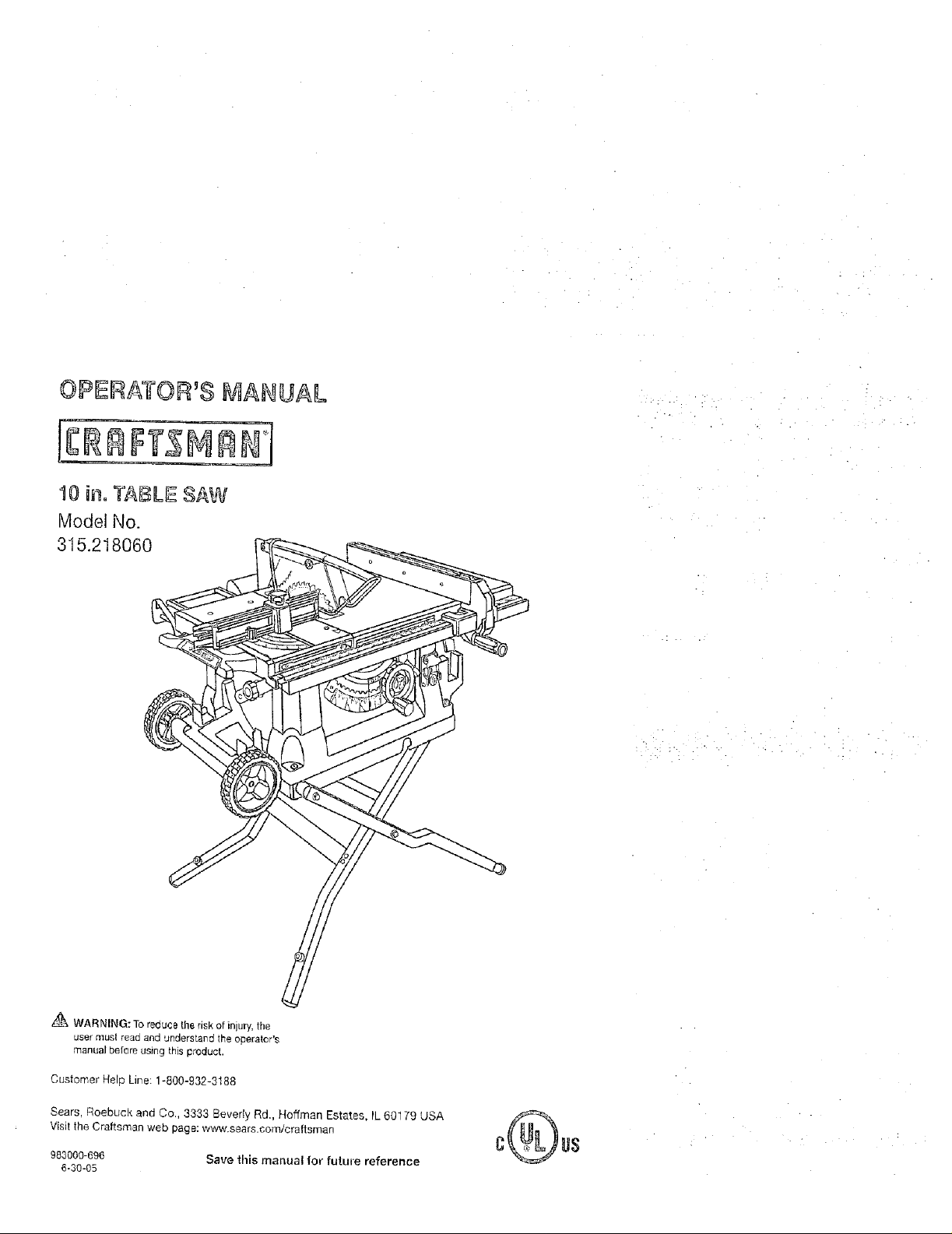

Craftsman 315218060 Owner’s Manual

_ WARNING: To reduce the risk of injury, the

user must read and 'Jnderstand the operator's

manual before using this product.

Customer Help Line: 1-800-932-3188

Sears, Roebuck and Co., 3333 Beverly Rd., Hoffman Estates, IL 60179 USA

Visit the Craftsman web page: w_,.sears.com/craftsman

983000-696

6-30-05

Save this manual for future reference

[] Waoanty ........................................................................................................................................................................ 2

Introduchon ..................................................................................................................................................................... 2

I_ General Sa(ety Rules ...............................................................................................................................................

Specific Safety Rules ................................................................................................................................................... 4-5

Symbols ....................................................................................................................................................................... 6-7

D _lectrical .............

u Glossar_ of Terr_s .......................................................................................................................................................... 9

E] Features ........................................................................................................................................................... 10-13

[] Tools Needed ................................................................................................................................................................. 13

"_ LOOSe Pads ................

........................................................................................................................................... 14

a Assembl_. ..................................................................................................................................................... t5-19

_3 Operation ................................................................................................................................................................. 19-34

a Adjustments .......................................................................................................................................................... 35-37

[3 Maintenance ............................................................................................................................................................ 38

Troublesheot..ng ....................................................................................................................................................... 39-40

Fx ploded View ...................................................................................................................................................... 43-50

_a Parts Ordedncj/Service .................................................................................................................................... Back Page

ONE YEAR FULL WARRANTY ON CRAFTSMAN TOOL

If this Craftsman tool fails due _o a detect in material or workmanship within one year from the dale of purchase. Call

1-800-4-MY-HOME ® to arrange for free repai_ If this tool is used for commercial or rental purposes, this warranty will

apply for only ninety days from the date of purchase This warranty applies onty while t_qis product is in the United States.

This warranty gives you spec tic lega r ghts, and you may also have other rights which vary t_om state to stale.

Sears, Roebuck and Ce., Dept. 817WA, Hoffman Estates, IL 60179

This loci has many features for making its use more pleasant and enjoyable. Safety, performance, and dependability

l_ave been given top priority in the design of this product makiFg it easy to maintain and operate.

A WARNING:Read and understand all ]nstruc-

gone. Failure to follow all instructions listed below,

may result in electric shock, fire and/or serious

persona_ injury.

READ ALL INSTRUCTIONS

13 KNOW YOUR POWER TOOL. Read the operator's

manuc_l c_llefu[iy. Lealn the saw's applications and

limitations as well as the specific potential hazards

related to this tool.

[_ GUARD AGAINST ELECTRICAL SI-IOCK BY PRE-

VENTING BODY CONTACT WITH GROUNDED

SURFACES. For exampte, pipes, radiators, ranges,

refrigerator enclosures.

g KEEP GUARDS IN PLACE and in good working order:

_] REMOVE ADJUSTING KEYS AND WRENCHES,

Form habit of checking to see thai k.eys and adjusting

wrenches are removed from tool before turning it on.

B KEEP WORK AREA CLEAN. Cluttered areas and

benches invge accidents. DO NOT leave tools or

pieces of wood on the saw while it is in operation,

[1 DO NOT USE IN DANGEROUS ENVIRONMENTS.

Do not use power tools in damp or we{ locations or

expose to rain. Keep the work area well lit.

B KEEP CHILDREN AND VISITORS AWAY. All visitors

should wear safety glasses end be kept a safe

distance from work area, Do not let visitors contact

tool or extension cord while operating.

a MAKE WORKSHOP ONILDPROOF with padlocks and

master switches, or by removing starter keys.

B DON'T FORCE TOOL. It will do the job better and

safer at the feed rate for which it was designed.

8 USE RIGHT TOOL. Don't force the tool or attachment

to do a iob il was not designed for. Don't use it for a

purpose not intended.

8 USE THE PROPER EXTENSION CORD. Make sure

your extension cord Js in good condition. Use only a

cord heavy enough to carry the current your product

wilt draw. An undersized cord will cause a diop ir_ line

voltage resulting in loss of power and overheating. A

wire gauge size (A.W.G) of at least 14 is recommended

for an extension cord 25 feet or less in length, If in

doubt, use the r_ext heavier gauge The smaller the

gauge number, the heavier the oord.

pa DRESS PROPERLY. Do act wear IoosecIothing,

gloves, neckties, or jewelry. They can _et caughl

and draw you into moving parLs Rubber gloves and

nonskid footwear are recommended when working

outdoors. Aieo wear protective hair covering to contain

}cog hair.

