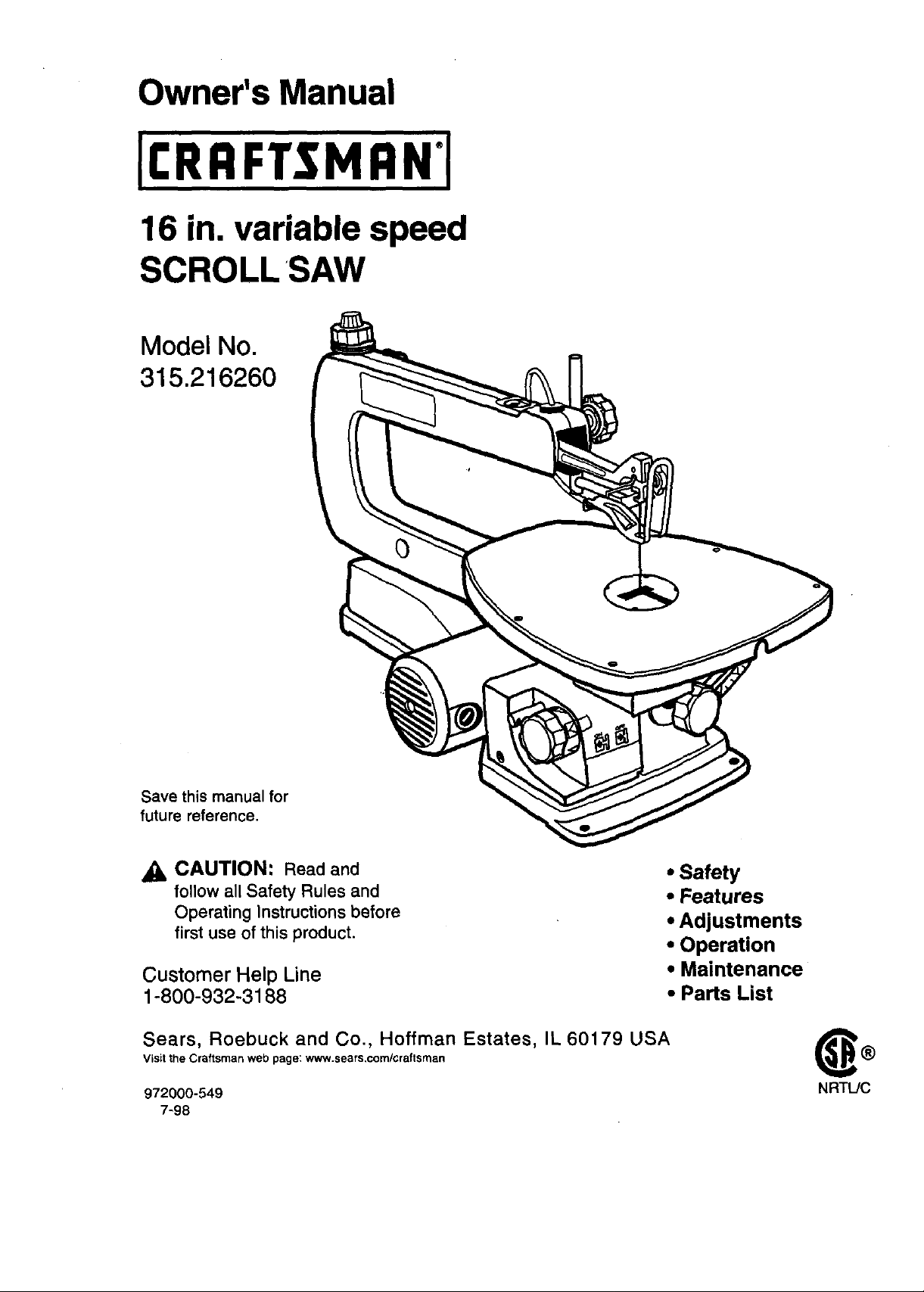

Craftsman 315216260 Owner’s Manual

Owner's Manual

II:RRFTSMRNI

16 in, variable speed

SCROLL SAW

Model No.

