Page 1

Sears, Roebuck and Co., Hoffman Estates, IL 60179, U.S.A.

Visit our website: www.sears.com/craftsman

CAUTION: Before using

this product, read this

manual and follow all

safety rules and operating

instructions.

Operator’s Manual

4-Cycle

GAS BLOWER VAC

Model No. 316.794980

• SAFETY

• ASSEMBLY

• OPERATION

• MAINTENANCE

• PARTS LIST

• ESPAÑOL, P. 19

769-02360

®

Page 2

2

SPARK ARRESTOR NOTE

NOTE: For users on U.S. Forest Land and in the states of

California, Maine, Oregon and Washington. All U.S. Forest

Land and the state of California (Public Resources Codes 4442

and 4443), Oregon and Washington require, by law that certain

internal combustion engines operated on forest brush and/or

grass-covered areas be equipped with a spark arrestor,

maintained in effective working order, or the engine be

constructed, equipped and maintained for the prevention of

fire. Check with your state or local authorities for regulations

pertaining to these requirements. Failure to follow these

requirements could subject you to liability or a fine. This unit is

factory equipped with a spark arrestor. If it requires

replacement, ask a Sears or other qualified service dealer to

install the Accessory Part #753-05297 Spark Arrestor Kit.

All information, illustrations, and specifications in this manual

are based on the latest product information available at the

time of printing. We reserve the right to make changes at any

time without notice.

TABLE OF CONTENTS

Rules for Safe Operation . . . . . . . . . . . . . . . . . . . . . . . . . .2

Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Know Your Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Assembly Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Oil and Fuel Information . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Starting/Stopping Instructions . . . . . . . . . . . . . . . . . . . . . .9

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Maintenance and Repair Instructions . . . . . . . . . . . . . . .12

Cleaning and Storage . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Troubleshooting Chart . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Repair Protection Agreement . . . . . . . . . . . . . . . . . . . . .17

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Service Numbers . . . . . . . . . . . . . . . . . . . . . . . .Backcover

WARNING

THE ENGINE EXHAUST FROM THIS PRODUCT CONTAINS

CHEMICALS KNOWN TO THE STATE OF CALIFORNIA TO

CAUSE CANCER, BIRTH DEFECTS OR OTHER

REPRODUCTIVE HARM.

CALIFORNIA PROPOSITION 65 WARNING

WARNING: When using the unit, you must follow

the safety rules. Please read these instructions

before operating the unit in order to ensure the

safety of the operator and any bystanders. Please

keep these instructions for later use.

• IMPORTANT SAFETY INSTRUCTIONS •

READ ALL INSTRUCTIONS BEFORE OPERATING

• Read the instructions carefully. Be familiar with the controls

and proper use of the unit.

• Do not operate this unit when tired, ill, or under the influence

of alcohol, drugs, or medication.

• Children and teens under the age of 15 must not use the unit,

except for teens guided by an adult.

• All guards and safety attachments must be installed properly

before operating the unit.

• Inspect the unit before use. Replace damaged parts. Check for

fuel leaks. Make sure all fasteners are in place and secure.

Replace parts that are cracked, chipped, or damaged in any

way. Do not operate the unit with loose or damaged parts.

• Carefully inspect the area before starting the unit. Remove all

debris and hard or sharp objects such as glass, wire, etc.

• Clear the area of children, bystanders, and pets. At a minimum,

keep all children, bystanders, and pets outside a 50 feet (15 m.)

radius; there still may be a risk to bystanders from thrown

objects. Bystanders should be encouraged to wear eye

protection. If you are approached, stop the unit immediately.

SAFETY WARNINGS FOR GAS UNITS

• Store fuel only in containers specifically designed and

approved for the storage of such materials.

• Avoid creating a source of ignition for spilled fuel. Do not

start the engine until fuel vapors dissipate.

• Always stop the engine and allow it to cool before filling the fuel

tank. Never remove the cap of the fuel tank, or add fuel, when

the engine is hot. Never operate the unit without the fuel cap

securely in place. Loosen the fuel tank cap slowly to relieve any

pressure in the tank.

• Add fuel in a clean, well-ventilated outdoor area where there are

no sparks or flames. Slowly remove the fuel cap only after stopping engine. Do not smoke while adding fuel. Wipe up any spilled

fuel from the unit immediately. Always wipe unit dry before using.

• Move the unit at least 30 feet (9.1 m) from the fueling source and

site before starting the engine. Do not smoke or allow sparks and

open flames near the area while adding fuel or operating the unit.

WHILE OPERATING

• Never start or run the unit inside a closed room or building.

Breathing exhaust fumes can kill. Operate this unit only in a

well-ventilated outdoor area.

• To reduce the risk of injury associated with thrown objects,

wear safety glasses or goggles that are marked as meeting

ANSI Z87. standards.

• Never run the unit without the the proper equipment

attached. When using this unit, always install the

blower/vacuum tubes and vacuum bag depending on model.

Make sure the vacuum bag is completely zipped closed.

• To reduce the risk of hearing loss associated with sound level(s),

always wear ear/hearing protection when operating this unit.

• Wear heavy, long pants, boots, gloves, and a long-sleeved

shirt. Do not wear loose clothing, jewelry, short pants,

sandals, or go barefoot. Secure hair above shoulder level.

• To avoid static electricity shock, do not wear rubber gloves

or any other insulated gloves while operating this unit.

• To reduce the risk of injury associated with objects being

drawn into rotating parts, do not wear loose clothing, jewelry,

scarves, and the like. Secure hair above shoulder level.

• Wear a face or dust mask if the operation is dusty. Long

sleeve shirts are recommended.

• Use the unit only in daylight or good artificial light.

• Keep outside surfaces free from oil and fuel.

• Avoid accidental starting. Be in the starting position whenever

pulling the starter rope. The operator and unit must be in a stable

position while starting. Refer to Starting/Stopping Instructions.

• Do not set unit on any surface except a clean, hard area

while engine is running. Debris such as gravel, sand, dust,

grass, etc. could be picked up by the air intake and thrown

out by the discharge opening, damaging unit, property, or

causing serious injury to bystanders or operator.

• Use the right tool. Only use this tool for the purpose intended.

• Do not force unit. It will do the job better and with less

likelihood of injury at a rate for which it was designed.

• Do not overreach or use from unstable surfaces such as

ladders, trees, steep slopes, rooftops, etc. Always keep

proper footing and balance.

• Always hold the unit with a firm grip when operating.

• Keep hands, face, and feet at a distance from all moving parts.

Do not touch or try to stop the impeller when it is rotating. Do

WARNING: Gasoline is highly flammable, and its

vapors can explode if ignited. Take the following

precautions:

WARNING:

When using the unit, you must follow

the safety rules. Please read these instructions before

operating the unit in order to ensure the safety of the

operator and any bystanders. Please keep these

instructions for later use.

RULES FOR SAFE OPERATION

Page 3

3

SAFETY AND INTERNATIONAL SYMBOLS

This operator's manual describes safety and international symbols and pictographs that may appear on this product. Read the

operator's manual for complete safety, assembly, operating and maintenance and repair information.

• CHOKE CONTROL

1. • FULL choke position

2. • PARTIAL choke position

3. • RUN choke position

not operate without guards in place.

• Do not put any object into openings. Do not use with any

opening blocked; keep free of dirt, debris, and anything that

may reduce the air flow.

• Do not touch the engine or muffler. These parts get extremely hot

from operation. When turned off they remain hot for a short time.

• Do not operate the engine faster than the speed needed to do

the job. Do not run the engine at high speed when not in use.

• Always stop the engine when operation is delayed or when

walking from one location to another.

• Stop the engine for maintenance, repair, to install or remove

the blower tubes or vacuum attachments. The unit must be

stopped and the impeller no longer turning to avoid contact

with the rotating blades.

• Use only original equipment manufacturer replacement parts when

servicing this unit. These parts are available from your authorized

service dealer. Do not use unauthorized parts, accessories, or

attachments for this unit. Doing so could lead to serious injury to

the user, or damage to the unit, and void your warranty.

• Never use this unit for spreading chemicals, fertilizers or

other substances which may contain toxic materials.

• To reduce fire hazard, replace faulty muffler and spark

arrestor, keep the engine and muffler free from grass, leaves,

excessive grease or carbon build up.

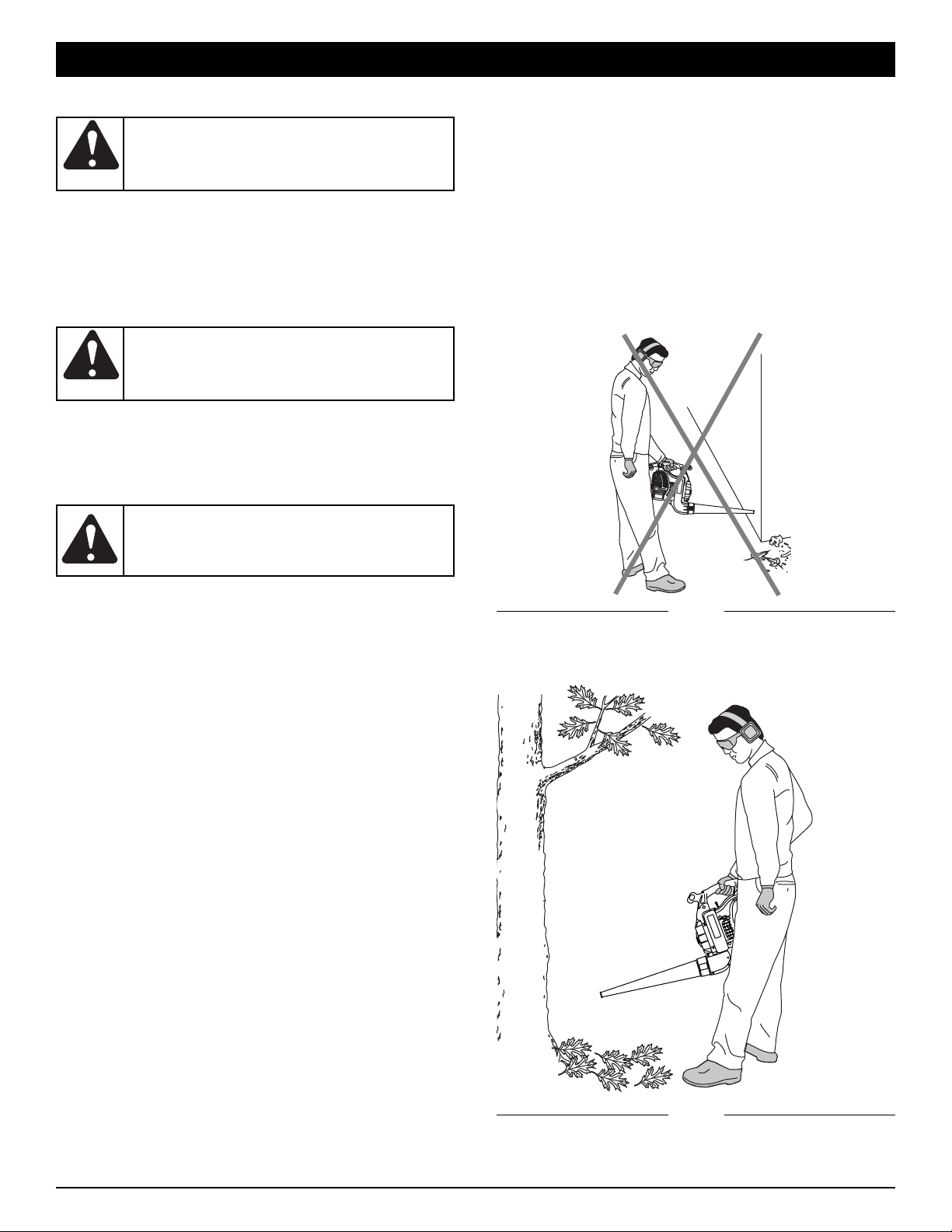

WHILE OPERATING UNIT AS A BLOWER

• Never point the blower in the direction of people or pets, or in the

direction of windows. Always direct the blowing debris away from

people, animals, and windows. Use extra caution when blowing

debris near solid objects such as trees, automobiles, walls, etc.

WHILE OPERATING UNIT AS A VACUUM

• Avoid situations that could catch the vacuum bag on fire. Do not

operate near an open flame. Do not vacuum warm ash from fireplaces, barbecue pits, brush piles, etc. Do not vacuum discarded

cigars or cigarettes unless the cinders are completely cool.