B ALWAYS WEAR SAFETY GLASSES WITH SIDE

SHIELDS, Everyday eyeglasses have only impact-

resistant lenses, they are NOT safety glasses,

i_ SECURE WORK. Use clamps or a visa to hold wed{

when practical. It's safer than using your hand and

frees both hands to operate tool

a DON_T OVERREACH. Keep proper fooling and

balance at all times.

8 MAINTAIN TOOLSWITH CARE. Keep tools sharp

and clean for better and safer performance. Follow

instructions fo_ lubFicating and changing accessories

_] DISCONNECT TOOLS. When not in use, before

servicing, or when changing attachments, blades, bits.

cutters, etc., all toots should be disconnected.

F3 AVOID ACCIDENTAL STARTING. Be sure switch is off

when plugging in any tool.

g USE RECOMMENDED ACCESSORIES. Consult the

operators manual Ior recommended accessories. The

use of improper accessories may risk iniury.

D NEVER STAND ON TOOL. Serious injury could occur

it the tool is tipped or if the cutting tool is uninlention-

ally contacted•

13 CHECK DAMAGED PARTS. Before further use of

the tool, a guard or other pad that is damaged should

be carefulry checked to determ, ine that it will operate

properly and penlorm its intended function. Check for

alignment of moving paris, binding of moving parts,

breakage of pans, n7ounting and any other conditions

thai may affect its operation. A guard or other part thai

is damaged must be properly repaired or replaced by

an authorized set&,ice center to avoid risk of personal

injury.

B USE THE RIGHT DIRECTION OF FEED, Feed work

into a blade or cutter against the direction of rotation of

blade or cutter only,

B NEVER LEAVE TOOL RUNNING UNATTENDED.

TURN THE POWER OFF. Don't leave tool until it

comes to a complele slop.

PROTECT YOUR LUNGS. Wear a face or dust mask if

the cutting operation is dusty.

u PROTECT YOUR HEARING. Wear hearing protection

ddring extended periods of operation.

B DO NOT ABUSE CORD. Never yank cord to discon-

nect from receptacle. Keep cord from heat, oil. and

sharp edges,

[] USEOUTDOOR EXTENSION CORDS. When tool

is used outdoors, use only extension cords wilh

approved ground cormection that a_e intended for use

outdoors and so marked.

ALWAYS KEEP THE BLADE GUARD AND RIVING

KNIFE/SPREADER/SPLITTER IN PLACE and in

working order,

B KEEP BLADES CLEAN, SHARP, AND WITH

SUFFICIENT SET. Sharp btades minimize stalting

and kickback.

[_ KEEP HANDS AWAY FROM CUTTING AREA. Keep

hands away from blades Do not reach underpeath

3

- ..; . . . " . . . ..

• • :- • " • • . ; "i .

work or around or over the blade while blade is

rotating. Do not attempt to remove cut material when

blade is moving,

[] BLADE COASTS AFTER BEING TURNED OFF.

e NEVER USE IN AN EXPLOSIVE ATMOSPHERE•

Normal sparking of the motor could ignite fumes.

B INSPECT TOOL CORDS PERIODICALLY• If damaged,

have repaired by a qualified service lechnician at

an authorized service (acillty. The conductor with

insulation having an outer surface that is green w_th

or without yellow stripes is the equbrnent-ground-

ing conductor. If repair or replacement of the electric

cord or plug is necessa!% do not connect the equip-

ment-grounding conductor to a live terminal Repair

er replace a damaged or worn cord immediately. Stay

constanUyawareofcordlocationend keep itweiraway

fromtherotatingblade.

INSPECT EXTENSION CORPS PERIODICALLY and

replaceifdamaged,

E]GROUND ALL TOOLS. Iftoolisequipped withthree-

prongplug,itshouldbe pluggedintoa three-hob

e}ectrlcalreceptacle.

B CHECK WITH A QUALIFIED ELECTRtCIAN or service

personnel if the grounding instructions are not com-

pletely understood or if in doubt as to whether the toe]

is properly grounded.

[] USE ONLY CORRECT ELECTRICAL DEVICES: 3-wire

extension cords that have 3-proeg grounding plugs and

3-pole receptacles that accept the tool's plug.

a DO NOT MODIFY the plug provided. II itwiU not tit the

outlet, have the proper outlet installed by a qualified

electrician•

_1 KEEP TOOL DRY, CLEAN, AND FREE FROM OIL

AND GREASE. Always use a clean cloth when clean-

ing. Never use brake fluids, gasoline, petroleum-based

products, or any solvents to clean tool,

STAY ALERT AND EXERCISE CONTROL, Watch

what you are doing and use common sense. Do not

operate tool when you are tired. Do not rush.

DO NOT USE TOOL IF SWITCH DOES NOT TURN IT

ON AND OFF. Have defeegve switches replaced by an

authorized service center.

la USE ONLY CORRECT BLADES. Do not use blades

with incorrect size holes. Never use blade washers or

blade bolts that are defective or incorrect. The maxi-

mum blade capacity of your saw is 10 in. (254 ram).

_9 BEFORE MAKING A CUT, BE SURE ALL ADJUST-

MENTS ARE SECURE.

Z] BE SURE BLADE PATH ISFREE OF NAILS. Inspect

[or and remove all nails from turnber before cutting.

B NEVER TOUCH BLADE or other moving parts during

use,

t_ NEVER START ATOOL WHEN ANY ROTATING COM-

PONENT IS IN CONTACT WITH THE WORKPIECE.

_' DO NOT OPERATE A TOOL WHILE UNDER THE

INFLUENCE OF DRUGS, ALCOHOL, OR ANY

MEDICATION.

I_1WHEN SERVICING use only identical replacement

parts. Use of any other pads may create a hazard or

cause product damage.

li_ USE ONLY RECOMMENDED ACCESSORIES listed

in this manual or addendums. Use of accessories

that are net listed may cause the risk of personal

injury, instructions for safe use of accessories are

included with the accessory.

B DOUBLE CHECK ALL SETUPS, Make sure blade is

tight and not making contact with saw or workpiece

before connecting to power supply•

• :-. •.

GUARD AGAtNST KICNBACK. Kickback occurs

when the blade stalls rapidly and workplace is driven

back towards the operator• It can pull your hand into

the blade resulting in echoes personal injury. Stay out

of blade path and turn switch off immediately if blade

binds or stalls.

a USE RIP FENCE. Always use a fence or straight edge

guide when rippir, g,

SUPPORT LARGE PANELS. To minimize risk of blade

pinching and Idckbaek, atways support large panels.

el REMOVE ALL FENCES AND AUXILIARY TABLES

belore trenspaJting saw. Failure to do so can "esult in

an accident causing possibie serious personal injun/.

ra ALWAYS USE BLADE GUARD, RIVING KNIFE/

SPREADER/SPLITTER, AND ANTI-KICKBACK

PAWLS on all "through-sawing' operations. Through-

sawing operations are those inwhich the blade cuts

completely Ihrough the workpiece as in ripping or

cross cutting. Keep lhe blade guard down, the anti-

kickbaak pawls down, and the riving knifeispreeded

splitter properly aligned to the saw blade.

ALWAYS SECURE WORK firmly against rip fence,

miter fence, or miter gauge.

ALWAYS USE A PUSH STICK FOR RIPPING NAR-

ROW STOCK. A push stick is a dev=ce used to push

a werkpiece through the blade instead of using your

hands Size and shape can vary but the push stick must

always De narrower than tbe wofi_piece to prevent the

push stick from contacting the saw blade. When ripping

narrew stock, always use a push stick, so your hand does

not come close to the saw blade. Use a featherbeard and

push blocks for oemthrough cuts

f_ NEVER perform any operation "|reehand" which

means using only your hands to support or guide the

workpiece, Always use either the rip tence or miler

fence to posRion and guide the work.

m NEVER ste,_d or t'_ve any part of your body in line

with the path of fhe saw blade.

NEVER reach behind, over, or within three inches of

the brads or cutter with either hand for any reason,

_, MOVE THE RIP FENCE out of the way when cross

cutting•

B NEVER use tip fence as cutoff gauge when c_'oss

cutting.

13 NEVER attempt to free a statted saw blade without

first turning the saw OFF and disconnecting the saw

from tr_e power source.

8 PROVIDE ADEQUATE SUPPORT to the rear and

sides of the saw table for wide or long work pieces•

Use a sturdy "oufriggar" suppoll it a table extension

more than 24 inches long is attached to the saw.

