Craftsman 319226560 Owner’s Manual

Save This Manual For Future Reference

OW °

MANUAL

Model No.

319.226560

Serial No.

®

Model and serial

numbers may be

found on the nam

plate located on the

front of the tool. You

should record both

the model and serial

number and retain it

in a safe place for

future use.

Caution:

Read, understand and

follow ALL Instruc-

tions and rules for

safe operation before

operating this tool.

LT/

C

SANDER

•Warranty

. Safety Instructions

" KnowYour Belt/Disc Sander

• Operation and Maintenance

• Repair Parts

226560102

226560102

Sears, Roebuck and Co., Hoffman Estates, lL 60179 U.S.A.

NRTL/C

LR 78936

FULL ONE-YEAR WARRANTY ON SEARS BELT and DISC SANDER

If this Sears Craftsman Belt and Disc Sander fails due to a defect in material or workmanship

within one year' from the date of purchase, RETURN ITTO THE NEAREST SEARS SERVICE

CENTER INTHE UNITED STATES, and Sears will repair it, free of charge.

If this Belt / Disc Sander is used for cormnercial or rental purposes, this warranty will apply

for ninety days from the date of purchase.

This warranty applies only while this product is in the United States.

This warranty gives you specific legal rights and you may also have other rights which vary

from state to state,

Sears, Roebuck and Co,, Dept. 817 WA, Hoffman Estates, IL 601 79

SAFETY INSTRUCTIONS FOR BELT/DISC SANDER

m BEFORE USING THE BELT/DISC SANDER:

1. READ and become familiar with this 6.

entire instruction manual. LEARN the

tools applications, limitations, and possible

hazards,

2_ AVOID DANGEROUS CONDITIONS.

DO NOT use power tools in wet or damp

areas or expose them to rain.

DO NOT use power tools in the presence

of flammable liquids or gases.

4. ALWAYS keep your woik area clean,

uncluttered and weU lit. DO NOT work on

floor surfaces that are slippery from

, sawdust or wax.

KEEP VISITORS AND CHILDREN

AWAY, Other people should keep a safe

distance from the work area, especially

when tool is operating

DO NOT FORCE THE TOOL. Never

force a tool to do a job for which it was not

designed It will do a better and safer job by

only using on jobs for which it was

designed.

,

DRESS FOR SAFETY. DO NOT wear

loose clothing, gloves, neckties, or jewelry

(rings, watches); they can get caught and

draw you into moving parts. ALWAYS

wear non-slip footwear; tie back long hair.

WEAR A FACE HASK OR DUST

HASK IF SANDING OPERATION

PRODUCES DUST.

,

ALWAYS remove the power cord plug

from the electric outlet when making

adjustments, changing pat,s, cleaning or

working on tool.

10. KEEP GUARDS IN PLACE AND IN

WORKING ORDER.

SAVE THESE INSTRUCTIONS

Page 2

SAFETY INSTRUCTmONS CONTINUED

11 ALWAYS WEAR EYE PROTECTION. Any Sander can throw foreign objects into the

eyes which could cause permanent eye damage ALWAYS Wear Safety

WEARYOUR Goggles (not glasses) that comply with ANSI safety standard Z87o t,

Everyday eyeglasses have only impact-resistant lenses._ they ARE NOT

safety glasses Safety Goggles are available at Sears,

NOTE: Glasses or goggles not in compliance with ANSI Z87,1 coiald

seriously hurt you when they break,

12_ AVOID ACCIDENTAL STARTING.

