Craftsman 315275062 Owner’s Manual

OWNER'S

MANUAL

MODEL NO.

315.275062

CAUTION:

Read Rules for

CRRFTSMRN

Safe Operation

and All Instruc-

tions Carefully

Thank You for Buying

Craftsman Tools

6-95

Industrial Electronic

Plunge Router

Double Insulated

Warranty

Introduction

Unpacking

Features

Adjustments

Operation

Maintenance

Repair Parts

Designed exclusively lot and sold only by

SEARS, ROEBUCK AND (30, Ho[fman Estates, IL 60t 79

Prlnled in U,S,A

ItthisCraftsmanIndustrialElectronicPlungeRouterfailsdue toadefectinmatedal orworkmanshipwithinoneyear

fromthe dateofpurchase,Sears willrepairitfree ofcharge,Thiswarrantyappliesonlywhilethis productisinuse

in the UnitedStates. WARRANTY SERVICE IS AVAILABLE BY SIMPLY RETURNING THE TOOL TO THE

NEAREST SEARS STORE OR SERVICE CENTER THROUGHOUTTHE LINrrED STATES.

This warrantygives you specifto legal rights, and yDumay also haveother rightswhichvaryfromstateto state.

SITARS;ROEBUCKAND CO

DEPT. 817WA

L ........................................................

HOFFMAN ESTATES, IL 60179

iNTRODUCTiON

DOUBLE INSULATION is a conceptin safety, in electrlo

powertools,whicheliminates lhe need for the usualthree

wire groundedpower cord and grounded supply system.

Whereverthere is electric currantin the toolthere are two

completesets of insulationtoprotecttheuser, /kit exposed

metal partsare isolatedfrom internalmetal motor compo-

nentswith protectingInsulation,

IMPORTANT- Servicing of a tool withdouble Insulation

requiresexl_ome care end knowledgeof the systemand

shouldbe pedormedonly bya qualifiedservice technician,

For_ervfcewe suggestyoureturn the tool toyour nearest

SearsStoreforrepair, Always useoriginal factoryreplace.

mentpadswhenservicing,

RULES FOR SAFE OPERATION

READ ALL INSTRUCTIONS

1., KNOW YOUR POWFJRTOOL - Read owner'smanual carefully Learnitsapplicationsandlimitationsas weliasthe

specific potentialhazards related tothistool..

2, GUARD AGAINST ELECTRICAL,SHOCK BY PREVENTINGBODY CONTACT WITHGROUNDED SURFACES.

Forexample: Pipes,radiators,ranges,refrigeratorenclosures

3o KEEP GUARDS tN PLACE andinworkingorder,

4, KEEP WORK AREA CLEAN. Clutteredareasand benchesinviteaccidents,

5. /WOLDDANGEROUS ENVIRONMENT, Don'tusepowertoolindampor wetlocationsorexpose torain. Keepwork

areawaitiIL

6 KEEP CHILDREN AND VISITORS AWAY. Allvisitorsshouldwear safety glassesand bekeptasafe _istance

from work area,, Do not I_t visitorscontact too! orextensioncord

7 STORE IDLE TOOLS. When not in use tools shouldbe storedInadry,highorlocked-upplace- outof lhe reachof

children

8., DON'T FORCE TOOL. It wilt dothe job better and safer stthe ratefor whichitwas designed.

9. USERIGHT TOOL, Don't force smalltoot or attachment todo thejob of a heavy duty tool Don't usetoot for purpose

notintended - for example- Don't use acircularsaw forcuttingtreelimbs ortogs.

10. WEAR PROPER APPAREL. No loose clothingorjewelrytoget caughtinmovingparts_Rubbergrovesand non-

skidfootwearate recommended whenworkingoutdoors Also,wear protecSvehaircoveringto containlonghairand

keep Itfrom beingdrawn into airvents

t!, ALWAYS WEAR SAFETY GLASSES. Everyday eyeglasseshave only tmpact-reslstant lenses; they are NOT

safetyglasses,

12 PROTECT YOUR LUNGS, Wear a face or dustmask tfoperationis dusty

13. PROTECT YOUR HEARING. Wear hearingprotection dudngextendedperiodso!operation

!4.. DON'T ABUSE CORD. Never carrytoo_by cordor yank itto disconnect from_eceptac_e Keepcordfromheat, eli

andsharpedges.

