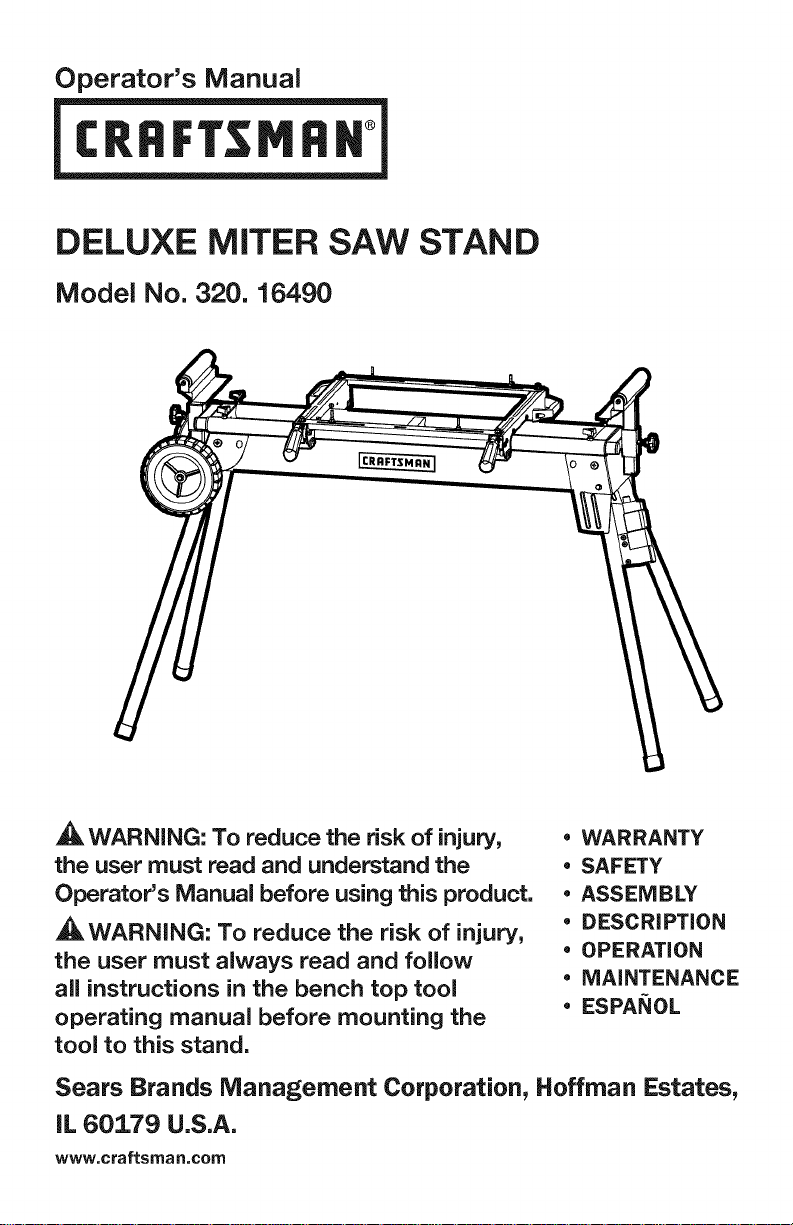

DELUXE MITER SAW STAND

Model No. 320. 16490

WARNING: To reduce the risk of injury,

the user must read and understand the

Operator's Manual before using this product.

_WARNING: To reduce the risk of injury,

the user must always read and follow

all instructions in the bench top tool

• WARRANTY

• SAFETY

• ASSEMBLY

• DESCRiPTiON

• OPERATION

• MAINTENANCE

• ESPANOL

operating manual before mounting the

tool to this stand.

Sears Brands Management Corporation, Hoffman Estates,

IL 60179 U.S.A.

www,craftsman,com

Warranty Page 2

Safety Symbols Pages 4-5

Safety Instructions Pages 6-7

Description Page 8

Assembly Pages 9-10

Operation Pages 11-18

Maintenance Page 18

Parts List Pages 19-21

CRAFTSMAN ONE YEAR FULL WARRANTY

FOR ONE YEAR from the date of purchase, this product is warranted

against any defects in material or workmanship. A defective product will be

replaced free of charge.

For warranty coverage details to obtain free replacement, visit the web

site: www.craftsman.com

This warranty is void if this product is ever used while providing commercial

services or if rented to another person.

This warranty gives you specific legal rights, and you may also have other

rights which vary from state to state.

Sears Brands Management Corporation, Hoffman Estates, IL 60179

This miter saw work stand has many features for making its use more pleasant

and enjoyable. Safety, performance, and dependability have been given top

priority in the design of this product making it easy to maintain and operate.

SAVE THESE iNSTRUCTiONS!

READ ALL iNSTRUCTiONS!

Page 2 16490 ManuaLRevised_12 0604

_,WARNING: Some dust created by power sanding, sawing, grinding, drilling

and other construction activities contains chemicals known to the state of

California to cause cancer, birth defects or other reproductive harm. Some

examples of these chemicals are:

• Lead from lead-based paints,

Crystalline silica from bricks and cement and other masonry products,and

Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type

of work. To reduce your exposure to these chemicals: work in a well ventilated

area, and work with approved safety equipment, such as those dust masks that

are specially designed to filter out microscopic particles.

The purpose of safety symbols is to attract your attention to possible dangers.

The safety symbols and the explanations with them deserve your careful

attention and understanding. The symbol warnings do not, by themselves,

eliminate any danger. The instructions and warnings they give are no substitutes

for proper accident prevention measures.

16490 Manual_Revised_12-0604 Page 3

,_ WARNING: Be sure to read and understand all safety instructions in this

Operator's Manual, including all safety alert symbols such as "DANGER",

"WARNING", and "CAUTION" before using this stand. Failure to follow all

instructions listed below may result in electric shock, fire, and/or serious

personal injury.

SYMBOL SIGNAL MEANING

SAFETY ALERT SYMBOL: Indicates DANGER, WARNING, OR CAUTION; may

be used in conjunction with other symbols or pictographs.

,_ DANGER: Indicates a hazardous situation which, if not avoided, will result in

death or serious injury.

,_ WARNING: Indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

_, CAUTION: Indicates a hazardous situation which, if not avoided, could result

in minor or moderate injury.

Damage prevention and Information Messages

These inform the user of important information and/or instructions that could

lead to equipment or other property damage if they are not followed. Each

message is preceded by the word "NOTICE", as in the example below:

NOTICE: Equipment and/or property damage may result if these instructions are

not followed.

,_, WARNING: To ensure safety and reliability, all repairs should be performed

by a qualified service technician.

_IL WARNING: The operation of any power tools can result in

foreign objects being thrown into your eyes, which can result

in severe eye damage. Before beginning power tool operation,

always wear safety goggles or safety glasses with side shield

and a full face shield when needed. We recommend a Wide

Vision Safety Mask for use over eyeglasses or standard safety

glasses with side shields. Always use eye protection that is

marked to comply with ANSI Z87.1.

