Craftsman 316.792570 Operator's Manual

Operator's Manual

M

UNIVERSAL POWER BROOM ATTACHMENT

Model No. 316.792570

,, SAFETY

o ASSEMBLY

OPERATION

CAUTION: Before using this product,

read this manual and follow all its Safety

Rules and Operating instructions.

Sears Brands Management Corporation, Hoffman Estates, IL 60179 U.S.A.

Visit our website: www.craftsrnan.com

769-08486 / 00 10/12

MAINTENANCE

PARTS LIST

ESPANOL, R 11

TABLEOFCONTENTS

Safety............................................... 2

Warranty............................................. 5

KnowYourUnit........................................ 5

Specifications......................................... 5

Assembly............................................. 6

Operation............................................. 7

Maintenance.......................................... 8

CleaningandStorage................................... 9

PartsList............................................ 23

Allinformation,illustrationsandspecificationsinthismanualarebased

onthelatestproductinformationavailableatthetimeofprinting.We

reservetherighttomakechangesatanytimewithoutnotice.

©SeamBrands,LLC

Thepurposeofsafetysymbolsistoattractyourattentionto

possibledangers.Thesafetysymbols,andtheirexplanations,

deserveyourcarefulattentionandunderstanding.Thesafety

warningsdonotbythemselveseliminateanydanger.The

instructionsorwarningstheygivearenotsubstitutesforproper

accidentpreventionmeasures.

SYMBOL MEANING

DANGER: Signals an EXTREME hazard.

Failure to obey a safety DANGER signal WILL result in

serious injury or death to yourself or to others.

WARNING: Signals a SERIOUS hazard.

Failure to obey a safety WARNING signal CAN result in

serious injury to yourself or to others.

CAUTION: Signals a MODERATE hazard.

Failure to obey a safety CAUTION signal MAY result in

property damage or injury to yourself or to others.

NOTE: Advises you of information or instructions vital to the

operation or maintenance of the equipment.

Read the operator's manual and follow all warnings and safety

instructions. Failure to do so can result in serious injury to the

operator and/or bystanders.

,, iMPORTANT SAFETY iNSTRUCTiONS ,,

READ ALL iNSTRUCTiONS BEFORE OPERATING

WARNING: When using the unit, all safety rules must be

followed. Please read these instructions before operating

the unit in order to ensure the safety of the operator and any

bystanders. Please keep these instructions for later use.

o

Carefully read and understand the operator's manual of the unit

that powers this attachment.

o

Read the instructions carefully. Be familiar with the controls and

proper use of the unit.

o

Do not operate this unit when tired, ill or under the influence of

alcohol, drugs or medication.

o

Children must not operate the unit. Teens must be accompanied

and guided by an adult.

o

All guards and safety attachments must be installed properly

before operating the unit.

o

Inspect the unit before use. Replace damaged parts. Check for

fuel leaks. Make sure all fasteners are in place and secure.

Replace parts that are cracked, chipped, or damaged in any

way. Do not operate the unit with loose or damaged parts.

o

Carefully inspect the area before starting the unit. Remove all

debris and hard or sharp objects such as glass, wire, etc.

o

Be aware of the risk of injury to the head, hands and feet.

o

Clear the area of children, bystanders and pets; keep them

outside a 50-foot (15 m) radius, at a minimum. Even then, they are

still at risk from thrown objects. Encourage bystanders to wear

eye protection. Ifyou are approached, stop the unit immediately.

SAFETY WARNINGS FOR ELECTRIC UNITS

WARNING: To reduce the risk of electrical shock, use

only extension cords approved for outdoor use, such as an

extension cord of cord type SW-A, SOW-A, STW-A, STOW-

A, SJW-A, SJOW-A, SJTW-W or SJTOW-A. Extension

cords are available from your local retailer. Use only round-

jacketed extension cords approved for outdoor use.

• CORD SETS: Make sure your cord set is in good condition.

When using a cord set, be sure to use a cord that is heavy

enough to carry the current that your unit will draw. An

undersized cord set will cause a drop in line voltage resulting in

loss of power and overheating. See the operator's manual for

the unit that will power this attachment for the recommended

cord size.

Inspect all extension cords and the unit power connection

periodically. Look closely for deterioration, cuts or cracks in the

insulation. Also inspect the connections for damage. Replace

the cords if any defects or damage appear.

