Craftsman 32061325 Owner’s Manual

12.0-VOLT LiTHiUM-iON

CORDLESS 3-3/8 in. CIRCULAR SAW

Model No. 320.61325

ENERGYSTAR®

_ owered by an

__ charger for a

qualified battery

better environment

WARNING: To reduce the risk of

injury, the user must read and understand

* Warranty

* Safety

*Assernbly

* Operation

* Maintenance

the Operator's manual before using

this product.

Sears Brands Management Corporation, Hoffman Estates, IL 60179 U.S.A.

www,crsftsrnan,corn

Charge battery

before first use

Warranty Page 2

Safety Symbols Page 3

Safety Instructions Pages 5-10

Glossary of Woodworking Terms Pages 10-11

Description Pages 12-13

Assembly Page 14

Operation Pages 14-30

Maintenance Pages 30-32

Troubleshooting Page 32

Exploded View and Parts List Page 33-36

Sears Repair Parts Phone Number Back Cover

CRAFTSMAN ONE YEAR FULL WARRANTY

FOR ONE YEAR from the date of purchase, this product is warranted

against any defects in material or workmanship. Defective product will be

replaced free of charge.

For warranty coverage details to obtain free replacement, visit the

web site: www.craftsman.com.

This warranty does not cover blades and bulbs, which are expendable

parts that can wear out from normal use within the warranty period.

This warranty is void if this product is ever used while providing

commercial services or if rented to another person.

This warranty gives you specific legal rights, and you may also have other

rights which vary from state to state.

Sears Brands Management Corporation, Hoffman Estates, IL 60179

SAVE THESE iNSTRUCTIONS!

READ ALL iNSTRUCTIONS

This cordless circular saw has many features for making its use more pleasant

and enjoyable. Safety, performance, and dependability have been given top

priority in the design of this product making it easy to maintain and operate.

WARNING: Some dust created by using power tools contains chemicals

known to the state of California to cause cancer and birth defects or other

reproductive harm.

61325 Manual_Revised_lO 0225 Page 2

The purpose of safety symbols is to attract your attention to possible dangers.

The safety symbols and the explanations with them deserve your careful

attention and understanding. The symbol warnings do not by themselves

eliminate any danger. The instructions and warning they give are no substitutes

for proper accident-prevention measures.

WARNING: Be sure to read and understand all safety instructions in this

manual, including all safety alert symbols such as "DANGER," "WARNING,"

and "CAUTION" before using this saw. Failure to following all instructions listed

below may result in electric shock, fire and/or serious personal injury.

SYMBOL SIGNAL MEANING

,_ SAFETY ALERT SYMBOL: Indicates DANGER, WARNING, OR CAUTION.

May be used in conjunction with other symbols or pictographs.

DANGER: Indicates an imminently hazardous situation, which, if not

avoided, will result in death or serious injury.

WARNING: Indicates a potentially hazardous situation, which, if not avoided,

could result in death or serious injury.

A_, CAUTION: Indicates an imminently hazardous situation, which, if not

avoided, may result in death or serious injury.

NOTE: These inform the user of import information and/or instructions that

could lead to equipment or other property damage if they are not followed. Each

message is preceded by the word "NOTE," as in the example below:

NOTE: Equipment and/or property damage may result if these instructions are

not followed.

WARNING: To ensure safety and reliability, all repairs should be performed

by a qualified service technician at Sears Service Center.

