Craftsman 316380190 Owner’s Manual

Operator’s Manual

2-Cycle

GAS CHAINSAW

Model No. 316.380190

• SAFETY

• ASSEMBLY

CAUTION: Before using this product,

read this manual and follow all its Safety

Rules and Operating Instructions.

Sears Brands Management Corporation, Hoffman Estates, IL 60179 U.S.A.

Visit our website: www.craftsman.com

769-11774 / 00 07/16

• OPERATION

• MAINTENANCE

• ESPAÑOL, P. 31

TABLE OF CONTENTS

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Know Your Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Oil and Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Starting and Stopping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Cleaning and Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Repair Protec

Service Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Back Cover

All information, illustrations and specifications in this manual are based

on the latest product information available at the time of printing.

We reserve the right to make changes at any time without notice.

© Sears Brands, LLC

tion Agre

ements . . . . . . . . . . . . . . . . . . . . . . . . . . .29

The purpose of safety symbols is to attract your attention to

possible dangers. The safety symbols, and their explanations,

deserve your careful attention and understanding. The safety

warnings do not by themselves eliminate any danger. The

instructions or warnings they give are not substitutes for proper

accident prevention measures.

SYMBOL MEANING

DANGER:Signals an EXTREME hazard.

Failure to obey a safety DANGER signal WILL result in

serious injury or death to yourself or to others.

WARNING:Signals a SERIOUS hazard.

Failure to obey a safety WARNING signal CAN result in

serious injury to yourself or to others.

CAUTION:Signals a MODERATE hazard.

Failure to obey a safety CAUTION signal MAY result in

property damage or injury to yourself or to others.

NOTE: Advises you of information or instructions vital to the

operation or maintenance of the equipment.

SAFETY

SPARK ARRESTOR NOTE

NOTE: For users on U.S. Forest Land and in the states of

California, Maine, Oregon and Washington. All U.S. Forest Land

and the state of California (Public Resources Codes 4442 and

4443), Oregon and Washington require, by law that certain internal

combustion engines operated on forest brush and/or grass-covered

areas be equipped with a spark arrestor, maintained in effective

work

maintained for the prevention of fire. Check with your state or local

authorities for regulations pertaining to these requirements. Failure

to follow these requirements could subject you to liability or a fine.

This unit is factory equipped with a spark arrestor. Replacement

requires Muffler Assembly Part #753-08106, installed at a Sears

Parts & Repai

Read the operator’s manual and follow all warnings and safety

instructions. Failure to do so can result in serious injury to the

operator and/or bystanders.

er, or the engine be constructed, equipped and

ing ord

r Service Center.

CALIFORNIA PROPOSITION 65

WARNING:This product contains a chemical

known to the state of California to cause cancer, birth defects

or other reproductive harm.

2

• IMPORTANT SAFETY INSTRUCTIONS •

READ ALL INSTRUCTIONS BEFORE OPERATING

WARNING:When using the unit, all safety rules

must be followed. Please read these instructions before

operating the unit in order to ensure the safety of the

operator and any bystanders. Please keep these

instructions for later use.

• Read the instructions carefully. Be familiar with the controls and

proper use of the unit. Know how to stop the unit and disengage

the controls quickly.

• Do not operate this unit when tired, ill or under the influence of

alcohol, drugs or medication.

• Never allow children to operate the unit. Never allow adults to

operate the unit without proper instruction.

• All g

before operating the unit.

• Inspect the unit before use. Replace damaged parts. Check for

fuel leaks. Make sure all fasteners are in place and secure.

Replace parts that are cracked, chipped, or damaged in any

way. Do not operate the unit with loose or damaged parts.

• Be aware of risk of injury to the head, hands and feet.

• Carefully inspect the ar

rocks, broken glass, nails, wire, string and other objects that

may be thrown or become entangled with the unit.

• Clear the area of children, bystanders and pets; keep them

outside a 50-foot (15 m) radius, at a minimum. Even then, they are

still at risk from thrown objects. Encourage bystanders to wear

eye protection. If you are approached, stop the unit immediately.

•

Squeeze the thro

automatically to the idle position. Make all adjustments or

repairs before using the unit.

s and safety attachments must be installed properly

uard

ea before

ttle control and check that it returns

starting the unit. Remove

SAFETY WARNINGS FOR GAS UNITS

WARNING:Use caution when handling fuel.

Gasoline is highly flammable and its vapors can explode if

ignited. Take the following precautions:

• Store fuel only in containers specifically designed and approved

for the storage of such materials.

• Always stop the engine and allow it to cool before filling the

tank. Never remove the fuel tank cap or add fuel when the

engine is hot. Always loosen the fuel tank cap slowly to relieve

any pressure in the tank before fueling.

• Always mix and add fuel in a clean, well-venti

where there are no sparks or flames. DO NOT smoke.

• Never operate the unit without the fuel cap securely in place.

• Avoid creating a source of ignition for spilled fuel. Wipe up any

spilled fuel from the unit immediately, before starting the unit.

Move the unit at least 30 ft. (9.1 m) from the fueling source and

site before starting the engine. DO NOT smoke.

• Never start or run the uni

Breathing exhaust fumes can kill. Operate this unit only in a well

ventilated outdoor area.

t inside a closed ro

lated outdoor are

om or building.

WHILE OPERATING

• Wear safety glasses or goggles that meet current ANSI Z87.1

standards and are marked as such. Wear ear/hearing protection

when operating this unit. Wear a face mask or dust mask if the

operation is dusty. Use a hard hat or other type of safety helmet.

• Wear safety boots and protective gloves. Wear heavy, snugfitting clothes, including long pants and a long-sleeve shirt. Do

not wear loo

barefoot. Secure hair above shoulder level.

• Make sure the saw chain is not in contact with anything before

starting the unit.

• Use the unit only in daylight or good artificial light.

• Avoid accidental starting. Be in the starting position whenever

pulling the starter rope. The operator and unit must be in a stable

position while starting. Refer to Startin

se the right tool. Only use this tool for its intended purpose: to

• U

cut wood. Do not use the unit for cutting plastic, masonry or

other non-wood building materials. Only use the unit as

described in this manual.

• Keep all body parts away from the saw chain when the unit is

running. Do not touch or try to stop moving parts.

• Do not touch the engine or muffler. These parts get extremely ho

from operation, even after the unit is turned off.

• Do not operate the unit faster than the speed needed to do the job.

Do not run the unit at high speed when not in use.

o not force the unit, especially near the end of a cut. It will do a

• D

better, safer job when used at the intended rate.

• Always turn the engine off when operation is delayed, when

setting the unit down or when carrying the unit from

o another. Make sure all moving parts come to a complete stop.

t

• Carry the unit by the front handle with the muffler positioned

away from the body and the guide bar positioned to the rear.

Cover the guide bar and saw chain with the scabbard when

carrying the unit.

• If you strike or become entangled with a foreign object, stop the

unit immediately and check for damage. Do not operate the uni

efore repairing damage. Do not operate the unit with loose or

b

damaged parts.

• Use only original equipment manufacturer (OEM) replacement

parts and accessories for this unit. These are available from a

Sears or other qualified service dealer. Use of any other parts or

accessories could lead to serious injury to the user, or damage

to the unit, and void the warranty.

• Keep the unit clean. Carefully remov

ebris that could block moving parts.

d

• To reduce fire hazard, replace a faulty muffler and spark arrestor.

Keep the engine and muffler free from grass, leaves, excessive

grease or carbon build up.

• If the unit starts to vibrate abnormally, stop the unit immediately.

Inspect the unit for the cause of the vibration. Vibration is

a

generally an indicator of trouble.

• Keep the work area c

start cutting until the work area is clear and free from

obstructions. Make sure there is secure footing and a planned

retreat path from falling trees or branches.

• Do not cut near electrical cables or power lines. Keep at least 50

feet (15 m) away from all power lines.

• For safer, more effective performance, make sure the guide bar

and chain are properly cle

harpened. Check the guide bar and chain at frequent intervals

s

for proper adjustment.

• When cutting a limb that is under tension, use extreme caution.

When the tension is released, the limb could spring back and

strike the operator, causing severe injury or death.

se clothing, jewelry,

lean. Cluttere

short pants, sandals or go

g and Stopping.

e vegetation and other

d areas invite injuries. Do not

aned, lubricated, tightened and

t

one location

t

3

• Use extreme caution when cutting small-sized brush and

saplings, as slender material may catch the saw chain and be

whipped toward the operator or pull the operator off balance.

• This saw is classified by UL as a Class 1C saw in accordance

with CSA Z62.1-03. It is intended for infrequent use by

homeowners, cottagers and campers, and for general

applications such as clearing, pruning, cutting firewood,

ot intended for prolonged use. If the intended use involves

n

etc. It is

prolonged periods of operation, this may cause circulatory

problems in the user’s hands due to vibration.

• Do not operate the unit in a tree or on a ladder unless

specifically trained to do so.

• Never remove, modify or make inoperative any safety device

furnished with the unit.

• Do not use the unit in the presence of flammable liquid

o not attempt operations beyond the operator’s capacity or

• D

s or gases.

experience.

• Do not operate a unit that is damaged, improperly adjusted or

not completely and securely assembled. Make sure moving

parts stop when the unit is turned off. Do not use the unit if it

does not turn on and off properly. Have defective parts replaced

by a Sears or other qualified service dealer.

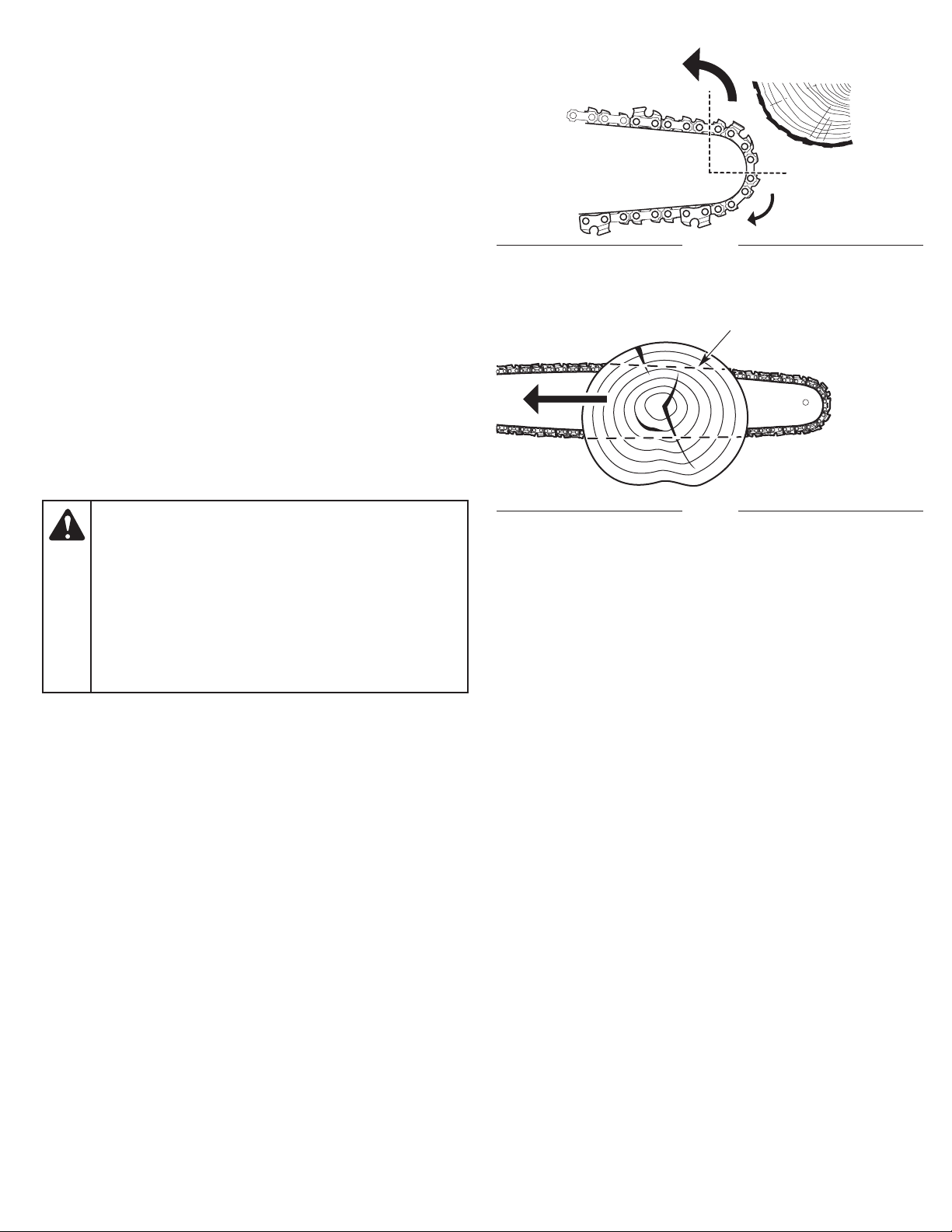

Rotational

Kickback

Kickback

Danger Zone

Saw Chain

Direction

Fig. A

Pinch

KICKBACK SAFETY

WARNING:Kickback may occur when the

nose or tip of the guide bar touches an object, or when the

wood closes in and pinches the saw chain in the cut. In

some cases, tip contact may cause a lightening-fast

reverse action, kicking the guide bar rapidly back to wards

the operator. Pinching the saw chain along the top of the

guide bar may push the guide bar rapidly back towards the

operator. Either of these r

control over the saw, which could result in serious injury to

he user. Contact with foreign objects within the wood can

t

also induce a loss of chain saw control.

