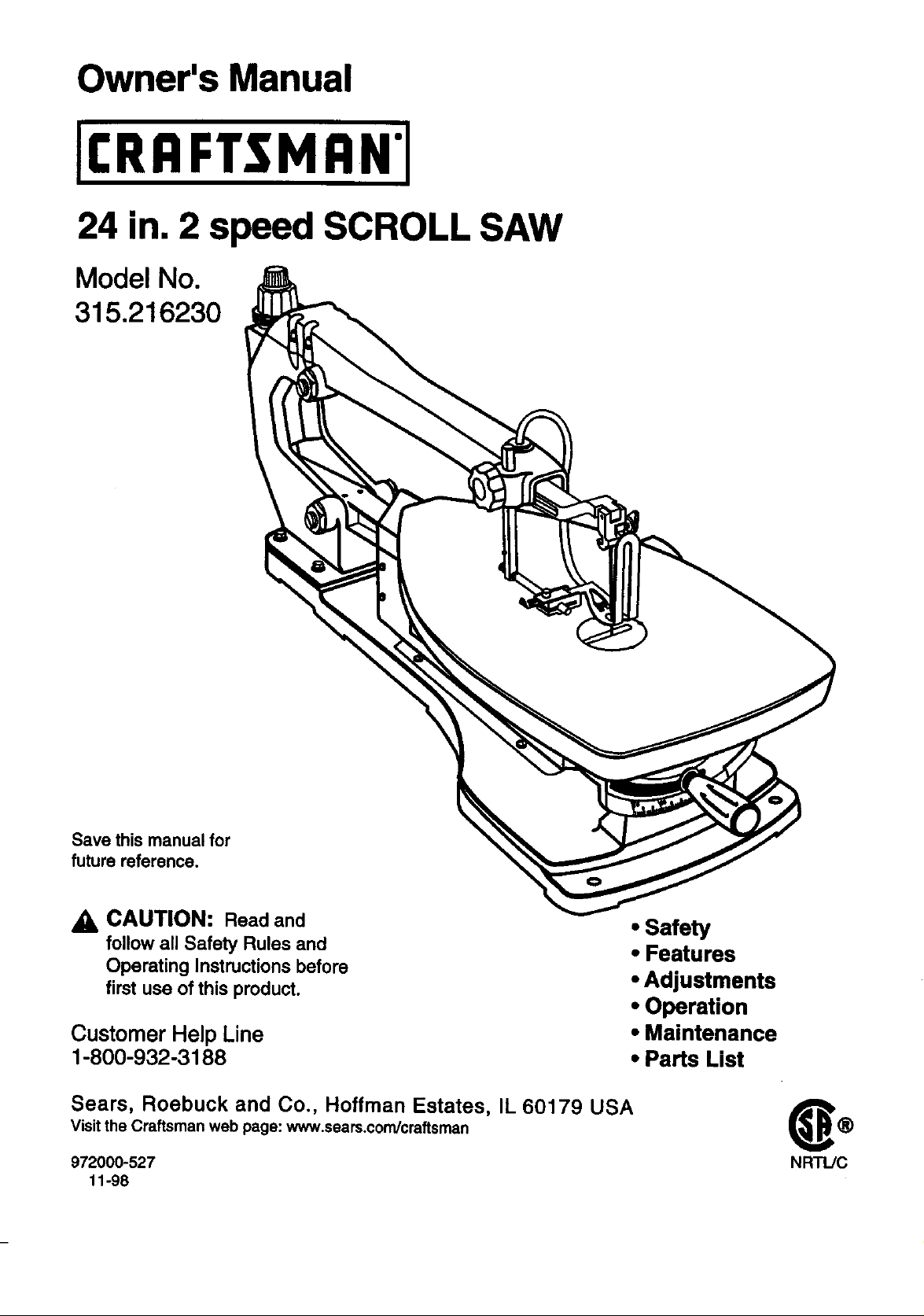

Craftsman 315216230 Owner’s Manual

Owner's Manual

II:RRFTSMRN'I

24 in. 2 speed SCROLL SAW

Model No.

315.216230

\

Save this manual for

future reference.

A_, CAUTION: Read and

follow all Safety Rules and

Operating Instructionsbefore

first use ofthis product.