315.216260

Save this manual for

future reference.

CAUTION: Read and

follow allSafety Rulesand

Operating Instructionsbefore

first use of thisproduct.

Customer Help Line

1-800-932-3188

Sears, Roebuck and Co., Hoffman Estates, IL 60179 USA

VisLtthe Craftsman web page: www.sears,com/craftsrnan

97200O-549

7-98

• Safety

• Features

• Adjustments

• Operation

• Maintenance

• Parts List

®

NRTL/C

• Table of Contents ........................................................................................................................................... 2

• Warranty and Introduction.............................................................................................................................. 2

• Rules For Safe Operation ......................................................................................................................... 3 - 5

• Electrical.......................................................................................................................................................... 6

• Glossary and ProductSpecifications............................................................................................................. 7

• Unpacking and Tools Needed ........................................................................................................................ 8

• Labels ............................................................................................................................................................. 9

• Features .................................................................................................................................................. 10-11

• Assembly................................................................................................................................................. 11-12

• Adjustments............................................................................................................................................. 12-15

• Operation................................................................................................................................................. 16-19

• Maintenance ............................................................................................................................................ 19-20

• Troubleshooting............................................................................................................................................ 20

• Exploded View and Repair Parts List...................................................................................................... 22-25

• Parts Ordering / Service ............................................................................................................................... 26

f

FULL ONE YEAR WARRANTY ON CRAFTSMAN SCROLL SAW

If this rRRFTSMRN" Scroll Saw fails due to a defect in material or workmanship within one year fromthe date of

purchase, Sears willrepair it, free of charge.

Contact a Sears Service Center for repair.

If this product is used for commercial or rental purposes, thiswarranty applies only for 90 days from the date of

purchase.

This warranty gives you specific legal rights, and you may also have other rights whichvary from state to state.

Sears, Roebuck and Co., Dept. 817WA, Hoffman Estates, IL 60179

Yoursaw has many features for makingcutting

operations more pleasant and enjoyable. Safety,

performance and dependability have been given top

priorityinthe design of this saw making iteasy to

maintain and operate.

_I, CAUTION: Carefully read throughthisentire

owner's manual before usingyour new saw. Pay

close attention to the Rules For Safe Operation,

and all Safety Alert Symbols includingDanger,

Warning and Caution. Ifyou use your saw

properly and only for what it is intended, you will

enjoy years ofsafe, reliable service.

_. Look for this symbol to point out important safety precautions. It means attention!H Your

safety is involved.

_IL WARNING:

The operationof any power tool can resultin foreign objects being thrownintoyour eyes,

which can result in severe eye damage. Before beginning power tool operation, always wear

safety gogglesor safety glasses with side shields and a full face shieldwhen needed. We

recommend Wide Vision Safety Mask foruse over eyeglasses or standard safety glasses

with side shields, available at Sears Retail Stores.

2

ThepurposeofsafetysymbolsIs to attract your attention to possible dangers. The safety symbols, and

the explanations with them, deserve your careful attention and understanding. The safety warnings do

not by themselves eliminate any danger. The instructions or warnings they give are not substitutes for

proper accident prevention measures.

SYMBOL

A

A

,a,

&

Note:

IMPORTANT

Servicing requires extreme care and knowledge of the system and shouldbe performed only by a qualified

service technician. For service we suggestyou return the tool to yournearest Sears storefor repair. Always use

originalfactory replacement parts when servicing.

_lb WARNING: Do not attempt to operate this tool

untilyou have read thoroughly and understand

completely all instructions,safety rules, etc.

contained in this manual. Failure to complycan

result in accidents involvingfire, electric shock,

or serious personal injury. Save 6wner's manual

and review frequently for continuingsafe

operation, and instructingothers who may use

this tool.

,_ WARNING: Do not connect your scrollsaw to a

power source untilyou have assembled and

adjusted the saw as described in this manual

and have read and understoodall precautions

and operating instructionsin the manual and

printed on the tool.

