Craftsman 316795860 Owner’s Manual

Operator's Manual

®

2-Cycle

WEEDWACKER_

GAS TRIMMER/BRUSHCUTTER

Model No. 316.795860

* SAFETY

* ASSEMBLY

* OPERATION

* MAINTENANCE

* PARTS LIST

* ESPANOL, R 13

CAUTION: Before

using this product,

read this manual

and follow all safety

rules and operating

instructions.

Sears Brands Management Corporation, Hoffman Estates, IL 60179 U.S.A.

Visit our website: www.craftsrnan.corn

769-05784 P00 01/10

CALiFORNiA PROPOSiTiON 65 WARNING

THE ENGINE EXHAUST FROM THIS PRODUCT CONTANNS CHEMICALS

KNOWN TO THE STATE OF CALHFORNIA TO CAUSE CANCER, BIRTH

DEFECTS OR OTHER REPRODUCTIVE HARM.

TABLE OF CONTENTS

Safety Rules ................................................. 2

Warranty .................................................... 4

Know Your Unit ............................................... 5

Assembly Instructions .......................................... 5

Oil and Fuel Information ........................................ 7

Starting/Stopping Instructions ................................... 7

Operating Instructions ......................................... 8

Maintenance and Repair Instructions .............................. 9

Cleaning and Storage ......................................... 10

Troubleshooting Chart ........................................ 11

Specifications ............................................... 12

Parts List ................................................... 29

Service Numbers ..................................... Back Cover

SPARK ARRESTOR NOTE

NOTE: For users on U.S. Forest Land and in the states of California, Maine,

Oregon and Washington. All U.S. Forest Land and the state of California

(Public Resources Codes 4442 and 4443), Oregon and Washington require, by

law that certain internal combustion engines operated on forest brush and/or

grass-covered areas be equipped with a spark arrestor, maintained in effective

working order, or the engine be constructed, equipped and maintained for the

prevention of fire. Check with your state or local authorities for regulations

pertaining to these requirements. Failure to follow these requirements could

subject you to liability or a fine. This unit is factory equipped with a spark

arrestor. If it requires replacement, ask your LOCAL SERVICE DEALER to install

the Accessory Part #753=06182 Muffler Assembly

The purpose of safety symbols is to attract your attention to possible

dangers. The safety symbols, and their explanations, deserve your careful

attention and understanding. The safety warnings do not by themselves

eliminate any danger. The instructions or warnings they give are not

substitutes for proper accident prevention measures.

SYMBOL MEANING

Attention is required in order to avoid serious personal injury. May

SAFETY ALERT: Indicates danger, warning or caution.

be used in conjunction with other symbols or pictographs.

NOTE: Advises of information or instructions vital to the operation or

_ DANGER: Failure to obey a safety warning will result in serious

NOTE= This Unit Can Use a Plug=in Power Start or Power Bit Start

Read the Operator's Manual and follow all warnings and safety

instructions. Failure to do so can result in serious injury to the operator

and/or bystanders. FOR QUESTIONS, CALL 1=800=4=MY=HOME®

maintenance of the equipment.

injury to yourself or to others. Always follow the safety precautions

to reduce the risk of fire, electric shock and personal injury.

to yourself and others. Always follow the safety precautions to

WARNING: Failure to obey a safety warning can result in injury

reduce the risk of fire, electric shock and personal injury.

electric shock and personal injury.

Optional Accessory!

Please refer to the Plug-In Power Start or Power Bit Start

operator's manual for proper use of these features. (Items Sold

Separately! Please refer to page 10 of this manual for more

information about purchasing these accessories.)

J

All information, illustrations, and specifications in this manual are based on the

latest product information available at the time of printing. We reserve the right

to make changes at any time without notice.

= IMPORTANT SAFETY INSTRUCTIONS =

READ ALL INSTRUCTIONS BEFORE OPERATING SAFETY WARNINGS FOR GAS UNITS

WARNING: When using the unit, all safety rules must be

followed. Please read these instructions before operating the unit

in order to ensure the safety of the operator and any bystanders.

Please keep these instructions for later use.

• Read the instructions carefully. Be familiar with the controls and proper

use of the unit.

Do not operate this unit when tired, ill, or under the influence of alcohol,

drugs, or medication.

Children and teens under the age of 15 must not use the unit, except for

teens guided by an adult.

All guards and safety attachments must be installed properly before

operating the unit.

Inspect the unit before use. Replace damaged parts. Check for fuel leaks.

Make sure all fasteners are in place and secure. Replace parts that are

cracked, chipped, or damaged in any way. Do not operate the unit with

loose or damaged parts.

Carefully inspect the area before starting the unit. Remove all debris and

hard or sharp objects such as glass, wire, etc.

Be aware of the risk of injury to the head, hands and feet.

Clear the area of children, bystanders, and pets. At a minimum, keep all

children, bystanders, and pets outside a 50 feet (15 m) radius; there still may

be a risk to bystanders from thrown objects. Bystanders should be

encouraged to wear eye protection. If approached, stop the unit immediately.

Use only Hassle-Free TM XTRA QUIET Spiral Line. Never use metal-reinforced

line, wire or rope. These can break off and become dangerous projectiles.

Squeeze the throttle control and check that it returns automatically to the

idle position. Make all adjustments or repairs before using unit.

[_ ARNING: Gasoline is highly flammable and its vapors can

• Always stop the engine and allow it to cool before filling the fuel tank.

• Always mix and add fuel in a clean, well-ventilated outdoor area where

• Never operate the unit without the fuel cap securely in place.

• Never start or run the unit inside a closed room or building. Breathing exhaust

WHILE OPERATING

explode if ignited. Take the following precautions:

Store fuel only in containers specifically designed and approved for the

storage of such materials.

Never remove the fuel tank cap or add fuel when the engine is hot.

Always loosen the fuel tank cap slowly to relieve any pressure in the tank

before fueling. Do not smoke.

there are no sparks or flames. Do not smoke.

Avoid creating a source of ignition for spilled fuel. Wipe up any spilled fuel

from the unit immediately before starting the engine. Move the unit at

least 30 feet (9.1 m) from the fueling source and site before starting the

engine. Do not smoke.

fumes can kill. Only operate this unit in a well-ventilated outdoor area.

Never start or run the unit inside a closed room or building. Breathing exhaust

fumes can kill. Operate this unit only in a well ventilated outdoor area.

Wear safety glasses or goggles that are marked as meeting ANSI Z87.1-

1989 standards. Also wear ear/hearing protection when operating this

unit. Wear a face or dust mask if the operation is dusty. Long sleeve shirts

are recommended.

Wear heavy, long pants, boots and gloves. Do not wear loose clothing,

jewelry, short pants, sandals or go barefoot. Secure hair above shoulder level.

The cutting head shield must always be in place while operating the unit. Do

not operate unit without both trimming lines extended, and the proper line

installed. Do not extend the trimming line beyond the length of the shield.

• Thecuttingattachmentmayspinduringidlespeedadjustments.Wear

protectiveclothingandobserveallsafetyinstructionstopreventserious

personalinjury.

AdjustthepositionoftheD-handletoprovidethebestgrip.

Besurethecuttingheadisnotincontactwithanythingbeforestartingtheunit.

Usetheunitonlyindaylightorgoodartificiallight.

Avoidaccidentalstarting.Beinthestartingpositionwheneverpullingthe

starterrope.Theoperatorandunitmustbeinastablepositionwhile

starting.SeeStarting/Stopping Instructions.

Use the right tool. Only use this tool for the purpose intended.

Do not overreach. Always keep proper footing and balance.

Always hold the unit with both hands when operating. Keep a firm grip on

both the front and rear handle or grips.

Keep hands, face, and feet at a distance from all moving parts. Do not

touch or try to stop the cutting head when it is rotating.

Do not touch the engine or muffler. These parts get extremely hot from

operation. They remain hot for ashort time after turning off the unit.

Do not operate the engine faster than the speed needed to cut, trim or

edge. Do not run the engine at high speed when not cutting.

