Craftsman 351217160 Owner’s Manual

Operator's Manual

£RRFT$14RN

5-Speed

WOOD LATHE

Model No.

351.217160

CAUTION:

Read and follow all Safety

Rules and Operating

Instructions before First

Use of this Product.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

7799.01 Draft (05/01/98)

Warranty ....................................... 2

Safety Rules .................................. 2-3

Assembly ...................................... 4

Installation .................................... 4-7

Operation ................................... 7-21

Maintenance ................................... 21

Troubleshooting ................................ 22

Parts Illustration and List ....................... 24-25

Espa_ol .................................... 26-49

FULL ONE YEAR WARRANTY ON CRAFTSMAN

5-SPEED WOOD LATHE

If this Craftsman wood lathe fails to give complete satisfaction

within one full year from the date of purchase, return it to the

nearest Sears Service Center in the United States and Sears

will repair it free of charge.

Warranty service is available by contacting Sears in-home

major brand repair service. This warranty gives you specific

legal rights and you may also have other rights which vary

from state to state.

If this wood lathe is used for commercial purposes, this war-

ranty applies for only 90 days from the date of purchase.

Sears, Roebuck and Co., Dept. 817 WA, Hoffman Estates, IL

60179

CAUTION: Always follow proper operating procedures as

defined in this manual -- even if you are familiar with use of

this or similar tools. Remember that being careless for even a

fraction of a second can result in severe personal injury.

BE PREPARED FOR JOB

• Wear proper apparel. Do not wear loose clothing, gloves,

neckties, rings, bracelets or other jewelry which may get

caught in moving parts of machine.

• Wear protective hair covering to contain long hair.

• Wear safety shoes with non-slip soles.

• Wear safety glasses complying with United States ANSI

Z87.1. Everyday glasses have only impact resistant lenses.

They are NOT safety glasses.

• Wear face mask or dust mask if operation is dusty.

• Be alert and think clearly. Never operate power tools when

tired, intoxicated or when taking medications that cause

drowsiness.

PREPARE WORK AREA FOR JOB

• Keep work area clean. Cluttered work areas invite accidents.

• Do not use power tools in dangerous environments. Do not

use power tools in damp or wet locations. Do not expose

power tools to rain.

• Work area should be properly lighted.

• Keep visitors at a safe distance from work area.

• Keep children out of workplace. Make workshop childproof.

Use padlocks, master switches or remove switch keys to

prevent any unintentional use of power tools.

• Keep power cords from coming in contact with sharp

objects, oil, grease, and hot surfaces.

TOOL SHOULD BE MAINTAINED

• Always unplug tool prior to inspection.

• Consult manual for specific maintaining and adjusting pro-

cedures.

• Keep tool lubricated and clean for safest operation.

• Keep all parts in working order. Check to determine that

the guard or other parts will operate properly and perform

their intended function.

• Check for damaged parts. Check for alignment of moving

parts, binding, breakage, mounting and any other condition

that may affect a tool's operation.

• A guard or other part that is damaged should be properly

repaired or replaced. Do not perform makeshift repairs.

(Use parts list provided to order replacement parts.)

• Never adjust attachments while running. Disconnect power

to avoid accidental start-up.

• Have damaged or worn power cords replaced immediately.

• Keep cutting tools sharp for efficient and safest operation.

KNOW HOW TO USE TOOL

• Use right tool for job. Do not force tool or attachment to do

a job for which it was not designed.

• Disconnect tool when changing attachments.

• Avoid accidental start-up. Make sure that the tool is in the

"off" position before plugging in, turning on safety discon-

nect or activating breakers.

• Do not force tool. It will work most efficiently at the rate for

which it was designed.

• Keep hands away from chuck, centers and other moving parts.

• Never leave tool running unattended. Turn the power off

and do not leave tool until it comes to a complete stop.

• Do not overreach. Keep proper footing and balance.

• Never stand on tool. Serious injury could occur if tool is

tipped or if centers are unintentionally contacted.

• Know your tool. Learn the tool's operation, application and

specific limitations.

• Handle workpiece correctly. Mount firmly in holding

devices. Protect hands from possible injury.

• Turn machine off if workpiece splits or becomes loose.

• Use cutting tools as recommended in "Operation."

WARNING: For your own safety, do not operate your wood

lathe until it is completely assembled and installed according to

instructions.

PROTECTION: EYES, HANDS, FACE, BODY, EARS

• If any part of your lathe is missing, malfunctioning, or has

been damaged or broken, cease operating immediately

until the particular part is properly repaired or replaced.

• Wear safety goggles that comply with United States ANSI

Z87.1 and a face shield or dust mask if operation is dusty.

Wear ear plugs or muffs during extended periods of operation.

• Small loose pieces of wood or other objects that contact a

spinning workpiece can be propelled at very high speed.

This can be avoided by keeping the lathe clean.

2

• Never turn the lathe ON before clearing the bed, head and

tailstock of all tools, wood scraps, etc., except the workpiece

and related support devices for the operation planned.

• Never place your face or body in line with the chuck or

faceplate.

• Never place your fingers or hands in path of cutting tools.

• Never reach in back of the workpiece with either hand to

support the piece, remove wood scraps, or for any other

reason. Avoid awkward operations and hand positions

where a sudden slip could cause fingers or hand to move

into a spinning workpiece.

• Shut the lathe OFF and disconnect power source when

removing the faceplate, changing the center, adding or

removing an auxiliary device, or making adjustments.

• Turn key lock switch to "off" and remove key when tool is

not in use.

• If the workpiece splits or is damaged in any way, turn lathe

OFF and remove the workpiece from the holders. Discard

damaged workpiece and start with a new piece of wood.

• Use extra care when turning wood with twisted grain or

wood that is twisted or bowed -- it may cut unevenly or

wobble excessively.

KNOW YOUR CUTTING TOOLS

• Dull, gummy, improperly sharpened or set cutting tools can

cause vibration and chatter during cutting operations.

Minimize potential injury by proper care of tools and regu-

lar machine maintenance.

THINK SAFETY

Safety is a combination of operator common sense and alert-

ness at all times when the lathe is being used.

• For your own safety, read all rules and precautions in the

operator's manual before using this tool.

• For eye protection, wear safety glasses complying with

United States ANSI Z87.1.

• Do not wear loose clothing, gloves, neckties, rings,

bracelets or other jewelry that could get caught in moving

parts of machine or workpiece. Wear protective hair cover-

ing to contain long hair.

• Tighten all clamps, fixtures and tailstock before applying

power. Check to make sure that all tools and wrenches

have been removed.

• With switch off, rotate workpiece by hand to make sure

that there is adequate clearance. Start the machine on

lowest speed setting to verify that the workpiece is secure.

• For large pieces, create a rough shape on another piece of

equipment before installing on faceplate.

• Do not mount any workpieces that have splits or knots.

• Remove any center from spindle when using an outboard

device for auxiliary turning.

• Never attempt to remount a faceplate turning to the face-

plate for any reason.

• Never attempt to remount a between-centers turning if the

original centers on the turning have been altered or removed.

• When remounting a between-centers turning that has non-

altered original centers, make sure that the speed is at the

lowest setting for start-up.

• Use extra caution when mounting a between-centers turning

to the faceplate, or a faceplate turning to between-centers,

for secondary operations. Make sure that the speed is at

the lowest setting for start-up.

• Never perform any operation with this lathe where the work-

piece is hand-held. Do not mount a reamer, milling cutter, drill

bit, wire wheel or buffing wheel to the headstock spindle.

• When hand-sanding faceplate or between-centers mount-

ed workpieces, complete all sanding BEFORE removing

the workpiece from the lathe.

• Never run the spindle in the wrong direction. The cutting

tool could be pulled from your hands. The workpiece

should always turn towards the operator.

• For spindle turning, ALWAYS position the tool rest above the

centerline of the workpiece and spindle (approximately 1/8").

• Use the drill chuck accessory in the tail stock only. Do not

mount any drill bit that extends more than 6" beyond chuck

jaws.

CAUTION: Follow safety instructions that appear on the belt

guard for your lathe.

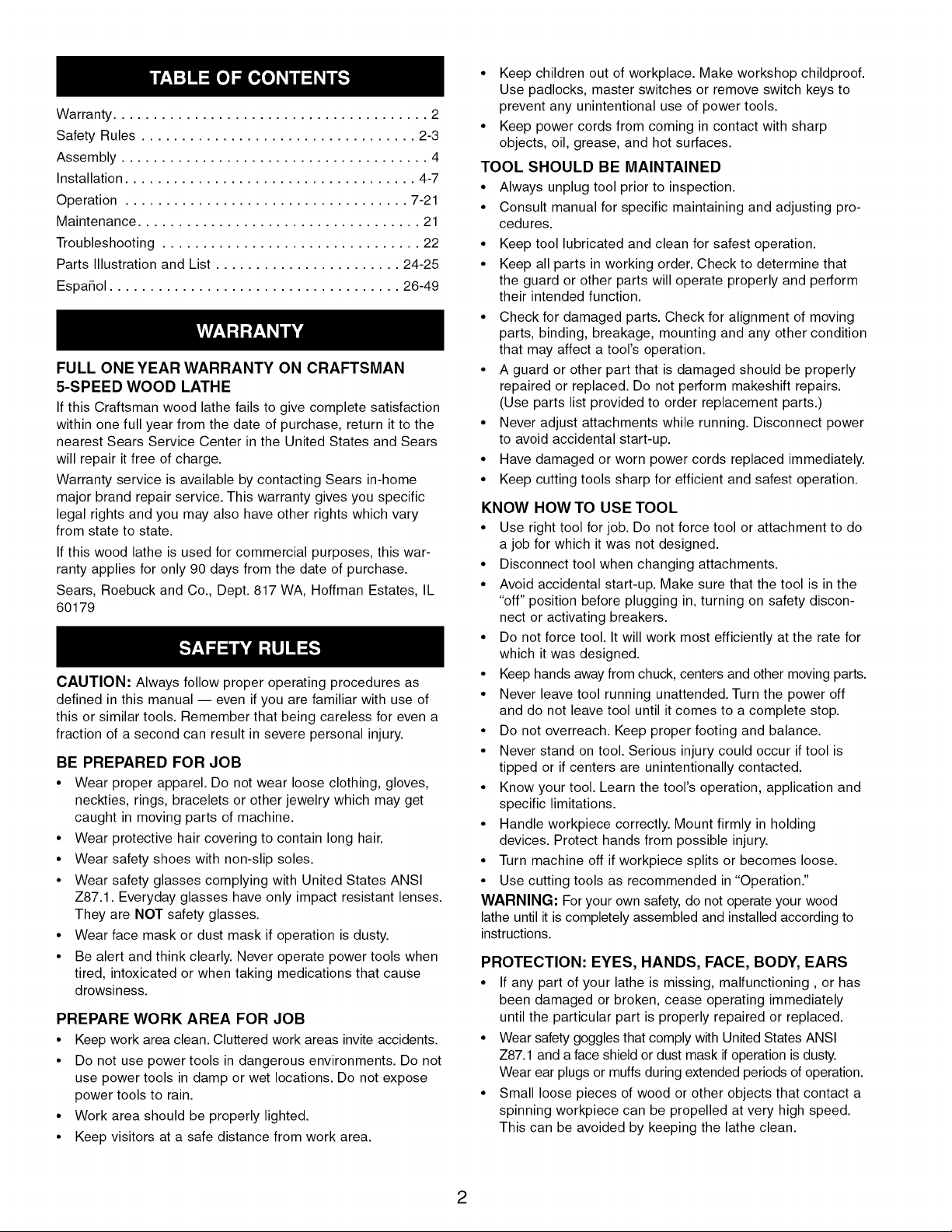

Refer to Figure 1.

Check for shipping damage. If damage has occurred, a claim

must be filed with carrier. Check for completeness. Immediately

report missing parts to dealer.

Your wood lathe is shipped complete in one carton and includes

a motor. Separate all parts from packing materials and check

each one with the unpacking list to make certain all items are

accounted for before discarding any packing material.

If any parts are missing, do not attempt to assemble the lathe,

plug in the power cord, or turn the switch on until the missing

parts are obtained and properly installed.

A

Head stock assembly and belt guard

B

Bed

C

Foot

D

Tail stock assembly

E

Tool rest bracket and base assembly

F

Center assembly - tail stock

G

Spur center

H

Tool rest- 12"

I

Tool rest - 6"

J

Bag containing loose parts and tools, centers,

hex wrenches and two brass slugs

K

Faceplate - 4"

L

Operator's manual (not shown)

A D

Figure 1 - Unpacking

H E

3

IMPORTANT:Thebediscoatedwithaprotectant.Toensure

properfitandoperation,removecoating.Coatingiseasily

removedwithmildsolvents,suchasmineralspirits,andasoft

cloth.Avoidgettingcleaningsolutiononpaintoranyofthe

rubberorplasticparts.Solventsmaydeterioratethesefinish-

es.Usesoapandwateronpaint,plasticorrubbercompo-

nents.Wipeallpartsthoroughlywithacleandrycloth.Apply

pastewaxtothebed.

RefertoFigures2-8and80.

CAUTION:Donotattemptassemblyifpartsaremissing.

