Craftsman 316794611 Owner’s Manual

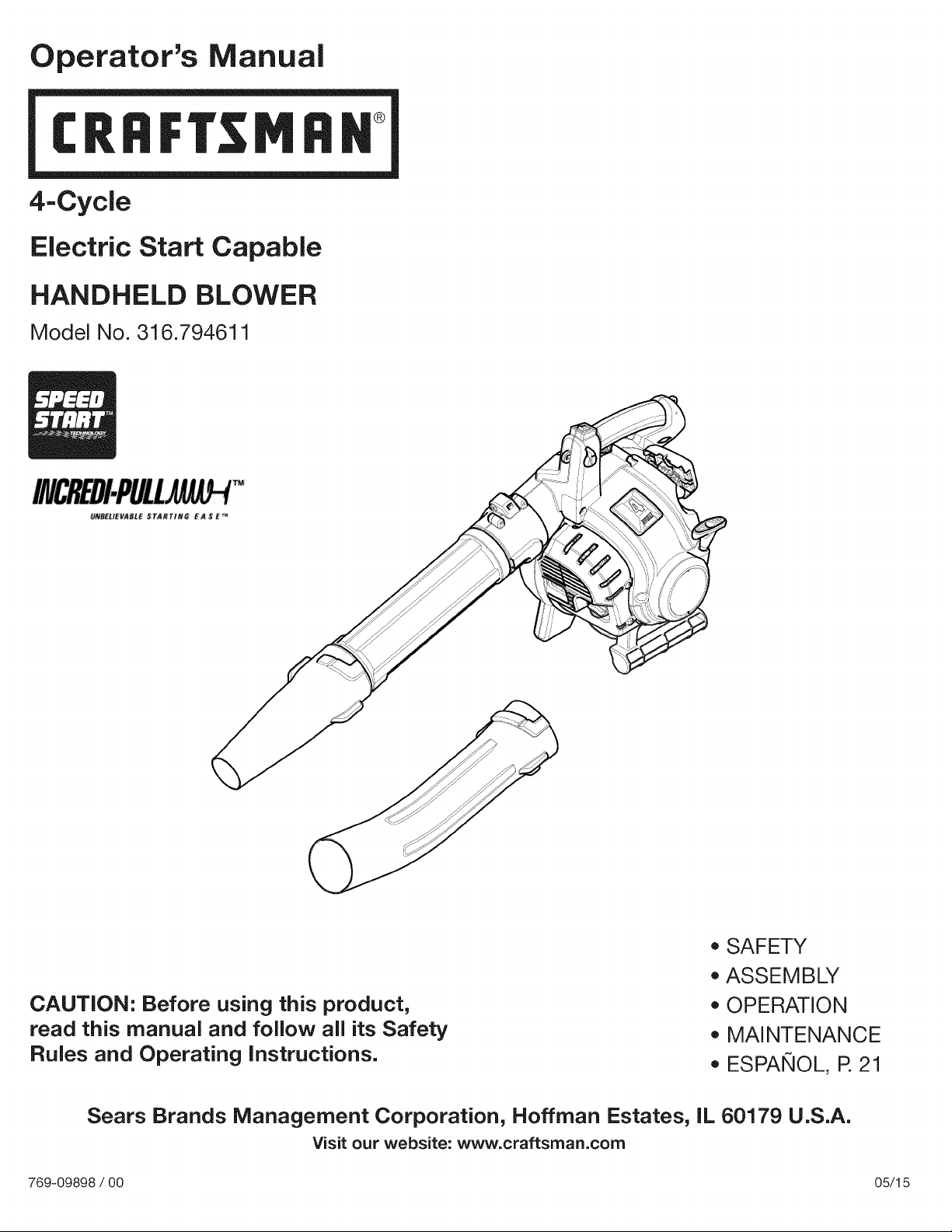

Operator's Manual

CRRFrSMRH

4-Cycle

Electric Start Capable

HANDHELD BLOWER

Model No. 316.794611

* SAFETY

* ASSEMBLY

CAUTION: Before using this product,

read this manual and follow all its Safety

Rules and Operating instructions.

Sears Brands Management Corporation, Hoffman Estates, IL 60179 U.S.A.

Visit our website: www.craftsrnan.corn

769-09898 / 00 05/15

* OPERATION

* MAINTENANCE

. ESPANOL, R 21

TABLEOFCONTENTS

Safety............................................... 2

Warranty............................................. 6

KnowYourUnit........................................ 7

Specifications......................................... 7

Assembly............................................. 8

OilandFuel........................................... 9

StartingandStopping.................................. 11

Operation............................................ 13

Maintenance......................................... 14

CleaningandStorage.................................. 17

Troubleshooting....................................... 18

RepairProtectionAgreements........................... 19

ServiceNumbers.............................. BackCover

Allinformation,illustrationsandspecificationsinthismanualarebased

onthelatestproductinformationavailableatthetimeofprinting.We

reservetherighttomakechangesatanytimewithoutnotice.

©SeamBrands,LLC

Thepurposeofsafetysymbolsistoattractyourattentionto

possibledangers.Thesafetysymbols,andtheirexplanations,

deserveyourcarefulattentionandunderstanding.Thesafety

warningsdonotbythemselveseliminateanydanger.The

instructionsorwarningstheygivearenotsubstitutesforproper

accidentpreventionmeasures.

SYMBOL MEANING

,ml

DANGER"

Failure to obey a safety DANGER symbol WiLL result in

serious injury or death to yourself or to others.

= Signals an EXTREME hazard.

WAR NING: Signals a SERIOUS hazard.

Failure to obey a safety WARNING symbol CAN result in

serious injury to yourself or to others.

Failure to obey a safety CAUTION symbol MAY result in

CAUTION: Signa,saMOOERATEhazard

property damage or injury to yourself or to others.

NOTE: Advises you of information or instructions vital to the

operation or maintenance of the equipment.

SPARK ARRESTOR NOTE

NOTE: For users on U.S. Forest Land and in the states of

California, Maine, Oregon and Washington. All U.S. Forest Land

and the state of California (Public Resources Codes 4442 and

4443), Oregon and Washington require, by law that certain internal

combustion engines operated on forest brush and/or grass-covered

areas be equipped with a spark arrestor, maintained in effective

working order, or the engine be constructed, equipped and

maintained for the prevention of fire. Check with your state or local

authorities for regulations pertaining to these requirements. Failure

to follow these requirements could subject you to liability or a fine.

This unit is factory equipped with a spark arrestor, if it requires

replacement, contact a Sears Parts & Repair Service Center to

install the appropriate muffler assembly.

WARNING: This product contains a chemical

_ CAUFORNIA PROPOSiTiON 65

Read the operator's manual and follow all warnings and safety

instructions. Failure to do so can result in serious injury to the

operator and/or bystanders.

known to the state of California to cause cancer, birth defects

or other reproductive harm.

• iMPORTANT SAFETY iNSTRUCTiONS •

READ ALL iNSTRUCTiONS BEFORE OPERATING

WARNING. When using the unit, all safety

instructions must be followed. Please read these

instructions before operating the unit in order to ensure the

safety of the operator and any bystanders. Please keep

these instructions for later use.

• Read the instructions carefully. Be familiar with the controls and

proper use of the unit.

