Craftsman 351217450 Owner’s Manual

Operator's Manual

CRRFTSMRN°I

5"

PLANER/MOLDER WITH DUST COLLECTION

Model No.

351.217450

Updated

CAUTION: Read and follow all Safety Rules and Operating Instructions

before First Use of this Product.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

•wv,_N.sears.co nllcnsftsman

20382.03 Draft (12/23/2003)

Warranty.................................... 2

Safety Rules ............................... 2-3

Unpacking .................................. 3

Assembly ................................. 3-5

Installation................................. 5-6

Operation ................................ 6-14

Maintenance ............................. 15-16

Troubleshooting........................... 17-18

Parts Illustrationand List ................... 19-26

EspaSol................................. 26-43

FU LL ONE YEAR WARRANTY

If this productfailsdue to a defect in material or work-

manship withinone year from the date of purchase,

Sears will at its option repair or replace it free of

charge. Contact your nearest Sears Service Center

(1-800-4-MY-HOME) to arrange for product repair, or

returnthis productto place of purchasefor replacement.

If this product is used for commercial or rental purpos-

es, this warranty will apply for 90 days from the date of

purchase.

This warranty applies only while this productis used in

the United States.

This warrantygives you specificlegal rights and you may

also have other rightswhich vary from state to state.

Sears, Roebuck and Co., Dept. 8t7WA, Hoffman

Estates, IL 60179

WARNING: Foryour own safety, read all of the rules

and precautions before operating tool.

CAUTION: Always follow proper operating procedures

as defined in this manual even if you are familiarwith

use ofthis or similar tools. Remember that being care-

lessfor even a fractionof a second can resultin severe

personal injury.

BE PREPARED FOR JOB

• Wear proper apparel. Do not wear loose clothing,

gloves, neckties, rings, bracelets or otherjewelry

which may get caught in movingparts of machine.

• Wear protective hair coveringto contain long hair.

• Wear safety shoes withnon-slip soles.

• Wear safety glasses complying with United States

ANSI Z87.1. Everyday glasses have onlyimpact

resistantlenses.They are NOT safety glasses.

• Wear face mask or dust mask ifoperation is dusty.

• Be alert and think clearly.Never operate power tools

when tired, intoxicatedor when taking medications

that cause drowsiness.

O Seam, Roebuck and Co.

PREPARE WORK AREA FOR JOB

• Keep work area clean.Clutteredwork areas invite

accidents. -, -.

• Do not use power tools in dangerous environments.

• Do not use power tools in damp or wet locations. Do

not expose power tools to rain.

• Work area should be proper{y lighted.

• Proper electrical receptacle shouldbe available for

tool.Three prong plug should be pluggeddirectly

intoproperly grounded, thrae-prong receptacle.

• Extension cords should have a groundingprong and

the three wires ofthe extensioncord should be of

the correct gauge.

• Keep visitors at a safe distance from work area.

• Keepchildren outofworkptace.Make worl_shop child-

proof. Use padlocks, master switchesor remove switch

keysto prevent any unintentional use ofpower tools.

TOOL SHOULD BE MAINTAINED i

Always unplugtool priorto inspection.

• Consultmanualfor specificmaintainingand adjust-

ingprocedures. :

• Keep tool lubricatedand clean for safestoperation.

• Remove adjustingtools. Form habitof checking to

see that adjustingtools are removedbef(_raswitch-

ing machineon.

• Keepall parts inworking order. Check to determine

that the guard or other parts will operate i)ropedy

and performtheir intendedfunction. ,

• Checkfor damaged pads, Check for aiignmentof

movingparts, binding,breakage, mountingand any

otherconditionthat may affect a tool'soperation.

• A guard or other part that is damaged should be

properlyrepairedor replaced. Do not perform

makeshiftrepairs.(Use parts listprovidedto order

replacement pads.)

KNOW HOW TO USE TOOL

• Use dght toolforjob. Do notforcetool orattachment

to do a jobfor which it was not designed.

• Disconnecttoolwhen changing blades. ,

• Avoidaccidental stad-up,Make surethatlthe switch

is in the OFF positionbefore pluggingin. _

• Donot force tool.It will work mostefficientlyat the

ratafor which it was designed,

• Keep hands away from movingpartsand Cutting

surfaces. • :'

• Never leave tool runningunattended.Turnthe power

offand do not leave tool untilitcomes to a complete

stop.

• Do not overreach.Keep properfooting and balance.

• Never standon tool.Seriousinjurycould occurif tool is

tippedor if blade is unintentionallycontacted.

• Knowyourtool. Learn the tool'soperation,applica-

tionand speciticlimitations.... :_,_

• Use recommendedaccessodes (refe=:topage 25).

Use of improperacoessodesmay cause riskof

injuryto persons. : -*L_

2

• Handle workpiece correctly.Protect handsfrom

possibleinjury.

• Turn machine off if it jams. Bladejams when it digs

too deeply into workpiece. (Motor force keeps it

stuck in the work.)

• Always keep drive, cutterhead and blade guards in

place and in proper operating condition.

• Feed work into blade or cutter againstdirectionof

rotation.

CAUTION: Think safety! Safety isa combination of

operator common sense and alertness at alltimes

when tool is being used.

WARNING: Do not attemptto operate tool untilit is

completely assembled accordingto the instructions.

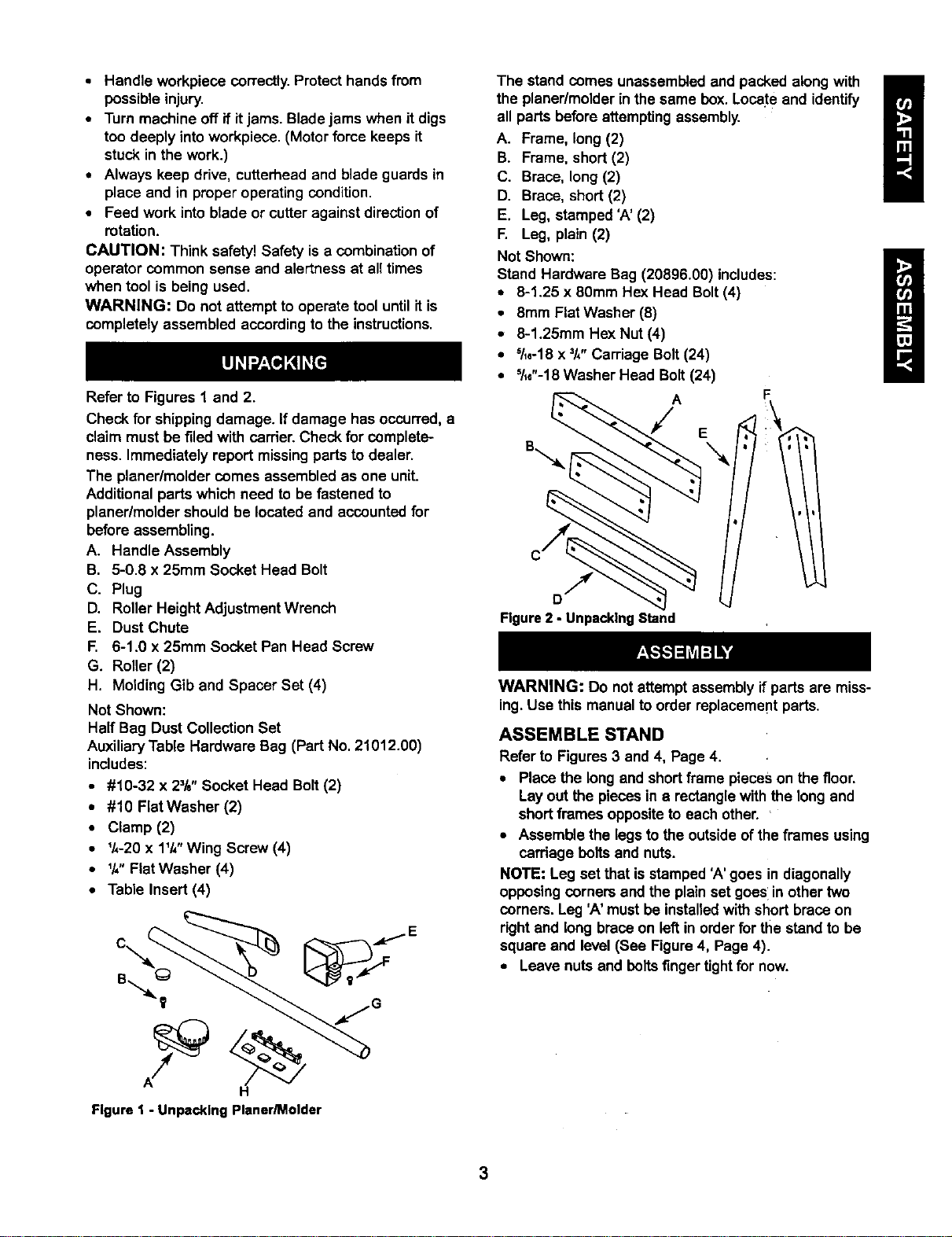

Refer to Figures 1 and 2.

Check for shipping damage. If damage has occurred,a

claim must be filedwith carder. Check for complete-

ness. Immediately report missingparts to dealer.

The planer/molder comes assembledas one unit.

Additional parts which need to be fastened to

planer/molder shouldbe located and accounted for

beforeassembling.

