Page 1

Sears, Roebuck and Co., Hoffman Estates, IL 60179, U.S.A.

Visit our website: www.sears.com/craftsman

CAUTION: Before using this product,

read this manual and follow all safety

rules and operating instructions.

Operator’s Manual

2-Cycle

WEEDWACKER

®

GAS TRIMMER

Model No. 316.791900

• SAFETY

• ASSEMBLY

• OPERATION

• MAINTENANCE

• PARTS LIST

• ESPAÑOL, P. 13

769-03836A 3/08

®

Page 2

2

• IMPORTANT SAFETY INSTRUCTIONS •

READ ALL INSTRUCTIONS BEFORE OPERATING

• Read the instructions carefully. Be familiar with the controls and

proper use of the unit.

• Do not operate this unit when tired, ill or under the influence of

alcohol, drugs or medication.

• Children must not operate the unit. Teens must be accompanied

and guided by an adult.

• Inspect the unit before use. Replace damaged parts. Check for

fuel leaks. Make sure all fasteners are in place and secure.

Replace cutting attachment parts that are cracked, chipped or

damaged in any way.

• Use only Hassle Free™ XTRA QUIET Spiral Line. Never use

metal-reinforced line, wire, chain or rope. These can break off

and become dangerous projectiles.

• Be aware of risk of injury to the head, hands and feet.

• Clear the area to be cut before each use. Remove rocks, broken

glass, nails, wire, string and other objects which may be thrown

or become entangled in the cutting attachment. Clear the area of

children, bystanders and pets; keep them outside a 50-foot

(15 m) radius, at a minimum. Even then, they are still at risk from

thrown objects. Encourage bystanders to wear eye protection. If

you are approached, stop the unit immediately.

• Squeeze the throttle control and check that it returns

automatically to the idle position. Make all adjustments or repairs

before using the unit.

FUEL SAFETY WARNINGS

• Store fuel only in containers specifically designed and approved

for the storage of such materials.

• Always stop the engine and allow it to cool before filling the fuel

tank. Never remove the fuel tank cap or add fuel when the engine is

hot. Never operate the unit without the fuel cap securely in place.

• Loosen the fuel tank cap slowly to relieve any pressure in the tank.

• Mix and add fuel in a clean, well-ventilated outdoor area where

there are no sparks or flames. Remove the fuel cap slowly, and

only after the engine stops. Do not smoke while fueling or mixing

fuel. Wipe up any spilled fuel from the unit immediately.

• Avoid creating a source of ignition for spilled fuel. Do not start the

engine until fuel vapors dissipate.

• Move the unit at least 30 feet (9.1 m) from the fueling source and site

before starting the engine. Do not smoke. Keep sparks and open

flames away from the area while adding fuel or operating the unit.

WHILE OPERATING

• Never start or run the unit inside a closed room or building.

Breathing exhaust fumes can be fatal. Operate this unit only in a

well-ventilated outdoor area.

• Wear safety glasses or goggles that meet ANSI Z87.1–1989 standards

and are marked as such. Wear ear/hearing protection when operating

this unit. Wear a face or dust mask if the operation is dusty.

• Wear heavy long pants, boots, gloves and a long sleeve shirt. Do

not wear loose clothing, jewelry, short pants, sandals or go

barefoot. Secure hair above shoulder level.

All information, illustrations, and specifications in this manual are based

on the latest product information available at the time of printing. We

reserve the right to make changes at any time without notice.

TABLE OF CONTENTS

Safety Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Know Your Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Assembly Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Oil and Fuel Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Starting/Stopping Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Maintenance and Repair Instructions . . . . . . . . . . . . . . . . . . . . . . .7

Cleaning and Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Troubleshooting Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E14

Service Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Back Cover

RULES FOR SAFE OPERATION

SPARK ARRESTOR NOTE

NOTE: For users on U.S. Forest Land and in the states of California,

Maine, Oregon and Washington. All U.S. Forest Land and the state of

California (Public Resources Codes 4442 and 4443), Oregon and

Washington require, by law that certain internal combustion engines

operated on forest brush and/or grass-covered areas be equipped with a

spark arrestor, maintained in effective working order, or the engine be

constructed, equipped and maintained for the prevention of fire. Check

with your state or local authorities for regulations pertaining to these

requirements. Failure to follow these requirements could subject you to

liability or a fine. This unit is factory equipped with a spark arrestor. If

it requires replacement, ask your LOCAL SERVICE DEALER to install the

Accessory Part #753-05169 Spark Arrestor Kit.

CALIFORNIA PROPOSITION 65 WARNING

WARNING

THE ENGINE EXHAUST FROM THIS PRODUCT CONTAINS

CHEMICALS KNOWN TO THE STATE OF CALIFORNIA TO CAUSE

CANCER, BIRTH DEFECTS OR OTHER REPRODUCTIVE HARM.

Read the Operator’s Manual and follow all warnings and safety

instructions. Failure to do so can result in serious injury to the operator

and/or bystanders.

FOR QUESTIONS, CALL 1-800-659-5917

SYMBOL MEANING

WARNING:

Failure to obey a safety warning can result in

injury to yourself and others. Always follow the safety precautions

to reduce the risk of fire, electric shock and personal injury.

CAUTION:

Failure to obey a safety warning may result in

property damage or personal injury to yourself or to others.

Always follow the safety precautions to reduce the risk of fire,

electric shock and personal injury.

The purpose of safety symbols is to attract your attention to possible

dangers. The safety symbols, and their explanations, deserve your

careful attention and understanding. The safety warnings do not by

themselves eliminate any danger. The instructions or warnings they

give are not substitutes for proper accident prevention measures.

SAFETY ALERT:

Indicates danger, warning or caution.

Attention is required in order to avoid serious personal

injury. May be used in conjunction with other symbols or

pictographs.

NOTE: Advises you of information or instructions vital to the

operation or maintenance of the equipment.

DANGER:

Failure to obey a safety warning will result in

serious injury to yourself or to others. Always follow the

safety precautions to reduce the risk of fire, electric shock

and personal injury.

WARNING:

Gasoline is highly flammable and its vapors

can explode if ignited. Take the following precautions:

WARNING:

When using the unit, you must follow the

safety rules. Please read these instructions before operating

the unit in order to ensure the safety of the operator and any

bystanders. Please keep these instructions for later use.

Page 3

3

RULES FOR SAFE OPERATION

• The cutting attachment shield must always be in place while

operating the unit. Do not operate unit without both trimming lines

extended, and the proper line installed. Do not extend the

trimming line beyond the length of the shield.

• This unit has a clutch. The cutting attachment remains stationary

when the engine is idling. If it does not, take the unit to a Sears or

other qualified service dealer for an adjustment.

• Adjust the D-handle to your size in order to provide the best grip.

• Be sure the cutting attachment is not in contact with anything

before starting the unit.

• Use the unit only in daylight or good artificial light.

• Avoid accidental starting. Be in the starting position whenever

pulling the starter rope. The operator and unit must be in a stable

position while starting. Refer to Starting/Stopping Instructions.

• Use the right tool. Only use this tool for its intended purpose.

• Always hold the unit with both hands when operating. Keep a firm

grip on both handles or grips.

• Keep hands, face, and feet away from all moving parts. Do not

touch or try to stop the cutting attachment when it rotates.

• Do not touch the engine, gear housing or muffler. These parts get

extremely hot from operation, even after the unit is turned off.

• Do not operate the engine faster than the speed needed to cut, trim

or edge. Do not run the engine at high speed when not cutting.

• Always stop the engine when cutting is delayed or when walking

from one cutting location to another.

•

If you strike or become entangled with a foreign object, stop the engine

immediately and check for damage. Do not operate before repairing

damage. Do not operate the unit with loose or damaged parts.

• Turn the engine to off and disconnect the spark plug for

maintenance or repair.

• Use only replacement parts or accessories recommended for this

tool that are distributed by Sears or a Craftsman outlet. Use of

any replacement parts or accessories purchased elsewhere may

be hazardous, and will also void your warranty.

• Keep unit clean of vegetation and other materials. They may

become lodged between the cutting attachment and shield.

• To reduce fire hazard, replace a faulty muffler and spark arrestor.

Keep the engine and muffler free from grass, leaves, excessive

grease or carbon build up.

OTHER SAFETY WARNINGS

• Never store the unit with fuel in the tank, inside a building where

fumes may reach an open flame (pilot lights, etc.) or sparks

(switches, electrical motors, etc.).

• Allow the engine to cool before storing or transporting. Be sure to

secure the unit while transporting.

• Store the unit in a dry place, secured or at a height to prevent

unauthorized use or damage. Keep out of the reach of children.

• Never douse or squirt the unit with water or any other liquid. Keep

handles dry, clean and free from debris. Clean after each use, see

Cleaning and Storage instructions (p. 11).

• Keep these instructions. Refer to them often and use them to

instruct other users. If you loan this unit to others, also loan them

these instructions.

SAVE THESE INSTRUCTIONS

This operator's manual describes safety and international symbols and pictographs that may appear on this product. Read the operator's

manual for complete safety, assembly, operating and maintenance and repair information.

• SAFETY & INTERNATIONAL SYMBOLS •

SYMBOL MEANING SYMBOL MEANING

• SAFETY ALERT SYMBOL

Indicates danger, warning or caution. May be used in

conjunction with other symbols or pictographs.

• WARNING - READ OPERATOR'S MANUAL

Read the operator’s manual(s) and follow all warnings

and safety instructions. Failure to do so can result in

serious injury to the operator and/or bystanders.

• WEAR EYE AND HEARING PROTECTION

WARNING:

Thrown objects and loud noise can cause

severe eye injury and hearing loss. Wear eye protection

meeting ANSI Z87.1-1989 standards and ear protection when

operating this unit. Use a full face shield when needed.

• UNLEADED FUEL

Always use clean, fresh unleaded fuel

• ON/OFF STOP CONTROL

ON / START / RUN

• ON/OFF STOP CONTROL

OFF or STOP

• HOT SURFACE WARNING

Do not touch a hot muffler or cylinder. You may get

burned. These parts get extremely hot from operation.

When turned off they remain hot for a short time.

• KEEP BYSTANDERS AWAY

WARNING: Keep all bystanders, especially children

and pets, at least 50 feet (15 m.) from the operating area.

• THROWN OBJECTS AND ROTATING CUTTER CAN

CAUSE SEVERE INJURY

WARNING: Small objects can be propelled at high

speed, causing injury. Keep away from the rotating rotor.

• PRIMER BULB

Push primer bulb, fully and slowly, 10 times.

• OIL

Refer to operator’s manual for the proper type of oil.

• SHARP BLADE

WARNING:

Sharp blade on cutting attachment shield.

To prevent serious injury, do not touch the line cutting blade.

Page 4

4

CRAFTSMAN FULL WARRANTY

If this Craftsman product fails due to a defect in material or workmanship within two years from the date of purchase, return it to any Sears

store, Parts & Repair Service Center, or other Craftsman outlet in the United States for free repair (or replacement if repair proves impossible).

This warranty applies for only 90 days from the purchase date if this product is ever used for commercial or rental purposes.

This warranty covers ONLY defects in material and workmanship. Sears will NOT pay for:

• Expendable items that can wear out from normal use within the warranty period, such as cutting line, filters or spark plugs.

• Repairs necessary because of accident or failure to operate or maintain the product according to all supplied instructions.