Usethismanualtoorderreplacementparts.

• Removeallcomponentsfromtheshippingcartonandverify

againstthepartslistonpage3.Cleaneachcomponentand

removeshippingpreservatives(coatings)asrequired.

• Afterselectinganappropriatebench,table,orlathestand,

settheheadstock(Figure80,No.26)andattachmentson

theleftside.Installthebed(structuraltube)(Figure80,No.

35)byinsertingtheleftkeyplate(Figure80,No.36)intothe

keyslot.Securethebedusingset-screw(Figure80,No.52).

• Slidethetoolrestsupport(Figure80,No.38)ontothebed

andmoveittothemidpoint.Slidethetailstock(Figure80,No.

50)ontotheendofthebed.Slidetheassemblytowardsthe

headabout4"andsecurewithsetscrew(Figure80,No.48).

• Attachthefoot(Figure80,No.51)totheendofthebed

andsecurewithsetscrew(Figure80,No.52).

• VerifythatthepulleysandtheV-belthavebeenproperly

installedandthatthebeltguard(Figure80,No.8)isin

placeandoperatingproperly.

• Examinethelinecord(Figure80,No.14)tomakesure

thattheplugisingoodconditionandthattheinsulation

hasnotbeendamagedduringtransit.

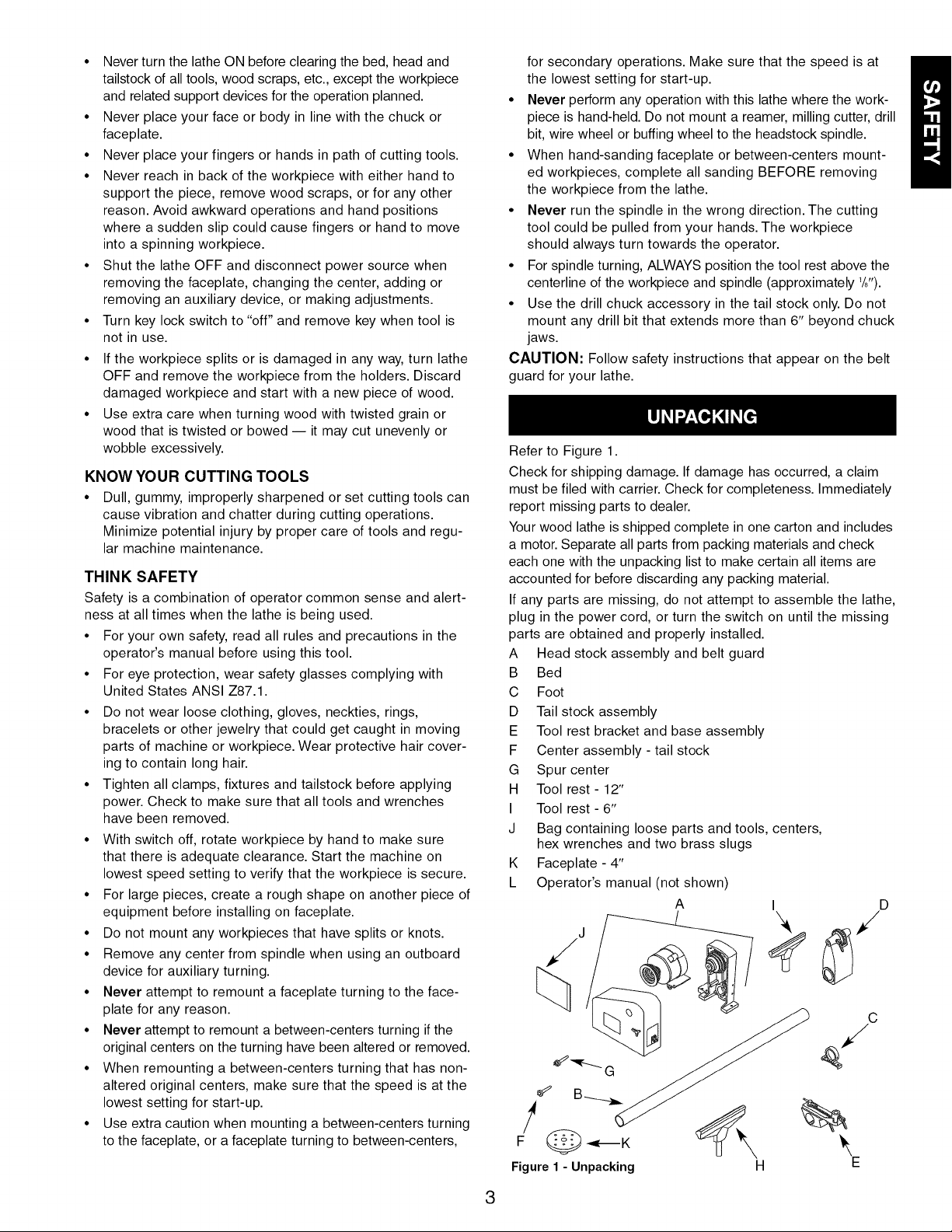

12mmWrench Screwdriver(medium)

• Be careful not to drill into metal legs or rails under the

bench top.

• Position the headstock assembly over the holes and feed

the two 9/19x 2" long carriage bolts (not supplied) down

through the holes in the headstock and the 3/8"holes in the

bench. Secure from underneath with flat washers, lock-

washers, and hex nuts (not supplied).

• Verify that the foot (Figure 80, No. 51) is resting flat on the

bench top. Mark the mounting hole locations using the

holes in the foot as a guide. Move the lathe and drill two

more 3/j, holes through the bench top. Place the lathe back

in position and feed four 9/16x 2" carriage bolts through the

holes in the head and foot. Secure from underneath with

flat washers, Iockwashers, and hex nuts as before.

STABILITY OF WOOD LATHE

If there is any tendency for the lathe to tip over or move dur-

ing certain cutting operations, such as cutting extremely

heavy pieces or long, out-of-round objects, the lathe should

be bolted down.

LOCATION OF WOOD LATHE

The lathe should bepositioned so that neither the operator

nor a casual observer is forcedto stand in line with the spin-

ning chuck or workpiece.

ASSEMBLY OF SPUR CENTER AND BEARING

CENTER

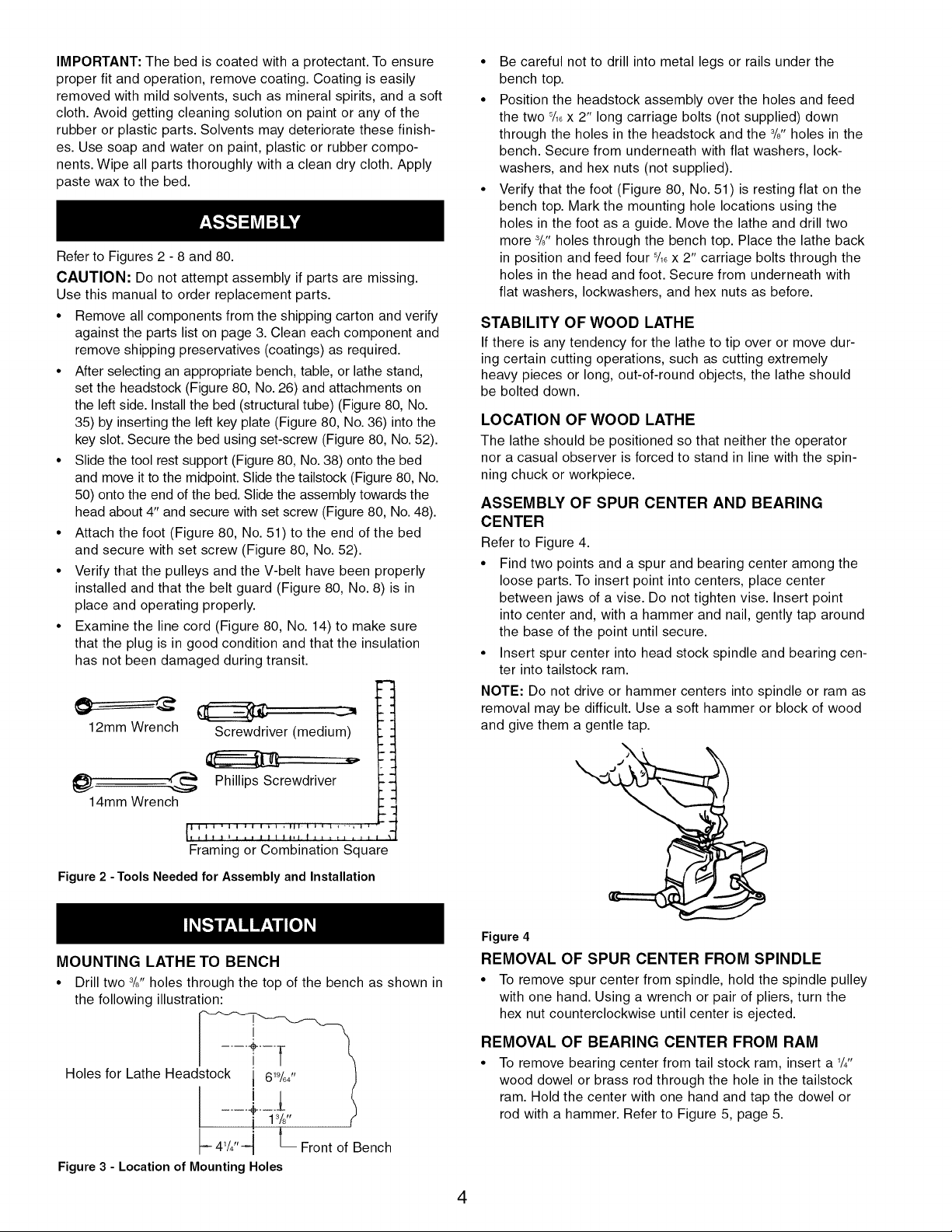

Refer to Figure 4.

• Find two points and a spur and bearing center among the

loose parts. To insert point into centers, place center

between jaws of a vise. Do not tighten vise. Insert point

into center and, with a hammer and nail, gently tap around

the base of the point until secure.

• Insert spur center into head stock spindle and bearing cen-

ter into tailstock ram.

NOTE: Do not drive or hammer centers into spindle or ram as

removal may be difficult. Use a soft hammer or block of wood

and give them a gentle tap.

@ PhillipsScrewdriver

----'4

14mmWrench

Framing or Combination Square

Figure 2 - Tools Needed for Assembly and Installation

MOUNTING LATHE TO BENCH

• Drill two 3/,, holes through the top of the bench as shown in

the following illustration:

Holes for Lathe --- I

Headstock i 619/64,, I

-4 LFrontof ench

Figure 3 - Locationof Mounting Holes

Figure 4

REMOVAL OF SPUR CENTER FROM SPINDLE

• To remove spur center from spindle, hold the spindle pulley

with one hand. Using a wrench or pair of pliers, turn the

hex nut counterclockwise until center is ejected.

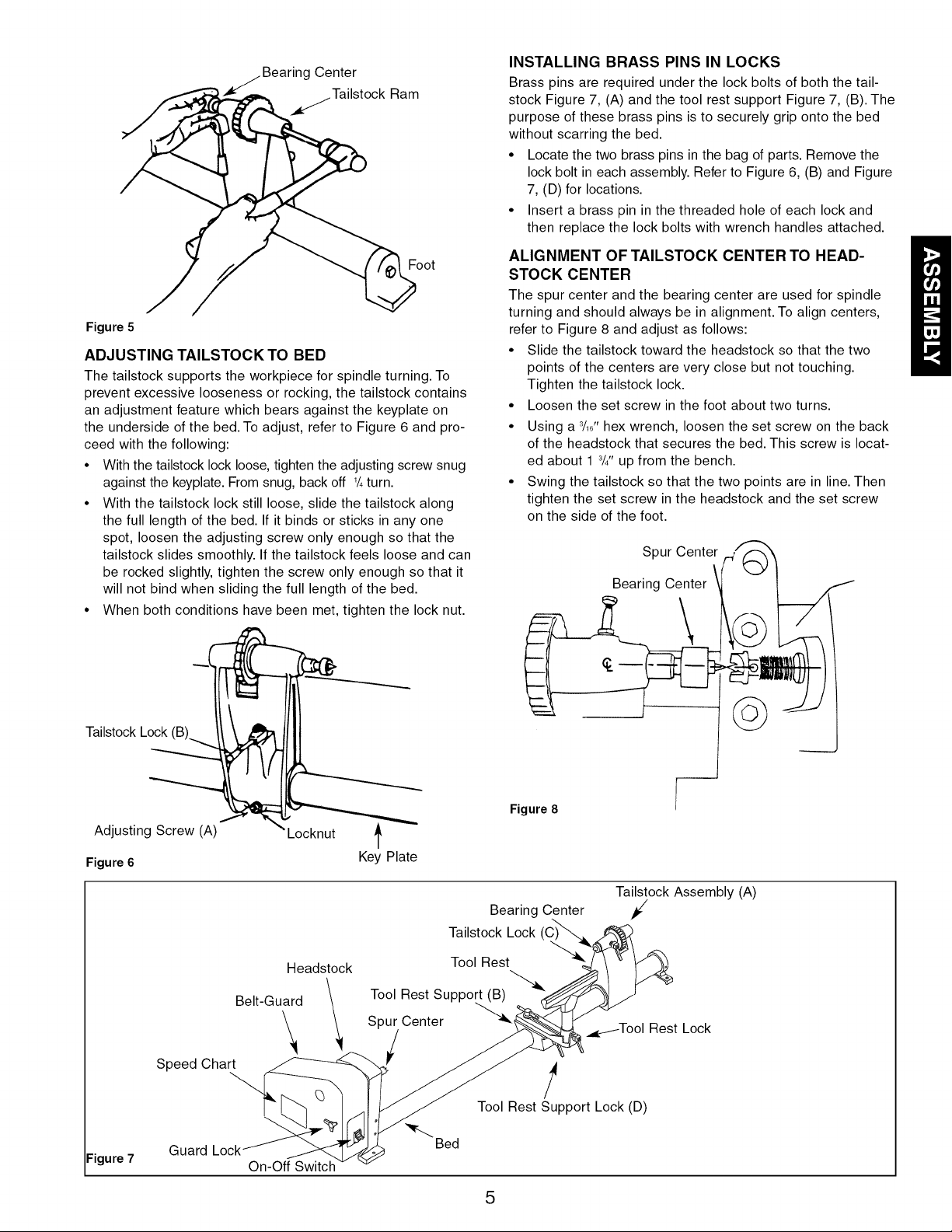

REMOVAL OF BEARING CENTER FROM RAM

• To remove bearing center from tail stock ram, insert a 1/411

wood dowel or brass rod through the hole in the tailstock

ram. Hold the center with one hand and tap the dowel or

rod with a hammer. Refer to Figure 5, page 5.

