Craftsman 351226151 Owner’s Manual

RightFax 11/14/2002 9:40 PAGE 2/33 RightFax

Operator's Manual

CRRFTSMRN°

15"

PLANER

Model No,

351.226151

CAUTION: Read and follow

all Safety Rules and Operating

Instructions before First Use

of this Product.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

www._ar_ conVcraftsm an

17857.00 Draft (01/11/02)

RightFax ii/14/2002 9:40 PAGE 3/33 RightF&x

PREPARE WORK AREA FOR JOB

• Keepwork area clean. Clutteredwork areas invite

Warranty .................................. 2

Safety Rules.............................. 2-3

Unpacking................................. 3

Assembly ................................ 3-4

Installation ............................... 4-6

Operation ................................ 6-9

Maintenance ............................ 9-12

TroubLeshooting............................ 13

Parts Illustration and LIst .................. 14-19

EspeSol ............................... 20-31

accidents.

• Do notuse powertoolstn dangerousenvironments.

• Do notuse powertoolsin damp or wet locations. Do

notexpose powertools to rain.

• Work area shouldbe properlylighted.

• Proper electricalreceptacle shouldbe availablefor

tool Three prongplug shouldbe pluggeddirectly

into properly grounded, three-prongreceptacle.

• Extensioncords shouldhave a groundingprongand

thethree wires ofthe extensioncord shouldbeof

the correctgauge.

• Keep visitorsat a safedistancefrom work area.

• Keepchildrenoutof workplace.Makeworkshopchild-

FULL ONE YEAR WARRANTY

If this product fails due to a defectin materialor work-

manshipwithinone yearfrom the dateof purchase,

Searswillat itsoption repairor replaceItfreeof

charge.Contactyour nearest Sears ServiceCenter

(1-800-4-MY-HOME) to arrangefor productrepair,or

returnthisprodu_ to place of purchasefor replacement.

If thlsproductIs usedfor commercialor rental purpos-

es, thiswarrantywill applyfor 90 days fromthe date of

purchase.

Thiswarrantyappliesonly while this productIs usedIn

the United States.

This warrantygivesyou specificlegal rights andyoumay

also have otherrightswhichvaryfromstate to state.

Sears, Roebuck and Co., Dept. 817WA, Hoffman

Estates, IL 60179

proof. Use padlocks,master switchasor removeswitch

kaysto preventany unintentionaluseof powertools.

TOOL SHOULD BE MAINTAINED

• Always unplugtool priorto Inspection.

• Consultmanualfor specificmaintaining andadjust-

ingprocedures,

• Keeptool lubricatedand cleanfor safestoperation.

• Removeadjustingtools.Formhabitofcheckingto

see that adjustingtools are removedbefore switch-

ingmachineon.

• Keepan parts Inworkingorder.Check to determine

thatthe guard or other parts willoperate properly

and perform their intendedfunction,

• Checkfor damaged parts.Check for alignment of

movingparts, binding,breakage, mountingand any

otherconditionthat may affecta toots operation.

• A guardor other partthat isdamaged shouldbe

properlyrepairedor replaced.Do notperform

makeshiftrepairs.(Use partslistprovidedto order

WARNING: For your own safety,read all of the rules

replacementparts.)

and precautions beforeoperatingtool.

CAUTION; Always follow properoperatingprocedures

as definedIn this manual even Ifyou are familiar with

use ofthis or similartools,Remember that being care-

less foreven a fractionof a secondcan resultIn severe

personalInjury.

BE PREPARED FOR JOB

• wear properapparel. Do notwear loose clothing,

gloves,neckties,rings,braceletsor otherJewelry

which may get caughtin moving partsof machine.

• Wear protectivehaircoveringto containlong hair.

• Wear safetyshoeswith non-slip soles.

• Wear safetyglassescomplyingwith UnitedStates

ANSI 7.87.1.Everydayglasseshave onlyImpact

resistantlenses.They are NOT safetyglasses.

• Wear face mask or dustmask ifoperationIs dusty.

• Be alert and think clearly.Never operate powertools

when tired, Intoxicated or when taking medications

that causedrowsiness.

© Sears, Roebud_and Co.

KNOW HOW TO USE TOOL

• Use righttool for job. Do notforcetoolor attachment

to do a Jobforwhich it was not designed.

• Disconnecttoolwhen changingblades.

• Avoidacoidentaistart-ul_ Make surethatthe switch

Is Inthe OFF positionbeforepluggingin.

• Do notforcetool, Itwill work most efficientlyat the

ratefor which it was designed,

• Keep hands awayfrom movingparts and cutting

surfaces.

• Never leavetool runningunattended.Turnthe power

offend donotleave tool untilit comes to a complete

stop,

• Do not overreach.Keep proper footing and balance.

• Never standontool.Seriousinjurycouldoccuriftoolis

tippedor if blade Is unintentionallycontacted.

• Knowyour tool.Learnthe tool'soperation,applica-

tionand specificlimitations,

2

RightFax 11/14/2002 9:40 PAGE 4/33 RightF&x

• Use recommendedaccessories(referto page 15).

Use of improper accessories maycauserisk of

injuryto persons.

• Handle werkpieca correctly. Protect handsfrom pos-

sibleinjury,

• Turn machineoft if itjams. Bladejams when itdigs

toodeeply into workplese. (Motorforcekeeps it

stuckin the work.)

• Alwayskeep drive, cutterheadand blade guards In

place and in proper operatingcondition.

• Feed work intoblade or cutteragainstdlrectfonof

rotation.

CAUTION: Think safety!Safety Is a combination of

operatorcommon senseand alertnessat alltimes

when toolis being used,

WARNING: Do notattempt to operate tool untilit is

completely assembledacoordlngtothe Instructions.

Check for shippingdamage. If damage hasoccurred,a

claim must be fliedwith carrier. Check forcomplete-

ness.Immediately report missingparts todealer.

Additionalpartswhich needto befastenedto the planer

shouldbe locatedand accountedforbeforeassembling.

Planer is shipped assembled exceptfor thefollowing:

two table extensionswifh rollers,handwhael,handle,

chip chute,knifegauge rod,two knife gauges,hardware

bag,8/10 mmand 12/16 mmopen-endwrenches,and

3, 4, 5 and6 rnmhex wrenches.

Hardware bag includes:

• 8-1.25 x 20ram Hex Head Bolt (6)

• 6-1.0 x 12mm Socket Head Bolt(3)

• 6-1.0 x 12ram HexWasher Head Bolt (3)

• 6-1.0mm H_ Nut (3)

• 10-1.25mm Hex Nut (1)

• 6turnFlatWasher (6)

• 8mm FlatWasher (6)

• 10mm FlatWasher (1)

• 6rnrnLockWasher (3)

• 8-1.25 x 12mmSet Screw (6)

• 3 CMI-11 E-ring(4)

• 4x 4x 10mm Kay

• DirectionIndicator

IMPORTANT: Table is coated wifh a protectant.To

ensureproperfit and operation,removecoating.

CoatingIs easily removedwith mildsolvents,suchas

mineral spirits,and a soft cloth.Avoidgettingsolution

on paint or any of the rubber or plasticparts.Solvents

may deterioratethese finishes. Use soapand water on

paint, plasticor rubbercomponents, Aftercleaning,

cover allexposed surfaceswith a lightcoating ofoil

Paste wax Is recommended for tabletop.

WARNING: Never usahighlyvolatilesolvents.Non-

flammablesolventsare recommendedto avoidpossible

fire hazard.

WARNING: Do not attempt assemblyif partsare

missing. Usethis manual to orderreplacement parts.

PLANER INSTALLATION

Referto Figure20.

Beforeplaner isassembled,a suitablelocationshould

be chosen.The planerweighs approximately550 Ibs

when completely assembled.Planer shouldbe assem-

bledon location.

Planer needsto be set on a flat, level surface.This

improvesstability, accuracyand preventswarpage

and failureofcast components and welds.Adjust

machine levelersor use shimsas required.

