Craftsman 351217020 Owner’s Manual

Operator's Manual

15"

PLANER

Model No.

351.217020

CAUTION: Read and follow

all Safety Rules and Operating

Instructions before First Use

of this Product. Keep this

manual with tool.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

www.sears.com/craftsman

21703.01 Draft (05/11/05)

Warranty.................................... 2

SafetyRules............................... 2-3

Unpacking.................................. 3

Assembly................................. 3-4

Installation................................. 4-5

KnowYourPlaner............................. 6

Operation................................ 6-11

Maintenance............................. 11-14

Troubleshooting............................. 15

PartsIllustrationandList................... 18-23

FULL ONE YEAR WARRANTY

If this product fails due to a defect in material or workman-

ship within one year from the date of purchase, Sears will

at its option repair or replace it free of charge. Contact

your nearest Sears Service Center (1-800-4-MY-HOME)

to arrange for product repair, or return this product to

place of purchase for replacement.

If this product is used for commercial or rental purpos-

es, this warranty will apply for 90 days from the date of

purchase.

This warranty applies only while this product is used in

the United States.

This warranty gives you specific legal rights, and you

may also have other rights which vary from state to state.

Sears, Roebuck and Co., Dept. 817WA, Hoffman

Estates, IL 60179

WARNING: For your own safety, read all of the rules

and precautions before operating tool.

CAUTION: Always follow proper operating procedures

as defined in this manual even if you are familiar with

use of this or similar tools. Remember that being care-

less for even a fraction of a second can result in severe

personal injury.

BE PREPARED FOR JOB

• Wear proper apparel. Do not wear loose clothing,

gloves, neckties, rings, bracelets or other jewelry

which may get caught in moving parts of machine.

• Wear protective hair covering to contain long hair.

• Wear safety shoes with non-slip soles.

• Wear safety glasses complying with United States

ANSI Z87.1. Everyday glasses have only impact

resistant lenses. They are NOT safety glasses.

• Wear face mask or dust mask if operation is dusty.

• Be alert and think clearly. Never operate power tools

when tired, intoxicated or when taking medications

that cause drowsiness.

PREPARE WORK AREA FOR JOB

• Keep work area clean. Cluttered work areas invite

accidents.

• Do not use power tools in dangerous environments.

• Do not use power tools in damp or wet locations. Do

not expose power tools to rain.

• Work area should be properly lighted.

• Proper electrical receptacle should be available for

tool. Three prong plug should be plugged directly

into properly grounded, three-prong receptacle.

• Extension cords should have a grounding prong and

the three wires of the extension cord should be of

the correct gauge.

• Keep visitors at a safe distance from work area.

• Keep children out of workplace. Make workshop child-

proof. Use padlocks, master switches or remove switch

keys to prevent any unintentional use of power tools.

TOOL SHOULD BE MAINTAINED

• Always unplug tool prior to inspection.

• Consult manual for specific maintaining and adjust-

ing procedures.

• Keep tool lubricated and clean for safest operation.

• Remove adjusting tools. Form habit of checking to

see that adjusting tools are removed before switch-

ing machine on.

• Keep all parts in working order. Check to determine

that the guard or other parts will operate properly

and perform their intended function.

• Check for damaged parts. Check for alignment of

moving parts, binding, breakage, mounting and any

other condition that may affect a tool's operation.

• A guard or other part that is damaged should be

properly repaired or replaced. Do not perform

makeshift repairs. (Use parts list provided to order

replacement parts.)

KNOW HOW TO USE TOOL

• Use right tool for job. Do not force tool or attachment

to do a job for which itwas not designed.

• Disconnect tool when changing blades.

• Avoid accidental start-up. Make sure that the switch

key is in the OFF position before plugging in.

• Do not force tool. It will work most efficiently at the

rate for which it was designed.

• Keep hands away from moving parts and cutting

surfaces.

• Never leave tool running unattended. Turn the power

off and do not leave tool until it comes to a complete

stop.

• Do not overreach. Keep proper footing and balance.

© Sears, Roebuck and Co. 2

• Never stand on tool. Serious injury could occur if tool is

tipped or if blade is unintentionally contacted.

• Know your tool. Learn the tool's operation, applica-

tion and specific limitations.

• Use recommended accessories (refer to page 19).

Use of improper accessories may cause risk of

injury to persons.

• Handle workpiece correctly. Protect hands from pos-

sible injury.

• Turn machine off if it jams. Blade jams when it digs

too deeply into workpiece. (Motor force keeps it

stuck in the work.)

• Always keep drive, cutterhead and blade guards in

place and in proper operating condition.

• Feed work into blade or cutter against direction of

rotation.

CAUTION: Think safety! Safety is a combination of

operator common sense and alertness at all times

when tool is being used.

WARNING: Do not attempt to operate tool until it is

completely assembled according to the instructions.

Check for shipping damage. If damage has occurred, a

claim must be filed with carrier. Check for complete-

ness. Immediately report missing parts to dealer.

Additional parts which need to be fastened to the planer

should be located and accounted for before assembling.

