Craftsman 351243951 Owner’s Manual

SAVE THIS MANUAL

FOR

FUTURE REFERENCE

IS_EA/R8

OWNER'S

MANUAL

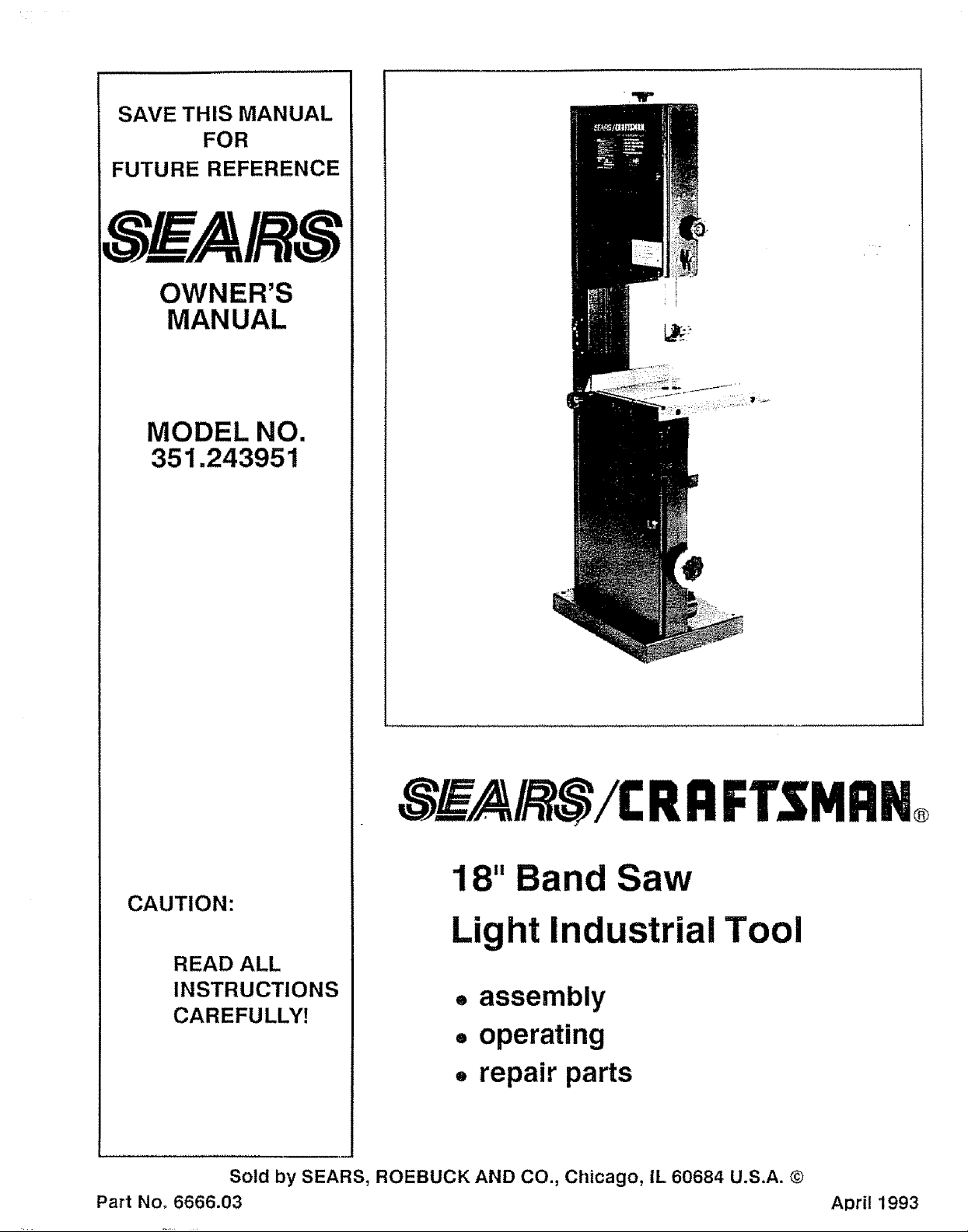

MODEL NO.

351.243951

8_A/,_,_/I: RI:1FTSMI:1N®

18" Band Saw

CAUTION:

Light Industrial Tool

READ ALL

INSTRUCTIONS

CAREFU LLY!