Page 4 16490 Manual_Revised_12 0604

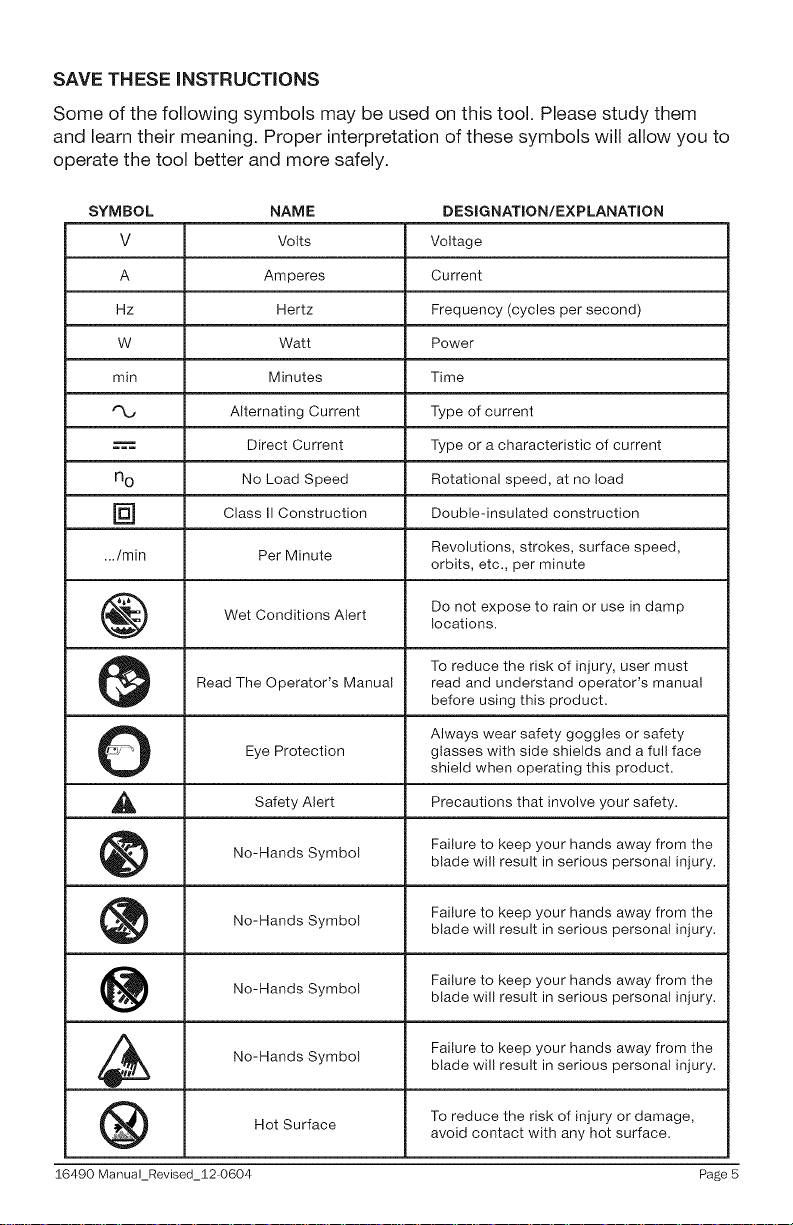

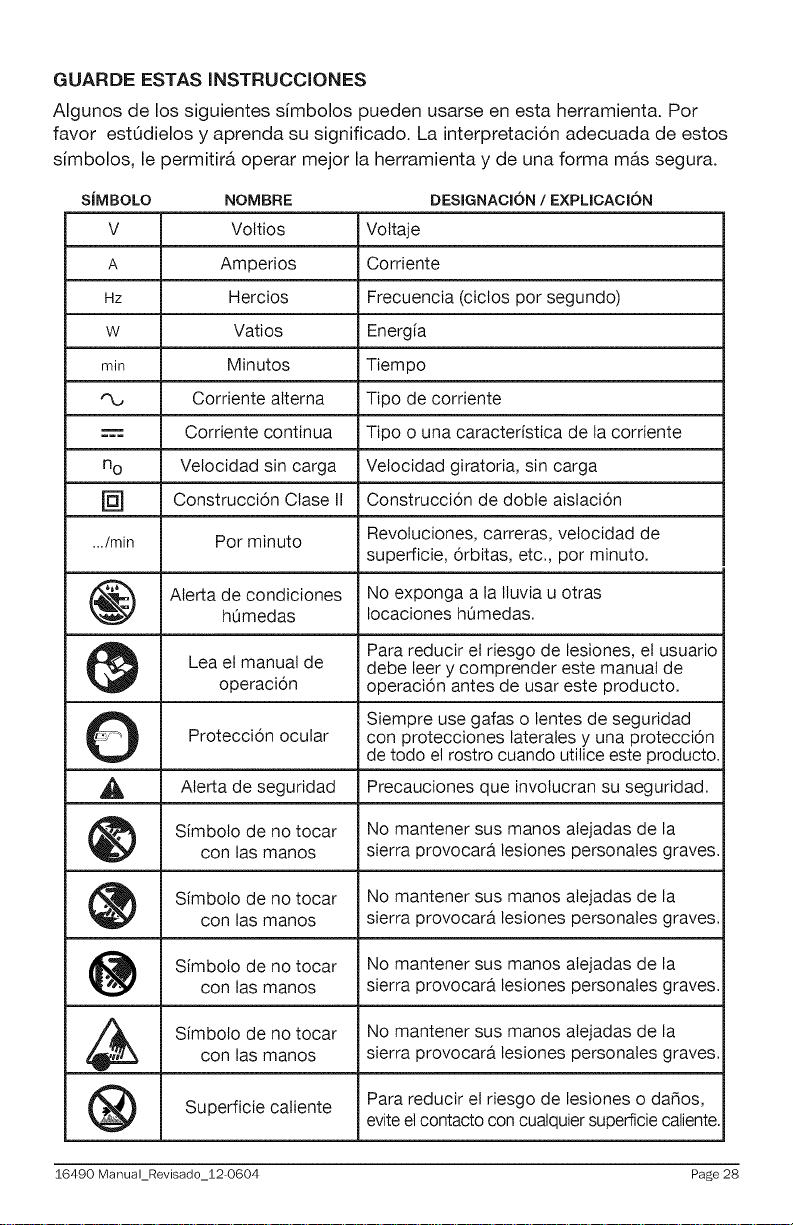

SAVE THESE iNSTRUCTiONS

Some of the following symbols may be used on this tool. Please study them

and learn their meaning. Proper interpretation of these symbols will allow you to

operate the tool better and more safely.

SYMBOL NAME DESIGNATION/EXPLANATION

V Volts Voltage

A Amperes Current

Hz Hertz Frequency (cycles per second)

W Watt Power

min Minutes Time

Alternating Current Type of current

====== Direct Current Type or a characteristic of current

n o No Load Speed Rotational speed, at no load

] Class II Construction Double-insulated construction

.../min Per Minute Revolutions, strokes, surface speed,

Wet Conditions Alert Do not expose to rain or use in damp

Read The Operator's Manual read and understand operator's manual

O Always wear safety goggles or safety

_1_ Alert Precautions that involve

Eye Protection glasses with side shields and a full face

Safety

No-Hands Symbol blade will result in serious personal injury.

No-Hands Failure to keep your hands away from the

No-Hands Symbol blade will result in serious personal injury.

No-Hands Symbol blade will result in serious personal injury.

Symbol

orbits, etc., per minute

locations.

To reduce the risk of injury, user must

before using this product.

shield when operating this product.

safety.

your

Failure to keep your hands away from the

blade will result in serious personal injury.

Failure to keep your hands away from the

Failure to keep your hands away from the

To reduce the risk of injury or damage,Hot Surface avoid contact with any hot surface.

16490 Manual_Revised_12-0604 Page 5

GENERAL SAFETY RULES

,_ WARNING: Read and understand all instructions. Failure to follow all

instructions in this Operator's Manual may result in electric shock, fire, and/or

serious personal injury.

Save all warnings and instructions for future reference.

READ AND SAVE THESE INSTRUCTIONS

,_ CAUTION: Do not modify or use this stand for any application other than

that for which it was designed.

ELECTRICAL SAFETY

= Power tool plugs must match the outlet. Never modify the plug in any

way. Do not use any adapter plugs with grounded power tools. Unmodified

plugs and matching outlets will reduce the risk of electric shock.

= Avoid body contact with grounded surfaces, such as pipes, radiators,

ranges, and refrigerators. There is an increased risk of electric shock if

your body is grounded.

= Do not expose power tools to rain or wet conditions. Water entering a

power tool will increase the risk of electric shock.

= Do not abuse the cord. Never use the cord for carrying, pulling, or

unplugging the power tool. Keep the cord away from heat, oil, sharp

edges, or moving parts. Damaged or entangled cords increase the risk of

electric shock.

When operating a power tool outdoors, use an extension cord suitable

for outdoor use. Use of a cord suitable for outdoor use reduces the risk of

electric shock.

if operating a power tool in a damp location is unavoidable, use a

ground fault circuit interrupter (GFCl} protected supply. Use of a GFCI

reduces the risk of electric shock.

SAFETY FOR WORK STAND

= Know your stand. Do not attempt to assemble or operate your miter saw

stand until you have read the safety instructions in this section.

= Only use your miter saw stand on a hard, dry and flat surface.

= Keep your work area clean and weU lit. Cluttered or dark areas invite accidents.

= Do not overreach. Keep proper footing and balance at all times.

= Do not load the miter saw stand with more than 330 Ibs.

Page 6 16490 ManuaLRevised_12 0604

• Store properly. Do not store the miter saw stand outdoors or in a

damp location.

• Do not stand or climb on miter saw stand. It could tip over, causing

serious injury.

• Do not permit children to use the stand unsupervised. It is not a toy.

• Be sure all locking pins are in the set-up position holes before using your

miter saw and miter saw miter saw stand.

= Take care when moving the stand, especially when a miter saw is mounted.

= Dress properly. Do not wear loose clothing or jewelry. Keep your hair,

clothing and gloves away from moving parts. Loose clothes, jewelry or long

hair can be caught in moving parts. Always wear non-slip footwear. Tie back

long hair. Roll long sleeves above the elbow.

= Always firmly attach the miter saw used with this stand. Do not attempt to

use the miter saw on your work stand until the miter saw is fastened firmly.

Be aware of tipping. When a large piece is cut from one end of a job, the

remaining piece may be heavy enough to tip the Miter Saw Stand. Always

ensure the workpiece is well supported.

Always keep all guards in place. Be sure all power tool guards are in good

working order and are in proper adjustment and alignment.

Always keep your hands away from the cutting area.

16490 Manual_Revised_12-0604 Page 7

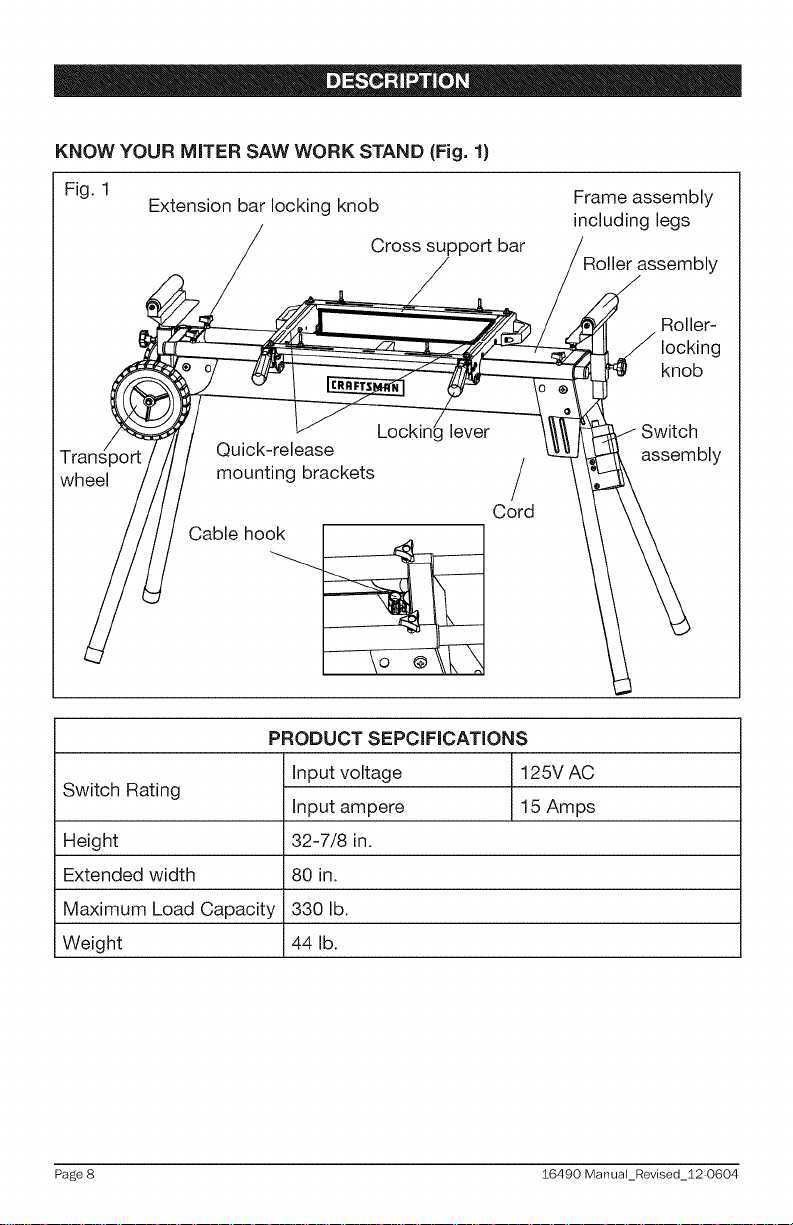

KNOW YOUR MITER SAW WORK STAND (Fig. 1}

Fig. 1

wheel

Extension bar locking knob

Quick-release

mounting brackets

Cable hook

PRODUCT SEPCIFICATIONS

Cross support bar

Lockin_ lever

Cord

Frame assembly

including legs

Roller-

locking

knob

}witch

assembly

Switch Rating

Height

Extended width

Maximum Load Capacity

Weight

Page 8 16490 ManuaLRevised_12 0604

Input voltage 125V AC

Input ampere 15 Amps

32-7/8 in.