Planer is shipped assembled except for the following:

two table extensions, handwheel handle, chip chute, two

roller gauge blocks, blade height gauge, roller assembly,

two roller brackets, floor leveling feet and hardware bag.

Hardware bag (Part No. 23516.00) includes:

• 8-1.25 x 25mm Socket Head Bolt (4)

• 8-1.25 x 12mm Socket Head Bolt (3)

• 8mm Flat Washer (7)

• 8mm LockWasher (4)

• 6-1.0 x 12mm Socket Head Bolt (4)

• 6-1.0 x 12mm Hex Head Bolt (3)

• 6mm Flat Washer (6)

• 6-1.0mm Hex Nut (3)

IMPORTANT: Table, table rollers and cutterhead are

coated with a protectant. To ensure proper fit and oper-

ation, remove coating. Coating is easily removed with

mild solvents, such as mineral spirits, and a soft cloth.

Use caution when cleaning the cutterhead, as the

blades are very sharp. Avoid getting solution on paint or

any of the rubber or plastic parts. Solvents may deterio-

rate these finishes. Use soap and water on paint, plas-

tic or rubber components. After cleaning, cover all

exposed surfaces with a light coating of oil. Paste wax

is recommended for table top.

WARNING: Never use highly volatile solvents. Non-

flammable solvents are recommended to avoid possible

fire hazard.

WARNING: Do not attempt assembly if parts are

missing. Use this manual to order replacement parts.

PLANER INSTALLATION

Before planer is assembled, a suitable location should

be chosen. The planer weighs approximately 500 Ibs

when completely assembled. Planer should be assem-

bled on location.

• Planer needs to be set on a flat, level surface. This

improves stability, accuracy and prevents warpage

and failure of cast components and welds.

• Make sure there is ample room on both infeed and

outfeed sides of planer for moving the workpiece

through the entire cut. There must be enough room

that neither the operators nor the bystanders will

have to stand in line with the wood while using the

tool.

• Good lighting and correct power supply (230 volts)

are also required for a proper work area.

• Place planer in its designated spot. Covers for

access to motor are on both front and rear sides of

stand. The planer is supplied with four lifting handles

that slide into the base on the infeed and outfeed

sides. The planer must be lifted by these handles

only and moved to the required location.

ATTACH LEVELING FEET

Refer to Figure 21, page 22.

• Required parts and hardware:

Foot (4)

10-1.5mm Hex Nut (4)

• Remove access covers (Key No. 53).

• Attach foot assemblies (Key Nos. 57 and 60) to the

cabinet (Key No. 52).

• With planer in position, check table surface length-

wise and crosswise with machinist level. Check that

all four corners are supported. Adjust foot as needed

and secure in position with hex nut.

• Replace access covers.

MOUNT HEIGHT ADJUSTMENT

HANDWHEEL HANDLE

Refer to Figure 20, page 20.

• Required parts: Handle

• Thread handle into handwheel.

• Tighten hex nut to secure handle.

MOUNT CHIP CHUTE

Refer to Figure 20, page 20.

• Required parts and hardware:

Chip Chute

6-1.0 x 12mm Hex Head Bolt (3)

6mm Flat Washer (6)

6-1.0mm Hex Nut (3)

8-1.25 x 12mm Socket Head Bolt (3)

8mm Flat Washer (3)

• Position chip chute on chipbreaker cover (Key No. 52)

so that the slots on chip chute and chipbreaker cover

are aligned and slots on chip chute and holes on the

roller case are aligned.

• Secure chip chute to chipbreaker cover using three

hex head bolts, six flat washers and three hex nuts.

• Secure chip chute to roller case (Key No. 1) using

three socket head bolts and three flat washers.

MOUNT REAR RETURN ROLLER

Refer to Figure 20, page 20.

• Required parts and hardware:

Roller Assembly

Roller Bracket (2)

6-1.0 x 12mm Socket Head Bolt (4)

• Attach one roller bracket(Key No. 55) to rollercase

(Key No. 1) using two socket head bolts (Key No. 58).

• Insert one end of roller assembly (Key No. 56) into

bracket attached in previous step.

• Insert the other end of roller assembly into remaining

bracket and attach to roller case.