This unit has an overspeed protection switch to keep the unit from

overheating. When the unit is run at full throttle while not in use for

extended lengths of time the overspeed protection switch will engage.

Always stop the engine when cutting is delayed or when walking from one

cutting location to another.

If the unit is struck or becomes entangled with a foreign object, stop the

engine immediately and check for damage. Do not operate before

repairing damage. Do not operate the unit with loose or damaged parts.

Stop and switch the engine to off for maintenance, repair, or for changing

the cutting head or other attachments.

Use only replacement parts and accessories listed in the Parts List section

of this operator's manual and distributed by a Craftsman outlet or service

center. Use of any replacement parts or accessories purchased

elsewhere may be hazardous and will also void the warranty.

Keep unit clean of vegetation and other materials. They may become

lodged between the cutting head and shield.

To reduce fire hazard, keep the engine and muffler free from grass, leaves,

excessive grease or carbon build up.

WHILE OPERATING WiTH CUTTING BLADE

Read and understand all safety warnings before operating this unit.

Always use the shoulder harness when using the brush blade accessory.

Keep the D-handle between the operator and cutting attachment or blade

at all times.

NEVER cut when the cutting blade is 30 inches (76 cm) or more above the

ground level.

Blade thrust may occur when the spinning blade contacts an object that it

does not immediately cut. Blade thrust can be violent enough to propel

the unit and/or operator in any direction, possibly causing a loss of

control. Blade thrust can occur without warning if the blade snags, stalls

or binds. This is more likely to occur in areas where it is difficult to see the

material being cut.

For operation with the brush blade, do not cut anything thicker than 1/2

inch or a violent kickback could occur.

Do not attempt to touch or stop the blade when it is rotating.

A coasting blade can cause injury while it continues to spin after the

engine is stopped or the throttle trigger is released. Maintain proper

control until the blade has completely stopped rotating.

Do not run the unit at high speed when not cutting.

If you strike or become entangled with a foreign object, stop the engine

immediately and check for damage. Have any damage repaired before

attempting further operations. Do not operate unit with a bent, cracked or

dull blade. Discard blades that are bent, warped, cracked or broken.

Do not sharpen the cutting blade. Sharpening the blade can cause the

blade tip to break off while in use. This can result in severe personal injury.

Replace the blade.

Do not use the cutting blade for edging or as an edger; severe personal

injury to yourself or others may incur. Use the cutting blade only for the

purpose described in this manual.

Stop the engine IMMEDIATELY if you feel excessive vibration. Vibration is

a sign of trouble. Inspect thoroughly for loose nuts, bolts or damage

before continuing. Repair or replace affected parts as necessary.

AFTER USE

Clean cutting blades with a household cleaner to remove any gum

buildup. Oil the blade with machine oil to prevent rust.

Lock up and store the cutting blade in an appropriate area to protect the

blade from unauthorized use or damage.

OTHER SAFETY WARNINGS

Never store the unit, with fuel in the tank, inside a building where fumes

may reach an open flame or spark.

Allow the engine to cool before storing or transporting. Be sure to secure

the unit while transporting.

Store the unit in a dry area, locked up or up high to prevent unauthorized

use or damage, out of the reach of children.

Never douse or squirt the unit with water or any other liquid. Keep handles

dry, clean and free from debris. Clean after each use. See the Cleaning

and Storage instructions.

Keep these instructions. Refer to them often and use them to instruct other

users. If loaning someone this unit, also loan them these instructions.

SAVE THESE iNSTRUCTiONS

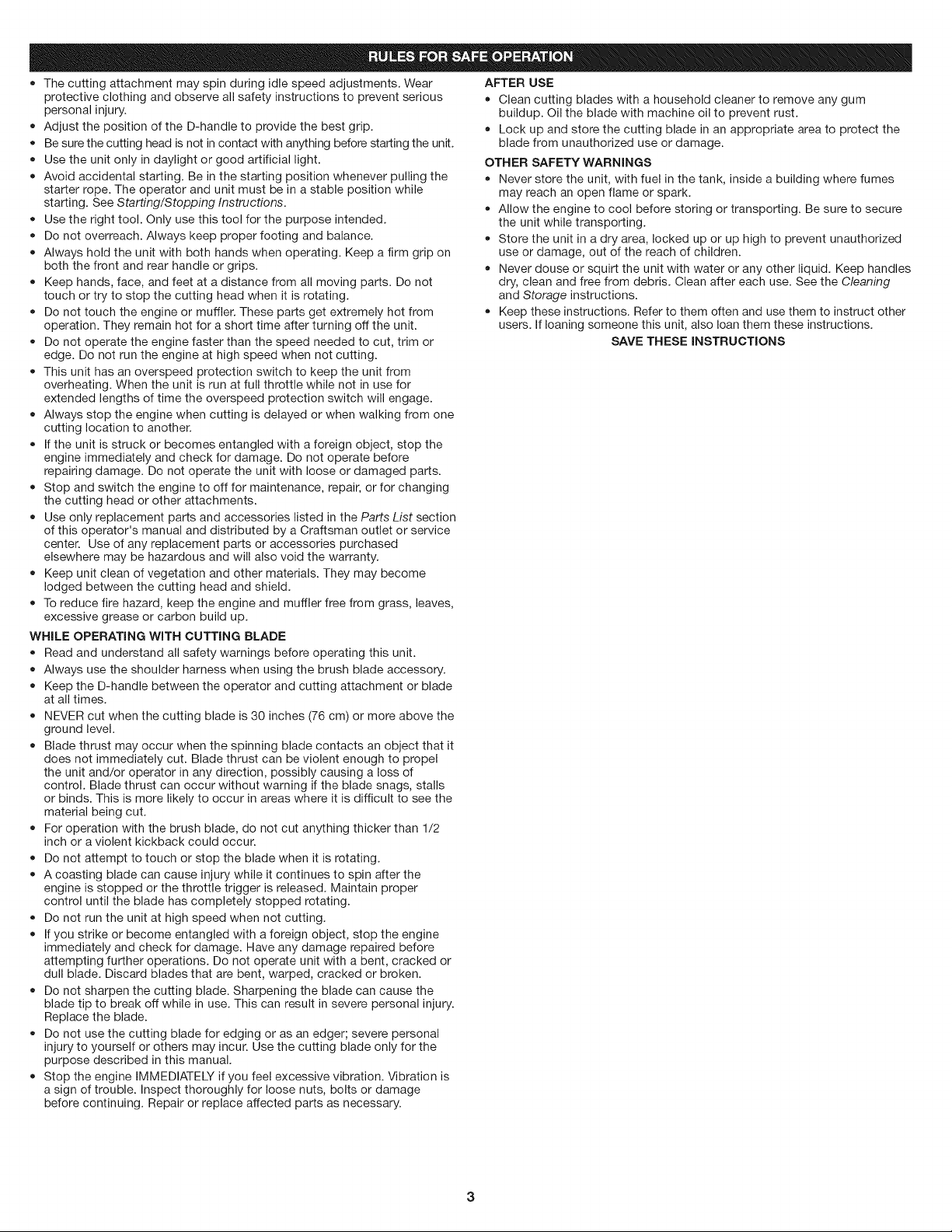

,,SAFETY & iNTERNATiONAL SYMBOLS ,,

This operator's manual describes safety and international symbols and pictographs that may appear on this product. Read the operator's manual for

complete safety, assembly, operating and maintenance and repair information.

SYMBOL MEANING SYMBOL MEANING

_iiiii_;i i

@

iiiiiWiii

W,

CRAFTSMAN FULL WARRANTY

If this Craftsman product fails due to a defect in material or workmanship within two years from the date of purchase, return it to any Sears store, Parts &

Repair Service Center, or other Craftsman outlet in the United States for free repair (or replacement if repair proves impossible).

This warranty applies for only 90 days from the purchase date if this product is ever used for commercial or rental purposes.

This warranty covers ONLY defects in material and workmanship. Sears will NOT pay for:

Expendable items that can wear out from normal use within the warranty period, such as cutting line, filters or spark plugs.

Repairs necessary because of accident or failure to operate or maintain the product according to all supplied instructions.