80 in.

330 lb.

44 lb.

,_ WARNING: If any parts are broken or missing, do not attempt to operate the

stand until the broken or missing part is replaced. Failure to do so could result in

possible serious injury.

,_ WARNING: Do not attempt to modify this stand or create accessories not

recommended for use with this stand. Any such alteration or modification is

misuse and could result in a hazardous condition leading to serious injury.

UNPACKING

* Carefully remove all the parts and accessories from the carton. Make sure

that all the items listed in the packing list are included.

* Inspect the stand carefully to make sure no that breakage or damage

occurred during shipping.

* Do not discard the packing material until you have carefully inspected and

satisfactorily operated the stand.

* If any parts are damaged or missing, please return the stand to the place

of purchase.

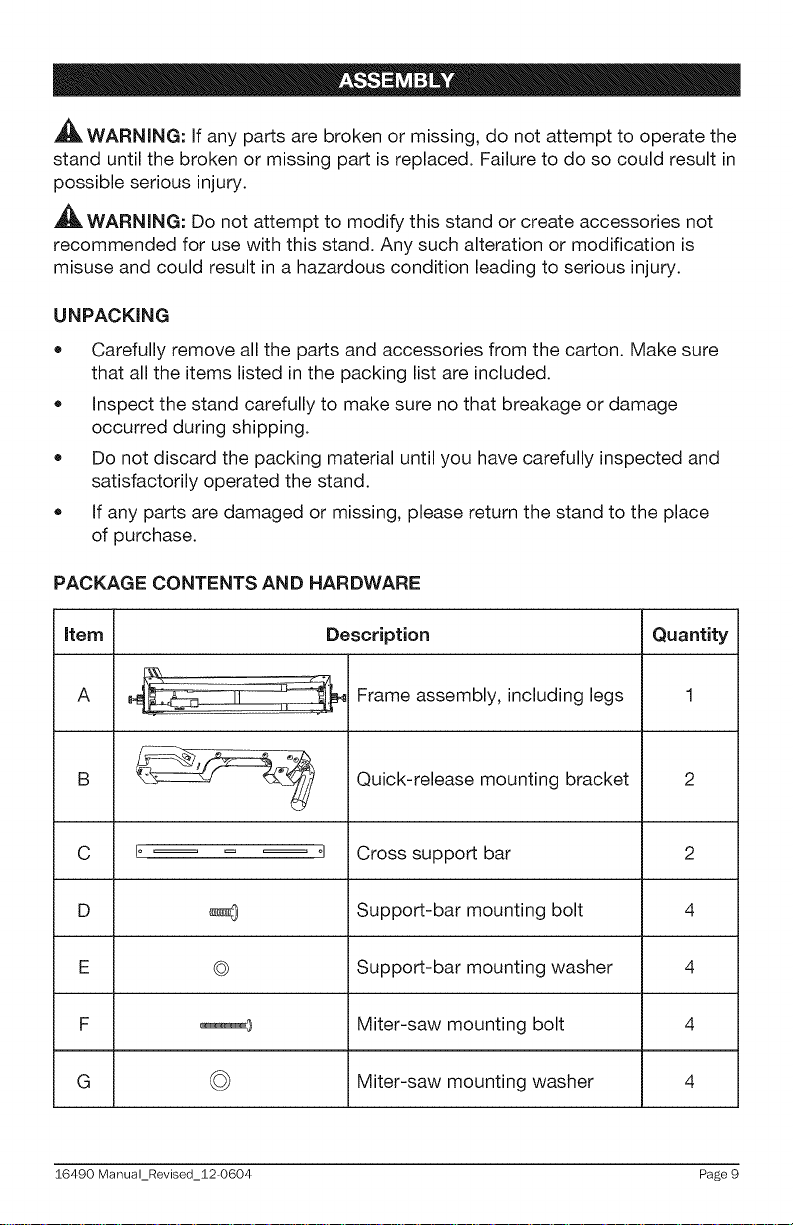

PACKAGE CONTENTS AND HARDWARE

item Quantity

A

_ Frame assembly, including legs

B

C zl Cross support bar 2

D Support-bar mounting bolt 4

E Support-bar mounting washer 4

F Miter-saw mounting bolt 4

G Miter-saw mounting washer 4

$6490 Manual_Revised_S2-0604 Page 9

©

©

Description

Quick-release mounting bracket

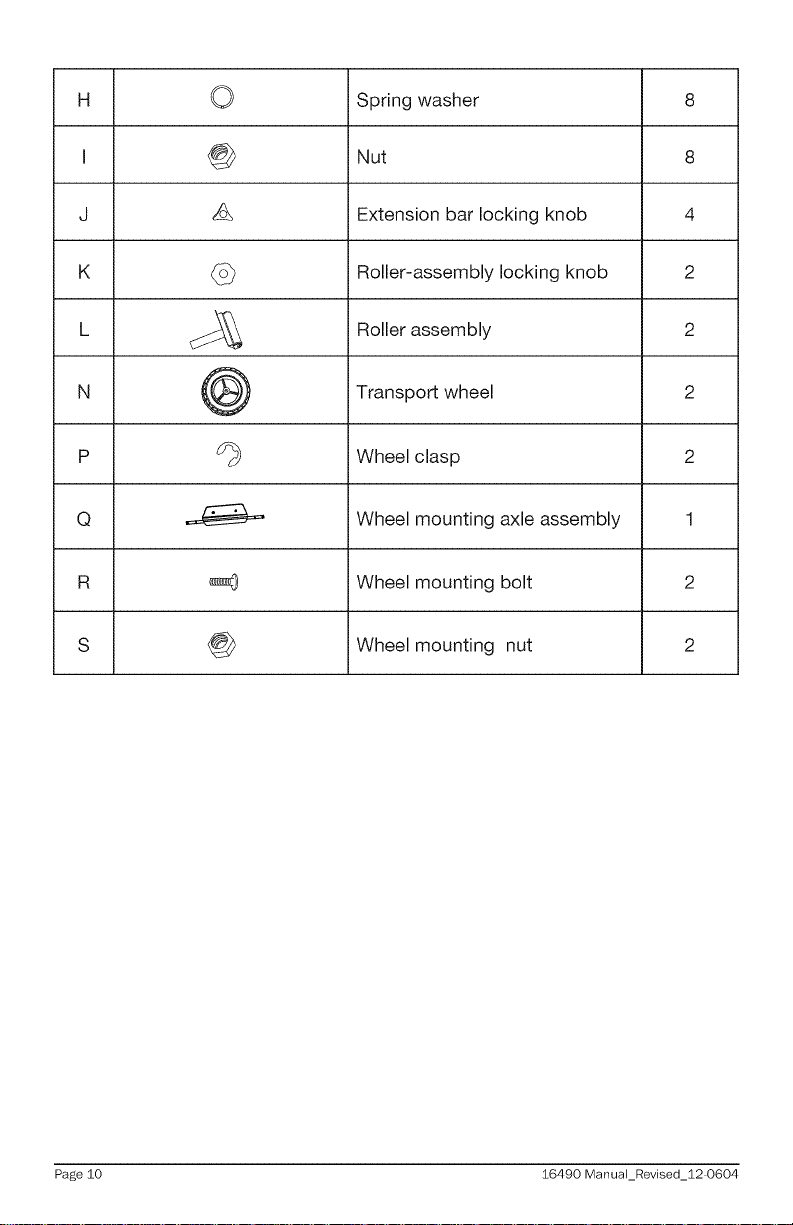

H 0 Spring washer 8

I @ Nut 8

J _ Extension bar locking knob 4

K _ Roller-assembly locking knob 2

L c:_ Roller assembly 2

N _ _ Transport wheel 2

p d_ Wheel clasp 2

Q Wheel mounting axle assembly 1

R _ Wheel mounting bolt 2

S _ Wheel mounting nut 2

Page 10 16490 ManuaLRevised_12 0604

A

,_b, WARNING: Do not use this stand as scaffolding or as a ladder. Make sure to

tighten all locking knobs and levers securely prior to use, Maximum capacity is

330 Ibs. Power tools on the stand should not exceed a combined overall height

of 60 inches from the floor.