Understanding Kickback

A basic understanding of kickback can help reduce or eliminate the

element of surprise and the chance of kickback-related injury.

Sudden surprise contributes to accidents.

• Rotational Kickback can happen when the upper tip of the

guide bar contacts an object while the chain is moving (Fig. A).

This can cause the chain to dig into the object and momentarily

stop moving. The guide bar is then ki

he operator in a lightning-fast reverse reaction.

t

• Linear Kickback can happen when the wood on either side of a

cut closes in and pinches the moving saw chain along the top of

the guide bar (Fig. B). This can cause the chain to instantly stop.

The chain force is then reversed, causing the saw to move in the

opposite direction, sending the saw straight back toward the

operator.

• P

an happen when the moving chain on the bottom of the

ull-In c

guide bar hits a foreign object inside the wood. This can cause

the chain to suddenly stop. The saw is then pulled forward and

away from the operator, which could potentially result in the loss

of control of the saw.

eactions may cause a loss of

cked up and back toward

Linear

Kickback

Fig. B

Kickback Safety Precautions

Take the following steps to reduce the chance of accident or injury:

• Do not rely exclusively upon the safety devices built into the unit.

• Do not cut above shoulder height.

• Do not overreach. Always keep proper footing and balance. Take

extra care when working on steep slopes or inclines.

• Do not make cuts with the tip of the guide bar.

• Make sure the area of operation is fr

m obstructions. Do not

ee fro

let the tip of the guide bar contact any object, such as a log,

branch, the ground or other obstruction.

• Always inspect the wood before cutting. Foreign objects could

damage the unit or cause serious personal injury. Never cut

through nails, metal rods, railroad ties or pallets.

• Do not operate the unit with one hand! Serious injury to the

operator, helpers or bystanders ma

sult from one-handed

y re

operation. This unit is intended for two-handed use. Always grip

the unit firmly with both hands when the unit is running. Hold the

front handle with the left hand and the rear handle with the right

hand. Firmly encircle the handles with the thumbs and fingers.

Do not let go. A firm grip will help maintain control of the unit

and reduce the chance of kickback.

• Stand slightly to

the left of the unit to avoid being in the dire

ct

line of the saw chain.

• Never start the saw when the guide bar is inside an existing cut.

Be extremely careful when re-entering a cut.

• Always begin a cut with the unit running at full speed. Fully

squeeze the throttle control and maintain a steady cutting

speed. Slower speeds increase the chance of kickback.

• Keep the saw housing pressed firmly agains

o not cut more than one log or branch at a time.

• D

t the wood.

• Do not twist the unit when removing the guide bar from a cut.

• Watch out for shifting objects (logs, branches, etc.) that might

pinch or fall onto the saw chain during operation.

4

• Only use wedges made of wood or plastic. Do not use metal to

hold a cut open.

• Follow the manufacture

instructions for the saw chain.

• Only use replacement bars and chains specified by the

manufacturer or the equivalent. These are available from a Sears

or other qualified service dealer. Use of any unauthorized parts

or accessories could lead to serious injury to the operator or

damage to the unit and will void the warranty.

• Use devices that reduce the risks assoc

uch as low-kickback chains, guide bar nose guards, chain

s

brakes and low-kickback guide bars. There are no other

replacement components for achieving kickback protection in

accordance with CSA Z62.3.

• A low-kickback saw chain is a chain that has met the kickback

performance requirements of ANSI/OPEI B175.1-2012 when

tested according to the provisions specified in ANSI/OPEI

B175.1-2012

ccordance with CSA Z62.3. Do not use a replacement saw

a

chain unless it has met these requirements for this specific

model or has been designated as a low-kickback replacement

saw chain in accordance with ANSI/OPEI B175.1-2012. As saw

chains are sharpened, some of the low-kickback qualities are

lost and extra caution should be used.

• Do not install a

kickback zones, which increase the chance of kickback and

serious injury. This increase is not significantly reduced by using

a low-kickback saw chain. Using a bow guide on this unit is

extremely dangerous.

. A low-kickback saw chain is a chain that is also in

bow guide on this unit. Bow guides have larg

r’s sharpening and maintenance

iated with kickback,

er

OTHER SAFETY WARNINGS

• Follow all maintenance instructions in this manual.

• All service, other than the maintenance procedures described in

this manual, should be performed by a Sears or other qualified

service dealer.

• Do not use the unit if it is not working correctly, has been

dropped, damaged, left outdoors or dropped into water. Have

the unit serviced by a Sears or other qualified service dealer.

• B

• Secure the unit while transporting.

• Always use the scabbard on the guide bar and saw chain during

• Always store the unit and fuel in a cool, dry and well-ventila

• Store the unit in a dry place, secured or at a height to prevent

• Never douse or squirt the unit with water or any other liquid. Keep

• K

inspecting, servicing, cleaning, storing, transporting or

efore

replacing any parts on the unit:

1. Stop the unit.

2. Make sure all moving parts have stopped.

3. Allow the unit to cool.

4. Disconnect the spark plug wire.

transportation and storage.

pace. Do not store fuel, or a unit with fuel in the tank, indoors

s

where fumes may reach open flames (pilot lights, etc.) or sparks

(switches, electrical motors, etc.).

unauthorized use or damage. Keep the unit out of the reach of

children.

handles dry, clean and free

the unit after each use. Refer to Cleaning and Storage. Do not use

solvents or strong detergents.

eep these instructions. Refer to them often and use them to

instruct other users. If you loan this unit to others, also loan

them these instructions.

from debris, oil, fuel and grease. Clean

ted

SAVE THESE INSTRUCTIONS

5

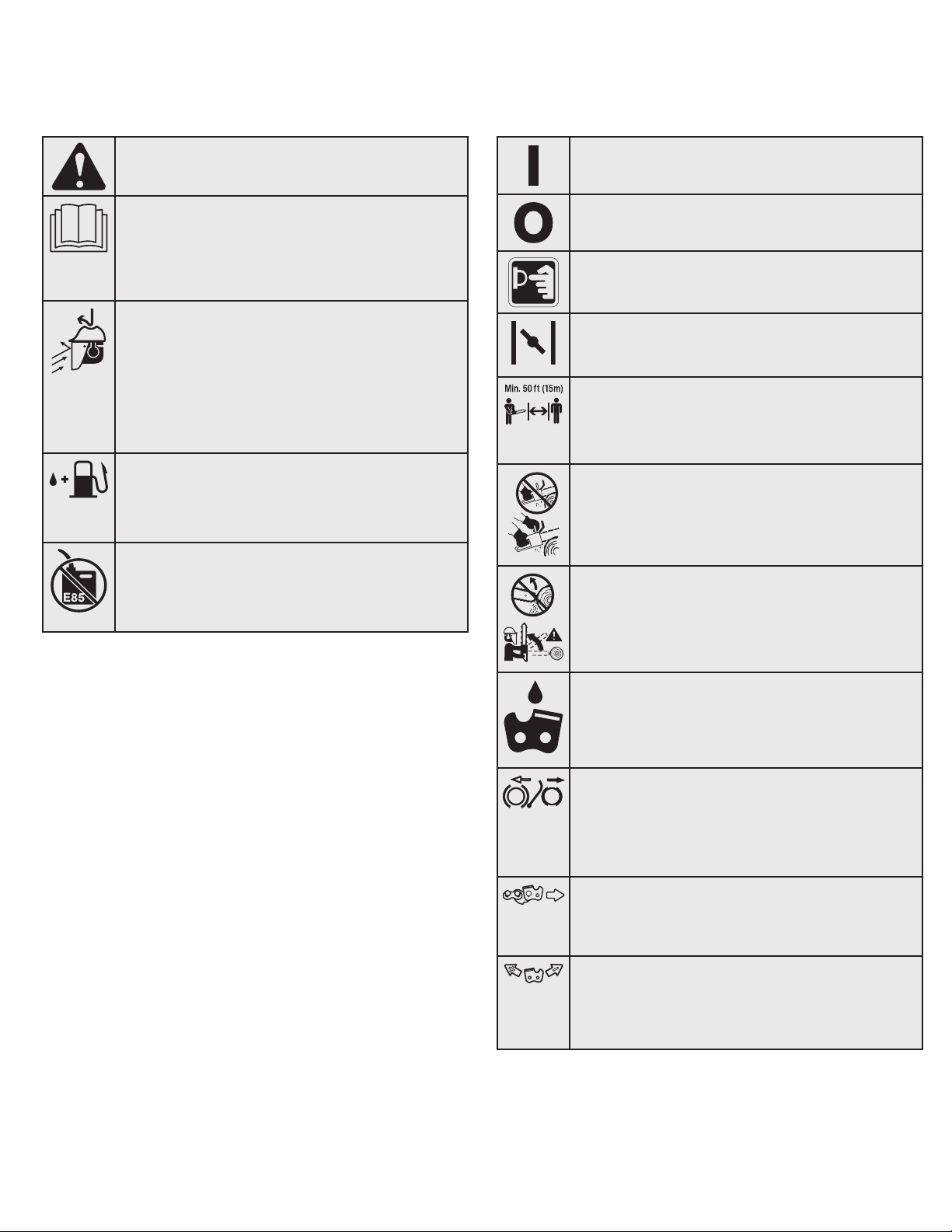

• SAFETY & INTERNATIONAL SYMBOLS •

This operator's manual describes safety and international symbols and pictographs that may appear on this product. Read the operator's

manual for complete safety, assembly, operating and maintenance and repair information.

SYMBOL MEANING SYMBOL MEANING

• SAFETY ALERT SYMBOL

Indicates danger, warning or caution. May be used in

conjunction with other symbols or pictographs.

• READ OPERATOR'S MANUAL

• ON/OFF STOP CONTROL

ON / START / RUN

• ON/OFF STOP CONTROL

OFF or STOP

WARNING: Read the operator’s manual(s)

and follow all warnings and safety instructions. Failure

to do so can result in serious injury to the operator

and/or bystanders.

• PRIMER BULB

Push primer bulb, fully and slowly, 10 times.

• WEAR HEAD, EYE AND HEARING PROTECTION

WARNING:Thrown objects and loud noise

can cause severe eye injury and hearing loss. Wear

eye protection meeting current ANSI Z87.1 standards

and ear protection when operating this unit. Wear

head protection when operating this unit; falling

objects can cause severe head injury. Use a full face

shield when needed.

• UNLEADED FUEL

Always use clean, fresh unleaded fuel.

• OIL

Refer to operator’s manual for the proper type of oil.

• DO NOT USE E85 FUEL IN THIS UNIT

WARNING:It has been proven that fuel

containing greater than 10% ethanol will likely

damage this engine and void the warranty.

• CHOKE CONTROL

• Pulled Out - FULL choke position

• Pushed In - RUN position

• KEEP BYSTANDERS AWAY

WARNING:Keep all bystanders, especially

children and pets, at least 50 feet (15 m) from the

operating area.

• USE BOTH HANDS

WARNING: Always use both hands while

operating the unit. Never use only one hand to

operate the unit.