READ ALL INSTRUCTIONS

• KNOW YOUR POWER TOOL. Read the owner's

manual carefully. Learn the saw's applications

and limitationsas well as the specificpotential

hazards related to this tool.

• GUARD AGAINST ELECTRICAL SHOCK BY

PREVENTING BODY CONTACT WITH

GROUNDED SURFACES. For example; pipes,

radiators, ranges, refrigeratorenclosures.

• KEEP GUARDS IN PLACE and in good working

order.

MEANING

SAFETY ALERT SYMBOL:

Indicates danger, warning or caution.May be used in conjunctionwith other symbolsor picto-

graphs.

DANGER: Failure to obey a safety waming willresult in serious injury to yourself or to others.

Always follow the safety precautions to reduce the risk of fire, electric shock and personal injury.

WARNING: Failureto obey a safety warningcan result in serious injuryto yourselfor to others.

Always follow the safety precautionsto reducethe riskof fire, electricshockand personalinjury.

CAUTION: Failure to obey a safety warning may resultin property damage or personal injuryto

yourself orto others. Alwaysfollow the safety precautionsto reduce the riskoffire, electricshock

and personal injury.

r

Advises you of information or instructionsvitaltothe operation or maintenance of the equipment.

• REMOVE ADJUSTING KEYS AND

WRENCHES. Get in the habit ofchecking to see

that hex keysand adjustingwrenches are

removed from tool before turning on the saw.

• KEEP THE WORK AREA CLEAN. Cluttered

work areas and work benches inviteaccidents.

DO NOT leave tools or pieces of wood on the

saw while itis in operation.

• DO NOT USE IN DANGEROUS ENVIRON-

MENTS. Do not use power toolsnear gasoline or

other flammable liquids,in damp or wet loca-

tions, or expose them to rain. Keep the work

area well lit.

• KEEP CHILDREN AND VISITORS AWAY. All

visitorsshouldwear safetyglasses and be kept s

safe distancefrom work area. Do not let visitors

contact tool or extension cord whileoperating.

• MAKE WORKSHOP CHILD-PROOF with

padlocks and master switches or by removing

starter keys,

• DO NOT FORCE THE TOOL. Itwill do thejob

better and safer at the rate for which it was

designed.

• USE THE RIGHT TOOL. Do not forcethe tool or

attachment to do a job it was not designed for.

Don't use it for a purposenot intended,

3

RULES FOR SAFE OPERATION (Continued)

U_E THE PROPER EXTENSION CORD. Make

m

sure your extension cord is ingood condition.

When usingan extension cord, be sure to use

one heavy enough to carry the current your

productwilldraw. An undersized cord willcause

a drop in line voltage resultingin'loss of power

and overheating. A wire gage size (A.W.G.) of at

least 18 is recommended for an extension cord

25 feet or less inlength. If in doubt, use the next

heavier gage. The smaller the gage number, the

heavier the cord.

INSPECT EXTENSION CORDS PERIODI-

CALLY and replace if damaged.

DRESS PROPERLY. Do not wear looseclothing,

gloves, neckties, rings,bracelets, or other

jewelry. They can get caught and draw you into

moving parts. Rubber glovesand nonslip foot-

wear are recommended. Alsowear protective

hair covering to containlong hair.

ALWAYS WEAR SAFETY GLASSES WITH

SIDE SHIELDS. Everyday eyeglasses have only

impact-resistant lenses; they are NOT safety

glasses.

PROTECT YOUR LUNGS. Wear a face or dust

mask ifthe cutting operation isdusty.

PROTECT YOUR HEARING. Wear hearing

protectionduring extended periods of operation.

m

SECURE WORK. Use clamps or a vise to hold

work when practical. It's safer than usingyour

hand and it frees both hands to operate tool.

• DO NOT OVERREACH. Keep proper footing and

balance at all times.

MAINTAIN TOOLS WITH CARE. Keep tools

sharp and clean for better and safer perfor-

mance. Followinstructionsfor lubricatingand

changing accessories.

DISCONNECT ALL TOOLS. When not in use,

before servicing,or when changingattachments,

blades, bits,cutters, etc., all toolsshould be

disconnected from power supply.