Make sure there is arnpleroom on beth Infeedand

outfeedsidesof planerfor movingthe workplace

throughthe entire cut,There must be enoughroom

that neitherthe operatorsnorthe bystanderswill

haveto stand in linewith thewoodwhile usingthe

tool.

Good lightingand correct powersupply(230 volts)

are alsorequiredfor e properwork area.

Place planer in its designatedspot.Door panelfor

accessto motor is on back side.The planeris sup-

pliedwithfour movinghandlesthat slide intothe

base onthe infeedand outfeed sides.The planer

can be liftedbythese handlesand movedto the

required location.

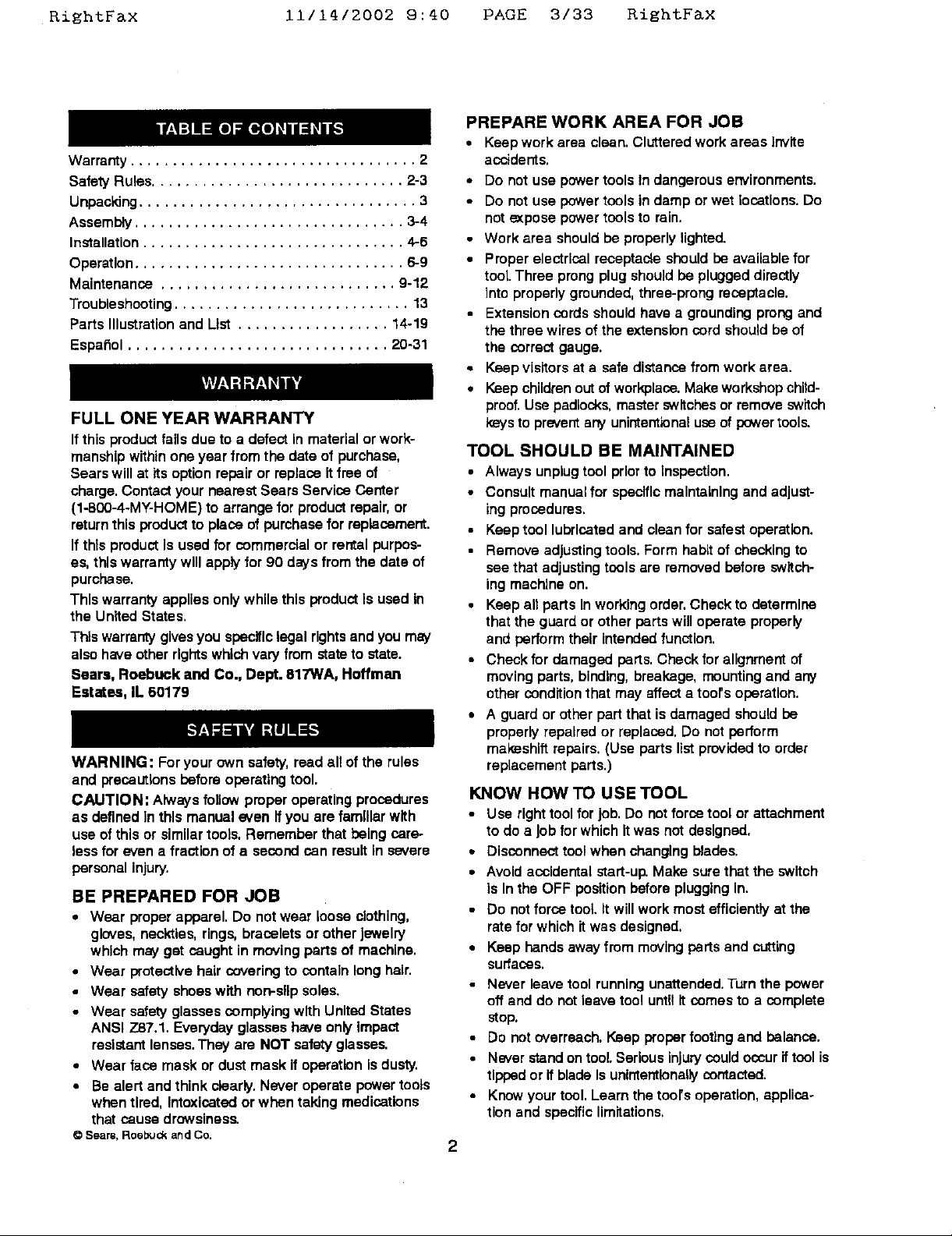

MOUNT TABLE EXTENSIONS

Refer to Figure1, page 4,

• Required hardware:

8-1.25 x 20mmHex Head Bblt(6)

8rnm FlatWasher (6)

8-1.25 x 12ramSet Screw(6)

• Mounttable extensionto planertable onthe lnfeed

sideusingthree 8-1.25 x 20mrnhe_ head boltsand

8mm flatwashers, Do nottighten bolts.

• Thread three 8-1.25 x 12mm set screwsinto exten-

sions.

•Placa long straight edge acrosstable and table

extensions.

• Adjustset screwssothat the table extensionis at

the same heightasthe table.

• Tightenbaitsto secureextension.

• Repeat abovesteps forthe outfeede0(tension.

3

RightFm× ii/1412002 9:40 PAGE 5/33 RightF&×

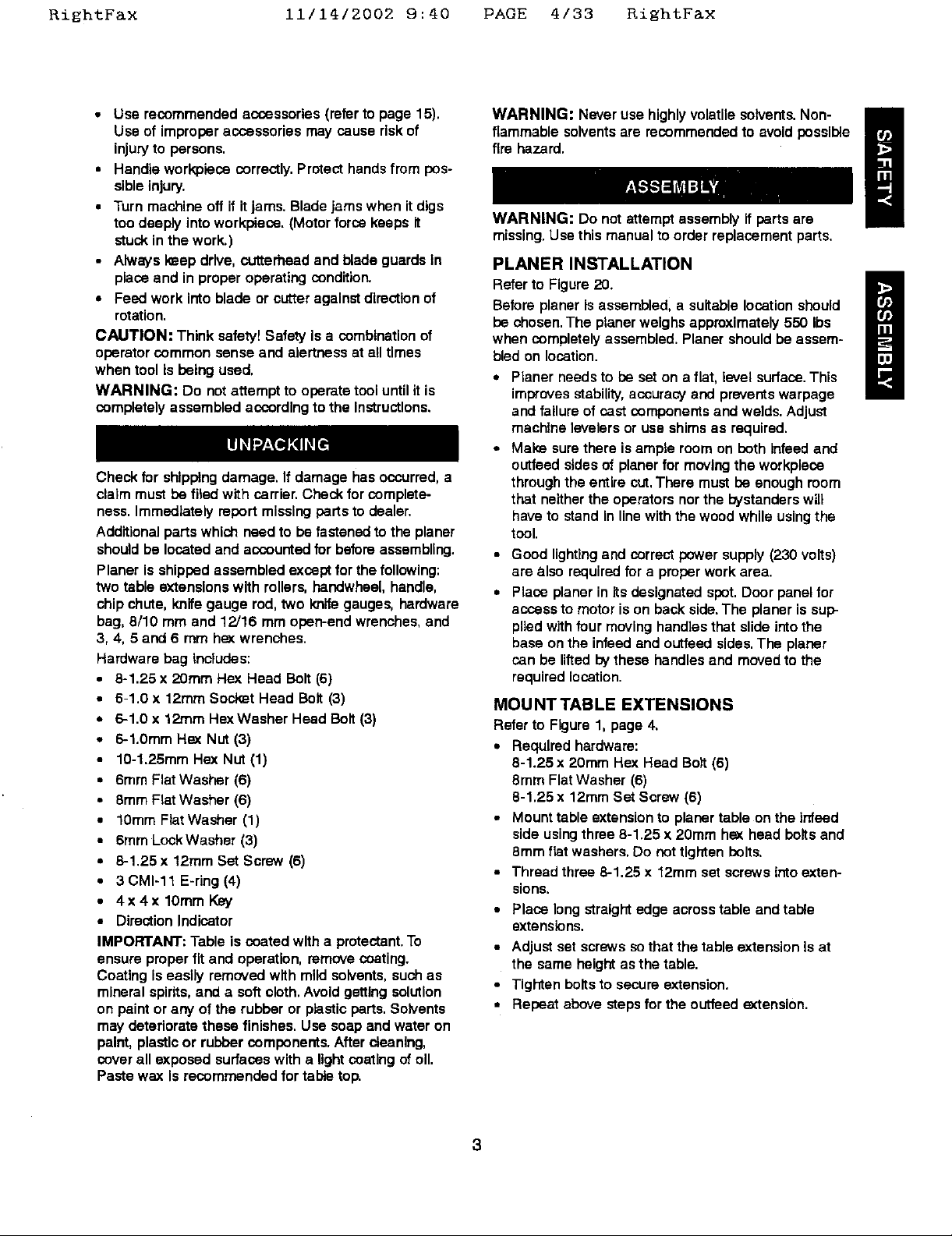

KNIFE GAUGE ASSEMBLY

Referto Figure2.