A. Handle Assembly

B. 5-0.8 x 25mm Socket Head Bolt

C. Plug

D. Roller Height AdjustmentWrench

E. Dust Chute

F. 6-1.0 x 25mm Socket Pan Head Screw

G. Roller (2)

H. Molding Gib and Spacer Set (4)

Not Shown:

Half Bag Dust Collection Set

Auxiliary Table Hardware Bag (Part No. 21012.00)

includes:

• #10-32 x 23/d' Socket Head Bolt(2)

• #10 FlatWasher (2)

• Clamp (2)

• 1/,-20x 11/," Wing Screw (4)

• 1/4"Flat Washer (4)

• Table Insert (4)

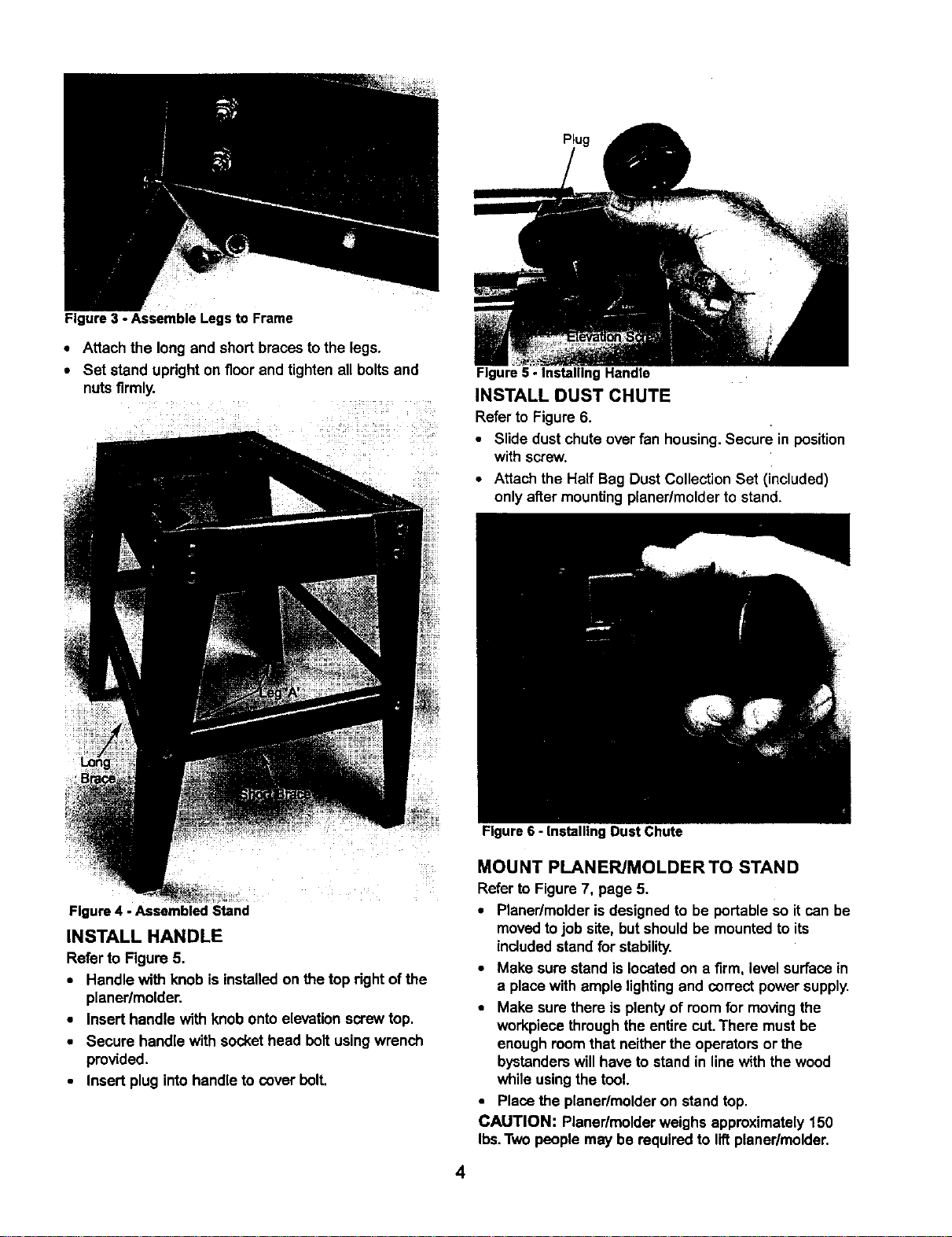

The stand comes unassemb_edand packed along with

the planer/molderin the same box. Locate and identify

all parts beforeattemptingassembly.

A. Frame, long (2)

B. Frame, short (2)

C. Brace, long (2)

D. Brace, short(2)

E. Leg, stamped 'A' (2)

F. Leg, plain (2)

Not Shown:

Stand Hardware Bag (20896.00) includes:

• 8-1.25 x 80ram Hex Head Bolt (4)

• 8mm Flat Washer (8)

• 8-1.25mm Hex Nut (4)

• S/le-18 X =/4" Carriage Bolt(24)

• 51_e"-18Washer Head Bolt (24)

A

F

E

Figure 2 - Unpacking Stand

WARNING: Do not attemptassembly if parts are miss-

ing. Use this manual to order replacement parts.

ASSEMBLE STAND

Refer to Figures 3 and 4, Page 4.

• Place the long and shortframe pieces on the floor.

Layout the pieces in a rectanglewiththe long and

shortframes oppositeto each other. '

• Assemble the legs to the outsideof the frames using

cardage boltsand nuts.

NOTE: Leg set that isstamped 'A' goes in diagonally

opposingcorners and the plainset goes'inother two

corners. Leg 'A'must be installedwith short brace on

rightand long brace on left in order for the stand to be

square and level(See Figure4, Page 4).

• Leave nuts and bolts finger tightfor now.

Figure1 - UnpackingPlaner/Molder

3

Figure3 - AssembleLegsto Frame

• Attach the long and short braces to the legs.

• Set stand upright on floor and tighten all boltsand

nuts firmly.

Figure5 - InstallingHandle

INSTALL DUST CHUTE

Refer to Figure 6,

• Slide dust chute over fan housing. Secure in position

with screw.

• Attach the Half Beg Dust Collection Set (included)

only after mounting planer/molder to stand.

Figure4 - Assembled Stand

INSTALL HANDLE

Refer to Figure 5.

• Handlewith knob is installedon the top rightof the

planer/molder.

• Insert handle with knob onto elevationscrewtop.

• Secure handle with sockethead bolt usingwrench

provided,

• Insert plug into handle to oover bolt.

Figure 6 - Installing Dust Chute

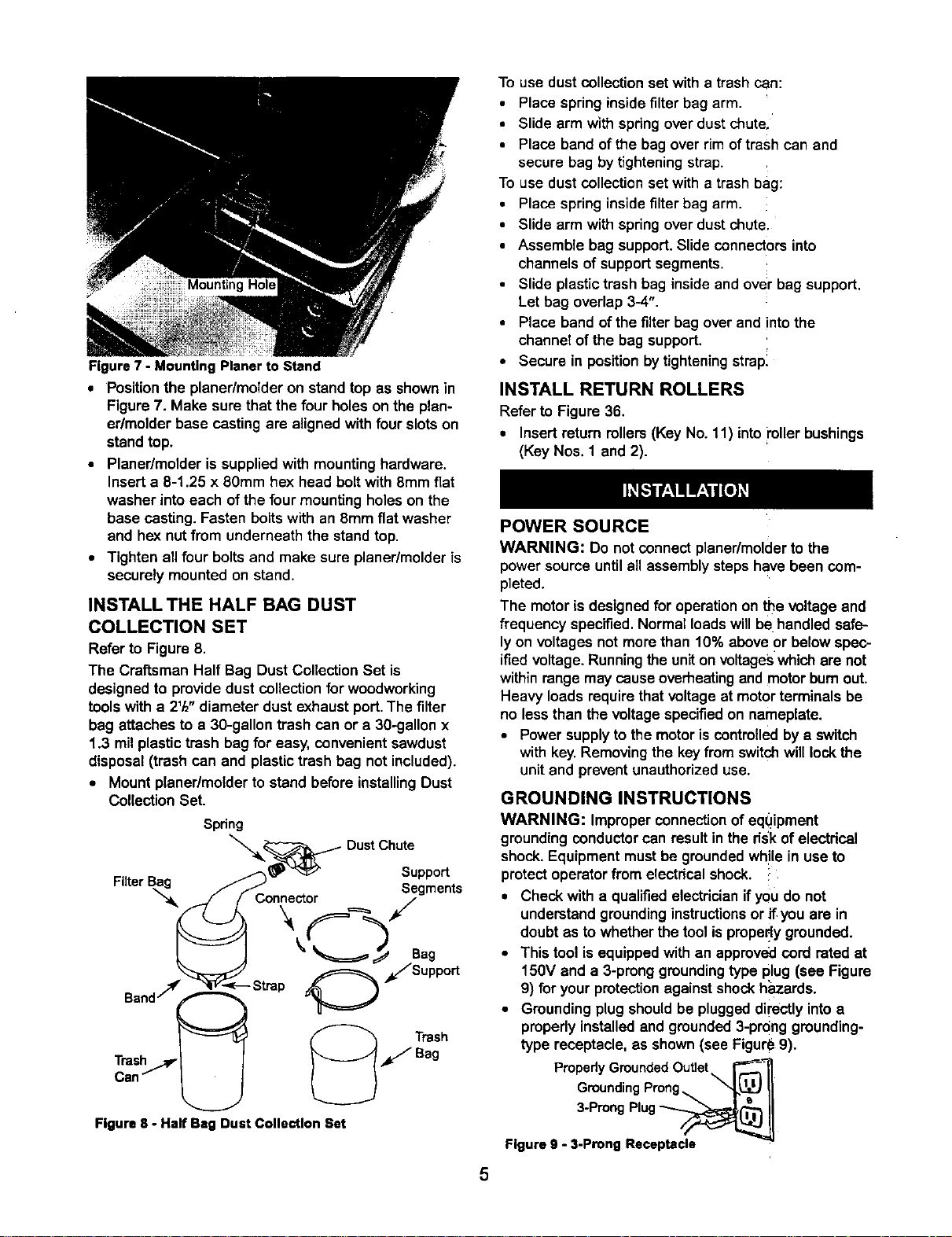

MOUNT PLANERJMOLDER TO STAND

Refer to Figure 7, page 5.

• Planer/molderis designed to be portable so itcan be

movedtojob site, but should be mountedto its

includedstand for stability.

• Make sure stand is located on a firm, level surface in

a place with ample lightingand correct powersupply.

• Make sure there is plenty of roomfor movingthe

workpiece throughthe entire cut.There must be

enoughroomthat neither the operators or the

bystanderswill have to stand in linewith the wood

whileusingthe tool.

• Place the planer/molderon stand top.

CAUTION: Planer/molder weighs approximately150

Ibs.Two people may be required to liftplaner/molder.

4

Figure 7 - Mounting Planer to Stand

• Position the planedmolder on stand top as shown in

Figure 7. Make sure that the four holes on the plan-

edmolder base casting are aligned with four slots on

standtop.

• Planer/molder is supplied with mounting hardware.

