Craftsman 315248200 Owner’s Manual

Owner's Manual

10 in. Stationary

TABLE SAW

O

Save this manual for

future reference

CAUTION: Read and follow all Safety

Rules and Operating Instructions before first

use of this product.

Customer Help Line: 1-800-932-3188

Sears, Roebuck and Co., Hoffman Estates, IL 60179 USA

Visit the Craftsman web page: www.sears.com/craftsman

972000-780

10-02

• Safety

• Features

• Assembly

• Operation

• Maintenance

• Parts List

FULL ONE YEAR WARRANTY ON CRAFTSMAN TABLE SAW

If this(RAFTSMAN Table Saw fails due to a defeat in matedal or workmanshipwithin one year from the date

of pumhase, Sears will repair it, free of charge.

Contacta Sears Service Canter for repair.

if this productis used for commercial or rental purposes,this warranty applies onlyfor 90 days from the date

ofpurchase.

Thiswarrantygivesyou specificlegalrights,and you may alsohaveotherdghtswhichvaryfromstateto

state.

Seare, Roebuck and Co., Dept. 8t7WA, Hoffman Estate,=,IL 60179

Yoursaw has manyfeatures for making cuttingoperations more pleasantend enjoyable. Safety, performance

and dependabilityhave been giventop priorityinthe designof this saw makingiteasy to maintainand operate,

CAUTION: Carefully read throughthisentire owner'smanual before usingyour new saw. Pay close

attentiontothe Rules ForSafe Operation, and all Safety Alert Symbols,includingDanger, Warning and

Caution. If you use yoursaw propedyand onlyfor what itis intended,youwill enjoyyears of safe, reliable

service.

,_, Lookfor this symbol to point out important safetyprecautions,It means attention!!!Yoursafety is involved.

• k WARNING:

The operation of any powertool san resultin foreign objectsbeing thrown into your eyes,

whichcan result in severe eye damage, Before beginningpower tool operation, always

wear safety goggles or safetyglasseswith side shieldsand a fullface shieldwhen needed.

We recommend a WideVision Safety Maskfor usa over eyeglasses or standardsafety

glasses with side shields,availableat Sears Retail Stores.

• Warranty and Introduction............................................................................................................................. 2

• Table Of Contents ...................................................................................................................................... 2-3

• Rules ForSafe Operation........................................................................................................................... 4-6

• Electrical ....................................................................................................................................................... 7

• Glossary and ProductSpecifications............................................................................................................ 8

• Unpacking and Accassodes ......................................................................................................................... 9

• Loose Parts List.......................................................................................................................................... 10

• Small Parts List...................................................................................................................................... 11-12

• Tools Needed .............................................................................................................................................. 13

• Labels ..................................................................................................................................................... 14-15

• Features ................................................................................................................................................. 16-17

• Assembly................................................................................................................................................ 16-29

InstallingHandwheals on Table Sew Base ................................................................................................. 18

AssemblingLeg Stand ........................................................................................................................... 16-19

CRAFTSMAN"TABLESAW315.228390 2

MountingtheLegStandontheTableSawBase........................................................................................ 19

AssemblingTable Extensions..................................................................................................................... 20

AligningTable Extensions ..................................................................................................... 20

Installingthe Rear Rail................................................................................................................................ 21

Installingthe Front Rail ............................................................................................................................... 22

Aligning Rip Fence and Rails ...................................................................................................................... 23

Mountingthe Motor...................................................................................................................................... 23

Installing the Belt and Belt Guard ............................................................................................................... 24

Checkingthe Throat Plate........................................................................................................................... 24

Installingthe BladeGuard ........................................................................................................................... 25

Aligning the RivingKnife withthe Blade ..................................................................................................... 26

Check Heeling (Paralleling)of the Saw Bladeto the Miter Gage Groove .................................................. 27

Checking RipFence and BladeAlignment .................................................................................................. 28

CheckingSquareness of ExtensionTables to Saw Table .......................................................................... 29

• Adjustments............................................................................................................................................ 30-34

Replacingthe Blade .................................................................................................................................... 30

Heeling (Paralleling)the Sawblade to Miter Gage Groove.................................................................... 31-32

Settingthe Bevel Stopsand Indicator.................................................................................................... 32-33

Adjustingthe Miter Gage ............................................................................................................................. 33

Removing/ Replacing the Throat Plate ...................................................................................................... 34

• BasicOperation of the Table Saw ......................................................................................................... 35-42

Causes of Kickback .................................................................................................................................... 35

Avoiding Kickback....................................................................................................................................... 35

CuttingAids................................................................................................................................................. 35

Types of Cuts .............................................................................................................................................. 36

Making a Cross Cut..................................................................................................................................... 37

Making a Rip Cut .................................................................................................................................... 37-38

Making a Miter Cut ...................................................................................................................................... 38

Making a Bevel Cross Cut ..................................................................................................................... 38-39

Making a Bevel Rip Cut ............................................................................................................................... 39

Making a Compound (Bevel) Miter Cut....................................................................................................... 40

Making a Large Panel Cut ........................................................................................................................... 41

Makinga Non-ThroughCUt ......................................................................................................................... 41

Makinga Dado Cut ...................................................................................................................................... 42

• Maintenance ................................................................................................................................................ 43

• Lubrication................................................................................................................................................... 43

• Troubleshooting...................................................................................................................................... 44.46

• ExplodedView and Repair Parts List..................................................................................................... 48-65

• Parts Ordering/ Sen/ica ................................................................................................................ back page

3 cnn_lrxHnr TABLESAW31,5,228390

The purposeof safety symbols isto attractyour attentionto possibledangers. The safety symbols,and the

explanationswiththem, deserve your careful attentionand understanding,The safety warnings do not by

themselves eliminateany danger. The instructionsorwarningsthey give are notsubstitutesfor proper accident

preventionmeasures.

SYMBOL MEANING

&

SAFETY ALERT SYMBOL

Indicates danger, warning,or caution. May be used in conjunctionwithother symbolsor

pictugraphs.

&

A

&

Note: Advisesyou of informationorInstructions vital to the operationor maintenanceofthe equipment,

IMPORTANT

Servicingrequiresextreme care and knowledgeofthe

system and should be performed onlybya qualified

servicetechnician, For servicewe suggestyou return

the toolto yournearest Sears store or repaircenter.

Alwaysuse odginalfactory replacement partswhen

servicing.

READ ALL INSTRUCTIONS

• KNOW YOUR POWER TOOL. Read the owner's

manual carefully, Leam the saw's applications

and limitationsas well as the specific potential

hazards related to this tool.

• DO NOT USE IN DANGEROUS ENVIRON-

MENT. Do not use power tools near gasoline or

other flammable liquids,in damp or wet loca-

tions, or expose them to rain. Keep the work

area well lit.

• MAKE WORKSHOP CHILD-PROOF with

padlocks and master switchesor by removing

starter keys.

• KEEP CHILDREN AND VISITORS AWAY. All

visitors sbou|dwear safety glasses and be kept

a safe distance from work area. Do not let

visitorscontact tool or extension cordwhile

operating.

• KEEP THE WORK AREA CLEAN. Cluttered

work areas and work benches inviteaccidents.

DO NOT leave toolsor pieces of wood on the

saw while it is in operation,

DANG ER: Failureto obey a safety warningwill result inseriousinjuryto yourselfor toothers,

Always followthe safety precautionsto reducethe riskof fire, electdc shockand personalinjuP/,

WARNING: Failureto obey a safety warningcan resultin sadous Injury to yourselfor to others,

Always followthe safetyprecautionsto reducethe riskof fire, electdc shockand personal injuw.

CAUTION: Failureto obey a safety warning may resultin propertydamage or personal injulyto

yourselforto others.Alwaysfollow the safety precautionsto reduce the dsk of fire,electricshock

and personal injury,

_, WARNING: Do not attemptto operate thistool

untilyou have read thoroughlyand understand

completelyall instructions,safetyrules,etc.

containedinthis manual. Failure to complycan

resultin accidentsinvolvingfire, electrical shock,

or serious personal injury.Save theowners

manualand reviewfrequentlyfor continuingsafe

operation,and instructingotherswho rneyusa

this tool.

• MAINTAIN TOOLS WITH CARE. Keeptools

sharpand clean for better and safer perfor-

mance. Follow instructionsfor lubricatingand

changing accessories,

• USE THE RIGHT TOOL FOR THE JOB. Do not

force the toolor attachmentto do a job it was

not designedfor. Usa it onlythe way it was

intended.