• KICKBACK

WARNING: Contact of the guide bar tip

with any object should be avoided. Tip contact may

cause the guide bar to move suddenly upward and

backward, which may cause serious injury.

• CHAIN OIL ADJUSTMENT INDICATOR

The chain must be continously coated with oil to

function properly. Make sure to set the oil adjustment

screw to allow a sufficient amount of oil to flow

continuously onto the chain.

• CHAIN BRAKE

The chain brake immediately stops the moving saw

chain in emergency situations. To manually engage

the chain brake, push the chain brake lever forward

completely. To disengage the chain brake, pull the

chain brake lever back completely.

• CHAIN DIRECTION

Make sure the saw chain faces the direction shown

when installed on the guide bar. Refer to Installing the

Guide Bar and Saw Chain in the Maintenance section.

• CHAIN TENSIONING

Always keep the saw chain properly tensioned. Turn

the chain-tensioning screw clockwise to tighten the

saw chain. Turn the chain-tensioning screw

counterclockwise to loosen the saw chain.

6

WARRANTY

CRAFTSMAN LIMITED WARRANTY

FOR TWO YEARS from the date of sale, this product is warranted against defects in material or workmanship.

WITH PROOF OF SALE, a defective product will receive free repair or replacement at option of seller.

ADDITIONAL LIMITED WARRANTY ON ENGINE CRANKSHAFT

FOR THE THIRD THROUGH TENTH YEAR from the date of sale, the engine crankshaft of this product is warranted against any defects in

material o

WITH PROOF OF SALE, a defective engine crankshaft will be replaced free of charge. You are responsible for the labor cost of crankshaft

installation. This additional warranty covers only the engine crankshaft, and does not apply to any other engine component.

r workmanship.

For warranty coverage details to obtain free repair or replacement, visit the web page: www.craftsman.com/

his warranty covers ONLY defects in material and workmanship. Warranty coverage does NOT include:

T

• Expendable items that can wear out from normal use within the warranty period, including but not limited to chain bar, chain, filters or

spark plug.

• Product damage resulting from user attempts at product modification or repair or caused by product accessories.

• Repairs necessary because of acci

• Preventive maintenance or repairs necessary due to improper fuel type, fuel mixture, contaminated or stale fuel.

This warranty is void if this product is ever used while providing commercial services or if rented to another person.

This warranty gives you specific legal rights, and you may also have other rights which vary fro

Sears Brands Management Corporation, Hoffman Estates, IL 60179

To order parts or schedule service for this product, call 1-888-331-4569.

dent or failure

to operate or maintain the product according to all supplied instructions.

m state to state.

warranty

7

APPLICATIONS

• Felling and limbing trees

• Cutting logs (bucking)

• Pruning trees

ASSEMBLY TOOLS REQUIRED:

• Flat-head screwdriver or multi-purpose tool

(provided)

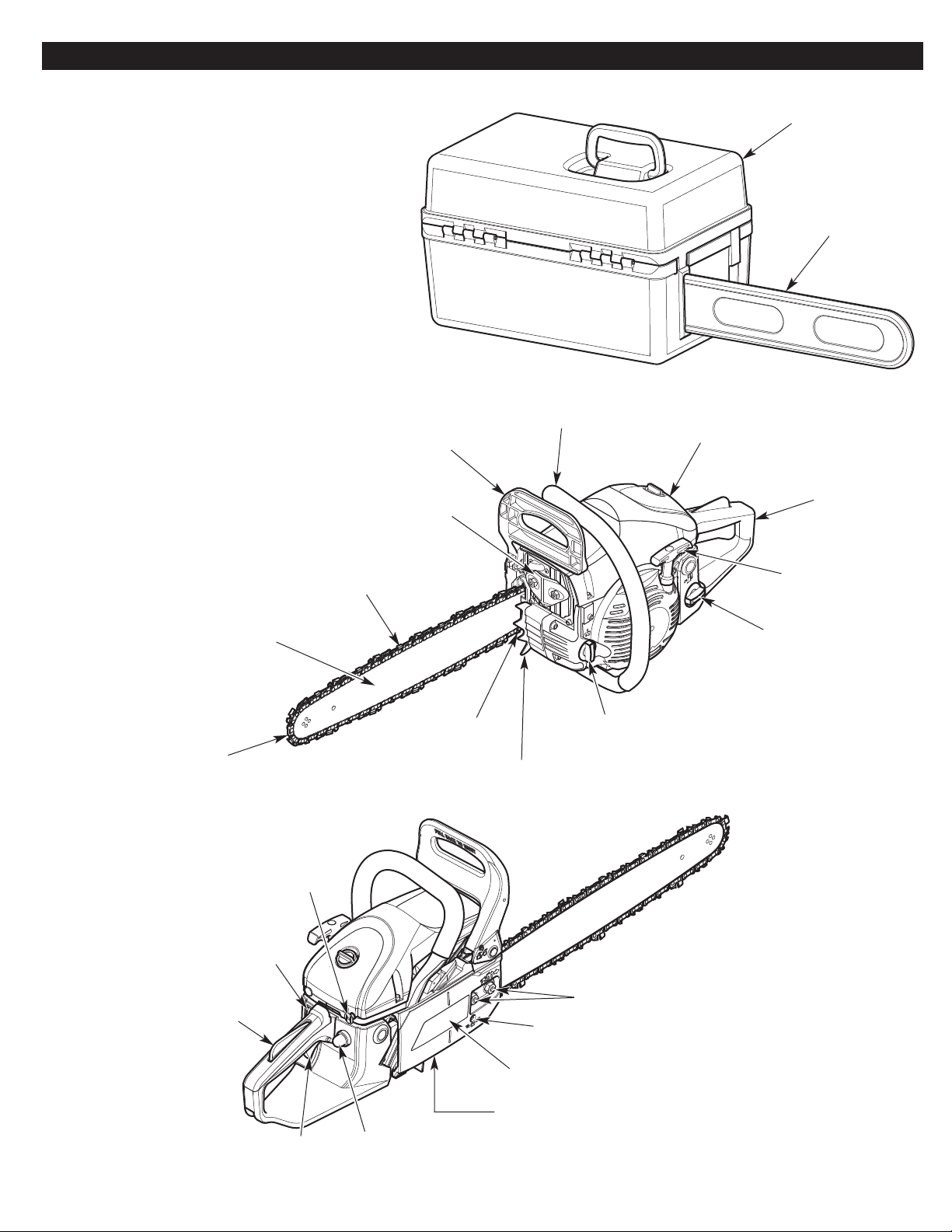

KNOW YOUR UNIT

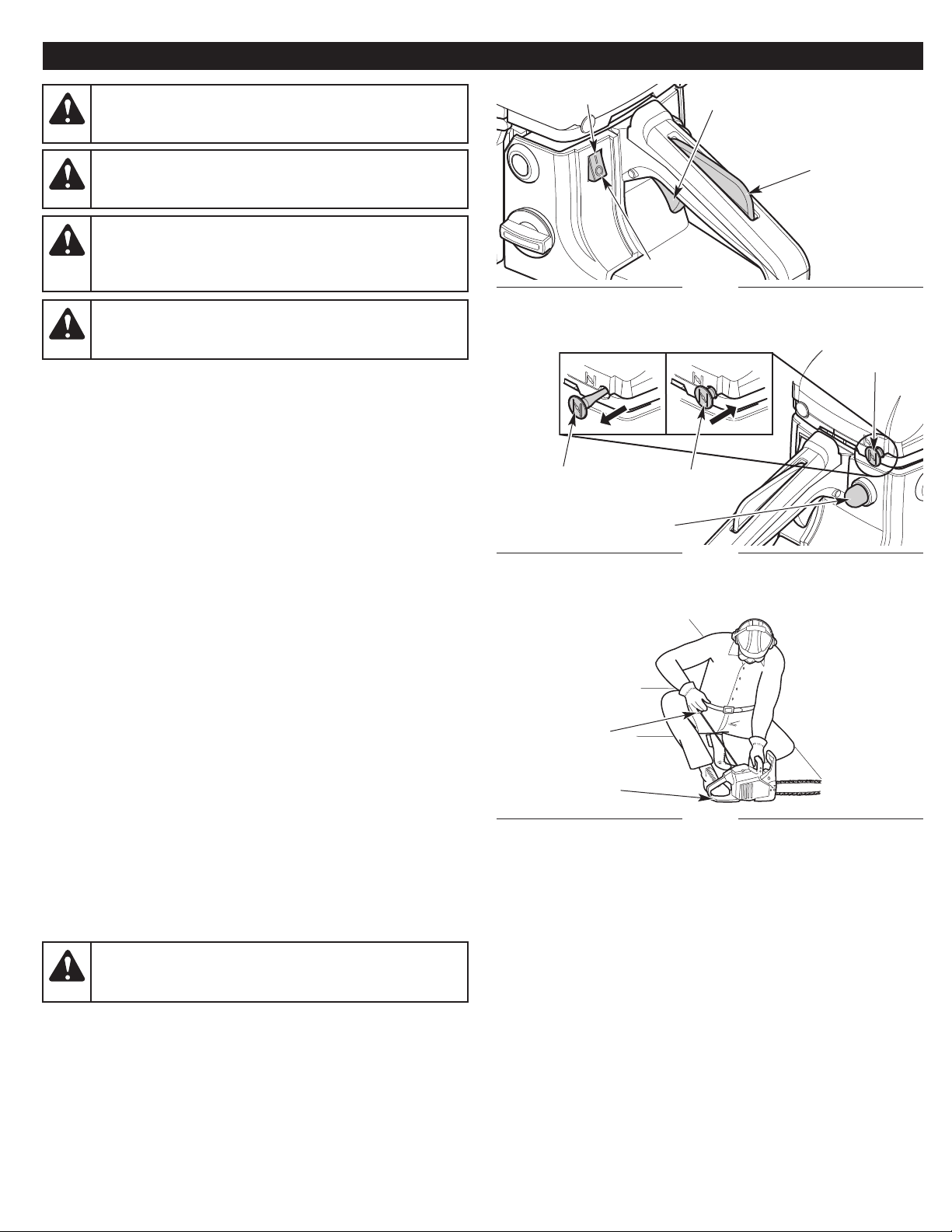

Carrying Case

Scabbard

Guide Bar Tip

Guide Bar

Chain Brake Lever /

Front Hand Guard

Low-Kickback

Saw Chain

Muffler

Chain Catcher

Front Handle

Spiked Bumper /

Bucking Spike

Air Filter Cover

(Spark Plug and Air Filter)

Rear Handle /

Boot Loop

Starter Rope Grip

Fuel Cap

Chain Oil

Reservoir Cap

On/Off Switch

Throttle Lockout

Throttle Control

Choke Knob

Bar-Retaining Nuts

Chain-Tensioning

Screw

Bar Cover

Chain Oil

Adjustment Screw

Primer Bulb

8

SAFETY FEATURES

• LOW-KICKBACK SAW CHAIN significantly reduces the chance of kickback and the intensity of kickback, due to specially designed

depth gauges and guard links.

• The SPARK ARRESTER SCREEN re

exhaust flow. Compliance with local, state and federal laws and/or regulations governing the use of a spark arrester screen is the user’s

responsibility. Refer to Spark Arrestor Note in the Safety section for additional information.

• The CHAIN BRAKE LEVER / FRONT HAND GUARD helps protect the operator’s

running. The chain brake lever is also used to manually engage the chain brake.

• The CHAIN BRAKE reduces the chance of injury if kickback occurs, by stopping the saw chain in milliseconds. The chain brake is

designed to engage automatically in response to kickback. The chain brake can also be activated by pushing the chain brake lever

forward

• The ON/OFF SWITCH immediately stops the engine when moved to the OFF position. The On/Off switch must be moved to the On

position to start the engine.

• The THROTTLE LOCKOUT prevents accidental acceleration of the engine. The throttle control cannot be squeezed unless the throttle

lockout is depressed.

• The CHAIN CATCH

intercept a whipping chain.

, either intentionally or if the operator’s hand strikes the lever during kickback.

duces the chance of injury if the saw chain breaks or derails during operation. The chain catcher is designed to

ER re

tains carbon and other flammable particles over 0.023 inches (0.6mm) in size from the engine

left hand if it slips off the front handle while the unit is

SPECIFICATIONS*

Engine Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Air-Cooled, 2-Cycle

Displacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46 cc (2.8 cu. in.)