Customer Help Line

1-800-932-3188

Sears, Roebuck and Co., Hoffman Estates, IL 60179 USA

Visit the Craftsman web page: www.sears.com/craftsman

972000-527

11-98

• Safety

• Features

• Adjustments

• Operation

• Maintenance

• Parts List

NRTL/C

Table of Contents ........................................................................................................................................... 2

Warranty and Introduction.............................................................................................................................. 2

Rules For Safe Operation ........................... :............................................................................................. 3 - 5

Electrical ......................................................................................................................................................... 6

+

• Glossary and Product Specifications ............................................................................................. _............... 7

• Unpacking and Tools Needed ........................................................................................................................ 8

• Labels ........................................................................................................................................................ 8.9

• Features .................................................................................................................................................. 10-11

• Assembly ................................................................................................................................................. 11-12

• Adjustments .................................................................. :.......................................................................... 12-15

• Operation ................................................................................................................................................. 16-18

• Maintenance ................................................................. _............................................................................... 19

• Troubleshooting ............................................................................................................................................ 20

• Exploded View and Repair Parts List ...................................................................................................... 22-27

• Parts Ordering / Service ............................................................................................................................... 28

FULL ONE YEAR WARRANTY ON CRAFTSMAN SCROLL SAW

If this CRAFTSMAN" Scroll Saw fails due to a defect in material or workmanship within one year from the date of

purchase, Sears will repair it, free of charge.

Contact a Sears Service Center for repair.

If this product is used for commercial or rental purposes, this warranty applies only for 90 days from the date of

purchase.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

Sears, Roebuck and Co., Dept. 817WA, Hoffman Estates, IL 60179

Your saw has many features for making cutting

operations more pleasant and enjoyable. Safety,

performance and dependability have been given top

priority in the design of this saw making it easy to

maintain and operate.

,_ CAUTION: Carefully read through this entire

owner's manual before using your new saw. Pay

close attention to the Rules For Safe Operation,

and all Safety Alert Symbols including Danger,

Warning and Caution. If you use your saw

properly and only for what it is intended, you will

enjoy years of safe, reliable service.

_1, Look for this symbol to point out important safety precautions. It means attention!!! Your

safety is involved.

_k WARNING:

The operation of any power tool can result inforeign objects being thrown into your eyes,

which can result in severe eye damage. Before beginning power tool operation, always wear

safety goggles or safety glasses with side shields and a full face shield when needed. We

recommend Wide Vision Safety Mask for use over eyeglasses or standard safety glasses

with side shields, available at Sears Retail Stores.

2

The purpose of safety symbols is to attract your attention to possible dangers. The safety symbols, and

the explanations with them, deserve your careful attention and understanding. The safety warnings do

not by themselves eliminate any danger. The instructions or warnings they give are not substitutes for

proper accident prevention measures.

SYMBOL

&

A

A

A

Note: Advises you of information or instructionsvitalto the operation or maintenance of the equipment.

IMPORTANT

Servicing requires extreme care and knowledge of the system and should be performed only by a qualified

service technician. For service we suggest you returnthe toolto your nearest Sears store for repair. Always use

original factory replacement parts when servicing.

_1= WARNING: Do not attempt to operate this tool

until you have read thoroughly and understand

completely all instructions, safety rules, etc.

contained in this manual. Failure to comply can

result in accidents involving fire, electric shock,

or serious personal injury. Save owner's manual

and review frequently for continuing safe

operation, and instructing others who may use

this tool.

,_ WARNING: Do not connect your scroll saw to a

power soume until you have assembled and

adjusted the saw as described in this manual

and have read and understood all precautions

and operating instructions in the manual and

printed on the tool.

READ ALL INSTRUCTIONS

M KNOW YOUR POWER TOOL. Read the owner's

manual carefully. Learn the saw's applications

and limitations as well as the specific potential

hazards related to this tool.

• GUARD AGAINST ELECTRICAL SHOCK BY

PREVENTING BODY CONTACT WITH

GROUNDED SURFACES. For example; pipes,

radiators, ranges, refrigerator enclosures.

• KEEP GUARDS IN PLACE and in good working

order.

MEANING

SAFETY ALERT SYMBOL:

Indicates danger, warning or caution. May be used in conjunction with other symbols or picto-

graphs.

DANGER: Failure to obey a safety warning will result in serious injuryto yourself or to others.

Always follow the safety precautions to reduce the risk of fire, electric shock and personal injury.

WARNING: Failure to obey a safety warning can result in serious injuryto yourself or to others.

Always follow the safety precautions to reduce the riskof fire, electric shock and personal injury.

CAUTION: Failure to obey a safety waming may result in property damage or personal injuryto

yourself orto others. Always follow the safety precautions to reduce the risk of fire, electric shock

and personal injury.

B REMOVE ADJUSTING KEYS AND

WRENCHES. Get in the habit of checking to see

that hex keys and adjusting wrenches are

removed from tool before turning on the saw.

M KEEP THE WORK AREA CLEAN. Cluttered

work areas and work benches invite accidents.

DO NOT leave tools or pieces ofwood on the

saw while it is in operation.