AVOID K_OKBACKS (work throwr_ back toward 'you}

by:

a_ Keeping b_ade sharp.

b) Keeping rip fence parallel to the saw blade•

c} Keeping dvir',9 _,£itelspreader/splittar, anti-kickback

pawls, and blade guard in place and operating•

d) Not r=Jeasi_g the work before it (s pushed all the

way past the saw blade using a push stick•

e) Not ripping work. that is b.eisted or warped or does

not have a straight edge to guide along the fence.

AVOID AWl{WARD OF'ERATIONS AND HAND

POSITIONS where a sudder_ slip could cause your

hand to m,_ve into the cutting tool

USE ONLY RECOMMENDED ACCESSORIES [isled in

this marius[ or adder_dums. Use of accessories that are

not listed may cause Ihe risk of personal injury. Instruc-

tions for safe use of accessories are included with the

accessory.

c_ I'.",AKESURE THE WORN AREA HAS AMPLE LIGHT-

ING to see the work and that no obstructions will inter-

fore with safe operation BEFORE performing any work

usingthe table saw.

n ALWAYS TURN OFF SAW before disconnecting it, to

a'Joid accidental staffing when reconnecting to power

supply•

THIS TOOL should have the following markings:

a) Wear eye protection.

b) Useeawbladeguardandrivingl_nffe/spreaded

splitter for every operation for whicll it can be

used, including all through sawing.

c] Keep hands out of the line of saw blade.

d) Use a push stick when required.

e) Pay particular altention to instructions on reducing

risk of kickbacK.

0 DOnot perform any operation freehand.

g) Nevei" leach around or over the saw blade.

e SAVETRESE INSTRUCTIONS, Refer to them

frequently and use toinstruct other users. Ifyou loan

someone this tool, loan them these instructions also.

_ WARNIN6: Some dust created by power sanding, sawing, gr nd rig, dri ing, and other conslruct[on activities

contains ctlemicals known to cause cancer, birth defects or other reproductive harm. Some examples of these

chemicals are:

• lead from lead-based paints.

a crystalline shies from blicks and cement and ether masonry Products, and

• arsenic and chromium from chemically4reated _urnber.

Your risk from these exoesures varies, depending on how often you do this type of weds.To reduce your exposure

to these chemicals: work in a well ventilated area, and work with approved safety equipment, such as those dust

masks that are specially designed to filter out microscopic particle.

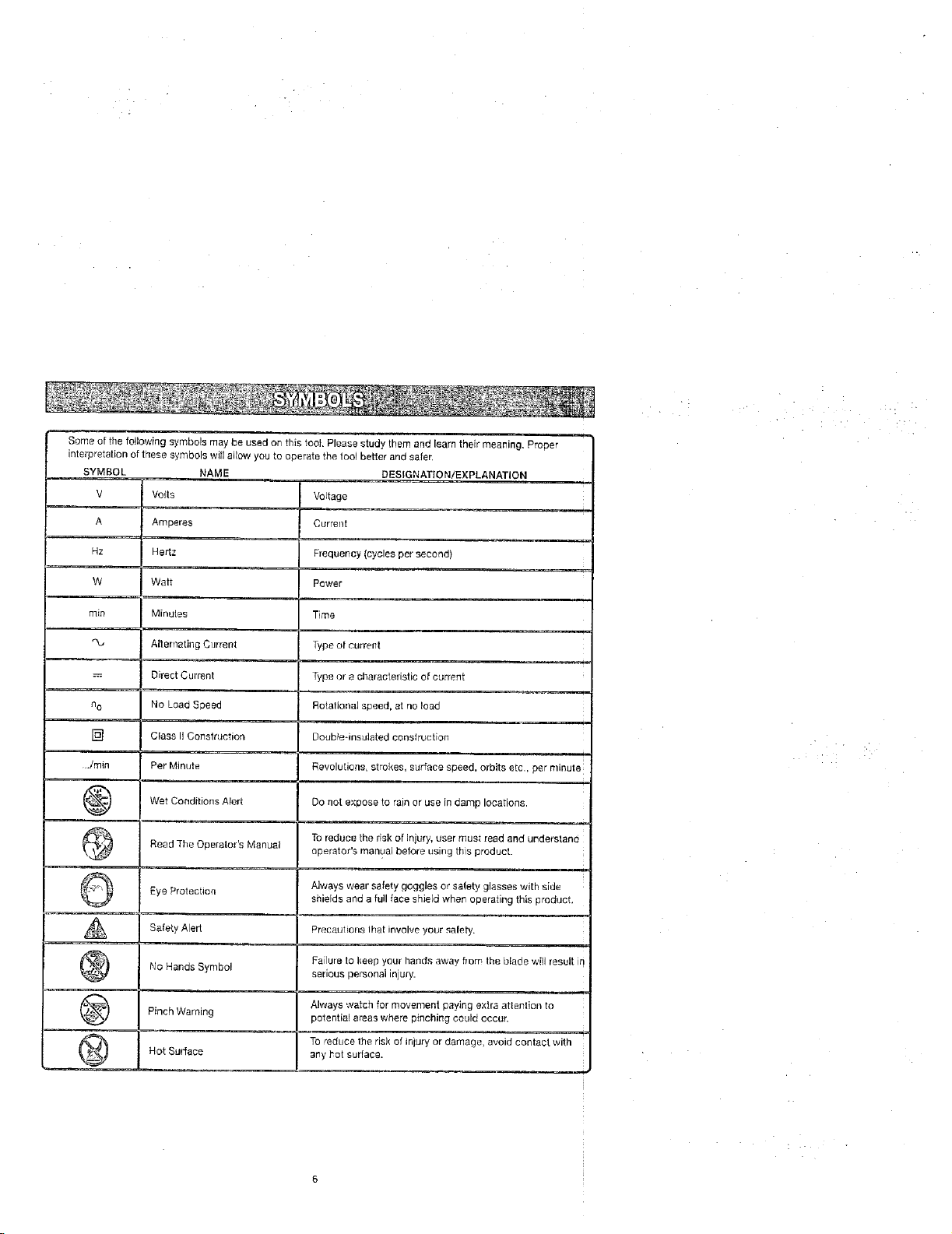

SomeofthefollowingsymbolsmaybeusedonthistoolPleasestudythemandlearntheirmeantng,Proper •

interpretationofthesesymbolswillallowyoutooperatethetoolbetterandsafer,

SYMBOL NAME DESIGNATION/EXPLANATION

V Vogs VoJtage

A

Amperes

Current

Hz

W

rain

no

[]

../rain

@

@

©

A

@

Hertz

Watt

Minules

Alternating Current

Direct Current

No Load Speed

Class II Construction

Per Minute

Wet Conditions Alert

Read The Operator's Manual

Eye Protection

Safety Alert

No Hands Symbol

Frequency (cycles per second)

Power

Time

Type of current

Type or e characteristic of current

Rotational speed, at no load

Doublednsulated construction

Revolutions, strokes, surface speed, orb tse c, per n nute

Do not expose to rain or use in damp locations.

Toreduce the risk of injury, user must read and understand

operator's man_:_albefore using this product.

Always wear safety goggles or safety glasses with side

shields and a full face shield when operating this product,

Precaulions Ihat involve your safety.

Failure to keep your hands away flora Ihe blade wilJ result io

serious personal injury.

@

@

Pinch Warning

Hot Surface

Always watch for movement paying extra attenlion to

potential a_as where pinching could occur.

To"educe the risk of injury or damage, avoid contact with

any hot surface.

The following signal words and meanings are intended to explain the levels of nsk associated with this eroduct

SYMBOL SIGNAL MEANING

DANGER: result in death or $er cos iiljury,

WARNING:

A result in minor or moderate iniury.

SERVICE

Servicing requites e×trome cote and knowledge and

should be performed only by a qualified service tech

nician, For service we suggest you return the product lo

yournearest AUTHORIZED SERV}CE CENTER for repair.

When servicing, use only identical replacement parts.

_ WARNING:

©

CAUTION:

CAU'[ION: (Without Safely Alert Symbol) Indicates a situation that {"nay result in

The operatia_ of any power tool can result in foreign objects being thrown into your eyes, wmcn car'

result in severe eye damage, Belore beginning power tool operation, always wear satet'y goggles or

safety glasses with side shields and a full face shield when needed• We recommend Wide Vision S_fety

Mask for use over eyeglasses or standard safety glasses w th side shields Always use eye orotectien

whtch is marked to comply with ANSI Z87.1.