• Preventive maintenance, or repairs necessary due to improper fuel mixture, contaminated or stale fuel.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

Sears, Roebuck and Co., Hoffman Estates, IL 60179

WARRANTY STATEMENT

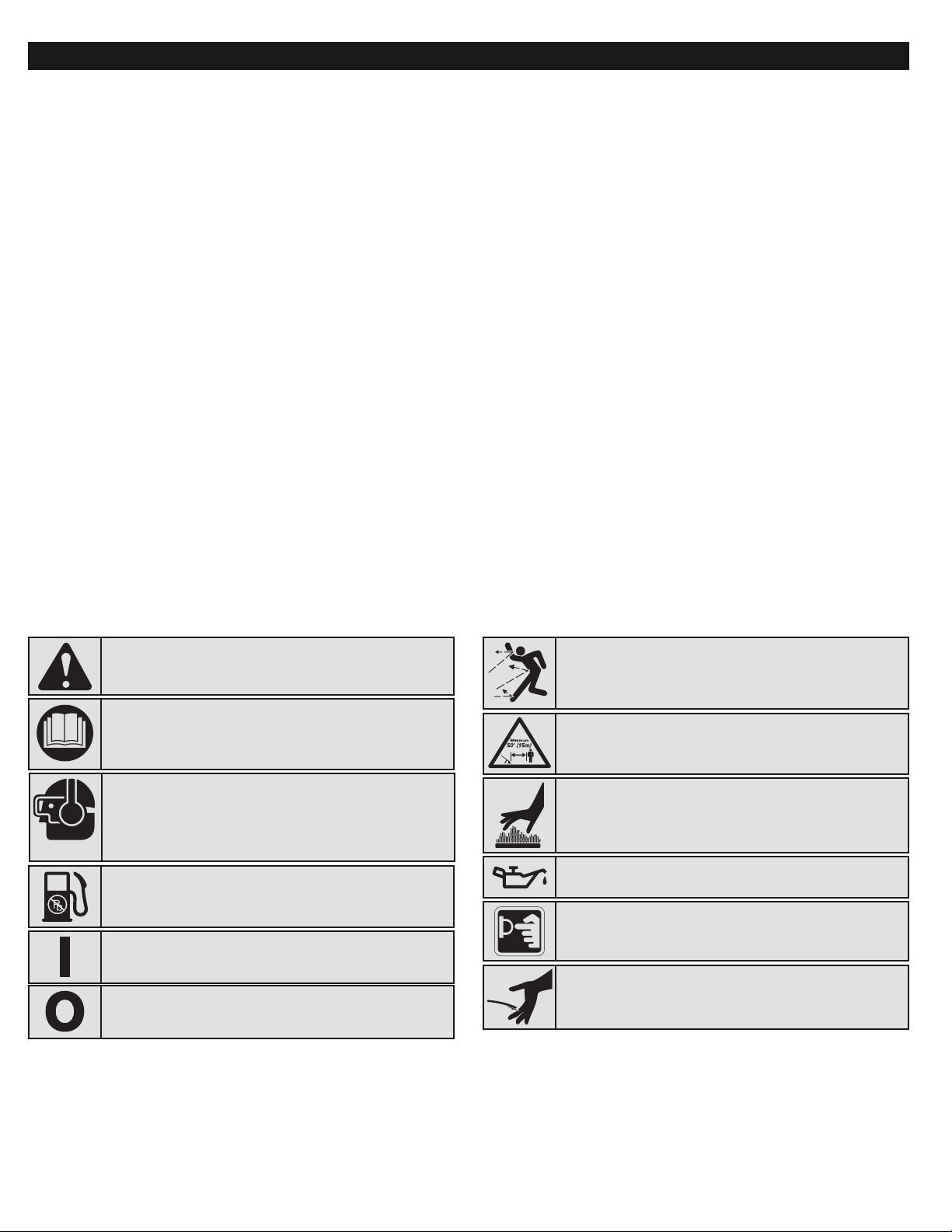

KNOW YOUR UNIT

Cutting Shield

Fuel Cap

D-Handle

Hassle Free®Plus Cutting Head

Shaft Grip

Shaft Housing

Starter

Rope Grip

Throttle Control

Air Filter/

Muffler Cover

Spark Plug

Muffler

Convertible™

Coupler

On/Off Stop Control

APPLICATIONS

As a trimmer:

• Cutting grass and light weeds.

• Edging

• Decorative trimming around trees, fences, etc.

Other optional accessories may be used with this unit.

Shoulder Strap

Loop

Primer Bulb

Line Cutting

Blade

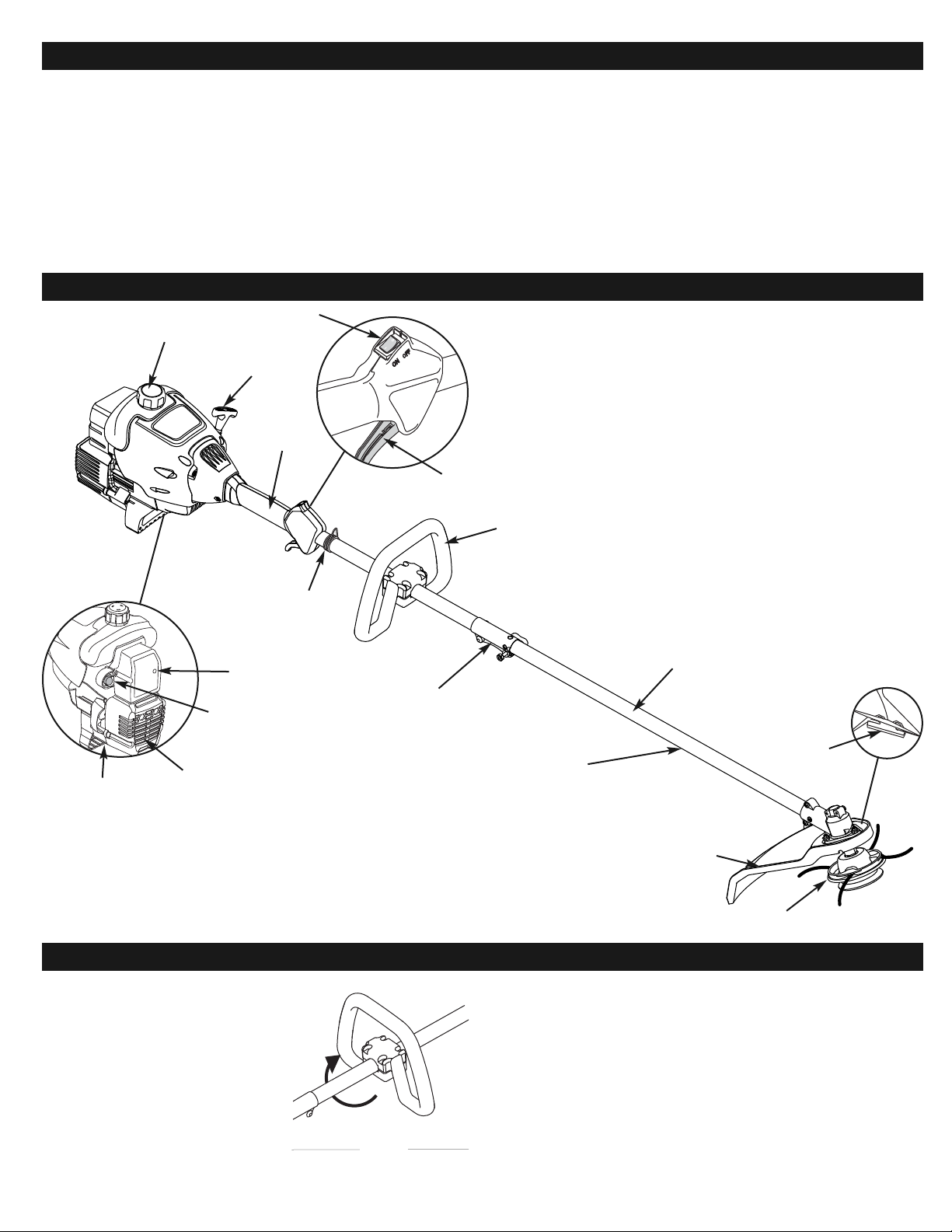

ADJUSTING THE D-HANDLE

1. Using a flathead or T-25 screwdriver,

loosen the 4 screws on the D-handle

enough to loosen it (Fig. 1).

2. Rotate the D-Handle to the upright

position on the front side of the

shaft housing (Fig. 1).

3. Hold the unit in the operating position

(Fig. 8). If necessary, reposition the Dhandle to the location that provides

the best grip.

4. Tighten the 4 screws until the Dhandle is secure.

ASSEMBLY INSTRUCTIONS

INSTALLING THE TRIMMER ATTACHMENT

Prior to use, make sure trimmer attachment is installed correctly.

Please refer to Operating the Convertible™ Coupler System for

proper installation.

NOTE: Remove red cap or hanger from lower shaft housing prior to

assembling to Convertible™ coupler

Trimmer Attachment

Fig. 1

Page 5

5

OIL AND FUEL MIXING INSTRUCTIONS

Old and/or improperly mixed fuel are the main reasons for the unit not

running properly. Be sure to use fresh, clean unleaded fuel. Follow the

instructions carefully for the proper fuel/oil mixture.

Definition of Blended Fuels

Today's fuels are often a blend of gasoline and oxygenates such as

ethanol, methanol, or MTBE (ether). Alcohol-blended fuel absorbs

water. As little as 1% water in the fuel can make fuel and oil

separate. It forms acids when stored. When using alcohol-blended

fuel, use fresh fuel (less than 60 days old).

Using Blended Fuels

If you choose to use a blended fuel, or its use is unavoidable, follow

recommended precautions:

• Always use the fresh fuel mix explained in your operator's manual

• Always agitate the fuel mix before fueling the unit

• Drain the tank and run the engine dry before storing the unit

Using Fuel Additives

The bottle of 2-cycle oil that came with your unit contains a fuel

additive which will help inhibit corrosion and minimize the formation of

gum deposits. It is recommended that you use our 2-cycle oil with this

unit. If unavailable, use a good 2-cycle oil de-signed for air-cooled

engines along with a fuel additive, such as STA-BIL

®

Gas Stabilizer or

an equivalent. Add 0.8 oz. (23 ml.) of fuel additive per gallon of fuel

according to the instructions on the container. NEVER add fuel

additives directly to the unit's fuel tank.

Thoroughly mix the proper ratio of 2-cycle engine oil with unleaded

gasoline in a separate fuel can. Use a 40:1 fuel/oil ratio. Do not mix

them directly in the engine fuel tank. See the table below for

specific gas and oil mixing

ratios.

NOTE: One gallon (3.8 liters)

of unleaded gasoline

mixed with one 3.2

oz. (95 ml.) bottle of

2-cycle oil makes a

40:1 fuel/oil ratio.

NOTE: Dispose of the old

fuel/oil mix in

accordance to

Federal, State and

Local regulations.