• The unit is designed to pickup dry material such as leaves,

grass, small twigs, and bits of paper. Do not attempt to

vacuum wet debris and/or standing water as this may result

in damage to the blower/ vacuum. To avoid severe damage

to the impeller, do not vacuum metal, broken glass, etc.

OTHER SAFETY WARNINGS

• Always disconnect the spark plug before performing

maintenance or accessing movable parts.

• Never store the unit, with fuel in the tank, inside a building

where fumes may reach an open flame (pilot lights, etc.) or

sparks (switches, electrical motors, etc.).

• Allow the engine to cool before storing or transporting. Be

sure to secure the unit while transporting.

• Store the unit in a dry place, either locked up or up high to prevent

unauthorized use or damage. Keep out of the reach of children.

• Never douse or squirt the unit with water or any other liquid.

Keep handles dry, clean, and free from debris. Clean after

each use, see Cleaning and Storage instructions.

• Keep these instructions. Refer to them often and use them to

instruct other users. If you loan this unit to others, also loan

these instructions to them.

SPECIAL NOTE: Exposure to vibrations through prolonged use

of gasoline powered hand tools could cause blood vessel or

nerve damage in the fingers, hands, and joints of people prone to

circulation disorders or abnormal swelling. Prolonged use in cold

weather has been linked to blood vessel damage in otherwise

healthy people. If symptoms occur such as numbness, pain, loss

of strength, change in skin color or texture, or loss of feeling in

the fingers, hands or joints, discontinue use of this tool and seek

medical attention. An anti-vibration system does not guarantee

avoidance of these problems. Users who operate power tools on

a regular basis must closely monitor their physical condition and

the condition of this tool.

SAVE THESE INSTRUCTIONS

SYMBOL MEANING

• ON/OFF STOP CONTROL

ON / START / RUN

• WARNING - READ OPERATOR'S MANUAL

Read the operator’s manual(s) and follow all warnings

and safety instructions. Failure to do so can result in

serious injury to the operator and/or bystanders.

• ON/OFF STOP CONTROL

OFF or STOP

SYMBOL MEANING

• SAFETY ALERT SYMBOL

Indicates danger, warning or caution. May be used

in conjunction with other symbols or pictographs.

• WEAR EYE AND HEARING PROTECTION

WARNING: Thrown objects and loud noise can

cause severe eye injury and hearing loss. Wear eye

protection meeting ANSI Z87.1 standards and ear

protection when operating this unit. Use a full face

shield when needed.

• KEEP BYSTANDERS AWAY

WARNING: Keep all bystanders, especially

children and pets, at least 50 feet (15 m) from the

operating area.

• HOT SURFACE WARNING

Do not touch a hot muffler, gear housing or cylinder.

You may get burned. These parts get extremely hot

from operation. They remain hot for a short time after

the unit is turned off.

• UNLEADED FUEL

Always use clean, fresh unleaded fuel

• OIL

Refer to operator’s manual for the proper type of

oil.

• THROTTLE CONTROL

Indicates “IDLE,” “LOW,” or “SLOWEST” speed

• THROTTLE CONTROL

Indicates “HIGH” or “FASTEST” speed

RULES FOR SAFE OPERATION

Page 4

4

TWO YEAR LIMITED WARRANTY

When used and maintained according to the operator's manual, if this product fails due to a defect in material or workmanship within

two years from the date of purchase, return it to any Sears store, Sears Parts & Repair Service Center, or other Craftsman outlet for

free repair. This warranty excludes spark plug, air filter, and vacuum bag, which are expendable parts that can wear out from normal

use in less than two years. This warranty applies for only 30 days from the date of purchase if this product is ever used for

commercial or rental purposes.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

Sears, Roebuck and Co., Hoffman Estates, IL 60179

California / EPA Emission Control Warranty Statement

Your Warranty Rights and Obligations

The California Air Resources Board, The Environmental Protection Agency and Sears, Roebuck and Co., are pleased to explain the

emission control system warranty on your 2005 and later small off-road engine. New small off-road engines must be designed, built

and equipped to meet stringent anti-smog standards. Sears, Roebuck and Co. must warrant the emission control system on your

small off-road engine for the periods of time listed below provided there has been no abuse, neglect or improper maintenance of your

small off-road engine.

Your Emission control system may include parts such as the carburetor or fuel-injection system, the ignition system, and catalytic

converter. Also included may be hoses, belts, connectors and other emission-related assemblies.

Where a warrantable condition exists, Sears will repair your small off-road engine at no cost to you including diagnosis, parts and

labor.

The 2005 and later small off-road engines are warranted for two years. If any emission-related part on your engine is

defective, the part will be repaired or replaced by Sears.

Owner’s Warranty Responsibilities

• As the small off-road engine owner, you are responsible for the performance of the required maintenance listed in your operator’s

manual. Sears recommends that you retain all receipts covering maintenance on your small off-road engine, but Sears cannot deny

warranty solely for the lack of receipts or for your failure to ensure the performance of all scheduled maintenance.

• As the small off-road engine owner, you should however be aware that Sears may deny you warranty coverage if your small offroad engine or a part has failed due to abuse, neglect, improper maintenance or unapproved modifications.

• You are responsible for presenting your small off-road engine to a Sears authorized service center as soon as problem exists. The

warranty repairs should be completed in a reasonable amount of time, not to exceed 30 days.

• If you have any questions regarding your warranty rights and responsibilities, you should call 1-800-4-MY-HOME

®

.

Manufacturer’s Warranty Coverage

• The warranty period begins on the date the engine or equipment is delivered to the retail purchaser.

• The manufacturer warrants to the initial owner and each subsequent purchaser, that the engine is free from defects in material and

workmanship which cause the failure of a warranted part for a period of two years.

• Repair and replacement of warranted part will be performed at no charge to the owner at an authorized Sears service center. For

the nearest location please contact Sears at: 1-800-4-MY-HOME

®

.

• Any warranted part which is not scheduled for replacement, as required maintenance or which is scheduled only for regular

inspection to the effect of “Repair or Replace as Necessary” is warranted for the period. Any warranted part which is scheduled for

replacement as required maintenance will be warranted for the period of time up to the first scheduled replacement point for that

part.

• The owner will not be charged for diagnostic labor which leads to the determination that a warranted part is defective if the

diagnostic work is performed at an authorized Sears Service Center.

• The manufacturer is liable for damages to other engine components caused by the failure of a warranted part still under warranty.

• Failures caused by abuse, neglect or improper maintenance are not covered under warranty.

• The use of add-on or modified parts can be grounds for disallowing a warranty claim. The manufacturer is not liable to cover failures

of warranted parts caused by the use of add-on or modified parts.

• In order to file a claim, go to your nearest authorized Sears Service Center. Warranty service or repairs will be provided at all

authorized Sears Service Centers.

• Any manufacturer approved replacement part may be used in the performance of any warranty maintenance or repair of emission

related parts and will be provided without charge to the owner. Any replacement part that is equivalent in performance or durability

may be used in non-warranty maintenance or repair and will not reduce the warranty obligations of the manufacturer.

• The following components are included in the emission related warranty: engine, air filter, carburetor, primer, fuel lines, fuel pick

up/fuel filter, ignition module, spark plug and muffler.

WARRANTY STATEMENT

Page 5

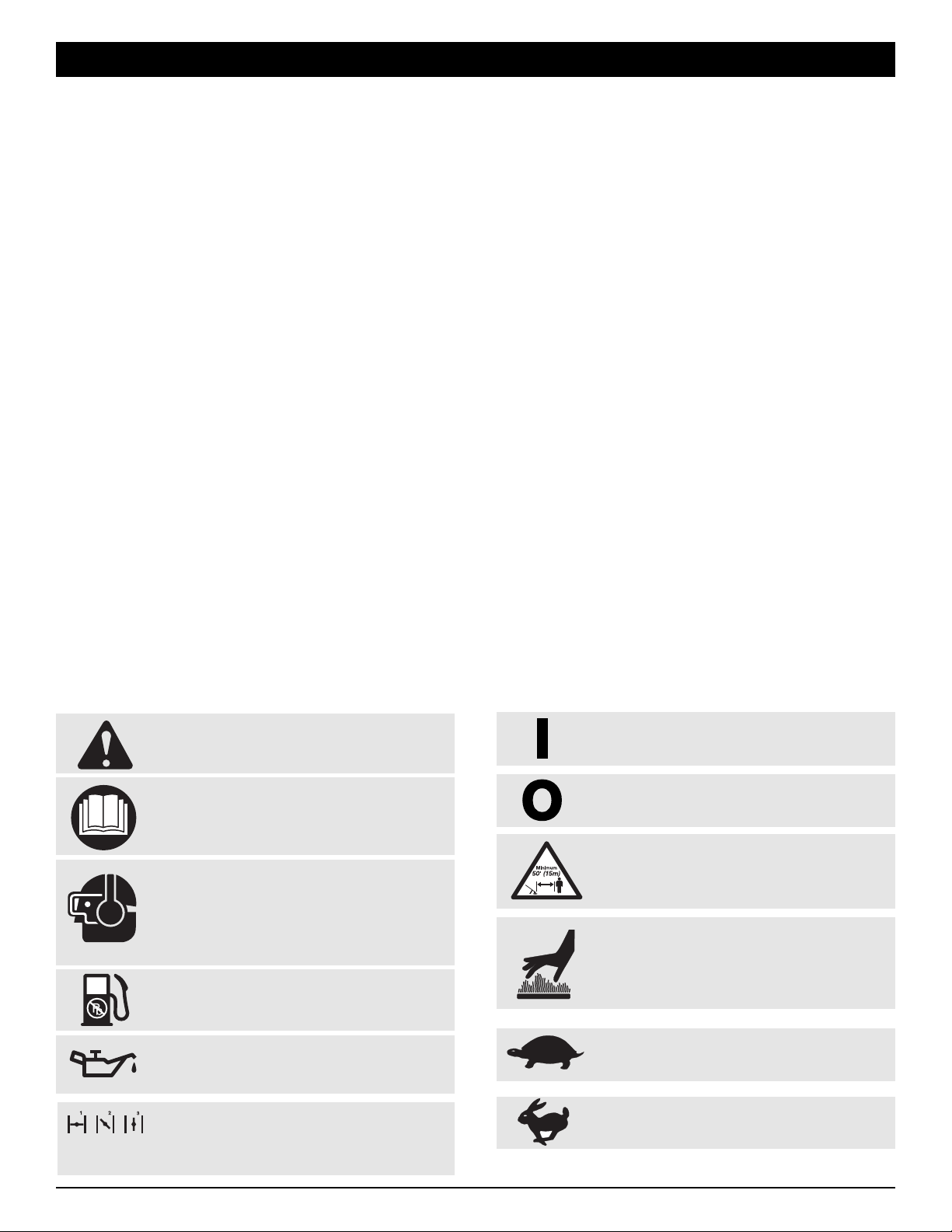

Assembled as a Blower

5

APPLICATIONS

As a blower:

• Cleaning yards, garages, driveways, porches,

patios, around walls, fences and more

As a vacuum:

• Picking up leaves and other light debris

Vacuum Bag

Blower

Outlet

Vacuum Bag

Zipper

Fuel

Cap

Primer

Bulb

Muffler Cover

Spark Plug

Muffler

Assembled as a Vacuum

Vacuum

Door

Front Handle

Vacuum Inlet

Vacuum

Tube

Rear Handle

Vacuum

Bag Hook

Vacuum Bag

Adapter

Rear Handle

Front Handle

Throttle Control

On/Off Stop

Control

Starter Rope

Grip

Blower Tube

Concentrator

Nozzle

Oil Filler Cap

Shoulder Strap

Attachment Points

Air Filter Cover

KNOW YOUR UNIT

Page 6

6

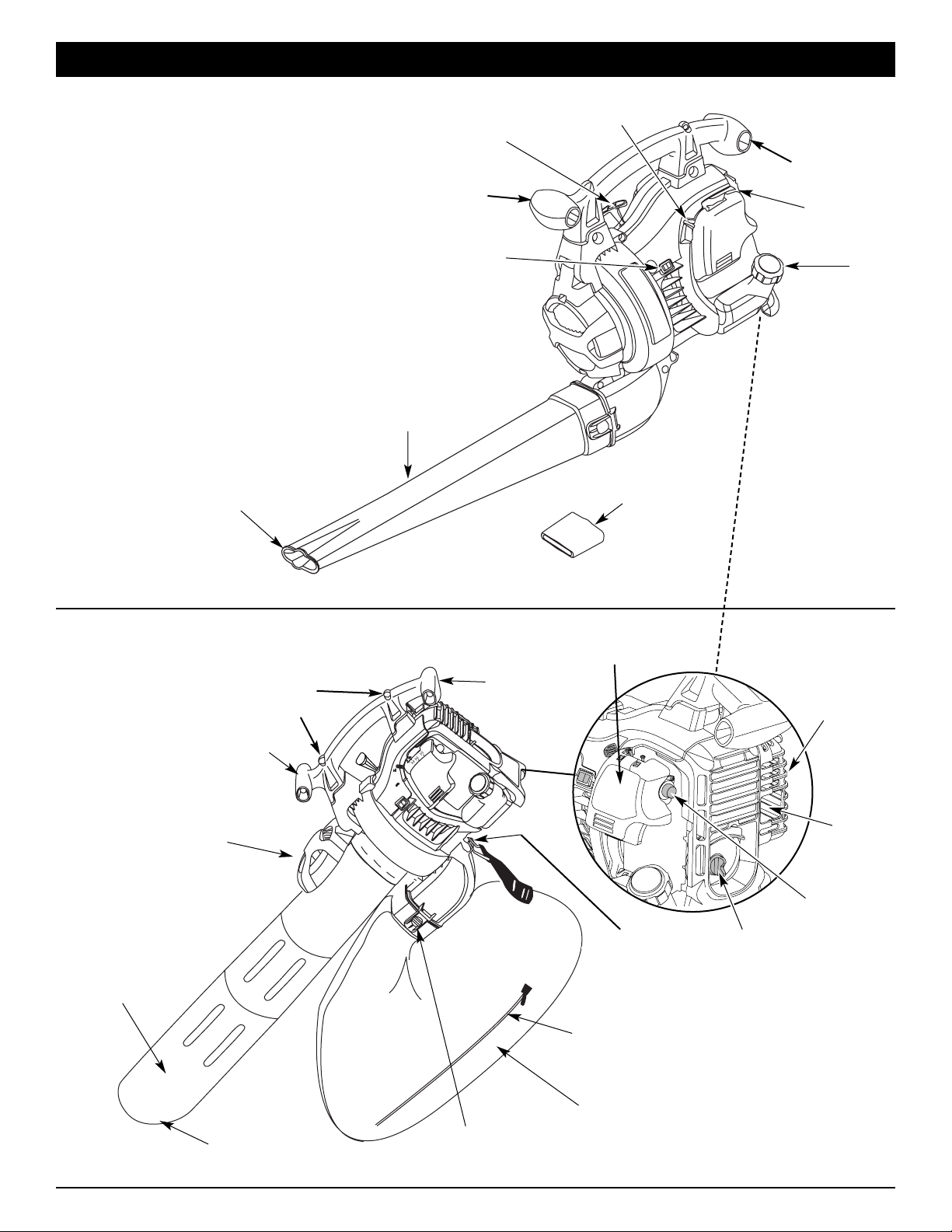

ASSEMBLING UNIT AS A BLOWER

Blower Tube Assembly

NOTE: If the unit was assembled as a vacuum unit, remove all

vacuum parts and store away in a secure place for

later use.

• Please note this unit comes with a high pressure concentrator

nozzle. This nozzle should be used when there is a need to

blow in a limited or concentrated area. In general uses, such

as leaf or grass blowing, the nozzle should not be used.

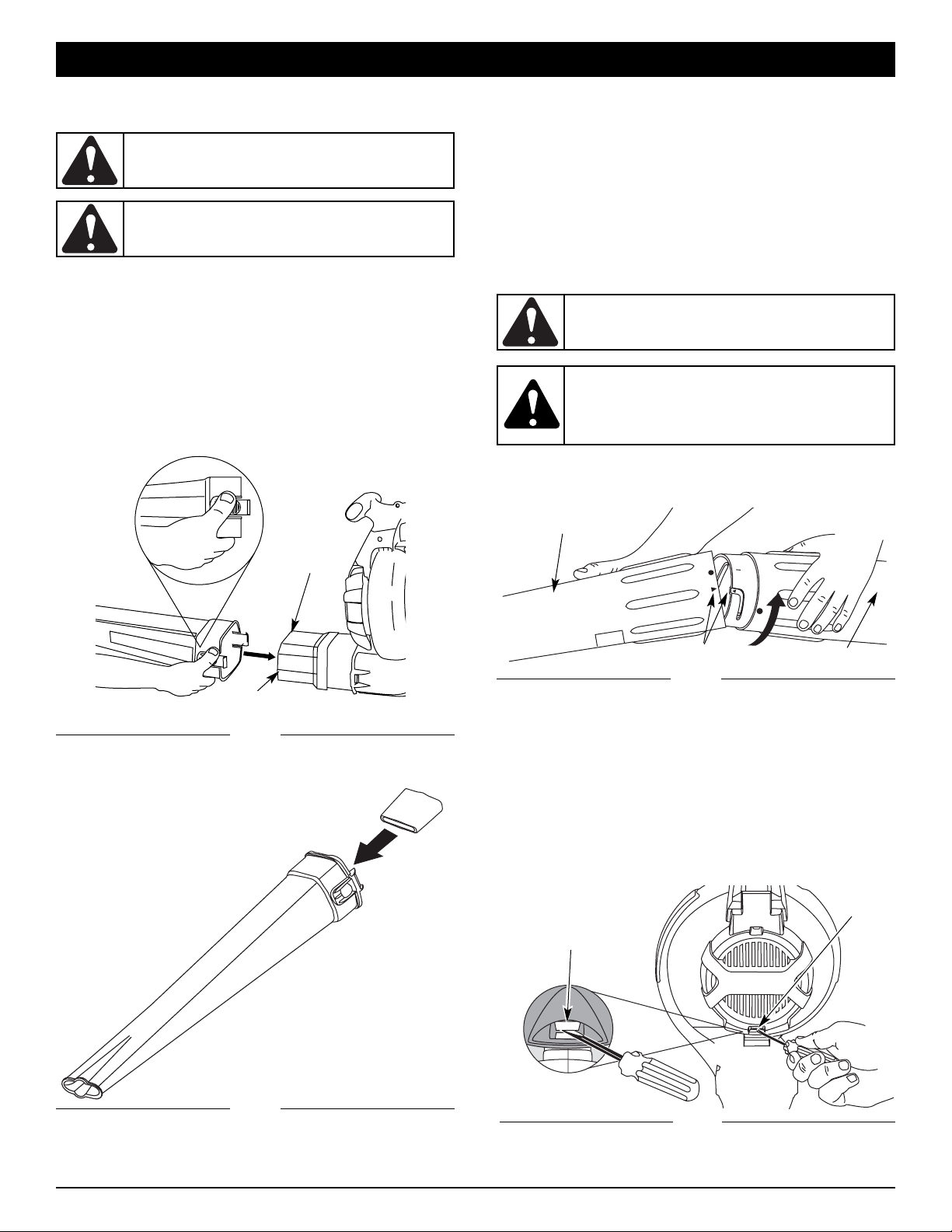

Installing Blower Tube

Install the blower tube over the blower outlet and push it on

until both tabs snap into place (Fig. 1).

ASSEMBLING UNIT AS A VACUUM

To assemble the unit as a vacuum, begin by removing the

blower tube. Refer to the previous section.

Vacuum Tube Assembly

NOTE: If the unit was assembled as a blower unit, remove the

blower tube and store away in a secure place for later use.

Installation

1. Align the small arrow on the lower vacuum tube with the

arrow on the upper vacuum tube (Fig. 3).

2. Grasp the lower and upper vacuum tubes firmly with both

hands, and push the lower vacuum tube into the upper

vacuum tube. Turn the lower vacuum tube clockwise until it

snaps into place and locks. When properly assembled, the

dot on the lower tube aligns with the dot on the upper tube.

3. Place the blower/vac so that the vacuum door is facing up.

Fig. 1

Fig. 3

Lower Vac Tube

Upper Vac Tube

4. Insert a flat head screwdriver under locking clip, lift upward

and open vacuum door (Fig. 4).

Fig. 4

ASSEMBLING THE GUTTER CLEAN-OUT ADAPTER

In order to use the gutter clean-out attachment kit, you must

install the gutter clean-out adapter (Part #753-05231 not

included). Push the adapter onto the blower outlet until both

tabs snap into place (Fig. 1). Refer to the Gutter Attachment Kit

manual for more information.

Arrows

Tabs

Locking

Clip

WARNING: To prevent serious personal injury,

stop the engine and allow the impeller to stop

before attaching or removing tubes.

WARNING: To prevent serious personal injury

or damage to the unit, the blower tube must be

installed while operating this unit as a blower.

WARNING: To prevent serious personal injury or

damage to the unit, always install vacuum tubes and

the vacuum bag, and make sure the vacuum bag is

completely zipped closed when operating this unit

as a vacuum.

WARNING: To prevent serious personal injury,

stop the engine and allow the impeller to stop

before attaching or removing tubes.

• When desired, insert the High Pressure Concentrator Nozzle

to increase the air velocity for demanding tasks (Fig. 2).

Removing

• Remove the blower tube by pressing both tabs at the same

time and pulling off the blower (Fig. 1).

Blower

Outlet

Fig. 2

ASSEMBLY INSTRUCTIONS

Vacuum

Door Slot

Page 7

7

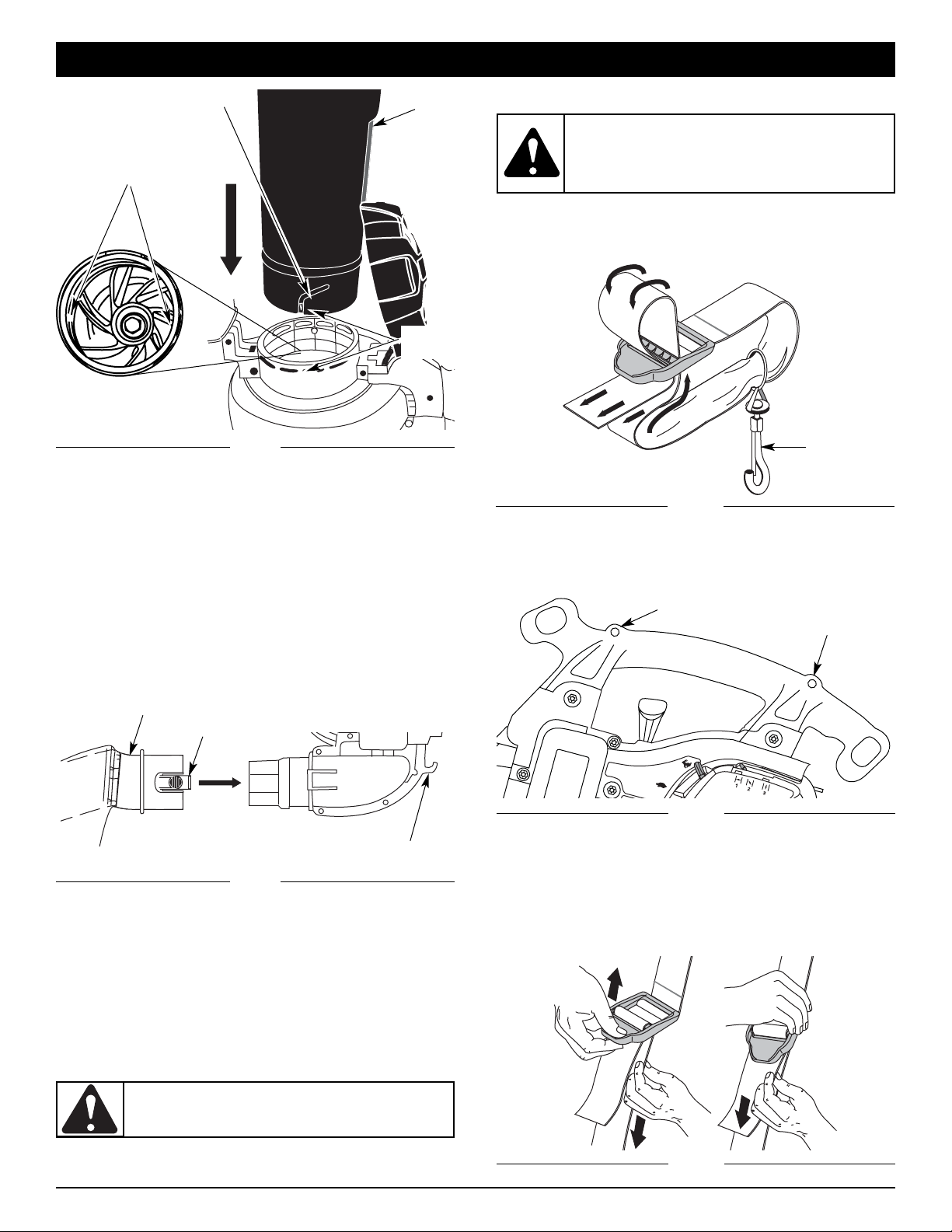

5. While holding the vacuum door open, insert the assembled

vacuum tube (put together in Step 2). Arrange the tube so

the flat area faces the vacuum door. The grooves on the

side of the tube will line up with the small tabs in the impeller

intake (Fig. 5). From the exterior, align the small arrow on the

vacuum tube with the arrow on the impeller intake.

