Craftsman 31525790 Owner’s Manual

OWNERS

MANUAL

MODEL NO.

315.25790

CAUTION:

Read Rules for

Safe Operation

and Instructions

Carefully

_ __....._i! ¸ .......

..... _,_

i

}

:!

i:_:i!:ii:i_i_iiiiil

TEMPLATE

FOR USE WITH ALL CRAFTSMAN ROUTERS

SAVE THIS

MANUAL FOR

FUTURE REFERENCE

SEARS, ROEBUCK AND CO., Hoffman Estates, IL 60179

612647-176 Pa_NT_DI._SA

5"93

Operation

Repair Parts

Sold only by

Introduction

RULES FOR SAFE OPERATION

DaSCONNECT TOOLS. When not in use, before assembling, before servicing, or

when changing attachments, blades, bits, cutters, etc,, all tools shoutd be discon-

nected.

2.

BE SURE ALL ADJUSTMENTS ARE PROPERLY SET AND SECURELY FASTENED.

3.

KEEP GUARDS IN PLACE and in working order.

4.

KEEP WORK AREA CLEAN. Cluttered areas and benches invite accidents.

5.

AVOID DANGEROUS ENVIRONMENT. Don't use power tool in damp or wet Iooa-

tions or expose to rain. Keep work area we!l tit.

6.

KEEP CHILDREN AWAY. Atl visitors should wear safety glasses and be kept a safe

distance from work area. Do not let visitors contact tool or extension cord.

7.

STORE iDLE TOOLS. When not in use, tools should be stored in a dry, high or

locked-up place -- out of the reach of children.

8.

WEAR PROPER APPAREL, No loose clothing or jewelry to get caught in moving

parts. Rubber gloves and footwear are recommended when working outdoors, Also,

wear protective hair covering to contain long hair.

9.

USE SAFETY GLASSES with all tools, Also face or dust mask if operation is dusty.

10.

SECURE WORK. Use clamps or a vise to hold work, It's safer than using your hand

and it frees both hands to operate tool.

11.

DON'T OVERREACH. Keep proper footing and balance at all times. Do not use on a

ladder or unstable support.

12.

NEVER USE iN AN EXPLOS0VE ATMOSPHERE. Normal sparking of the motor could

ignite fumes.

13.

KEEP TEMPLATE DRY, CLEAN, AND FREE FROM OIL AND GREASE,

14.

STAY ALERT, Watch what you are doing and use common sense. Do not operate

tool when you are tired, Do not rush.

15.

DRUGS, ALCOHOL, MEDICATION. Do not operate tool while under the influence of

drugs, alcohol, or any medication.

16.

CHECK FREQUENTLY DURING OPERATmON TO INSURE REQUIRED POSIT_ON

AND TO PREVENT HOLDING MECHANISM FROM BECOMING LOOSENED.

17.

SECURE Dovetail Template to a workbench. See Figures 5 & 6, Page 4.

18,

SAVE THESE mNSTRUCT]ONS.

The operation of any Power Tool con result in tereign objects being thrown into your

eyes which can result in severe eye damage, Before cornmeneirmg power tool opera-

tion, always wear safety goggles or safety glasses with side shields and a full face

shield when needed. We recommend Wide Vision Salary Mask for use over

eyeglasses or standard safety glasses with side shields, available at Sears Catalog