• DRESS PROPERLY. Do not wear loose cloth-

ing. gloves, neckties, rings, bracelets, or other

jewelry. They can get caught and draw you into

moving parts. Rubber gloves and nonslip

footwear are recommended.Also wear protec-

tive hair covedng to contain long hair.

• ALWAYS WEAR SAFETY GLASSES WITH

SIDE SHIELDS. Everyday eyeglasses have only

impact-rasistantlenses; they are NOT safety

glaseas.

• NEVER STAND ON TOOL, Serious injurycould

or.curifthe tool is tipped or if the blade is

unintentionallycontacted.

EIIRFTIMRIr TABLESAW315.228390 4

RULES FOR SAFE OPERATION (Continued)

• DO NOT OVERREACH. Keep properfootingand

balance at all times.

• SECURE WORK. Usa clamps or • vise to hold

work when practical. It's safer then usingyour

handand frees bothhandsto operate tool.

• USE THE PROPER EXTENSION CORD. Make

sure your extension cord is in good condition,

Use only a cord heavy enoughto carry the

currentyour product will drew,An undersized

cordwillcause a drop in linevoltage resultingin

loss of powerand overheating.A wire gage size

(A.W,G.) ofat least 14 is recommendedfor an

extension cord 25 feat or less in length. If in

doubt, usethe next heavier gage. The smaller

the gage number, the heavierthe cord.

• AVOID ACCIDENTAL STARTING. Be sure

switchis off when pluggingin,

• REMOVE WRENCHES AND ADJUSTING

KEYS, Get in the habit of checking- before

turning on tool - that hex keys and adjusting

wrenches are removedfrom tool.

CHECK DAMAGED PARTS. Beforeusingthe

tool again, check any damaged parts, including

guards,for proper operation and perfon_anca.

Check alignment of movingparts, bindingof

moving parts, breakage of parts, saw stability,

mountingand any other conditionsthat may

affect its operation. A damaged part muStbe

proparlyrepaired or replaced bya qualified

service technician at a Sears Store or repair

center to avoid riskof personalinjury.

USE ONLY CORRECT BLADES. Use the dght

blade size, style and cuttingspeed for the

matedal and the type of cut. Bladeteeth should

point downtoward the frontofthe table.

• USE RECOMMENDED ACCESSORIES. Using

improper accessories may risk injury.

USE ONLY SEARS REPLACEMENT PARTS.

All repairs, whether electrical or mechanical,

shouldbe made by a qualified sarvice technician

at a Sears Store or repair center.

• KEEP GUARDS IN PLACE and in goodworking

order, This includesthe bladeguard, dying

knife, and anti-ldckback pawls.

• CHECK DIRECTION OF FEED. Feed work into

a blade orcutter against the direction of rotation

of the blade or cutter only.

DISCONNECT ALL TOOLS. When notin use,

before saP.'icing, or when changing attachments,

blades, bits,cutters, etc., all tools should be

disconnectedfrom power supply.

• DO NOT FORCE THE TOOL. Itwill dothe job

better and more safely at the rate for which it

was designed,

• NEVER LEAVE TOOL RUNNING UNAT-

TENDED. TURN THE POWER OFF. Do not

leave tool until it comes to a complete Stop.

• BEFORE MOUNTING, DISCONNECTING OR

REMOUNTING THE MOTOR; unplugthe saw

and removethe switchkey.

A WARNING: When servicing,use only identical

Creflsman replacement parts. Use of any other

parts may create a hazard or cause product

damage.

• NEVER USE THIS TOOL IN AN EXPLOSNE

ATMOSPHERE. Normal sparkingofthe motor

could ignite fumes,

• MAKE SURE THE WORK AREA HAS AMPLE

LIGHTING to see the work and that no obStruc-

tions willinterferewith safe operation BEFORE

performingany work usingthis tool.

• DO NOT USE TOOL IF SWITCH DOES NOT

TURN n" ON AND OFF. Have defective

switches replaced by a qualified servicetechni-

cian at a Sears Store or repair center.

• GUARD AGAINST ELECTRICAL SHOCK by

preventingbodycontactwith grounded surfaces

such as pipes, radiators, ranges, refrigerator

enclosures.

• GROUND ALL TOOLS. See Electrical page.

• WEAR A DUST •ASK to keep from inhaling

fine particles.

• PROTECT YOUR HEARING. Wear hsaring

protectiondudngextended periodsof operation,

• DO NOT OPERATE THIS TOOL WHILE UN-

DER THE INFLUENCE OF DRUGS, ALCOHOL,

OR ANY MEDICATION.

• STAY ALERT AND EXERCISE CONTROL.

Watch whatyou ere doingand usecommon

sense. Do not operate tool when you are

tired. Do not rash.

• AVOID AWKWARD OPERATIONS AND HAND

PosmoNs where a sudden slipcouldcause

your handto move intothe blade. ALWAYS

make sure you have good balance.

• ALWAYS SUPPORT LARGE WORK PIECES

while cuttingto minimizerisk of blade pinching

and kickback.Saw may slip. walk or slide while

cutting large or heavy boards.

• GUARD AGAINST KICKBACK, Kickbackcan

occurwhen the blade stalls, drivingthe work

piece beck towardthe operator. It can pullyour

hand intothe blade, resultingin sedous personal

injury.Stay out ofthe blade path and turnswitch

off immediatelyif blade bindsor stalls.

5 I;IIIIFI'ZNRN" TABLESAW315.228390

RULES FOR SAFE OPERATION (Continued)

• USE A SUPPORT FOR THE SIDES AND BACK •

OF THE SAW TABLE when sawingwide or long

workpleoas. Usa e sturdy "outrigger"support if e

table extensionis more than 24 inches longand •

isattached to the saw, to prevent tipping,

CUT ONLY WOOD, PLASTIC OR WOOD-LIKE

MATERIALS. Do not cut metal.

NEVER cut more then one piece at a time. DO

NOT STACK more than one workpieceon the

saw table at a time,

DO NOT REMOVE THE SAW'S BLADE

GUARDS. Never operate the saw with any

guard or cover removed, Make sureall guards

are operating propedybefore each use,

NEVER PERFORM ANY OPERATION FREE-

HAND. Alwaysplace the workplaceto be cut on

the saw table and positionitfirmlyagainstthe

fence as a backstop.

USE THE RIP FENCE. Always usa a fence or

straight edge guide when ripping,

BEFORE MAKING A CUT, be sure all adjust-

ments are secure.

BE SURE THE BLADE PATH • FREE OF

NAILS. Inspect for and remove all nailsfrom

lumber before cutting.

• BE SURE THE BLADE CLEARS THE

WORKPIECE, Never start the saw with the

blade touching the workplace,

• KEEP HANDS AWAY FRO• CUTTING AREA.

Do not reach underneath work or in blade cutting

path withyour hands and fingers for any reason.

Alwaysturn the power off,

USE A PUSHBLOCK OR PUSH STICK for

workpiecas so small that yourfingers go under

the blade guard. NEVER TOUCH BLADE or

other moving parts dudng usa, for any reason,

_lb WARNING: Blade coasts after balngturned off.

• ALLOW THE MOTOR TO COME UP TO FULL

SPEED before startinga out to avoid blade

bindingor stalling.

• ALWAYS PUSH THE WORKPIEGE; never pull

ittoward the saw.

• DO NOT FEED THE MATERIAL TOO

QUICKLY, Do not force the workplace against

the blade.

• ALWAYS TURN OFF SAW before disconnect-

ing it, to avoid accidental =talting when recon-

nectingto power supply. NEVER leavethe table

saw unattended while connectedto a power

source.

BEFORE CHANGING THE SETUP, REMOVING

COVERS, GUARDS, OR BLADE; unplugthe

saw end remove the switchkey.

KEEP TOOL DRY, CLEAN, AND FREE FROM

OIL AND GREASE. Always use a clean cloth

when Cleaning.Never use brake fluids, gesaline,

petroleum-based products,or any solventsto

clean tool.

• KEEP BLADES CLEAN, SHARP AND WITH

SUFFICIENT SET. Sharp blades minimize

stallingand kickback,

• USE ONLY OUTDOOR EXTENSION CORDS,

Use only extensioncordswith the marking

"Acceptablefor usa with outdoor appliances;

store cords indoorswhile not in usa."Use

extension cordswith an electrical rating not less

than the saw's rating,Always disconnect the

extension cord from the outletbefore discon-

nectingthe product from the extension cord.

• INSPECT TOOL CORDS AND EXTENSION

CORDS PERIODICALLY and, if damaged, have

repairedby a qualifiedservice technicianat a

Sears store or repair center. Stay constantly

aware of cordlocationand keep it well away

fromthe moving blade.