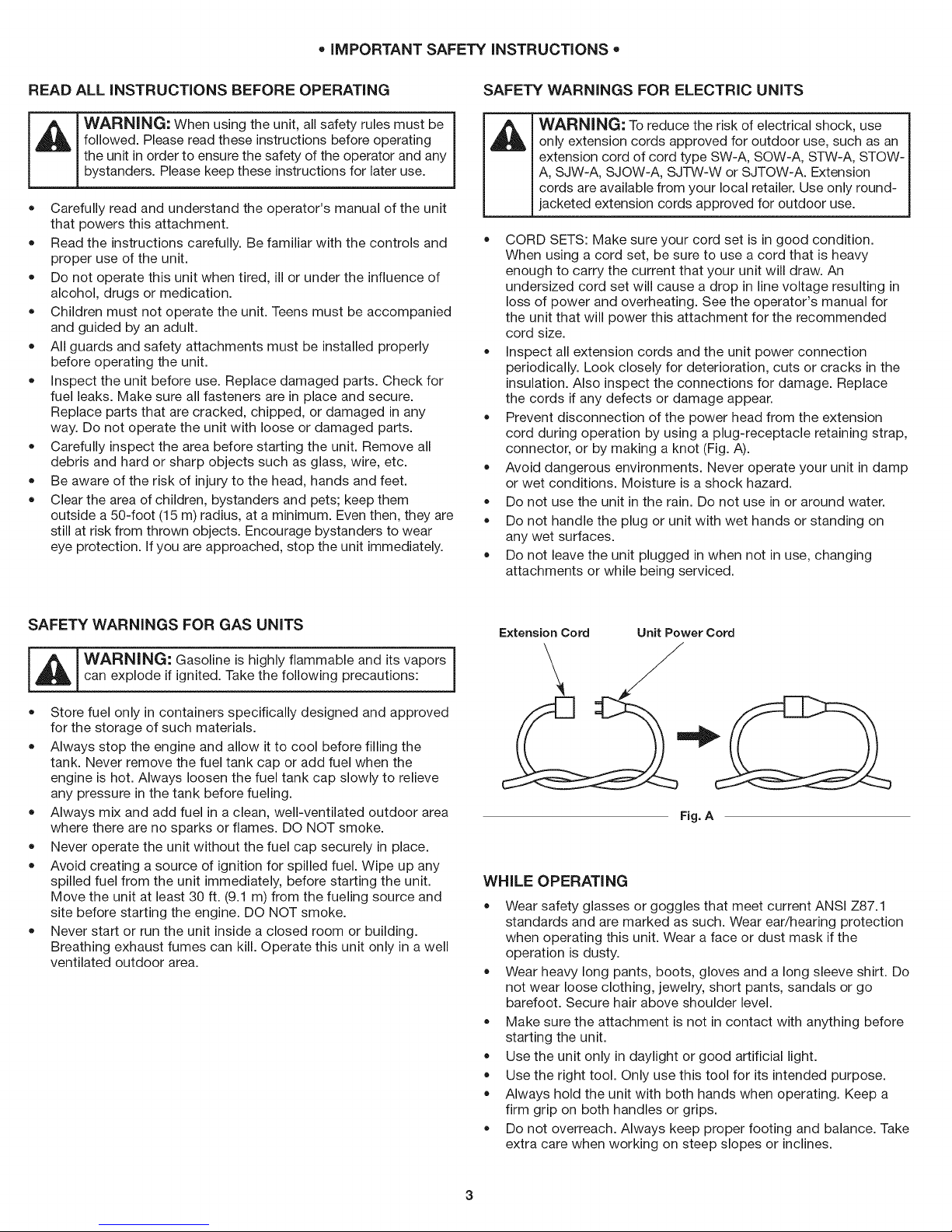

Prevent disconnection of the power head from the extension

cord during operation by using a plug-receptacle retaining strap,

connector, or by making a knot (Fig. A).

Avoid dangerous environments. Never operate your unit in damp

or wet conditions. Moisture is a shock hazard.

Do not use the unit in the rain. Do not use in or around water.

Do not handle the plug or unit with wet hands or standing on

any wet surfaces.

Do not leave the unit plugged in when not in use, changing

attachments or while being serviced.

SAFETY WARNINGS FOR GAS UNITS

H_kb !_'ARNING: Gasoline is highly flammable and its vapors I

can explode if ignited. Take the following precautions:

Store fuel only in containers specifically designed and approved

for the storage of such materials.

Always stop the engine and allow it to cool before filling the

tank. Never remove the fuel tank cap or add fuel when the

engine is hot. Always loosen the fuel tank cap slowly to relieve

any pressure in the tank before fueling.

