Craftsman 351215690 Owner’s Manual

Operator's Manual I

4 x 36" Belt, 8" Disc

6 x 48" Belt, 9" Disc

SANDER WITH DUST COLLECTION

Model Nos.

351.215690

351.225930

CAUTION: Read and follow

all Safety Rules and Operating

Instructions before First Use

of this Product. Keep this

manual with tool.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

wwwosears.com/craftsman

21969.02 Draft (06/11/04)

Warranty......................................... 2

SafetyRules...................................... 2

Unpacking....................................... 3

Assembly...................................... 3-4

installation...................................... 4-6

Operation...................................... 6-9

Maintenance..................................... 9

Troubleshooting.................................. 10

PartsIllustrationandList........................ 12-17

EspaSol...................................... 18-27

FULL ONE YEAR WARRANTY

If this productfails due to a defect in matarial or workmanship

withinone year from the date of purchase, Sears will at its

optionrepairor replace it free of charge.Contactyour nearest

Sears Service Center (1-800-4-MY-HOME) to arrange for

product repair,or return this productto place of purchase for

replacement.

If this productisused for commercial or rentalpurposes, this

warranty will applyfor 90 days from the date of purchase.

This warranty applies only while thisproduct isused in the

United States.

This warrantygives you specific legal rights and you may also

have other rights which vary from state to state.

Sears, Roebuck and Co., Dept. 817WA, Hoffman Estates,

IL 60179

WARNING: Foryour own safety,read all of the instructions

and precautions before operating tool.

CAUTION: Always follow proper operating procedures as

defined in this manual even if you are familiar with use of this

or similar tools. Remember that being careless for even a

fraction of a second can result in severe personal injury.

BE PREPARED FOR JOB

• Wear proper apparel. Do not wear loose clothing,gloves,

neckties, rings,bracelets or other jewelrywhich may get

caught inmoving parts of machine.

• Wear protective hair coveringto contain longhair.

• Wear safety shoes with non-slip soles.

• Wear safety glasses complyingwith United States ANSI

Z87.1. Everyday glasses have only impact resistantlenses.

They are NOT safety glasses.

• Wear face mask or dust mask if operationis dusty.

• Be alert and think clearly.Never operate powertools when

tired, intoxicatedor when taking medications that cause

drowsiness.

PREPARE WORK AREA FOR JOB

• Keep work area clean, Cluttered work areas inviteaccidents.

• Do notuse power tools in dangerous environments.Do not

use powertools in damp or wet locations.Do not expose

power toolsto rain.

• Work area should be properly lighted.

• Proper electrical receptacle should be available for tool.

Three-prong plug should be plugged directly into properly

grounded, three-prong receptacle.

• Extension cords should have agrounding prong and thethree

wires of the extension cord should be of the correct gauge.

• Keep visitors at a safe distance from work area.

• Keep children out of workplace. Make workshop childproof.

Use padlocks, master switches or remove switch keys to

prevent any unintentional use of power tools.

TOOL SHOULD BE MAINTAINED

• Always unplug tool prior to inspection.

• Consult manual for specific maintaining andadjusting

procedures.

• Keep tool lubricated and clean for safest operation.

• Remove adjusting tools. Form habit of checking to see that

adjusting tools are removed before switching machine on.

• Keep all parts in working order. Check to determine that the

guard or other parts will operate properly and perform their

intended function.

• Check for damaged parts. Check for alignment of moving

parts, binding, breakage, mounting and any other condition

that may affect a toors operation.

• A guard or other part that is damaged should be properly

repaired or replaced. Do not perform makeshift repairs.

(Use parts list provided to order replacement parts.)

KNOW HOWTO USETOOL

• Use right toolfor job. Do not force tool or attachmentto do

a job for which it was not designed.

• Disconnect tool when changing belt or abrasive disc.

• Avoid accidental start-up. Make sure that the tool is in the

"OFF" position before plugging in.

• Do not force tool. It will work most efficiently at the rate for

which it was designed.

• Keep hands away from moving parts and sanding surfaces.

• Never leave tool running unattended. Turn the power off

and do not leave tool until it comes to a complete stop.

• Do not overreach. Keep proper footing and balance.

• Never stand on tool. Serious injury could occur if tool is

tipped or if belt or disc are unintentionally contacted.

• Know your tool. Learn the tool's operation, application and

specific limitations.

• Use recommended accessories (refer to page 15). Use of

improper accessories may cause risk of injury to persons.

• Handle the workpiece correctly. Protecthands from possi-

ble injury.

• Turn machine off if it jams. Belt jams when it digs too

deeply into workpiece. (Motor force keeps it stuck in the

work.)

• Support workpiece with miter gauge, belt platen or work

table.

• Maintain '/_,"maximum clearance between table and sand-

ing belt or disc.

CAUTION: Think safety! Safety is a combination of operator

common sense and alertness at all times when tool is being

used.

WARNING: Do not attempt to operate tool until it is com-

pletely assembled according to the instructions.

