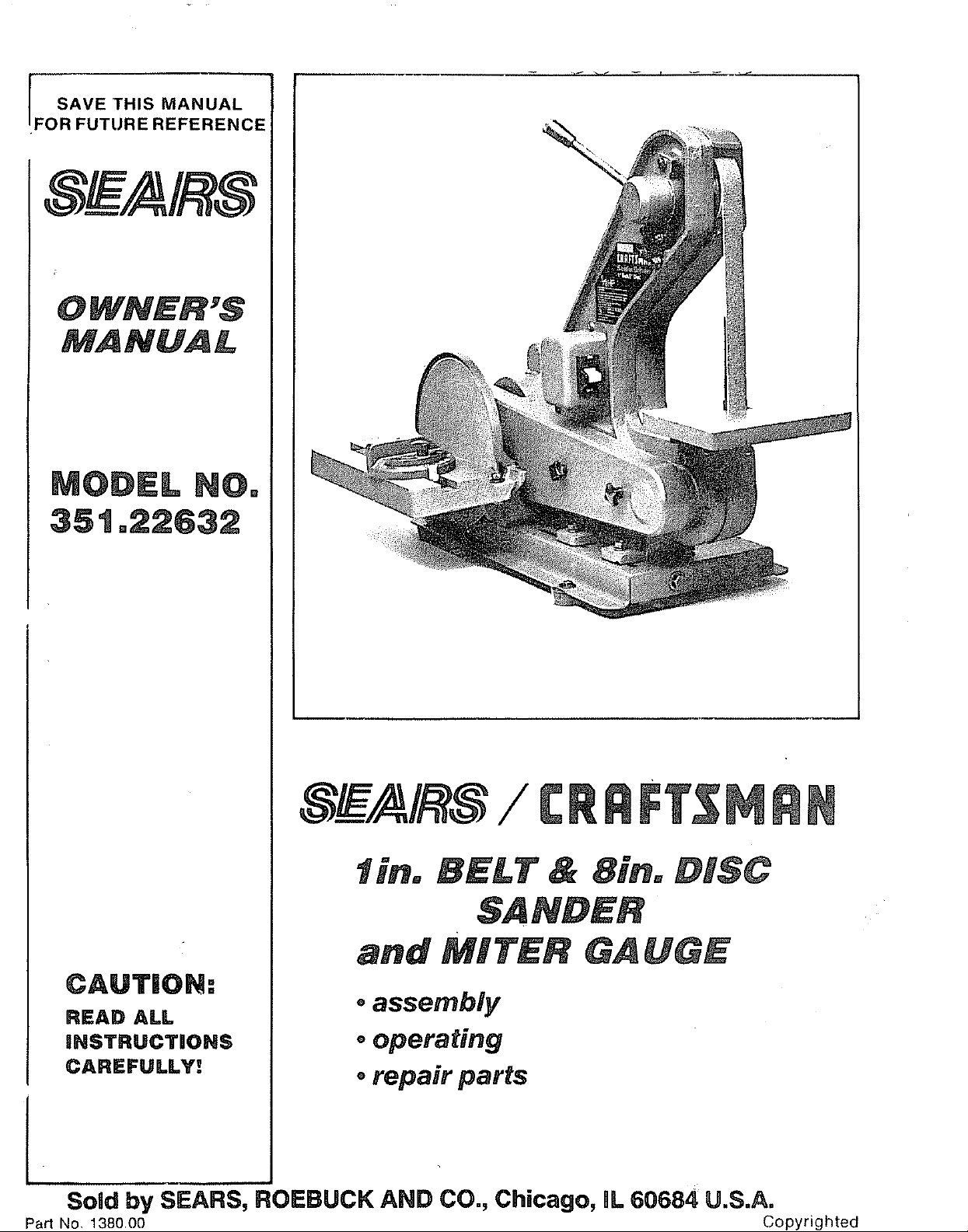

Craftsman 351226321, 35122632 Owner’s Manual

MANUAL,

MODEL N@o

351 °22532

and MITER

CAUTION:

READ ALL

gNSTRUCTgONS

CAREFULLy!

i . i,,

Sold by SEARS, ROEBUCK AND CO., Chicago, 0L60684 U.S.A.