Always mix and add fuel in a clean, well-ventilated outdoor area

where there are no sparks or flames. DO NOT smoke.

Never operate the unit without the fuel cap securely in place.

Avoid creating a source of ignition for spilled fuel. Wipe up any

spilled fuel from the unit immediately, before starting the unit.

Move the unit at least 30 ft. (9.1 m) from the fueling source and

site before starting the engine. DO NOT smoke.

Never start or run the unit inside a closed room or building.

Breathing exhaust fumes can kill. Operate this unit only in a well

ventilated outdoor area.

Extension Cord Unit Power Cord

Fig. A

WHILE OPERATING

Wear safety glasses or goggles that meet current ANSI Z87.1

standards and are marked as such. Wear ear/hearing protection

when operating this unit. Wear a face or dust mask if the

operation is dusty.

Wear heavy long pants, boots, gloves and a long sleeve shirt. Do

not wear loose clothing, jewelry, short pants, sandals or go

barefoot. Secure hair above shoulder level.

Make sure the attachment is not in contact with anything before

starting the unit.

Use the unit only in daylight or good artificial light.

Use the right tool. Only use this tool for its intended purpose.

Always hold the unit with both hands when operating. Keep a

firm grip on both handles or grips.

Do not overreach. Always keep proper footing and balance. Take

extra care when working on steep slopes or inclines.

3

• Keep hands, face, and feet away from all moving parts. Do not

touch or try to stop moving parts.

Do not operate the unit faster than the speed needed to do the job.

Do not run the unit at high speed when not in use.

Use extreme caution when reversing or pulling the unit towards you.

Do not force the unit. It will do a better, safer job when used at

the intended rate.

Always stop the unit when operation is delayed or when walking

from one location to another.

Ifyou strike or become entangled with a foreign object, stop the

unit immediately and check for damage. Do not operate before

repairing damage. Do not operate the unit with loose or

damaged parts.

Use only original equipment manufacturer (OEM) replacement

parts and accessories for this unit, as listed in the Parts List

section of this manual. Use of any other parts or accessories

could lead to serious injury to the user, or damage to the unit,

and void the warranty.

Keep the unit clean. Carefully remove vegetation and other

debris that could block moving parts.

If the unit starts to vibrate abnormally, stop the unit immediately.

Inspect the unit for the cause of the vibration. Vibration is

generally an indicator of trouble.

OTHER SAFETY WARNINGS

All service, other than the maintenance procedures described in

this manual, should be performed by a Sears or other qualified

service dealer.

Before inspecting, servicing, cleaning, storing, transporting or

replacing any parts on the unit:

1. Stop the unit.

2. Make sure all moving parts have stopped.

3. Allow the unit to cool.

4. For gas-powered units, disconnect the spark plug wire. For

electric-powered units, disconnect the unit from the power source.

Never store the unit with fuel in the tank, inside a building where

fumes may reach an open flame (pilot lights, etc.) or sparks

(switches, electrical motors, etc.).

Be sure to secure the unit while transporting.

Store the unit in a dry place, secured or at a height to prevent

unauthorized use or damage. Keep out of the reach of children.

Never douse or squirt the unit with water or any other liquid.

Keep handles dry, clean and free from debris. Clean after each

use, see Cleaning and Storage instructions.

Keep these instructions. Refer to them often and use them to

instruct other users. If you loan this unit to others, also loan

them these instructions.

SAVE THESE INSTRUCTIONS

,, SAFETY & INTERNATIONAL SYMBOLS ,,

This operator's manual describes safety and international symbols and pictographs that may appear on this product. Read the operator's

manual for complete safety, assembly, operating and maintenance and repair information.

SYMBOL MEANING SYMBOL MEANING

• SAFETY ALERT SYMBOL

JA !nd catesdanger,war!ingorcau!!on.Maybeusedn

conJuncti0n with other symbols or p!ctographsl

'o READ OPERATOR'S MANUAL

I WARNING: Read the operat0r

fo!low a!! warnings and safety instruction& Failure to

do so can result in serious injury to the operator

. and!or bystanders.

WARNING: Thi0wn objects and ioUd noise Can

cause Severe eye injury and hearing 10sslWear eye

Pi0tect!0n meeting cUrrent ANS! z87:i standards and

ear protection when operating this unit, Use a fU!! face

shield when needed.