Preventive maintenance, or repairs necessary due to improper fuel mixture, contaminated or stale fuel.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

Sears, Roebuck and Co., Hoffman Estates, IL 60179

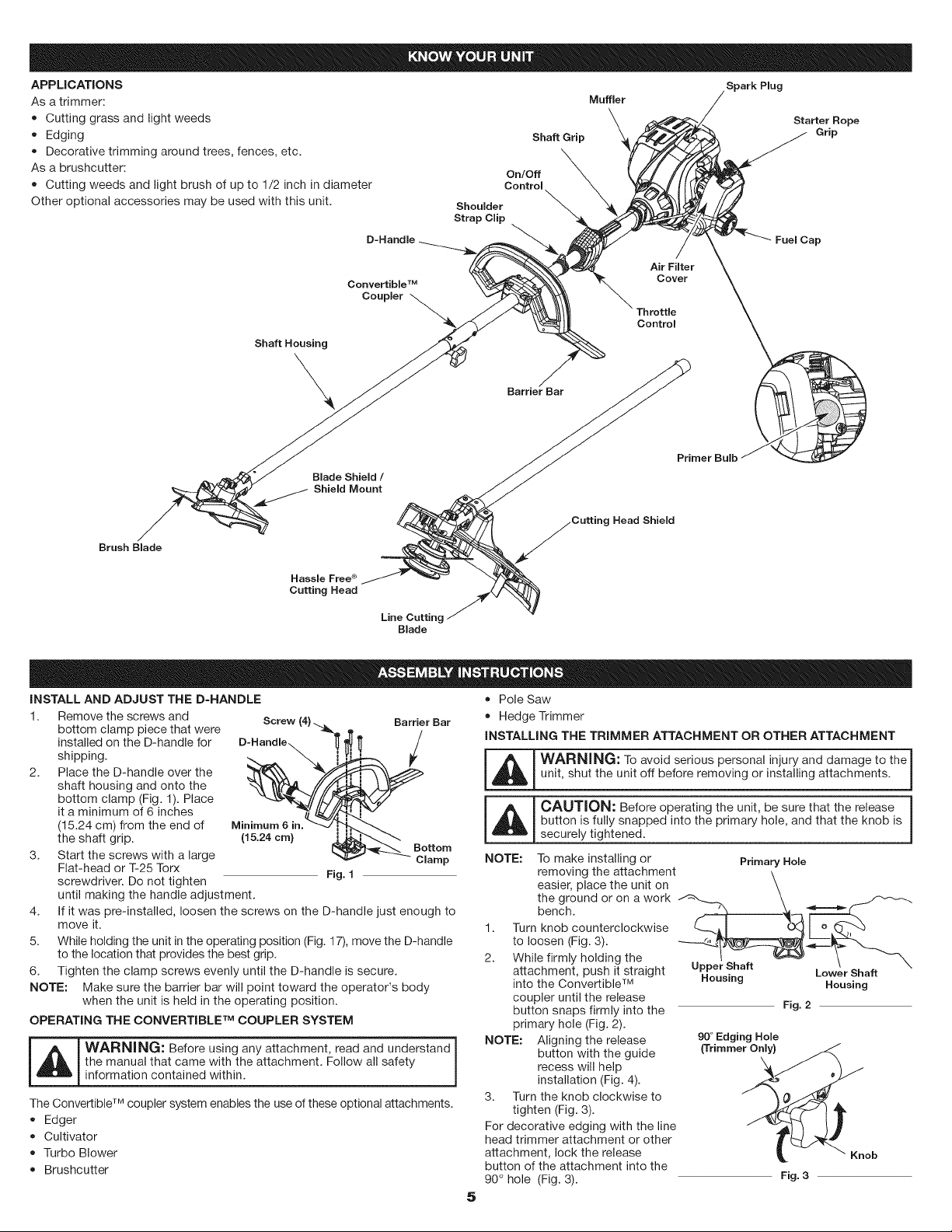

APPLICATIONS

Asatrimmer:

• Cuttinggrassandlightweeds

Edging

Decorativetrimmingaroundtrees,fences,etc.

Asabrushcutter:

Cuttingweedsandlightbrushofupto1/2inchindiameter

Otheroptionalaccessoriesmaybeusedwiththisunit.

Convertible TM

D-Handle

Shoulder

Strap Clip

On/Off

Control

Shaft Grip

Muffler

Air Filter

Cover

Spark Plug

Starter Rope

Fuel Cap

Grip

Coupler

Shaft Housing

\

Blade Shield /

Shield Mount

Brush Blade

Hassle Free ®

Cutting Head

Line Cutting

Blade

iNSTALL AND ADJUST THE D-HANDLE

1. Remove the screws and Screw (4).

bottom clamp piece that were

installed on the D-handle for

shipping.

2. Place the D-handle over the

shaft housing and onto the

bottom clamp (Fig. 1). Place

it a minimum of 6 inches

(15.24 cm) from the end of

the shaft grip.

3. Start the screws with a large

Flat-head or T-25 Torx

screwdriver. Do not tighten

until making the handle adjustment.

4. If it was pre-installed, loosen the screws on the D-handle just enough to

move it.

5. While holding the unit inthe operating position (Fig. 17), move the D-handle

to the location that provides the best grip.

6. Tighten the clamp screws evenly until the D-handle is secure.

NOTE: Make sure the barrier bar will point toward the operator's body

OPERATING THE CONVERTIBLE TM COUPLER SYSTEM

_ ARNING: Before using any attachment, read and understand

The Convertible TM coupler system enables the use of these optional attachments.

• Edger

• Cultivator

• Turbo Blower

• Brushcutter

when the unit is held in the operating position.

the manual that came with the attachment. Follow all safety

information contained within.

Minimum 6 in.

(15.24 cm)

Fig. 1

Barrier Bar

/

Bottom

Clamp

Throttle

Control

Barrier Bar

Primer Bulb

Head Shield

• Pole Saw

• Hedge Trimmer

INSTALLING THE TRIMMER ATTACHMENT OR OTHER ATTACHMENT

I A I WARNING: To avoid serious personal injury and damage to the I

_ unit, shut the unit off before removing or installing attachments.

!_!CAUTION:Beforeoperatingtheunit, besurethattherelease I

NOTE:

1.

2.

NOTE: Aligning the release

3. Turn the knob clockwise to

For decorative edging with the line

head trimmer attachment or other

attachment, lock the release

button of the attachment into the

90° hole (Fig. 3).

5

button is fully snapped into the primary hole, and that the knob is

securely tightened.

To make installing or Primary Hole

easier, place the unit on

the ground or on a work

removing the attachment _,

bench.

to loosen (Fig. 3).

Turn knob counterclockwise--_" '____t__, rq r------_

While firmly holding the

attachment, push it straight Upper Shaft

into the Convertible TM

coupler until the release

button snaps firmly into the

primary hole (Fig. 2).

button with the guide

recess will help

installation (Fig. 4).

tighten (Fig. 3).

Housing LowerShaft

90 ° Edging Hole

(Trimmer Only)

Housing

Fig. 2

REMOVING THE TRIMMER ConvertibleTM Release Button

ATTACHMENT OR OTHER Coupler

1. Turn the knob

counterclockwise to loosen

(Fig. 3).

2. Press and hold the release

ATTACHMENT _1

button (Fig. 4).

3. While firmly holding the

upper shaft housing, pull the Guide Recess

attachment straight out of

the Convertible TM coupler

Fig. 4

(Fig. 2).

