Craftsman 32057271 Owner’s Manual

Operator's ManuaJ

®

C3 1/4" iMPACT DRIVER

Model No. 5727.1

* WARRANTY

®

LISTED

_WARNING: To reduce the risk of injury,

the user must read and understand the

Operator's Manual before using this product.

Sears Brands Management Corporation, Hoffman Estates,

IL 60179 U.S.A.

www, craftsman,com

* SAFETY

* DESCRiPTiON

* ASSEMBLY

* OPERATION

* MAINTENANCE

* ESPANOL

Warranty Page 2

Safety Symbols Pages 4-5

Safety Instructions Pages 6-8

Description Pages 9-10

Assembly Page 10

Operation Pages 11-14

Maintenance Page 15

Troubleshooting Page 15

Parts List Pages 16-17

CRAFTSMAN LiMiTED WARRANTY

FOR ONE YEAR from the date of sale, this product is warranted against any

defects in material or workmanship.

WITH PROOF OF SALE, a defective product will be replaced free of charge.

For warranty coverage details to obtain free replacement, visit the web

page: www.craftsman.com/warranty

This warranty does not cover the bit, which is an expendable part that can

wear out from normal use within the warranty period.

This ONE YEAR warranty is void if this product is ever used while providing

commercial services or if rented to another person. For 90 DAY commercial

and rental use terms, see the Craftsman warranty web page.

This warranty gives you specific legal rights, and you may also have other

rights which vary from state to state.

Sears Brands Management Corporation, Hoffman Estates, IL 60179.

SAVE THESE INSTRUCTIONS!

READ ALL INSTRUCTIONS!

This impact driver has many features for making its use more pleasant and

enjoyable. Safety, performance, and dependability have been given top priority

in the design of this product making it easy to maintain and operate.

2 © Sears Brands, LLC

,_, DANGER: People with electronic devices, such as pacemakers, should

consult their physician(s) before using this product. Operation of electrical

equipment in close proximity to a heart pacemaker could cause interference or

failure of the pacemaker.

_,WARNING: Some dust created by power sanding, sawing, grinding, drilling

and other construction activities contains chemicals known to the state of

California to cause cancer, birth defects or other reproductive harm. Some

examples of these chemicals are:

• Lead from lead-based paints

Crystalline silica from bricks and cement and other masonry products, and

Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type

of work. To reduce your exposure to these chemicah work in a well ventilated

area, and work with approved safety equipment, such as those dust masks that

are specially designed to filter out microscopic particles.

Thepurposeofsafetysymbolsistoattractyourattentiontopossibledangers.

Thesafetysymbolsandtheexplanationswiththemdeserveyourcareful

attentionandunderstanding.Thesymbolwarningsdonot,bythemselves,

eliminateanydanger.Theinstructionsandwarningstheygivearenosubstitutes

forproperaccidentpreventionmeasures.

,_, WARNING: Be sure to read and understand all safety instructions in this

manual, including all safety alert symbols such as "DANGER," "WARNING," and

"CAUTION" before using this tool. Failure to follow all instructions listed in this

manual may result in electric shock, fire, and/or serious personal injury.

SYMBOL SIGNAL MEANING

SAFETY ALERT SYMBOL: indicates DANGER, WARNING, or CAUTION; may

be used in conjunction with other symbols or pictographs.

DANGER: Indicates a hazardous situation which, if not avoided, will result in

death or serious injury.

,_, WARNING: Indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

_, CAUTION: Indicates a hazardous situation which, if not avoided, could

result in minor or moderate injury.

Damage prevention and Information Messages

These inform the user of important information and/or instructions that could

Beadto equipment or other property damage if they are not followed. Each

message is preceded by the word "NOTICE", as in the example below.

NOTICE: Equipment and/or property damage may result if these instructions are

not followed.

_WARNING: To ensure safety and reliability, all repairs should be performed

by a qualified service technician.