Insert e 8-1.25 x 80mm he)( head bolt with 8mm fiat

washer into each of the four mounting holes on the

base casting. Fasten bolts with an 8mm fiat washer

and hex nut from underneath the stand top.

• Tighten ell four bolts and make sure planer/molder is

securely mounted on stand.

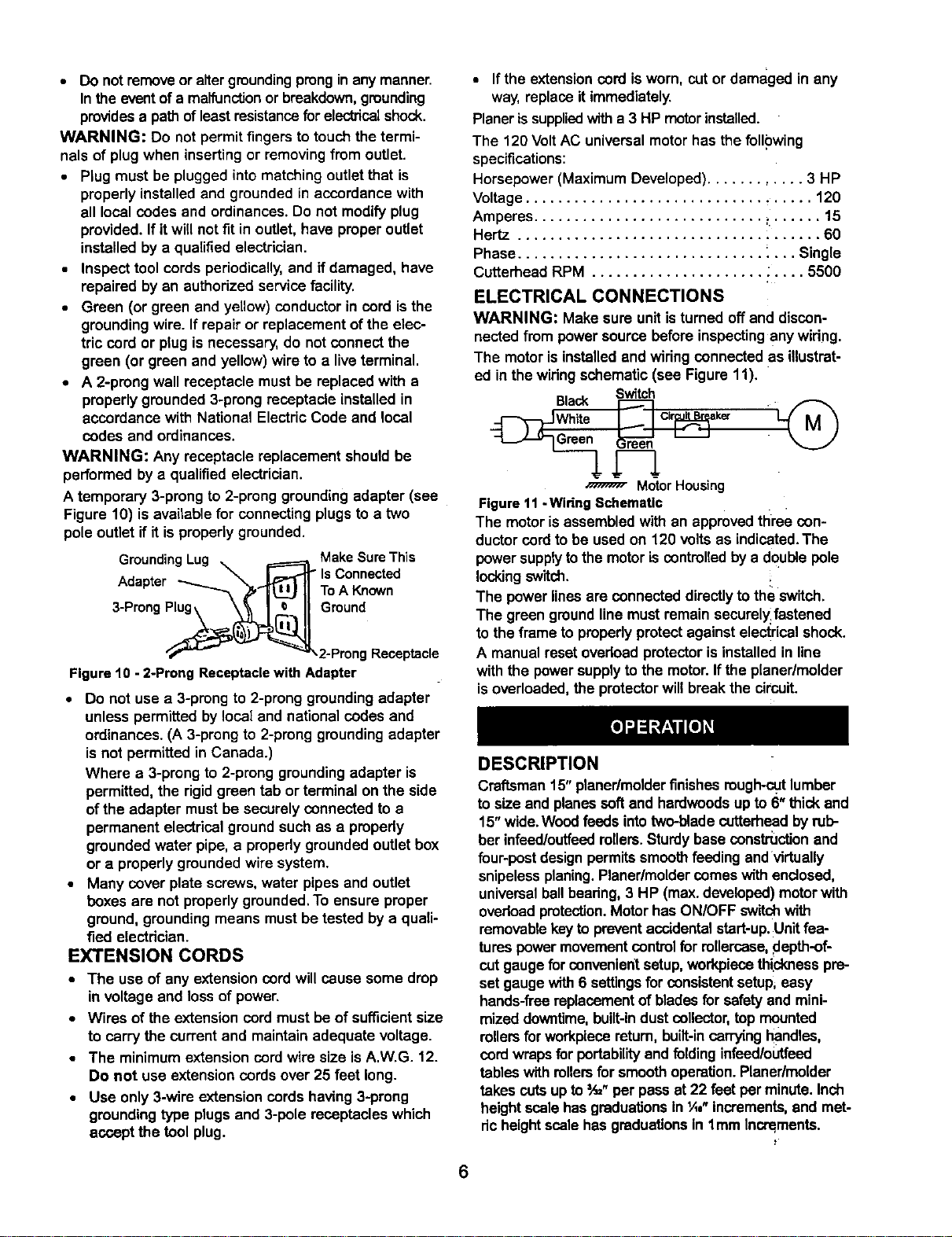

INSTALL THE HALF BAG DUST

COLLECTION SET

Refer to Figure 8.

The Craftsman Half Bag Dust ConectionSet is

designedto providedust collectionfor woodworking

toolswith a 21/2"diameter dust exhaustport.The filter

bag attaches to a 30-gallon trash can or a 30-gallon x

1.3 milplastic trash bag for easy, convenientsawdust

disposal(trash can and plastic trash bag not included).

• Mountplaner/molder to stand before installingDust

CollectionSet.

Spring

Filter

__ DustChute

J'_- nne r Segments

/' co. /

Support

/s,.port

To use dust collection set with a trash can:

• Place spring insidefilter bag arm.

• Slide arm with spring over dust chute,

• Place band of the bag over rim of trash can and

secure bag by tightening strap.

To use dust collection set with a trash bag:

• Place spring inside filter bag arm.

• Slide arm with spring over dust chute.

• Assemble bag support. Slide connectors into

channels of support segments.

• Slide plastic trash bag inside and over bag support.

Let bag overlap 3-4".

• Place band of the filter bag over and into the

channel of the bag support.

• Secure in positionby tighteningstrapl

INSTALL RETURN ROLLERS

Refer to Figure 36.

• Insert return rollers(Key No. 11) into miler bushings

(Key Nos. 1 and 2).

POWER SOURCE

WARNING: Do not connect planer/molderto the

powersource untilall assemblysteps have been com-

pleted.

The motor is designedfor operationon the voltageand

frequency specified. Normal loadswillbe handled safe-

lyon voltages not morethan 10% above or below spec-

ifiedvoltage. Runningtheuniton voltageswhichare not

withinrange may cause overheatingand motorbum out.

Heavy loads requirethatvoltageat motor terminals be

no less than the voltage specifiedon nameplate.

• Power supply to the motoriscontrolledby a switch

with key. Removing the key from switchwill lock the

unitand prevent unauthorizeduse.

GROUNDING INSTRUCTIONS

WARNING: Improperconnection of equipment

groundingconductor can resultin the risk of electdcal

shock.Equipment mustbe groundedwh!le in use to

protectoperatorfrom electdcal shock. :

• Checkwith a qualifiedelectrician if you do not

understandgroundinginstructionsorif you are in

doubt as to whetherthe tool is prope,dygrounded.

• This tool is equippedwith an approvedcord rated at

150V and a 3-pronggroundingtype plug (see Figure

9) for your protectionagainst shockh;_zards.

• Groundingplug shouldbe pluggeddirectly intoa

properly installedand grounded3-prong grounding-

type receptacle, as shown (see Figur_ 9).

PropedyGroundedOutlet\ r_l

GroundingProng,,, Xx'l._ II

Figure8 - Half Ba, Dust CollectionSet

3 ProngPlug_O_j I]

Figureg - 3-ProngReceptacle

5

• Do not removeor altergroundingpronginany manner.

Inthe eventofa malfunction or breakdown, grounding

providesa pathof least resistanceforelectricalshock.

WARNING: Do not permit fingers to touchthe termi-

nals of plug when insertingor removingfrom outlet.

• Plug must be plugged into matchingoutlet that is

properly installed and groundedin accordance with

all local codes and ordinances. Do not modify plug

provided.If it will not fit in outlet, have proper outlet

installed bya qualified electrician.

• Inspect tool cordsperiodically,and if damaged, have

repaired byan authorized service facility.

• Green (or green and yellow)conductorin cord isthe

groundingwire. If repair or replacement of the elec-

tric cord or plug is necessary,do not connect the

green (or green and yellow) wire to a live terminal.

• A 2-prong wall receptacle mustbe replaced with a

properly grounded 3-prong receptacle installed in

accordance with National Electric Code and local

codes and ordinances.

WARNING: Any receptacle replacement should be

performed by a qualified electrician.

A temporary 3-prong to 2-prong grounding adapter (see

Figure 10) is available for connecting plugs to a two

pole outlet if it isproperly grounded.

GroundingLug _ r==_MakoeSUrc_e'rhis

Adapter IIToAKnown

3-ProngP__.. Ground

"_"--'- _"_2-Prong Receptacle

Figure10 - 2-ProngReceptaclewith Adapter

• Do not use a 3-prong to 2-prong groundingadapter

unless permitted by local and national codes and

ordinances.(A 3-prong to 2-prong groundingadapter

is not permittedin Canada.)

Where a 3-prongto 2-preng groundingadapter is

permitted, the rigidgreen tab or terminal on the side

of the adapter must be securely connected to a

permanent electricalground such as a propedy

groundedwater pipe, a propedy groundedoutletbox

or a properlygrounded wire system.

• Many cover plate screws, water pipes and outlet

boxes are not properlygrounded.To ensure proper

ground, groundingmeans mustbe tested by a quali-

fied electrician.

EXTENSION CORDS

• The use of any extensioncord will cause some drop

in voltage and lossof power.

• Wires of the extension cord mustbe of sufficientsize

to carry the currentand maintainadequate voltage.

• The minimumextension cord wire size isA.W.G. 12.

Do not use extension cords over 25 feet long.

• Use only 3-wire extensioncords having3-prong

groundingtype plugs and 3-pole receptacles which

accept the tool plug.

• Ifthe extensioncord is worn, cutor damaged in any

way, replaceit immediately.

Planeris suppliedwitha 3 HP motor installed.

The 120 Volt AC universalmotorhas the following

specifications:

Horsepower (Maximum Developed)............ 3 HP

Voltage................................... 120

Amperes............................ _...... 15

Hertz ..................................... 60

Phase.............................. _... Single

Cutterhead RPM ..................... : .... 5500

ELECTRICAL CONNECTIONS

WARNING: Make sure unit is turned off and discon-

nected from powersource beforeinspectingany widng.

The motor is installedand wiringconnected as illustrat-

ed in the wiring schematic (see Figure 11).

Switch

Cir k_"

MotorHousing

Figure11- WiringSchematic

The motor is assembled with an approvedthree con-

ductorcordto be used on 120 volts as indicated.The

power supplytothe motoris controlledby a double pole

locking switch. !.

The power linesare connecteddirectlyto the switch.

The green groundlinemust remainsecurel_fastened

to the frame to propedyprotectagainst electricalshock.