Page2

RULES FOR SAFE OPERATION (Continued)

15. SECURE WORK. Usectampsor avise tohold work Bolh handsare needed tooperate thetool

16_ DON'T OVERREACH, Keep properfooting and balance at alltimes Donot useon a ladderorunstablesupport

17. MAINTAIN TOOLS WITH CARE Keep tools sharpatafltimes,and cleanfor bestand safestperformance.Follow

instruclionsfor lubricating and changingaccessodes_

18. DISCONNECT TOOLS, When notin use,before servicing, or whenchangingaltachments, blades,bits, cutters,

etc.,all toolsshould bedisconnectedf.rampowersupply.

19.. REMOVEADJUSTING KEYS AND WRENCHES, Formhabitofchec.kingtoseethatkeysandadjuslingwrenches

are removed fromtoolbefore turningiton..

20., AVOID ACCIDENTAL STARTING. Don'tcarry plugged-in tools with finger on switch Be sureswitchisoff when

pluggingin.,

21. MAKESURE YOUR EXTENSION CORD ISIN GOODCONDITION.When using an extension cord,be sureto use

one heavy enoughto carry thecurrentyour produclwittdraw.Anundersized cordwillcause a drop tnlinevoltage

resulting in lossof power and ove_eattng. A wlre gauge size (A.W.G) of at least 14 is recommendedfor an

extensioncord 25 feet or less In length.,A cord exceeding25 feet is not recommended,i1in doubt, use lh next

heaviergage. The smallerthe gage number, the heavierthe cord

22. OUTDOOR USE EXTENSION CORDS, When tootis usedoutdoors,useonlyextensioncords suitable foruse

outdoors,Outdoor approvedcordsare marked withthesuilixW,.A,forexample -SJTW-A or SJOW_A.

23. KEEPCUTTERS CLEAN AND SHARP. Shaq_cuttersminimizeslallingandkickback.

24. KEEP HANDS AWAY PROM CUTTING AREA. Keep handsaway from cutlers. Do not reach underneathwork

whilecutterisrotating. Donot attempt toremovematerialwhilecutteris rotating

25 NEVER USE INAN EXPLOSWE ATMOSPHERE. Normalsparkingel the motor couldignite fumes.,

26 INSPECT TOOL CORDS PERIOOICALLY and if damaged, have repaired atyour nearest SearsRepair Center

Stay constantlyaware el cordlocation.

27,. INSPECT EXTENSION CORDS PERIODICALLY andreplacetfdamaged.

28 KEEP HANDLES DRY, CLEAN, AND FREE FROM OIL AND GREASE, Always usea cleanclolhwhencleaning.

Neveruse brake fluids,gasoline, petroleum.based produclsoranystrong solventsto cleanyour tool,

29 STAYALERT. Watchwhat you aredoing anduse commonsense. Donor operate toolwhen you aretired, Donot

rush.

30 CHECK DAMAGED PARTS. Before ludheruseof thetool,aguardor otherpartthatisdamaged should be carefully

checkedtodetermine that ttwilloperate properlyandperformitsintendedfunction,.Check for alignment of moving

parts,blndtng of moving parts, breakage of parts,mounting,and anyotherconditionsthaimay affeclitsoperation., A

guardor other part that tsdamaged should be propedyrepaired or replaced by an authorizedservice center unless

Indicatedelsewherein thtsinstruction manual

31. DONOT USE TOOL IF SWITCH DOES NOT TURN IT ON AND OFF. Have defective switches replaced by an

authorizedservicecenter

32 Inspectfor and removeallnailsfrom tumber before muting..

33 DRUGS, ALCOHOL, MEDICATION. Do not operate tool while under the influence oFdrugs,alcohol, or any

medication

34. WHENSERVICING USEONLY IDENTICAL CRAFTSMAN REPLACEMENTPARTS.

35 POLARIZED PLUGS, To reduce the rfskofelectricshock,thistoolhasa polarizedplug(onebladeiswiderthanthe

other), This plugwtl!fit in a polarized outlet only one way. If theplugdoes notfit fully in theoutlet, reverse theplug.

if it stltldoes notfit,contacta qualifiedelectricianto install the proper outteL Do notchange lhe plugin anyway.

36. DONOT USE TOOL UNDER "BROWN-OUT" OR OTHERLOW VOLTAGE CONDITIONS, Also. do notuse with

any devicethat could cause lhe power supply voltagetochange,,

37. WHEN USING THIS ROUTER WITH A ROUTER TABLE, HELP PREVENT POSSIBLE SERIOUS INJURY BY

KEEPING THE Cbq'TERGUARDED AT ALL TIMES. Useonlyroutertables,wlih guards,thathave beendesigned

foruse on reuters thaiare of thistype, size, and weigh!

38 SAVETHESE INSTRUCTIONS. Review them frequentlyand usethemto Instructotherswho may use Ibis tool If

youloan someone thistool, loan them theseinstructionsalso.