• Required parts and hardware:

KnifeGauge Rod

KnifeGauge (2),

3-CMI 11 E-Ring(4)

The knifegauge assemblyIs usedto verifythe heightof

bladeedges and to makeadjustmentsif necessary.

• Slide knifegauge onto knifegaugerod.

• Positionknifegauge on the rod so thatthere isa

grooveon eithersideof gauge.

• PressIn E-rings,one ineach groove,end secure

knifegaugeposition.

Figure1- MountTi 4eExtensions

MOUNT HEIGHT ADJUSTMENT

HANDWHEEL

Refer to Figure 19.

• Requiredparts and hardware:

Handwhael

Handle

4 x 4x lOmm Key (1)

lOmm Flat Washer (1)

10-1.25mm Hex Nut(1)

Direction Indicator (1)

• Positionthe k_=yin the keywayonthe worm shaft

• Repeat above steps forthe other knifegauge on the

otherend ofthe rod.

¢J_0 " rod

Figure2 - KnifeGaugeAssembly

(KeyNo.58).

• Slide handwheel over worm shaftsothat the keyway

isaligned with key on worm shaft.

• Slide the direction Indicator onthe worm shaft.Make

surethe directionindicatorpointscorrectly.

• Use flat washer and hexnutto securehandwheelto

worm shaft.

• Thread handle intohandwhael.

MOUNT CHIP CHUTE

Refer to Figure 19.

• Required parts and hardware:

Chip Chute

6-1.0 x 12ram Hex Washer Head Bolt(3)

6-1.0mm Hex Nut (3)

6ram FlatWasher (6)

6-1.0 x 12ramSocle_tHead Bolt(3)

6ram LockWasher (3)

• Positionchipchuteon chipbreakercover(KeyNo.68)

sothatthe slotson chip chute and chlpbreekercover

are alignedand slotson chipchuteand holesonthe

rollercase are aligned.

• Secure chipchute to chlpbreakerusingthree hex

washer head bolts,sixflatwashersand three he:<

nuts.

• Secure chip chute to roller case using three socket

head bolts and lock washers.

POWER SOURCE

Refer to Figure3, page 5.

WARNING: Do not connectplaner to the power

sourceuntilall assemblysteps havebeen completed.

The motoris designedfor operationonthe voltageand

frequency specified.Normal loadswillbe handled safe-

lyon voltagesnot morethan 10% aboveor below spec-

ifiedvoltage.Runningthe uniton voltageswhich are not

wifhlnrange may cause overheatingandmotorburnout,

Heavy loadsrequire that voltageat motorterminals be

no less thanthe voltage specifiedon nameplate.

GROUNDING INSTRUCTIONS

WARNING: Improperconnection of equipment

groundingconductor can resultIn the riskof electrical

shock.Equipmentshouldbe groundedwhile In use to

protectoperatorfrom electricalshock,

Check witha qualifiedelectricianif groundinginstruc-

tionsare not understoodor if in doul_ as to whetherthe

toolIs properlygrounded.

This toolts equippedwith an approved3-conductor

cord rated up to 250V and a 3-pronggroundingtype

plug ratedat 250V (See Figure3) for yourprotection

againstshockhazards.

Do notremoveor altergroundingprongIn any manner.

In the event of a malfunction or breakdown,grounding

provides a pathof least reslstancafor electricalshock.

4

Righ%F&x 11/14/2002 9:40 PAGE 6/33 RightFax

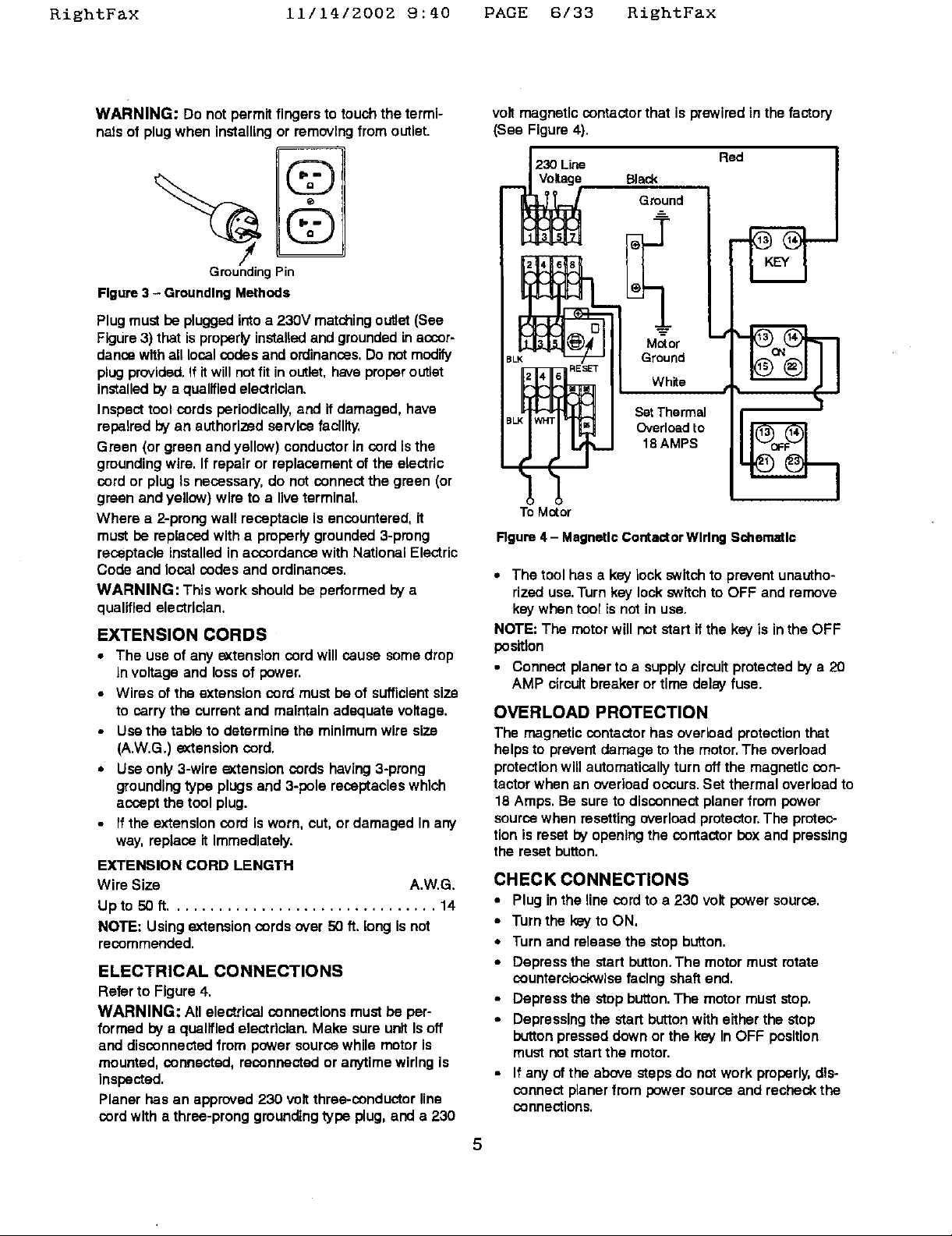

WARNING: Do not permit fingers totouch the termi-

nals of plug when installing or remevlncfromoutlet.