A manual resetovedoad protector is installedin line

with the power supplytothe motor.If the planer/molder

isoverloaded,the protectorwill break the circuit.

DESCRIPTION

Craftsman15" planer/molderfinishesrough-cutlumber

to size and planessoft and hardwoodsup to 6"thickand

15"wide.Woodfeeds intotwo-blade cutterheadbyrub-

ber infead/outfeedrollers.Sturdybase censtmcUon and

four-post designpermitssmoothfeeding andvirtually

snipelessplaning.Planer/moldercomeswithenclosed,

universalball beadng, 3 HP (max.developed)motorwith

ovedoad protection.Motorhas ON/OFF switchwith

removablekeyto preventaccidentalstart-up.Unit fea-

tures power movementcontrolfor rollercase,depth-of-

cut gauge for convenient setup,workpiecethid(ness pre-

set gauge with6 settingsfor consistentsetup,easy

hands-flea replacementof blades for safetyand mini-

mizeddowntime,built-industcollector, top mounted

rollersfor workpiecareturn, built-incarryinghandles,

cordwraps forportability and folding infeed/outfeed

tables with rollersforsmoothoperation.Planer/molder

takes cutsupto =A_"per pass at 22 feet per minute.Inch

heightscale hasgraduationsin 'A,"increments,and met-

dcheightscalehas graduationsin lmm Incrslments.

6

Table Size ............................. 15 x 16"

ExtensionTable Size .................... 15 x 11"

Base Size ............................. 32 x16"

WorkpieceWidth (max.) ...................... 15"

WorkpieceThickness (max.) ................... 6"

Maximum Depth of Cut ..................... 3/32"

Cuts Per Minute ......................... 11,000

Feed Rate........................... 11122FPM

Overall Dimensions .......... 56" H x 34" W x 40" D

Weight ................................ 150 Ibs

OPERATION SAFETY RULES

WARNING: For yourown safety, road all of the

instructionsand precautions before operating tool.

WARNING: Operation of any powertoolcan result in

foreignobjects being thrown intoeyes which can result

in severe eye damage. Always wear safety goggles

complyingwith United States ANSI Z87.1 (shown on

package) before commencing powertool operation.

CAUTION: Always observe the following safety pre-

cautions:

• Know general power tool safety. Make sure all pre-

cautions are understood (see pages 2, 3 and 7).

• Whenever adjustingor replacingany partson

planer/molder,turn switchOFF and removeplugfrom

power source.

• Make sure all guards are properlyattached and

securely fastened.

• Make sure all movingparts are free from interference.

• Always wear eye protectionor face shield.

• Make sure blades are aligned and properlyattached

to cutterhead.

• Do not plug in planer/molder unlessswitchis in off

position. After turning switchon, allow planer/molder

to come to fullspeed beforeoperating.

• Keep hands clear of all movingparts.

• Do notforce cut. Slowing or stallingwilloverheat

motor.Allow automaticfeed tofunction properly.

• Use quality lumber.Blades last longerand cuts are

smoother with good qualitywood.

• Do not plane material shorter than 17", narrower

than ¾", wider than 15" or thinner than t/8".

• Never make planing cut deeper than =/_".

• Maintain the proper relationshipsof infeedand out-

feed table surfaces and cutterhead blade path.

• Do not back the work toward the infeedtable.

• Takeprecautionsagainstkickback.Donot permit any-

one to stand or cross in line of cutterhead'srotation.

Kickbackor thrown debds willtravelin thisdirection.

• Turn switchoffand disconnect power whenever plan-

er/molder is notin use.

• Replace blades as they become damaged or dull.

• Keepplaner/molder maintained.Followmaintenance

instructions(see pages 16-16).

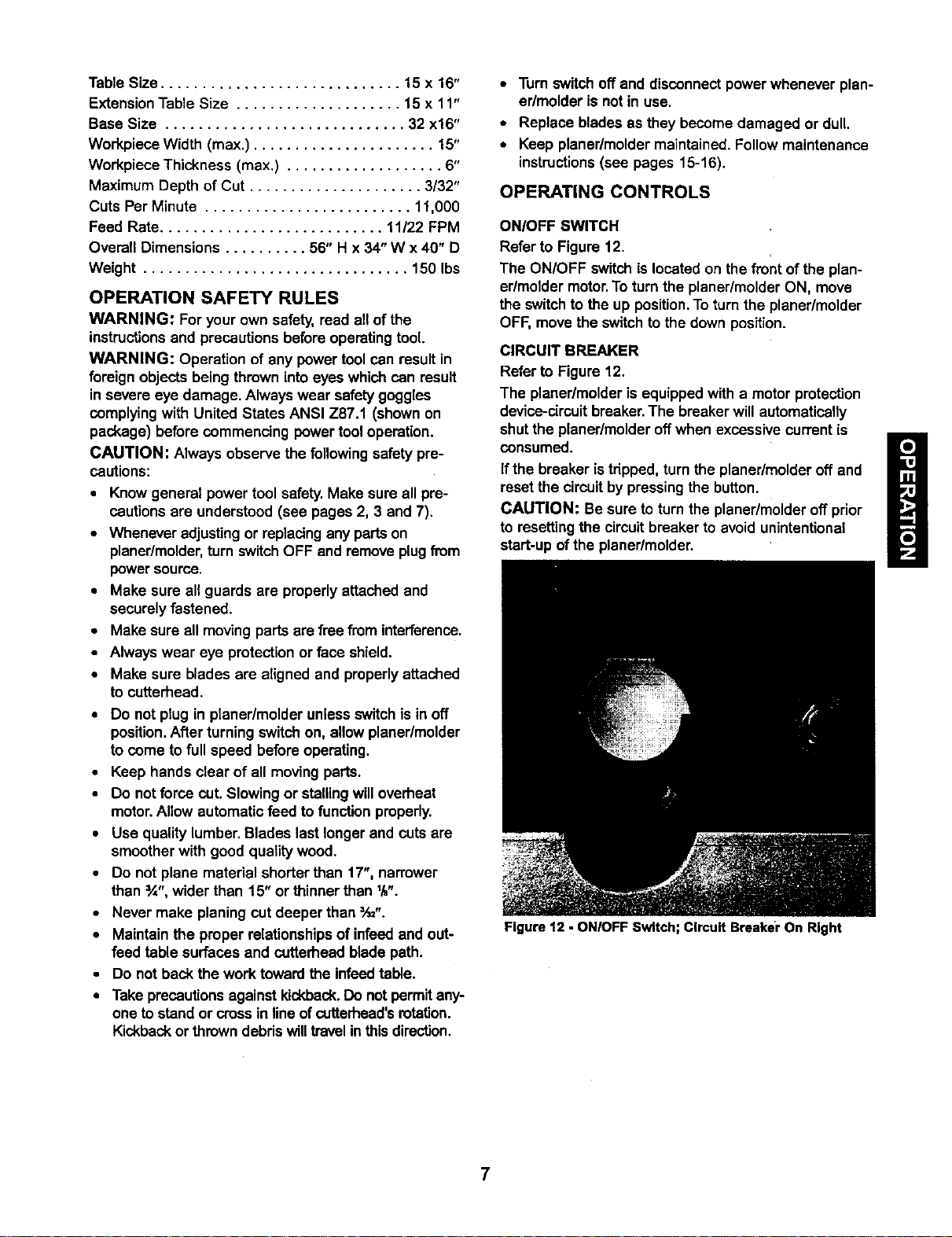

OPERATING CONTROLS

ON/OFF SWITCH

Refer to Figure 12.

The ON/OFF switch islocated on the front of the plan-

er/molder motor.Toturn the planar/molderON, move

the switch to the up position. To turnthe planer/molder

OFF, move the switch to the down position.

CIRCUIT BREAKER

Refer to Figure 12.

The planer/molder is equipped with a motorprotection

device-circuitbreaker.The breakerwill automatically

shut the planer/molder off when excessivecurrent is

consumed.

If the breaker is tripped, turn the planer/molderoff and

resetthe circuitby pressing the button.

CAUTION: Be sure to turn the planer/molderoff prior

to resettingthe circuitbreaker to avoid unintentional

start-upof the planer/molder.

Figure 12 - ONIOFF Switch; Circuit Breaker On Right

SWITCH LOCK

Refer to Figure 13.

The planer/molder can be lockedfrom unauthorized

use by lockingthe switch.To lockthe switch:

• Turn the switch to OFF positionand disconnect plan-

er/molder from power source.

• Pull the key out. The switchcannot be turned on with

the key removed.

NOTE: Should the key be removed from the switch at

the ON position,the switchcan be turned off but cannot

be turned on.

• To replace key, slide key intothe sloton switch until

itsnaps.