4

Center

Ram

Foot

Figure 5

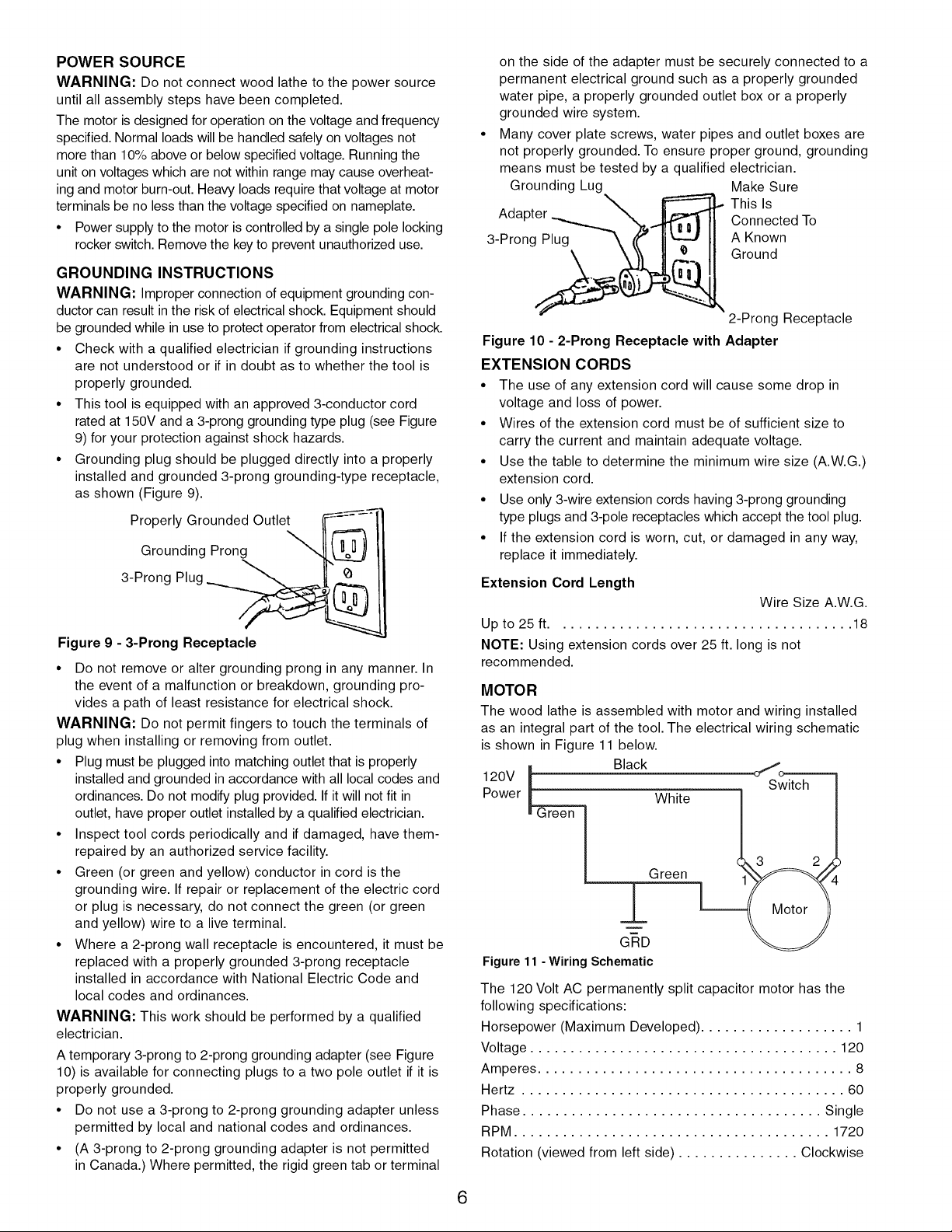

ADJUSTING TAILSTOCK TO BED

The tailstock supports the workpiece for spindle turning. To

prevent excessive looseness or rocking, the tailstock contains

an adjustment feature which bears against the keyplate on

the underside of the bed. To adjust, refer to Figure 6 and pro-

ceed with the following:

• With the tailstock lock loose, tighten the adjusting screw snug

against the keyplate. From snug, back off 1/4turn.

• With the tailstock lock still loose, slide the tailstock along

the full length of the bed. If it binds or sticks in any one

spot, loosen the adjusting screw only enough so that the

tailstock slides smoothly. If the tailstock feels loose and can

be rocked slightly, tighten the screw only enough so that it

will not bind when sliding the full length of the bed.

• When both conditions have been met, tighten the lock nut.

INSTALLING BRASS PINS IN LOCKS

Brass pins are required under the lock bolts of both the tail-

stock Figure 7, (A) and the tool rest support Figure 7, (B). The

purpose of these brass pins is to securely grip onto the bed

without scarring the bed.

• Locate the two brass pins in the bag of parts. Remove the

lock bolt in each assembly. Refer to Figure 6, (B) and Figure

7, (D) for locations.

• Insert a brass pin in the threaded hole of each lock and

then replace the lock bolts with wrench handles attached.

ALIGNMENT OF TAILSTOCK CENTER TO HEAD-

STOCK CENTER

The spur center and the bearing center are used for spindle

turning and should always be in alignment. To align centers,

refer to Figure 8 and adjust as follows:

• Slide the tailstock toward the headstock so that the two

points of the centers are very close but not touching.

Tighten the tailstock lock.

• Loosen the set screw in the foot about two turns.

• Using a 3/16H hex wrench, loosen the set screw on the back

of the headstock that secures the bed. This screw is locat-

ed about 1 3/4"up from the bench.

• Swing the tailstock so that the two points are in line. Then

tighten the set screw in the headstock and the set screw

on the side of the foot.

Spur Center f4_

Bearing Center \

m

D

Tailstock Lock

Adjusting Screw (A) t

Figure 6 Key Plate

Headstock

Tool Rest Suppo_,

Spur Center

/ .411_Tool Rest Lock

Figure 7

Belt-Guard !

\

Speed Chart

Guard Lock

On-Off Switch

Figure 8

Bearing Center

Tailstock Lock

Tool Rest

/

Tool Rest Support Lock (D)

Bed

©

Tailstock Assembly (A)

/

5

POWER SOURCE

WARNING: Do not connect wood lathe to the power source

until all assembly steps have been completed.

The motor is designed for operation on the voltage and frequency

specified. Normal loads will be handled safely on voltages not

more than 10% above or below specified voltage. Running the

unit on voltages which are not within range may cause overheat-

ing and motor burn-out. Heavy loads require that voltage at motor

terminals be no less than the voltage specified on nameplate.

• Power supply to the motor is controlled by a single pole locking

rocker switch. Remove the key to prevent unauthorized use.

GROUNDING INSTRUCTIONS

WARNING: Improper connection of equipment grounding con-

ductor can result inthe risk of electrical shock. Equipment should

be grounded while in use to protect operator from electrical shock.

• Check with a qualified electrician if grounding instructions

are not understood or if in doubt as to whether the tool is

properly grounded.

• This tool is equipped with an approved 3-conductor cord

rated at 150V and a 3-prong grounding type plug (see Figure

9) for your protection against shock hazards.

• Grounding plug should be plugged directly into a properly

installed and grounded 3-prong grounding-type receptacle,

as shown (Figure 9).

Grounded Outlet

Grounding Prong

3-Prong Plug

Properly __

Figure 9 - 3-Prong Receptacle

• Do not remove or alter grounding prong in any manner. In

the event of a malfunction or breakdown, grounding pro-

vides a path of least resistance for electrical shock.

WARNING: Do not permit fingers to touch the terminals of

plug when installing or removing from outlet.

• Plug must be plugged into matching outlet that is properly

installed and grounded in accordance with all local codes and

ordinances. Do not modify plug provided. If it will not fit in

outlet, have proper outlet installed by a qualified electrician.

• Inspect tool cords periodically and if damaged, have them-

repaired by an authorized service facility.

• Green (or green and yellow) conductor in cord is the

grounding wire. If repair or replacement of the electric cord

or plug is necessary, do not connect the green (or green

and yellow) wire to a live terminal.

• Where a 2-prong wall receptacle is encountered, it must be

replaced with a properly grounded 3-prong receptacle

installed in accordance with National Electric Code and

local codes and ordinances.

WARNING: This work should be performed by a qualified

electrician.

A temporary 3-prong to 2-prong grounding adapter (see Figure

10) is available for connecting plugs to a two pole outlet if it is

properly grounded.

• Do not use a 3-prong to 2-prong grounding adapter unless

permitted by local and national codes and ordinances.

• (A 3-prong to 2-prong grounding adapter is not permitted

in Canada.) Where permitted, the rigid green tab or terminal

on the side of the adapter must be securely connected to a

permanent electrical ground such as a properly grounded

water pipe, a properly grounded outlet box or a properly

grounded wire system.

• Many cover plate screws, water pipes and outlet boxes are

not properly grounded. To ensure proper ground, grounding

means must be tested by a qualified electrician.

Grounding Lug Make Sure

Ada This Is

3-Prong Plug A Known

Figure 10 - 2-Prong Receptacle with Adapter

EXTENSION CORDS

• The use of any extension cord will cause some drop in

voltage and loss of power.

• Wires of the extension cord must be of sufficient size to

carry the current and maintain adequate voltage.

• Use the table to determine the minimum wire size (A.W.G.)

extension cord.

• Use only 3-wire extension cords having 3-prong grounding

type plugs and 3-pole receptacles which accept the tool plug.

• If the extension cord is worn, cut, or damaged in any way,

replace it immediately.

Extension Cord Length

Up to 25 ft..................................... 18

NOTE: Using extension cords over 25 ft. long is not

recommended.