M DO NOT USE IN DANGEROUS ENVIRON-

MENTS. Do not use power tools near gasoline or

other flammable liquids, in damp or wet loca-

tions, or expose them to rain. Keep the work

area we, lit.

• KEEP CHILDREN AND VISITORS AWAY. All

visitors should wear safety glasses and be kept a

safe distance from work area. Do not let visitors

contact tool or extension cord while operating.

• MAKE WORKSHOP CHILD-PROOF with

padlocks and master switches or by removing

starter keys.

• DO NOT FORCE THE TOOL. It will do the job

better and safer at the rate for which it was

designed.

M USE THE RIGHT TOOL. Do not force the tool or

attachment to do a job itwas not designed for.

Don't use it for a purpose not intended.

3

RULES FOR SAFE OPERATION (Continued)

m USE THE PROPER EXTENSION CORD. Make

sure your extension cord is ingood condition.

When using an extension cord, be sure to use

one heavy enough to carry the current your

product will draw. An undersized cord will cause

a drop in line voltage resulting in loss of power

and overheating. A wire gage size (A.W.G.) of at

least 18 is recommended for an extension cord

25 feet or less in length. If in doubt, use the next

heavier gage. The smaller the gage number, the

heavier the cord.

INSPECT EXTENSION CORDS PERIODI-

CALLY and replace if damaged.

DRESS PROPERLY. Do not wear loose clothing,

gloves, neckties, rings, bracelets, or other

jewelry. They can get caught and drew you into

moving pads. Rubber gloves and nonslipfoot-

wear are recommended. Also wear protective

hair covering to contain long hair.

ALWAYS WEAR SAFETY GLASSES WITH

SIDE SHIELDS. Everyday eyeglasses have only

impact-resistant lenses; they are NOT safety

glasses.

PROTECT YOUR LUNGS. Wear a face or dust

mask ifthe cutting operation is dusty.

PROTECT YOUR HEARING. Wear hearing

protection during extended pedods of operation.

SECURE WORK. Use clamps or a vise to hold

work when practical. It's safer than using your

hand and it frees both hands to operate tool.

DO NOT OVERREACH. Keep proper footing and

balance at all times.

MAINTAIN TOOLS WITH CARE. Keep tools

sharp and clean for better and safer perfor-

mance. Follow instructions for lubricatingand

changing accessodes.

DISCONNECT ALL TOOLS. When not in use,

before servicing, or when changing attachments,

blades, bits, cutters, etc., all toolsshould be

disconnected from power supply.

AVOID ACCIDENTAL STARTING. Be sure

switch is off when plugging in.

USE RECOMMENDED ACCESSORIES. The

use of improper accessories may cause risk of

injury.

NEVER STAND ON TOOL. Sedous injury could

occur ifthe tool istipped or if the blade is unin-

tentionally contacted.

CHECK DAMAGED PARTS. Before further use

of the tool, a guard or other part that is damaged

should be carefully checked to determine that it

will operate propedy and perform its intended

function. Check for alignment of moving pads,

binding of moving pads, breakage of pads, saw

stability, mounting and any other conditionsthat

may affect itsoperation. A guard or other part

that is damaged must be properly repaired or

replaced by a qualified service technician at a

Sears store to avoid dsk of personal injury.

DIRECTION OF FEED. Feed work into a blade

or cutter against the movement of the blade or

cutter only.

NEVER LEAVE TOOL RUNNING UNAT-

TENDED. TURN THE POWER OFF. Do not

leave tool until it comes to a complete stop.

USE ONLY CORRECT BLADES. Use the right

blade size, style and cutting speed for the

matedal and the type of cut. Blade teeth should

point down toward the table. Sharp blades

minimize stalling and kickback. Correctly adjust

blade tension.

TO PROTECT THE OPERATOR and minimize

blade breakage, ALWAYS adjust the hold down

foot until it rests on top of the workplece to

prevent the workplece from liftingwhile cutting,

but not so much that the workpiece drags. Never

operate the saw with any guard or cover re-

moved. Make sure all guards are operating

propedy before each use.

KEEP HANDS AWAY FROM CUTTING AREA.

Do not hand hold pieces so small that your

fingers go under the blade guard. Never reach

underneath work or behind, under, or within

three inches of the blade and its cutting path with

your hands and fingers for any reason. Do not

attempt to remove cut matedal when blade is

moving.

_1, WARNING: Blades coast after turn off.

• AVOID PINCHING THE BLADE. Be cautious

when cutting off matedal which is irregular in

cross section. For example, molding must lay flat

on the table and not be permitted to rock.