Do not operate this unit when tired, ill or under the influence of

alcohol, drugs or medication.

Never allow children to operate the unit. Teens must be trained,

accompanied and supervised by an adult. Never allow adults to

operate the unit without proper instruction.

All guards and safety attachments must be installed properly

before operating the unit.

Inspect the unit before use. Replace damaged parts. Check for

fuel leaks. Make sure all fasteners are in place and secure.

Replace parts that are cracked, chipped, or damaged in any

way. Do not operate the unit with loose or damaged parts.

Be aware of risk of injury to the head, hands and feet.

Carefully inspect the area before starting the unit. Remove

rocks, broken glass, nails, wire, string and other objects that

may be thrown or become entangled with the unit.

Clear the area of children, bystanders and pets; keep them

outside a 50-foot (15 m) radius, at a minimum. Even then, they are

still at risk from thrown objects. Encourage bystanders to wear

eye protection. If you are approached, stop the unit immediately.

Squeeze the throttle control and check that it returns

automatically to the idle position. Make all adjustments or

repairs before using the unit.

Do not change the engine governor settings or overspeed the

engine.

This unit is intended for occasional, household use only.

SAFETY WARNINGS FOR GAS UNITS

its vapors can explode if ignited. Take the following

WARN ING: Gasoline is highly flammable and

precautions:

Store fuel only in containers specifically designed and approved

for the storage of such materials.

Always stop the engine and allow it to cool before filling the

tank. Never remove the fuel tank cap or add fuel when the

engine is hot. Always loosen the fuel tank cap slowly to relieve

any pressure in the tank before fueling.

Always add fuel in a clean, well-ventilated outdoor area where

there are no sparks or flames. DO NOT smoke.

Never operate the unit without the fuel cap securely in place.

Avoid creating a source of ignition for spilled fuel. Wipe up any

spilled fuel from the unit immediately, before starting the unit.

Move the unit at least 30 ft. (9.1 m) from the fueling source and

site before starting the engine. DO NOT smoke.

Never start or run the unit inside a closed room or building.

Breathing exhaust fumes can kill. Operate this unit only in a well

ventilated outdoor area.

m

WHILE OPERATING

Wear safety glasses or goggles that meet current ANSI / ISEA

Z87.1 standards and are marked as such. Wear ear/hearing

protection when operating this unit. Wear a face mask or dust

mask if the operation is dusty.

Wear heavy long pants, boots, gloves and a long sleeve shirt. Do

not wear loose clothing, jewelry, short pants, sandals or go

barefoot. Secure hair above shoulder level.

Use the unit only in daylight or good artificial light.

Avoid accidental starting. Be in the starting position whenever

pulling the starter rope. The operator and unit must be in a

stable position while starting. Refer to Starting and Stopping.

Use the right tool. Only use this tool for its intended purpose.

Always hold the unit with a firm grip when operating.

Do not overreach. Always keep proper footing and balance. Take

extra care when working on stairs, steep slopes or inclines. To avoid

serious injury, do not operate the unit while on a ladder or a roof.

Keep hands, face, and feet away from all moving parts. Do not

touch or try to stop moving parts.

Do not touch the engine or muffler. These parts get extremely

hot from operation, even after the unit is turned off.

Do not operate the unit faster than the speed needed to do the

job. Do not run the unit at high speed when not in use.

Do not force the unit. It will do a better, safer job when used at

the intended rate.

Always stop the unit when operation is delayed or when walking

from one location to another.

Before setting the unit down, always make sure the engine is off

and all moving parts have stopped.

If you strike or become entangled with a foreign object, stop the

unit immediately and check for damage. Do not operate the unit

before repairing damage. Do not operate the unit with loose or

damaged parts.

Turn the engine off and disconnect the spark plug for

maintenance or repair.

Use only original equipment manufacturer (OEM) replacement

parts and accessories for this unit. These are available from a

Sears or other qualified service dealer. Use of any other parts or

accessories could lead to serious injury to the user, or damage

to the unit, and void the warranty.

Keep the unit clean. Carefully remove vegetation and other

debris that could block moving parts.

To reduce fire hazard, replace a faulty muffler and spark arrestor.

Keep the engine and muffler free from grass, leaves, excessive

grease or carbon build up.

If the unit starts to vibrate abnormally, stop the unit immediately.

Inspect the unit for the cause of the vibration. Vibration is

generally an indicator of trouble.

3

BLOWER SAFETY

• Do not insert anything into the air openings, blower tube or

nozzle. Do not operate the unit if any of the air openings or

tubes are blocked. Keep the air openings free from dust, lint,

hair and anything else that may reduce airflow.

Do not operate the unit without the blower tube securely attached.

Do not use the unit to spray liquids, especially flammable or

combustible liquids, such as gasoline. Do not use the unit in

areas where such liquids are present.

Do not use the unit for spreading chemicals, fertilizer or any

other substance that may contain toxic materials.

Do not set the unit down on any surface while the unit is

running. Debris can be picked up by the air intake and thrown

out the discharge opening, resulting in damage to the unit or

property or causing serious injury to bystanders or the operator.

During operation, never point the unit in the direction of people,

animals, windows or automobiles. Always direct blowing debris

away from people, animals, windows or automobiles.

Use extra caution when blowing debris near solid objects, such

as trees, walls, fences, etc. When possible, blow away from

such objects, not toward them.

Take care when working near valuable plants. The force of the

blown air could damage tender plants.

Never attempt to clear a clogged air intake opening while the unit

is running.

Keep hair, fingers and all other body parts away from moving

parts and openings.

OTHER SAFETY WARNINGS

Maintain the unit with care.

All service, other than the maintenance procedures described in

this manual, should be performed by a Sears or other qualified

service dealer.

Never remove, modify or make inoperative any safety device

furnished with the unit.

Before inspecting, servicing, cleaning, storing, transporting or

replacing any parts on the unit:

1. Stop the unit.

2. Make sure all moving parts have stopped.

3. Allow the unit to cool.

4. Disconnect the spark plug wire.

Secure the unit while transporting.

Never store the unit with fuel in the tank, inside a building where

fumes may reach an open flame (pilot lights, etc.) or sparks

(switches, electrical motors, etc.).

Store the unit in a dry place, secured or at a height to prevent

unauthorized use or damage. Keep the unit out of the reach of

children.

Never douse or squirt the unit with water or any other liquid.

Keep handles dry and clean (free from debris, oil and grease).

Clean the unit after each use. Refer to Cleaning and Storage. Do

not use solvents or strong detergents.

Keep these instructions. Refer to them often and use them to

instruct other users. If you loan this unit to others, also loan

them these instructions.

SAVE THESE INSTRUCTIONS

,, SAFETY & iNTERNATiONAL SYMBOLS ,,

This operator's manual describes safety and international symbols and pictographs that may appear on this product. Read the operator's

manual for complete safety, assembly, operating and maintenance and repair information.

SYMBOL MEANING

Z_ , SAFETY ALERT SYMBOL

Indicates danger, waining or cauti0n: MaY be Used in

conjunction with other Symbols or pictographs;

', READOPERATOR,SMANUAL

WARNING" = Read the operator's

manua!(s) and follow a!Jwarnings and safety

instructionsl Failure to dose can result in serious

.... injury to the 0perat0r and!0r bystanders.