Sold by SEARS, ROEBUCK AND CO., Chicago, IL 60684 U.S.A. ©

Part Noo 6666.03 April 1993

o assembly

• operating

. repair parts

FULL ONE-YEAR WARRANTY ON SEARS/CRAFTSMAN 18" Band Saw

If, within one full year from the date of purchase this Sears Craftsman 18" Band Saw fails due to a

defect in material or workmanship, Sears will repair it free of charge.

WARRANTY SERVICE 1SAVAILABLE BY SIMPLY RETURNING THE BAND SAW TO THE

NEAREST SEARS STORE OR SERVICE CENTER THROUGHOUT THE UNITED STATES.

This warranty gives you specific legal rights, and you may have other rights which vary from state

to state.

SEARS, ROEBUCK AND CO., D/817 WA, 3333 Beverly Road, Hofman Estates, IL 60179

GENERAL SAFETY INSTRUCTIONS FOR POWER TOOLS

BEFORE ANY WORK IS DONE READ THE CAU-

TIONS LISTED BELOW CAREFULLY. WORKING

SAFELY PREVENTS ACCIDENTS.

OPERATOR SHOULD BE PREPARED FOR JOB:

a. Wear proper apparel. Do not wear loose clothing,

gloves, neckties, rings, bracelets or other jewelry

which may get caught in moving parts of the saw,

b Wear protective hair covering to contain long hair

c. Wear safety shoes with non-slip sole&

d, Wear safety glasses. Everyday glasses have only

impact resistant lenses. They are not safety glasses°

e Wear face mask or dust mask if ct_ing operation

is dusty°

f. Be alert and think clearly. Never operate power

tools when tired, intoxicated or when taking

medications that cause drowsiness,,

WORK AREA SHOULD BE READY FOR JOB:

a Keep work area clean. Cluttered work areas and

workbenches invite accidents,

b Do not use power tools in dangerous environ-

ments. Do not use power tools in damp or wet

location& Do not expose power tools to rain.

c Work area should be properly lighted,

d. The proper electrical outlet should beavailabIefor

the logic A three-prong plug should be plugged

directly into a properly grounded, three-prong

receptacle.

e Extension cords should have a grounding prong

and the three wires of the extension cord should be

the correct gauge,

f Keep visitors a safe distance from work area.

g. Keep children out of workplace° Make workshop

childproof,, Use padlocks, master switches and

remove starter keys to prevent any unintentional

use of power tools

SAW SHOULD BE MAINTAINED:

a, Always unplug band saw prior to inspection,

b Consult the owner's manual for specific maintain-

ing and adjusting procedures

c Keep band saw lubricated.,

d Use sharp blades and keep the saw clean for safest

operation.

e., Remove adjusting keys and wrenches. Form

habit of checking to see that keys and adjusting

wrenches are removed before turning on saw_

f Keep all guards in place and in working order.

g, Keep all parts in working order. Check to deter-

mine that the guard or other parts will operate

properly and perform their intended function_

ho Check for damaged parts. Check for alignment of

moving parts, binding of moving parts, breakage of

parts, mounting and any other condition that may

affect a tool's operation.

i, A guard or other part that is damaged should be

properly repaired or replaced. Do not perform

makeshift repairs., (Use the parts list provided with

owner's manual to order replacement parts,,)

OPERATOR SHOULD KNOW HOW TO USE SAW:

a Use the right tool for the job, Do not force atool

or attachment to do a job for which it was not

designed.

b, Disconnect saw from power when changing

blade°

c, Avoid accidental start-up. Make surethat the saw

is in the "off" position before plugging in,

d Do not force a tool It wilt work most efficiently at

the rate for which it was designed.

e, Use recommended accessories, Consult the

owner's manual for recommended accessories.

The use of improper accessories may cause risk of

injuryto persons.

f Handle the workpiece correctly,, Use push sticks

or push blocks when required Protect hands from

possible injury°

g Turn the saw off if it jams. A blade jams when it

digs too deeply into the workpiece. (The motor

force keeps it stuck in the workplace.)

h Never leave saw running unattended, Turn the

power off and do not leave saw until it comes to a

complete stop.

i, Do not overreach. Keep proper footing and

balance.

j. Never stand on saw, Serious injury could occur if

saw istipped or ifblade isunintentionally contacted

k Keep hands away from moving parts and blade

I, Know your saw. Learn its operation, application

and specific limitations.