Indicates an imrninent!y hazardous siluatlon, which, if not avoided, will

indicates a potenhaliy hazardous situat on, which, f not avoided, could

_esult in death or selbus illjur'j•

Indicates a potentia ly hazardous situation, which, it Rot avoided may

propelly damage.

SAVE THESE INSTRUCTIONS

_-_\ WARNING: To avoid serious personal mlUrY,do not

attempl to use this p_odoct until you read thoroughly

and understand completely the opera[ol s ruanu_l

Save this operator's manual and review frequentl[v for

continuing safe operation and instructing o[ners WhO

may use this product,

EXTENSION CORDS

Use only 3-wire extension cords that have 3-prong

grounding plugs and 3-pole receptacles that accept the

tool's plug. When using a power tooiat aconsiderable

distance from the power source, use an extension cord

heavy enough lo carry the current that the tool will draw.

Art undersized extension cord will cause a drop in line

voltage, resulting in a loss of power and causing the

motor to overheat. Lisa the chart provided below to

determine the minimum wire size required in an extension

cord, Only round jacketed cords listed by Underwdter's

Laboratories (UL) should be used.

"Ampere _atng ton tC_l dale _late t

012,0 2.r-3,4 3.5-5.0 51-70 7,1-12.0 12.1-16.0

Cord Length Wire Size (A.W.G.)

25' !6 16 16 16 14 14

50' 16 16 t5 14 14 12

100' 16 16 14 12 10 -

"*Used on 12 gauge - 20 amp circuit.

NO]E: AWG = Am_ic_r_ Wire G_ge

When working with the tool outdoors, ueean extension

cord that is designed for outside use. This is indicated by

Ihe letters "WA 'ron the cord's jacket.

Before using an extensron cord, inspect it for loose or

exposed wires and cut or worn insulation,

_, WARNING: Keep the extension cord clear of the

working area. Position the cord so that itwill not get

caught on lumber, tools or other obstructions while

you are working with a power tool. Failure le do so

can result in serious personal injury.

[1,

[JL_ WARNING: Check extension cords before each

use. g damaged replace immediately, Never use tool

with a dereaged cord since touching the damaged

area could cause electrical shock resulting in serious

injury,

ELECTRICAL CONNECTION

This tool is powered by a precision buitl electric motor.

It should be connected to a power supply that Is 120

volts, 60 Hz, AC only [normal household current}. Do I

not operate this tool on direct current (DC). A substantial

voltage drop will cause a loss of power and the motor w!ll

overheat. ]f the saw does not operate when plugged intq

an outlet, double check the power supply.

SPEED AND WIRING

The no-load speed of this tool is approy,imateltt _,,800 rp_n.

This speed isnot constant and decreases under s load (_r

with lower voltage. For voltage, the wiring in a shop is a_

important as the motor's horsepower rating A line intend-

ed on_yfor lights cannot properly cart,/a power tool motor.

Wire that is heavy enough for a short distance will be toq

light for a greater distance. A line that can support one |

power tool may not be able to supped two or three tool.

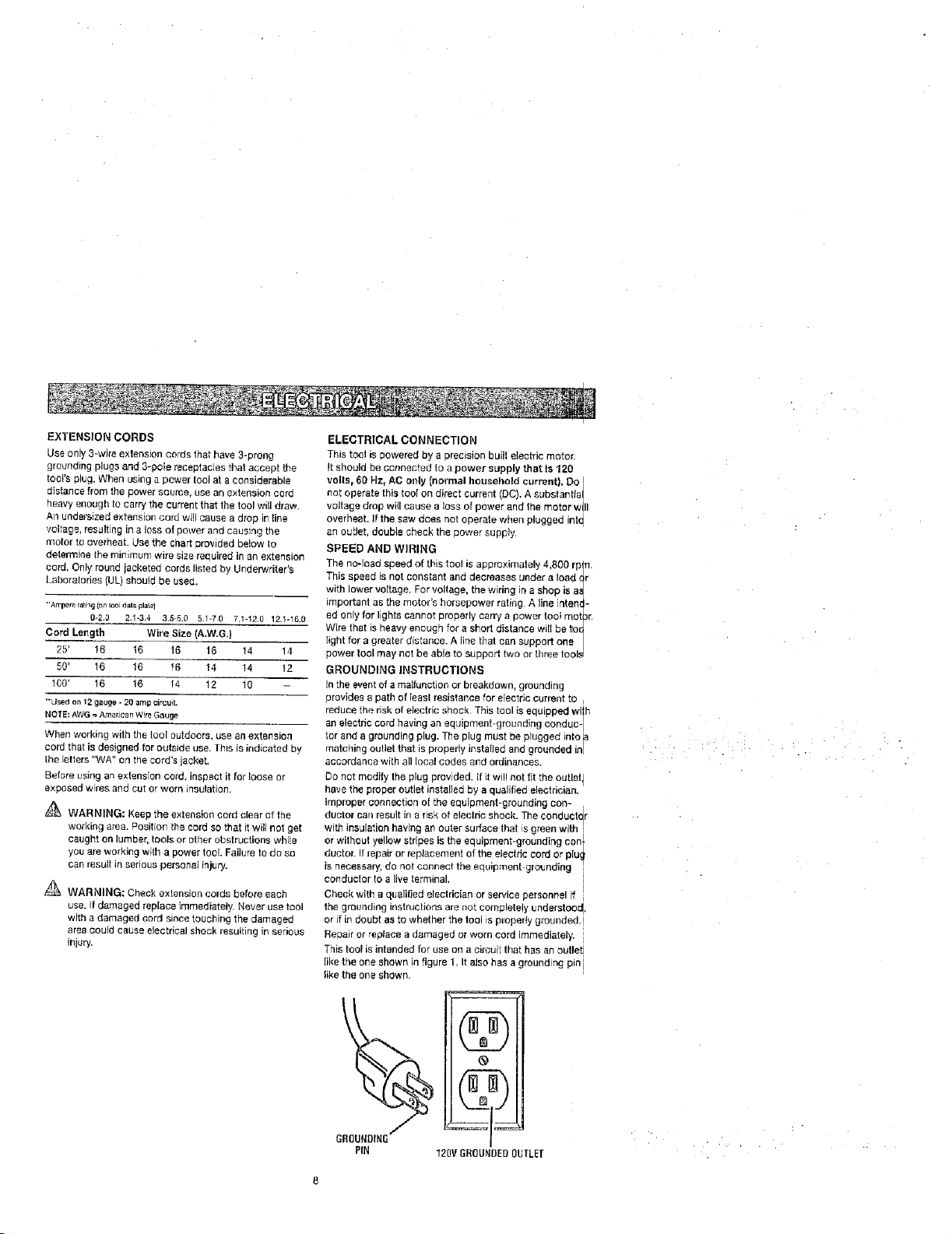

GROUNDING INSTRUCTIONS

Inthe event of a malfunction or breakdown, grounding

provldes a path of leasl resistance for electric current to

reduce the risk of electric shock. This tool isequipped Wilh

an electdc cord having an equipment-grounding conduc- I

tcr and a grounding plug. The plug must be plugged into _a

matching outlet that is properly instarled and grounded in/

accordance with all local codes and ordinances.

Do net modify the plug provided. {fit will not fit the outlet I

have the proper outlet installed by a qualified electrician.

Improper connection of the equipment-grounding con-

duotor can result in a risk of electric shock. The ¢onduclctr

with insulation having an outer surface that is green wil,h

or without yellow stripes is the equipment-grounding con_

ducton If repair or replacement of the etecfric cord or plu_

is necessary, do not connect the equipment grounding "

conductor to a live terminal. I

Check with a qualilied electrician or service personnel if i

the grounding instructions are not completely understood,

or it in doubt a_ to whether the tool is plo[_edy grounded.[

Repairorreplaoeadamagedorworncordimmediately. i

This tool is intended for use on a circuit that has an outlet i

like the one shown in figure 1. It also has a grounding pin i

like the one shown,

®

(gg

120V GR(]g_BEBOUTLEI

• 'i ...... i _ :. :: L ..