AVOID ACCIDENTAL STARTING. Be sure

switch is offwhen pluggingin.

USE RECOMMENDED ACCESSORIES. The

use of improperaccessories may cause riskof

injury.

NEVER STAND ON TOOL. Serious injury could

occurif the tool istipped or ifthe blade is unin-

tentionallycontacted.

CHECK DAMAGED PARTS. Before further use

of the tool,a guard or other part that isdamaged

should be carefullychecked to determine that it

willoperate properly and perform itsintended

function. Check for alignment ofmoving parts,

bindingof movingparts, breakage of parts, saw

stability,mounting and any other conditionsthat

may affect its operation. A guard or other part

that is damaged must be properly repaired or

replaced by a qualified service technicianat a

Sears store to avoid risk of personal injury.

DIRECTION OF FEED. Feed work intoa blade

or cutter against the directionof rotation ofthe

blade or cutter only.

NEVER LEAVE TOOL RUNNING UNAT-

TENDED. TURN THE POWER OFF. Do not

leave tool until itcomes to a complete stop.

m

USE ONLY CORRECT BLADES. Use the right

blade size, style and cuttingspeed for the

material and the type of cut. Blade teeth should

pointdown toward the table. Sharp blades

minimize stalling and kickback. Correctly adjust

blade tension.

TO PROTECT THE OPERATOR and minimize

blade breakage, ALWAYS adjust the hold down

foot tojust clear the workpiece. Never operate

the saw with any guard or cover removed. Make

sure all guardsare operatingproperly before

each use.

KEEP HANDS AWAY FROM CUTTING AREA.

Do not hand hold pieces so small that your

fingers go under the blade guard. Never reach

underneath work or behind, under, or within

three inches of the blade and itscutting path with

your hands and fingers for any reason. Do not

attemptto remove cut material when blade is

moving.

,_k WARNING: Blades coast afterturn off.

• AVOID PINCHING THE BLADE. Be cautious

when cuttingoff material which is irregular in

cross section. For example, moldingmustlay flat

on the table and not be permitted to rock.

• DO NOT ABUSE CORD. Never yank cord to

disconnect it from receptacle. Keep cord from

heat, oil, and sharp edges.

• INSPECT TOOL CORDS PERIODICALLY and if

damaged, have repaired by a qualified service

technicianat a Sears store. Stay constantly

aware of cord locationand keep it well away

from the rotatingblade.

• DO NOT USE TOOL IF SWITCH DOES NOT

TURN IT ON AND OFF. Have defective switches

replaced bya qualified service technician at a

Sears store.

RULES FOR SAFE OPERATION (Continued)

KEEP TOOL DRY, CLEAN, AND FREE FROM

OIL AND GREASE. Always use a clean cloth

when cleaning. Never use brake fluids, gasoline,

petroleum-based products,or any solventsto

clean tool

A LARGE PIECE OF MATERIAL SHOULD BE

SUPPORTED while cutting.To minimize riskof

blade pinching and kickback, always support

long workpieces. Saw may slip, walk or slide

while cutting long or heavy boards.

BEFORE MAKING A CUT, BE SURE ALL

ADJUSTMENTS ARE SECURE.

BEFORE CHANGING THE SETUP, REMOVING

COVERS, GUARDS OR BLADE, UNPLUG THE

SAW, AND REMOVE THE SWITCH KEY.

• DO NOT FEED THE MATERIAL TOO QUICKLY

while cutting. Do not force the workpiece against

the blade.

• NEVER CUT MORE THAN ONE WORKPIECE

AT A TIME. If making a stacked cut, all of the

pieces mustbe secured to each other with

masking tape or double stick tape to make one

workpiece. Do not put more than one workpiece

on the saw table at a time. Always hold the work

firmlyagainst the table. See page 18.

• AVOID CU'I-FING NAILS. Inspect for and

remove all nails from lumber before cutting.

• NEVER PERFORM LAYOUT, ASSEMBLY, OR

SETUP WORK ON THE TABLE while the

cutting tool isoperating.