Order or Retail Stores,

Page 2

INTRODUCTION

ASSEMBLY

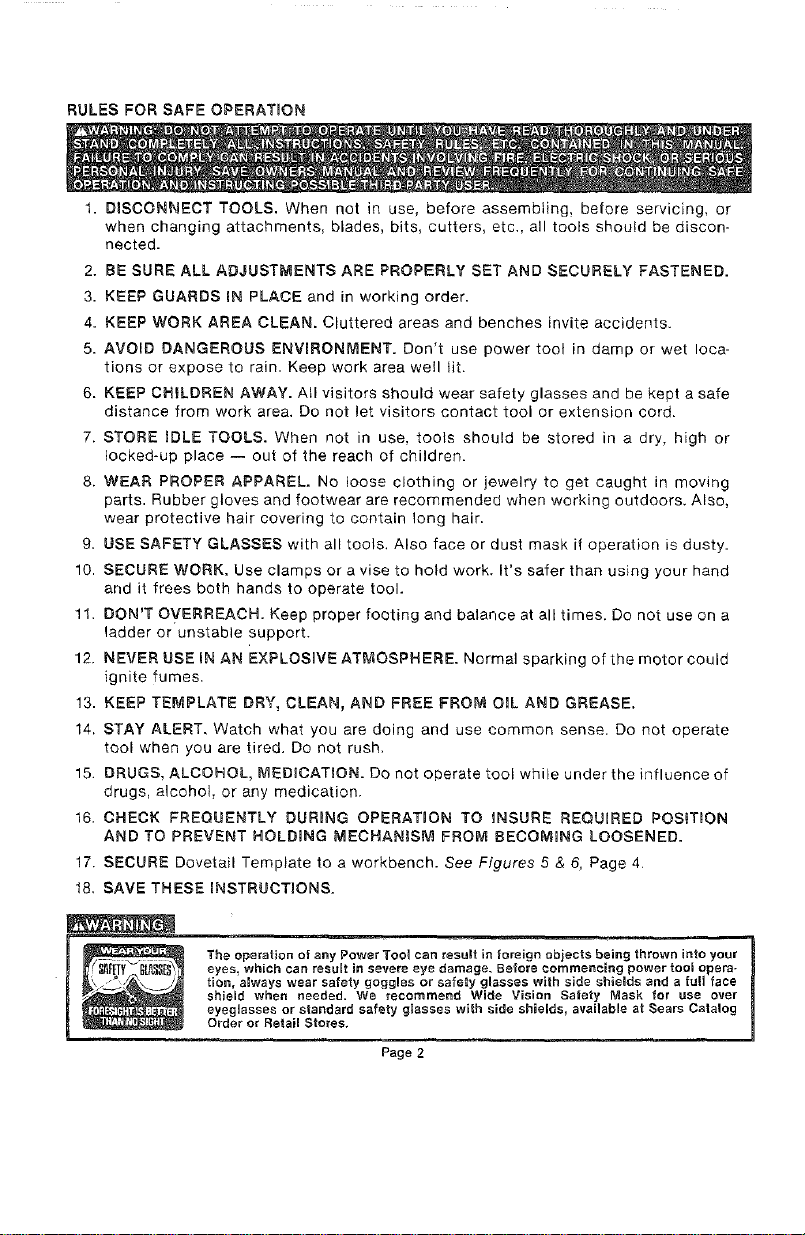

Unpack your dovetail template, separating and

removing all loose parts from the packaging

materials. Check each item with the "Table of Loose

Parts" to make sure all items listed have been pack

ed with your dovetail template. See Figure 1.

ASSEMBLE YOUR DOVETAIL

TEMPLATE AS FOLLOWS:

1. Insert hex bolts through holes in your dovetail

base and tit into molded slots on bottom side of

base.

2. Secure hex bolt with push nuts supplied. See

Figure 1.

3. Place one spring over each hex bolt.

4. Place a washer on top of each spring, then install

clamp bar on top of washer. NOTE: For proper

assembly, be sure to turn each clamp bar as

shown in Figure 1.

5. Place a second washer on top and/or end of each

clamp bar.

6. Thread wing nut onto each hex bolt to secure

washers, clamp bars, and springs.

Item No.

1

2

3

4

5

6

7

8

9

10

TABLE OF LOOSE PARTS

Dovetail Template ........................ 1

Hex Bolt (#1/4-20 x 2-7/8") ................. 4

Push Nut ................................ 4

Spring .................................. 4

Washer ................................. 8

Clamp Bar ............................. 2

Wing Nut ................................