WARNING: The operation of any power tools can result in

foreign objects being thrown into your eyes, which can result

in severe eye damage. Before beginning power tool operation,

always wear safety goggles or safety glasses with side shield

and a full face shield when needed. We recommend a Wide

Vision Safety Mask for use over eyeglasses or standard safety

glasses with side shields. Always use eye protection which is

marked to comply with ANSI Z87.1.

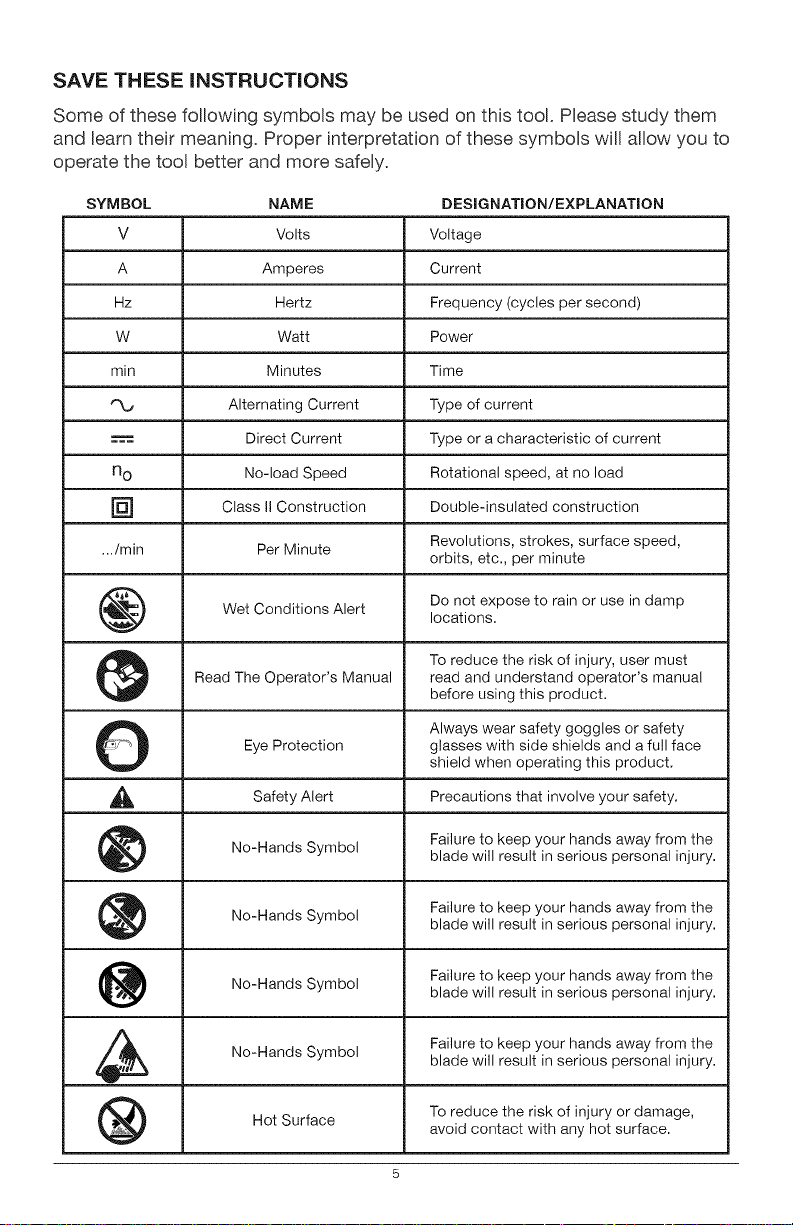

SAVE THESE iNSTRUCTiONS

Some of these following symbols may be used on this tool. Please study them

and Beam their meaning. Proper interpretation of these symbols will allow you to

operate the tool better and more safely.