IS DO NOT ABUSE CORD, Never yank cordto

disconnectit from receptacle. Keep cordfrom

heat, oil, and sharp edges.

• SAVE THESE INSTRUCTIONS. Refer to them

frequentlyand use to instructother users, If you

loan someonethis tool, loan them these instruc-

t_onsalso.

WARNING: Some dust created by power

,&

sanding, sawing, grinding, ddlling, and other

construction activities contains chemicals

known to cause cancer, birth defects or other

reproductive harm, Some examples of these

chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement

end other masonry products, and

, arsenic and chromium from chemically-

treated lumbar,

Your dskfrom these exposures vades,

depending on how often you do this type of

work. To reduce your exposure to these

chemicals: work in a well ventilated area, and

work with approved safety equipment, such as

those dust masks that are specially designed

to filter out microscopic particles.

SAVE THESE INSTRUCTIONS

[IIRFIrSI4RN"TABLESAW$I_228390 6

EXTENSION CORDS

Use only3-wirs extensioncords that have 3-prong

groundingplugsand 3-pole receptaclesthat accept

the tool'splug.When usinga powertool at a consid-

erable distancefrom the power source, use an

extensioncord heavy enough to carrythe currentthat

thetool willdraw. An undersizedextensioncordwill

cause a dropin linevoltage, resultingina lossof

power and causingthe motor to overheat, Use the

chart providedbelowto determinethe minimumwire

size requiredin an extensioncord. Only round jack-

eted cordslistedby Underwriter'sLaboratories(UL)

shouldbe used,

Length of Extension Cord Wire Size (A.W.G.)

Up to 25 feet 14

26-100 feet 12

When workingwiththe tool outdoors,use an exten-

sioncordthat isdesignedfor outsideuse. Thisis

indicatedbythe lettersWA on the cord'sjacket.

Before usingan extensioncord, inspectitfor loose or

exposedwires and cut orwom insulation.

A_ CAUTION: Keep the cordaway from the cutting

arsa and positionthe cord sothat Itwill not be

caughton lumber, tools, or otherobjectsduring

cuttingoperations.

ELECTRICAL CONNECTION

Your Sears Craftsman Table Saw is powered by a

precisionbuiltelectricmotor. It shouldbe connected

to a power supply that is 120 volts, 60 Hz, AC only

(normal household cun'ent). Do notoperatethis tool

on directcurrent (DC), A substantialvoltagedropwill

cause a loss of powerand the motorwilloverheat. If

the saw does not operate when pluggedintoan

outlet, double check the powersupply.

SPEED AND WIRING

GROUNDING INSTRUCTIONS

In the event of a malfunctionor breakdown,grounding

providese path ofleast resistancefor electriccurrent

to reducethe riskof electricshock.This tool is

equippedwithan electdccord having an equipment-

groundingconductorand a groundingplug.The plug

mustbe pluggedintoa matchingoutletthat is properly

installedand groundedin accordancewith all local

codes and ordinances.

Do not modifythe plugprovided. If itwill not fitthe

outlet,havethe properoutlet installedby a qualified

electrician,improperconnectionofthe equiprnent-

groundingconductorcan result ina riskof electric

shook.The conductor with insulationhavingan outer

surfacethatisgreen withor withoutyellow stripesis

the equipment-groundingconductor. If repairor

replacementofthe electriccordor plugis necessary,

do notconnectthe equipment-groundingconductor to

a live terminal.

Check with a qualifiedelectricianor service personnel

ifthe groundinginstructionsare net completely

understood,or if in doubtas towhether the toolis

properlygrounded.

Repairor replacea damagedorwom cord immedi-

ately.

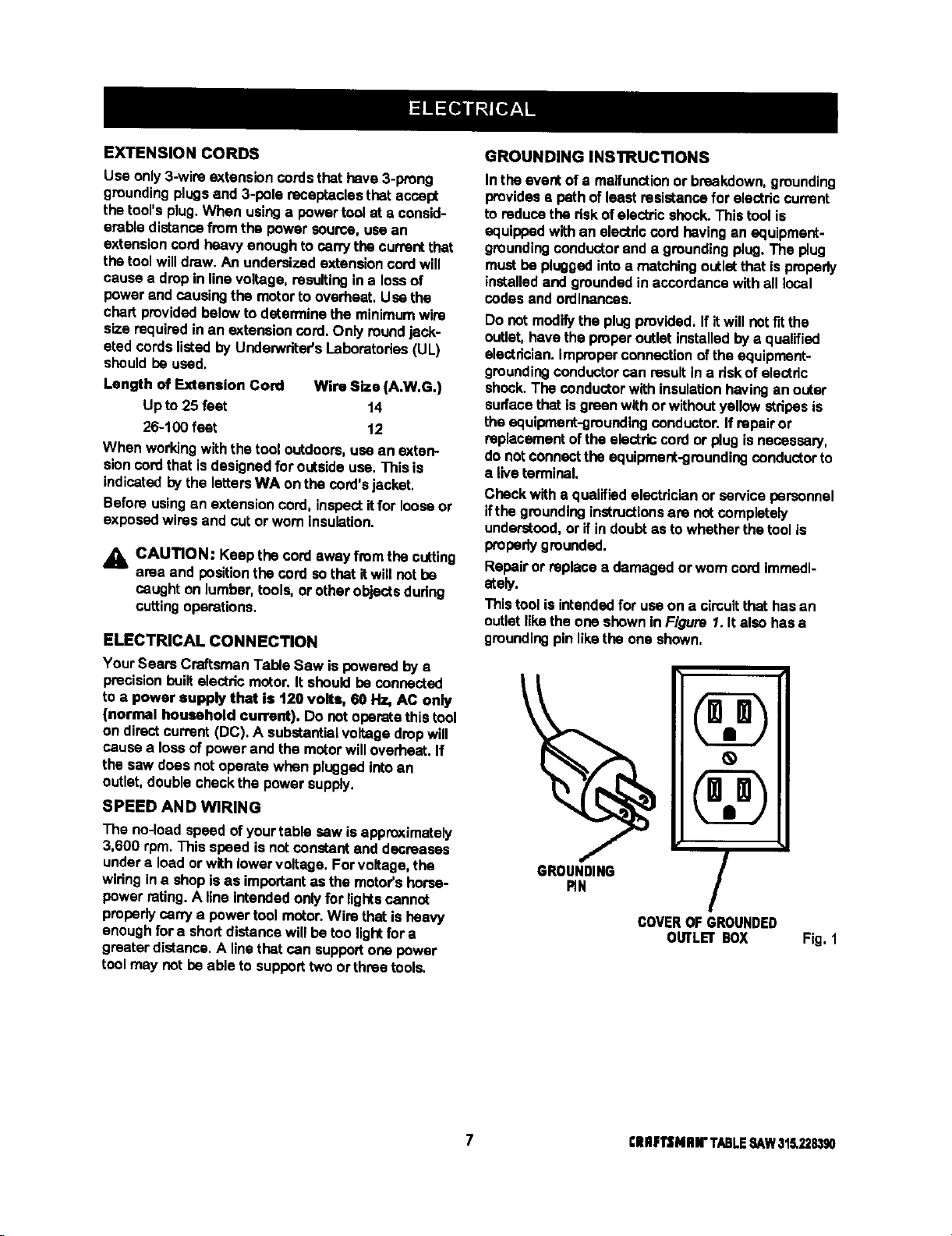

This toolis intendedfor use on a cimultthat has an

outletlikethe one shownin Figure 1. It also has •

groundingpin likethe one shown,

\

The no-load speed of yourtable saw is approximately

3,600 rpm. This speed is notconstant and decreases

undera load or withlower voltage. For voltage,the

wiringina shop is as importantas the motor's horse-

power rating.A line intended only for lightscannot

probedycarry a power tool motor.Wire thatis heavy

enoughfor a short distancewill be too lightfor a

greeterdistance. A linethat can supportone power

toolmay not be able to supporttwo orthrae tools.

GROUNDING

RN

COVEROFGROUNDED

7 ClllF1'$Nlnr TABLESAW315,228390

/

OtRLEr BOX

Fig, 1

Anti-Kickback Pawls

Toothedsafety devices behindthe blade designedto

stop a workpiece from being kickedback at the

operatorduringa ripping operation.

Arbor

The shaft on whicha blade or cuttingtool is mounted.

Bevel Cut

A cuttingoperation madewith the blade at any angle

otherthan 90° to the saw table.