OIL & FUEL INFORMATION

UNLEADED GAS 2 CYCLE OIL

1 GALLON US

(3.8 LITERS)

3.2 FL. OZ.

(95 ml)

1 LITER 25 ml

MIXING RATIO - 40:1

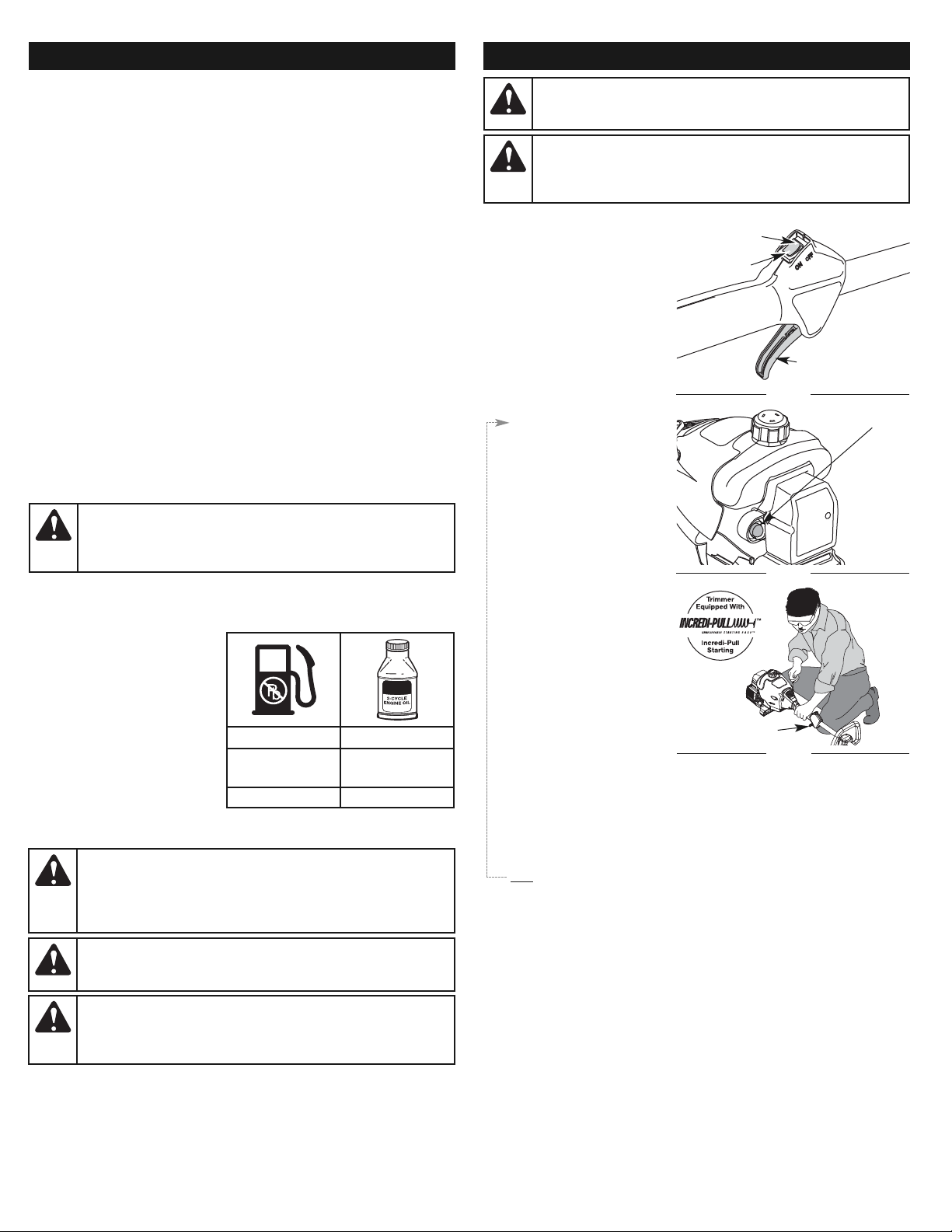

STARTING INSTRUCTIONS

STARTING/STOPPING INSTRUCTIONS

1. Mix gas with oil. See

Oil and Fuel Mixing

Instructions.

2. Fill the fuel tank with

the fuel/oil mixture.

NOTE: There is no need

to turn the unit

on. The On/Off

Stop Control is in

the ON ( I )

position at all

times (Fig. 2).

3.

Fully press and release

the primer bulb 10 times,

slowly. Some amount of

fuel should be visible in

the primer bulb and fuel

lines (Fig. 3). If you can’t

see fuel in the bulb,

press and release the

bulb as many times as it

takes until you can see

fuel in it.

4.

Crouch in the starting

position (Fig. 4). Do not

squeeze the throttle,

and pull the starter rope

with a controlled and

steady motion until the

unit starts. Wait 10 to

15 seconds, then

squeeze the throttle to

control the cutting

speed.

NOTE:

The unit uses the

INCREDI-PULL™ starting system, which significantly

reduces the effort required to start the engine. You must pull

the starter rope out far enough to hear the engine attempt to

start. There is no need to pull the rope briskly-- there is no

harsh resistance when pulling. Be aware that this starting

method is vastly different from (and much easier than) what

you may be used to.

IF... The engine does not start, go back to step 3.

NOTE: If the unit is hot and fails to start within 3 pulls of the

starter rope, squeeze the throttle control and pull the

starter rope until the unit starts.

STOPPING INSTRUCTIONS

1. Release your hand from the throttle control. Allow the

engine to cool down by idling.

2. Press and hold On/Off Stop Control in the OFF (O) position

until engine comes to a complete stop (Fig. 2).

5

CAUTION:

For proper engine operation and maximum

reliability, pay strict attention to the oil and fuel mixing

instructions on the 2-cycle oil container. Using improperly

mixed fuel can severely damage the engine.

WARNING:

Gasoline is extremely flammable. Ignited

vapors may explode. Always stop the engine and allow it

to cool before filling the fuel tank. Do not smoke while

filling the tank. Keep sparks and open flames at a distance

from the area.

WARNING:

Remove fuel cap slowly to avoid injury from

fuel spray. Never operate the unit without the fuel cap

securely in place.

WARNING:

Add fuel in a clean, well ventilated outdoor

area. Wipe up any spilled fuel immediately. Avoid creating

a source of ignition for spilt fuel. Do not start the engine

until fuel vapors dissipate.

WARNING:

Operate this unit only in a well-ventilated

outdoor area. Carbon monoxide exhaust fumes can be

lethal in a confined area.

WARNING:

Avoid accidental starting. Make sure you are

in the starting position when pulling the starter rope (Fig. 5).

To avoid serious injury, the operator and unit must be

in a stable position while starting.

Start/On ( I )

Stop/Off (O)

Throttle Control

Fig. 2

Starting

Position

Throttle Control

Fig. 4

Primer Bulb

Fig. 3

Page 6

6

OPERATING INSTRUCTIONS

OPERATING THE CONVERTIBLE™ COUPLER SYSTEM

The Convertible™ coupler system enables the use of these optional

attaachments.

• Edger

• Cultivator

• Turbo Blower

• Brushcutter

• Pole Saw

• Blade Pruner

• Hedge Trimmer

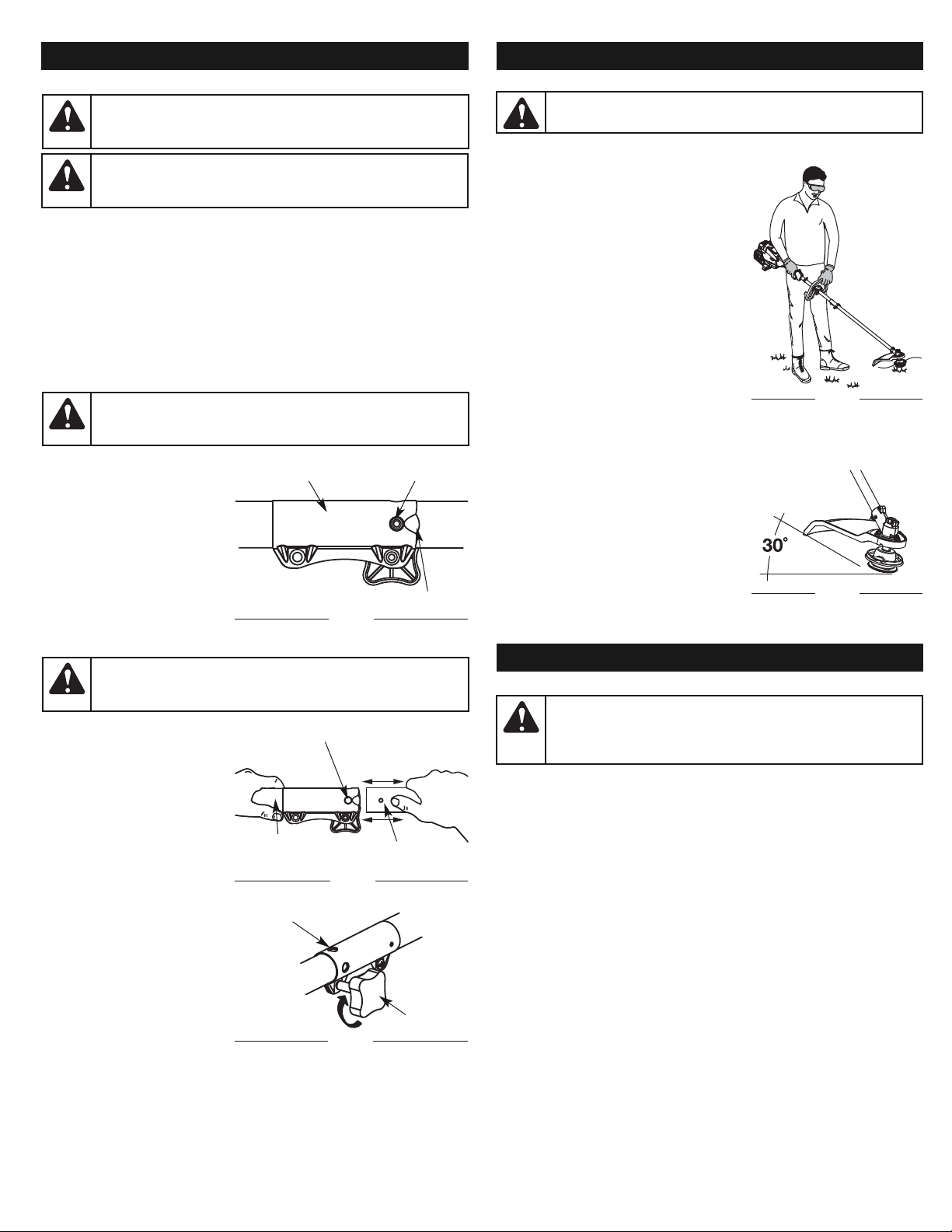

REMOVING THE TRIMMER ATTACHMENT OR OTHER ATTACHMENT

1. Turn the knob

counterclockwise to

loosen (Fig. 7).

2. Press and hold the

release button (Fig. 5).

3. While firmly holding the

upper shaft housing, pull

the trimmer attachment or

other attachment straight

out of the Convertible™

coupler (Fig. 6).

REMOVING THE TRIMMER

ATTACHMENT OR OTHER ATTACHMENT

NOTE: To make installing or

removing the

attachment easier,

place the unit on the

ground or on a work

bench.

1. Turn knob

counterclockwise to

loosen (Fig. 7).

2. While firmly holding the

trimmer attachment or

other attachment, push it

straight into the

Convertible™ coupler

until the release button

snaps firmly into the

primary hole (Fig. 6).

NOTE: Aligning the release

button with the guide

recess will help

installation (Fig. 5).

3. Turn the knob clockwise to tighten (Fig. 7).

For decorative edging with the line head trimmer attachment or

other attachment, lock the release button of the attachment into the

90° hole (Fig. 7).

HOLDING THE TRIMMER

Before operating the unit, stand in the operating position (Fig. 8).