© Sears, Roebuck and Co. 2

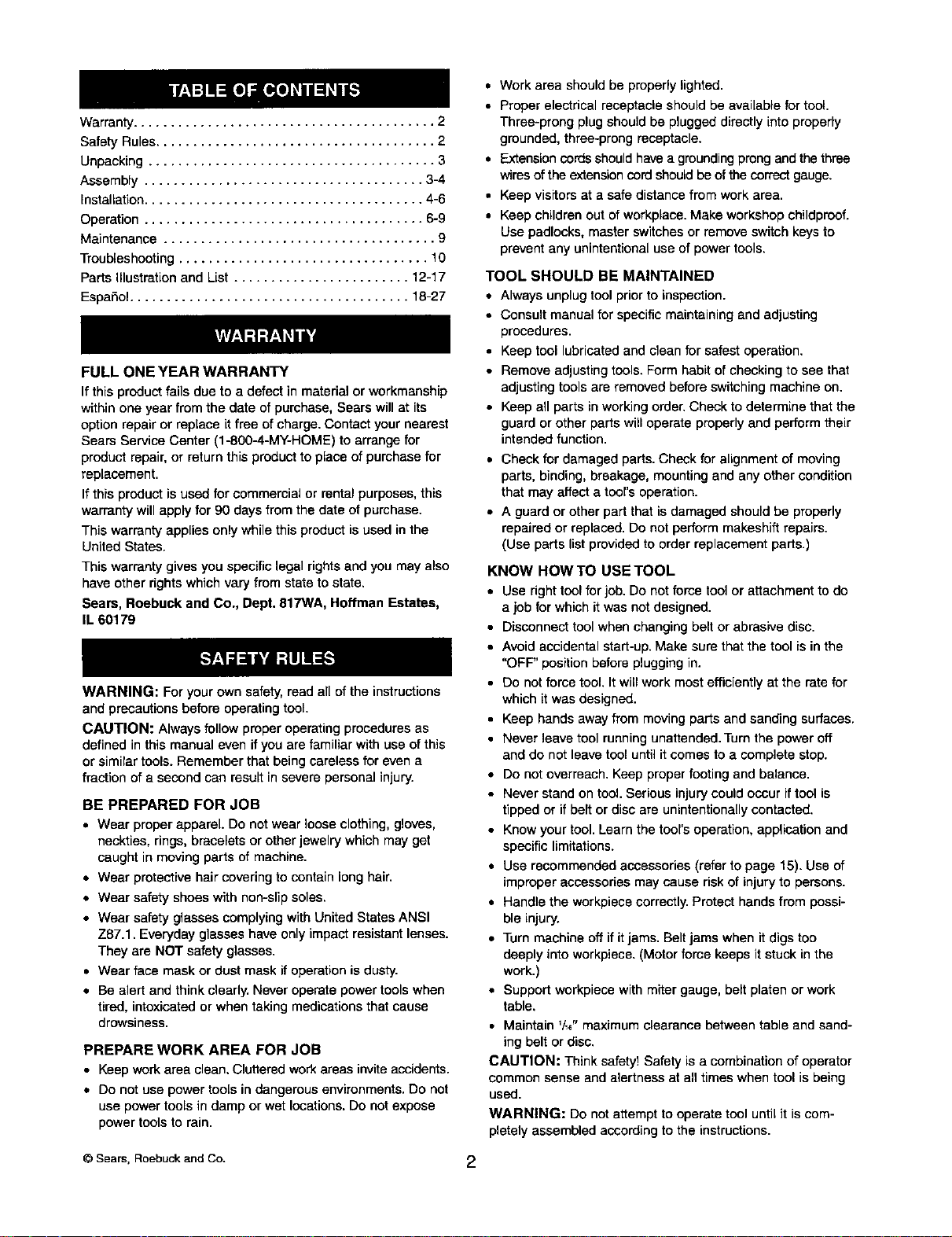

Refer to Figure 1.

Check for shipping damage. If damage has occurred, a claim

must be filled with carrier. Check for completeness.

Immediately report missing parts to dealer.

The sander comes assembled as one unit. Additional parts

which need to be fastened to sander, should be located and

accounted for before assembling.

A Sander

B Dust Collection Bag

C Bag Clamp

D Miter Gauge Assembly

E Work Stop

F Support Rod

G Table Assembly

H Line Cord Hook (2) with Screws (4)

B

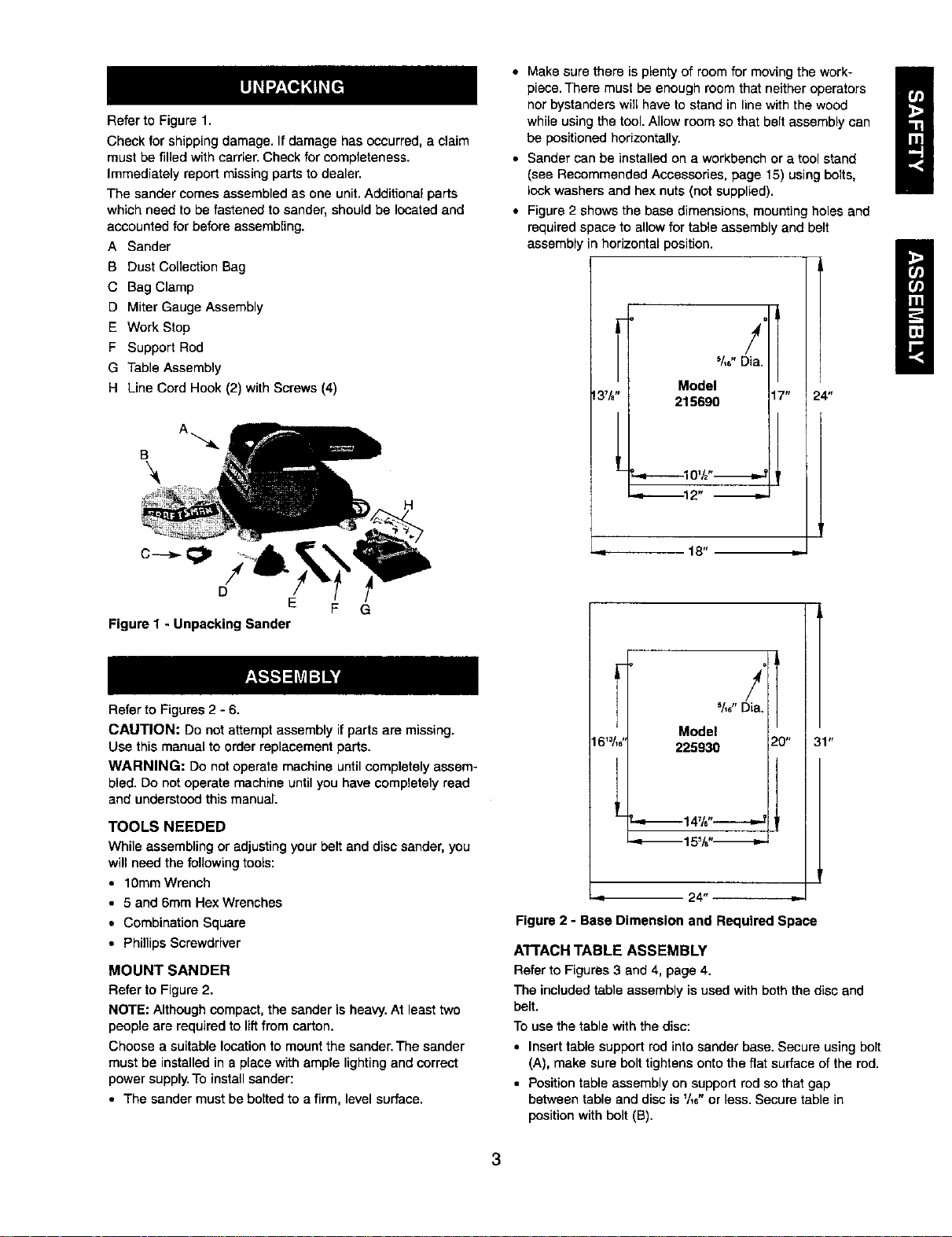

• Make sure there is plenty of room for moving the work-

piece.There must be enough room that neither operators

nor bystanders will have to stand in line with the wood

while using the tool. Allow room so that belt assembly can

be positioned horizontally.

