Page 1

Operator’s Manual

4 Cycle

CULTIVATOR / EDGER

Model No. 316.29270

CAUTION: Before using

this product, read this

manual and follow all

Safety Rules and

Operating Instructions.

• Safety

ES

• Assembly

•Operation

• Maintenance

•Parts

• Español

Sears, Roebuck and Co., Hoffman Estates, IL 60179, U.S.A.

Visit our Sears website: www.sears.com/craftsman

Printed in U.S.A.

FORM NO.

769-00027A.fm

(4/03)

Page 2

TABLE OF CONTENTS

Content Page

Warranty 2

Safety 3

Assembly 5

Operation 6

Maintenance 9

Content Page

Service and Storage 12

Troubleshooting 13

Parts List 14

WARRANTY

Limited Warranty on Craftsman Cultivator / Edger

For two (2) years from the date of purchase, if this Craftsman Equipment is maintained, lubricated, and tuned up

according to the instructions to the operator’s manual, Sears will repair or replace free of charge any parts found

to be defective in material or workmanship. Warranty service is available free of charge by returning Craftsman

equipment to your nearest Sears Service Center. In-home warranty service is available but a trip charge will

apply. This Warranty applies only while this product is in the United States.

This Warranty does not cover:

• Expendable items which become worn during normal use, such as spark plugs, air cleaners, b elts, and oil

filters.

• Tire replacement or repair caused by punctures from outside objec ts, such as nails, thorns, stumps, or glass.

• Repairs necessary because of operator abuse, including b ut not limited to, damage caused by objects, such

as stones or metal debris, oversized stock, impacting o bjects that bend the frame or crankshaft, or overspeeding the engine.

• Repairs necessary because of operator negligence, including but not limited to, electrical a nd mechanical

damage caused by improper storage, failure to use the proper grade and amount of engine oil, or failure to

maintain the equipment according to the instructions contained in the operator’s manual.

• Engine (fuel system) cleaning or repairs caused by fuel determine to be contaminated or oxidized (stale). In

general, fuel should be used within 30 days of its pu rchase date.

• Equipment used for commercial or rental purposes.

TO LOCATE THE NEAREST SEARS SERVICE CENTER OR TO SCHEDULE SERVICE, SIMPLY CONTACT

SEARS AT 1-800-4-MY-HOME®.

This warranty gives you specific legal rights and you may also have othe r rights, which vary from state to state.

PRODUCT SPECIFICATION

Engine 4 Cycle

Engine Oil Type SAE 30

Engine Oil Capacity 3.4 Fluid Ounces

Fuel Capacity: Approximately 1 Quart

Spark Plug Champion RDZ-19H

Spark Plug Gap .025" (0.655 mm)

Model Number.........................................................

Serial Number...........................................................

Date of Purchase......................................................

Record both serial number and date of purchase and

keep in a safe place for future reference.

2

316.29270

Page 3

SAFETY

WARNING: This symbol points out important sa fety instructions which, if not followe d, could

endanger the personal safety and/or property of yourself and others. Read and follow all

instructions in this manual before attempting to op erate this machine. Failure to comply with these

instructions may result in personal injury. When you see this symbol - heed its warnin g.

WARNING: The Engine Exhaust from this product contains chemicals known to

the State of California to cause cancer, birth defects or other reproductive harm.

DANGER

manual. As with any type of power equipment, carelessness or error on the part of the o perator can

result in serious injury. This machine is capable of amputating hands and feet and throwing objects.

Failure to observe the following safety instructions could result in serious injury or death.

: This machine was built to be operated according to the rules for safe operation in this

Training

1. Read, understand, and follow all instructions on

the machine and in the manual(s) before

attempting to assemble and operate. Keep this

manual in a safe place for future and regular

reference and for ordering replacement parts.

2. Be familiar with all controls and their proper

operation. Know how to stop the machine and

disengage them quickly.

3. Never allow children under 14 years old to

operate this machine. Children 14 years old and

over should read and understand the operation

instructions and safety rules in this manual and

should be trained and supervised by a parent.

4. Never allow adults to operate this mac hine

without proper instruction.

5. Keep bystanders, helpers, pets, and children at

least 50 feet from the machine while it is in

operation. Stop machine if anyone enters the

area.

PREPARATION

1. Thoroughly inspect the area where the

equipment is to be used. Remove all stones,

sticks, wire, and other foreign objects which could

be tripped over and cause personal injury.

2. Wear sturdy, rough-soled work shoes and close-

fitting slacks and shirts. Loose fitting clothes or

jewelry can be caught in movable parts. Never

operate this machine in bare feet or sandals.

3. Wear safety glasses or goggles that are marked

as meeting ANSI Z87.1 standards and ear/

hearing protection when operating this unit. Wear

a face or dust mask if the operation is dusty.

4. This unit has a clutch. The tines remain stationary

when the engine is idling. If they do not, have the

unit adjusted by an authorized service dealer.

5. Squeeze the throttle control and check that it

returns automatically to the idle position.

6. Never leave this machine unattended with the

engine running.

7. Never attempt to make any adjustments while

engine is running, except where specifically

recommended in the operator’s manual.

8. To avoid personal injury or property damage u se

extreme care in handling gasoline. Gasoline is

extremely flammable and the vapors are

explosive. Serious personal injury can occur

when gasoline is spilled on yourself or your

clothes which can ignite. Wash your skin and

change clothes immediately.

a. Use only an approved gasoline container.

b. Extinguish all cigarettes, cigars, pipes, and

other sources of ignition.

c. Never fuel machine indoors.

d. Never remove gas cap or add while the

engine is hot or running.

e. Allow engine to cool at least two minutes

before refueling.

f. Never over fill fuel tank. Fill tank to no more

than 1/2 inch below bottom of filler neck to

provide space for fuel expansion.

g. Replace gasoline cap and tighten securely.

h. If gasoline is spilled, wipe it off the engine

and equipment. Move machine to another

area. Wait 5 minutes before starting the

engine.

i. Never store the machine or fuel container

inside where there is an open flame, spark,

or pilot light (e.g. furnace, water heater,

space heater, clothes dryer, etc.)

j. Allow machine to cool at least 5 minutes

before storing.

OPERATION

1. Do not put hands and feet near rotating parts.

Contact with the rotating parts can amputate

fingers, hands, and feet.

2. Do not operate machine while under the influence

of alcohol or drugs.

3. Never operate this machine without good visibility

or light. Always be sure of your footing and keep a

firm hold on the handles.

4. Keep bystanders, helpers, pets, and children at

least 50 feet from the machine while it is in

3

Page 4

operation. Stop machine if anyone enters the area.

5. Be careful when cultivating in hard ground. The

tines may catch in the ground and propel the

cultivator forward. If this occurs, let go of the handle

and do not restrain the machine.

6. Never operate the machine at high transport

speeds on hard or slippery surfaces.

7. Exercise caution to avoid slipping or falling.

8. Look down, behind, and use care when pulling

machine towards you.

9. Start the engine according to the instructions found

in this manual and keep feet well away from the

tines at all times.

10. After striking a foreign object, stop the engine,

disconnect the spark plug wire and ground agains t

the engine. Thoroughly inspect the machine for any

damage. Repair the damage before starting and

operating.

11. Disengage all clutch and stop engine before you

leave the operating position (behind the handle).

Wait until the tines come to a complete stop before

unclogging the tines, making any adjustments, or

inspections.

12. Never run an engine indoors or in a poorly

ventilated area. Engine exhaust contains carbon

monoxide, an odorless and deadly gas.

13. Muffler and engine become hot and can cause a

burn. Do not touch.

14. Use caution when cultivating near fences, buildin gs

and underground utilities. Rotating tines can cause

property damage or personal injury.

15. Do not overload machine capacity by attempting to

cultivate soil to deep or to fast of a rate.

16. If the machine should start making an unusual

noise or vibration, stop the engine, disconnect the

spark plug wire and ground it against the engine.

Inspect thoroughly for damage. Repair any damage

before starting and operating.

17. Keep all shields, guards and safety devices in place

and operating properly.

18. Never pick up or carry machine while the engine is

running.

19. Use only attachments and accessories available by

the Sears. Failure to do so, can result in personal

injury.

20. If situations occur which are not covered in this

manual, use care and good judgment. Contact your

nearest Sears service center.

Maintenance And Storage

1. Never tamper with safety devices. Check their

proper operation regularly.

2. Check bolts and screws for proper tightness at

frequent intervals to keep the machine in safe

working condition. Also, visually inspect machine

for any damage.

3. Before cleaning, repairing, or inspecting, stop the

engine and make certain the tines and all moving

parts have stopped. Disconnect the spark plug wire

and ground it against the engine to prevent

unintended starting.

4. Do not change the engine governor settings or

over-speed the engine. The governor controls the

maximum safe operating speed of the engine.

5. Maintain or replace safety and instruction labels, as

necessary.

6. Follow this manual for safe loading, unloading,

transporting, and storage of this machine.

7. Never store the machine or fuel container inside

where there is an open flame, spark or pilot ligh t

such as a water heater, furnace, clothes dryer etc.

8. Always refer to the operator’s manual for proper

instructions on off-season storage.

9. Always store unit in cultivator mode (all four tines

on unit) to avoid tip over.

10. If the fuel tank has to be drained, do this outdoors.

11. Observe proper disposal laws and regulations for

gas, oil, etc. to protect the environment.

WARNING: Restrict the use of this power

machine to persons who read, understand

and follow the warnings and instructions in

this manual and on the machine.

4

Page 5

ASSEMBLY

IMPORTANT:

oil in the engine. After assembly, see OPERATION

section of this manual for proper fuel and engine oil

fill-up.

NOTE: Reference to right or left hand side of the

cultivator / edger is observed from the operating

position.

This unit is shipped without gasoline or

Removing Unit From Carton

• Remove staples, break glue on top flaps, or cut

tape at carton end and peel along top flap to open

carton.

• Remove all loose parts that may be included with

unit.

• Cut along corners, lay carton down flat, and

remove packing material.

• Roll or slide unit out of carton and check carton

thoroughly for loose parts.

Loose Parts In Carton

• Operator’s Manual

• 3.4 fl.oz. (100ml) Bottle of Engine Oil

• Edger Wheel

• Edger Blade

Wing Nut

Marked

Lines

Carriage

Bolt

Lower Handle

Connector

Upper Handle

Connector

Disconnecting Spark Plug

Before setting up your cultivator / edger, disconnect

the spark plug wire from the spark plug and ground to

a stud on the engine.

