Craftsman 351218331, 141218331 Owner’s Manual

Operator's Manual

1O"

CONTRACTOR TABLE SAW

Model No.

351.218331

/

. Safety

• Unpacking

CAUTION:

Read and follow all Safety

Rules and Operating

Instructions before First

Use of this Product. Keep

this Manual with Tool.

Sears Brands Management Corp., Hoffman Estates, IL 60179 U.S.A.

wv,rw,craftsman.com

36998.01 Draft (05/24113)

• Assembly

• Operation

= Maintenance

• Parts List

• Espa_ol

Warranty ......................................... 2

Safety Rules .................................... 2-5

Unpacking ...................................... 5-6

Assembly ..................................... 6-13

installation .................................... 13-14

Operation .................................... 14-19

Maintenance .................................... 20

Troubleshooting ............................... 22-23

Repair Protection Agreement ....................... 23

Parts Illustration and List ........................ 24-35

Espaffol ...................................... 36-59

CRAFTSMAN ONE YEAR FULL WARRANTY

FOR ONE YEAR from the date of purchase, this product is

warranted against any defects in material or workmanship.

Defective product will receive free repair or free replacement if

repair is unavailable.

For warranty coverage details to obtain repair or replace-

merit, visit the website: www.craftsman.com

This warranty does not cover the blade or belt, which is an

expendable part that can wear out from normal use within the

warranty period.

This warranty is void if this product is ever used while provid-

ing commerciaI services or if rented to another person.

This warranty gives you specific legal rights, and you may

also have other rights which vary from state to state.

Sears Brands Management Corporation, Hoffman Estates,

IL 60179

WARNING: For your own safety, read all of the instructions

and precautions before operating tool.

PROPOSITION 65 WARNING: Some dust created by using

power tools contain chemicals known to the state of California

to cause cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

• Lead from lead-based paints.

• Crystalline silica from bricks and cement and other

masonry products.

• Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures vary, depending on how often

you do this type of work. To reduce your exposure to these

chemicals: work in a well ventilated area and work with

approved safety equipment. Always wear OSHA/NIOSH

approved, properly fitting face mask or respirator when using

such tools.

CAUTION: Always follow proper operating procedures as

defined in this manual -- even if you are familiar with use of

this or similar tools. Remember that being careless for even a

fraction of a second can result in severe personal injury.

WARNING: THIS PRODUCT CONTAINS LEAD. A CHEMI-

CAL KNOWN TO THE STATE OF CALIFORNIA TO CAUSE

CANCER AND BIRTH DEFECTS OR OTHER REPRODUC-

TIVE HARM. WASH HANDS AFTER HANDLING.

BE PREPARED FOR JOB

• Wear proper apparel. Do not wear loose clothing, gloves,

neckties, rings, bracelets or other jewelry which may get

caught in moving parts of machine.

Sears Brands Management Corporation

• Wear protective hair covering to contain long hair.

• Wear safety shoes with non-slip soles.

° Wear safety glasses complying with United States ANSI

Z87.1. Everyday glasses have only impact resistant lens-

es. They are NOT safety glasses.

° Wear face mask or dust mask if operation is dusty.

° Be alert and think clearly. Never operate power tools when

tired, intoxicated or when taking medications that cause

drowsiness.

PREPARE WORK AREA FOR JOB

* Keep work area clean. Cluttered work areas invite acci-

dents,

, Do not use power tools in dangerous environments. Do not

use power tools in damp or wet locations. Do not expose

power tools to rain.

o Work area should be properly lighted.

° Keep visitors at a safe distance from work area.

° Keep children out of workplace. Make workshop childproof.

Use padlocks, master switches or remove switch keys to

prevent any unintentional use of power tools.

° Keep power cords from coming incontact with sharp

objects, oil, grease and hot surfaces.

TOOL SHOULD BE MAINTAINED

° Always unplug tool prior to inspection.

. Consult manual for specific maintaining and adjusting pro-

cedures.

- Keep tool lubricated and clean for safest operation.

° Remove adjusting tools. Form habit of checking to see that

adjusting tools are removed before switching machine on.

. Keep al! parts in working order. Check to determine that

the guard or other parts will operate properly and perform

their intended function.

. Check for damaged parts. Check for alignment of moving

parts, binding, breakage, mounting and any other condi-

tion that may affect a tool's operation.

° A guard or other part that is damaged should be properly

repaired or replaced. Do not perform makeshift repairs.

(Use parts list provided to order replacement parts.)

• Maintain proper adjustment of rip fence and blade guard.

° Never adjust saw while running. Disconnect power to avoid

accidental start-up.

- Have damaged or worn power cords replaced immediately.

. Keep blade sharp for efficient and safest operation.

KNOW HOWTO USE TOOL

. Use right tool for job. Do not force too] or attachment to do

a job for which it was not designed.

. Disconnect tool when changing blade.

° Avoid accidental start-up. Make sure that the tool is in the

"off" position before plugging in, turning on safety discon-

nect or activating breakers.

° Do not force tool. It will work most efficiently at the rate for

which it was designed.

o Keep hands away from blade and moving parts and cutting

surfaces.

. Never leave tool running unattended. Turn the power off

and do not leave tool until it comes to a complete stop.

° Do not overreach. Keep proper footing and balance.

. Never stand on tool. Serious injury could occur if tool is

tipped or if blade is unintentionally contacted.

o Know yourtoo]. Learn the tool's operation, application and

specific limitations.

° Handle workpiece correctly. Press firmly against table.

Protect hands from possible injury.

• Turn machine off if it jams. Blade jams when it digs too

deeply into workpiece. (Motor force keeps it stuck in the

work.)

• Feed work into the blade only as recommended in

"Operation"

WARNING; For your own safety, do not operate your saw until it

is completely assembled and installed according to instructions.

STABILITY OF SAW

If there is any tendency for the saw to tip over or move during

certain cutting operations, such as cutting extremely heavy

panels or long heavy boards, the saw should be bolted down.

tf you attach any kind of extensions over 24" wide to either

end of the saw, make sure you either bolt the saw to the floor,

as appropriate, or support the outer end of the extension from

the bench or floor, as appropriate.

LOCATION

The saw should be positioned so neither the operator nor a

casual observer is forced to stand in line with the saw blade.

KICKBACKS

A kickbackoccursduringa rip-typeoperationwhena part or

allof workpieceisthrownback violentlytowardoperator.

Keepyourface andbodyto one sideofthesawblade,outof

linewitha possible kickback.

Kickbacksand possibleinjuryfrom themcanusuallybe avoid-

edby:

• Maintainingripfence parallel to saw blade.

° Keepingsaw bladesharp.Replace or sharpen anti-kick-

backpawlswhenpointsbecomedull.

• Keepingsawblade guard, spreader,andanti-kickback

pawls in placeand operatingproperly.The spreader must

be in alignmentwiththe saw bladeand the pawlsmust

stopa kickbackonceit hasstarted. Checktheiraction

beforeripping.

• Not ripping workthat is twistedor warpedor doesnot

havea straight edge toguidealongthe rip fence.