WARN !NG==Thrownobjectsandloud

, WEAR EYEAND HEARING PROTECTION

noise can cause Severe eye injury and hearing Iossl

Wear eye pr0tection meeting current ANSI/ISEA

Z8711 standards and ear protection when operating

this unit. Use a full face shield when needed.

Always use clean, freSh unleaded fuel.

,OiL

Refer to operators manUaJ for the proper type of oJJ,

' DO NOT USE E85 FUEL IN THIS UNiT

WARNING. ,t has been proven that fue!

containing greater than 10% ethane! wiJl likely

damage this engine and void the warranty.

[]

SYMBOL MEANING

oON/OFF STOP CONTROL

I J ON/START/RUN

_l_ =ON/OFF STOP CONTROL

V OFF or STOP

_] ' PRIMER BULB

Push primer bulb, fully and slowly, 10 times.

H I'q I 'l

2. • PARTIAL choke position

. 3. • RUN choke position

/%, • THROWN OBJECTS CAN CAUSE SEVERE INJURY

WAdRatN ! sNeeGd.csma_l objects can be

prop g p , g j ry.

mn50ft

_. extry'nely hot frmmYgeratUonewhen tamped og, they

, KEEP BYSTAN DERS AWAY

®

p ' y P , ( )

. from the operating area.

, HOT SURFACE []

WAeRr. yN _ N 9 b D° nd°tt_uch ahtt me_ff'er

remain hot for a short time.

_=

ii_j, _ ' BLOWERS - ROTATING IMPELLER BLADES CAN

CAUSE SEVERE INJUR_

WARNING: stopthe unit and a ow the

impeller to stop before changing tubes, cleaning or

performing any maintenance. Keep hands and feet

. away from moving parts.

5

CRAFTSMANLiMiTED WARRANTY

FOR TWO YEARS from the date of sale, this product is warranted against defects in material or workmanship.

WITH PROOF OF SALE, a defective product will receive free repair or replacement at option of seller.

For warranty coverage details to obtain free repair or replacement, visit the web page: www.craftsman.com/warranty

This warranty covers ONLY defects in material and workmanship. Warranty coverage does NOT include:

= Expendable items that can wear out from normal use within the warranty period, such as spark plugs or filters.

• Product damage resulting from user attempts at product modification or repair or caused by product accessories.

• Repairs necessary because of accident or failure to operate or maintain the product according to all supplied instructions.

• Preventive maintenance, or repairs necessary due to improper fuel mixture, contaminated or stale fuel.

This warranty is void if this product is ever used while providing commercial services or if rented to another person.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

Sears Brands Management Corporation, Hoffman Estates, IL 60179

To order parts or schedule service for this product, call 1-888-331-4569.