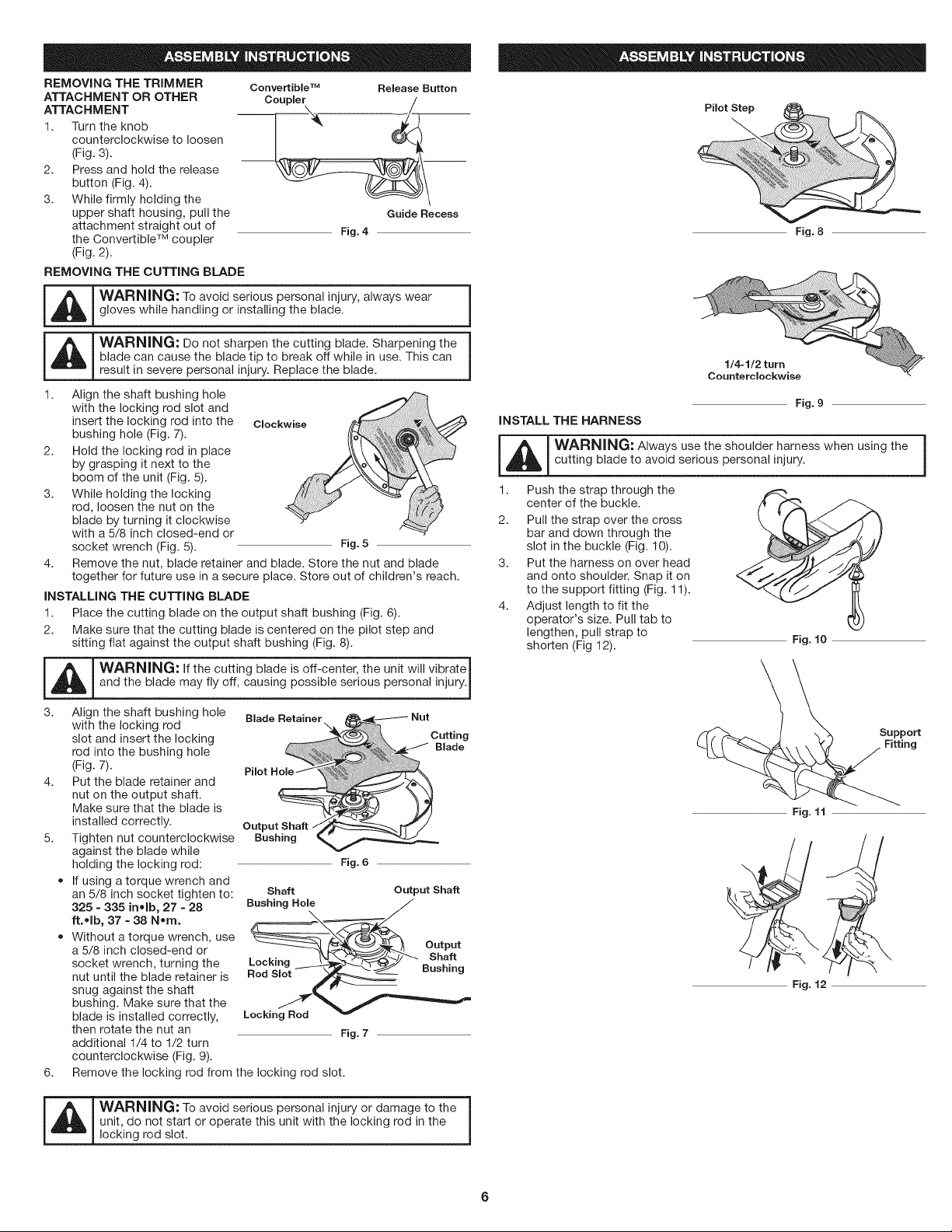

REMOVING THE CUTTING BLADE

m

Pilot Step L

i:

Fig. 8

_L_ ARNING: To avoid serious personal injury, always wear

_ ARNING: Do not sharpen the cutting blade. Sharpening the

gloves while handling or installing the blade.

blade can cause the blade tip to break off while in use. This can

result in severe personal injury. Replace the blade.

1. Align the shaft bushing hole

with the locking rod slot and

insert the locking rod into the Clockwise

bushing hole (Fig. 7).

2.

Hold the locking rod in place

by grasping it next to the

boom of the unit (Fig. 5).

3.

While holding the locking

rod, loosen the nut on the

blade by turning it clockwise

with a 5/8 inch closed-end or

socket wrench (Fig. 5). Fig. 5

4. Remove the nut, blade retainer and blade. Store the nut and blade

together for future use in a secure place. Store out of children's reach.

INSTALLING THE CUTTING BLADE

1. Place the cutting blade on the output shaft bushing (Fig. 6).

2. Make sure that the cutting blade is centered on the pilot step and

sitting flat against the output shaft bushing (Fig. 8).

_L_ ARNING: If the cutting blade is off-center, the unit will vibrate

3. Align the shaft bushing hole Blade Retainer

and the blade may fly off, causing possible serious personal injury.I

with the locking rod

slot and insert the locking

rod into the bushing hole

Cutting

Blade

(Fig. 7).

4. Put the blade retainer and

nut on the output shaft.

Make sure that the blade is

installed correctly.

5. Tighten nut counterclockwise

Output Shaft

Bushing

against the blade while

holding the locking rod: Fig. 6

• If using a torque wrench and

an 5/8 inch socket tighten to:

325 - 335 inolb, 27 - 28

ft.olb, 37 =38 Norn.

• Without a torque wrench, use

a 5/8 inch closed-end or

Shaft Output Shaft

Bushing Hole

socket wrench, turning the

nut until the blade retainer is

snug against the shaft

bushing. Make sure that the

blade is installed correctly,

then rotate the nut an Fig. 7

additional 1/4 to 1/2 turn

counterclockwise (Fig. 9).

6. Remove the locking rod from the locking rod slot.

Counterclockwise

Fig. 9

iNSTALL THE HARNESS

_ ARNING: Always use the shoulder harness when using the

1. Push the strap through the

cutting blade to avoid serious personal injury.

center of the buckle.

2. Pull the strap over the cross

bar and down through the

slot inthe buckle (Fig. 10).

3. Put the harness on over head

and onto shoulder. Snap it on

to the support fitting (Fig. 11).

4. Adjust length to fit the

operator's size. Pull tab to

lengthen, pull strap to

shorten (Fig 12).

Fig. 10

I

Fig. 11

Fig. 12

Support

Ing

_ ARNING: To avoid serious personal injury or damage to the

unit, do not start or operate this unit with the locking rod in the

locking rod slot.