Anti-Kickback Pawls (radial arm and table saws)

A device which, when properly installed and maintained

is designed to stop the workplace from being kicked back

toward the front of the saw during a ripping operation.

Arbor

The shaft on which a blade or cutting tool is mounted.

Bevel Gut

A cLltting operation re,ado with the blade at any angle

ether than 90_ to the tab{e sudace.

Chamfer

A cut removing a wedge from a block so the end (or part

of the end) is angled rather than at 90".

Compound Cut

A cross cut made with both a miter and a bevel angb.

Cross Cut

A cutting or shaping operalio=_made across the grain or

the width of the workpiece.

Cutter Heed Iplaners and jointers}

A rotating piece of adjustable btades. The cutter head

removes material from the wod{piece.

Dado Cut

A non-through cut which produces a squa_e-sided notch

or trough in the workpiece (requires a special blade}

Featherboard

A device tJsed to help control the workpiece by guiding it

securely against the table or fence during any ripping

operation.

FPM or SPM

Feet per minute (or strokes per minute}, used inreference

to blade movement.

Freehand

Performing a cat without the workplace being guided by a

fence, miter gauge, or other aids.

Gum

A sticky, sap-based residue from wood products.

Heal

Alignment of the blade lo the fence.

Kerr

]'he matedal removed by the blade in a through cut or the

slot produced by the blade in a non-through or partial cut.

Kickback

A hazard that can occur when the blade binds or stalls,

throwingthe workpiece back toward operator.

Leading End

the end ol the wod_piece pushed into the tool first.

Miter Cut

A curling operation made with the workpiece at any angle

to the blade other lhan 90°.

Non-Through Cuts

Any cutting operalien where the blade does not extol d

completely through the thickness of the workpiece.

Pilot Role (drill presses)

A smatl hole drilled ina workpiece that serves as a gt {de

for dfilhng large holes accurately.

Push 8locks and Push Slicks

Devices used to feed the workpiece through the saw

blade during cutting operations. A push stick (not ap xsh

block} should be used for narrow ripping operations. _/rom

These aids help keep the operator's hands well away

the blade.

Resaw

A cutting operat_n to [educe the thickness of the wor

piece to make thinner p_eces.

Resin

A sticky, sap-based substance that has hardened.

Revelations Per Minute (RPM)

The number of turns completed by a spinning object i

one Minute.

Ripping or Rip Cut

A cutting operation along the length of the workplace.

Riving Knife/SpreaderlSpl_tter (table saws)

A metal piece, sJightlv thinner than the blade, _.¢hiohh,

keep the kerr open and also helps to prevent kickbacl

Sew Blade Path

The area over, under, behind, or }nfront ot the blade. ,_

it applies to the workplace, that area which will be or h

been cut by the blade.

Set

The distance that the tip ef the saw blade tooth is ben1

set) outward from the face of the blade.

Snipe (planers) [

Depression made at either end of a workpiece by cutter

blades when the workpieee is not properly supportedq

Through Sawing |

Any cutting operation where the blade extends completely

through the thickness of the wo[kpiece.

Throw-Back

The throwing back of a workpiece usually caused by tl

workpiece being dropped into the blade or being plact

inadvertently in contact with the blade.

t,Vorl{plece or Material

The item on which the operation is being done

Worktable

Surface where the workpiece rests while performing a

curling, drilling, pianing, or sanding operation.

,?..

PRODUCT SPECIFICATIONS

Blade Arbor .............................................................. 5/8 in. Rating .............................................. 120 V, 50 Hz, AC

Blade Diameter .......................................................... 10 in. Input ................................................................ 15 Amper_

Blade Tilt ................................................................. O° * 45° No Load Speed ................................................. 5,000imi

Net Weight without Leg Stand ............................. 61,5 Ibs. Cutting Depth at 0°: .................................... 3 1/'2 i

Net Weight with Leg Stand ................................... 82.5 Ibs. Cutting Depth at 45": ............................................ 2-1/2 i

OUTFEED

SUPPORT

BRACKET(S}

STORAGE

MITER

FENCE

SPREADER

SLIDING

MITERTABLE

FRONT

RAIL

ANTI-KICKBACK GUARD

PAWLS

BLAOE

RIP FENCE EXTENSION

BEVEL

SCALE

TABLE

LOCKINGLEVEF

TABLETILT

HANDLE

_BEVEL

LOCKING

LEVER

HEIGHT]BEVEL

ADJUSTINGHANDWHEEI

FOOT

F_g

IO

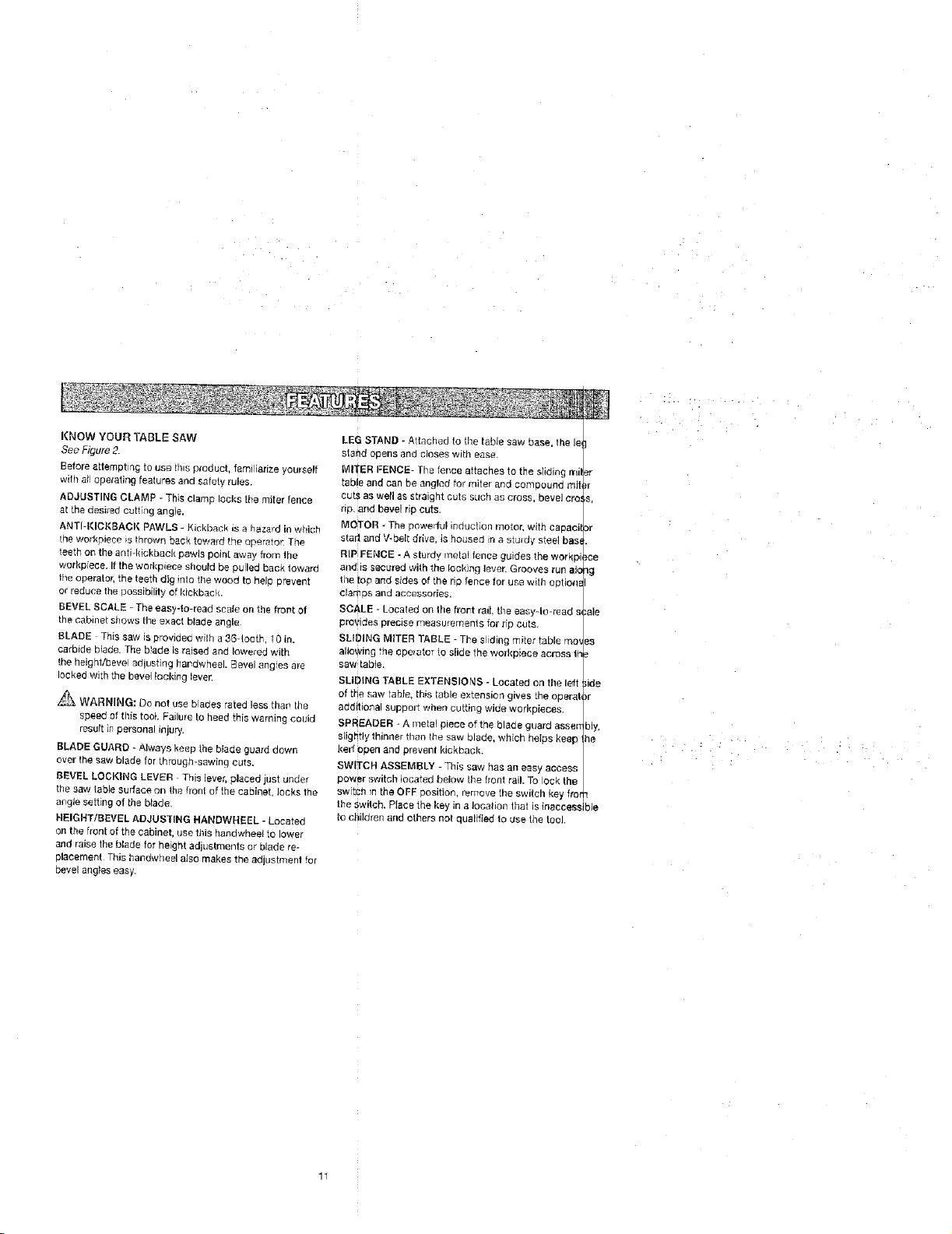

KNOW YOUR TABLE SAW

See Figure 2.

Before attemptin G to use fins aroduct, faml iarize yourself

with at operating features ana safety rules.