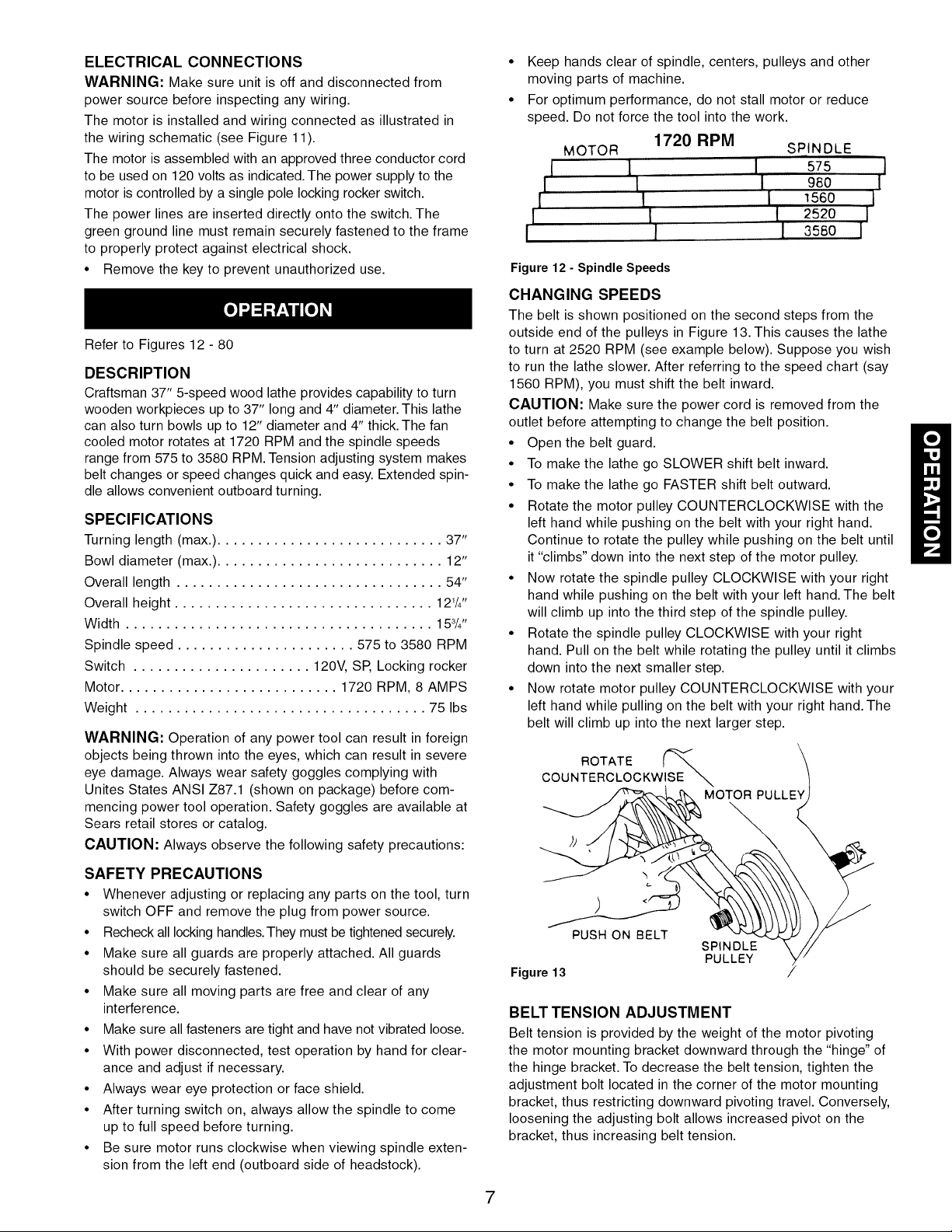

MOTOR

The wood lathe is assembled with motor and wiring installed

as an integral part of the tool. The electrical wiring schematic

is shown in Figure 11 below.

120V } Black

Power _ White

Green

Connected To

Ground

2-Prong Receptacle

Wire Size A.W.G.

±

GND

Figure 11 - Wiring Schematic

The 120 Volt AC permanently split capacitor motor has the

following specifications:

Horsepower (Maximum Developed) ................... 1

Voltage ...................................... 120

Amperes ....................................... 8

Hertz ........................................ 60

Phase ..................................... Single

RPM ....................................... 1720

Rotation (viewed from left side) ............... Clockwise

6

ELECTRICAL CONNECTIONS

WARNING: Make sure unit is off and disconnected from

power source before inspecting any wiring.

The motor is installed and wiring connected as illustrated in

the wiring schematic (see Figure 11).

The motor is assembled with an approved three conductor cord

to be used on 120 volts as indicated. The power supply to the

motor is controlled by a single pole locking rocker switch.

The power lines are inserted directly onto the switch. The

green ground line must remain securely fastened to the frame

to properly protect against electrical shock.

• Remove the key to prevent unauthorized use.

Refer to Figures 12- 80

DESCRIPTION

Craftsman 37" 5-speed wood lathe provides capability to turn

wooden workpieces up to 37" long and 4" diameter. This lathe

can also turn bowls up to 12" diameter and 4" thick. The fan

cooled motor rotates at 1720 RPM and the spindle speeds

range from 575 to 3580 RPM. Tension adjusting system makes

belt changes or speed changes quick and easy. Extended spin-

dle allows convenient outboard turning.

SPECIFICATIONS

Turning length (max.) ............................ 37"

Bowl diameter (max.) ............................ 12"

Overall length ................................. 54"

Overall height ................................ 121/4''

Width ...................................... 153/4''

Spindle speed ...................... 575 to 3580 RPM

Switch ...................... 120V, SP, Locking rocker

Motor ........................... 1720 RPM, 8 AMPS

Weight .................................... 75 Ibs

WARNING: Operation of any power tool can result in foreign

objects being thrown into the eyes, which can result in severe

eye damage. Always wear safety goggles complying with

Unites States ANSI Z87.1 (shown on package) before com-

mencing power tool operation. Safety goggles are available at

Sears retail stores or catalog.

CAUTION: Always observe the following safety precautions:

• Keep hands clear of spindle, centers, pulleys and other

moving parts of machine.

• For optimum performance, do not stall motor or reduce

speed. Do not force the tool into the work.

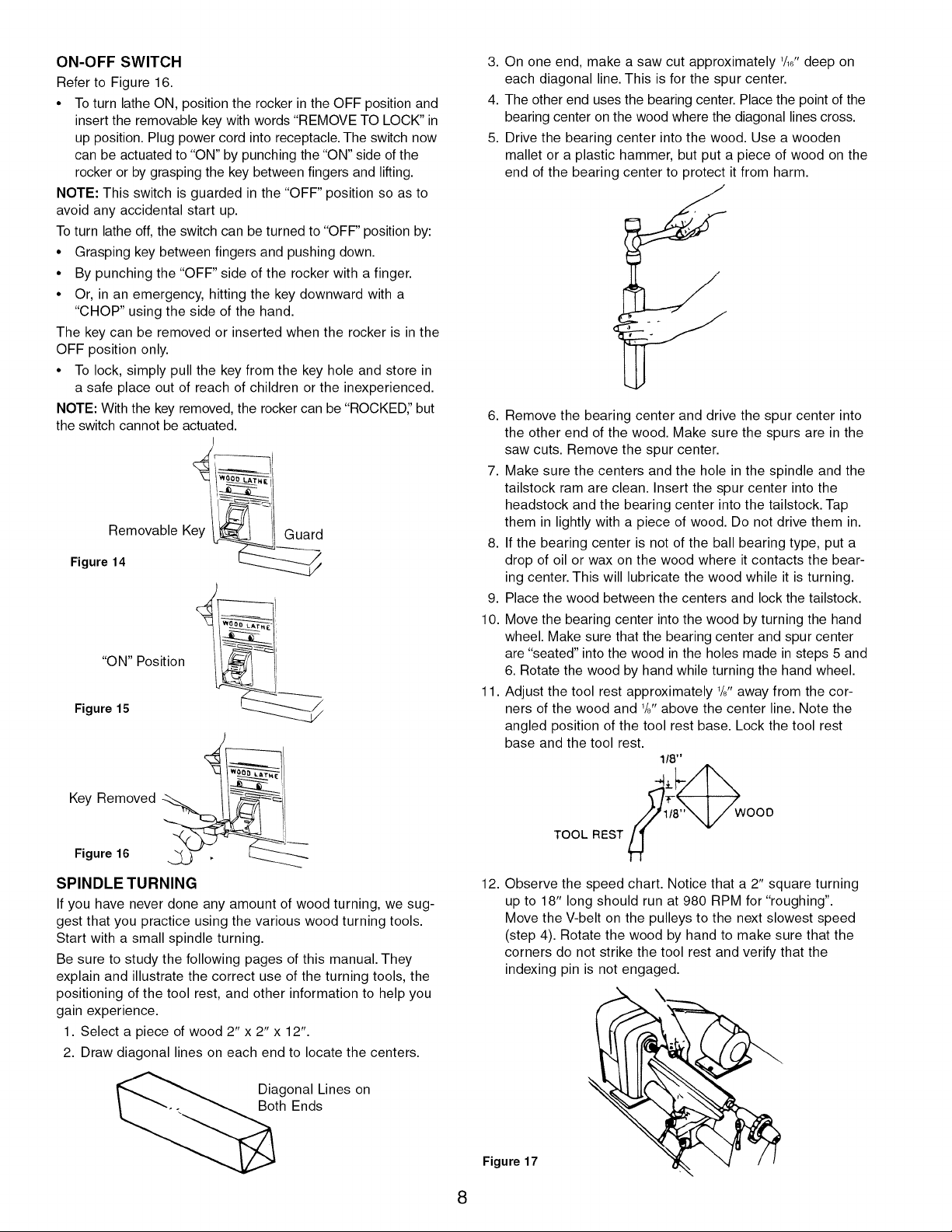

MOTOR

1720 RPM

I 1

I I

1 I

I 1

I I

Figure 12 - Spindle Speeds

CHANGING SPEEDS

The belt is shown positioned on the second steps from the

outside end of the pulleys in Figure 13. This causes the lathe

to turn at 2520 RPM (see example below). Suppose you wish

to run the lathe slower. After referring to the speed chart (say

1560 RPM), you must shift the belt inward.

CAUTION: Make sure the power cord is removed from the

outlet before attempting to change the belt position.

• Open the belt guard.

• To make the lathe go SLOWER shift belt inward.

• To make the lathe go FASTER shift belt outward.

• Rotate the motor pulley COUNTERCLOCKWISE with the

left hand while pushing on the belt with your right hand.

Continue to rotate the pulley while pushing on the belt until

it "climbs" down into the next step of the motor pulley.

• Now rotate the spindle pulley CLOCKWISE with your right

hand while pushing on the belt with your left hand. The belt

will climb up into the third step of the spindle pulley.

• Rotate the spindle pulley CLOCKWISE with your right

hand. Pull on the belt while rotating the pulley until it climbs

down into the next smaller step.

• Now rotate motor pulley COUNTERCLOCKWISE with your

left hand while pulling on the belt with your right hand. The

belt will climb up into the next larger step.

COUNTERCLOCKWISE

ROTATE 1

MOTOR PULLE

SPINDLE

575 ,,11Ii, 980

I 560 I

t 2520 I

I 356o l

SAFETY PRECAUTIONS

• Whenever adjusting or replacing any parts on the tool, turn

switch OFF and remove the plug from power source.

• Recheck all locking handles. They must be tightened securely.

• Make sure all guards are properly attached. All guards

should be securely fastened.

• Make sure all moving parts are free and clear of any

interference.

• Make sure all fasteners are tight and have not vibrated loose.

• With power disconnected, test operation by hand for clear-

ance and adjust if necessary.

• Always wear eye protection or face shield.

• After turning switch on, always allow the spindle to come

up to full speed before turning.

• Be sure motor runs clockwise when viewing spindle exten-

sion from the left end (outboard side of headstock).

PUSH ON BELT

Figure 13

BELT TENSION ADJUSTMENT

Belt tension is provided by the weight of the motor pivoting

the motor mounting bracket downward through the "hinge" of

the hinge bracket. To decrease the belt tension, tighten the

adjustment bolt located in the corner of the motor mounting

bracket, thus restricting downward pivoting travel. Conversely,

loosening the adjusting bolt allows increased pivot on the

bracket, thus increasing belt tension.

SPINDLE

PULLEY

7

ON-OFF SWITCH

Refer to Figure 16.

• Toturn lathe ON, position the rocker in the OFF position and

insert the removable key with words "REMOVE TO LOCK" in

up position. Plug power cord into receptacle. The switch now

can be actuated to "ON" by punching the "ON" side of the

rocker or by grasping the key between fingers and lifting.

NOTE: This switch is guarded in the "OFF" position so as to

avoid any accidental start up.

Toturn lathe off, the switch can be turned to "OFF" position by:

• Grasping key between fingers and pushing down.

• By punching the "OFF" side of the rocker with a finger.

• Or, in an emergency, hitting the key downward with a

"CHOP" using the side of the hand.

The key can be removed or inserted when the rocker is in the

OFF position only.

• To lock, simply pull the key from the key hole and store in

a safe place out of reach of children or the inexperienced.

NOTE: With the key removed, the rocker can be "ROCKED;' but

the switch cannot be actuated.

)

Removable Key t_ !t Guard

Figure 14

"ON" Position

Figure 15

3. On one end, make a saw cut approximately 1/16tt deep on

each diagonal line. This is for the spur center.

4. The other end uses the bearing center. Place the point of the

bearing center on the wood where the diagonal lines cross.

5. Drive the bearing center into the wood. Use a wooden

mallet or a plastic hammer, but put a piece of wood on the

end of the bearing center to protect it from harm.

6. Remove the bearing center and drive the spur center into

the other end of the wood. Make sure the spurs are in the

saw cuts. Remove the spur center.

7. Make sure the centers and the hole in the spindle and the

tailstock ram are clean. Insert the spur center into the

headstock and the bearing center into the tailstock. Tap

them in lightly with a piece of wood. Do not drive them in.

8. If the bearing center is not of the ball bearing type, put a

drop of oil or wax on the wood where it contacts the bear-

ing center. This will lubricate the wood while it is turning.

9. Place the wood between the centers and lock the tailstock.

10. Move the bearing center into the wood by turning the hand

wheel. Make sure that the bearing center and spur center

are "seated" into the wood in the holes made in steps 5 and

6. Rotate the wood by hand while turning the hand wheel.

11. Adjust the tool rest approximately 1/8"away from the cor-

ners of the wood and 1/8"above the center line. Note the

angled position of the tool rest base. Lock the tool rest

base and the tool rest.

1/8"

Key Removed

Figure 16

SPINDLE TURNING

If you have never done any amount of wood turning, we sug-

gest that you practice using the various wood turning tools.

Start with a small spindle turning.