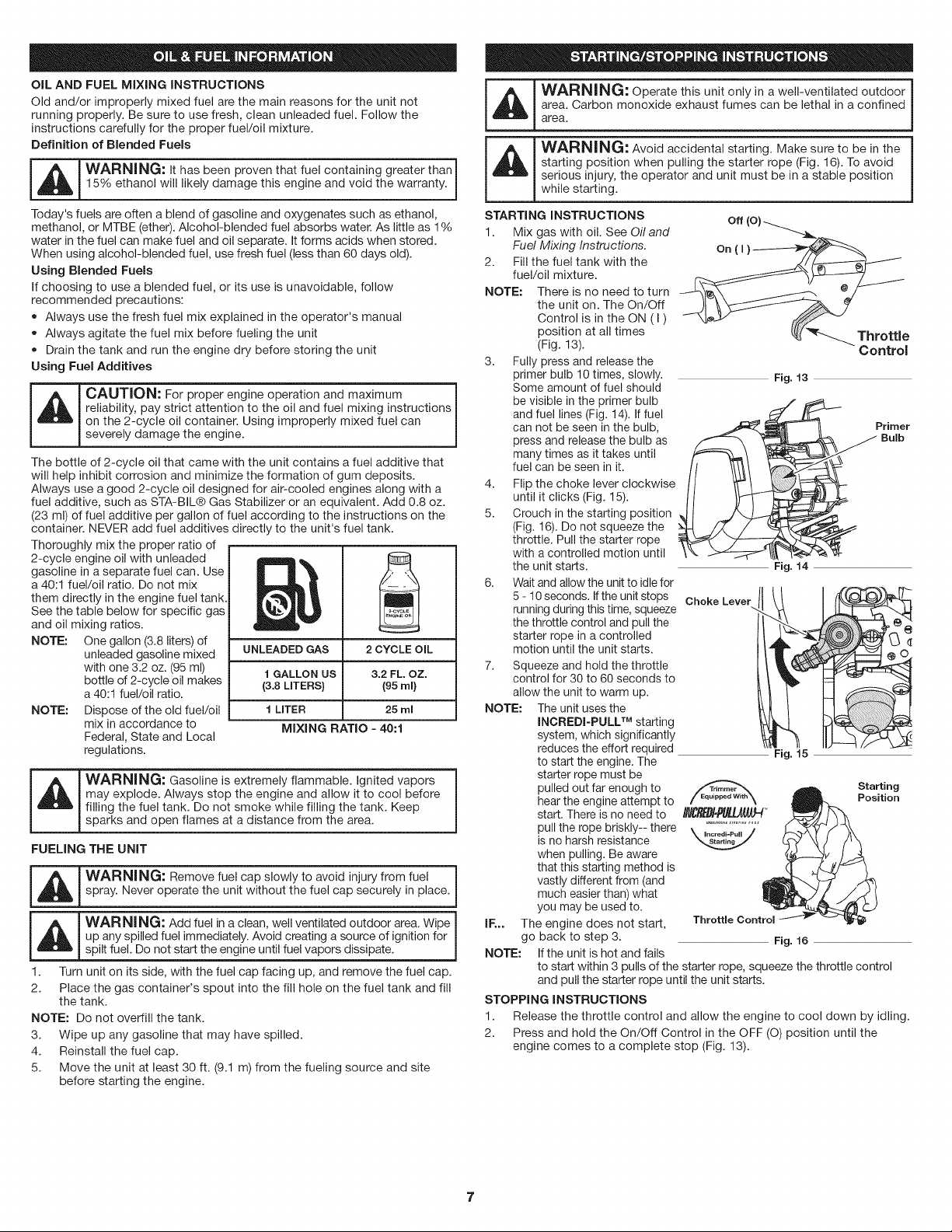

OiL AND FUEL MiXiNG iNSTRUCTiONS

Old and/or improperly mixed fuel are the main reasons for the unit not

running properly. Be sure to use fresh, clean unleaded fuel. Follow the

instructions carefully for the proper fuel/oil mixture.

Definition of Blended Fuels

m

_L_ WARNING" It has been proven that fuel containing greater than I

Today's fuels are often a blend of gasoline and oxygenates such as ethanol,

methanol, or MTBE (ether). Alcohol-blended fuel absorbs water. As little as 1%

water in the fuel can make fuel and oil separate. It forms acids when stored.

When using alcohol-blended fuel, use fresh fuel (less than 60 days old).

Using Blended Fuels

If choosing to use a blended fuel, or its use is unavoidable, follow

recommended precautions:

• Always use the fresh fuel mix explained in the operator's manual

• Always agitate the fuel mix before fueling the unit

• Drain the tank and run the engine dry before storing the unit

Using Fuel Additives

The bottle of 2-cycle oil that came with the unit contains a fuel additive that

will help inhibit corrosion and minimize the formation of gum deposits.

Always use a good 2-cycle oil designed for air-cooled engines along with a

fuel additive, such as STA-BIL® Gas Stabilizer or an equivalent. Add 0.8 oz.

(23 ml) of fuel additive per gallon of fuel according to the instructions on the

container. NEVER add fuel additives directly to the unit's fuel tank.

Thoroughly mix the proper ratio of

2-cycle engine oil with unleaded

gasoline in a separate fuel can. Use

a 40:1 fuel/oil ratio. Do not mix

them directly in the engine fuel tank.

See the table below for specific gas

and oil mixing ratios.

NOTE: One gallon (3.8 liters) of

NOTE: Dispose of the old fuel/oil

_ WARNING: Gasoline is extremely flammable. Ignited vapors

FUELING THE UNIT

m

_L_ WARNING: Remove fuel cap slowly to avoid injury from fuel

_[_ WARNING: Add fuel in a clean, well ventilated outdoor area. Wipe

1. Turn unit on its side, with the fuel cap facing up, and remove the fuel cap.

2. Place the gas container's spout into the fill hole on the fuel tank and fill

NOTE: Do not overfill the tank.

3. Wipe up any gasoline that may have spilled.

4. Reinstall the fuel cap.

5. Move the unit at least 30 ft. (9.1 m) from the fueling source and site

15% ethanol will likely damage this engine and void the warranty. I

CAUTION: For proper engine operation and maximum

reliability, pay strict attention to the oil and fuel mixing instructions

on the 2-cycle oil container. Using improperly mixed fuel can

severely damage the engine.

i -- - .

q

unleaded gasoline mixed

with one 3.2 oz. (95 ml)

bottle of 2-cycle oil makes

a 40:1 fuel/oil ratio.

mix in accordance to

Federal, State and Local

regulations.

may explode. Always stop the engine and allow it to cool before

filling the fuel tank. Do not smoke while filling the tank. Keep

sparks and open flames at adistance from the area.

spray. Never operate the unit without the fuel cap securely in place.

up any spilled fuel immediately. Avoid creating a source of ignition for

spilt fuel. Do not start the engine until fuel vapors dissipate.

the tank.

before starting the engine.

UNLEADED GAS

1GALLON US

(3.8 MTERS)

1 LITER

MiXiNG RATIO =40:1

2 CYCLE OIL

3.2 FL.OZ.

(95ml)

25 ml

WARNING: Operate this unit only in a well-ventilated outdoor

area. Carbon monoxide exhaust fumes can be lethal in a confined

area.

WARNING; Avoid accidental starting. Make sure to be in the

,mL

STARTING INSTRUCTIONS off (o)

1. Mix gas with oil. See Oil and "__

2. Fill the fuel tank with the

NOTE: There is no need to turn

3. Fully press and release the

4. Flip the choke lever clockwise

5. Crouch in the starting position

6. Wait and allow the unit to idle for

7. Squeeze and hold the throttle

NOTE: The unit uses the

IF... The engine does not start, Throttle Control

NOTE: If the unit is hot and fails

STOPPING iNSTRUCTIONS

1. Release the throttle control and allow the engine to cool down by idling.

2. Press and hold the On/Off Control in the OFF (O) position until the

starting position when pulling the starter rope (Fig. 18). To avoid

serious injury, the operator and unit must be in a stable position

while starting.

Fuel Mixing Instructions. on (m)_

fuel/oil mixture.

the unit on. The On/Off

Control is in the ON (I)

(Fig.positionat all times13). _ "_r_ Thorn°ttrIo_

primer bulb 10 times, slowly.

Some amount of fuel should

be visible in the primer bulb

and fuel lines (Fig. 14). If fuel

can not be seen in the bulb,

press and release the bulb as

many times as it takes until

fuel can be seen in it.

until it clicks (Fig. 15).

(Fig. 16). Do not squeeze the

throttle. Pull the starter rope

with a controlled motion until

the unit starts.

5 - 10seconds. Ifthe unit stops Choke Lever j

running during this time, squeeze

the throttle control and pull the

starter rope in a controlled

motion until the unit starts.

control for 30 to 60 seconds to

allow the unit to warm up.

INCREDI-PULL TM starting

system, which significantly

reduces the effort required

to start the engine. The

starter rope must be

pulled out far enough to

hear the engine attempt to

start. There is no need to I/I/C_'W-P_,4JJ,(H'

pull the rope briskly-- there ........................

is no harsh resistance _°o,_a!-P.,

when pulling. Be aware

that this starting method is

vastly different from (and

much easier than) what

you may be used to.

go back to step 3. Fig. 16

to start within 3 pulls of the starter rope, squeeze the throttle control

and pull the starter rope until the unit starts.

engine comes to a complete stop (Fig. 13).