5/16" Guide Bushing...., .................. 1

7/16" Guide Bushing ...................... 1

Screw (10o32 x 1/2" Flat Head) .............. 3

Description Quantity

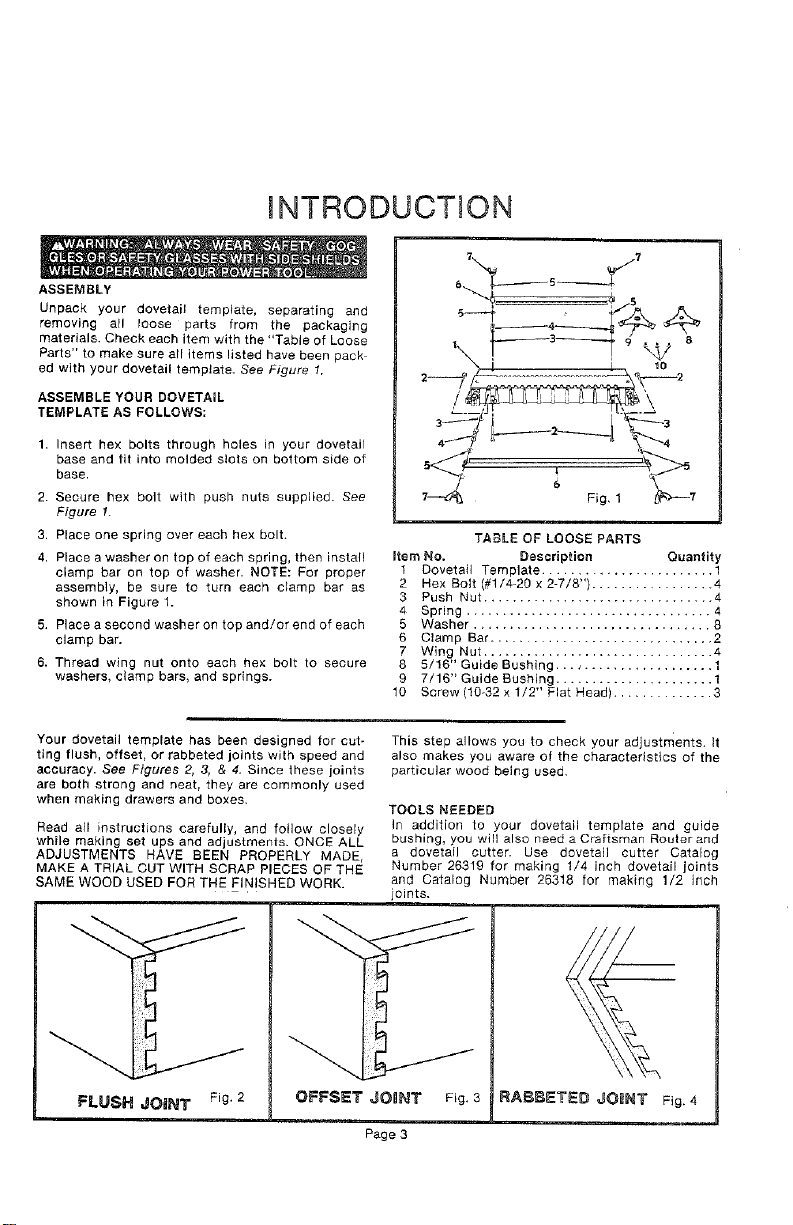

Your dovetail template has been designed for cut-

ting flush, offset, or rabbeted joints with speed and

accuracy. See Figures 2, 3, & 4. Since these joints

are both strong and neat, they are commonly used

when making drawers and boxes.

Read atl instructions carefully, and follow closely

while making set ups and adjustments. ONCE ALL

ADJUSTMENTS HAVE BEEN PROPERLY MADE,

MAKE A TRIAL CUT WITH SCRAP PIECES OF THE

SAME WOOD USED FOR THE FINISHED WORK.

FLUSH JOINT Fig. 2 OFFSET JOnNT

This step allows you to check your adjustments, it

also makes you aware of the characteristics of the

particular wood being used,

TOOLS NEEDED

In addition to your dovetail template and guide

bushing, you will also need a Craftsman Rouler and

a dovetail cutter. Use dovetail cutter Catalog

Number 26319 for making 1/4 inch dovetail joints

and Catalog Number 26318 for making 1/2 inch

joints.