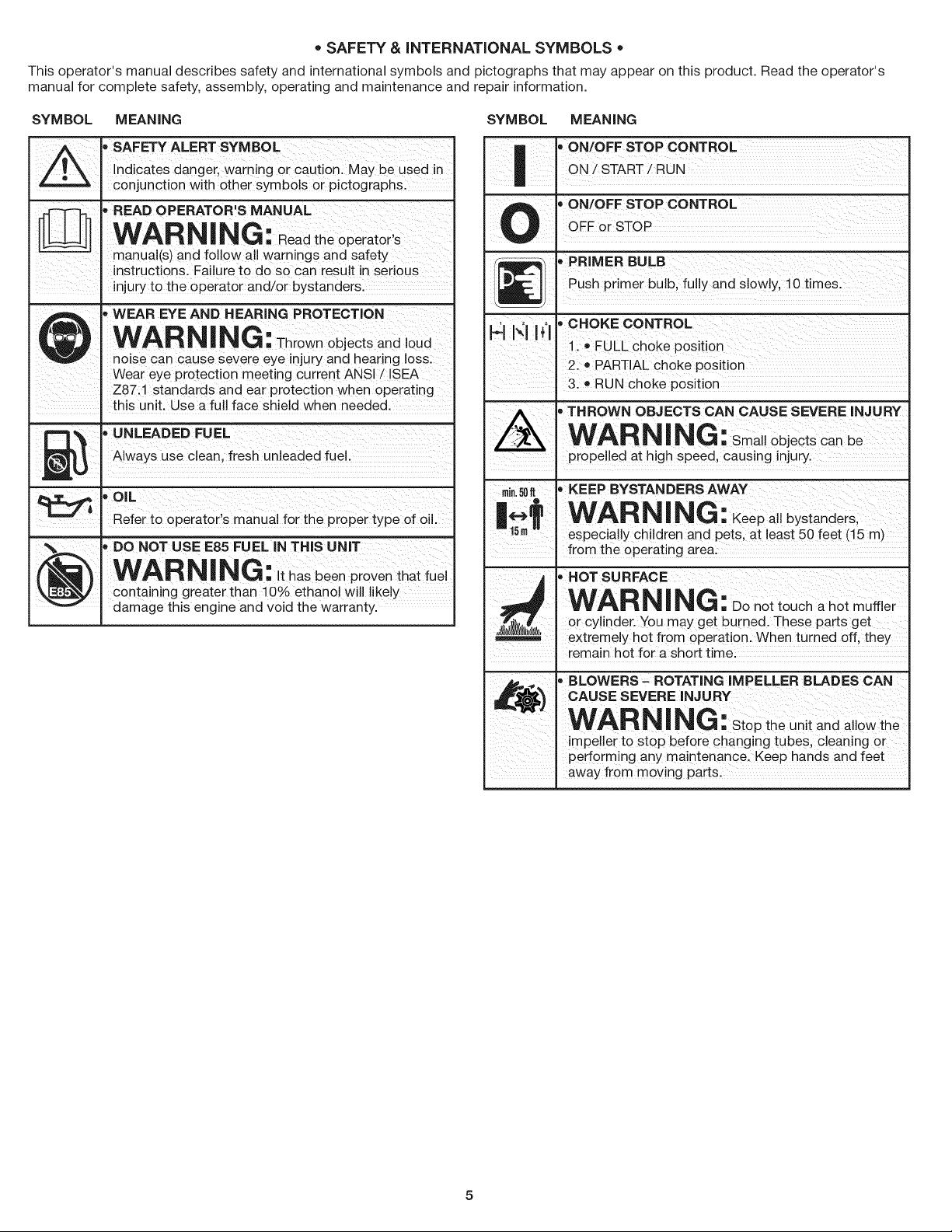

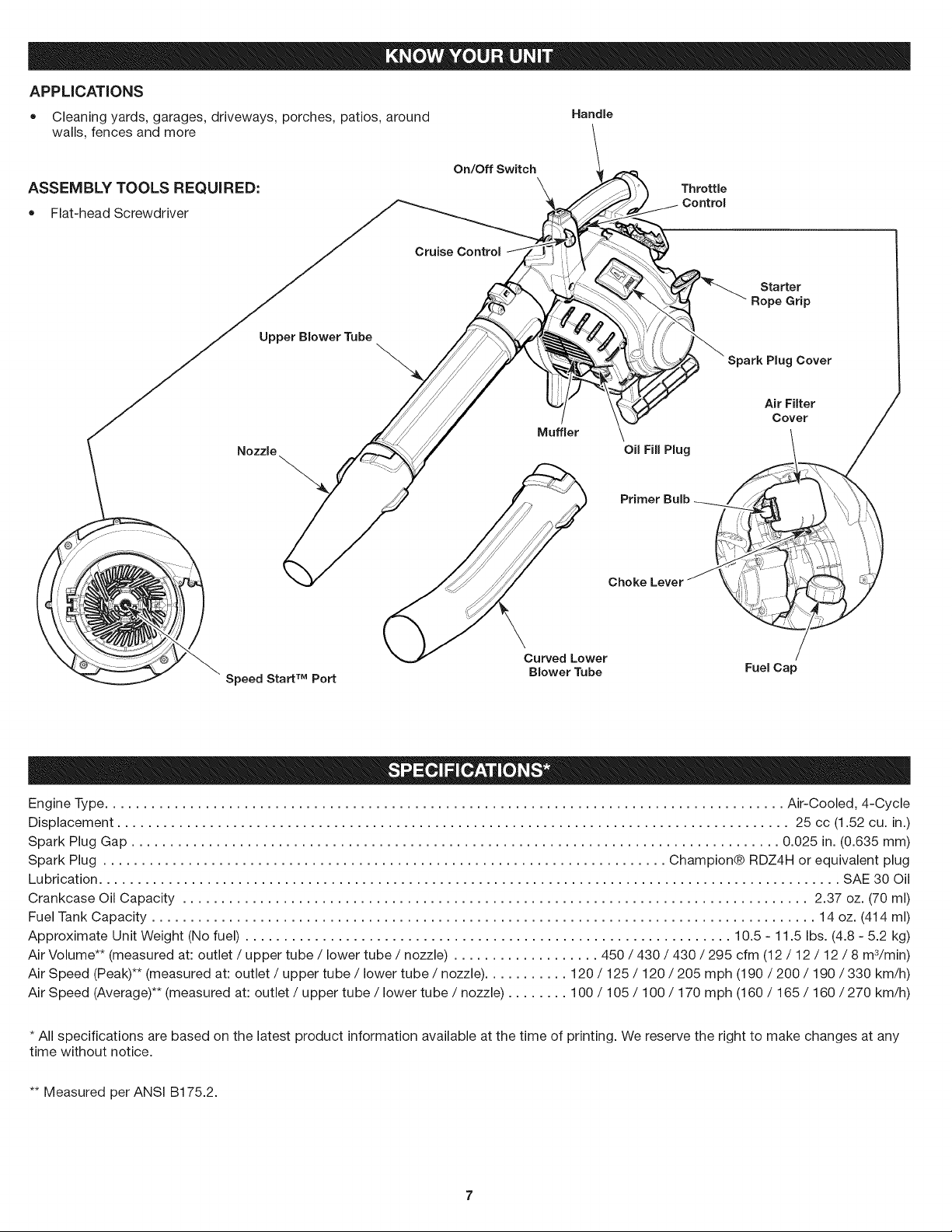

APPLiCATiONS

= Cleaningyards,garages,driveways,porches,patios,around Handle

walls,fencesandmore

On/Off Switch

ASSEMBLY TOOLS REQUIRED: Throttle

• Flat-head Screwdriver

Cruise Control

Upper Blower Tube

Muffler

Nozzle

Oil FlU Plug

Primer Bulb

Control

Starter

Rope Grip

Cover

Air Filter

Cover

-\

Choke Lever

Curved Lower

Speed Start TM Port

Blower Tube Fuel Cap

Engine Type........................................................................................ Air-Cooled, 4-Cycle

Displacement ....................................................................................... 25 cc (1.52 cu. in.)

Spark Plug Gap .................................................................................... 0.025 in. (0.635 mm)

Spark Plug ......................................................................... Champion® RDZ4H or equivalent plug

Lubrication ................................................................................................ SAE 30 Oil

Crankcase Oil Capacity ................................................................................. 2.37 oz. (70 ml)

Fuel Tank Capacity ...................................................................................... 14 oz. (414 ml)

Approximate Unit Weight (No fuel) ............................................................... 10.5 - 11.5 Ibs. (4.8 - 5.2 kg)

Air Volume** (measured at: outlet / upper tube / lower tube / nozzle) ................... 450 / 430 / 430 / 295 cfm (12 / 12 / 12 / 8 m3/min)

Air Speed (Peak)** (measured at: outlet / upper tube / lower tube / nozzle) ........... 120 / 125 / 120 / 205 mph (190 / 200 / 190 / 330 km/h)

Air Speed (Average)** (measured at: outlet / upper tube / lower tube / nozzle) ........ 100 / 105 / 100 / 170 mph (160 / 165 / 160 / 270 km/h)

* All specifications are based on the latest product information available at the time of printing. We reserve the right to make changes at any

time without notice.