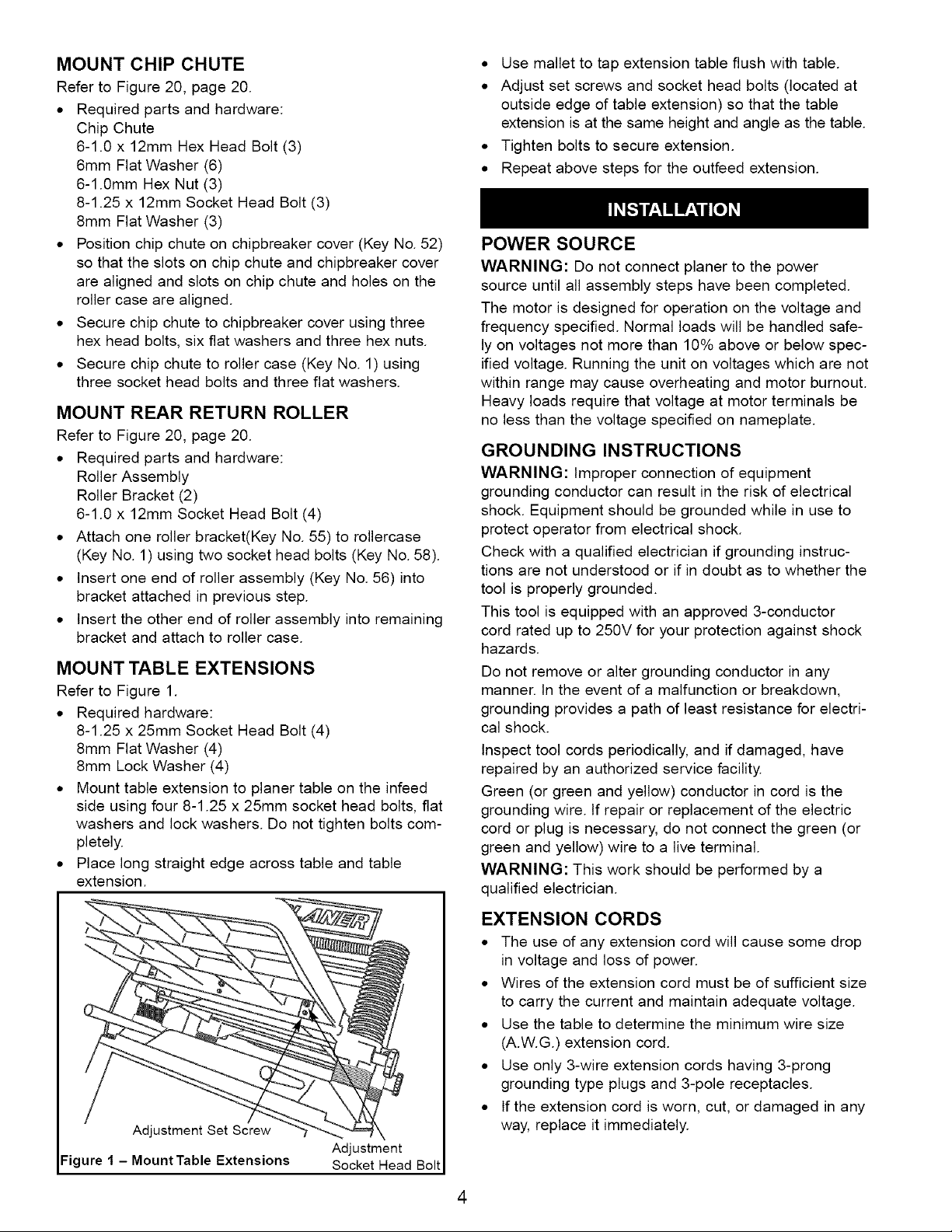

MOUNT TABLE EXTENSIONS

Refer to Figure 1.

• Required hardware:

8-1.25 x 25mm Socket Head Bolt (4)

8mm Flat Washer (4)

8mm Lock Washer (4)

• Mount table extension to planer table on the infeed

side using four 8-1.25 x 25mm socket head bolts, flat

washers and lock washers. Do not tighten bolts com-

pletely.

• Place long straight edge across table and table

extension.

• Use mallet to tap extension table flush with table.

• Adjust set screws and socket head bolts (located at

outside edge of table extension) so that the table

extension is at the same height and angle as the table.

• Tighten bolts to secure extension.

• Repeat above steps for the outfeed extension.

POWER SOURCE

WARNING: Do not connect planer to the power

source until all assembly steps have been completed.

The motor is designed for operation on the voltage and

frequency specified. Normal loads will be handled safe-

ly on voltages not more than 10% above or below spec-

ified voltage. Running the unit on voltages which are not

within range may cause overheating and motor burnout.

Heavy loads require that voltage at motor terminals be

no less than the voltage specified on nameplate.

GROUNDING INSTRUCTIONS

WARNING: Improper connection of equipment

grounding conductor can result in the risk of electrical

shock. Equipment should be grounded while in use to

protect operator from electrical shock.

Check with a qualified electrician if grounding instruc-

tions are not understood or if in doubt as to whether the

tool is properly grounded.

This tool is equipped with an approved 3-conductor

cord rated up to 250V for your protection against shock

hazards.

Do not remove or alter grounding conductor in any

manner. In the event of a malfunction or breakdown,

grounding provides a path of least resistance for electri-

cal shock.

Inspect tool cords periodically, and if damaged, have

repaired by an authorized service facility.

Green (or green and yellow) conductor in cord is the

grounding wire. If repair or replacement of the electric

cord or plug is necessary, do not connect the green (or

green and yellow) wire to a live terminal.

WARNING: This work should be performed by a

qualified electrician.

Adjustment Set Screw

Figure I - MountTable Extensions

I

Adjustment

Socket Head Bolt

EXTENSION CORDS

• The use of any extension cord will cause some drop

in voltage and loss of power.

• Wires of the extension cord must be of sufficient size

to carry the current and maintain adequate voltage.