Be sure to study the following pages of this manual. They

explain and illustrate the correct use of the turning tools, the

positioning of the tool rest, and other information to help you

gain experience.

1. Select a piece of wood 2" x 2" x 12".

2. Draw diagonal lines on each end to locate the centers.

Diagonal Lines on

Both Ends

TOOL REST

12. Observe the speed chart. Notice that a 2" square turning

up to 18" long should run at 980 RPM for "roughing".

Move the V-belt on the pulleys to the next slowest speed

(step 4). Rotate the wood by hand to make sure that the

corners do not strike the tool rest and verify that the

indexing pin is not engaged.

Figure 17

8

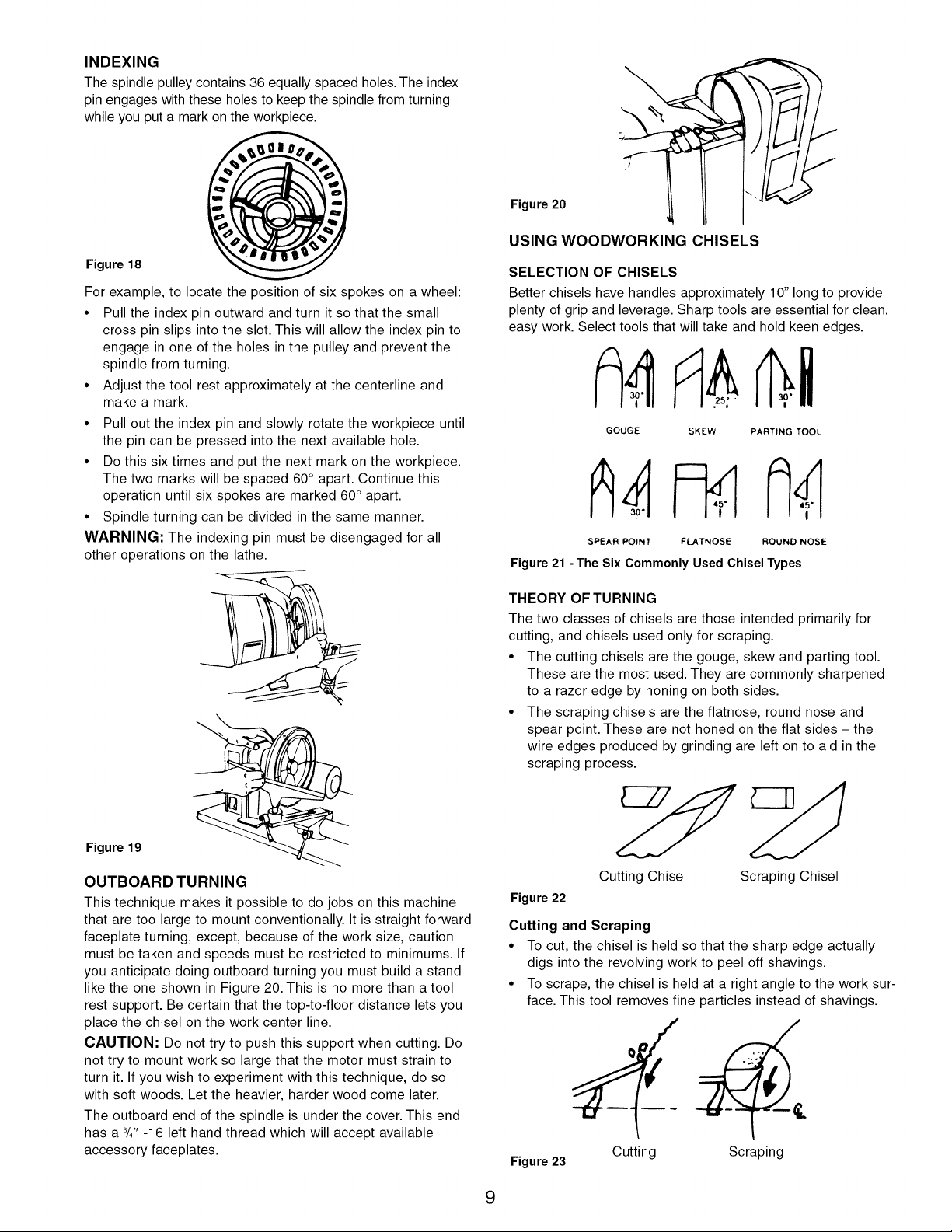

INDEXING

The spindle pulley contains 36 equally spaced holes. The index

pin engages with these holes to keep the spindle from turning

while you put a mark on the workpiece.

Figure 18

For example, to locate the position of six spokes on a wheel:

• Pull the index pin outward and turn it so that the small

cross pin slips into the slot. This will allow the index pin to

engage in one of the holes in the pulley and prevent the

spindle from turning.

• Adjust the tool rest approximately at the centerline and

make a mark.

• Pull out the index pin and slowly rotate the workpiece until

the pin can be pressed into the next available hole.

• Do this six times and put the next mark on the workpiece.

The two marks will be spaced 60 ° apart. Continue this

operation until six spokes are marked 60 ° apart.

• Spindle turning can be divided in the same manner.

WARNING: The indexing pin must be disengaged for all

other operations on the lathe.

Figure 20

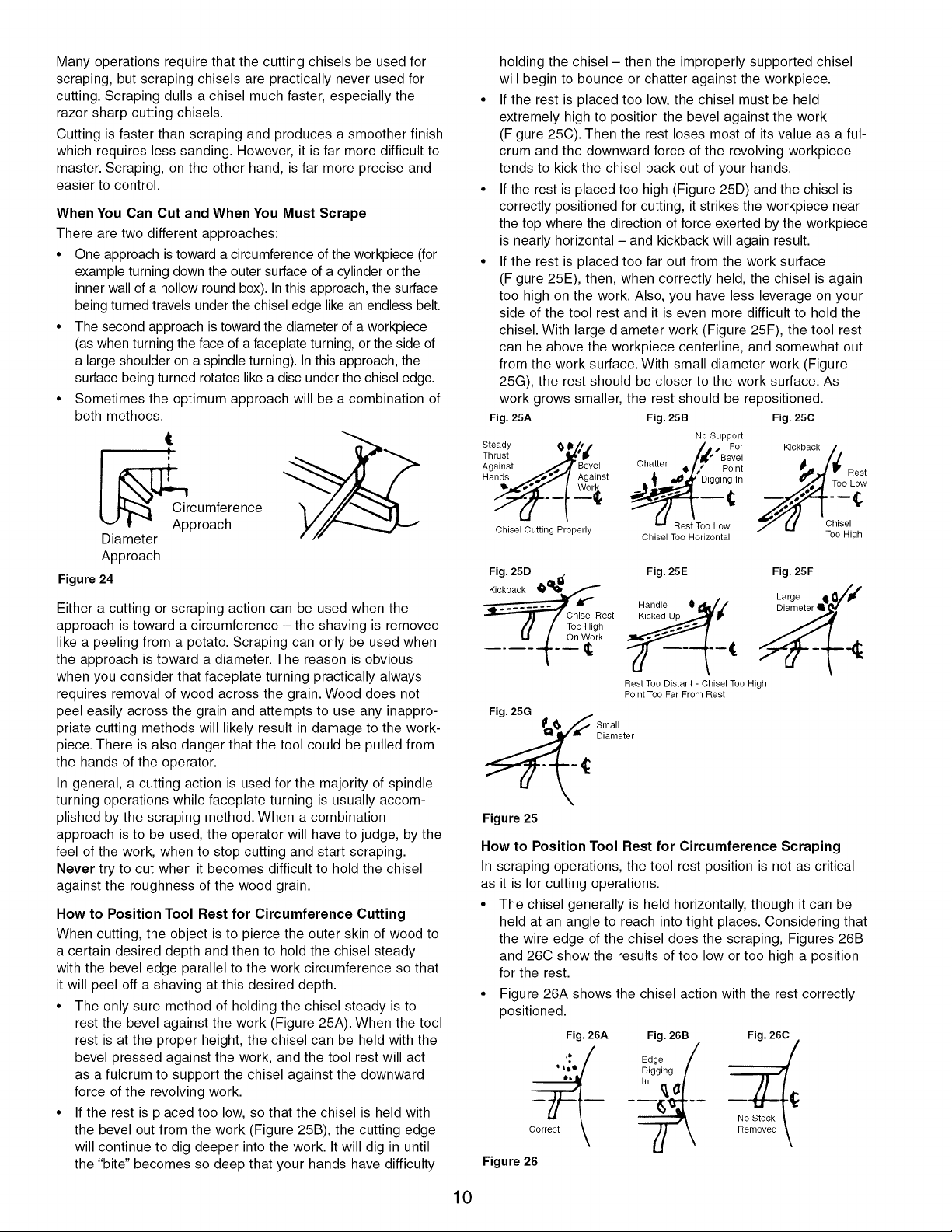

USING WOODWORKING CHISELS

SELECTION OF CHISELS

Better chisels have handles approximately 10" long to provide

plenty of grip and leverage. Sharp tools are essential for clean,

easy work. Select tools that will take and hold keen edges.

GOUGE SKEW PARTING TOOL

SPEAR POINT FLATNOSE ROUND NOSE

Figure21 - The Six Commonly Used Chisel Types

Figure 19

OUTBOARD TURNING

This technique makes it possible to do jobs on this machine

that are too large to mount conventionally. It is straight forward

faceplate turning, except, because of the work size, caution

must be taken and speeds must be restricted to minimums. If

you anticipate doing outboard turning you must build a stand

like the one shown in Figure 20. This is no more than a tool

rest support. Be certain that the top-to-floor distance lets you

place the chisel on the work center line.

CAUTION: Do not try to push this support when cutting. Do

not try to mount work so large that the motor must strain to

turn it. If you wish to experiment with this technique, do so

with soft woods. Let the heavier, harder wood come later.

The outboard end of the spindle is under the cover. This end

has a 3/4"-16 left hand thread which will accept available

accessory faceplates.

THEORY OF TURNING

The two classes of chisels are those intended primarily for

cutting, and chisels used only for scraping.

• The cutting chisels are the gouge, skew and parting tool.

These are the most used. They are commonly sharpened

to a razor edge by honing on both sides.

• The scraping chisels are the flatnose, round nose and

spear point. These are not honed on the flat sides - the

wire edges produced by grinding are left on to aid in the

scraping process.

2<

Cutting Chisel

Figure 22

Cutting and Scraping

• To cut, the chisel is held so that the sharp edge actually

digs into the revolving work to peel off shavings.

• To scrape, the chisel is held at a right angle to the work sur-

face. This tool removes fine particles instead of shavings.

Figure 23

Cutting Scraping

Scraping Chisel

9

Many operations require that the cutting chisels be used for

scraping, but scraping chisels are practically never used for

cutting. Scraping dulls a chisel much faster, especially the

razor sharp cutting chisels.

Cutting is faster than scraping and produces a smoother finish

which requires less sanding. However, it is far more difficult to

master. Scraping, on the other hand, is far more precise and

easier to control.

When You Can Cut and When You Must Scrape

There are two different approaches:

• One approach is toward a circumference of the workpiece (for •

example turning down the outer surface of a cylinder or the

inner wall of a hollow round box). In this approach, the surface

being turned travels under the chisel edge like an endless belt.

• The second approach is toward the diameter of a workpiece

(as when turning the face of a faceplate turning, or the side of

a large shoulder on a spindle turning). In this approach, the

surface being turned rotates like a disc under the chisel edge.

• Sometimes the optimum approach will be a combination of

both methods.

!

J _Circumference

"--" t - Approach

Diameter

Approach

Figure 24

Either a cutting or scraping action can be used when the

approach is toward a circumference - the shaving is removed

like a peeling from a potato. Scraping can only be used when

the approach is toward a diameter. The reason is obvious

when you consider that faceplate turning practically always

requires removal of wood across the grain. Wood does not

peel easily across the grain and attempts to use any inappro-

priate cutting methods will likely result in damage to the work-

piece. There is also danger that the tool could be pulled from

the hands of the operator.

In general, a cutting action is used for the majority of spindle

turning operations while faceplate turning is usually accom-

plished by the scraping method. When a combination

approach is to be used, the operator will have to judge, by the

feel of the work, when to stop cutting and start scraping.

Never try to cut when it becomes difficult to hold the chisel

against the roughness of the wood grain.