Spark Plug Gap. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.025 in. (0.635 mm)

Spark Plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion® RCJ6Y or equivalent plug

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Bar and Chain Oil

Fuel/Oil Ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40:1

Fuel Tank Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 oz. (650 mL)

Chain Oil R

Approximate Unit Weight (without fuel or chain oil) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 - 15 lbs. (6.3 - 6.8 kg)

Guide Bar Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 in. (45.7 cm)

Saw Chain Pitch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.325 in. (8.3 mm)

Saw Chain Gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.050 in. (1.3 mm)

eservoir Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . 8.45 oz. (250 mL)

* All specifications are based on the latest product information available at the time of printing. We reserve the right to make changes at any

time without notice.

REPLACEMENT PARTS

Please contact the Customer Support Department to order replacement parts.

Part #

753-08242 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

753-08267 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

753-08105 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Description

Saw Chain (18 in. / 45.7 cm)

Guide Bar (18 in. / 45.7 cm)

Bar-Retaining Nuts

9

ASSEMBLY

ADDING BAR AND CHAIN OIL: INITIAL USE

This unit comes from the factory with the chain oil reservoir empty.

Refer to Adding Bar and Chain Oil instructions in the Maintenance

section.

ADJUSTING THE CHAIN TENSION: INITIAL USE

The saw chain must be properly tensioned before attempting to

start or operate the unit. The saw chain may also require additional

tensioning as the saw chain heats up during operation. Refer to

A

djusting the Chain Tension instructions in the Maintenance section.

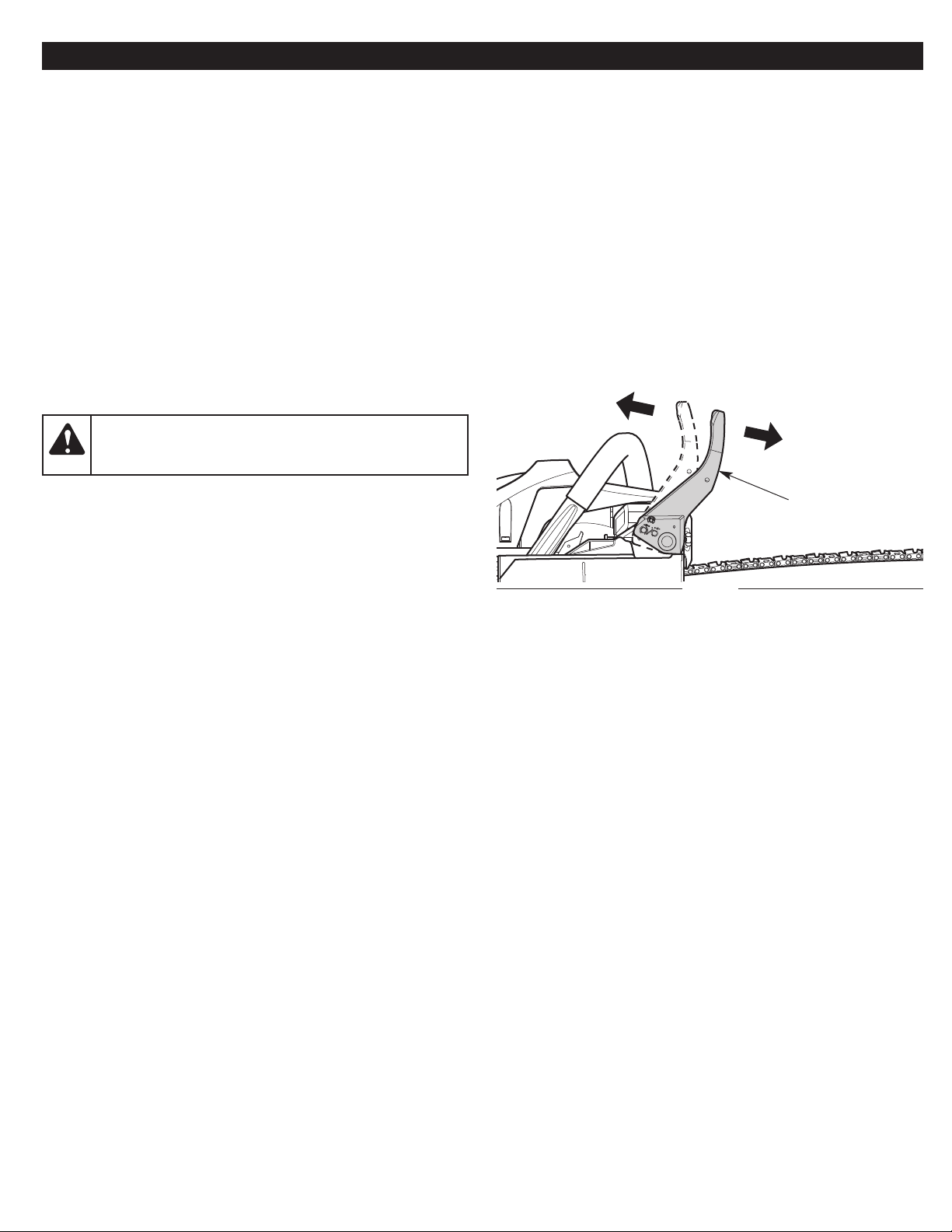

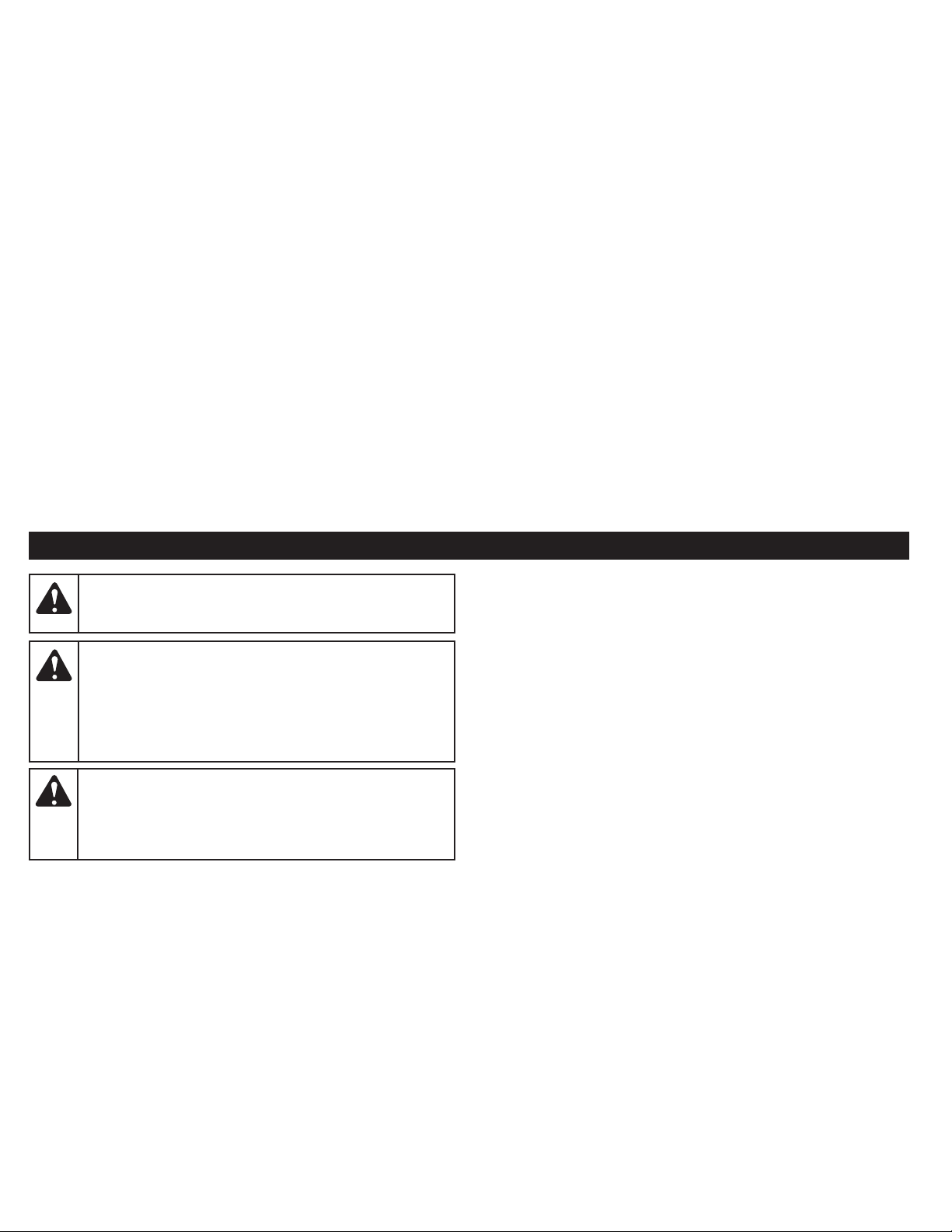

TESTING THE CHAIN BRAKE

WARNING:

deliberately. Keep the saw chain from touching anything.

Do not let the chain saw tip forward.

Always test the chain brake before using the unit.

1. Set the unit on a flat, level surface.

2. Make sure the chain brake lever is pulled back in the

disengaged position (Fig. 1).

3. Start the unit. Refer to Starting Instructions in the Starting and

Stopping section. Maintain a proper grip

nit in the Operation section.

U

4. While the unit is running, squeeze the throttle control to 1/3

throttle and then engage the chain brake by pushing the chain

brake lever forward with the left hand (Fig. 1). The chain should

stop moving abruptly.

IF... If the chain stops moving, the chain brake is working correctly.

IF... If the chain does not stop moving, have the unit serviced by

ears or other qualified service dealer.

S

5. Stop the engine and return the chain brake to the disengaged

position. Refer to Stopping Instructions in the Starting and

Stopping section.

Always activate the chain brake slowly and

. Refer to Holding the

a

Disengaged

Engaged

Chain Brake Lever

Fig. 1

10

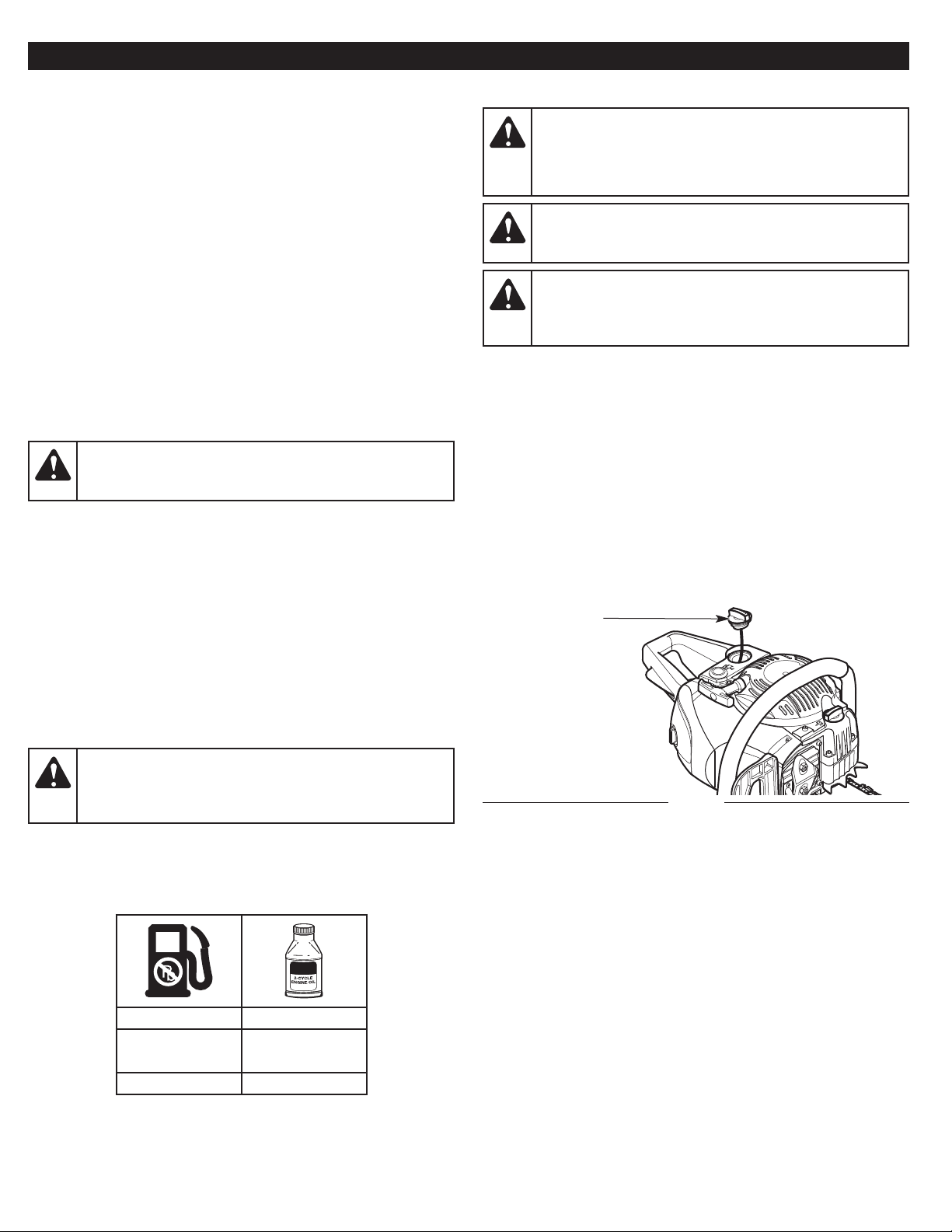

OIL AND FUEL

OIL AND FUEL MIXING INSTRUCTIONS

The use of old and/or improperly mixed fuel is the most common cause

of performance problems. Use only fresh, clean unleaded gasoline.