ADJUSTING CLAMP - This cramp locks the miter fence

at tne aes_rsd curt ng angle.

ANTI-I(IGKBAOI( PAWLS - Kickback _s a heza,d in wttich

the workplace _sthrown back toward the opera;or: The,

teeth on the eng-k_ckb_c_, paw_s po_r_t away f[om the

workpiece. If the workplace should be Ouilec Back towage

the operator, the teeth dig rote the wood to held arl_vent

or reduce the uo£s_Olll|y of kickback.

BEVEL SCALE - The easy4o-read scale on the froPt Ol

the cabinet shows the exact blade angle

BLADE This saw is providsc with a 36-1ooB" I 0 In.

carbrde blade. The b_aoe Jsrased end lowered with

the heighVbeve adlusting hardwheel. _evel ang'es ale

locked with the be_,el _ock_ng _evsr

_,-_ WARNING: Do not use bla0es rated less rna_ the

speed of this too}. Failure to heed this warning COUId

result i# personal injury.

BLADE GUARD - Always keep the blade guard daws

over the saw blade for through-sawing curs.

BEVEL LOCKING LEVER This ever, sicced just unaer

the saw table surface on the front of the cabinet oaks the

angle setting of the blade

HEIGHT/BEVEL ADJUSTING HANBWN_:EL - Locates

on the front of the cabinet, use this handwheel to lower

and raise the blade for height adjustments or blade re-

placement This t_a_dwhee! a_ao makes the ad,Jstmeet far

bevel angles easy.

LEG STAND * Attached to the table saw base, the le

stand ooens ano ClOSeS WIUq ease.

MITER FENCE- The fence attaches to the sliding rrli

table and can be angled for miter and comsound mg

cut_. as w_II as s_fa_gnt cuts such as cross bevel ere

rip. and bevel ric cuts.

MOTOR - The oeweriul _neuc_on meter, with capaci

starl and V-belt drive Is hodsed _na sturdy steel bas

RiP FENCE - A _turdy metal lence guides the wdrkp

and is secured with the locking lever• Grooves rull ale

the to_ and sides of the - 3 fence for use with optiona

clar_Ds and accessories.

SCALE - Losaled on lhe frort rail. the easy-lo-read s_

provides Dreclse measurements tar rio cute.

SLIDING MtlTER TABLE - The siding miter table mo_

allowing rne coclater to s}ide the worhBlece across lh

sew table.

SLIDING TASLE EXTENSIONS - Located on the left

of the saw table this table extension gwes the costal

additional support when cutting wide workpieoes.

SPREA[}ER - A metal piece of the blade guara assen

slightly '_" nner than the saw blade, which heIps }<eeD

kerr open and prevent kickback.

SWlTC_ ASSEMBLY - This saw has an easy access

cower switch located below the bent rail. To ock the

switch _n the OFF aositior remove the switch key fi'o

the switch. Place the key in a location that is inaeees_

to children and others not 3ualifiec to use the tool.

}r

or

ce

_g

ale

,de

)r

bly.

he

n

ibis

11

i -•- • •

i •

OPERATING COMPONENTS

The upper podioo of the blade pro}ects up through the

tabie and is staTounded by an insert called the throat

plate. The height of the blade is set with a handwheel on

the front of the cabinet. To accommodate wide panels,

the saw table has rails on each aide, Detailed instructions

are provided in the Operation section of this manual for

the basis cuts: cross cuts, miter cuts, bevel cuts, and

compound cuts.

The sliding miter table assembly is used for sloes cutting

operations. The miter fence is easily adjusted to cut wood

at an angle by loosening the adiustJn§ clamp, setting the

fence to the miter scale, and retightening the clamp. The

sliding miter table, which rests on a base mounted on the

rails, can be repositioned along the rails for wide work. it

can be reversed so the projecting base is in the back and

can be moved from the left side to the right side as need-

ed, With the miter fence removed, the miter table offers

additional support for other operations such as ripping.

The rip fence is used to position work for lengthwise cuts.

A scale on the front rail shows the distance between the

rip fence and the blade.

It is very important to use the blade guard assembly for all

Ihrough-sawi#g operations. The blade guard assembly

includes: riving kniteispreader/splitter, anti-kickback

pawls, and plastic blade guard.

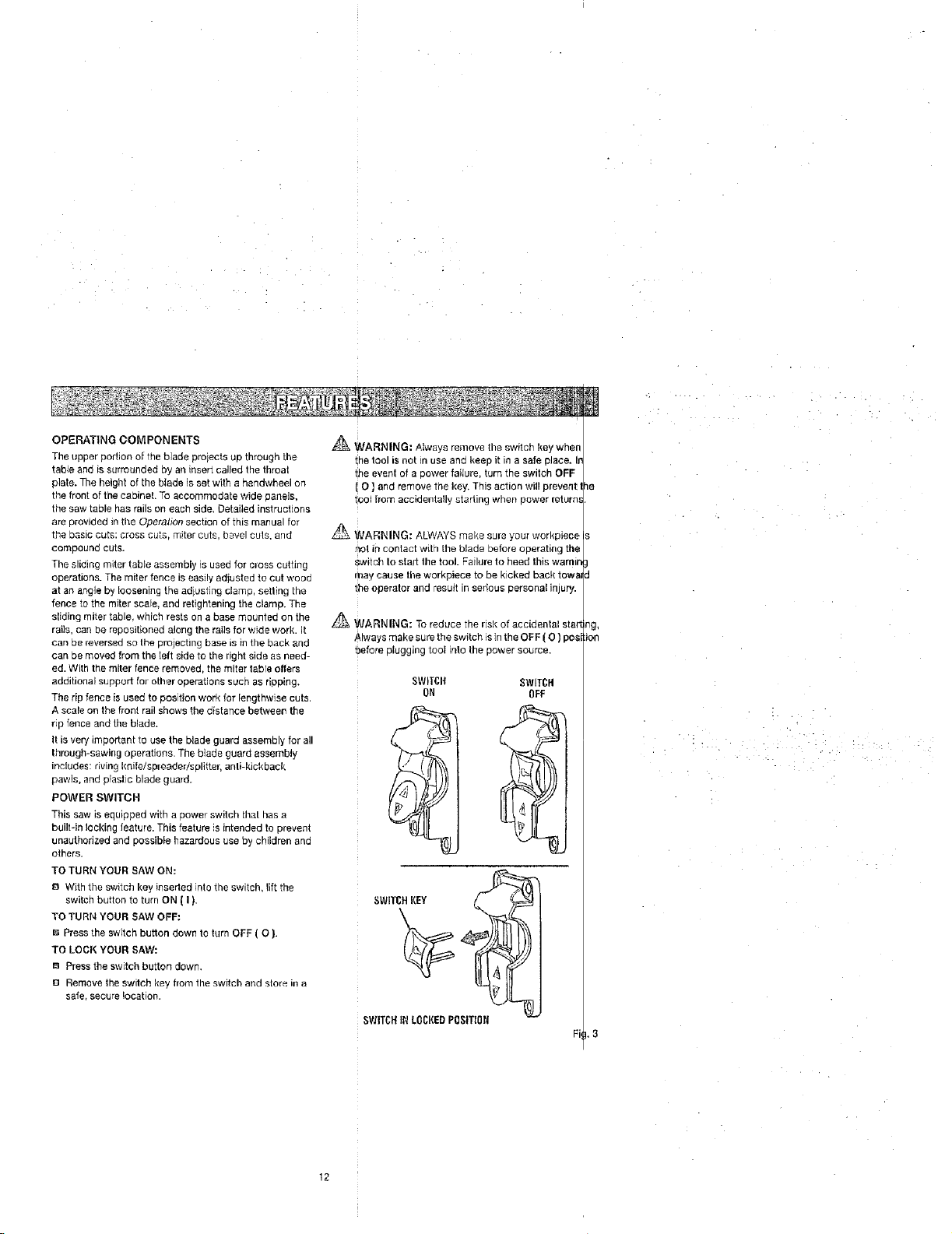

POWER SWITCH

This saw is equipped with a power switch thai has a

built-in locking feature. This feature is intended to prevent

unauthorized and possible hazardous use by children and

others.

TO TURN YOUR SAW ON:

8 With the switch key inserted into the switch, lift the

switch button to turn ON [ I ).

TO TURN YOUR SAW OFF:

I_ Press the switch button down to turn OFF ( O ).