6. Push the vacuum tube in firmly and grip it with both hands.

Turn the tube clockwise as far as possible until it snaps into

place and locks. When properly assembled, the dot on the

vacuum tube will align with the dot on the impeller intake.

8. Attach the vacuum bag to the vacuum bag hook located at

the underside of the unit.

9. Keep the bag zipped and shut.

Removing the Vacuum Bag

1. Unhook the bag.

2. Remove the vacuum bag by pressing both tabs on the

vacuum bag elbow at the same time and pulling the bag

off the blower (Fig. 6).

3. Install the blower tube in order to assemble the unit as a blower.

4. Make sure the vacuum door is securely latched shut.

Elbow

Tabs

Installing the Vacuum Bag

7. Install the vacuum bag adapter over the blower outlet and

push on it until both tabs snap into place (Fig. 6). Position

the bag so it hangs below the unit.

Fig. 6

Flat

Area

Tabs

Impeller Intake

Vacuum Tube

Groove

Fig. 5

Vacuum Bag Hook

Align

Arrows

WARNING: Never operate the unit in the blower

configuration without the vacuum door secured

and latched shut.

Fig. 9

3. Snap the clip on to the support fittings on the front or back

of the handle. Clip to the front portion of the handle when

using the unit as a blower, and clip to the back portion of

the handle when using the unit as a vacuum (Fig. 8).

4. While standing in the operating position, adjust the length

to fit the operator’s size. Pull the tab to lengthen, pull the

strap to shorten (Fig. 9).

5. Do not allow the shoulder strap to dangle. Always unclip

the shoulder strap from the unit when the shoulder strap is

not on the operator’s shoulder.

INSTALLING THE SHOULDER STRAP

1. Push the strap through the center of the buckle.

2. Pull the strap over the cross bar and down through the slot

in the buckle (Fig. 7).

Fig. 7

Clip

Attach Here for

Blowing

Attach Here for

Vacuuming

Fig. 8

WARNING: To avoid serious personal injury,

never attempt to start the unit when standing with

the unit clipped to the shoulder strap. Always

follow the starting procedures as described in the

Starting/ Stopping Instructions section.

ASSEMBLY INSTRUCTIONS

Page 8

RECOMMENDED OIL TYPE

Using the proper type and weight of oil in the crankcase is

extremely important. Check the oil before each use and

change the oil regularly. Failure to use the correct oil, or using

dirty oil, can cause premature engine wear and failure.

Use a high-quality SAE 30 weight oil of API (American

Petroleum Institute) service class SF, SG, SH.

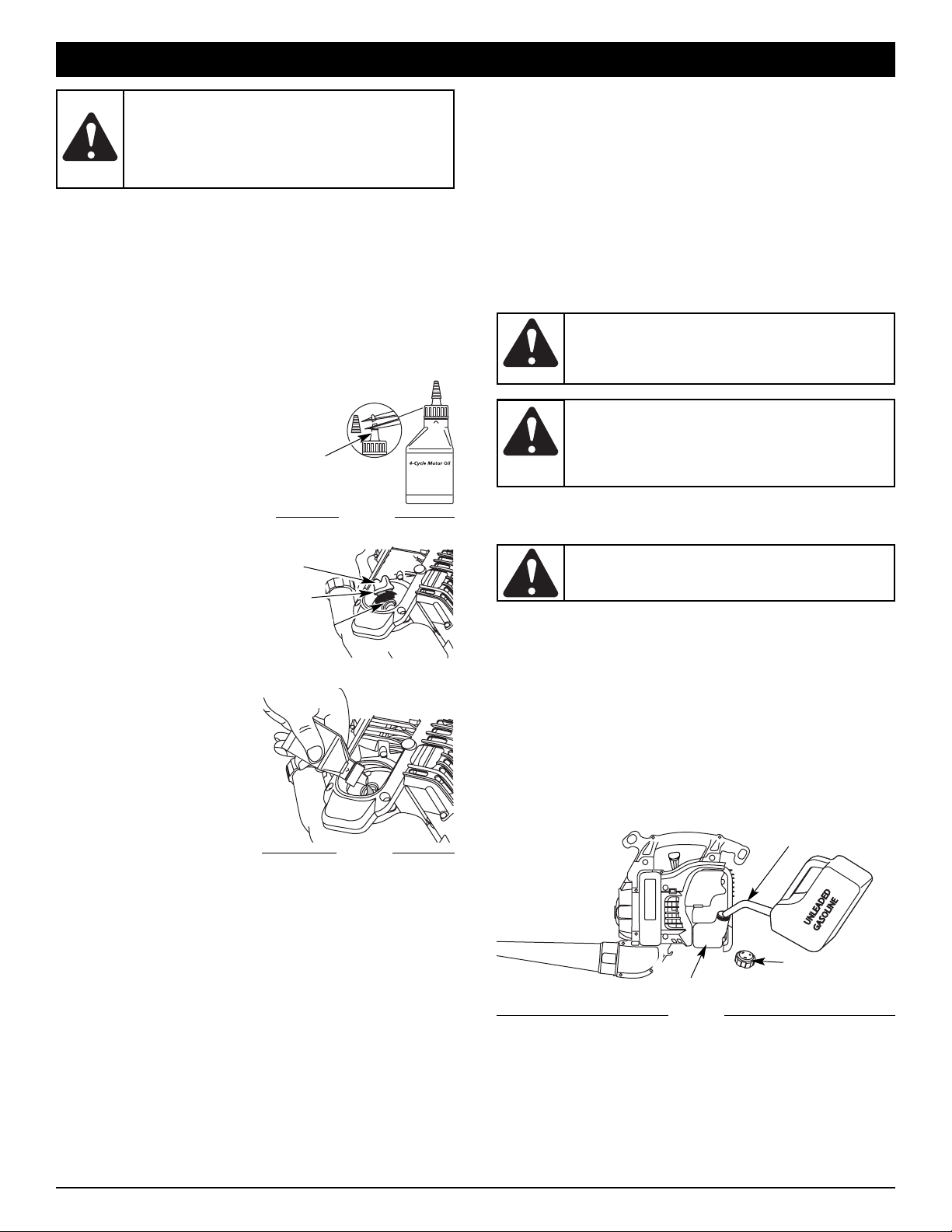

ADDING OIL TO CRANKCASE: INITIAL USE

NOTE: This unit is shipped without oil. In order to avoid

damage to the unit, put oil in the crankcase before you

attempt to start the unit.

Your unit is supplied with one 3.04

fluid oz. (90 ml.) bottle of SAE 30

SF, SG, SH oil (Fig. 10).

NOTE: Save the empty oil bottle.

It can be used to measure

the correct amount during

future oil changes. See

Changing the Oil.

1. Unscrew the top of the bottle

of oil and remove the paper

seal covering the opening.

Replace the top. Next, cut

the tip off the funnel spout

(Fig. 10).

2. Tip unit so that the back of

the engine is facing up in a

vertical position.

3. Remove the oil fill plug from

the crankcase (Fig. 11).

4. Pour the entire bottle of oil

into the oil fill hole (Fig. 12).

NOTE: Never add oil to the fuel

or fuel tank.

5. Wipe up any oil that may

have spilled and reinstall the

oil fill plug.

Check oil before each use and

change as needed. Refer to

Checking the Oil Level.

RECOMMENDED FUEL TYPE

Old fuel is the primary reason for improper unit performance.

Be sure to use fresh, clean, unleaded gasoline.

NOTE: This is a four cycle engine. In order to avoid damage to

the unit, do not mix oil with gasoline.

Definition of Blended Fuels

Today's fuels are often a blend of gasoline and oxygenates

such as ethanol, methanol or MTBE (ether). Alcohol-blended

fuel absorbs water. As little as 1% water in the fuel can form

acids when stored. Use fresh fuel (less than 60 days old), when

using alcohol-blended fuel.

Using Blended Fuels

If you choose to use a blended fuel, or its use is unavoidable,

follow recommended precautions:

• Always use fresh unleaded gasoline

• Use a gas stabilizer fuel additive

• Drain tank and run the engine dry before storing unit

Using Fuel Additives

The use of a gas stabilizer will inhibit corrosion and minimize

the formation of gum deposits. Using a fuel additive can keep

fuel from forming harmful deposits in the carburetor for up to

six (6) months. Add 0.8 oz. (23 ml.) of fuel additive per gallon of

fuel according to the instructions on the container. NEVER add

fuel additives directly to the unit's gas tank.

FUELING THE UNIT

1. Remove the fuel cap (Fig. 13).

2. Place the gas container’s spout into the fill hole on the fuel

tank (Fig. 13) and fill the tank.

NOTE: Do not overfill the tank.

3. Wipe up any gasoline that may have spilled.

4. Reinstall the fuel cap.

5. Move the unit at least 30 ft. (9.1 m) from the fueling source

and site before starting the engine.

NOTE: Dispose of the old gasoline in accordance to Federal,

State and Local regulations.

Fig. 10

Funnel

Spout

8

Fig. 13

Fuel Cap

Fuel Tank

Gas Can Spout

OIL AND FUEL INFORMATION

WARNING: Remove fuel cap slowly to avoid injury

from fuel spray. Never operate the unit without the

fuel cap securely in place.

Oil Fill Plug

Oil Fill Hole

O-Ring

Fig. 11

Fig. 12

WARNING: Add fuel in a clean, well ventilated

outdoor area. Wipe up any spilled fuel immediately.

Avoid creating a source of ignition for spilt fuel. Do

not start the engine until fuel vapors dissipate.

WARNING: Gasoline is extremely flammable.

Ignited vapors may explode. Always stop the engine

and allow it to cool before filling the fuel tank. Do

not smoke while filling the tank. Keep sparks and

open flames at a distance from the area.

WARNING: OVERFILLING OIL CRANKCASE MAY

CAUSE SERIOUS PERSONAL INJURY. Check and

maintain the proper oil level in the crank case; it is

important and cannot be overemphasized. Check

the oil before each use and change it as needed.

See Changing the Oil.