Check for the following:

• The operator is wearing eye

protection and proper clothing

• With a slightly-bent right arm, the

operator’s hand is holding the shaft grip

• The operator’s left arm is slightly bent,

the left hand holding the D-handle

• The unit is at waist level

• The trimmer attachment is parallel to

the ground and easily contacts the

grass without the need to bend over

TIPS FOR BEST TRIMMING RESULTS

• Keep the trimmer attachment parallel

to the ground.

•

Cut from left to right whenever possible.

Cutting to the right improves the unit's

cutting efficiency. Clippings are thrown away from the operator.

• Trim only when grass and weeds are dry.

• The life of your cutting line is dependent upon:

- Following the trimming tips

- What vegetation is being cut

- Where vegetation is being cut

DECORATIVE TRIMMING

Decorative trimming is accomplished by

removing all vegetation around trees,

posts, fences and more. Rotate the

whole unit so that the trimmer

attachment is at a 30° angle to the ground (Fig. 9).

WARNING:

Always wear eye, hearing, foot and body

protection to reduce the risk of injury when operating this unit.

WARNING:

Before you begin using any attachment, read

and understand the manual that came with the attachment.

Follow all safety information contained within.

CAUTION:

Before operating this unit, be sure that the

release button is fully snapped into the primary hole (Fig. 12),

and that the knob (Fig. 13) is securely tightened.

WARNING:

To avoid serious personal injury and

damage to the unit, shut the unit off before removing or

installing all attachments.

CAUTION:

These attachments are to be snapped into

the primary hole only. Using the wrong hole could lead to

personal injury or damage to the unit.

Release Button

Convertible™

Coupler

Guide Recess

Fig. 5

90˚ Edging Hole

(Trimmer Only)

Knob

Fig. 7

Primary Hole

Lower Shaft

Housing

Fig. 6

Upper Shaft

Housing

Fig. 8

Fig. 9

MAINTENANCE SCHEDULE

Perform these required maintenance procedures at the frequency

stated in the table. These procedures should also be a part of any

seasonal tune-up.

NOTE:

Some maintenance procedures may require special tools or

skills. If you are unsure about these procedures take your unit to

Sears or other qualified service dealer. Call 1-800-4-MY-HOME

®

for more information.

NOTE: Maintenance, replacement, or repair of the emission

control devices and system may be performed by a Sears

or other qualified service dealer. Call 1-800-4-MY-HOME

®

for more information.

In order to assure peak performance of your engine, inspection of the

engine exhaust port may be necessary after 50 hours of operation. If

you notice lost RPM, poor performance or general lack of acceleration,

this service may be required. If you feel your engine is in need of this

inspection, refer service to a Sears or other qualified service dealer.

Call 1-800-4-MY-HOME

®

for more information. DO NOT attempt to

perform this process yourself as engine damage may result from

contaminants involved in the cleaning process for the port.

WARNING:

To prevent serious injury, never perform

maintenance or repairs with unit running. Always service

and repair a cool unit. Disconnect the spark plug wire to

ensure that the unit cannot start.

OPERATING INSTRUCTIONS

MAINTENANCE & REPAIR INSTRUCTIONS

Page 7

7

AIR FILTER MAINTENANCE

The condition of the air filter is important

to the operation of the unit. A dirty air

filter will restrict air flow and change the

air/fuel mixture. This is often mistaken

for an out of adjustment carburetor.

Check the condition of the air filter

before adjusting the idle speed screw.

Refer to Air Filter Maintenance.

Removing the Air Filter/Muffler

Cover

1. Remove the four (4) screws

securing the air filter/ muffler

cover (Fig. 14). Use a flat blade

or T20 Torx bit screwdriver.

2. Pull the cover from the

engine. Do not force.

Cleaning the Air Filter

Failure to maintain your air

filter properly can result in

poor performance or can

cause permanent damage to

your engine.

1. Remove air filter/muffler

cover. Refer to Removing

the Air Filter/Muffler

Cover above.

2.

Turn cover over and look

inside to locate the air filter.

Remove the air filter from

inside the air filter/muffler

cover (Fig. 15).

3. Wash the filter in detergent

and water (Fig. 16). Rinse

the filter thoroughly.

Squeeze out excess water.

Allow it to dry completely.

4. Apply enough clean SAE

30 oil to lightly coat the

filter (Fig. 17).

5. Squeeze the filter to

spread and remove

excess oil (Fig. 18).

6. Replace the air filter

inside the air filter/muffler

cover (Fig. 15).

NOTE: Operating the unit

without the air filter

and air filter/muffler

cover assembly will

VOID the warranty.

Reinstalling the Air

Filter/Muffler Cover

1. Place the air filter/muffler

cover over the back of the

carburetor and muffler.

Align the screw holes.

2. Insert the four (4) screws

into the holes in the air

filter/muffler cover (Fig.

14) and tighten. Do not

over tighten.

MAINTENANCE & REPAIR INSTRUCTIONS

WARNING:

To avoid

serious personal injury,

always turn your unit off

and allow it to cool before

you clean or service it.

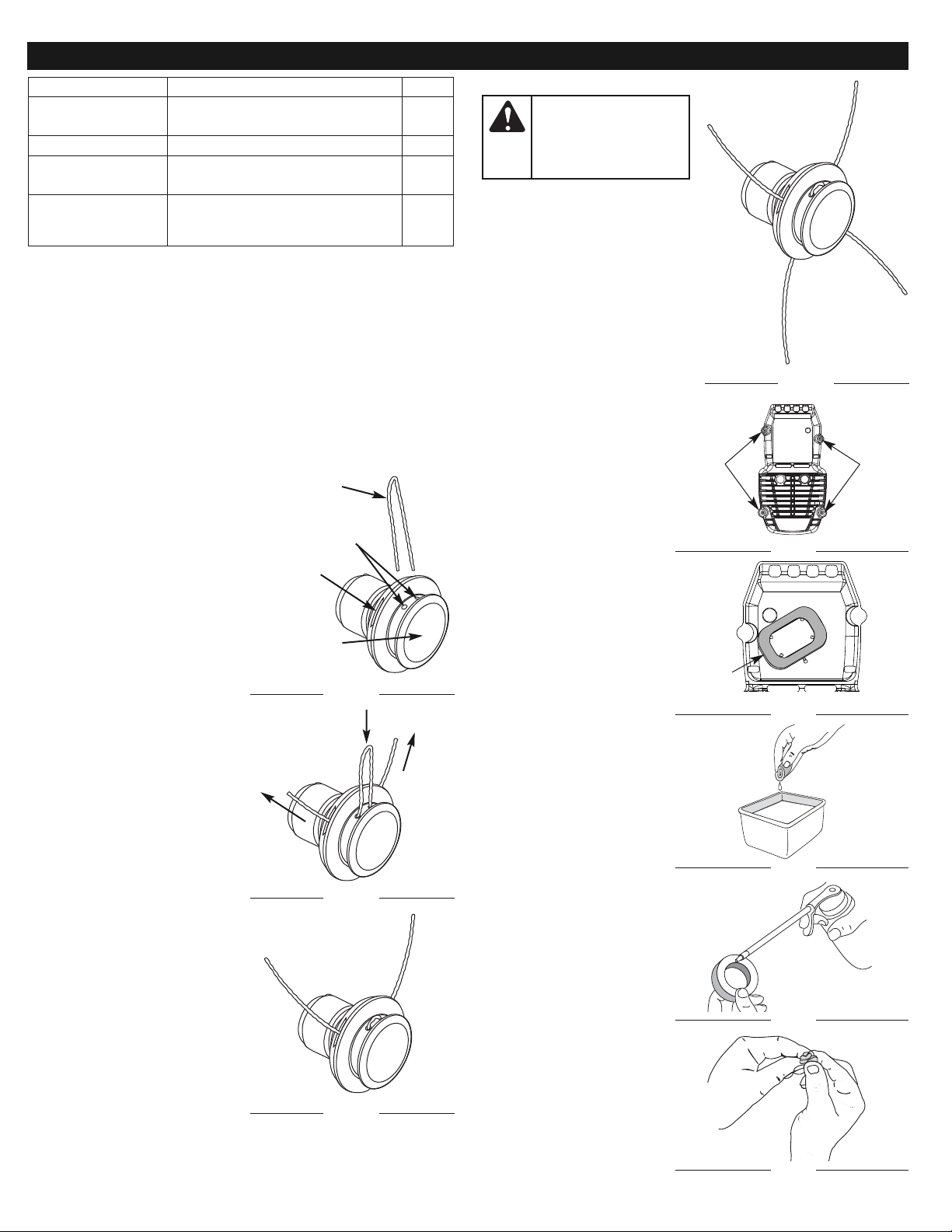

LINE REPLACEMENT

for Hassle-Free™ Plus Cutting Head

Always use Craftsman Hassle-Free™ XTRA QUIET Spiral Line.

Choose the line size best suited for the job at hand. Red colored line

is designed for cutting grass and small weeds. Black colored line is

designed for cutting larger weeds and light brush.

NOTE: Before inserting new line into the holes in the cutting head,

identify the proper holes. Follow directions as shown on the

glide plate. Do Not attempt to remove the cutting head from

the unit when replacing line.

NOTE: Do not mix lines. Use 2 black or 2 red only.

1. Remove the old line and line glide plate from the cutting head.

2. Clean entire surface of cutting head.

3. Reinstall line glide plate (Fig. 10).

The glide plate is a keyed item

and will only fit one way. If it does

not go into the cutting head

smoothly, DO NOT force it.

Rotate the glide plate until it

slides into the cutting head easily.

NOTE: The glide plate must be

installed in the cutting head

before inserting new line.

4. Insert both ends of your line

through the insertion holes in the

side of the cutting head (Fig. 10).

5.

Push and/or pull the line so that

the line is snug against the hub

and is fully extended through the

positioning tunnels (Fig. 11).

6. Correctly installed line will be

the same length on both sides

(Fig. 12).

NOTE: Make sure that when

installing new line, that the

line is as close to even as

possible. Any variation in

lengths may cause the unit

to vibrate excessively. If this

happens, stop the unit and

make sure the line is even.

7. Repeat steps 4 thru 6 to install

the second trimmer line.

8. Correctly installed, the four

lines will all be the same

length (Fig. 13).

Some line breakage will occur from:

• Entanglement with foreign matter

• Normal line fatigue

• Attempting to cut thick, stalky

weeds

• Forcing the line into objects

such as walls or fence posts

NOTE: During normal use the

trimming line may become worn unevenly which may cause

excessive vibrations in the unit. If this becomes

uncomfortable or uncontrollable, stop the unit and replace

the line. Refer to the Line Replacement instructions above.

