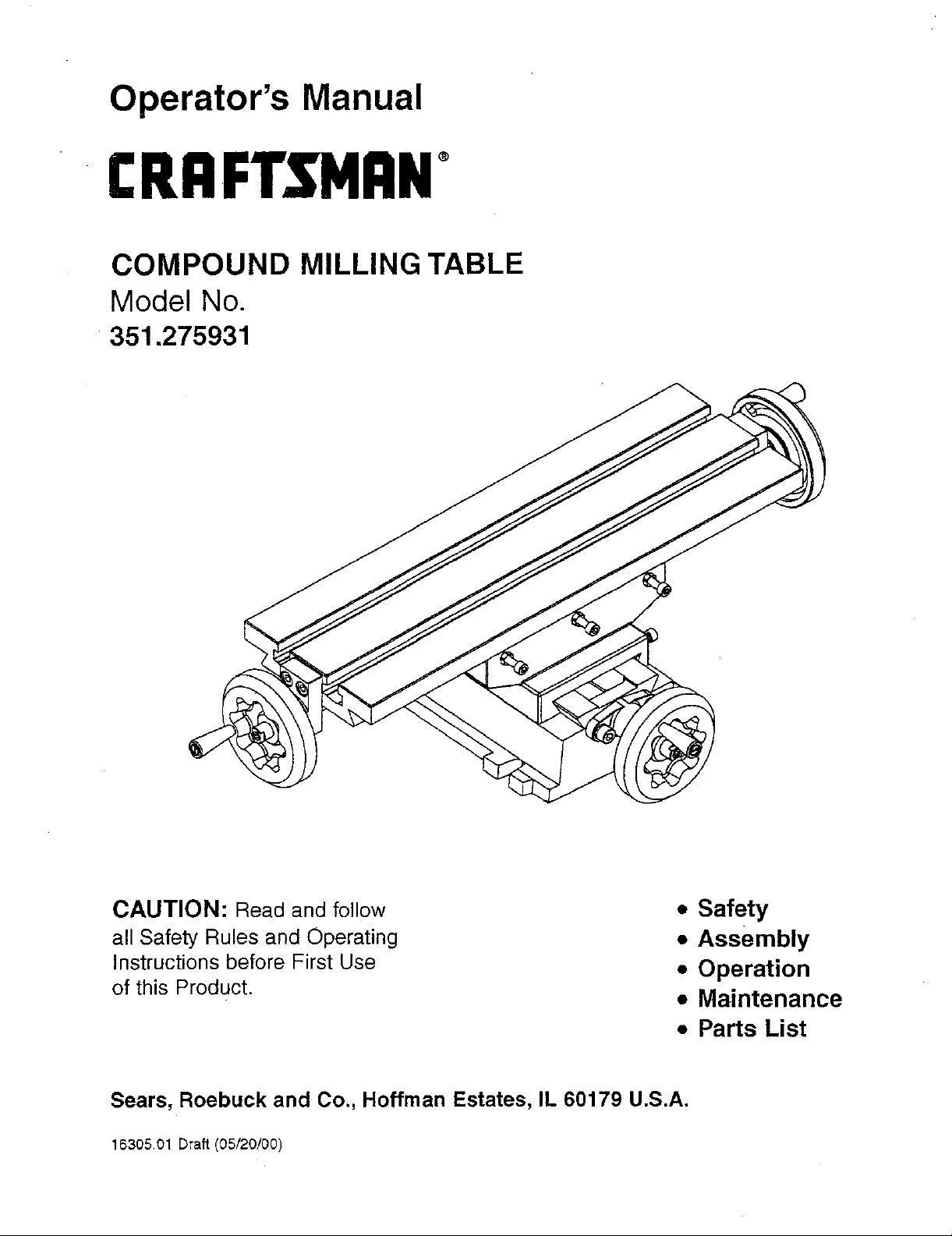

COMPOUND MILLING TABLE

Model No.