Follow the instructions carefully for the proper gasoline/oil mixture.

Definition of Blended Fuels

Today's fuels are often a blend of gasoline and oxygenates such as

ethanol, methanol or MTBE (ether). Alcohol-blended fuel absorbs

water. As little as

eparate, forming acids when stored. ALWAYS use fresh fuel (less

s

than 30 days old).

NOTE: Dispose of old fuel according to federal, state and local

regulations.

Using Blended Fuels

If using a blended fuel:

• Always use the fresh fuel mix explained in your operator's manual

• Use the fuel additive STA-BIL® or an equivalent

• Always agitate the fuel mix before fueling

• D

rain the tank and run the engine dry before storing the unit

WARNING:

has been proven that fuel containing greater than 10%

ethanol will likely damage this engine and void the warranty.

Using Fuel Additives

The bottle of 2-cycle oil provided with this unit contains a fuel

additive to help inhibit corrosion and minimize gum deposits.

Always use the brand of 2-cycle oil that came with this unit. If this is

unavailable, use a 2-cycle oil designed for air-cooled engines and

mix it with a fuel additive, such as STA-BIL Fuel Stabilizer or an

e

quivalent. Add 0.8 oz. (23 mL) of fuel additive per gallon of fuel,

according to the instructions on the container. NEVER add fuel

additives directly to the unit's fuel tank.

Mixing the Fuel

NOTE: This unit comes with a 3.2 oz. (95 mL) bottle of 2-cycle oil.

To obtain the correct fuel mixture described below, pour the

entire bottle into one gallon of unleaded gasoline.

1% water in the fuel can make fuel and oil

the unit

DO NOT USE E85 FUEL IN THIS UNIT. It

FUELING THE UNIT

WARNING:

vapors may explode. Always stop the engine and allow it

to cool before filling the fuel tank. Do not smoke while

filling the tank. Keep sparks and open flames at a distance

from the area.

WARNING:

from fuel spray. Never operate the unit without the fuel cap

securely in place.

WARNING:

area. Wipe up any spilled fuel immediately. Avoid creating

a source of ignition for spilled fuel. Do not start the engine

until fuel vapors dissipate.

1. Position the unit with the fuel cap facing up.

2. Remove the fuel cap (Fig. 2).

3. Place the fuel container spout into the fill hole on the fuel tank

and fill the tank.

NOTE: Do not overfill the tank.

4. Wipe up any fuel that may have spilled.

5. Reinstall the fuel cap.

6. Move the unit at least 30 ft. (9.1 m) from the fuel container and

the fueling site before starting the engine.

Fuel Cap

Gasoline is extremely flammable. Ignited

Remove the fuel cap slowly to avoid injury

Add fuel in a clean, well ventilated outdoor

CAUTION:

reliability, pay strict attention to the gasoline and oil mixing

instructions on the 2-cycle oil bottle. Using improperly

mixed fuel can severely damage the engine.

Thoroughly mix t

engine oil. Do not mix them directly in the unit’s fuel tank. Use a

separate fuel can. Use a 40:1 gasoline/oil ratio. See the table below

for specific gasoline and oil mixing ratios.

For proper engine operation and maximum

per ratio of unleaded gasoline with 2-cycle

he pro

Unleaded gasoline 2-cycle oil

1 gallon U.S.

(3.8 L)

1 L 25 mL

MIXING RATIO - 40:1

3.2 fl. oz.

(95 mL)

Fig. 2

11

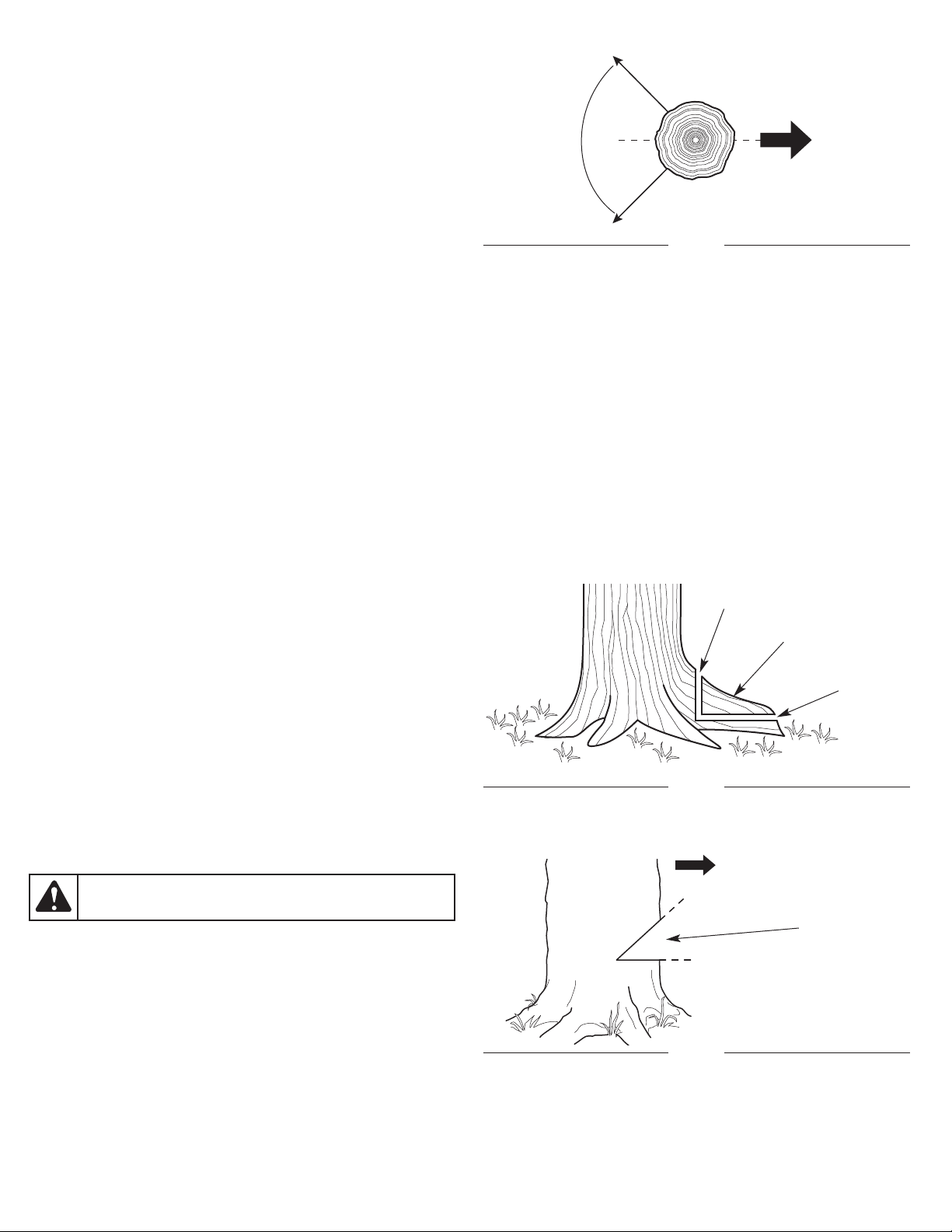

STARTING AND STOPPING

WARNING:

Operate this unit only in a well-ventilated

outdoor area. Carbon monoxide exhaust fumes can be

lethal in a confined area.

WARNING:

Avoid accidentally starting the unit. To avoid

serious injury, the operator and the unit must be in a stable

position when pulling the starter rope (Fig. 5).

WARNING:

Never operate the unit without the guide bar

and saw chain properly installed. Make sure the bar-retaining

nuts are tight and the guide bar cover is securely assembled.

Make sure the saw chain is properly tensioned.

WARNING:

The saw chain will spin after the engine

starts. Keep hands and feet clear of the saw chain and do

not allow the saw chain to contact any object(s).

STARTING INSTRUCTIONS

1. Mix gasoline with oil. Refer to Oil and Fuel Mixing Instructions.

2. Fill the fuel tank. Refer to Fueling the Unit.

3. Fill the chain oil reservoir with bar and chain oil. Refer to Adding

Bar and Chain Oil in the Maintenance section.

4. Make sure the chain brake is disengaged. Refer to Testing the

Chain Brake in the Assembly section.

5. Move the On/Off switch to the On position (Fig. 3).

6.

Slowly pre

cannot be seen in the primer bulb, press and release the primer

bulb until fuel is visible.

7. Pull the choke knob out to Position 1 (Fig. 4).

NOTE: DO NOT touch the throttle control until step 14 (Fig. 3).

8. DO NOT touch the throttle control (Fig. 3). Set the unit on a flat,

level surface. Clear the area of any objects that could contact

the

. DO NOT touch the throttle control. Crouch in the starting

9

position (Fig. 5). Hold the front handle with the left hand. Hold

the starter rope grip with the right hand. Insert the right foot into

the boot loop to help hold the unit firmly in place.

10. DO NOT touch the throttle control. Pull the starter rope with a

controlled and steady motion 5 times (Fig. 5).

11. DO NOT touch the throttle control

osition 2 (Fig. 4).

P

12. DO NOT touch the throttle control. Pull the starter rope with a

controlled and steady motion 3 to 5 times to start the engine.

13. DO NOT touch the throttle control. Allow the engine to warm up

for 30 to 60 seconds.

14. Press and hold the throttle lockout. Lightly squeeze and release

the throttle control to idle the engine.

ss and release the primer bulb 10 times (Fig. 4). If fuel

saw chain.

. Push the choke knob in to

On ( I ) / Start

Position 1

Starter

Rope Grip

Boot Loop

Throttle Control

Throttle Lockout

Off (O) / Stop

Fig. 3

Choke Knob

Position 2

Primer Bulb

Fig. 4

Starting

Position

Fig. 5

WARNING:

The saw chain should not move when the

engine runs at idle. If it does move, refer to Adjusting the

Idle Speed in the Maintenance section.

15. To reduce the chance of injury, engage the chain brake until you

a

re ready to begin operation. When ready, disengage the chain

brake. Then press the throttle lockout and squeeze the throttle

control to accelerate the engine, as needed.

NOTE: The engine is properly warmed up when it accelerates

without hesitation.

IF... the engine hesitates, continue the warm-up.

IF... the engine does not start, begin the starting procedure with

step 4.

12

IF... the engine fails to start after

nob to Position 2, press the throttle lockout and squeeze the

k

throttle control. Pull the starter rope with a controlled and steady

motion 3 to 8 times. The engine should start. If it does not,

repeat this instruction.

IF... the engine is already warm, make sure the On/Off switch is in

the On position, crouch in the starting position, pull the choke

knob out to Position 1 and

osition 2. Begin the starting procedure with step 12.