/ _,,o,ppoo.,.o\

Fig. 13

Fig. 14

i!!;;i¸ii¸ e O

Fig. 15

Starting

Position

e

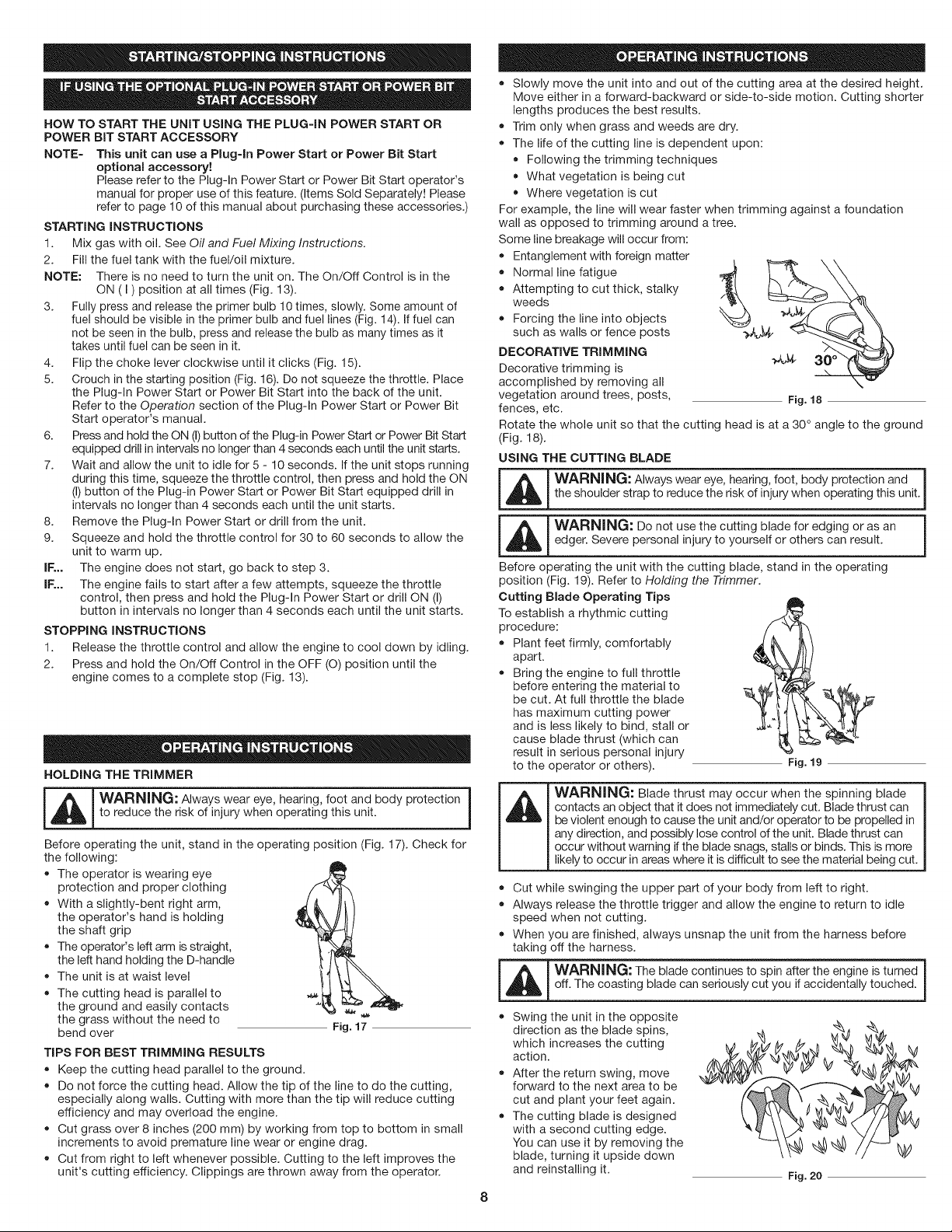

HOW TO START THE UNiT USING THE PLUG-IN POWER START OR

POWER BiT START ACCESSORY

NOTE= This unit can use a Plug-in Power Start or Power Bit Start

STARTING iNSTRUCTIONS

1. Mix gas with oil. See Oil and Fuel Mixing Instructions.

2. Fill the fuel tank with the fuel/oil mixture.

NOTE: There is no need to turn the unit on. The On/Off Control is inthe

3. Fully press and release the primer bulb 10 times, slowly. Some amount of

4. Flip the choke lever clockwise until it clicks (Fig. 15).

5. Crouch in the starting position (Fig. 16). Do not squeeze the throttle. Place

6. Press and hold the ON (I)button of the Plug-in Power Start or Power Bit Start

7. Wait and allow the unit to idle for 5 - 10 seconds. If the unit stops running

8. Remove the Plug-In Power Start or drill from the unit.

9. Squeeze and hold the throttle control for 30 to 60 seconds to allow the

iF... The engine does not start, go back to step 3.

iF... The engine fails to start after afew attempts, squeeze the throttle

STOPPING INSTRUCTIONS

1. Release the throttle control and allow the engine to cool down by idling.

2. Press and hold the On/Off Control in the OFF (O) position until the

HOLDING THE TRIMMER

-- i_L_ ARNING: Always wear eye, hearing, foot and body protection

Before operating the unit, stand in the operating position (Fig. 17). Check for

the following:

• The operator is wearing eye

TiPS FOR BEST TRIMMING RESULTS

• Keep the cutting head parallel to the ground.

optional accessory!

Please refer to the Plug-In Power Start or Power Bit Start operator's

manual for proper use of this feature. (Items Sold Separately! Please

refer to page 10 of this manual about purchasing these accessories.)

ON (I) position at all times (Fig. 13).

fuel should be visible in the primer bulb and fuel lines (Fig. 14). If fuel can

not be seen in the bulb, press and release the bulb as many times as it

takes until fuel can be seen in it.

the Plug-In Power Start or Power Bit Start into the back of the unit.

Refer to the Operation section of the Plug-In Power Start or Power Bit

Start operator's manual.

equipped drill in intervals no longer than 4 seconds each until the unit starts.

during this time, squeeze the throttle control, then press and hold the ON

(I)button of the Plug-in Power Start or Power Bit Start equipped drill in

intervals no longer than 4 seconds each until the unit starts.

unit to warm up.

control, then press and hold the Plug-In Power Start or drill ON (I)

button in intervals no longer than 4 seconds each until the unit starts.

engine comes to a complete stop (Fig. 13).

to reduce the risk of injury when operating this unit.

protection and proper clothing

With a slightly-bent right arm,

the operator's hand is holding

the shaft grip

The operator's leftarm is straight,

the left hand holding the D-handle

The unit is at waist level

The cutting head is parallel to

the ground and easily contacts

the grass without the need to Fig. 17

bend over

Do not force the cutting head. Allow the tip of the line to do the cutting,

especially along walls. Cutting with more than the tip will reduce cutting

efficiency and may overload the engine.

Cut grass over 8 inches (200 mm) by working from top to bottom in small

increments to avoid premature line wear or engine drag.

Cut from right to left whenever possible. Cutting to the left improves the

unit's cutting efficiency. Clippings are thrown away from the operator.

Slowly move the unit into and out of the cutting area at the desired height.

Move either in a forward-backward or side-to-side motion. Cutting shorter

lengths produces the best results.

Trim only when grass and weeds are dry.

The life of the cutting line is dependent upon:

Following the trimming techniques

What vegetation is being cut

Where vegetation is cut

For example, the line will wear faster when trimming against a foundation

wall as opposed to trimming around a tree.

Some line breakage will occur from:

• Entanglement with foreign matter

Normal line fatigue

Attempting to cut thick, stalky

weeds

Forcing the line into objects

such as walls or fence posts

DECORATIVE TRiMMiNG

Decorative trimming is

accomplished by removing all

vegetation around trees, posts,

fences, etc.

Rotate the whole unit so that the cutting head is at a 30 ° angle to the ground

(Fig. 18).

USING THE CUTTING BLADE

-- i_ WARNING: Always wear eye, hearing, foot, body protection and

_ ARNING: Do not use the cutting blade for edging or as an

Before operating the unit with the cutting blade, stand in the operating

position (Fig. 19). Refer to Holding the Trimmer.

Cutting Blade Operating Tips

To establish a rhythmic cutting

procedure:

-- i_1_ ARNING: The blade continues to spin after the engine is turned

the shoulder strap to reduce the risk of injury when operating this unit.

edger. Severe personal injury to yourself or others can result.

Plant feet firmly, comfortably

apart.