• Not releasing workuntil youhavepushedit allthe way

pastthe saw blade.

• Usinga push stick for rippingwidthslessthan6 inches.

• Not confiningthecutoffpiecewhen ripping orcrosscutting.

PROTECTION: EYES, HANDS, FACE, BODY, EARS

• If any part of yoursaw ismissing, malfunctioning, or has

beendamagedorbroken(such asthe motor switch, elec-

troniccontrols,otheroperatingcontrol,a safety device or

powercord),cease operatingimmediately until the partic-

ularpart is properly.repairedorreplaced.

• Wear safety gogglesthat complywithUnitedStatesANSI

Z87.1 anda face shield or dustmask if operationisdusty.

Wear ear plugsor muffsduringextendedperiodsof oper-

ation.

• Small loose pieces of wood or other objects that contact

the rear of the revolving blade can be thrown back at the

operator at excessive speed. This can usually be avoided

by keeping the guard and spreader in place for all thru-

sawing operations (sawing entirely thru work) and by

removing all loose pieces from the table with a long stick

of wood immediately after they are cut off.

• Use extra caution when the guard assembly is removed for

resawing, dadoing, or rabbeting--replace guard as soon

as that operation is completed.

° Never turn the saw ON before clearing the table of all

tools, wood scraps, etc., except the workpiece and related

feed or support devices for the operation planned.

° Never place your face or body in line with the cutting tool.

° Never place your fingers or hands in path of saw blade or

other cutting tool.

° For rip or rip-type cuts, the following end of a workpiece to

which a push stick or push board is applied must be

square (perpendicular to the fence) in order that feed

pressure applied to the workpiece by the push stick or

block does not cause the workpiece to come away from

the fence, and possibly cause a kickback.

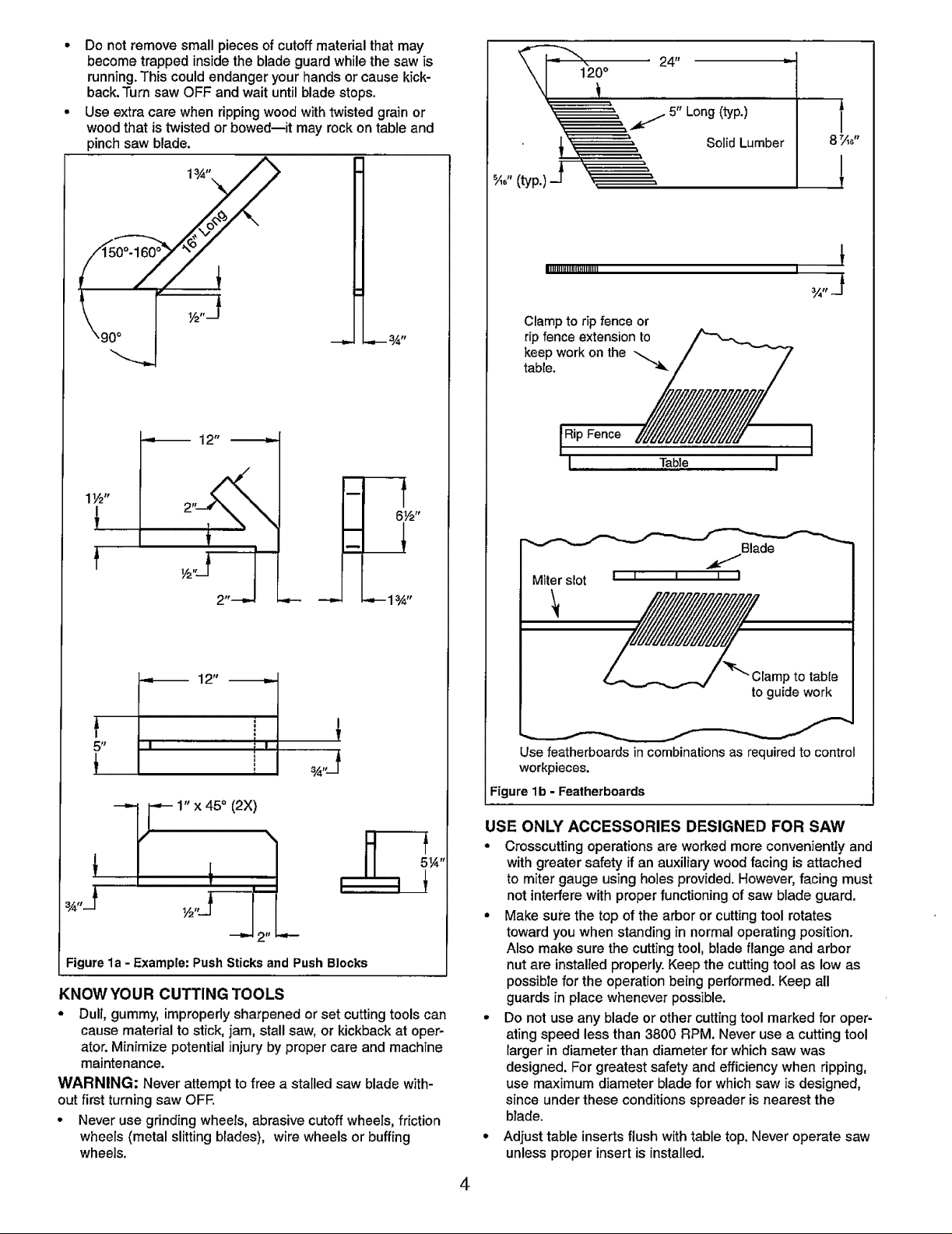

• During rip and rip-type cuts, workpiece must be held down

on table and against fence with a push stick, push block,

or featherboards, as applicable (see Figures la and l b,

page 4).

Push Stick: A safety device used to push the workpiece

through a cutting operation. Used most often when rip cutting

thin workpieces.

The push stick and push block examples shown below are use-

ful for keeping hands and fingers away from saw blade during

ripping, rabbeting and dadoing. Apply downward pressure and

push workpiece through the cut and past the blades. Several

other configurations may be suitable for safe operation.

Featherboards are used to keep the work in contact with the rip

fence or table during the cutting operation. Use of featherboards

can help to prevent kickbacks and binding. Featherboards

should be used for all "non thru-sawing" operations.

• Never reach in back of the cutting tool with either hand to

hold down or support the workpiece, remove wood scraps,

or for any other reason. Avoid awkward operations and

hand positions where a sudden slip could cause fingers or

hand to move into a saw blade or other cutting tool.

° Do not perform layout, assembly, or setup work on the

table while the cutting tool is rotating.

• Do not perform any operation freehand--always use either

rip fence or miter gauge to position and guide the work.

° Never use the rip fence when cross-cutting or the miter gauge

when ripping. Do not use rip fence as a length stop. Never

hold onto or touch free-end of workpiece or a free-piece that

is cut off, while power is ON and/or saw blade is rotating.

• Shut the saw OFF and disconnect power source when

removing the table insert, changing the cutting tool,

removing or replacing the blade guard, or making adjust-

ments.