Grounding Pin

Figure 3 - Grounding Methods

Plugmust be pluggedintoa 230V matchingoutlet(See

Figure3) that is properlyinstaUedandgroundedin aocer-

dancewithall localcodesand ordinances,Do notmodify

plugprovided.If it will notfit inoutlet,have properoutlet

Installed_ a qualifiedelectrician.

Inspecttoolcordsperiodically,and ifdamaged, have

repeited by an authorized servlsefacility,

Green (orgreenand yellow)conductorin cord isthe

groundingwire.If repair or replacementof the electric

cordor plug isnecessaw, donot connect the green (or

greenand yellow) wire to a liveterminal.

Where a 2-pmng wall receptacleIs encountered,it

mustbe replacedwith a properlygrounded3-prong

receptacleinstalledin accordancewith NationalElectric

Code and local codesand ordinances.

WARNING: This work should be performed by a

qualified electrician.

EXTENSION CORDS

• The use of any extensioncordwillcause some drop

Lnvoltageand lossof power.

• Wires of the extensioncord must be of sufficientsize

to carry the currentand maintainadequate voltage.

• Usethe table to determine the minimumwire size

(A.W.G.) extensioncord.

* Useonly 3-wireextension cordshaving3-prong

groundingtype plugsand 3-pole receptacleswhich

acceptthe toolplug.

If the extensioncord is worn, cut, or damaged in any

way,replace it Immediately.

EXTENSION CORD LENGTH

Wire Size A.W.G.

Upto 50ft................................ 14

NOTE: Usingextensioncords ever 50 ft. long Isnot

recommended.

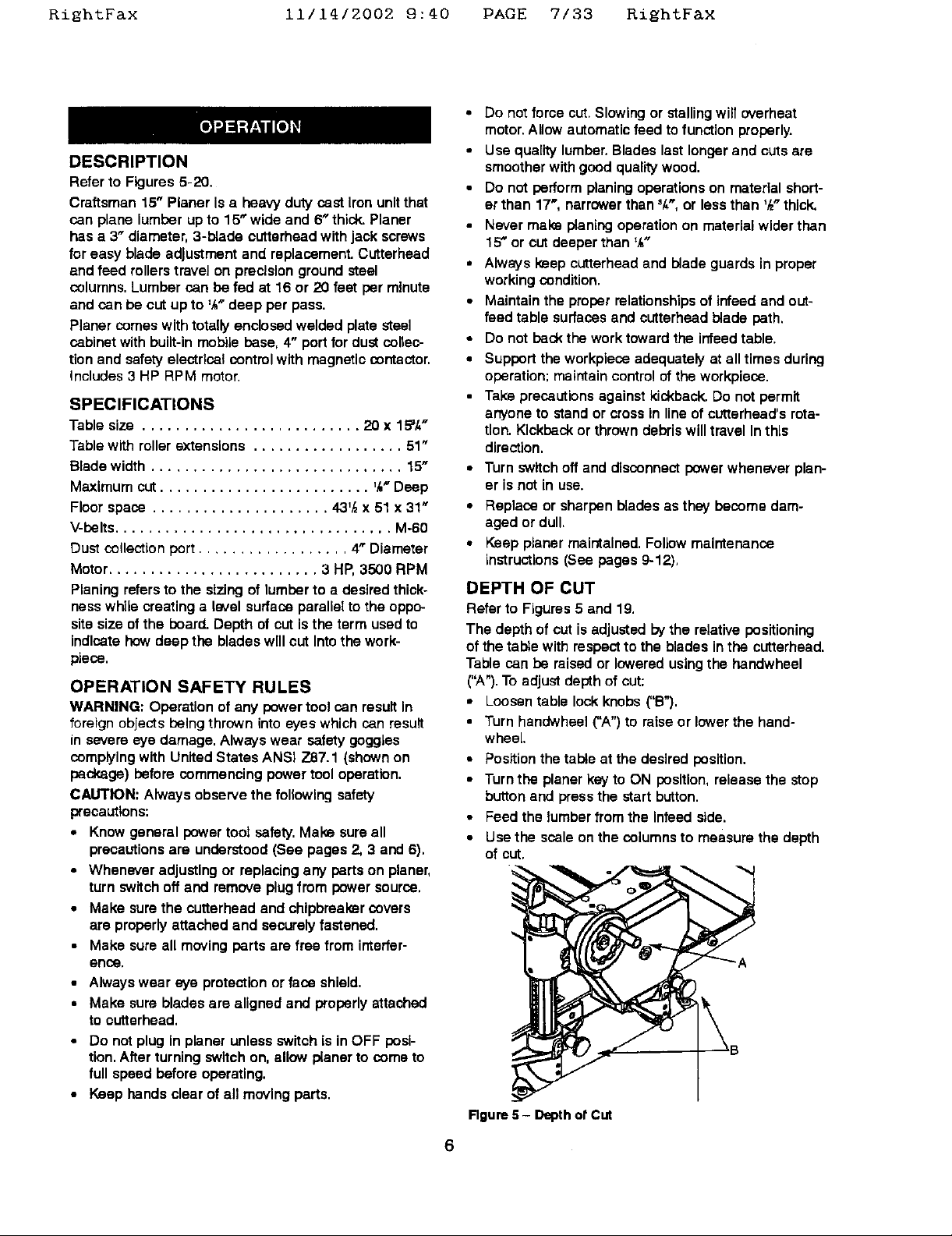

ELECTRICAL CONNECTIONS

Referto Figure 4.

WARNING: All eleotricalconnections mustbe per-

formed bya qcallfled electrician.Make sureunitisoff

and disconnectedfrom powersourcewhile motoris

mounted,connected, reconnectedor anytimewiring is

Inspected.

Planerhasan approved230 voltthree-conduotorline

curdwitha three-pronggroundingtypeplug,and a 230

volt magnetic contactor that is prewired in the factory

(See Figure 4),

Black Red

Ground

Ground

Motor ,M

White t

SetThermal

18AMPS

Ovedoadto

To Motor

Rgure 4 - Magnetic Contactor Wiring Schematic

• The toolhas a key lock switchto prevent unautho-

rized use.Turnkey lockswitchto OFF andremove

keywhentool isnot in use.

NOTE: The motorwellnotstart ifthe key is inthe OFF

position

• Connect planerto a supplycircuitprotectedbya 20

AMP circuitbreakeror time delayfuse.

OVERLOAD PROTECTION

The magneticcentactor has overloadprotectionthat

helpsto preventdamage to the motor.The overload

protectionwillautomaticallyturn offthe magneticcen-

tactorwhen an overloadoccurs.Set thermaloverloadto

18 Amps. Be suretodisconnectplanerfrom power

sourcewhen resettingoverloadprotector.The protec-

tionis resetby openingthe contactor boxand pressing

the resetbutton.

CHECK CONNECTIONS

• Plugin theline cord to a 230 volt power source.

• Turnthe keyto ON,

• Turn and release the stopbutton,

• Depress the start button.The motormust mtate

counterclockwise facingshaftend.

• Depress the stopbutton.The motormust stop.

• Depressingthe start buttonwith eitherthe stop

buttonpresseddown or the key InOFF position

mustnotstart the motor.

• If any of the above steps do notwork properly,dis-

connectplaner from power source and recheckthe

connections.

5

RightFax 11/14/2002 9:40 PAGE 7/33 KiEhtFax

Do notforce cut.Slowingor stalling willoverheat

motor.Allow automaticfeed to functionproperly.

DESCRIPTION

Referto Figures5-20.

Craftsman15" Planer isa heavyduty cast ironunitthat

can plane lumbar upto 15"wide and 6" thick`Planer

hasa 3" diameter,3-blade cutterheadwith jack screws

for easy blade adjustmentand replacement.Cutterhead

and feed rollerstravel on precisiongroundsteel

columns.Lumbercan be fed at 16 or20 feet per minute

and can becut up to ',V"deep per pass.