._,._ ', THROWN OBJECTSAND ROTATING PARTS CAN

/_ CAUSE SEVERE iNJURY

/ _-- _"Ib 'j

/-_J_ WARNING: Small objects can be propelled at high

-_f _ speed, causing injury.Keep away from rotating parts.

WARNING: Keep all bystanders, especially children

t KEEP BYSTANDERS AWAY

and pets, at least 50 feet (15 m) from the operating area.

_ _POWER BROOMS - ROTATING BRUSHES CAN

W

_& CAUSE SEVERE INJURY

WARNING: Stop the engine/motor and allow all

' moving parts to stop before installingor removing any

parts or attachments, or before cleaning or performing

any maintenance. Keep hands and feet away from

moving parts.

CRAFTSMANTWO YEAR FULL WARRANTY

FOR TWO YEARS from the date of purchase, this product iswarranted against any defects in material or workmanship. A defective product

will be replaced free of charge.

For warranty details to obtain free replacement, visit the web site: www.craftsman.com

This warranty does not cover the brushes and skid shoe, which are expendable parts that can wear out from normal use within the warranty period.

This warranty isvoid if this product is ever used while providing commercial services or if rented to another person.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

Sears Brands Management Corporation, Hoffman Estates, IL 60179

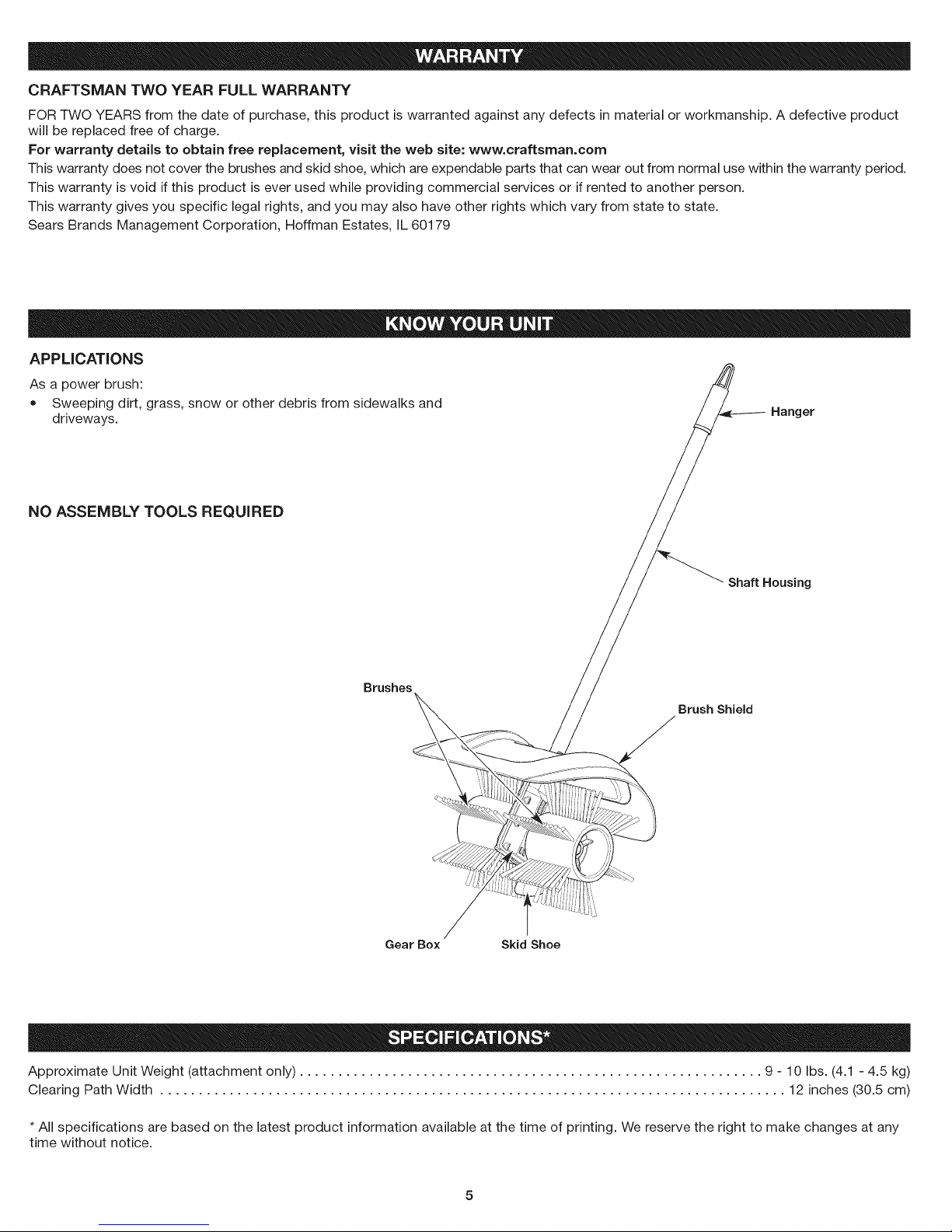

APPLICATIONS

As a power brush:

• Sweeping dirt, grass, snow or other debris from sidewalks and

driveways. Hanger

NO ASSEMBLY TOOLS REQUIRED

Brushes

Gear Box Skid Shoe

Shaft Housing

Brush Shield

Approximate Unit Weight (attachment only) ............................................................ 9 - 10 Ibs. (4.1 - 4.5 kg)

Clearing Path Width ................................................................................. 12 inches (30.5 cm)

* All specifications are based on the latest product information available at the time of printing. We reserve the right to make changes at any

time without notice.

5

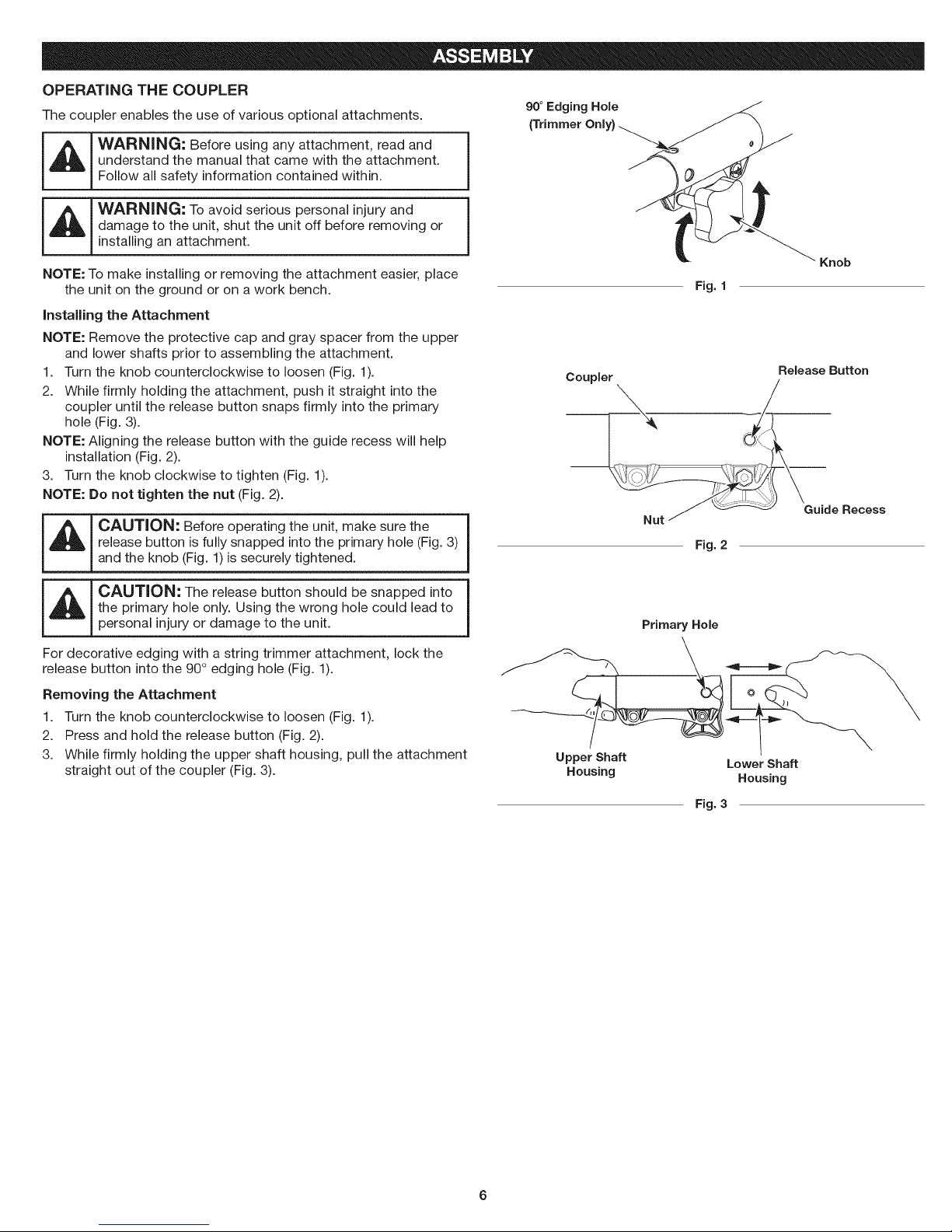

OPERATING THE COUPLER

The coupler enables the use of various optional attachments.