Page3

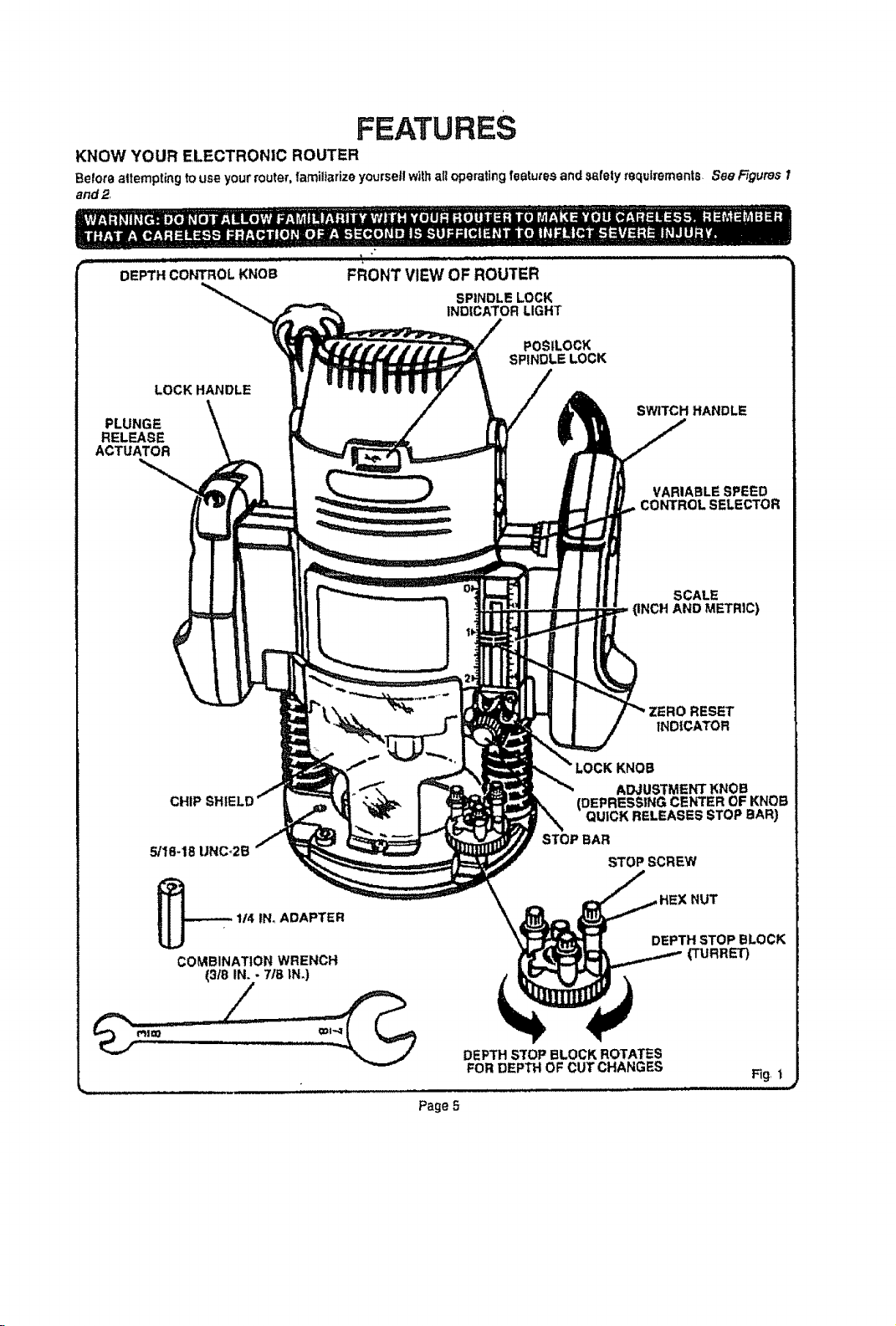

UNPACKING

Yournew plungerouter comesfullyassembled. Afterremoving it fromthe box.inspecti_carefuflyto makesure that itIs

not damagedend that nopartsare missing, See Figure Io Thefollowingaocesso_esshould also be includedin the box"

1o CombinationWrench(3/8 In - 718In.,) 4., Roller(Contour)Guide

2, 1t4In. Adapter 5 GufdeBushing

3. EdgeGuide

FEATURES

Your electronicrouter is a versatile woodworkingtoo! whichwitl give you years of trouble-free performance. It is

engineeredwiththeprofessionaltn mind, butits ease of operationsnowsthe amateurtoproduceworkwhichis beautiful

and precise,,

3.5 HORSEPOWER MOTOR

Your routar has a powerful3°5 horsepowermotor wilh

sufficientpower to handle thetoughestroutingjobs. The

motoralsohas externallyaccessiblebnJshesfor ease of

servicing,,

SOFT START

The softstart featurebuildsmotor RPM graduallyto minf_

mize sled.up torque Pressing or releasingthe "on-aft"

tdggert_l{ rumyour reufer on or off_

DEPTH CONTROL KNOB

A large depth controlknob makes precise depth of cul

changespossible, it also is very hefpfutwhen making

depth o! cut changes with your router mountedupside

downon_t routertable.