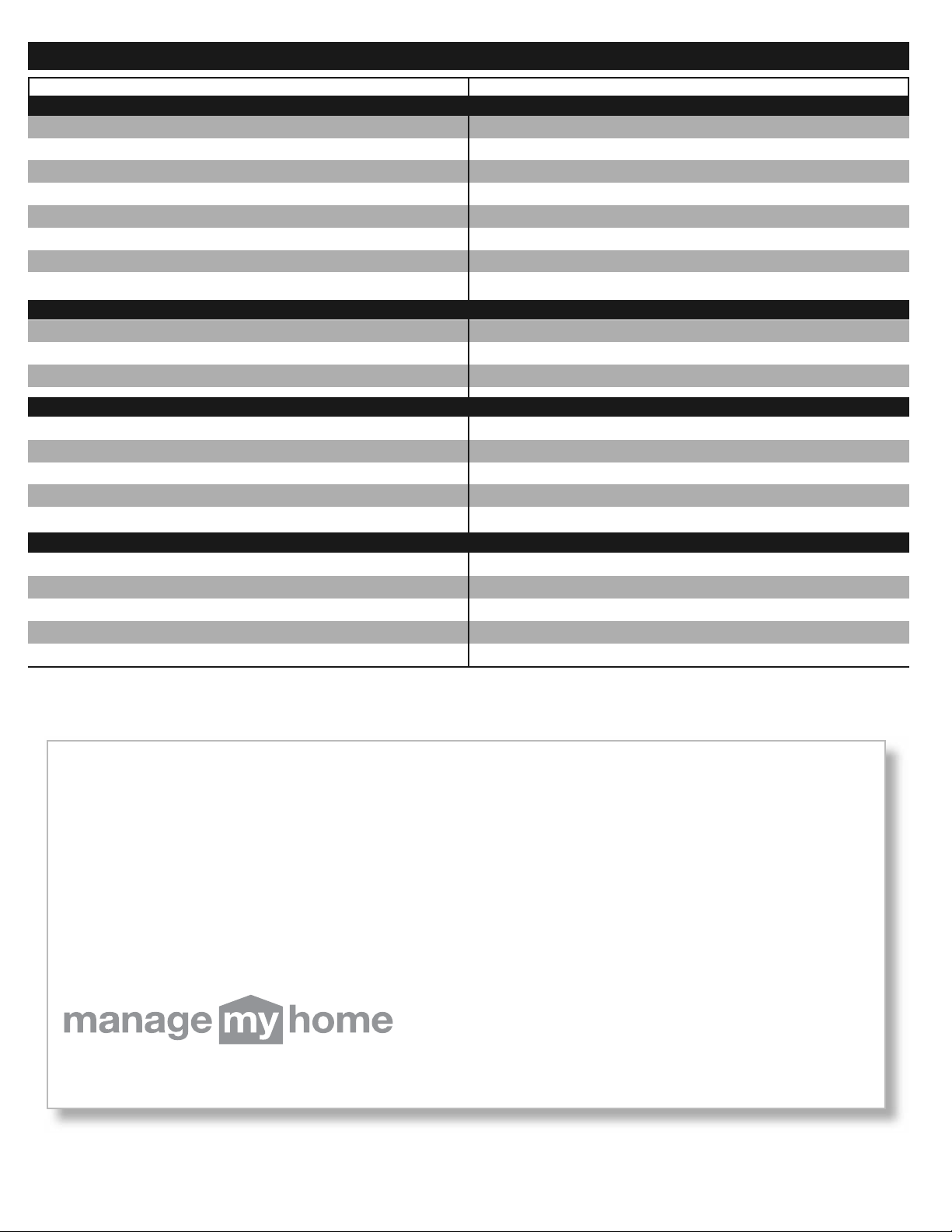

FREQUENCY MAINTENANCE REQUIRED SEE

Before starting

engine

Fill fuel tank with fresh fuel p. 5

Every 10 hours Clean and re-oil air filter p. 7

Every 25 hours Check and clean spark arrestor

Check spark plug condition and gap

p. 8

p. 8

Every 50 hours Inspect exhaust port and spark

arrestor screen for clogging or

obstruction

p. 8

Screws

Fig. 14

Screws

Air Filter

Fig. 15

Fig. 16

Fig. 17

Fig. 18

Inside Muffler C over

Positioning

Tunnel

Trimming

Line

Fig. 10

Insertion

Holes

Glide Plate

Fig. 11

Fig. 12

Fig. 13

Page 8

TRANSPORTING

• Allow the engine to cool before transporting.

• Drain fuel from unit.

• Tighten fuel cap before transporting.

• Secure the unit while transporting.

CLEANING

Use a small brush to clean off the outside of the unit. Do not use strong

detergents. Household cleaners that contain aromatic oils such as pine

and lemon, and solvents such as kerosene, can damage plastic housing

or handle. Wipe off any moisture with a soft cloth.

STORAGE

•

Never store a fueled unit where fumes may reach an open flame or spark.

• Allow the engine to cool before storing.

• Store the unit locked up to prevent unauthorized use or damage.

• Store the unit in a dry, well-ventilated area.

• Store the unit out of the reach of children.

LONG TERM STORAGE

If you plan on storing the unit for an extended time, use the

following storage procedure:

1. Carefully drain the fuel tank by running the unit dry or remove

fuel cap and tip the motor housing over and drain oil/gas fuel

into a container with the same 2-cycle fuel mixture. Do not use

fuel that has been stored for more than 60 days.

2. Start the engine and allow it to run until it stalls. This ensures

that all fuel has been drained from the carburetor.

3. Allow the engine to cool. Remove the spark plug and put 1 oz.

(30 ml) of any high quality motor oil or 2-cycle oil into the

cylinder. Pull the starter rope slowly to distribute the oil.

Reinstall the spark plug.

NOTE: Remove the spark plug and drain all of the oil from the

cylinder before attempting to start the trimmer after storage.

4. Thoroughly clean the unit and inspect it for any loose or

damaged parts. Repair or replace damaged parts and tighten

loose screws, nuts or bolts. The unit is ready for storage.

8

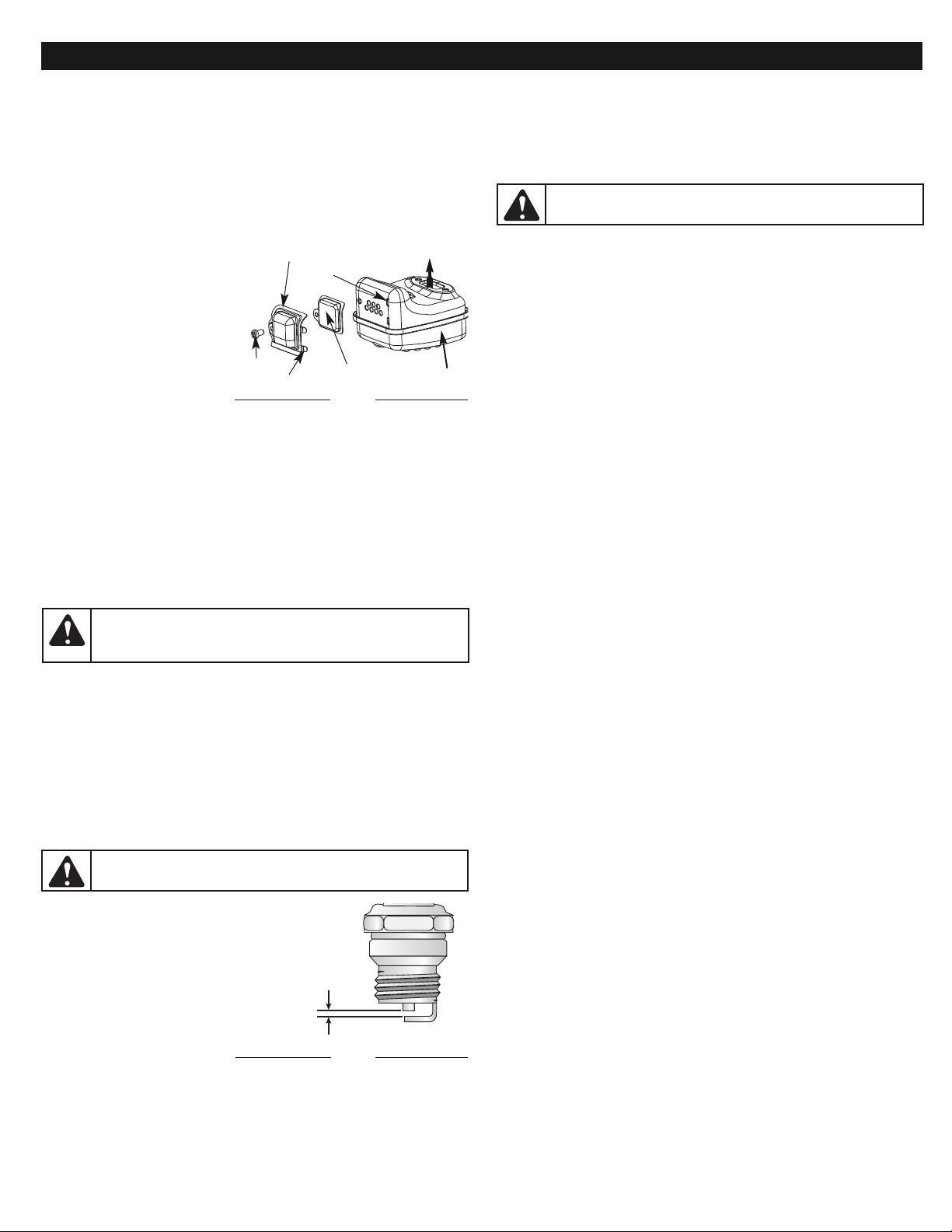

SPARK ARRESTOR MAINTENANCE

NOTE: Pay close attention when disassembling the muffler so you

can put it back together correctly. Failure to do so will

damage the unit and may cause serious personal injury.

1. Remove air filter/muffler cover. Refer to Removing the Air

Filter/Muffler Cover.

2.

Locate the muffler, but do not remove it. Find the screw on the

bottom of the muffler (Fig. 19). This screw holds the Spark Arrestor

Hood Assembly and the spark arrestor screen to the bottom of the

muffler. Remove this screw using either a Torx T20 or flat blade

screwdriver.

3. Using a small flat blade

screwdriver, carefully pry

up the spark arrestor

screen from the recessed

hole, taking care to notice

that the “raised” part of

the spark arrestor screen

is inside the recessed hole.

Remove the spark arrestor

screen from the muffler.

4. Clean the spark arrestor screen with a wire brush. Replace it if it

is damaged, or if you are unable to clean it thoroughly.

5. Reinstall the spark arrestor screen by putting the “raised”

portion of the screen inside the recessed hole of the muffler.

Make sure that the spark arrestor screen fits flat against the

muffler.

6. Place the spark arrestor hood on top of the spark arrestor plate

with the “raised” side up and the opening facing AWAY from the

engine (Fig. 18). Verify that the exhaust will be directed AWAY

from the engine.

7. Replace the screw you removed in Step 2 and tighten securely.

8. Reinstall the air filter/muffler cover (Fig. 13).

CARBURETOR ADJUSTMENT

NOTE: Careless adjustments can seriously damage your unit. Contact

a Sears or other qualified service dealer to make carburetor

adjustments. Call 1-800-4-MY-HOME

®

for more information.

REPLACING THE SPARK PLUG

Use a Champion RDJ7Y spark plug or equivalent. Remove the plug

after every 25 hours of operation and check its condition.

1. Stop the engine and allow it to cool. Grasp the plug boot firmly

and pull it from the spark plug.

2. Clean around the spark plug. Remove the spark plug from the

cylinder head by turning a 5/8-inch socket counterclockwise.

3. Replace a cracked, fouled

or dirty spark plug. Set

the air gap at 0.025 in.

(0.635 mm) using a feeler

gauge (Fig. 20).

4.

Install a correctly-gapped

spark plug in the cylinder

head. Tighten by turning the

5/8-inch socket clockwise

until snug. If using a torque

wrench, torque to:

110-120 in.•lb. (12.3-13.5 N•m). Do not over-tighten.