Planarcomes with totallyenclosedwelded platesteel

cabinet withbuilt-inmobilebase, 4" portfor dustcollec-

tionand safetyelectricalcontrolwith magneticcontector.

includes3 HP RPM motor.

SPECIFICATIONS

Tablesize .......................... 20 x 15'/,"

Tablewith rollerextensions .................. 51"

Bladewidth .............................. 15"

Maximumcut......................... ,/,"Deep

Floorspace ..................... 4-3'hx 51 x 31"

V-pelts................................. M-60

Dust collectionport .................. 4" Diameter

Motor ......................... 3 HP,3500 RPM

Planing refers to the sizingof lumbar to a desired thick-

ness while creatinga level surfaceparallel to the oppc-

site sizeof the board.Depth of cut is the term used to

Indicate how deep the blades will cut Into the work-

piece.

OPERATION SAFETY RULES

WARNING: Operation of any power tool can resultIn

foreign objects beingthrown intoeyes which can result

in severe eye damage. Always wear safety goggles

complying with UnitedStates ANSI 7_87.1(shownon

package) before commencingpowertool operation.

CAUTION: Always observethe following safety

precautions:

• Knowgeneral powertool safety.Make sureall

precautionsare understood(See pages 2, 3 and 6).

Use qualitylumber.Blades lastlongerand cutsare

smootherwithgood qualitywood.

Do not performplaningoperationson materialshort-

erthan 17•, narrowerthans/,,, or less than '/="thick,

Never make planing operationon materialwider than

15" or cutdeeperthan ',V'

Always keep cutterheadand bladeguards in proper

workingcondition.

Maintainthe properrelationshipsof Infeed and out-

feed table surfacesand cutterheadblade path.

Do not packthe worktowardthe infeedtable.

Supportthe workpieceadequatelyat all times during

operation;maintain controlof theworkpieca.

Take precautionsagainst kickback.Do not permit

anyoneto stand or crossin line of cutterheads rota-

tion. Kickbackor throwndebriswilltravel Inthis

direction.

Turn switchoff and disconnectpowerwheneverplan-

er isnot in use.

Replace or sharpen bladesas they become dam-

aged or dull.

Keep planar maintained.Followmaintenance

instructions (See pages 9-12).

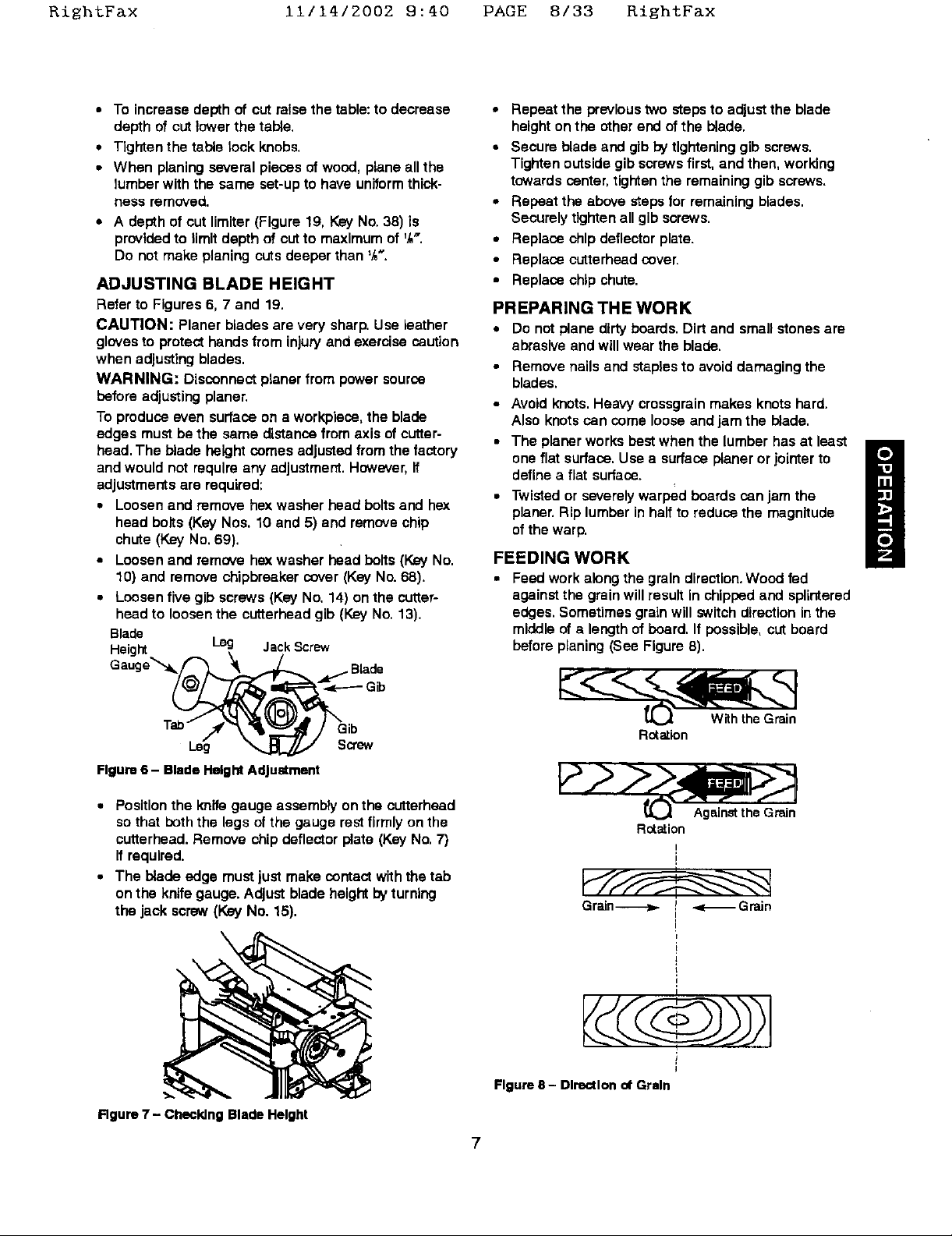

DEPTH OF CUT

Refer to Figures 5 and 19.

The depth of cut is adjusted by the relative positioning

of the table with respect to the blades in the cutterhead.

Table can be raised or lowered using the handwheel

("A").To adjust depth of cut:

• Loosen table lock knobs ("B").

• Turn handwheel CA") to raise or lowerthe hand-

wheel

• Position the table at the desired position.

• Turn the planer key to ON position, release the stop

button and press the start button.

• Feed the lumber from the Infeed side.

• Use the scaleon the columnsto measure the depth

of cut.

• Whenever adjustingor replacingarTypartson planer,

turnswitchoff and removeplugfrom powersource.

• Make surethe cutterheadand chipbreakercovers

are properlyattached and securelyfastened.

• Make sureall movingparts are free from interfer-

enoe.

• Always wear eye protection or face shield.

• Make sure blades are aligned and properly attached

to cutterhead.

• Do notplug in planer unless switchis inOFF posi-

tion.After turningswitch on, allowplanerto come to

full speedbeforeoperating.

• Keep hands clear of all moving parts.

Rgure 5- Depthof CUt

6

RightFax 11/14/2002 9:40 PAGE 8/33 RishtFax

• To increase depthof cut raisethe table:to decrease

depthof cutlowerthe table.

• Tighten the table lock knobs.

• When planingseveral pieces of wood, planeall the

lumber with the same set-upto have uniformthick-

ness removed.

A depth of cut limiter (Figure 19, Key No. 38) is

provided to limit depth of cut to maximum of 'At

Do not make planing outs deeper than _,V'.

ADJUSTING BLADE HEIGHT

Refer to Figures 6, 7 and 19,

CAUTION: Planer blades are very sharp.Use laather

glovesto protecthandsfrom injury and exercisecaution

when adjustingblades.

WARNING: Disconnectplanerfrom powersource

beforeadjustingplaner.