Compound Cut

A cutwithboth a miterangle and a bevel angle.

Crosscut

A cuttingoperationmade acrossthe grainorthe width

of theworkpiece,

Dado

A non-throughcutthat gives a square notchor trough;

requiresa special blade.

Featherboard

A deviceto helpguide workpiecesduring ripcuts.

Freehand (for table saw)

Dangerouspracticeof making a cut withoutusingrip

or miterfences. See Safety Rules.

Gum

A sticky,sap-based residuefrom wood products.

Heel

Alignmentof the blade.

Kerr

The matedal removedbythe blade ina throughcut or

the slotproduced bythe blade In a non-throughcut.

Kickback

A hazardthat can occur when blade binds or stalls,

throwingworkpleceback toward operator.

Leading End

The end of the workpiece pushed intothe cuttingtool

first.

Miter Cut

A cuttingoperation made with the miter gage at any

angle otherthan 0°.

Molding

A non-through cutthat gives a varied shape to the

workpieceand requiresa special blade.

Push Stick

A device used to feed the workpiecethroughthe saw

blade dudngnarrowcuttingoperations. It helpskeep

the operator'shands well away from the blade,

Rabbet

A notch in the edge of a workpiece.

Rw

A cutting operation to reduce the thickness of the

workpiece in order to make thinner pieces.

Resin

A sticky,sap-bssed substance.

RIp Cut

A cutmade withthe the grain of the workpiece.

SawbladiePath

The area directlyin linewith the blade-- over,under,

behind,or in frontof it. Also, the workpiecearea

whichwillbe or has been cutbythe blade.

Set

The distance that the tip of the saw bladetoothisbent

(or set) outwardfromthe face ofthe blade.

Throw-Back

Saw throwingback a workpiece;similarto kickback.

Through Sawing

Any cuttingoperation where the blade extends

completelythroughthe workpiece.

TratIIng End

The workpiece end last cutby the blade in a rip cut.

Workplace

The itemon whichthe cuttingoperation is beingdone.

The surfacesofa workpiesaare commonlyreferredto

as faces, ends, and edges.

Worktable

The surface on whichthe workpiece restswhile

performinga cuttingoperation.

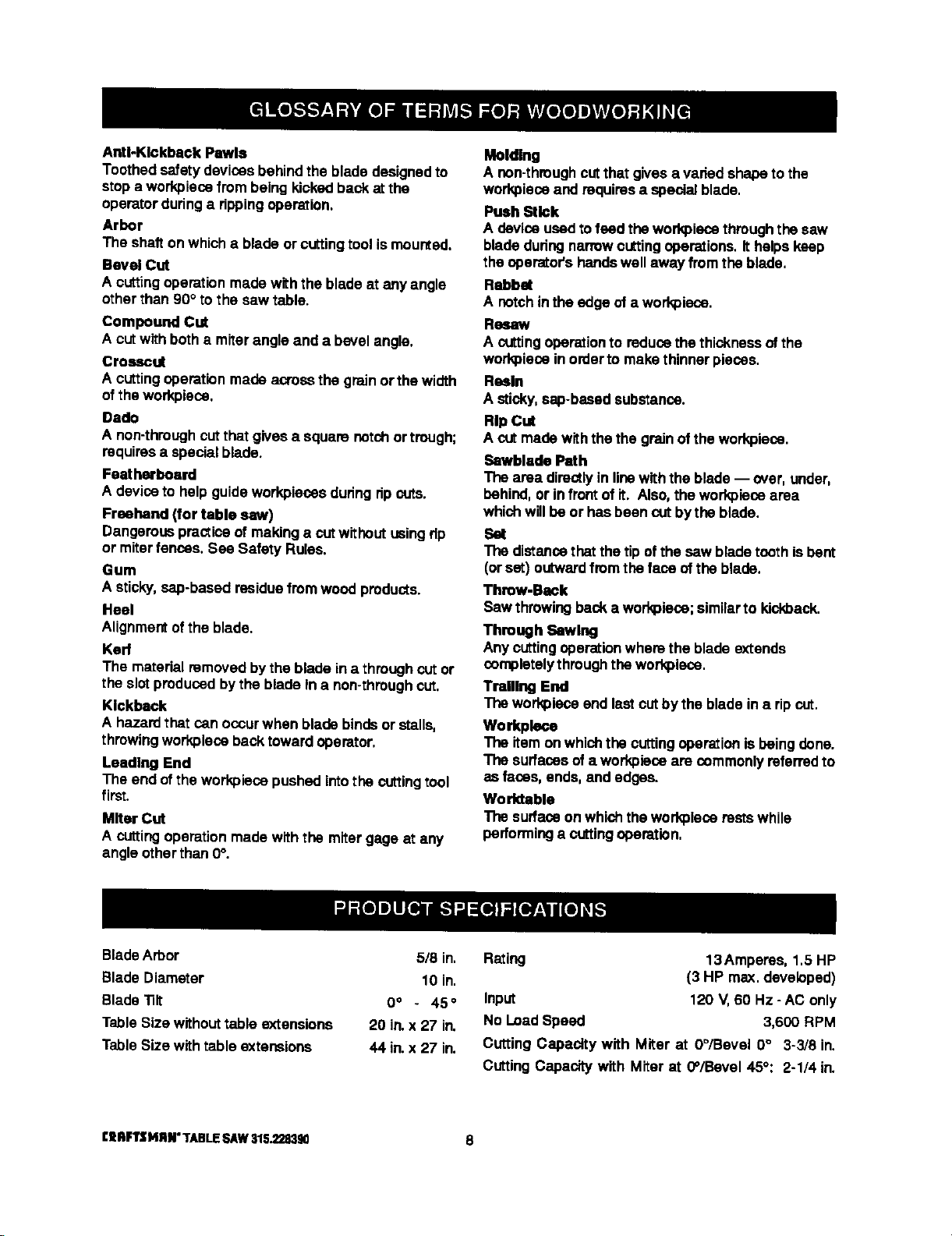

BladeArbor 5/8 in,

BLadeDiameter 10 in.

Blade "13it O° - 45 °

TableSize withouttable extensions 20 in.x 27 in.

TableSize with table extensions 44 in.x 27 in.

£11RFTSMRN" TABLE ,SAW315.228390 8

Rating 13 Amperes, 1,5 HP

(3 HP max. developed)

Input 120 V, 60 Hz -AC only

No Load Speed 3,600 RPM

Cutting Capacity with Miter at 0°/Bevel 0° 3-3/8 in.

CuttingCapacity wIth Miter at 0°/Bevel 45°: 2-1/4 in.