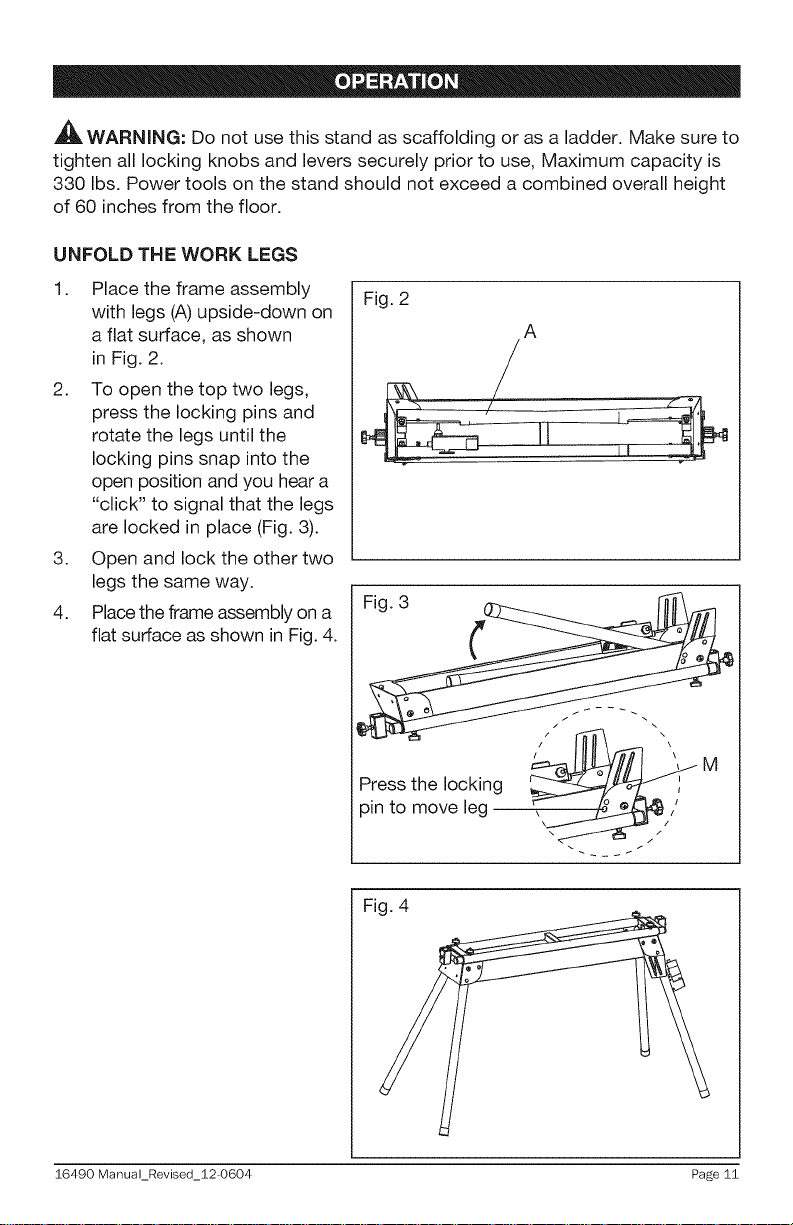

UNFOLD THE WORK LEGS

1. Place the frame assembly

with legs (A) upside-down on

a flat surface, as shown

in Fig. 2.

2. To open the top two legs,

press the locking pins and

rotate the legs until the

locking pins snap into the

open position and you hear a

"click" to signal that the legs

are locked in place (Fig. 3).

3. Open and lock the other two

legs the same way.

4. Place the frame assembly on a

flat surface as shown in Fig. 4.

Fig. 2

A

/ \

M/ _

Press the locking

3in to move leg _,//"

Fig. 4

16490 Manual_Revised_12-0604 Page 11

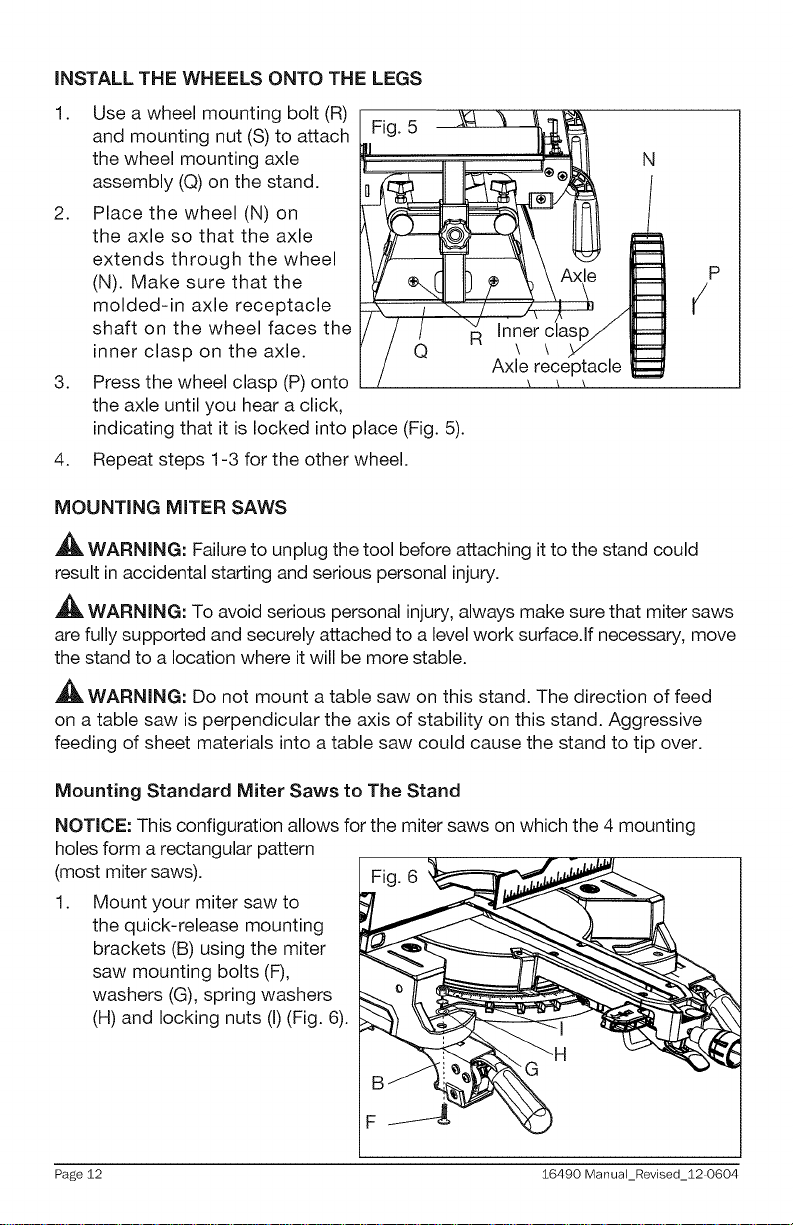

iNSTALL THE WHEELS ONTO THE LEGS

1.

Use a wheel mounting bolt (R)

and mounting nut (S) to attach Fig. 5

the wheel mounting axle

N

assembly (Q) on the stand.

2.

Place the wheel (N) on

the axle so that the axle

extends through the wheel

(N). Make sure that the

molded-in axle receptacle

shaft on the wheel faces the

inner clasp on the axle.

3.

Press the wheel clasp (P) onto

the axle until you hear a click,

indicating that it is locked into place (Fig. 5).

4.

Repeat steps 1-3 for the other wheel.

MOUNTING MITER SAWS

_1_ WARNING: Failure to unplug the tool before attaching it to the stand could

result in accidental starting and serious personal injury.

WARNING: To avoid serious personal injury, always make sure that miter saws

are fully supported and securely attached to a level work surface.If necessary, move

the stand to a location where it will be more stable.

,_ WARNING: Do not mount a table saw on this stand. The direction of feed

on a table saw is perpendicular the axis of stability on this stand. Aggressive

feeding of sheet materials into a table saw could cause the stand to tip over.

Mounting Standard Miter Saws to The Stand

NOTICE: This configuration allows for the miter saws on which the 4 mounting

holes form a rectangular pattern

(most miter saws).

1. Mount your miter saw to

the quick-release mounting

brackets (B) using the miter

saw mounting bolts (F),

washers (G), spring washers

(H) and locking nuts (I) (Fig. 6).

Page 12 16490 ManuaLRevised_12 0604

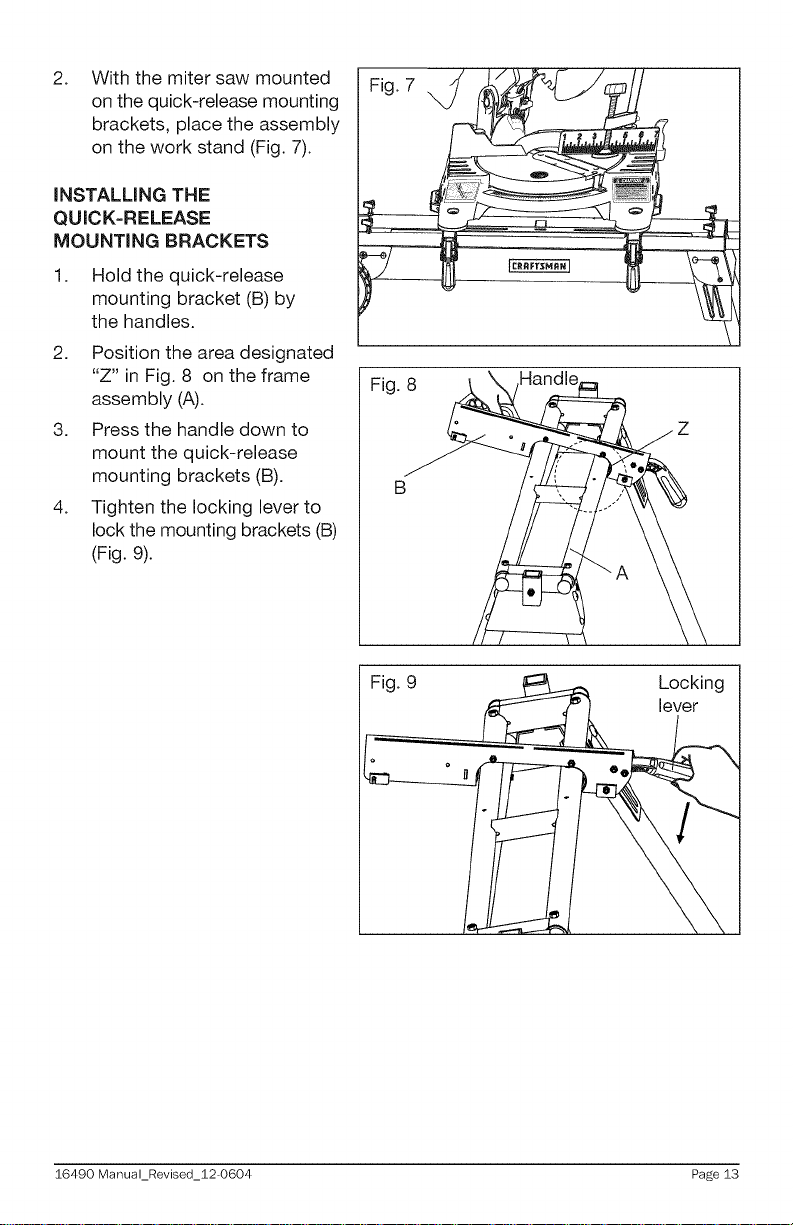

With the miter saw mounted

2. Fig. 7

on the quick-release mounting

brackets, place the assembly

on the work stand (Fig. 7).

iNSTALLiNG THE

QUICK=RELEASE

MOUNTING BRACKETS

1.

Hold the quick-release

mounting bracket (B) by

the handles.

2. Position the area designated

"Z" in Fig. 8 on the frame

assembly (A).

3. Press the handle down to

mount the quick-release

mounting brackets (B).