-2-

CONTENTS

Warranty ............................................. 2

General Safety Instructions

for Power Tools .................................. 2

Safety Instructions for Sand Saw ................. 3

Motor and Electrical Specifications ................. 4

Unpacking ....................................... 4

Assembly ............................................. 5

Electrical Connections .......................... 5

Operating Instructions ........................... 5 - 9

Maintenance ........................................... 9

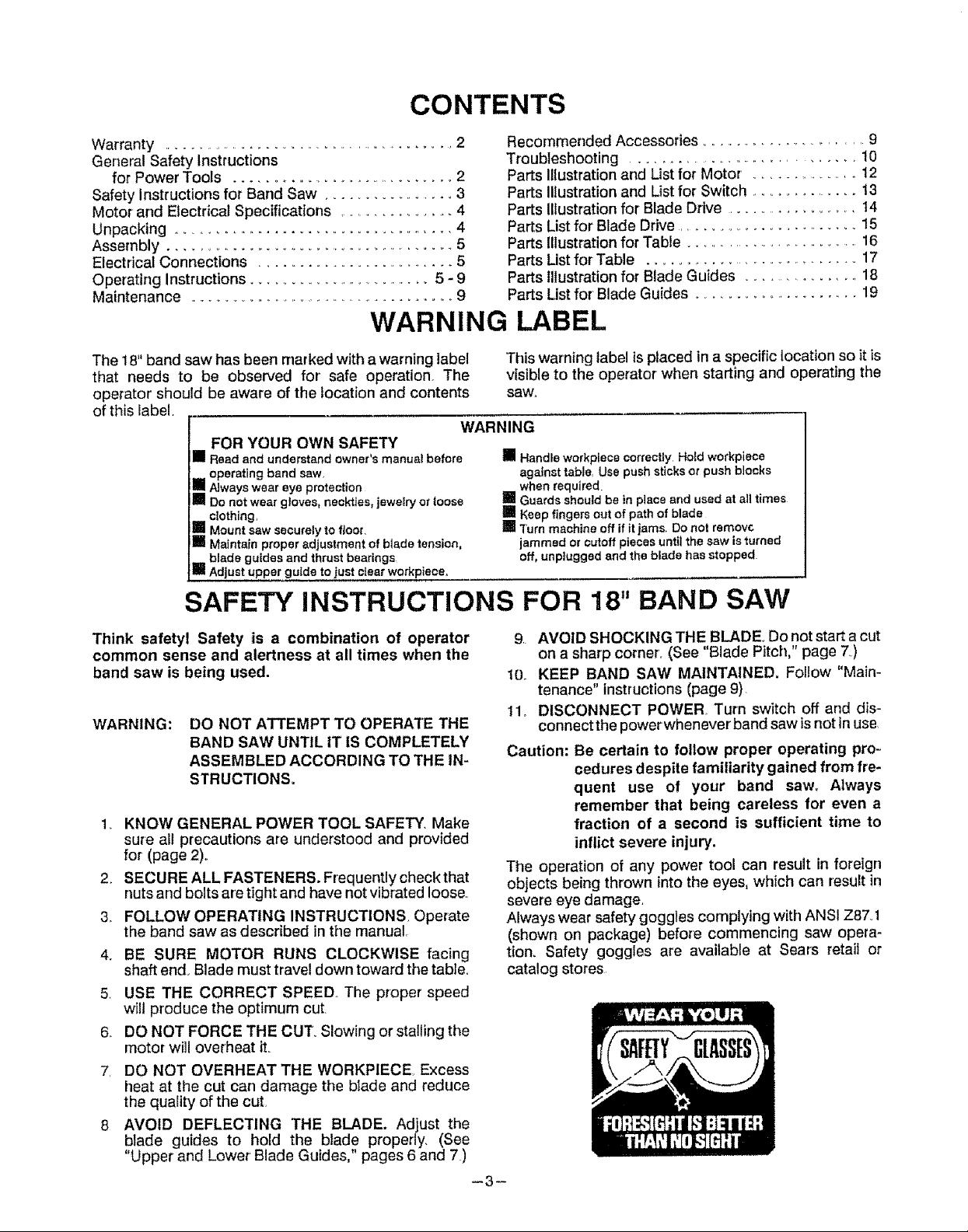

WARNING LABEL

The 18" band saw has been marked with a warning label

that needs to be observed for' safe operation, The

operator should be aware of the location and contents

of this label.