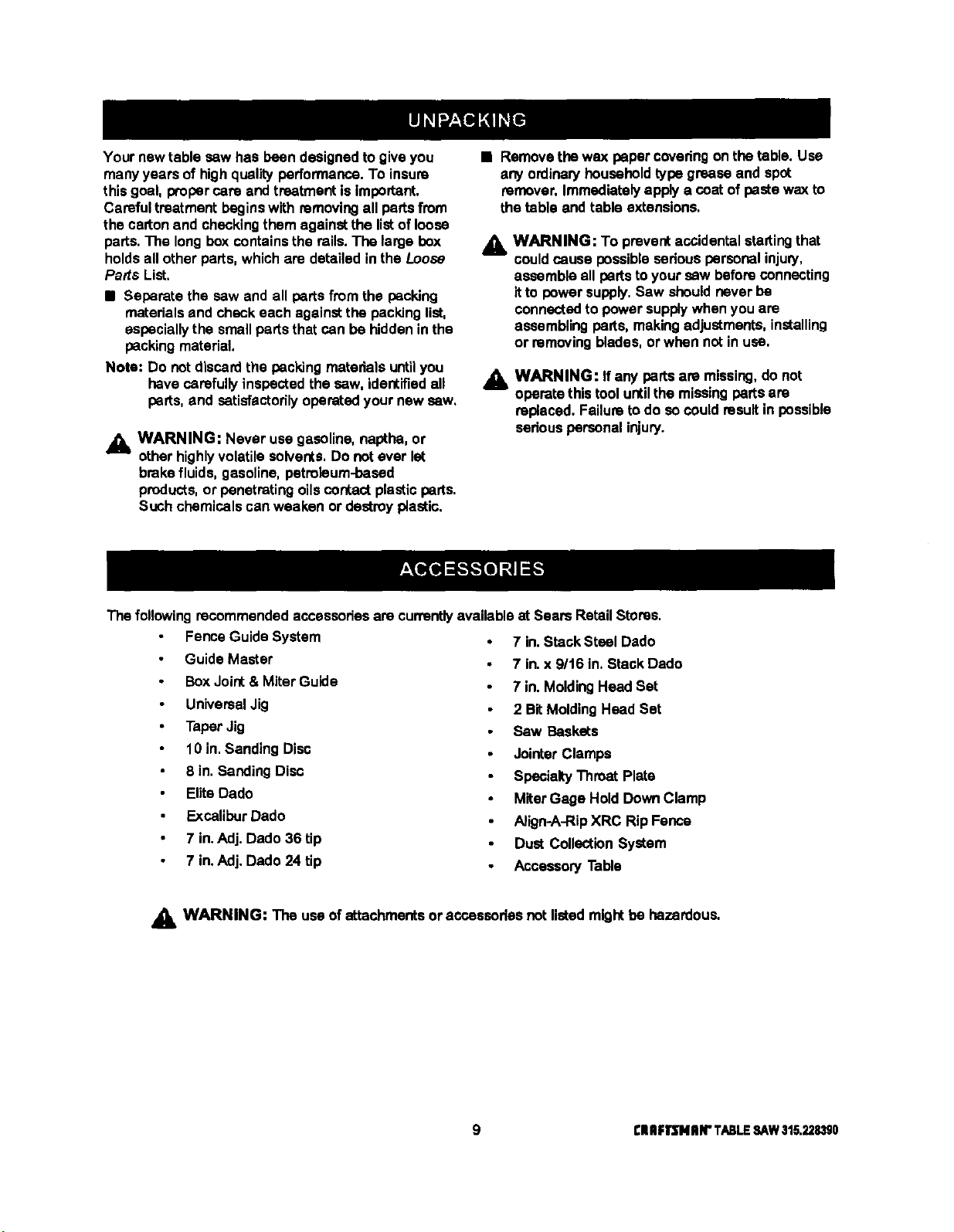

Your new table saw has been designedto give you

many years of highquality performance.To insure

this goal, Woparcare andtreatment is important.

Careful treatment beginswith removingall partsfrom

the cartonand checkingthem againstthe listof loose

parts.The longbox containsthe rails.The large box

holdsall other parts,whichare detailed in the Loose

Parts List,

• Separate the saw and all partsfrom the packing

materialsand check each againstthe packinglist,

especiallythe smallparts that can be hiddeninthe

packing material.

Note: Do not discardthe packing matadals untilyou

havecarefullyinspected the sew, identifiedall

parts, and satisfactorilyoperated your new saw.

WARNING: Never use gasoline,naptha, or

otherhighlyvolatile solvents.Do not ever let

brakefluids, gasoline,petroioumJoased

products,or penetrating oils contact plasticparts.

Such chemicals can weaken or destroy plastic.

• Removethe wax paper covedngon the table. Use

anyordinaryhouseholdtypegrease and spot

remover. Immediatelyapply a coat of pastawax to

thetable and table extensions.

WARNING: To preventaccidental startingthat

couldcause possible sadous personal injury,

assemble all parts to your sew beforeconnecting

itto powersupply.Saw should never be

connectedto power supplywhen you are

assemblingparts, makingadjustments,installing

or removingblades, or when notin use.

_1= WARNING: If any parts are missing,do not

operatethis tool untilthe missingpartsare

replaced. Failuretodo socould resultin possible

seriouspersonalinjury.

The followingrecommendedaccassodesare currentlyavailableat Sears Retail Stores.

Fence Guide System

Guide Master

BoxJoint& Miter Guide

UniversalJig

TaperJig

10 in.Sanding Disc

8 in.Sanding Disc

Elite Dado

ExcaliburDado

7 in.Adj. Dado 36 tip

7 in.Adj. Dado 24 tip

7 in.Stack Steel Dado

7 in.x 9/t6 in, Stack Dado

7 in. MoldingHead Set

2 BitMoldingHead Set

Saw Baskets

JointerClamps

SpecialtyThroat Plate

MiterGage Hold DownClamp

Align.A-RipXRC Rip Fence

Dust Collection System

Accessory Table

A_. WARNING: The useof attachmentsor accassedes not listedmightbe hazardous.

9 ElUlIqrENIIN"TABLESAW31.5.2,?.8,_0

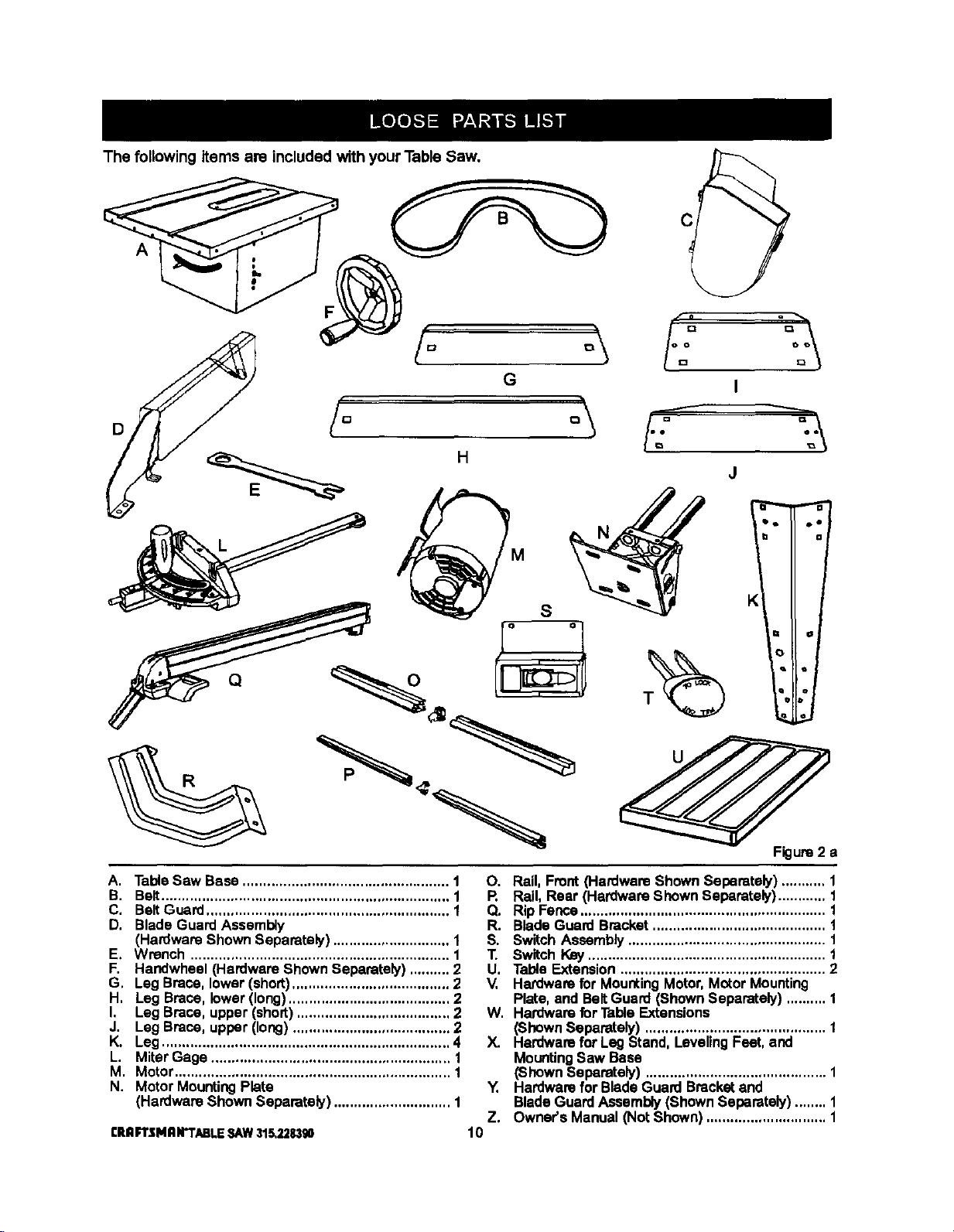

The following items are included with your Table Saw.