Ensure that the power switch is in the

"OFF" position before plugging in the

power cord

13, REMOVE ADJUSTING TOOLS. Form

habit of checking to see that tools and

adjusting wrenches are removed from the

sander before turning it on_

14_ USE ONLY RECOMMENDED

ACCESSORIES. Using improper

accessories can be hazardous. If in doubt,

check the instruction manual that comes

with that accessory,

15, NEVER LEAVE A TOOL RUNNING

UNATTENDED. Turn the power switch

to "OFF", DO NOT leave too! until it has

come to complete stop

16. NEVER STAND ON A TOOL. Serious

injury could result ff the tool tips or you

accidentally hit the sander, DO NOT

store anything above or near the toot

where anyone might stand on the tool to

reach it

17. DON'T OVERREACH. Keep proper

footing and balance at all times. Wear

oil-resistant r_ubber_soted footwear. Keep

floor clear of oil, scrap and other debris

18. MAINTAIN TOOLS WITH CARE.

Always keep tools clean and in good

working order

t9, CHECK DAMAGED PARTS. Before

each use of tool, a guard or other part that

is damaged should be carefully checked to

determine that it will operate properly and

perform its intended function. Check for

alignment of moving parts, binding of

moving parts, breakage of parts, mounting

or any other conditions that may affect its

operation, A guard or other part that is

damaged should be properly repaired or

replaced°

20_ MAKE WORKSHOP CHILDPROOF.

By use of padlocks, master switches, or by

removing starter keys_

21,

DRUGS, ALGOHOL OR

MEDICATIONS. DO NOT operate tool if

you are under the i_n£1uence of drugs,

alcohol or medication that could affect

3,our ability to use the tool properly,

22

SECURE ALL WORK. When practical,

use clamps or a vise to hold work, It is sager

than using your hands and prevents round

or odd-shaped pieces from turning.

, DIRECTION OF FEED. Feed work into a

23

blade or cutter against the direction of

rotation of the blade or cutter ordyo

24

WARNING: Dust generated from certain

materials can be injuriou s to your health.

Always operate sander in well ventilated

areas and provide for proper dust removal

SAVE THESE INSTRUCTIONS

Page 3

SAFETY INSTRUCTIONS CONT/NUED

[] ADDITIONAL SA!FETY INSTRUCTIONS FOR BELT/DISC

DO NOT OPERATE YOUR SANDER UNTIL IT IS COMPLETELY ASSEMBLED AND

INSTALLED ACCORDING TO THE INSTRUCTIONS.

I .THIS SANDER IS DESIGNED TO SAND

WOOD OR WOOD-LIKE PRODUCTS

ONLY. Sanding or grinding other materials

could result in fire, injury or- damage to

workpiece_

2 MOUNT AND USE this sander on

hoxizontal surfaces only. Operating sander

when mounted on non-horizontal surfaces

might result in motor damage_

3 IF THERE IS ANY TENDENCY for the

machine to tip over or move during any

use, the sander must be securely fastened

to the bench top or supporting surface,

4. MAKE SURE the sanding belt is instaUed

in the correct direction See directional

arrow on back of belt,

5. ALWAYS have the tracking adjusted

properly so the belt does not run off the

pulleys

6 DO NOT USE sanding belts or discs that

are damaged, torn, loose, Use only correct

size sanding belt mid disc

7 ALWAYS HOLD the workpiece firmly

when sandingAvoid awkward hand

positions when a slip could cause a hand

to move into the sanding belt or disc.

Sand only one workpiece at a time.

8, ALVVAYS HOLD the workpiece firmly on

the table when disc sanding and when

using either table when belt sanding,

9, ALWAYS SAND ON THE

DOWNWARD SIDE of the sanding disc

when using the disc sander Sanding on the

upward side of the disc could cause the

workpiece to fly up which could be

hazardous,

10 ALWAYS maintain a minimum clearance

of 1/16 inch or less between tile table or

backstop and the sanding belt or disc

1 1, DO NOT sand pieces of material that are

too small to be safely supported

12. WHEN sanding a large workpiece, provide

additional support at table height.

13. DO NOT sand with the workpiece

unsupported. Support the workpiece with

the backstop or tableiFhe only exception

is curved work performed on the outer

sanding drum.

14. ALWAYS remove scrap pieces and other

objects from the table, backstop or belt

before turning the sander "ON?'

15 N EVE R perform layout, assembly or set-up

work on the table while the sander is

operating,

16 NEVER use solvents to clean plastic parts,

Solvents could possibly dissolve or other

wise damage the material, Only a soft damp

cloth should be used to clean plastic parts,

17. SHOULD any part of your sander be

missing, damaged, or fail in any way, or

any electrical components fail to perform

properly, shut off switch and iemove plug

f_'om power supply outlet. Replace

missing, damaged Or failed parts before

resuming operation

18 NEVER YANK THE POWER CORD

out of the receptacle. Keep cords away

from heat, oil and sharp edges.