Part No, 138000 Copyrighted

oassembly'

ooperating

, repair parts

FULL ONE YEAR WARRANTY ON SEARS CRAFTSMAN

If within one year from the date of purchase, this Sears Craftsman Belt & Disc Sander fails due

_=< to a defect in material or workmanship, Sears will repair it, free of charge

WARRANTY SERVICE IS AVAILABLE BY SIMPLY CONTACTING THE NEAREST SEARS ==_

c_<

STORE OR SERVICE CENTER THROUGHOUT THE UNITED STATES.

This warranty gives you specific legal rights, and you may also have other rights which vary from

state to state.

SEARS, ROEBUCK AND CO., DEPT.698/731A SEARS TOWER, CHICAGO, IL 60684

GENERAL SAFETY INSTRUCTIONS FOR POWER TOOLS

BEFORE ANY WORK IS DONE, READ THE

CAUTIONS LISTED BELOW CAREFULLY.

WORKING SAFELY PREVENTS ACCIDENTS°

1 OPERATOR SHOULD BE PREPARED FOR THE

JOB:

a Do not wear loose clothing, jewelry or gloves

that will get caught in moving parts of the

machine_

b, Wear safety shoes with non-slip soles.

c Wear safety glasses.

d. Wear face mask or dust mask when needed.

e. Be alert, and think clearly.

f. Never operate power tools when tired,

intoxicated, or when taking medications that

cause drowsiness.

2. WORK AREA SHOULD BE READY FOR THE JOB:

a, An uncluttered work area ensures that the oper-

ator has ample room for movement and place-

ment of the work_ Clean floors ensure good

footing

b, Environment should be suitable for tool; Power

tools should not be used in damp locations, or

gaseous, explosive atmospheres.

c. Area should be properly lighted_

d Proper electrical outlet should be available for

the tool.

1. Three-prong plug should be plugged directly

into a properly grounded three-prong

receptacle

2. If work area is not grounded, a qualified elec-

trician should install the proper electrical

system.

e_ Extension cords should have a grounding prong,

and the three wires of the extension cord should

be the correct gauge.

f Keep visitors a safe distance away from work

area_

3 TOOL SHOULD BE MAINTAINED:

a. Always unplug power tool prior to inspection

or maintenance.

b. Consult the owner's manual for specific main-

taining and adjusting procedures,

c, Keep machine lubricated

d. Use sharp blades, and keep the tool clean for

best, and safest operation,

e. Never leave adjusting keys and wrenches on

machine; remove them

L Workbed of power tool should only be used to

support the workpiece and necessary

accessories_

g Use recommended accessories only, and follow

manufacturer's instructions.

h, Keep all guards in place.

i Keep all parts in working order; do not perform

makeshift repairs (Use the Parts List provided

with the owner's manual to order replacement

parts.)

j. Make sure the machine is mounted correctly;

never attempt to stabilize a floor or benchtop tool

by standing on it, or by holding it in position

4, OPERATOR SHOULD KNOW HOW TO USE THE

TOOL:

a_

Use the right tool for the job.

b.

Avoid accidental start-up; make sure that the

machine is in the OFF position before plugging

it in.

c Do not force a tool; it will work most efficiently

at the rate for which it was designed

d. Turn the machine OFF if it jams: A blade jams

when it digs too deeply into the work. (The motor

force keeps it stuck in the work.)

e. Handle the work piece correctly.

1. Secure the work with clamps, or a vise when-

ever possible; leave hands free to operate the

machine

2 Use push sticks or push blockswhen required;

protect hands from possible injury.

f Do not overreach: Keep the proper footing and

balance_

g. Keep hands away from moving parts and cutting

surfaces

h Know your power tool: learn its operation,

applications and specific limitations.