Provide adequate support to the rear and sides of the saw

table for wide or long workpieces.

o

Plastic and composition materials (like hardboard) may be

cut on your saw. However, since these are usually quite

hard and slippery, the anti-kickback pawls may not stop a

kickback. Therefore, be especially attentive to following

proper setup and cutting procedures for ripping. Do not

stand, or permit anyone else to stand, in line with a poten-

tial kickback.

If you stall or jam the saw blade in the workpiece, turn saw

OFF and remove the workpiece from the saw blade.

Check to see if the saw blade is parallel to the miter

gauge grooves and if the spreader is in proper alignment

with the saw blade. If ripping at the time, check to see if

the rip fence is parallel with the saw blade. Readjust as

required.

3

Donotremovesmallpiecesofcutoffmaterialthatmay

becometrappedinsidethebladeguardwhilethesawis

running.Thiscouldendangeryourhandsorcausekick-

back.TurnsawOFFandwaituntilbladestops.

Useextracarewhenrippingwoodwithtwistedgrainor

woodthatistwistedorbowed--itmayrockontableand

pinchsawblade.

24"

5" Long (typ.)

. i__ Solid Lumber

/ °77 i

_ 12" _

11/2 t_

i

l

i f

6½"

• I

._-1¾"

(typ.)J ', '.

5/_6tt

IIit1IIIIIII1|111111IIII I

Clamp to rip fence or

rip fence extension to

keep work on the

table.

rip Fence ........

I Table I

Miter slot

I

Blade

i i _ l I

#

5"

i

Figure la - Example: PushSticks and Push Blocks

KNOW YOUR CUTTING TOOLS

• Dull, gummy, improperly sharpened or set cutting tools can

cause material to stick, jam, stall saw, or kickback at oper-

ator. Minimize potential injury by proper care and machine

maintenance.

WARNING: Never attempt to free a stalled saw blade with-

out first turning saw OFR

• Never use grinding wheels, abrasive cutoff wheels, friction

wheels (metal slitting blades), wire wheels or buffing

wheels.

) to table

toguide work

Use featherboards in combinations as required to control

workpieces.

Figure lb - Fealherboards

USE ONLY ACCESSORIES DESIGNED FOR SAW

• Crosscutting operationsare workedmore convenientlyand

withgreatersafety if an auxiliarywoodfacing isattached

to miter gaugeusingholesprovided. However,facing must

notinterferewith properfunctioning of saw blade guard.

° Makesu£ethetop of thearboror cuttingtoolrotates

towardyouwhenstandingin normaloperatingposition.

Also makesure the cuttingtool,bladeflange and arbor

nutare installedproperly.Keepthe cuttingtoolas lowas

possibleforthe operationbeingperformed. Keep all

guardsin placewheneverpossible.

• Do notuse any blade or othercuttingtool markedfor oper-

ating speed lessthan3800 RPM. Neverusea cuttingtool

larger in diameter than diameter for whichsaw was

designed.For greatestsafetyand efficiencywhen ripping,

use maximum diameter blade for whichsaw is designed,

since underthese conditionsspreader is nearest the

blade.

° Adjust tableinsertsflush withtable top.Never operatesaw

unlessproperinsertisinstalled.

4

• Never feed materiaI into the cutting tool from the rear of

the saw. An accident and serious injury could result.

THINK SAFETY

Safetyisa combinationof operatorcommonsenseand alert-

ness at alltimes whenthe sawis beingused.

Neveruseanother personas a substitutefor a tableexten-

sion,or asadditionalsupportfor a workpiecethat is longeror

widerthanbasicsaw table,or toassistinfeeding, supporting

orpullingtheworkpiece.

Do notpullthe workpiecethroughthesaw blade--position

yourbodyat the infeedside of the guard;startand complete

the cutfrom that same side.This wil]require addedtablesup-

portfor longor wideworkpiecesthatextendbeyond the

lengthorwidthofthe sawtable.

CAUTION: Followsafetyinstructionsthatappearonthe front

ofyoursaw.

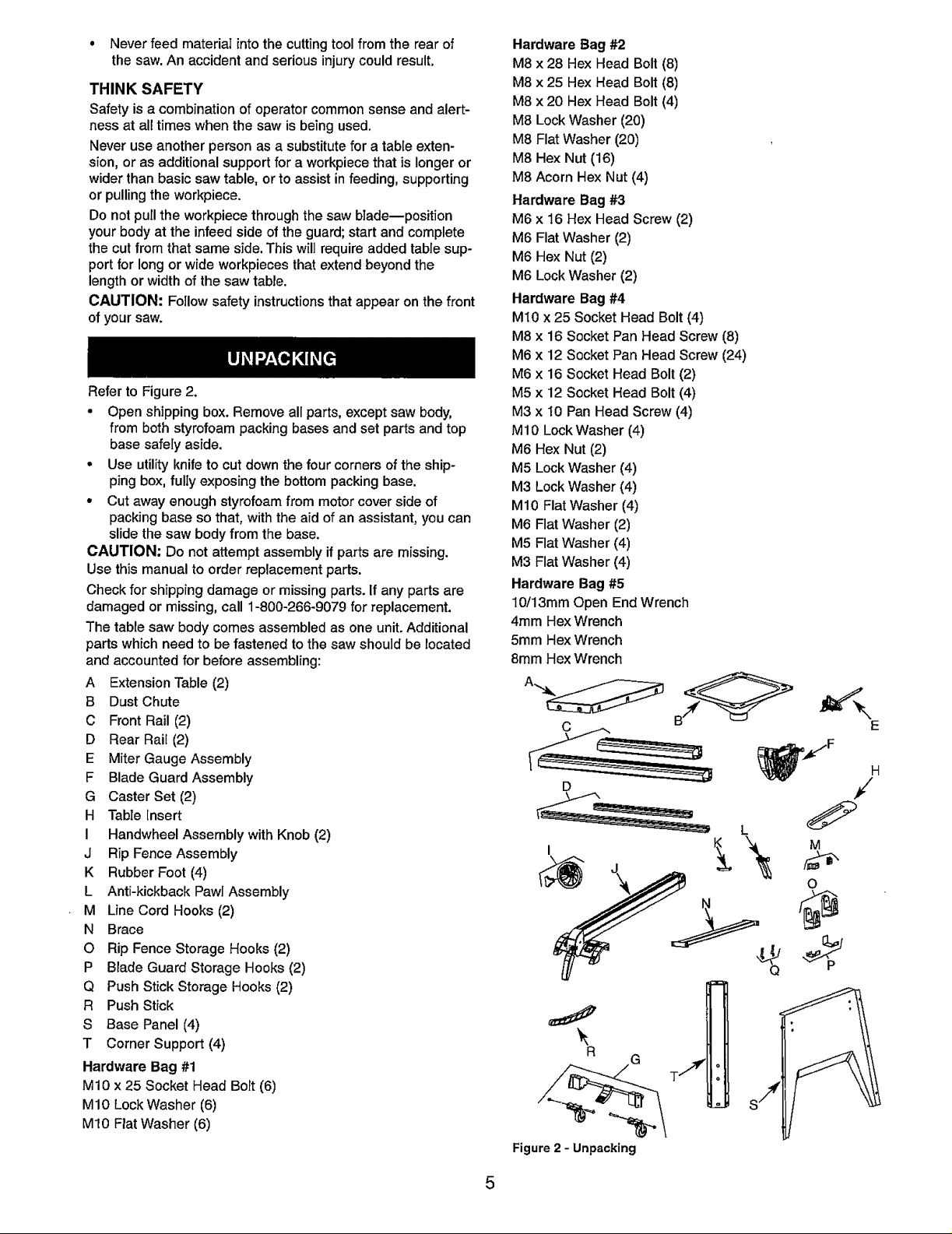

Refer to Figure 2.