• DO NOT ABUSE CORD. Never yank cord to

disconnect itfrom receptacle. Keep cordfrom

heat, oil, and sharp edges.

INSPECT TOOL CORDS PERIODICALLY and if

damaged, have repaired by a qualified service

technician at a Sears store. Stay constantly

aware of cord location and keep it well away

from the rotating blade.

DO NOT USE TOOL IF SWITCH DOES NOT

TURN IT ON AND OFF. Have defective switches

replaced by a qualified service technician at a

Sears store.

4

RULES FOR SAFE OPERATION (Continued)

KEEP TOOL DRY, CLEAN, AND FREE FROM

OIL AND GREASE. Always use a clean cloth

when cleaning. Never use brake fluids, gasoline,

petroleum-besed products, or any solvents to

clean tool.

A LARGE PIECE OF MATERIAL SHOULD BE

SUPPORTED while cutting. To minimize dsk of

blade pinching and kickback, always support

long workpieces. Saw may slip, walk or slide

while cutting long or heavy boards.

BEFORE MAKING A CUT, BE SURE ALL

ADJUSTMENTS ARE SECURE.

• BEFORE CHANGING THE SETUP, REMOVING

COVERS, GUARDS OR BLADE, UNPLUG THE

SAW.

nmDO NOT FEED THE MATERIAL TOO QUICKLY

while cutting. Do not force the workpiece against

the blade.

NEVER CUT MORE THAN ONE WORKFIECE

AT A TIME. If making a stacked cut, all of the

pieces must be secured to each other with

masking tape or double stick tape to make one

workpieca. Do not put more than one workpiece

on the saw table at a time. Always hold the work

firmly against the table. See page 17.

M AVOID AWKWARD OPERATIONS AND HAND

POSITIONS where a sudden slip could cause

your hand to move intothe blade. ALWAYS

make sure you have good balance. Do not cut

pieces of material that are too small to hold

comfortably in your hand.

M REPLACEMENT PARTS. All repairs, whether

electrical or mechanical, should be made by

qualified service technician at a Sears store or

repair center.

_, WARNING: When servicing use only identical

Craftsman replacement parts. Use of any other

parts may create a hazard or cause product

damage.

B NEVER USE IN AN EXPLOSIVE ATMO-

SPHERE. Normal sparking of the motor could

ignite fumes.

M DO NOT OPERATE THIS TOOL WHILE UN-

DER THE INFLUENCE OF DRUGS, ALCOHOL,

OR ANY MEDICATION.

M

STAY ALERT AND EXERCISE CONTROL.

Watch what you are doing and use common

sense. Do not operate tool when you are tired.

Do not rush.

AVOID CUTTING NAILS. Inspect for and

remove all nails from lumber before cutting.

NEVER PERFORM LAYOUT, ASSEMBLY, OR

SETUP WORK ON THE TABLE while the

cutting tool is operating.

NEVER TOUCH BLADE or other moving parts

during use.

NEVER START A TOOL WHEN THE BLADE IS

IN CONTACT WITH THE WORKPIECE. Clear

the table of debris before turning your scrollsaw

on.

ALLOW THE MOTOR TO COME UP TO FULL

SPEED before starting a cut.

FIRMLY CLAMP OR BOLT your scroll saw to a

firm, level workbench or table. The most comfort-

able saw table height is at approximately hip

height.

SAVE THESE INSTRUCTIONS

MAKE SURE THE WORK AREA HAS AMPLE

LIGHTING to see the work and that no obstruc-

tions will interfere with safe operation BEFORE

performing any work using your saw.

ALWAYS TURN OFF SAW before disconnecting

it, to avoid accidental starting when reconnecting

to power supply. NEVER leave the scroll saw

unattended while connected to a power source.

_lJ WARNING: Do notallow familiarity with your

saw make you careless. Remember that a

careless fraction of a second issufficient to inflict

severe injury.

SAVE THESE INSTRUCTIONS. Refer to them

frequently and use to instruct other users. If you

loan someone this tool, loan them these instruc-

tions also.

EXTENSION CORDS

Use only 3-wire extension cords that have 3-prong

grounding plugs and 3-pole receptacles that accept

the tool's plug. When using a power tool at a consider-

able distance from the power source, use an exten-

sion cord heavy enough to carry the current that the

tool will draw. An undersized extension cord will

cause a drop in line voltage, resulting in a loss of

power and causing the motor to overheat. Use the

chart provided below to determine the minimum wire

size required in an extension cord. Only roundjack-

eted cords listed by Underwfiter's Laboratories (UL)

should be used.

Length of Extension Cord Wire Size (A.W.G.)

Up to 25 feet 18

26-100 feet 16

When working with the tool outdoors, use an exten-

sion cord that is designed for outside use. This is

indicated by the letters WA on the cord's jacket.