CONTENTS

Warranty ......................................................... 2

General Safety Instructions

for Power Tools ........................................ 2

Safety Instructions

for Belt & Disc Sander ............................... 3

Motor Specifications

and Electrical Requirements ....................... 4

Electrical Connections ..................................... 5

Unpacking and Checking Contents ................... 5

Tools Needed .................................................. 6

Assembly ........................................................ 6

Operation ........................................................ 8

Maintenance ................................................. 10

Trouble Shooting ........................................... 11

Replacement Parts List.................................. 12

Replacement Parts Illustration ........................ 14

SAFETY BNSTRUCTnONS FOR l in. BELT & 8in. DiSC SANDER

WARN|NG-" DO NOT ATTEMPT TO OPERATE

BELT & DISC SANDER UNTIL IT IS COMPLETELY

ASSEMBLED ACCORDING TO THE INSTRUCTIONS.

1 KNOW GENERAL POWER TOOL SAFETY. Make

sure all precautions are understood and provided

for (page 2)

2 SECURE ALL FASTENERS, Frequently check

that nuts and bolts are tight and have not vibrated

loose

3 FOLLOW OPERATION INSTRUCTIONS. Operate

the belt and disc sander as described in this

manual (page 8)

4 BE SURE MOTOR RUNS CLOCKWISE. Abrasive

belt must travel down

5 DISC SAND ON DOWN SIDE (RIGHT SIDE). The

disc should pull work towards the table_

11. KEEP SANDER MAINTAINED. Follow

maintenance instuctions (page 10)

12. DISCONNECT POWER, Turn switch "off" and

diconnect the power whenever sander is not be-

ing used

CAUTION: DO NOT ALLOW FAMILIARITY (GAINED)

FROM FREQUENT USE OF YOUR BELT AND DISC

SANDER TO BECOME COMMONPLACE ALWAYS

REMEMBER THAT A CARELESS FRACTION OF A

SECOND IS SUFFICIENT TO INFLICT SEVERE

INJURY

The operation of any power tool can result in foreign

objects being thrown into the eyes. which can result

in severe eye damage. Always wear safety goggles

complying with ANSI Z87.1 (shown on package) before

commencing power tool operation Safety Goggles are

available at Sears retail or catalog stores

6 SUPPORT WORKPIECE. Maintain control of

workpiece at all times

7. DO NOT FORCE WORK, Slowing or stalling the

motor will overheat it

8, DO NOT OVERHEAT WORK_ Move metal across

the abrasive and cool it when it becomes hot

9 DO NOT WET GRIND OR POLISH. Never use a

steady stream of water on the workpiece Only

quench the workpiece in water to cool it,

10 DO NOT GRIND OR POLISH MAGNESIUM. It

could catch on fire

THINK SAFETY: Safety is a combination of operator

common sense and alertness at all times when the Belt

& Disc Sander is being used.