• Open shipping box. Remove all parts, except saw body,

from both styrofoam packing bases and set parts and top

base safely aside.

• Use utility knife to cut down the four corners of the ship-

ping box, fulIy exposing the bottom packing base.

• Cut away enough styrofoam from motor cover side of

packing base so that, with the aid of an assistant, you can

slide the saw body from the base.

CAUTION; Do not attempt assembly if parts are missing.

Use this manual to order replacement parts.

Check for shipping damage or missing parts. If any parts are

damaged or missing, call 1-800-266-9079 for replacement.

The table saw body comes assembled as one unit. Additional

parts which need to be fastened to the saw should be located

and accounted for before assembling:

A Extension Table (2)

B Dust Chute

C Front Rail (2)

D Rear Rail (2)

E Miter Gauge Assembly

F Blade Guard Assembly

G Caster Set (2)

H Table Insert

I Handwheel Assembly with Knob (2)

J Rip Fence Assembly

K Rubber Foot (4)

L Anti-kickback Pawl Assembly

M Line Cord Hooks (2)

N Brace

O Rip Fence Storage Hooks (2)

P Blade Guard Storage Hooks (2)

Q Push Stick Storage Hooks (2)

R Push Stick

S Base Panel (4)

T Corner Support (4)

Hardware Bag #1

M10 x 25 Socket Head Bolt (6)

M10 Lock Washer (6)

M10 Fiat Washer (6)

Hardware Bag #2

M8 x 28 Hex Head Bolt (8)

M8 x 25 Hex Head Bolt (8)

M8 x 20 Hex Head Bolt (4)

M8 Lock Washer (20)

M8 Flat Washer (20)

M8 Hex Nut (16)

M8 Acorn Hex Nut (4)

Hardware Bag #3

M6 x 16 Hex Head Screw (2)

M6 Flat Washer (2)

M6 Hex Nut (2)

M6 Lock Washer (2)

Hardware Bag #4

MIO x 25 Socket Head Bolt (4)

M8 x 16 Socket Pan Head Screw (8)

M6 x 12 Socket Pan Head Screw (24)

M6 x 16 Socket Head Bolt (2)

M5 x 12 Socket Head Bolt (4)

M3 x 10 Pan Head Screw (4)

M10 Lock Washer (4)

M6 Hex Nut (2)

M5 Lock Washer (4)

M3 Lock Washer (4)

M10 Flat Washer (4)

M6 Flat Washer (2)

M5 Flat Washer (4)

M3 Flat Washer (4)

Hardware Bag #5

10/13mm Open End Wrench

4ram Hex Wrench

5mm Hex Wrench

8mm Hex Wrench

D

• O

R

Figure2 - Unpacking

T7"

o

o

E

H

J

L

5

IMPORTANT: Table is coated with a protectant. To ensure

proper fit and operation, remove coating. Coating is easily

removed with mild solvents, such as mineral spirits, and a soft

cloth. Avoid getting solution on paint or any of the rubber or

plastic parts. Solvents may deteriorate these finishes. Use

soap and water on paint, plastic or rubber components. After

cleaning, cover all exposed surfaces with a light coating of oil.

Paste wax is recommended for table top.

WARNING; Never use highly volatile solvents. Non flamma-

ble solvents are recommended to avoid possibte fire hazard.

Refer to Figures 3-34.

CAUTION: Do not attempt assembly if parts are missing.

Use this manual to order replacement parts.

Be certain all parts are clean and free of shipping preserva-

tive. Also, completely remove all parts of packing. Saw cabinet

should be directly on the floor.

SAW INSTALLATION

Positioning the saw on a level surface will improve stability

and accuracy and prevent warpage and failure of cast

components and welds.

WARNING: Make certain that the saw is disconnected from

the power source.