• Use the table to determine the minimum wire size

(A.W.G.) extension cord.

• Use only 3-wire extension cords having 3-prong

grounding type plugs and 3-pole receptacles.

• If the extension cord is worn, cut, or damaged in any

way, replace it immediately.

4

EXTENSION CORD LENGTH

Wire Size A.W.G.

Up to 50 ft.................................. 12

NOTE: Using extension cords over 50 ft. long is not

recommended.

MOTOR

The planer is assembled with motor and wiring

installed. The 230 Volt AC capacitor start motor has the

following specifications:

Horsepower ................................. 3

Voltage ................................... 230

Amperes ................................. 16.5

Hertz ..................................... 60

Phase .................................. Single

RPM .................................... 3450

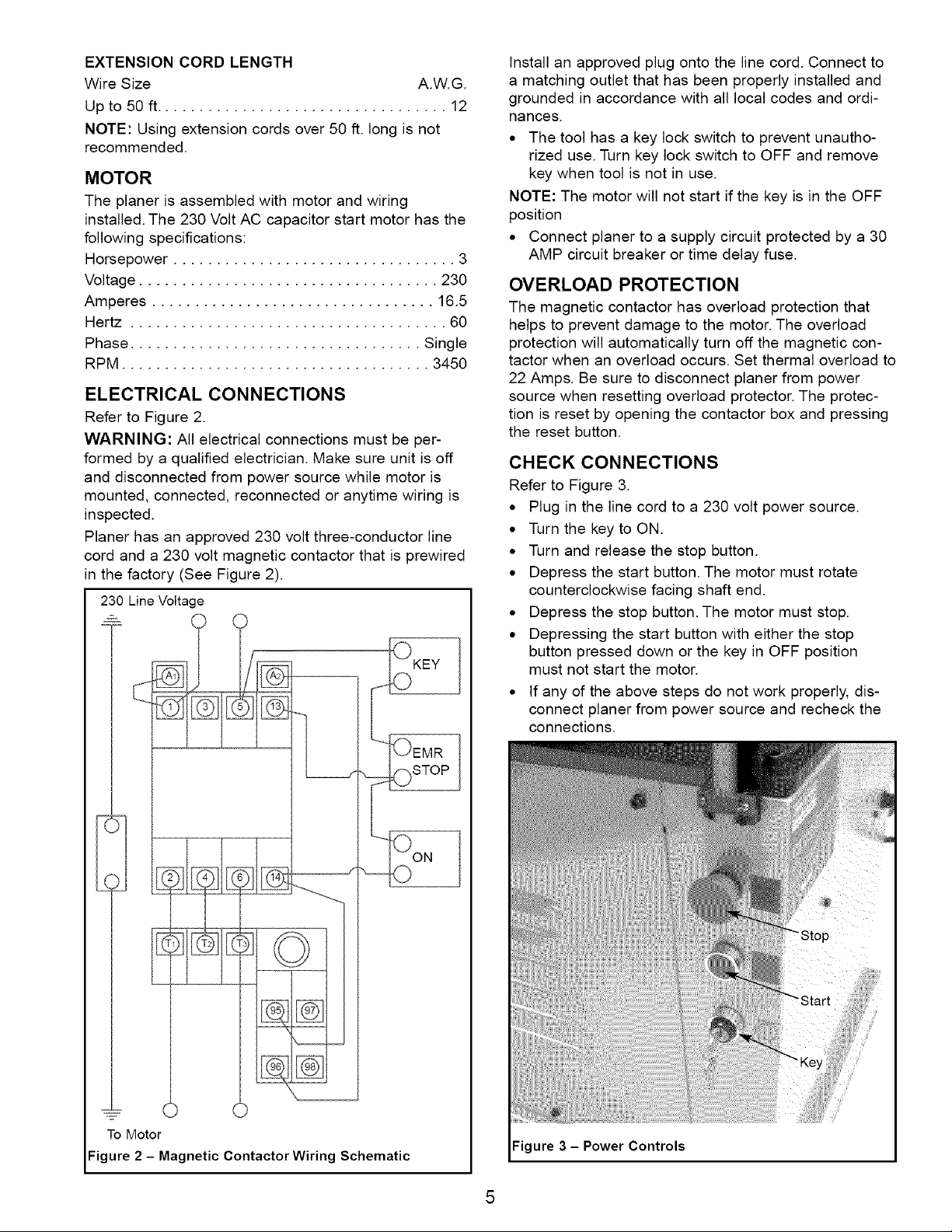

ELECTRICAL CONNECTIONS

Refer to Figure 2.

WARNING: All electrical connections must be per-

formed by a qualified electrician. Make sure unit is off

and disconnected from power source while motor is

mounted, connected, reconnected or anytime wiring is

inspected.

Planer has an approved 230 volt three-conductor line

cord and a 230 volt magnetic contactor that is prewired

in the factory (See Figure 2).

230 Line Voltage

Install an approved plug onto the line cord. Connect to

a matching outlet that has been properly installed and

grounded in accordance with all local codes and ordi-

nances.