5. Reattach the plug boot.

MAINTENANCE & REPAIR INSTRUCTIONS

Screws

Fig. 19

Ta bs

Spark Arrestor Hood

0.025 in.

(0.635 mm)

Fig. 20

WARNING:

If the spark arrestor hood and spark arrestor

screen are not tightened securely, they could fall off causing

damage to the unit and possible serious personal injury.

WARNING:

Do not sand blast, scrape or clean spark plug

electrodes. Grit in the engine could damage the cylinder.

WARNING:

To avoid serious personal injury, always turn your

trimmer off and allow it to cool before you clean or maintain it.

Spark Arrestor

Screen

Muffler

Engine

Slots

Page 9

Empty fuel tank Fill fuel tank with properly mixed fuel

Primer bulb wasn't pressed enough Press primer bulb fully and slowly 10 times

Engine is flooded Pull the starter rope while holding the throttle control

Old or improperly mixed fuel Drain gas tank and add fresh fuel mixture

Fouled spark plug Replace the spark plug

Plugged spark arrestor Clean or replace spark arrestor

The outside temperature is below 40º F Pull the starter rope up to 10-15 times

The outside temperature is above 90º F Pull the starter rope up to 10-15 times

TROUBLESHOOTING

Old or improperly mixed fuel Drain gas tank and add fresh fuel mixture

Improper carburetor adjustment Take to a Sears authorized service dealer for an adjustment

Cutting attachment bound with grass Stop the engine and clean the cutting attachment

Dirty air filter Clean or replace the air filter

Plugged spark arrestor Clean or replace spark arrestor

PROBLEM SOLUTION

Air filter is plugged Replace or clean the air filter

Old or improperly mixed fuel Drain gas tank and add fresh fuel mixture

Improper carburetor adjustment Take to a Sears authorized service dealer for an adjustment

Old or improperly mixed fuel Drain gas tank and add fresh fuel mixture

Improper carburetor adjustment Take to a Sears authorized service dealer for an adjustment

Air filter is plugged Replace or clean air filter

Fouled spark plug Replace the spark plug

Plugged spark arrestor Clean or replace spark arrestor

ENGINE WILL NOT START

ENGINE WILL NOT IDLE

ENGINE WILL NOT ACCELERATE

ENGINE LACKS POWER OR STALLS WHEN CUTTING

NEED MORE HELP?

You’ll find the answer and more on managemyhome.com – for free!

I

Find this and all your other product manuals online.

I

Get answers from our team of home experts.

I

Get a personalized maintenance plan for your home.

I

Find information and tools to help with home projects.

brought to you by Sears

9

Page 10

10

SPECIFICATIONS

* All specifications are based on the latest product information available at the time of printing. We reserve the right to make changes at

any time without notice.

ENGINE*

Engine Type ............................................................................................................................................................................Air-Cooled, 2 Cycle

Displacement ........................................................................................................................................................................... 32 cc (1.95 cu in.)

Idle Speed RPM...................................................................................................................................................................... 2,600 - 3,600 rpm

Operating RPM ................................................................................................................................................................................. 6,800+ rpm

Ignition Type............................................................................................................................................................................. Electronic Ignition

Ignition Switch.............................................................................................................................................................................. Rocker Switch

Spark Plug Gap................................................................................................................................................................... 0.025 in. (0.635 mm)

Spark Plug...................................................................................................................................................Champion RDJ7Y or equivalent plug

Lubrication .................................................................................................................................................................................. Fuel/Oil Mixture

Fuel/Oil Ratio ................................................................................................................................................................................................. 40:1

Carburetor ...................................................................................................................................................................... Diaphragm, All-Position

Starter.......................................................................................................................................................... Incredi-Pull™ Starting Auto Rewind

Muffler..................................................................................................................................................................................... Baffled with Guard

Throttle .............................................................................................................................................................................. Manual Spring Return

Fuel Tank Capacity....................................................................................................................................................................... 13 oz. (384 ml)

Drive Shaft Housing ................................................................................................................................ Steel Tube (Craftsman Convertible™)

Throttle Control ....................................................................................................................................................................... Finger-Tip Trigger

Approximate Unit Weight (No fuel, with Hassle Free

®

, shield, and D-handle) ................................................................................ 14 lbs. (6 kg)

Cutting Mechanism ..................................................................................................................................................... Hassle Free™ Plus Head

Trimming Line ........................................................................................................................................ Hassle Free™ XTRA QUIET Spiral Line

DRIVE SHAFT & CUTTING ATTACHMENT*

REPAIR PROTECTION AGREEMENTS

Congratulations on making a smart purchase. Your new Craftsman® product is designed and manufactured for years of dependable

operation. But like all products, it may require repair from time to time. That’s when having a Repair Protection Agreement can save you

money and aggravation.

Here is what the Repair Protection Plan Agreement includes:

Expert service by our 10,000 professional repair specialists

Unlimited service and no charge for parts and labor on all covered repairs

Product replacement up to $1500 if your cover product can not be fixed

Discount of 10% from regular price of service and related installed parts not covered by the agreement; also, 10% off regular price of

preventive maintenance checks

Fast help by phone – we call it Rapid Resolution - phone support from a Sears representative. Think of us as a “talking owner’s maunal.”

Once you purchase the Repair Protection Agreement, a simple phone call is all that it takes for you to schedule service. You can call anytime

day or night, or schedule a service appointment online.

The Repair Protection Agreement is a risk-free purchase. If you cancel for any reason during the product warranty period, we will provide a full refund.

Or a prorated refund anytime after the prodduct warranty period expires. Purchase you Repair Protection Agrrement today!

Some limitations and exclusions apply. For prices and additional information call 1-800-827-6655.

*Coverage in Canada varies on some items. For full datails call Sears Canada at 1-800-361-6665.

Sears Installation Service

For Sears professional installation of home appliances, garage door openers, water heaters, and other major home items, in the U.S.A. or

Canada call 1-800-4-MY-HOME

®

.

Page 11

11

CALIFORNIA / EPA EMISSION CONTROL WARRANTY STATEMENT

Your Warranty Rights and Obligations

The California Air Resources Board, the Environmental Protection Agency, and Sears, Roebuck and Co. ( Sears) are pleased to explain the emission

control system warranty on your 2007 and later small off-road engine. In California and the 49 states, new small off-road engines must be designed,

built and equipped to meet the state’s stringent anti-smog standards. Sears must warrant the emission control system on your small off-road engine

for the periods of time listed below provided there has been no abuse, neglect or improper maintenance of your small off-road engine.

Your emission control system may include parts such as the carburetor or fuel-injection system, the ignition system, and catalytic converter. Also

included may be hoses, belts, connectors and other emission-related assemblies.

Where a warrantable condition exists, Sears will repair your small off-road engine at no cost to you including diagnosis, parts and labor.

The 2007 and later small off-road engines are warranted for two years. If any emission-related part on your engine is defective, the part will be repaired

or replaced by Sears.

Owners Warranty Responsibilities

As the small off-road engine owner, you are responsible for the performance of the required maintenance listed in your operator’s manual. Sears

recommends that you retain all receipts covering maintenance on your small off-road engine, but Sears cannot deny warranty solely for the lack

of receipts or for your failure to ensure the performance of all scheduled maintenance.

• As the small off-road engine owner, you should however be aware that Sears may deny you warranty coverage if your small off-road engine

or a part has failed due to abuse, neglect, improper maintenance or unapproved modifications.

• You are responsible for presenting your small off-road engine to a Sears Authorized Service Center as soon as a problem exists. The

warranty repairs should be completed in a reasonable amount of time, not to exceed 30 days.

If you have any questions regarding your warranty rights and responsibilities, you should call 1-800-4-MY-HOME

®

.

Manufacturer’s Warranty Coverage

• The warranty period begins on the date the engine or equipment is delivered to the retail purchaser.

• The manufacturer warrants to the initial owner and each subsequent purchaser, that the engine is free from defects in material and

workmanship which cause the failure of a warranted part for a period of two years.

• Repair or replacement of warranted part will be performed at no charge to the owner at an Authorized Sears Service Center. For the nearest

location please contact Sears at: 1-800-4-MY-HOME

®

.

• Any warranted part which is not scheduled for replacement, as required maintenance or which is scheduled for only for regular inspection

to the effect of “Repair or Replace as Necessary” is warranted for the warranty period. Any warranted part which is scheduled for

replacement as required maintenance will be warranted for the period of time up to the first scheduled replacement point for that part.

• The owner will not be charged for diagnostic labor which leads to the determination that a warranted part is defective, if the diagnostic work

is performed at an Authorized Sears Service Center.

• The manufacturer is liable for damages to other engine components caused by the failure of a warranted part still under warranty.

• Failures caused by abuse, neglect or improper maintenance are not covered under warranty.

• The use of add-on or modified parts can be grounds for disallowing a warranty claim. The manufacturer is not liable to cover failures of

warranted parts caused by the use of add-on or modified parts.

• In order to file a claim, go to your nearest Authorized Sears Service Center. Warranty services or repairs will be provided at all Authorized

Sears Service Centers.

• Any manufacturer approved replacement part may be used in the performance of any warranty maintenance or repair of emission related

parts and will be provided without charge to the owner. Any replacement part that is equivalent in performance or durability may be used

in non-warranty maintenance or repair and will not reduce the warranty obligations of the manufacturer.

Emission Warranty Parts List:

The following components are included in the emission-related warranty of the engine: air filter, carburetor, primer, fuel lines, fuel pick up/ fuel

filter, ignition module, spark plug, and muffler. Valves and Cam are additionally included if your engine is a 4-Stroke Model.

CALIFORNIA EVAPORATIVE EMISSION CONTROL WARRANTY STATEMENT

Your Warranty Rights and Obligations

The California Air Resources Board and Sears, Roebuck and Co. ( Sears) is pleased to explain the evaporative emission control system’s warranty

on your 2007 model year and later small off-road (equipment type) engine. In California, new equipment that use small off-engines must be designed,

built, and equipped to meet the State’s stringent anti-smog standards Sears must warrant the evaporative emission control system on your small

off-road Lawn & Garden engine for the period listed below provided there has been no abuse, neglect or improper maintenance of your equipment.

Your evaporative emission control system may include parts such as: carburetors, fuel tanks, fuel lines, fuel caps, valves, canisters, filters, vapor

hoses, clamps, connectors, and other associated components. For engines less than or equal to 80 cc, only the fuel tank is subject to the

evaporative emission control warranty requirements of this section. The displacement of your small off road engine is less than 80 cc.

Manufacturer’s Warranty Coverage

This evaporative emission control system is warranted for two years. If any evaporative emission-related part on your equipment is defective,

the part will be repaired or replaced by Sears.

Owner’s Warranty Responsibilities

• As the small off-road Lawn & Garden engine owner, you are responsible for performance of the required maintenance listed in your owner’s

manual. Sears recommends that you retain all receipts covering maintenance on your Lawn & Garden Engine but Sears cannot deny

warranty solely for the lack of receipts.

• As the small off-road Lawn & Garden engine owner, you should however be aware that the Sears may deny you warranty coverage if your

fuel tank has failed due to abuse, neglect, or improper maintenance or unapproved modifications.

• You are responsible for presenting your Lawn & Garden fuel tank to Sears distribution center or service center as soon as the problem exists.

The warranty repairs should be completed in a reasonable amount of time, not to exceed 30 days. If you have a question regarding your

warranty coverage, you should contact Sears at 1-800-4-MY-HOME

®

.