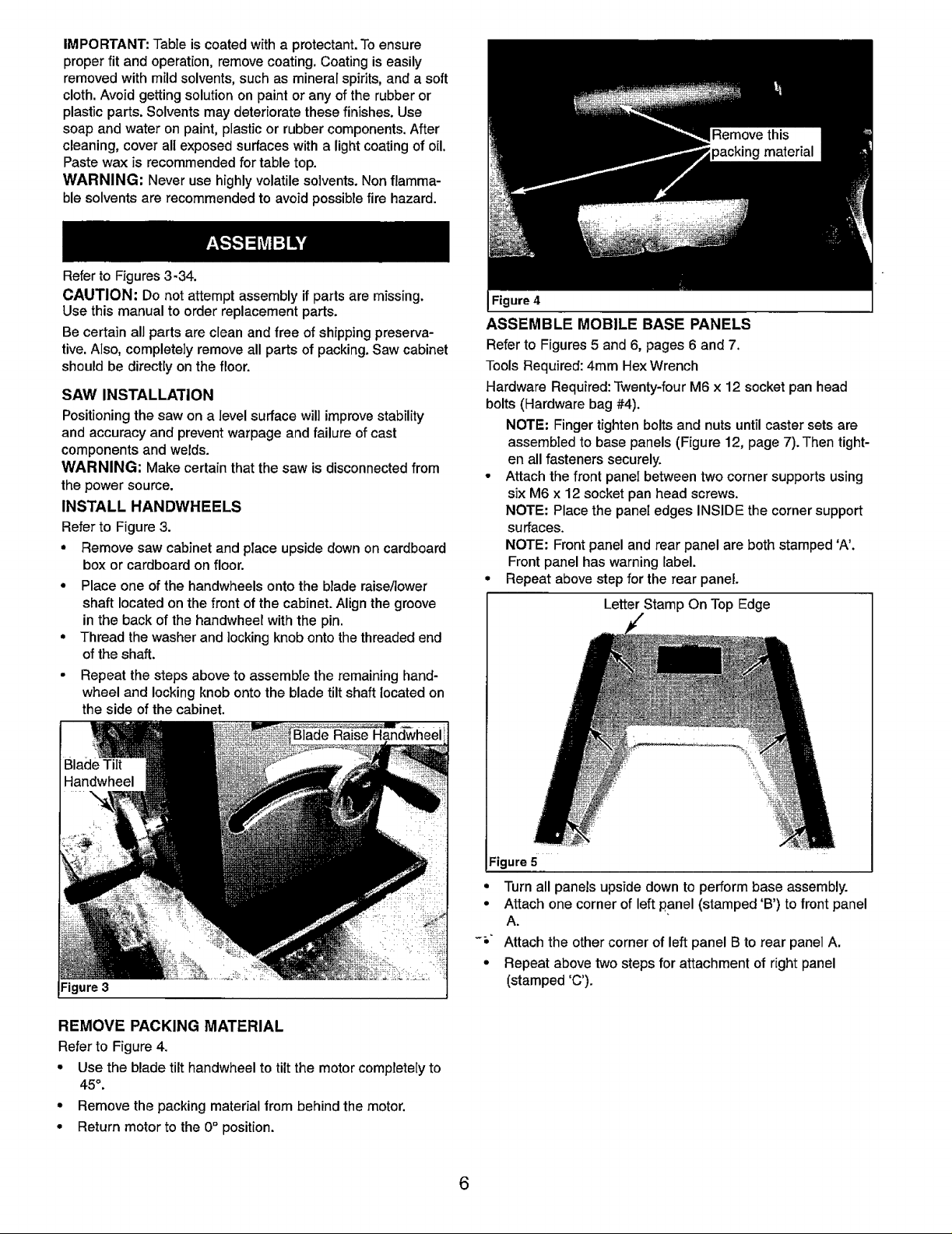

INSTALL HANDWHEELS

Refer to Figure 3.

• Remove saw cabinet and place upside down on cardboard

box or cardboard on floor.

• Place one of the handwheels onto the blade raise!lower

shaft located on the front of the cabinet. Align the groove

in the back of the handwheel with the pin.

• Thread the washer and ]ocking knob onto the threaded end

of the shaft.

• Repeat the steps above to assemble the remaining hand-

wheel and locking knob onto the blade tilt shaft located on

the side of the cabinet.

Figure4

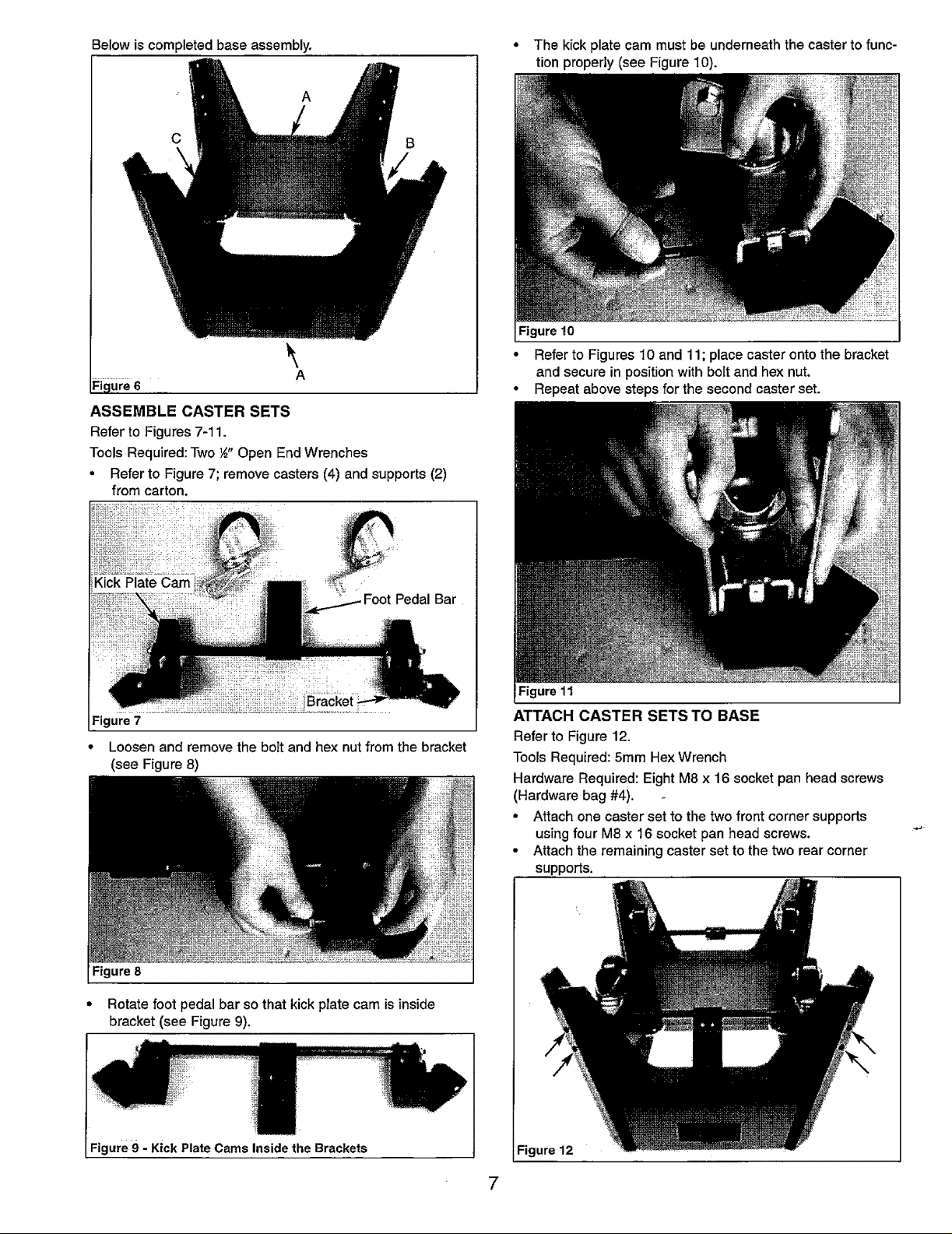

ASSEMBLE MOBILE BASE PANELS

Refer to Figures 5 and 6, pages 6 and 7.

Tools Required: 4ram Hex Wrench

Hardware Required: Twenty-four M6 x 12 socket pan head

bolts (Hardware bag #4).

NOTE: Finger tighten bolts and nuts until caster sets are

assembled to base panels (Figure 12, page 7). Then tight-

en all fasteners securely.

• Attach the front panel between two corner supports using

six M6 x 12 socket pan head screws.

NOTE: Place the paneI edges INSIDE the corner support

surfaces.

NOTE: Front panel and rear panel are both stamped 'A'.

Front panel has warning label.

° Repeat above step for the rear panel

Letter Stamp On Top Edge

REMOVE PACKING MATERIAL

Referto Figure4.

• Usethe bladetilt handwheel totiltthe motorcompletelyto

45°.

• Removethe packing materialfrom behindthe motor.

• Returnmotorto the 0° position.

Figure 5....

• Turn all panels upside down to perform base assembly.

• Attach one corner of left panel (stamped 'B') to front panel

A.

-_ Attach the other corner of left panel B to rear panel A.

• Repeat above two steps for attachment of right panel

(stamped 'C').

6

Below is completed base assembly.

• The kick plate cam must be underneath the caster to func-

tion properly (see Figure 10).

A

C

A

ASSEMBLE CASTER SETS

Refer to Figures 7-11.

Tools Required: Two _" Open End Wrenches

Refer to Figure 7; remove casters (4) and supports (2)

from carton.