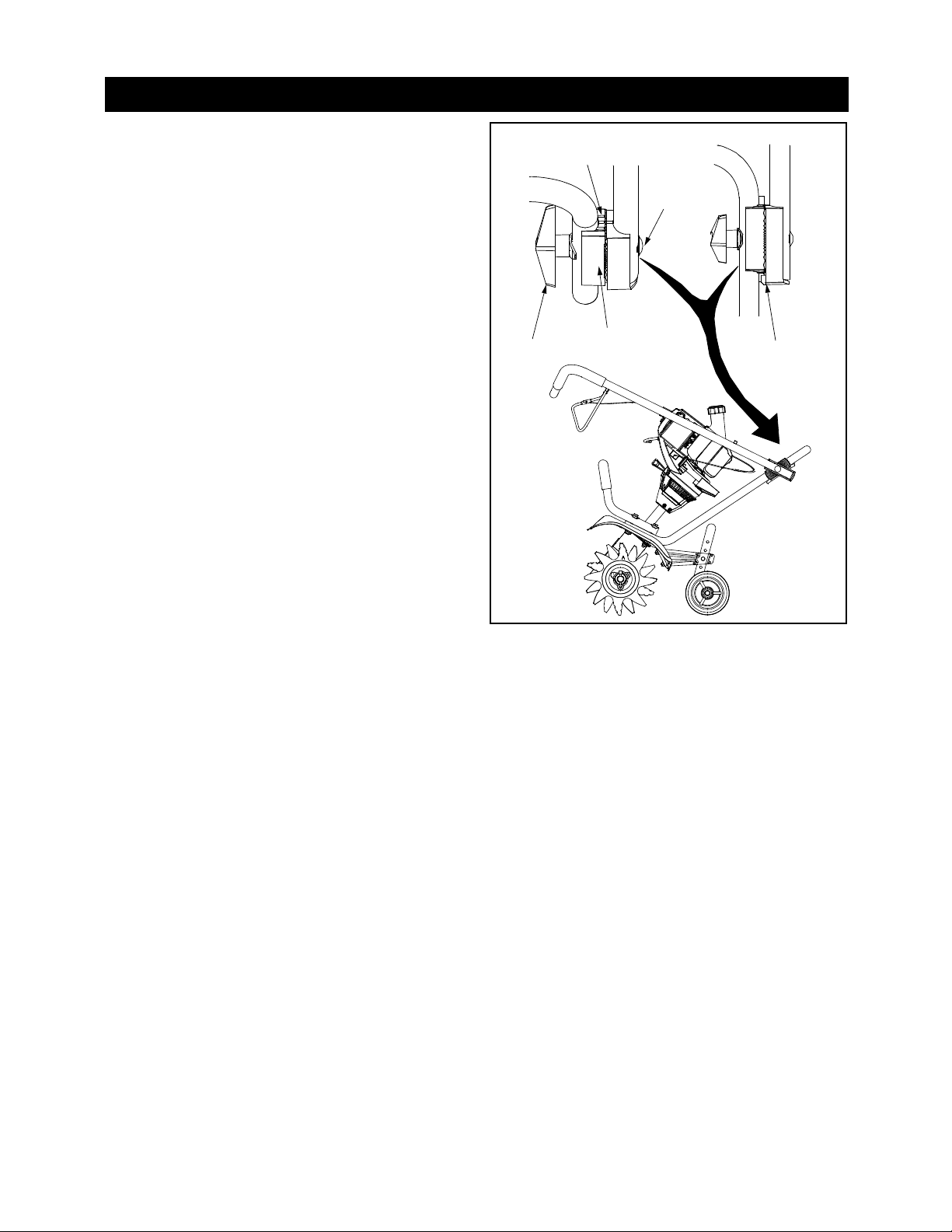

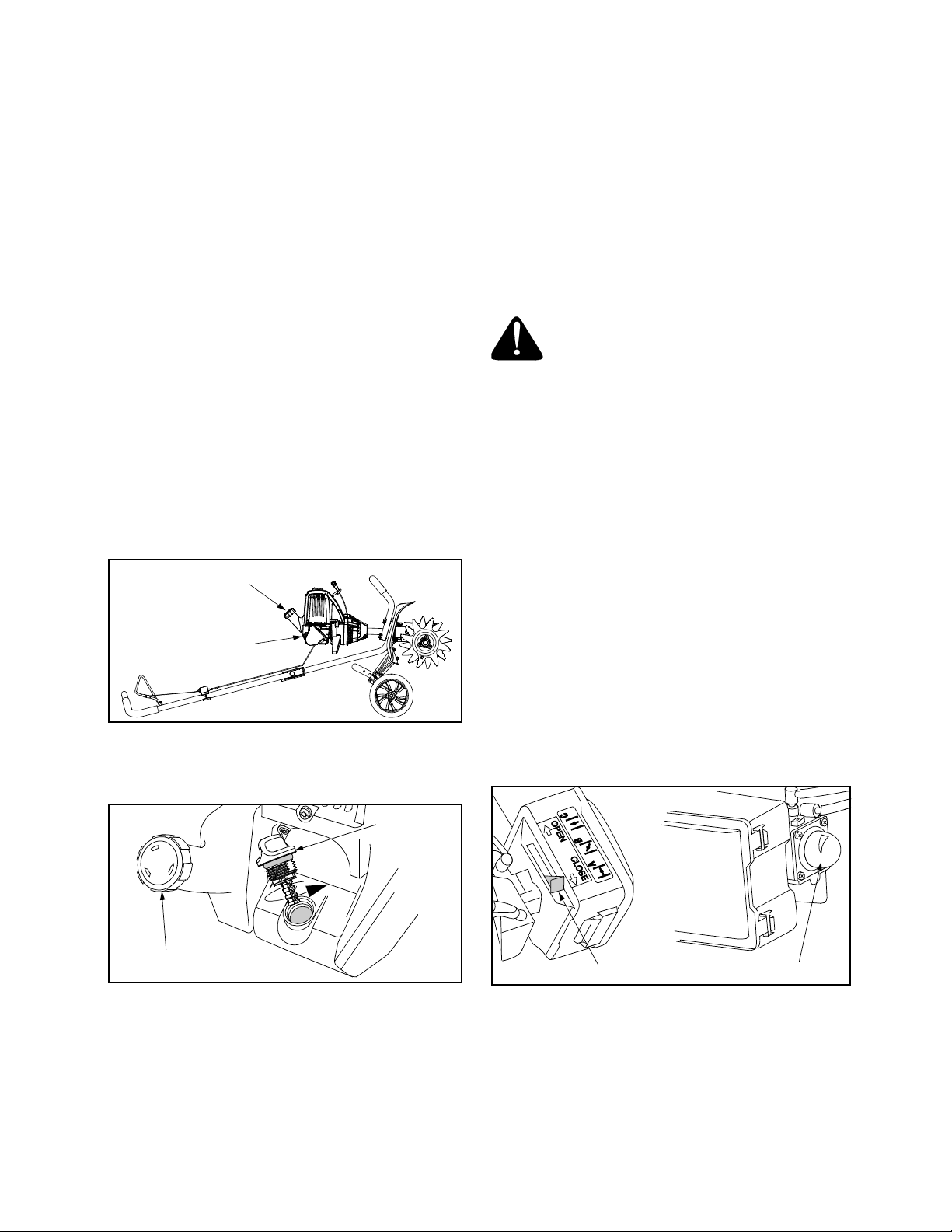

Setting Up Your Cultivator / Edger

• Loosen each wing nut enough to sep arate the

plastic connectors between the upper and lower

handle. Gently lift up and pull out on the upper

handle to raise the handle toward the operating

position. See Figure 1.

• Separate the connectors and position the bottom

tip of upper handle connector in front of the

bottom tip of lower handle connector.

• The lower handle connector has three marked

lines on the top and the upper handle connector

has one marked line.

• Position the connectors aligning the marked line

on the upper connector with the middle marked

line on the lower connector.

• To secure the upper and lower handle, tighten the

wing nuts and washers (carriage bolts must be

seated properly into the outer handle and

grooves must line up between connectors).

• If not already, tighten the cable tie on the right

side of handle.

Figure 1

5

Page 6

Starter Handle

Front Handle

Cultivator

Tines

OPERATION

On/Off Switch

Throttle Control

Handle

Connectors

Primer

Edger Wheel

Edger Blade

Choke Lever

Read this operator’s manual and safety rules before

operating your cultivator / edger. Compare the

illustrations with your unit to familiarize yourself with

the location of various controls and adjustments.

See Figure 2.

Starter Handle

The starter handle is attached to an eyebolt in the

front of the engine.

Throttle Control

The throttle control is located on the upper handle.

Squeezing the control against handle speeds up the

engine and engages the cultivator / edger tines.

Release the handle to stop the tines.

Choke Lever

The choke lever is located on the left side of engine

and it is used to enrich the fuel mixture when starting

a cold engine.

A

Close

B

Partial

C

Open

Primer Button

The primer button is located on the right side of

engine and it is used in conjunction with the choke to

enrich the fuel mixture in the carburetor when starting

a cold engine.

On/Off Switch

The On/Off switch is located on the upper hand le.

The switch must be in the On (I) to start engine and

Figure 2

Off (O) to stop engine.

Handle Connectors

The handle connectors are on each side between

lower and upper handle. They are used to lock the

upper handle in a set position.

Front Handle

The front handle can be used when transportin g the

unit.

Tines

The tines are used to cultivate, furrow, and prepare

your garden for seeding.

Wheel Support Bracket

The wheel support bracket is attached to the tailpiece

bracket behind the cultivator / edger. It is used to

adjust the wheels to a higher or lower restin g position.

Edger Wheel and Blade

The edger wheel and blade are separate parts that d o

not come attached on the cultivator / edger. They are

to be used instead of the cultivator tines for vertical

edging.

Stopping Engine

• Push the On/Off switch to Off (O) position to stop

engine and tines.

• Disconnect spark plug wire from spark plug an d

ground against the engine.

6

Page 7

Oil Fill-Up

Using the proper type and weight of oil in the

crankcase is extremely important. Check the oil

before each use and change the oil regularly. Failure

to use the correct oil or using dirty oil can cause

premature engine wear and failure. Refer to

Maintenance Section.

