Craftsman 351226712 Owner’s Manual

SAVE THIS MANUAL

FOR

FUTURE REFERENCE

OWNER'S

MANUAL

MODEL NO.

351.226712

/£RRFrSHRN®

l x 6" Belt & Disc Sander

CAUTION:

READ ALL

INSTRUCTIONS

CAREFULLY!

Sold by SEARS, ROEBUCK AND CO., Chicago, IL 60684 U.S.A. ©

Part No. 3899.01 AUGUST 1993

• safety instructions

= operating instructions

• replacement parts

FULL ONE YEAR WARRANTY ON SEARS/CRAFTSMAN 1x 6" BELT & DISC SANDER

if within one full year from tile date of purchase, this Sears Craftsman 1x 6" Belt & Disc Sander fails due to a

defect in material or workmanship, Sears will repair it, free of charge.

WARRANTY SERVICE iS AVAILABLE BY SIMPLY CONTACTING THE NEAREST SEARS STORE OR SERVICE

CENTER THROUGHOUT THE UNITED STATES.

This warranty gives you specific legal rights, and you may have other rights whictl vary from state to state,

SEARS, ROEBUCK AND CO., D817/WA, HOFFMAN ESTATES, IL 60179

GENERAL SAFETY INSTRUCTIONS FOR POWER TOOLS

BEFORE ANY WORK IS DONE READ THE CAUTIONS

LISTED BELOW CAREFULLY, WORKING SAFELY

PREVENTS ACCIDENTS,

OPERATOR SHOULD BE PREPARED FOR JOB:

a+ Wear proper apparel+ Do not wear loose clothing,

gloves, neckties, rings, bracelets or other jewelry

which may get caught in moving parts of machine

b. Wear protective hair covering to contain long hair.

c Wear safety shoeswith non-slip soles+

d.. Wear safety glasses+ Everyday glasses have only

impact resistant lenses+They are not safety glasses

e. Wear face mask or dust mask if sanding operation

isdusty+

f Be alert and think clearly. Never operate power

tools when tired, intoxicated or when taking med-

ications that cause drowsiness.

WORK AREA SHOULD BE READY FOR JOB:

a+ Keep work area clean+ Cluttered work areas and

workbenches invite accidents,,

b+ Do not use power tools in dangerous environ-

merits+ Do not use power' tools in damp or. wet

locations. Do not expose power tools to rain.

c+ Work area should be properly lighted.

d+ Proper electrical outlet should beavailablefortooL

Three-prong plug should be plugged directly into

properly grounded, three-prong receptacle+

e+ Extension cords should have a grounding prong

and the three wires of the extension cord should be

the correct gauge+

f+ Keep visitors a safe distance from work area+

g+ Keep children out of workplace+ Make workshop

child-proof. Use padlocks, master' switches and

remove starter' keys to prevent any unintentional use

of power tools,

TOOL SHOULD BE MAINTAINED:

a+ Always unplug power tool prior,to inspection.

b+ Consult owner's manual for specific maintainirlg

and adjusting pr.ocedureso

c+ Use clean belts and keep the tool clean for safest

operation+

d. Remove adjusting keys and wrenches. Form

habit of checking to see that keys and adjusting

wrenches are removed before turning tool on.

e+ Keep all guards in place and in workingorder.

f+ Keep all parts in working order. Check to deter-

mine that the guard or other parts will operate

propedy and perform their' intendedfunction+

g Check for damaged parts+ Check for atignment of

moving parts, binding of moving parts, breakage of

parts, mounting and any other condition that may

affect a tool's operation

h+ A guard or other part that is damaged should be

properly repaired or replaced. Do not perform

makeshift repairs_ (Use the parts list provided to

+ order replacement parts+)

OPERATOR SHOULD KNOW HOW TO USE TOOL:

a+ Use right tool for the job. Do not force tool or'

attachment to do a job for which it was not de+

signed.

b. Disconnect tool when changing accessories,

such as belt, disc, miter gauge and the like.

c Avoid accidental start-up. Make sure that the

machine is in the "off" position before plugging in+

d° Do not force a tool It will work most efficiently at

the rate for which it was designed

e+ Use recommended accessories, Referto page 11.