Page 9

9

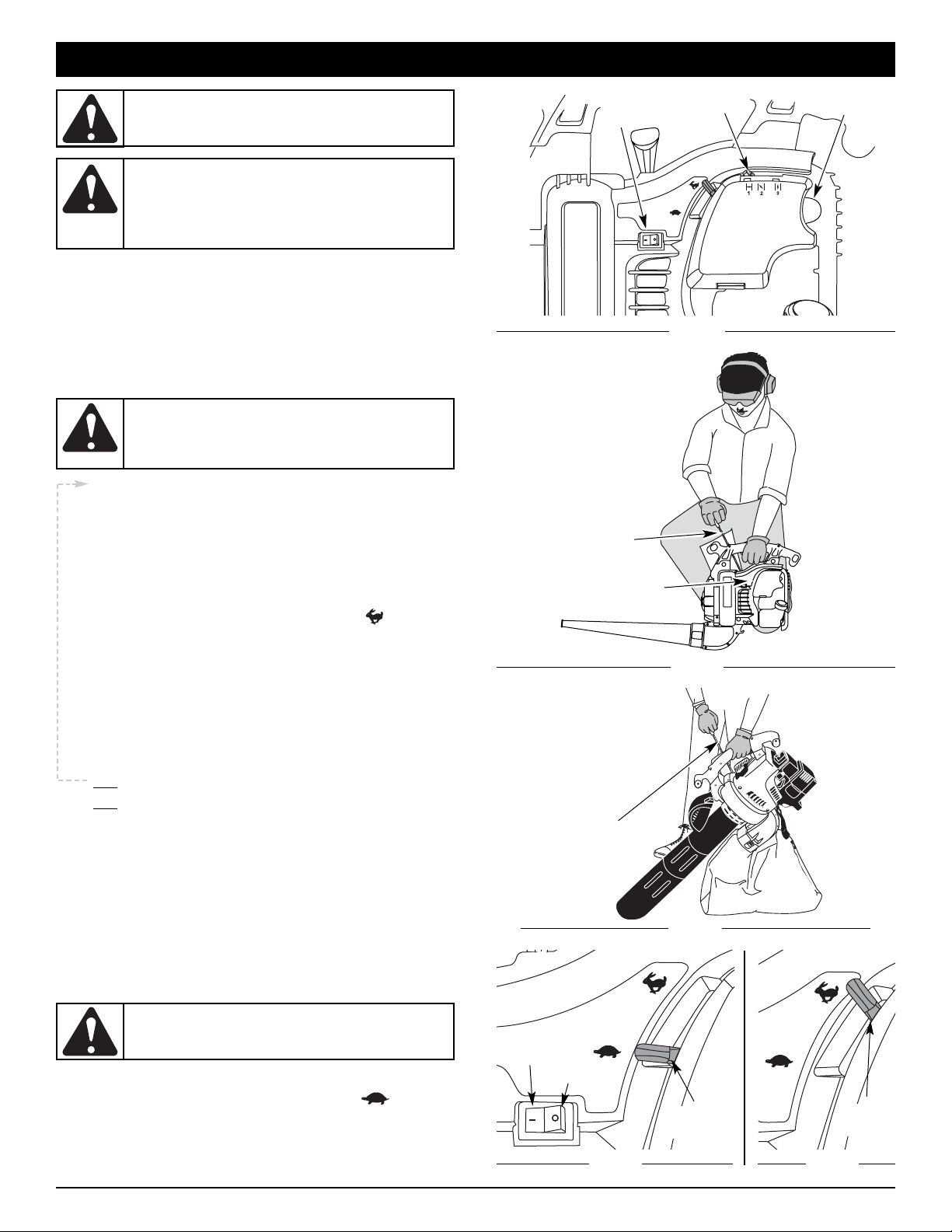

Start/On (I)

Stop/Off (O)

Throttle

Control

Fig. 17

STARTING INSTRUCTIONS

WARNING: Avoid accidental starting. Make sure

you are in the starting position when pulling the

starter rope (Fig. 15 or 16). To avoid serious injury,

the operator and unit must be in a stable position

while starting.

WARNING: Operate this unit only in a wellventilated outdoor area. Carbon monoxide exhaust

fumes can be lethal in a confined area.

Starter Rope

Throttle Control

Fig. 15

Primer Bulb

Fig. 14

Choke Lever

STARTING/STOPPING INSTRUCTIONS

1. Check the oil level in the crankcase. Refer to

Checking the Oil Level.

2. Fill the fuel tank with fresh, clean unleaded gasoline.

Refer to Fueling the Unit.

NOTE: There is no need to turn the unit on. The On/Off

Stop Control is in the ON ( I ) position at all times.

3. Fully press and release the primer bulb 10 times,

slowly. Some amount of fuel should be visible in

the primer bulb and fuel lines (Fig. 14). If you can’t

see fuel in the bulb, press and release the bulb as

many times as it takes before you can see fuel in it.

4. Place the choke lever in Position 1 (Fig. 14).

5. Crouch in the blower starting position (Fig. 15) or

stand in the vacuum starting position (Fig. 16). Move

the throttle control to the fast position ( ) (Fig. 18).

Pull the starter rope out with a smooth and steady

motion 5 times.

6. Place the choke lever in Position 2 (Fig. 14).

7. Pull the starter rope out with a smooth and steady

motion 1 to 4 times to start the engine.

8. Allow the engine to warm up for 15 to 30 seconds.

9. Place the choke lever in Position 3 (Fig. 14). The

unit is ready for use.

IF...

The engine does not start, go back to step 3.

IF...

The engine fails to start after a few attempts, place

the choke lever in Position 3. Pull the starter rope

out with a smooth and steady motion 3 to 8 times—

the engine should start. If not, pull 3 to 8 more times.

NOTE: The unit uses the Incredi-Pull™ starting system

with MAX FIRE IGNITION™ , which significantly

reduces the effort required to start the engine.

You must pull the starter rope out far enough to

hear the engine attempt to start. There is no

need to pull the rope briskly-- there is no harsh

resistance when pulling. Be aware that this

starting method is vastly different from (and

much easier than) what you may be used to.

Vacuum

Starting

Position

Starter

Rope

Blower

Starting

Position

Fig. 16

STOPPING INSTRUCTIONS

1. Move the throttle control to the idle position ( ) (Fig. 17).

Allow the engine to cool down by idling.

2. Press and hold On/Off Stop Control in the OFF (O) position

until engine comes to a complete stop (Fig. 14)

WARNING: To avoid serious personal injury, always

remove the vacuum bag prior to refueling the unit.

The bag may become a fire hazard when saturated

with fuel.

Throttle

Control

Fig. 18

On/Off

IMPORTANT: Move the throttle to idle, or shut the

unit off, when not operating, when setting the unit

down, or when performing maintenance.

Page 10

10

OPERATING INSTRUCTIONS

HOLDING THE BLOWER/VACUUM

Before operating the unit, stand in the operating position.

Check for the following:

• Operator is wearing proper clothing, such as boots, safety

glasses or goggles, ear/hearing protection, gloves, long

pants and long sleeve shirt

• If the conditions are dusty, the operator is wearing a dust

mask or face mask

• The unit is in good working condition

• The tubes are in place and secure

OPERATING TIPS

• Be sure the vacuum bag is zipped closed before operating

the unit.

• Assure the unit is not directed at anybody or any loose debris

before starting the unit.

• Verify that the unit is in good working condition. Make sure

the tubes are in place and secure.

• Always hold the unit securely when operating. Keep a firm

grip on both the front and rear handles.

• To reduce the risk of hearing loss associated with sound

level(s), hearing protection is required.

• Operate power equipment only at reasonable hours— not

early in the morning or late at night when people might be

disturbed. Comply with times listed in local ordinances.

Usual recommendations are 9:00 am to 5:00 pm, Monday

through Saturday.

• To reduce noise levels, limit the number of pieces of

equipment used at any one time.

• To reduce noise levels, operate power blowers at the lowest

possible speed to do the job.

• Check your equipment before operation, especially the

muffler, air intakes and air filters.

• Use rakes and brooms to loosen debris before blowing.

• In dusty conditions, slightly dampen surfaces or use a mister

attachment when water is available.

• Conserve water by using power blowers instead of hoses for

many lawn and garden applications, including areas such as

screens, patios, grills, porches, and gardens.

• Watch out for children, pets, open windows or freshly

washed cars, and blow debris safely away.

• Use the full blower nozzle extension so the air stream can

work close to the ground.

• Clean up after using blowers and other equipment. Dispose

of debris appropriately.

Fig. 19

Fig. 20

WARNING: To avoid serious personal injury, wear

goggles or safety glasses at all times when

operating this unit. Wear a face mask or dust mask

in dusty locations.

WARNING: To prevent serious personal injury or

damage to the unit, make sure blower tubes or

vacuum tubes and the vacuum bag are in place

before you operate the unit.

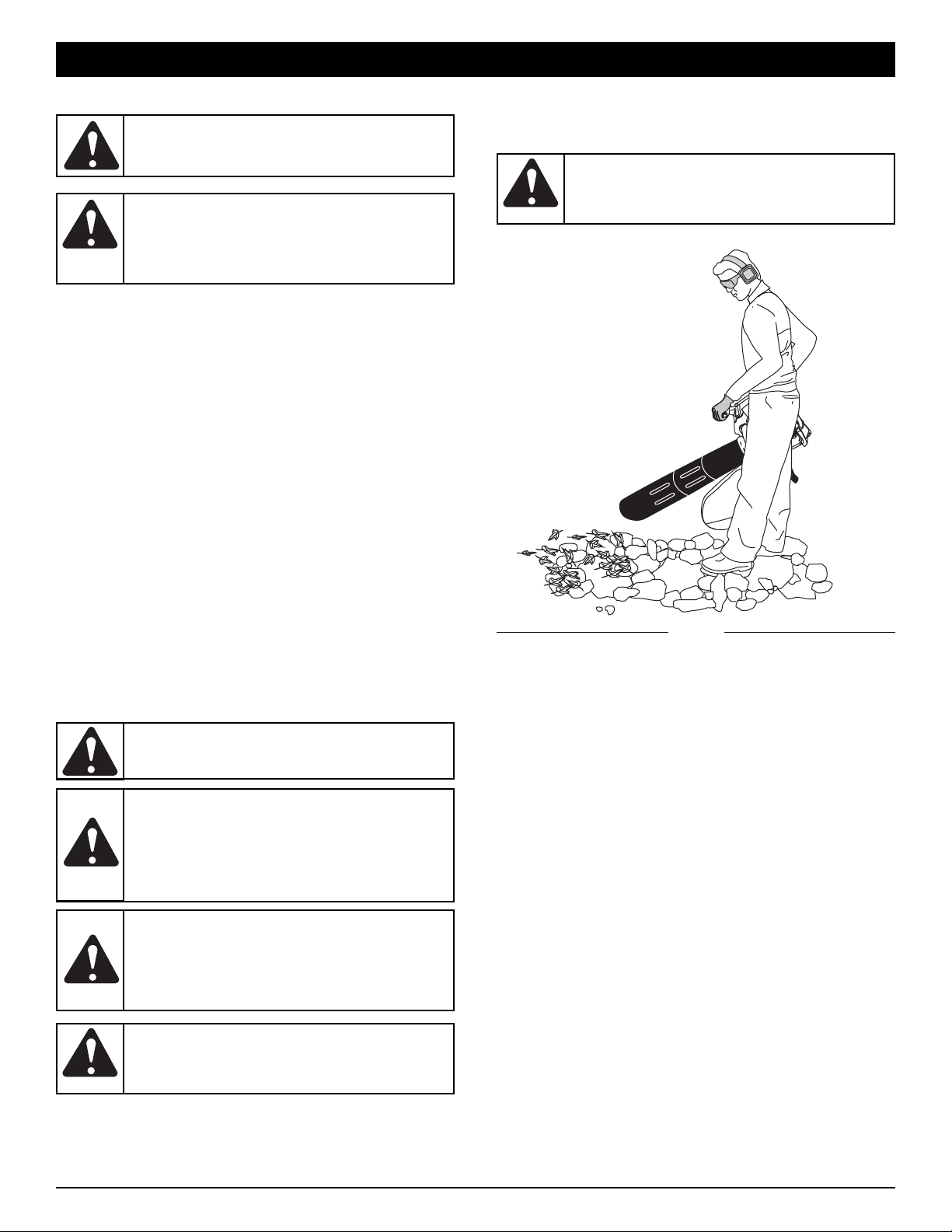

OPERATING AS A BLOWER

Please note this unit comes with a high pressure concentrator

nozzle. This nozzle should be used when there is a need to blow

in a limited or concentrated area. In general uses, such as leaf or

grass blowing, the nozzle should not be used.

1 Use the blower for trees, shrubs, flower beds and hard-to-

clean areas (Fig. 19).

2. Use the unit around buildings and for other normal cleaning

procedures (Fig. 19).

3. Use the blower around walls, overhangs, fences and

screens (Fig. 20).

CORRECT POSITION

INCORRECT POSITION

WARNING - Hot Surface: After starting the

unit, always stand on the left side of the unit to

operate it as shown in Figure 20. Do not operate

the unit as shown in figure 19.

Page 11

11

OPERATING INSTRUCTIONS

Fig. 21

OPERATING AS A VACUUM

Check for the following before operating the unit:

• Operator is wearing proper clothing, such as boots, safety

glasses or goggles, ear/hearing protection, gloves, long

pants and long sleeve shirt

• If the conditions are dusty, operator is equipped with a dust

mask or face mask

• The unit is in good working condition-- the vacuum tubes

and vacuum bag are in place and secure.

• The vacuum shoulder strap is in place and correctly adjusted.

Operation Procedure

Use the unit for vacuuming up light debris like leaves and

paper.