FOR YOUR OWN SAFETY

[] Read and understand owner's manual before

[] operating band saw

_ _ways wear eye protection

m Do not wear gloves, neckties, jewelry or loose

] clothing,

Mount saw securely to floor,

[] Maintain proper adjustment of blade tension,

]blade guides and thrust bearings

Adjust upper guide to just clear workpfeoe,

Recommended Accessories ........................ 9

Troubleshooting ............................... 10

Parts Illustration and Listfor Motor' +............... 12

Parts Illustrationand Listfor Switch ................ 13

Parts Illustration for Blade Drive ................... 14

Parts Listfor Blade Drive .............................. 15

Parts Illustration for Table .......................... 16

Parts List for Table .............................. 17

Parts illustration for Blade Guides ................. 18

Parts List for Blade Guides ...................... 19

This warning label is placed in a specific location so it is

visible to the operator when starting and operating the

saw,,

WARNING

i Handle workpiece correctly Hold workpiece

against table, Use push sticks or push blocks

m when required

Guards should be in place and used at all times

[] Keep fingers out of path of blade

[] Turn machine off if it jams. Do not remove

jammed or cutoff pieces until the saw is turned

off, unplugged and the blade has stopped

SAFETY INSTRUCTIONS FOR 18" BAND SAW

Think safetyl Safety is a combination of operator

common sense and alertness at all times when the

band saw is being used.

WARNING: DO NOT ATTEMPT TO OPERATE THE

BAND SAW UNTIL IT IS COMPLETELY

ASSEMBLED ACCORDING TO THE IN-

STRUCTIONS.

1,+ KNOW GENERAL POWER TOOL SAFETY, Make

sure all precautions are understood and provided

for (page 2)+

2. SECURE ALL FASTENERS. Frequently check that

nuts and bolts are tight and have not vibrated loose

3,. FOLLOW OPERATING INSTRUCTIONS, Operate

the band saw as described in the manual,

4+ BE SURE MOTOR RUNS CLOCKWISE facing

shaft end+Blade must travel down toward the table+

5, USE THE CORRECT SPEED. The proper speed

will produce the optimum cut

6,. DO NOT FORCE THE CUT+ Slowing or stalling the

motor will overheat it+

7, DO NOT OVERHEAT THE WORKPIECE Excess

heat at the cut can damage the blade and reduce

the quality of the cut

8 AVOID DEFLECTING THE BLADE, Adjust the

blade guides to hold the blade properly, (See

"Upper and Lower Blade Guides," pages 6 and 7)

9, AVOID SHOCKING THE BLADE+ Do not start a cut

on a sharp comer',, (See "Blade Pitch." page 7+)

I0+ KEEP BAND SAW MAINTAINED, Follow "Main-

tenance" instructions (page 9)

11+ DISCONNECT POWER Turn switch off and dis-

connect the powerwhenever band saw is not in use

Caution; Be certain to follow proper operating pro-

cedures despite familiarity gained from fre-

quent use of your band saw+ Always

remember that being careless for even a

fraction of a second is sufficient time to

inflict severe injury.

The operation of any power tool can result in foreign

objects being thrown into the eyes. which can result in

severe eye damage,

Always wear safety goggles complying with ANSI Z87+1

(shown on package) before commencing saw opera-

tion+ Safety goggles are available at Sears retail or

catalog stores

-3-

MOTOR

MOTOR

The band saw is supplied with a motor° The 120 volt AC

capacitor start motor has the following specifications:

Max° Developed Horsepower ....................... 2

Voltage .......................................... 120

Amperes .......................................... 7

Hertz ........... .................................... 60

Phase ........................................ Single

RPM ............................................... 1725

Rotation (viewed from shaft end) ........... Clockwise

POWER SOURCE

1_ The motor is designed for operation on the voltage

and frequency specified on motor nameplate_

2. Normal loads will be handled safely on voltages not

more than 10% above or below nameplate voltage

3. Running unit on voltages which are not within this

range may cause overheating and motor burnout.