,_ WARNING: The operation of any power tools can result in

foreign objects being thrown into your eyes, which can result in

severe eye damage. Before beginning power tool operation,

always wear safety goggles or safety glasses with side shield

and a full face shield when needed. We recommend a Wide

Vision Safety Mask for use over eyeglasses or standard safety

glasses with side shields. Always use eye protection which is

marked to comply with ANSI Z87.1

SAVE THESE INSTRUCTIONS

6t325 Manual_Revised_lO 0225 Page 3

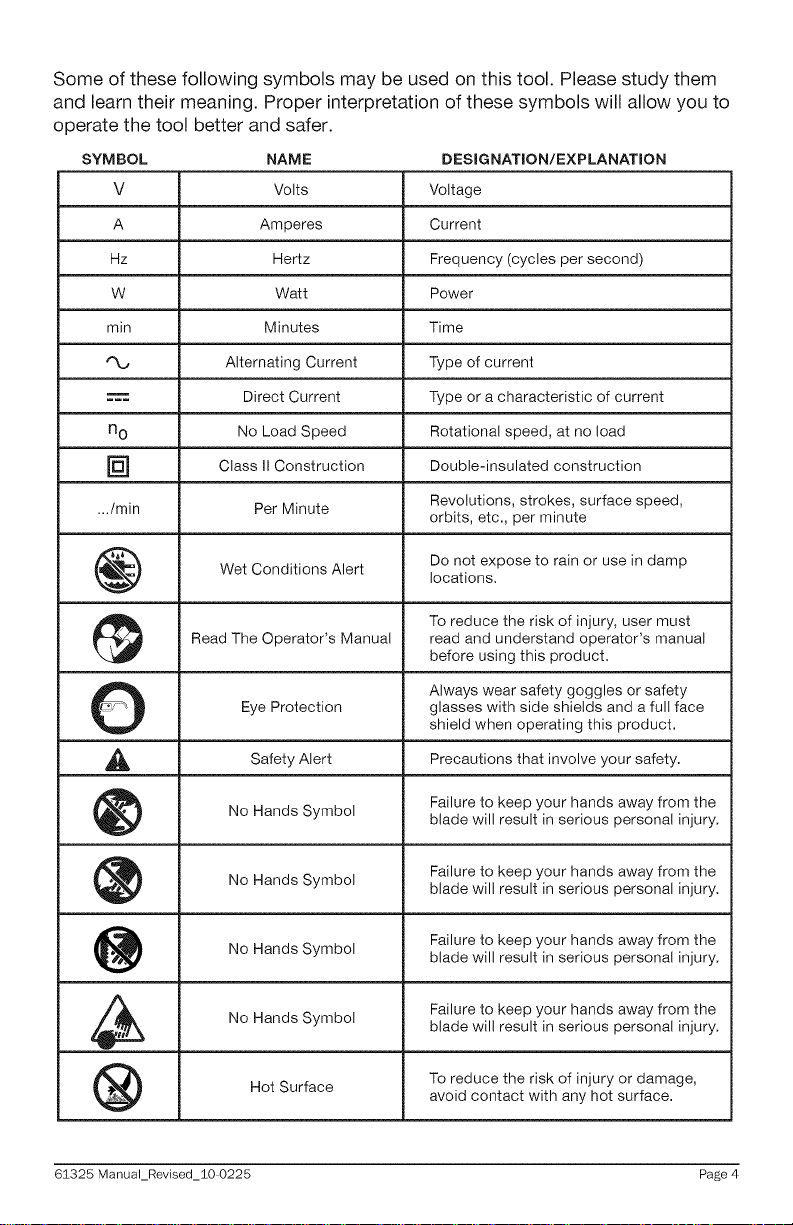

Some of these following symbols may be used on this tool. Please study them

and learn their meaning. Proper interpretation of these symbols will allow you to

operate the tool better and safer.

SYMBOL NAME DESIG NATION/EXPLANATION

V Volts Voltage

A Amperes Current

Hz Hertz Frequency (cycles per second)

W Watt Power

min Minutes Time

"_ Alternating Current Type of current

Direct Current Type or a characteristic of current

n o No Load Speed Rotational speed, at no load

] Class II Construction Double-insulated construction

.../min Per Minute Revolutions, strokes, surface speed,

Wet Conditions Alert locations.

i_ To reduce the risk of injury, user must

O Always wear safety goggles or safety

Read The Operator's Manual read and understand operator's manual

Eye Protection glasses with side shields and a full face

Safety your safety.

Alert Precautions that involve

No Hands Symbol Failure to keep your hands away from theblade will result in serious personal injury.