Hold the vacuum, tilting the suction tube slightly (2-4 inches or

50-100 mm above the ground), and use a sweeping action to

collect light debris (Fig. 21). The debris will flow into the

vacuum bag. Items such as small leaves and small twigs will

be mulched as they pass through the fan housing, allowing the

vacuum bag to hold more debris.

When the bag is full, suction will noticeably decrease. Turn off

the unit and allow the impeller to stop before you unzip the

bag. Unzip the bag and empty the contents before continuing.

Refer to Emptying the Vacuum Bag.

Emptying the Vacuum Bag

1. Remove the bag from the vacuum bag hook.

2. While wearing eye protection and a dust mask, unzip the

vacuum bag and empty the contents into a garbage bag or

container.

3. Turn the bag inside out after initial emptying and vigorously

WARNING:

As a vacuum, the unit is designed to

pick up dry material such as leaves, grass, small twigs

and bits of paper. To avoid serious personal injury, do

not attempt to vacuum wet debris and/or standing

water as this may result in damage to the blower/

vacuum. To avoid severe damage to the impeller, do

not vacuum metal, broken glass or similar items.

WARNING: When the upper and lower vacuum

tubes are removed, make sure the vacuum door is

snapped closed and secured before using the unit, to

avoid injury from the impeller.

WARNING:

To prevent serious personal injury or

damage to the unit, always install vacuum tubes,

vacuum bag and make sure the vacuum bag is

completely zipped closed when operating this unit as

a vacuum.

WARNING: To avoid serious personal injury, never

unzip the vacuum bag without stopping the unit

first.

WARNING: To avoid serious personal injury, turn

off the unit and allow the impeller to stop before

opening vacuum door or installing or removing

vacuum bag.

WARNING: Avoid situations that could catch the

vacuum bag on fire. Do not operate near an open

flame. Do not vacuum warm ash from fireplaces,

barbecue pits, brush piles, etc. Do not vacuum

discarded cigars or cigarettes unless the cinders

are completely cool.

WARNING - Hot Surface: After starting the

unit, always stand on the left side of the unit to

operate it as shown in Figure 21.

shake out dust and debris.

4. Zip close and reinstall the vacuum bag.

Page 12

12

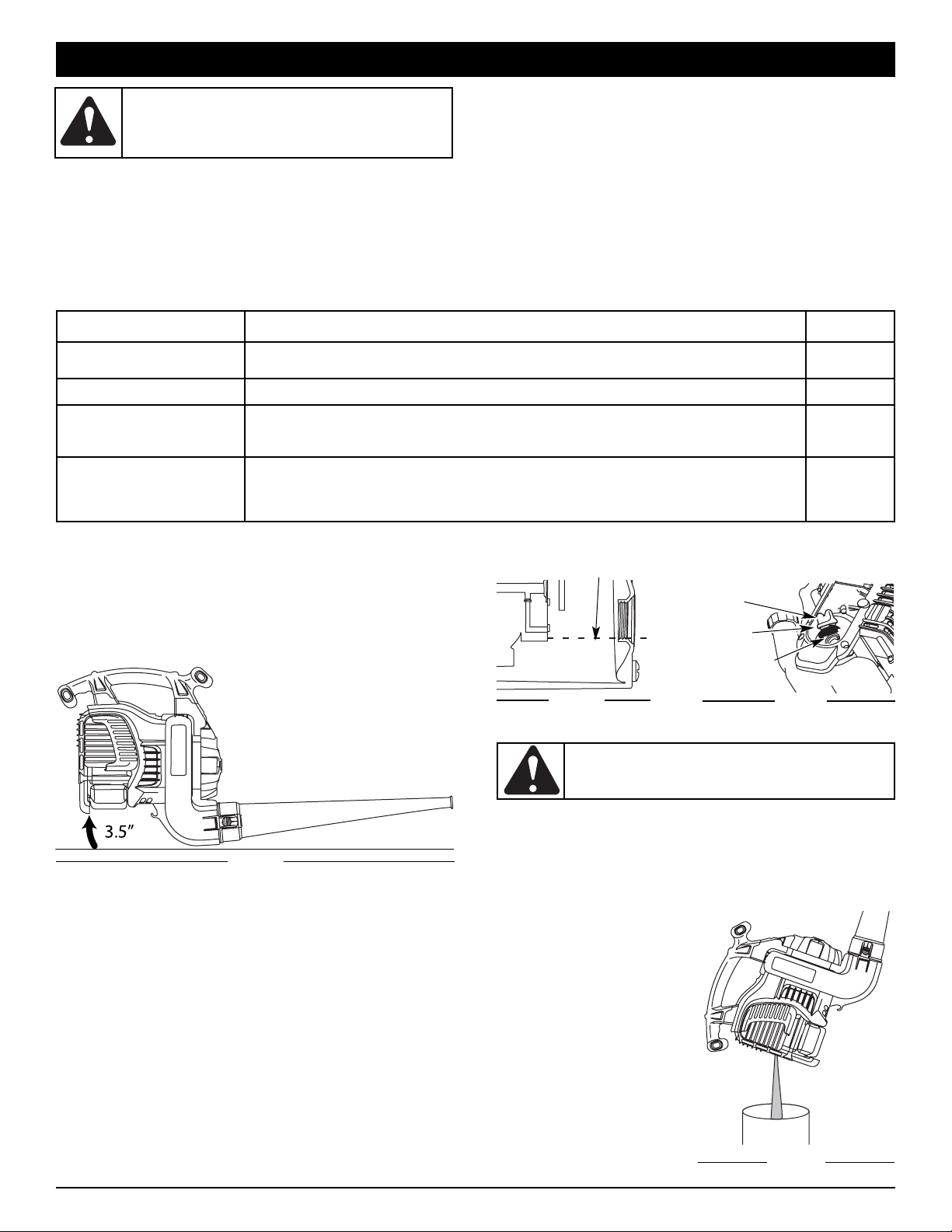

CHECKING THE OIL LEVEL

The importance of checking and maintaining the proper oil level

in the crankcase cannot be overemphasized. Check oil before

each use:

1. Stop the engine and allow oil to drain into the crankcase.

2. Place the engine on a level surface (Fig. 22).

3. Raise the rear of the unit 3.5 inches to get a proper oil level

reading.

4. Clean the area around the dipstick before removing it. Keep

dirt, grass clippings, and other debris out of the engine.

5. Remove the oil fill plug.

6. Look into the oil fill hole (use a flashlight if needed). The oil

should be just touching the innermost thread (Fig. 23).

7. If the oil level is not touching the innermost thread on the

oil fill hole, add a small amount of oil to the oil fill hole and

recheck (Fig. 23). Repeat this procedure until the oil level

reaches the innermost thread on the oil fill hole.

NOTE: Do not overfill the unit.

NOTE: Make sure the O-ring is in place on the oil fill plug when

checking and changing the oil (Fig. 24).

Oil Fill Plug

Oil Fill Hole

O-Ring

Max Oil Fill Line

Fig. 24

Fig. 23

WARNING: To prevent serious injury, never

perform maintenance or repairs with unit running.

Always service and repair a cool unit. Disconnect the

spark plug wire to ensure that the unit cannot start.

FREQUENCY MAINTENANCE REQUIRED SEE

Before starting engine

Fill fuel tank with fresh fuel

Check oil

p. 8

p. 12

Every 10 hours Clean and re-oil air filter p. 13

1st change at 10 hours

2nd change at 25 hours

Every 25 hours after

Change oil

Change oil

Clean spark arrestor and change oil

p. 12

p. 12

p. 15 & 12

10 hours on new engine

Every 25 hours

Every 25 hours

Check rocker arm to valve clearance and adjust

Check rocker arm to valve clearance and adjust

Check spark plug condition and gap

p. 14

p. 14

p. 15

MAINTENANCE AND REPAIR INSTRUCTIONS

MAINTENANCE SCHEDULE

Perform these required maintenance procedures at the

frequency stated in the table. These procedures should also

be a part of any seasonal tune-up.

NOTE: Some maintenance procedures may require special tools

or skills. If you are unsure about these procedures take

your unit to a Sears or other qualified service dealer.

NOTE: Maintenance, replacement, or repair of the emission

control devices and system may be performed by a

Sears or other qualified service dealer.

In order to assure peak performance of your engine, inspection

of the engine exhaust port may be necessary after 50 hours of

operation. If you notice lost RPM, poor performance or general

lack of acceleration, this service may be required. If you feel

your engine is in need of this inspection, refer service to a

Sears or other qualified service dealer for repair. DO NOT

attempt to perform this process yourself as engine damage

may result from contaminants involved in the cleaning process

for the port.

CHANGING THE OIL

For a new engine, change the oil after the first 10 hours of

operation. Change the oil while the engine is still warm. The oil

will flow freely and carry away more impurities.

1. Remove the oil fill plug.

2. Pour the oil out of the oil fill hole and into a container by

tipping the unit to a

vertical position (Fig. 25).

Allow ample time for

complete drainage.

3. Wipe up any oil residue

on the unit and clean up

any oil that may have

spilled. Dispose of the

oil according to Federal,

State and local

regulations.

4. Refill the crankcase with

3.04 fluid ounce (90 ml)

of SAE 30 SF, SG, SH oil.

NOTE: Use the bottle and

spout saved from

initial use to

WARNING: Wear gloves to prevent injury when

handling unit.

Fig. 25

Fig. 22

Page 13

13

7. Reinstall the air filter

cover. Position the

slots on the top of the

air filter cover onto the

tabs at the top of the

back plate (Fig. 31).

8. Swing the cover down

until the tab on the air

filter backplate snaps

into place in the slot

on the air filter cover

(Fig. 32).

CARBURETOR ADJUSTMENT

The idle speed of the engine is adjustable. An idle adjustment

screw is between the air

filter cover and the engine

starter housing (Fig. 33).

NOTE: Careless

adjustments can

seriously damage

your unit. A Sears

or other qualified

service dealer

should make

carburetor

adjustments.

Check Fuel

Old fuel is usually the reason for improper unit performance.

Drain and refill the tank with fresh fuel prior to making any

adjustments. Refer to Oil and Fuel Information.

Clean Air Filter

The condition of the air filter is important to the operation of

the unit. A dirty air filter will restrict air flow. This is often

mistaken for an out of adjustment carburetor. Check the

condition of the air filter before adjusting the idle speed screw.

Refer to Air Filter Maintenance.

MAINTENANCE AND REPAIR INSTRUCTIONS

measure the correct amount of oil. The top of the label

on the bottle measures approximately 3.04 ounces (90

ml) (Fig. 26). Check the level, See Checking the Oil

Level. If the level is low, add a small amount of oil and

recheck. Do not overfill (Fig. 23).

5. Replace the oil fill plug.

6. Reconnect the spark plug boot.

AIR FILTER MAINTENANCE

Cleaning the Air Filter

Clean and re-oil the air filter every 10 hours of operation. It is an

important item to maintain. Failure to maintain your air filter

properly can result in poor performance or can cause

permanent damage to your engine.

1. Open the air filter cover. Push the tab on the under side of the

cover inward. Then pull the air filter cover out and up from the

bottom of the cover (Fig. 27).

2. Remove the air filter (Fig. 27).

3. Wash the filter in detergent and water (Fig. 28). Rinse the

filter thoroughly and allow it to

dry.

4. Apply enough clean SAE 30

motor oil to lightly coat the filter

(Fig. 29).

5. Squeeze the filter to spread and

remove excess oil (Fig. 30).

6. Replace the filter (Fig. 31).

NOTE: If the unit is operated

without the air filter, you will

VOID the warranty.

Fill Level

Fig. 26

WARNING: To avoid serious personal injury,

always turn the unit off and allow it to cool before

you clean or service it.

Fig. 28

Fig. 29

Fig. 30

Fig. 31

Locking Tab

Tabs

Back Plate

Air Filter

Air Filter Cover

Air Filter

Tab

Fig. 32

Air Filter Cover

Air Filter

Tab

Fig. 27

Idle Adjustment Screw

Fig. 33

Page 14

14

The recommended clearance for both intake and exhaust is

.003 – .006 in. (.076 – 0.152 mm). Use a standard automotive

.005 in. (0.127 mm) feeler gauge. The feeler gauge should slide

between the rocker arm and valve stem with a slight amount of

resistance, without binding. See Figures 37 and 38.

13. If the clearance is not within specification:

a. Turn the adjusting nut using a 5/16 inch (8 mm) wrench or

nut driver (Fig. 38).