• NEVER TOUCH BLADE orother moving parts

during use,

• NEVER START A TOOL WHEN THE BLADE IS

IN CONTACT WITH THE WORKPIECE. Clear

the table of debris before turning your scrollsaw

on,

ALLOW THE MOTOR TO COME UP TO FULL

SPEED before starting a cut.

FIRMLY CLAMP OR BOLT your scrollsaw to a

firm, level workbench or table. The most comfort-

able sawtable height is at approximately hip

height.

• AVOID AWKWARD OPERATIONS A_D HAND

POSITIONS where a sudden slip could cause

your hand to move into the blade. ALWAYS

make sureyou have good balance. Do not cut

pieces of material that are too small to hold

comfortablyin your hand.

• REPLACEMENT PARTS. All repairs, whether

electrical or mechanical, shouldbe made by

qualified service technician ata Sears store or

repair center.

_1= WARNING: When servicing use onlyidentical

Craftsman replacement parts. Use ofany other

parts may create a hazard or cause product

damage.

• NEVER USE IN AN EXPLOSIVE ATMO-

SPHERE. Normal sparkingof the motor could

ignitefumes.

• DO NOT OPERATE THIS TOOL WHILE UN-

DER THE INFLUENCE OF DRUGS, ALCOHOL,

OR ANY MEDICATION.

STAY ALERT AND EXERCISE CONTROL.

Watch what you are doingand use common

sense. Do not operate tool when you are tired.

Do not rush.

• MAKE SURE THE WORK AREA HAS AMPLE

LIGHTING to see the work and that noobstruc-

tionswill interfere with safe operation BEFORE

performingany work using yoursaw.

• ALWAYS TURN OFF SAW before disconnecting

it, to avoidaccidental starting when reconnecting

to power supply. NEVER leave the scrollsaw

unattendedwhile connected to a power source.

_. WARNING: Do not allow familiaritywith your

saw make youcareless. Remember that a

careless fractionof a second is sufficientto inflict

severe injury.

SAVE THESE INSTRUCTIONS. Refer tothem

frequentlyand use to instructother users. If you

loan someone thistool, loan them these instruc-

tions also.

SAVE THESE INSTRUCTIONS

5

EXTENSION CORDS

Use only 3-wire extension cords that have 3-prong

grounding plugs and 3-pole receptacles that accept

the tool's plug. When using a power tool at a consider-

able distance from the power source, use an exten-

sion cord heavy enough to carry the current that the

tool will draw. An undersized extension cord will

cause a drop in line voltage, resulting in a loss of

power and causing the motor to overheat. Use the

chart provided below to determine the minimum wire

size required in an extension cord. Only round jack-

eted cords listed by Underwriter's Laboratories (UL)

should be used.

Length of Extension Cord

Up to 25 feet

26-100 feet 16

When working with the tool outdoors, use an exten-

sion cord that is designed for outside use. This is

indicated bythe letters WA on the cord's jacket.

Before using an extension cord, inspect it for loose or

exposed wires and cut or worn insulation.

_i, CAUTION: Keep the cord away from the cutting

area and position the cord so that it will not be

caught on lumber, tools, or other objects during

cutting.

Wire Size (A.W.G.)

18

ELECTRICAL CONNECTION

Your Sears Craftsman Scroll Saw is powered by a

precision built electric motor. It should be connected

to a power supply that Is 120 volts, 60 Hz, AC only

(normal household current). Do not operate this tool

on direct current (DC). A substantial voltage drop will

cause a loss of power and the motor will overheat. If

the saw does not operate when plugged into an outlet,

double check the power supply.