• The tool has a key lock switch to prevent unautho-

rized use. Turn key lock switch to OFF and remove

key when tool is not in use.

NOTE: The motor will not start if the key is in the OFF

position

• Connect planer to a supply circuit protected by a 30

AMP circuit breaker or time delay fuse.

OVERLOAD PROTECTION

The magnetic contactor has overload protection that

helps to prevent damage to the motor. The overload

protection will automatically turn off the magnetic con-

tactor when an overload occurs. Set thermal overload to

22 Amps. Be sure to disconnect planer from power

source when resetting overload protector. The protec-

tion is reset by opening the contactor box and pressing

the reset button.

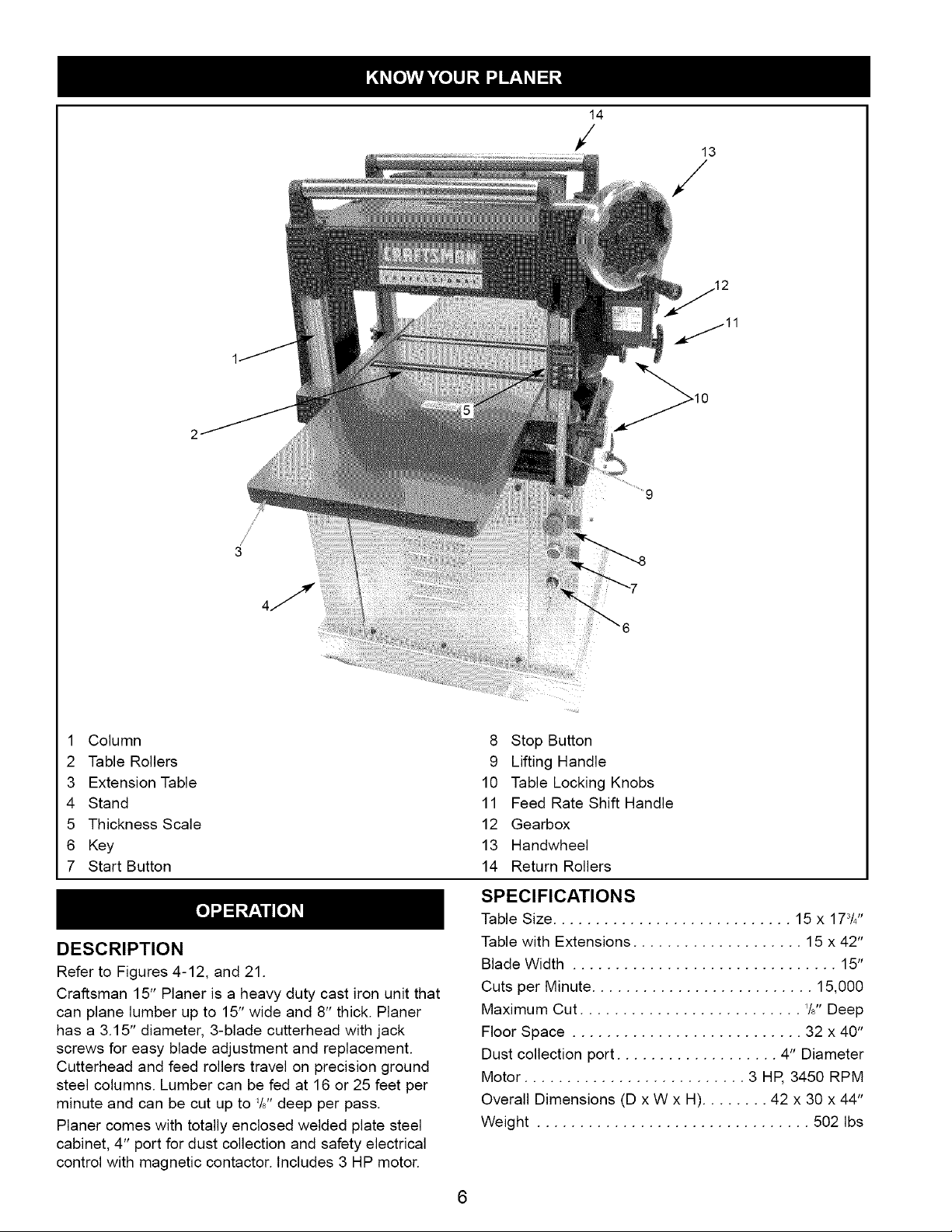

CHECK CONNECTIONS

Refer to Figure 3.

• Plug in the line cord to a 230 volt power source.

• Turn the key to ON.

• Turn and release the stop button.

• Depress the start button. The motor must rotate

counterclockwise facing shaft end.

• Depress the stop button. The motor must stop.

• Depressing the start button with either the stop

button pressed down or the key in OFF position

must not start the motor.

• If any of the above steps do not work properly, dis-

connect planer from power source and recheck the

connections.