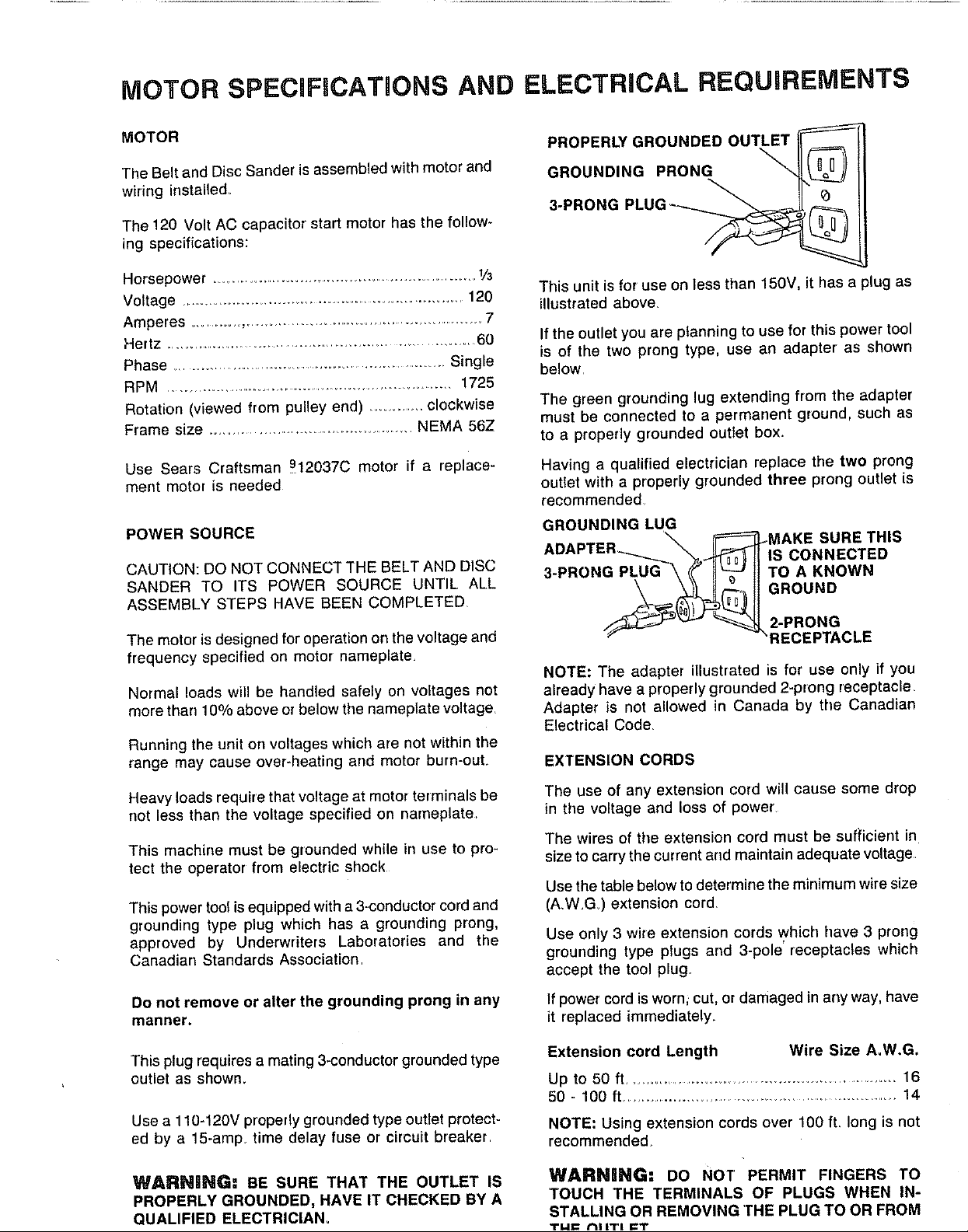

MOTOR SPECIFICATOONS AND ELECTRICAL REQUIREMENTS

MOTOR

The Belt and Disc Sander is assembled with motor and

wiring installe&

The 120 Volt AC capacitor start motor has the follow-

ing specifications:

Horsepower ................................................................. 1/3

Voltage ................................................................. 120

Amperes .............,......................................................... 7

Hertz ......................................................................... 60

Phase ................................................................ Single

RPM .......................................................................... 1725

Rotation (viewed from pulley end) ............. clockwise

Frame size .................................................. NEMA 56Z

Use Sears Craftsman _912037C motor if a replace.

ment motor is needed

POWER SOURCE

CAUTION: DO NOT CONNECT THE BELT AND D)SC

SANDER TO ITS POWER SOURCE UNTIL ALL

ASSEMBLY STEPS HAVE BEEN COMPLETED

The motor is designed for operation on the voltage and

frequency specified on motor nameplate,

Normal loads will be handled safely on voltages not

more than 10% above or below the nameplate voltage.