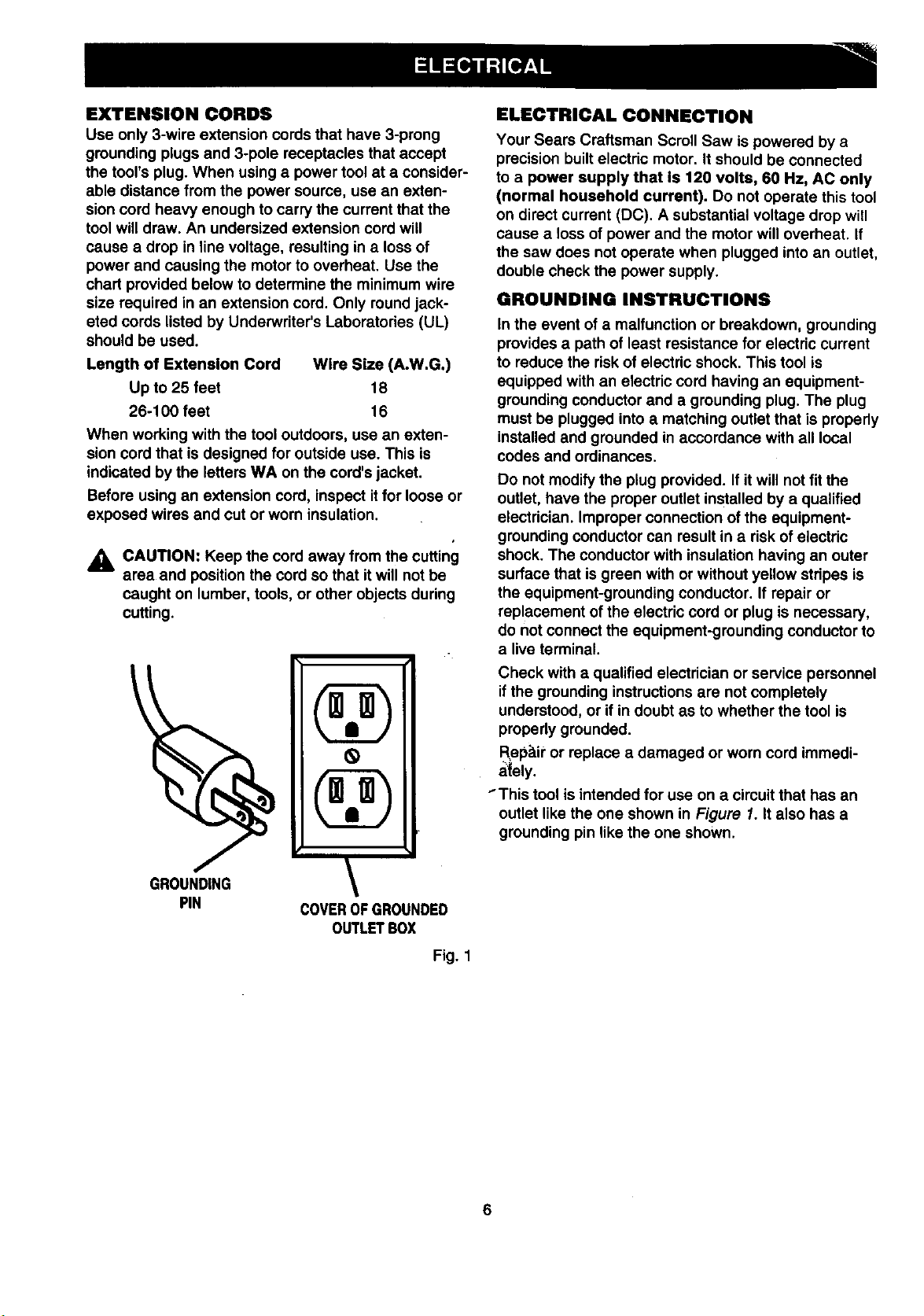

GROUNDING INSTRUCTIONS

In the event of a malfunction orbreakdown, grounding

provides a path of least resistance for electric current

to reduce the riskof electric shock. This tool is

equipped with an electric cord having an equipment-

grounding conductor and a grounding plug. The plug

must be plugged into a matching outlet that is propedy

installed and grounded in accordance with all local

codes and ordinances.

Do not modify the plug provided. If itwill not fit the

outlet, have the proper outlet installed by a qualified

electrician. Improper connection of the equipment-

grounding conductor can result in a risk of electric

shock. The conductor with insulation having an outer

surface that is green with or without yellow stripes is

the equipment-grounding conductor. If repair or

replacement of the electric cord or plug is necessary,

do notconnect the equipment-grounding conductor to

a live terminal.