4. Tighten the locking lever to

lock the mounting brackets (B)

(Fig. 9).

Fig. 8

B

\

Fig. 9 _ Locking

16490 Manual_Revised_12-0604 Page 13

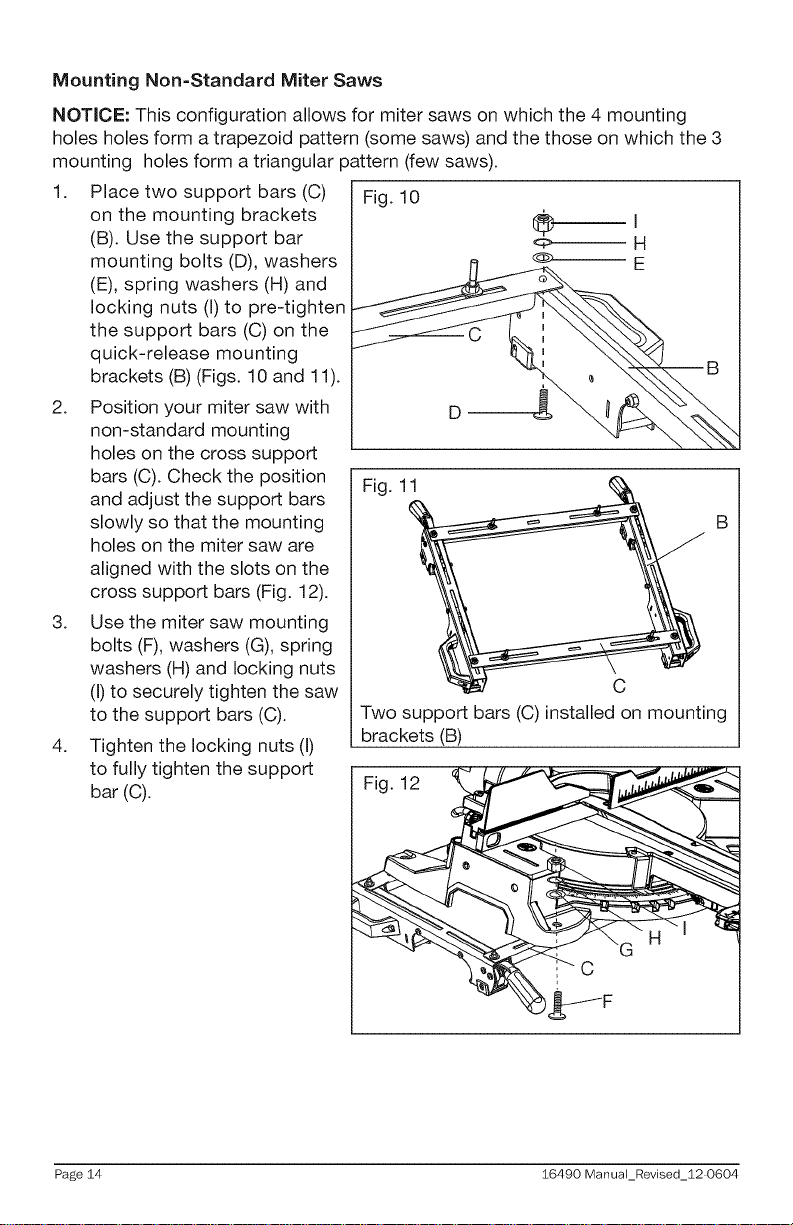

Mounting Non=Standard Miter Saws

NOTICE: This configuration allows for miter saws on which the 4 mounting

holes holes form a trapezoid pattern (some saws) and the those on which the 3

mounting holes form a triangular pattern (few saws).

1. Place two support bars (C)

on the mounting brackets

(B). Use the support bar

mounting bolts (D), washers

(E), spring washers (H) and

locking nuts (I) to pre-tighten

the support bars (C) on the

quick-release mounting

brackets (B) (Figs. 10 and 11).

2. Position your miter saw with

non-standard mounting

holes on the cross support

bars (C). Check the position

and adjust the support bars

slowly so that the mounting

holes on the miter saw are

aligned with the slots on the

cross support bars (Fig. 12).

3. Use the miter saw mounting

bolts (F), washers (G), spring

washers (H) and locking nuts

(I)to securely tighten the saw

to the support bars (C).

4. Tighten the locking nuts (I)

to fully tighten the support

bar (C).

Fig. 10

Fig. 11

C

Two support bars (C)installed on mounting

brackets (B)

Fig. 12

B

C

Page 14 16490 Manual_Revised_12 0604

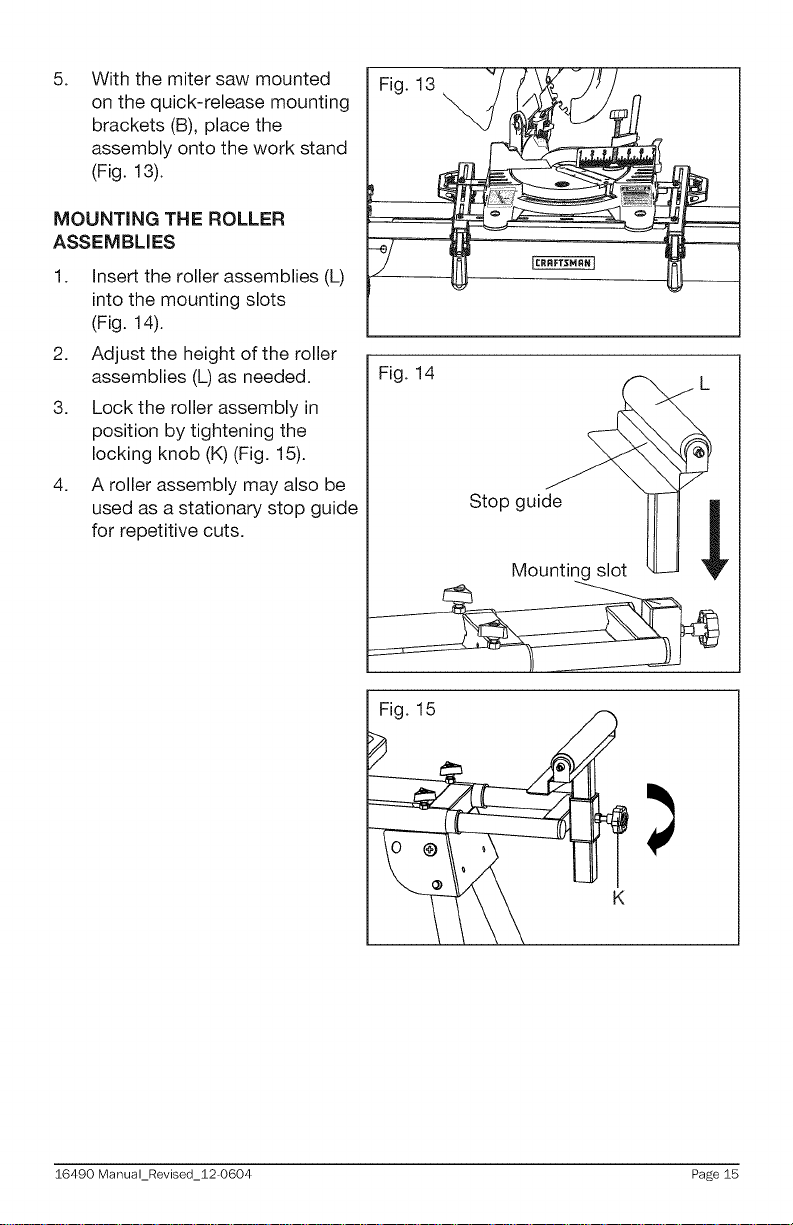

5. With the miter saw mounted

on the quick-release mounting

brackets (B), place the

assembly onto the work stand

(Fig. 13).

MOUNTING THE ROLLER

ASSEMBLIES

1. Insert the roller assemblies (L)

into the mounting slots

(Fig. 14).

2. Adjust the height of the roller

assemblies (L) as needed.

3. Lock the roller assembly in

position by tightening the

locking knob (K) (Fig. 15).

4. A roller assembly may also be

used as a stationary stop guide

for repetitive cuts.

Fig. 14

St°p_ii

Fig. 15

K

16490 Manual_Revised_12-0604 Page 15

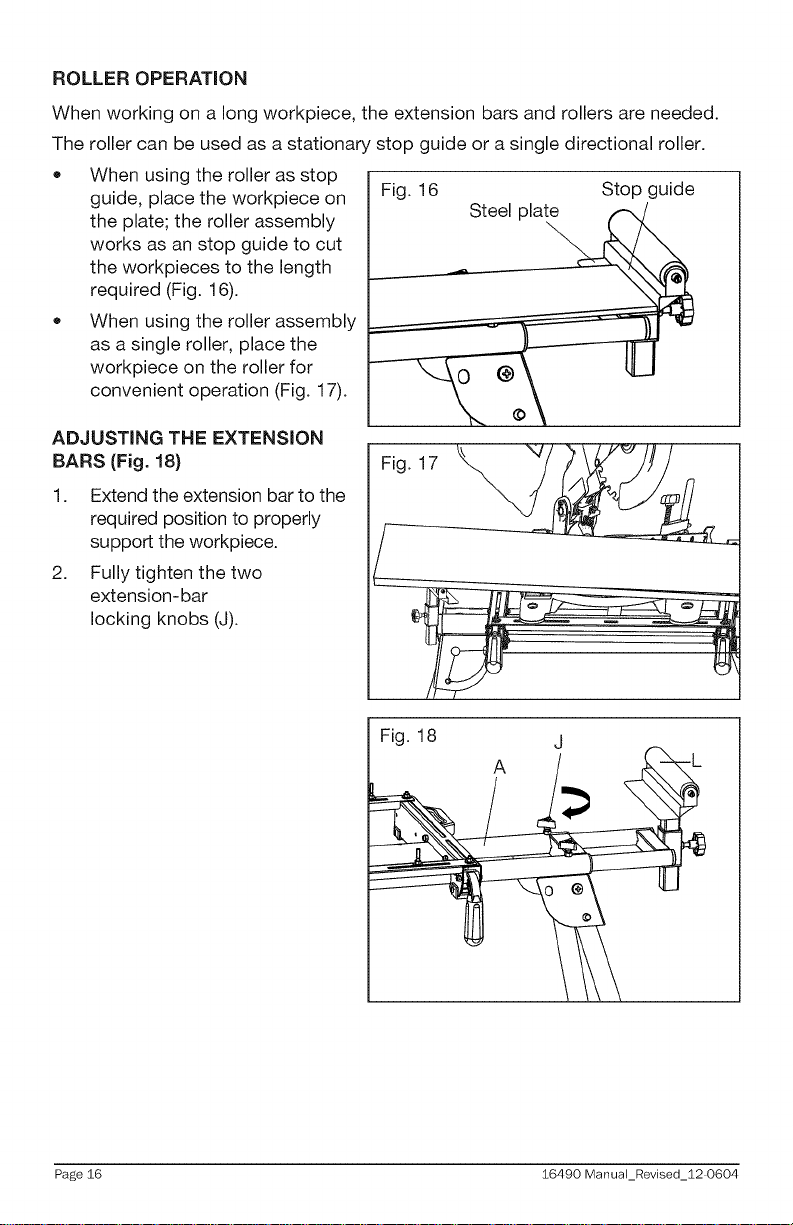

ROLLER OPERATION

When working on a long workpiece, the extension bars and rollers are needed.