DEPTH STOP SYSTEM

The depthstop block!ocaled on the base of your router

provides three adjustable stops and throe fixedstopsfor

quick depth of cut changes, A depth adiustment scale

makes quick adjustmentsto depth of cut changes pos-

sible. The spring loadedadjustmentknob quickreleases

stop bar by depressingcenterof knob,

1/4 IN. AND !/2 IN. SHANK CAPACITY

Your router has a 1t2 in, ctlameter coital that accepts

cutterswith !/2 in. shanks. An adapterhasbeenprovided

Sothat cutterswith1t4 ln.shank bitscan alsobe used.

CHIP SHIELD

A clearplasticsee-through chip shield has beenprovided

onthe baseof yourrouter for protectionagainstflyingdual

and chips,, It is designedto fit the front openingof the

routerbase.,

POStLOCK SPINDLE LOCK

A positockaplndielock securesthe spindleso that only

one wrench is needed to loosen cotternul and change

cutters. A spindle lock indicator light alerts you that

spines is lookedif you connectrouterto power supply

beforeunlockingspindle, NOTE: Yourrouterwillnotrun if

spindleislocked.,

"LOCK-ON" FEATURE"

Your router Is equipped with a 'lock-on" feature that is

convenientwhencontinousoperation forextendedperiods

of time isrequired

LARGE HANDLES

Your router haslarge oversizedhandlesforeasyhandling

and maintaining propercontrolwhen routing The left

handle allows you to set cutterdepthof cutwhenmaking

plungecuts,whitethe dghthandleprovideseasy access

tothe "on-oil" tdgger, "lock.on'button, and vadsblespeed

controlselector_ Thehandleshave also been desEgnedso

thatthey are comfortableand easytograsp whenoperat-

ing in differentpositionsor at different angles,,

VARIABLE SPEED SWITCH WITH ELECTRONIC

SPEED CONTROL (Feedback Switch)

Yourrouterhas advancedelectronic features,designedto

assist you in getting the maximum use from your router_

By making proper speed selections,your muter can be

adjusted to specticroutingneeds. Th{eeliminates much of

the guesswork previouslyneeded toperforma given job,

BOththeexpenenced and inexperienced router usersben-

slit, obtainingprofessionaltfkerosuIIs with fewer job er-

rors,,

The vadablespeedcontrolallows the routerspeed to be

adjustedfrom10,060 to 25,000 rpm The variablespeed

controlselelctor is convenientlylocated inside the right

handleneartheoperator'sthumborhand°

The electronicfeature ofyourrouter introducesthe tlexibil.

ityo! adlustlng the motor_peedto requiredjobconditlo_so

An electronic speed controlmodulesenses the load alP

plied to the motor, and increases or decreases motor

voltageto compensateforand maintaindesiredRPM

Speed can be set accordfngto the approximatecutter

diameter you will be using and to the hardnessof the

matedaJbeingcuL The best cutsaremade whenthecutter

isfedthroughmatedalat the prope_"rateof feed.

ROUTER ACCESSORIES

Your router comes equippedwith several accessories,

The edgeguide keepsthe cutterparallelwithan edge of

the workplacewhen culling groovesand rabbets. The

ro|ler (contour)guideallowsthe router to be usedto trim

laminatesandmakeouts parallelwithan irregularlyshaped

edge. The template guide bushingenablesthe router to

followa template for makingduptfceteshapes.