• Sander can be installed on a workbench or a tool stand

(see Recommended Accessories, page 15) using bolts,

lock washers and hex nuts (not supplied).

• Figure 2 shows the base dimensions, mounting holes and

required space to allow for table assembly and belt

assembly in horizontal position.

!37/.`

-,9---12"

Model

215690

-,P------1 0'/2"_

D

Figure I - Unpacking Sander

Referto Figures 2 - 6.

CAUTION: Do not attempt assembly if parts are missing.

Use this manual to order replacement parts.

WARNING: Do not operate machine until completely assem-

bled. Do not operate machine until you have completely read

and understood this manual.

TOOLS NEEDED

While assembling or adjustingyour belt and disc sander, you

will need the following tools:

• 10ram Wrench

• 5 and 6mm Hex Wrenches

• Combination Square

• Phillips Screwdriver

MOUNT SANDER

Refer to Figure2,

NOTE: Althoughcompact, the sander is heavy,At least two

people are required to liftfrom carton.

Choose a suitable location to mount the sander. The sander

must be installed in a place with ample lighting and correct

power supply. To installsander:

• The sander must be bolted to a firm, level surface.

E

F G

18"

161_

Figure 2 - Base Dimension and Required Space

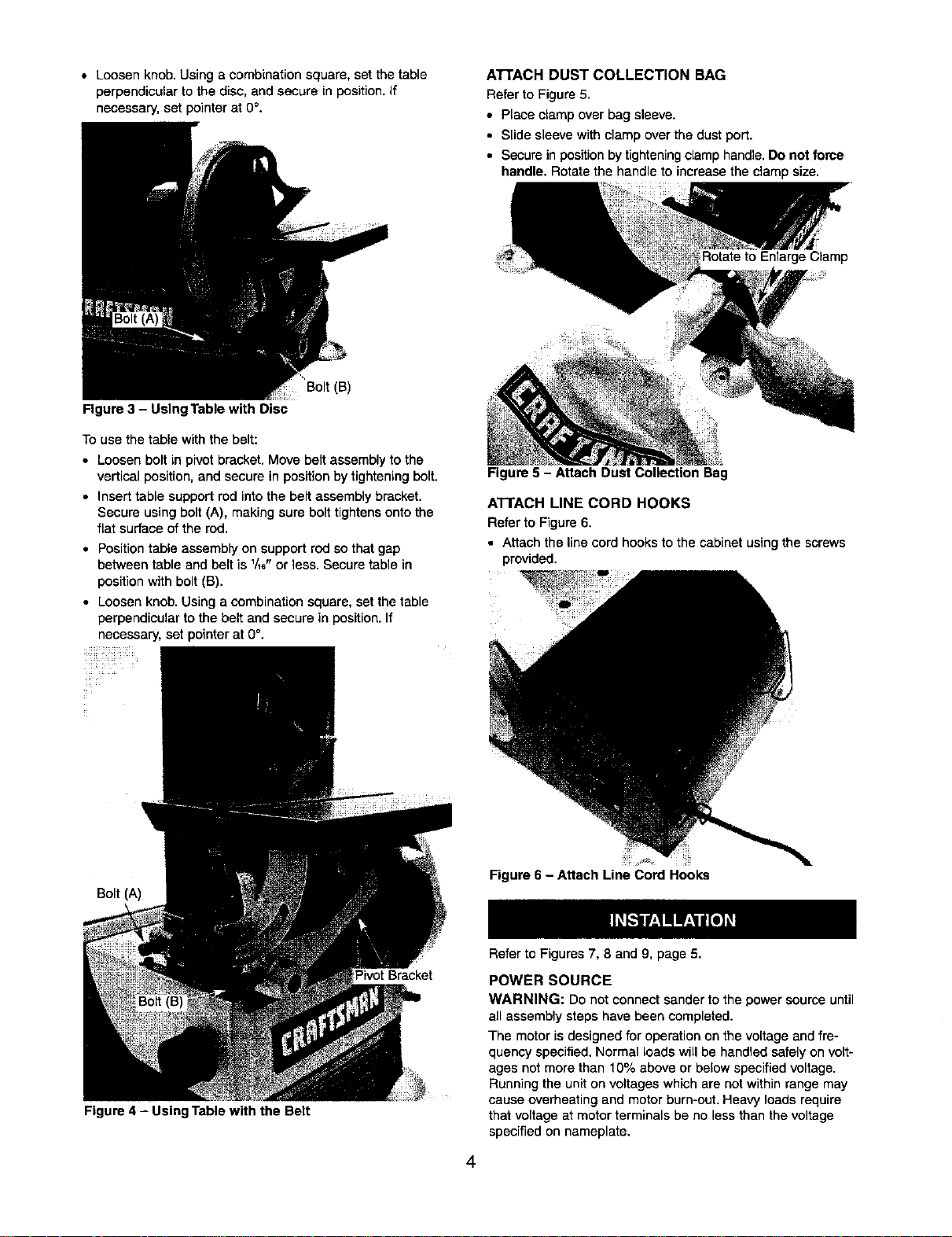

A'n'ACH TABLE ASSEMBLY

Refer to Figures 3 and 4, page 4,

The included table assembly is used with boththe disc and

belt.

To use the table with the disc:

• Insert table support rod into sander base. Secure using bolt

(A), make sure bolt tightens onto the flat surface of the rod.

• Positiontable assembly on support rod so that gap

between table and disc is _/_e"or less. Secure table in

position with bolt (B).

Model

225930

"_---14 78"------'_

15%"_

24"

0" 31"

3

• Loosen knob. Using a combination square, set the table

perpendicular to the disc, and secure in position. If

necessary, set pointer at 0°.

Bolt (B)

Figure 3 - Using Table with Disc

To use the table with the belt:

• Loosen bolt in pivot bracket. Move belt assembly to the

vertical position, and secure in position by tightening bolt.

• Insert table supportrod into the belt assembly bracket.

Secure using bolt (A), making sure bolt tightens onto the

flat surface of the rod.