19 HAVE AN ELECTRICIAN REPLACE

OR REPAIR damaged or worn cords

immediately,

SANDER

i SAVE THESE INSTRUCTIONS ]

Page 4

SAFETY INSTRUCTHO.NS CONTINUED

l_ ADDITIONAL SAFETY RNSTRUCTIONS FOR BELT/DISC SANDER

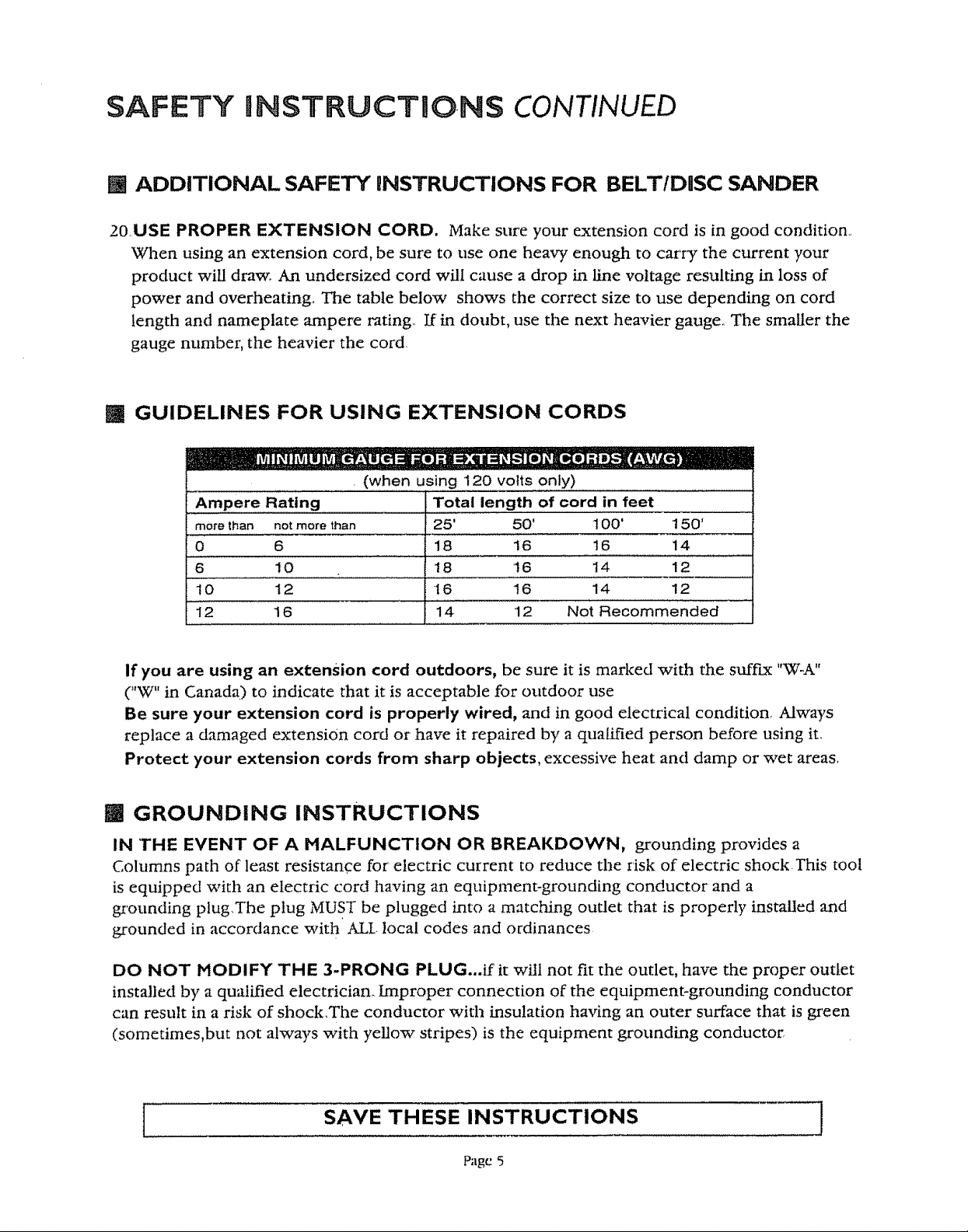

20USE PROPER EXTENSION CORD. Make sure your extension cord is in good condition

When using an extension cord, be sure to use one heavy enough to carry the current your