Figure 13 - Removing Locklng Key

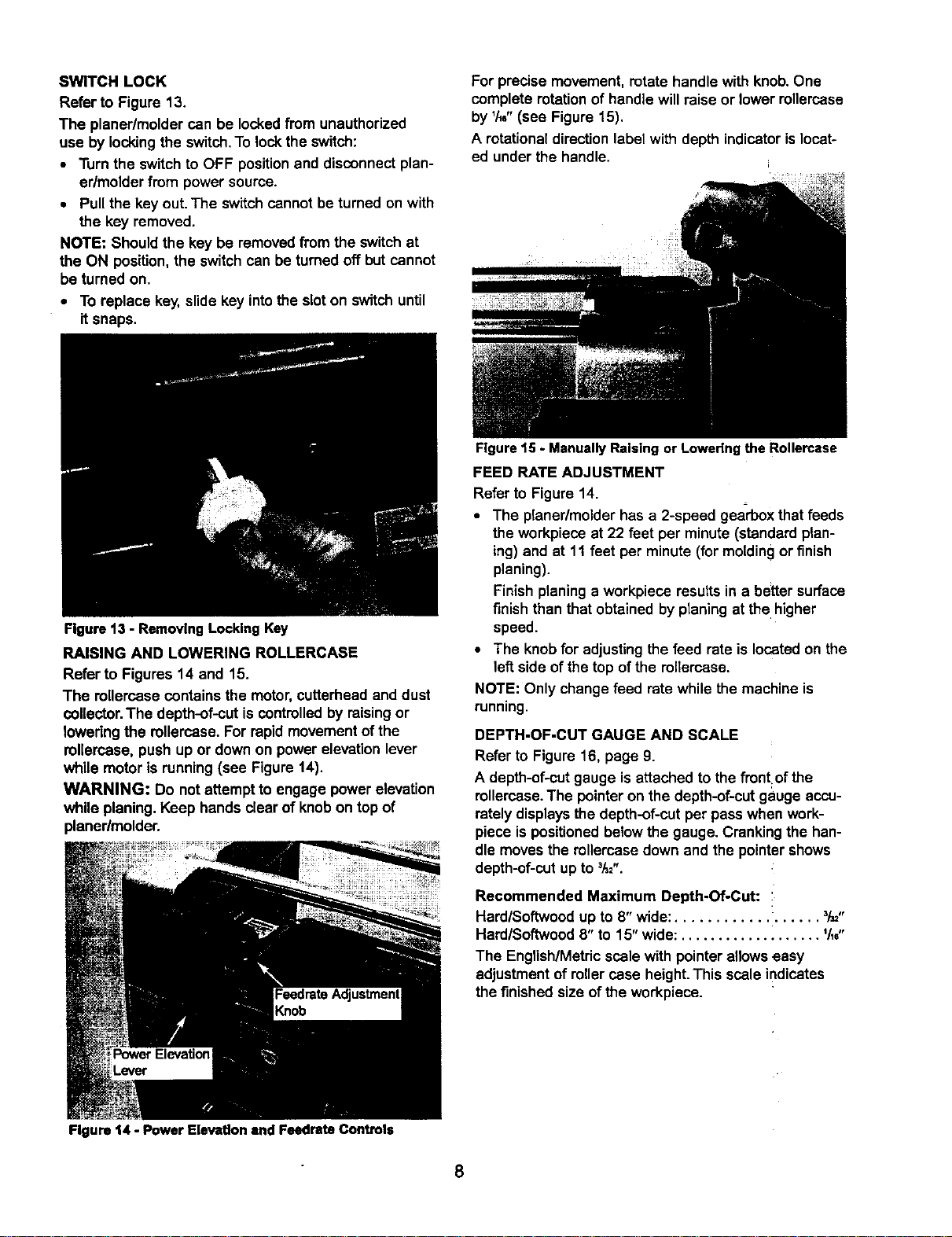

RAISING AND LOWERING ROLLERCASE

Refer to Figures 14 end 15.

The rollercasecontains the motor,cutterhead and dust

collector.The depth-of-cut is controlled by raisingor

loweringthe rollercase. For rapid movementof the

rollercase, push up or down on power elevation lever

while motor is running(see Figure 14).

WARNING: Do notattempt to engage powerelevation

while planing.Keep hands clear of knob on top of

planer/molder.

For precise movement, rotate handle with knob.One

complete rotationof handle willraise or lower renercase

by 1/16"(see Figure 15).

A rotationaldirectionlabelwith depth indicatorislocat-

ed under the handle.

Figure 15 - Manually Raising or Lowering the Rollercase

FEED RATE ADJUSTMENT

Refer to Figure 14.

• The planer/molder has a 2-speed gearbox that feeds

the workpiece at 22 feet per minute(standard plan-

ing) and at 11 feet per minute(for moldingor finish

planing).

Finish planinga workpiece results in a better surface

finish than that obtained by planing at the higher

speed.

• The knob for adjustingthe feed rate is located on the

left side of the top ofthe mllercese.

NOTE: Only change feed rate while the machine is

running.

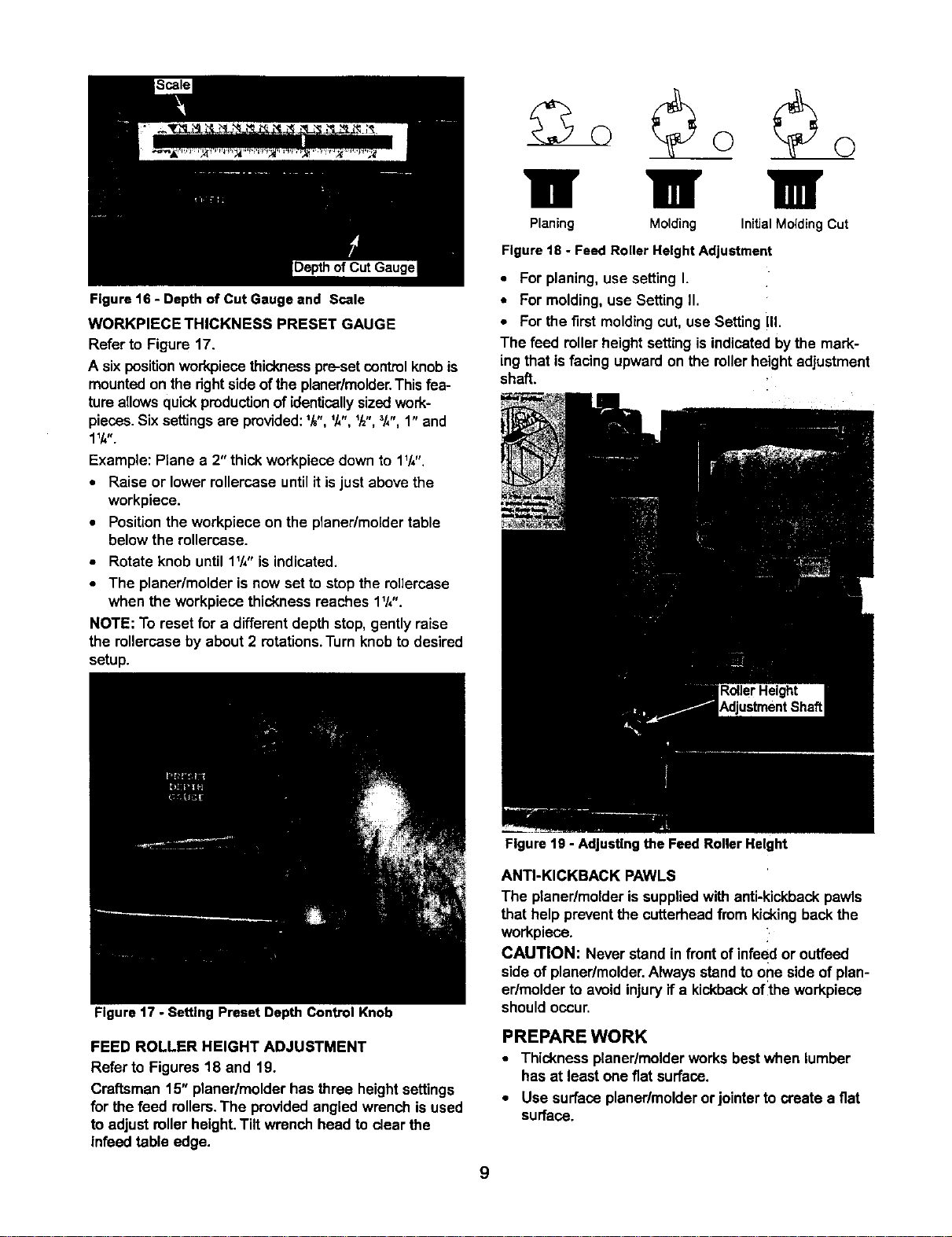

DEPTH-OF-CUT GAUGE AND SCALE

Refer to Figure 16, page 9.

A depth-of-cutgauge is attached to the front of the

rellercase.The pointeron the depth-of-cut gauge accu-

ratelydisplays the depth-of-cutper passwhen work-

piece is positioned below the gauge. Crankingthe han-

dle moves the mllercase down and the pointer shows

depth-of-cutup to 3h=".

Recommended Maximum Depth-Of-Cut:

Hard/Softwood up to 8" wide:.................. 3/_,,

Hard/Softwood 8" to 15" wide: ................... 1/_,,,

The English/Metricscale with pointerallowseasy

adjustment of roller case height.This scale indicates

the finishedsize of the workpiece.

Figure 14 - Power Elevation and Feedrate Controls

8

Figure16 - Depthof Cut Gauge and Scale

WORKPIECE THICKNESS PRESET GAUGE

Refer to Figure 17.

A sixpositionworkpiecethicknesspre-setcontrolknobis

mountedon the rightsideof the planer/molder. This fea-

tureallowsquick productionof identically sizedwork-

pieces.Six settingsare provided:lk", lk", _h",3k",1" and

1tk,,.

Example: Ptene a 2" thick workpiece down to 1V4".

• Raise or lower rollercese until itisjust above the

workpiece.

• Positionthe workpiece on the planer/moldertable

belowthe rollercese.

• Rotate knob until 1V,"is indicated.

• The planer/molder is now set to stop the rellercase

when the workpiecethicknessreaches 1W'.

NOTE: To reset for a differentdepth stop,gently raise

the rellercese by about 2 rotations.Turnknob to desired

setup.