Bring the engine to full throttle

before entering the material to

be cut. At full throttle the blade

has maximum cutting power

and is less likely to bind, stall or

cause blade thrust (which can

result in serious personal injury

to the operator or others). Fig. 19

WARNING: Blade thrust may occur when the spinning blade

contacts an object that it does not immediately cut. Blade thrust can

be violent enough to cause the unit and/or operator to be propelled in

any direction, and possibly lose control of the unit. Blade thrust can

occur without warning if the blade snags, stalls or binds. This is more

likely to occur in areas where itisdifficult to see the material being cut.

Cut while swinging the upper part of your body from left to right.

Always release the throttle trigger and allow the engine to return to idle

speed when not cutting.

When you are finished, always unsnap the unit from the harness before

taking off the harness.

off. The coasting blade can seriously cut you if accidentally touched.

Swing the unit inthe opposite

direction as the blade spins,

which increases the cutting

action.

After the return swing, move

forward to the next area to be

cut and plant your feet again.

The cutting blade is designed

with a second cutting edge.

You can use it by removing the

blade, turning it upside down

and reinstalling it.

Fig. 18

Fig. 20

8

Toreducethechanceofmaterialwrappingaroundtheblade,followthesesteps:

• Cutatfullthrottle.

Swingtheunitintomaterialtobecutfromyourlefttoyourright(Fig.20).

Avoidthematerialjustcutasyoumakethereturnswing.

runningorbladeturning.Toavoidseriouspersonalinjury,turnoff

_[_J ARNING:Donotclearawayanycutmaterialwiththeengine

theengine.Allowthebladetostopbeforeremovingmaterials

wrappedaroundthebladeshaft.

MAINTENANCESCHEDULE

maintenance or repairs with unit running. Always service and

_ ARNING: To prevent serious injury, never perform

Perform these required maintenance procedures at the frequency stated in

the table. These procedures should also be a part of any seasonal tune-up.

NOTE: Some maintenance procedures may require special tools or skills. If

NOTE: Maintenance, replacement, or repair of the emission control devices

FREQUENCY MAINTENANCE REQUIRED SEE

Before starting engine Fill fuel tank with fresh fuel

Every 10 hours Clean and re-oil air filter 3.9

Every 25 hours Check spark plug condition and gap 3.10

LINE REPLACEMENT

for Hassle-Free TM Cutting Head

_ ARNING: Never use metal-reinforced line, wire, chain or

Always use Craftsman® Hassle-Free TM XTRA QUIET Spiral Line. Choose the

line size best suited for the job at hand. Red colored line is designed for

cutting grass and small weeds. Black colored line isdesigned for cutting

larger weeds and light brush.

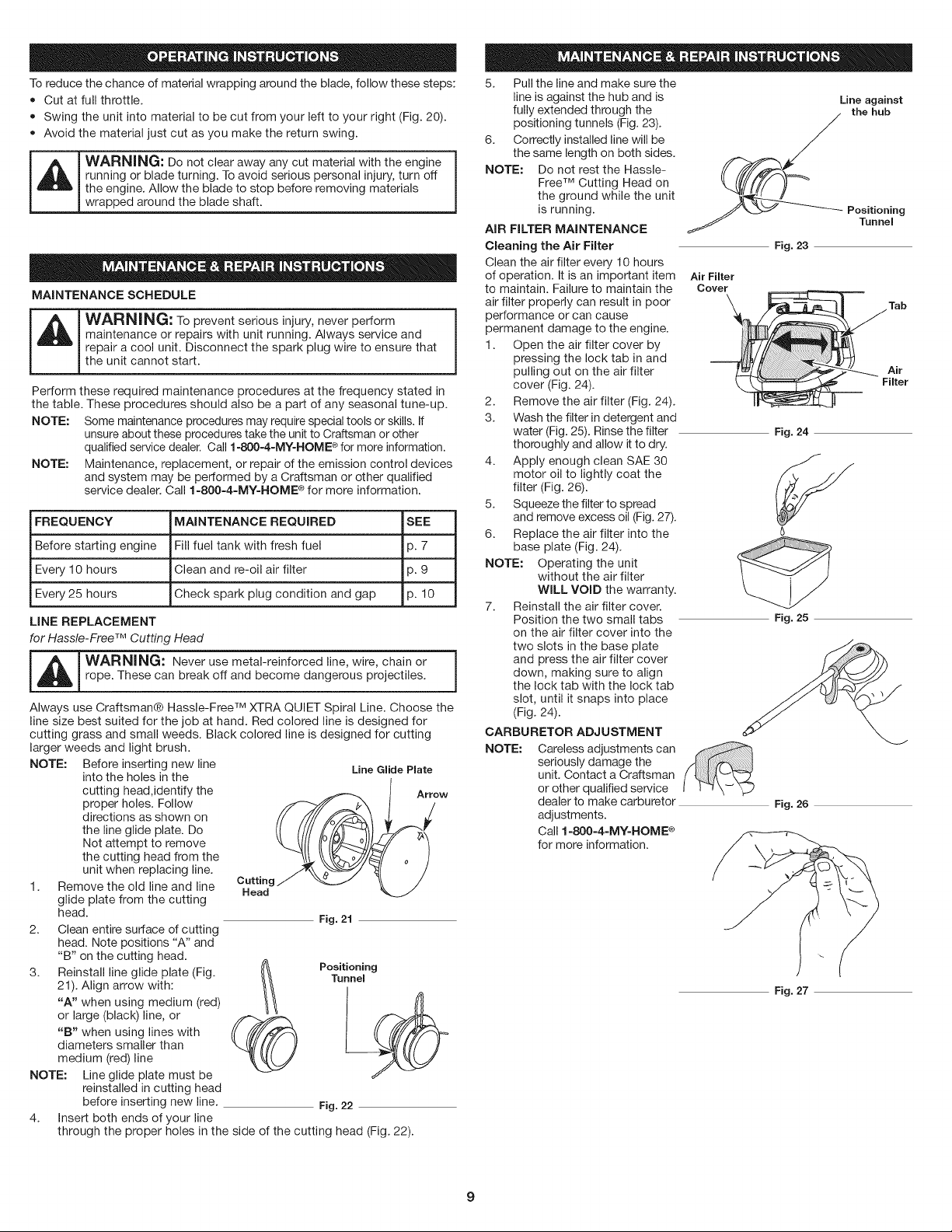

NOTE: Before inserting new line

1. Remove the old line and line

2. Clean entire surface of cutting

3. Reinstall line glide plate (Fig.

NOTE: Line glide plate must be

4. Insert both ends of your line

repair a cool unit. Disconnect the spark plug wire to ensure that

the unit cannot start.

unsure about these procedures take the unit to Craftsman or other

qualified service dealer. Call 1-800=4-MY=HOME efor more information.

and system may be performed by a Craftsman or other qualified

service dealer. Call 1-800-4-MY=HOME ®for more information.

rope. These can break off and become dangerous projectiles.

into the holes in the

cutting head,identify the

proper holes. Follow

directions as shown on

the line glide plate. Do

Not attempt to remove

the cutting head from the

unit when replacing line.

glide plate from the cutting

head.

head. Note positions "A" and

"B" on the cutting head.

21). Align arrow with:

"A" when using medium (red)

or large (black) line, or

"B" when using lines with

diameters smaller than

medium (red)line

reinstalled in cutting head

before inserting new line.

through the proper holes in the side of the cutting head (Fig. 22).

Head

Line Glide Plate

Fig. 21

Positioning

Tunnel

Fig. 22

3.7

Arrow

5. Pull the line and make sure the

line is against the hub and is

fully extended through the

positioning tunnels (Fig. 23).

6. Correctly installed line will be

the same length on both sides.

NOTE: Do not rest the Hassle-

AIR FILTER MAINTENANCE

Cleaning the Air Filter

Clean the air filter every 10 hours

of operation. It is an important item

to maintain. Failure to maintain the

air filter properly can result in poor

performance or can cause

permanent damage to the engine.