B

Figure 10

• Refer to Figures 10 and 11; place caster onto the bracket

and secure in position with bolt and hex nut.

= Repeat above steps for the second caster set.

Figure 7

* Loosen and remove the bolt and hex nut from the bracket

(see Figure 8)

Figure 8

• Rotate foot pedal bar so that kick plate cam is inside

bracket (see Figure 9).

Figure11

ATTACH CASTER SETS TO BASE

Refer to Figure 12.

ToolsRequired:5ram HexWrench

HardwareRequired: EightM8 x 16 socket pan head screws

(Hardwarebag #4).

• Attach onecastersetto thetwofront cornersupports

using four M8 x 16 socketpan headscrews.

• Attach the remaining caster settothe two rearcorner

supports.

Figure 9 - Kick Plate Cams Inside the Brackets

Figure 12

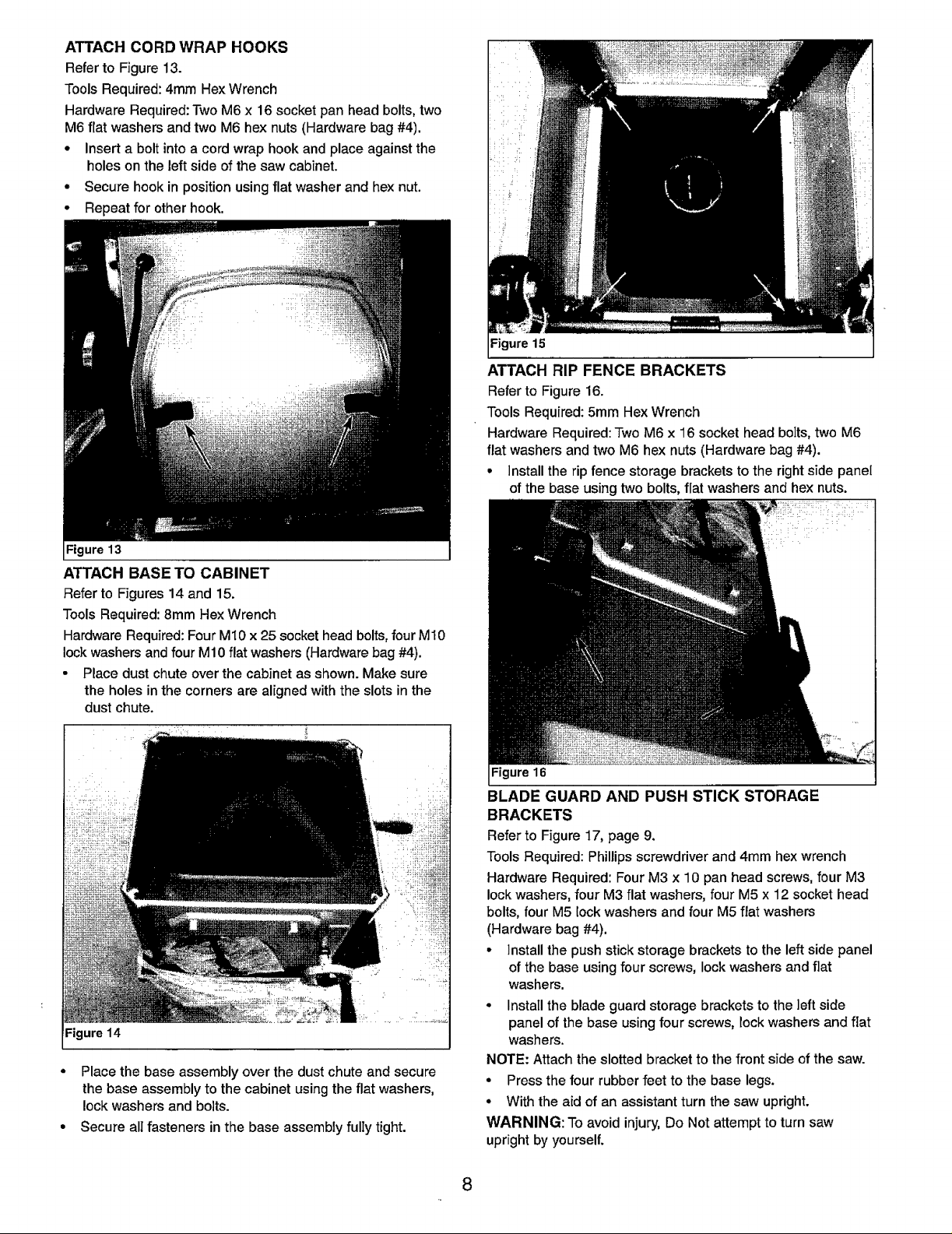

ATTACH CORD WRAP HOOKS

Refer to Figure 13.

Tools Required: 4mm Hex Wrench

Hardware Required: Two M6 x 16 socket pan head bolts, two

M6 flat washers and two M6 hex nuts (Hardware bag #4).

• Insert a bolt into a cord wrap hook and place against the

holes on the left side of the saw cabinet.

° Secure hook in position using flat washer and hex nut.

° Repeat for other hook.

Figure 15

ATTACH RIP FENCE BRACKETS

Refer to Figure 16.

Tools Required: 5mm Hex Wrench

Hardware Required: Two M6 x 16 socket head bolts, two M6

flat washers and two M6 hex nuts (Hardware bag #4).

° Install the rip fence storage brackets to the right side panel

of the base using two bolts, fiat washers and hex nuts.

Figure 13

ATTACH BASE TO CABINET

Refer to Figures 14 and 15.

Tools Required: 8mm Hex Wrench

Hardware Required: Four Mt0 x 25 socket head bolts,four M10

lock washers and four M10 flat washers (Hardware bag #4).

• Place dust chute over the cabinet as shown. Make sure

the holes in the corners are aligned with the slots in the

dust chute.

Figure14

• Place the base assembly over the dust chute and secure

the base assembly to the cabinet using the flat washers,

lock washers and bolts.

• Secure all fasteners in the base assembly fully tight.