Use a high-quality SAE 30 weight oil of API

(American Petroleum Institute) service class SF, SG,

or SH.

NOTE: This unit is shipped without oil in the engine.

In order to avoid damage to the unit, put the

recommended oil in the crankcase before attempting

to start unit.

This unit is shipped with one 3.4 fluid oz. (100ml)

bottle of SAE 30 SF, SG, or SH oil.

NOTE: For cold weather operation, temperatures

below 40°F (4°C) use a high-quality SAE 10W30

weight oil of API (American Petroleum Institute)

service class SF, SG, or SH.

• When adding oil, the unit must be laid back in

the horizontal position on a flat surface with

the upper handle touching the ground.

See Figure 3.

• Wipe up any oil that may have spilled and reinstall

the oil fill plug/dipstick.

Gas Fill-Up

Old fuel is the primary reason for the unit not running

properly. Be sure to use fresh, clean, and unleaded

gasoline. Use fresh fuel (less than 60 days old), when

using alcohol-blended fuel.

• When adding fuel, unit must be laid back in the

horizontal position on a flat surface.

• Remove fuel cap and remove the tag from the

fuel tank neck. Refer to Figure 4.

WARNING: Use extreme care when handling gasoline. Gasoline is extremely

flammable and the vapors are explosive.

Never fuel machine indoors or while the

engine is hot or running. Extinguish cigarettes, cigars, pipes, and other sources

of ignition.

• Place spout of gas container into the fill hole on

the fuel tank and fill tank.

• Wipe up any gasoline that may have spilled and

reinstall the fuel cap.

• Move the unit at least 30 ft. (9.1m) from the

fueling source and site before starting the engine.

Add Fuel

Add Oil

Figure 3

• Remove the oil plug/dipstick from the crankcase

and pour 3.4 fl. oz. (100ml.) bottle of oil into the

oil fill hole. Save bottle for refill. See Figure 4.

DipStick

Fuel Cap

Figure 4

IMPORTANT:

maintaining the proper oil level in the crankcase

cannot be overemphasized. DO NOT OVERFILL.

NOTE: This is a 4-cycle engine. In order to avoid

damage to the unit, do not mix oil with gasoline.

The importance of checking and

Starting Engine

• Before starting make sure spark plug wire is

attached to spark plug.

• Check oil level and fill fuel tank with fresh fuel.

• Push On/Off switch on upper handle to On (I).

• Place choke lever in Close (A) position.

See Figure 5.

• Fully press and release the primer bulb slowly 5

to 7 times. Gasoline should be felt and visible in

the bulb. Press primer a few more times, if

gasoline is not noticed. See Figure 5.

Choke Lever

Figure 5

• Squeeze the throttle control to the wide open

position. Refer to Figure 2.

• Place right foot on the right side of cultivator

wheel.

• Pull the starter rope briskly 3 to 5 times or until

engine attempts to run.

• Move the choke to Partial (B) position.

7

Primer Bulb

Page 8

NOTE: The en gine will not operate in the Close (A)

position.

• Pull the starter rope again 1 to 3 times until

engine starts.

• Move choke lever to Open (C) position and run at

full throttle for 30 seconds.Release throttle lever.

• With tines off the ground, depress the throttle

lever against the upper handle to increase engine

speed and rotate tines.

WARNING: Never run the engine indoors

or in a poorly ventilated area. Engine

exhaust contains carbon monoxide, an

odorless and deadly gas. Keep hands,

feet, hair, and loose clothing away from

rotating tines.

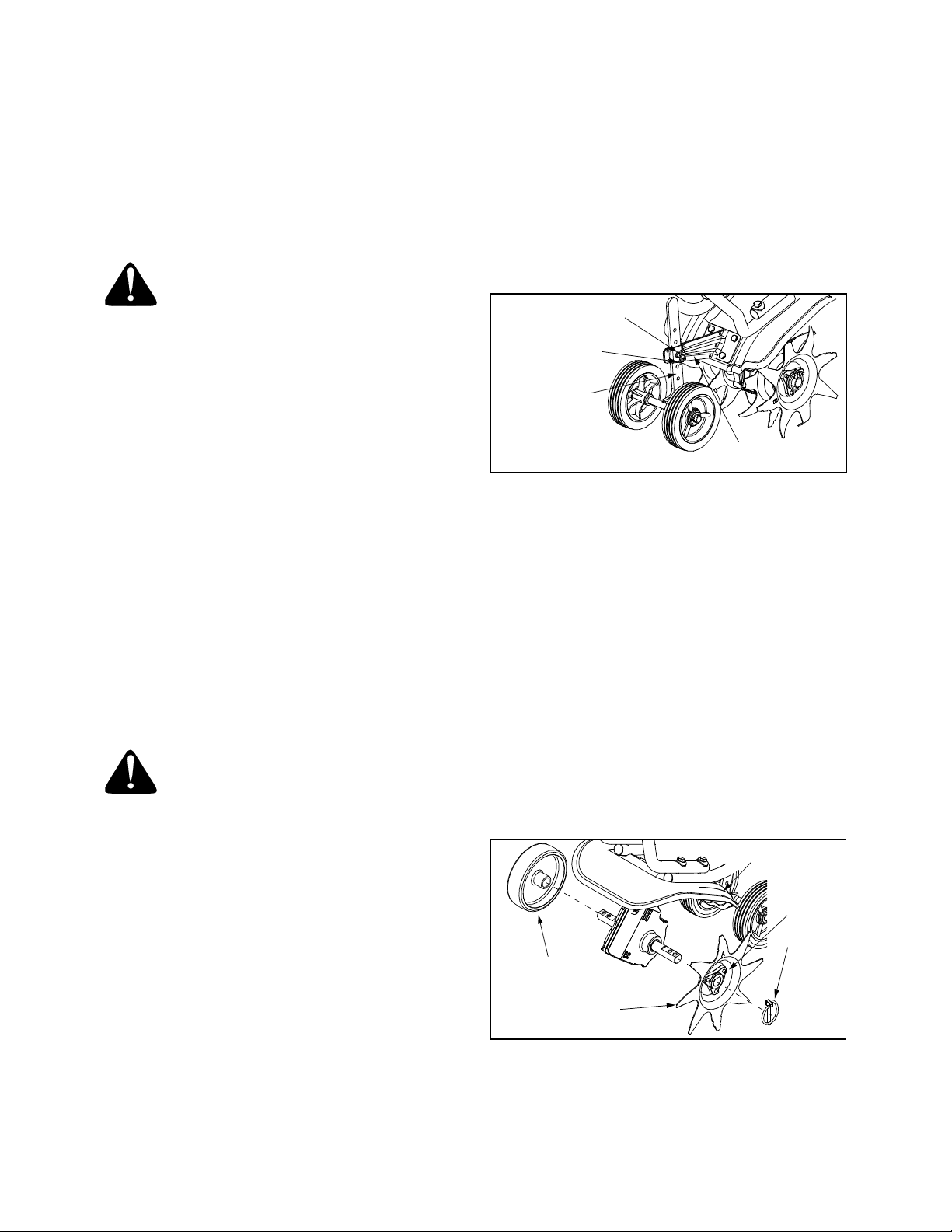

Adjusting the Wheel Support Bracket

To adjust the wheel support bracket proceed as

follows:

• Stop engine and disconnect spark plug to avoid

accidental starting.

• Remove cotter pin from the clevis pin and slide

pin out of tailpiece bracket. See Figure 6.

• Slide the wheel support bracket up or down in the

tailpiece, aligning the holes to the desire height.

• Place the clevis pin through the hole and secure

with a cotter pin.

Clevis Pin

Cotter Pin

Starting A Warm Engine

• Push On/Off switch on upper handle to On (I).

• Move the choke to Partial (B) position.

• Fully press and release the primer bulb slowly 5

to 7 times. Gasoline should be felt and visible in

the bulb. Press primer a few more times, if

gasoline is not noticed. See Figure 5.

• Squeeze the throttle control to the wide open

position. Refer to Figure 2.

• Place right foot on the right side of cultivator

wheel.

• Pull the starter rope briskly 3 to 5 times or until

engine starts.

• Move choke lever to Open (C) position.

• With tines off the ground, depress the throttle

lever against the upper handle to increase engine

speed and rotate tines.

Using Your Cultivator

WARNING: Never pick up or carry the

unit while the engine is running. Serious

personal injury could result.

• Move the cultivator to the work area prior to

starting the engine. The cultivator may be

transported by pushing it on the wheels or

carrying it by the handles.

• Start the engine referring to Starting Engine.

• With both hands on the upper handle and

squeezing the throttle control, slowly lower the

cultivator until the tines make contact with the

ground.

• Once the tines are in the ground, continue to

cultivate at a moderate pace until you are familiar

with the controls and the handling of the

cultivator.

• To adjust the cultivating depth, adjust the wheel

support bracket. See Adjusting The Wheel

Bracket.

For cultivation, a two to three inch depth is desirable .

When laying out plant rows, be sure to allow enough

width to permit cultivation between the rows.

Wheel Support

Bracket

Tailpiece Bracket

Figure 6

Attaching the Edger Wheel And Blade

To convert the cultivator to an edger proceed as

follows:

• Push the On/Off switch to Off (O) position to stop

engine and tines and disconnect spark plug to

avoid accidental starting.

• It may be necessary to lay the cultivator / edger

back in a horizontal position on a flat level surface

with the upper handle touching the ground.

• Remove the click pin from each end of the tine

shaft and slide the tines off the shaft.

• Slide the edger wheel, with the hub facing inward,

onto the right side of the tine shaft and secure

with the click pin in the inside hole. See Figure 7.

• Slide the edger blade with the hub facing out onto

the left side of tine shaft and secure with the click

pin in the inside hole. See Figure 7.

Edger Guide

Line

Hub

Click Pin

Edger Wheel

Edger Blade

Figure 7

• Guide edger blade along a flowerbed, sidewalk,

or driveway with the edger wheel along the

outside edge. Use the edger guide line to line u p

edger blade. See Figure 7.

8

Page 9

MAINTENANCE

MAINTENANCE

SCHEDULE

Check Engine Oil

Change Engine Oil

E

N

Clean Air Filter

GI

N

E

Check Spark Plug

Check Spark Arrester

Rocker Arm Clearance

NOTE: Maintenance, replacement, or repair of

the emission control devices and system may be

performed by any non-road engine repair establishment, individual or authorized service dealer.