P

a few attempts, move the choke

then push the choke knob back in to

STOPPING INSTRUCTIONS

1. Release the throttle control and allow the engine to idle.

2. Move the On/Off switch to the Off position (Fig. 3). Wait for the

saw chain to come to a complete stop.

Emergency Stopping

1. Push the chain brake lever forward to engage the chain brake.

Refer to Testing the Chain Brake in the Assembly section.

2. Move the On/Off switch to the Off position.

OPERATION

WARNING:

necessary before beginning operation. Refer to Adjusting the

Chain Tension in the Maintenance section.

WARNING:

before operation. Check the oil level constantly so that it

does not drop below half full. Make sure the chain oil

adjustment screw is set appropriately. Refer to Setting the

Chain Oil Adjustment Screw in the Maintenance section.

The saw chain must be continuously coated with oil to

function properly.

WARNING:

foot and body protection to reduce the risk of injury when

operating this unit. Wear head protection. Use a full face

shield when needed. Refer to the Safety section for

appropriate safety equipment information.

TIPS FOR BEST RESULTS

• Follow all safety instructions. Refer to the Safety section.

• Only cut wood and materials made of wood. Do not attempt to

cut sheet metal, plastics, masonry or any other non-wood

materials.

• Practice cutting a few small logs before beginning a major

cutting operation.

• Do not attempt to cut trees or logs with diameters larger than 14

in. (35.6 cm).

Always check the chain tension and adjust as

Make sure the chain oil reservoir is full

Always wear appropriate eye, hearing, hand,

13

PREPARING THE WORK AREA

• Clear the area of children, bystanders and pets; keep them

outside a 50-foot (15 m) radius, at a minimum. Even then, they

are still at risk from thrown objects. Encourage bystanders to

wear eye protection. If you are approached, stop the unit

immediately. When felling, the safe distance is at least twice the

height of the tallest tree in the work area. When bucking, keep

workers

• K

start cutting until the work area is clear and free from

obstructions. Make sure there is secure footing and a planned

retreat path from falling trees or branches.

• Do not cut near electrical cables or power lines. Keep at least 50

feet (15 m) away from all power lines.

• Use the unit only in daylight or goo

at least 15 feet (4.6 m) apart.

eep the work area clean. Cluttered areas invite injuries. Do not

d artificial light.

Correct Grip

Thumbs Below the Handles

Fig. 6

HOLDING THE UNIT

WARNING:

hand and the rear handle with the right hand. Always keep

all body parts to the left of the chain line.

• Firmly encircle the handles with the thumbs and fingers (Fig. 6).

This will help reduce the chance of losing control of the unit if

kickback occurs. Any grip with thumbs and fingers on the same

side of the handles is dangerous (Fig. 7).

• Always grip the unit firmly with both hands when the unit is

running.

• Hold the front handle with the left hand. Keep the left arm

straight to help w

old the rear handle with the right hand. Keep the right arm

• H

slightly bent.

• Use these hand placements whether the operator is left-handed

or right-handed. This will help keep the operator slightly to the

left of the unit and out of the direct line of the chain saw if

kickback occurs (Fig. 8 and Fig. 9).

• Stand in a stable position with feet apart and firmly planted.

• Do not

cut above shoulder height. Do not overre

Always hold the front handle with the left

ithstand potential kickback.

ach.

Incorrect Grip

Correct Stance

Thumb

Above the

Handle

Fig. 7

Chain Line

CUTTING PROCEDURE BASICS

1. Start the unit. Refer to Starting Instructions in the Starting and

Stopping section.

2. Keep your fingers off the throttle control until you are ready to

make a cut.

3. Accelerate the unit to full speed before cutting.

4. Press the unit against the wood and maintain a firm, steady

pressure through most of the cut. Do not put pressure on th

nit at the end of the cut.

u

5. Maintain a steady speed throughout the cut. Keep the unit

running through the entire cut.

6. Do not try to force the saw through the wood. Allow the saw

chain to do the cutting. Exert only light pressure. Forcing the cut

could result in damage to the unit or personal injury.

7. Release the throttle control as soon as the cut is completed.

Allow the saw chain to come to a com

uide bar and engine may experience unnecessary wear if the

g

plete stop. The saw chain,

unit is run without a cutting load.

e

Fig. 8

Chain Line

Incorrect Stance

Fig. 9

14

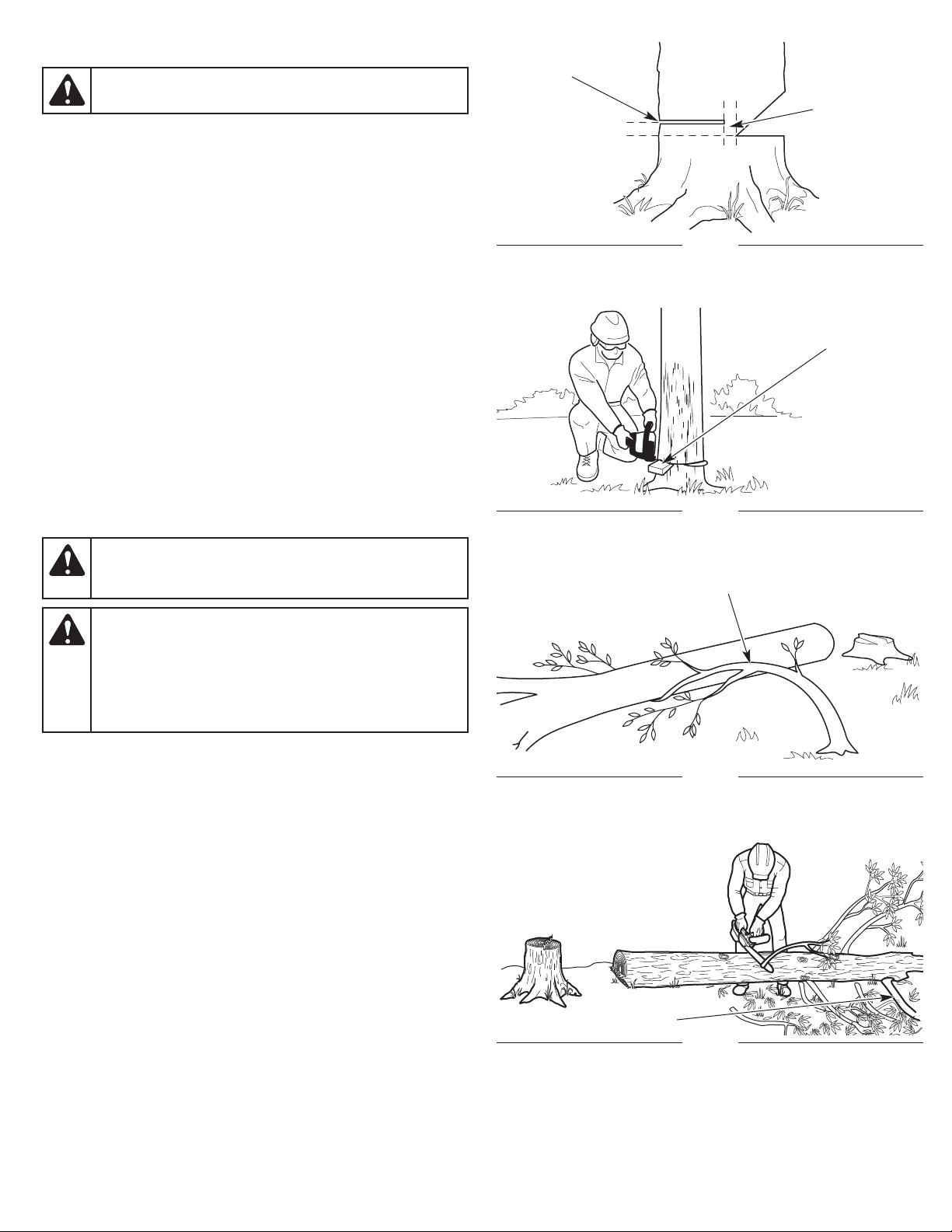

FELLING: SAFETY

90°

Felling is the process of cutting down a tree. Follow these safety

precautions to reduce the risk of serious injury, property damage

and damage to electrical lines:

• Do not fell trees with an extreme lean. Do not fell trees with

rotten limbs, loose bark or hollow trunks. Have these trees

pushed or dragged down with heavy equipment.

• Do not cut trees near buildings or electrical lines. L

perations for professionals. If a felled tree does contact an

o

electrical line, notify the utility company immediately.

• Check the tree for damaged or dead branches that could fall

and cause serious injury.

• Remove dirt, stones, loose bark, nails, wire and other

obstructions from the portion of the tree that will be cut.

• When bucking and felling operations are performed by two or

more persons

in the same general are

a, they should be

separated from each other by a distance of at least twice the

height of the tree to be felled.

• Consider the force and direction of the wind. Consider the lean

and balance of the tree. Consider the location of large branches.

All of these factors influence the direction that the tree will fall. Do

not try to fell a tree in a direction other than its natural fall

o not fell trees during periods of precipitation or high winds.

• D

• Determine a safe and expedient escape route. Clear the area

around the tree and make sure there are no obstructions

blocking the escape route. Establish a 90º corridor of escape,

approximately 135º from the line of fall (Fig. 10).

• Stay uphill from the tree; it will most likely roll or slide after it falls.

eave these

line.

Path of Safe

Retreat

135º From Planned

Line of Fall

Planned

Line of Fall

135º From Planned

Line of Fall

Fig. 10

FELLING: PROCEDURE

Small trees, up to 6 - 7 inches (15 - 18 cm) in diameter, are usually

felled in a single cut. Larger trees require a sequence of two cutting

operations: a notched undercut followed by a felling back cut. It

may also be necessary to remove buttress roots.

Step 1: Removing Buttress Roots

Buttress roots are large roots that extend above the ground and

help support the tree. If the tree has large buttress roots th

mpede the felling process, follow these steps to remove them:

i

1. Make a horizonal cut into the buttress root (Fig. 11). To prevent

the guide bar from being pinched by the weight of the wood,

always make this cut first.

2. Make a vertical cut into the buttress root (Fig. 11).

3. Remove the loose section from the work area.

Step 2: Making the Notched Undercut

WARNING:

Never walk in front of a tree with a notched

undercut.

This cut determines which direction the tre

e will fall. Always make

this cut on the side of the tree facing the direction where the tree

should fall. Make the cut at 90º to the line of fall.

1. Make a horizontal cut into the trunk of the tree (Fig. 12). The cut

should be about 1/3 the diameter of the tree and close to the

ground. To prevent the guide bar from being pinched by the

weight of the wood, always make this cut first.

2. Make a 45º cut i

nto the trunk of the tre

e, above the first cut (Fig.

12). Continue cutting until the two cuts meet.

3. Remove the loose section from the work area.

at might

1/3 Diameter

Second Cut

Buttress Root

First Cut

Fig. 11

Direction of Fall

Second Cut

Notched

Undercut

First Cut

Fig. 12

15

Step 3: Making the Felling Back Cut

WARNING:

Always recheck the area for bystanders,

animals and obstacles before making the felling back cut.

This cut fells the tree.

1. Make a horizontal cut into the opposite side of the tree from the

notched undercut (Fig. 13). Make the cut approximately 2 inches

(5 cm) above the bottom of the notched undercut (Fig. 13).

2. As the cut gets close to the notched undercut, only a thin band

of wood will support the tree. This band of wood is referred to as

the hinge (Fig. 13). The hinge helps contro

l the fall of the tree.

Leave approximately 2 inches (5 cm) of hinge in place. Do not

cut through the hinge. Cutting through the hinge could cause the

tree to fall in any direction.

3. Periodically glance up during the felling back cut to see if the

tree is going to fall in the correct direction. If there is a chance

that the tree might not fall in the desired direction, or if the

tre

e

might rock back and bind the chain saw, remove the guide bar

from the cut, stop the unit and use wedges to open the cut and

direct the fall (Fig. 14). Only use soft plastic or wooden wedges.

Drive the wedges into the cut slowly. Once the wedges are in

place and the cut is held open, either carefully reinsert the guide

bar and continue the cut or slowly drive the wedges in further to

push the tree o

. As the hinge gets smaller, the tree should begin to fall. When the

4

ver.

tree begins to fall, remove the chain saw from the cut, stop the

engine and set the unit down immediately. Promptly exit the area

along the retreat path, but keep watching the tree as it falls.