Figure16

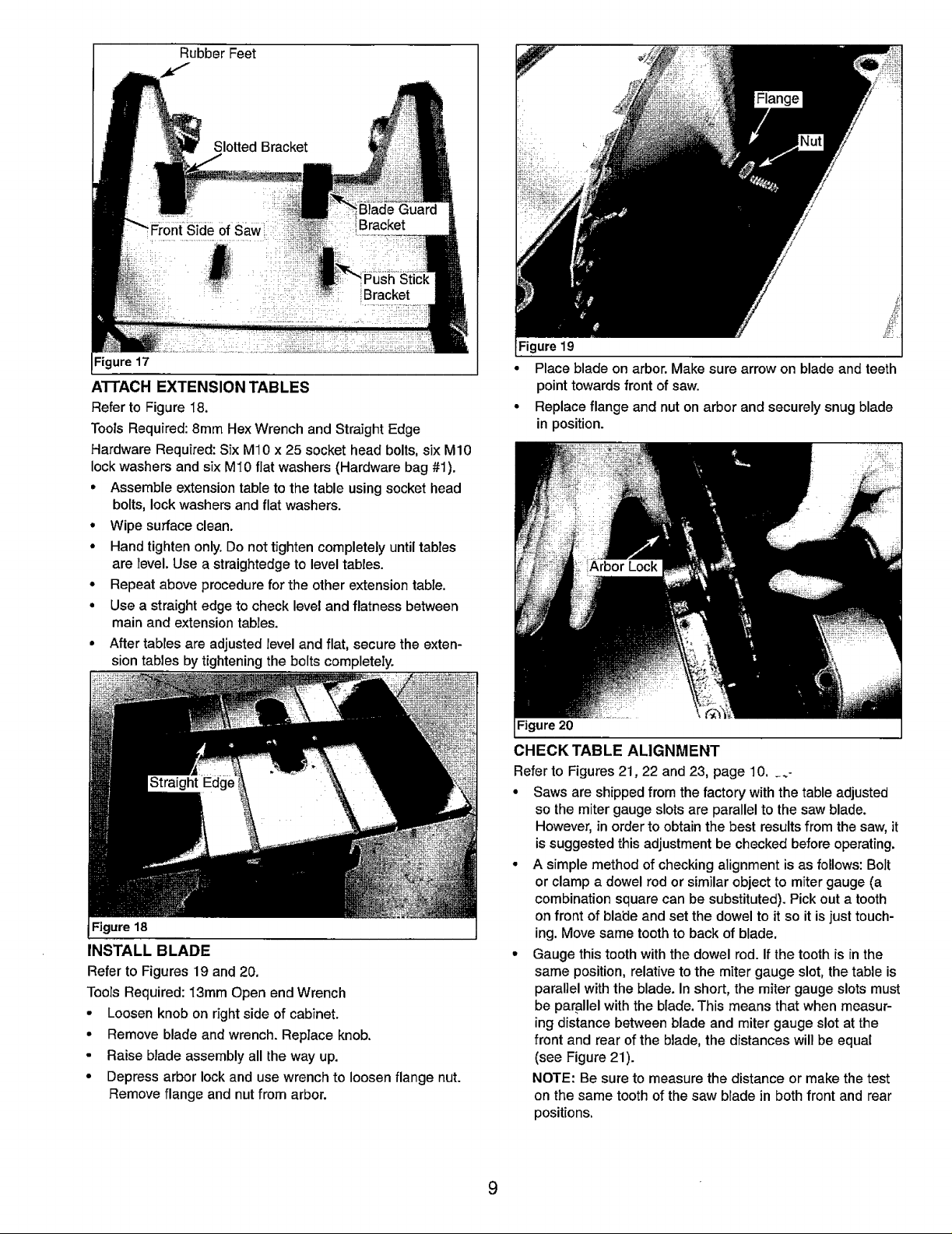

BLADE GUARD AND PUSH STICK STORAGE

BRACKETS

Refer to Figure 17, page 9.

Tools Required: Phillipsscrewdriver and 4ram hex wrench

Hardware Required: Four M3 x 10 pan head screws, four M3

lock washers, four M3 flat washers, four M5 x 12 socket head

bolts, four M5 lock washers and four M5 fiat washers

(Hardware bag #4).

• Install the push stick storage brackets to the left side panel

of the base using four screws, lock washers and flat

washers.

• Install the blade guard storage brackets to the ]eft side

panel of the base using four screws, lock washers and flat

washers.

NOTE: Attach the slotted bracket to the front side of the saw.

• Press the four rubber feet to the base legs.

• With the aid of an assistant turn the saw upright.

WARNING: To avoid injury, Do Not attempt to turn saw

upright by yourself.

8

Rubber Feet

Slotted Bracket

Figure 17

ATTACH EXTENSION TABLES

Referto Figure I8.

ToolsRequired:8ram HexWrench andStraightEdge

HardwareRequired:Six M10 x25 socketheadbolts,six M10

lockwashersandsix MI0 flat washers(Hardwarebag#1).

• Assemble extension tableto thetable usingsockethead

bolts,lockwashersandflat washers.

• Wipe surfaceclean.

• Handtightenonly.Do nottightencompletelyuntil tables

are level. Usea straightedgeto leveltables.

° Repeataboveprocedure for the other extensiontable.

° Usea straight edgeto checklevelandflatnessbetween

main and extensiontables.

° After tables are adjusted level andflat, secure the exten-

sion tables bytightening the bolts completely.

Figure19

° Placeblade onarbor.Make sure arrow on blade and teeth

point towards front of saw.

• Replaceflange and nut on arbor and securely snug blade

in position.

Figure 18

INSTALL BLADE

Referto Figures19 and 20.

ToolsRequired:13ram Openend Wrench

- Loosen knob on right side of cabinet.

• Remove blade and wrench. Replace knob.

• Raiseblade assemblyall the way up.

• Depress arbor lockand use wrench to loosen flange nut.

Removeflange and nut from arbor.

Figure 20

CHECK TABLE ALIGNMENT

Refer to Figures21, 22 and 23, page 10. _.-

• Saws are shippedfrom thefactory withthe tableadjusted

so themitergaugeslotsare parallel to thesaw blade.

However,in orderto obtainthebest resultsfrom thesaw, it

issuggestedthisadjustmentbe checkedbeforeoperating.

• A simple method ofcheckingalignment isas follows: Bolt

orclampa dowelrod or similar objectto mitergauge(a

combinationsquarecan be substituted). Pick outa tooth

onfront of bla_leand setthe dowel to it so it isjusttouch-

ing.Move sametoothto backof blade.

• Gauge thistoothwiththedowel rod. Ifthetoothis in the

same position,relative tothe miter gaugeslot, the tableis

paral]elwiththeblade. In short, the mitergaugeslots must

be parallelwiththe blade.This means thatwhenmeasur-

ingdistancebetween blade andmitergauge slot atthe

front and rear oftheblade,thedistanceswillbe equal

(see Figure21).

NOTE: Be sure to measure the distance ormake the test

onthe same toothof the saw bladein both front andrear

positions.

9

° If an adjustment is necessary, proceed as follows: Loosen

and remove the six socket pan head screws and the rear

panel (see Figure 22). Loosen the three hex head bolts on

the trunnion (see Figure 23) and shift trunnions until a

position is found where the saw blade is parallel to the

miter guage slots.

NOTE: Saw blade should also be centered within its table

insert opening.

'r_l Rear

Saw !

.Blade }

I

i

i

I

!

i

L......... 1._1

i I

-N- -@-

Front

_"Miter Gauge Slotsf

Figure 21 - Aligning MiterBlots to Blade

, Tighten the hex head bolts and lock washers very securely.

This procedure will set the table and blade in parallel posi-

tion and prevent the trunnion from shifting.

NOTE: If you perform this adjustment, leave the back panel off

to perform rear rail assembly as described in the next section.

RAIL ASSEMBLY

Referto Figures24-29.

ToolsRequired:13ramOpen endWrench

HardwareRequired: EightM8 x 28 hexhead bolts, eightM8 x

25 hex head bolts,four M8 x 20 hexheadbolts, twentyM8

lockwashers,twentyM8 flat washers,sixteenM8 hex nuts

andfour M8 acorn nuts.(Hardwarebag#2).