In order to assure peak performance of your engine,

inspection of the engine exhaust port may be

necessary after 50 hours of operation. If you notice

lost RPM, poor performance, or general lack of

acceleration, this service may be required. If you feel

your engine is need of this inspection, refer to a Sears

service center. DO NOT attempt to perform this

process yourself as engine damage may result from

contaminants envolved in the cleaning process for the

port.

WARNING: Always stop engine and disconnect spark plug wire before cleaning

or doing any kind of maintenance on

your cultivator / edger.

Checking Oil

Be

e

e

s

s

u

u

u

h

c

a

e

e

e

r

r

o

e

f

t

f

A

o

h

h

c

a

0

1

t

s

r

i

F

s

r

s

r

u

o

h

5

2

y

r

e

v

E

u

o

h

0

5

y

r

e

v

E

e

s

r

g

a

r

o

t

s

e

r

o

f

e

B

Add Fuel

Add Oil

Figure 8

• Remove the oil fill plug/dipstick and wipe off oil.

Reinsert it all the way back in.

• Remove the oil fill plug/dipstick and check oil

level. Oil should be up to the top of the dipstick .

Refer to Figure 4.

• If the level is low, add a small amount of oil to the

oil fill hole and recheck. Repeat until the oil level

reaches the top of the dipstick. See Figure 9.

NOTE: Make sure the O-ring is in place on the oil fill

plug/dipstick when checking and changing the oil.

WARNING: To prevent extensive engine

wear and damage to the unit, always

maintain the proper oil level in the crankcase. Never operate the unit with the oil

level below the bottom of the dipstick.

• Check oil before each use.

• Stop engine and allow oil to drain into the

crankcase.

• When checking oil, the unit must be laid back

in the horizontal position on a flat surface with

the upper handle touching the ground.

See Figure 8.

• Keep dirt and debris out of the engine. Clean the

area around the oil fill plug/dipstick before

removing it.

O-Ring

Full

Oil Fill

Plug/Dipstick

Figure 9

Changing Oil

• Remove the oil fill plug/dipstick.

• Tip the unit back or away from the air filter to pour

the oil out of the oil fill hole and into a container.

• Wipe up any oil residue on the unit and clean up

any oil that may have spilled. Dispose of the oil

according to federal, state, and local regulations.

9

Page 10

• When adding oil, the unit must be laid back in

the horizontal position on a flat surface with

the upper handle touching the ground.

See Figure 8.

• Refill the crankcase with 3.4 fl.oz. (100 ml.) of

SAE 30 SF, SG, or SH oil.

• Replace the oil fill plug/dipstick.

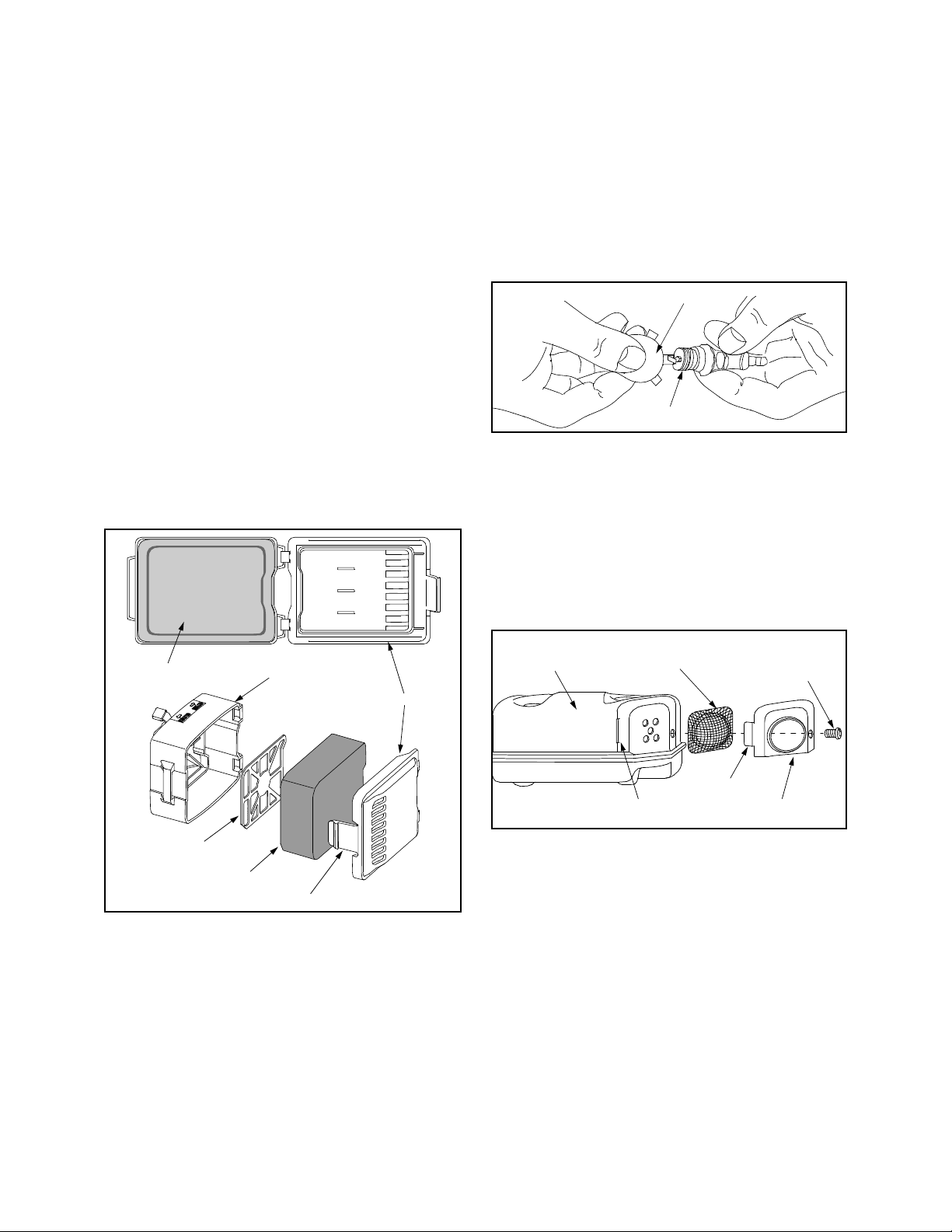

Air Filter Maintenance

• Open the air filter cover on side of engine by

pushing the tab on the left side in and swinging

the air filter cover out and off. See Figure 10.

• Remove the air filter and screen.

• Wash the filter in detergent and water. Rinse the

filter thoroughly and allow it to dry.

• Apply enough clean SAE 30 motor oil to lightly

coat the filter and squeeze the filter to spread and

remove excess oil.

• Replace the screen and filter.

• Position the hooks on the right side of the air filter

cover into the slots at the righ t side of the air filter

housing.

• Swing the cover to the left until the tab on the air

filter cover snaps into place in the slot.

• Stop the engine and allow it to cool. Grasp the

plug wire firmly and pull the cap from the spark

plug.

• Clean dirt from around the spark plug and

remove the spark plug from the cylinder head by

turning counterclockwise using a socket.

• Set the air gap at 0.025 in (0.655 mm.) using a

feeler gauge. See Figure 11.

• Install a correctly gapped spark plug in the

cylinder head and tighten by turning the socket

clockwise until snug. Do not over tighten.

.025" Feeler Gauge

Spark Plug

Figure 11

Spark Arrestor Maintenance

• Remove the muffler cover, if equipped, by

pressing down on the corner with a flat blade

screwdriver. Slide the notches on the sides of the

muffler cover over the tabs on the engine cover

and remove.

• Remove the screw attaching the spark arrestor

cover to the muffler. See Figure 12.

Air Filter

Screen

Air Filter

Air Filter

Housing

Air Filter Cover

Tab

Figure 10

Carburetor Adjustment

If the engine will not idle, hesitates or stalls on

acceleration, or there is a loss of engine power have

the carburetor adjusted by an Sears service center.

Replacing The Spark Plug

The spark plug should be removed and check after

every 25 hours of operation. To replace the spark

plug proceed as follows:

Spark Arrestor

Muffler

• Pull the tab on the spark arrestor cover out of the

muffler and remove the spark arrestor cover.

• Remove the spark arrestor screen from the spark

arrestor cover.

• Clean the spark arrestor screen with a wire brush

or replace screen.

• Reinstall the spark arrester screen, spark

arrestor cover, and screw.

Screen

Slot

Figure 12

Screw

Tab

Spark Arrester

Cover

Rocker Arm Clearance

This requires disassembly of the engine. If you feel

unsure or unqualified to perform this adjustment, take

the unit to a Sears service center.

NOTE: Insp ect the valve to rocker arm clearance with

a feeler gauge after the first 10 hours of operation

10

Page 11

and then every 50 hours of operation thereafter.

IMPORTANT:

The engine must be cold when checking

or adjusting the valve clearance. This task should be

performed inside in a clean and dust free area. A new

gasket must be used in this adjustment. A new rocker

arm gasket (part # 791-182099)can be purchased from

your Sears service center.

• Remove the muffler cover by pressing down on the

corner with a flat blade screwdriver. Slide the

notches on the sides of the muffler cover over the

tabs on the engine cover and remove.

• Remove the two screws on top of the engine cover

with a phillips screwdriver. See Figure 13.

Screw

• Remove the rocker arm cover and gasket.

Pull the starter rope slowly to bring the piston to the top

of its travel. Make sure:

• The piston should be at the top of its travel while

looking in the spark plug hole. See Figure 14.

• Both rocker arms should move freely and both

valves are closed.

If not, repeat this step.

• Slide the feeler gauge between the rocker arm and

the valve return spring. Measure the clearance

between the valve stem and rocker arm. Do both

intake and exhaust valves. See Figure 15.

The recommended clearance for both intake and

exhaust is .003-.006” (.076-.152mm). Use a standard

(.127mm) feeler gauge. The feeler gauge should slide

between the rocker arm and valve stem with a slight

amount of resistance without binding.

Rocker Arms Adjusting Nuts

Gasket

Engine Cover

Remove Screws

Muffler

Figure 13

• Remove the screw on back of the engine cover.

See Figure 13.