The roller can be used as a stationary stop guide or a single directional roller.

• When using the roller as stop

guide, place the workpiece on

the plate; the roller assembly

works as an stop guide to cut

the workpieces to the length

required (Fig. 16).

When using the roller assembly

as a single roller, place the

workpiece on the roller for

convenient operation (Fig. 17).

ADJUSTING THE EXTENSION

BARS (Fig. 18}

1. Extend the extension bar to the

required position to properly

support the workpiece.

2. Fully tighten the two

extension-bar

locking knobs (J).

I

Fig. 16 Stop guide

Steel plate

Fig. 17

Fig. 18

A

Page 16 16490 ManuaLRevised_12 0604

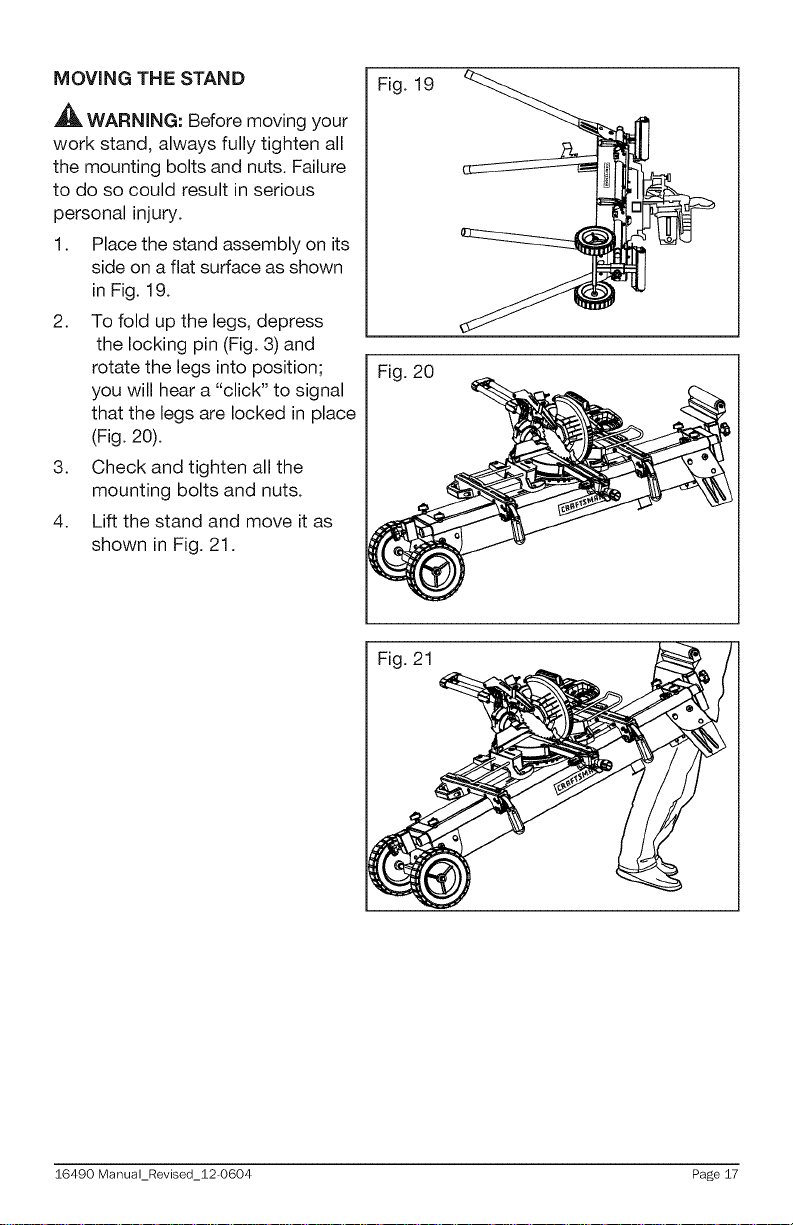

MOVING THE STAND

WARNING: Before moving your

work stand, always fully tighten all

the mounting bolts and nuts. Failure

to do so could result in serious

personal injury.

1. Place the stand assembly on its

side on a flat surface as shown

in Fig. 19.

2. To fold up the legs, depress

the locking pin (Fig. 3) and

rotate the legs into position;

you will hear a "click" to signal

that the legs are locked in place

(Fig. 20).

3. Check and tighten all the

mounting bolts and nuts.

4. Lift the stand and move it as

shown in Fig. 21.

Fig. 19

Fig. 20

Fig. 21

16490 Manual_Revised_12-0604 Page 17

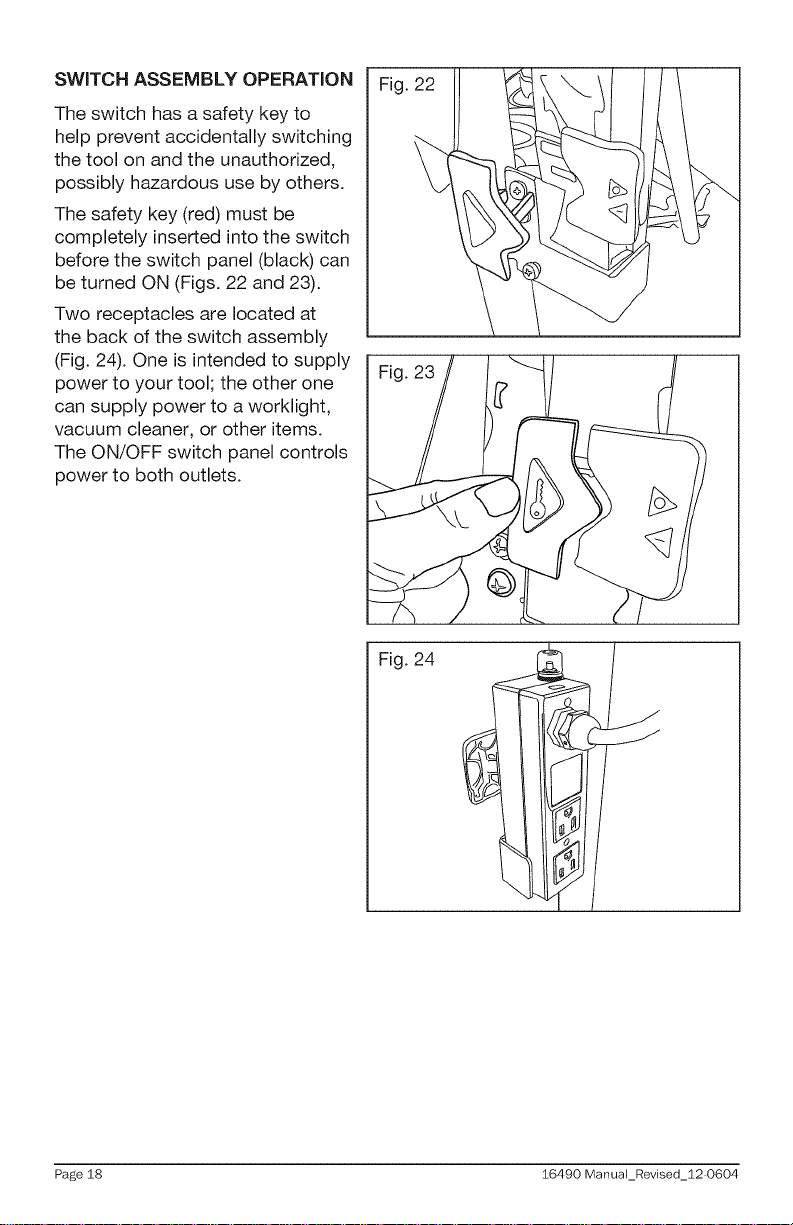

SWITCH ASSEMBLY OPERATION

The switch has a safety key to

help prevent accidentally switching

the tool on and the unauthorized,

possibly hazardous use by others.

The safety key (red) must be

completely inserted into the switch

before the switch panel (black) can

be turned ON (Figs. 22 and 23).

Two receptacles are located at

the back of the switch assembly

(Fig. 24). One is intended to supply

power to your tool; the other one

can supply power to a worklight,

vacuum cleaner, or other items.

The ON/OFF switch panel controls

power to both outlets.