90° Edging Hole

(Trimmer Only)

_ WARNING: Before using any attachment, read and

I _ I WARNING: To avoid serious persona' injury and j

NOTE: To make installing or removing the attachment easier, place

installing the Attachment

NOTE: Remove the protective cap and gray spacer from the upper

1. Turn the knob counterclockwise to loosen (Fig. 1).

2. While firmly holding the attachment, push it straight into the

NOTE: Aligning the release button with the guide recess will help

3. Turn the knob clockwise to tighten (Fig. 1).

NOTE: Do not tighten the nut (Fig. 2).

l,_ICAUTION:Thereleasebuttonshouldbesnappedinto I

understand the manual that came with the attachment.

Follow all safety information contained within.

damage to the unit, shut the unit off before removing or

installing an attachment.

the unit on the ground or on a work bench.

and lower shafts prior to assembling the attachment.

coupler until the release button snaps firmly into the primary

hole (Fig. 3).

installation (Fig. 2).

release button is fully snapped into the primary hole (Fig. 3)

c,o,,o°; e o eo e ati theun,t,ma esu ethe1

and the knob (Fig. 1) is securely tightened.

theprimaryholeonly.Using thewrong holecouldleadto

personalinjuryor damage totheunit.

J

Knob

Fig. 1

Release Button

--__7 Lu,de Recess

Fig. 2

PrimaryHole

For decorativeedging witha stringtrimmerattachment,lockthe

releasebuttonintothe90° edginghole(Fig.I).

Removing the Attachment

1. Turn the knob counterclockwise to loosen (Fig. 1).

2. Press and hold the release button (Fig. 2).

3. While firmly holding the upper shaft housing, pull the attachment

straight out of the coupler (Fig. 3).