• Position table assembly on support rod sothat gap

between table and belt is _/_e"or less. Secure table in

position with bolt (B).

• Loosen knob. Using a combination square, set the table

perpendicular to the belt and secure in position. If

necessary, set pointer at 0°.

ATI'ACH DUST COLLECTION BAG

Refer to Figure 5,

• Place clamp over bag sleeve.

• Slide sleeve with clamp over the dust port.

• Secure in position by tightening clamp handle. Do not force

handle. Rotate the handle to increase the clamp size.

Rotate to Enlarge Clamp

Figure 5 - Atlach Dust Collection Bag

ATTACH LINE CORD HOOKS

Refer to Figure6.

• Attachthe line cord hooksto the cabinet using the screws

provided.

Bolt (A)

Figure 4 - Using Table with the Belt

Pivot Bracket

Figure6 - AttachLine CordHooks

Refer to Figures 7, 8 and 9, page 5.

POWER SOURCE

WARNING: Do not connectsander tothe power sourceuntil

all assembly steps have been completed.

The motor is designed for operation on the voltage and fre-

quency specified. Normal loads will be handled safely on volt-

ages not more than 10% above or below specified voltage.

Running the unit on voltages which are not within range may

cause overheating and motor burn-out. Heavy loads require

that voltage at motor terminals be no less than the voltage

specified on nameplate.

4

Powersupplytothemotoriscontrolledbyasinglepole

lockingrockerswitch.Removethekeytopreventunautho-

rizeduse.

GROUNDING INSTRUCTIONS

WARNING: Improper connection of equipment grounding

conductor can result in the risk of electrical shock. Equipment

should be grounded while in use to protect operator from

electrical shock.

• Check with a qualified electrician if grounding instructions

are not understood or if in doubt as to whether the tool is

properly grounded.

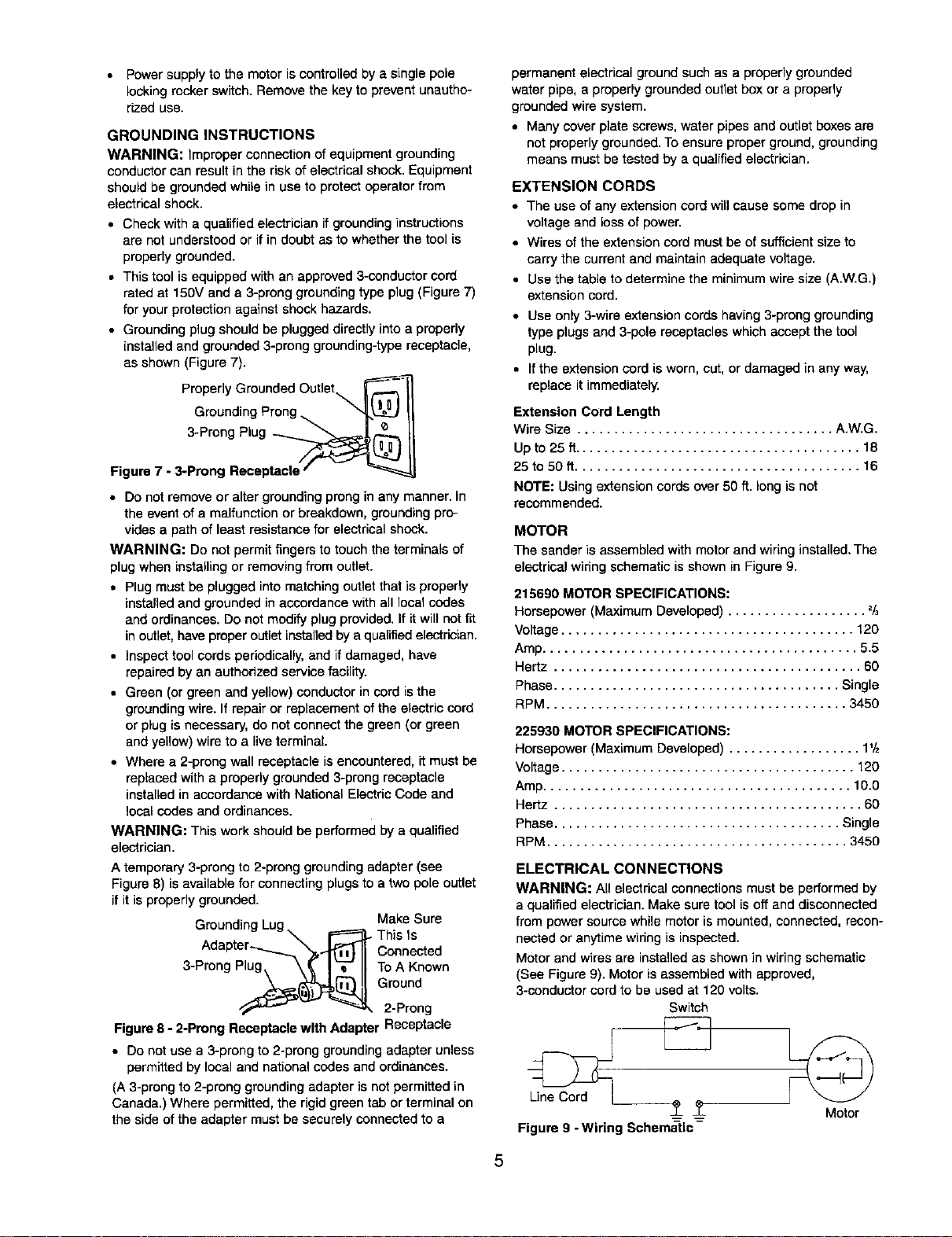

• This tool is equipped with an approved 3-conductor cord

rated at 150V and a 3-prong grounding type plug (Figure 7)

for your protection against shock hazards.

• Grounding plug should be plugged directly into a properly

installed and grounded 3-prong grounding-typo receptecie,

as shown (Figure 7).

Properly Grounded Outlet _-i(-_

3Grro_gdp,gu:'_{_/"JL %L_J '!

Figure 7 - 3-Prong Receptacle • --_===_J

• Do not remove or alter grounding prong in any manner. In

the event of a malfunction or breakdown, groundingpro-

vides a path of least resistance for electrical shock.

WARNING: Do not permit fingers to touch the terminals of

plug when installing or removing from outlet.

• Plug must be plugged into matching outlet that is properly

installedand grounded in accordance with all lecal codes

and ordinances. Do not modify plug provided. If itwill not fit

in outlet, have proper outlet installed by a qualified electrician.