351.275931

CAUTION: Read and follow

all Safety Rules and Operating

Instructions before First Use

of this Product.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

16305.01 Draft (05/20/00)

• Safety

• Assembly

• Operation

• Maintenance

• Parts List

Warranty ....................................... 2

Safety Rules .................................... 2

Unpacking ..................................... 2

Assembly ....................................... 2

Operation .................................... 2-3

Maintenance .................................... 3

Parts Illustration and List ......................... 4-5

FULL ONE YEAR WARRANTY

if this product fails due toa defect in material or workmanship

withinone year from the date of pumhase, Sears will at its

option repair or repiaae it free of charge.

Contact your nearest Sears Service Center to arrange for

product repair, or return this product to place of purchase for

replacemnt.

ti this product is used for commercial or rental purposes, this

warranty will apply for 90 days from the date of purchase.

This warranty gives you specific legal rights, and you may

also'have other rightswhich vary from state to state.

Sears, Roebuck and Co., Dept 817WA, Hoffman Estates, IL

6O179

• Understand and follow all safety instructions supplied with drill

pre._s,or other machines on which milling table is used,

• Mount table to work surface by polting or clamping base

securely in four mounting locations.

• Be alert and think clearly. Always check your set up; for

example, rotate accessory by hand before applying power.

• Make sure workpiaces, guides, fences, or power heads are

securely clamped, as applicable, Do not force accessory.

Be positive you are feeding in right direction.

• Never feed "_ree-hancFwithout table guide and/or guides.

Use vises or appropriate clamps to secure each workplace,

securely clamping them to work surface.

• Use only accessories designed for mill. Keep power tool

guard in place. Dress properly. Do not wear jewelry, gloves,

or loose clothing.

• Wear a face shield or safety glasses. Never place hands in

jeopardy.

WARNING:Never use highly volatile solvents. Avoid getting

cleaning solution on paint as it may tend to deteriorate these

finishes. Use soap and water onpainted components.

Refer to Figure 1,

• Attach each handle (Key No. g) to handwheai (Key No. 13)

with handle screw (Key No. 10).

• Tighten each screw securely.

• Attach one hendwhee[ (Key No. 13) to cross feed screw

(Kay No. 21) with key (Key No. 5) and locking nut (Key No.

12).

• Attach two handwhesls to longitudinal feed screw (Key No.

7) with keys and locking nuts.

• Tighten each locking nut securely.

DESCRIPTION

Craftaman Compound Milling Table is manufactured from cast

iron and steel The table fits most drill presses. Milling opera-

tions can be done by moving work right and left (longitudinal),

or front and back (cross) directions. The table can also be

used to accurately position or index a workpiece under a drill

but when not doing milling operations. A U-clamp hold down

set is included with the table.

• The Milling Table is heavy. Do not lift it by the crank handles.

• Make sure that drill press table is fastened securely, does

not shift in any direction, andis clean and free of nicks and

burrs.

,, Center table on drill press.There are two 5/,. slots on each

side of base for secudng to dn'll press.

• If drill press table has T-slots, use four T-nut clamp assam-

bliss, two on each side, to secure milling table. Clamp

assemblies are not supplied.

• If drill press table has slots to fit T-nuts, use four bolts with

heavy washem (not supplied) and attach T-nuts tobottom of

table. Secure milling table w_thlocking nuts (not supplied).

• If drill press table does not have T-slots or threaded holes,

drill and tap four holes, matching location of %" slots in

base. Fasten milling table with four bolts and heavy wash-

sis (not supplied).

SPECIFICATIONS

Table .................................... 18'/, x 6"

T-Slots ....................................... %="

Check for shipping damage. If damage has occurred, a claim

must be filed with carrier immediately. Check for complete-

ness. immediately report missing parts to dealer.

NOTE: The tool has been coated with a protective coating.

in order to ensure proper fit and operation, the coating must

be removed. Removed coating with mild solvents, such as

mineral spirits,and a soft cloth. Nonflammable solvents are

recommended. After cleaning, cover all exposed surfaces with

a light coating of oil. Be sure to lubricate table as described in

"Maintenance".

T-Slots (center tocenter) ........................ 2%_"

Longitudinal Travel.............................. 12"

Cross Travel ................................... 8"

Value of One Division ........................ 0,0008"

Cross Travel

per One Revolution .......................... 0.0787"

Longitudinal Travel

per One Revolution .......................... 0.0787"

2

Loading...

Loading...