Use of improper accessories may cause risk of injury

to persons

f+ Handle the workpiece correctly. Use m_tergauge

when required, Protect hands from possibleinjury+

g+ Direction of feed. Feed work into a belt or disc

against direction of rotation of the belt or+disc.

h+ Turn the machine off if it jams. Disconnect plug

from power' source before servicing tool.,

L Never leave a tool running unattended+ Turn the

power off and do not leave sander until it comes to

a complete stop+

j+ Do not overreach. Keep proper footing and

balance,

k+ Never stand on tool Serious injury could occur if

tool is tipped or'if abrasive belt or disc is unintention-

ally contacted+

I+ Keep hands away from moving parts and sanding

surfaces+

m+ Know your power tool. Learn itsoperation, applica-

tion and specific limitations+

-2-

CONTENTS

Warranty ................................ 2

General Safety Instructions

for Power Tools ...................... 2

Safety Instructions

for Belt & Disc Sander ................. 3

Motor Specifications

and Electrical Requirements ............ 4

Electrical Connections .................. 4 & 5

WARNING LABEL

The belt and disc sander has been marked with awarning

label that needs to be observed for safe operation. The

operator should be aware of the location and contents

of thts label

WARNING

FOR SAFE OPERATION SEE OWNER'S MANUAL

1_ Always wear safety gog_le_ complying with ANSI Z871

II When soMctng use anty Identlca, I replacement pads

M Suppottwo;kplecewIlhbacksloporwoTklable

H Maintain 1116" max clearance beM,een table and sanding belt ot d_ec

Im Mount securely to workbench

SAFETY INSTRUCTIONS FOR

Unpacking and Checking Contents ........... 5

Tools Needed ............................ 5

Assembly ............................... 6

Operation ............................... 6

Maintenance .......................... 8 & 9

Trouble Shooting ......................... 9

Replacement Parts Illustration .............. 10

Replacement Parts List .................... 11

This warning label is placed in a specific location so it is

visible to the operator when starting and operating the

belt and disc sander.

l"x 6" BELT & DISC SANDER

WARNING: DO NOT ATTEMPT TO OPERATE BELT

& DISC SANDER UNTIL IT IS COM-

PLETELY ASSEMBLED ACCORDING

TO THE INSTRUCTIONS.

t Know general power tool safety, Make sure all

precautions are understood and provlded for (page

2. Secure all fasteners. Frequently check that nuts

and bolts are tight and have not vibrated loose,

3. Follow operation instructions. Operate the belt

and disc sander as described in this manual (pages

6 through 8).

4,, Be sure motor runs clockwise on disc side.

Abrasive belt must traveldown

,,

Perform disc sanding on down side (rightside).

The disc should pull work towards the table°

6_

Support workpiece. Use backstop or work table

The backstop for the abrasive belt isthe belt platen

(Key No. 25) as described in "Operating Instruc-

tions" (page 7),,

,

Do not force work° Slowing or stalling the motor

will overheat it,

8_

Do not overheat work. Move metal across the

abrasive and cool itwhen itbecomes hot.

9,

Do not wet grind or polish. Never use a steady

stream of water on the workpieceo Only quench the

workpiece in water to cool it.

10o Do not grind or polish magnesium. Itcould catch

on fire.

11_ Keep sander maintained. Follow "Maintenance

instructions" (page 9).

12 Disconnect power, Turn :switch off and disconnect

power whenever sander is not in use.

CAUTION: Be certain to follow proper operating

procedures despite familiarity gained

from frequent use of your belt and disc

sander. Always remember that being

careless for even a fraction of a second

is sufficient time to inflict severe injury.

The operation of any power tool can result In foreign

objects being thrown into the eyes, which can result in

severe eye damage,

Always wear safety goggles complying with ANSI Z87ot

(shown on package) before commencing power tool

operation° Safety goggles are available at Sears retail or

catalog stores.