• inspecttool cords periodically, and if damaged, have

repaired by an authorized service facility.

• Green (or green and yellow) conductor in cord isthe

grounding wire. If repair or replacement of the electric cord

or plug is necessary, do not connect the green (or green

and yellow) wire to a live terminal.

• Where a 2-prong wall receptacle is encountered, it must be

replaced with a properly grounded 3-prong receptacle

installed in accordance with National Electdc Cede and

local codes and ordinances.

WARNING: This work should be performed by a qualified

electrician.

A temporary 3-prong to 2-prong grounding adapter (see

Figure 8) is availablefor connecting plugs to a two pole outlet

if it is properly grounded.

Grounding Lug _ Make Sure

Adapter'_ "_.-t_ _ Connected

\ _ This Is

3-ProngPlug\ I'----"IImoAKnown

_L_l Ground

/-F*_-'_ _ 2-Prong

Figure 8 - 2-Prong Receptacle with Adapter Receptacle

• Do not use a 3-prong to 2-prong grounding adapter unless

permitted by local and national cedes and ordinances.

(A 3-prong to 2-prong grounding adapter is not permitted in

Canada.) Where permitted, the rigid green tab or terminal on

the side of the adapter must be securely connected to a

permanent electrical ground such as a properly grounded

water pipe, a properly grounded outlet box or a properly

grounded wire system.

• Many cover plate screws, water pipes and outlet boxes are

not properly grounded. To ensure proper ground, grounding

means must be tested by a qualified electrician.

EXTENSION CORDS

• The use of any extension cord will cause some drop in

voltage and loss of power.

• Wires of the extension cord must be of sufficient size to

carry the current and maintain adequate voltage.

• Use the table to determine the minimum wire size (A.W.G.)

extension cord.

• Use only 3-wire extension cords having 3-prong grounding

type plugs and 3-pole receptacles which accept the tool

plug.

• If the extension cord is worn, cut, or damaged in any way,

replace it immediately.

Extension Cord Length

Wire Size ................................... A.W.G.

Up to 25 ff....................................... 18

25 to 50tt ....................................... 16

NOTE: Using extensioncords over 50 ft. long isnot

recommended.

MOTOR

The sander is assembled with motorand wiringinstalled, The

electricalwiring schematicis shownin Figure 9.

215690 MOTOR SPECIFICATIONS:

Horsepower (Maximum Developed) ................... 2/3

Voltage........................................ 120

Amp........................................... 5.5

Hertz .......................................... 60

Phase....................................... Single

RPM ......................................... 3450

225930 MOTOR SPECIFICATIONS:

Horsepower (Maximum Developed) .................. 1V2

Voltage........................................ 120

Amp.......................................... 10.0

Hertz .......................................... 60

Phase ....................................... Single

RPM ......................................... 3450

ELECTRICAL CONNECTIONS

WARNING: All electrical connections must be performed by

a qualified electrician. Make suretool is off and disconnected

from powersource while motor is mounted, connected,recon-

nected or anytimewiring is inspected.

Motor and wiresare installed as shown in wiringschematic

(See Figure 9). Motor is assembled with approved,

3-conductor cord tobe used at 120volts.

Switch

_- _- Motor

Figure 9 -Wiring Schem_lc =

The power lines are inserted directly onto the switch. The

green ground line must remain securely fastened to the frame

to properly protect against electrical shock. The power supply

to the motor is controlled by a single pole locking rocker switch.

• Remove the key to prevent unauthorized use.

Refer to Figures 10 - 19.

DESCRIPTION

The Craftsman Belt and Disc Sanders are constructedof

rugged die cast aluminum and cast iron providing stability and

vibration-free operation. The belt and disc are used to sand,

deburr, bevel and grind large workpieces of wood and plastic.

The belt housing can be pivoted from vertical to

horizontal for sanding large, straight workpieces. The idler

drum permits the sanding of contoured shapes and finishes.

The disc can be used to sand or bevel surfaces.

Built-indust collection system collects dust from the belt and

disc, and exhausts the dust into an included 30-micron

collection bag.

The adjustable miter gauge can be used on both the belt and

disc tables for guiding the workpieca at a desired angle while

sanding. Work stop included for sanding longpieces on the

belt.

SPECIFICATIONS

MODEL 215690

Belt size .................................... 4 x 36"

Belt platenarea ............................... 5 x 9"

Belt speed ................................ 1900 FPM

Disc diameter .................................... 8"

Disc speed ............................... 3000 RPM

Table dimensions.............................. 6 x 9"

Table tilts ................................... 0 to 45"

Dust port diameter ................................ 2"

Base dimensions ............................ 12 x 17"

Switch ............................. SR Lockingrocker

Weight ...................................... 77 Ibs

MODEL 225930

Belt size .................................... 6 x 48"

Belt platen area .............................. 7 x 17"

Belt speed ................................ 2700 FPM

Disc diameter .................................... 9"

Disc speed ............................... 3500 RPM

Table dimensions ............................. 7 x 10"

Table tilts................................... 0 to 45°

Dust portdiameter ................................ 2"

Base dimensions........................... 15%x 20"

Switch ............................. SP,Lockingrocker

Weight ..................................... 110 Ibs

WARNING: Operation of any powertool can result inforeign

objectsbeing thrown into the eyes, which can result in severe

eye damage. Always wear safety gogglescomplyingwith

United States ANSI Z87.1 (shownon package) before com-

mencing powertooloperation. Safety gogglesare availableat

Sears retail stores or catalog.

CAUTION: Always observe following safety precautions.

SAFETY PRECAUTIONS

• Whenever adjustingor replacing any parts on the tool, turn

switchOFF and removethe plug from power source.

• Recheck table knob and bolts. They must be tightened

securely.

• Make sure all guards are properly attached. All guards

should be securely fastened.

• Make sure all moving parts are free and clear of any

interference,

• Make sure all fasteners are tight and have not vibrated loose.

• With power disconnected, test operation by hand for clear-

ance and adjustif necessary.

• Always wear eye protection or face shield.

• Make sure abrasive belt always tracks properly. Correct

tracking gives optimum performance.

• After turning switch on, always allow belt and disc to come

up to full speed before sanding or grinding.

• Be sure disc turns counterclockwise. Abrasive belt must

travel downward.

• Avoid kickback by sanding in accordance with the direction-

al arrows.

• Keep your hands clear of abrasive belt, disc and all moving

parts.