1. Open the air filter cover by

2. Remove the air filter (Fig. 24).

3. Wash the filter in detergent and

4. Apply enough clean SAE 30

5. Squeeze the filter to spread

6. Replace the air filter into the

NOTE: Operating the unit

7. Reinstall the air filter cover.

CARBURETOR ADJUSTMENT

NOTE: Careless adjustments can

Free TM Cutting Head on

the ground while the unit

is running.

pressing the lock tab in and

pulling out on the air filter

cover (Fig. 24).

water (Fig. 25). Rinse the filter

thoroughly and allow it to dry.

motor oil to lightly coat the

filter (Fig. 26).

and remove excess oil (Fig.27).

base plate (Fig. 24).

without the air filter

WILL VOiD the warranty.

Position the two small tabs

on the air filter cover into the

two slots in the base plate

and press the air filter cover

down, making sure to align

the lock tab with the lock tab

slot, until it snaps into place

(Fig. 24).

seriously damage the

unit. Contact a Craftsman

or other qualified service

dealer to make carburetor

adjustments.

Call 1-800-4-MY-HOME ®

for more information.

Line against

the hub

Fig. 23

Air Filter

Cover

Fig. 24

<

Fig. 25

Fig. 26

Fig. 27

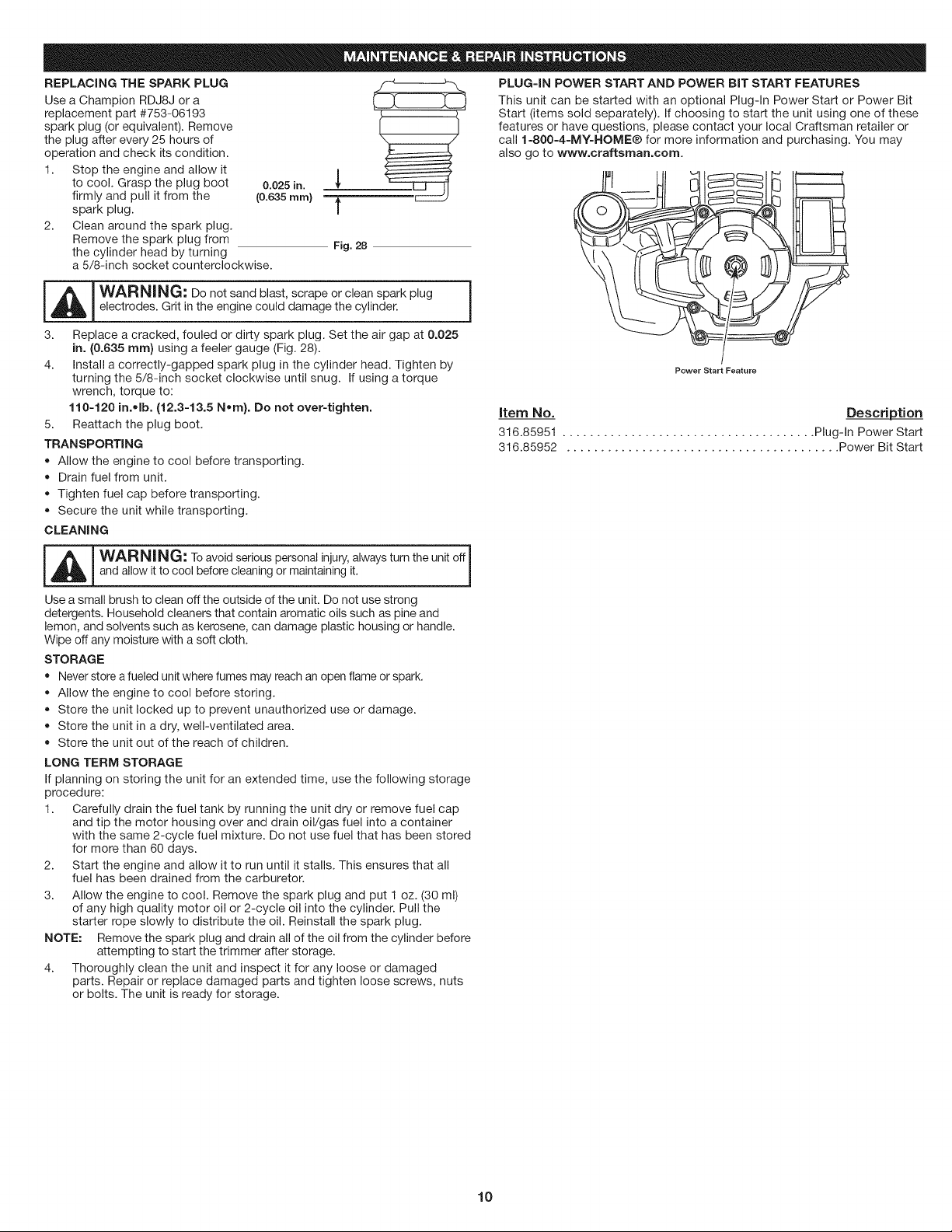

REPLACING THE SPARK PLUG

Use a Champion RDJ8J or a

replacement part #753-06193

spark plug (or equivalent). Remove

the plug after every 25 hours of

operation and check its condition.

1. Stop the engine and allow it

to cool. Grasp the plug boot

firmly and pull it from the

spark plug.

2. Clean around the spark plug.

Remove the spark plug from

the cylinder head by turning

a 5/8-inch socket counterclockwise.

m

0.025 in.

(0.635 ram)

PLUG=IN POWER START AND POWER BIT START FEATURES

This unit can be started with an optional Plug-In Power Start or Power Bit

Start (items sold separately). If choosing to start the unit using one of these

features or have questions, please contact your local Craftsman retailer or

call 1-800-4=MY-HOME® for more information and purchasing. You may

also go to www.craftsman.com.

t

Fig. 28

_L_ ARNING: Do not sand blast, scrape or clean spark plug

3. Replace a cracked, fouled or dirty spark plug. Set the air gap at 0.025

4. Install a correctly-gapped spark plug in the cylinder head. Tighten by

5. Reattach the plug boot.

TRANSPORTING

• Allow the engine to cool before transporting.

• Drain fuel from unit.

• Tighten fuel cap before transporting.

• Secure the unit while transporting.

CLEANING

m i_L_ ARNING: To avoid serious personal injury, always turn the unit off

Use a small brush to clean off the outside of the unit. Do not use strong

detergents. Household cleaners that contain aromatic oils such as pine and

lemon, and solvents such as kerosene, can damage plastic housing or handle.

Wipe off any moisture with a soft cloth.

STORAGE

• Never store a fueled unit where fumes mayreach an open flame or spark.

• Store the unit locked up to prevent unauthorized use or damage.

• Store the unit in a dry, well-ventilated area.

• Store the unit out of the reach of children.

LONG TERM STORAGE

If planning on storing the unit for an extended time, use the following storage

procedure:

1. Carefully drain the fuel tank by running the unit dry or remove fuel cap

2. Start the engine and allow it to run until it stalls. This ensures that all

3. Allow the engine to cool. Remove the spark plug and put 1 oz. (30 ml)

NOTE: Remove the spark plug and drain all of the oil from the cylinder before

4. Thoroughly clean the unit and inspect it for any loose or damaged

electrodes. Grit in the engine could damage the cylinder.

in. (0.635 rnrn} using a feeler gauge (Fig. 28).

turning the 5/8-inch socket clockwise until snug. If using a torque

wrench, torque to:

110-120 in.oib. (12.3=13.5 Nora}. Do not over=tighten.

and allow it to cool before cleaning or maintaining it.

Allow the engine to cool before storing.

and tip the motor housing over and drain oil/gas fuel into a container

with the same 2-cycle fuel mixture. Do not use fuel that has been stored

for more than 60 days.

fuel has been drained from the carburetor.

of any high quality motor oil or 2-cycle oil into the cylinder. Pull the

starter rope slowly to distribute the oil. Reinstall the spark plug.

attempting to start the trimmer after storage.

parts. Repair or replace damaged parts and tighten loose screws, nuts

or bolts. The unit is ready for storage.

Power Start Feature

item No. Description

316.85951 ..................................... Plug-In Power Start

316.85952 ........................................ Power Bit Start

10

Loading...

Loading...