SYMBOL NAME DESIGNATION/EXPLANATION

V Volts Voltage

A Amperes Current

Hz Hertz Frequency (cycles per second)

W Watt Power

min Minutes Time

Alternating Current Type of current

Direct Current Type or a characteristic of current

n O No-load Speed Rotational speed, at no load

[] Class II Construction Double-insulated construction

.../min Per Minute Revolutions, strokes, surface speed,

Wet Conditions Alert Do not expose to rain or use in damp

Read The Operator's Manual read and understand operator's manual

O Always wear safety goggles or safety

Eye Protection glasses with side shields and a fulI face

Safety your safety.

Alert Precautions that involve

No=Hands Symbol Failure to keep your hands away from theblade will result in serious personal injury.

No=Hands Failure to keep your hands away from the

No-Hands Failure to keep your hands away from the

No-Hands Symbol Failure to keep your hands away from the

Symbol

Symbol

orbits, etc., per minute

locations.

To reduce the risk of injury, user must

before using this product.

shield when operating this product.

blade will result in serious personal injury.

blade will result in serious personal injury.

blade will result in serious personal injury.

Hot Surface To reduce the risk of injury or damage,

avoid contact with any hot surface.

5

GENERAL POWER TOOL SAFETY WARNINGS

,_ WARNING: Read aft safety warnings and instructions. Failure to follow the

warnings and instructions may result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

The term "power tool" in the warnings refers to your mains=operated (corded)

power tool or battery=operated (cordless) power tool.

WORK AREA SAFETY

• Keep work area clean and well lit. Cluttered or dark areas invite accidents.

• Do not operate power tools in explosive atmospheres, such as in the

presence of flammable liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

= Keep children and bystanders away while operating a power tool.

Distractions can cause you to lose control.

ELECTRICAL SAFETY

• Power tool plugs must match the outlet. Never modify the plug in any

way. Do not use any adaptor plugs with earthed (grounded) power tools.

Unmodified plugs and matching outlets will reduce risk of electric shock

• Avoid body contact with earthed or grounded surfaces such as pipes,

radiators, ranges and refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

• Do not expose power tools to rain or wet conditions. Water entering a

power tool will increase the risk of electric shock.

• Do not abuse the cord. Never use the cord for carrying, pulling or

unplugging the power tool. Keep cord away from heat, oil, sharp edges or

moving parts. Damaged or entangled cords increase the risk of electric shock.

• When operating a power tool outdoors, use an extension cord suitable

for outdoor use. Use of a cord suitable for outdoor use reduces the risk of

electric shock.

if operating a power tool in a damp location is unavoidable, use a

ground fault circuit interrupter (GFCl} protected supply. Use of a GFCI

reduces the risk of electric shock.

PERSONAL SAFETY

• Stay alert, watch what you are doing and use common sense when

operating a power tool. Do not use tool while tired or under the

influence of drugs, alcohol, or medication. A moment of inattention while

operating power tools may result in serious personal injury.

• Use personal protective equipment. Always wear eye protection. Protective

equipment such as dust mask, non-skid safety shoes, hard hat, or hearing

protection used for appropriate conditions will reduce personal injuries.

• Prevent unintentional starting. Ensure the switch is in the off-position

before connecting to power source and/or battery pack, picking up or

carrying the tool. Carrying power tools with your finger on the switch or

energizing in power tools that have the switch on invites accidents.

• Remove any adjusting key or wrench before turning the power tool

on. A wrench or a key left attached to a rotating part of the power tool may

result in personal injury.

• Do not overreach. Keep proper footing and balance at all times. This

enables better control of the power tool in unexpected situations.

• Dress properly. Do not wear loose clothing or jewelry. Keep your hair,

clothing and gloves away from moving parts. Loose clothes, jewelry or

long hair can be caught in moving parts.

• If devices are provided for the connection of dust extraction and

collection facilities, ensure these are connected and properly used. Use

of these devices can reduce dust-related hazards.

POWER TOOL USE AND CARE

• Do not force the power tool. Use the correct power tool for your

application. The correct power tool will do the job better and more safely at

the rate for which it was designed.