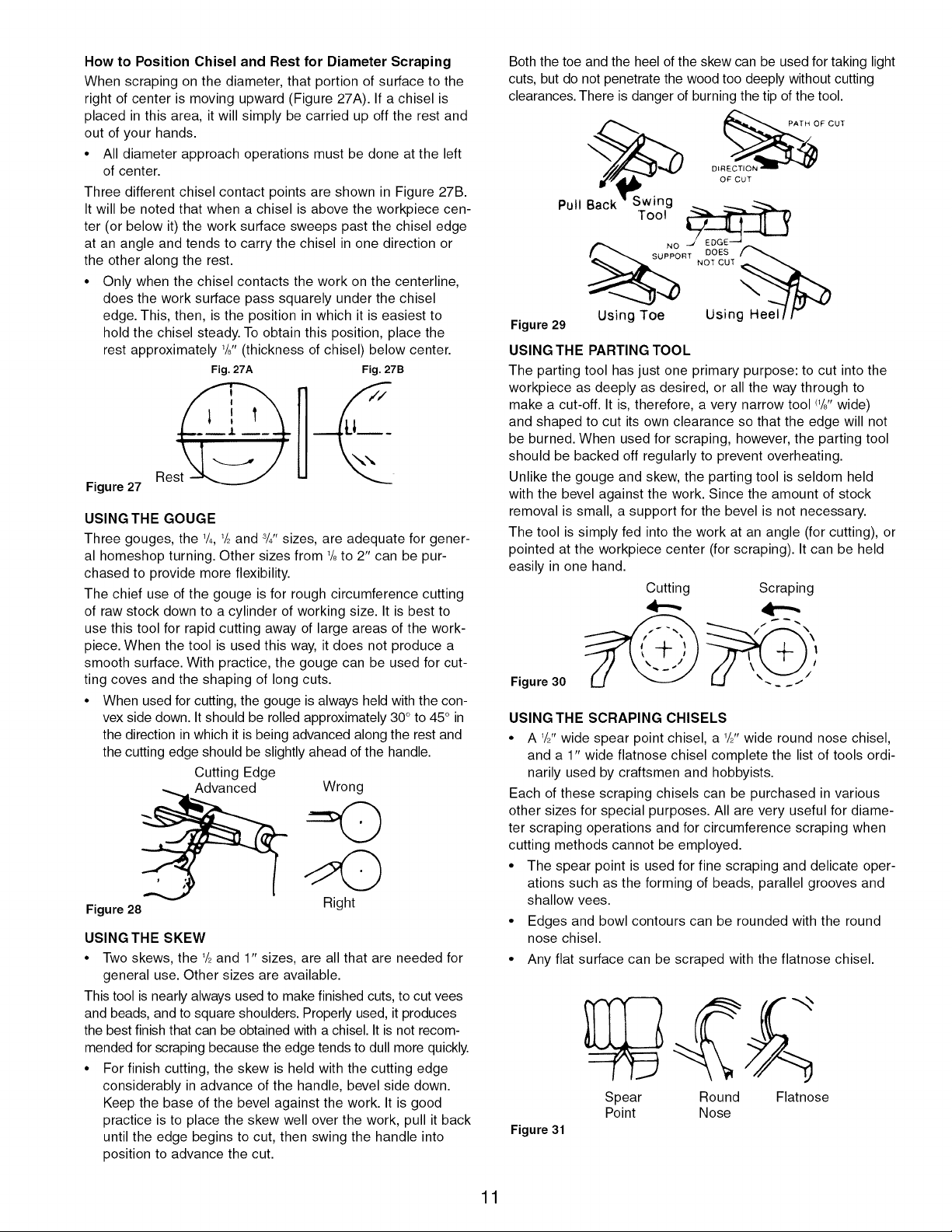

How to Position Tool Rest for Circumference Cutting

When cutting, the object is to pierce the outer skin of wood to

a certain desired depth and then to hold the chisel steady

with the bevel edge parallel to the work circumference so that

it will peel off a shaving at this desired depth.

• The only sure method of holding the chisel steady is to

rest the bevel against the work (Figure 25A). When the tool

rest is at the proper height, the chisel can be held with the

bevel pressed against the work, and the tool rest will act

as a fulcrum to support the chisel against the downward

force of the revolving work.

• If the rest is placed too low, so that the chisel is held with

the bevel out from the work (Figure 25B), the cutting edge

will continue to dig deeper into the work. It will dig in until

the "bite" becomes so deep that your hands have difficulty

holding the chisel - then the improperly supported chisel

will begin to bounce or chatter against the workpiece.

If the rest is placed too low, the chisel must be held

extremely high to position the bevel against the work

(Figure 25C). Then the rest loses most of its value as a ful-

crum and the downward force of the revolving workpiece

tends to kick the chisel back out of your hands.

If the rest is placed too high (Figure 25D) and the chisel is

correctly positioned for cutting, it strikes the workpiece near

the top where the direction of force exerted by the workpiece

is nearly horizontal - and kickback will again result.

If the rest is placed too far out from the work surface

(Figure 25E), then, when correctly held, the chisel is again

too high on the work. Also, you have less leverage on your

side of the tool rest and it is even more difficult to hold the

chisel. With large diameter work (Figure 25F), the tool rest

can be above the workpiece centerline, and somewhat out

from the work surface. With small diameter work (Figure

25G), the rest should be closer to the work surface. As

work grows smaller, the rest should be repositioned.

Fig. 25A Fig. 25B Fig. 25C

Steady 1) II/o I

Thrust "_,' I1

Against __,,,'_.A Bevel

Hands .,,,,L_.,_.,,_[ Against

Chisel Cutting Properly

Fig. 25D

Kickback __

Too High

On Work

Chisel Rest

Fig. 25G _

_ sm_leter

Figure 25

Chatter

Chisel Too Horizontal

Fig. 25E Fig. 25F

H_andle 0 l_J' LargeDiarneterIili_ f

Rest Too Distant - Chisel Too High

Point Too Far From Rest

No Support

/j.,, For

IL" Bevel

ff' Point

Kickback

Too Low

Chisel

Too High

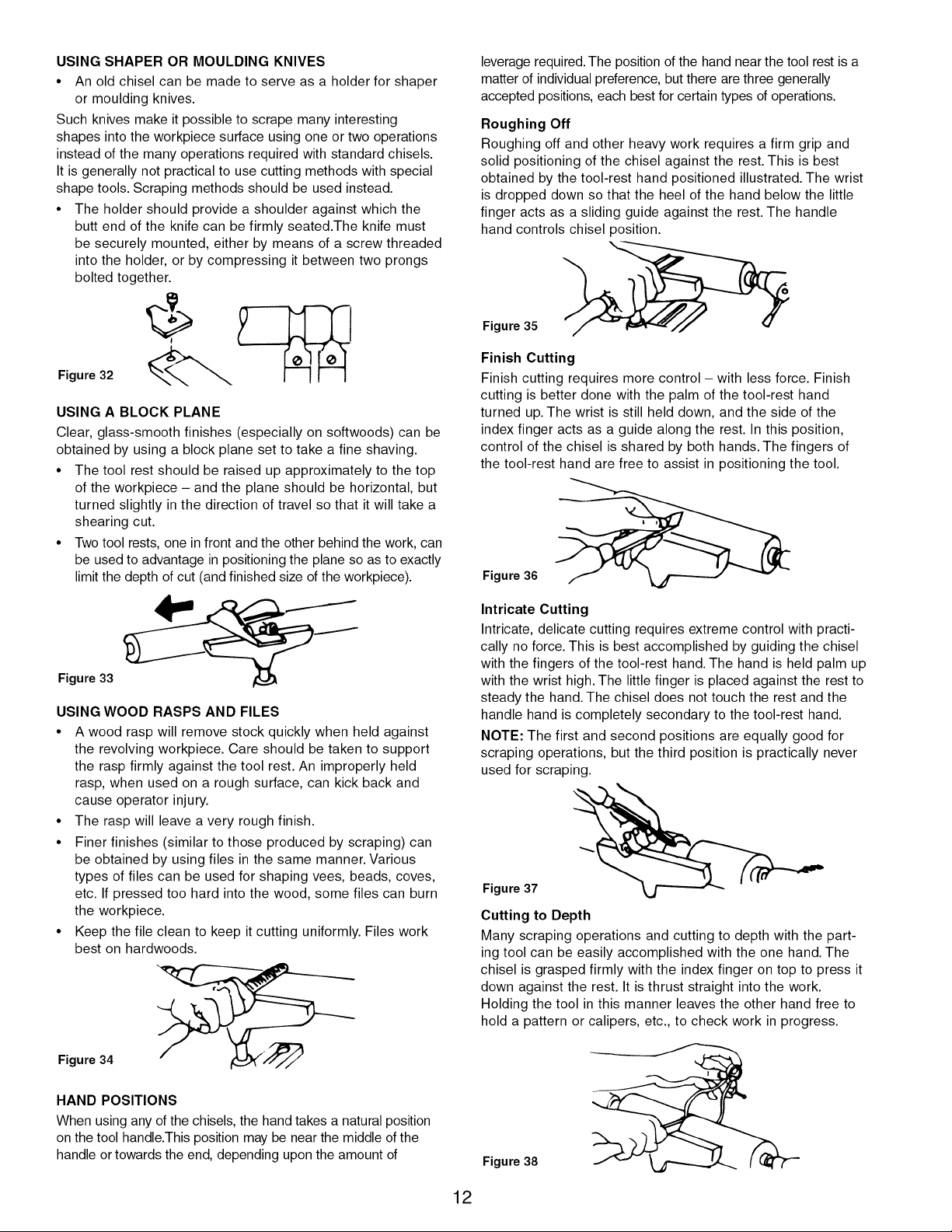

How to Position Tool Rest for Circumference Scraping

In scraping operations, the tool rest position is not as critical

as it is for cutting operations.

• The chisel generally is held horizontally, though it can be

held at an angle to reach into tight places. Considering that

the wire edge of the chisel does the scraping, Figures 26B

and 26C show the results of too low or too high a position

for the rest.

• Figure 26A shows the chisel action with the rest correctly

positioned.

Fig. 26A Fig. 26B Fig. 260

• _o,_° Digging

• In

'_ Edge

Figure 26

Rest

10

How to Position Chisel and Rest for Diameter Scraping

When scraping on the diameter, that portion of surface to the

right of center is moving upward (Figure 27A). If a chisel is

placed in this area, it will simply be carried up off the rest and

out of your hands.

• All diameter approach operations must be done at the left

of center.

Three different chisel contact points are shown in Figure 27B.

It will be noted that when a chisel is above the workpiece cen-

ter (or below it) the work surface sweeps past the chisel edge

at an angle and tends to carry the chisel in one direction or

the other along the rest.

• Only when the chisel contacts the work on the centerline,

does the work surface pass squarely under the chisel

edge. This, then, is the position in which it is easiest to

hold the chisel steady. To obtain this position, place the

rest approximately 1/8"(thickness of chisel) below center.

Fig. 27A Fig. 27B

U___

Figure 27

USINGTHE GOUGE

Three gouges, the 1/4, 1/2and 8/4"sizes, are adequate for gener-

al homeshop turning. Other sizes from 1/8to 2't can be pur-

chased to provide more flexibility.

The chief use of the gouge is for rough circumference cutting

of raw stock down to a cylinder of working size. It is best to

use this tool for rapid cutting away of large areas of the work-

piece. When the tool is used this way, it does not produce a

smooth surface. With practice, the gouge can be used for cut-

ting coves and the shaping of long cuts.

• When used for cutting, the gouge is always held with the con-

vex side down. It should be rolled approximately 30° to 45° in

the direction in which it is being advanced along the rest and

the cutting edge should be slightly ahead of the handle.

Figure 28

USING THE SKEW

• Two skews, the 1/2and 1" sizes, are all that are needed for

general use. Other sizes are available.

This tool is nearly always used to make finished cuts, to cut vees

and beads, and to square shoulders. Properly used, it produces

the best finish that can be obtained with a chisel. It is not recom-

mended for scraping because the edge tends to dull more quickly.

• For finish cutting, the skew is held with the cutting edge

considerably in advance of the handle, bevel side down.

Keep the base of the bevel against the work. It is good

practice is to place the skew well over the work, pull it back

until the edge begins to cut, then swing the handle into

position to advance the cut.

Rest

Cutting Edge

Advanced

Wrong

Right

Both the toe and the heel of the skew can be used for taking light

cuts, but do not penetrate the wood too deeply without cutting

clearances. There is danger of burning the tip of the tool.

DtR_F CUT

OF CUT

Pull Back SwingTool

NO

Figure 29

Using Toe Using Heel / r"

USING THE PARTING TOOL

The parting tool has just one primary purpose: to cut into the

workpiece as deeply as desired, or all the way through to

make a cut-off. It is, therefore, a very narrow tool <1/8"wide)

and shaped to cut its own clearance so that the edge will not

be burned. When used for scraping, however, the parting tool

should be backed off regularly to prevent overheating.

Unlike the gouge and skew, the parting tool is seldom held

with the bevel against the work. Since the amount of stock

removal is small, a support for the bevel is not necessary.

The tool is simply fed into the work at an angle (for cutting), or

pointed at the workpiece center (for scraping). It can be held

easily in one hand.

Cutting Scraping

4"-'-

Figure 30

USING THE SCRAPING CHISELS

• A 1/2Itwide spear point chisel, a 1/2"wide round nose chisel,

and a 1" wide flatnose chisel complete the list of tools ordi-

narily used by craftsmen and hobbyists.

Each of these scraping chisels can be purchased in various

other sizes for special purposes. All are very useful for diame-

ter scraping operations and for circumference scraping when

cutting methods cannot be employed.

• The spear point is used for fine scraping and delicate oper-

ations such as the forming of beads, parallel grooves and

shallow vees.

• Edges and bowl contours can be rounded with the round

nose chisel.

• Any flat surface can be scraped with the flatnose chisel.

Spear Round

Point Nose

Figure 31

Flatnose

11

USING SHAPER OR MOULDING KNIVES

• An old chisel can be made to serve as a holder for shaper

or moulding knives.