Page 4

FEATURES

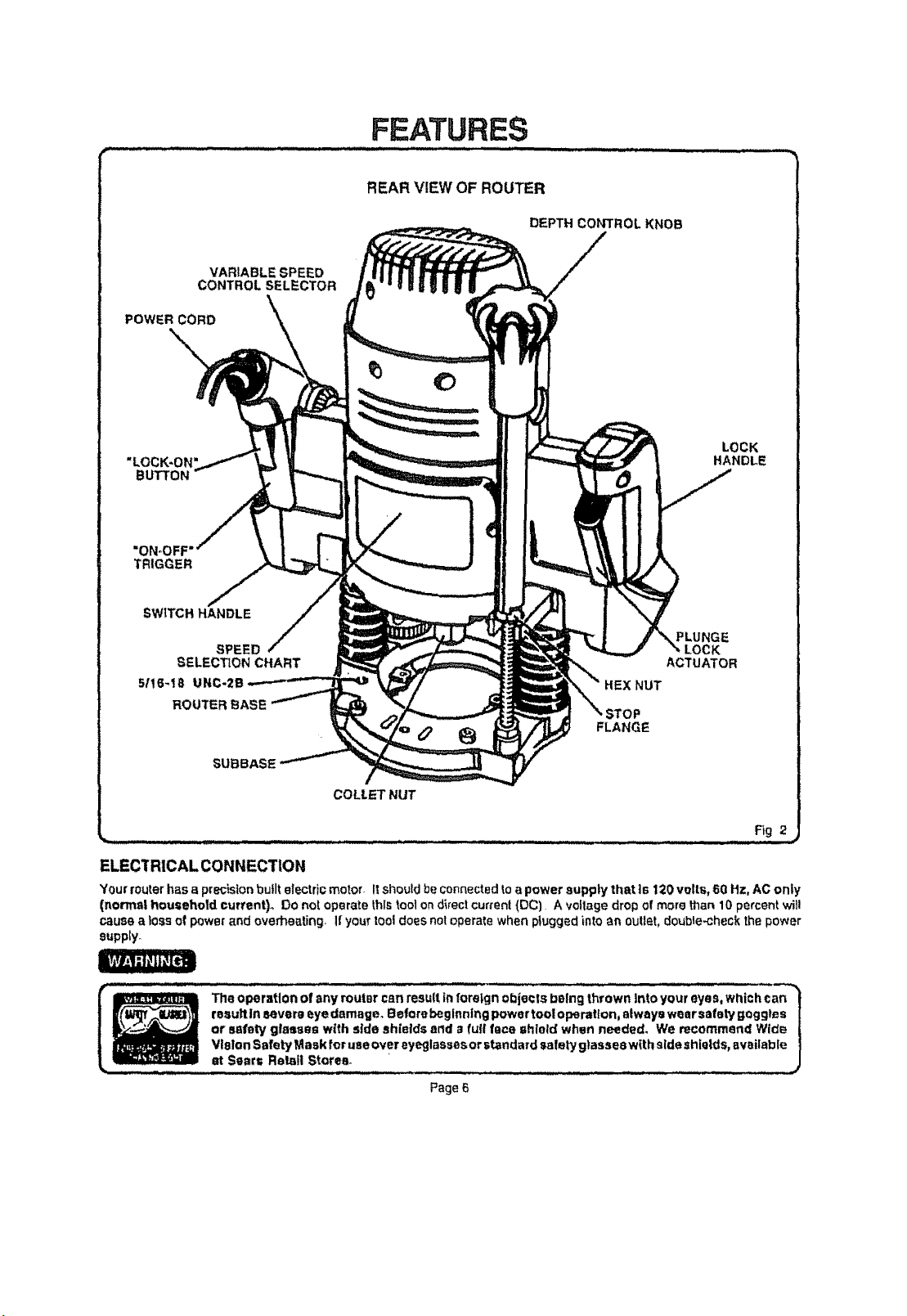

KNOW YOUR ELECTRONIC ROUTER

Belote altempting to use your router, familiarize yourse|l withall operating features and safely requirements. See Figures 1

and 2.

DE 'cobOL KNOB"

LOCK HANDLE

PLUNGE

RELEASE

ACTUATOR

FRONT VIEW OF ROUTER

SPINDLE LOCK

INDICATOR LIGHT

POSILOCK

SPINDLE LOCK

SWITCH HANDLE

VARIABLE SPEED

CONTROL SELECTOR

SCALE

(INCH AND METRIC)

ZERO RESET

INDICATOR

CHIP

5/18-18 UNC_2B

114 tN_ADAPTER

COMBINATION WRENCH

(3t8 IN. - 7IB IN.)