GROUNDING iNSTRUCTIONS

WARNING: CHECK WITH A QUALIFIED

ELECTRICIAN OR SERVICE PERSON-

NEL IF GROUNDING INSTRUCTIONS

ARE NOT UNDERSTOOD OR IF IN

DOUBT AS TO WHETHER BAND SAW

IS PROPERLY GROUNDED.

DO NOT PERMIT FINGERS TO TOUCH

TERMINALS OF PLUGS WHEN IN-

STALLING OR REMOVING PLUG,

The band saw is provided with a 3-conductor cord and

ground type plug which has a grounding prong ap-

proved by Underwriters Laboratories and the Canadian

Standards Association

AND ELECTRICAL SPECIFICATIONS

Do not remove or alter grounding prong in any manner_

In the event of a malfunction or breakdown, grounding

provides a path of least resistance for electrical current

to reduce risk of electrical shock.

The plug must be plugged into a matching outlet that is

properly installed and grounded in accordance'with all

local codes and ordinances_

Do not modify plug provided. If itwitl not fit in the outlet,

have the proper outlet installed by aqualified electrician°

Improper connection of the equipment-grounding con-

ductor can result in a risk of electrical shock.

The conductor with insulation having an outer surface

which is green or yellow with green stripe isthe equip-

ment-grounding conductor,,

If repair or replacement of the electrical cord or plug is

necessary, make sure the equipment-grounding con-

ductor is not connected to a line terminal,

EXTENSION CORDS

I. The useof any extension cord wilt cause some drop

in the voltage and loss of power,

2. Wires of the extension cord must be sufficient in size

to carry the current and maintain adequate voltage.

3. Use the table below to determine the minimum wire

size (AWoG.) extension cord.

4_ Use only 3-wire extension cords having 3-prong

grounding type plugs and 3-pole receptacles which

accept the tool plug.

5, If power cord is worn, cut or damaged in any way,

have it replaced immediately.,

Extension Cord Length Wire Size A.W.G,

Upto50 ft........................................... t6

50 - 100 ft........................................... 14

NOTE: Using extension cords over 100 ft. long is

not recommended.

UNPACKING

Check for shipping damage_ tf any damage or loss has

occurred, immediately fife a claim with the carrier°

IMPORTANT: TABLE AND RIP FENCE ARE COATED

WITH A PROTECTIVE COATING WHICH MUST BE

REMOVED FOR PROPER FIT AND OPERATION,

Remove coating with mild solvents such as mineral

spirits and a soft cloth, Nonflammable solvents are

recommended. After cleaning, cover all exposed sur-

faces with a light coating of oil, Paste ,wax is recom-

mended for table tops

Caution:Never use highly volatile solvents, Avoid

getting cleaning solution on paint, rubber or

plastic parts as it may tend to deteriorate

these 1inishes, Use soap and water on paint,

plastic or rubber components.

Band saw comes assembled except for following parts:

1 Table is shipped in a box next to saw

2, Motor is shipped in a box next to saw

3. Motor pulley V-belts are shipped behind upper

cabinet door

Parts shipped in a separate box within crate:

4. Rip fence and rip fence knob

5, 120 Volt plug, 2 each wire nuts, and strain relief

6, 2 Each band saw mounting brackets

7, Motor mount bracket

8 Standard and wide table inserts

9 Miter gauge assembly

10_ Handwheel, handle, 6-1,0 x 8ram set screw and

extra long 3mm hex wrench

11_ Hex pin for table

12, 4 Each 5/16-18 x 3/4", 8 each 5/16-18 x 1" and 1

each 5/16_18 x 1 1/8" hex head bolts

13, 20 Each 5/16" and 4 each 8mm flat washers

14 12 Each 5/16" and 4 each 8ram lock washers

15 4 Each 8mm-1.25 x 25ram hex head bolts

16, 9 Each 5/16"-18 hex nuts

-4-

ASSEMBLY

MOUNT MOTOR

Refer to Figure 2

NOTE: Do not mount motor pulley to motor until

motor is mounted to sawn

! Mount motor (Key No 1) to motor mount bracket

(Key No 2) using four each 5/16-18 x 1" he× head

bolts (Key NOr,6), eight each flat washers (Key

No. 7) and four each lock washers (Key No, 8), Be

sure to mount motor to bracket using holes in

motor base as shown inFigure 2

2 Mount motor mount bracket to band saw base

using four each 8ram-1,25 x 25mm hex head bolts

(Key Noo 3), four each 8ram lock washers (Key

No 4) and four' each 8mm flat washers (Key No 5).