No Hands Failure to keep your hands away from the

No Hands Failure to keep your hands away from the

No Hands Symbol Failure to keep your hands away from the

Symbol

Symbol

orbits, etc., per minute

Do not expose to rain or use in damp

before using this product.

shield when operating this product.

blade will result in serious personal injury.

blade will result in serious personal injury.

blade will result in serious personal injury.

Hot Surface To reduce the risk of injury or damage,avoid contact with any hot surface.

63_325Manual_Revised_lO 0225 Page 4

GENERAL SAFETY RULES

A

WARNING: Read all safety warnings and instructions. Failure to follow the

warnings and instructions may result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

The term "power tool" in the warnings refers to your mains-operated (corded)

power tool or battery-operated (cordless) power tool.

WORK AREA SAFETY

= Keep work area clean and well lit. Cluttered or dark areas invite accidents.

• Do not operate power tools in explosive atmospheres, such as in the

presence of flammable liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

= Keep children and bystanders away while operating a power tool.

Distractions can cause you to lose control.

ELECTRICAL SAFETY

= Power tool plugs must match the outlet. Never modify the plug in any

way. Do not use any adapter plugs with earthed (grounded) power tools.

Unmodified plugs and matching outlets will reduce risk of electric shock.

= Avoid body contact with earthed or grounded surfaces such as pipes,

radiators, ranges and refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

= Do not expose power tools to rain or wet conditions. Water entering a

power tool will increase the risk of electric shock.

= Do not abuse the cord. Never use the cord for carrying, pulling or

unplugging the power tool Keep cord away from heat, oil, sharp edges or

moving parts. Damaged or entangled cords increase the risk of electric shock.

= When operating a power tool outdoors, use an extension cord suitable

for outdoor use. Use of a cord suitable for outdoor use reduces the risk of

electric shock.

= if operating a power tool in a damp location is unavoidable, use a

residual current device (RCD) protected supply. Use of an RCD reduces

the risk of electric shock.