• Disconnect the spark plug wire and clean dirt

around plug. Remove the spark plug from the cylinder head by turning a 5/8” socket counterclockwise.

• Remover engine cover.

NOTE: Pull the starter rope out a little to give some

slack and to ease the removal of the engine cover.

• Clean dirt from around the rocker arm cover and

remove the screw holding the rocker arm cover with

a large flat blade screwdriver or Torx T25 bit.

See Figure 14.

Rocker Arm Cover

Spark Plug Hole

Figure 14

Feeler Gauge

Adjusting Nut

Rocker Arm

.003-.006

(.076-.152mm)

Feeler Gauge

Figure 15

If the clearance is not within specification :

• Turn the adjusting nut using a 5/16” (8mm) wrench

or nut driver.

• To increase clearance, turn the adjusting nut

counterclockwise.

• To decrease clearance, turn the adjusting nut

clockwise.

• Recheck both clearances and adjust as nec essary.

• Reinstall the rocker arm cover using a new gasket.

Torque the screw to 20-30in-lb (2.2-3.4 Nm).

• Reinstall the engine cover and check alignment of

the cover before tightening the screws.

• Replace the muffler cover and slip the long tabs on

the cover into the engine cover. Slide the notches

on the side of muffler cover over the tabs on engine

cover. Snap into place.

• Check spark plug, reinstall, and attach spark plug

wire.

11

Page 12

SERVICE AND STORAGE

WARNING: Do not at any time make any

adjustment to the unit without first

stopping engine and disconnecting

spark plug wire.

Tine Removal and Replacement

NOTE: All four tines should be replaced at the same

time, because they will wear evenly through normal

use.

• Push the On/Off switch to Off (O) position to stop

engine and tines and disconnect spark plug to

avoid accidental starting.

• It may be necessary to lay the cultivator back in a

horizontal position on a flat level surface with the

upper handle touching the ground.

• Remove the click pin from each end of the tin e

shaft and slide the tines off the shaft.

• Slide new tines on with hubs facing out. The four

tines are marked with letters A and B. Place one

A and one B tine on the tine shaft. See Figure 16.

• Secure new tines to shaft with click pins.

NOTE: It may be necess ary to wash the dirt off the

tines and shaft for ease of removal.

Storing Your Cultivator / Edger

• Thoroughly clean the unit and inspect for any

loose or damaged parts. Repair or replace

damaged parts and tighten loose screws, nuts, or

bolts.

• Wipe equipment with a oiled rag to prevent rust.

• Never store the unit with fuel in the tank where

fumes may reach an open flame or spark.

• Always store unit in cultivator mode (all four tines

on unit) to avoid tip over.

Engine

If the unit will be stored for longer than 60 days:

• Clean engine by removing dirt and debris with a

cloth or brush from cooling fins, air intake screen,

levers, and linkage. This will help ensure

adequate cooling engine speed.

• Drain all gasoline from the gas tank into a

container and dispose in accordance with federal,

state, and local regulations.

• Start the engine and allow it to run until it stalls.

This ensures that all gasoline has been drained

from the carburetor.

• Allow the engine to cool and remove the spark

plug and put 1 oz. (30ml) of high quality motor oil

into the cylinder. Pull the starter rope slowly to

distribute the oil and reinstall the spark plug.

B Tine

Hubs

Figure 16

A Tine

Click Pin

NOTE: Remove the spark plug and drain all of the oil

from the cylinder before attempting to start the unit

after storage.

• When changing oil, refer to the Maintenance

section. Dispose of the oil in accordance with

federal, state, and local regulations.

• Store unit in a clean, dry area. Do not store next

to corrosive materials such as fertilizer.

• For more compact storage, store unit in the

shipping position with the upper handle folded

toward engine. See ASSEMBLY section for

details.

12

Page 13

TROUBLESHOOTING

Problem Cause Remedy

Engine fails to start 1. Spark plug wire disconnected.

2. Ignition switch is OFF (O).

3. Fuel tank empty or stale fuel.

4. Primer bulb wasn’t pressed enough.

5. Engine flooded.

6. Faulty spark plug.

Engine flooded 1. Too much gasoline primed through

engine.

Engine runs erratic 1. Spark plug wire loose.

2. Blocked fuel line or stale fuel.

3. Vent in gas cap plugged.

4. Water or dirt in fuel system.

5. Dirty air filter.

6. Carburetor out of adjustment.

Engine overheats 1. Engine oil level low.

2. Dirty air filter.

3. Carburetor not adjusted properly.

Occasional skip (hesitates)

at high speed

Idles poorly 1. Spark plug fouled, faulty or gap too

NOTE: For repairs beyond the minor adjustments listed above, contact your nearest Sears service center or other

qualified service center or call 1-800-4-MY-HOME®.

1. Spark plug gap too close. 1. Adjust gap to .025”.

wide.

2. Carburetor improperly adjusted.

3. Dirty air filter.

1. Connect wire to spark plug.

2. Turn switch to ON (I) .

3. Fill tank with clean, fresh gasoline.

4. Press primer bulb fully and slowly 5-7

times.

5. Use starting procedure with choke lever

in the Open (C) position.

6. Clean, adjust gap, or replace.

1. With the choke lever in the Open (C)

position.

2. Squeeze the throttle control to the wide

open position.

3. Place right foot on the right side of

cultivator wheel.

4. Pull the starter rope briskly 3 to 5 times

or until engine starts.

5. With tines off the ground, depress the

throttle lever against the upper handle

to increase engine speed and rotate

tines.

1. Connect and tighten spark plug wire.

2. Clean fuel line; fill tank with clean, fresh

gasoline

3. Clear vent.

4. Drain fuel tank. Refill with fresh fuel.

5. Clean or replace air filter.

6. See qualified service center.

1. Fill crankcase with proper oil.

2. Clean or replace air filter.

3. See qualified service center.

1. Reset gap to .025” or replace spark

plug.

2. See qualified service center.

3. Clean or replace air filter.

13

Page 14

PARTS LIST

Sears Craftsman 4 Cycle Cultivator / Edger Model 316.29270

16

13

15

3

2

5

8

7

11

11

12

9

13

14

1

4

6

8

18

19

37

32

31

22

28

39

29

17

22

38

27

40

23

26

33

10

22

25

34

21

20

24

36

35

14

Page 15

Sears Craftsman 4 Cycle Cultivator / Edger Model 316.29270

Ref.

No.

1. 753-04042 Throttle Control

2. 753-04043 Torsion Spring

3. 791-182673 On/Off Switch

4. 753-04044 Foam Grip

5. 753-04045 Throttle Cable

6. 753-04046 Upper Handle

7. 753-04047 Upper Handle Connector

8. 753-04048 Carriage Bolt 5/16-18 x 3.0

9. 753-04049 Cable Tie

10. 791-181840 Drive Shaft

11. 753-04050 Lower Handle Connector

12. 753-04051 Wing Knob 5/16-18

13. 753-04052 Shoulder Washer .32 0 I D x .93 OD

14. 753-04053 Lower Handle

15. 753-04054 Hex Cap Screw 5/16-18 x 2.25

16. 753-04055 Front Handle

17. 753-04056 Flange Lock Nut 5/16-18

18. 753-04057 Cotter Pin

19. 753-04058 Tailpiece Bracket Assembly

20. 753-04059 Clevis Pin

Part No. Part Description

Ref.

No.

21. 753-04060 Hex Cap Screw 1/4-20 x .50

22. 753-04061 Hex Lock Nut 1/4-20

23. 753-04062 Cap Push

24. 753-04063 Wheel Support Bracket Assembly

25. 753-04064 Wheel 7.0

26. 753-04065 Hex Cap Screw 1/4-20 x 1.75

27. 753-04066 Flat Washer .271 ID x .630 OD

28. 753-04067 Tine Shield

29. 753-04075 Gearbox

31. 753-04074 Inner Tine

32. 753-04073 Outer Tine

33. 753-04072 Inner Tine

34. 753-04071 Outer Tine

35. 753-04070 Click Pin

36. 753-04069 Edger Tine

37. 753-04068 Edger Wheel 5.0

38. 753-04076 Drive Shaft Housing

39. 753-04077 Gearbox Antirotation Screw

40. 753-04078 Retainer Sleeve

Part No. Part Description

15

Page 16

Sears Craftsman 4 Cycle Cultivator / Edger Model 316.29270

1

2

3

18

16

82

73

9

11

10

5

90

17

91

12

19

21

13

14

42

72

86

66

65

96

64

67

62

58

50

95

55

56

57

49

46

94

65

70

47

63

45

78

79

61

4

80

81

76

6

7

8

44

43

15

48

51

52

54

53

60

59

83

74

73

20

24

40

88

35

22

87

75

93

89

92

23

39

77

25

90

38

26

28

27

29

36

30

37

31

32

33

34

67

68

69

71

85

86

16

Page 17

Sears Craftsman 4 Cycle Cultivator / Edger Model 316.29270

Ref.

No.

1. 791-182339 Engine Cover Screws

2. 791-182651 Starter Rope Eyelet

3. 753-04028 Engine Cover

4. 791-182652 Eyelet Nut

5. 791-181025 Valve Cover Screw

6. 791-182098 Valve Cover

7. 791-182099 Valve Cover Gasket

8. 791-182340 Rocker Adjustment Nut

9. 791-182101 Rocker Arm Pivot

10. 791-182100 Rocker Arm

11. 791-182341 Rocker Arm Stud

12. 791-182103 Valve Spring Retainer

13. 791-181038 Valve Spring

14. 791-181033 Push Rod

15. 791-182102 Push Rod Guide

16. 791-182700 Cylinder Head (incl. 11& 15)

17. 791-182344 Cylinder Screw

18. 753-1226 Intake Baffle

19. 791-182749 Carburetor Mount Gasket

20. 791-181034 Nut

21. 753-04029 Carburetor Mount (incl 20)

22. 791-182348 Carburetor Mount Screw

23. 791-182732 Carburetor Gasket

24. 791-182654 Carburetor w/ Primer

25. 753-04030 Air Filter Gasket

26. 791-182655 Filter Cover Assy (incl. 27,28,31-34)

27. 791-182097 Breather Tube Assembly

28. 791-181000 Grommet Washer

29. 791-182409 Washer

30. 791-181750 Carburetor Stud

31. 753-04032 Keps Nut

32. 791-182657 Air Filter Plate

33. 791-182658 Air Filter

34. 791-182659 Air Filter Cover

35. 753-04033 Fuel Cap

36. 791-182352 Fuel Return Line

37. 791-182353 Fuel Pick-up Line w/ Filter

38. 791-181080 Screw

39. 791-182354 Washer

40. 753-04034 Fuel Tank Assy (Incl. 35-37)

41. 753-04035 Fuel Tank Bushing

42. 791-182356 Fuel Tank Shield

43. 753-1232 Muffler Baffle

44. 791-181048 Muffler Gasket

45. 753-04036 Muffler

46. 791-180890 Spark Arrestor Screen

47. 753-04037 Screen Cover

48. 791-181046 Screw

49. 753-1233 Muffler Shield

50. 791-182361 Muffler Mounting Screw

51. 791-181247 Palnut

Part No. Part Description

Ref.