Refer to Figure 4

3 Slide motor pulley (Key NQ 38) onto motor' shaft

with motor key in motor' shaft groove and motor

pulley groove° Align motor pulley with step pulley

(Key No_ 32) using a straight edge so that V-

grooves in motor pulley are aligned with V-grooves

in step pulley. Secure motor pulley with two set

screws (Key No. 40),

4 Slide belt tension handwheel (Key No..51) onto belt

tension shaft (Key No_52) and secure handwheel

with setscrew (Key No. 55) using 3mm hexwrench

Thread handle (Key Nov53) into handwheeL

5 Mount motor V-belt (Key No, 38) on motor pulley

and step pulley. Tension V-belts by rotating tension

handwheel

Refer to Figure 5._

6 Mount table usingfour each 5/16-18 x3/4" hex head

bolts (Key No 12), four each lock washers (Key

No, 13) and four eachflatwashers (KeyNo 14). Do

not tighten bolts Press the standard insert (Key

No. 2) into hole on top of table with beveled slot

aligned parallel with slot in table. Position table so

that blade is centered with insert slot and blade is

parallel with miter gauge slot Secure table by

tightening four each 5/16-18 x 3/4" hex head bolts

7 Thread 5/16"_18 hex nut (Key No. 16) onto 5/16-18

x I 1/8" hex head bolt (Key No,_15).Thread bolt into

threaded hole on bottom left side of table. Adjust

table perpendicular to blade using a square and

rotate 5/16-t8 x 1 1/8" bolt so that it holds table in

perpendicular position. Rotate hex nut against

table to secure bolt,

8 Mount two each mounting brackets (Key No.,24) to

holes on front side of band saw base using four

each 5/!64 8× 1"hex head bolts (Key No, 25), eight

each flat washers (Key No. 14), four each lock

washers (Key No_ 13) and four each 5/16_'-18hex

nuts (Key No 16). Secure mounting brackets to

floor using two each anchor bolts (not supplied).

ELECTRICAL CON NECTIONS

WIRING MOTOR

WARNING: ALL ELECTRICAL CONNECTIONS

MUST BE PERFORMED BY A

QUALIFIED ELECTRICIAN.

Refer to Figure 2

The motor (Key No, 1) should be wired for 120 volts and

clockwise rotation as viewed from shaft end of motor

A schematic supplied with motor will describe proper

wiring procedures

Refer to Figure 3

Wire motor tine cord (Key No,.6) to motor using strain

relief (Key No, 8) and two wire nuts (not shown),

OPERATING INSTRUCTIONS

The 18"Band Saw isaversatile cutting tool and provides

four different cutting speeds so the saw can be used to

cut a variety of materials. The band saw offers con-

venient tensioning and tracking so changing blades is

not cumbersome The band saw can accommodate

blade widths up to 1"for many types of cuts

WARNING: ALWAYS OBSERVE THE FOLLOWING

SAFETY PRECAUTIONS.

Use proper blade for workpiece. Make sure blade

guides are positioned and adjusted correctly

Mount strain relief to motor connection box by removing

a "knock-out" on connection box and locking the strain

relief through "knock-out" hole with strain relief nut

Pass motor cord through strain relief and secure cord

with screw and nut on strain relief.

Wire motor with wire nuts provided Be sure to ground

motor with green grounding wire in motor cord

INSTALL PLUG

Refer to Figure 3

Wire line cord to plug (Key No, 9) provided Be sure to

ground plug using green grounding wire in line cord

Check to make sure blade is tensioned correctly_ Be

sure blade istracking correctly Align table to blade

Choose the proper speed for cutting operation

After turning on saw. allow blade to come to full speed

before attempting any cutting operation

Support workpiece properly Use a smooth steady feed

to guide work through cut

Keep hands away and out of line with moving parts

Always wear eye protection

-5-

OPERATING iNSTRUCTiONS (Continued)

REMOVING BLADE

Refer to Figure 4,.