STOP BAR

DEPTH S'fOP BLOCK ROTATES

FOR DEPTH OF CUT CHANGES

Page 5

KNOB

ADJUSTMENT KNOB

(DEPRESSING CENTER OF KNOB

QUICK RELEASES STOP BAR)

NUT

DEPTH STOP BLOCK

(TURRET)

Fig. 1

VARIABLE SPEED

CONTROL SELECTOR

POWER CORD k

"LOCK*ON

BUTTON

=ON-OFF

TRIGGER

FEATURES

REAR VIEW OF ROUTER

DEPTH CONTROL KNOB

LOCK

HANDLE

SWITCH HANDLE

SPEED

SELECTION CHART

5/!6-18 UNC-2E

ROUTER BASE

SUBBASE

HEX NUT

FLANGE

K

ACTUATOR

COLL.ETNUT

• . ....L .... , UJ,,.,tvu,u_II UII'L I,. .... I..I -- =

Fig 2

ELECTRICAL CONNECTION

Your routerhasa precistonbufltelectric motor. Itshoutdbecennected toapowersuppiy thatts 120voltr,,60 Hz,AC only

(normal househotdcurrent). Donotoperatethistoo] ondirectcurten!(PC) A vo!lagedropof more than10percent wil!

causea lossofp_we_and overheating, ifyour tooldoes notoperatewhen plugged into an oulf_,t,double,checkthe power

supply_

i | _ Z _11 The operation of any route, csn result |n fore|gn objects being thrown Into your ayes, which car=

i i _U_ _e_u_t_nsever_eyedamage_Be__rebeg_nnIng_p_wert____p_ra___n_a_way_wearsafetygogg_es|

+ --_ or safety glasses with side shields and a full lace shield when needed, We recommend Wid_ |