** Measured per ANSi B175.2.

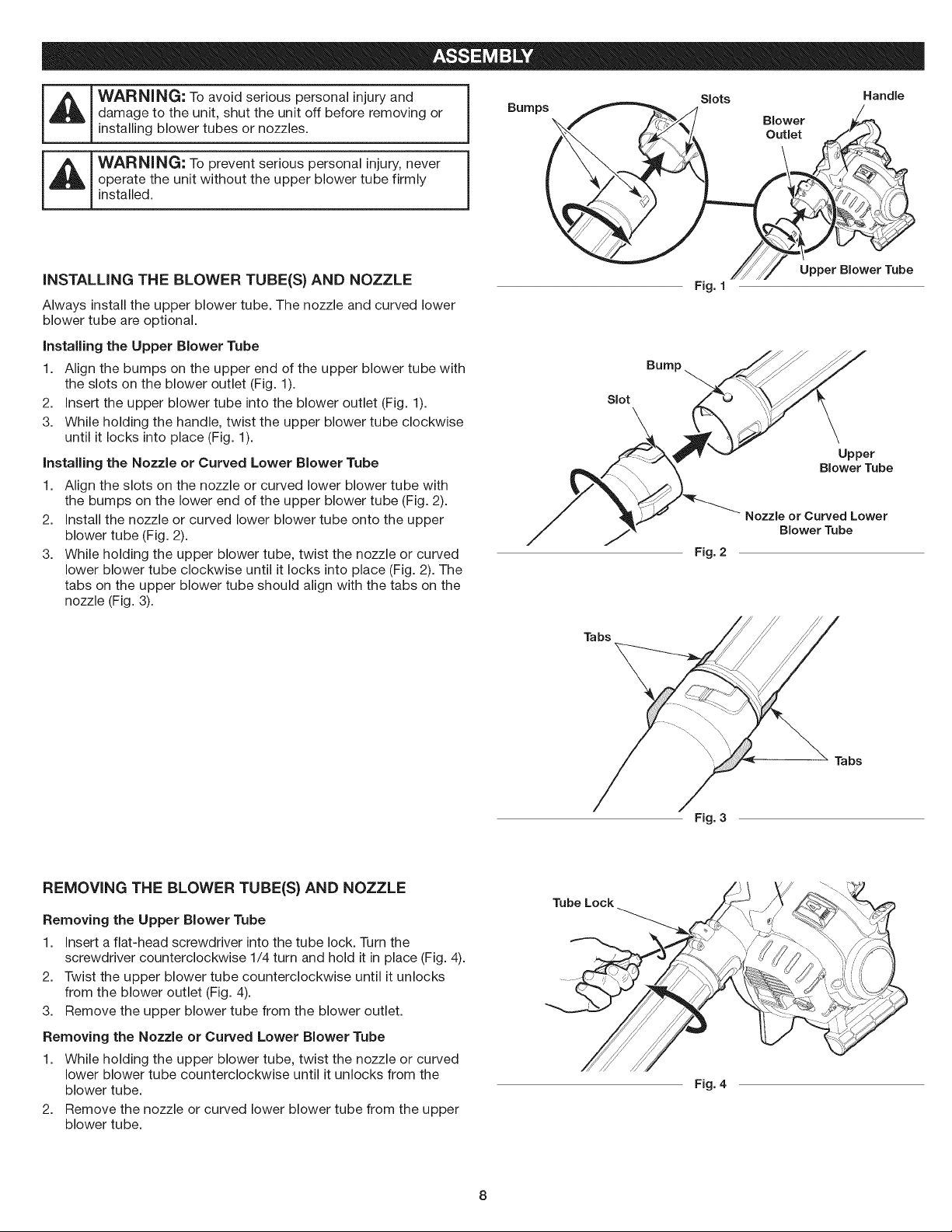

I_ IWARNING: To avoid serious personal injury and

damage to the unit, shut the unit off before removing or

installing blower tubes or nozzles.

!

Bumps

SEots

Handle

Blower

Outlet

[ _lLi, J _JARNING: T° prevent serious personal injury, never j

operate the unit without the upper blower tube firmly

installed.

iNSTALLiNG THE BLOWER TUBE(S) AND NOZZLE

Always install the upper blower tube. The nozzle and curved lower

blower tube are optional.

Installing the Upper Blower Tube

1. Align the bumps on the upper end of the upper blower tube with

the slots on the blower outlet (Fig. 1).

2. Insert the upper blower tube into the blower outlet (Fig. 1).

3. While holding the handle, twist the upper blower tube clockwise

until it locks into place (Fig. 1).

Installing the Nozzle or Curved Lower Blower Tube

1. Align the slots on the nozzle or curved lower blower tube with

the bumps on the lower end of the upper blower tube (Fig. 2).

2. Install the nozzle or curved lower blower tube onto the upper

blower tube (Fig. 2).

3. While holding the upper blower tube, twist the nozzle or curved

lower blower tube clockwise until it locks into place (Fig. 2). The

tabs on the upper blower tube should align with the tabs on the

nozzle (Fig. 3).

Slot

Bump

Fig. 1

Fig. 2

Upper Blower Tube

Upper

Blower Tube

Nozzle or Curved Lower

Blower Tube

REMOVING THE BLOWER TUBE(S) AND NOZZLE

Removing the Upper Blower Tube

1. Insert a flat-head screwdriver into the tube lock. Turn the

screwdriver counterclockwise 1/4 turn and hold it in place (Fig. 4).

2. Twist the upper blower tube counterclockwise until it unlocks

from the blower outlet (Fig. 4).

3. Remove the upper blower tube from the blower outlet.

Removing the Nozzle or Curved Lower Blower Tube

1. While holding the upper blower tube, twist the nozzle or curved

lower blower tube counterclockwise until it unlocks from the

blower tube.

2. Remove the nozzle or curved lower blower tube from the upper

blower tube.

Tabs

Tabs

/

Fig. 3

Tube Lock

Fig. 4

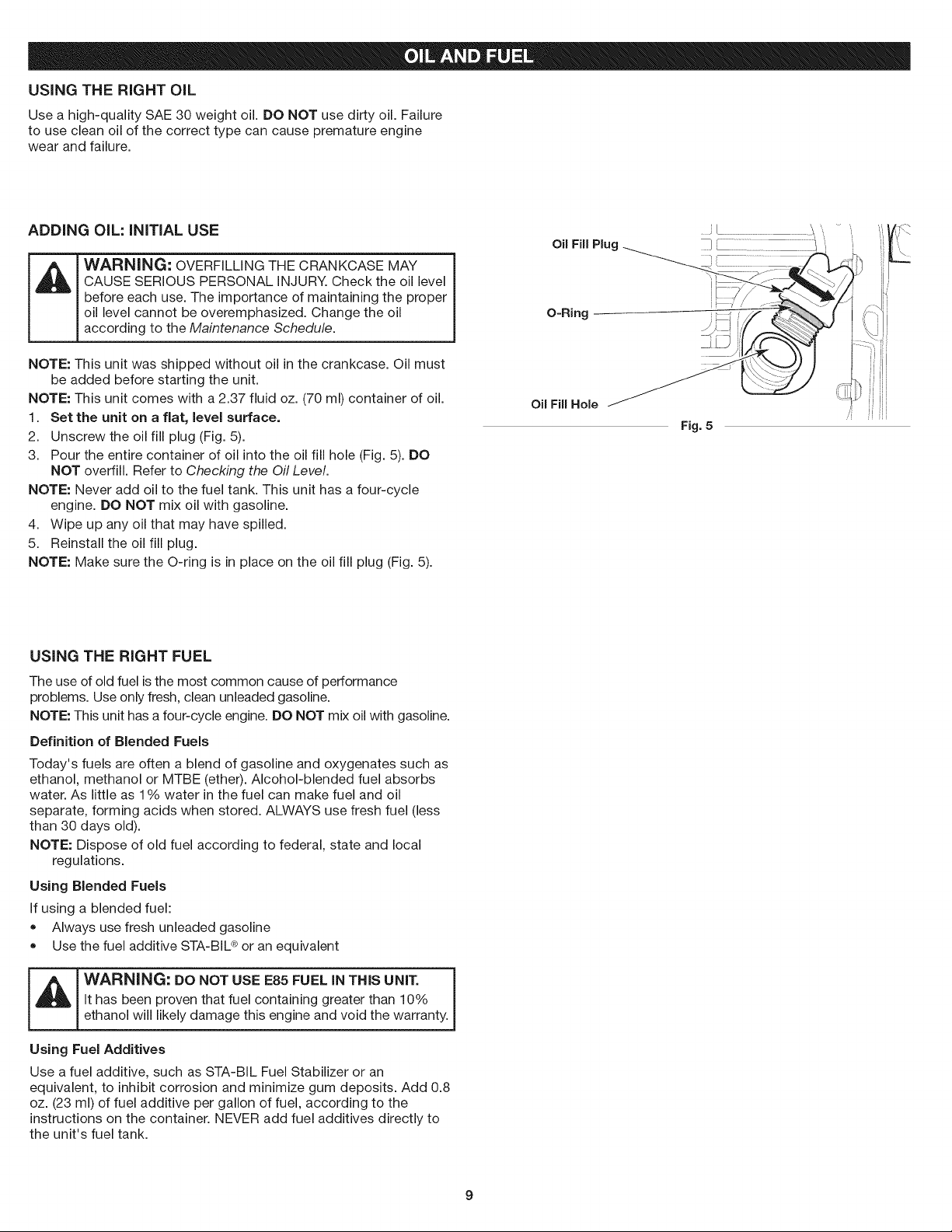

USING THE RIGHT OiL

Use a high-quality SAE 30 weight oil. DO NOT use dirty oil. Failure

to use clean oil of the correct type can cause premature engine

wear and failure.