• insert two M8 x 28 he)(headbotts andtwoM8 x 25 hex

head boltsinto theT-slotofthe right front guide rail.(The

two longerboltswillattach tothe table;the two shorter

bolts attachto thetableextension.)

• Attach rightfront railto the tableand right table extension

using flat washers,lockwashersand hexnuts.

NOTE: Hand tightenallhardwareduring rail assembly.Do not

completelytightenhardwareuntil ail railsare mounted.

° Attach leftfront railinthesame manner.(The two longer

bolts attachto the table;the two shorter bolts attach to

table extension.)

NOTE:You may have to shiftrightrail as far rightas it will go

toattach leftrail.

Figure 22 - Remove Rear Panel

Figure 24 - Right Front Rail

, Position rails so that rails are butted together and the joint

between rails isaligned with right side of the blade. You

may need a mallet to lightlytap rails together. Make sure

rails are completely butted together at the joint.

° Use a straight edge as shown to check level and flatness

between right and left rail. Use a combination square as

shown to make certain that both front rails are parallel to

the table surface.

• After front rails are adjusted leveI and flat, tighten the

screws completely.

° Secure all hardware completely.

Figure 23 - Adjust Trunnions to Align Blade and Miter Slot

Figure 25 - Use Straight Edge to Align Rail Joint to Blade

10

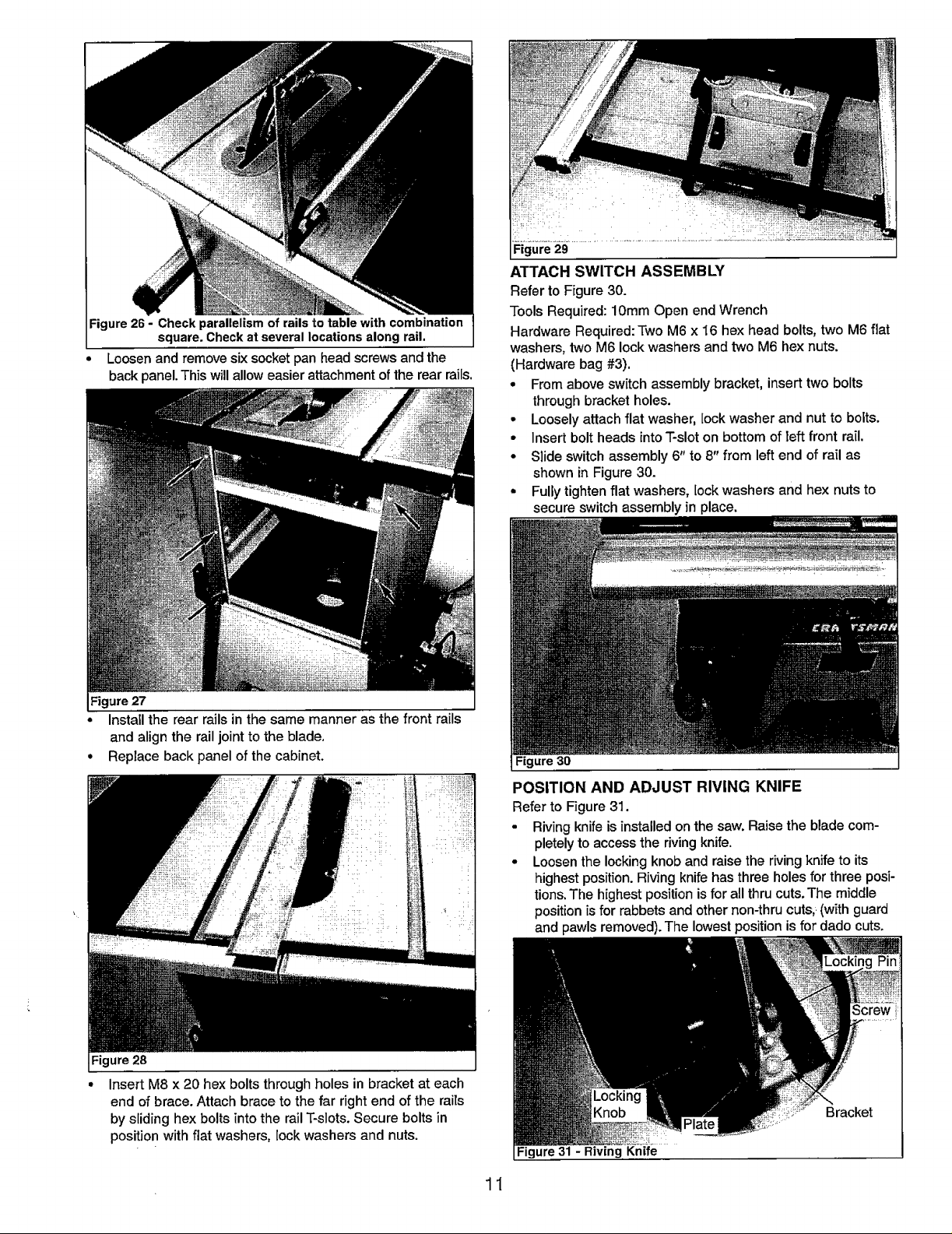

Figure 26 - Check parallelism of rails to table with combination

square. Check at several locations along rail.

Loosen and remove six socket pan head screws and the

back panel, This will allow easier attachment ofthe rear rails.

i!:_i: , _ :

IiZZLIIL i:...........................ii ii :_ '_•

Figure29

ATTACH SWITCH ASSEMBLY

Refer to Figure 30.

Tools Required: 10mm Open end Wrench

Hardware Required: Two M6 x I6 hex head bolts, two M6 flat

washers, two M6 lock washers and two M6 hex nuts.

(Hardware bag #3).

• From above switch assembly bracket, insert two bolts

through bracket holes.

° Loosely attach flat washer, lock washer and nut to bolts.

• Insert bolt heads into T-slot on bottom of left front rail.

• Slide switch assembly 6" to 8" from left end of rail as

shown in Figure 30.

• Fullytighten flat washers, lockwashers and hex nuts to

secure switch assembly in place.

Figure27

• Install the rear rails in the same manner as the front rails

and align the rail joint to the blade,

• Replace back panel of the cabinet.

Figure28

• Insert M8 x 20 hex bolts through holes in bracket at each

end of brace. Attach brace to the far right end of the rails

by sliding hex bolts into the railT-slots. Secure bolts in

position with fiat washers, lock washers and nuts.

Figure 30

POSITION AND ADJUST RIVING KNIFE

Refer to Figure 31.

• Riving knife is installed onthe saw. Raise the blade com-

pletely to access the riving knife.

° Loosen the locking knob and raise the riving knife to its

highest position.Riving knifehas three holes for three posi-

tions. The highest position isfor all thru cuts, The middle

position is for rabbets and other non-thru cuts,_(with guard

and pawls removed). The lowest position is for dado cuts.

Bracket

Figure 31 - Riving Knife

11

Loading...

Loading...