To Motor

Figure 2 - Magnetic Contactor Wiring Schematic

Figure 3 - Power Controls

/

/

/

3

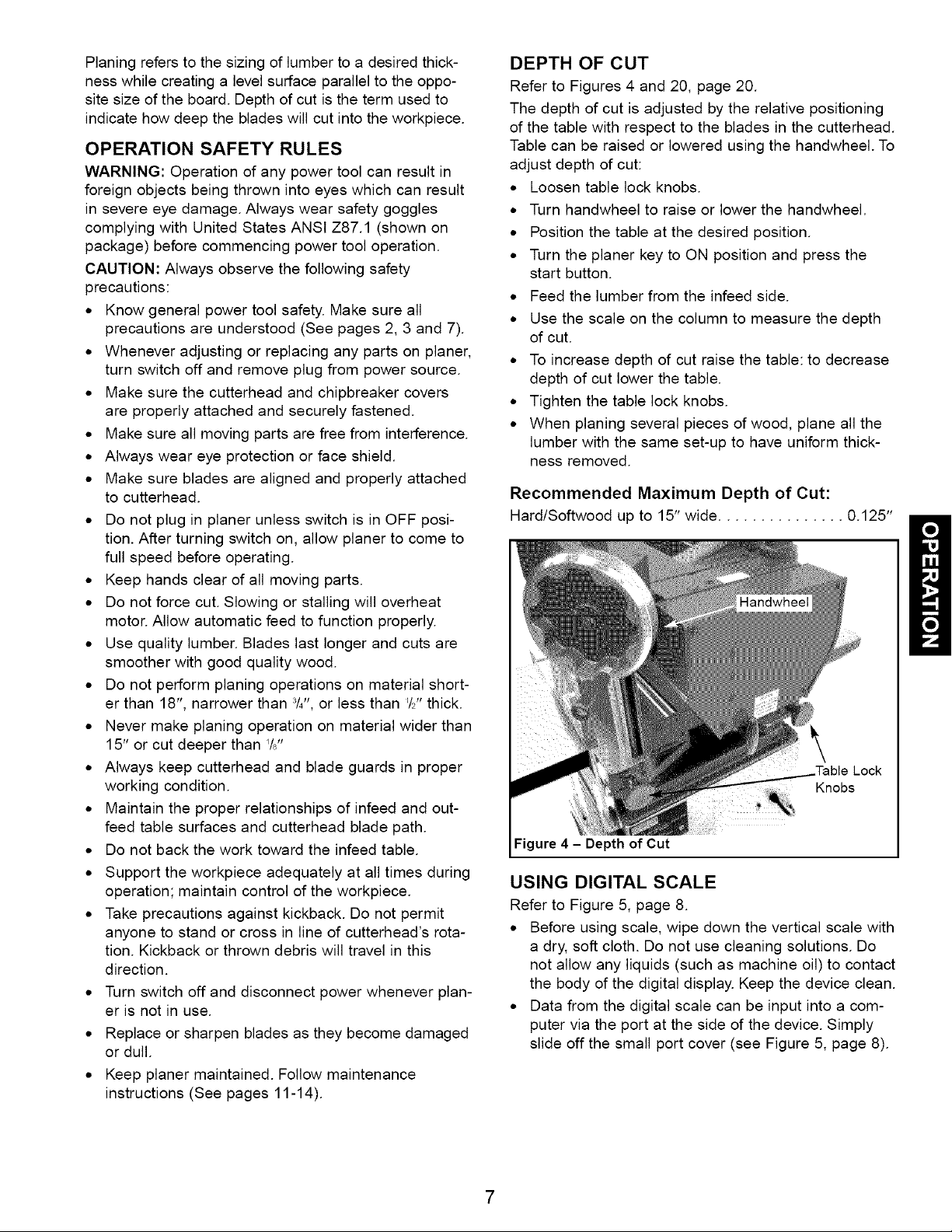

1 Column

2 Table Rollers

3 Extension Table

4 Stand

5 Thickness Scale

6 Key

7 Start Button

DESCRIPTION

Refer to Figures 4-12, and 21.

Craftsman 15" Planer is a heavy duty cast iron unit that

can plane lumber up to 15" wide and 8" thick. Planer

has a 3.15" diameter, 3-blade cutterhead with jack

screws for easy blade adjustment and replacement.

Cutterhead and feed rollers travel on precision ground

steel columns. Lumber can be fed at 16 or 25 feet per

minute and can be cut up to '/J' deep per pass.

Planer comes with totally enclosed welded plate steel

cabinet, 4" port for dust collection and safety electrical

control with magnetic contactor. Includes 3 HP motor.

8 Stop Button

9 Lifting Handle

10 Table Locking Knobs

11 Feed Rate Shift Handle

12 Gearbox

13 Handwheel

14 Return Rollers

SPECIFICATIONS

Table Size ............................ 15 x 173/4"

Table with Extensions .................... 15 x 42"

Blade Width ............................... 15"

Cuts per Minute .......................... 15,000

Maximum Cut .......................... 76"Deep

Floor Space ........................... 32 x 40"

Dust collection port ................... 4" Diameter

Motor .......................... 3 HP, 3450 RPM

Overall Dimensions (D x W x H)........ 42 x 30 x 44"

Weight ................................ 502 Ibs

6

Planing refers to the sizing of lumber to a desired thick-

ness while creating a level surface parallel to the oppo-

site size of the board. Depth of cut is the term used to

indicate how deep the blades will cut into the workpiece.