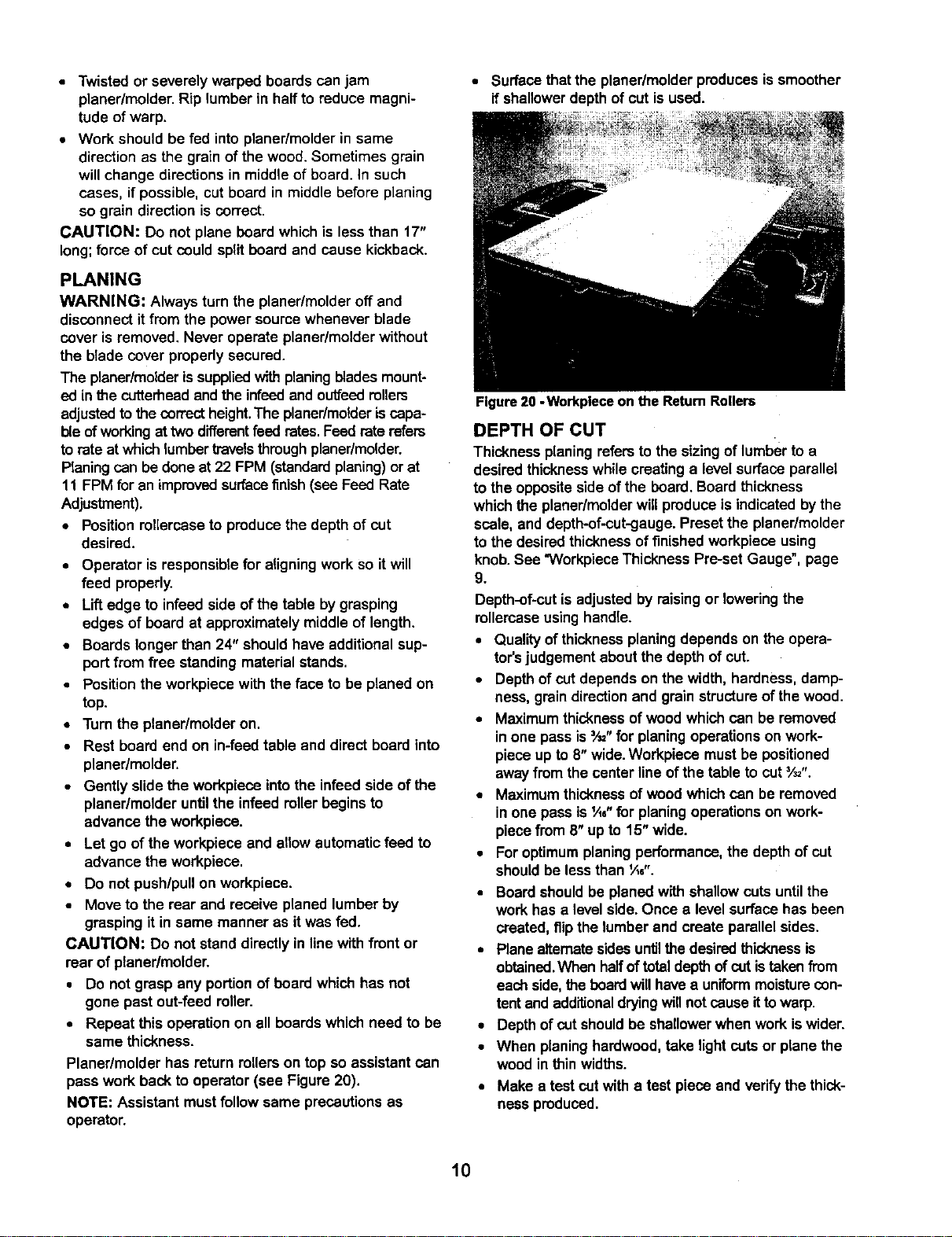

111 1B /

Planing Molding InitialMolding Cut

Figure 18 - Feed Roller Height Adjustment

• For planing, use setting I.

• For molding, use Setting II.

• For the first molding cut, use Setting III.

The feed roller height setting is indicated by the mark-

ing that is facing upward on the rollerheight adjustment

shaft.

Figure 17 - Setting Preset Depth Control Knob

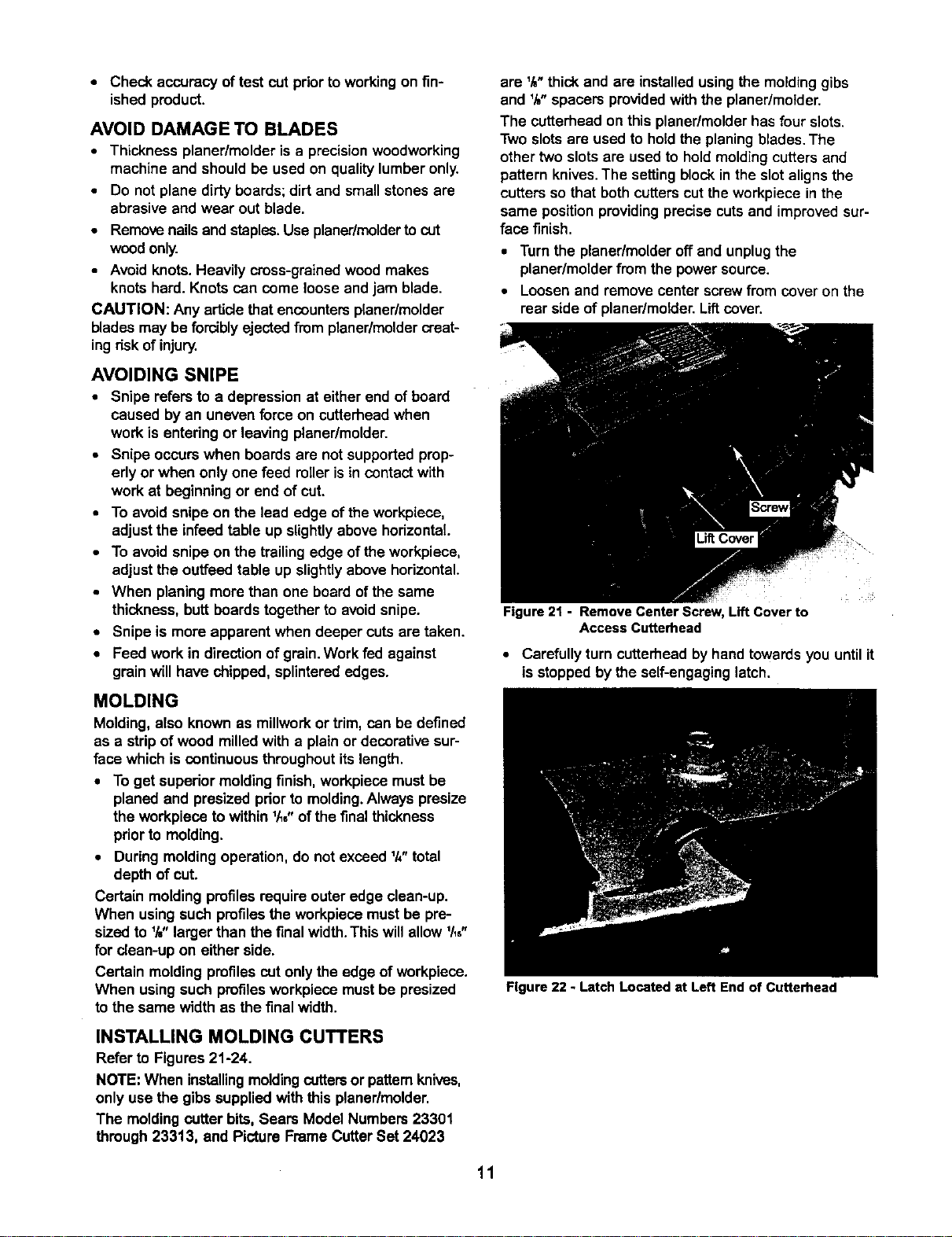

FEED ROLLER HEIGHT ADJUSTMENT

Refer to Figures 18 and 19.

Craftsman 15" planedmolder has three height settings

for the feed rollers.The provided angled wrench is used

to adjust rollerheight.Tilt wrenchhead to clear the

infeed table edge.

Figure 19 - Adjusting the Feed Roller Height

ANTI-KICKBACK PAWLS

The planer/molder issuppliedwith anti-kickbackpawls

that help prevent the cutterheadfrom kickingback the

workpiece.

CAUTION: Neverstand infront of infeedor outfeed

side of planer/molder.Alwaysstand to o_e side of plan-

er/molder to avoid injuryif a kickbackofthe workpiece

shouldoccur.

PREPARE WORK

• Thickness planer/molderworks best when lumber

has at least one fiat surface.

• Use surface planer/molderor jointerto create a fiat

surface.

9

• Twisted or severely warped boards can jam

planer/molder.Rip lumber in hall to reduce magni-

tude of warp.

• Work shouldbe fed into planer/molder in same

directionas the grainof the wood. Sometimes grain

willchange directions in middle of board. In such

cases, if possible, cut board in middle before planing

so grain direction is correct.

CAUTION: Do not plane board which is less than 17"

long; force of cut could split board and cause kickback.

PLANING

WARNING: Always turn the planer/molder off and

disconnectit from the power source whenever blade

cover is removed. Never operate planer/molderwithout

the blade cover properly secured.

The planer/molderissuppliedwith planingbladesmount-

ed in the cutterheadandthe infeedand ouffeedrollers

adjustedto the correct height.The planer/molderis capa-

ble of workingat twodifferentfeed rates.Feed rate refers

to rateat which lumber travelsthrough planer/molder.

Planingcan be done at 22 FPM (standardplaning)orat

11 FPM foran improvedsurfacefinish (see Feed Rate

Adjustment).

• Positionrollercaseto producethe depth of cut

desired.

• Operator isresponsiblefor aligningwork so it will

feed properly.

• Liftedge to infeed side of the table by grasping

edges of board at approximatelymiddle of length.

• Boards longerthan 24" should have additional sup-

port from free standingmaterial stands.

• Positionthe workpiece with the face to be planed on

top.

• Turn the planer/molder on.

• Rest board end on in-feed table and direct board into

planer/molder.

• Gently slide the workpiece intothe infeed side of the

planer/molder untilthe infeed rollerbegins to

advance the workpiece.

• Let go of the workpiece and allow automatic feed to

advance the workpiece.

• Do not push/pullon workpiece.

• Moveto the rear and receive planed lumber by

graspingit in same manner as it was fed.

CAUTION: Do not stand directlyin line with front or

rear of planer/molder.

• Do not grasp any portionof board whichhas not

gone past out-feed roller.

• Repeat this operation on all boards which need to be

same thickness.

Planer/molder has return milers on top so assistantcan

pass work back to operator (see Figure 20).

NOTE: Assistant mustfollow same precautionsas

operator.

• Surfacethatthe planer/molderproducesis smoother

if shallowerdepth of cut is used.

Figure 20 -Workplece on the Return Rollers

DEPTH OF CUT

Thickness planingrefers to the sizing of lumberto a

desired thicknesswhile creating a level surface parallel

to the oppositeside of the beard. Boardthickness

which the planer/molderwill produce is indicated by the

scale, and depth-of-cut-gauge.Preset the planer/molder

to the desiredthicknessof finishedworkpiece using

knob.See "VVorkpieceThickness Pre-set Gauge", page

9.

Depth-of-cutis adjustedby raisingor loweringthe

rollercaseusing handle.

• Qualityof thicknessplaningdepends on the opera-

tor'sjudgement aboutthe depth of cut.

• Depthof cut depends on the width, hardness,damp-

ness, grain directionand grain structureof thewood.

• Maximumthicknessof wood which can be removed

inone pass is=,_"for planingoperations on work-

piece up to 8"wide.Workpieca mustbe positioned

awayfrom the centerline ofthe table to cut3/=,,.