Fig, 3

Page 3

OPERATION

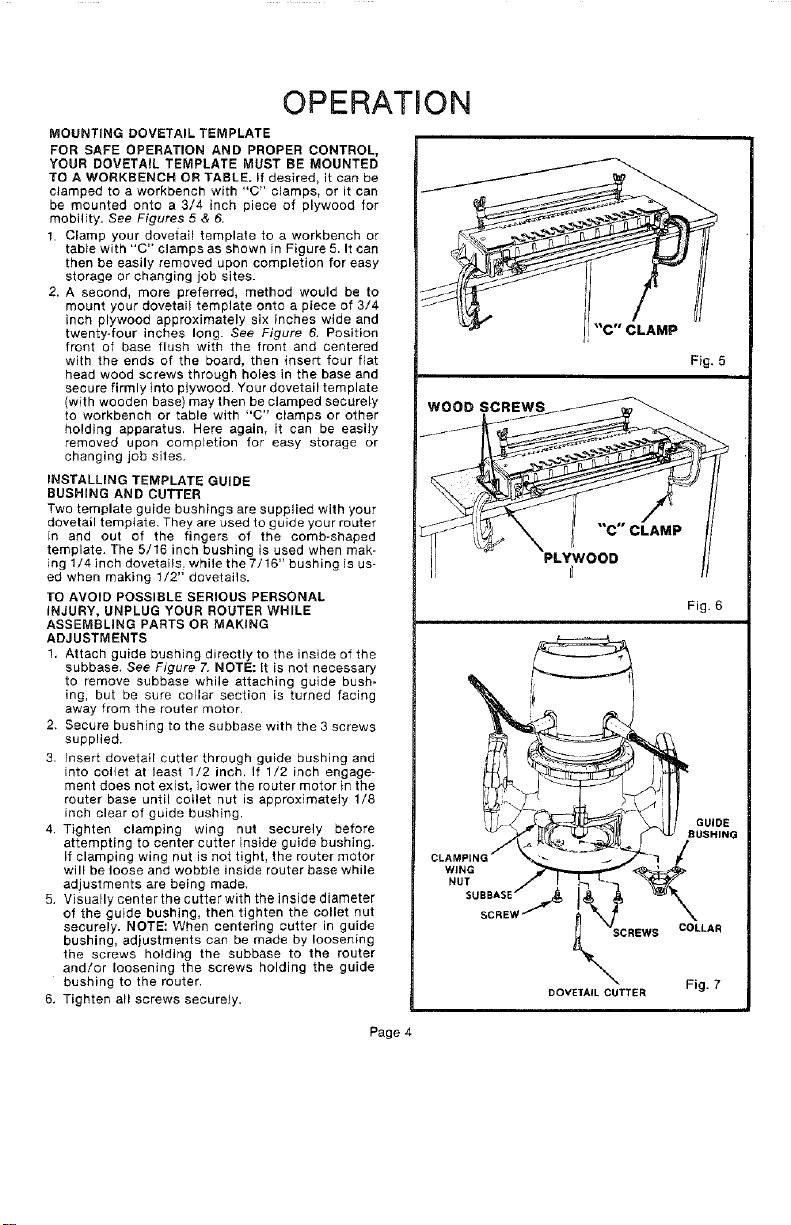

MOUNTING DOVETAIL TEMPLATE

FOR SAFE OPERATION AND PROPER CONTROL,

YOUR DOVETAIL TEMPLATE MUST BE MOUNTED

TO A WORKBENCH OR TABLE. If desired, it can be

clamped to a workbench with "C" clamps, or it can

be mounted onto a 3/4 inch piece of plywood for

mobility. See Figures 5 & 6.

1. Clamp your dovetail template to a workbench or

tab}e with "C" clamps as shown in Figure 5. It can

then be easily removed upon completion for easy

storage or changing job sites.

2. A second, more preferred, method would be to

mount your dovetai_ template onto a piece of 3/4

inch plywood approximately six inches wide and

twenty-four inches long. See Figure 6. Position

front of base flush with the front and centered

with the ends of the board, then insert four fiat

head wood screws through holes in the base and

secure firmly into plywood. Your dovetail template

(with wooden base) may then be clamped securely

to workbench or table with "C" clamps or other

holding apparatus. Here again, it can be easily

removed upon completion for easy storage or

changing job sites.