Before using an extension cord, inspect it for loose or

exposed wires and cut or worn insulation.

_1= CAUTION: Keep the cord away from the cutting

area and position the cord so that itwillnot be

caught on lumber, tools, or other objects dudng

cutting.

ELECTRICAL CONNECTION

Your Sears Craftsman Scroll Saw is powered by a

precision built electric motor. It should be connected

to a power supply that Is 120 volts, 60 Hz, AC only

(normal household current). Do not operate this tool

on direct current (DC). A substantial voltage drop will

cause a loss of power and the motor will overheat. If

the saw does not operate when plugged into an outlet,

double check the power supply.

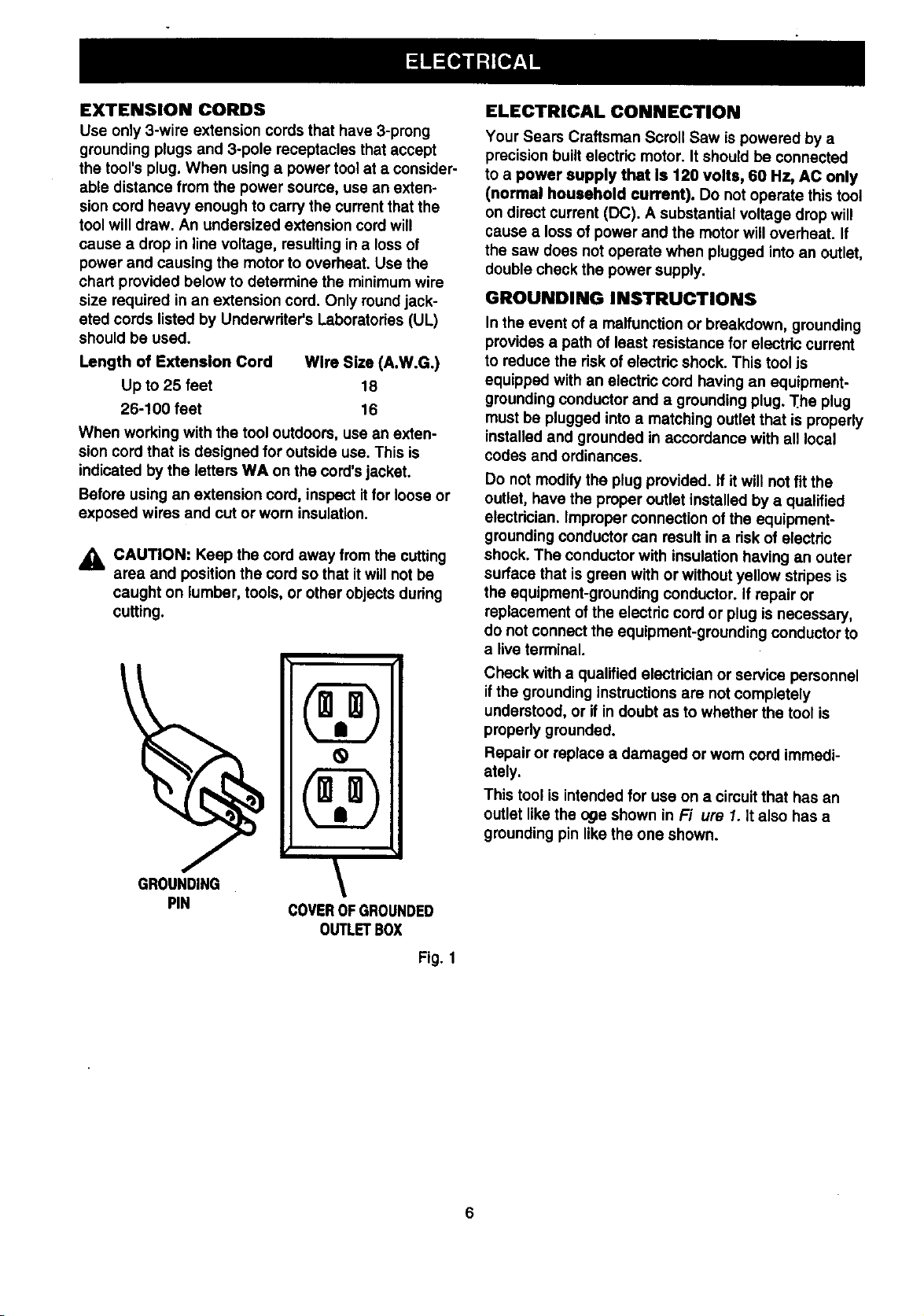

GROUNDING INSTRUCTIONS

In the event of a malfunction or breakdown, grounding

provides a path of least resistance for electdc current

to reduce the risk of electdc shock. This toolJs

equipped with an alectdc cord having an equipment-

grounding conductor and a grounding plug. T.heplug

must be plugged intoa matching outlet that is properly

installed and grounded in accordance with all local

codes and ordinances.