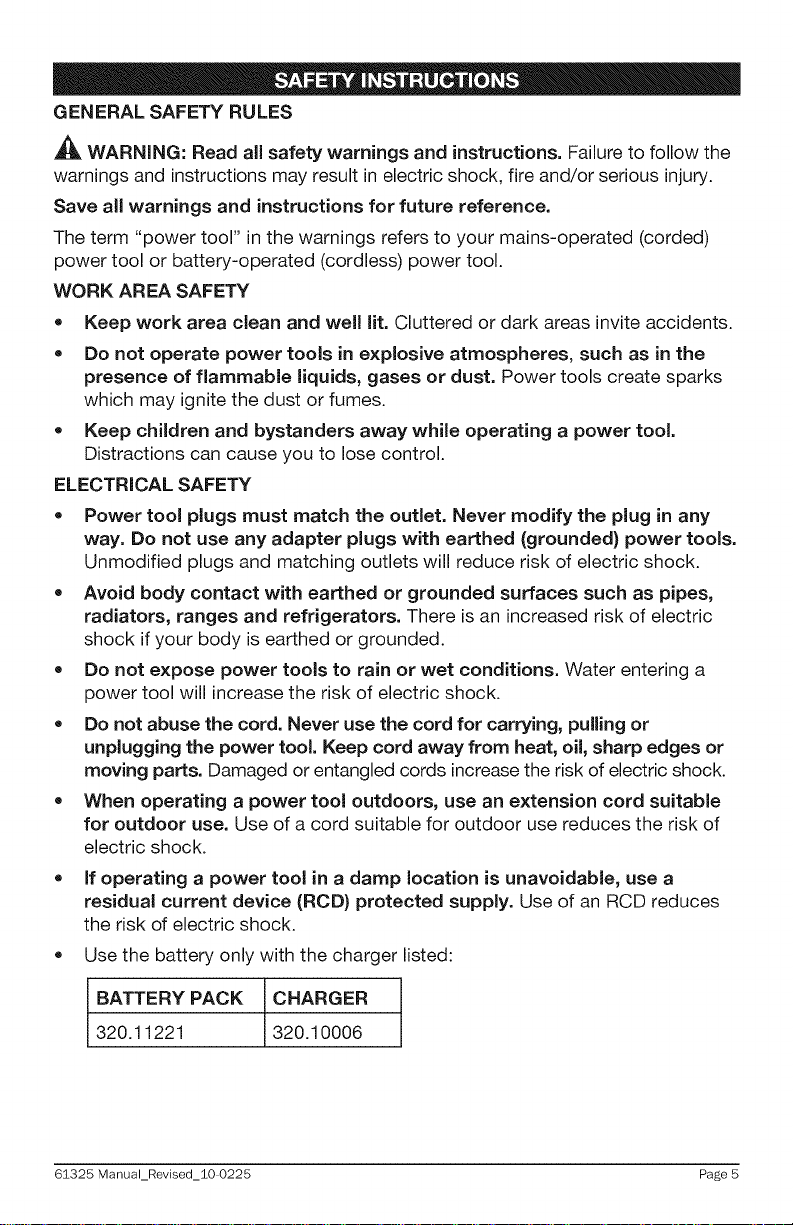

• Use the battery only with the charger listed:

BATTERY PACK CHARGER

320.11221 320.10006

61325 Manual_Revised_lO 0225 Page 5

PERSONAL SAFETY

= Stay alert, watch what you are doing and use common sense when

operating a power tool. Do not use tool while tired or under the

influence of drugs, alcohol, or medication. A moment of inattention while

operating power tools may result in serious personal injury.

= Use personal protective equipment. Always wear eye protection. Protective

equipment, such as dust mask, non-skid safety shoes, hard hat, or hearing

protection, used for appropriate conditions will reduce personal injuries.

= Prevent unintentional starting. Ensure that the switch is in the OFF

position before connecting to power source and/or battery pack, picking

up, or carrying the tool. Carrying power tools with your finger on the switch

or energizing in power tools that have the switch on invites accidents.

= Remove any adjusting key or wrench before turning the power tool on.

A wrench or a key left attached to a rotating part of the power tool may result

in personal injury.

• Do not overreach. Keep proper footing and balance at all times. This

enables better control of the power tool in unexpected situations.

• Dress properly. Do not wear loose clothing or jewelery. Keep your hair,

clothing and gloves away from moving parts. Loose clothes, jewelry or

long hair can be caught in moving parts.

= If devices are provided for the connection of dust extraction and

collection facilities, ensure these are connected and properly used. Use

of these devices can reduce dust-related hazards.

POWER TOOL USE AND CARE

Do not force the power tool. Use the correct power tool for your

application. The correct power tool will do the job better and more safely at

the rate for which it was designed.

Do not use the power tool if the switch does not turn it on and off. Any power

tool that cannot be controlled with the switch is dangerous and must be repaired.

Disconnect the plug from the power source and/or the battery pack

from the power tool before marking any adjustments, changing

accessories, or storing power tools. Such preventive safety measures

reduce the risk of starting the power tool accidentally.

Store idle power tools out of the reach of children and do not allow

persons unfamiliar with the power tool or these instructions to operate

the power tool. Power tools are dangerous in the hands of untrained users.

= Maintain power tools. Check for misalignment or binding of moving

parts, breakage of parts and any other condition that may affect the

power tool's operation, if damaged, have the power tool repaired before

use. Many accidents are caused by poorly maintained power tools.

= Keep cutting tools sharp and clean. Properly maintained cutting tools with

sharp cutting edges are less likely to bind and are easier to control.

61325 Manual_Revised_10 0225 Page 6

Use the power tool, accessories and, tool bits etc. in accordance with

these instructions, taking into account the working conditions and the

work to be performed. Use of the power tool for operations different from

those intended could result in a hazardous situation.

BATTERY TOOL USE AND CARE

• Recharge only with the charger specified by the manufacturer. A charger

that is suitable for one type of battery pack may create a risk of fire when

used with another battery pack.

• Use power tools only with specifically designated battery packs. Use of

any other battery packs may create a risk of injury and fire.

• When battery pack is not in use, keep it away from other metal objects,

such as paper clips, coins, keys, nails, screws or other small metal

objects, that can make a connection from one terminal to another.

Shorting the battery terminals together may cause burns or a fire.