product will draw_ An undersized cord will c;mse a drop in line voltage resulting in loss of

power and overheating° The table below shows the correct size to use depending on cord

length and nameplate ampere rating If in doubt, use the next heavier gauger The smaller the

gauge number, the heavier the cord

m GUIDELINES FOR USING EXTENSION CORDS

tTJll_lltTJlil|Tt|i___ii t_'];;ll_;[o ;l_:_llt¢l_l--"][t]i'l|l'IO]_}i},: i vT

, (when using 120 volts only)

Ampere Rating Total length of cord in feet

more than not more than 25' 50' 100' '150'

0 6 18 16 16 14

6 10 18 16 14 12

t0 12 16 16 14 12

12 16 14 12 Not Recommended

= _ 1 ,, .....

if you are using an extension cord outdoors, be sure it is marked with the suffix "W-A"

("W" in Canada) to indicate that it is acceptable for outdoor use

Be sure your extension cord is properly wired, and in good electrical condition Mways

replace a damaged extension cord or have it repaired by a qualified person before using it,

Protect your extension cords from sharp objects, excessive heat and damp or wet areas,

i GROUNDING INSTRUCTIONS

IN 'THE EVENT OF A blALFUNCTION OR BREAKDOWN, grounding provides a

Columns path of least resistance for electric current to reduce the risk of electric shockThis tool

is equipped with an electric cord having an equipment-grounding conductor and a

grounding plugThe plug MUST be plugged into a matching outlet that is properly installed and

grounded in accordance with' A_LL local codes and ordinances

DO NOT MODIFY THE 3-PRONG PLUG...if it will not fit the outlet, have the proper outlet

installed by a qualified electrician, Improper connection of the equipment-grounding conductor

can result in a risk of shock,The conductor with insulation having an outer surface that is green

(sometimes,but not always with yellow stripes) is the equipment grounding conductor