Do not modify the plug provided, tf it will not fit the

outlet, have the proper outlet installed by a qualified

electrician. Improper connection of the equipment-

grounding conductor can result in a risk of electric

shock. The conductor with insulation having an outer

surface that is green with or without yellow stdpes is

the equipment-grounding conductor. If repair or

replacement of the electric cord or plug is necessary,

do notconnect the equipment-grounding conductor to

a live terminal.

Check with a qualified electrician or service personnel

if the grounding instructions are not comptetely

understood, or if in doubt as to whether the tool is

properly grounded.

Repair or replace a damaged or worn cord immedi-

ately.

This tool is intended for use on a circuitthat has an

outlet like the (xje shown in Fiure 1. It also has a

grounding pin like the one shown.

GROUNDING

PIN COVEROFGROUNDED

OUTLETBOX

Fig. I

6

Bevel Cut

A cutting operation made with the table at any angle

other than 90" to the blade.

Crosscut

A cutting or shaping operation made across the grain

of the workpiece.

Compound Cut

A compound cut is a cut made using a miter angle

and a bevel angle at the same time.

Freehand (for scroll saw)

Performing a cut without using a fixture to assure a

straight cut (normally a curved or irregular shape).

Gum

A sticky, sap based residue from wood products.

Kerr

The material removed by the blade in a through cut or

the slot produced by the blade in a nonthrough or

partial cut.

Leading End

The end of the workplace pushed into the cuttingtool

first.

Nonferrous Metal

Metal that does not contain iron; such as aluminum,

brass, and copper.

Push Stick

A device used to feed the workplace through the saw

blade during narrow ripping type operations and helps

keep the operator's hands well away from the blade.

Reeln

A sticky, sap base substance that has hardened.

Ripping

A cutting operation along the length of the workpiece.

Saw Blade Path

The area directly inline -- over, under, behind, or in

front of the blade. As it applies to the workpiece, that

area which will be, or has been, cut by the blade.

Set

The distance that the tip of the saw blade tooth is bent

(or set) outward from the face of the blade.

SPM

Strokes per minute. Used in reference to blade

movement.

Throw-Back

Throwing of a workpiece in a manner similar to a

kickback, usually associated with a cause other than

the kerf closing, being dropped intothe blade, or

being placed inadvertently in contact withthe blade.

Through Sawing

Any cuttingoperation where the blade extends

completely through the thickness of the workpiece.

Workplece

The item on which the cutting operation is being done.

The surfaces of a workpiece are commonly referred to

as faces, ends, and edges.

Worktable

The surface on which the workpiece rests while

performing a cutting or sanding operation.

Throat

Motor

Ddve

Blade Length

24 in. Table Size 20-1/2 in. x 11 in.

120 V, 1.4 amp 60 HZ-AC only Table "nit 0°- 47" right

2 Speed Overall Dimensions 14 in. W

1725 Strokes per minute 29-1/2 in. L

825 Strokes per minute 15 in. H

5 in. plain or pin Net Weight 87 lb.

,_ WARNING: To prevent accidental starting or

electrical shock that could cause possible

serious personal injury, assemble all parts to

your saw before connecting it to power supply.

Saw should never be connected to power supply

when you are assembling parts, making

adjustments, lubricating, installingor removing

blades, cleaning, or when not in use.

• This saw is very heavy. To avoid back injury, get

help when lifting the saw.

• Carefully lift saw from the carton and place it on

a level work surface.

• Remove pack of 4 extra blades and owner's

manual from the carton.

_, WARNING: If any parts are missing, do not

operate this tool until the missing parts are

replaced. Failure to do so cou_l result in possible

sedous personal injury.

• Do not discard the packing materials until you

have carefully inspected the saw, identified all

parts, and satisfactorily operated your new saw.

Note: If any parts are damaged or missing, do not

attempt to plug in the power cord and turn the switch

on untilthe damaged or missing parts are obtained

and are installed correctly.

Your scroll saw table was covered with a lubricant and

a cover at the factory to prevent rust. Remove the

plastic cover and clean with a soft cloth and a small

amount of mineral spirits, or rubbing alcohol. DO not

use acetone, gasoline, or lacquer thinner. These are

dangerous and may also damage plastic and rubber

parts of your saw.

Your scroll saw comes completely assembled. A

package of 4 extra blades and an owner's manual are

included with your saw.