ADDING OiL: iNiTiAL USE

WARNING: OVERFILLING THE CRANKCASE MAY

CAUSE SERIOUS PERSONAL iNJURY. Check the oil level

before each use. The importance of maintaining the proper

oil level cannot be overemphasized. Change the oil

according to the Maintenance Schedule.

NOTE: This unit was shipped without oil in the crankcase. Oil must

be added before starting the unit.

NOTE: This unit comes with a 2.37 fluid oz. (70 ml) container of oil.

1. Set the unit on a flat, level surface.

2. Unscrew the oil fill plug (Fig. 5).

3. Pour the entire container of oil into the oil fill hole (Fig. 5). DO

NOT overfill. Refer to Checking the Oil Level.

NOTE: Never add oil to the fuel tank. This unit has a four-cycle

engine. DO NOT mix oil with gasoline.

4. Wipe up any oil that may have spilled.

5. Reinstall the oil fill plug.

NOTE: Make sure the O-ring is in place on the oil fill plug (Fig. 5).

USING THE RIGHT FUEL

The use of old fuel is the most common cause of performance

problems. Use only fresh, clean unleaded gasoline.

NOTE: This unit has afour-cycle engine. DO NOT mix oil with gasoline.

Definition of Blended Fuels

Today's fuels are often a blend of gasoline and oxygenates such as

ethanol, methanol or MTBE (ether). Alcohol-blended fuel absorbs

water. As little as 1% water in the fuel can make fuel and oil

separate, forming acids when stored. ALWAYS use fresh fuel (less

than 30 days old).

NOTE: Dispose of old fuel according to federal, state and local

regulations.

Using Blended Fuels

If using a blended fuel:

•+ Always use fresh unleaded gasoline

+ Use the fuel additive STA-BIL + or an equivalent

JL ............. \',

oil Fill Plug_.___ • _ .........................1 '+

O=Ring - -- +

o,+++ +++

Fig. 5

I

I_lb IWARNING: DO NOT USE E85 FUEL iN THiS UNIT. |

Using Fuel Additives

Use a fuel additive, such as STA-BIL Fuel Stabilizer or an

equivalent, to inhibit corrosion and minimize gum deposits. Add 0.8

oz. (23 ml) of fuel additive per gallon of fuel, according to the

instructions on the container. NEVER add fuel additives directly to

the unit's fuel tank.

It has been proven that fuel containing greater than 10%

ethanol will likely damage this engine and void the warranty.

J

9

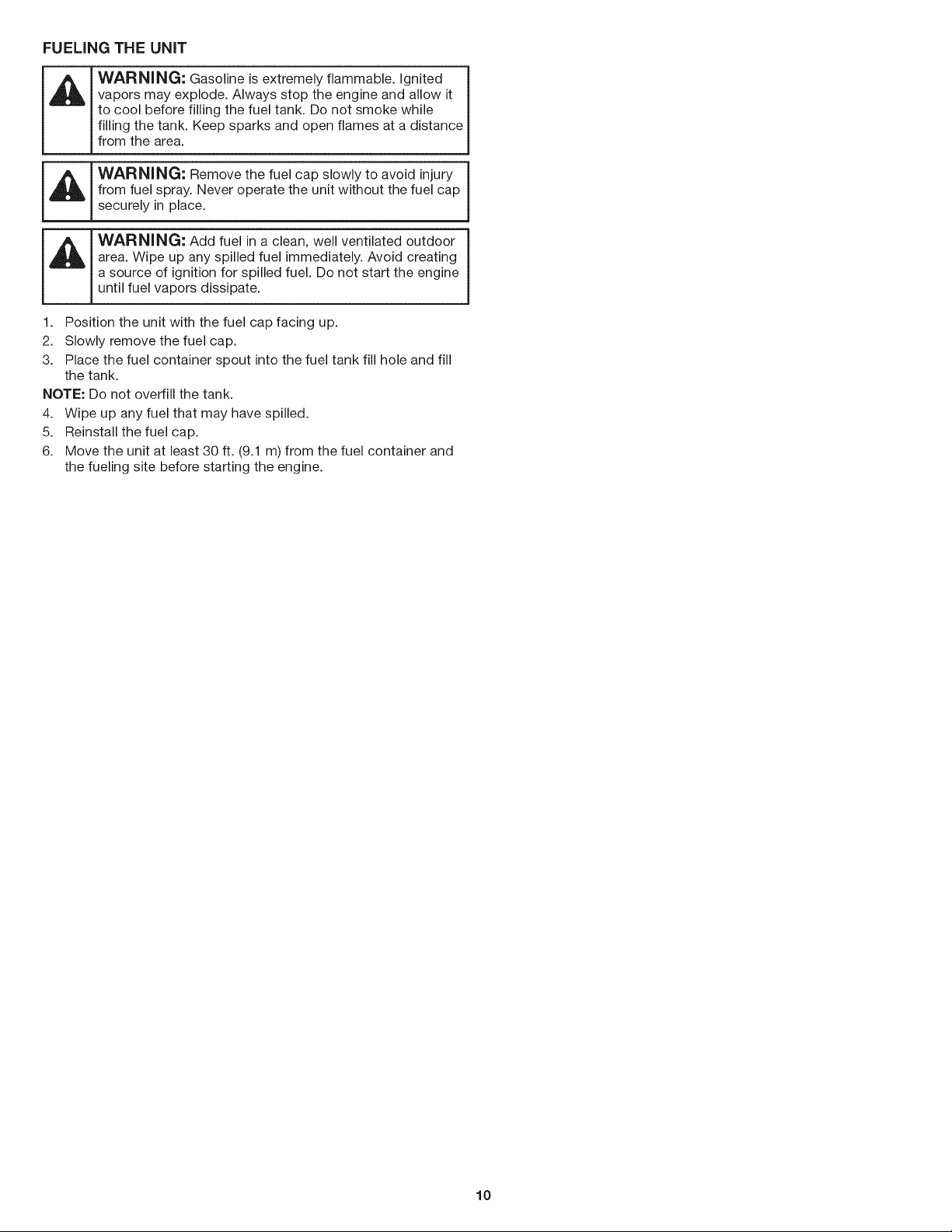

FUELING THE UNiT

WARNING: Gasoline is extremely flammable, ignited

vapors may explode. Always stop the engine and allow it

to cool before filling the fuel tank. Do not smoke while

I'1

1. Position the unit with the fuel cap facing up.

2. Slowly remove the fuel cap.

3. Place the fuel container spout into the fuel tank fill hole and fill

NOTE: Do not overfill the tank.

4. Wipe up any fuel that may have spilled.

5. Reinstall the fuel cap.

6. Move the unit at least 30 ft. (9.1 m) from the fuel container and

filling the tank. Keep sparks and open flames at a distance

from the area.

WARNING: Remove the fuel cap slowly to avoid injury

from fuel spray. Never operate the unit without the fuel cap

securely in place.

WARNING: Add fuel in a clean, well ventilated outdoor

area. Wipe up any spilled fuel immediately. Avoid creating

a source of ignition for spilled fuel. Do not start the engine

until fuel vapors dissipate.

the tank.

the fueling site before starting the engine.

10

outdoor area. Carbon monoxide exhaust fumes can be

I_lb IWARNING: Operate this unit only in a well-ventilated

lethal in a confined area.