• Under abusive conditions, liquid may be ejected from the battery;

avoid contact, if contact accidentally occurs, flush with water, if liquid

contacts eyes, additionally seek medical help. Liquid ejected from the

battery may cause irritation or burns.

SERVICE

• Have your power tool serviced by a qualified repair person using only

identical replacement parts. This will ensure that the safety of the power

tool is maintained.

• When servicing a power tool, use only identical replacement parts.

• Follow instructions in the Maintenance section of this manual. Use of

unauthorized parts or failure to follow Maintenance instructions may create a

risk of shock or injury.

SPECiFiC SAFETY RULES FOR CIRCULAR SAW

_, DANGER: Keep hands and body away from and to the side of the blade.

Contact with blade will result in serious injury.

WARNING: To reduce the risk of injury, check guarding system. It must

cover the blade instantly! Hold the saw with both hands. Support and clamp

work. Wear eye protection.

DANGER: Keep hands away from cutting area and the blade. Keep your

second hand on the auxiliary handle or motor housing. If both hands are

holding the saw, they cannot be cut by the blade.

61325 Manual_Revised_lO 0225 Page 7

• Do not reach underneath the workpiece. The guard cannot protect you

from the blade below the workpiece.

• Adjust the cutting depth to the thickness of the workpiece. Less than a

full tooth of the blade should be visible below the workpiece.

• Never hold the piece being cut in your hands or across your leg. Secure

the workpiece to a stable platform, it is important to support the work

properly to minimize body exposure, blade binding or loss of control.

= Hold the power tool by its insulated gripping surfaces when performing

an operation where the cutting tool may contact hidden wiring or its

own cord. Contact with a "live" wire will also make exposed metal parts of

the tool "live" and shock the operator.

= When ripping, always use a rip fence or straight edge guide (sold

separately). This improves the accuracy of cut and reduces the chance of

blade binding.

= Always use blades with the correct size and shape of arbor holes.

Blades that do not match the mounting hardware of the saw will run

erratically, causing loss of control.

= Never use damaged or incorrect blade washers or bolt. The blade

washers and bolt were specially designed for your saw for optimum

performance and safety of operation.

CAUSES AND OPERATOR PREVENTION OF KICKBACK:

• Kickback is a sudden reaction to a pinched, bound or misaligned saw

blade, causing an uncontrolled saw to lift up and out of the workpiece

toward the operator.

When the blade is pinched or bound tightly by the kerf closing down, the blade

stalls and the motor reaction drives the unit rapidly back toward the operator.

If the blade becomes twisted or misaligned in the cut, the teeth at the back

edge of the blade can dig into the top surface of the wood causing the blade

to climb out of the kerf and jump back toward the operator. Kickback is the

result of misuse and/or incorrect operating procedures or conditions and can

be avoided by taking proper precautions, as given below:

Maintain a firm grip with both hands on the saw and position your arms

to resist kickback forces. Position your body to either side of the blade,

but not in line with the blade. Kickback could cause the saw to jump

backwards, but kickback forces can be controlled by the operator, if proper

precautions are taken.

• When blade is binding or when interrupting a cut for any reason, release

the trigger and hold the saw motionless in the material until the blade

comes to a complete stop. Never attempt to remove the saw from the

work or pull the saw backward while the blade is in motion or kickback

may occur. Investigate and take corrective actions to eliminate the cause of

blade binding.

61325 Manual_Revised_lO 0225 Page 8

When restarting a saw in the workpiece center the saw blade in the kerf

and check that saw teeth are not engaged into the material, if the saw

blade is binding, it may walk up or kickback from the work piece as the saw

is restarted.

• Support large panels to minimize the risk of blade pinching and

kickback. Large panels tend to sag under their own weight. Supports must

be placed under the panel on both sides, near the line of cut and near the

edge of the panel.

= Do not use dull or damaged blades. Unsharpened or improperly set blades

produce a narrow kerr, causing excessive friction, blade binding and kickback.

= Blade depth and bevel adjusting locking levers must be tight and secure

before making a cut. If the blade adjustment shifts while cutting, it may

cause binding and kickback.