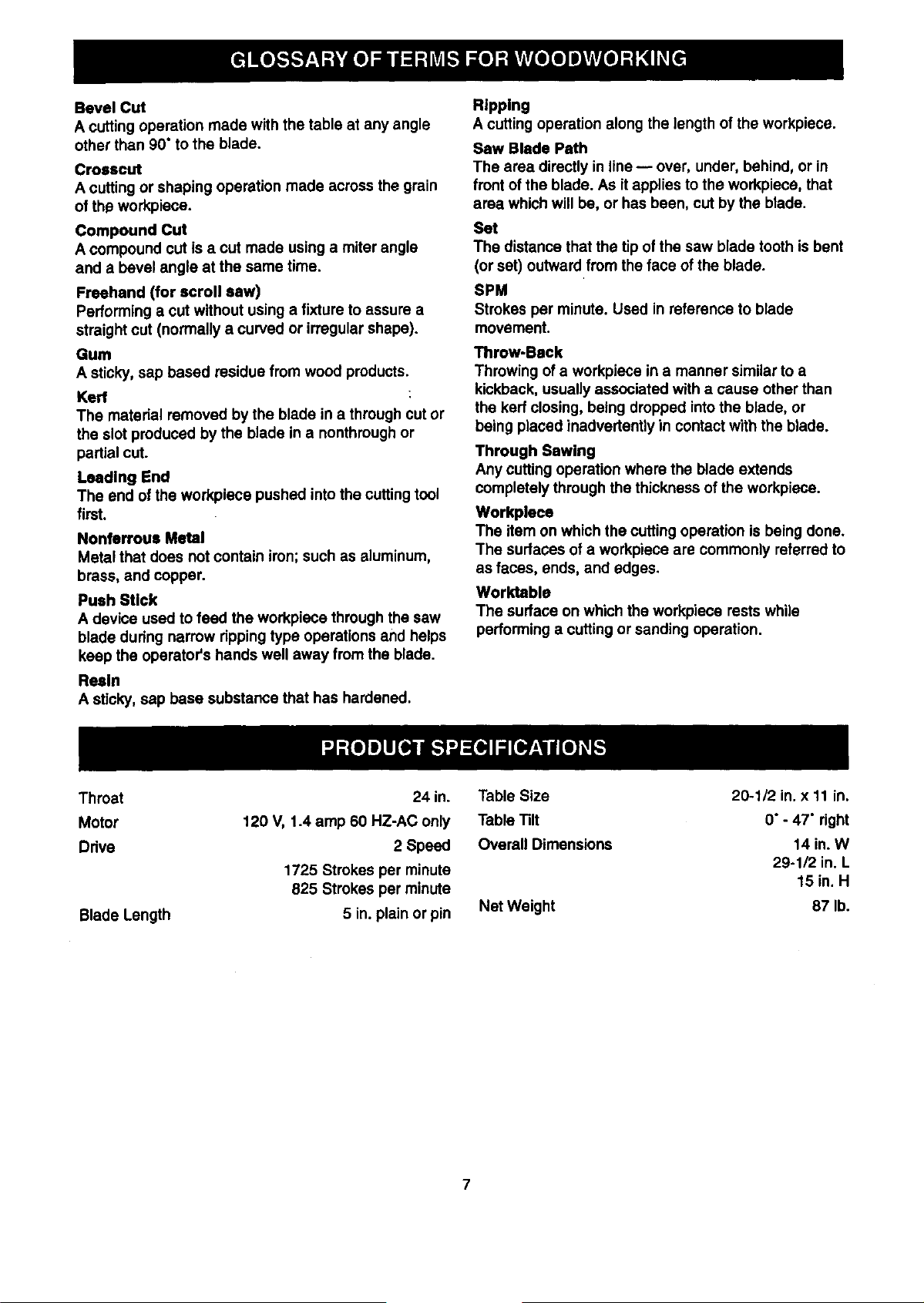

The following tools (not included) are needed for

adjustments and alignment:

• Small Combination Square

• Adjustable wrench

• Phillips Screwddver

SMALL

COMBINATION

SQUARE

PHILLIPSSCREWDRIVER

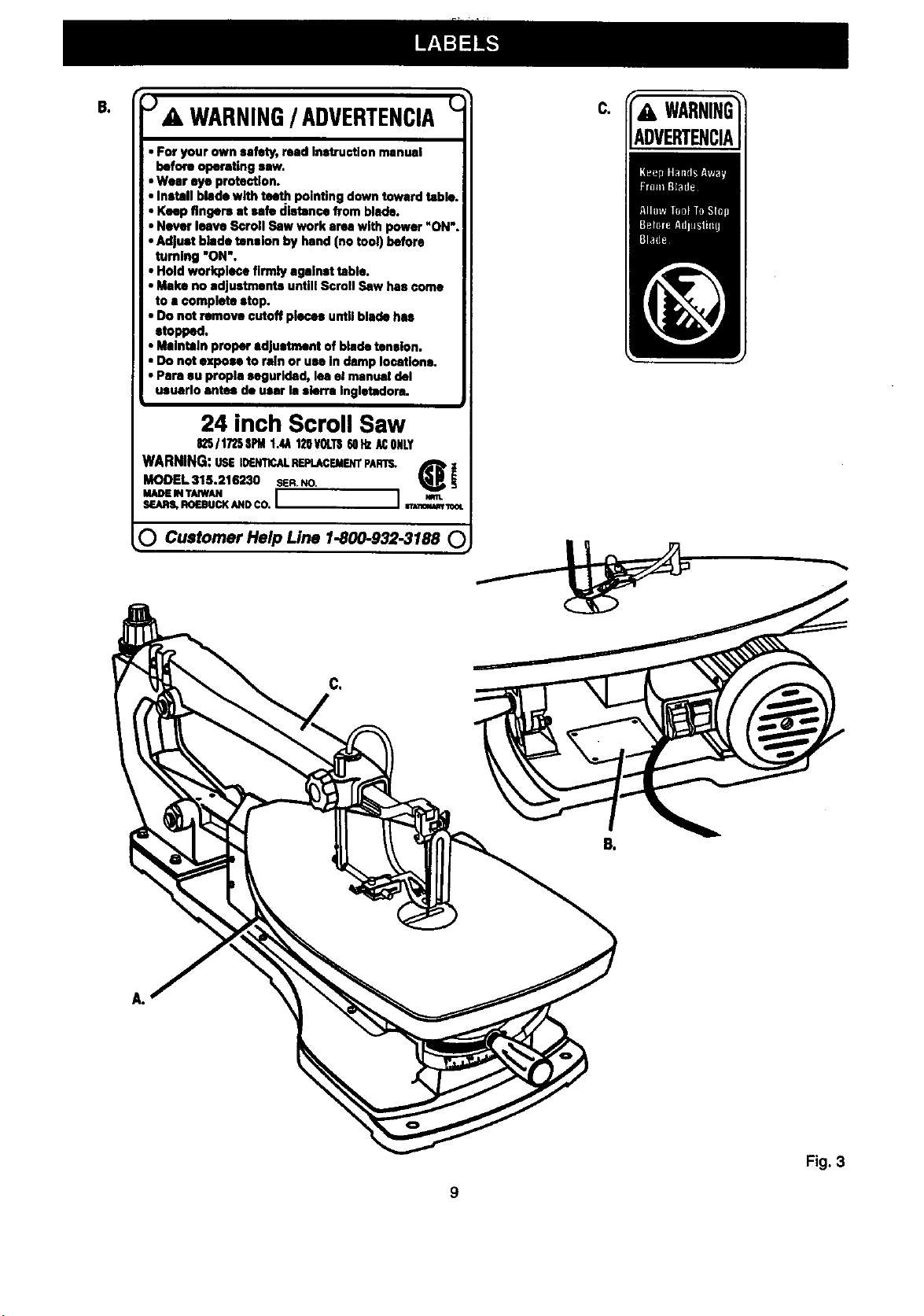

The following labels are on the scroll saw with locations indicated.

A,

Fig. 2

CRAFTSMAN°

24.in. Scroll Saw

8

2.Speed

eq

J_ WARNING/ ADVERTENCIA

• For your own safety, read Instruction manual

before operating saw.

• Wear aye protection.

• install blade with tee_ pointingdown toward table.

• Keepfingers at safe distance from blade.

• Never leave Scroll Sawwork area with power "ON'.

• Adjust blade tension by hand (no tool) before

turning "ON•.

• Hold workplace firmly against table.

• Make noedjustmonte untill Scroll Saw has come

to a complete stop.

• Do not remove cutoffpieces untilblade has

stepped.

• Maintain proper adjustment of bladetension.

• Do not expose to rain or uee in damp locations.

• Pare au propla eaguridad, lee el manual del

usuarlosntce do uear le sierra inglatedore.

24 inch Scroll Saw

92511725SPM1.4A120VOLTS60lb ACONLY

WARNING: use IDF.NTICALREPLACEMENTPARTS. _

MODEL 315.216230 SER.NO.

MADIE IN TAIWAN

SEARS, ROEBUCKAND CO. i i sr_ looL

,O Customer Help Line 1-800-932-3188 O

i

Fig. 3

9

Loading...

Loading...