Such knives make it possible to scrape many interesting

shapes into the workpiece surface using one or two operations

instead of the many operations required with standard chisels.

It is generally not practical to use cutting methods with special

shape tools. Scraping methods should be used instead.

• The holder should provide a shoulder against which the

butt end of the knife can be firmly seated.The knife must

be securely mounted, either by means of a screw threaded

into the holder, or by compressing it between two prongs

bolted together.

leverage required. The position of the hand near the tool rest is a

matter of individual preference, but there are three generally

accepted positions, each best for certain types of operations.

Roughing Off

Roughing off and other heavy work requires a firm grip and

solid positioning of the chisel against the rest. This is best

obtained by the tool-rest hand positioned illustrated. The wrist

is dropped down so that the heel of the hand below the little

finger acts as a sliding guide against the rest. The handle

hand controls chisel position.

Figure 35 _

Figure 32 _ _l

USING A BLOCK PLANE

Clear, glass-smooth finishes (especially on softwoods) can be

obtained by using a block plane set to take a fine shaving.

• The tool rest should be raised up approximately to the top

of the workpiece - and the plane should be horizontal, but

turned slightly in the direction of travel so that it will take a

shearing cut.

• Two tool rests, one in front and the other behind the work, can

be used to advantage in positioning the plane so as to exactly

limit the depth of cut (and finished size of the workpiece).

Figure 33

USING WOOD RASPS AND FILES

• A wood rasp will remove stock quickly when held against

the revolving workpiece. Care should be taken to support

the rasp firmly against the tool rest. An improperly held

rasp, when used on a rough surface, can kick back and

cause operator injury.

• The rasp will leave a very rough finish.

• Finer finishes (similar to those produced by scraping) can

be obtained by using files in the same manner. Various

types of files can be used for shaping vees, beads, coves,

etc. If pressed too hard into the wood, some files can burn

the workpiece.

• Keep the file clean to keep it cutting uniformly. Files work

best on hardwoods.

Figure 34

Finish Cutting

Finish cutting requires more control - with less force. Finish

cutting is better done with the palm of the tool-rest hand

turned up. The wrist is still held down, and the side of the

index finger acts as a guide along the rest. In this position,

control of the chisel is shared by both hands. The fingers of

the tool-rest hand are free to assist in positioning the tool.

Figure 36

Intricate Cutting

Intricate, delicate cutting requires extreme control with practi-

cally no force. This is best accomplished by guiding the chisel

with the fingers of the tool-rest hand. The hand is held palm up

with the wrist high. The little finger is placed against the rest to

steady the hand. The chisel does not touch the rest and the

handle hand is completely secondary to the tool-rest hand.

NOTE: The first and second positions are equally good for

scraping operations, but the third position is practically never

used for scraping.

Figure37

Cutting to Depth

Many scraping operations and cutting to depth with the part-

ing tool can be easily accomplished with the one hand. The

chisel is grasped firmly with the index finger on top to press it

down against the rest. It is thrust straight into the work.

Holding the tool in this manner leaves the other hand free to

hold a pattern or calipers, etc., to check work in progress.

HAND POSITIONS

When using any of the chisels, the hand takes a natural position

on the tool handle.This position may be near the middle of the

handle or towards the end, depending upon the amount of

Figure38

12

MAKING STANDARD CUTS

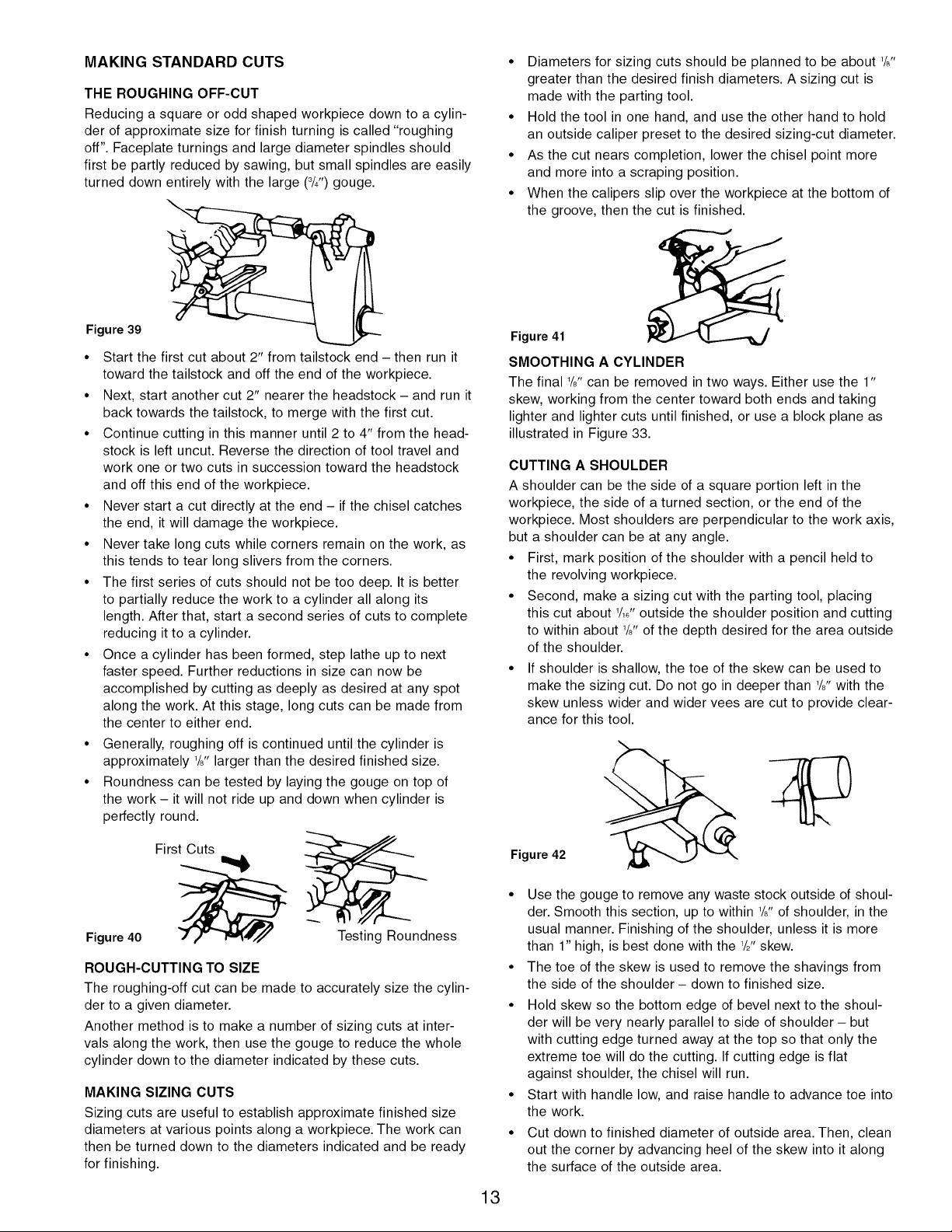

THE ROUGHING OFF-CUT

Reducing a square or odd shaped workpiece down to a cylin-

der of approximate size for finish turning is called "roughing

off". Faceplate turnings and large diameter spindles should

first be partly reduced by sawing, but small spindles are easily

turned down entirely with the large (3/4")gouge.

• Diameters for sizing cuts should be planned to be about 1/8"

greater than the desired finish diameters. A sizing cut is

made with the parting tool.

• Hold the tool in one hand, and use the other hand to hold

an outside caliper preset to the desired sizing-cut diameter.

• As the cut nears completion, lower the chisel point more

and more into a scraping position.

• When the calipers slip over the workpiece at the bottom of

the groove, then the cut is finished.

Figure 39

• Start the first cut about 2" from tailstock end - then run it

toward the tailstock and off the end of the workpiece.

• Next, start another cut 2" nearer the headstock - and run it

back towards the tailstock, to merge with the first cut.

• Continue cutting in this manner until 2 to 4" from the head-

stock is left uncut. Reverse the direction of tool travel and

work one or two cuts in succession toward the headstock

and off this end of the workpiece.

• Never start a cut directly at the end - if the chisel catches

the end, it will damage the workpiece.

• Never take long cuts while corners remain on the work, as

this tends to tear long slivers from the corners.

• The first series of cuts should not be too deep. It is better

to partially reduce the work to a cylinder all along its

length. After that, start a second series of cuts to complete

reducing it to a cylinder.

• Once a cylinder has been formed, step lathe up to next

faster speed. Further reductions in size can now be

accomplished by cutting as deeply as desired at any spot

along the work. At this stage, long cuts can be made from

the center to either end.

• Generally, roughing off is continued until the cylinder is

approximately 1/8"larger than the desired finished size.

• Roundness can be tested by laying the gouge on top of

the work - it will not ride up and down when cylinder is

perfectly round.

Figure 41

SMOOTHING A CYLINDER

The final 1/,, can be removed in two ways. Either use the 1"

skew, working from the center toward both ends and taking

lighter and lighter cuts until finished, or use a block plane as

illustrated in Figure 33.

CUTTING A SHOULDER

A shoulder can be the side of a square portion left in the

workpiece, the side of a turned section, or the end of the

workpiece. Most shoulders are perpendicular to the work axis,

but a shoulder can be at any angle.

• First, mark position of the shoulder with a pencil held to

the revolving workpiece.

• Second, make a sizing cut with the parting tool, placing

this cut about 1/16"outside the shoulder position and cutting

to within about 1/,, of the depth desired for the area outside

of the shoulder.

• If shoulder is shallow, the toe of the skew can be used to

make the sizing cut. Do not go in deeper than 1/,, with the

skew unless wider and wider vees are cut to provide clear-

ance for this tool.

First Cuts

Figure 40 _ Testing Roundness

ROUGH-CUTTING TO SIZE

The roughing-off cut can be made to accurately size the cylin-

der to a given diameter.

Another method is to make a number of sizing cuts at inter-

vals along the work, then use the gouge to reduce the whole

cylinder down to the diameter indicated by these cuts.

MAKING SIZING CUTS

Sizing cuts are useful to establish approximate finished size

diameters at various points along a workpiece. The work can

then be turned down to the diameters indicated and be ready

for finishing.

Figure 42

• Use the gouge to remove any waste stock outside of shoul-

der. Smooth this section, up to within 1/,, of shoulder, in the

usual manner. Finishing of the shoulder, unless it is more

than 1" high, is best done with the 1/2"skew.

• The toe of the skew is used to remove the shavings from

the side of the shoulder - down to finished size.

• Hold skew so the bottom edge of bevel next to the shoul-

der will be very nearly parallel to side of shoulder - but

with cutting edge turned away at the top so that only the

extreme toe will do the cutting. If cutting edge is flat

against shoulder, the chisel will run.

• Start with handle low, and raise handle to advance toe into

the work.

• Cut down to finished diameter of outside area. Then, clean

out the corner by advancing heel of the skew into it along

the surface of the outside area.

13

Tilt the cutting edge, with handle raised up so that only the

extreme heel does this cutting.

If shoulder is at end of work, the process is called squaring

the end. In this case, reduce outer portion to a diameter

about 1/4"larger than tool center diameter.Then, later, saw

off the waste stock.

Wrong Right

Figure 43

CUTTING VEES

Vee grooves can be cut with either the toe or heel of the skew.

• When the toe is used, the cutting action is exactly the

same as when trimming a shoulder except that the skew is

tilted to cut at the required bevel. Light cuts should be

taken on first one side and then the other, gradually

enlarging the vee to the required depth and width.

• When the heel is used, the skew is rotated down into the

work, using the rest as a pivot. Otherwise, cutting position

and sequence of cuts are the same. As when using the

toe, it is important that cutting be done only by extreme

end of cutting edge.

• If deep vees are planned, it is quicker to start them by

making a sizing cut at the center of each vee.

• Vees can also be scraped with the spear point chisel or a

three-sided file.