SAVE THESE INSTRUCTIONS

I

Page 5

SAFETY INSTRUCTIONS CONTINUED

m GROUNDING INSTRUCTIONS CONTINUED

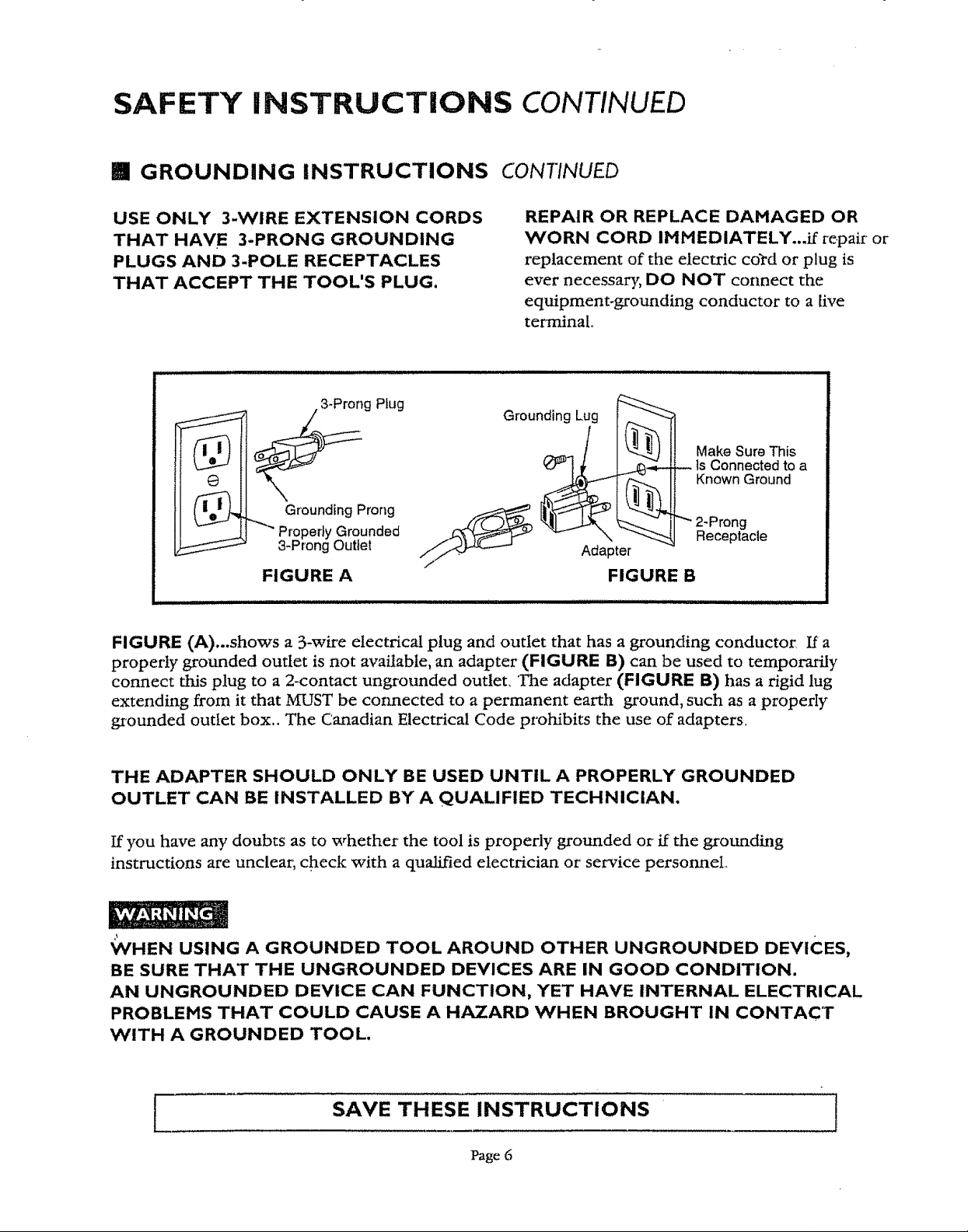

USE ONLY 3-WIRE EXTENSION CORDS

THAT HAVE 3-PRONG GROUNDING

PLUGS AND 3-POLE RECEPTACLES

THAT ACCEPT THE TOOL'S PLUG.

ii iti ,,,

_ s3_ProngPtug

Grounding Prong

"Properly Grounded

3-Prong Outlet

FIGURE A

tllllll

FIGURE (A)...shows a 3-wire electrical plug and outlet that has a grounding conductor If a

properly grounded outlet is not available, an adapter (FIGURE B) can be used to temporarily

connect this plug to a 2-contact ungrounded outlet, The adapter (FIGURE B) has a rigid lug

extending from it that MUST be com, lected to a permanent earth ground, such as a properly

grounded outlet box., The Canadian Electrical Code prohibits the use of adapters,

REPAIR OR REPLACE DAMAGED OR

VVORN CORD IMMEDIATELY...if repair or

replacement of the electric cord or plug is

ever necessary, DO NOT connect the

equipment-grounding conductor to a live

terminal.

Grounding Lug

FIGURE B

Make Sure This

Is Connected to a

Known Ground

"_ 2-Prong

Receptacle

THE ADAPTER SHOULD ONLY BE USED UNTIL A PROPERLY GROUNDED

OUTLET CAN BE INSTALLED BY A QUALIFIED TECHNICIAN.

If you have any doubts as to whether the tool is properly grounded or' if the grounding

instructions are unclear; check with a qualified electrician or service personnel

_/HEN USING A GROUNDED TOOL AROUND OTHER UNGROUNDED DEVICES,

BE SURE THAT THE UNGROUNDED DEVICES ARE IN GOOD CONDITION.

AN UNGROUNDED DEVICE CAN FUNCTION, YET HAVE INTERNAL ELECTRICAL

PROBLEMS THAT COULD CAUSE A HAZARD WHEN BROUGHT IN CONTACT

WITH A GROUNDED TOOL.

[

SAVE THESE INSTRUCTIONS

Page 6

J

Loading...

Loading...