Check with a qualified electrician or service personnel

if the grounding instructions are not completely

understood, or if in doubt as to whether the tool is

properly grounded.

Repair"or replace a damaged or worn cord immedi-

ately.

"This tool is intended for use on a circuitthat has an

outlet like the one shown in Figure 1. It also has a

grounding pin like the one shown.

GROUNDING

PIN COVEROF GROUNDED

OUTLETBOX

Fig. 1

6

Bevel Cut

A cutting operation made with the table at any angle

other than 90" to the blade.

Crosscut

A cutting or shaping operation made across the grain

of the workpiece.

Compound Cut

A compound cut is a cut made using a miter angle

and a bevel angle at the same time.

Freehand (for scroll saw)

Performing a cut without the workpiece properly

supported on the table.

Gum

A sticky, sap based residue from wood products.

Kerr

The matedal removed by the blade in a through cut or

the slot produced by the blade in a nonthrough or

partial cut.

Leading End

The end of the workpiece pushed into the cutting tool

fimt.

Miter Cut

A cutting operation made with the saw table at an_

angle other than 90" to the blade.

Nonferrous Metal

Metal that does not contain iron; such as aluminum,

brass, and copper.

Push Stick

A device used to feed the workpiece through the saw

blade during narrow rippingtype operations and helps

keep the operator's hands well away from the blade.

Resaw

A cutting operation to reduce the thickness of the

workpiece to make thinner pieces.

Resin

A sticky, sap base substance that has hardened.

Ripping

A cutting operation along the length of the workpiece.

Saw Blade Path

The area directly in line -- over, under, behind, or in

front of the blade. AS it applies to the workpiece, that

area which will be, or has been, cut by the blade.

Set

The distance that the tip of the saw blade tooth is bent

(or set) outward from the face of the blade.

SPM

Strokes per minute. Used in reference to blade

movement.

Throw-Back

Throwing of a workpiece in a manner similar to a

kickback. Usually associated with a cause other than

the kerr closing, such as a workpiece notbeing

against the fence, being dropped intothe blade, or

being placed inadvertently incontact with the blade.

Through Sawing

Any cutting operation where the blade extends

completely through the thickness of the workpiece.

Workpiece

The item on which the cutting operation is being done.

The surfaces of a workpiece are commonly referred to

as faces, ends, and edges.

Worktable

The surface on which the workpiece rests while

performing a cutting or sanding operation.

Throat

Motor

Drive

Blade Length

Table Size

16 in.

120 V, 1.2 amp 60 HZ-AC only

Variable Speed

500-1700 Strokes per minute

5 in. plain or pin

10-1/4 in. x 12 in.

Table Tilt

Overall Dimensions

Net Weight

7

47" right and 12" left

12in. W

24-1/2 in. L

14in. H

27.5 lb.

,_ WARNING: To prevent accidental startingor

electrical shock that couldcause possible

serious personal injury,assemble all parts to

your saw before connecting it to power supply.

Saw should never be connected to power supply

when you are assembling parts, making

adjustments, lubricating, installingor removing

blades, cleaning, orwhen not in use.

Carefully lift saw from the carton and place it on

a level work surface.

Remove pack of 4 extra blades and owner's

manual from the carton.

_, WARNING: If any partsare missing, do not

operate this tool untilthe missing parts are

replaced. Failure to do socould resultin possible

serious personal injury.