Fig. 22

Fig. 24

J

Page 18 16490 ManuaLRevised_12 0604

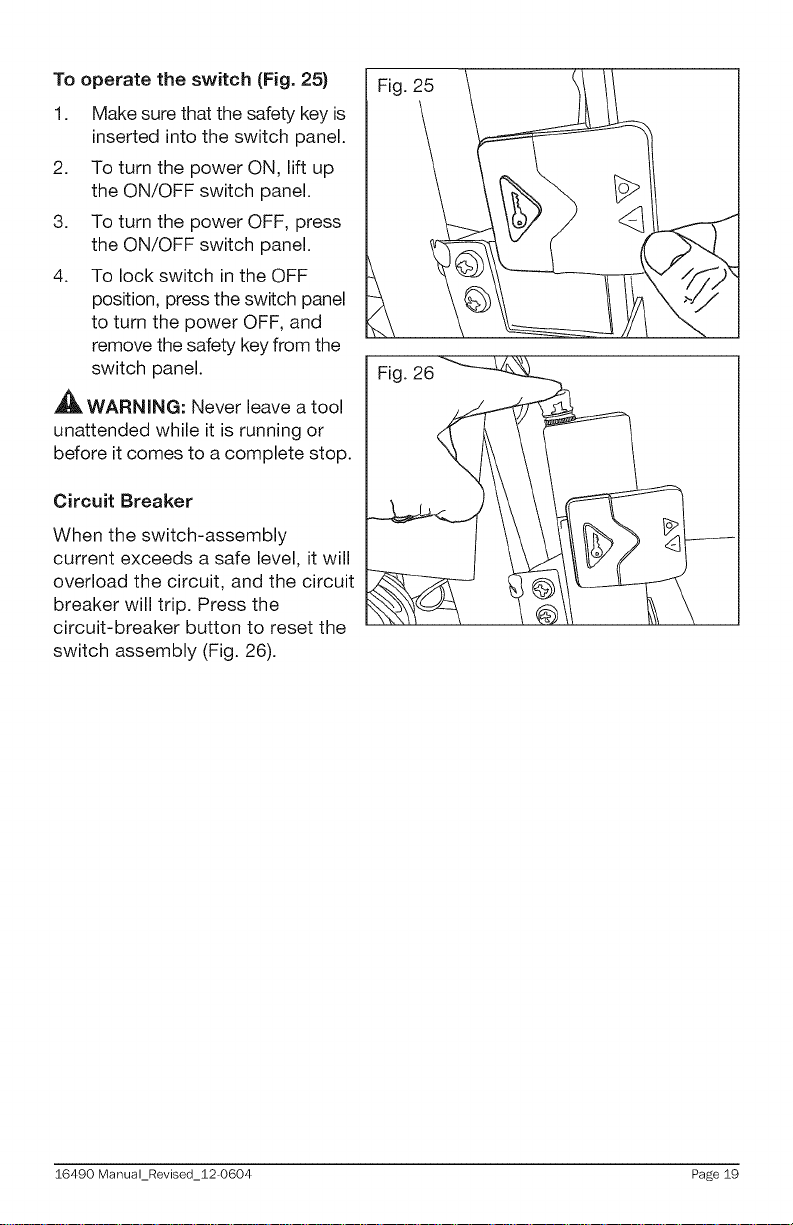

To operate the switch (Fig. 25)

1. Make sure that the safety key is

inserted into the switch panel.

2. To turn the power ON, lift up

the ON/OFF switch panel.

3. To turn the power OFF, press

the ON/OFF switch panel.

4. To lock switch in the OFF

position, press the switch panel

to turn the power OFF, and

remove the safety key from the

switch panel.

,_ WARNING: Never leave a tool

unattended while it is running or

before it comes to a complete stop.

Circuit Breaker

When the switch-assembly

current exceeds a safe level, it will

overload the circuit, and the circuit

breaker will trip. Press the

circuit-breaker button to reset the

switch assembly (Fig. 26).

Fig. 25

16490 Manual_Revised_12-0604 Page 19

,_ WARNING: When servicing, use only identical replacement parts. Use of any

other parts may create a hazard or cause product damage.

GENERAL MAINTENANCE

Avoid using solvents when cleaning plastic parts. Most plastics are susceptible

to damage from various types of commercial solvents and may be damaged by

their use. Use clean cloths to remove dirt, dust, oil, grease, etc.

WARNING: When servicing, use only identical replacement parts. Use of any

other parts may create a hazard or cause product damage. To ensure safety and

reliability, all repairs should be performed by a qualified service technician.

,_WARNING: Keep the miter saw stand dry, clean, and free from oil and

grease. Always use a clean cloth when cleaning. Never use brake fluids,

gasoline, petroleum based products or any strong solvent to clean the bench

grinder stand. Chemicals can damage, weaken or destroy plastic which may

result in serious personal injury.

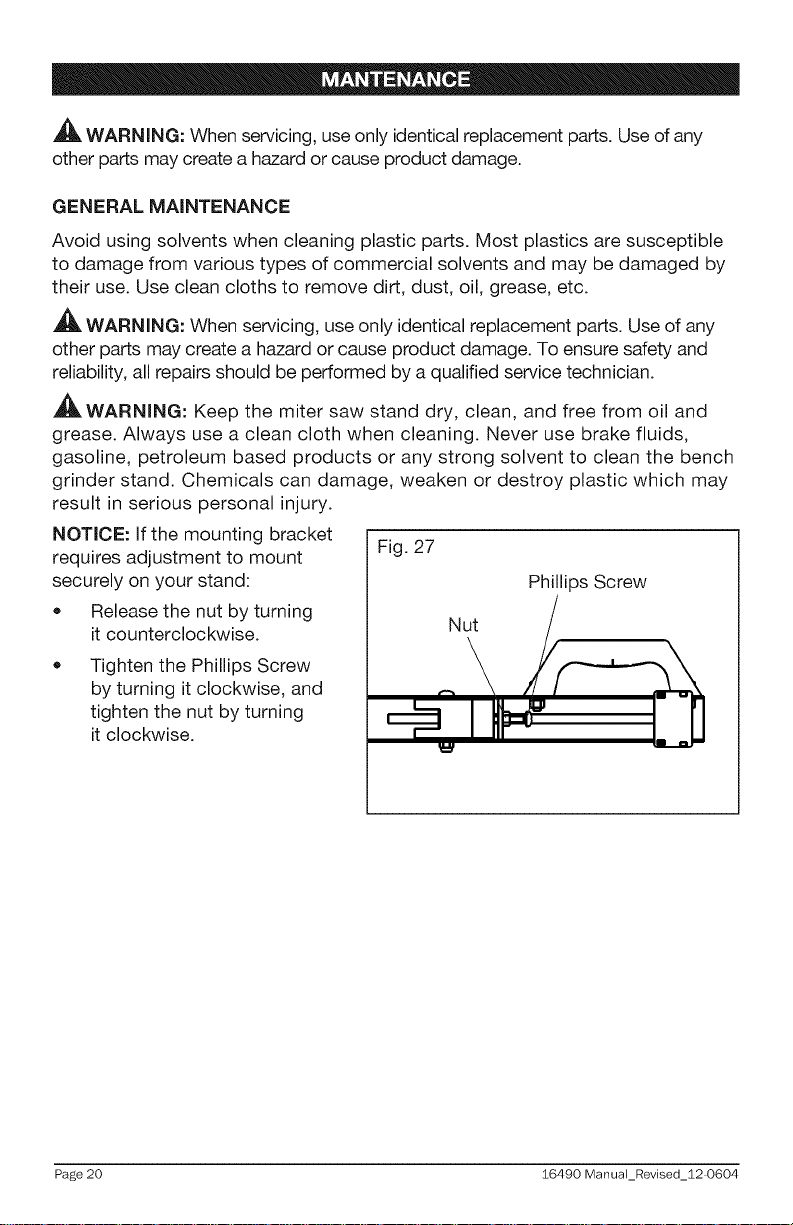

NOTICE: If the mounting bracket

requires adjustment to mount Fig. 27

securely on your stand: Phillips Screw

* Release the nut by turning

it counterclockwise. Nut

Tighten the Phillips Screw

by turning it clockwise, and

tighten the nut by turning

it clockwise.

Page 20 16490 ManuaLRevised_12 0604

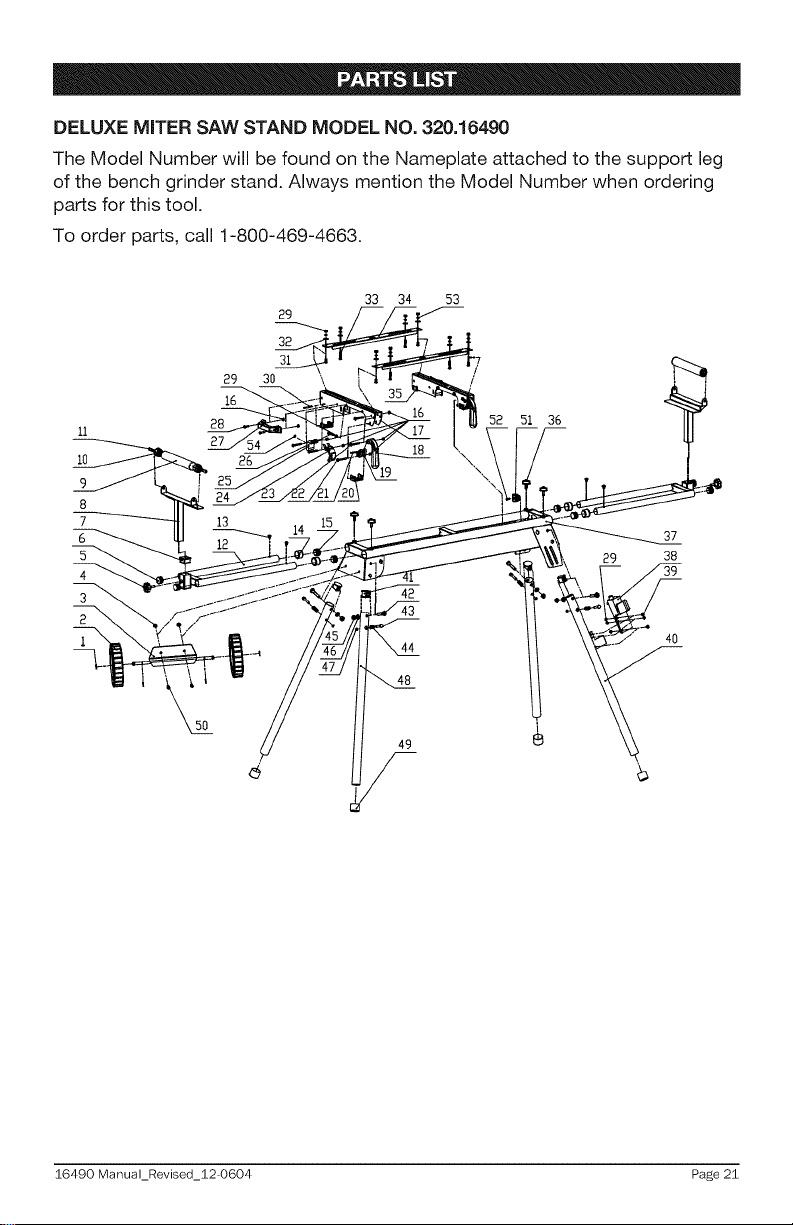

DELUXE MITER SAWSTAND MODEL NO. 320.16490

The Model Number will be found on the Nameplate attached to the support leg

of the bench grinder stand. Always mention the Model Number when ordering

parts for this tool.