TO LOOK YOUR SAW:

m Press the switch button down.

I_1Remove the switch key from the switch and store in a

safe, secure location.

_ WARNING: Atways remove the switch key when

_hetool is not in use and keep it in a safe place. Ir

the event of a power faiture, turn the switch OFF

O ] and remove the key. This action will prevent I

tool from accidentally starling when power return_

WARNING: ALWAYS make sure your workpiece

not in contact with the blade before operating the

switch to stad the tool. Failure to heed this warnin

may cause tile workpiece to be kicked back towa_

the operator and result in serious personal injury.

WARNING: To reduce the risk of accidental star1

Always make sure the switch is in the OFF (O) pest

before plugging tool into the power source.

SWITCI'I SWITCH

ON OFF

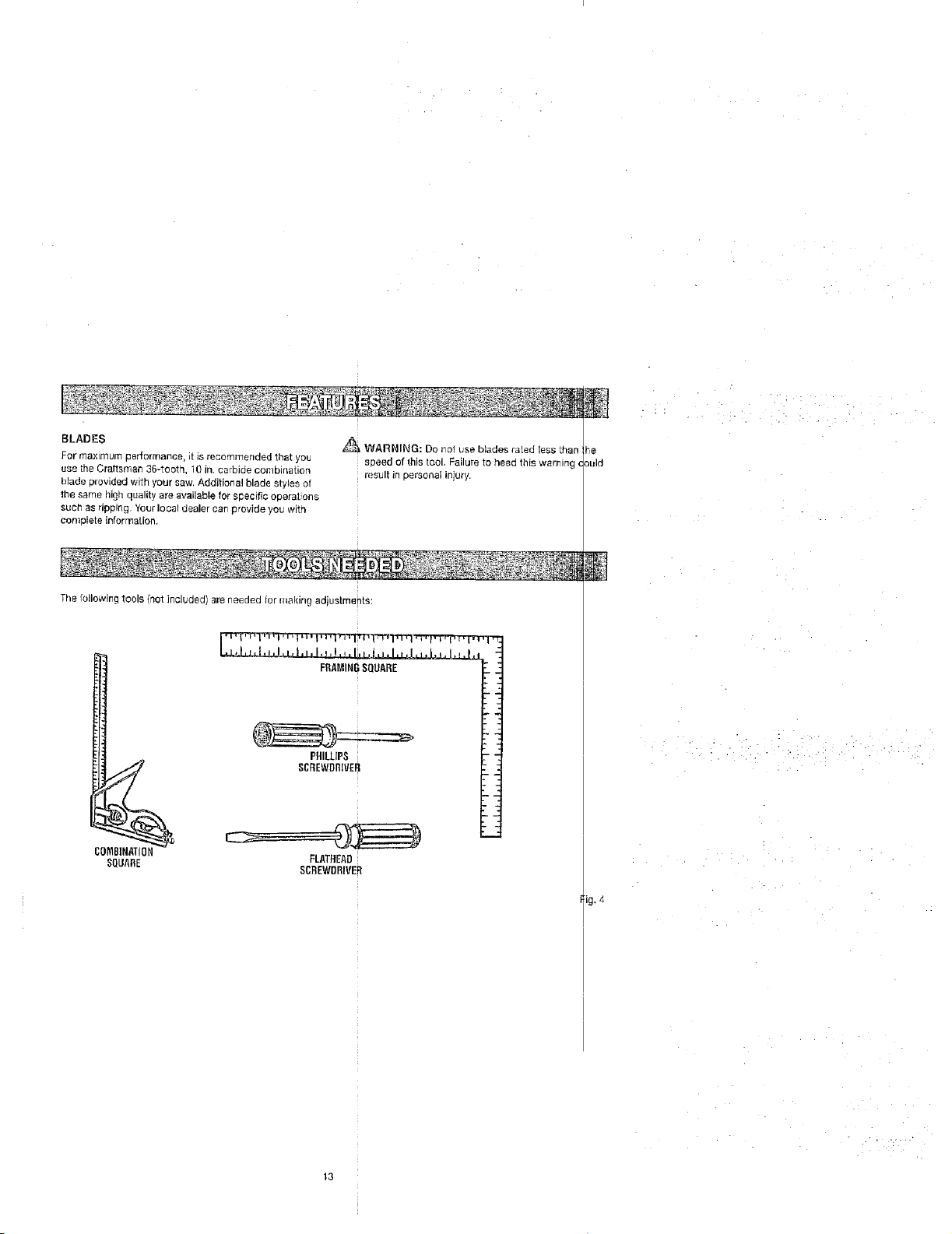

BLADES

For maximum performance, it is recommended that you

use the Craftsman 36-tooth, 10 in. carbide combination

blade provided with your saw, Additiona_ blade styles of

the same high quality are available for specific operat one

such as ripping, Your local dealer can provide you with

complete information,

The following tools {not included) are needed for making adjustmenta:

_ WARNING: Do no_ use blades raled less than

speed of this tool. Failure to heed this warning (

result in personal injury.

ould

COMBINATION

SQLIARE

,L_L,J._.#._,, I,,, I, _,!, q,I, bJ.LI, !, _

FRAMINGSQUARE "_

PHILLIPS T "1

SCREWDRNEH : :

FLATHEAD

SCREWDRIVER

;i

ig.4

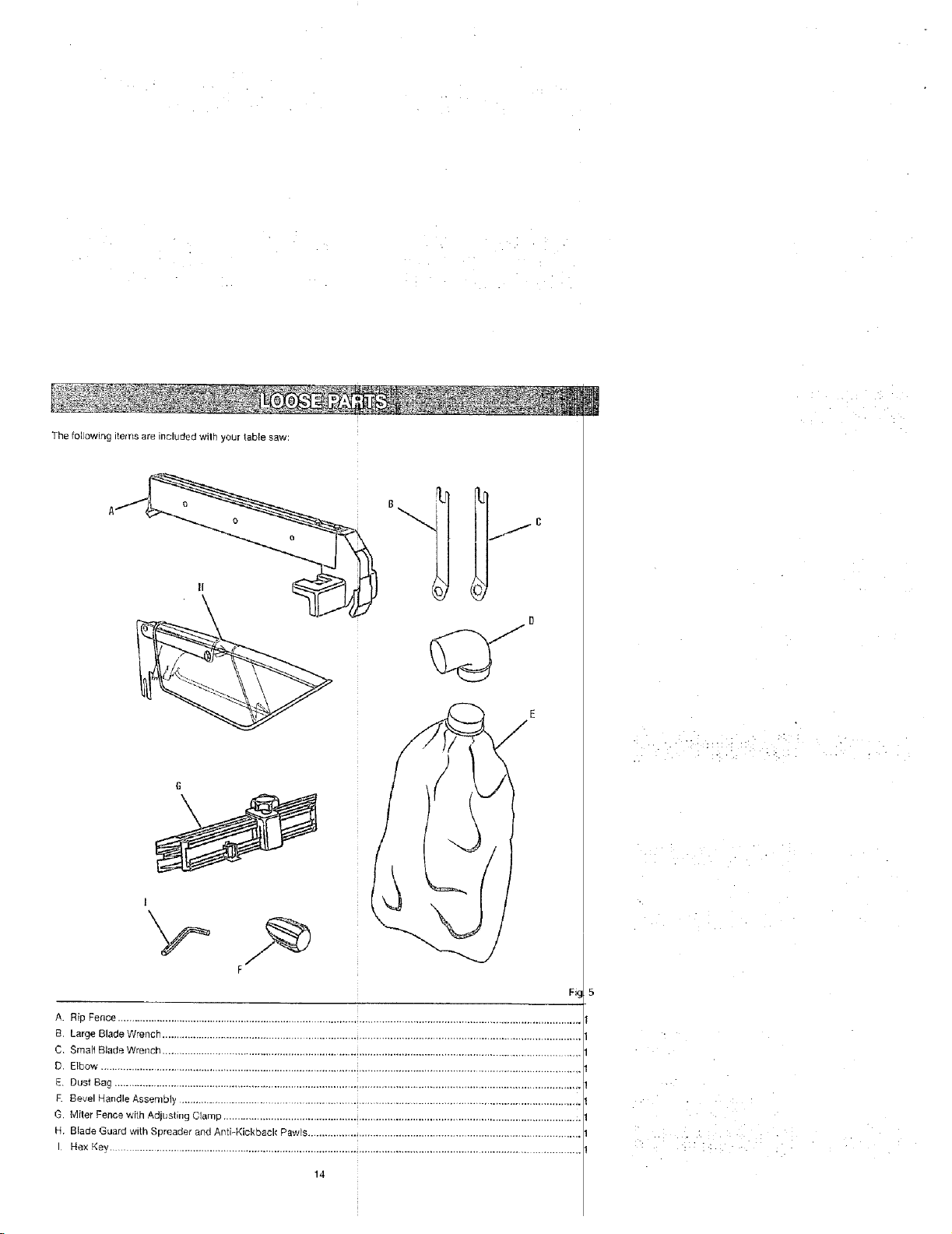

The following items are included wilh your table saw:

6

A. Rip Fence ...................................................................................................................................................................