Felling

Back Cut

2 inches

(5 cm)

Hinge

2 inches

(5 cm)

Fig. 13

Wedge

Fig. 14

DANGER:

If the tree starts to fall in the wrong direction

and binds the chain saw, leave the unit and evacuate the

area immediately! Do not try to save the chain saw!

WARNING:

Stay clear of spring poles when operating the

unit. Spring poles are branches, logs, roots or saplings that

are bent under tension by other wood (Fig. 15). When the

tension is released, spring poles can strike the operator,

causing serious injury and potentially knocking the chain

saw into the operator’s body. Use extreme caution when

cutting spring poles or when releasing the cause of tension.

LIMBING

Limbing is the process of removing branches from a fallen tree.

1. Leave the larger support limbs under the tree for last (Fig. 16).

These will keep the tree off the ground during the limbing process.

2. Cut one limb at a time. Stand on the opposite side of the tree

from the limb (Fig. 16). Keep the trunk between the operator and

the chain saw. To avoid binding the chain saw, branches under

tension

should be cut fro

3. Remove the cut limbs from the work area.

m the bottom up.

Spring Pole

Fig. 15

16

Support Limb

Fig. 16

BUCKING: SAFETY

Bucking is the process of cutting a fallen tree into logs of desired

lengths. Follow these safety precautions to reduce the risk of

serious injury:

• Clear the area of objects or obstructions that could contact the

guide bar and result in kickback.

• When bucking on a slope, always stand on the uphill side of the

fallen tree.

• If possible, the end of the tree to be cu

t should be raised off

the ground. A saw horse is ideal for this purpose. If a saw horse

is not available, use other logs or any remaining limb stumps.

Make sure the tree if firmly supported.

• Do not let the saw chain contact the ground or saw horse.

• Cut one log at a time. Release the throttle control and allow the

saw chain to come to a complete stop before moving on to the

next log.

• Keep feet and a

DANGER:

ll other body parts clear of falling logs.

Use extreme caution when cutting a fallen

tree that is still attached to the root structure. When the

trunk is separated from the roots, the stump has a high

potential for rocking back into the hole created by the

roots. This can result in serious injury or death. Never

stand in the hole left by the roots. Never allow others to

stand near the root structure.

of

Log Supported

on One End

Log Supported

Two Ends

Second Cut

First Cut (1/3 Diameter)

Fig. 17

First Cut (1/3 Diameter)

Load

Second Cut

Fig. 18

Load

BUCKING: PROCEDURE

Cutting Logs Under Stress

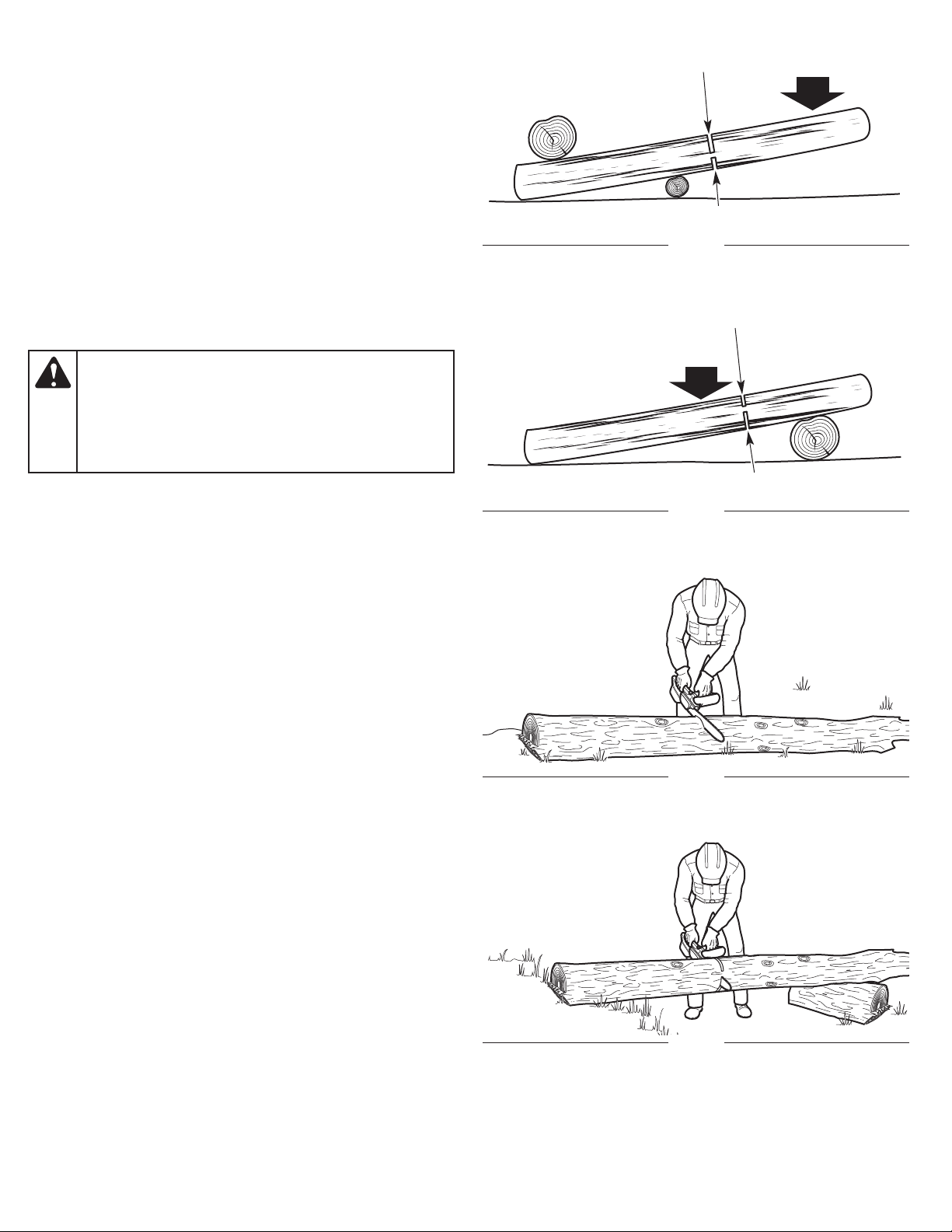

When logs are supported on one or both ends, the wood tends to

bend during the cutting process. This can cause the chain saw to

become pinched between the two sides. Pay extra attention.

1. Make the first cut approximately 1/3 the diameter of the log. Do

not cut deeper than 1/3.

• If the log is supported on one end (Fig. 17), make the first cut

from below (un

f the log is supported on two ends (Fig. 18), make the first cut

• I

from above (overbucking). Refer to Overbucking.

2. Make the second cut from the opposite side until the two cuts

meet. If the diameter of the wood is large enough, insert soft plastic

or wooden wedges to hold the cut open and prevent pinching (Fig.

21). Take care not to touch the wedges with the saw ch

utting Fully-Supported Logs

C

When logs are supported along the entire length, extra care should

be taken to make sure the saw chain does not contact the ground

or other support structure (Fig. 19).

1. Cut through the log as much as possible, without cutting into

the ground or support structure. Cut from above (overbucking).

Refer to Overbucking.

2. Roll the log over and finish cutting through the log f

(overbucking).

derbucking). Refer to Underbucking.

ro

ain.

m above

Overbucking

Fig. 19

Underbucking

17

Fig. 20

Overbucking

1. Begin cutting from above, with the bottom of the saw chain

against the top of the log (Fig. 19).

2. Exert light, downward pressure. The saw will tend to pull away

from the operator. Be prepared and hold the saw firmly to

maintain control.

Underbucking

1. Begin cutting from below, with the top of the saw chain against

the bottom of the log (Fig. 20).

2. Exert light, upward pressure. The saw wil

l tend to push toward the

operator. Be prepared and hold the saw firmly to maintain control.

Wedge

Fig. 21

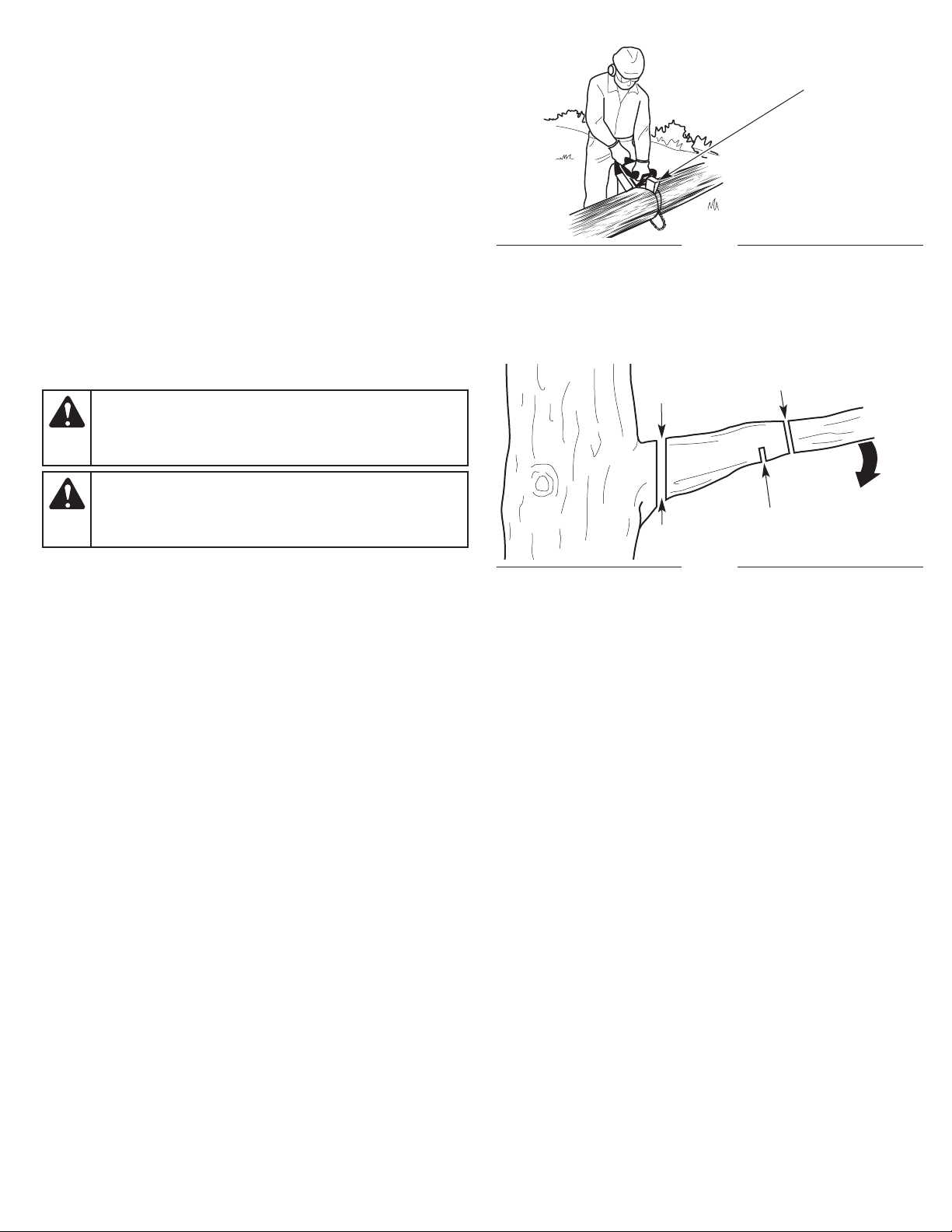

PRUNING

WARNING:

pole saw to cut limbs above shoulder height or hire a

professional. Do not operate the unit in a tree or on a

ladder unless specifically trained to do so.

WARNING:

Always wear appropriate head protection. Plan an escape

route away from falling limbs. Do not position any body

parts directly below the limb when cutting.

Pruning is the process of cutting limbs from a living tree.

1. Make the first cut approximately 6 inches (15 cm) from the tree

trunk. Cut upward, from the underside of the limb. Use the top

of the guide bar to make this cut. Cut a third of the way through

the diameter of the limb (Fig. 22).

2. Make the second cut 2 - 4 inches (5 - 10 cm) farther out on the

limb. Cut downward, from the top of

he guide bar to make this cut. Cut completely through the limb

t

(Fig. 22).