• Maximumthicknessof wood whichcan be removed

in one pass is _A0"for planingoperationson work-

piece from 8"up to 15"wide.

Foroptimumplaning performance, the depth of cut

shouldbe less than ¼6".

Board should be planed with shallowcuts untilthe

work has a levelside. Once a levelsurface has been

created, flipthe lumberand create parallel sides.

• Plane alternatesidesuntilthe desiredthickness is

obtained.When halloftotal depth of cut is taken from

each side,the board willhavea uniformmoisturecon-

tentand additionaldryingwillnot causeit to warp.

• Depthof cut shouldbe shallowerwhen workis wider.

• When planinghardwood, take light cuts or plane the

wood in thin widths.

Make a test cut witha test piece and verifythe thick-

ness produced.

10

• Check accuracy oftest cut prior to working on fin-

ishedproduct.

AVOID DAMAGE TO BLADES

• Thickness planer/molder is a precision woodworking

machine and should be used on qualitylumber only.

• Do not plane dirty boards;dirt and small stonesare

abrasive and wear out blade.

• Removenails and staples.Use planer/molderto cut

woodonly.

• Avoid knots. Heavily cross-grained wood makes

knots hard. Knots can come loose and jam blade.

CAUTION: Any article that encountersplaner/molder

bladesmay be forciblyejectedfrom planer/moldercreat-

ingdsk of injury.

AVOIDING SNIPE

• Snipe refersto e depression at either end of board

caused by an unevenforce on cutterheadwhen

work is entering or leaving planer/molder.

• Snipe occurswhen boards are not supportedprop-

erly or when only one feed roller is in contact with

work at beginningor end of cut.

• To avoid snipe on the lead edge of the workpiece,

adjustthe infeedtable up slightlyabove hodzontaL

• To avoid snipe on the trailingedge of the workpiece,

adjustthe ouffeed table up slightlyabove horizontal.

• When planing more than one board ofthe same

thickness, butt boardstogether to avoidsnipe.

• Snipe is more apparent when deeper cuts are taken.

• Feedwork in direction of grain.Work fed against

grain will have chipped, splintered edges.

MOLDING

Molding, also known as millworkor trim, can be defined

as a stripof wood milledwith a plain or decorativesur-

face which is continuous throughoutitslength.

• Toget superiormoldingfinish, workpieca mustbe

planed and presized pdor to molding.Always presize

the workpieca to within ',_,"of the final thickness

priorto molding.

• During moldingoperation, do not exceed I/,, total

depth of cut.

Certain molding profilesrequireouter edge clean-up.

When using such profilesthe workpieca must be pre-

sized to t_,,larger than the final width.This willallow '1,,"

for clean-up on either side.

Certain moldingprofilescut onlythe edge of workpieca.

When using such profilesworkpieca must be presized

to the same widthas the final width.

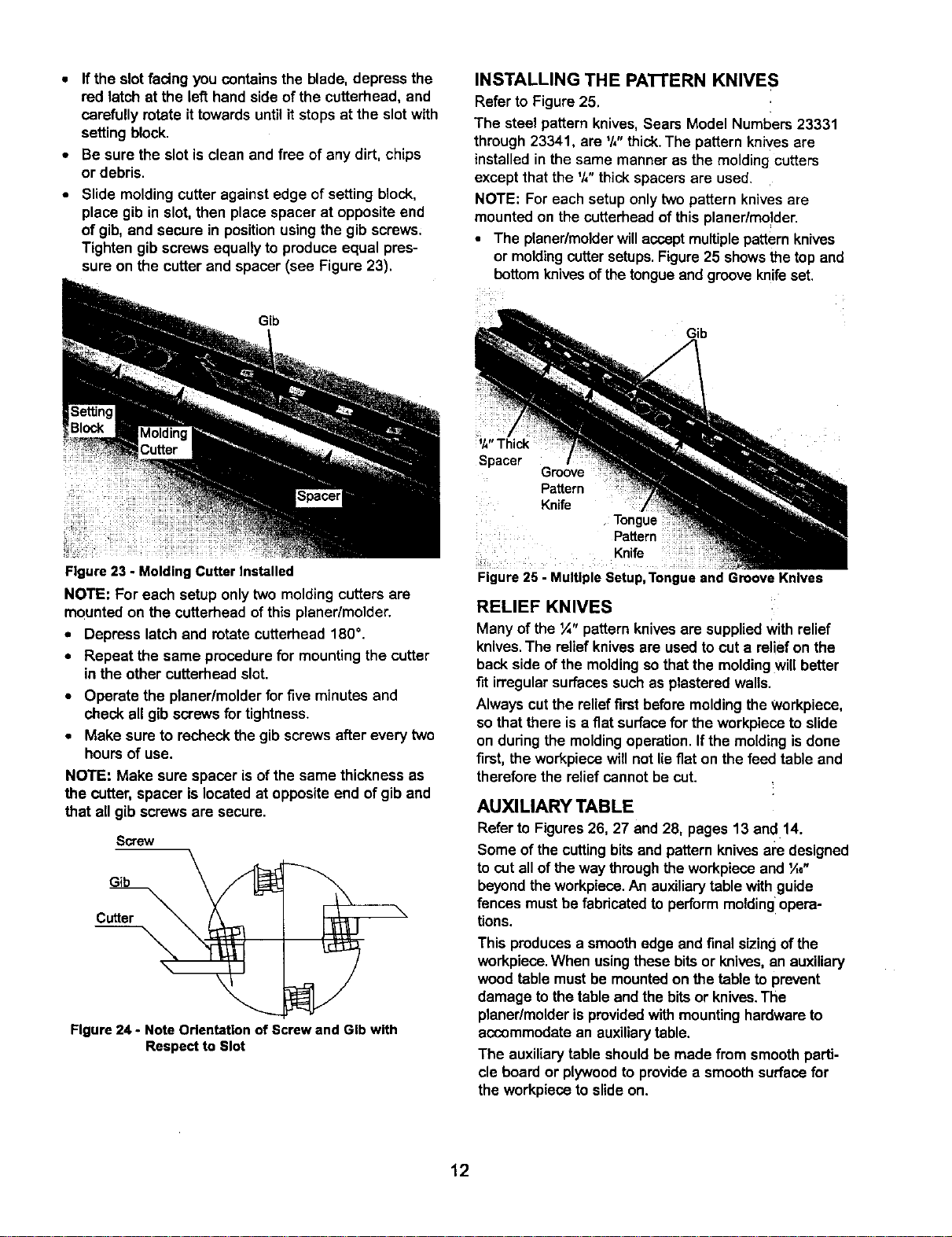

are 'k" thickand are installed using the moldinggibs

and lk" spacers providedwith the planer/molder.

The cutterhead on this planer/molderhas four slots.

Two slotsare used to hold the planing blades.The

other two slots are used to hold moldingcuttersand

pattern knives.The settingblockin the slot alignsthe

cuttersso that both cutterscut the workpiece in the

same positionprovidingprecise cutsand improved sur-

face finish.

• Turn the planer/molderoff and unplugthe

planer/molderfrom the power source.

• Loosenand removecenter screw from cover on the

rear side of planer/molder.Lif_cover.

Figure 21 - Remove Center Screw, Lift Cover to

Access Cutterhead

• Carefully turn cutterheadby hand towards you until it

is stopped by the self-engaging latch.

Figure 22 - Latch Located at Left End of Cutterhead

INSTALLING MOLDING CUTTERS

Refer to Figures 21-24.

NOTE: When installingmoldingcuttersor pattamknives,

only use the gibssupplied with this planer/molder.

The moldingcutter bits, Sears Model Numbers 23301

through 23313, and Picture Frame Cutter Set 24023

11

Ifthe slotfacing you containsthe blade, depress the

red latch at the left hand side of the cutterhead, and

carefully rotate it towardsuntilit stops at the slot with

setting block.

Be sure the slot is clean and free of any dirt, chips

or debris.

Slide molding cutter against edge of setting block,

place gib in slot, then place spacer at opposite end

of gib, and secure in position using the gib screws;

Tighten gib screws equally to produce equal pres-

sure on the cutter and spacer (see Figure 23).

Figure23 - MoldingCutterInstalled

NOTE: For each setup only two molding cutters are

mounted on the cutterhead of this planer/molder.

• Depress latch and rotate cutterhead 180=.

• Repeat the same procedurefor mountingthe cutter

in the other cutterhead slot.

• Operate the planer/molderfor five minutes and

check all gibscrews fortightness.

• Make sure to recheckthe gib screws after every two

hoursof use.

NOTE: Make sure spacer is ofthe same thicknessas

the cutter, spacer is located at oppositeend of gib and

that all gib screws are secure.

Screw

Gib

Cutter

Figure 24 - Note Odentatlon of Screw and GIb with

Respect to Slot

INSTALLING THE PA'I-rERN KNIVES

Refer to Figure 25.

The steel patternknives, Sears Model Numbers 23331

through 23341, are '/," thick.The patternknives ere

installedin the same manneras the molding cutters

except that the '/,"thick spacersare used.

NOTE: For each setup onlytwo pattern knivesare

mounted on the cutterheadof this planer/mo!der.

• The planer/molderwillacoept multiple pattern knives

or moldingcuttersetups.Figure 25 showsthe topand

bottomknivesofthe tongueand grooveknifeset.

Gib

1/4"Thick

Spacer /

Figure 25 - Multiple Setup, Tongue and Groove Knives

Groove

Pattern

Knife

Tongue

Pattern

Knife

RELIEF KNIVES

Many of the ¼" pattern knivesare supplied with relief

knives,The reliefknives are usedtocut a relief on the

backside of the moldingso that the moldingwill better

fit irregular surfacessuch as plasteredwalls.

Always cut the relief first before molding the workpieca,

so that there is a fiat surface for the workpieca to slide

on during the molding operation. If the molding is done

first, the workpiece will not lie fiat on the feed table and

therefore the relief cannot be cut.

AUXILIARY TABLE

Refer to Figures26, 27 and 28, pages 13 and 14.

Some of the cuttingbitsand pattern knivesam designed

to cut all of the way through the workpiece and '/,e"

beyondthe workpieca.An auxiliarytable withguide

fences mustbe fabdcated to perform moldingIopera-

tions.