Page 12

12

Defects Warranty Requirements

(a) The warranty period begins on the date the engine or equipment is delivered to an ultimate purchaser.

(b) General Evaporative Emissions Warranty Coverage. The fuel tank must be warranted to the ultimate purchaser and any subsequent owner

that the evaporative emission control system when installed was:

(1) Designed, built, and equipped so as to conform with all applicable regulations; and

(2) Free from defects in materials and workmanship that causes the failure of a warranted part for a period of two years.

(c) The warranty on evaporative emissions-related parts will be interpreted as follows:

(1) Any warranted part that is not scheduled for replacement as required maintenance in the written instructions must be warranted for the

warranty period defined in subsection (b)(2). If any such part fails during the period of warranty coverage, it must be repaired or replaced

by Sears. Any such part repaired or replaced under the warranty must be warranted for a time not less than the remaining warranty

period.

(2) Any warranted part that is scheduled only for regular inspection in the written instructions must be warranted for the warranty period defined in

subsection (b)(2). A statement in such written instructions to the effect of “repair or replace as necessary” will not reduce the period of warranty

coverage. Any such part repaired or replaced under warranty must be warranted for a time not less than the remaining warranty period.

(3) Any warranted part that is scheduled for replacement as required maintenance in the written instructions must be warranted for the

period of time prior to the first scheduled replacement point for that part. If the part fails prior to the first scheduled replacement, the

part must be repaired or replaced by the Sears. Any such part repaired or replaced under warranty must be warranted for a time not less

than the remainder of the period prior to the first scheduled replacement point for the part.

(4) Repair or replacement of any warranted part under the warranty provisions of this article must be performed at no charge to the owner

at a warranty station.

(5) Not withstanding the provisions of subsection (4) above, warranty services or repairs must be provided at distribution centers that are

franchised to service the subject engines or equipment.

(6) The owner must not be charged for diagnostic labor that leads to the determination that a warranted part is in fact defective, provided

that such diagnostic work is performed at a warranty station.

(7) Throughout the evaporative emission control system’s warranty period set out in subsection (b)(2), Sears must maintain a supply of

warranted parts sufficient to meet the expected demand for such parts.

(8) Manufacturer approved replacement parts must be used in the performance of any warranty maintenance or repairs and must be provided

without charge to the owner. Such use will not reduce the warranty obligations of the manufacturer issuing the warranty.

(9) The use of any add-on or modified parts will be grounds for disallowing a warranty claim made in accordance with this article. The

manufacturer issuing the warranty will not be liable under this Article to warrant failures of warranted parts caused by the use of an addon or modified part.

(10)

Sears shall provide any documents that describe the warranty procedures or policies within five working days of request by the Air Resources Board.

Emission Warranty Parts List

(1) Fuel Tank

Written instructions for the maintenance and use of the evaporative emissions control system by the owner shall be furnished with each new engine or equipment.

Page 13

Sears, Roebuck and Co., Hoffman Estates, IL 60179, U.S.A.

Visite nuestro sitio web: www.sears.com/craftsman

PRECAUCION: Lea el manual

del operador y siga todas las

advertencias e instrucciones

de seguridad.

Manual del Operador

2-Tiempos

WEEDWACKER

®

RECORTADOR A GASOLINA

Modélo No. 316.791900

• SEGURIDAD

• MONTAJE

• FUNCIONAMIENTO

• MANTENIMIENTO

• LISTADO DE PIEZAS

769-03836A 3/08

®

Page 14

E2

• IMPORTANTE INFORMACION DE SEGURIDAD •

LEA TODAS LAS INSTRUCCIONES ANTES DE LA OPERACION

• Lea todas las instrucciones con cuidado. Conozca bien los

controles y el uso correcto de la unidad.

• No opere esta unidad si está cansado, enfermo, o bajo los

efectos del alcohol, drogas o medicamentos.

• Los niños y los adolescentes menores de 15 años no deben operar

las unidades, excepto por los adolescentes guiados por un adulto.

•

Inspeccione la unidad antes de utilizarla. Cambie las partes dañadas.

Verifique si existen pérdidas de combustible. Asegúrese de que los

sujetadores estén bien colocados y asegurados. Cambie las partes

accesorias de corte que estén quebradas, cascadas o dañadas de

cualquier forma. Asegúrese de que el accesorio de corte está bien

instalado y ajustado con firmeza. Asegúrese de que la protección

accesoria de corte esté bien conectada y colocada según se recomienda.

• Use sólo línea despiral Hassle Free™ XTRA QUIET. No use nunca

línea reforzada con metal, alambre, cadena ni soga, etc. Estas

pueden desprenderse y convertirse en un proyectil peligroso.

• Tenga en cuenta el riesgo de lesiones en la cabeza, manos y pies.

• Oprima el control del regulador y verifique que regrese

automáticamente a la posición de mínima. Haga todos los

ajustes o reparaciones antes de usar la unidad.

•

Limpie el área de corte antes de cada uso. Retire todos los objetos como

rocas, vidrios rotos, clavos, alambre o cuerda los cuales pueden ser

despedidos o enredarse en el accesorio de corte. Aleje a todos los niños,

espectadores y animales domésticos. Mantenga todos los niños,

espectadores y animales domésticos a un radio de por lo menos 50 pies

(15 m); aún así puede existir un riesgo de objetos despedidos contra los

espectadores. Los espectadores deben usar protección para sus ojos. Si

alguien se le acerca, pare el motor y el accesorio de corte de inmediato.

• Esta unidad no fue diseñada para ser usada como cortamalezas.

No conecte ni opere esta unidad con ningún tipo de cuchilla ni

accesorio para cortar malezas.

ADVERTENCIAS DE SEGURIDAD A GASOLINA

• Guarde el combustible en envases que hayan sido diseñados y

aprobados para el almacenamiento de dichos materiales.

• Antes de llenar el tanque de combustible, apague siempre el

motor y espere que se enfríe. No retire nunca la tapa del tanque

de combustible ni cargue combustible mientras el motor esté

caliente. No opere nunca la unidad sin la tapa del combustible

colocada firmemente en su lugar. Afloje la tapa del combustible

lentamente para disipar la presión del tanque.

• Mezcle y cargue el combustible en un área exterior bien ventilada

donde no haya chispas ni llamas. Quite lentamente la tapa del

combustible sólo después de apagar el motor. No fume mientras

carga o mezcla el combustible. Limpie de inmediato todo el

combustible que se haya derramado.

• Evite crear una fuente de encendido por combustible derramado.

No arranque el motor hasta que se hayan disipado los vapores

del combustible.

• Aleje la unidad a por lo menos 30 pies (9.1 m.) del lugar de carga

de combustible antes de arrancar el motor. No fume, mantenga

las chispas y las llamas abiertas lejos del área mientras carga el

combustible u opera la unidad.

DURANTE LA OPERACION

•

No arranque ni opere la unidad en una sala o edificio cerrado. Los

gases de escape de monóxido de carbono pueden ser letales en un

área cerrada. Opere esta unidad sólo en un área exterior bien ventilada.

Toda la información, las ilustraciones y las especificaciones contenidas en

este manual se basan en la información más reciente disponible en el

momento de impresión del manual. Nos reservamos el derecho de hacer

cambios en cualquier momento sin aviso previo.

INDICE DE CONTENIDOS

Normas para una operación segura . . . . . . . . . . . . . . . . . . . . . . .E2

Garantía . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E4

Conozca su unidad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E4

Instrucciones de ensamble . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E4

Información del aceite y del combustible . . . . . . . . . . . . . . . . . . .E5

Instrucciones de arranque y apagado . . . . . . . . . . . . . . . . . . . . .E5

Instrucciones de operación . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E6

Instrucciones de mantenimiento y reparación . . . . . . . . . . . . . . .E7

Limpieza y almacenamiento . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E8

Resolución de problemas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E9

Especificaciones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E10

Lista de piezas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E14

Numeros de servicio . . . . . . . . . . . . . . . . . . . . . . . . .Contraportada

NORMAS PARA UNA OPERACION SEGURA

PARACHISPAS

NOTA: Para los usuarios en tierras forestales de los EE.UU. y en los estados

de California, Maine, Oregon y Washington. Todos los terrenos forestales de

los EE.UU. y el estado de California (Códigos de Recursos Públicos 4442 y 4443),

Oregon y Washington, requieren por decreto, que ciertos motores de combustión

interna que se hagan funcionar en zonas boscosas y/o zonas cubiertas por

pastizales, estén equipados con un parachispas, que sean mantenidos en buen

estado de funcionamiento o que el motor sea construido, esté equipado y sea

mantenido para evitar incendios. Consulte los reglamentos pertinentes a esos

requisitos con las autoridades estatales o locales. El incumplimiento de esos

requisitos puede responsabilizarle o someterle a la imposición de una multa. Esta

unidad fue equipada en la fábrica con un parachispas. Si requiere sustitución,

hay una Pantalla Parachispas disponible, Pieza #753-05169 al contactar el

departamento de servicio.

PROPOSICIÓN 65 DE CALIFORNIA

ADVERTENCIA

LAS EMISIONES DEL MOTOR DE ESTE PRODUCTO CONTIENEN

SUBSTANCIAS QUIMICAS QUE EL ESTADO DE CALIFORNIA

CONOCE COMO CAUSANTES DECANCER, DEFECTOS DE

NACIMIENTO U OTROS DAÑOS REPRODUCTIVOS.

Lea el manual del operador y siga todas las advertencias e instrucciones

de seguridad. De no hacerlo, el operador y/o los espectadores pueden

sufrir graves lesiones.

SI TIENE PREGUNTAS, LLAME AL 1-800-659-5917

SIMBOLO SIGNIFICADO

ADVERTENCIA:

El no seguir una advertencia de seguridad

puede conducir a que usted u otras personas sufran lesiones.

Siga siempre las precauciones de seguridad para reducir el

riesgo de incendio, descarga eléctrica y lesiones personales.

PRECAUCIÓN:

El no seguir una advertencia de

seguridad puede conducir a daño patrimonial o a que usted

u otras personas sufran lesiones personales. Siga siempre

las precauciones de seguridad para reducir el riesgo de

incendio, descarga eléctrica y lesiones personales.

Los símbolos de seguridad se utilizan para llamar su atención sobre

posibles peligros. Los símbolos de seguridad y sus explicaciones merecen

toda su atención y comprensión. Los símbolos de seguridad no eliminan

ningún peligro por sí mismos. Las instrucciones o advertencias que ofrecen

no substituyen las medidas adecuadas de prevención de accidentes.

ALERTA DE SEGURIDAD:

Indica peligro, advertencia o

precaución. Debe prestar atención para evitar sufrir graves lesiones

personales. Puede ser utilizado junto con otros símbolos o figuras.

NOTA: Le ofrece información o instrucciones que son esenciales

para la operación o mantenimiento del equipo.

PELIGRO:

El no obedecer una advertencia de seguridad puede

conducir a que usted u otras personas sufran graves lesiones. Siga

siempre las precauciones de seguridad para reducir el riesgo de

incendio, descarga eléctrica y lesiones personales.

ADVERTENCIA:

La gasolina es muy inflamable y sus gases

pueden explotar si se encienden. Tome las siguientes precauciones:

ADVERTENCIA:

Al utilizar la unidad, debe observar las

reglas de seguridad. Lea estas instrucciones antes de operar la

unidad a fin de garantizar la seguridad del operador y cualquier

transeúnte. Guarde estas instrucciones para uso posterior.