A

D

A. TableSaw Base ................................................... 1

B. Belt....................................................................... 1

C, BeltGuard ............................................................ 1

D, Blade Guard Assembly

(Hardware Shown Separately) ............................. 1

E, Wrench ................................................................ 1

F, Handwheel (Hardware Shown Separately) .......... 2

G, LegBrace, lower (short)....................................... 2

H, Leg Brace, lower(long)........................................ 2

I, Leg Brace, upper (short) ...................................... 2

J. Leg Brace, upper (long) ....................................... 2

K. Leg ....................................................................... 4

L. Miter Gage ........................................................... 1

M. Motor.................................................................... 1

N. Motor MountingPlate

(Hardware Shown Separately) ............................. 1

CRnFTSMnN'TABLESAW315,228,390

O. Rail,Front (Hardware Shown Separately) ........... 1

R Rail, Rear (Hardware Shown Separately)............ 1

Q. Rip Fence............................................................. 1

R. Blade Guard Bracket........................................... 1

S. Switch Assembly ................................................. 1

T. Switch Key........................................................... 1

U, Table Extension ................................................... 2

V, Hardware for MountingMotor,Motor Mounting

Plate, and BeltGuard (ShownSeparately) .......... 1

W. Hardware for Table Extensions

(ShownSeparately) ............................................. 1

X. Hardware for Leg Stand, Leveling Feet, and

MountingSaw Base

(Shown Separately) ............................................. 1

Y. Hardwarefor BladeGuard Bracketand

BladeGuardAssembly(Shown Separately) ........ 1

Z. Owner's Manual (Not Shown) .............................. 1

10

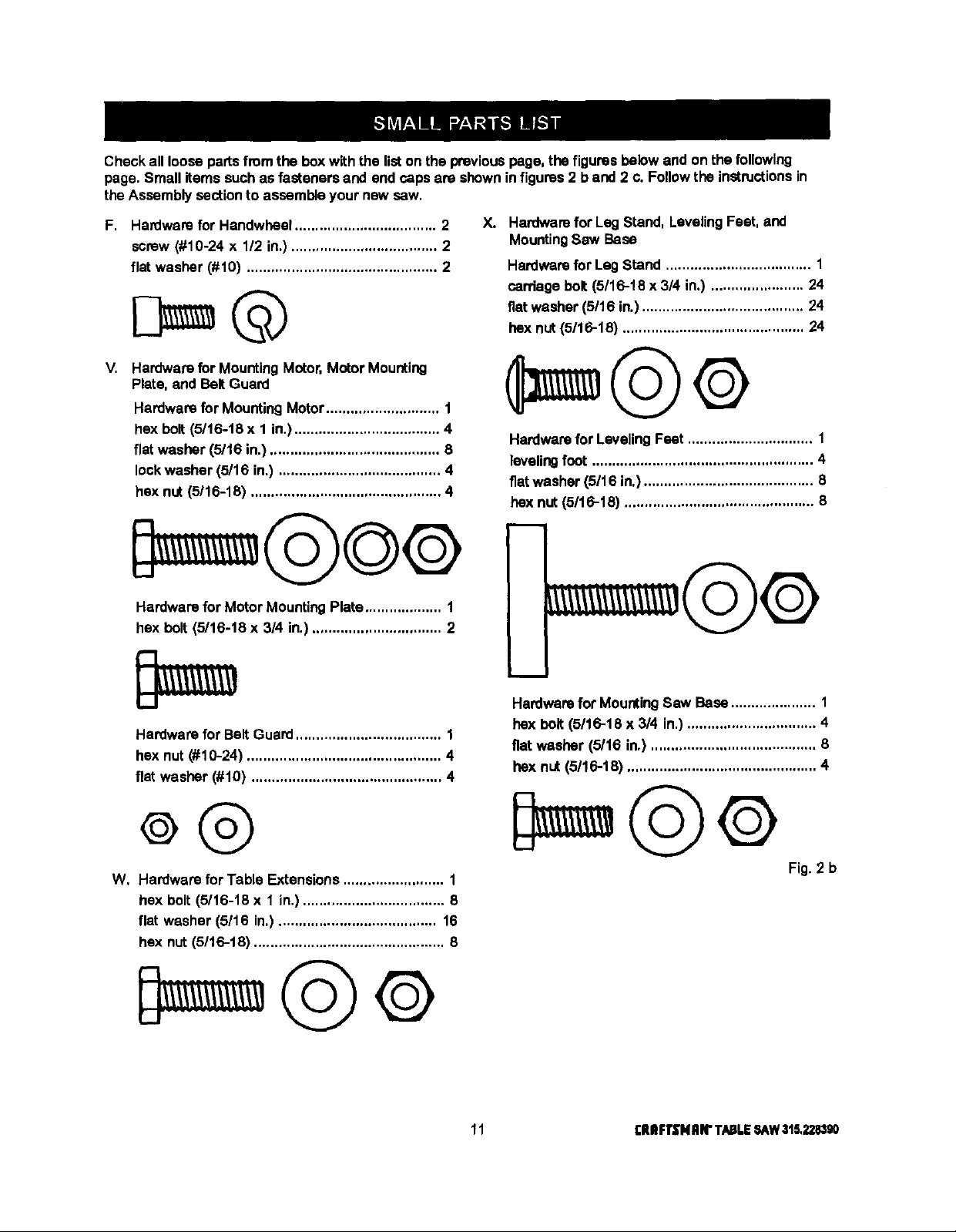

Checkallloosepartsfromtheboxwiththelistonthepreviouspage,thefiguresbelowandonthefollowing

page.Smallitems such as fasteners and end capsare shownin figures2 b and 2 c. Follow the instructionsin

the Assembly sectionto assemble your new sew.