Running the unit on voltages which are not within the

range may cause over-heating and motor burn-out

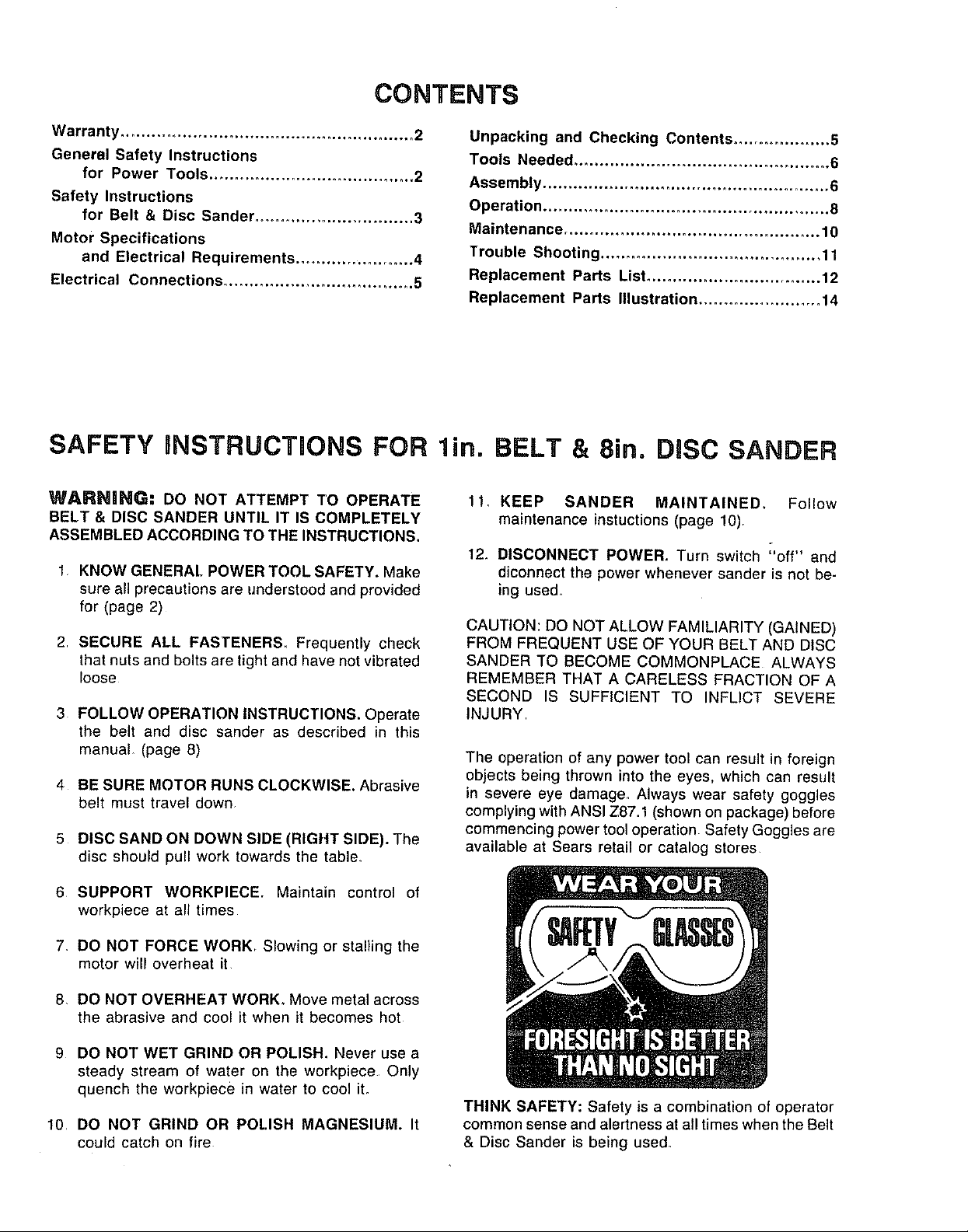

PROPERLY GROUNDED OUTLET

GROUNDING PRONG

3-PRONG PLUG

This unit is for use on less than 150V, it has a plug as

illustrated above.

If the outlet you are planning to use for this power tool

is of the two prong type, use an adapter as shown

below,

The green grounding lug extending from the adapter

must be connected to a permanent ground, such as

to a properly grounded outlet box.

Having a qualified electrician replace the two prong

outlet with a properly grounded three prong outlet is

recommended

GROUNDING LUG

A...... _ ;f=:_MAKE SURE THIS

u_r'rcn_ "_'_l IS CONNECTED

3-PRONGPLUG \ _ If_IITOAKNOWN

/."_"_'- "_"_ 2-PRONG

_" RECEPTACLE

NOTE: The adapter illustrated is for use only if you

already have a properly grounded 2-prong receptacle

Adapter is not allowed in Canada by the Canadian

Electrical Code.

EXTENSION CORDS

Heavy loads require that voltage at motor terminals be

not less than the voltage specified on narneplate,

This machine must be grounded while in use to pro-

tect the operator from electric shock

This power tool is equipped with a 3-conductor cord and

grounding type plug which has a grounding prong,

approved by Underwriters Laboratories and the

Canadian Standards Association,

Do not remove or alter the grounding prong in any

manner.