!

serious injury, the operator and the unit must be in a stable

WARNING: Avoid accidentally starting the unit. To avoid

position when pulling the starter rope (Fig. 8).

directed toward people, animals, windows, automobiles or

WARNING: When starting the unit, make sure it is not

loose debris.

STARTING iNSTRUCTiONS

NOTE: This unit uses the INCREDI-PULL TM starting system, which

significantly reduces the effort required to start the engine.

NOTE: This unit includes a cruise control, which allows the operator

to maintain the desired engine speed without having to squeeze

the throttle control.

1. Check the oil level. Refer to Checking the Off Level

2. Fill the fuel tank. Refer to Fueling the Unit.

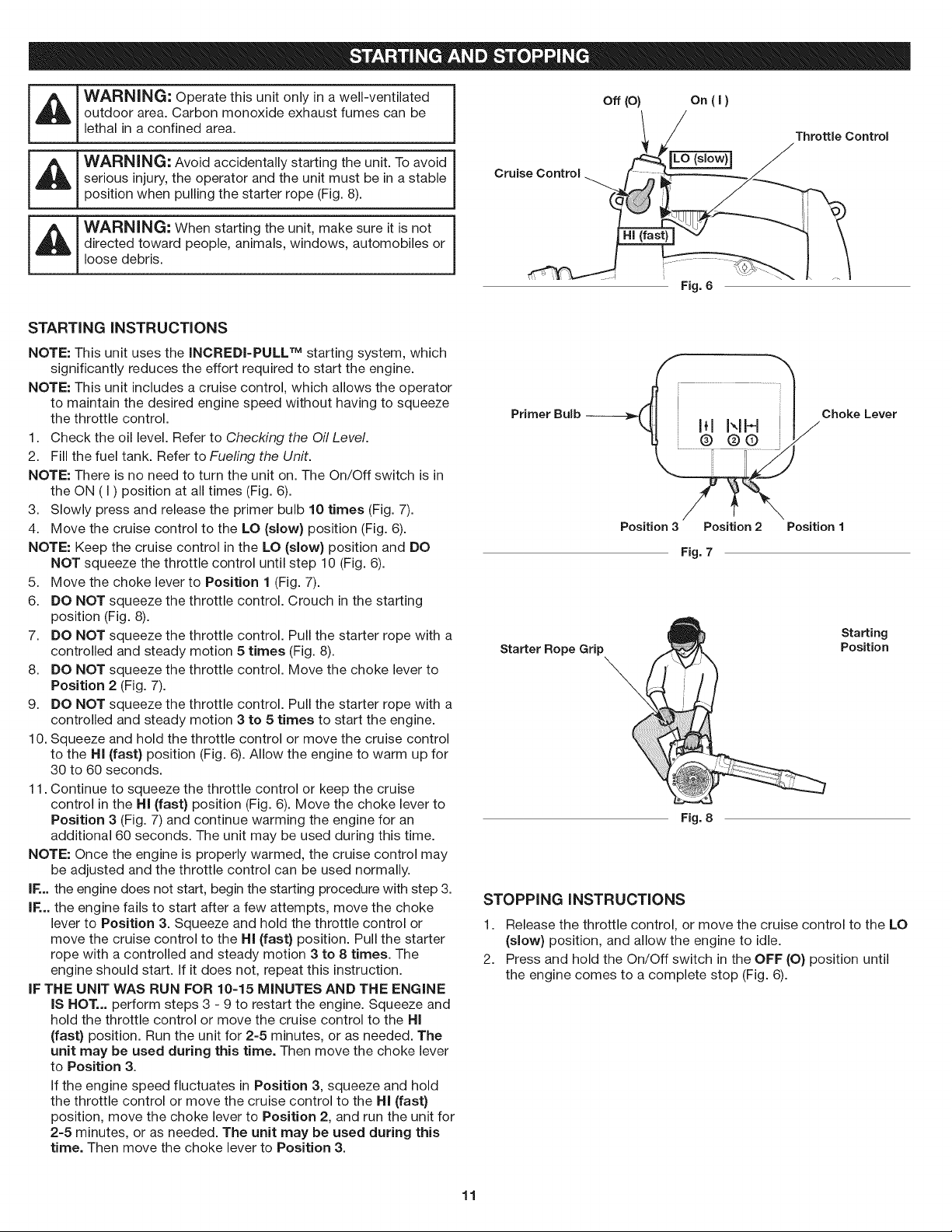

NOTE: There is no need to turn the unit on. The On/Off switch is in

the ON (I) position at all times (Fig. 6).

3. Slowly press and release the primer bulb 10 times (Fig. 7).

4. Move the cruise control to the LO (slow) position (Fig. 6).

NOTE: Keep the cruise control in the LO (slow) position and DO

NOT squeeze the throttle control until step 10 (Fig. 6).

5. Move the choke lever to Position 1 (Fig. 7).

6. DO NOT squeeze the throttle control. Crouch in the starting

position (Fig. 8).

7. DO NOT squeeze the throttle control. Pull the starter rope with a

controlled and steady motion 5 times (Fig. 8).

8. DO NOT squeeze the throttle control. Move the choke lever to

Position 2 (Fig. 7).

9. DO NOT squeeze the throttle control. Pull the starter rope with a

controlled and steady motion 3 to 5 times to start the engine.

10. Squeeze and hold the throttle control or move the cruise control

to the Hi (fast) position (Fig. 6). Allow the engine to warm up for

30 to 60 seconds.

11. Continue to squeeze the throttle control or keep the cruise

control in the Hi (fast) position (Fig. 6). Move the choke lever to

Position 3 (Fig. 7) and continue warming the engine for an

additional 60 seconds. The unit may be used during this time.

NOTE: Once the engine is properly warmed, the cruise control may

be adjusted and the throttle control can be used normally.

IF... the engine does not start, begin the starting procedure with step 3.

IF... the engine fails to start after a few attempts, move the choke

lever to Position 3. Squeeze and hold the throttle control or

move the cruise control to the HI (fast) position. Pull the starter

rope with a controlled and steady motion 3 to 8 times. The

engine should start. If it does not, repeat this instruction.

IF THE UNIT WAS RUN FOR 10-15 MINUTES AND THE ENGINE

IS HOT... perform steps 3 - 9 to restart the engine. Squeeze and

hold the throttle control or move the cruise control to the HI

(fast} position. Run the unit for 2-5 minutes, or as needed. The

unit may be used during this time. Then move the choke lever

to Position 3.

If the engine speed fluctuates in Position 3, squeeze and hold

the throttle control or move the cruise control to the Hi (fast)

position, move the choke lever to Position 2, and run the unit for

2=5 minutes, or as needed. The unit may be used during this

time. Then move the choke lever to Position 3.

off (o)

Cruise Control

On(I)

Throttle Control

J

J

Fig.6

Primer Bulb --

Position3 Position2 Position 1

Starter Rope Grip

STOPPING iNSTRUCTiONS

1. Release the throttle control, or move the cruise control to the LO

(slow) position, and allow the engine to idle.

2. Press and hold the On/Off switch in the OFF (O) position until

the engine comes to a complete stop (Fig. 6).

........................

NH i /C.okeLever

Fig. 7

Fig. 8

Starting

Position

11

ThisunitcanbestartedwithanoptionalSpeedStartTM accessory

(items sold separately). Please refer to the Speed Start TM accessory

operator's manual for the proper use of this feature.