= Use extra caution when making a "plunge cut" into existing walls or other

blind areas. The protruding blade may cut objects that can cause kickback.

• Check the lower guard for proper closing before each use. Do not

operate the saw if the lower guard does not move freely and close

instantly. Never clamp or tie the lower guard into the open position. If

the saw is accidentally dropped, the lower guard may be bent. Raise the

lower blade guard with the retracting handle. Make sure it moves freely and

does not touch the blade or any other part, in all angles and depths of cut.

• Check the operation of the lower guard spring, if the guard and the

spring are not operating properly, they must be serviced before use. The

lower guard may operate sluggishly due to damaged parts, gummy deposits

or a build-up of debris.

= Lower guard should be retracted manually only for special cuts such

as "plunge cuts" and "compound cuts." Raise the lower blade guard

with the retracting handle. As soon as the blade enters the material, the

lower guard must be released. For all other sawing, the lower guard should

operate automatically.

= Always observe that the lower guard is covering the blade before placing

the saw down on a bench or the floor. An unprotected, coasting blade will

cause the saw to walk backwards, cutting whatever is in its path. Be aware of

the time it takes for the blade to stop after the switch is released.

= When making a plunge cut with the bevel setting other than 90 °, ensure

that the guide plate of the saw will not shift. While performing the

"plunge cut" when the blade bevel setting is not at 90 °. Blade A blade

shifting sideways will cause binding and likely kick back.

= Use the appropriate riving knife for the blade being used. For the riving

knife to work, it must be thicker than the body of the blade, but thinner than

the tooth set of the blade.

61325 Manual_Revised_lO 0225 Page 9

= Adjust the riving knife as described in this instruction manual. Incorrect

spacing, positioning and alignment can make the riving knife ineffective in

preventing kickback.

= Always use the riving knife except when plunge cutting. The riving knife

must be replaced after plunge cutting. The riving knife causes interference

during plunge cutting and can create kickback.

= For the riving knife to work, it must be engaged in the workpiece. The

riving knife is ineffective in preventing kickback during short cuts.

= Do not operate the saw if riving the knife is bent. Even a slight

interference can slow the closing rate of a guard.

• Hold power tool by insulated gripping surfaces when performing an

operation where the cutting tool may contact hidden wiring or its own

cord. Contact with a "live" wire will also make exposed metal parts of the

tool "live" and shock the operator.

Spindle

The shaft on which a blade or cutting tool is mounted. Also called the Arbor.

Revolutions Per Minute (RPM)

The number of turns completed by a spinning object in one minute.

Saw Blade Path

The area over, under, behind or in front of the blade, as it applies to the

workpiece. That area which will be or has been cut by the blade.

Set

The distance that the saw blade tooth is bent (or set) outward from the face of

the blade.

Miter Cut

A cutting operation made with the blade at any angle other than 90o to the fence.

Compound Miter Cut A compound miter cut is a cut made using a miter angle

and a bevel angle at the same time.

Cross cut

A cutting or shaping operation made against the grain of the workpiece.

Bevel Cut

A cutting operation made with the blade at any angle other than 90o to the miter table.

Dado Cut

A non-through cut which produces a square-sided notch or trough in the

workpiece (requires special blade).

Chamfer Cut

A cut removing a wedge from a block of wood so the end (or part of the end) is

angled at other than 90 °.

61325 Manual_Revised_10 0225 Page 10

Ripping or Rip Cut

A cutting operation along the length of the workpiece.

Freehand Cut

Performing a cut without using a fence, miter gauge, fixture, work clamp, or

otherproper device to keep the workpiece from twisting or moving during the cut.

Through Sawing

Any cutting operation where the blade extends completely through the thickness

of the workpiece.

Non-Through Cuts

Any cutting operation where the blade does not extend completely through the

thickness of the workpiece, like a dado cut.

Leading End

The end of the workpiece pushed into tool first.

Kerr

The material removed by the blade in a through cut or the slot produced by the

blade in a non-through or partial cut.

Kickback

A hazard that can occur when the blade binds or stalls, throwing the workpiece

back toward operator.