F. Hardware for Handwheel................................... 2

screw (#10-24 x 1/2 in.) .................................... 2

flat washer (#10) ............................................... 2

V. Hardware for MountingMotor,Motor Mounting

Plate, and BeltGuard

Hardwarefor MountingMotor............................ 1

hex bolt (5116-18x 1 in.).................................... 4

flat washer (5/16 in.) .......................................... 8

lockwasher (5/16 in.) ........................................ 4

hex nut (5116-18) ............................................... 4

Hardware for Motor MountingPlate................... 1

hex bolt (5/16-18 x 3/4 in.)................................ 2

X. Hardwarefor Leg Stand, LevelingFeet, and

MountingSaw Base

Hardwarefor LagStand .................................... 1

carriage bolt (5/16-t8 x 3/4 in.) ....................... 24

fiatwasher (5/16 in.)........................................ 24

hex nut (5116-18) ............................................. 24

Hardwarefor LevelingFeet ............................... 1

levelingfoot ....................................................... 4

flatwasher (5/16 in.).......................................... 8

hex nut (5116-18) ............................................... 8

i

m

Hardware for Belt Guard.................................... 1

hex nut (#10-24) ................................................ 4

flat washer (#10) ............................................... 4

W, Hardware for Table Extensions ......................... 1

hex bolt (5/16-18 x 1 in.) ................................... 8

flat washer (5/16 in.)....................................... 16

hex nut (5/16-18) ............................................... 8

Hardwarefor MountingSaw Base ..................... 1

hex bolt (5116-18 x 3/4 in.) ................................ 4

fiat washer (5/16 in.) ......................................... 6

hex nut (5/16-18) ............................................... 4

Fig. 2 b

11 rlUIFTSNRIrTABLESAW315,228,190

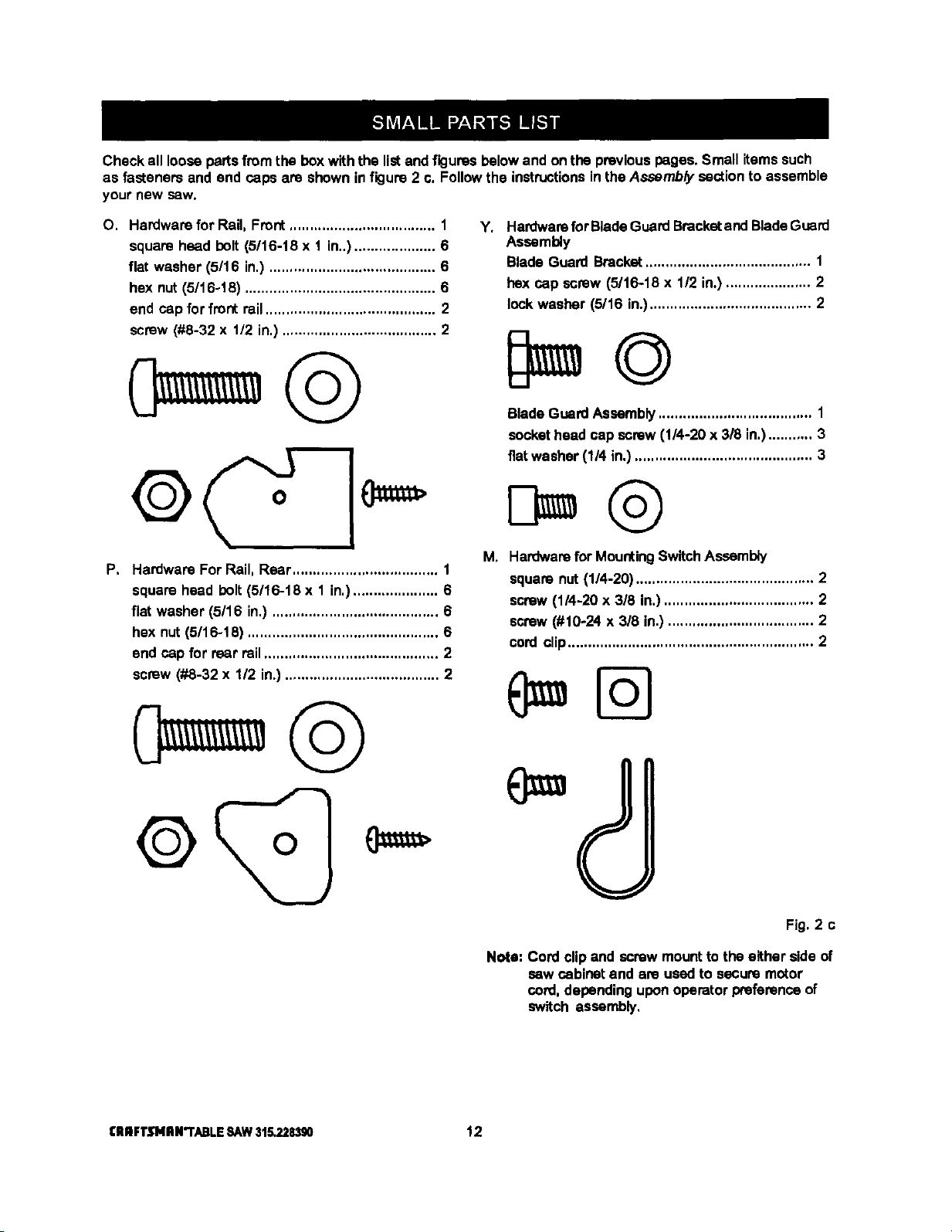

Checkalllooseparsfromtheboxwiththelistandfiguresbelowandonthepreviouspages.Smallitemssuch

asfasteners and end caps are shownin figure 2 c. Followthe instructionsin the Assembly section to assemble

your new sew.

O. Hardware for Rail, Front.................................... 1

square head holt (5/16-18 x 1 in..).................... 6

flat washer (5/16 in.) ......................................... 6

hex nut (5/16-18) ............................................... 6

end cap for front rail.......................................... 2

screw (#8-32 x 112in.) ...................................... 2

P, Hardware For Rail, Rear.................................... 1

square head bolt(5/16-18 x 1 in,)..................... 6

flat washer (5/16 in.) ......................................... 6

hex nut(5/16-18) ............................................... 6

end cap for rear rail........................................... 2

screw (#8-32 x 1/2 in.) ...................................... 2

Hardwarefor BladeGuardBracketand BladeGuard

Y*

Assembly

Blade Guard Bracket......................................... 1

hex cap screw (5/16-18 x 112in.) ..................... 2

lock washer (5/16 in.)........................................ 2

BladeGuardAssembly...................................... 1

sockethead cap screw (1/4-20 x 318in.)........... 3

fiatwasher (1/4 in.)............................................ 3

i_

Hardwarefor MountingSwitchAssembly

squara nut (1/4-20) ............................................ 2

screw(1/4-20 x 3/8 in.)..................................... 2

screw(#10-24 x 3/8 in.) .................................... 2

cord clip............................................................. 2

I:ll n FTJflNII N"I'ABLE SAW 315.228390 12

(

Fig. 2 c

Note: Cord clipand screw mountto the either side of

saw cabinet and are usedto secure motor

cord,dependinguponoperator preferancaof

switch assembly,

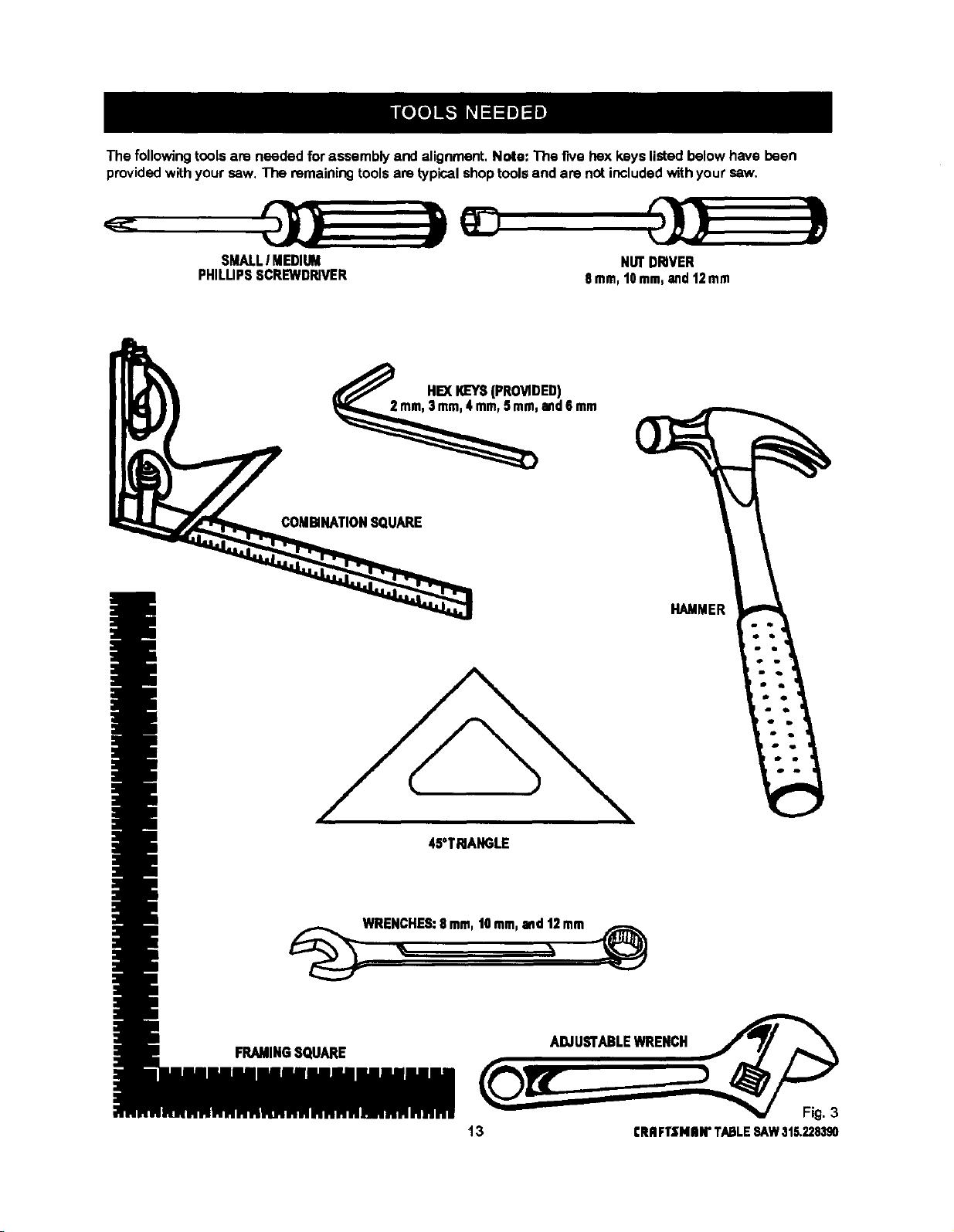

The following tools are needed for assembly and alignment, Note: The five hex keys listed below have been

provided with your saw. The remaining tools are typical shop tools and are not included with your saw.