3. Make the third cut as close to the tree trunk as possible. Cut

upward, from the underside of the limb stub. Use the top of the

guide bar to make this cut. Cut a third of the way through the

diameter of the limb (Fig. 22).

4. Make the fourth cut directly above the third cut. Cut downward,

from the top o

ake this cut. Cut completely through the limb stub to meet the

m

third cut (Fig. 22). This will remove the limb stub.

Do not cut above shoulder height. Use a

Falling branches can cause serious injury.

the limb. Use the bottom of

f the limb stub. Use the bottom of the guide bar to

Fourth Cut

Second Cut

First Cut

Third Cut

Fig. 22

18

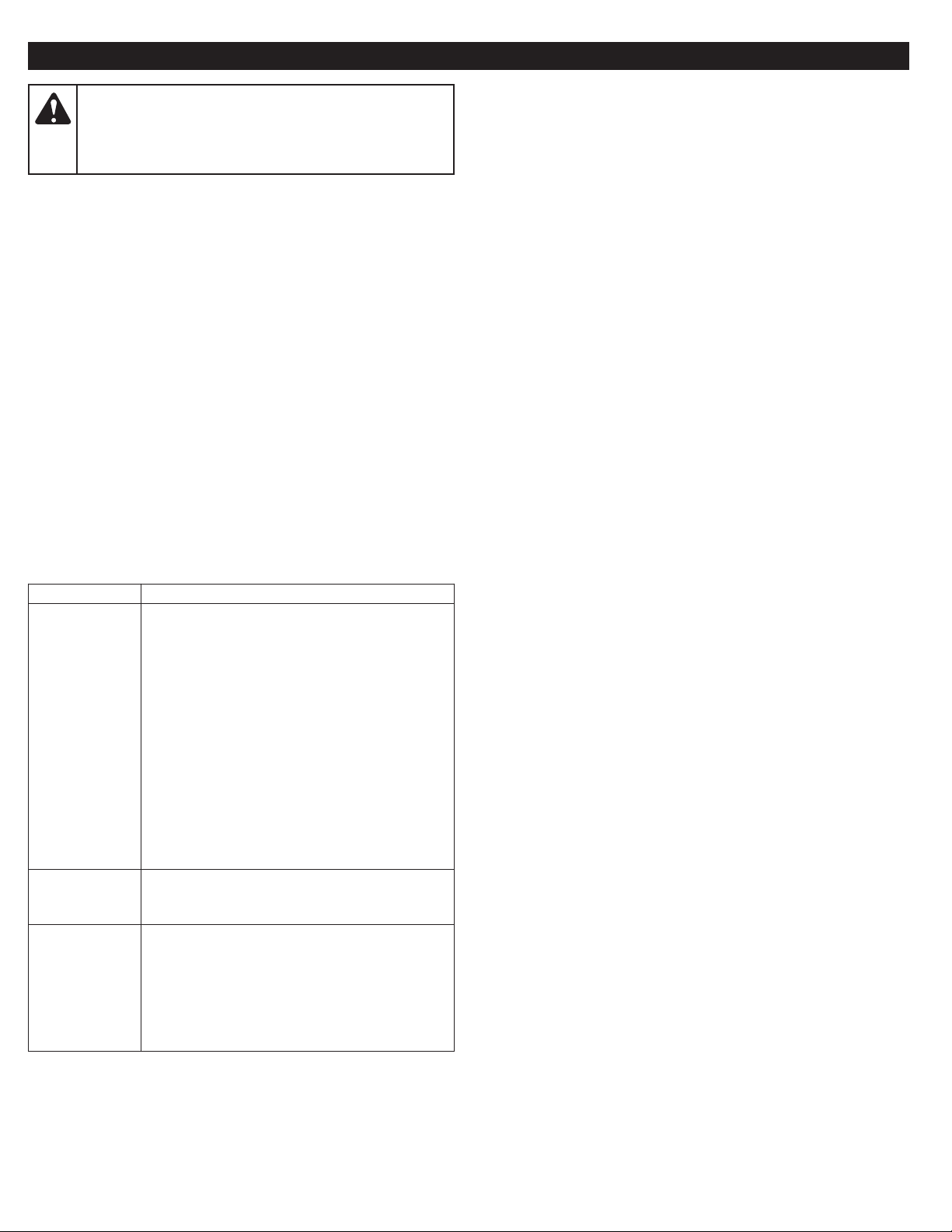

MAINTENANCE

WARNING:

maintenance or repairs while the unit is running. Always

allow the unit to cool before servicing or repairing the unit.

Disconnect the spark plug wire to prevent the unit from

starting accidentally.

To prevent serious injury, never perform

MAINTENANCE SCHEDULE

Perform these required maintenance procedures at the frequency

stated in the table. These procedures should also be a part of any

seasonal tune-up.

All service, other than the maintenance procedures described in

this manual, should be performed by a Sears or other qualified

service dealer.

NOTE: Some maintenance procedures may require special tools or

skills. If you are unsu

a Sears or other qualified service dealer. Call 1-888-331-4569

for more information.

NOTE: Maintenance, replacement, or repair of the emission control

devices and system may be performed by a Sears or other qualified

service dealer. Call 1-888-331-4569 for more information.

NOTE: Please read the California/EPA statement that came with the

unit for a complete list

control devices, such as the spark arrestor, muffler, carburetor, etc.

about these procedures, take the unit to

re

ing of terms and coverage for the emissions

CUSTOMER RESPONSIBILITY

FREQUENCY MAINTENANCE REQUIRED

Before each

use

After each use • Clean the unit and inspect decals. Refer to

Every 10 hours • Check the spark plug condition and gap.

• Check for loose screws, nuts or bolts

(tighten as needed)

• Check for damaged or worn parts*

• Check the saw chain sharpness. Refer to

Sharpening the Saw Chain.

• Test the chain brake*. Refer to Testing the

Chain Brake.

• Check the chain tension (adjust as needed).

Refer to Adjusting the Chain Tension.

• Fill the chain oil reservoir (refill frequently).

Refer to Adding Bar and Chain Oil.

• Fill the fuel tank with

fuel. Refer to the Oil and Fuel section.

• Clean the air filter. Refer to Maintaining the

Air Filter.

Cleaning in the Cleaning and Storage

section.

Refer to Maintaining the Spark Plug.

• Clean the guide bar groove and oil

passages. Lubricate the sprocket tip. Refer

to Maintaining the Guide Bar.

• Clean the cylinder fins. Refer to Cleaning in

the Cleaning and Storage section.

fre

sh, properly mixed

* If maintenance or replacement is required, have the unit serviced

by a Sears or other qualified service dealer.

19

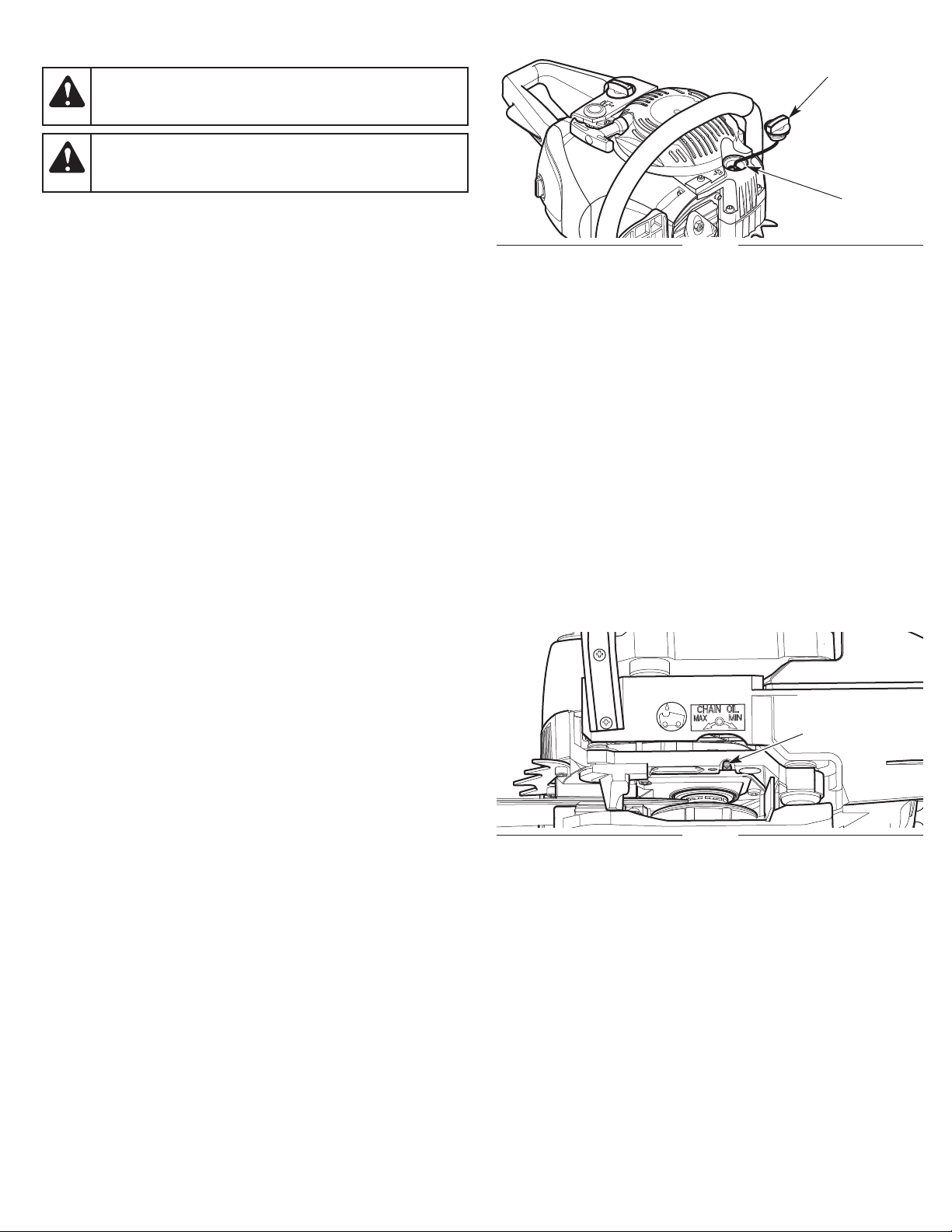

ADDING BAR AND CHAIN OIL

DANGER:

irreparable damage to the unit. Make sure the chain oil

reservoir is always filled. Always use bar and chain oil.

Failure to fill the chain oil reservoir will cause

Chain Oil

Reservoir Cap

WARNING:

Oil constantly flows from the chain oil

reservoir to oil the saw chain. Check the chain oil level

frequently so that it does not drop below half full.

The guide bar and saw chain require lubrication to minimize friction.

Never starve the guide bar and chain of lubricating oil. Running the

unit without enough oil will decrease cutting efficiency, shorten the

life of the saw chain, cause rapid dulling of the saw chain and

excessive wear to the guide bar from overheating. An insufficient

amount of lubricating oil is evidenced b

iscoloration or pitch build-up.

d

y smoke, guide bar

Only use bar and chain oil that is formulated to perform over a wide

range of temperatures with no diluting required in the chain oil

reservoir. Do not use motor oil or any other petroleum-based oil. Do

not use dirty, used or contaminated oil. Damage may occur to the

guide bar or saw chain. Dispose of old oil according to federal, state

and local regul

. Set the unit on a flat, level surface.

1

ations.

2. To prevent debris from entering the chain oil reservoir, use a damp

cloth to clean the chain oil reservoir cap and surrounding area.

3. Unscrew the chain oil reservoir cap (Fig. 23).

4. Carefully pour the oil into the chain oil reservoir. DO NOT overfill.

5. Reinstall the chain oil reservoir cap.

6. Wipe up any oil that may have spilled.

Chain Oil

Reservoir

Fig. 23

ADJUSTING THE BAR AND CHAIN OIL FLOW

Bar and chain oil will slowly flow from the chain oil reservoir onto the

chain. Approximately one tank of bar and chain oil is used for every

tank of fuel.

1. To increase the oil flow, turn the automatic oiler adjustment

screw counterclockwise with a flat-head screwdriver (Fig. 24).

2. To decrease the oil flow, turn the automatic oiler adjustment

screw clockwise with

a flat-head scre

wdriver (Fig. 24).

Chain Oil

Adjustment Screw

Fig. 24

20

Loading...

Loading...