OPERATION SAFETY RULES

WARNING: Operation of any power tool can result in

foreign objects being thrown into eyes which can result

in severe eye damage. Always wear safety goggles

complying with United States ANSI Z87.1 (shown on

package) before commencing power tool operation.

CAUTION: Always observe the following safety

precautions:

• Know general power tool safety. Make sure all

precautions are understood (See pages 2, 3 and 7).

• Whenever adjusting or replacing any parts on planer,

turn switch off and remove plug from power source.

• Make sure the cutterhead and chipbreaker covers

are properly attached and securely fastened.

• Make sure all moving parts are free from interference.

• Always wear eye protection or face shield.

• Make sure blades are aligned and properly attached

to cutterhead.

• Do not plug in planer unless switch is in OFF posi-

tion. After turning switch on, allow planer to come to

full speed before operating.

• Keep hands clear of all moving parts.

• Do not force cut. Slowing or stalling will overheat

motor. Allow automatic feed to function properly.

• Use quality lumber. Blades last longer and cuts are

smoother with good quality wood.

• Do not perform planing operations on material short-

er than 18", narrower than 3/4",or less than 'tZ' thick.

• Never make planing operation on material wider than

15" or cut deeper than W'

• Always keep cutterhead and blade guards in proper

working condition.

• Maintain the proper relationships of infeed and out-

feed table surfaces and cutterhead blade path.

• Do not back the work toward the infeed table.

• Support the workpiece adequately at all times during

operation; maintain control of the workpiece.

• Take precautions against kickback. Do not permit

anyone to stand or cross in line of cutterhead's rota-

tion. Kickback or thrown debris will travel in this

direction.

• Turn switch off and disconnect power whenever plan-

er is not in use.

• Replace or sharpen blades as they become damaged

or dull.

• Keep planer maintained. Follow maintenance

instructions (See pages 11-14).

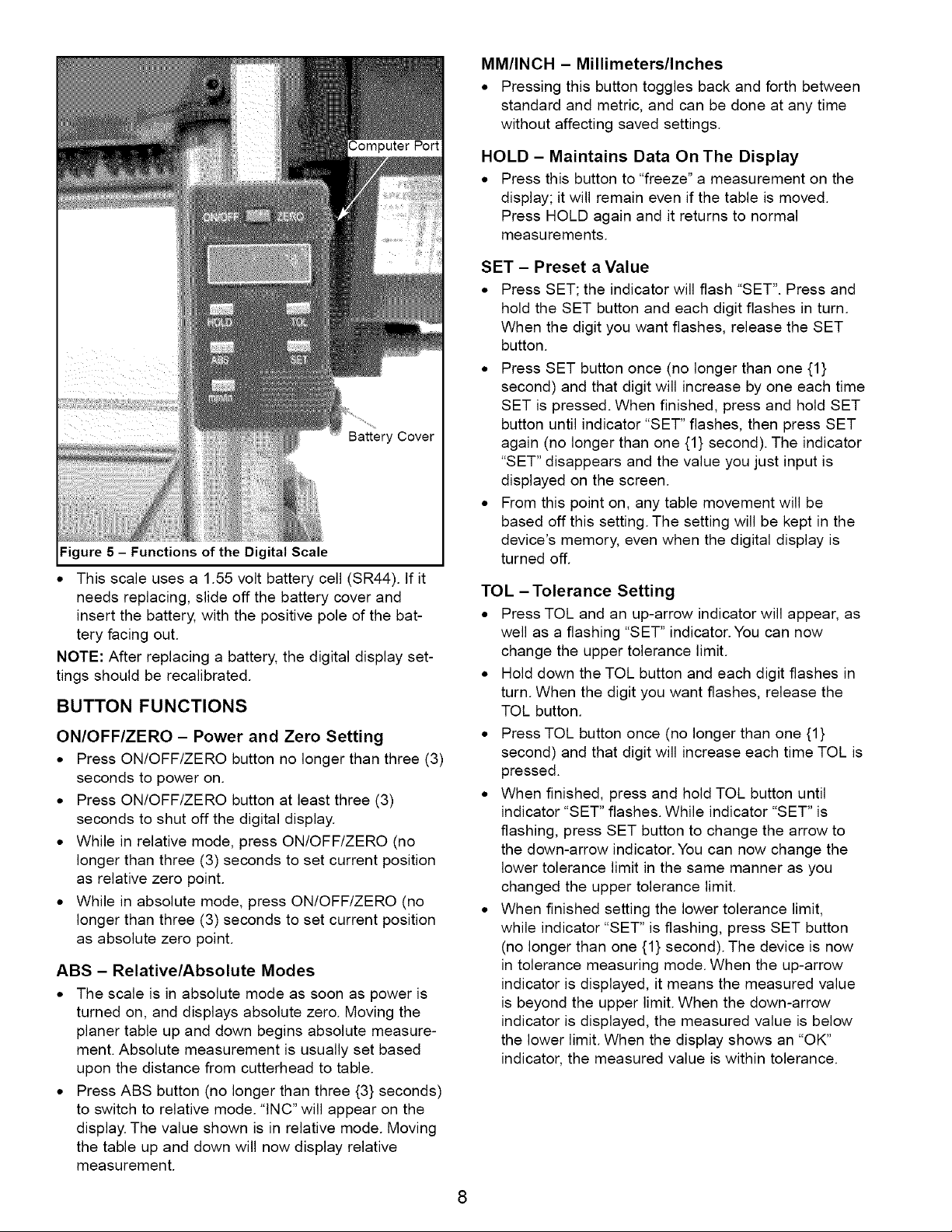

DEPTH OF CUT

Refer to Figures 4 and 20, page 20.