• For optimum performance, do not stall motor or reduce

speed. Do not force the work into the abrasive.

• Always support workpiece with table or work stop when

sanding with belt and with table when sanding with disc.

• Never push a sharp corner of the workpiece rapidlyagainst

the belt or disc. Abrasive backing may tear.

• Replace abrasives when they become loaded (glazed) or

frayed.

ON/OFF SWITCH

Refer to Figure 10, page 7.

The ON/OFF switchis located on the upper front right ofthe

cabinet. Toturn the sander ON, pull the switchto the up

position.Toturn the sander OFF, push the switch to the down

position.

The sander can be locked from unauthorized use by locking

the switch. To lockthe switch:

• Turn the switch to OFF position and disconnect sander

from power source.

• Pull the key out.The switch cannot be turned on with the

key removed.

NOTE: Should the key be removed from the switch at the ON

position, the switch can be turned off but cannot be turned on

again.

• To replace key, slide key into the slot on switch until it snaps.

Figure 10 - Locking Switch in OFF Position

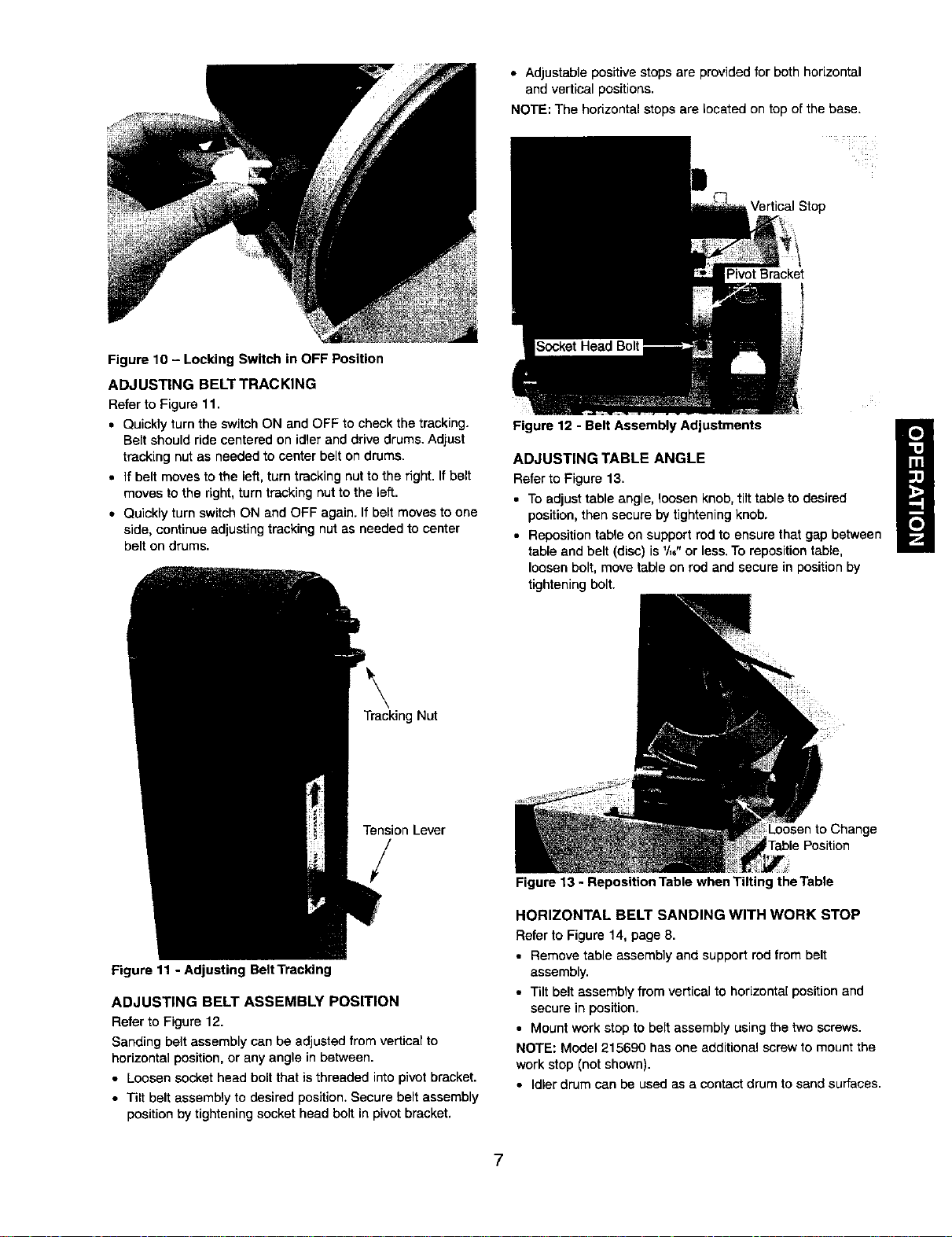

ADJUSTING BELT TRACKING

Refer to Figure 11.

• Quickly turn the switchON and OFF to check the tracking.

Boltshould ride centered on idlerand drive drums. Adjust

tracking nutas needed to center belt on drums.

• ff belt moves tothe left, turn trackingnut to the fight. Ifbelt

moves to the right,turn trackingnut to the left.

• Quickly turnswitch ON and OFF again. If belt moves to one

side, continue adjusting tracking nutas needed to center

belt on drums.

• Adjustable positive stops are provided for both horizontal

and vertical positions.

NOTE: The horizontal stops are located on top of the base.

Vertical Stop

Pivot Bracket

Figure 12 - Belt Assembly Adjustments

ADJUSTING TABLE ANGLE

Referto Figure 13.

• To adjust table angle, loosen knob,tilt table to desired

position,then secure by tighteningknob.

• Repositiontable on support rodto ensure thatgap between

table and belt (disc) is1/,,,or less.To repositiontable,

loosenbolt, move tableon rod and secure in position by

tightening bolt.

lq

lJ

Tracking Nut

Tension Lever

/

Figure 11 - Adjusting Belt Tracking

ADJUSTING BELT ASSEMBLY POSITION

Refer to Figure 12.

Sanding belt assembly can be adjusted from vertical to

horizontal position, or any angle in between.

• Loosen socket head bolt that is threaded into pivot bracket.

• Tilt belt assembly to desired position. Secure belt assembly

position by tightening socket head bolt in pivot bracket.