• To increase clearance, turn the adjusting nut

counterclockwise.

• To decrease clearance, turn the adjusting nut clockwise.

b.Recheck both clearances, and adjust as necessary.

14. Reinstall the rocker arm cover using a new gasket. Torque

the screw to 20–30 in•lb (2.2–3.4 N•m).

11. Pull the starter rope slowly to bring the piston to the top of

its travel (known as top dead center). Check that:

• The piston is at the top of its travel while looking in the

spark plug hole (Fig. 37)

• Both rocker arms move

freely, and both valves are

closed.

If these statements are not true,

repeat this step.

12. Slide the feeler gauge

between the rocker arm and

the valve return spring.

Measure the clearance

between the valve stem and

rocker arm (Fig. 37 & 38).

Measure both the intake and

exhaust valves.

MAINTENANCE AND REPAIR INSTRUCTIONS

Adjust Idle Speed Screw

If, after checking the fuel and cleaning the air filter, the engine

still will not idle, adjust the idle speed screw as follows:

1. Start the engine and let it run at a high idle for a minute to

warm up. Refer to Starting/Stopping Instructions.

2. Move the throttle control to the idle position ( ) and let

the engine idle. If the engine stops, insert a small phillips

screwdriver in between the Air Filter Cover and the Engine

Cover (Fig. 33). Turn the idle speed screw in, clockwise, 1/8

of a turn at a time (as needed) until the engine idles smoothly.

Checking the fuel, cleaning the air filter, and adjusting the idle

speed should solve most engine problems. If not and all of the

following are true:

• the engine will not idle

• the engine hesitates or stalls on acceleration

• there is a loss of engine power

Have the carburetor adjusted by a Sears or other qualified

service dealer.

ROCKER ARM CLEARANCE

This requires disassembly of the engine. If you feel unsure or

unqualified to perform this, take the unit to a Sears or other

qualified service dealer

NOTE: Inspect the valve to rocker arm clearance with a feeler

gauge after the first 10 hours of operation and every

25 hours of operation.

• The engine must be cold when checking or adjusting the

rocker arm clearance.

• This task should be performed inside, in a clean, dust free

area.

1. Remove the 2 handle screws with flat blade or T20 torx head

screwdriver, while holding the nuts with 3/8” nut driver (Fig. 34).

2. Remove top bolt located near starter rope handle with

tools mentioned in step 1 (Fig. 34).

3. Loosen the 3 screws indicated in Figure 34.

4. Open vacuum door, prop open with hand.

5. Remove handle.

6. Remove the five (5) screws on the back of the engine

cover with a Flat-blade or T-25 Torx screwdriver (Fig. 35).

7. Remove the engine cover (Fig. 35).

8. Disconnect the spark plug wire.

9. Clean dirt from around the spark plug. Remove the spark

plug from the cylinder head by turning a 5/8 in. socket

counterclockwise.

10. Clean dirt from around the rocker arm cover. Remove the

screw holding the rocker arm cover with a large flat blade

screwdriver or Torx T-25 bit (Fig. 36). Remove the rocker

arm cover and gasket.

Remove

Screws

Fig. 35

View Of The Rear Engine Cover

Remove

Screws

Rocker

Arm

Cover

Fig. 36

Spark

Plug

Hole

Adjusting Nuts

Feeler Gauge

Rocker Arms

Fig. 37

INTAKE

EXHAUST

Spark Plug

Hole

Remove

Screws

Fig. 34

Loosen

Screws

Page 15

15. Check the spark plug and reinstall. See Replacing the Spark

Plug.

16. Reinstall the spark plug wire.

17. Reinstall the engine cover. Check alignment of the cover

before tightening the screws. Tighten screws.

18. Push rear end of handle into rear screw location.

19. Slide screw through plastic housing and handle. (Do not

tighten screw.)

20. Open vacuum door, prop open with hand.

21. Push front end of handle into front screw location.

22. Slide front handle screw through plastic housing. (Do not

tighten screw.)

23. Tighten screw near switch and near vacuum door hinge.

24. Tighten handle screws while holding nuts with 3/8” nut driver.

REPLACING THE SPARK PLUG

Use a replacement part number 753-05255 or Champion spark plug,

#RDZ19H. The correct spark gap is 0.025 in. (0.655 mm.). Remove

the plug after every 25 hours of operation and check its condition.

1. Stop the engine and allow it

to cool. Remove the five (5)

screws on the back of the

engine cover with a Flathead or T-25 Torx

screwdriver (Fig. 35).

2. Grasp the plug wire firmly

and pull the cap from the

spark plug.

3. Clean dirt from around the

spark plug. Remove the

spark plug from the cylinder

head by turning a 5/8 in.

socket counterclockwise.

4. Replace cracked, fouled or dirty spark plug. Set the spark

gap at 0.025 in. (0.655 mm.) using a feeler gauge (Fig. 39).

5. Install a correctly-gapped spark plug in the cylinder head.

Turn the 5/8 in. socket clockwise until snug.

If using a torque wrench torque to: 110-120 in.•lb. (12.3-13.5 N•m)

Do not over tighten.

15

Feeler Gauge

Adjusting Nut

Rocker Arm

.003–.006 in.

(.076–.152 mm)

Valve Stem

MAINTENANCE AND REPAIR INSTRUCTIONS

Fig. 38

0.025 in.

(0.655 mm.)

Fig. 39

WARNING: Do not sand blast, scrape or clean

electrodes. Grit in the engine could damage the

cylinder.

WARNING: To avoid serious personal injury,

always turn your unit off and allow it to cool before

you clean or service it.

Fig. 40

Muffler

Spark Arrestor Screen

Diverter

T-20 Screw

Slot

T-25 Screw

SPARK ARRESTOR MAINTENANCE

1. Remove the rear engine cover. See Rocker Arm Clearance.

2. With a flat blade screwdriver or Torx T-20 bit and a T-25

bit, remove the screws attaching the spark arrestor diverter

to the muffler (Fig. 40).

3. Pull the the spark arrestor diverter out of the muffler.

Remove the spark arrestor diverter.

4. Remove the spark arrestor screen from the spark arrestor

diverter.

5. Clean the spark arrestor screen with a wire brush or

replace it.

6. Reinstall the spark arrestor screen, spark arrestor diverter

and screws.

7. Reinstall the rear engine cover.

CLEANING

Use a small brush to clean off the outside of the unit. Do not

use strong detergents. Household cleaners that contain

aromatic oils such as pine and lemon, and solvents such as

kerosene, can damage plastic housing or handle. Wipe off any

moisture with a soft cloth.

STORAGE

• Never store the unit with fuel in the tank where fumes may

reach an open flame or spark.

• Allow the engine to cool before storing.

• Lock up the unit to prevent unauthorized use or damage.

• Store the unit in a dry, well-ventilated area.

• Store the unit out of the reach of children.

LONG TERM STORAGE

1. Drain all gasoline from the gas tank into a container. Do not

use gas that has been stored for more than 60 days. Dispose

of the old gasoline in accordance to Federal, State, and Local

regulations.

2. Start the engine and allow it to run until it stalls. This ensures

that all gasoline has been drained from the carburetor.

3. Allow the engine to cool. Remove the spark plug and put 5

drops of high quality motor oil into the cylinder. Pull the starter

rope slowly to distribute the oil. Reinstall the spark plug.

NOTE: Remove the spark plug and drain all of the oil from the

cylinder before attempting to start the blower after storage.

4. Change the oil, referring to Changing the Oil. Dispose of the

old oil in accordance to Federal, State and Local regulations.

5. Thoroughly clean the unit and inspect for any loose or

damaged parts. Repair or replace damaged parts and tighten

loose screws, nuts or bolts. The unit is ready for storage.

TRANSPORTING

• Allow the engine to cool before transporting.

• Secure the unit while transporting.

• Drain the gas tank before transporting.

• Tighten gas cap before transporting.

Page 16

16

TROUBLESHOOTING

NOTE: F

or repairs beyond the minor adjustments listed above, contact your nearest Sears Parts & Repair center (1-800-4-MY-HOME®)

or other qualified service dealer.

CAUSE ACTION

Old fuel Drain gas tank and add fresh fuel

Improper carburetor adjustment Take to a Sears or other qualified service dealer for adjustment

Fouled spark plug Replace the spark plug

Plugged spark arrestor Clean or replace spark arrestor

CAUSE ACTION

Empty fuel tank Fill fuel tank with new fuel

Primer bulb wasn't pressed enough Press primer bulb fully and slowly 10 times

Old fuel Drain gas tank and add fresh fuel

Fouled spark plug Replace the spark plug

Plugged spark arrestor Clean or replace spark arrestor

ENGINE WILL NOT START

ENGINE WILL NOT IDLE

ENGINE WILL NOT ACCELERATE

ENGINE LACKS POWER OR STALLS

CAUSE ACTION

Air filter is plugged Replace or clean the air filter

Old fuel Drain gas tank and add fresh fuel

Improper carburetor adjustment Adjust carburetor

CAUSE ACTION

Old fuel Drain gas tank and add fresh fuel

Improper carburetor adjustment Take to a Sears or other qualified service dealer for adjustment

Dirty air filter Clean or replace the air filter

Plugged spark arrestor Clean or replace spark arrestor

SPECIFICATIONS

ENGINE*

*All specifications are based on the latest product information available at the time of printing. We reserve the right to make changes

at any time without notice.

Engine Type............................................................................................................................................................... Air-Cooled, 4-Cycle

Displacement ................................................................................................................................................................. 1.8 cu. in. (29 cc)

Vacuum Operating RPM .......................................................................................................................................................... 6,800+ rpm

Blower Operating RPM.............................................................................................................................................................7,200+ rpm

Idle Speed RPM ........................................................................................................................................................... 3,200 – 4,400 rpm

Ignition Type ......................................................................................................................................... Electronic MAX FIRE IGNITION™

Ignition Switch.............................................................................................................................................................. Momentary Switch

Valve clearance................................................................................................................................... 0.003–0.006 in. (0.076–0.152 mm)

Spark Plug ............................................................................................................Champion Spark Plug #RDZ19H or Similar Spark Plug

Spark Plug Gap ..................................................................................................................................................... 0.025 inch (0.655 mm)

Lubrication ................................................................................................................................................................................ SAE 30 Oil

Crankcase Oil Capacity ..................................................................................................................................................... 3.04 oz (90 ml)

Fuel ............................................................................................................................................................................................ Unleaded

Carburetor ............................................................................................................................................................ Diaphragm, All-Position

Starter................................................................................................................................................ Incredi-Pull™ Starting Auto Rewind

Muffler .......................................................................................................................................................................... Baffled with Guard

Throttle............................................................................................................................................................................... Variable Speed

Fuel Tank Capacity .............................................................................................................................................................. 14 oz (414 ml)

Page 17

17

Repair Protection Agreements

Congratulations on making a smart purchase. Your new

Craftsman® product is designed and manufactured for years of

dependable operation.

But like all products, it may require repair from time to time.

That’s when having a Repair Protection Agreement can save

you money and aggravation.

Purchase a Repair Protection Agreement now and protect

yourself from unexpected hassle and expense.

Here’s what’s included in the Agreement:

˛ Expert service by our 12,000 professional repair specialists

˛ Unlimited service and no charge for parts and labor on all

covered repairs

˛ Product replacement if your covered product can’t be fixed

˛ Discount of 10% from regular price of service and service-

related parts not covered by the agreement; also, 10% off

regular price of preventive maintenance check

˛ Fast help by phone – phone support from a Sears

technician on products requiring in-home repair, plus

convenient repair scheduling

Once you purchase the Agreement, a simple phone call is all

that it takes for you to schedule service. You can call anytime

day or night, or schedule a service appointment online.

Sears has over 12,000 professional repair specialists, who have

access to over 4.5 million quality parts and accessories. That’s

the kind of professionalism you can count on to help prolong

the life of your new purchase for years to come. Purchase your

Repair Protection Agreement today!

Some limitations and exclusions apply.

For prices and additional information call 1-800-827-6655.

Sears Installation Service

For Sears professional installation of home appliances, garage

door openers, water heaters, and other major home items, in

the U.S.A. call 1-800-4-MY-HOME®

Convenios de Cobertura de Gastos para Reparaciones

Felicidades por haber hecho una compra inteligente. Su nuevo

producto Craftsman está diseñado y fabricado para que opere

de manera confiable durante años. Pero como todos los

productos, pudiera necesitar una reparación cada cierto

tiempo. Por eso el tener un Convenio de Cobertura de Gastos

para Reparaciones puede ahorrarle dinero y disgustos.