Page 15

E3

NORMAS PARA UNA OPERACION SEGURA

• Use lentes o gafas de protección que cumplan con las

normas ANSI Z87.1–1989, y protección para sus oídos/audición

mientras opere esta unidad. Use siempre una máscara facial o

para protegerse contra el polvo si la operación levanta polvo.

• Use pantalones largos y gruesos, botas, guantes y camisa de manga

larga. No use ropa holgada, alhajas, pantalones cortos, sandalias ni

esté descalzo. Sostenga el cabello sobre el nivel de los hombros.

• La protección accesoria de corte debe estar siempre colocada en

su lugar mientras opere la unidad. No opere la unidad con las dos

líneas de corte extendidas, y la línea correcta instalada. No

extienda la línea de corte más allá de la longitud de la protección.

• Esta unidad no tiene embrague. El accesorio de corte continúa

girando cuando el motor está en marcha en vacío. Para evitar

lesiones, haga que un técnico de servicio autorizado ajuste la unidad.

•

Ajuste la manija en D a su tamaño de modo que le brinde el mejor agarre.

• Asegúrese de que el accesorio de corte no está en contacto con

ningún objeto antes de arrancar la unidad.

• Use la unidad únicamente con la luz del día o con buena luz artificial.

• Evite arrancar la unidad accidentalmente. Colóquese en posición

de inicio siempre que tire de la cuerda de arranque. El operador y

la unidad deben estar en una posición estable al comenzar. Lea

las instrucciones de Arranque y Apagado.

• Use la herramienta adecuada. No use esta unidad para ninguna

tarea para la cual no ha sido diseñada.

• No se estire demasiado. Mantenga siempre una posición y

equilibrio adecuados.

• Sostenga siempre la unidad con ambas manos mientras esté en

funcionamiento. Sostenga con firmeza tanto el mango como la

manija auxiliar.

•

Mantenga las manos, la cara y los pies lejos de todas las partes

móviles. No intente tocar ni detener el accesorio de corte mientras gira.

• No toque el motor, el bastidor del engranaje ni el silenciador.

Estas partes se calientan mucho con la operación. Luego de

apagar la unidad, permanecen calientes durante un tiempo breve.

• No opere el motor a una velocidad mayor que la necesaria para

cortar, recortar o recortar los bordes. No haga funcionar el motor

a alta velocidad mientras no está cortando.

• Apague siempre el motor cuando demore el corte o mientras

camina entre zonas de corte.

•

Si golpea o se enreda con algún objeto extraño, apague el motor de

inmediato y verifique si hay daños. Repare todos los daños antes de

volver a intentar operar la unidad. No opere la unidad si tiene piezas

flojas o dañadas.

• Apague el motor para realizar todo el mantenimiento,

reparaciones o cambio del accesorio de corte u otros accesorios.

•

Use sólo piezas y accesorios de repuesto del fabricante del equipo

original para esta unidad. Puede obtenerlos en su proveedor de servicio

autorizado. El uso de piezas y accesorios que no son equipo origina;

puede causar graves lesiones al operador o el daño de su unidad, y la

cancelación de su garantía.

• Mantenga la unidad libre de vegetación y otros materiales.

Pueden alojarse entre el accesorio de corte y la protección.

•

Para reducir el riesgo de incendio, cambie los silenciadores y

amortiguadores de chispas defectuosos, mantenga el motor y el silenciador

libre de pasto, hojas, grasa excesiva o acumulaciones de carbono.

OTRAS ADVERTENCIAS DE SEGURIDAD

•

No guarde nunca la unidad con combustible en el tanque en un edificio

donde los gases puedan llegar a una llama abierta o a una chispa.

• Espere que el motor se enfríe antes de guardar o transportar la

unidad. Asegúrese de que la unidad esté segura al transportarla.

• Guarde la unidad bajo llave en un lugar adecuado y seco para

evitar que sea usada por personas no autorizadas y se dañe,

fuera del alcance de los niños.

•

Nunca moje ni rocíe la unidad con agua ni con ningún otro líquido.

Mantenga las manijas secas, limpias y sin residuos. Limpie la unidad

luego de cada uso, lea las instrucciones de Limpieza y Almacenamiento.

• Guarde estas instrucciones. Consúltelas con frecuencia y

utilícelas para enseñar a otros usuarios. Si le presta esta unidad a

alguien, préstele también estas instrucciones.

CONSERVE ESTAS INSTRUCCIONES

Este manual del operador describe los símbolos y figuras de seguridad e internacionales que pueden aparecer en este producto. Lea el

manual del operador para obtener información completa acerca de la seguridad, ensamble, operación y mantenimiento y reparación.

• SIMBOLOS DE SEGURIDAD E INTERNACIONALES •

SIMBOLO SIGNIFICADO SIMBOLO SIGNIFICADO

• SIMBOLO DE ALERTA DE SEGURIDAD

Indica peligro, advertencia o precaución. Puede ser

utilizado junto con otros símbolos o figuras.

• ADVERTENCIA - LEA EL MANUAL DEL

OPERADOR

Lea el manual del operador y siga todas las advertencias

e instrucciones de seguridad. De no hacerlo, el operador

y/o los espectadores pueden sufrir graves lesiones.

• USE PROTECCION OCULAR Y AUDITIVA

ADVERTENCIA:

Los objetos arrojados por la unidad y

el ruido fuerte pueden causar graves lesiones oculares y

pérdida auditiva. Utilice protección ocular que cumpla con las

normas ANSI

Z87.1–1989

y protección auditiva cuando opere

esta unidad. Use una careta completa cuando la necesite.

• COMBUSTIBLE SIN PLOMO

Use siempre combustible limpio, nuevo y sin plomo.

• CONTROL DE ENCENDIDO Y APAGADO

ENCENDIDO /ARRANQUE /MARCHA

• CONTROL DE ENCENDIDO Y APAGADO

APAGADO o PARADO

• ADVERTENCIA DE CALIENTE

No toque un silenciador ni un cilindro caliente. Puede

quemarse. Estas partes se calientan mucho con el

uso. Luego de apagarse permanecen calientes

durante un corto tiempo.

• MANTENGA ALEJADOS A LOS ESPECTADORES

ADVERTENCIA:

Mantenga a todos los espectadores,

en especial a niños y animales domésticos a por lo menos

50 pies (15 m) del área de corte.

• LOS OBJETOS DESPEDIDOS Y LA CUCHILLA

ROTATIVA PUEDEN CAUSAR GRAVES LESIONES

ADVERTENCIA:

No opere esta unidad si la

protección plástica de línea no está colocada en su lugar.

Manténgase alejado del accesorio de corte giratorio.

• PRIMER BULB

Push primer bulb, fully and slowly, 10 times.

• INDICADOR DE ACEITE

Consulte el manual del operador para obtener información

acerca del tipo correcto de aceite.

• CUCHILLA AFILADA

ADVERTENCIA: La protección del accesorio de

corte contiene una cuchilla afilada. Para prevenir

graves lesiones, no toque la cuchilla.

Page 16

E4

GARANTÍA TOTAL DE CRAFTSMAN

Si este producto de Craftsman Professional falla debido a un defecto en el material o en la mano de obra dentro de un período de tres años

a partir de la fecha de compra, devuélvalo a cualquier tienda o Centro de Servicio de Piezas y Reparaciones Sears u otro establecimiento de

Craftsman en los Estados Unidos para que sea reparado sin costo alguno (o ser reemplazado si resulta imposible repararlo).

Esta garantía se aplica solamente durante 90 días si este producto en algún momento se utiliza para fines comerciales o de alquiler.

Esta garantía abarca SOLAMENTE los defectos en el material o en la mano de obra. Sears NO pagará:

• Los artículos consumibles que se desgasten debido al uso normal dentro del período de garantía.

•

Las reparaciones necesarias debidas a accidente así como por no operar o no mantener el equipo de acuerdo con todas las instrucciones provistas.

• Mantenimiento preventivo, o las reparaciones necesarias debido a mezcla incorrecta de combustible, combustible contaminado o viejo.

Esta garantía le concede a usted derechos legales específicos, y usted pudiera tener otros derechos que varían de un estado a otro.

Sears, Roebuck and Co., Hoffman Estates, IL 60179

GARANTÍA

CONOZCA SU UNIDAD

Tapa del combustible

Manija en D

Mango del

eje

Bastidor del

eje

Manija de la

cuerda de

arranque

Control del regulador

Cubierta del silenciador /

filtro de aire

Bujía de

encendido

Silenciador

Convertible™

acoplador

Control de encendido y apagado

APLICACIONES

Como recortadora;

• Corte de césped y hierbas delgadas

• Recorte de bordes

• Recorte decorativo alrededor de árboles, cercos, etc.

Puede usar otros accesorios con la unidad. Lea la lista de accesorios.

Adaptador de

apoyo

Bombilla del cebador

Cuchilla de

corte de

línea

AJUSTE DE LA MANIJA EN D

1. Using a flathead or T-25 screwdriver,

loosen the 4 screws on the D-handle

enough to loosen it (Fig. 1).

2. Rotate the D-Handle to the upright

position on the front side of the

shaft housing (Fig. 1).

3. Hold the unit in the operating position

(Fig. 8). If necessary, reposition the Dhandle to the location that provides

the best grip.

4. Tighten the 4 screws until the Dhandle is secure.

INSTRUCCIONES DE ENSAMBLE

INSTALACIÓN DEL ACCESORIO RECORTADOR

Antes del uso, la marca la fijación segura de trimmer es instalada

correctamente. Refiérase por favor a Operar el Convertible™

Sistema de Acoplador para la instalación apropiada.

NOTA: Quite la tapa roja o el gancho de la cubierta inferior del eje

antes de ensamblar al acoplador Convertible™

Protector de corte

Cabezal de corte Hassle Free® PLUS

Accesorio de corte

Fig. 1

Page 17

E5

INSTRUCCIONES PARA MEZCLAR EL ACEITE Y EL COMBUSTIBLE

El combustible viejo o mal mezclado son los motivos principales del

mal funcionamiento de la unidad. Asegúrese de usar combustible

nuevo, limpio y sin plomo. Siga las instrucciones en detalle para

mezclar correctamente el aceite y el combustible.

Definición de los combustibles de mezcla

Los combustibles actuales con frecuencia son una mezcla de gasolina y

oxigenantes como por ejemplo etanol, metanol o MTBE (éter). El combustible

mezclado con alcohol absorbe agua. Una cantidad tan pequeña como el 1%

de agua en el combustible puede causar la separación del combustible y el

aceite. Forma ácidos cuando está almacenado. Cuando use combustible

mezclado con alcohol, use combustible nuevo (de menos de 60 días).

Uso de combustibles de mezcla

Si usted opta por usar un combustible de mezcla o si su uso es

inevitable, tome las precauciones recomendadas.

• Use siempre una mezcla fresca de combustible según lo indica

su manual del operador.

•

Agite siempre la mezcla de combustible antes de cargarlo en la unidad.

• Drene el tanque y haga funcionar el motor en seco antes de

guardar la unidad.

Uso de aditivos en el combustible

La botella de aceite de 2 ciclos que vino con su unidad contiene un aditivo

en el combustible que ayudará a inhibir la corrosión y a reducir la formación

de depósitos de goma. Se recomienda que use sólo el aceite de 2 ciclos

con esta unidad. Si es inevitable, use un buen aceite de 2 ciclos elaborado

para motores enfriados por aire junto con un aditivo para el combustible