THINK SAFETY: Safety is a combination of operator

common sense and alertness at alt

times when the belt & disc sander is

being used_

-3-

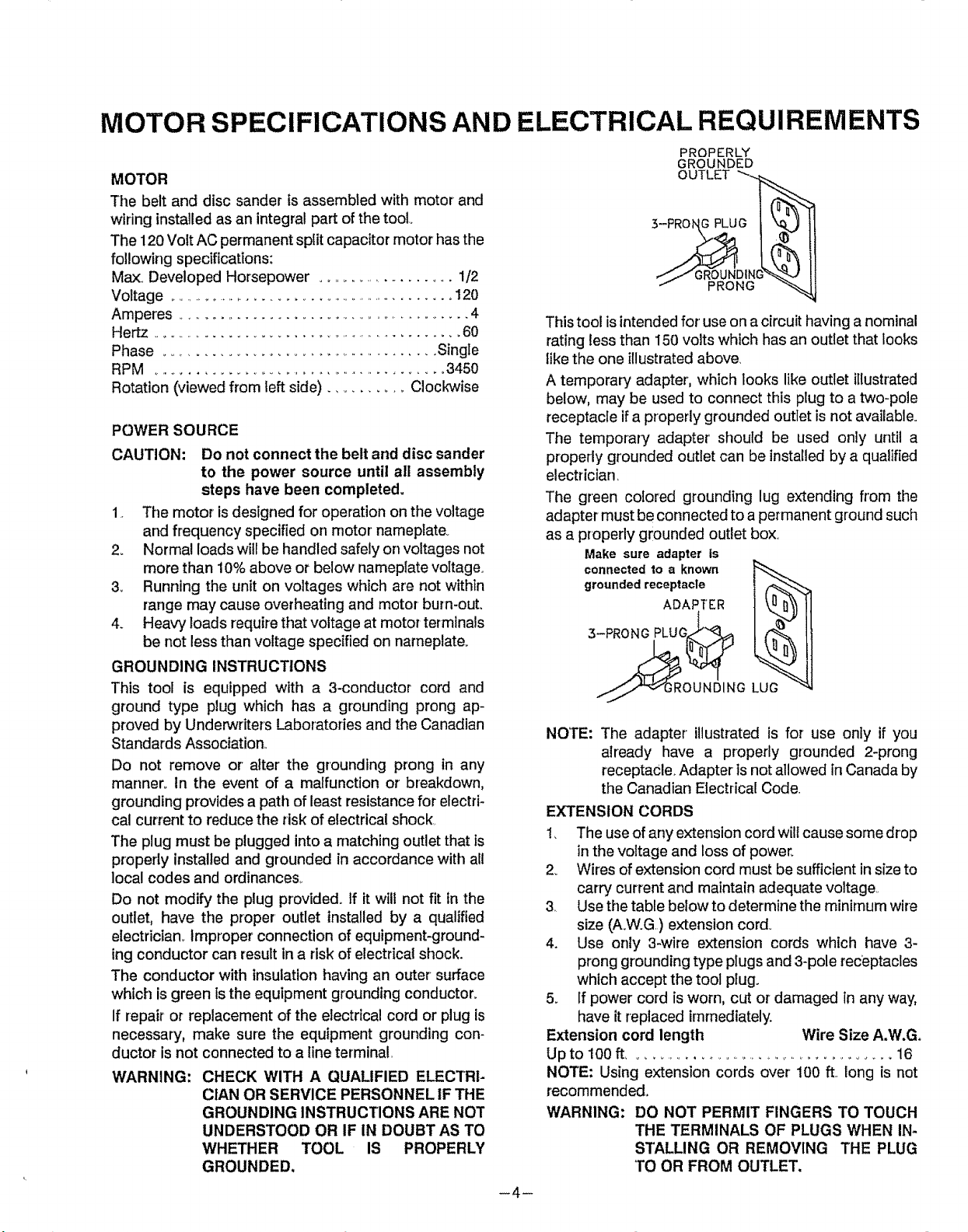

MOTOR SPECIFICATIONS AND ELECTRICAL REQUIREMENTS

PROPERLY

GROUNDED

MOTOR

The belt and disc sander is assembled with motor and

wiring insta!led as an integral part of the tool..