INSTALLING TEMPLATE GUIDE

RUSHING AND CUTTER

Two template guide bushings are supplied with your

dovetail template. They are used to guide your router

in and out of the fingers of the comb-shaped

template. The 5/16 inch bushing is used when mak-

ing 1/4 inch dovetails, while the 7/16" bushing is us-

ed when making 1/2" dovetails.

1"O AVOID POSSIBLE SERIOUS PERSONAL

INJURY, UNPLUG YOUR ROUTER WHILE

ASSEMBLING PARTS OR MAKING

ADJUSTMENTS

1. Attach guide bushing directly to the inside of the

subbase, See Figure 7. NOTE: It is not necessary

to remove subbase while attaching guide bush-

ing, but be sure collar section is turned facing

away from the router motor.

2. Secure bushing to the subbase with the 3 screws

supplied.

3. Insert dovetail cutter through guide bushing and

into collet at least 1/2 inch, If 1/2 inch engage-

ment does not exist, lower the router motor in the

router base until collet nut is approximately 1/8

inch clear of guide bushing.

4. Tighten clamping wing nut securely before

attempting to center cutter inside guide bushing.

If clamping wing nut is not tighL the router motor

will be loose and wobble inside router base while

adjustments are being made.

5. Visually center the cutter with the inside diameter

of the guide bushing, then tighten the collet nut

securely. NOTE: When centering cutter in guide

bushing, adjustments can be made by loosening

the screws holding the subbase to the router

and!or loosening the screws holding the guide

bushing to the router.

6, Tighten all screws securely.