\

Upper Shaft Lower Shaft

Housing Housing

Fig. 3

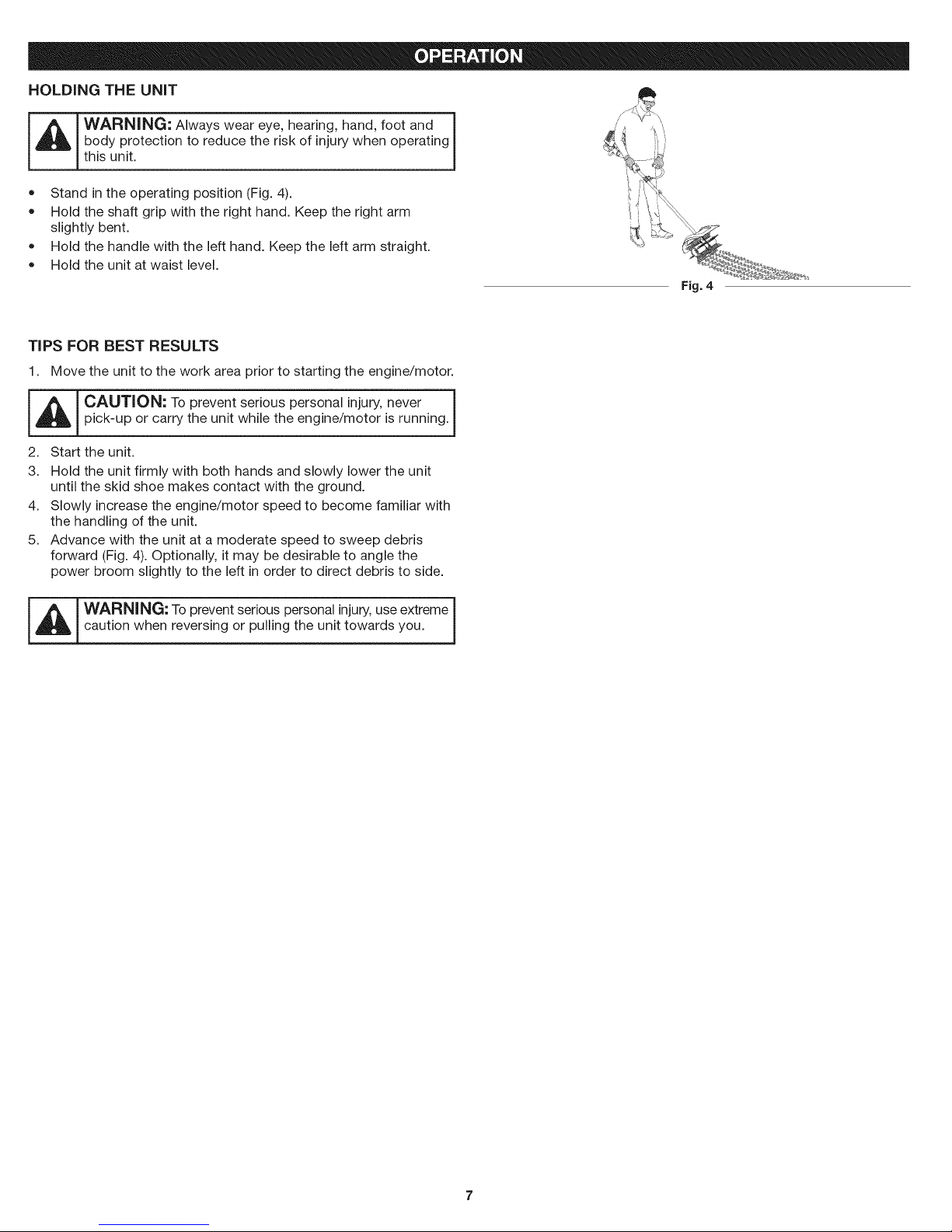

HOLDING THE UNiT

_WARNING: Always wear eye, hearing, hand, foot and I

• Stand in the operating position (Fig. 4).

• Hold the shaft grip with the right hand. Keep the right arm

body protection to reduce the risk of injury when operating I

this unit. j

slightly bent.

Hold the handle with the left hand. Keep the left arm straight.

Hold the unit at waist level.

TiPS FOR BEST RESULTS

1. Move the unit to the work area prior to starting the engine/motor.

_ CAUTION: To prevent serious personal injury, never |

2. Start the unit.

3. Hold the unit firmly with both hands and slowly lower the unit

4. Slowly increase the engine/motor speed to become familiar with

5. Advance with the unit at a moderate speed to sweep debris

pick-up or carry the unit while the engine/motor is running.

until the skid shoe makes contact with the ground.

the handling of the unit.

forward (Fig. 4). Optionally, it may be desirable to angle the

power broom slightly to the left in order to direct debris to side.

Fig. 4

!

J

_L______.[ARNING: To prevent serious personal injury, use extreme _

caution when reversing or pulling the unit towards you.