SMALLI MEDIUM

PHILUPSSCREWDRIVER

COMBINATIONSQUARE

NUTDRIVER

8ram,t0 mm,and12mm

HEXI_EYS(PROVIDED)

and6mm

HAMMER

45°TRIANGLE

_WRE_HES: 8.m, ,Omm,and_2mm _¢_

FRAMINGSQUARE ADJUSTABLEWRENCH

13 CRRFTSNIIW TABLESAW315.228390

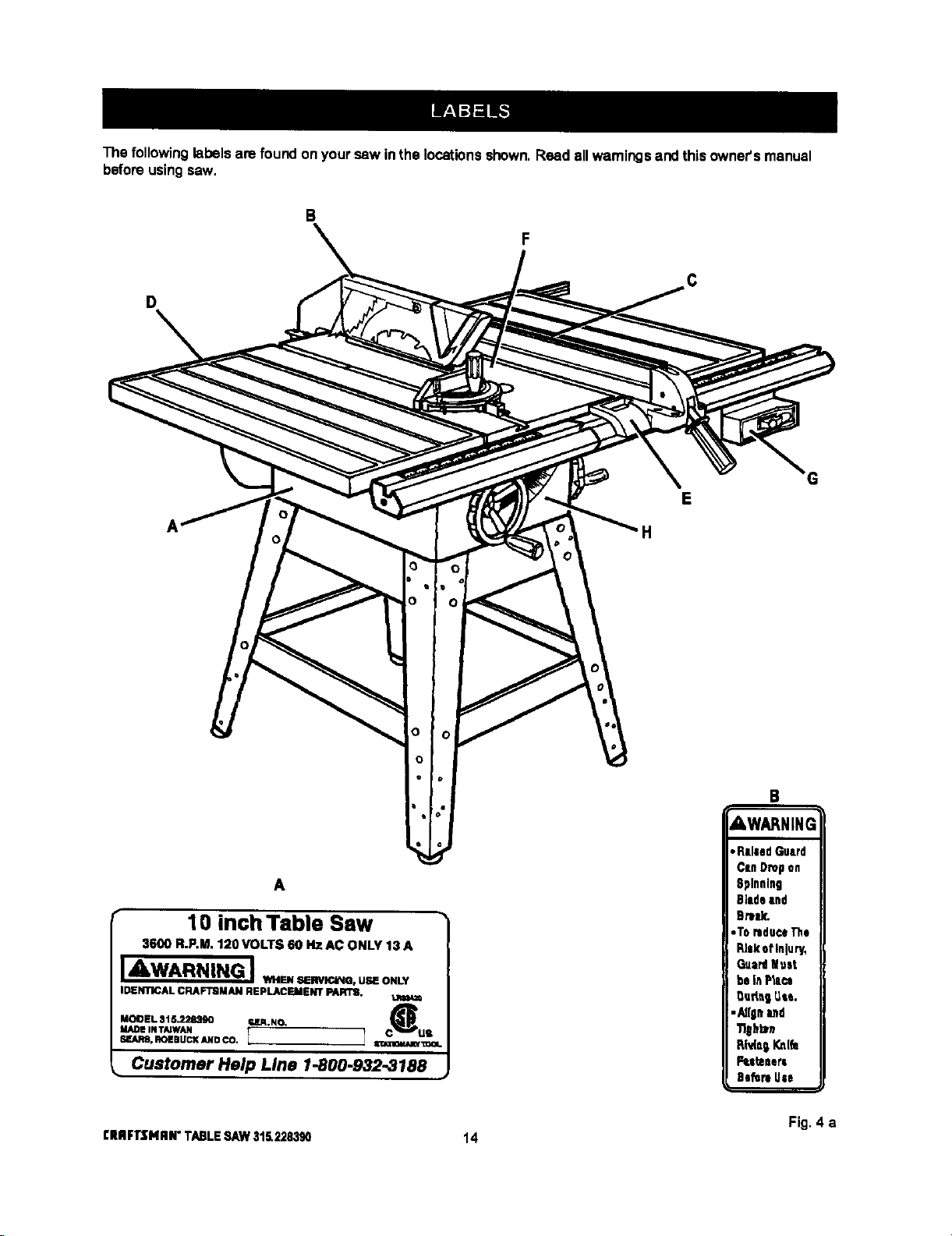

The following labelsare found onyour saw inthe locationsshown.Read allwarningsand this owner'smanual

beforeusingsaw.

B

D

E

H

A

10 inch Table Saw

3600 R.P.M. 1;!0 VOLTS 60 HZ AC ONLY 13 A

JAWARNING J,,....._--.. u.o._,

IDENTICAL CRAFTBMAN REPLACEMENT PARTS.

MODEL 315.228390 ra,lR.NO. C_

MADE IN TAIWAN US

SF.ARS.ROEBUCI(ANDCO. I 1 S_I_.-lCaUUWI:=OI.

Customer Help Line 1-800.932.3188

CRRFI"$NRN"TABLESAW315.228390 14

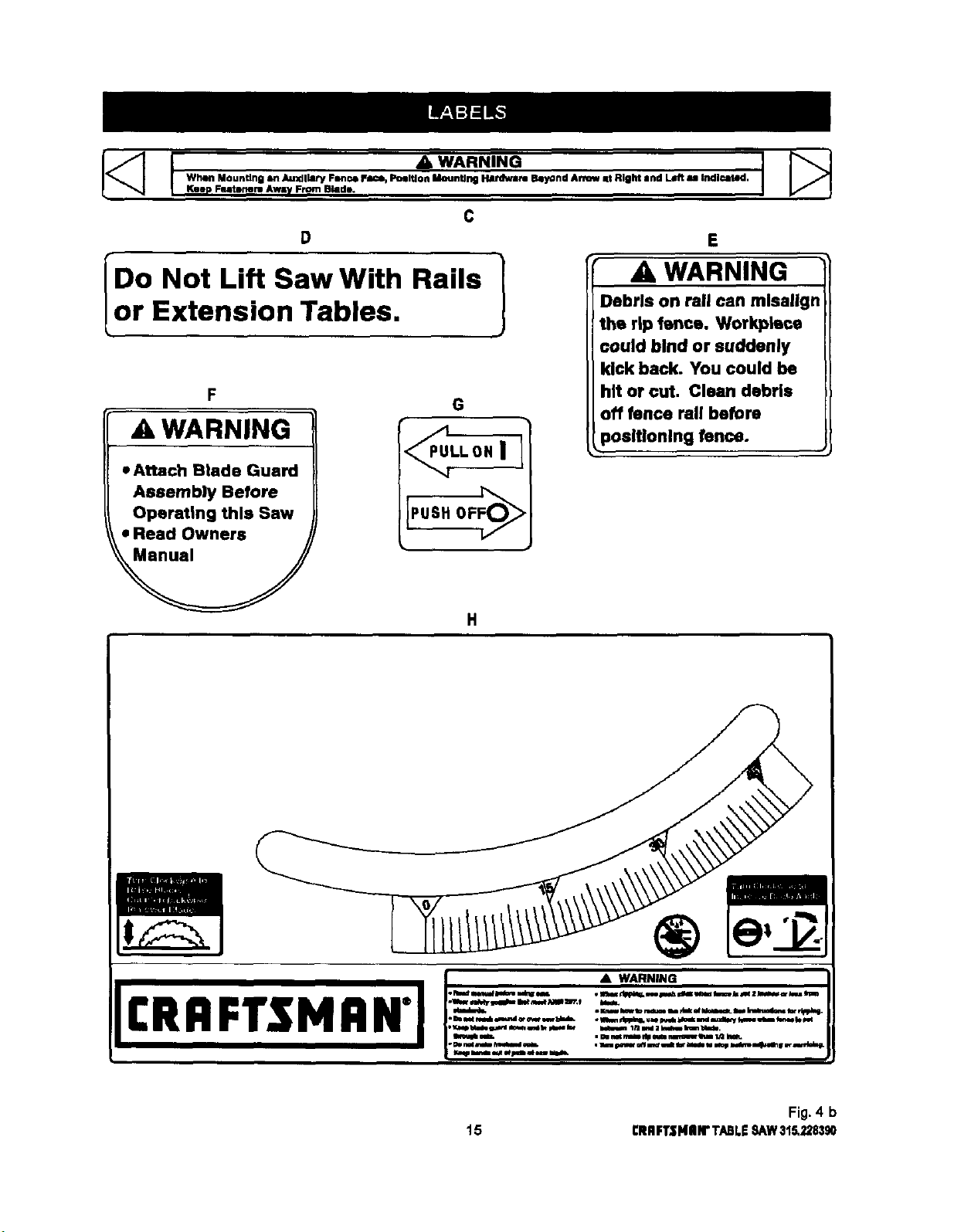

B

AWARNING

Fig. 4 a

C

• D •

IDo Not Lift Saw With Rails 1

_or Extension Tables, J

F

• G

A WARNING

• Attach Btade Guard

Assembly Before

Operating this Saw

• Read Owners

E

WARNING

Debris on Pall can mlsallgn

the rip fence. Workplace

could bind or suddenly

kick back. You could be

hit or cut, Clean debris

off fence Pall before

3ositlonlng fence.

£RRFr$ H RN"FI:_-:z: .'i_-_-"____:_=.J

Fig. 4 b

15 CRRFTZNIIN"TABLE8/kW315.228,190

Loading...

Loading...