The depth of cut is adjusted by the relative positioning

of the table with respect to the blades in the cutterhead.

Table can be raised or lowered using the handwheel. To

adjust depth of cut:

• Loosen table lock knobs.

• Turn handwheel to raise or lower the handwheel.

• Position the table at the desired position.

• Turn the planer key to ON position and press the

start button.

• Feed the lumber from the infeed side.

• Use the scale on the column to measure the depth

of cut.

• To increase depth of cut raise the table: to decrease

depth of cut lower the table.

• Tighten the table lock knobs.

• When planing several pieces of wood, plane all the

lumber with the same set-up to have uniform thick-

ness removed.

Recommended Maximum Depth of Cut:

Hard/Softwood up to 15" wide ............... 0.125"

Lock

Knobs

Figure 4 - Depth of Cut

USING DIGITAL SCALE

Refer to Figure 5, page 8.

• Before using scale, wipe down the vertical scale with

a dry, soft cloth. Do not use cleaning solutions. Do

not allow any liquids (such as machine oil) to contact

the body of the digital display. Keep the device clean.

• Data from the digital scale can be input into a com-

puter via the port at the side of the device. Simply

slide off the small port cover (see Figure 5, page 8).

Battery Cover

Figure5 - Functions of the Digital Scale

• This scale uses a 1.55 volt battery cell (SR44). tf it

needs replacing, slide off the battery cover and

insert the battery, with the positive pole of the bat-

tery facing out.

NOTE: After replacing a battery, the digital display set-

tings should be recalibrated.

BUTTON FUNCTIONS

ON/OFF/ZERO - Power and Zero Setting

• Press ON/OFF/ZERO button no longer than three (3)

seconds to power on.

• Press ON/OFF/ZERO button at least three (3)

seconds to shut off the digital display.

• While in relative mode, press ON/OFF/ZERO (no

longer than three (3) seconds to set current position

as relative zero point.

• While in absolute mode, press ON/OFF/ZERO (no

longer than three (3) seconds to set current position

as absolute zero point.

ABS - Relative/Absolute Modes

• The scale is in absolute mode as soon as power is

turned on, and displays absolute zero. Moving the

planer table up and down begins absolute measure-

ment. Absolute measurement is usually set based

upon the distance from cutterhead to table.

• Press ABS button (no longer than three {3} seconds)

to switch to relative mode. "INC" will appear on the

display. The value shown is in relative mode. Moving

the table up and down will now display relative

measurement.

MM/INCH - Millimeters/Inches

• Pressing this button toggles back and forth between

standard and metric, and can be done at any time

without affecting saved settings.

HOLD - Maintains Data On The Display

• Press this button to "freeze" a measurement on the

display; it will remain even if the table is moved.

Press HOLD again and it returns to normal

measurements.

SET - Preset a Value

• Press SET; the indicator will flash "SET". Press and

hold the SET button and each digit flashes in turn.

When the digit you want flashes, release the SET

button.

• Press SET button once (no longer than one {1}

second) and that digit will increase by one each time

SET is pressed. When finished, press and hold SET

button until indicator "SET" flashes, then press SET

again (no longer than one {1} second). The indicator

"SET" disappears and the value you just input is

displayed on the screen.

• From this point on, any table movement will be

based off this setting. The setting will be kept in the

device's memory, even when the digital display is

turned off.

TOL - Tolerance Setting

• Press TOL and an up-arrow indicator will appear, as

well as a flashing "SET" indicator. You can now

change the upper tolerance limit.

• Hold down the TOL button and each digit flashes in

turn. When the digit you want flashes, release the

TOL button.

• Press TOL button once (no longer than one {1}

second) and that digit will increase each time TOL is

pressed.

• When finished, press and hold TOL button until

indicator "SET" flashes. While indicator "SET" is

flashing, press SET button to change the arrow to

the down-arrow indicator. You can now change the

lower tolerance limit in the same manner as you

changed the upper tolerance limit.

• When finished setting the lower tolerance limit,

while indicator "SET" is flashing, press SET button

(no longer than one {1} second). The device is now

in tolerance measuring mode. When the up-arrow

indicator is displayed, it means the measured value

is beyond the upper limit. When the down-arrow

indicator is displayed, the measured value is below

the lower limit. When the display shows an "OK"

indicator, the measured value is within tolerance.

8

Loading...

Loading...