The 18" Band Saw is designed for convenient blade

changing. The table is provided with a slot which allows

the blade to be removed without disturbing the table.

Remove the stud so it will not obstruct removal of blade.

Loosen lever (Key Noo 17) which locks tracking knob

(Key No. t6).

Loosen blade tension by rotating handwheel (Key

No. 15)o

When removing blade be careful because blade may

spring from saw when tension is released. The released

blade can be removed and replaced with another blade,,

INSTALLING BLADE

To replace the blade, the table stud must be removed as

described in "Removing Blade" above.

Although many of the adjustments may not be altered

when the blade is removed, every adjustment should be

checked prior to using a newly installed blade,

Follow safety precautions which should be observed

every time the band saw isturned on,

Make sure the blade teeth are pointing in the correct

direction. Blade teeth must point down° Turn blade in-

side out if necessaryH

Center the blade on the blade wheel. Tension and track

the blade as described in the following sections.

NOTE: Do not use a new blade to complete a

previously started cut,

TENSIONING BLADE

Refer to Figure 4.

Tension blade by turning the handwheel (Key No. 15).

Be sure blade guides are not interfering with the path of

the blade.

Tighten blade until it is properly tensioned, A properly

tensioned blade will ring slightly when back of blade is

plucked, (Like a string on an instrument ,)

NOTE: CHECK THE TENSION OF A NEW BLADE.

ADDITIONAL TENSION MAY BE RE-

QUIRED AFTER A FEW MINUTES OF

OPERATION.

TRACKING BLADE

Refer To Figure 6.

Track the blade after it has been tensioned°

Proper tracking is achieved when drive wheel and idler

wheels are aligned,

The knob (Key No, 16) is used to tilt tracking bracket

(Key No. 6) and align blade wheels,

A change intension of blade will affect wheel alignment

Turn idler wheel (Key No 4) by hand and observe how

blade rides on the wheels

If blade tends to ride out of the cabinet, turn knob

clockwise to tilt idler wheel up.

If blade tends to ride into the cabinet, turn tracking knob

counterclockwise to tilt idler wheel down,

When blade is tracking properly, lock the position by

holding the knob and tightening the lever (Key No,, 17)

against the cabinet.

ALIGNMENT OF DRIVE WHEEL

Refer to Figure 4.

A blade under high tension may also pull drive wheel out

of alignment.

Alignment of drive wheel can be adjusted with hex bolts

(Key No, 27),

Lock position with nuts (Key No. 28).

NOTE: Only attempt adjusting drive wheel align-

ment if blade cannot be properly tracked

with tracking adjustment alone.

BLADE GUIDES

Refer to Figure &

Blade guides support the band saw blade at sides and

the rear of blade. The blade guides should be adjusted

to prevent twisting and deflection of blade,

Blade guides should not touch blade when no material

or workpiece is in contact with the blade,. Guides need

to be adjusted as described below,,

UPPER BLADE GUIDES

Refer to Figure 6

The upper blade guides employ two ball bearing sets on

adjusting pins for side support and a thrust bearing on

an adjusting pin at the rear.

The guide depth bracket (Key No. 26) should be posi-

tioned so bearing on either side of blade will support as

much of blade width as possible without interfering with

the tooth set.,

Adjust guide depth bracket by loosening bolt (Key No,

11) and sliding bracket into position.

Secure position of upper guide casting by tightening

bolt, Adjust guide bearings to the side of the blade with

a hex wrench.

Use a feeler gauge to check that the bearing is about

0°002" away from the blade

Lock the adjustment by tightening the bolt and nut (Key

Nos,, 34 and 13).

Loosen handle (Key No. 23) and push adjusting pin to

set thrust bearings 04002"away from back of the blade,

Secure the position of the rear bearing by tightening

handle,

Adjust height of the upper guide bearings to clear the

workpiece by 1/4"

Loosen knob (Key No, !) and reposition rack within

guides,

Tighten knob to secure position on height adjustment

-6-

Loading...

Loading...