Loosen to Change

_TablePosition

Figure 13 - Reposition Table when Tilting the Table

HORIZONTAL BELT SANDING WITH WORK STOP

Refer to Figure 14, page 8.

• Remove table assembly and support rodfrom belt

assembly.

• Tilt belt assembly from vertical to horizonta[position and

secure in position.

• Mount work stopto beltassembly using thetwo screws.

NOTE: Model 215690 has one additionalscrew to mountthe

work stop (not shown).

• Idlerdrum can be used as a contact drum to sand surfaces.

Figure 14 - Attaching the Work Stop

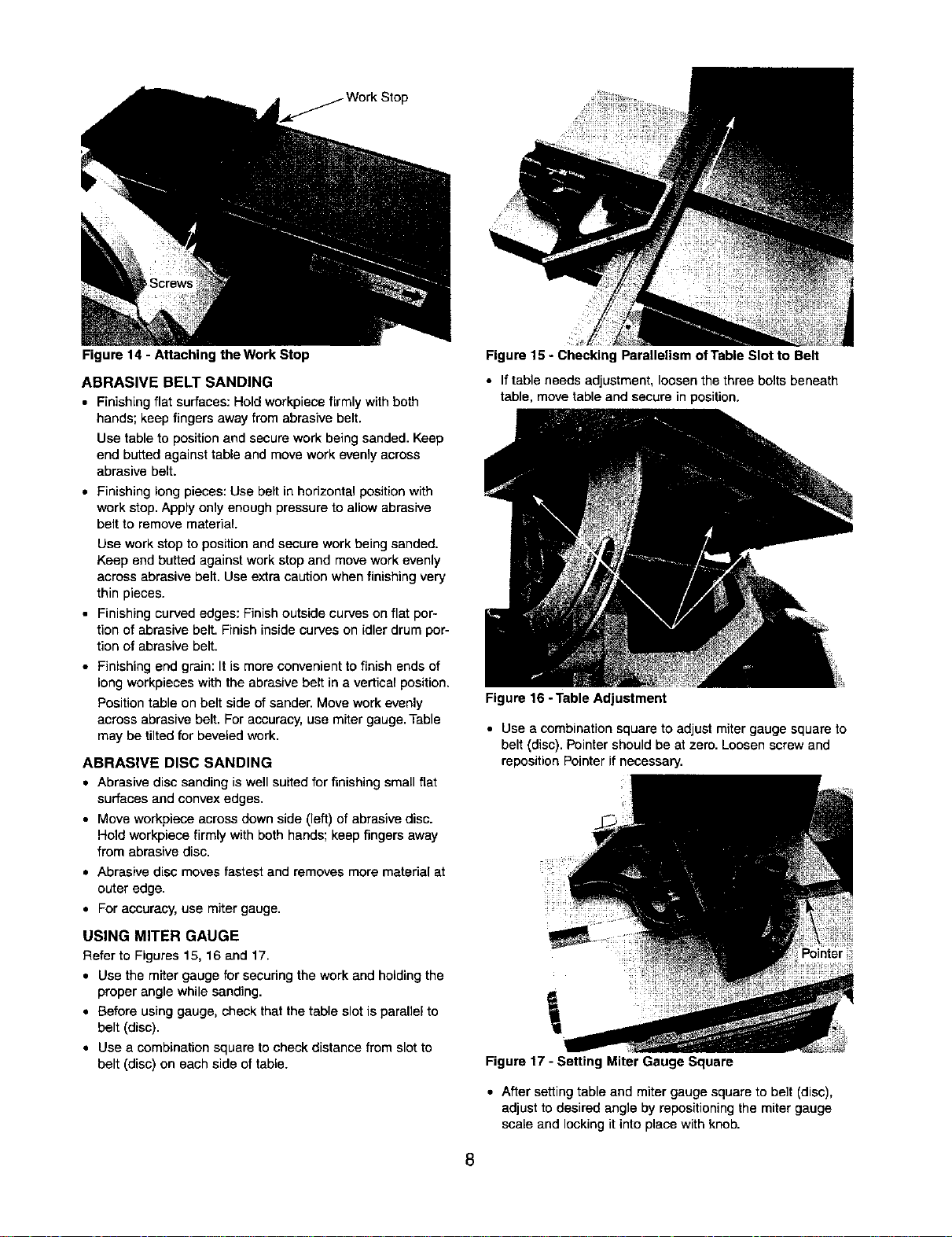

ABRASIVE BELT SANDING

• Finishing flat surfaces: Hold workpiece firmly withboth

hands; keep fingers away from abrasive belt.

Use table to position and secure work being sanded. Keep

end butted against table and move work evenly across

abrasive belt.

• Finishing long pieces: Use belt in horizontal position with

work stop. Apply only enough pressure to allow abrasive

belt to remove material

Use work stop to positionand secure work being sanded.

Keep end butted against work stop and move work evenly

across abrasive belt. Use extra caution when finishing very

thin pieces.

• Finishing curved edges: Finish outside curves on flat por-

tion of abrasive belt. Finish inside curves on idler drum por-

tion of abrasive belt.

• Finishing end grain: It is more convenient to finish ends of

long workpieces with the abrasive belt in a vertical position.

Positiontable on belt side of sander. Move work evenly

across abrasive belt. For accuracy, use miter gauge. Table

may be tilted for beveled work.

ABRASIVE DISC SANDING

• Abrasive disc sanding is well suited for finishing small flat

surfaces and convex edges.

• Move workpiece across down side (left) of abrasive disc.

Hold workpiece firmly with both hands; keep fingers away

from abrasive disc.

• Abrasive disc moves fastest and removes more material at

outer edge.

• For accuracy, use miter gauge.

USING MITER GAUGE

Refer to Figures 15, 16 and 17.

• Use the miter gauge for securing the work and holding the

proper angle while sanding.

• Before using gauge, check that the table slot is parallel to

belt (disc).

• Use a combination square to check distance from slot to

belt (disc) on each side of table.

Figure 15 - Checking Parallelism ofTable Slot to Belt

• If table needs adjustment, loosenthe three boltsbeneath

table, movetable and secure in position.

Figure 16 - Table Adjustment

• Use a combination square to adjust mitergauge square to

belt (disc). Pointer should be at zero. Loosen screw and

reposition Pointer if necessary.

Figure 17 - Setting Miter Gauge Square

• After setting table and miter gauge square to belt (disc),

adjust to desired angle by repositioning the miter gauge

scale and locking itinto place with knob.