To produce even surfaceon a workplace,the blade

edges mustbe the same distancefrom axis of cutter-

head.The blade height comes adjustedfrom the factory

andwould not raqulra any adjustment.However,if

adjustments are required;

• Loosenand remove hex washer head boltsand hex

head bolts (Key Nos. 10 and 5) and removechip

chute (KeyNo.69).

• Loosenand remove hex washer head bolts(Key No.

10) and removechipbraakercover (Key No. 68).

• Loosenfive gib screws(Key No. 14) on the cutter-

head to loosenthe cutterheadgib (Key No.13).

Blade

Height leg JackScrew

Gauge'_

• Repeat the previoustwo steps to adjustthe blade

heightonthe other endof the blade.

• Secure blade and glb bytighteninggib screws.

Tightenoutsidegib screwsfirst, and then, working

towardscenter, tightenthe remaininggib screws.

• Repeat the abovesteps for remainingblades.

Securelytightenall gib screws.

• Replace chipdeflectorplate.

• Replace cutterheadcover.

• Replace chip chute.

PREPARING THE WORK

• Do not plane dirty boards. Dirt and small stones are

abrasive and will wear the blade.

Remove nails and staples to avoiddamagingthe

blades.

• Avoid knots. Heavy crossgrain makes knots hard.

Also knots san come loose and jam the blade.

• The planer works best when the lumber has at least

one flat surface. Use a surface planer or jointer to

define a flat surface.

• Twisted or severely warped boards can jam the

planer. Rip lumber in half to reduce the magnitude

of the warp.

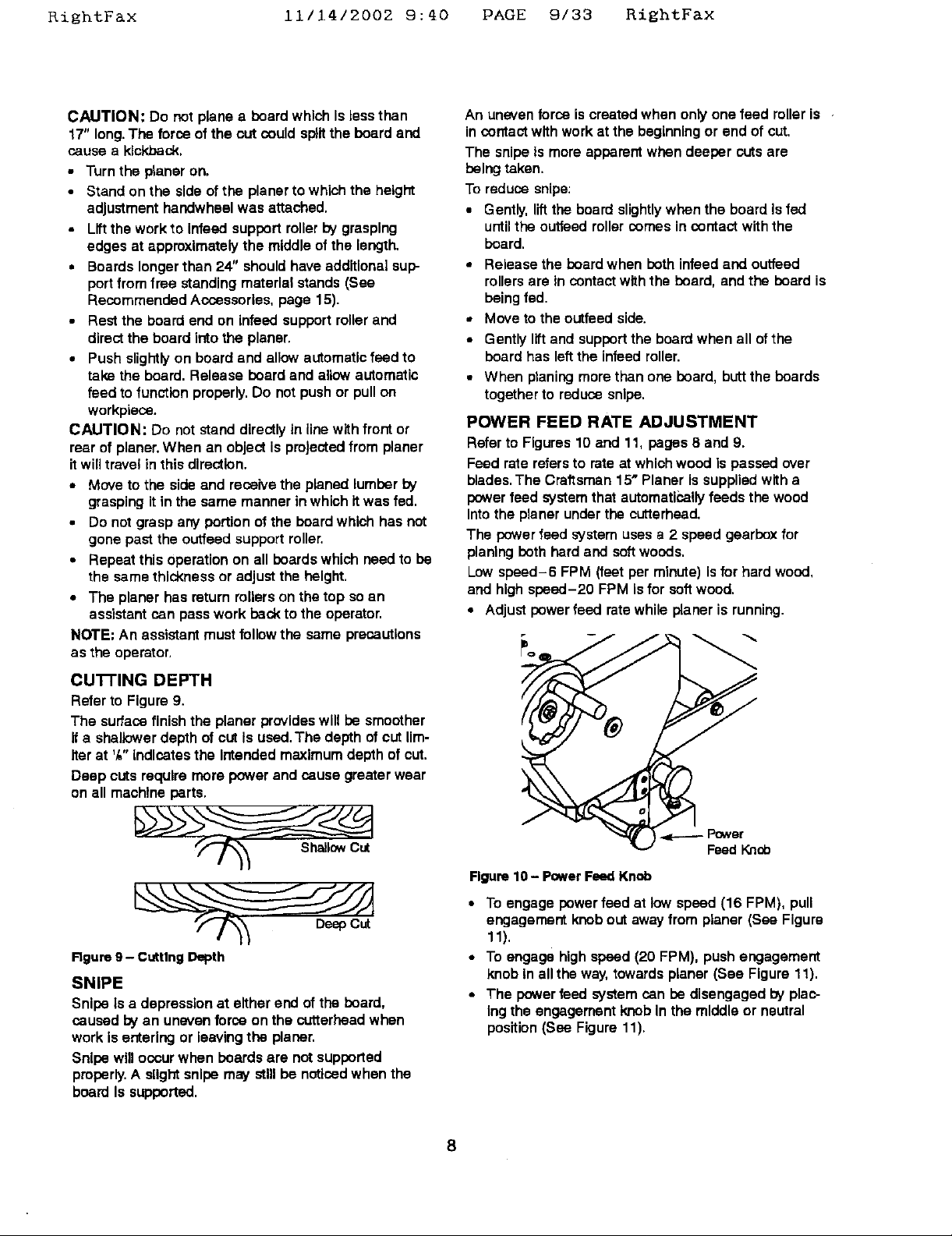

FEEDING WORK

• Feed work along the grain direction. Wood fed

against the grain will result in chipped and splintered

edges. Sometimes grain will switch direction inthe

middle of a length of board. If possible, cut board

before planing (See Figure 8).

m

6_

Figure 6- Blade Height Adjustment

• Position the knife gauge assembly on the cutterhead

so that both the legs of the gauge rest firmly on the

cutterhead. Remove chip deflector plate (Key No, 7)

if required.

• The blade edge must just make contact with the tab

on the knife gauge. Adjust blade height by turning

the jack screw (Key No. 15),

\

Rgure 7 - Checking Blade Height

Rotation

Rotation

Grain----->. I -._-_Grain

Figure 8 - Direction ot Grain

Against the Grain

!

I

!

!

i

RightF&x iii14/2002 9:40 PAGE 9/33 RightF&x

CAUTION: Do not plane a beard which Is less than

17" long. The force of the cut could split the board and

cause a kickback,

• Turn the planer on.

• Stand on the side of the planer to which the height

adjustment handwheal was attached.

• Lift the workto infeed support roller by grasping

edges at approxlmeteiy the middle of the length,

• Boards longer than 24" should have additional sup-

port from free standing material stands (See

Recommended Accessories, page 15).

• Rest the board end on infeed support roller and

direct the board Into the planer.

• Push slightly on board and allow automatic feed to

takB the board. Release beard and allow automatic

feed to function properly. Do not push or pull on

workpiace.

CAUTION: Do not stand directly in line with front or

rear of planer. When an object is projected from planer

itwill travel in this direction.

• Move to the side and receive the planed lumber by

grasping it in the came manner in which itwas fed,

• Do not grasp any portion of the board which has not

gone past the outfeed support roller,

• Repeat this operation on all beards which need to be

the same thickness or adjust the height.

• The planer has return roflers on the top so an

assistant can pass work beck to the operator,

NOTE: An assistant must follow the same precautions

as the operator_

C U'I-I'ING DEPTH

Refer to Figure9.

The surfacefinishthe planer provideswill be smoother

it a shallowerdepth of cut Is used.The depth of cutUm-

iter at ',_"indicatesthe intended maximum depthof cut.

Deep cutsrequire morepowerand cause greater wear

on all machine parts.

An unevenforce is createdwhen onlyone feed rolleris

in contactwith workat the beginningor end of cut.

The snipeis moreapparentwhen deeper cutsare

being taken.

To reduce snipe:

• Gently, liftthe board slightlywhen the board Is fed

untilthe outfeadrollercomesin contactwith the

board.

• Release the boardwhen beth infeed and ouffaad

rollersare incontactwiththe beard, andthe beard is

beingfad.

• Moveto the outfaed side.

• Gentlyliftand supportthe boardwhen all of the

beard has leftthe infeed roller.

• When planing morethan one beard, buttthe boards

togetherto reduce snipe.