No.

52. 753-1199 Recoil Pulley

53. 753-1236 Recoil Spring

54. 791-182366 Nut Clip

55. 791-181079 Pull Handle

56. 791-611061 Rope Guide

57. 791-182661 Rope

58. 791-181020 Starter Housing Screw

59. 753-04038 Starter Housing Assy (incl. 51-58)

60. 791-182537 Wire Grommet

61. 791-182368 Clutch Washer

62. 791-182369 Clutch w/ Washer

63. 791-153592 Clutch Drum

64. 753-1239 Clutch Cover

65. 791-181345 Clutch Cover Screw

66. 753-04039 Switch Assembly

67. 791-182725 Ignition Module w/ Screws

68. 791-181065 Spacer

69. 791-182736 Flywheel

70. 791-181861 Screw

71. 791-182743 Shroud Assembly w/ Screws

72. 791-182376 Crankcase Assembly

73. 791-610309 Oil Seal

74. 791-182372 Bearing

75. 791-182380 Crank Shaft

76. 791-182375 90° Elbow

77. 791-182379 Breather Hose

78. 791-181015 Cam Gear

79. 753-1242 Cam Follower Set

80. 791-181013 Cam Bracket

81. 791-181012 Cam Bracket Screw

82. 791-181040 Intake & Exhaust Valves

83. 791-182374 Cylinder Gasket

84. 791-181018 Oil Pan Gasket

85. 791-182377 Oil Pan (Includes 84 & 86)

86. 791-181020 Oil Pan Screw

87. 753-04041 Dipstick Assembly

88. 791-182290 O-Ring

89. 791-181009 Connecting Rod

90. 791-181008 Wrist Pin Button

91. 753-1243 Piston

92. 791-181006 Wrist Pin

93. 791-182295 Piston Ring Set

94. 791-182519 Antirotation Screw

95. 753-1240 Screw

96. 753-1241 Nut

* 753- 124 5 Short Block (5-13, 15, 16, 71-83, 89-93)

* 791-182745 Cylinder Assembly

* 791- 182 156 Carburetor Repair Kit

* 753-1248 Gasket Diaphragm Repair Kit

* 791- 180 852 B Spark Plug

Part No. Part Description

* Parts Not Shown

17

Page 18

Emission Warranty Statement

California / EPA emission control Warranty Statement

The California air resources board, EPA

(Environmental Protection Agency), and Sears are

pleased to explain the mission control system warranty

on your 2000 and later small off-road engine. In

California and the 49 states, new small off-road engines

must be designed, built and equipped to meet the

states stringent anti-smog standards. Sears must

warrant the emission controls system on your small offroad engine for the periods of time listed below

provided there has been no abuse, neglect or improper

maintenance of your small off-road engine.

Your emission control system may include parts such

as the carburetor or fuel-injection system, the ignition

system, and catalytic converter. Also included may be

hoses, belts, connectors, and other emission-related

assemblies.

Where a warrantable condition exists, Sears will repair

your small off-road engine at no cost to you, including

diagnosis, parts, and labor.

The 2000 and later small off-road engines are

warranted for two years. If any emission-related part on

your engine is defective, the part will be repaired or

replaced by Sears.

Owner’s Warranty Responsibilities:

As the small off-road engine owner, you are

responsible for the performance of the required

maintenance listed in your operator’s manual. Sears

recommends that you retain all receipts covering

maintenance on your small off-road engine, but Sears

cannot deny warranty solely for the lack of receipts or

for your failure to ensure the performance of all

scheduled maintenance.

As the small off-road engine owner, you should

however be aware that Sears may deny you wa rranty

coverage if your small off-road engine or a part has

failed due to abuse, neglect, improper maintenance or

unapproved modifications.

You are responsible for presenting your small off-road

engine to a Sears service center as soon as a problem

exists. The warranty repairs should be completed in a

reasonable amount of time, not to exceed 30 days.

Manufacturer’s Warranty Coverage:

The warranty period begins on the date the engine or

equipment is delivered to the retail purchaser.

The manufacturer warrants to the initial owner and

each subsequent purchaser, that the engine is free

from defects in material and workmanship which cause

the failure of a warranted part for a period of two years .

Repair or replacement of warranted part will be

performed at no charge to the owner at a Sears service

center.

Any warranty part which is not scheduled for

replacement, as required maintenance or which is

scheduled only for regular inspection to the effect of

“repair or replace as necessary” is warranted for the

warranty period. Any warranted part which is scheduled

for replacement as required maintenance will be

warranted for the period of time up to the first scheduled

replacement point for that part.

The owner will not be charged for diagnostic labor

which leads to the determination that a warranted part

is defective, if the diagnostic work is performed at a

Sears service center.

The manufacturer is liable for damages to other eng ine

components caused by the failure of a warranted part

still under warranty.

Failures caused by abuse, neglect, or improper

maintenance are not covered under warranty.

The use of add-on or modified parts can be grounds fo r

disallowing a warranty claim. The manufacturer is not

liable to cover failures of warranted parts caused by the

use of add-on or modified parts.

In order to file a claim, go to your nearest Sears serv ice

center. Warranty services or repairs will be provided at

all authorized Sears service centers.

Any manufacturer approved replacement part may be

used in the performance of any warranty maintenance

or repair of emission related parts and will be provided

without charge to the owner. Any replacement part that

is equivalent in performance or durability may be used

in non-warranty maintenance or repair and will not

reduce the warranty obligations of the manufacturer.

The following components are components are

included in the emission related warranty of the engine

air filter, carburetor, primer, fuel lines, fuel pick up/fuel

filter, ignition module, spark plug and muffler.

18

Page 19

ÍNDICE

Índice de materias Página

Garantía 19

Seguridad 20

Montaje 23

Funcionamiento 24

Mantenimiento 28

Índice de materias Página

Servicio y almacenamiento 32

Solución de problemas 33

Lista de las piezas 14

GARANTÍA

Garantía limitada de la cultivadora/ bordeadora Craftsman

Por un período de dos (2) años a partir de la fecha de comp ra, con la condición de que a este equipo Craftsman

se le realiza el mantenimiento, la lu bricación y ajustes de acuerdo con las instr ucciones que aparece n en el

manual del operador’, Sears llevará a cabo reparaciones o reem plazos necesarios sin cargo cualq uiera de las

piezas que resulten defectuosas en sus materiales o fabricación. El servicio de garantía está disponible sin cargo

si lleva su equipo Craftsman al Centro de Servicio Técnico de Sears más cercano.El servicio de garantí a a

domicilio está disponible pero se aplicará un cargo de traslado. Esta garantía es válida únicamente mientras el

producto se encuentre dentro de los Estados Unido s.

Esta garantía no cubre:

• Artículos de duración limitada que sufren desgaste bajo condiciones normales de usol, tales como bujías de

encendido, purificadores de aire, correas y filtros de aceite.

• Reemplazo o reparación de neumáticos debido a pinchaduras causadas por o bjetos externos, ta les como

clavos, espinas, tocones o vidrio.

• Reparaciones necesarias debido al abuso del operador, incluyendo pero sin limitarse a daño causad o por

objetos, tales como piedras o desechos de metal, troncos de un tamañ o demasiado grande, objetos que

hacen impacto que puedan doblar la est ructura o el cárter o puedan sobreaceler ar el motor.

• Reparaciones necesarias debido a negligencia del operador, incluyendo pero sin lim itarse a daños eléctricos

y mecánicos causados por almacenamiento incorrect o, falla en la calidad o cantidad del aceite de motor

utilizado, o falla para mantener el equipo de acuerdo con las instrucciones contenidas en el manual del

operador’.

• Limpieza o reparaciones del (sistema de combustible del) motor causadas por combustib le que se encontró

que estaba contaminado u oxidado (vencido). En general, el combustible debería ser utilizadodentro de los

30 días posteriores a la fecha de compra.

• Equipos utilizados para fines comerciales o de alquiler.

PARA UBICAR EL CENTRO DE SERVICIO TÉCNICO SEARS MÁS CERCANO O PARA PROGRAMAR EL

SERVICIO TÉCNICO, SIMPLEMENTE COMUNÍQUESE CON SEARS AL TELÉFONO 1-800-4-MY-HOME®.

Esta garantía le otorga derechos legales específicos y también usted pu ede tener otros derechos, los cuales

varían de un estado a otro.

ESPECIFICACIÓN DE PRODUCTO

Motor 4 Carrera

Tipo de aceite del motor SAE 30

Capacidad de aceite del motor 3.4 onzas líquidas

Capacidad de combustible: Aproximadamente 1 cuarto

Bujía Champion RDZ-19H

Separación de la bujía .025" (0.655 mm)

19

Número de Modelo..................................................

Número de Serie......................................................

Fecha de compra....................................................

Guarde el número de serie y la fecha de compra en

un lugar seguro para referencia futura.

316.29270

Page 20

SEGURIDAD

ADVERTENCIA: L a presencia de este símbolo indica que se trata de instrucciones import antes

de seguridad que debe respetar para evita r poner en riesgo su segurid ad personal y / o material y

de otras personas. Lea y siga todas las instrucciones contenidas en este manual ant es de intentar

poner esta máquina en funcionamiento. De no hacerlo puede ocasionar lesiones. Cuando

encuentre este símbolo - respete la a dvertencia que a parece a contin uación del mismo.

ADVERTENCIA: El escape del motor de este producto contiene productos

químicos que el estado de California considera que pueden producir cáncer,

defectos de nacimiento u otros problemas reproductivos.