8

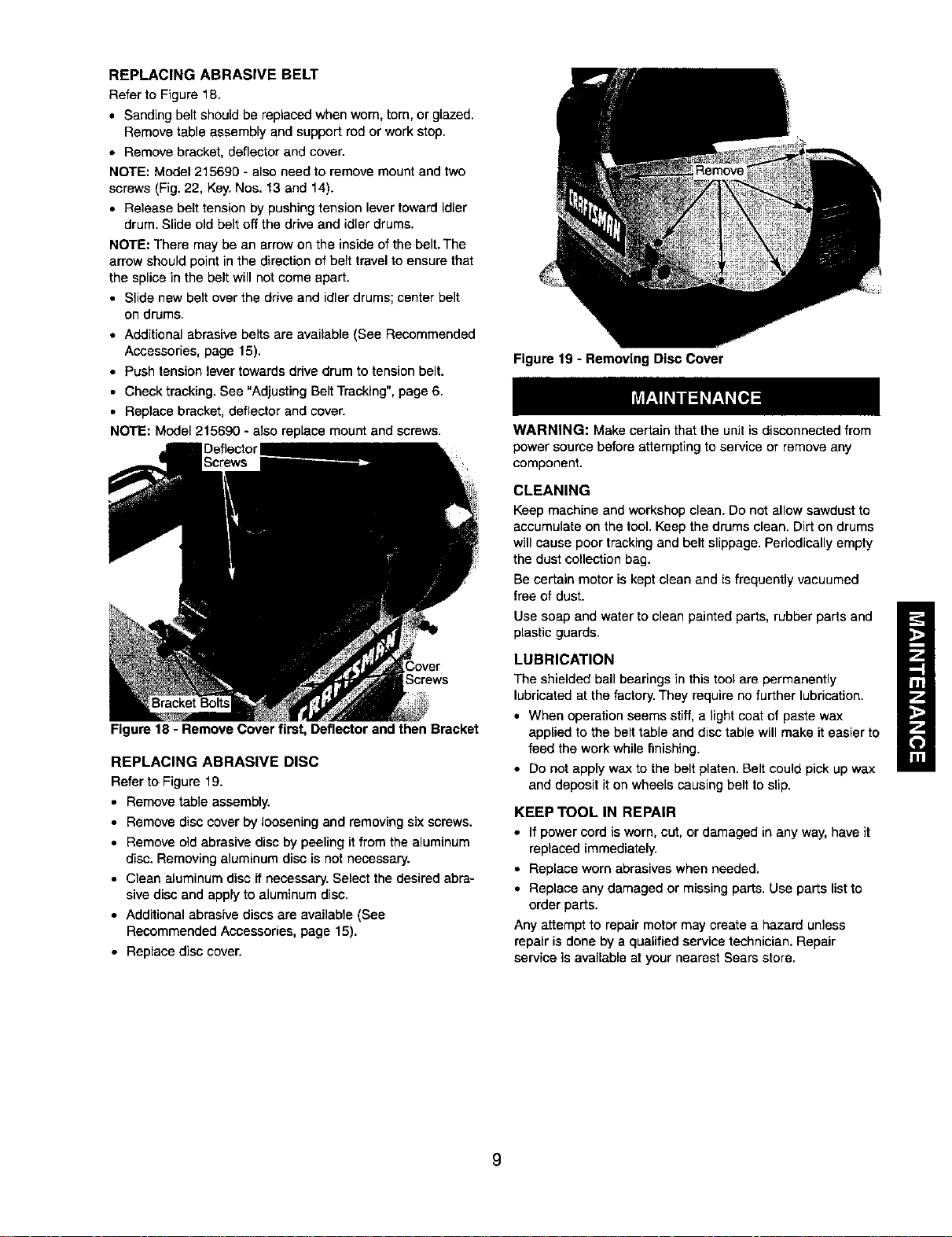

REPLACING ABRASIVE BELT

Refer to Figure 18.

• Sanding belt should be replaced when worn, torn, or glazed.

Remove table assembly and support rod or work stop.

• Remove bracket, deflector and cover.

NOTE= Model 215690 - also need to remove mount and two

screws (Fig. 22, Key. Nos. 13 and 14).

• Release belt tension by pushing tension lever toward idler

drum. Slide old belt off the drive and idler drums.

NOTE: There may be an arrow on the inside of the belt. The

arrow should point in the direction of belt travel to ensure that

the splice in the belt will not come apart.

• Slide new belt over the drive and idler drums; center belt

on drums.

• Additional abrasive belts are available (See Recommended

Accessories, page 15).

• Push tension lever towards drive drum to tension belt.

• Check tracking. See "Adjusting Belt Tracking", page 6.

• Replace bracket, deflector and cover.

NOTE: Model 215690 - also replace mount and screws.

_crews

Figure 18 - Remove Cover first, Deflector and then Bracket

REPLACING ABRASIVE DISC

Refer to Figure 19.

• Remove table assembly.

• Remove disc cover by loosening and removing six screws.

• Remove old abrasive disc by peeling it from the aluminum

disc. Removing aluminum disc is not necessary.

• Clean aluminum disc ff necessary. Select the desired abra-

sive disc and apply to aluminum disc.

• Additional abrasive discs are available (See

Recommended Accessories, page 15).

• Replace disc cover.

Figure 19 - Removing Disc Cover

WARNING: Make certain that the unit is disconnected from

power source before attempting to service or remove any

component.

CLEANING

Keep machine and workshopclean. Do not allow sawdust to

accumulate on the tool. Keep the drums clean. Dirt on drums

will cause poor tracking and belt slippage. Periodically empty

the dust collection bag.

Be certain motor is kept clean and is frequently vacuumed

free of dust.

Use soap and water to clean painted parts, rubber parts and

plastic guards.

LUBRICATION

The shielded ball bearings in this tool are permanently

lubricated at the factory. They require no further lubrication.

• When operation seems stiff, a light coat of paste wax

applied to the belt table and disc table will make it easier to

feed the work while finishing.

• Do not apply wax to the belt platen. Belt could pick up wax

and deposit it on wheels causing belt to slip.

KEEP TOOL IN REPAIR

• If power cord is worn, cut, or damaged in any way, have it

replaced immediately.

• Replace worn abrasiveswhen needed.

• Replace any damaged or missing parts. Use parts list to

order parts.

Any attempt to repair motor may create a hazard unless

repair is done by aqualified servicetechnician.Repair

service is available at your nearest Sears store.

9

Loading...

Loading...