This plug requires a mating 3-conductor grounded type

outlet as shown.

Use a 110-120V properly grounded type outlet protect-

ed by a 15-amp. time delay fuse or circuit breaker

WARNaNG: BE SURE THAT THE OUTLET IS

PROPERLY GROUNDED, HAVEIT CHECKED BY A

QUALIFIED ELECTRICIAN°

The use of any extension cord will cause some drop

in the voltage and loss of power

The wires of the extension cord must be sufficient in

size to carry the current and maintain adequate voltage.

Use the table below to determine the minimum wire size

(A WG,) extension cord.

Use only 3 wire extension cords which have 3 prong

grounding type plugs and 3-pole' receptacles which

accept the tool plug

If power cord is worn; cut, or damaged in any way, have

it replaced immediately_

Extension cord Length Wire Size A.W.G.

Up to 50 ft ................................................................. 16

50 - 100 ft................................................................ 14

NOTE: Using extension cords over 100 fL long is not

recommended.

WARNBNG: DO NOT PERMIT FINGERS TO

TOUCH THE TERMINALS OF PLUGS WHEN IN-

STALLING OR REMOVING THE PLUG TO OR FROM

ELECTRICAL CONNECTIONS

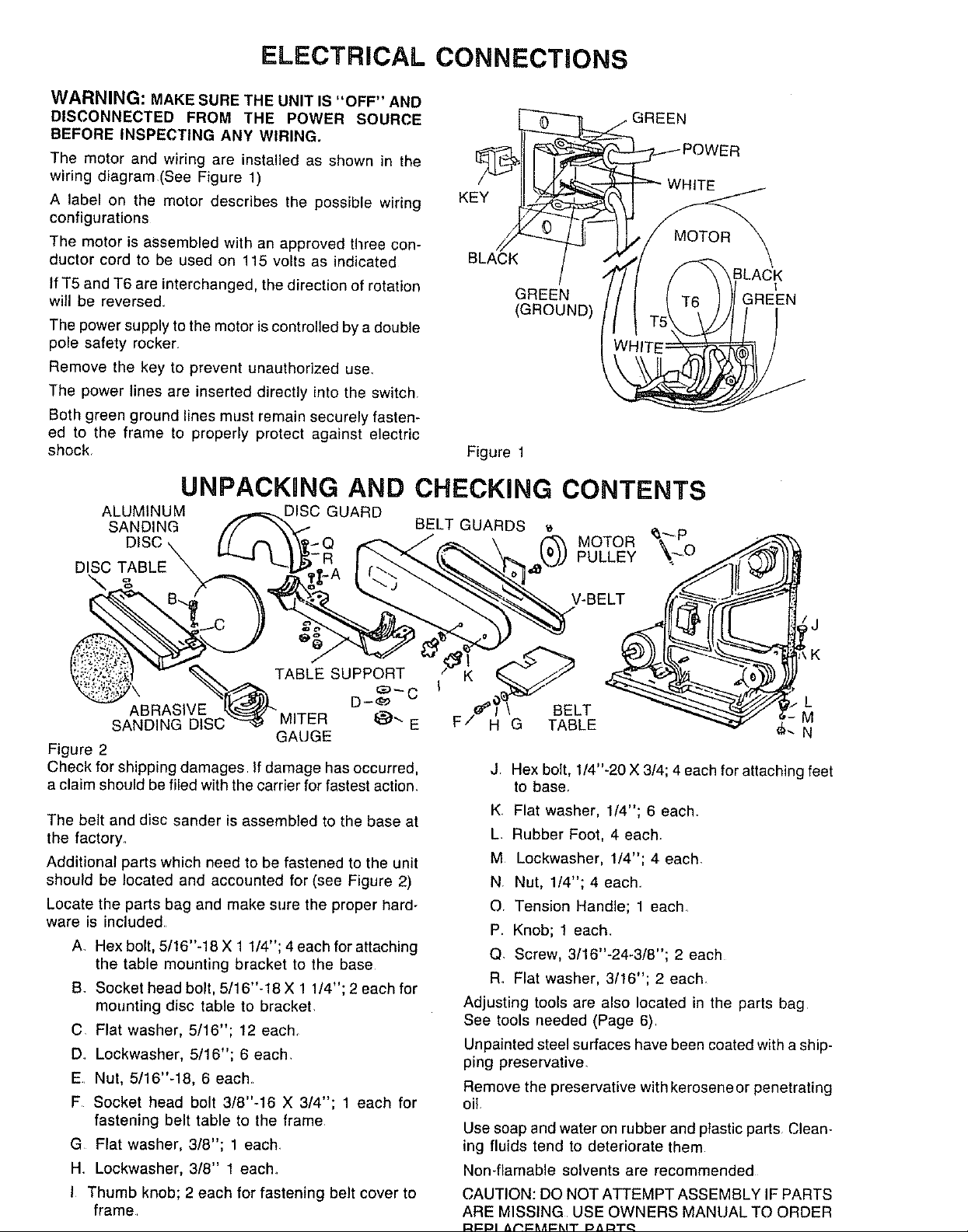

WARNING: MAKE SURE THE UNIT IS "OFF" AND

DISCONNECTED FROM THE POWER SOURCE

BEFORE INSPECTING ANY WIRING.

The motor and wiring are installed as shown in the

wiring diagram(See Figure 1)

A label on the motor describes the possible wiring

configurations

The motor is assembled with an approved three con-

ductor cord to be used on 115 volts as indicated

If T5 and T6 are interchanged, the direction of rotation

will be reversed

The power supply to the motor is controlled by a double

pole safety rocker

Remove the key to prevent unauthorized use_

The power lines are inserted directly into the switch.

Both green ground lines must remain securely fasten-

ed to the frame to properly protect against electric