,.Sea,...,e_,Sto_;,...+ ........_ ...........................+............... j

Page 6

ADJUSTMENTS

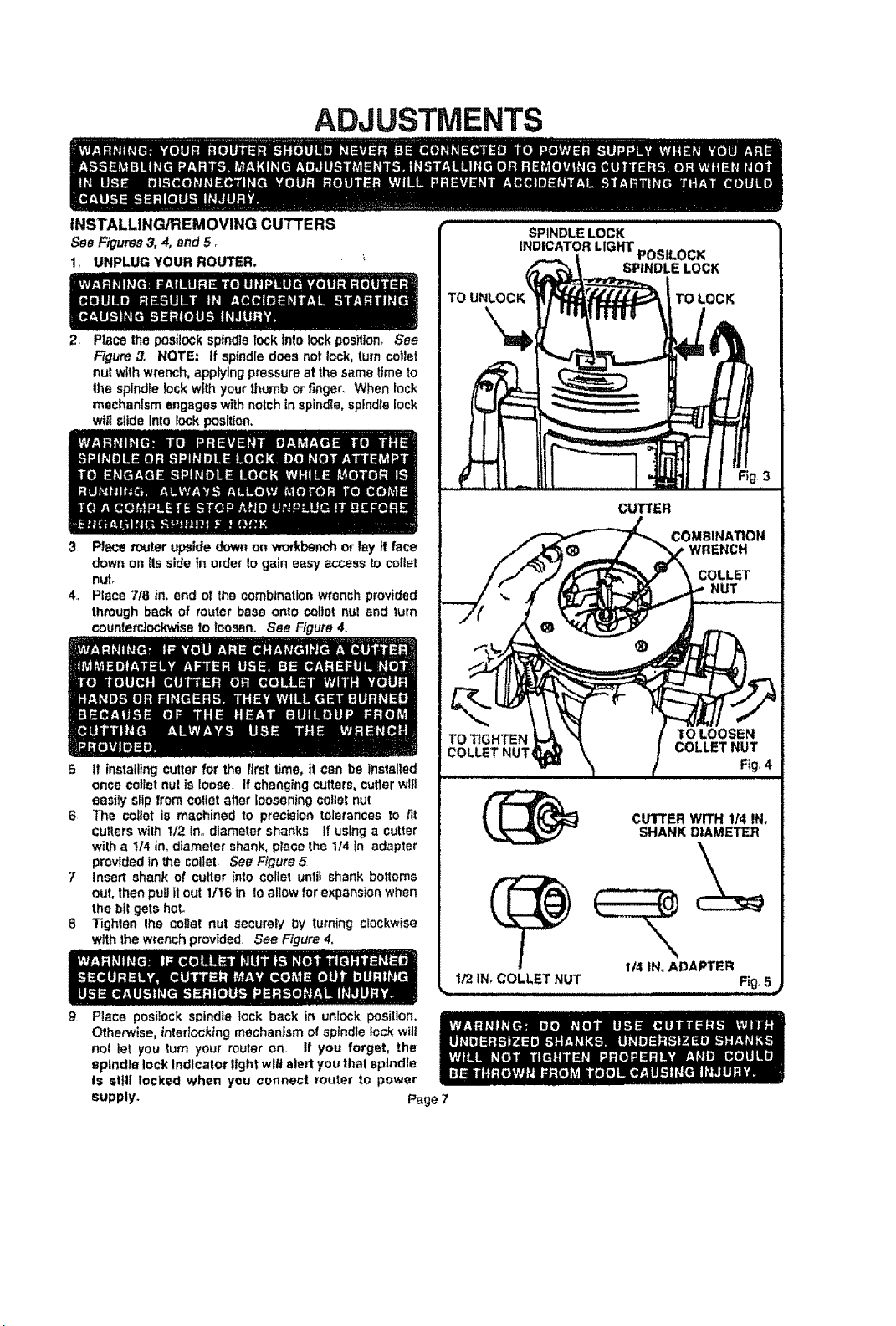

INSTALLING/REMOVING CUTTERS

See Figures3, 4, and 5 _

I. UNPLUG YOUR ROUTER,

2+

Placethe posilock spfndtelock Into lock position, See

Figure3. NOTE: if spindledoes not lock, turncotlet

nutwithwrench,applylng pressureat the sametime to

Ihe spindlelock withyourthumbor finger. When lock

mechanism engageswithnotch in spindle,spindlelock

wiltslide Intolockposition.

3 Place touter upsidedownon workbenchor lay it face

down on its sidein orderto gain easyaccess to collet

nLff_

4, Place 718in, end of the combinationwrenchprovided

throughback of routerbase onto coital nut and turn

counte_ockwisa to loosen. See Figure4,

TO

SPINDLE LOCK

INDICATOR LIGHT POSILOCK

SPINDLE LOCK

TO LOCK

CUTTER

COMBIHATIOI, t

;t3

WRENCH

COLLET

NUT

5 If installing cutterfor the firs! time.it can be installed

once colfetnut is loose+ Ifchangingcutters,cutterwilt

easily slipfromcollet at_erlooseningcolietnut

6 The collar is machined to precisiontolerancesto tit

cutterswith I/2. in,,diametershanks If usinga cutter

with a !14 in, diametershank,place the 1/4 in adapter

providedin the colleL See Figure.5

7 Insert shankof cutter into coltet unlit shank bottoms

out.then puii fl out 11t6in Ioallow forexpansionwhen

the bit getshot.

8 Tighten Ihe coital nut securely by turningclockwise

with thewrenchprovided, See Figure4.

9,

Place posilock spindle lock back in unlock position.

Otherwise, interlocking mechanism of sptndle lock will

nol let you turn your router on. If you forget, the

spindle lock Indicator light wilt alert you thai spindle

is still locked when you connect router to power

supply.

Page 7

TO TIGHTEN

COLLET NUT_

CUTTERWITH 114IN.