Adquiera un Convenio de Cobertura de Gastos para

Reparaciones ahora y protéjase de problemas y gastos

inesperados.

He aquí lo que incluye el Convenio:

- Servicio proporcionado por nuestros 12.000

especialistas expertos en reparaciones profesionales

- Servicio ilimitado sin cargos por piezas ni mano de

obra, en todas las reparaciones cubiertas

- Reemplazo del producto, si sus productos cubiertos

no pueden arreglarse

- Descuento del 10% del precio regular del servicio y de

piezas relacionadas con el servicio no cubiertas por el

convenio; además, descuento del 10% del precio

regular de los chequeos de mantenimiento preventivo

- Ayuda rápida por teléfono: apoyo telefónico por parte

de un técnico de Sears en los productos que requieren

reparación en el hogar, además de la programación de

la reparación a una hora conveniente

Una vez que usted adquiera el Convenio, basta con una

llamada telefónica para programar el servicio. Usted puede

llamar a cualquier hora del día o de la noche, o programar por

Internet una cita para el servicio.

Sears tiene más de 12.000 especialistas en reparaciones

profesionales, que tienen acceso a más de 4,5 millones de

piezas y accesorios de calidad. Ese es el tipo de

profesionalismo con el que usted puede contar para ayudar a

prolongar la vida útil de su nueva adquisición durante años.

¡Adquiera hoy mismo su Convenio de Cobertura de Gastos

para Reparaciones!

Se aplican algunas limitaciones y exclusiones. Para precios

e información adicional, llame al 1-800-827-6655.

Servicio de Instalación de Sears

Para la instalación por parte de profesionales de Sears de

efectos electrodomésticos; abridores de puertas de garaje,

calentadores de agua y demás artículos domésticos de mayor

cuantía, en los EE.UU., llame al 1–800-4-MY-HOME®.

Page 18

18

NOTES

Page 19

PARACHISPAS

NOTA: Para los usuarios en tierras forestales de los EE.UU.

y en los estados de California, Maine, Oregon y Washington.

Todos los terrenos forestales de los EE.UU. y el estado de

California (Códigos de Recursos Públicos 4442 y 4443), Oregon

y Washington, requieren por decreto, que ciertos motores de

combustión interna que se hagan funcionar en zonas boscosas

y/o zonas cubiertas por pastizales, estén equipados con un

parachispas, que sean mantenidos en buen estado de

funcionamiento o que el motor sea construido, esté equipado y

sea mantenido para evitar incendios. Consulte los reglamentos

pertinentes a esos requisitos con las autoridades estatales o

locales. El incumplimiento de esos requisitos puede

responsabilizarle o someterle a la imposición de una multa. Esta

unidad fue equipada en la fábrica con un parachispas. Si

requiere sustitución, hay una Pantalla Parachispas disponible,

Pieza # 753-05245 al contactar el departamento de servicio.

Toda la información, las ilustraciones y las especificaciones

contenidas en este manual se basan en la información más

reciente disponible en el momento de impresión del manual.

Nos reservamos el derecho de hacer cambios en cualquier

momento sin aviso previo.

ADVERTENCIA

LAS EMISIONES DEL MOTOR DE ESTE PRODUCTO

CONTIENEN SUBSTANCIAS QUIMICAS QUE EL

ESTADO DE CALIFORNIA CONOCE COMO CAUSANTES

DECANCER, DEFECTOS DE NACIMIENTO U OTROS

DAÑOS REPRODUCTIVOS.

INDICE DE CONTENIDOS

Normas para una operación segura . . . . . . . . . . . . . . . .19

Garantía . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Conozca su unidad . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Instrucciones de ensamble . . . . . . . . . . . . . . . . . . . . . . .24

Información del aceite y del combustible . . . . . . . . . . . .26

Instrucciones de arranque y apagado . . . . . . . . . . . . . . .27

Instrucciones de operación . . . . . . . . . . . . . . . . . . . . . . .28

Instrucciones de mantenimiento y reparación . . . . . . . . .30

Limpieza y almacenamiento . . . . . . . . . . . . . . . . . . . . . .33

Cuadro de solución de problemas . . . . . . . . . . . . . . . . .35

Especificaciones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Cobertura de Gastos de Reparaciones . . . . . . . . . . . . . .36

Lista de Piezas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Números de Servicio . . . . . . . . . . . . . . . . . .Contraportada

CALIFORNIA PROPOSITION 65 WARNING

ADVERTENCIA: Al utilizar la unidad, debe observar

las reglas de seguridad. Lea estas instrucciones

antes de operar la unidad a fin de garantizar la

seguridad del operador y cualquier transeúnte.

Guarde estas instrucciones para uso posterior.

• IMPORTANTE INFORMACION DE SEGURIDAD •

LEA TODAS LAS INSTRUCCIONES ANTES DE LA OPERACION

• Lea todas las instrucciones con cuidado. Conozca bien los

controles y el uso correcto de la unidad.

• No opere esta unidad si está cansado, enfermo, o bajo los

efectos del alcohol, drogas o medicamentos.

• Los niños y los adolescentes menores de 15 años no deben

operar las unidades, excepto por los adolescentes guiados

por un adulto.

• Inspeccione la unidad antes de utilizarla. Cambie las partes

dañadas. Verifique si existen pérdidas de combustible.

Asegúrese de que los sujetadores estén bien colocados y

asegurados. Cambie las partes accesorias de corte que estén

quebradas, cascadas o dañadas de cualquier forma. Asegúrese

de que el accesorio de corte está bien instalado y ajustado con

firmeza. Asegúrese de que la protección accesoria de corte esté

bien conectada y colocada según se recomienda.

• Use siempre la línea de repuestos de 0,080 pulg del

fabricante del equipo original. No use nunca línea reforzada

con metal, alambre, cadena ni soga, etc. Estas pueden

desprenderse y convertirse en un proyectil peligroso.

• Tenga en cuenta el riesgo de lesiones en la cabeza, manos y pies.

• Limpie el área de corte antes de cada uso. Retire todos los objetos

como rocas, vidrios rotos, clavos, alambre o cuerda los cuales

pueden ser despedidos o enredarse en el accesorio de corte. Aleje

a todos los niños, espectadores y animales domésticos. Mantenga

todos los niños, espectadores y animales domésticos a un radio

de por lo menos 15 m (50 pies); aún así puede existir un riesgo de

objetos despedidos contra los espectadores. Los espectadores

deben usar protección para sus ojos. Si alguien se le acerca, pare

el motor y el accesorio de corte de inmediato.

• Oprima el control del regulador y verifique que regrese

automáticamente a la posición de mínima. Haga todos los

ajustes o reparaciones antes de usar la unidad.

ADVERTENCIAS DE SEGURIDAD PARA LOS

RECORTADORES A GASOLINA

• Guarde el combustible en envases que hayan sido diseñados

y aprobados para el almacenamiento de dichos materiales.

• Antes de llenar el tanque de combustible, apague siempre el

motor y espere que se enfríe. No retire nunca la tapa del

tanque de combustible ni cargue combustible mientras el

motor esté caliente. No opere nunca la unidad sin la tapa del

combustible colocada firmemente en su lugar. Afloje la tapa

del combustible lentamente para disipar la presión del tanque.

• Cargue el combustible en un área exterior bien ventilada

donde no haya chispas ni llamas. Quite lentamente la tapa

del combustible sólo después de apagar el motor. No fume

mientras carga el combustible. Limpie de inmediato todo el

combustible que se haya derramado.

• Evite crear una fuente de encendido por combustible

derramado. No arranque el motor hasta que se hayan

disipado los vapores del combustible.

• Aleje la unidad a por lo menos 9,1 m (30 pies), del lugar de

carga de combustible antes de arrancar el motor. No fume,

mantenga las chispas y las llamas abiertas lejos del área

mientras carga el combustible u opera la unidad.

DURANTE LA OPERACIÓN

• No arranque ni opere la unidad en un cuarto o edificio

cerrado. Los gases de escape de monóxido de carbono

pueden ser letales en un área cerrada. Opere esta unidad

sólo en un área exterior bien ventilada.

• Para reducir el riesgo de lesiones asociadas con los objetos

lanzados, utilice gafas de protección que tengan una marca

de clasificación normativa ANSI Z87.

• Nunca haga funcionar la unidad sin que ésta tenga

conectado el equipo apropiado. Cuando use esta unidad,

instale siempre los tubos de la sopladora / aspiradora y la

bolsa de recolección, dependiendo del modelo. Asegurese

de cerrar completamente la bolsa de recolección.

• Para reducir el riesgo de pérdida auditiva asociada con los

niveles de sonido, use siempre protección para las orejas /

oídos cuado haga funcionar esta unidad.

• Use pantalones largos gruesos, botas, guantes y una camisa

de mangas largas. No use ropa, suelta, joyas, pantalones

cortos, sandalias ni ande descalzo. Recójase el cabello por

encima de la altura de los hombros.

• Para evitar el choque de electricidad estática, no se ponga

guantes de caucho o guantes aislados mientras haga

funcionar esta unidad.

• Para reducir el riesgo de lesión asociada con objetos que sean

atraídos hacia las piezas que giran, no use ropa suelta, joyas,

bufandas ni cosas parecidas. Asegurese el cabello por encima

del nivel de los hombros.

ADVERTENCIA: La gasolina es muy inflamable y

sus gases pueden explotar si se encienden. Tome

las siguientes precauciones:

19

NORMAS PARA UNA OPERACIÓN SEGURA

Page 20

MIENTRAS OPERA COMO ASPIRADORA

• Evite situaciones que puedan prenderle fuego a la bolsa de

recolección. No la haga funcionar cerca de una llama

abierta. No aspire cenizas tibias de chimeneas, hoyos para

asado, montones de maleza, etc. No aspire cigarros o

cigarrillos descartados a menos que las cenizas estén

completamente frías.

• La unidad está diseñada para recoger material seco tal

como hojas, césped, ramitas y pedazos de papel. No intente

aspirar desechos mojados o agua estancada ya que eso

puede ocasionarle daños a la sopladora / aspiradora. Para

evitarle daños graves al rotor, no aspire metales, vidrios

rotos, etc.

OTRAS ADVERTENCIAS DE SEGURIDAD

• Desconecte la bujía en todo momento antes de hacerle

mantenimiento o alcanzar las piezas movibles.

• Nunca guarde la unidad con combustible en el tanque

dentro de un edificio en donde los gases puedan alcanzar

una llama expuesta (pilotos, etc) o chispas (interruptores,

motores eléctricos, etc.)

• Permita que el motor se enfríe antes de guardarla o

transportarla. Asegúrese de sujetar la unidad mientras la

transporta.

• Guarde la unidad en un lugar seco, bien sea bajo llave o

suficientemente alto para que evite el uso no autorizado o

daños. Manténgala fuera del alcance de los niños.

• Nunca remoje o chorree la unidad con agua o cualquier otro

líquido. Mantenga los mangos secos, limpios y libres de

escombros. Límpiela después de cada uso, vea las

Instrucciones de Limpieza y Almacenamiento.

• Conserve estas instrucciones. Consúltelas con frecuencia y

úselas para instruir a otros usuarios. Si le presta esta unidad

a otras personas, también incluya las instrucciones.

NOTA ESPECIAL: La exposición a las vibraciones mediante el

uso prolongado de herramientas manuales a gasolina puede

causar daños en los vasos sanguíneos o nervios de los dedos,

manos y articulaciones en las personas que presentan una

predisposición a trastornos circulatorios o inflamaciones

anormales. Por otra parte, el uso prolongado en el clima frío ha

sido relacionado con el daño de vasos sanguíneos en personas

sanas. En caso de ocurrir síntomas como adormecimiento, dolor,

pérdida de fuerza, cambio en el color o textura de la piel o pérdida

de sensación en los dedos, manos o articulaciones, abandone el

uso de esta herramienta y obtenga atención médica. Un sistema

antivibratorio no garantiza la prevención de estos problemas. Los

usuarios que operan herramientas motrices en forma regular y

continua deben controlar con cuidado su condición física y la

condición de esta herramienta.

CONSERVE ESTAS INSTRUCCIONES

20

NORMAS PARA UNA OPERACIÓN SEGURA