This produces a smoothedge and finalsizingofthe

workpiece.When usingthese bits or knives,an auxiliary

wood table mustbe mountedon the table to prevent

damage to the table and the bitsor knives.The

planer/molderis providedwithmountinghardwareto

accommodatean auxiliarytable.

The auxiliary table shouldbe made fromsmoothparti-

cle board or plywoodto providea smooth surfacefor

the workpieceto slide on.

12

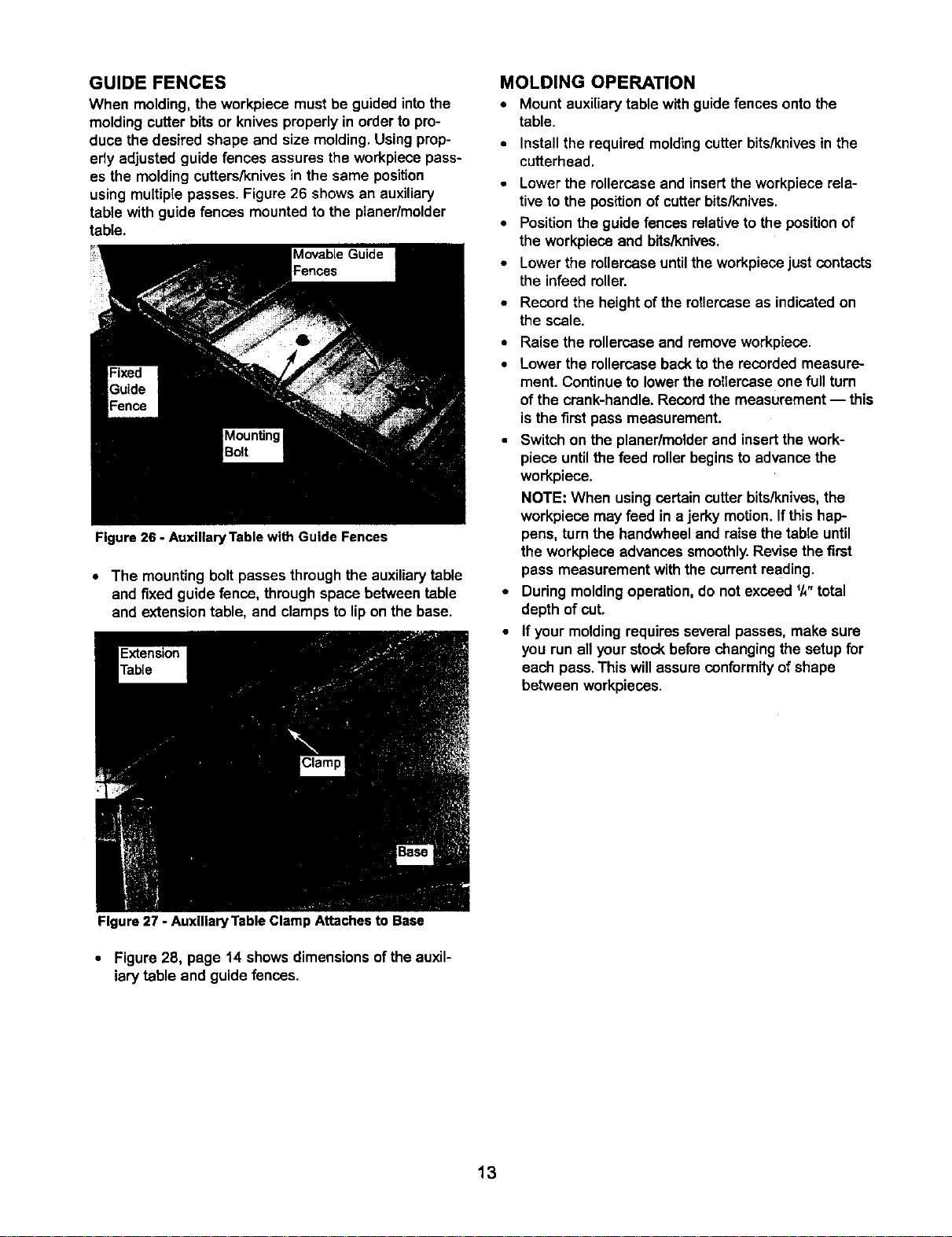

GUIDE FENCES

When molding,the workpiece must be guided intothe

molding cutter bits or knives properlyin order to pro-

duce the desired shape and size molding.Usingprop-

edy adjusted guide fences assures the workpiecepass-

es the molding cutters/knivesin the same position

using multiple passes. Figure 26 shows an auxiliary

table with guide fences mounted to the planer/molder

table.

Figure 26 - AuxlliaryTable with Guide Fences

• The mounting boltpasses through the auxiliarytable

and fixed guide fence, through space between table

and extensiontable, and clamps to lipon the base.

MOLDING OPERATION

• Mount auxiliarytable withguide fences ontothe

table.

• Install the required moldingcutter bits/knives in the

cutterhead.

• Lower the rollercaseand insert the workpiecerela-

tiveto the positionof cutter bits/knivas.

• Positionthe guide fencesrelativeto the positionof

the workpiece and bits/knives.

• Lower the rollercaseuntilthe workpiecejust contacts

the infeedroller.

• Record the height of the rollercaseas indicatedon

the scale.

• Raisethe rellercase and removeworkpiece.

• Lower the rollercasebacktothe recordedmeasure-

ment. Continueto lowerthe rollercaseone full turn

of the crank-handle.Recordthe measurement -- this

isthe first pass measurement.

• Switchon the planer/molderand insertthe work-

piece untilthe feed rollerbegins toadvance the

workpiece.

NOTE: When usingcertain cutterbits/knives,the

workpiece may feed in a jerky motion. If this hap-

pens, turnthe bandwheel and raise the table until

the workpiece advances smoothly.Revise the first

pass measurement with the current reading.

• During moldingoperation, do not exceed I/," total

depth of cut.

• If your moldingrequiresseveral passes,make sure

you run all yourstockbeforechangingthe setup for

each pass.This will assure conformity of shape

between workpieces.

Figure 27 - Auxiliary Table Clamp Attaches to Base

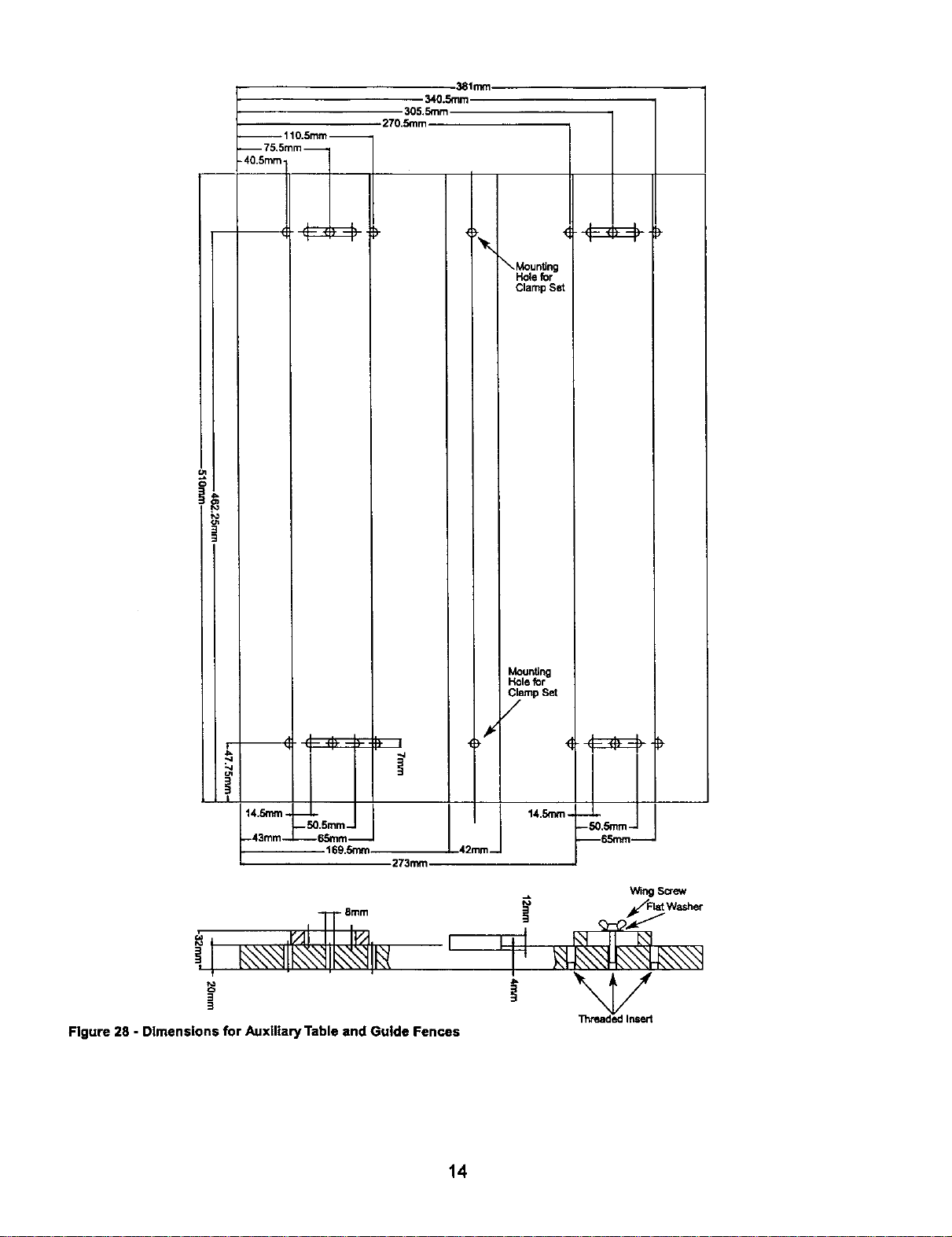

• Figure 28, page 14shows dimensionsof the auxil-

iary table and guide fences.

13

110.Smm--

75,5mm

305.5mm

270.5mm

38tmm

340.5mm

Mounting

I

I

• I

-4

-43ram-- -- 6.Smm--

1

169.5mm

273mm,

Ll;'im

3

Figure 28 - Dimensions for Auxiliary Table and Guide Fences

Mounting

Hole _r

Clamp Set

/

J

42 m_ 14.Smrn.

Wing Screw

Flat Washer

!

i

14

Loading...

Loading...