SHANKDIAMETER

114IN. ADAPTER

1/2 IN,COLLET NUT Fig.,5_

ADJUSTMENTS

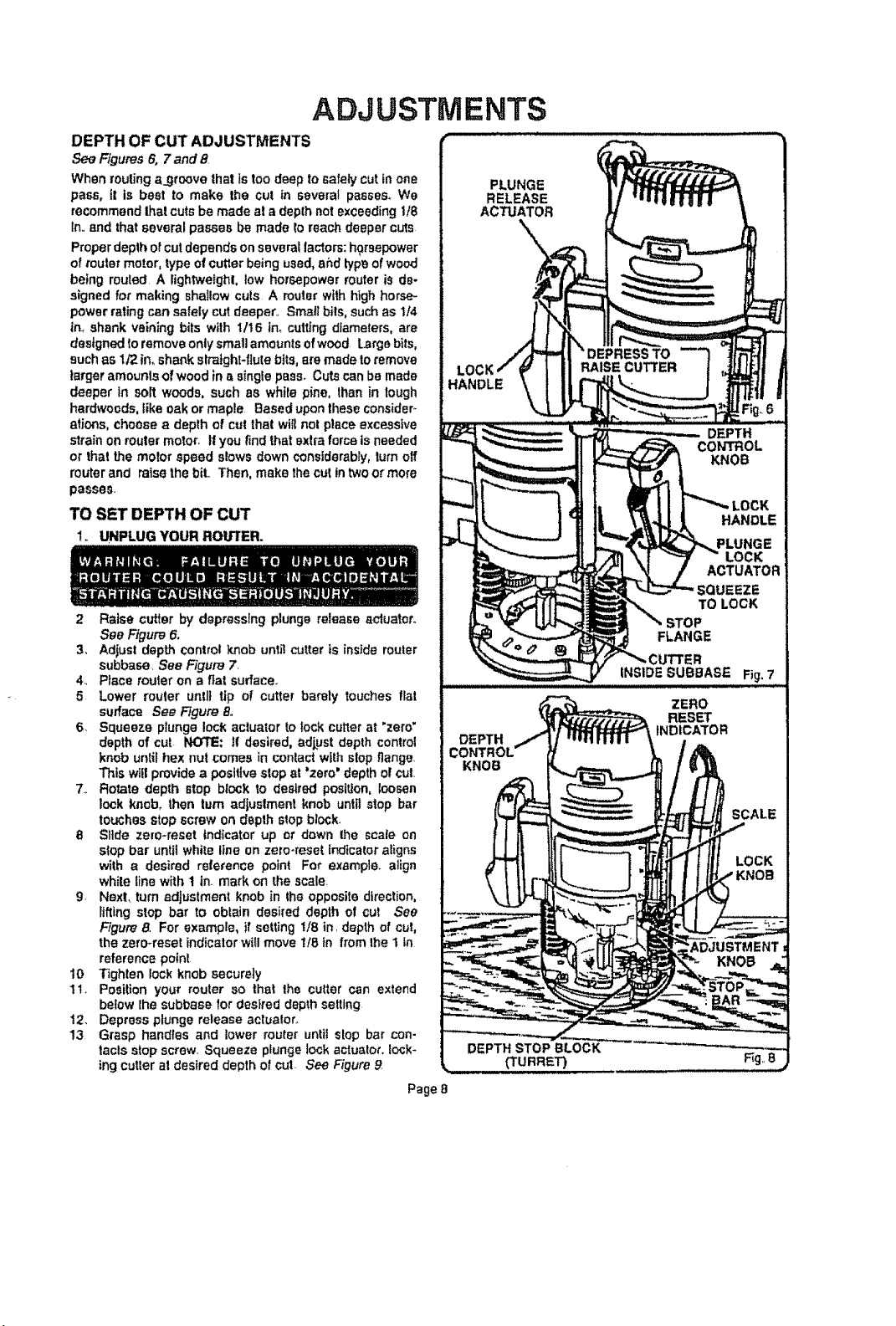

DEPTH OF CUT ADJUSTMENTS

See Figures6, 7 and 8

When routing a_groovethat istoodeepto safely cutin one

pass, it is beet to make the cut in several passes.We

recommendthatcute be made ala depthnot exceedingU8

In,.and thatseveralpassesbe made rereachdeepercuts

Properdepthofcutdependson severallactors: horsepower

ofrouter motor,typeofcutterbeingused,ahd typeofwood

being routed.A lightweight, low horsepowermuter is de-

signedfor makingshaIIow culs A muterwithhigh horse-

powerrating cansafelycut deeper.. Smallbils, suchas It4

innshankveiningbits with 1/16 inocuttingdiameters,are

designedtoremoveontysmallamountsofwood large bits,

suchas 1/2in, shankslraight-fiutebits,ammadeto remove

largeramountsof woodin asinglepass. Cutscanbe made

deeper in soft woods, such as white pine, lhan in lough

hardwoods,like oak ormaple Based upon theseconsider-

aticms,choose a depth of cut thatwiltnot place excessive

strainon routermotor. If youfindthatextraforceisneeded

or that the reeler speedslowsdownconsiderably,turnoff

muterand raisethe bit. Then,make thecutintweet more

passes.

TO SET DEPTH OF CUT

1. UNPLUG YOUR ROU']rER.

2 Raise cutter by depressing plunge release aduatoro

See Figure 6.

3, Adjust depth control knob unti! c'_tter is inside router

subbese. See Figure 7

4. Place router on a fiat surface..

5 Lower router unlit tip of cutter barely touches flat

surface See Figure 8,

6 Squeeze plunge lock actuator to lock cutter at 'zero'

depth of cut NOTE: tf desired, adjpst depth control

knob until hex nul comes in contact with slop flange.

This wtl!provide a positive stop at "zero" depth of cut.

7., Rotate depth stop block to desired position, loosen

lock knob, then turn adjustment knob until stop bar

touches stop screw on depth stop block,

8 Slide ze[o-reset indicator up or down the scale on

stop bar until white line on zero-meet indicator aligns

with a desired reference point For example, align

while line with 1 in. mark on the scale.

g, Next, turn adjustment knob in lhe opposite direction,

lifting stop bar to obtain desired depth of cul See

Figure 8, For example, if setting 1t8 in. depth of cut,

the zero-reset indicator will move 1t8 in from the 1 in

reference point

10 Tighten lock knob securely

11. Position your router so that the cutter can extend

below lhe subbase for desired depth setting

12. Depress plunge release actuaIor.

13 Grasp handles and lower muter until slop bar con-

tacls stop screw. Squeeze plunge lock actuato_. Io_k-

tng cutter at desired depth of cut. See Figure 9

Page 8

Loading...

Loading...