Workpiece or Material

The item on which the cutting operation is being done. The surfaces of a

workpiece are commonly referred to as faces, ends and edges.

Gum

A sticky, sap-based residue from wood products.

Resin

A sticky, sap-based substance that has hardened.

61325 Manual_Revised_10 0225 Page 11

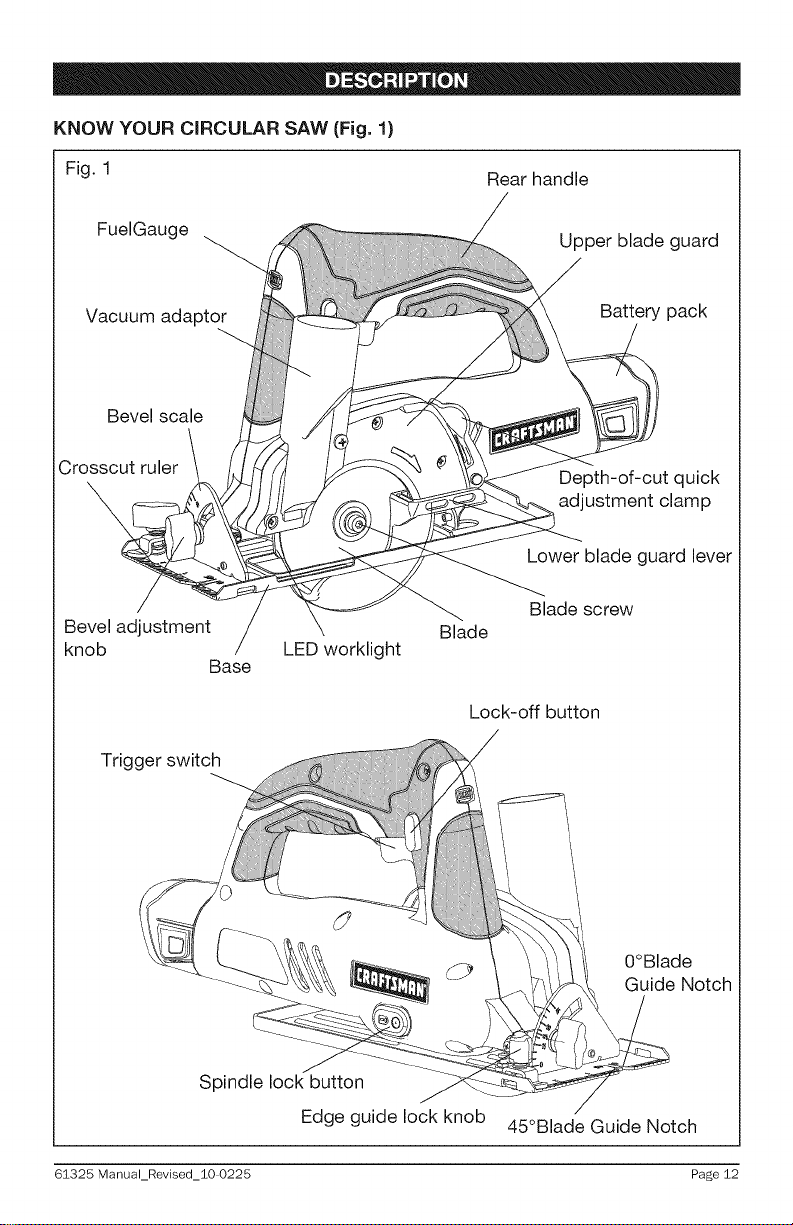

KNOW YOUR CIRCULAR SAW (Fig. 1)

Fig. 1

FuelGauge

Vacuum adaptor

Bevel scale

Crosscut ruler

Bevel adjustment

knob

Base

Rear handle

Upper blade guard

Battery pack

Depth-of-cut quick

adjustment clamp

Lower blade guard lever

Blade screw

Blade

LED worklight

Lock-off button

Trigger switch

0°Blade

Guide Notch

Spindle lock button

Edge guide lock knob

61325 Manual_Revised_lO 0225 Page 12

45°Blade Guide Notch