Figure 44

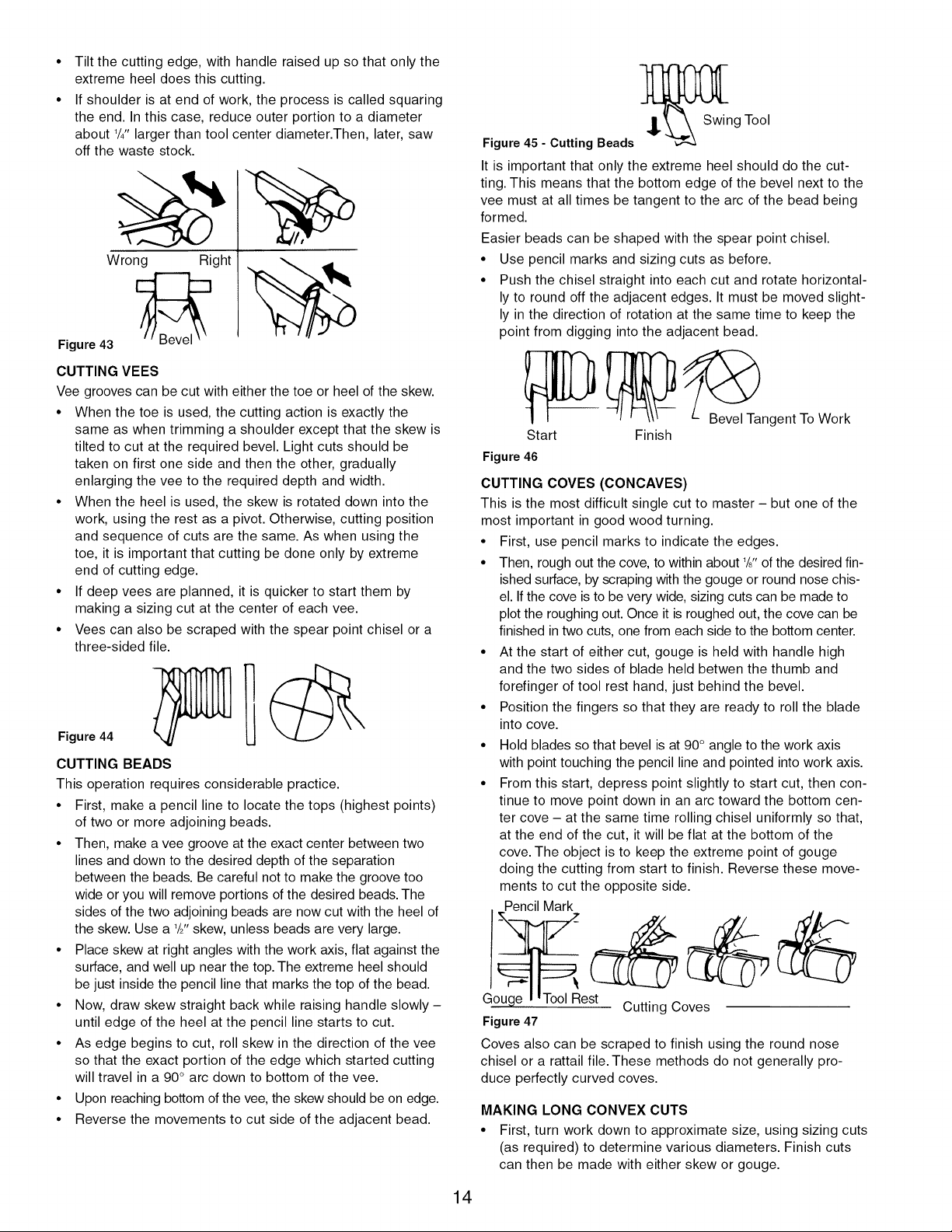

CUTTING BEADS

This operation requires considerable practice.

• First, make a pencil line to locate the tops (highest points)

of two or more adjoining beads.

• Then, make a vee groove at the exact center between two

lines and down to the desired depth of the separation

between the beads. Be careful not to make the groove too

wide or you will remove portions of the desired beads. The

sides of the two adjoining beads are now cut with the heel of

the skew. Use a 1/2"skew, unless beads are very large.

• Place skew at right angles with the work axis, flat against the

surface, and well up near the top. The extreme heel should

be just inside the pencil line that marks the top of the bead.

• Now, draw skew straight back while raising handle slowly -

until edge of the heel at the pencil line starts to cut.

• As edge begins to cut, roll skew in the direction of the vee

so that the exact portion of the edge which started cutting

will travel in a 90° arc down to bottom of the vee.

• Upon reaching bottom of the vee, the skew should be on edge.

• Reverse the movements to cut side of the adjacent bead.

__Swing Tool

Figure 45 - Cutting Beads

It is important that only the extreme heel should do the cut-

ting. This means that the bottom edge of the bevel next to the

vee must at all times be tangent to the arc of the bead being

formed.

Easier beads can be shaped with the spear point chisel.

• Use pencil marks and sizing cuts as before.

• Push the chisel straight into each cut and rotate horizontal-

ly to round off the adjacent edges. It must be moved slight-

ly in the direction of rotation at the same time to keep the

point from digging into the adjacent bead.

B_evel Tangent To Work

Start

Figure 46

CUTTING COVES (CONCAVES)

This is the most difficult single cut to master - but one of the

most important in good wood turning.

• First, use pencil marks to indicate the edges.

• Then, rough out the cove, to within about '/J' of the desired fin-

ished surface, by scraping with the gouge or round nose chis-

el. Ifthe cove is to be very wide, sizing cuts can be made to

plot the roughing out. Once it is roughed out, the cove can be

finished in two cuts, one from each side to the bottom center.

• At the start of either cut, gouge is held with handle high

and the two sides of blade held betwen the thumb and

forefinger of tool rest hand, just behind the bevel.

• Position the fingers so that they are ready to roll the blade

into cove.

• Hold blades so that bevel is at 90° angle to the work axis

with point touching the pencil line and pointed into work axis.

• From this start, depress point slightly to start cut, then con-

tinue to move point down in an arc toward the bottom cen-

ter cove - at the same time rolling chisel uniformly so that,

at the end of the cut, it will be flat at the bottom of the

cove. The object is to keep the extreme point of gouge

doing the cutting from start to finish. Reverse these move-

ments to cut the opposite side.

Pencil Mark

Gouge I WToolRest Cutting Coves

Figure 47

Coves also can be scraped to finish using the round nose

chisel or a rattail file. These methods do not generally pro-

duce perfectly curved coves.

MAKING LONG CONVEX CUTS

• First, turn work down to approximate size, using sizing cuts

(as required) to determine various diameters. Finish cuts

can then be made with either skew or gouge.

Finish

14

• If the skew is used, the principles of the operation are the

same as those employed in cutting a bead - except that

the curve is longer and may be irregular. Use the extreme

heel throughout - start at longer end of curve (if curve is

irregular) and progress toward steeper end.

• If gouge is used, make cut in the same direction. Start with

the handle well back of point - swinging handle in the

direciton of tool travel to overtake the point, if necessary,

when the steep part of the curve is reached. Object is to

have the extreme point doing the cutting throughout with

the bevel as tangent to curve as possible.

Figure 48 - Chisel Inclinedin Direction of Cut

MAKING LONG TAPER CUTS

Long taper cuts are made like long convex cuts, with the skew

or gouge. However, the angle between the cutting edge and

handle is kept constant during the entire cut. The handle is

not swung around.

• Always cut downhill. Do not cut too deeply at the center of

the taper.

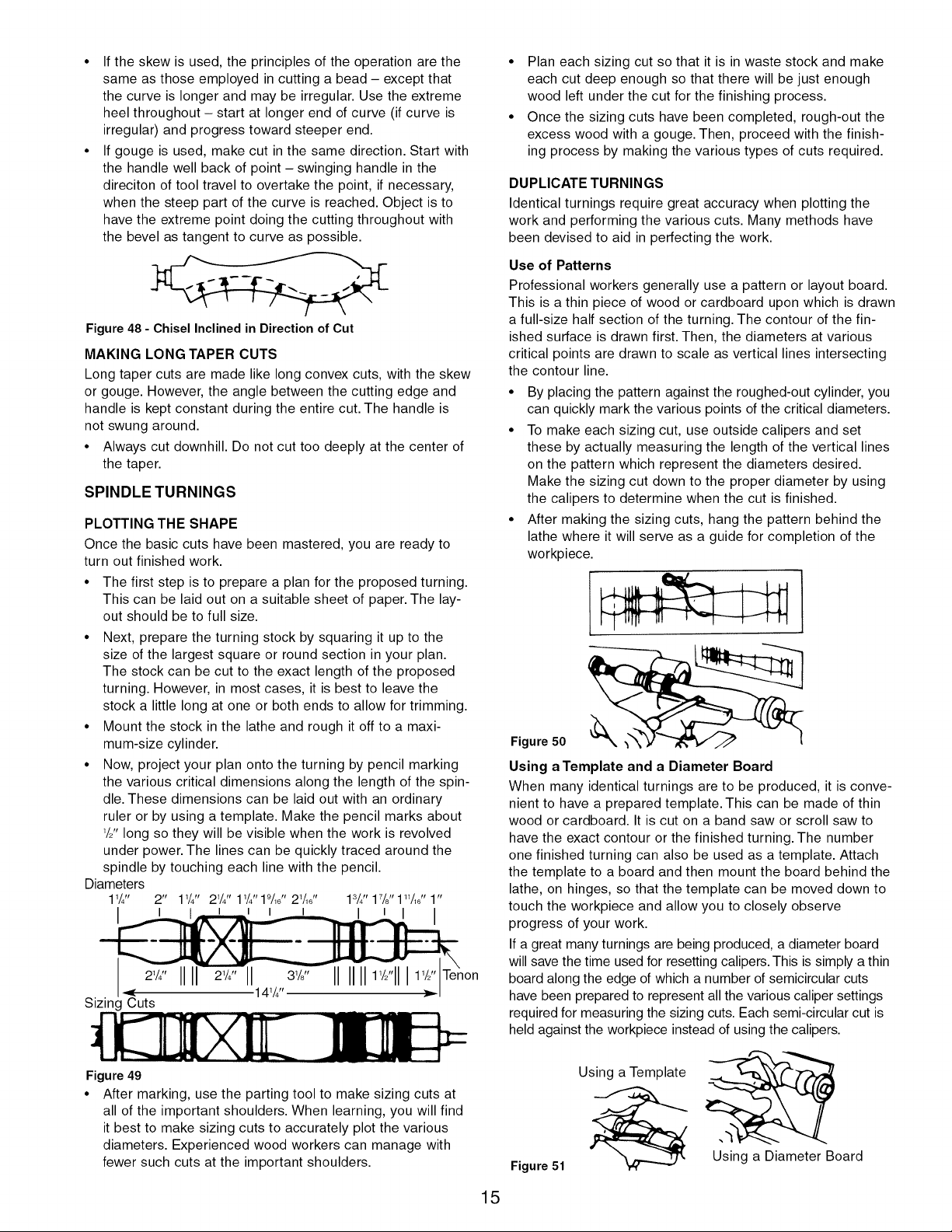

SPINDLE TURNINGS

PLOTTING THE SHAPE

Once the basic cuts have been mastered, you are ready to

turn out finished work.

• The first step is to prepare a plan for the proposed turning.

This can be laid out on a suitable sheet of paper. The lay-

out should be to full size.

• Next, prepare the turning stock by squaring it up to the

size of the largest square or round section in your plan.

The stock can be cut to the exact length of the proposed

turning. However, in most cases, it is best to leave the

stock a little long at one or both ends to allow for trimming.

• Mount the stock in the lathe and rough it off to a maxi-

mum-size cylinder.

• Now, project your plan onto the turning by pencil marking

the various critical dimensions along the length of the spin-

dle. These dimensions can be laid out with an ordinary

ruler or by using a template. Make the pencil marks about

_12"long so they will be visible when the work is revolved

under power. The lines can be quickly traced around the

spindle by touching each line with the pencil.

Diameters

1_/4'' 2" 1_/4'' 21/41'1_/4"19/_6'' 21/16'' 13/41'17/8"111/16'' 1"

_non

Sizin/ _uts 141/4't _1

• Plan each sizing cut so that it is in waste stock and make

each cut deep enough so that there will be just enough

wood left under the cut for the finishing process.

• Once the sizing cuts have been completed, rough-out the

excess wood with a gouge. Then, proceed with the finish-

ing process by making the various types of cuts required.

DUPLICATE TURNINGS

Identical turnings require great accuracy when plotting the

work and performing the various cuts. Many methods have

been devised to aid in perfecting the work.

Use of Patterns

Professional workers generally use a pattern or layout board.

This is a thin piece of wood or cardboard upon which is drawn

a full-size half section of the turning. The contour of the fin-

ished surface is drawn first. Then, the diameters at various

critical points are drawn to scale as vertical lines intersecting

the contour line.

• By placing the pattern against the roughed-out cylinder, you

can quickly mark the various points of the critical diameters.

• To make each sizing cut, use outside calipers and set

these by actually measuring the length of the vertical lines

on the pattern which represent the diameters desired.

Make the sizing cut down to the proper diameter by using

the calipers to determine when the cut is finished.

• After making the sizing cuts, hang the pattern behind the

lathe where it will serve as a guide for completion of the

workpiece.

Figure 50 _

Using a Template and a Diameter Board

When many identical turnings are to be produced, it is conve-

nient to have a prepared template. This can be made of thin

wood or cardboard. It is cut on a band saw or scroll saw to

have the exact contour or the finished turning. The number

one finished turning can also be used as a template. Attach

the template to a board and then mount the board behind the

lathe, on hinges, so that the template can be moved down to

touch the workpiece and allow you to closely observe

progress of your work.

If a great many turnings are being produced, a diameter board

will save the time used for resetting calipers. This is simply a thin

board along the edge of which a number of semicircular cuts

have been prepared to represent all the various caliper settings

required for measuring the sizing cuts. Each semi-circular cut is

held against the workpiece instead of using the calipers.

Figure 49

• After marking, use the parting tool to make sizing cuts at

all of the important shoulders. When learning, you will find

it best to make sizing cuts to accurately plot the various

diameters. Experienced wood workers can manage with

fewer such cuts at the important shoulders.

Using a Template

Using a Diameter Board

Figure 51

15

Loading...

Loading...