B. Large Blade Wrench ...................................................................................................................................................

C. Smalt Blade Wrench ................................................................................................................................................

D, Elbow ......................................................................................... _............................................................................

E. Dust Bag ................................................................................................................................................................

E Bevel HandleAssembly ..........................................................................................................................................

G. Miter Fence wi[h Adjusting Clamp ........................................................................................................................... i

H. Blade Guard with Spreader and Anti-Kickback Pawls ...............................................................................................

I Hex Key .............................................................................................................................................................

14

UNPACKING

This product requires assembly.

IJ Carefully lift saw from the carton and place it on a level

work sudace.

NOTE: This too! is heavy. To avoid back injury, keep

your knees bent and lift with your legs, nat your back,

and get help when reeded.

19 Inspect the took carefully to make sure no breakage or

damage occurred during shipping.

E1 Do not discard the pacldng material until you have

carefully iospected and satbfaetobty operated the tool.

The saw is factory set for accurate cutting. After

assembling it, check for accuracy. If shipping has

influenced the settings, refer' to specific procedures

explained in this manual

El if any parts are damaged or missing, please can

1-800-932-3188 for assistance.

_ WARNING: If any parts are missing, do not operate

this tool until the missing parts are replaced. Failure

to do so could result in possible seric)us personal

injury.

_ WARNING: Do not attempt to modify this tool

or create accessories not recommended for use

with this tool Any such alteration or modification is

misuse and could resull in a hazardous condition

leading to possible serious personal injury.

_ WARNING: Do not connect to power supply until

assembly is complete. Failure to comply could result

in accidental starting and possible serious personal

injury.

,_,_"_ WARNING: Do not lift the saw without help. Hold

it close to your body. Keep your knees bent and

lift with your legs, not your back. Ignoring these

precautions can ,esult in back injury.

_ WARNING: Never stand directly in line with the

blade or allow hands 10 come closer than 3 in. to the

blade. Do not reach over or across the blade Failure

to heed this warning can result in serious personal

illlLiry.

A WARNING: To avoid serious personal injury, always

make sure the table saw is securely mounted to

a workbench or an approved leg stand NEVER

operate the saw on the floor.

MOUNTING HOLES

This toot comes mounled to a leg stand. ]f you chose

remove the leg stand, the table saw must be mounted

firm _upporfing surface such as a worl_bench or leg sin _d,

Four bolt holes have been provided in the saw's basel

this porpose. Each of the four mounting holes should b

boll_ securely using 3/8 in. machine botts, lock wash_

and Nex nuts (not included). Bolls should be of sufficiei t

length to accommodate the saw base, lock washers, I_ _x

nuts, and the thickness of the workbench. Tighten all < ur

bolts securely.

Carefully check the workbench after mounting to make

sure that r_omovement can occur du[ng use. If any tip

ping, sliding, or we kirlg is noted, secure the workberi to

the fleer before operating.

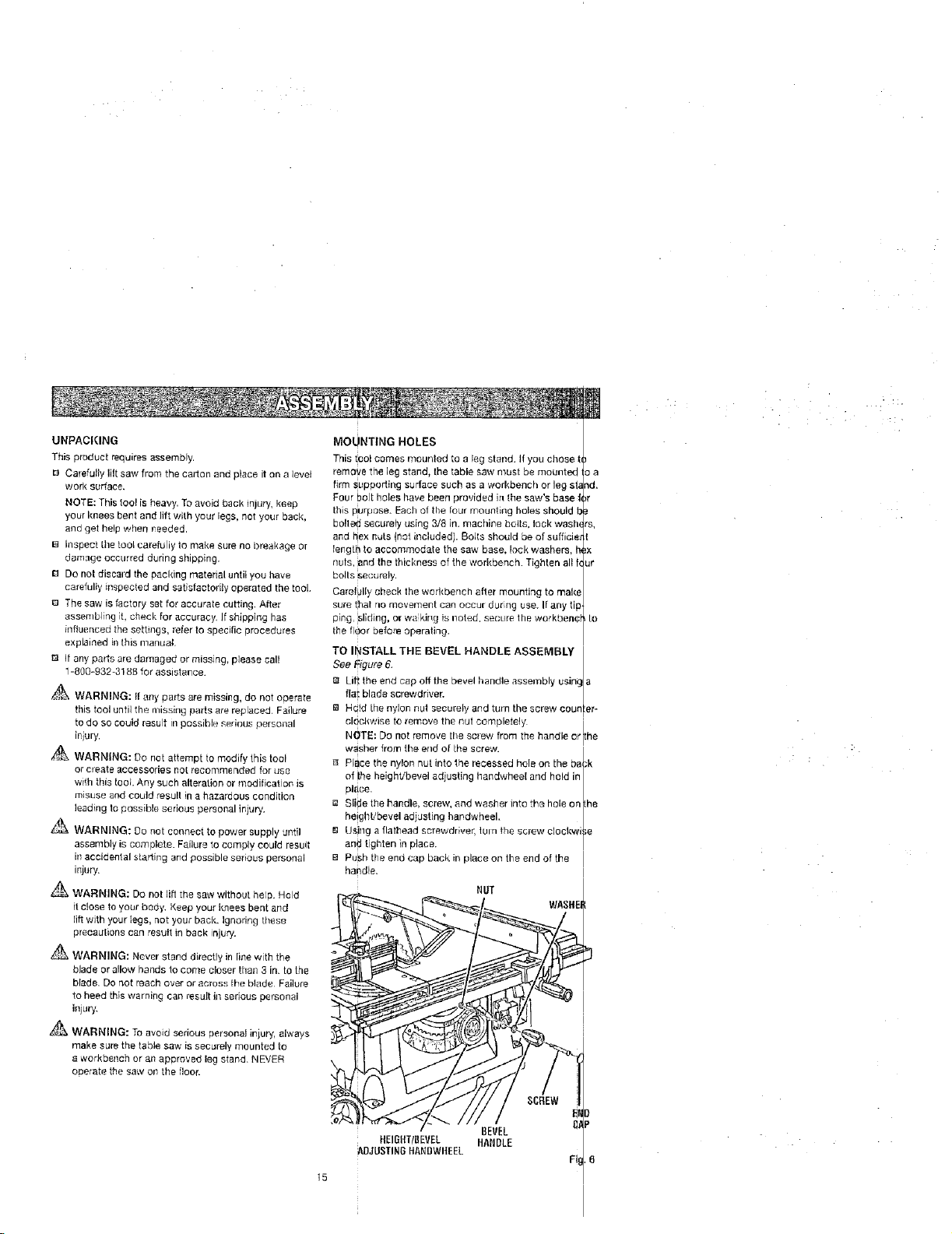

TO INSTALLTHE BEVEL HANDLE ASSEMBL I

See Figure 6. I

r_ Lift the end cap off the bevel handle assembly using Ia

flu i blade screwdriver. /

Ea Hdld [he nylon nut securely and turn the screw couoler-

clockwise to remove the nut completely

NOTE: Do not remove tile screw from the handle o:rlthe

washer from the end of [he screw.

Place the nylon nut into the recessed hole on the ba_,k

of ihe heightibevel adjusting handwheel arid hold in/

pl_ce, l

[] Slide the handle> screw, and washer into the hole on I[he

height/bevel ad _eting handwheeh /

B Using a flatlqead screwdriver, iul n the screw clockwise

and tighten in place. /

[] Push the end cap back in place on the end of the

handle.

NUT

I

i

/

ftEIGItTIBEVEL HANDLE

ADJUSTINGftANBWHEEL

BEVEL

Loading...

Loading...