PELIGRO: Esta máquina está diseñada para ser utilizada respetando las reglas de seguridad

contenidas en este manual. Al igual que con todos los equipos eléctricos si el operador es

descuidado o comete errores puede ocasionar lesiones graves. Esta máquina pue de amputar

manos y pies y arrojar objetos. De no respetar las instrucciones de seguridad siguientes se pueden

producir lesiones graves o la muerte.

Capacitación

1. Lea, comprenda y siga todas las instrucciones de

la máquina y de el o los manuales antes de

intentar montarla y operarla. Guarde este manual

en un lugar seguro para referencias futuras y

regulares y para solicitar repuestos.

2. Familiarícese con todos los controles y con el uso

adecuado de los mismos. Sepa cómo detener la

máquina y cómo desengranar los controles

rápidamente.

3. Nunca permita que niños menores de 14 años

operen esta máquina. Los niños de 14 años y

más deben leer y comprender las instr ucciones

de operación y las reglas de seguridad

contenidas en este manual y deben ser

capacitados y supervisados por uno de los

padres.

4. Nunca permita que adultos sin conocimientos

acerca de la máquina operen la misma.

5. Mantenga a los transeúntes, ayudantes,

mascotas y niños al menos a 50 pies de la

máquina mientras está funcionando. Detenga la

máquina si alguien entra en la zona.

PREPARACIÓN

1. Revise minuciosamente la zona donde se

utilizará el equipo. Quite las piedras, palos,

alambres y otros objetos extraños que puedan

desengancharse y causar lesiones.

2. Utilice zapatos de trabajo resistentes, de suela

fuerte y pantalones y camisas ajustados. Las

prendas sueltas o las alhajas pueden qu edar

atrapadas en las piezas movibles. Nunca opere

esta máquina estando descalzo o con sandalias.

3. Use gafas de seguridad o gafas de protección

que cumplan con las normas ANSI Z87.1 y

protectores auditivos cuando opere e sta unidad.

Utilice una máscara para polvos si la operación

de la máquina levanta polvo.

4. Esta unidad tiene un embrague. Los dientes

permanecen detenidos cuando el motor está

inactivo. En caso de no ser así, haga ajustar la

unidad con un servicio técnico autorizado.

5. Apriete el control de la mariposa y ve rifique que

vuelva automáticamente a la posición inactiva.

6. Nunca deje la máquina en funcionamiento sin

vigilancia.

7. Nunca intente hacer ajustes mientras la máquina

está en funcionamiento, excepto que esté

específicamente recomendado en el manual

del’operador.

8. Para evitar lesiones o daños sea sumamente

cuidadoso al manipular la gasolina. La ga solina

es altamente inflamable y los vapores son

explosivos. Se puede lesionar gravemente si

derrama gasolina sobre usted o sobre la ropa ya

que se puede encender. Lave la piel y cámbiese

de ropa de inmediato.

a. Utilice sólo recipientes para gasolina

autorizados.

b. Apague todos los cigarrillos, cigarros,

pipas y otras fuentes de combustión.

c. Nunca cargue combustible en la máquina

en un espacio cerrado.

d. Nunca extraiga la tapa de nafta o agregue

nafta mientras el motor está caliente o en

funcionamiento.

e. Deje que el motor se enfríe por lo menos

dos minutos antes de volver a cargar

combustible.

f. Nunca recargue el tanque de combustib le.

Llene el tanque no más de 1/2 pulga da por

debajo de la base del cuello del filtro para

dejar espacio para la dilatación del

combustible.

g. Vuelva a colocar la tapa de la gasolina y

ajústela bien.

h. Limpie la gasolina derramada sobre el

motor y el equipo. Traslade la máqu ina a

20

Page 21

otra zona. Espere 5 minutos antes de

encender el motor.

i. Nunca almacene la máquina o el recipiente

de combustible en un espacio cerrado donde

haya fuego, chispas o luz piloto (por ejemplo,

hornos, calentadores de agua, calefacto res,

secadores de ropa, etc.)

j. Deje que la máquina se enfríe por lo menos

5 minutos antes de guardarla.

FUNCIONAMIENTO

1. No coloque las manos y los pies cerca de las

piezas rotativas. El contacto con piezas rotativas

puede amputar dedos, manos y pies.

2. No opere la máquina bajo la influencia del alco hol o

las drogas.

3. Nunca opere esta máquina sin buena visibilidad o

iluminación. Siempre debe estar seguro de que

está bien afirmado y sostenga bien las manijas.

4. Mantenga a los transeúntes, ayudantes, mascotas

y niños al menos a 50 pies de la máquina mientras

está funcionando. Detenga la máquina si alguien

entra en la zona.

5. Sea cuidadoso cuando cultive en terreno sólido.

Los dientes pueden clavarse en la tierra y

propulsar la cultivadora hacia adelante. Si esto

ocurre, suelte la manija y no refrene la máquina.

6. Nunca opere la máquina a altas velocidades de

transporte en superficies duras o resbaladizas.

7. Tenga cuidado para evitar que se produzcan

resbaladuras o caídas.

8. Mire hacia abajo y hacia atrás y tenga cuidado

cuando tire la máquina hacia usted.

9. Arranque el motor de acuerdo con las instrucciones

del manual y aleje los pies de los dientes en todo

momento.

10. Después de golpear con algún objeto extraño,

detenga el motor, desconecte el cable de la bujía y

conecte el motor a masa. Inspeccione

minuciosamente para ver si la máquina está

dañada. Repare el daño antes de arrancar y

operar.

11. Desenganche todos los embragues y detenga el

motor antes de dejar la posición de operación

(detrás de la manija). Espere hasta que los dien tes

se detengan completamente antes de

destrabarlos, hacer algún ajuste o inspecciones.

12. Nunca encienda el motor en espacios cerrados o

en una zona poco ventilada. El escape del motor

contiene monóxido de carbono, un gas inodoro y

letal.

13. El silenciador y el motor se calientan y producen

una quemadura. No los toque.

14. Tenga cuidado cuando cultiva cerca de vallas,

edificios y servicios subterráneos. Los dientes

rotativos pueden causar daños materiales o

lesiones.

15. No sobrecargue la capacidad de la máquina

intentando cultivar el suelo a un nivel demasiado

profundo o a un ritmo demasiado rápido.

16. Si la máquina arranca haciendo un sonido o una

vibración rara, detenga el motor, desconecte el

cable de la bujía y conéctelo a masa contra el

motor. Inspeccione la máquina minuciosamente

para ver si está dañada. Repare todos los daños

antes de encender y operar la máquina.

17. Mantenga todas las pantallas, protectores y

dispositivos de seguridad en su lugar y en correcto

funcionamiento.

18. Nunca levante o transporte la máquina cuando

está en movimiento.

19. Use sólo dispositivos de sujeción o accesorios

disponibles en Sears. Si no lo hace, esto puede

tener como resultado lesiones.

20. Si se presentan situaciones que no están previstas

en este manual sea cuidadoso y use el sentido

común. Contacte a su centro de servicio t écnico

Sears más cercano.

Mantenimiento y almacenamiento

1. Nunca manipule los dispositivos de seguridad de

manera imprudente. Controle periódicamente que

funcionen de forma adecuada.

2. Verifique frecuentemente que los pernos y tornillos

estén ajustados correctamente para ase gurarse de

que la máquina esté trabajando de manera segura.

Además realice una inspección visual de la

máquina para controlar si la misma está dañada.

3. Antes de limpiar, reparar o revisar, detenga el

motor y asegúrese de que los dientes y todas las

partes móviles se hayan detenido. Desconecte el

cable de la bujía y póngalo de manera que haga

masa contra el motor para evitar que se encienda

de manera accidental.

4. No cambie la configuración del regulador del motor

ni lo opere a una velocidad demasiado elevada. El

regulador controla la velocidad máxima segura de

operación del motor.

5. Mantenga o reemplace las etiquetas de seguridad

e instrucciones según sea necesario.

6. Siga las instrucciones de este manual para que la

carga, descarga, transporte y almacenamiento de

esta máquina sean seguros.

7. Nunca almacene la máquina o el recipiente de

combustible en un espacio cerrado donde haya

fuego, chispas o luz piloto como por ejemplo,

calentadores de agua, hornos, secadores de ropa,

etc.

8. Siempre remítase al manual del ’operador para

obtener instrucciones adecuadas acerca del

almacenamiento fuera de tempora da.

9. Si es necesario evacuar el tanque de combustible,

hágalo en exteriores.

10. Respete las leyes y reglamentaciones referentes a

la disposición correcta de gas, aceite, etc. pa ra

proteger el medio ambiente.

21

Page 22

Declaración de Garantía de Emisión

California / la emisión de MINISTERIO DEL MEDIO

AMBIENTE controla la Declaración De la garantía la

tabla(el consejo) de recursos de aire de California, el

MINISTERIO DEL MEDIO AMBIENTE (la Agencia de

protección de medio ambiente), y Chamusca están

contento de explicar la garantía de sistema de centro

de control sobre su 2000 y el pequeño motor poster ior

fuera de caminos. En California y los 49 estados,

pequeños motores nuevos fuera de caminos debe n ser

diseñados, construidos y equipados para encontrar los

estados normas de anti-niebla-tóxica rigurosas.

Chamusca debe garantizar que la emisión controla el

sistema sobre su pequeño motor fuera de caminos

durante los períodos de tiempo puesto en una lista

debajo proporcionado no hubo ningún abuso,

negligencia o el mantenimiento impropio de su

pequeño motor fuera de ca minos.

Su sistema de control de emisión puede incluir partes

como el carburador o el sistema de inyección de

combustible, el sistema de ignición, y el catalizador.

También incluido puede ser mangueras, cinturones,

conectores, y otras asambleas relacionadas a emisión.

Donde una condición justificable existe, Chamusca le

reparará su pequeño motor f uera de camino s gratis,

incluyendo el diagnóstico, partes, y el trabajo. Los

pequeños motores 2000 y posteriores fue ra de

caminos son garantizados durante dos años. Si

cualquier parte relacionada a emisión sobre su motor

es defectuosa, la parte será reparada o substituida por

Chamusca.