The 120 Volt AC permanent split capacitor motor' has the

following specifications:

Max..Developed Horsepower ...................... 1/2

Voltage ................................................. 120

Amperes .............................................. 4

Hertz .............................................. 60

Phase ...........................................Single

RPM ..........................................3450

Rotation(viewedfromleftside)..........Clockwise

POWER SOURCE

CAUTION: Do not connect the belt and disc sander

to the power source until all assembly

steps have been completedo

1. The motor is designed for operation on the voltage

and frequency specified on motor nameptatev

2_ Normal loads will be handled safely on voltages not

more than 10% above or below nameplate voltage.

3. Running the unit on voltages which are not within

range may cause overheating and motor-burn-ouL

4. Heavy loads require that voltage at motor terminals

be not lessthan voltage specified on nameplate.

GROUNDING INSTRUCTIONS

This tool is equipped with a 3-conductor cord and

ground type plug which has a grounding prong ap-

proved by Underwriters Laboratories and the Canadian

Standards Association.

Do not remove or' alter' the grounding prong in any

manner° In the event of a malfunction or breakdown,

grounding provides a path of least resistance for electri-

cal current to reduce the risk of electrical shock

The plug must be plugged into a matching outlet that is

properly installed and grounded in accordance with all

local codes and ordinances,.

Do not modify the plug provided° If it will not fit In the

outlet, have the proper' outlet installed by a qualified

electrictan_ improper connection of equipment-ground-

ing conductor can result in a rlsk of electrical shock.

The conductor with insulation having an outer surface

which is green tsthe equipment grounding conductor.

If repair or replacement of the electrical cord or plug is

necessary, make sure the equipment grounding con-

ductor is not connected to a line terminal.

WARNING: CHECK WITH A QUALIFIED ELECTRI-

CIAN OR SERVICE PERSONNEL IF THE

GROUNDING INSTRUCTIONS ARE NOT

UNDERSTOOD OR IF IN DOUBT AS TO

WHETHER TOOL IS PROPERLY

GROUNDED,

This toot is intended for'use on a circuit having a nominal

rating tess than I50 volts which has an outlet that looks

tike the one illustrated above.

A temporary adapter', which looks like outlet illustrated

below, may be used to connect this plug to a two-pole

receptacle if a properly grounded outlet isnot available.

The temporary adapter should be used only until a

properly grounded outlet can be installed by a qualified

electrician,

The green colored grounding lug extending from the

adapter must be connected to a permanent ground such

as a properly grounded outlet box.

Make sure adapter ts

connectedto a known

grounded receptacle

3-PRONG PLUG_

NOTE: The adapter illustrated is for use onIy if you

already have a properly grounded 2-prong

receptacle. Adapter ts not allowed in Canada by

the Canadian Electrical Code.

EXTENSION CORDS

1_ The use of any extension cord wilt cause some drop

in the voltage and loss of power.

2. Wires of extension cord must be sufficient in size to

carry current and maintain adequate voltage

3, Use the table below to determine the minimum wire

size (A.W.G) extension cord°

4. Use only 3-wire extension cords which have 3-

prong grounding type plugs and 3-pole receptacles

which accept the tool plug.

5. If power cord is worn, cut or damaged in any way,

have it replaced immediately.

Extension cord length Wire Size A.W.Go

Upto 100ft ..............................................16

NOTE: Using extensioncords over'100 ft.,longisnot

recommended°

WARNING: DO NOT PERMIT FINGERS TO TOUCH

-4-

OUTLET "_

"" PRONG "_

ADAPTER

THE TERMINALS OF PLUGS WHEN IN-

STALLING OR REMOVING THE PLUG

TO OR FROM OUTLET.

Loading...

Loading...