POWER FEED RATE ADJUSTMENT

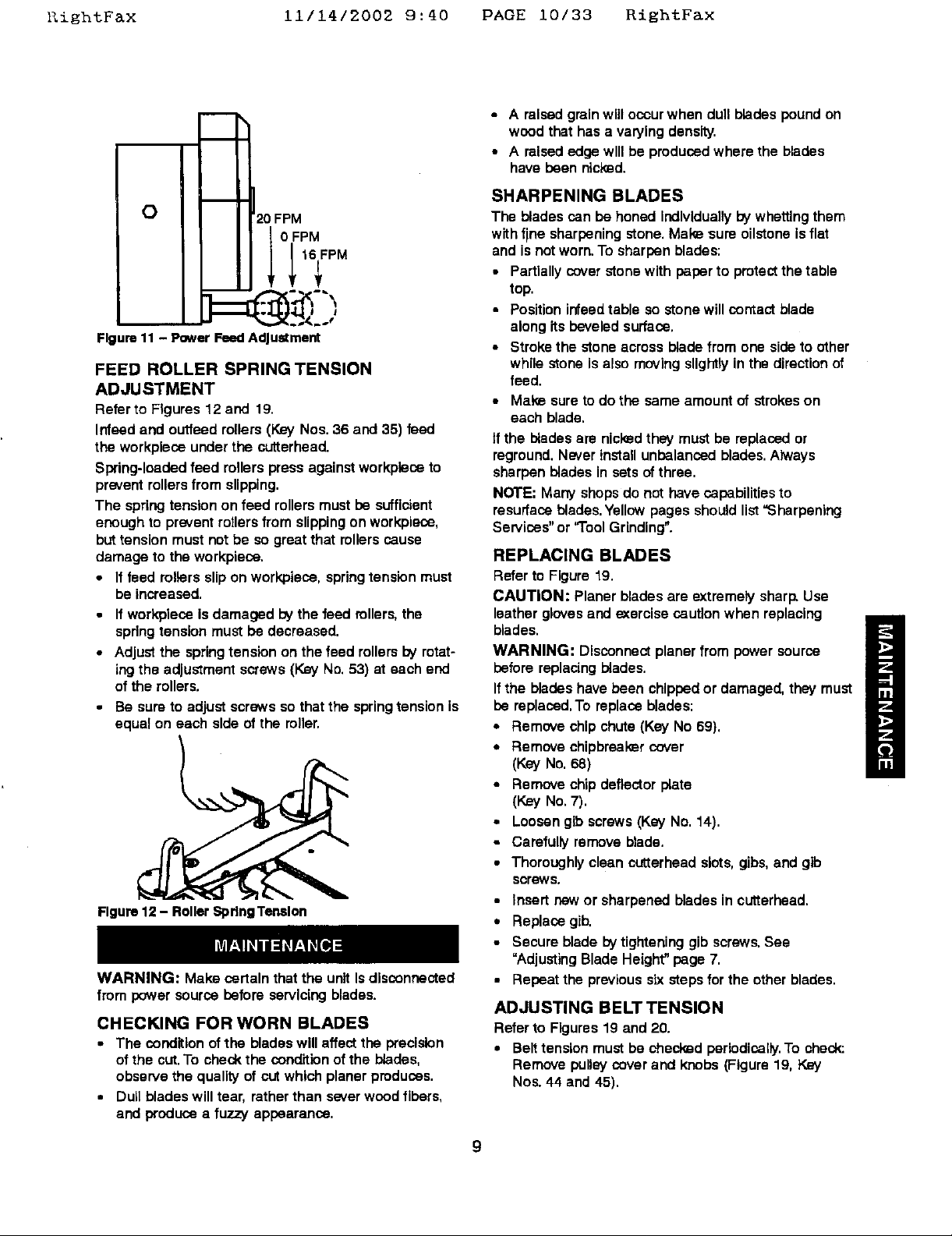

Refer to Figures10 and 1% pages 8 and 9.

Feed rate refersto rate at whichwood is passed over

blades.The Craftsman15" Planer is suppliedwitha

powerfeed systemthat automaticallyfeeds the wood

Intothe planerunderthe cutterhead.

The powerfeed system usesa 2 speed gearboxfor

planingbeth herd and softwoods.

Lowsbeed-6 FPM (feet per minute)Isfor hard wood,

and highspeed-20 FPM isfor soft wood.

• Adjustpower feed ratewhile planer is running.

Rgure9- CuttingDepth

SNIPE

Snipe Is a depressionat either end ofthe beard,

caused by an unevenforce on the cutterbeedwhen

work is entering or leevingthe planer,

Snipewilloccurwhen beards are not supported

properly,A slightsnipe may stnibe noticedwhenthe

board Is supported,

-4e----- Power

Feed Knob

Figure 10 - Power Feed Knob

• To engage power fead at low speed (16 FPM), pull

engagementknobout awayfrom planer (See Figure

11).

• To engagehigh speed (20 FPM), pushengagement

knobin allthe way,towardsplaner (See Figure11).

• The powerfeed system can be disengagedby plac-

Ingthe engagementknob In the middleor neutral

position(See Figure 11).

8

_ightFax 11/14/2002 9:40 PAGE 10/33 RightFax

m

i

O

Figure 11 - Power Feed AdJuldment

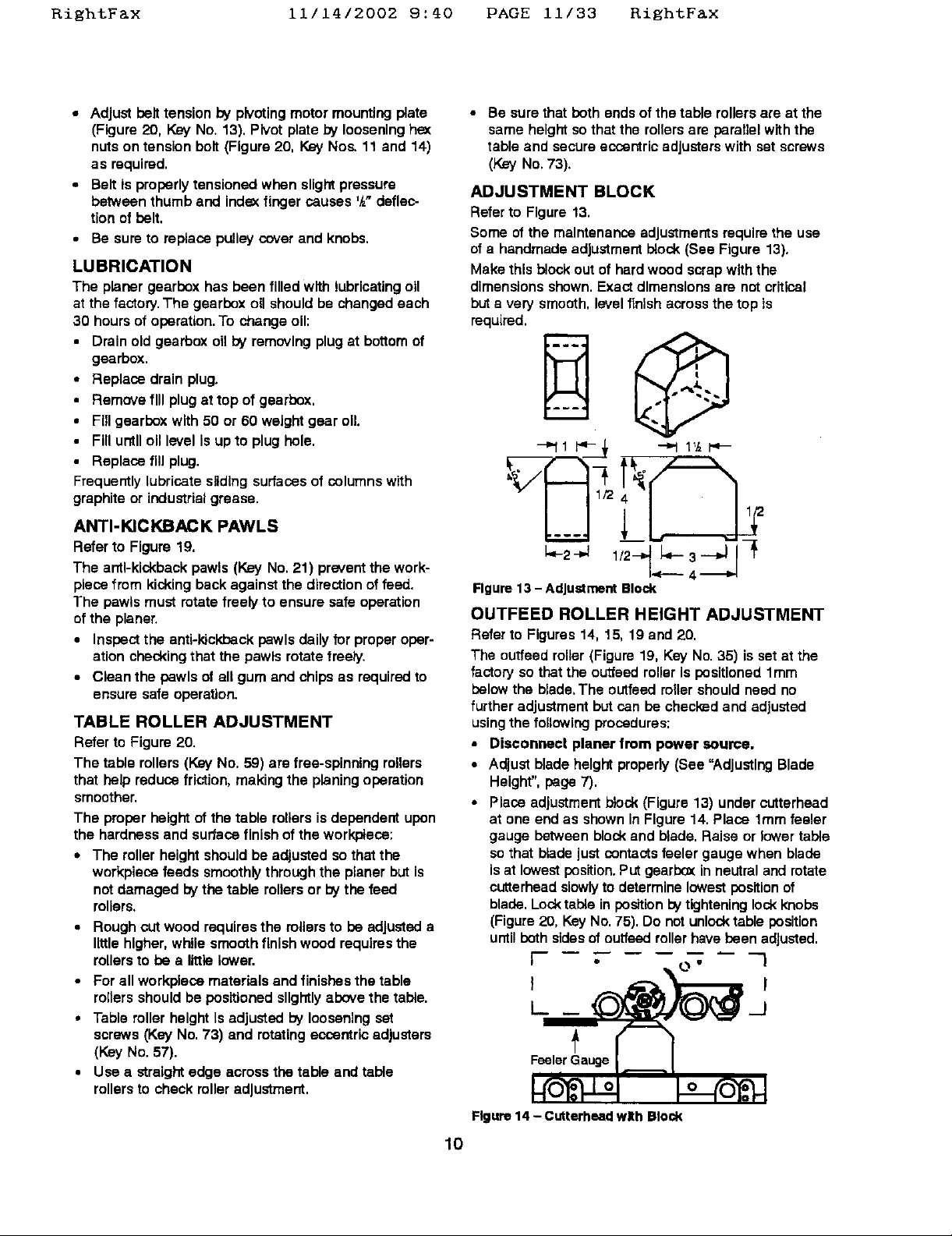

FEED ROLLER SPRING TENSION

ADJUSTMENT

Refer to Figures 12 and 19.