Las responsabilidades De la garantía del Dueño

Como:

el pequeño dueño fuera de ca minos de motor, usted es

responsable del funcionamiento del mantenimiento

requerido puesto en una lista en el manual de su

operador. Chamusca recomienda que usted conserve

todos los ingresos que cubren el mantenimie nto sobre

su pequeño motor fuera de caminos, pero Chamusca

no puede negar la garantía únicamente para la

carencia de ingresos o para su fracaso de asegurar el

funcionamiento de todo el mantenimiento previsto.

Como el pequeño dueño fuera de caminos de motor,

usted sin embargo debería ser consciente que

Chamusca puede negarle la cobertura de la garantí a si

su pequeño motor fuera de caminos o una parte han

fallado debido al abuso, la negligencia, el

mantenimiento impropio o modificaciones

desaprobadas. Usted es responsable de pr esentar su

pequeño motor fuera de caminos a un Chamusca el

centro de reparaciones en cuanto un problema existe.

La reparación de la garantía debería ser completada en

una cantidad de tiempo razonable, no exceder 30 días.

La cobertura De la garantía del Fabricante:

el período de la garantía comienza el día el motor o el

equipo es entregado al comprador de venta al público.

El fabricante garantiza al dueño inicial y cada

comprador subsecuente, que el motor e s libre(gratis)

de defectos en el material y la habilidad que causa el

fracaso de una parte garantizada para el per iodo de

dos años. La reparación o el reemplazo(suplente) de la

parte garantizada serán realizados gratis al dueño en

un Chamusca el centro de reparaciones.

Cualquier parte de la garantía que no es prog ramada

para el reemplazo(suplente), como el ma ntenimiento

requerido o que es programada sólo para la in spección

regular al efecto " de la reparación o sustituye como es

necesario " es garantizado durante el período de la

garantía. CUALQUIER parte garantizada que es

programada para el reemplazo(suplente) como el

mantenimiento requerido será garantizada durante el

período de tiempo hasta el primer punto de

reemplazo(suplente) previsto para aquella parte. El

dueño no será acusado para el trabajo d iagnóstico que

conduce a la determinación que una parte garantizada

es defectuosa, si el trabajo diagnóstico es realizado en

un Chamusca el centro de reparaciones.

El fabricante es obligado de daños a otros

componentes de motor causados por el f racaso de una

parte garantizada todavía coforme a la ga rantía. Los

fracasos causados por el abuso, la negligencia, o el

mantenimiento impropio no son cubiertos coforme a la

garantía. El empleo de añade - sobre o las partes

modificadas pueden ser tierras(razones) para rechazar

una reclamación de la garantía. El fabricante no es

obligado de cubrir los fracasos de las partes

garantizadas causadas por el empleo de añaden sobre o partes modificadas. Para presentar una

demanda, ir a su cercano Chamusca el centro de

reparaciones. Proporcionarán servicios de la garant ía o

la reparación en todo autorizado Chamusca centros de

reparaciones.

Cualquier fabricante se aprobó la pieza de recambio

puede ser usada en el funcionamiento de cualquier

mantenimiento de la garantía o r eparación de emisión

partes relacionadas y proporcionará sin el precio(la

carga) al dueño. Cualquier pieza de recambio que está

equivalente en el funcionamiento o la durabilidad

puede ser usada en el mantenimiento no-la-garan tía o

reparar y no reducirá las obligaciones de la garantí a del

fabricante. Los componentes siguientes son

componentes son incluidos en la emisión la garantía

relacionada del filtro de aire de motor, el carburador, la

cartilla, canalizaciones, el pico de combustible encima

de/combustible filtra, el módulo de ignición, la bujía y el

silenciador.

22

Page 23

MONTAJE

IMPORTANT:

aceite en el motor. Después de l montaje, consulte la

sección de FUNCIONAMIENTO para el correcto

llenado de combustible y aceite del motor.

NOTE: Desde la posición de funcionamiento, se

observa la referencia a la derecha o a la izquierda de

la cultivadora / bordeadora.

Esta unidad es enviada sin gasolina ni

Cómo Sacar La Unidad De La Caja

• Saque las grapas, rompa el pegamento de las

aletas superiores o corte la cinta del extremo de

la caja y tire a lo largo de la aleta superior para

abrir la caja.

• Enlevez toutes les parties lâches qui peuvent être

incluses avec l'unité.

• Corte a lo largo de las esquinas, extienda la caja

plana hacia abajo y saque el material de

embalaje.

• Haga rodar o deslice la unidad fuera de la caja y

revise minuciosamente la caja para cont rolar si

hay piezas sueltas.

Parties Lâches dans Carton

• Le manuel d'Opérateur

• 3.4 Fl.oz. (100ml) Bouteille d'Huile-moteur

• Edger Roue

• Edger Lame

• Ubique los conectores que se alinean con la línea

marcada en el conector superior con la línea

marcada del medio en el conector inferior.

• Para asegurar la manija superior e inferior, ajuste

las tuercas aladas y las arandelas (los pernos del

carro deben estar alojados correctamen te en la

manija exterior y las ranuras deben alinearse

entre los conectores).

• Si aún no lo ha hecho, ajuste el amarre del cable

en el lado derecho de la manija.

Marcado

Líneas

Carro

Perno

Tuerca alada

Manija inferior

Conector

Manija superior

ConectorConector

Desconexión De La Bujía

Antes de configurar la cultivadora / borde adora,

desconecte el cable de la bujía y conéctelo a masa a

un espárrago en el motor.

Configuración de su cultivadora /

bordeadora

• Afloje cada tuerca alada lo suficiente como para

separar los conectores plásticos entre la manija

superior e inferior. Eleve lentamente y tire de la

manija superior para elevar la manija hacia la

posición de funcionamiento. Vea Figura 1.

• Separe los conectores y ubique la punta inferior

del conector de la manija superior enfrente de la

punta inferior del conector de la manija inferior.

• El conector de la manija inferior tiene tres líneas

marcadas y el conector de la de la manija

superior tiene una línea marcada.

Figura 1

23

Page 24

Manija del

arrancador

Manija frontal

Cultivadora

Dientes

FUNCIONAMIENTO

Interruptor

encendido / apagado

Palanca de la mariposa

Manija

Conectores

Cebador

Rueda de

la bordeadora

Cuchilla de

la bordeadora

Palanca de obturación

Lea este manual del’operador y las reglas de

seguridad antes de operar su cultivadora /

bordeadora. Compare las ilustraciones con su unidad

para familiarizarse con la ubicación de los distintos

controles y ajustes. Vea Figura 2.

Manija del arrancador

La manija del arrancador está conectada a un perno

de anilla en el frente del motor.

Palanca de la mariposa

La palanca de la mariposa está ubicada en la manija

superior. Al apretar la palanca contra la manija se

acelera el motor y se engranan los dientes de la

cultivadora / bordeadora. Suelte la manija para

detener los dientes.

Palanca de obturación

La palanca de obturación está ubicada del lado

izquierdo del motor y se utiliza para enriquecer la

mezcla de combustibles cuando se arranca u n motor

en frío.

A

Cerrar

B

Parcial

C

Abrir

Botón del cebador

El botón del cebador está ubicado del lado derecho

del motor y se utiliza en conjunto con el obturador

para enriquecer la mezcla de combust ible en el

carburador cuando se arranca un motor en frío.

Figura 2

Interruptor encendido / apagado.

El interruptor encendido /apagado está ubicado en la

manija superior. El interruptor debe estar en

“Encendido” (I) para arrancar el motor y en “Apagado”

(O) para detenerlo.

Conectores de manija

Los conectores de manija se ubican a ambos lados

entre la manija inferior y superior. Se utilizan para

trabar la manija superior en una posición

determinada.

Manija frontal

La manija delantera puede ser u sada transportan do

la unidad.

Dientes

Los dientes se utilizan para cultivar, surcar y preparar

su jardín par la siembra.

Ménsula de soporte de la rueda

La ménsula de soporte de la rueda está conectada a

la ménsula de la pieza posterior ubicada detrás de la

cultivadora / bordeadora. Se utiliza para ajustar las

ruedas a una posición de descanso mayor o menor.

Rueda y cuchilla de la bordeadora

La rueda y la cuchilla de la bordeadora son partes

separadas que no vienen conectadas a la cultivadora/

bordeadora. Deben utilizarse en lugar de los dientes

de la cultivadora para el recorte de bordes verticales.

24

Page 25

Detención del motor

• Presione el interruptor encendido / apagado y

colóquelo en posición Apagado (O) para detener

el motor y los dientes.

• Desconecte el cable de la bujía y póngalo de

manera que haga masa contra el motor.

IMPORTANTE:

mantenimiento del nivel apropiado del aceite en el

cárter del motor no puede ser puesta demasiado

énfasis. NO SOBRELLENAR.

NOTE: Este es un motor de 4 ciclos. Para evitar

dañar la unidad, no mezcle aceite con gasolina.

La importancia de comprobación y el

Llenado de aceite

Es extremadamente importante utilizar el aceite del

tipo y peso adecuado en el cárter . Controle el aceite

antes de cada uso y cambie el aceite de manera

regular. La no utilización del aceite correcto o el uso

de aceite sucio puede causar un desgaste y una falla

prematura del motor.

Use un aceite pesado de alta calidad SAE 30 de API

(American Petroleum Institute) clase de se rvicio SF,

SG, o SH.

NOTE: Esta unidad es enviada sin aceite en el

motor. Con el objetivo de evitar daños a la unidad,

coloque el aceite recomendado en el cárter an te s de

intentar arrancar la unidad.

Esta unidad se entrega con una botella de 3.4 onza s

líquidas (100ml) de aceite SAE 30 SF, SG, o SH.

NOTE: Para el funcionamiento en clima frío, las

temperaturas debajo de 40°F (4°C) usan un aceite

pesado SAE 10W30 de API (American Petroleum

Institute), clase de servicio SF, SG, o SH.

• Añadiendo el aceite, la unidad debe ser puesta

atrás en la posición horizontal sobre una

superficie plana con la manija superior que toca

la tierra(razón). Vea Figura 3.

• Limpie el aceite que se pueda haber derramado y

reinstale el tapón de llenado de aceite / varilla del

nivel del aceite.

Llenado de nafta

La principal razón de un mal funcionamiento de la

unidad es que el combustible sea viejo. Asegúrese de

utilizar gasolina fresca, limpia y sin plomo. Use

combustible fresco (que no tenga más de 60 días de

vida), cuando utilice combustible con mezcla de

alcohol.

• Añadiendo el combustible, la unidad debería