• Do not use the power tool if the switch does not turn it on and off. Any

power tool that cannot be controlled with the switch is dangerous and must

be repaired.

• Disconnect the plug from the power source andlor the battery pack

from the power tool before making any adjustments, changing

accessories, or storing power tools. Such preventive safety measures

reduce the risk of starting the power tool accidentally.

• Store idle power tools out of the reach of children and do not allow

persons unfamiliar with the power tool or these instructions to operate

the power tool. Power tools are dangerous in the hands of untrained users.

• Maintain power tools. Check for misalignment or binding of moving

parts, breakage of parts and any other condition that may affect the

power tool's operation, if damaged, have the power tool repaired

before use. Many accidents are caused by poorly maintained power tools.

Keepcuttingtoolssharpandclean.Properlymaintainedcuttingtoolswith

sharpcuttingedgesarelesslikelytobindandareeasiertocontrol.

Usethepower tool, accessories, too[ bits, etc. in accordance with

these instructions, taking into account the working conditions and the

work to be performed. Use of the power tool for operations different from

those intended could result in a hazardous situation.

BATTERY TOOL USE AND CARE

• Recharge only with the charger specified by the manufacturer. A

charger that is suitable for one type of battery pack may create a risk of fire

when used with another battery pack.

• Use power tools only with specifically designated battery packs. Use of

any other battery packs may create a risk of injury and fire.

= When battery pack is not in use, keep it away from other metal objects,

like paper clips, coins, keys, nails, screws or other small metal objects

that can make a connection from one terminal to another. Shorting the

battery terminals together may cause burns or a fire.

= Under abusive conditions, liquid may be ejected from the battery;

avoid contact. If contact accidentally occurs, flush with water. If liquid

contacts eyes, additionally seek medical help. Liquid ejected from the

battery may cause irritation or burns.

SERVICE

Have your power too[ serviced by a qualified repair person using only

identical replacement parts. This will ensure that the safety of the power

tool is maintained.

Follow instructions in the Maintenance section of this manual. Use of

unauthorized parts or failure to follow Maintenance instructions may create

a risk of shock or injury.

SPECiFiC SAFETY RULES FOR iMPACT DRIVER

Hold power tools by their insulated gripping surfaces when performing

an operation where the cutting tool may contact hidden wiring. If a

cutting accessory contacts a "live" wire, it may make exposed metal parts

of the power tool "live" and could give the operator an electric shock.