shock

Figure 1

GREEN

(GROUND)

UNPACKING AND CHECKING CONTENTS

ALUMINUM DISC GUARD

SANDING BELT GUARDS

o,sc

DISC TABLE PULLEY

GREEN

_.-.----- POWER

WHITE

ILACK

1

GREEN

TABLE SUPPORT 114_...___4_"_)

ABRASIVE t£._ ..... u'- BELT L

SANDING DISC _ IVH/CH _"" E H G TABLE M

GAUGE N

Figure 2

Check for shipping damages If damage has occurred,

a claim should be filed with the carrier for fastest action.

The belt and disc sander is assembled to the base at

the factory.

Additional parts which need to be fastened to the unit

should be located and accounted for (see Figure 2)

Locate the parts bag and make sure the proper hard-

ware is included.

A Hex bolt, 5/16"-18 X 1 1/4"; 4 each for attaching

the table mounting bracket to the base

B. Socket head bolt, 5/16"-18 X 1 1/4"; 2 each for

mounting disc table to bracket.

C Flat washer, 5/16"; 12 each+

D Lockwasher, 5/16"; 6 each.

E Nut, 5/16"-18, 6 each

F Socket head bolt 3/8"-16 X 3/4"; 1 each for

fastening belt table to the frame

G Flat washer, 3/8"; 1 each.

H Lockwasher, 3/8" 1 each.

I Thumb knob; 2 each for fastening belt cover to

frame

V-BE LT _l i/'"_:"_'_'-_- I!_

J. Hex bolt, 1/4"-20 X 3/4; 4 each for attaching feet

to base.

K Flat washer, 1/4"; 6 each.

L. Rubber Foot, 4 each.

M Lockwasher, 1/4"; 4 each.

N. Nut, 1/4"; 4 each.

O. Tension Handle; 1 each_

P. Knob; 1 each.

Q. Screw, 3/16"-24-3/8"; 2 each

R. Flat washer, 3/16"; 2 each

Adjusting tools are also located in the parts bag

See tools needed (Page 6)

Unpainted steel surfaces have been coated with a ship-

ping preservative.

Remove the preservative with kerosene or penetrating

oil.

Use soap and water on rubber and plastic parts Clean-

ing fluids tend to deteriorate them

Non41amable solvents are recommended

CAUTION: DO NOT ATTEMPT ASSEMBLY iF PARTS

ARE MISSING USE OWNERS MANUAL TO ORDER

Loading...

Loading...