Page 4

WOOD SCREWS

Fig. 5

"C" CLAMP

PLYWOOD

r_

Fig. 6

SCREWS COLLAR

DOVEfAIL CUTTER Fig. 7

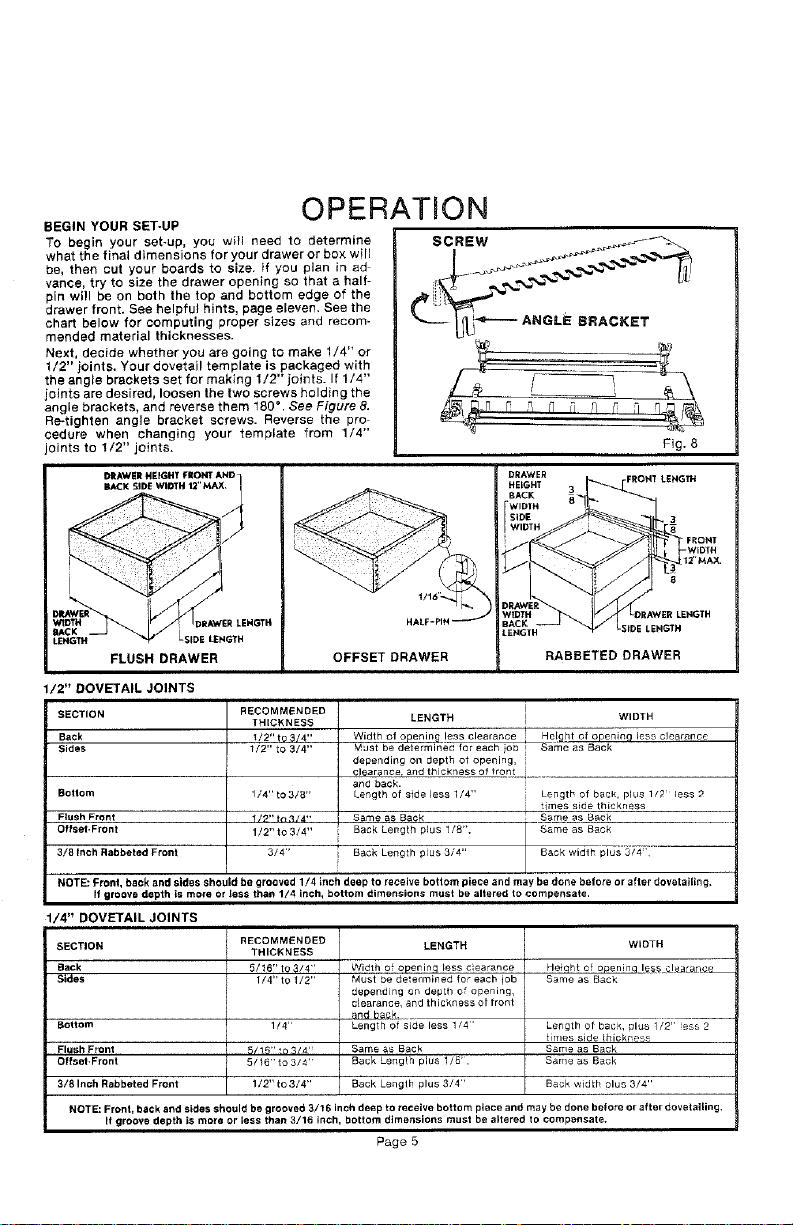

BEGIN YOUR SET-UP

To begin your set-up, you will need to determine

what the final dimensions for your drawer or box will

be, then cut your boards to size. if you plan in ad

vance, try to size the drawer opening so that a half-

pin will be on both the top and bottom edge of the

drawer front. See helpful hints, page eleven. See the

chart below for computing proper sizes and recom-

mended material thicknesses.

Next, decide whether you are going to make 1/4" or

1/2" joints. Your dovetail template is packaged with

the angle brackets set for making 1/2" joints. If 1/4"

joints are desired, loosen the two screws holding the

angle brackets, and reverse them 180 ° . See Figure 8.

Re-tighten angle bracket screws. Reverse the pro

cedure when changing your template from 1/4"

joints to 1/2" joints.

OPERATION

SCREW

L£NGTH LSIDE LENGTH

FLUSH DRAWER

OFFSET DRAWER

RABBETED DRAWER

LENGTH

/2" DOVETAIL JOINTS

SECTION

Back

Sides

Bottom

Flush Front

Offset.Front

3/8Inch Rabbeted Front

NOTE: Pronl, back and sides should be grooved 1/4 inch deep to receive bottom piece and may be done belore or after dovetailing,

If groove depth is mo_e or less than 1/4 inch, bottom dimensions must be altered to compensate.

RECOMMENDED

THICKNESS

/2" t9 _/4"

1/2" to 3/4"

1/4"to 3/8"

1/?"in 314""

1/2"to 3/4"

3/4"

LENGTH WIDTH

Width of openin_ less clearance He!ght of openinc] less clearance

Must be determined, for each io_3 _ Same as Back

depending on depth of opening,

clearance, and thickness of fron[_._ ......

and back.

Length of side less 1/4" Length of back, plus 1/2 less 2

S_me as Back Same as Back

Back Length plus 1/8", Same as Back

Length plus

Back 3/4" Back width plus 3/4'

times side thickness

1/4" DOVETAIL JOINTS

SECTION

Back

Sides

Bottom

Fl_sh Front

Offset.Front

3/8 Inch Rabbeted Front

NOTE: Front, back and sides should be grooved 3/16 inch deep to receive bottom piece and may be done before or Mter dovetaging,

R groove depth is more or less than 3/16 inch, bottom dimensions must be altered to compensale.

RECOMMENDED

THICKNESS

5/t6" to $/4'

1/4" to 1/2"

1/4"

5/16"to 3/4"

1/2"to 3/4"

LENGTH

Width of opening less c ea,ance

Must be determined for each lob

depending on deptB of opening,

c_e_,ran_e, and thickness Of front

and b6g_

Lenglh of side less 1/4'

Same as Back

Back Length plus 1/8',

Back Lenglh plus 3/4"

Page 5

Heiqht of openinq le_ea_arlcL

Same as Back

Length of back, ulus 1/2" ess 2

times side thickness

Same as Back

Same as B_ck

Back width olus 3/4"

WIDTH

Loading...

Loading...