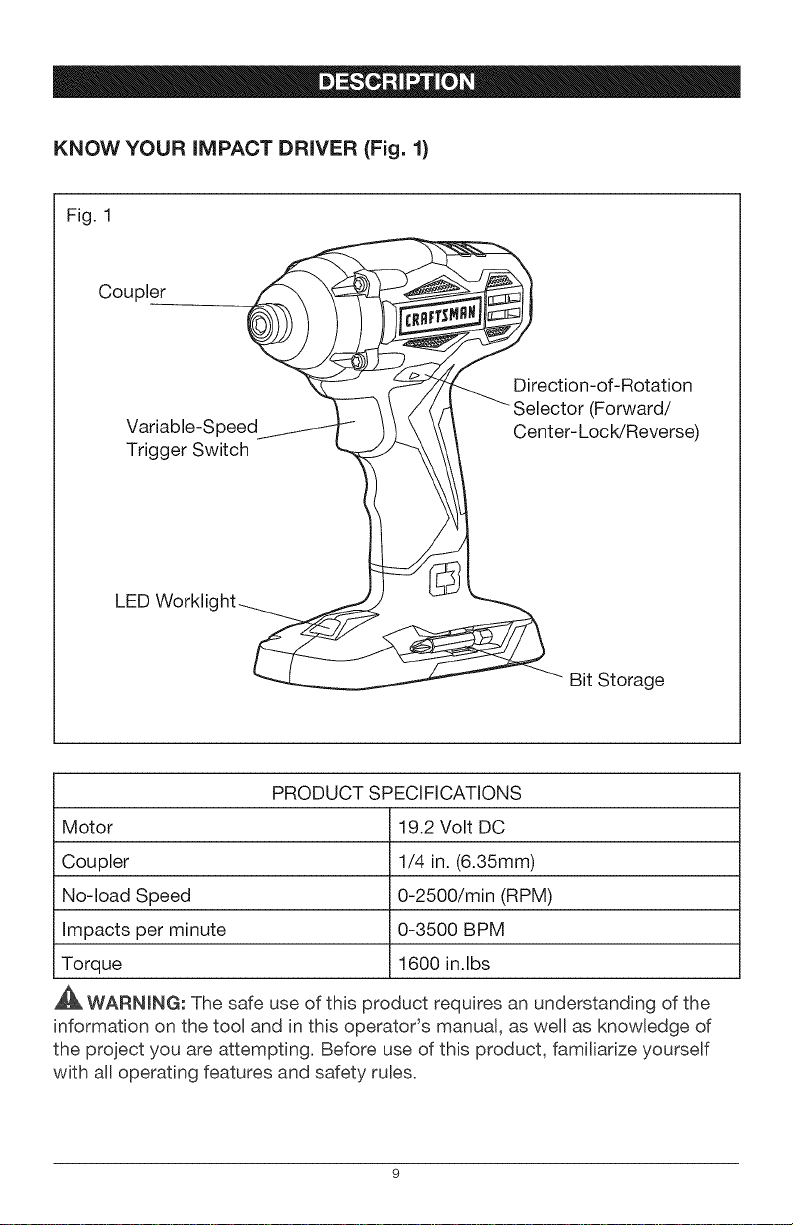

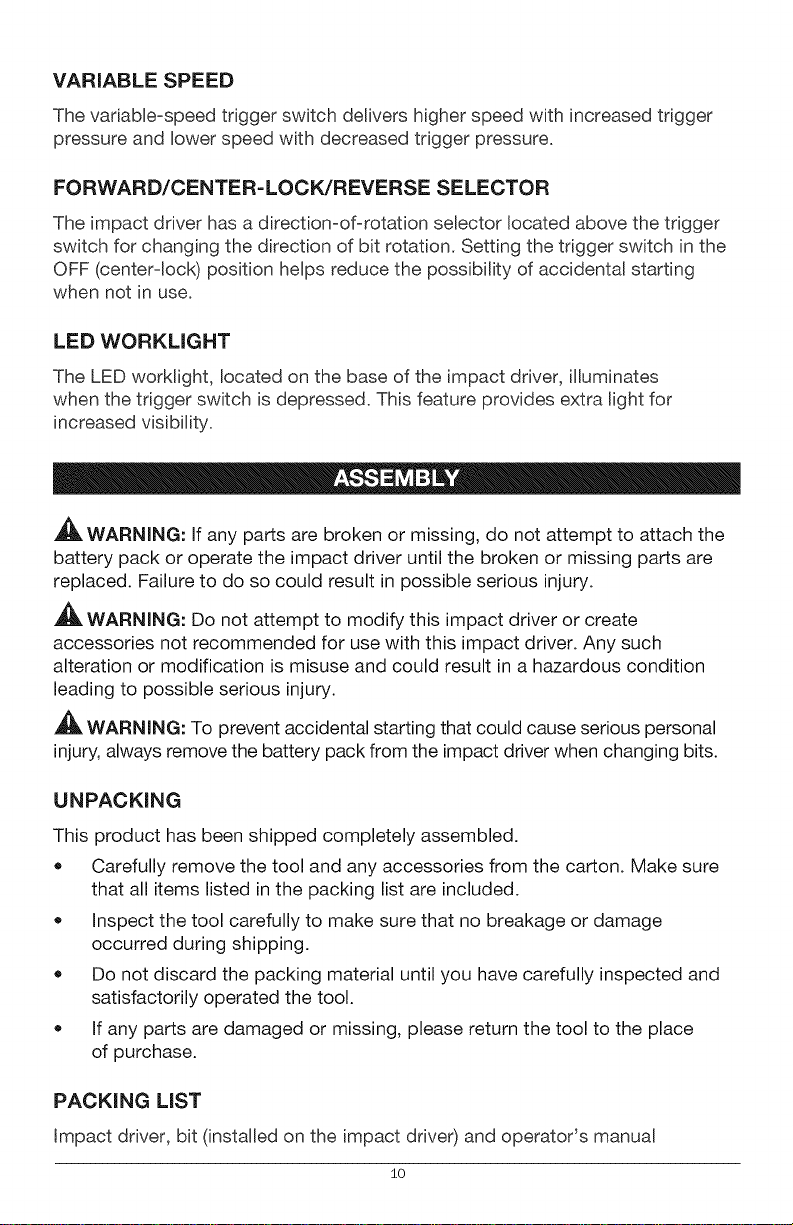

KNOW YOUR iMPACT DRIVER (Fig. 1)

Fig. 1

Coupler

Variable-Speed

Trigger Switch

LED Worklight-__

Direction-of-Rotation

(Forward/

Center-LocWReverse)

Bit Storage

PRODUCT SPECIFICATIONS

Motor 19.2 Volt DC

Coupler 1/4 in. (6.35mm)

No-load Speed 0-2500/min (RPM)

Impacts per minute 0-3500 BPM

Torque 1600 in.lbs

WARNING: The safe use of this product requires an understanding of the

information on the tool and in this operatoCs manual, as well as knowledge of

the project you are attempting. Before use of this product, familiarize yourself

with all operating features and safety rules.

VARIABLE SPEED

The variable=speed trigger switch delivers higher speed with increased trigger

pressure and Bowerspeed with decreased trigger pressure.

FORWARD/CENTER=LOCK/REVERSE SELECTOR

The impact driver has a direction=of=rotation selector located above the trigger

switch for changing the direction of bit rotation. Setting the trigger switch in the

OFF (centerqock) position helps reduce the possibility of accidental starting

when not in use.

LED WORKLIGHT

The LED worklight, located on the base of the impact driver, illuminates

when the trigger switch is depressed. This feature provides extra Bight for

increased visibility.

,&

_A, WARNING: If any parts are broken or missing, do not attempt to attach the

battery pack or operate the impact driver until the broken or missing parts are

replaced. Failure to do so could result in possible serious injury.

_, WARNING: Do not attempt to modify this impact driver or create

accessories not recommended for use with this impact driver. Any such

alteration or modification is misuse and could result in a hazardous condition

leading to possible serious injury.

_, WARNING: To prevent accidental starting that could cause serious personal

injury, always remove the battery pack from the impact driver when changing bits.

UNPACKING

This product has been shipped completely assembled.

• Carefully remove the tool and any accessories from the carton. Make sure

that all items listed in the packing list are included.

Inspect the tool carefully to make sure that no breakage or damage

occurred during shipping.

Do not discard the packing material until you have carefully inspected and

satisfactorily operated the tool.

If any parts are damaged or missing, please return the tool to the place

of purchase.

PACKING LIST

Impact driver, bit (installed on the impact driver) and operator's manual

10

This product will accept Craftsman C3 19.2V lithium-ion battery packs. For

complete charging instructions, refer to the Operator's Manual for the battery

packs and chargers.

_, WARNING: To prevent accidental starting that could cause serious personal

injury, always remove the battery pack from the tool when assembling parts,

making adjustments, installing or removing bit, cleaning, or when it is not in use.