J

WARNING: To prevent serious injury, never perform

Ji

NOTE: Some maintenance procedures may require special tools or

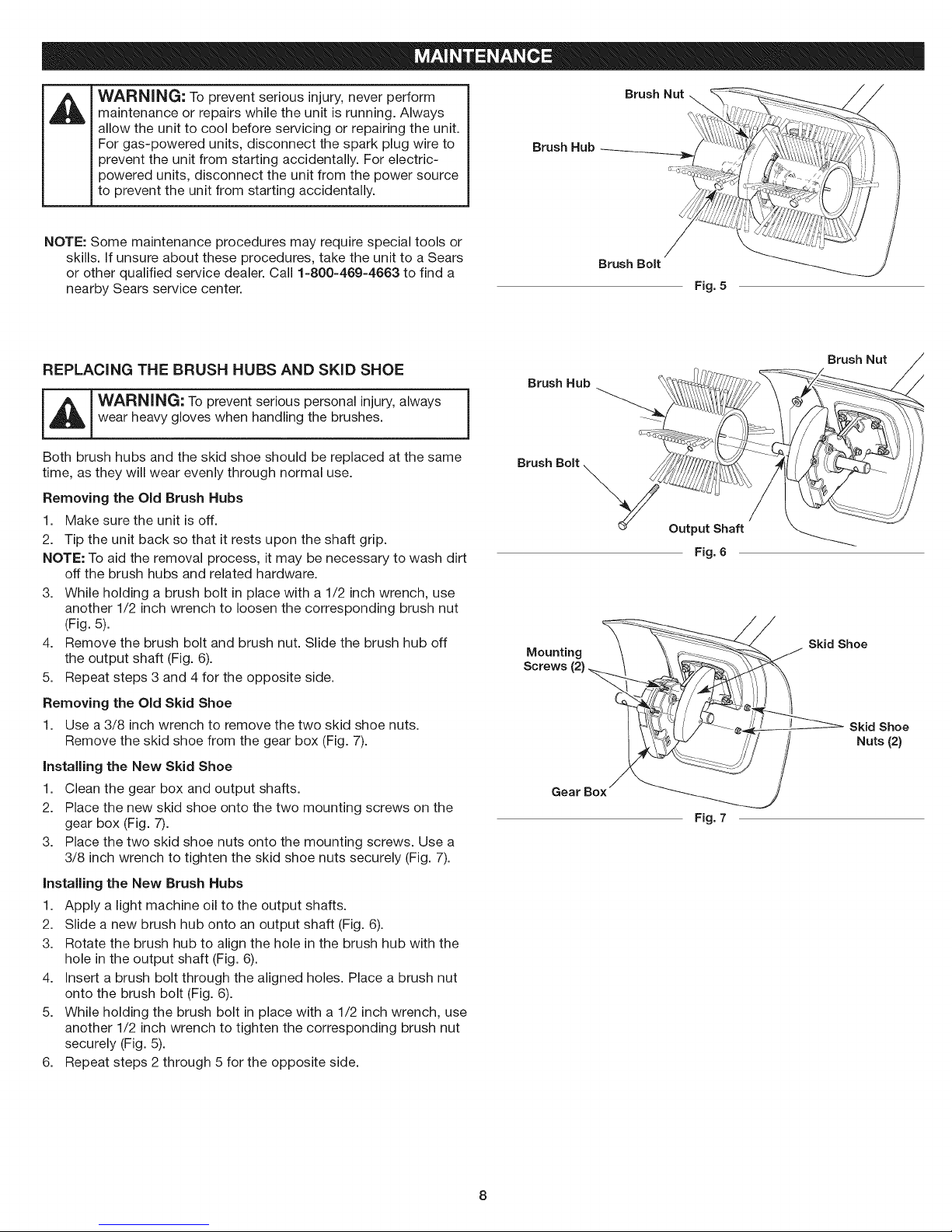

REPLACING THE BRUSH HUBS AND SKiD SHOE

maintenance or repairs while the unit is running. Always

allow the unit to cool before servicing or repairing the unit.

For gas-powered units, disconnect the spark plug wire to

prevent the unit from starting accidentally. For electric-

powered units, disconnect the unit from the power source

to prevent the unit from starting accidentally.

skills, if unsure about these procedures, take the unit to a Sears

or other qualified service dealer. Call 1-800-469-4663 to find a

nearby Sears service center.

Brush Nut _

_. J /:;

Brush Hub _;X/g_

Brush Bolt

Fig. 5

_ WARNING: To prevent serious personal injury, always j

wear heavy gloves when handling the brushes.

Both brush hubs and the skid shoe should be replaced at the same

time, as they will wear evenly through normal use.

Removing the Old Brush Hubs

1. Make sure the unit is off.

2. Tip the unit back so that it rests upon the shaft grip.

NOTE: To aid the removal process, it may be necessary to wash dirt

off the brush hubs and related hardware.

3. While holding a brush bolt in place with a 1/2 inch wrench, use

another 1/2 inch wrench to loosen the corresponding brush nut

(Fig. 5).

4. Remove the brush bolt and brush nut. Slide the brush hub off

the output shaft (Fig. 6).

5. Repeat steps 3 and 4 for the opposite side.

Removing the Old Skid Shoe

1. Use a 3/8 inch wrench to remove the two skid shoe nuts.

Remove the skid shoe from the gear box (Fig. 7).

Installing the New Skid Shoe

1. Clean the gear box and output shafts.

2. Place the new skid shoe onto the two mounting screws on the

gear box (Fig. 7).

3. Place the two skid shoe nuts onto the mounting screws. Use a

3/8 inch wrench to tighten the skid shoe nuts securely (Fig. 7).

Installing the New Brush Hubs

1. Apply a light machine oil to the output shafts.

2. Slide a new brush hub onto an output shaft (Fig. 6).

3. Rotate the brush hub to align the hole in the brush hub with the

hole in the output shaft (Fig. 6).

4. Insert a brush bolt through the aligned holes. Place a brush nut

onto the brush bolt (Fig. 6).

5. While holding the brush bolt in place with a 1/2 inch wrench, use

another 1/2 inch wrench to tighten the corresponding brush nut

securely (Fig. 5).

6. Repeat steps 2 through 5 for the opposite side.

Mounting

Screws

Gear Box

Fig. 6

Skid Shoe

Skid Shoe

Nuts (2}

Fig. 7

Loading...

Loading...