To order parts, call 1-800-469-4663.

29

32

31

29 30 \

16

Ii

IO

9

8

7

6

5

4

3

28 52 51 36

33 34 53

48

/

I

37

38

4o

16490 Manual_Revised_12-0604 Page 21

DELUXE MITER SAW STAND MODEL NO. 320.16490

The Model Number will be found on the Nameplate attached to the support leg

of the bench grinder stand. Always mention the Model Number when ordering

parts for this tool.

To order parts, call 1-800-469-4663.

1010602005 Shield ring 4

2 1020220002 Transport wheel 2

3 2040508002 Wheel mounting axle assembly 1

4 1010202005 Nut 2

5 1020211002 Hand wheel 2

6 1021501001 Insert block 4

7 1020904001 Bushing 2

8 2050509006 Roller support 2

9 2040701003 Roller 2

10 1020505001 Cover 4

11 1010101002 Screw 4

12 1010203002 Extension bar 2

13 1010122025 Screw 4

14 1021504001 Block 4

15 1021501002 Block 4

16 1010202004 Nut 14

17 2040107005 Brackets 2

18 1020103002 Locking lever 2

19 1020801002 Connector 2

20 1021601002 Square block 2

21 1010402011 Bolt 2

22 1010118005 Screw 8

23 1010118006 Screw 2

24 1029901002 Clamping block 2

25 1020701001 Fixed block 2

Page 22 16490 ManuaLRevised_12 0604

1010119002 Screw 2

27 1020102001 Handle 2

28 1010108006 Blot 4

29 1010201004 Nut 13

30 1010402012 Bolt 2

31 1010103010 Bolt 4

32 1010301030 Washer 8

33 1010103009 Bolt 4

34 2040307001 Connecting plate 2

35 1021601001 Square block 2

36 102102001 Screw 4

37 2040803003 Frame assembly 1

38 1029913012 Switch assembly 1

39 1010122009 Screw 3

40 2029903007 Leg 1

41 1021503001 Block 4

42 1010118004 Bolt 4

43 1010407001 Bolt 4

44 1010603017 Spring 4

45 1010202001 Nut 4

46 1010301001 Washer 4

47 1010602001 Shield ring 4

48 2040102001 Leg 3

49 1020906006 Footpad 4

50 1010122033 Screw 2

51 1020403007 Terminal block 1

52 1010132004 Screw 1

53 1010303003 Spring washer 8

54 1010301007 Plain Washer 2

16490 Manual_Revised_12-0604 Page 23

Manual del Propietario

SOPORTE DE SIERRA DE

DE LUJO

Modelo N° 320.16490

ADVERTENCIA: Para reducir el

riesgo de lesiones, el usuario debe leer

y comprender el Manual de Operaci6n

antes de usar este producto.

ADVERTENCIA: Para reducir el riesgo

de lesiones, el usuario siempre debe leer

y seguir las instrucciones del manual del

propietario de la herramienta antes

de instalarla.

INGLETE

• GARANTiA

• SEGURIDAD

• NIONTAJE

• DESCRIPCION

• OPERACi6N

• MANTENIMIENTO

• ESPANOL

Sears Brands Management Corporation, Hoffman Estates,

IL 60179 U.S.A.

www,craftsman,com

Garantia Pagina 25

Simbolos de Seguridad Paginas 27-28

Instrucciones de Seguridad Paginas 29-30

Descripcion Pagina 31

Montaje Paginas 32-33

Operacion Paginas 11-19

Mantenimiento Pagina 20

Lista de piezas Paginas 21-23

GARANTiA TOTAL DE UN A_lO DE CRAFTSMAN

POR UN ANO despues de la fecha de compra, este producto esta

garantizado por cualquier defecto de materiales o fabricaci6n. Si cuenta

con la prueba de compra, el producto defectuoso sera reemplazado sin

costo alguno.

Para detalles sobre la cobertura de garantia para obtener una

devoluci6n gratuita, visite la p_gina web: www.craftsman.com

Esta garantia se anulara, si el producto ha sido usado mientras se proveia

servicios comerciales o si se ha rentado a otra persona.

Esta garantia le otorga derechos legales especificos. Puede que usted

tenga otros derechos que varien de un Estado a otro.

Corporacion Sears Brands Management, Hoffman Estates, IL 60179

Esta sierra de inglete tiene muchas caracteristicas disefiadas para hacer su uso

mas placentero. AI disefiar este producto, se le ha otorgado maxima prioridad a

la seguridad, el rendimiento y la confiabilidad, haciendolo facil de mantener

y operar.

iGUARDE ESTAS INSTRUCCIONES!

! LEA TODAS LAS INSTRUCCIONES!

Page 25 16490 ManuaLRevisado_12 0604

,_ ADVERTENClA: Algunas particulas de polvo que se generan al lijar,

serruchar, afilar, o perforar, con herramientas electricas, asi como las

actividades de construccion, contienen quimicos que el estado de California

reconoce como causantes de cancer, nacimientos defectuosos u otros daSos

reproductivos. Algunos ejemplos de estos quimicos son:

• Plomo de pinturas hechas a base de plomo

Silice cristalizado de ladrillos y cemento y otros productos de albaSileria, y

Arsenio y cromo de la madera tratada quimicamente

El riesgo por el contacto con estos quimicos, varia dependiendo de cuan

frecuente realice este tipo de trabajo. Para reducir el contacto con estos

quimicos: trabaje en un Area bien ventilada, y con equipo con seguridad

aprobada; tales como mascaras para el polvo que esten especialmente

dise_adas para filtrar las particulas microscopicas.

El proposito de los simbolos de seguridad es el de dirigir su atencion hacia

los peligros posibles. Los simbolos de seguridad y las explicaciones que los

acompaSan merecen una cuidadosa atencion y entendimiento. Los simbolos

de advertencia no eliminan los peligros pot si mismos. Las instrucciones y

advertencias que proveen no son sustitutas de las medidas adecuadas de

prevencion de accidentes.

16490 Manual_Revisado_12-0604 Page 26

_, ADVERTENClA: AsegOrese de leer y comprender todas las instrucciones

de seguridad en este manual de operacion, incluyendo todos los simbolos

de seguridad de alerta tales como "PELIGRO", "ADVERTENClA", y

"PRECAUClON" antes de usar esta herramienta. El no seguir todas las

instrucciones que se indican a continuacion, puede ocasionar descarga

electrica, incendio, y/o grave lesion personal.

SIGNIFICADO DE LOS SIMBOLOS

SiMBOLO DE SEGURIDAD DE ALERTA: indica PELIGRO, ADVERTENCIA, o

PRECAUCION; pueden set usados junto con otros simbolos o pictogramas.

,_ PELIGRO: indica una situacion peligrosa que de no ser evitada, producira la

muerte o lesion grave.

,_ ADVERTENClA: indica una situacion potencialmente peligrosa que de no

set evitada, podria producir la muerte o lesion grave.

,_ PRECAUClON: indica una situacion potencialmente peligrosa que de no

set evitada podria producir lesiones menores o moderadas.

Prevenci6n de daSo y mensajes informativos

Le informan al usuario de informacion importante y/o instrucciones que podrian

producir daSo al equipo u otra propiedad si no se cumplen. Cada mensaje esta

precedido por la palabra "NOTA", como se muestra en el ejemplo aqui abajo:

AVlSO: Da_o al equipo u/o otra propiedad puede producirse si no se cumplen

estas instrucciones.

,_ ADVERTENClA: para asegurarse la seguridad y la confiabilidad, todas las

reparaciones deben realizarse pot un tecnico de servicio calificado.

_k

,_ ADVERTENClA: La operacion de cualquier herramienta

electrica puede causar el lanzamiento de objetos extraSos

dentro de sus ojos, Io cual puede resultar en una lesion severa

del ojo. Antes de iniciar la operacion de la herramienta

electrica, siempre use anteojos o gafas protectoras con

proteccion lateral y una mascara protectora para la cara

cuando sea necesario. Le recomendamos una MAscara de

Seguridad de Vision Amplia para usarse sobre sus lentes o

gafas de seguridad estandar con proteccion lateral. Siempre

use proteccion a los ojos con la etiqueta de cumplimiento de

ANSI Z87.1.

Page 27 :$6490 Manual_Revisado_12 0604

GUARDE ESTAS INSTRUCCIONES

Algunos de los siguientes simbolos pueden usarse en esta herramienta. Por

favor est6dielos y aprenda su significado. La interpretacion adecuada de estos

simbolos, le permitir& operar mejor la herramienta y de una forma mas segura.

SJMBOLO NOMBRE DESIGNACl6N / EXPLICACl6N

V Voltios Voltaje

A Amperios Corriente

Hz Hercios Frecuencia (ciclos por segundo)

w Vatios Energia

min Minutos Tiempo

"%, Corriente alterna Tipo de corriente

Corriente continua Tipo o una caracteristica de la corriente

no Velocidad sin carga Velocidad giratoria, sin carga

[] Construcci6n Ctase II Construcci6n de dobte aislaci6n

.../min Por minuto Revoluciones, carreras, velocidad de

superficie, 6rbitas, etc., por minuto.

Aterta de condiciones No exponga a la Iluvia u otras

hOmedas Iocaciones hOmedas.

Lea et manual de debe leer y comprender este manual de

operaci6n operaci6n antes de usar este producto.

O Siempre use gafas o lentes de seguridad

Protecci6n ocular con protecciones laterales y una protecci6n

Para reducir et riesgo de lesiones, et usuario

de todo el rostro cuando utilice este producto.

_1_ Aterta de seguridad Precauciones que involucran su seguridad.

Simbolo de no tocar No mantener sus manos atejadas de la

con las manos sierra provocara lesiones personales graves.

Simbolo de no tocar No mantener sus manos alejadas de la

con las manos sierra provocara lesiones personales graves.

Simbolo de no tocar No mantener sus manos atejadas de la

con las manos sierra provocara lesiones personales graves.

Simbolo de no tocar No mantener sus manos alejadas de lacon las manos sierra provocara lesiones personales graves.

Superficie caliente Para reducir el riesgo de lesiones o daNos,

eviteel contacto con cualquier superficie caliente.

16490 Manual_Revisado_12-0604 Page 28

Loading...

Loading...