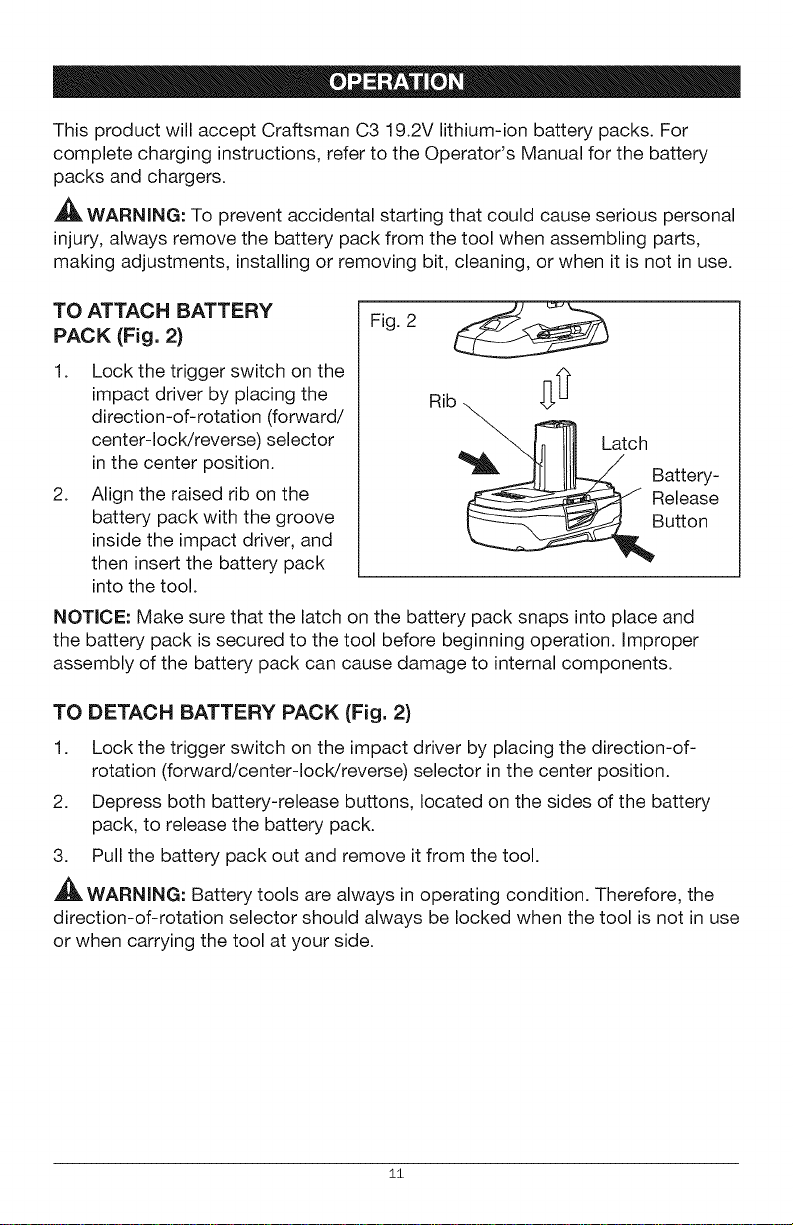

TO ATTACH BATTERY

Fig. 2

PACK (Fig, 2)

1. Lock the trigger switch on the

impact driver by placing the

direction-of-rotation (forward/

center-lock/reverse) selector

in the center position.

2. Align the raised rib on the

battery pack with the groove

inside the impact driver, and

then insert the battery pack

into the tool.

NOTICE: Make sure that the latch on the battery pack snaps into place and

the battery pack is secured to the tool before beginning operation. Improper

assembly of the battery pack can cause damage to internal components.

Latch

Battery-

Release

Button

TO DETACH BATTERY PACK (Fig. 2)

1. Lock the trigger switch on the impact driver by placing the direction-of-

rotation (forward/center-locWreverse) selector in the center position.

2. Depress both battery-release buttons, located on the sides of the battery

pack, to release the battery pack.

3. Pull the battery pack out and remove it from the tool.

,_. WARNING: Battery tools are always in operating condition. Therefore, the

direction-of-rotation selector should always be locked when the tool is not in use

or when carrying the tool at your side.

11

Loading...

Loading...