Infeed and outfeed rollers (Key Nos. 36 and 35) feed

the workplace under the cutterhaad.

Swing-loaded feed rollers press against workplece to

prevent rollers from slipping.

The spring tension on feed rollers must be sufficient

enough to prevent rotlers from slipping on wcrkpiece,

but tension must not be so great that rollers cause

damage to the workplace.

• If feed milers slip on workpfece, spring tension must

be increased.

20 FPM

0 FPM

• Ifworkpleca is damaged bythe feed rollers,the

springtensionmust be decreased.

• Adjustthe springtension on thefeed rollersbyrotat-

ingthe adjustmentscrews(KeyNo.53) at each end

of the rollers.

• Be sure toadjustscrews sothat the springtensionis

equal on each side of the roller.

Figure 12 - Roller Spdng Tenelon

WARNING: Make certain that the unit Is disconnected

from power source before servicingblades.

CHECKING FOR WORN BLADES

• The condition of the blades will affect the precision

of the cut. To check the condition of the blades,

observe the quality of cut which planer produces.

• Dull blades will tear, rather than sever wood fibers,

and produce a fuzzy appearance.

• A raised grain will ocour when dull blades pound on

wood that has a varying density.

• A raised edge will be produced where the blades

have been nicked.

SHARPENING BLADES

The blades can be honed individually by whetting them

with fine sharpening stone. Make sure oilstone is flat

and is not worn. To sharpen blades:

• Partially cover stone with paper to protect the table

top.

• Position infead table so stone will contact blade

along its beveled surface.

• Stroke the stone across blade from one side to other

while stone is also moving slightly in the direction of

feed.

• Make sure to do the same amount of strokes on

each blade.

tf the blades are nici_d they must be replaced or

reground. Never install unbalanced blades. Always

sharpen blades in sets of three.

NOTE: Many shops do not have capabilities to

resurface blades. Yellow pages should list "Sharpening

Services" or "1"oolGrinding".

REPLACING BLADES

Refer to Figure19.

CAUTION: Planer blades are extremelysharp,Usa

leatherglovesand _0cercisecautionwhen replacing

blades.

WARNING: Disconnectplanerfrom powersource

beforereplacingblades.

Ifthe bladeshave been chippedor damaged, they must

be replaced.To replacablades:

• Remove chip chute(Key No 69),

• Remove chipbreakercover

(Key No.68)

• Remove chip deflectorplata

(Key No.7).

• Loosen gib screws(Key No. 14).

* Carefully remove blade.

• Thoroughlyclean cutterhaadslots,gibs,and gib

screws.

• insert new or sharpened bladesin cuttarhead,

• Replacegib,

• Secure bladeby tighteninggib screws.See

"Adjusting Blade Height"page 7,

• Repeat the previoussixstepsforthe otherblades,

ADJUSTING BELT TENSION

Refer to Figures 19 and 20.

• Belt tension must be checked periodically. To check:

Remove pulley cover and knobs (Figure 19, Key

Nos. 44 and 45).

9

RightFax 11/14/2002 9:40 PAGE 11/33 R±ghtF&x

• Adjust bolt tension by pivoting motor mounting plate

(Figure 20, Key No. 13). Pivot plate by loosening he_

nuts on tension bolt (Figure 20, Key Nos. 11 and 14)

as required.

• Belt ts properly tensioned when slight pressure

between thumb and inde_€finger causes '/z" deflec-

tion of bolt.

• Be sure to replace pulley cover and knobs,

LUBRICATION

The planergearbox has beenfilledwith lubrioatingoil

at the factory. The gearbox oil shouldbe changedeach

30 hours of operation.To changeo11:

• Drain old gearbox oil by removingplugat bottomof

gearbox.

• Replace drain plug.

• Remove fill plugat top of gearbox,

• Fillgearbox with 50 or 60 weightgear o11.

• Fill untiloll levelIs up to plughole.

• Replace fill plug.

Frequentlylubricateslidingsurfacesof columnswith

graphiteor industrialgrease.

ANTI-KICKBACK PAWLS

Refer to Figure 19,

The anti-kickback pawls (Key No. 21 ) prevent the work-

piece from kicking back against the direction of feed.

The pawls must rotate freely to ensure safe operation

of the planer.

• Inspect the anti-kickback pawls daily for proper oper-

ation checking that the pawls rotate freely.

• Clean the pawls of all gum and chips as required to

ensure safe operation.

TABLE ROLLER ADJUSTMENT

Refer to Figure 20.

The tablerollers(KeyNo. 59) are free-spinningrollers

that helpreducefriction, makingthe planingoperation

smoother.

The properheightof the table rollersisdependentupon

the hardnessand surfacefinishof the work,piece:

• The rollerheight shouldbe adjusted sothatthe

workplacefeeds smoothlythroughthe planerbutis

not damaged bythe table rollersor bythe feed

rollers.

• Roughcutwood requiresthe rollersto be adjusteda

littlehigher,while smoothfinishwood requiresthe

rollersto be a littlelower.

• Forall workplacematerialsand finishesthe table

rollersshould be positionedslightlyabove the table.

• Table roller heightIsadjusted by looseningset

screws(KeyNo.73) and rotatingeccentricadjusters

(Key No.57).

• Use a straight edge acrossthe table and table

rollersto checkmiler adjustment.

• Be sure thatboth ends of the table rollersare at the

same heightso that the rollersare parallel withthe

table and secureeccentricadjusterswith set screws

(Key No.73),

ADJUSTMENT BLOCK

Refer to Figure 13.

Some ofthe maintenance adjustmentsrequirethe use

ofa handmadeadjustmentblock (See Figure 13).

Makethis block out of hard wood scrapwiththe

dimensionsshown.Exactdimensionsare notcritical

but a very smooth,levelfinishacrossthe top Is

required.

_"11 i'_- ,_ _ 1'/_1_-

Figure 13 - Adjustment Block

OUTFEED ROLLER HEIGHT ADJUSTMENT

Referto Figures 14, 15, 19 and 20.

The outfeed roller(Figure19, Key No.35) isset at the

factory so that the outfeedrollerIs positioned 1ram

belowthe blade.The outfeedrollershouldneed no

further adjustmentbut can be checkz_dand adjusted

usingthe following procedures:

• Disconnect planer from power source.

• Adjust bladeheight properly(See "Adjusting Blade

Height".page 7).

• Place adjustmentbiock(Figure 13) under cutterhead

at one end as shownIn Figure14. Place 1ramfeeler

gauge betweenblockand blade.Raise or lower table

sothat bladejustcontactsfeeler gaugewhen blade

isat lowestposition.Putgearboxin neutraland rotate

cutterheadslowlyto determine lowestposition of

blade.Locktable in position _ tighteninglockknobs

(Figure20, KeyNo. 75). Do not unlocktable position

untilbothsidesof ouffeedrollerhave been adjusted.

l" , O" I

I-.__ _J

'

,°rOooo°"]

Figure 14 - Cutterheed w£h Block

10

Loading...

Loading...