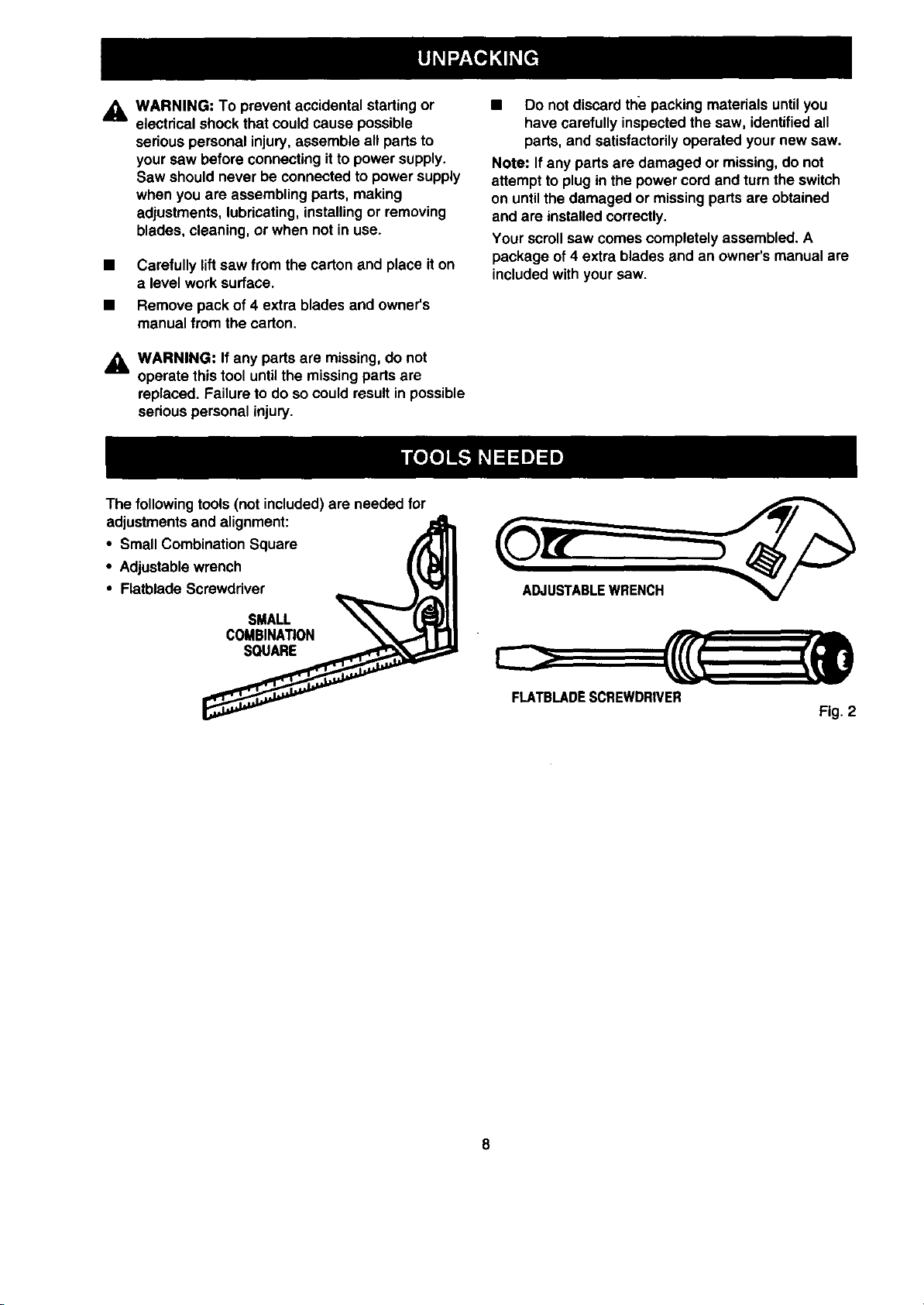

The following tools (not included) are needed for

adjustments and alignment:

• Small Combination Square

• Adjustablewrench

• Flatblade Screwdriver

• Do not discardthe packing materials until you

have carefully inspected the saw, identifiedall

pads, and satisfactorilyoperated yournew saw.

Note: If any parts are damaged or missing,do not

attempt to plugin the power cord and turnthe switch

on untilthe damaged or missingparts are obtained

and are installedcorrectly.

Your scroll saw comes completely assembled. A

package of 4 extra blades and an owner's manual are

includedwith your saw.

SMALL

COMBINA_ON

SQUARE

FLATBLADESCREWDRIVER

Fig. 2

Loading...

Loading...