Please contact your local Craftsman retailer, call 1-888-331-4569 or

visit www.craftsman.com for more information.

STARTING iNSTRUCTiONS

NOTE: This unit includes a cruise control, which allows the operator

to maintain the desired engine speed without having to squeeze

the throttle control.

1. Check the oil level. Refer to Checking the Oil Level.

2. Fill the fuel tank. Refer to Fueling the Unit.

NOTE: There is no need to turn the unit on. The On/Off switch is in

the ON (I) position at all times (Fig. 6).

3. Slowly press and release the primer bulb 10 times (Fig. 7).

4. Move the cruise control to the LO (slow} position (Fig. 6).

NOTE: Keep the cruise control in the LO (slow} position and DO

NOT squeeze the throttle control until step 12 (Fig. 6).

5. Move the choke lever to Position 1 (Fig. 7).

6. DO NOT squeeze the throttle control. Crouch in the starting

position (Fig. 8).

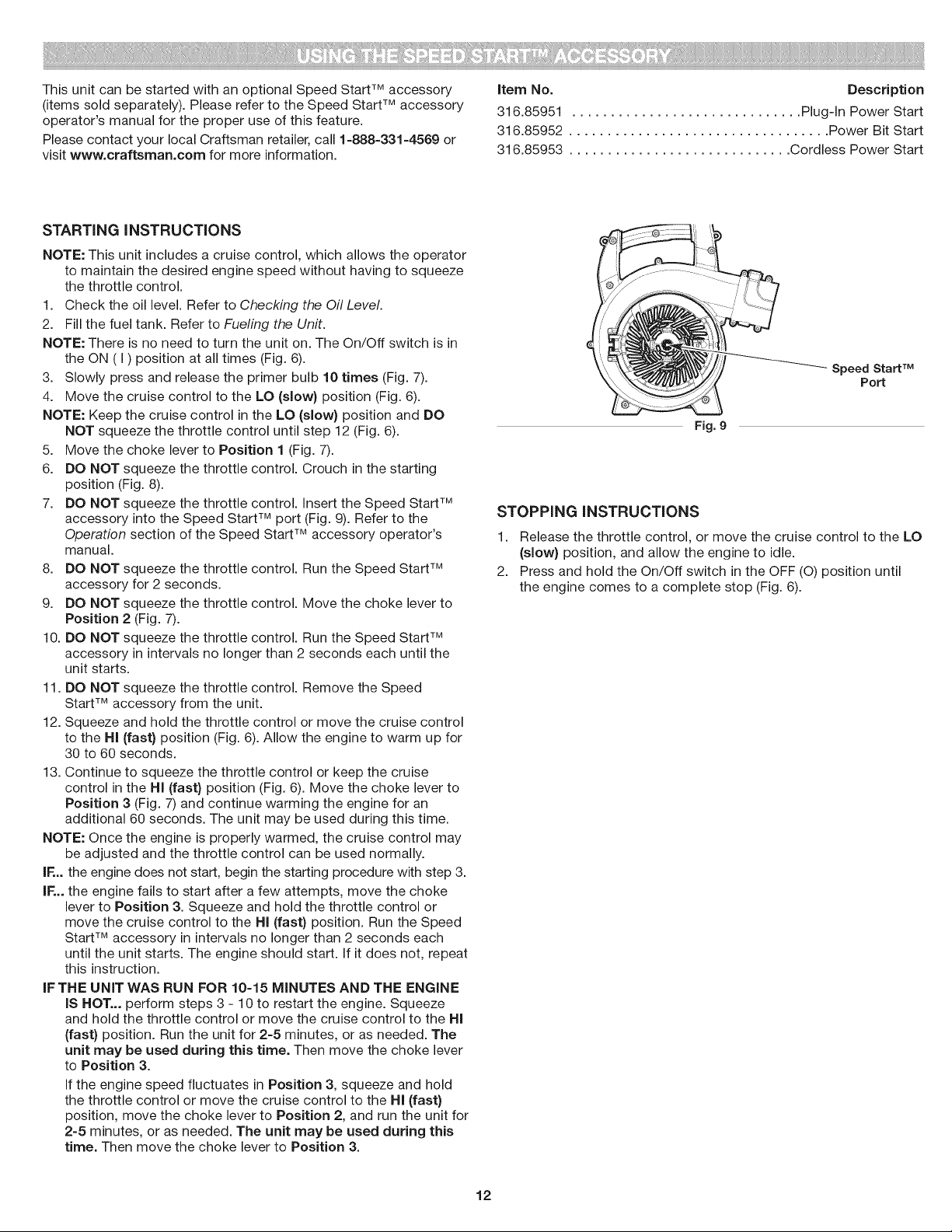

7. DO NOT squeeze the throttle control, insert the Speed Start TM

accessory into the Speed Start TM port (Fig. 9). Refer to the

Operation section of the Speed Start TM accessory operator's

manual.

8. DO NOT squeeze the throttle control. Run the Speed Start TM

accessory for 2 seconds.

9. DO NOT squeeze the throttle control. Move the choke lever to

Position 2 (Fig. 7).

10. DO NOT squeeze the throttle control. Run the Speed Start TM

accessory in intervals no longer than 2 seconds each until the

unit starts.

11. DO NOT squeeze the throttle control. Remove the Speed

Start TM accessory from the unit.

12. Squeeze and hold the throttle control or move the cruise control

to the HI (fast} position (Fig. 6). Allow the engine to warm up for

30 to 60 seconds.

13. Continue to squeeze the throttle control or keep the cruise

control in the HI (fast} position (Fig. 6). Move the choke lever to

Position 3 (Fig. 7) and continue warming the engine for an

additional 60 seconds. The unit may be used during this time.

NOTE: Once the engine is properly warmed, the cruise control may

be adjusted and the throttle control can be used normally.

IF... the engine does not start, begin the starting procedure with step 3.

IF... the engine fails to start after a few attempts, move the choke

lever to Position 3. Squeeze and hold the throttle control or

move the cruise control to the HI (fast} position. Run the Speed

Start TM accessory in intervals no longer than 2 seconds each

until the unit starts. The engine should start. If it does not, repeat

this instruction.

IF THE UNIT WAS RUN FOR 10-15 MINUTES AND THE ENGINE

IS HOT... perform steps 3 - 10 to restart the engine. Squeeze

and hold the throttle control or move the cruise control to the Hi

(fast} position. Run the unit for 2-5 minutes, or as needed. The

unit may be used during this time. Then move the choke lever

to Position 3.

If the engine speed fluctuates in Position 3, squeeze and hold

the throttle control or move the cruise control to the HI (fast}

position, move the choke lever to Position 2, and run the unit for

2-5 minutes, or as needed. The unit may be used during this

time. Then move the choke lever to Position 3.

Item No. Description

316.85951 .............................. Plug-in Power Start

316.85952 .................................. Power Bit Start

316.85953 ............................. Cordless Power Start

Speed Start TM

Port

Fig. 9

STOPPING INSTRUCTIONS

1. Release the throttle control, or move the cruise control to the LO

(slow} position, and allow the engine to idle.

2. Press and hold the On/Off switch in the OFF (O) position until

the engine comes to a complete stop (Fig. 6).

12

Loading...

Loading...